Submitted:

08 September 2024

Posted:

09 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- What are the fundamental aspects that underline the significance of the textile industry?

- What are the key components and functionalities of the supply chain within this sector, and why is it imperative to analyze and understand them?

- How are decision-making methods applied within the supply chain of textiles, and what are their implications for operational efficiency and strategic planning?

- How can the management and design of the supply chain be categorized based on decision-making methodologies?

- What trajectories and considerations should be taken into account for advancing decision-making processes within the supply chain, and what potential avenues exist for future research and development in this domain?

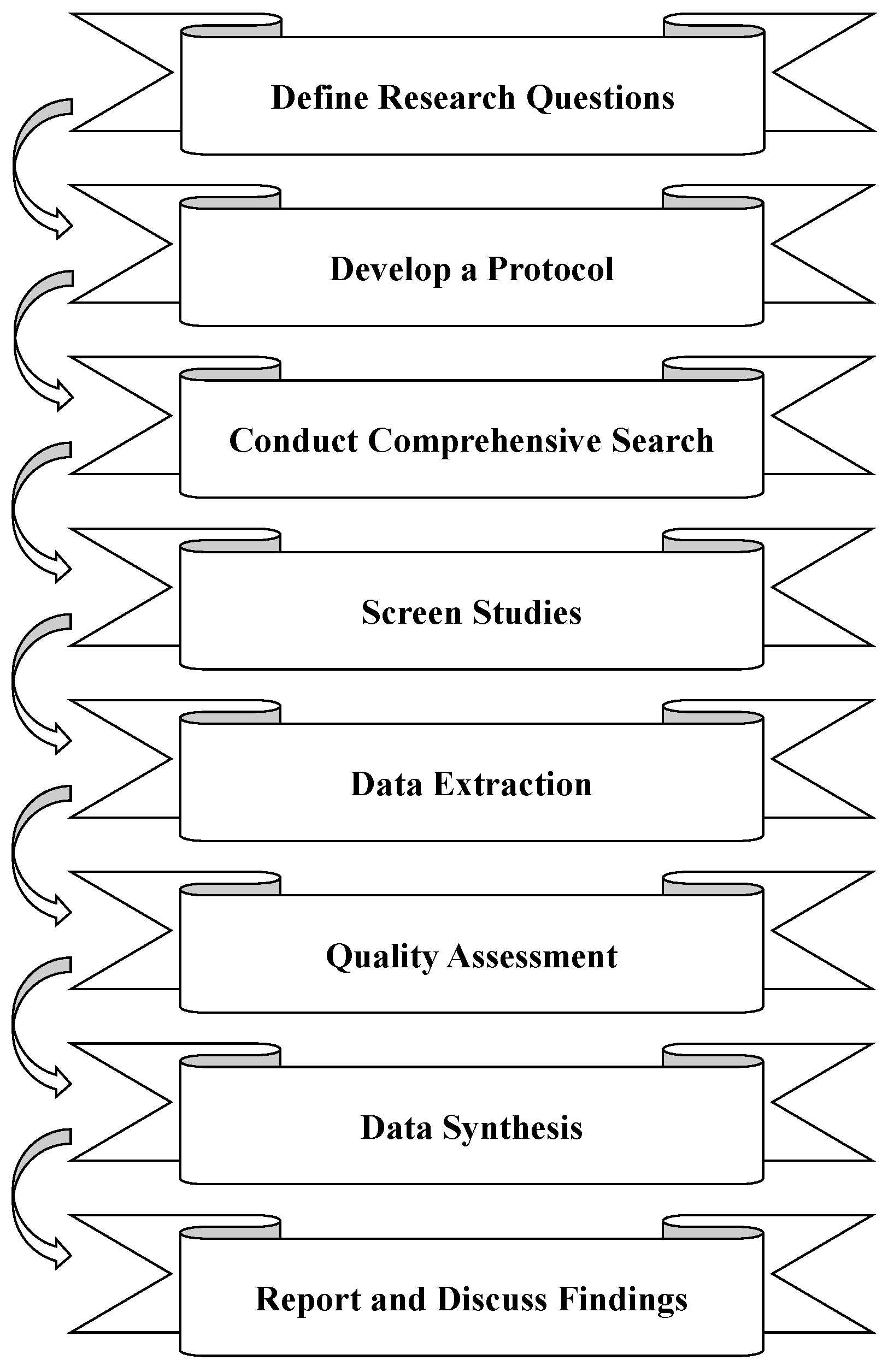

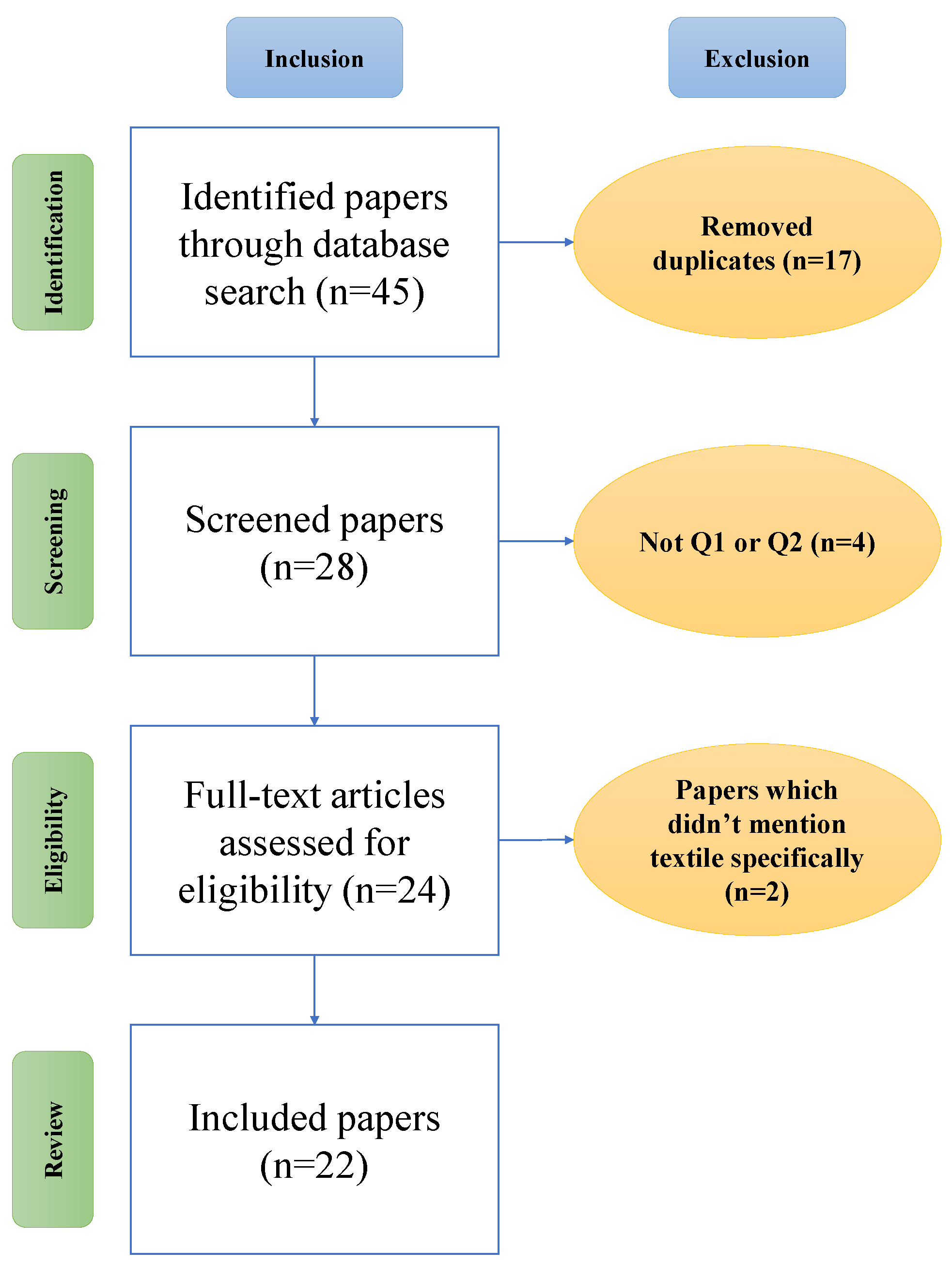

2. Methodology

- Scopus: TITLE-ABS-KEY ( ( “MCDM” OR “multiple criteria decision making” OR “multiple criteria decision-making” ) AND ( “textile*” ) AND ( “supply-chain” OR “supply chain” ) ) AND ( LIMIT-TO ( DOCTYPE, “ar” ) ) AND ( LIMIT-TO ( LANGUAGE, “English” ) )

- WoS: (“MCDM” OR “multiple criteria decision making” OR “multiple criteria decision-making”) AND (“textile*”) AND (“supply-chain” OR “supply chain”) (Topic) and Article or Proceeding Paper (Document Types) and English (Languages)

3. Insights and Analysis

| RQ1 | RQ2 | RQ3 | RQ4 | RQ5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Paper | Fundamental Aspects | Textile Industry Significance | Supply Chain Components | Supply Chain Functions | Importance of Analysis | Decision-Making Methods | Implications for Efficiency and Planning | Supply Chain Management and Design Categorization | Advancing Decision-Making Processes | Future Research Avenues |

|

Guneri et al. 2009 [19] |

Integrated Fuzzy and Linear Programming Model for Supplier Selection | Critical for achieving a competitive advantage by selecting optimal suppliers in the textile industry | Supplier selection criteria, decision-making inputs | Supplier evaluation, order assignment | Enhances strategic purchasing through a comprehensive MCDM approach incorporating both tangible and intangible factors | Fuzzy set theory, linear programming | Streamlines the supplier selection process by quantifying criteria and constraints, leading to improved resource allocation | Provides a structured framework for evaluating multiple sourcing options in complex supply chains | Facilitates better relationships between buyers and suppliers through systematic selection methodologies | Encourages further exploration of hybrid approaches combining fuzzy set theory with other decision-making methods to address various operational challenges |

|

Chithambaranathan et al. 2015 [20] |

Performance Analysis Framework for Supply Chains | Essential for optimizing the performance of textile supply chains through effective member evaluation | Supply chain members, performance metrics | Performance analysis, benchmarking, member integration | Crucial for continuous improvement and competitive advantage in supply chains | Fuzzy-TOPSIS, VIKOR | Facilitates systematic performance assessment and improvement strategies, enhancing decision-making | Provides a structured approach for evaluating and comparing supply chain member performance | Supports organizations in achieving synergy among supply chain partners through collaborative performance metrics | Promotes exploration of additional MCDM methodologies and the adaptation of the framework for evaluating environmental performance |

|

Fallahpour et al. 2017 [21] |

Supplier evaluation and selection using gene expression programming (GEP) | Vital for enhancing accuracy and efficiency in selecting suppliers in the textile supply chain | Supplier performance criteria, evaluation models | Supplier evaluation, prioritization | Essential for improving decision-making processes in supplier selection | Gene Expression Programming (GEP) | Offers a robust mathematical model to guide supplier performance assessments, reducing evaluation timelines | Positions GEP as a superior alternative to traditional AI methods for supplier selection | Facilitates comprehensive evaluations and simulations for supplier performance enhancement | Encourages incorporation of sustainability criteria and fuzzy data representation in future models, exploring advanced AI methodologies like SA-GP and MGGP |

|

Burney and Ali 2019 [22] |

Fuzzy-AHP for Supplier Selection in Textile Industry - Pakistan | Crucial for enhancing supplier evaluation and optimizing procurement in the textile industry | Suppliers, procurement criteria, supply chain management | Supplier evaluation, supplier ranking, contract negotiation | Vital for ensuring cost-effectiveness and quality in sourcing decisions | Fuzzy-AHP | Facilitates improved decision-making under uncertainty, leading to better supplier performance | Addresses complex decision-making scenarios with multiple conflicting criteria in the textile sector | Empowers procurement managers with a structured approach to evaluate and select suppliers | Encourages exploration of alternative fuzzy membership functions and additional criteria for a comprehensive supplier selection framework |

|

Raut et al. 2019 [23] |

Barriers to Sustainable Development in T&A Supply Chains | Essential for understanding and overcoming challenges to ensure the sustainability of the textile and apparel sector | Government policies, infrastructure, investment, stakeholder engagement | Supplier evaluation, risk management, policy development | Crucial for enabling sustainable practices in the T&A industry and addressing socio-economic impacts | not mentioned | Aids in identifying and ranking key barriers to sustainable development, enabling targeted interventions | Identifies critical factors influencing sustainability and guides decision-makers in T&A supply chain management | Provides a framework for systematically analyzing interrelationships among barriers to sustainability | Suggests further validation of the ISM model using complementary methods like SEM to enhance robustness and accuracy |

|

Ulutaş 2019 [24] |

Integrated Fuzzy MCDM Model for Supplier Selection | Crucial for improving supplier performance and overall supply chain efficiency in the Turkish textile sector | Fabric suppliers, evaluation criteria | Supplier evaluation, performance ranking | Essential for addressing uncertainties in supplier performance assessments | Fuzzy-AHP, Fuzzy-OCRA | Enhances decision-making accuracy and reduces risks associated with supplier selection | Utilizes fuzzy logic to manage ambiguity in expert evaluations during the supplier selection process | Offers a comprehensive model that integrates multiple fuzzy decision-making techniques for supplier selection | Encourages exploration of Fuzzy OCRA in other MCDM scenarios, such as logistics, warehousing, and machinery selection |

|

Ali et al. 2020 [25] |

Fuzzy-AHP-TOPSIS Decision Support System for Supplier Selection | Essential for enhancing supplier selection processes in Pakistan’s textile sector, particularly under volatile market conditions | Cotton suppliers, evaluation criteria | Supplier evaluation, procurement, cost management | Vital for improving production efficiency and meeting customer demands in a competitive environment | Fuzzy-AHP, TOPSIS | Optimizes supplier selection, reduces procurement costs, and enhances supply chain efficiency | Integrates fuzzy logic with established decision-making techniques to address complexities in supplier selection | Establishes a novel framework that can guide decision-makers in selecting suppliers effectively | Encourages further research into the applicability of the model across different industries in Pakistan and beyond |

|

Wang et al. 2020 [6] |

Supplier Selection Model for the Textile and Garment Industry | Critical for enhancing competitiveness and adapting to market changes in Vietnam’s textile sector | Raw material suppliers, evaluation criteria | Supplier evaluation, relationship management, risk reduction | Essential for improving supplier selection dynamics amidst market volatility | Fuzzy-AHP, PROMETHEE II | Aids in decision-making by optimizing supplier selection criteria, enhances overall process efficiency | Integrates qualitative and quantitative criteria for a comprehensive assessment of suppliers | Provides a systematic framework for evaluating suppliers based on multiple criteria, reducing subjectivity in decision-making | Encourages application of the model in other sectors, e.g., finance and construction, promoting cross-industry adaptability |

|

Yang and Wang 2020 [26] |

Green Innovation Criteria for Sustainable Supply Chain Management | Crucial for the competitive edge and compliance in China’s textile manufacturing sector | Suppliers, economic, environmental, and social criteria | Supplier selection, green procurement, innovation implementation | Key to addressing sustainability challenges and enhancing operational efficiency | Fuzzy-AHP, Fuzzy-TOPSIS | Improves selection accuracy of suppliers aligned with sustainability goals, enhances overall supply chain performance | Integrates diverse criteria into decision-making for more sustainable supply chain operations | Implements a novel decision framework to facilitate the adoption of green practices | Suggests exploring additional MCDM methods and criteria across different sectors for comprehensive evaluations |

|

Celik et al. 2021 [27] |

Green Supplier Selection in the Textile Industry | Essential for improving environmental performance and compliance in the textile supply chain | Green suppliers, evaluation criteria, sub-criteria | Supplier evaluation, green procurement, risk management | Vital for aligning procurement practices with sustainability goals | BWM with interval type-2 fuzzy numbers (IT2FBWM) interval type-2 fuzzy TODIM (IT2F-TODIM) |

Enhances the decision-making process by incorporating uncertainties, improving supplier selection accuracy | Integrates both qualitative and quantitative criteria for a holistic view of green supplier performance | Provides a robust framework for decision-makers, addressing uncertainties in GSS assessments | Encourages application in diverse sectors, such as sustainable material selection and landfill site selection, while improving expert involvement in evaluations |

|

Wang et al. 2021 [28] |

Three-Layer Fuzzy MCDM Approach | Critical for the efficient selection of outsourcing manufacturers in the apparel and textile industry | Outsourcing manufacturers, sustainability criteria, performance metrics | Supplier selection, performance evaluation, risk management | Enhances the accuracy and robustness of supplier evaluations under uncertainty | Fuzzy-AHP, Fuzzy-TOPSIS | Improves supplier selection processes, increases competitiveness, and ensures sustainability in supply chain operations | Combines qualitative and quantitative criteria for comprehensive supplier assessment | Integrates best practices from multiple decision-making frameworks, providing a structured approach for managers | Encourages exploration of heuristic algorithms and simulation techniques to handle uncertainty and evaluate more suppliers in future studies |

|

Ulutaş et al. 2022 [29] |

Sustainable Supplier Selection in the Textile Industry | Vital for minimizing environmental impacts and enhancing social responsibility within the textile supply chain | Suppliers, sustainability criteria (economic, environmental, social) | Supplier evaluation, procurement strategies, risk management | Addresses the complexity of selecting sustainable suppliers through a structured decision-making approach | Grey BWM, Grey WISP | Increases transparency in supplier selection, fosters stronger supplier relationships, and ensures compliance with sustainability standards | Categorizing suppliers based on sustainability performance; Strengthening eco-conscious supplier networks | Integrates expert judgments into a robust framework for sustainability assessment, adaptable to various decision-making contexts | Encourages exploration of additional sustainability criteria, application to other industries, and incorporation of objective data for improved accuracy in supplier evaluations |

|

Bait et al. 2022 [30] |

Optimal Foreign Location Selection in Emerging Markets | Crucial for enhancing textiles and clothing sector competitiveness by strategically locating production facilities | Potential host countries, workforce, infrastructure, technology suppliers | Location planning, investment decision-making, risk assessment | Provides a structured approach to evaluate and mitigate risks associated with establishing manufacturing plants in emerging markets | AHP, TOPSIS | Facilitates informed decision-making for investors, minimizes investment risk, and aligns operations with local market conditions | Integration of MCDM models to evaluate emerging markets’ suitability for foreign investment | Offers a comprehensive framework for decision-makers to assess country gaps and risks, enhancing overall investment strategies | Encourages future exploration of network analysis methods, local data integration for improved accuracy, and application across diverse manufacturing sectors to identify optimal investment opportunities |

|

Paul et al. 2022 [31] |

Integrated Supplier Selection in the Textile Industry | Essential for ensuring timely and cost-effective delivery of raw materials in the textile industry, impacting production efficiency | Suppliers, Raw materials (cotton, yarn, fabric), chemicals, machinery | Supplier evaluation, procurement processes, operational planning | Helps identify optimal suppliers amidst complex, conflicting criteria to ensure seamless production | IRN, BWM, EDAS | Enhances decision-making accuracy and reduces biases, ultimately leading to improved supplier relations and operational effectiveness | Application of MCDM methods in supplier selection; proactive risk management in supply chain | Offers a structured framework for collective decision-making, utilizing expert opinions to refine supplier selection | Encourages exploration of additional MCDM tools and decision support frameworks to handle operational parameter changes and improve solution accuracy in supplier rankings |

|

Tuş and Aytaç Adali 2022 [32] |

Green Supplier Selection in the Textile Industry | Critical for achieving sustainability goals in the textile industry; highlights the importance of environmental considerations in supplier partnerships | Green suppliers, raw materials, production processes | Supplier selection, procurement, sustainability assessments | Green supplier selection significantly impacts both the ecological footprint and overall operational efficiency of textile firms | Fuzzy Stepwise Weight Assessment Ratio Analysis (SWARA-F), Fuzzy Measurement Alternatives, and Ranking according to the COmpromise Solution (MARCOS-F) | Supports cost efficiencies and environmental improvements, leading to enhanced competitiveness in a green economy | Integration of sustainability into supply chain management; fostering environmentally responsible practices | Provides a robust framework for decision-makers to evaluate suppliers based on comprehensive green criteria | Future research can expand criteria applicability, utilize more complex MCDM approaches, and involve diverse industries to generalize findings; explore various fuzzy membership and defuzzification methods to enhance decision-making accuracy |

|

Kao 2022 [33] |

MCDM Model for Supplier Selection during COVID-19 | Addresses the unique challenges faced by the clothing and textiles industry due to the pandemic, emphasizing stable supplier relationships critical for SCM | Suppliers, manufacturers, resources | Supplier evaluation, selection, logistics | The integration of qualitative and quantitative criteria enhances decision-making in uncertain environments | Fuzzy-TOPSIS, Multisegment Goal Programming (MSGP) | Improved supplier selection processes optimize resource use and enhance competitiveness, especially in volatile market conditions | Sustainable supply chain management; supplier resilience and reliability in crisis scenarios | Provides guidelines for decision-makers, making it easier to adapt supplier selection processes to current challenges | Exploring other MCDM methods and extending applicability beyond C&T to other sectors facing similar challenges; comparisons with existing frameworks for improving supplier selection practices |

|

Caristi et al. 2022 [34] |

Supplier Selection in the Textile Industry Amid Global Market Evolution | Enhances competitive advantage by enabling firms to effectively evaluate and select suppliers, which is critical for meeting customer demands and sustainable production | Raw material suppliers, outsourcing partners, logistics | Supplier selection, procurement, performance evaluation | A structured model helps navigate complex supplier evaluations amidst qualitative and quantitative criteria, aligning with customer and environmental needs | Fuzzy-TOPSIS | Improved supplier selection processes lead to reduced costs, enhanced sustainability, improved service quality, and increased customer satisfaction | Sustainable supply chain management; integration of green purchasing practices | Facilitates a practical application of supplier selection criteria in real-world contexts; bridges the gap between theoretical models and industry practices | Further empirical validation of the model across varied contexts; comparative analysis with other MCDM models in the textile sector; expansion of the criteria set based on diverse industry needs |

|

Rahman et al. 2022 [35] |

Sustainable Supplier Selection in the Textile Dyeing Industry, Bangladesh | Critical for achieving sustainability in Bangladesh’s textile dyeing industry, reducing reliance on harmful chemicals; supporting compliance with environmental standards | Suppliers, chemical inputs, waste management | Supplier selection, performance evaluation, sustainability compliance | Developing a framework for identifying sustainable suppliers enhances decision-making, mitigating environmental toxicity from chemical usage | Stepwise Weight Assessment Ratio Analysis (SWARA), Weighted Aggregated Sum Product Assessment (WASPAS) | A structured approach leads to better supplier choices that align with sustainability goals, improving long-term viability and environmental impact | Sustainable supplier selection; supplier evaluation in chemical-intensive industries | Integration of MCDM methods provides a comprehensive evaluation of supplier sustainability; promotes understanding of multi-criteria considerations | expansion on additional criteria for evaluation, apply the framework to other sectors, and investigate the impacts of sustainability disruptions on supply chain practices |

|

Wang et al. 2022 [36] |

Hybrid MCDM model for Supplier Selection in the Garment Industry, Vietnam | Vital for enhancing supply chain efficiency in Vietnam’s textile and garment sector; addresses dependency on foreign raw materials, promoting sustainable local sourcing | Suppliers, raw material sources, production facilities | Supplier evaluation, procurement, performance ranking | Aids decision-makers in navigating complex supplier selection processes under uncertainty, directly impacting operational and financial outcomes | Fuzzy-AHP, TOPSIS | Improved supplier selection processes enhance quality control, reduce procurement costs, and foster stronger supplier relationships; and better alignment with market demands | Supplier selection optimization; enhancement of procurement strategies in textile supply chains | Fostering the integration of fuzzy decision-making methods in supplier selection; promoting better clarity and reliability in complex decision contexts | explore hybrid models with other MCDM methods, conduct comparisons of existing models, and assess supplier performance in post-pandemic scenarios |

|

Ecer and Torkayesh 2024 [37] |

Sustainable Circular Supplier Selection (SCSS) framework using stratified fuzzy decision-making, Turkey | Enhances sustainable practices and environmental efficiency in textile production; addresses waste reduction and resource usage | Suppliers, raw materials, end-of-life products | Procurement, production, waste management, reverse logistics | Identifies and prioritizes suppliers based on sustainability and circular economy criteria; considers uncertainty in decisions | Stratified Fuzzy Full Consistency Method (SFUCOM-F) and Mixed Aggregation by Comprehensive Normalization Technique (MACONT-F) | Improved decision-making leads to optimized supplier choices, waste reduction, and enhanced sustainability; circular economy principles integrated into sourcing strategy | Circular supply chain management; sustainable supply chain design | Development of decision support tools that incorporate future uncertainties; integration of economic, social, and environmental aspects in supply chain decisions | Exploration of advanced decision-making tools using machine learning; analysis of larger datasets for improved selection criteria; use of new fuzzy set extensions |

|

Hashim et al. 2024 |

Supply Chain Reliability (SCR) risk identification and mitigation methodology, Pakistan | Critical for maintaining operational consistency and customer satisfaction in the textile sector; impacts profitability and competitiveness | Supply chain partners, logistics, manufacturing facilities, regulatory frameworks | Risk management, prevention strategies, performance evaluation | Identifying and prioritizing risks to enhance supply reliability and mitigate disruptions, especially in uncertain environments | Fuzzy -FMEA, Fuzzy-AHP, Fuzzy-TOPSIS | Effective risk management strategies lead to improved supply reliability, reduced costs, and minimized disruptions; enhance decision-making under uncertainty | Supply chain risk management (SCRM); crisis management in textile supply chains | Developing comprehensive risk mitigation strategies; enhancing SCR through multi-faceted approaches to risk assessment | Research on inter-relationships between identified risks; applying advanced techniques like ISM, DEMATEL, SWARA, ANP, and VIKOR in risk management; comparative studies across textile supply chains in various economies |

|

Pamucar et al. 2024 |

Green Supplier Selection Decision Support Tool | Essential for improving the environmental performance of textile companies and meeting sustainability goals; enhances competitive advantage | Supplier evaluation metrics, green technology, sustainability criteria | Supplier selection, environmental management, compliance assessment | Provides a structured approach to selecting environmentally friendly suppliers, incorporating both economic and environmental criteria | Fermatean Fuzzy Preference Selection Index (FF-PSI), Fermatean Fuzzy Combined Compromise Solution (FF-CoCoSo) | Streamlined selection processes for green suppliers lead to cost-effective and sustainable operational practices; support strategic sourcing decisions aligning with environmental goals | Green supply chain management; environmentally conscious supplier selection | Integration of fuzzy logic into MCDM tools for more effective decision-making in supplier selection; addressing complexities in evaluating environmental and economic factors | Future studies can expand on integrating social criteria into supplier evaluations; incorporate objective data collection methods; explore applications of FF methods in various industries like health, agriculture, and logistics |

3.1. Fundamental Importance of the Textile Industry

3.2. Key Components of the Textile Supply Chain

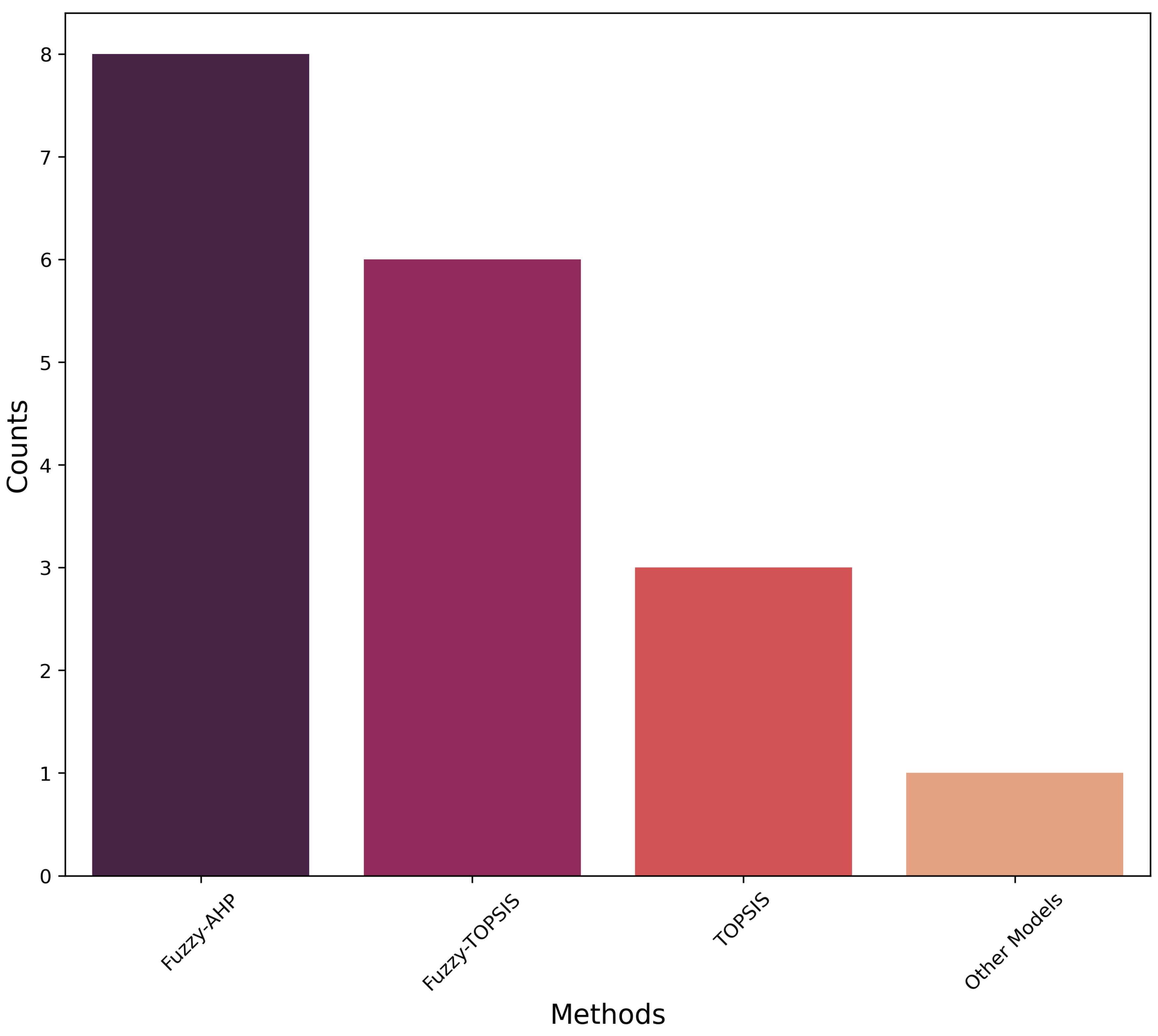

3.3. Decision-Making in Textile Supply Chains

3.4. Categorizing Supply Chain Management Approaches

- Traditional Decision-Making Frameworks: Some papers emphasize structured frameworks and methodologies that focus on evaluating and comparing various options in the supply chain. For instance, Guneri et al. provide a structured framework for evaluating multiple sourcing options in complex supply chains, while Chithambaranathan et al. focus on the structured evaluation of supply chain member performance. These approaches gather performance-related data to facilitate informed decision-making, particularly in environments characterized by complexity and conflicting criteria, as discussed by Burney and Ali.

- MCDM Models: A significant number of studies employ MCDM models to assess multiple factors involved in supply chain decisions. For example, Bait et al. analyze the suitability of emerging markets for foreign investment using MCDM approaches, and Paul et al. implement these methods in supplier selection while addressing proactive risk management. Furthermore, various studies combine qualitative and quantitative criteria for a more comprehensive assessment. Both Wang et al. and Celik et al. demonstrate this integration, focusing on supplier performance and sustainability, respectively. These MCDM approaches enable decision-makers to handle multiple conflicting criteria, which is essential in today’s complex supply chain environments.

- Integrated Fuzzy Logic Approaches: Several papers adopt fuzzy logic to better manage uncertainties in supply chain decision-making. Ulutaş utilizes fuzzy logic to navigate ambiguity in expert evaluations during supplier selection, while Ali et al. integrate fuzzy logic with established decision-making techniques to address supplier selection complexities. This methodology helps in making more robust decisions where ambiguity and vagueness are prevalent, particularly in sectors requiring sustainability considerations, as noted in the papers by Raut et al. and Tuş and Aytaç Adali.

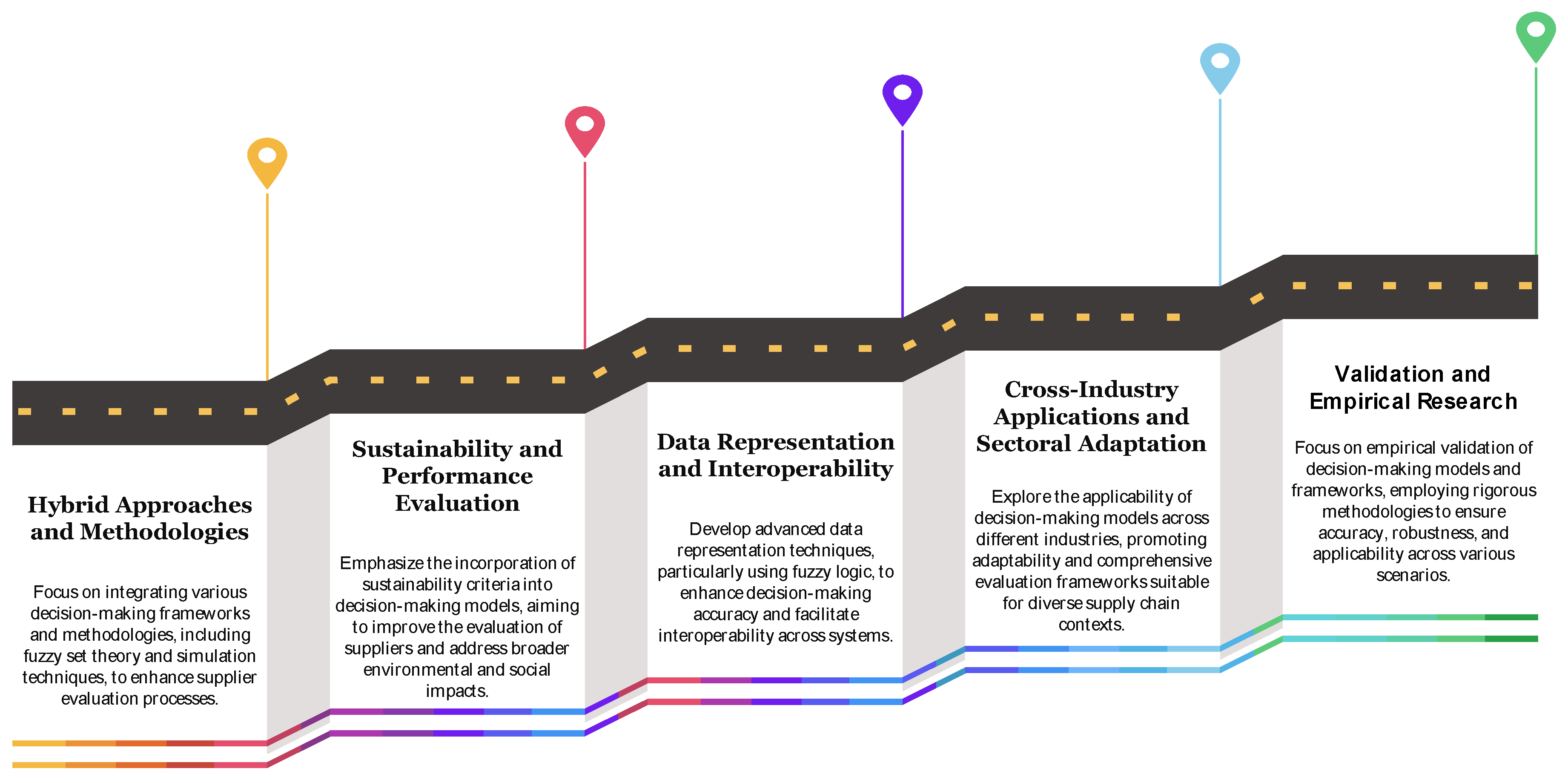

3.5. Future Directions in Supply Chain Decision-Making

4. Discussion

5. Conclusions

References

- K. Farhana, A. S. F. Mahamude, and M. T. Mica, “The Scenario of Textile Industry in Malaysia: A Review for Potentiality,” Mater. Circ. Econ., vol. 4, no. 1, p. 20, Dec. 2022. [CrossRef]

- Economic Analyst, Croatia and A. Gavranovic, “How to deal with new challenges? Economic, technological and social aspects of the textile and clothing industry,” Text. Leather Rev., vol. 1, no. 1, pp. 29–33, Jun. 2018. [CrossRef]

- Khadaria, A. Kumari, A. Pareek, D. Parekh, and D. Mittal, “Review of Sustainable Supply Chain Management in Textile Industry,” INTERANTIONAL J. Sci. Res. Eng. Manag., vol. 06, no. 05, Apr. 2022. [CrossRef]

- J. Rita, “The Role of the Supply Chain in Developing Innovation Processes in the Textile Industry,” in Industry and Innovation: Textile Industry, J. Moleiro Martins, Ed., in SDGs and Textiles. , Cham: Springer Nature Switzerland, 2024, pp. 53–63. [CrossRef]

- S. G. Teng and H. Jaramillo, “Linking tactical and operational decision-making to strengthen textile/apparel supply chains,” Int. J. Logist. Syst. Manag., vol. 1, no. 2/3, p. 244, 2005. [CrossRef]

- C.-N. Wang, V. T. H. Viet, T. P. Ho, V. T. Nguyen, and V. T. Nguyen, “Multi-Criteria Decision Model for the Selection of Suppliers in the Textile Industry,” Symmetry, vol. 12, no. 6, p. 979, Jun. 2020. [CrossRef]

- H. Taherdoost and A. Brard, “Analyzing the Process of Supplier Selection Criteria and Methods,” Procedia Manuf., vol. 32, pp. 1024–1034, 2019. [CrossRef]

- S. Thiruchelvam and J. E. Tookey, “Evolving Trends of Supplier Selection Criteria and Methods,” Int. J. Automot. Mech. Eng., vol. 4, pp. 437–454, Dec. 2011. [CrossRef]

- K. Kozioł-Nadolna and K. Beyer, “Determinants of the decision-making process in organizations,” Procedia Comput. Sci., vol. 192, pp. 2375–2384, 2021. [CrossRef]

- Biju Patnaik University of Technology (BPUT), Rourkela, Odisha, India, S. K. Sahoo, S. S. Goswami, and Biju Patnaik University of Technology (BPUT), Rourkela, Odisha, India, “A Comprehensive Review of Multiple Criteria Decision-Making (MCDM) Methods: Advancements, Applications, and Future Directions,” Decis. Mak. Adv., vol. 1, no. 1, pp. 25–48, Dec. 2023. [CrossRef]

- P. Kumar and A. Tiwari, “MCDM-Based Decision Support System for Product Design and Development,” in Design for Tomorrow—Volume 2, vol. 222, A. Chakrabarti, R. Poovaiah, P. Bokil, and V. Kant, Eds., in Smart Innovation, Systems and Technologies, vol. 222. , Singapore: Springer Singapore, 2021, pp. 575–584. [CrossRef]

- M. Behzadian, S. Khanmohammadi Otaghsara, M. Yazdani, and J. Ignatius, “A state-of the-art survey of TOPSIS applications,” Expert Syst. Appl., vol. 39, no. 17, pp. 13051–13069, Dec. 2012. [CrossRef]

- S. A. R. Khan, Z. Yu, H. Golpira, A. Sharif, and A. Mardani, “A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions,” J. Clean. Prod., vol. 278, p. 123357, Jan. 2021. [CrossRef]

- Z. Guo, W. Wong, S. Leung, and M. Li, “Applications of artificial intelligence in the apparel industry: a review,” Text. Res. J., vol. 81, no. 18, pp. 1871–1892, Nov. 2011. [CrossRef]

- J. Dal Forno, W. V. Bataglini, F. Steffens, and A. A. Ulson De Souza, “Industry 4.0 in textile and apparel sector: a systematic literature review,” Res. J. Text. Appar., vol. 27, no. 1, pp. 95–117, Feb. 2023. [CrossRef]

- S. Arora and A. Majumdar, “Machine learning and soft computing applications in textile and clothing supply chain: Bibliometric and network analyses to delineate future research agenda,” Expert Syst. Appl., vol. 200, p. 117000, Aug. 2022. [CrossRef]

- D. Tranfield, D. Denyer, and P. Smart, “Towards a methodology for developing evidence-informed management knowledge by means of systematic review,” Br. J. Manag., vol. 14, no. 3, pp. 207–222, 2003.

- S. Kraus, M. Breier, and S. Dasí-Rodríguez, “The art of crafting a systematic literature review in entrepreneurship research,” Int. Entrep. Manag. J., vol. 16, no. 3, pp. 1023–1042, Sep. 2020. [CrossRef]

- F. Guneri, A. Yucel, and G. Ayyildiz, “An integrated fuzzy-lp approach for a supplier selection problem in supply chain management,” Expert Syst. Appl., vol. 36, no. 5, pp. 9223–9228, Jul. 2009. [CrossRef]

- P. Chithambaranathan, N. Subramanian, and Pl. K. Palaniappan, “An innovative framework for performance analysis of members of supply chains,” Benchmarking Int. J., vol. 22, no. 2, pp. 309–334, Mar. 2015. [CrossRef]

- Fallahpour, K. Y. Wong, E. U. Olugu, and S. N. Musa, “A Predictive Integrated Genetic-Based Model for Supplier Evaluation and Selection,” Int. J. Fuzzy Syst., vol. 19, no. 4, pp. 1041–1057, Aug. 2017. [CrossRef]

- S. Burney and S. M. Ali, “Fuzzy multi-criteria based decision support system for supplier selection in textile industry,” IJCSNS, vol. 19, no. 1, p. 239, 2019.

- R. Raut, B. B. Gardas, and B. Narkhede, “Ranking the barriers of sustainable textile and apparel supply chains: An interpretive structural modelling methodology,” Benchmarking Int. J., vol. 26, no. 2, pp. 371–394, Feb. 2019. [CrossRef]

- Ulutaş, “Supplier Selection by Using a Fuzzy Integrated Model for a Textile Company,” Eng. Econ., vol. 30, no. 5, pp. 579–590, Dec. 2019. [CrossRef]

- S. M. Ali, S. A. Burney, and S. Y. Khan, “Fuzzy-AHP-TOPSIS: An integrated multi-criteria decision support system for supplier selection in Pakistan’s textile industry,” Ijcsns, vol. 20, no. 4, p. 91, 2020.

- Y. Yang and Y. Wang, “Supplier Selection for the Adoption of Green Innovation in Sustainable Supply Chain Management Practices: A Case of the Chinese Textile Manufacturing Industry,” Processes, vol. 8, no. 6, p. 717, Jun. 2020. [CrossRef]

- E. Celik, M. Yucesan, and M. Gul, “Green supplier selection for textile industry: a case study using BWM-TODIM integration under interval type-2 fuzzy sets,” Environ. Sci. Pollut. Res., vol. 28, no. 45, pp. 64793–64817, Dec. 2021. [CrossRef]

- C.-N. Wang, T.-D. T. Pham, and N.-L. Nhieu, “Multi-Layer Fuzzy Sustainable Decision Approach for Outsourcing Manufacturer Selection in Apparel and Textile Supply Chain,” Axioms, vol. 10, no. 4, p. 262, Oct. 2021. [CrossRef]

- Ulutaş, A. Topal, D. Pamučar, Ž. Stević, D. Karabašević, and G. Popović, “A New Integrated Multi-Criteria Decision-Making Model for Sustainable Supplier Selection Based on a Novel Grey WISP and Grey BWM Methods,” Sustainability, vol. 14, no. 24, p. 16921, Dec. 2022. [CrossRef]

- S. Bait, S. Marino Lauria, and M. M. Schiraldi, “A risk-based hybrid multi-criteria approach to support managers in the industrial location selection in developing countries: A case study of textile sector in Africa,” J. Clean. Prod., vol. 335, p. 130325, Feb. 2022. [CrossRef]

- Department of Production Engineering, Jadavpur University, Kolkata, West Bengal, India, V. K. Paul, S. Chakraborty, National Institute of Industrial Engineering, Mumbai, India, S. Chakraborty, and Department of Production Engineering, Jadavpur University, Kolkata, West Bengal, India, “An integrated IRN-BWM-EDAS method for supplier selection in a textile industry,” Decis. Mak. Appl. Manag. Eng., vol. 5, no. 2, pp. 219–240, Oct. 2022. [CrossRef]

- Tuş and E. Aytaç Adali, “Green Supplier Selection Based on the Combination of Fuzzy SWARA (SWARA-F) and Fuzzy MARCOS (MARCOS-F) Methods,” Gazi Univ. J. Sci., vol. 35, no. 4, pp. 1535–1554, Dec. 2022. [CrossRef]

- H. Kao, “Integrated Fuzzy-MSGP Methods for Clothing and Textiles Supplier Evaluation and Selection in the COVID-19 Era,” Math. Probl. Eng., vol. 2022, pp. 1–13, Jul. 2022. [CrossRef]

- G. Caristi, R. Boffardi, C. Ciliberto, R. Arbolino, and G. Ioppolo, “Multicriteria Approach for Supplier Selection: Evidence from a Case Study in the Fashion Industry,” Sustainability, vol. 14, no. 13, p. 8038, Jun. 2022. [CrossRef]

- M. M. Rahman, A. B. M. M. Bari, S. M. Ali, and A. Taghipour, “Sustainable supplier selection in the textile dyeing industry: An integrated multi-criteria decision analytics approach,” Resour. Conserv. Recycl. Adv., vol. 15, p. 200117, Nov. 2022. [CrossRef]

- C.-N. Wang, C.-F. Pan, V. Tinh Nguyen, and S. Tam Husain, “Sustainable Supplier Selection Model in Supply Chains During the COVID-19 Pandemic,” Comput. Mater. Contin., vol. 70, no. 2, pp. 3005–3019, 2022. [CrossRef]

- F. Ecer and A. E. Torkayesh, “A Stratified Fuzzy Decision-Making Approach for Sustainable Circular Supplier Selection,” IEEE Trans. Eng. Manag., vol. 71, pp. 1130–1144, 2024. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).