1. Introduction

In this digital revolution, robots have played a significant role in various applications of industries and domestic services. Many humanoid robots are simulated to perform tasks using artificial intelligence techniques (Yongan et al, 2017). In domestic applications, robot-based cleaning methodologies are getting popular to clean vessels, toilets, car wash, glass doors, windows, etc. Window cleaning robots are catching the cleaning industry focusing on windowpanes, glass tiles, and the risky job of cleaning façade glasses. The Window cleaning robots are available in different designs where microcontroller-based robots find a prominent place. Vacuum Cleaning Robots (VCR) can be used at homes, malls, companies, etc. This robot technology will reduce the cost of the cleaning process and increase the efficiency of cleaning and safety for humans. Normally the VCR will work using sensors, motors, and battery/electrical power with filters. It can be designed in different sizes according to the nature of the application. Hence, VCRs have more functions and have many advantages over human cleaning. The objective of this work is to develop a VCR and analyze its performance related to optimizing the distance coverage rate and area coverage rate, minimizing the repeat coverage area, missing rate, and energy consumption rate, and improving the efficiency in cleaning. In this work, we developed and analyzed a microcontroller-based vacuum cleaning robot that can be used for glass façade in vertical or horizontal positions.

2. Literature Review

Kuisong et al. (2017) have researched to determine the performance metrics for coverage of cleaning robots with motion capture systems. The researchers have taken three popular cleaning robots including laser type. They have evaluated the performance of the coverage algorithm of a cleaning robot with three metrics namely, coverage rate, repeat coverage area ratio and distance traveled. Experiments were conducted with the area of the test platform as 9.5 m2 and comparisons have been made to identify the efficient robot. They have concluded that laser-based cleaning robots are more efficient than randomized cleaning robots. Asafa et al (2018) developed a disc-shaped vacuum cleaner robot controlled by an Arduino mega-controller for office and home use. The robot is driven by a DC motor with 4 ultrasonic sensors placed 90° apart. Navigation efficiency, sweeping capacity, and power consumption were used to evaluate the performance of the developed robot. The paper reveals that the device will be deployed for office and home use with fully autonomous duty. Jinqiang et al (2018) developed a garbage-cleaning robot using a deep neural network. Authors have mentioned that garbage cleaning on grass can be used in schools, parks, and gardens which will efficiently work without human intervention. This deep learning-based robot can give cleaning efficiency up to 95% compared to the traditional methods. A design and analysis of an automatic vacuum which is a disc-shaped robot with an Arduino microcontroller and a vacuum system using the axial fan was discussed by Harish et al (2020). In this paper, three ultrasonic sensors were attached at the front and the microcontroller is programmed to move along a user-defined path. The simulation was done with Coppelia Robotics software. In the simulation, researchers have done obstacle avoidance and vacuum analysis for the robot. They have also demonstrated the velocity and pressure contour on a 2D plane with a magnitude plot using ANSYS software. Zhenjing et al (2021) surveyed window-cleaning robots in which authors discussed various window-cleaning mechanisms, algorithms, locomotion mechanisms, adhesion mechanisms, sensors, and controller units. This paper revealed a detailed review of the key techniques and applications of window-cleaning robots. Anıl and Hatice (2022) developed a vacuum cleaner robot controlled by Android smartphones. Remote control of the robot was done through a Bluetooth connection between the Raspberry Pi and Android smartphone. Random walk and snake algorithms were used as the navigation algorithm. Using a cliff sensor, the robot has been prevented from falling through spaces such as stairs. Nakagawa and Date (2023) developed an autonomous blower robot for cleaning and collecting fallen leaves from trees which can be used to clean the garden or children's park. The design has three variable speed wheel moving mechanisms. The researchers have used blowers to clean the leaves in large areas and evaluated the robot’s ability to clean. Nansai et al (2018) developed a façade cleaning robot with a biped mechanism to maximize its area coverage while cleaning. The developed robot uses active suction cups to adhere to glass walls and consists of mechanical linkage to navigate the glass surface to do the cleaning. This paper discusses the robot's control system, which consists of inverse kinematics, a fifth polynomial interpolation, and sequential control. Parween et al (2021) developed a reconfigurable robot, Mantis-mini, with a dry-cleaning mechanism and linear actuator-based transitioning mechanism. This robot consists of three suction elements that have independent differential drives. The structural analysis was carried out in this paper to verify the structural deformation and frequency behavior. This paper mainly focuses on the design parameter analysis rather than the performance analysis of the robot. Bisht et al (2022) presented a unique design concept, dynamic modeling, and control strategies for efficient coverage path planning of a glass façade cleaning robot. Simulation of path optimization result of this paper shows that the robot motion for Horizontal Line Sweep (HLS) compared to vertical line sweep (VLS), spiral line sweep (SLS), and special cell diffusion (SCD) motion. The path is the most energy efficient. The application of glass façade robots can be extended for cleaning photovoltaic panels. Antonelli et al (2020) developed an autonomous robotic device for the waterless cleaning of photovoltaic panels in a desert zone using the “Arduino Due” platform. Ze et al (2024) proposed a design of a passive adaptive wall climbing robot based on 5 bar mechanisms. This design can be applied to curved permeable metal walls, such as large ships’ outer bodies. The author claimed that the 5-bar mechanism improves the adaptability of the robot by adjusting its posture so that the driving wheels can fit the wall completely. In this paper, the authors used permanent magnet wheels for vertical climbing. In the requirement analysis of the glass façade robot, Shiyao Caia et al (2020) gave six points in wall climbing and Inspection such as safe and reliable climbing mechanisms, identification of the surrounding environment and obstacles, The ability to cross or avoid obstacles, Motion control, Efficient inspection methods and the ability to record and export the inspection results. The research gap in past literature is the cost and efficiency. So, there is a requirement in the cleaning industry for the best robot which is low cost with high efficiency and more covering area.

3. Methodology

The design of the robot has been done using a microcontroller based on an operating voltage of 24 V and a rated power of 75W. Arduino microcontroller and random walk mechanism are used in this work. Ultrasonic sensors are used to detect obstacles. The control system is a closed loop as given in

Figure 1. The input of 24V will be given to the locomotion mechanism and the vacuum adhesion mechanism will make the robot hold on to the glass panels. The robot's movement will be decided based on the random walk mechanism thereby the cleaning process takes place. The distance and detection sensors continuously give feedback to the controller to have more coverage area. The specification for the cleaning robot is given in

Table 1. According to the software design the controller will control the robot by adjusting the input commands through the remote. The challenge encountered in the development of robots is to integrate hardware with software. The other challenge is adhesion during the vertical cleaning. There is a chance of the robot falling from the facade. So, a rope is attached to the robot which can facilitate tying it with a rigid hanger as a safety measure.

3.1. Random Walk Algorithms

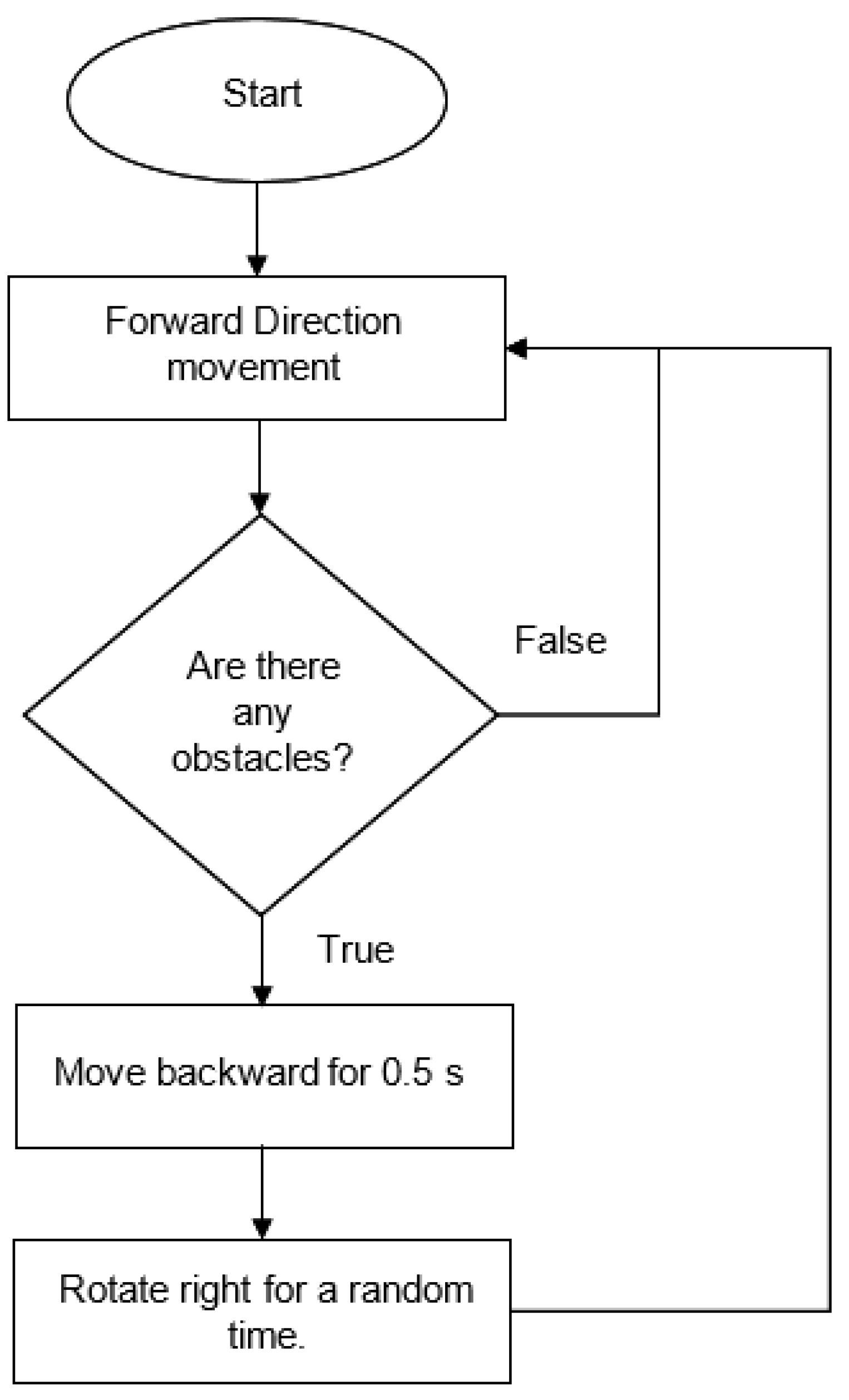

The random walk algorithm is used in this robot. These algorithms are useful in low-cost vacuum cleaner robots and the main advantage of the algorithm is that it does not require a precise route plan. The disadvantage is that the robot passes through the same area several times. In this algorithm, robots travel in the forward direction till any obstacle is detected by sensors. If obstacles are detected, the robot stops and changes the direction of the system according to the random number generated by the controller. The flow chart is given in

Figure 2. The random rotation time is adjusted as

The algorithms can be entirely random in which after each collision with an obstacle the robot randomizes a new heading without considering the place where it starts. This algorithm is highly suitable for small areas or corners. (Hasan et al 2014). A random walk-based algorithm can be integrated with sensors to decide to turn left or right when there is an obstacle in the path. This way the robot can turn without hitting obstacles. In this algorithm, a random number is generated, and the random turn is performed thereafter. So, the random movement will be based on surroundings which are highly required in cleaning the façade.

3.2. Operational Procedure of the Robot

There may be a chance to clean glasses at higher heights, a remote-based user interface system will allow one to perform tasks without any unsafe conditions. The user interface is remote with many keys for more convenience to control the robot's movement and improve the efficiency of the cleaning process. There are two types of keys on the remote to control the device viz., N – mode key and Z – mode key. The N-mode key directs the device to move in the path of the N-shaped route to wipe the vertical surface. This allows the device to move forward and reverse during the operation. The Z-mode key instructs the device to move in a zig-zag manner to wipe the surfaces. This allows the device to move from left to right along sideways during the operations. In addition to these keys, forward, reverse, right, and left side movements can be adjusted through the corresponding up, down, right, and left arrow keys.

3.3. Operational Limitations of the Robot

Should be used only on glasses or polished layers without broken surfaces, advertisement papers, or bumps.

Should be used only on planar surfaces without curved or beveled surfaces.

Preferred to use on the glass thickness without frames or with frame if the frame thickness is greater than 5 mm.

Should be used only on non-wet surfaces to avoid slipping or risks of falling.

The device should not be dipped in water for cleaning purposes.

Battery charging should not be carried out in an overheating or undercooled environment. This may affect battery life.

The device should not be placed in an upside-down manner.

4. Performance Metrics and Their Calculations

The following key performance indicators are evaluated for the cleaning robot:

Area coverage rate: Area coverage rate is one of the key performance indicators to measure the efficiency of the smart cleaning robot. It represents the total area covered by the robot in the given area.

Repeat coverage area: There may be every chance that the robot may pass through the same place again during the operation. This constitutes the repetition of the area covered and should be minimized. Repeat coverage area becomes a key performance indicator. This is best achievable by defining the path of the cleaning robot.

The distance coverage rate is the distance traveled by the cleaning robot in the defined path as per the controller software to the least distance traveled to cover the entire area of the given space. This is a key performance indicator to calculate the efficiency of the cleaning robot.

The cleaning rate indicates the effectiveness of the robot in cleaning the dust. It is the ratio of the ability of the robot to suck the dust to the total dust present in the given area.

5. Performance Analysis and Discussion

The robot is developed as per the specification given in

Table 1 and tested for cleaning on both horizontal and vertical glass panes. The robot is tested to analyze the cleaning performance as shown in

Figure 3 and

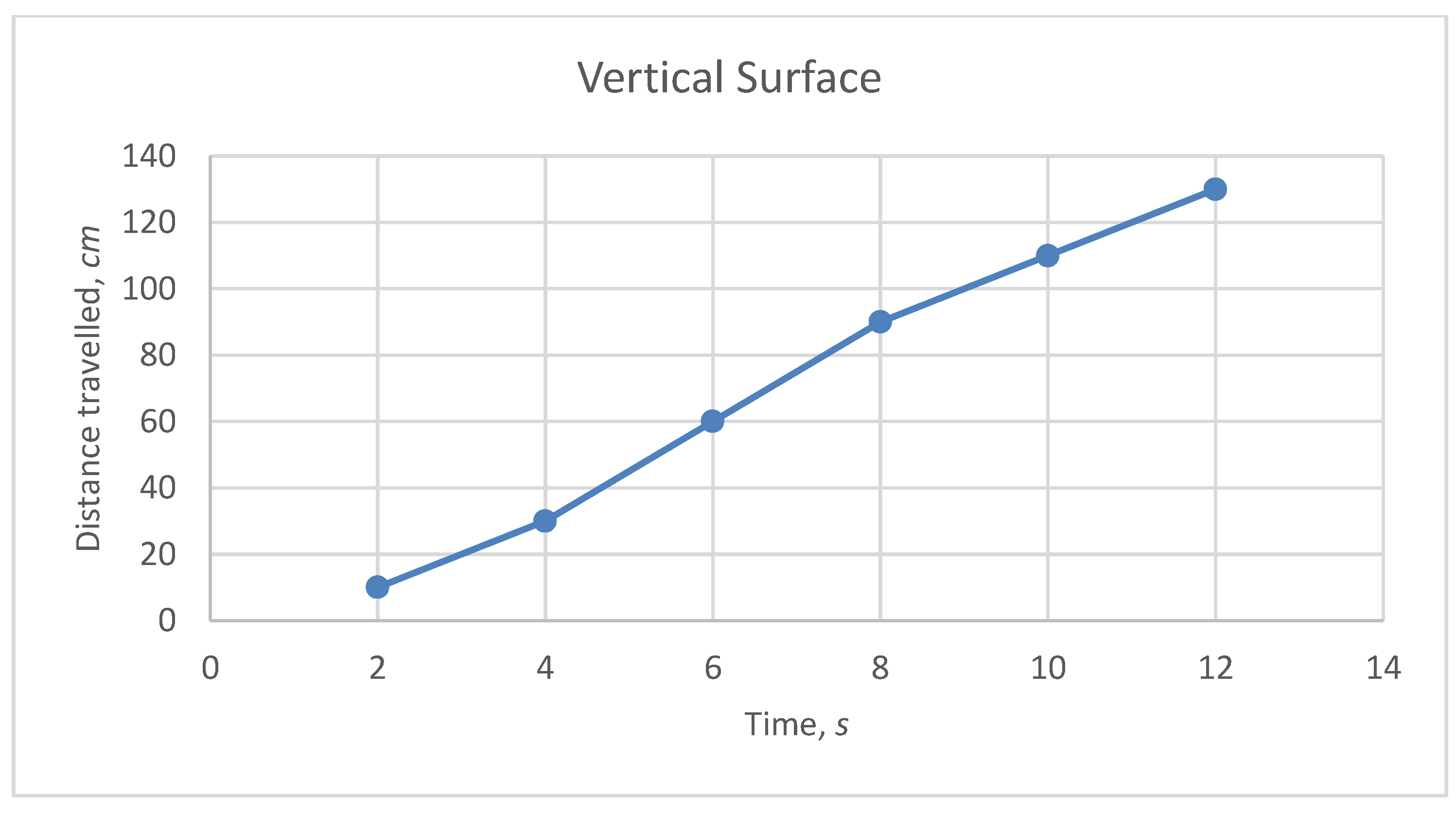

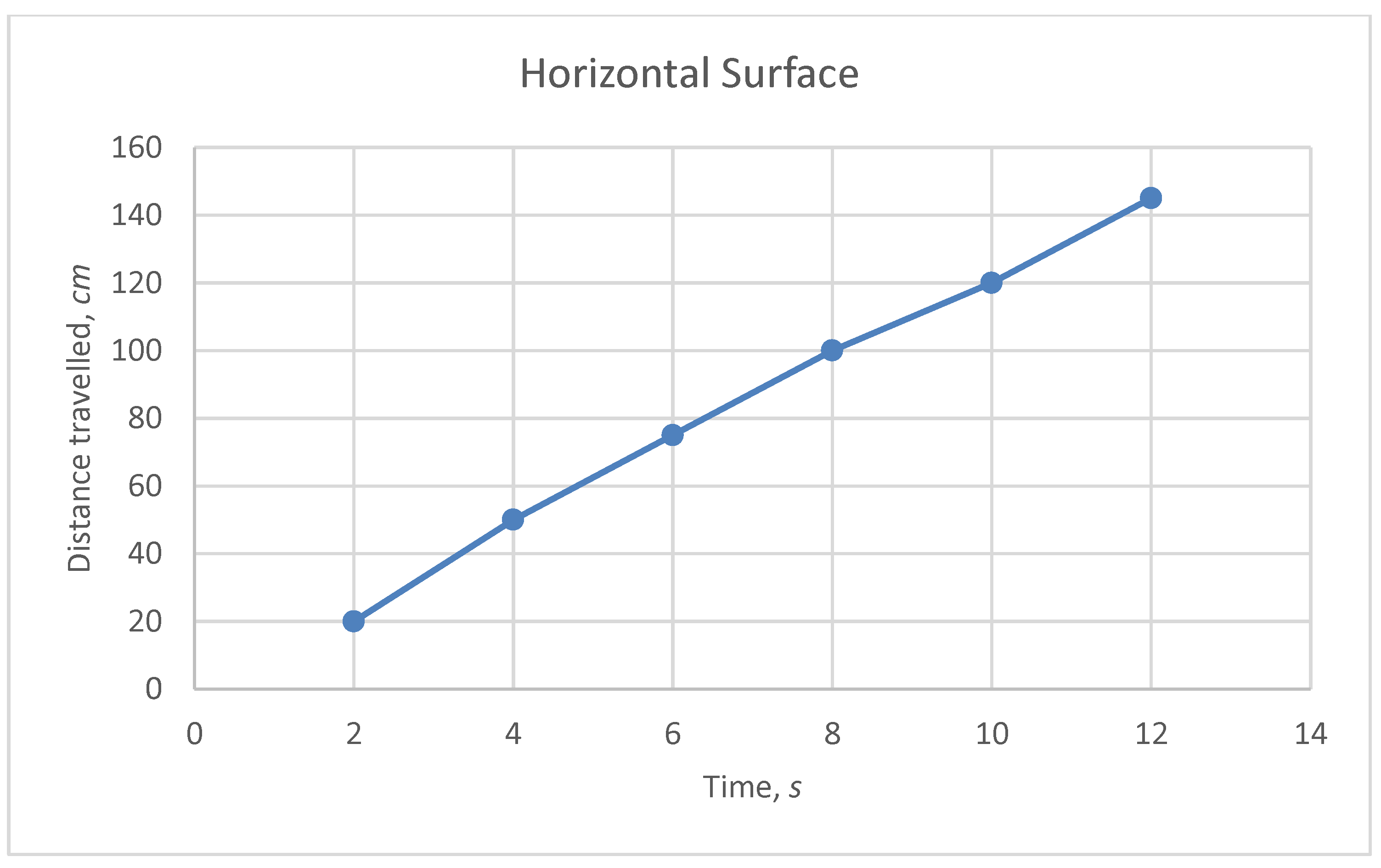

Figure 4. In the initial performance analysis, the distance traveled concerning time is observed for both horizontal and vertical cleaning. The distance traveled in cm is noted against the time from 2 sec to 12 sec for both cleanings.

Table 2 and

Table 3 show the distance traveled by the robot and

Figure 5 and

Figure 6 shows the line diagram of the distance travelled against the timing from 2 s to 12 s.

The total distance covered on the vertical surface is 130 cm in a 12 s period. The distance covered period is increasing due to increasing height. The distance covered period is increasing with the increasing height. In the horizontal surface, the total distance is 145 cm in a 12s period. More distance is covered on horizontal surfaces than on vertical surfaces due to the gravitational effect as well as the clamping effect. Overall, the result shows that vertical cleaning takes more time than horizontal cleaning. This is because the gravitational effect plays an important role during cleaning. During testing the seasonal effects are minimal and so not considered. So, the cleaning procedure will take more time on vertical surfaces whereas horizontal surfaces can be cleaned in less time. To calculate the coverage rate of

the glass surface is analyzed. During testing nearly

has been covered by the robot during horizontal cleaning whereas

has been covered for vertical cleaning.

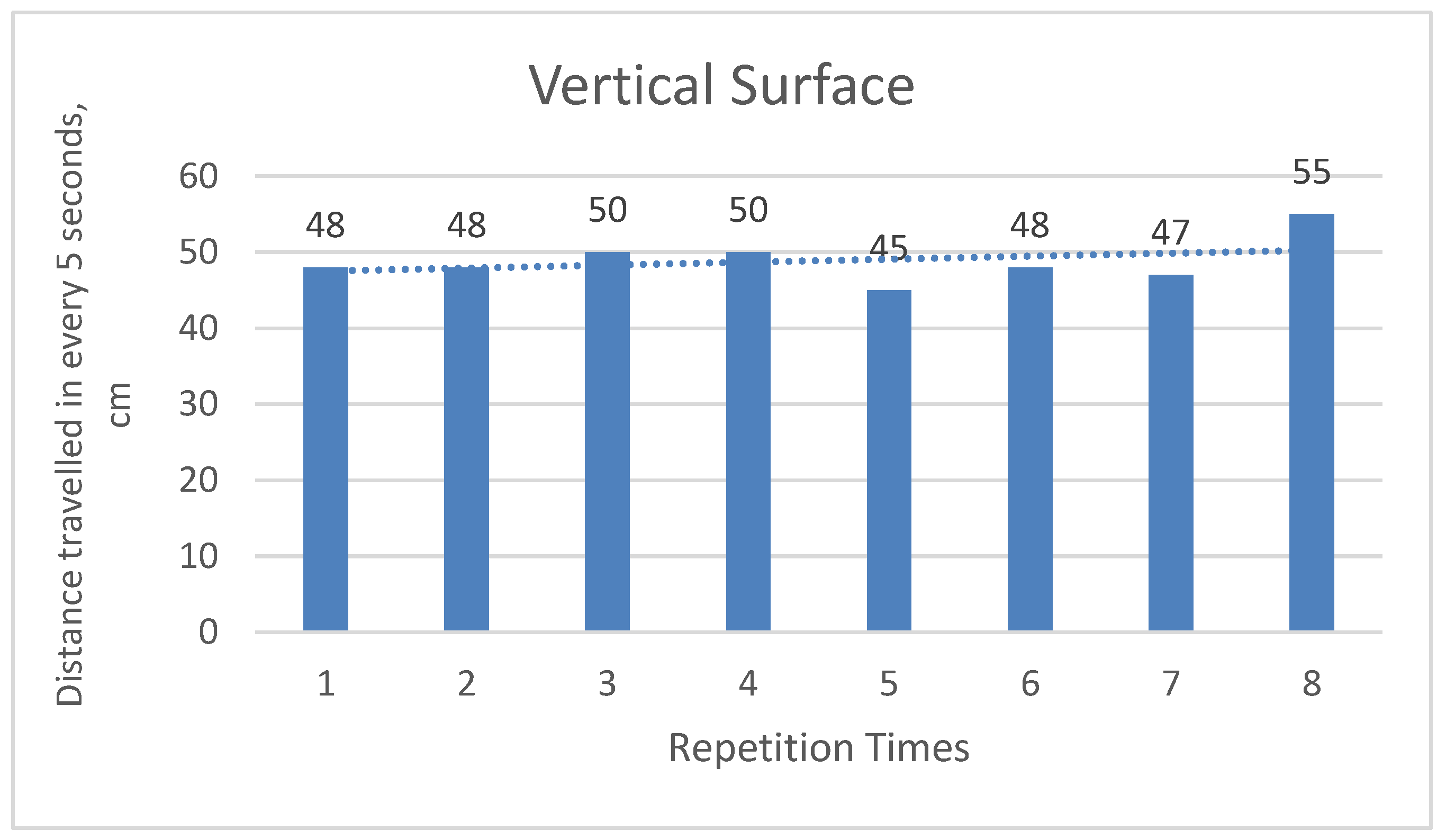

To understand the repeatability, the distance traveled for every 5s is observed 8 times during vertical cleaning and tabulated in

Table 4. The distance covered in 5 sec varies from 45 to 55 cm which means the repeatability is not consistent, but the distance traveled is good. The trend is shown in

Figure 7. In horizontal cleaning, it reaches up to 60 cm since the distance coverage is more compared to vertical cleaning.

Table 5 shows the distance traveled every 5 seconds and the relevant line diagram is given in

Figure 8.

Comparing these two-line diagrams in

Figure 7 and

Figure 8, the repeatability performance line is more straight on the horizontal surface than the vertical one. There is a variation in the repeatability of the vertical surface cleaning which means there is an effect due to gravitation and clamping time.

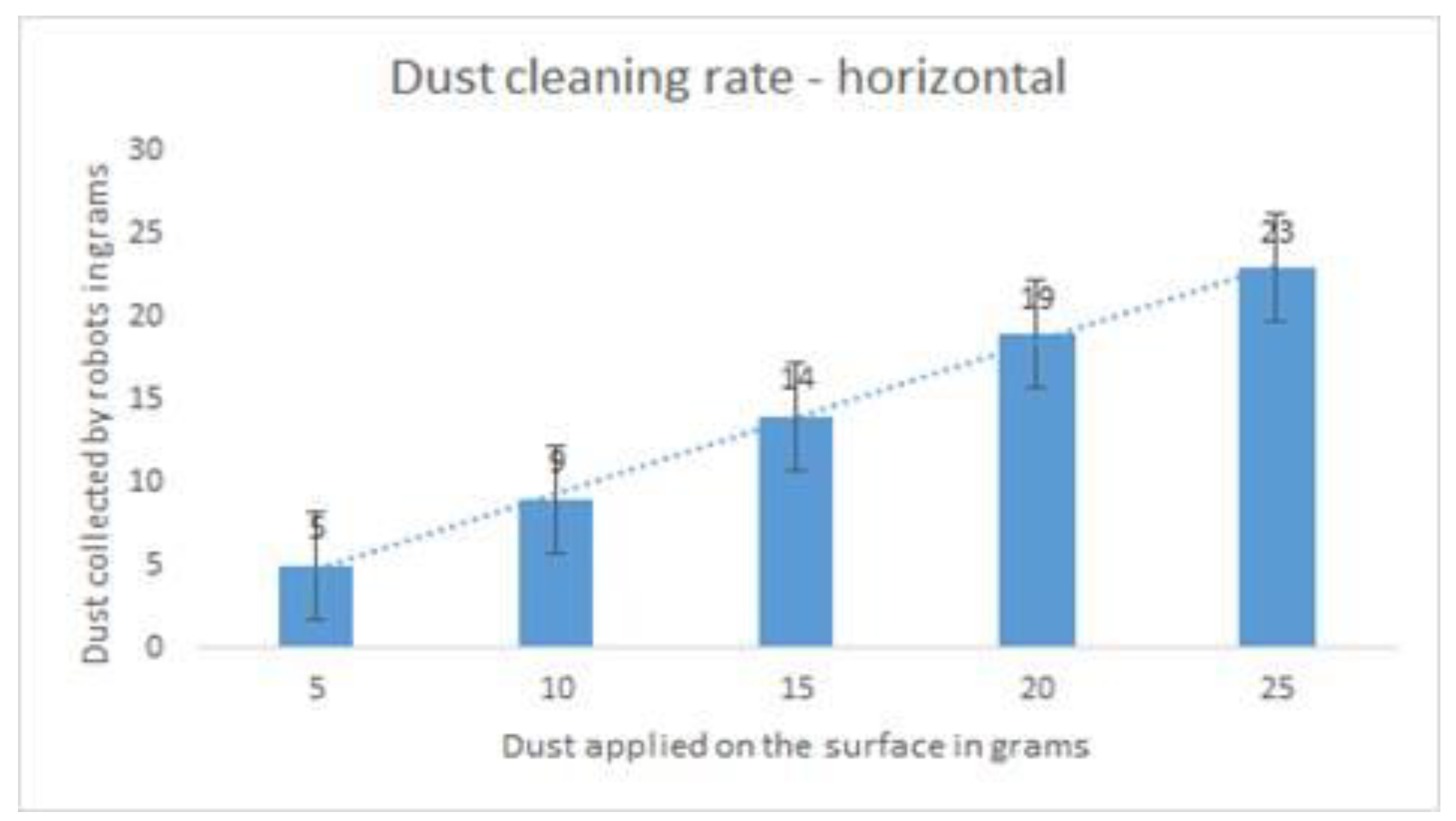

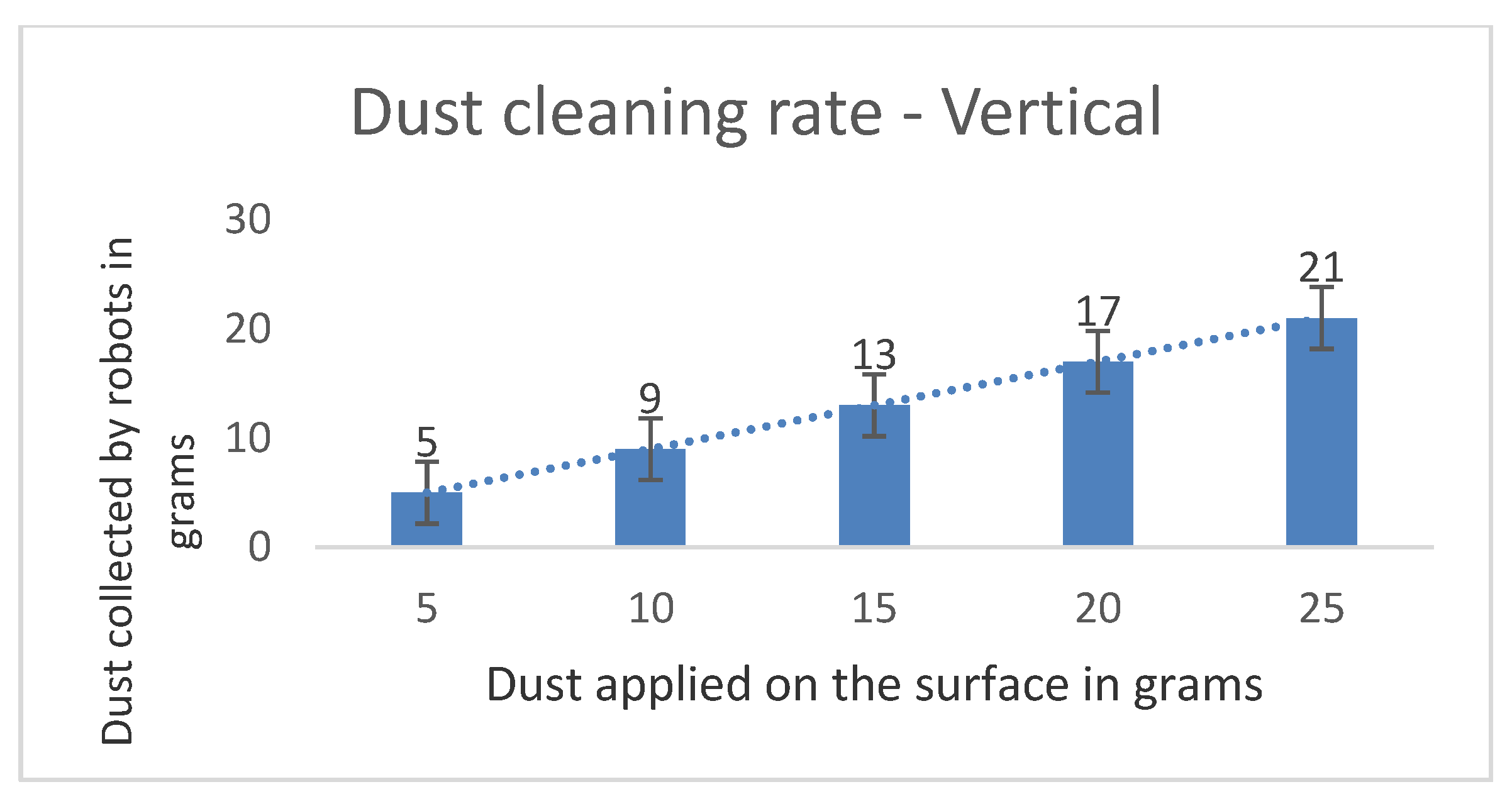

The dust collection efficiency has been calculated by applying some known weight of dust on the surface. After cleaning, the collection of dust is weighted, and dust collection efficiency has been calculated.

Table 6 and

Table 7 show the dust collected by the robot during horizontal and vertical cleaning and dust collection efficiencies are calculated.

Figure 9 and

Figure 10 show the collection of dust in grams. It is noted that the average efficiency of the robot in horizontal cleaning is 94.06% whereas for vertical it is 89.134%. During both the horizontal and vertical cleaning process, the efficiency is higher for fewer grams of dust. For example, 5 gm of dust is collected completely, and the efficiency is 100%. But with more amount of dust, the cleaning efficiency has been decreased gradually.

So, it has been clear that the robot is working better for cleaning horizontal surfaces than vertical. However, with the evolution of recent technologies, cleaning on vertical surfaces is possible with robots where high risks are involved, and cleaning is better than human cleaning. There is a limitation noticed in that the proposed robot efficiency is higher for less amount of dust and not for dustier and rusty surfaces.

6. Comparison in Terms of Efficiency

The paper authored by Zhenjing et al (2021) tabulated the cleaning efficiency performance of several windows cleaning robots in m

2/h as in

Table 8.

The calculation for cleaning efficiency in m2/h on a horizontal surface:

Dimensions of the cleaning robot are 22 cm X 22 cm X 5 cm.

Distance covered in 12 s is 145 cm.

Total area covered in cm

2/s

Cleaning efficiency in m

2/hr.

The calculation for cleaning efficiency in m2/hr. on a Vertical surface:

Distance covered in 12 s is 130 cm.

Cleaning efficiency in m2/hr.

So, compared with the efficiency of the robots which are listed in

Table 8. The efficiency is in alignment with the Sky Boy robot whose dimension is 1300x402x470 mm compared to the proposed robot which has 220x220x50 mm. In comparison with the similar size of the robot “WINDORO”, the proposed robot is giving more efficiency in both vertical and horizontal operation (95.7

where WINDORO has recorded 62

. So, the developed robot has given better efficiency in its category and is also much more cost-effective compared to other robots.

7. Conclusion and Future Development

In this work, a vacuum-type cleaning robot has been modeled and its performances are analyzed. The analysis has been done to understand the robot's efficiency and effectiveness in cleaning both vertical and horizontal glass panels. The robot is powered by 24V DC and has a rated power of 75W. The robot has been powered either through a battery or direct electricity connections under the given conditions. Performance evaluation has been done to understand coverage area, repeat coverage area, distance coverage rate, cleaning rate effectiveness, and dust collection efficiency based on a random walk algorithm. On the vertical surface, the robot took 12 sec to reach 130 cm whereas it covered 145cm distance in 12 sec on the horizontal glass surface. When the robot is trailed for 5 sec, a 48.875 cm distance is covered on the vertical glass surface and 57.625 cm on the horizontal glass surface. Dust collection efficiency on horizontal surfaces is 94.06% and vertical is 89.134%. The random walk algorithm has been used due to its accuracy and cost-effectiveness. In the future, we can say, it is possible to use different algorithms, different cleaning mechanisms, and additional sensors to improve the effectiveness of the vacuum cleaning robot. More sensors and an effective algorithm can give more efficiency in cleaning. There are some disadvantages in vacuum technology which can be replaced by new and effective adhesion techniques in future developments.

Acknowledgments

The authors would like to acknowledge the National University of Science and Technology Management for the opportunity given to do this research work and for publication.

Disclosure of Interests

The whole work copyright is to the authors and the given work does not have any conflict of interest.

References

- Kuisong: Z., Guangda, C., Guowei, C., Yingfeng, C., Feng, W., Xiaoping, C.: (2017) Performance Metrics for Coverage of Cleaning Robots with MoCap System. Springer International Publishing. 267–274.

- Yongan, H., Hao, W., Honghai, L., Zhouping, Y. (2017).: Intelligent Robotics and Applications. In: 10th International Conference, ICIRA 2017, Wuhan, China, August 16–18, doi: 10.1007/978-3-319-65298-6 25. [CrossRef]

- Asafa, T.B., Afonja, T.M., Olaniyan, E.A., Alade, H.O. (2018): Development of a vacuum cleaner robot, Alexandria Engineering Journal 57, 2911–2920 https://doi.org/10.1016/j.aej.2018.07.005. [CrossRef]

- Jinqiang, B., Shiguo, L., Zhaoxiang, L., Kai, W., Dijun, L. (2018): Deep Learning Based Robot for Automatically Picking Up Garbage on the Grass. In: IEEE Transactions on Consumer Electronics, vol. 64 (3), pp. 382 – 389, doi: 10.1109/TCE.2018.2859629. [CrossRef]

- Harish, B.S., Prajith, K. P., Siddharth, B., Prashanth, B.N. (2020).: Design and Analysis of Automatic Robotic Vacuum Cleaner, International Journal of Advanced Research in Engineering and Technology, 11(11), 728-736, doi: 10.34218/IJARET.11.11.2020.069. [CrossRef]

- Zhenjing, Li., Qingsong, X., Lap, M.T. (2021) A Survey on Techniques and Applications of Window-Cleaning Robots. Published in: IEEE Access, vol. 9, pp. 111518 – 111532 doi: 10.1109/ACCESS.2021.3103757. [CrossRef]

- Anıl, E., Hatice, D. (2022): Design and implementation of a cost-effective vacuum cleaner robot, Turkish Journal of Engineering, 6(2), 166-177, doi: 10.31127/tuje.830282. [CrossRef]

- Nakagawa, N., Date, H. (2023) Development of an Autonomous Blower Robot for Cleaning up and Collecting Fallen Leaves, In: 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand doi: 10.1109/CASE56687.2023.10260356. [CrossRef]

- Hasan, K.M, Reza, K.J., et al. (2014) “Path planning algorithm development for autonomous vacuum cleaner robots”. In: Informatics, Electronics & Vision (ICIEV), 2014 International Conference on. IEEE. 2014, pp. 1–6.

- Akinfiev, T., Armada, M., and Nabulsi,S (2009) “Climbing cleaning robot for vertical surfaces,” Industrial Robot: An International Journal, vol. 36, no. 4, pp. 352–357, 2009. [CrossRef]

- Moon, S. M. Shin C. Y, Huh J., Oh K. W., and Hong D., (2015) “Window cleaning system with water circulation for building façade maintenance robot and its efficiency analysis,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 2, no. 1, pp. 65–72. [CrossRef]

- Qian Z.-Y., Zhao Y.-Z., Fu Z., and. Cao Q.-X, (2006) “Design and realization of a non-actuated glass-curtain wall-cleaning robot prototype with dual suction cups,” International Journal of Advanced Manufacturing Technology, vol. 30, no. 1-2, pp. 147–155, 2006. [CrossRef]

- Zhang H., Zhang J., Liu R., and Zong G., (2007) “Mechanical design and dynamics of an autonomous climbing robot for elliptic half-shell cleaning,” International Journal of Advanced Robotic Systems, vol. 4, no. 4, pp. 437–446.

- Tokhi O., Zhang H., Zhang J., Wang W., Liu R., and Zong G., (2007) “A series of pneumatic glass-wall cleaning robots for high-rise buildings,” Industrial Robot: An International Journal, vol. 34, no. 2, pp. 150–160. [CrossRef]

- 15. Elkmann N., Lucke M., Krüger T., Kunst D., and Stürze T., (2008) “Kinematics and sensor and control systems of the fully automated facade cleaning robot Sirius for Fraunhofer headquarters in Munich,” in Field and Service Robotics. Springer, pp. 505–512. [CrossRef]

- Wang W., Tang B., Zhang H., and Zong G., (2010) “Robotic cleaning system for glass facade of high-rise airport control tower,” Industrial Robot: An International Journal, vol. 37, no. 5, pp. 469–478. [CrossRef]

- Choi, Y.-H. and Jung K.-M., (2011) “Windoro: The world’s first commercialized window cleaning robot for domestic use,” in Proc. 2011 8th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI),2011, pp. 131–136. [CrossRef]

- Nansai S., Onodera,K., Veerajagadheswar, P., Elara, M.R., and Iwase, M., 2018. "Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism" Applied Science 8, no. 12: 2398. https://doi.org/10.3390/app8122398. [CrossRef]

- Parween, R.; Elara, M.R.; Saldi, Z.S.; Ng, T.; Rayaguru, M.M. (2021) Modeling and Analysis of a Glass Façade Robot., Buildings (MDPI), 11,225. https://doi.org/10.3390/buildings11060225. [CrossRef]

- Bisht,R.S., Pathak, P.M., Panigrahi,S.K (2022) Design and development of a glass façade cleaning robot, Mechanism and Machine Theory,Volume 168,2022,104585,ISSN 0094-114X, https://doi.org/10.1016/j.mechmachtheory.2021.104585. [CrossRef]

- Antonelli, M.G., Zobel, P.B., De Marcellis, A., Palange, E., (2020), Autonomous robot for cleaning photovoltaic panels in desert zones, Mechatronics, Volume 68, 2020, 102372, ISSN 0957-4158, https://doi.org/10.1016/j.mechatronics.2020.102372. [CrossRef]

- Ze, J., Zhe Zhao, Bo Chen, Yichao Li, Yongsheng Zhao, Yundou Xu, (2024), Design and analysis of a passive adaptive wall-climbing robot based on five-bar mechanisms, Ocean Engineering, Volume 298, 2024,117140,ISSN0029-8018,https://doi.org/ 10.1016/ j.oceaneng.2024.117140. [CrossRef]

- Shiyao, C., Zhiliang, M. and Jianfeng Guob (2020), Analysis on the Implementation Mechanism of an Inspection Robot for Glass Curtain Walls in High-rise Buildings, Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC 2020), Kitakyushu, Japan, October 27-28, 2020.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).