1. Introduction

The need for humanity to find ways to minimize carbon gases emission in the atmosphere and apply these solutions is urgent. Previous studies show a link between short-term exposure to ambient air pollution and cardiovascular and respiratory-related mortality (Bravo et al., 2015). Also, previous studies indicate that air pollution is associated with excessive respiratory e cardiovascular morbidity and mortality in which, public health is the major problem generated by air pollutants emitted by industrial plants and internal combustion motorized vehicles (Ko et al., 2007).

In the last years, humanity has been spending all efforts to finish this era in which fossil haw material was the primary energy source. Although petroleum has been substituted by new cleaner and renewable biofuels, it is almost sure that the end of this fossil fuel will not happen in the next three decades (Scherzinger1&Kaltschmitt, 2021).The framework of decarbonization has, basically, two principal pillars: expand investments in sectors responsible for renewable energy and improve those technologies that can promote a sustainable well-establish. Because of these initiatives, in 2018, the capacity of renewable power systems has reached 3,378 Gigawatts (Amein et al., 2021).

It is almost a unanimous conclusion that the causes of climate change occurring in the world are the result of human behavior. One of the initiatives to try to reverse this situation is change our energy sources from fossil to renewable like biomass, for example(Rodriguez-Diaz et al., 2016).An example of renewable energy that is being used experimentally in urban public transport and road freight transport, is biodiesel from any kinds of biomass. This new model of energy presents many benefits if compared with diesel from petroleum. Some of these benefits are acceptable properties for diesel engine, non-toxic for environment, biodegradability, high safety and renewability (Thoai et al., 2017; Chouhan &Sarma, 2011; Knothe& Razon, 2017).

The quality of biodiesel has how most important two properties, among the others properties, which are, ester content and total glycerol content(EN 14105, 2011). Some results obtained by previous studies say that the efficiency of the biodiesel production process is due to the ester content(Alptekin & Canakci, 2011; Silva et al., 2011). However, previous studies have proposed a new evaluation method based on the content of total glycerol (Thoai et al., 2017).

One investigation was conducted about the production process of biodiesel based on total glycerol content, and the raw material used in this case was refined palm oil. To generate the model that describes process behavior was used Response Surface Method (RSM) and statistical method of analysis of variance (ANOVA) (Thoai et al., 2017).

In the broader sense, optimization could be according to a tendency to search for the best solution under a particular problem or a specific circumstance or, in more frequently situations, a current process under study (Sieniutycz & Jezowski, 2009).The list of more common optimization problems could be presented, linear, nom-linear, and combinatorial. There is a specific solution method for each of these types of problems like Linear Programming, SIMPLEX, Response Surface Method, Heuristic, and Metaheuristic algorithms (Adjiman et al., 2004).

In the present study, the optimization method of metaheuristic algorithms was used. This method is a subfield of stochastic optimization, a general class algorithm, and technique that employs some degree of randomness to find the best solution (or more best as possible) of problems with a hard quantity of possible solutions (Luke, 2010).

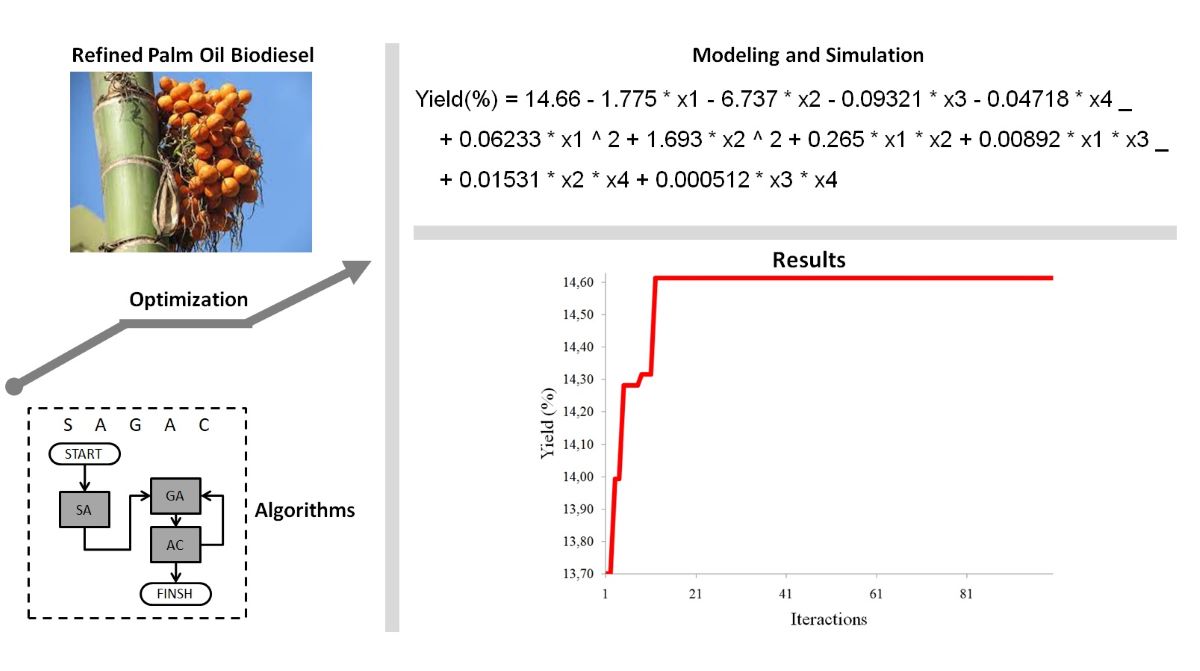

Beyond heuristic and metaheuristic algorithms, there is the possibility to join two or more algorithms in only one aiming the best quality of each one, improving the performance in the optimization process. This mix of algorithms to compose a more efficient optimization algorithm is named the Hybrid algorithm. There are any king of these Metaheuristic Hybrid algorithms, which may be composed of heuristic or metaheuristic algorithms(Gelves-Tello et al., 2016). The current study used a Hybrid Metaheuristic algorithm composed of them Simulated Annealing algorithm and the Genetic Algorithm modified, which includes a mechanism (function) named how Acceleration Convergence.

The present research refers to the improvement of Refined Palm Oil Biodiesel production process which can minimize use of natural resources as water and energy, and minimize its costs, as well. Consequently, its final products can become more affordable.

2. Materials and Methods

The steps of this study are a set of tasks described in a logical sequence to get a series of results. The needed material to execute each task is presented as these tasks are explained.

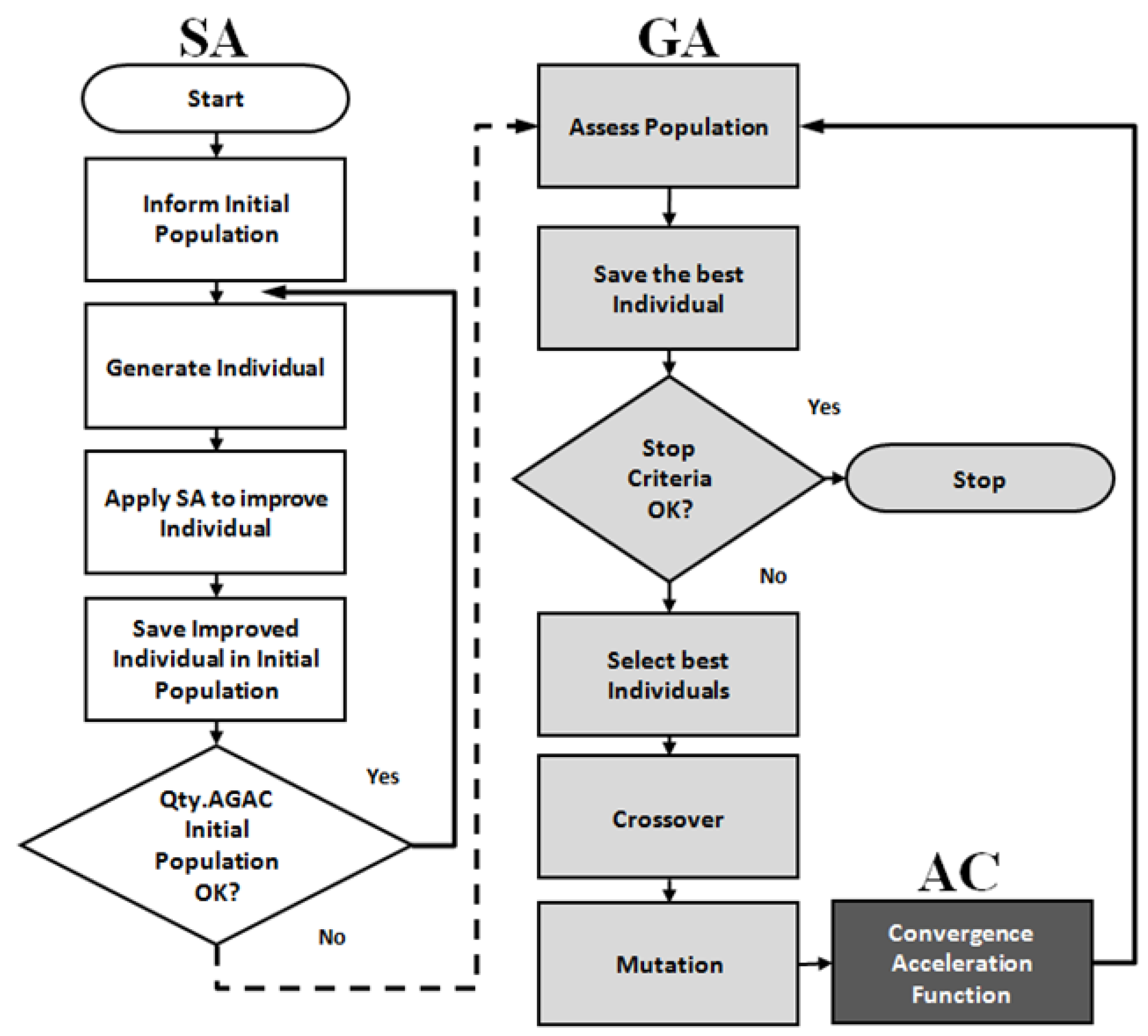

2.1. SAGAC algorithm

SAGAC algorithm is a hybrid metaheuristic algorithm which has a composition of two known algorithms, Simulated Annealing (SA) and Genetic Algorithm (GA). The novelty that is presented in this algorithm, is in the inclusion of a mechanism (function) inside of Genetic Algorithm, precisely in the crossover function as shown in

Figure 1.

This new function (mechanism) is able to promote a acceleration of finding new better results during algorithm processing, causing a acceleration in the convergence of results.

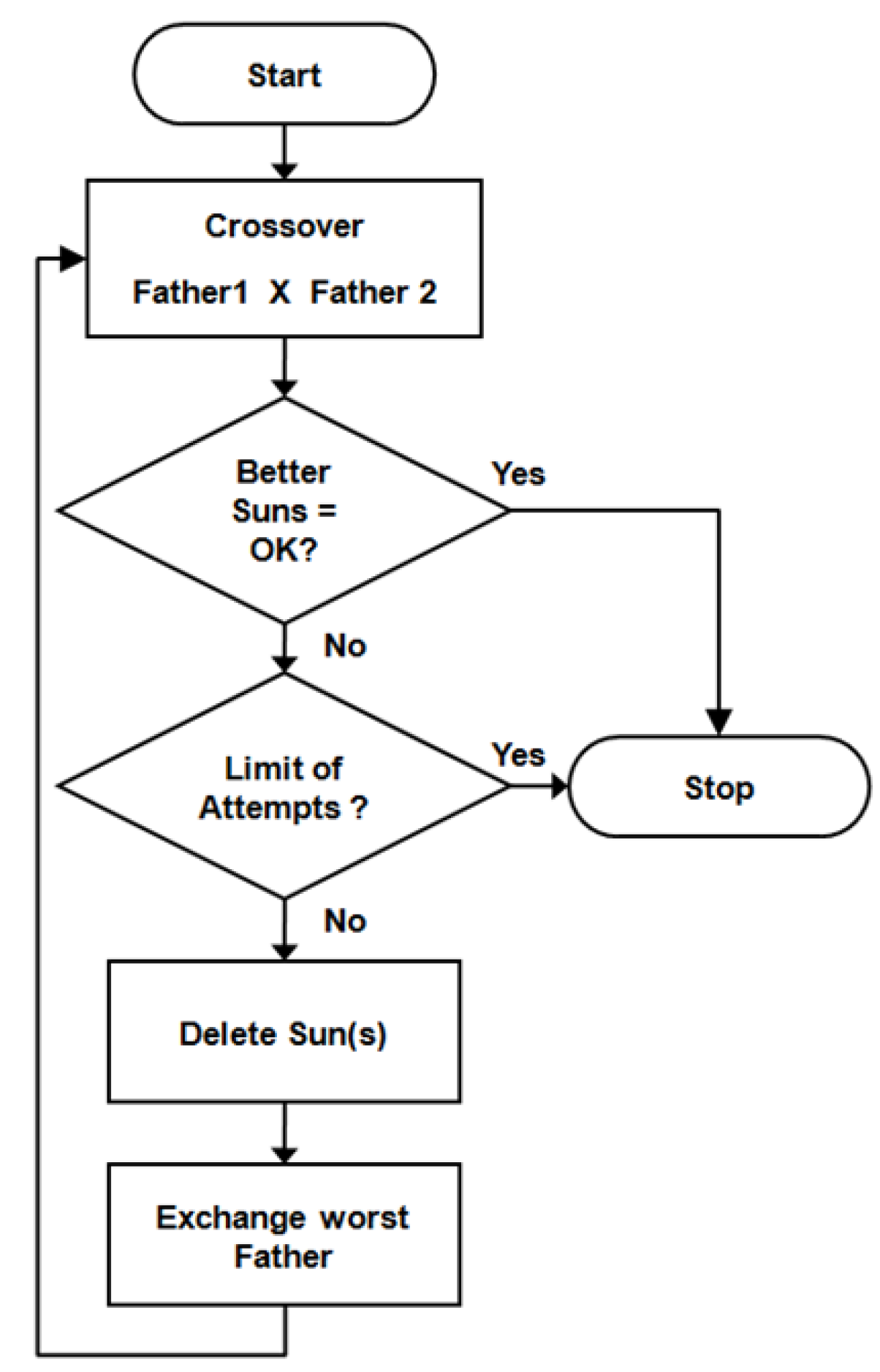

2.2. The functionality of Acceleration Convergence (AC)

In the

Figure 2 is shown flowchart with steps of acceleration convergence (AC) mechanism.

The steps of AC mechanism (function) were organized to optimize the quality of results (individuals of a population) generated by Genetic Algorithm (GA). All process occurs during crossover functionality, where after individuals parents generate them individuals descendants (suns) through crossover of them chromosomes. After descendants generation, they are evaluated by fitness function (process model) and, a check is made if they have enough valuation greater than or equal worst individual in elite group. If not, that descendent is discarded (excluded). A comparison between parents is made too, and that parent which has worst evaluation is exchanged by another elite individual. Then, crossover process run again and, it cycle occurs while unless, one of the descendants don't has enough evaluation to belongs to the elite group or, the number of trials defined by operator is reached.

2.3. Setup Parameters of SAGAC

In this topic is presented processing parameters of SAGAC algorithm and, values that have been assigned to each of them (Xu et al 2015, Zhang et al 2007, Mitchel 1997, Kirkpatrick et al 1983). Just to remember, SAGAC algorithm is a hybrid algorithm that is a composition of two metaheuristic algorithms, Simulated Annealing (SA) and Genetic Algorithm (GA). Therefore, the it has all parameters responsible to processing behavior of those algorithms. Is important to notice that there is a one more parameters that belong to the Acceleration Convergence (AC) mechanism (function) and, this parameters defines a number of tries that AC is processed for each generation of GA. In

Table 1 are shown used values for each parameter of SAGAC algorithms.

As can be seen in

Table 1, SAGAC algorithm contains the union of all parameters of the algorithms that compose it. Including a new parameter belonging to Convergence Acceleration (AC) mechanism (function) and which defines the maximum number of attempts to generate descendent individuals with ratings greater than or equal to the worst rating of individuals in the elite group.

2.4. SAGAC Algorithm Encoding

It was necessary to encode it in a programming language to run the SAGAC algorithm and transform it into a practical application. The SAGAC algorithm application was developed in VBA/Excel® language in this case study. The choice for this language is justified because, most of the time, the data originating from research and the data resulting from the performed experiments are organized and stored in spreadsheets in the Excel® software.

2.5. Experimental Procedure

One crucial part of the application beyond the SAGAC algorithm is the process model that will be optimized and the range variation of model variables (process factors) Xu et al. (2015), 300 experimental trials were carried out. After these 300 assays are generated, data refer to the performance SAGAC algorithm for optimizing the biodiesel model process. The results were statistically analyzed and compared with results reported by Thoai et al. (2017). The proposed study provides the refinement of palm oil production biodiesel model submitted to optimization by the SAGAC algorithm to find the best values of its variables. The problem formulation is described in equation 1(Thoai et al., 2017).

Subject to:

x1: [3.00 ≤ Molar ratio (mol/mol) ≤ 9,00]

x2: [0.50 ≤ Catalyst content (wt%) ≤ 1.30]

x3: [45,0 ≤ Temperature oC) ≤ 65,0]

x4: [30 ≤ Time (min) ≤ 70]

Before starting run experiments is necessary to define the values of processing parameters of the SAGAC algorithm. For this specific study the parameters values were defined as follow: SA parameters (initial temperature = 100 and temperature decay scheme = 1), GA parameters(initial population = 400, individuals per generation = 100, elitism rate = 40%, and mutation rate = 4% and the stopping criterion of the algorithm was processed for 100 generations); and AC parameter(quantity of attempts to generate children in the elite = 1) (Benvenga & Nääs, 2021;Santana et al., 2010; Almeida et al., 2014; Sivamani & Baskar, 2018; Librantz et al., 2010).

3. Results

After running 300 experimental assays, a large amount of data is generated, and a set of analyses are done for interpreting this data.

3.1. Statistical Analysis

3.1.1. Data Distribution

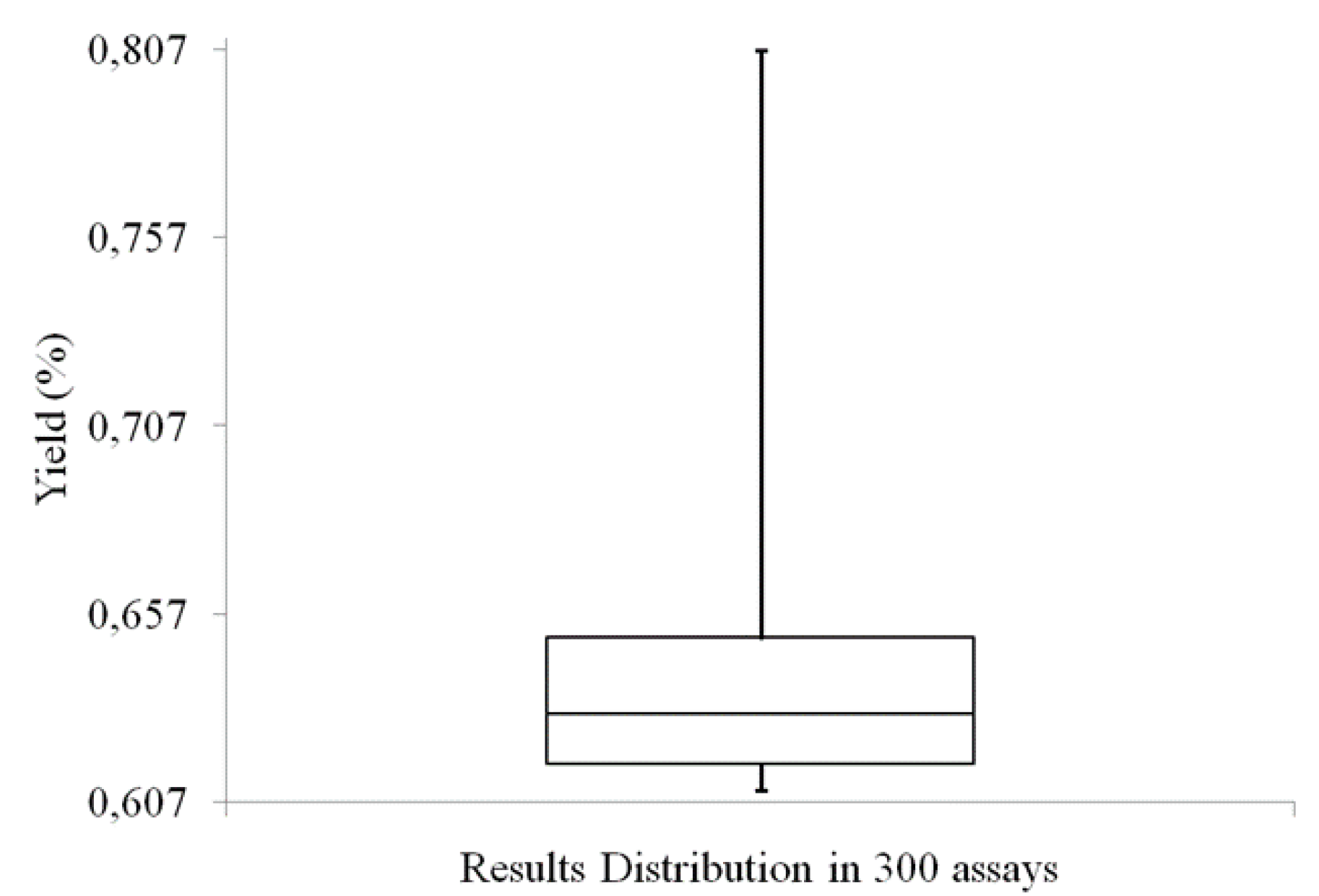

The first statistically analyzed result is about data distribution regarding 300 optimization assays.

Figure 3 presents a box plot graph that describes how 300 yield data from refined palm oil biodiesel production, obtained by SAGAC optimization, are distributed.

The graph in

Figure 3 shows the main statistical measures that describe the distribution of yield biodiesel production data as: Mean = 0.64, Median = 0.63, Standard Deviation = 0.03, Minimum value = 0.61, Maximum value = 0.81, First Quartile = 0.62, Second Quartile = 0.63 and Third Quartile = 0.65.

3.1.2. Correlation Data

After describing how data is distributed, another description of data refers to process factors (model variables) that relate to each other. The statistical way to describe this relationship between factors of any process is the correlation.

Table 2 presents the correlation between the refined model's independent variables for the palm oil biodiesel production process and the dependent variable, the process yield.

3.1.3. Variance Analysis

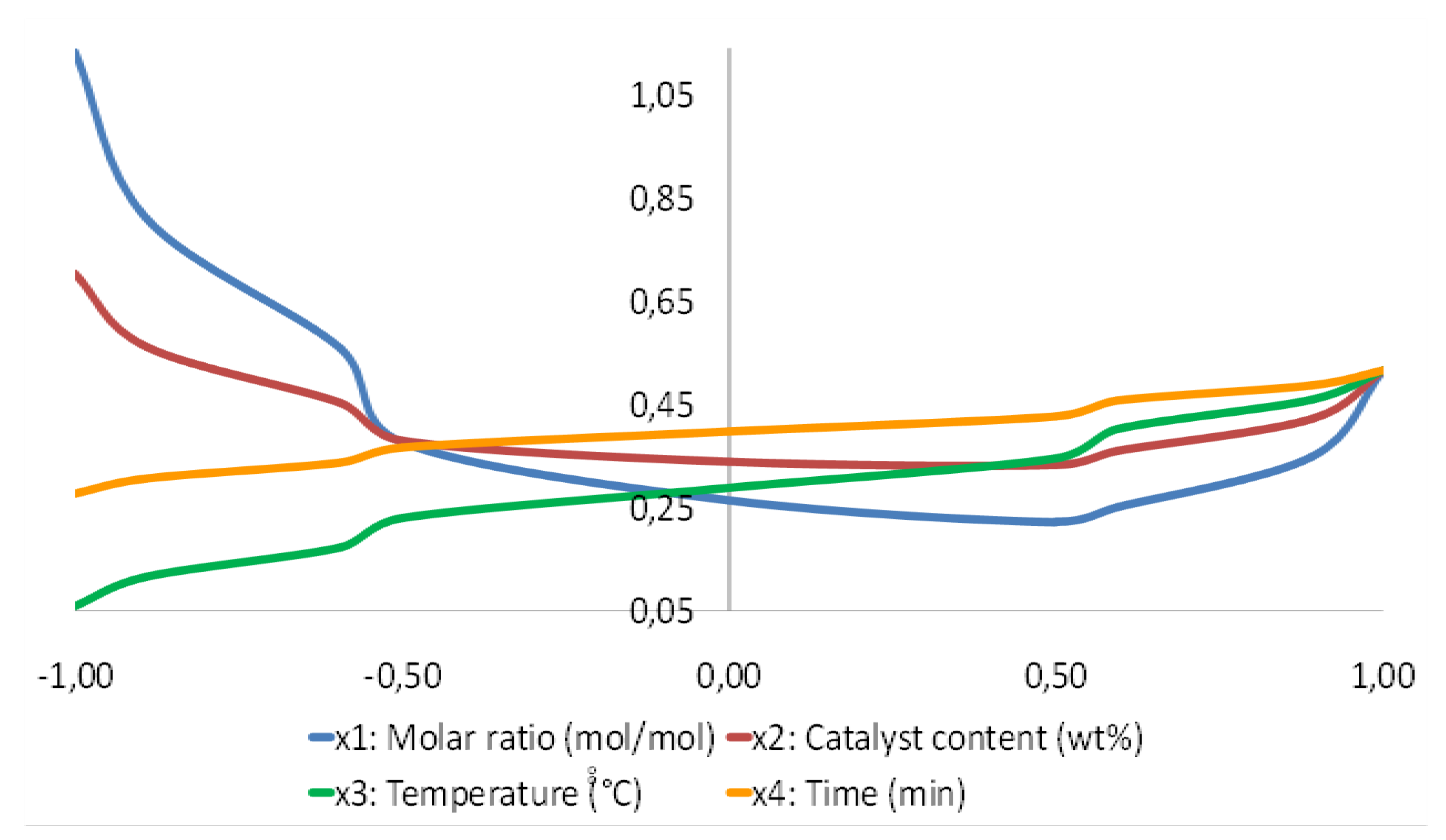

Figure 4 shows a comparation between the variation of production income and values of the factors involved in the process.

The graph in

Figure 4 shows the influence of each factor (model variable) which composes the refined palm oil biodiesel production process (Equation 1).To generate a graph that refers to total glycerol content (%) the curve of each factor is made with varied data of curve factor and maximum range value of each of other factors.

3.2. Optimization Data

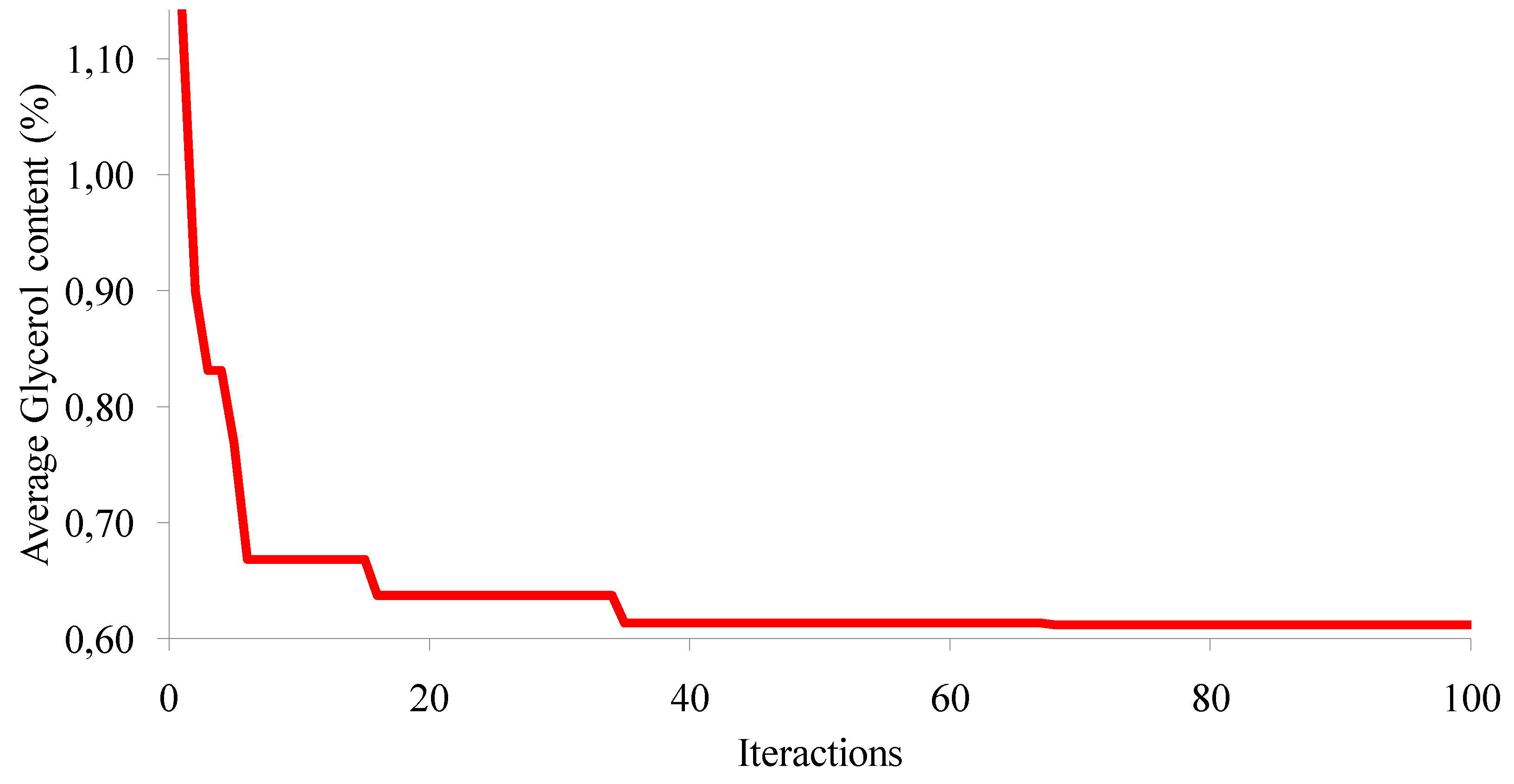

3.2.1. Optimization Convergence

Figure 5 shows the convergence curve of average results obtained each of 100 iterations of optimization processing is presented. The convergence curve presents the improvement results level. In this case, were ran 300 optimization experiments.

The convergence curve shown in

Figure 5 is made by average of 300 results of SAGAC algorithm in each of the 100 iterations in optimization processing. In this way, it was possible to visualize the average performance of the algorithm during the optimization process.

3.2.2. Results Comparison

The performed experiments generated Glycerol content (%) data through the relationship between process factors (independents variables) described by equation 1.

4. Discussion

The data generated during the experimental processing tests were organized, tabulated and submitted to statistical calculations to generate information that, after an analysis, could be relevant for this study and generate useful knowledge.

In the

Figure 3, the boxplot graph shows the data dispersion of results obtained by SAGAC algorithm in which is possible to identify the algorithm performance in the 300 optimization assays for refined palm oil biodiesel process. First information that is possible to identify is that majority results is near than minimum result = 0.6100 data (best result).Regarding to relation between Standard Deviation and Mean measures, the value is equal to 3.08%, which means that deviation of results is small, that is, with little oscillation. Other data presented by graph in

Figure 3 are first quartile = 0.6173, second quartile = 0.6304, third quartile = 0.6509 and maximum result = 0.8066 (worst result).

In the

Table 2, is shown the correlation of all independent variables (x1:Molar Ratio, x2:Catalyst Content, x3:Temperature and x4:Time) of process model (equation 1) with each others and the correlation between these independent variables and dependent variable (Glycerol Content). The most significant data is about correlation between Molar Ratio and Catalyst that is equal to -0.9, that means that correlation is inverse.

In case of sensibility analysis, represented in the graph in

Figure 4 it is noted that, the best condition of the biodiesel production process is more dependent on the Time(x4) variable levels, in which its values directly influence the process, while other variables (Molar ration, Catalyst content and Temperature) exert a minor influence.

The convergence curve, presented by graph in the

Figure 5, shows the average convergence results obtained by SAGAC algorithm in 300 experimental assays. In average, the algorithm get first results (glycerol content value) around 1.1%, improving (minimizing) these results until 0.61 around during first 37 iteration average, after that, the convergence level drops to almost zero. It means as there is an advance in the number of iterations performed by the algorithm during optimization, there is a regression in the improvement level of the results obtained.

Finaly, the comparison between results obtained by SAGAC algorithm and (THOAI et al., 2017) is shown by

Table 3 which have EM 14105 values equal to 0.24 and 0.26 wt% respectively. Considering these results, SAGAC had a performance 7.69% better.

5. Conclusions

Among the aspects that justify the use of methodologies which promote the improvement of production processes results, whether maximization or minimization. The waste elimination, the reduction of costs and the increase in productivity are some of them. Another important aspect that should be mentioned is the promotion of reduction in use of resources by the process, whether they are human, financial and especially natural resources, thus making the production of goods and services more socially correct, economic and environmentally sustainable. SAGAC algorithm is a union of two widely used methods of optimization, Simulated Annealing and Genetic Algorithm with inclusion of acceleration convergence mechanism. In this study, a comparison between SAGAC and Thoai et al., (2017) results were made and a results improvement of 7.69% was presented by SAGAC algorithm.

References

- Adjiman, C. S., Androulakis, I. P., &Floudas, C. A., (2004). Global optimization of mixed-integer nonlinear problems. AIChE Journal, 46(9), 1769-1797. Author 1, A.; Author 2, B. Title of the chapter. In Book Title, 2nd ed.; Editor 1, A., Editor 2, B., Eds.; Publisher: Publisher Location, Country, 2007; Volume 3, pp. 154–196. [CrossRef]

- Ahmed AO (2017) B.Sc. Production of biodiesel via transesterfication ofwaste cooking oil catalyzed by zinc oxide nanoparticle, Dissertation,Faculty of Engineering and Technology, University of GeziraAuthor 1, A.B.; Author 2, C. Title of Unpublished Work. Abbreviated Journal Name year, phrase indicating stage of publication (submitted; accepted; in press).

- Almeida, S. S., Alves, W. A.L., Araújo, S. A., Santana, J. C. C., Narain, N. and Souza, R. R. (2014). Use of simulated annealing in standardization and optimization of the acerola wine production. Food Sci. Technol. Int. 34(2), 292-297. Author 1, A.B.; Author 2, C.D.; Author 3, E.F. Title of Presentation. In Proceedings of the Name of the Conference, Location of Conference, Country, Date of Conference (Day Month Year). [CrossRef]

- Alptekin E, Canakci M. Optimization of transesterification for methyl ester production from chicken fat. Fuel 2011; 90: p. 2630–2638.Title of Site. Available online: URL (accessed on Day Month Year).

- Al-Sakkari E, G., El-Sheltawy S.T., Abadir M.F., Attia N.K., El-Diwani G. (2016) Investigation of cement kiln dust utilization for catalyzing biodiesel production via response surface methodology. Int J Energy Res 41:593–603.

- Amein, Hamza & Kassem, Mahmoud & Hassan, Muhammed. (2021). Integration of transparent insulation shells in linear solar receivers for enhanced energy and exergy performances. Renewable Energy. [CrossRef]

- Benvenga M., Nääs I., (2021). Hybrid Metaheuristic Algorithm (Sagac) Used in Optimization of Vacuum Cooling Treatment of Postharvest Broccoli. Revista FSA. 18. 160-172. 10.12819/2021.18.7.10.

- Bravo, Mercedes & Son, Jiyoung& Freitas, Clarice & Gouveia, Nelson & Bell, Michelle. (2015). Air pollution and mortality in São Paulo, Brazil: Effects of multiple pollutants and analysis of susceptible populations. Journal of exposure science & environmental epidemiology. 26. [CrossRef]

- Chouhan APS, Sarma AK. Modern heterogeneous catalysts for biodiesel production: A comprehensive review. Renewable and SustainableEnergy Reviews 2011; 15: p. 4378–4399.

- El-Sheltawy ST, Al-Sakkari EG (2016) Recent trends in solid waste utilization for biodiesel production. J Solid Waste Technol Manag. [CrossRef]

- EN Standard 14105. Fat and oil derivatives - Fatty Acid methyl esters (FAME) - Determination of free and total glycerol and mono-di-triglyceride content. Austrian Standard Instituate: Wein 2011.

- Field, C. B. C. and Michalak, A. M. (2015). Water, Climate, Energy, Food: Inseparable & Indispensable, 114(3), 7-17. https://www.jstor.org/stable/24711226.

- Gelves-Tello, N. A., Mora-Moreno, R. A., &Lamos-Diaz, H. (2016). Solving the vehicle routing problem with stochastic demands using spiral optimization/Solucion del problema de ruteo de vehiculos con demandasestocasticasmediante la optimizacion por espiral/ Solucao do problema de roteamento de veiculos com demandasestocasticasmediante a otimizacao por espiral. Revista Facultad de Ingenieria, 25(42), 7+. https://link.gale.com/apps/doc/A459001280/IFME?u=anon~3e6b6b7f&sid=googleScholar&xid=ef1588c6.

- Giraçol J., Passarini K. C., Silva Filho S. C., Calarge F. A., Tambourgi E. B. and Santana J. C. C. (2011). Reduction in ecological cost through biofuel production from cooking oils: an ecological solution for the city of Campinas. J Clean Prod, 19, 1324-1329. [CrossRef]

- Holland, H. J. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence. MIT Press, Ann Arbor, 1975.

- Holland, H. J. Genetic Algorithms. Scientific Press, p. 66-72, 1992.

- Kirkpatrick, S., Gelatti, C. D., Vecchi, M. P. (1983) Optimization by Simulted Annealing. Science, New Series, 220, 671-680. https://science.sciencemag.org/content/220/4598/671.

- Knothe G, Razon LF. Biodiesel fuels. Progress in Energy and Combustion Science 2017; 58: p. 36–59. [CrossRef]

- Ko FW, Tam W, Wong TW, Chan DP, Tung AH, Lai CK, Hui DS. Temporal relationship between air pollutants and hospital admissions for chronic obstructive pulmonary disease in Hong Kong. Thorax. 2007 Sep;62(9):780-5. Epub 2007 Feb 20. PMCID: PMC2117326. [CrossRef] [PubMed]

- Librantz, A. F., Coppini, N. L., Baptista, E. A., Araújo, S. E. and Rosa, A. F. C. (2010). Genetic algorithm applied to investigate cutting process parameters influence on workpiece price formation. Mater. Manuf. Process,26:3, 550-557. https://www.tandfonline.com/doi/abs/10.1080/10426914.2010.512817. [CrossRef]

- Ling JSJ, Tan YH, Mubarak NM, Kansedo J, Saptoro A, Nolasco-Hipolito C (2019) A review of heterogeneous calcium oxide based catalyst from waste for biodiesel synthesis. SN Appl Sci 1:1–8. [CrossRef]

- Luke S., (2010), Essentials of Metaheuritics - A Set of Undergraduate Lecture Notes by, Department of Computer Science, George Mason University, Zeroth Edition, Online Version 0.8.

- Mitchell, T. M. (1997). Machine Learning. McGraw-Hill Science, Redmond, EUA, 249-270.

- Rodriguez-DiazE., VasquezJ. C., Guerrero J. M.,(2016), "Intelligent DC Homes in Future Sustainable Energy Systems: When efficiency and intelligence work together," in IEEE Consumer Electronics Magazine, vol. 5, no. 1, pp. 74-80. [CrossRef]

- Santana, J. C. C., Araújo, A. S., Librantz, A. F. H. and Tambourgi, E. B. (2010). Optimization of the corn malt drying by use of genetic algorithm. Dry. Technol., 28, 1236–1234. [CrossRef]

- Scherzinger M., Kaltschmitt M., (2021), Techno-economic assessment of common reed and sewage sludgeco-fermentation improved by vapothermal pre-treatment, Clean Technologies and Environmental Policy, Springer Nature. [CrossRef]

- Sieniutycz, S., &Jezowski, J. (2009). Energy optimization in process systems. Elsevier.

- Silva GF, Camargo FL, Ferreira ALO. Application of response surface methodology for optimization of biodiesel production by transesterification of soybean oil with ethanol. Fuel Processing Technology 2011; 92: p. 407–413. [CrossRef]

- Sivamani, S. and Baskar, R., (2018), Process design and optimization of bioethanol production from cassava bagasse using statistical design and genetic algorithm.Prep. Biochem. Biotechnol.48:9, 834-841. [CrossRef]

- Sulaiman S (2016) Overview of catalysts in biodiesel production. ARPN J Eng Appl Sci 11(1):439–448.

- Thangaraj PR (2019) Catalysis in biodiesel production—a review. Clean Energy 3:2–23. [CrossRef]

- Thoai D. N., Kumar A., Prasertsit K., Tongurai C., (2017), Evaluation of Biodiesel Production Process by the Determining of the Glycerol Content in Biodiesel, Energy Procedia 138, 544 - 551, International Conference on Alternative Energy in Developing Countries and Emerging Economies. [CrossRef]

- Zhang, Y., Rao, Y. and Zhou, M. (2007). GASA Hybird Algorithm Applied in Airline Crew Rostering System. Tsinghua Sci Technol, 12. [CrossRef]

- Xu S., WANG Y., LU P., Improved imperialist competitive algorithm with mutation operator for continuous optimization problems,. Neural Comput&Applic, 2015. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).