1. Introduction

With the continuous growth of global energy demand, oil and gas resources and their products are extensively utilized across various sectors of production and daily life, playing a vital role in the development of the national economy [

1]. A significant number of steel pipelines serve as the primary means of transportation during the extraction and conveyance of oil and gas resources. According to incomplete statistics, pipelines account for 51% of global crude oil transportation, while water transport constitutes 45%, with the remaining 4% managed by rail and road transport [

2,

3]. As China develops its oil and gas resources, the construction of pipelines—often referred to as industrial arteries—has significantly increased. By the end of 2021, China had constructed approximately 150,000 kilometers of long-distance oil and gas pipelines, with around 5,414 kilometers newly built, reflecting a growth of 1,594 kilometers compared to 2020 [

4]. Consequently, the reliability and safety of pipeline transportation for oil and gas have become increasingly important.

Due to the unique characteristics of oil and gas resources, incidents such as perforation leaks and explosions during pipeline transportation can result in economic losses and safety concerns [

5,

6]. Currently operational oil and gas pipelines, subjected to specific working environments, loads, and boundary conditions, are directly influenced by environmental factors such as seawater corrosion, nearshore debris impact, and geological stress. The damaging processes that threaten pipeline safety in these complex conditions exhibit significant randomness and interdependence [

7,

8]. Moreover, since the medium transported through oil and gas pipelines primarily consists of corrosive substances like natural gas, crude oil, and carbon dioxide, internal damage can also occur, further adding to the uncertainty of pipeline integrity [

9,

10]. A substantial body of research indicates that both the internal and external environments of pipelines make them vulnerable to corrosion, which is one of the most prevalent failure modes affecting oil and gas pipelines and directly impacts their failure pressure [

11,

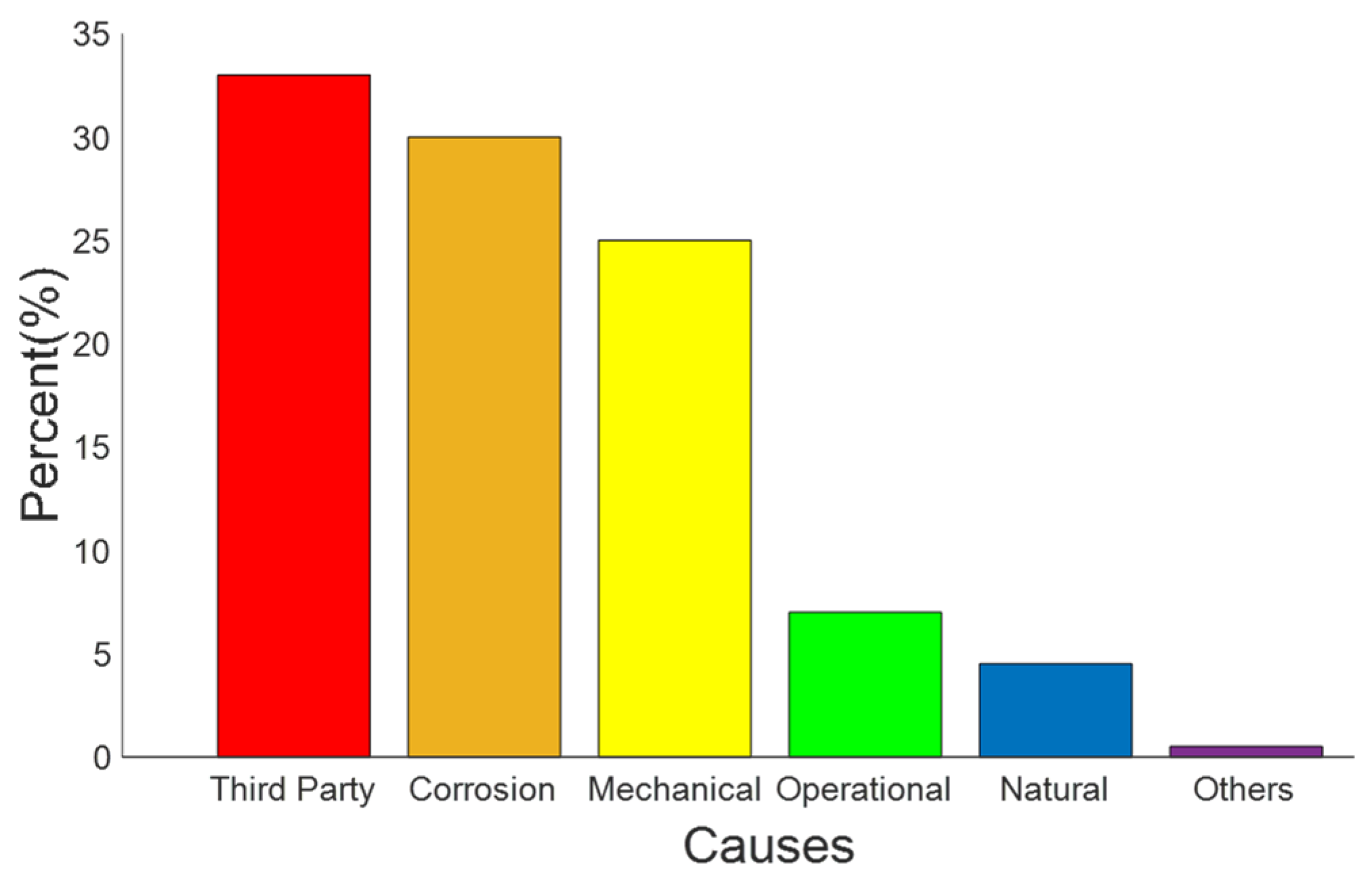

12]. Statistics reveal that corrosion, following third-party activities, is a leading cause of pipeline failure, accounting for 30% of all failure factors, as illustrated in

Figure 1 [

13]. Therefore, it is essential to study the failure pressure of corroded pipelines to determine whether they should remain in service, be repaired, or replaced, which can help prevent premature decommissioning that leads to economic waste and safety incidents. This research also aids engineers in assessing the safety status of pipelines and informs maintenance planning and safety management [

14,

15], providing a scientific basis for pipeline maintenance and management.

Research indicates that the presence of corrosion defects results in a reduction of the wall thickness in pipelines, thereby diminishing their load-bearing capacity. The failure pressure of a pipeline is typically defined as the critical pressure at which a rupture or leak occurs under specific conditions. Factors such as the morphology, depth, and location of corrosion defects all affect the failure pressure of pipelines [

16]. In examining the failure pressure of corroded pipelines, various assessment criteria have been established both domestically and internationally. In the 1970s, the Battelle Memorial Institute in the United States developed the semi-theoretical, semi-empirical formula NG-18 based on fracture mechanics and explosive test results, which was among the earliest formulas used for calculating pipeline failure stress [

17]. This formula has since served as the theoretical foundation for many subsequent assessment criteria and standards. Representative evaluation standards include ASME-B31G, the modified ASME B31G (0.85dl), RSTRENG, API 579, and DNV-RP-F101, as shown in

Table 1 [

18,

19,

20,

21,

22,

23,

24,

25]. However, these assessment methods for the failure pressure of corroded pipelines exhibit certain limitations when characterizing the failure pressure of different grades of steel pipelines. They tend to be overly conservative in guiding the maintenance and operation of pipelines in practical engineering, leading to premature repairs or replacements and increased operational costs [

26,

27,

28,

29,

30].

In recent years, with the advancement of computer virtual simulation technology and finite element theory, researchers have employed finite element analysis software to investigate the failure pressure of corroded pipelines, yielding promising results [

31,

32,

33]. Alongside developments in artificial intelligence and deep learning, significant strides have been made in the safety assessment of corroded pipelines. Researchers have utilized various deep learning models to improve prediction accuracy and efficiency. Li integrated kernel principal component analysis with a Bayesian regularization neural network to develop the KPCA-BRANN model for predicting corrosion degradation in offshore pipelines [

34]. Su introduced a method for rapidly predicting the failure stress of corroded pipelines with high accuracy [

35]. Chen applied a backpropagation neural network to forecast the reliability of pipelines under diverse loading conditions [

36]. Adriano presented real images of corrosion defects as inputs to create a fast and accurate prediction model using deep learning [

37]. However, despite extensive research on the effects of single corrosion defects, studies addressing multiple corrosion defects remain relatively limited. Liu compared various machine learning models and ultimately proposed a pipeline safety assessment prediction model based on extreme gradient boosting algorithms [

38]. Nevertheless, the treatment of boundary conditions for corroded areas in virtual simulations and the assumptions regarding actual corrosion conditions can result in discrepancies in the simulation outcomes when characterizing the failure pressure of real corroded pipelines. Furthermore, the validation data for artificial neural network-based corrosion pipeline failure pressure prediction models is typically sourced from simulated experiments, leading to overfitting when representing the failure pressure of actual corroded pipelines.

To accurately evaluate the failure pressure of corroded pipelines, this study employs the finite element numerical simulation method (FEM), utilizing SolidWorks and ABAQUS software to create a three-dimensional model of an oil and gas pipeline with corrosion defects. Based on the type of corrosion, boundary conditions for the affected areas are established, and reasonable assumptions are made. By applying various internal pressure loads, this study examines the impact of the pipeline model length and the structural parameters of corrosion defects on pipeline stress. A nonlinear regression equation for predicting the failure pressure of corroded pipelines is formulated using MATLAB with the iterative least squares method. Subsequently, a hydraulic testing platform is constructed for the API 5L X65 pipeline with corrosion defects to experimentally assess the effects of corrosion defect parameters on pipeline stress and failure pressure, thereby evaluating and validating the failure pressure prediction equation.

2. Methodology

2.1. Failure Identification of Corroded Pipeline

This paper employs the Finite Element Method (FEM) to investigate the stress levels and failure pressure of corroded pipelines. Given the stochastic nature of corrosion defects in terms of both location and shape, this study specifically examines the impact of the structural characteristic parameters of a single corrosion defect on the stress distribution and failure pressure of pipelines. The investigation incorporates numerical simulations and experimental studies using a single corrosion defect as a case study. The proposed method can also be extended to analyze corrosion clusters comprising multiple defects. Determining the failure pressure of corroded pipelines is essential for establishing pipeline failure criteria. Both finite element simulations and experimental approaches require predefined criteria to assess pipeline failure accurately. Typically, the failure of oil and gas pipelines is predominantly due to plastic deformation in the corroded areas. According to the Von Mises yield criterion, the distortional energy is considered the primary cause of yielding failure. Irrespective of the stress state, as long as the distortional energy at a point within the component reaches the critical value under uniaxial stress conditions, the material will undergo yielding failure. Specifically, when the Von Mises equivalent stress in the corroded region reaches the yield strength of the pipeline material, plastic deformation occurs, posing a risk of perforation and leakage. The equation adhering to the Von Mises yield criterion is presented in Equation (1).

In the following expressions,

τM represents the Von Mises equivalent shear stress,

σy signifies the yield strength, and

σ1,

σ2, and

σ3 denote the first, second, and third principal stresses respectively, where

σ1>

σ2 >

σ3. The formula for the Von Mises equivalent stress is given in Equation (2). where

σM refers to the Von Mises equivalent stress.

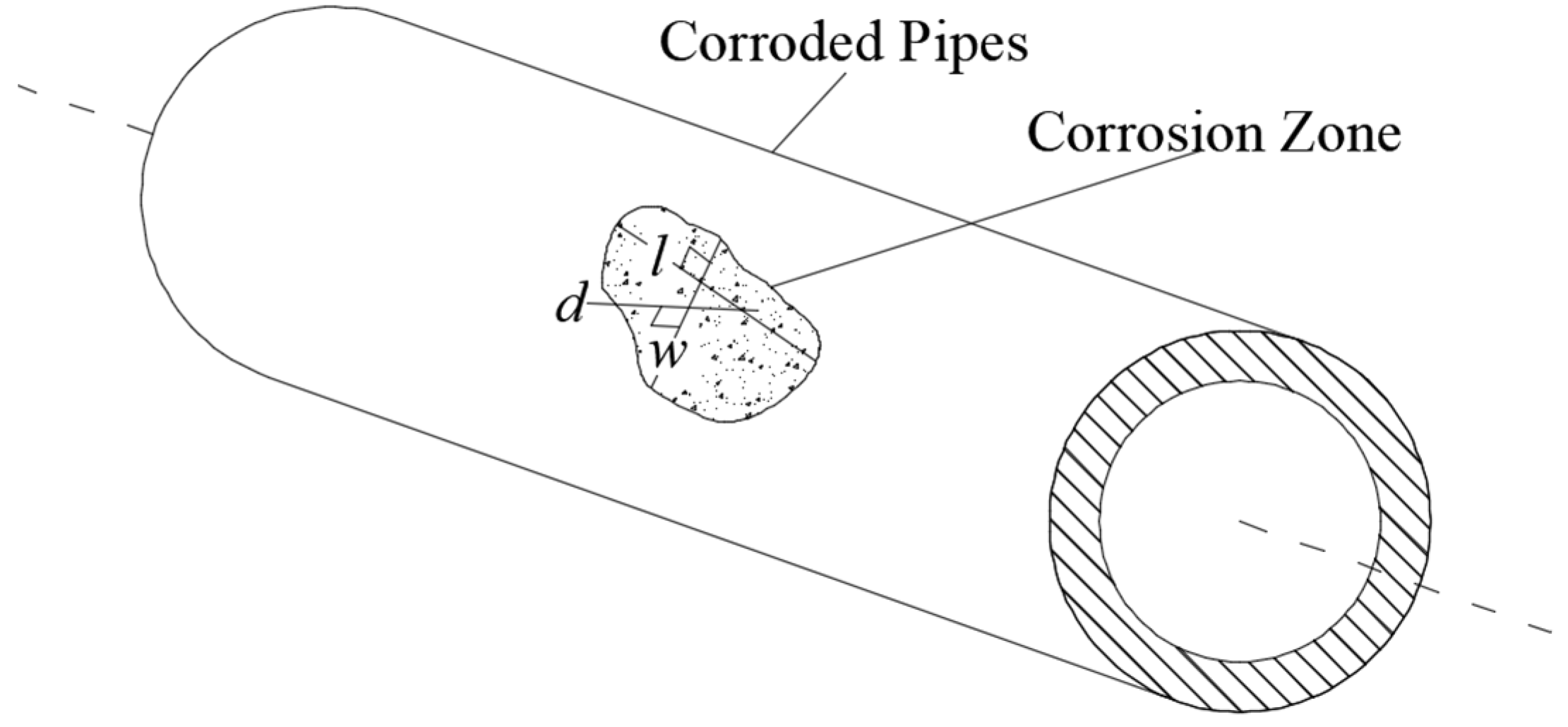

2.2. Corrosion Pipeline Model Simplification

Given the long-distance transportation characteristics of oil and gas pipelines and the complexity of their operating environments, pipelines must withstand not only the internal pressure from oil and gas but also possible transverse concentrated loads, axial tensile and compressive loads, bending loads, and various load couplings. These combined effects result in complex and difficult-to-predict stress states. Consequently, in the design and construction phases of oil and gas pipelines, it is generally recommended to avoid loads other than internal pressure. Therefore, in simulation models, only the internal pressure from oil and gas is considered. Since most oil and gas pipelines are buried deep underground, and considering the interactions between the pipeline, soil, and the surrounding environment, this study focuses solely on the effects of corrosion on the pipeline. Therefore, only sections with corrosion defects are analyzed. Corroded regions are the weakest parts of the pipeline, and accurately simulating these defects is crucial for the precision of stress level assessments. The parameters of corrosion defects significantly influence the stress levels and failure pressure of pipelines. These parameters, including corrosion length (

l ), corrosion width (

w ), and corrosion depth (

d ), are defined as shown in

Figure 2.

Research has shown that localized and uniform corrosion are the primary failure modes of pipelines. During simulation modeling, the corroded region can be simplified as an axial rectangular groove with a common base, resembling a segment of a cylindrical ring intersecting with the pipeline. Pipeline corrosion results from prolonged exposure to the surrounding environment rather than from short-term localized damage. Consequently, the surface of corrosion defects does not exhibit a stepped distribution. To avoid stress concentration, rounded transitions are applied at the intersections of the groove structure in the pipeline model, enhancing the accuracy of simulation results for corroded pipelines.

2.3. Finite Element Simulation Modeling

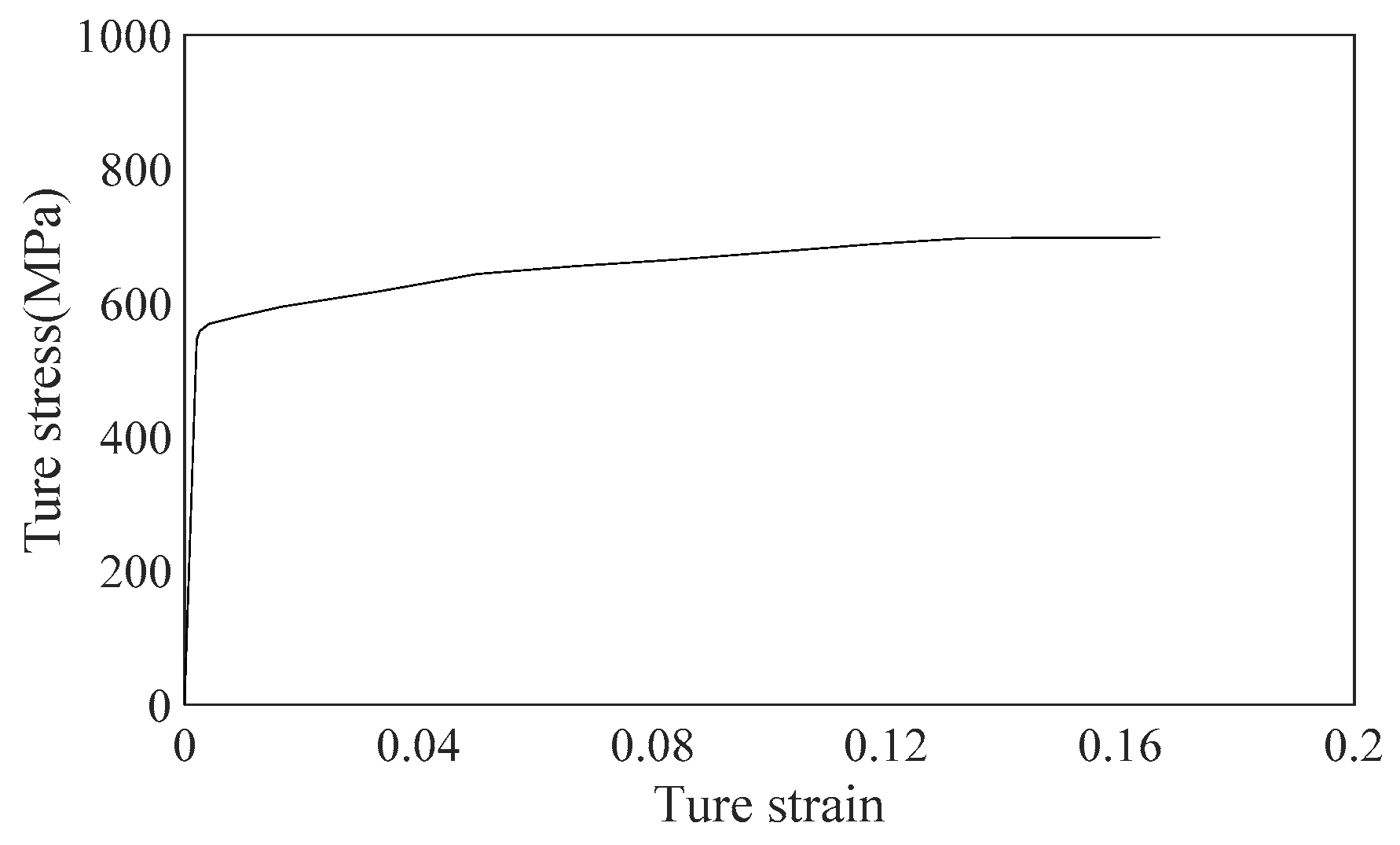

Based on the Von Mises yield criterion and the aforementioned simplified model of the corroded pipeline, a full-scale 3D solid model of an API 5L X65 pipeline with localized uniform corrosion defects was constructed using SolidWorks. Conducting simulation experiments with proportionally scaled models enhances the authenticity of the calculated data. The mechanical properties of the material for the API 5L X65 pipeline are shown in

Table 2. The geometric parameters of the pipeline model and the normalized corrosion defect parameters used in the simulation experiments are listed in

Table 3. The true stress-strain curve for the API 5L X65 pipeline material is illustrated in

Figure 3.

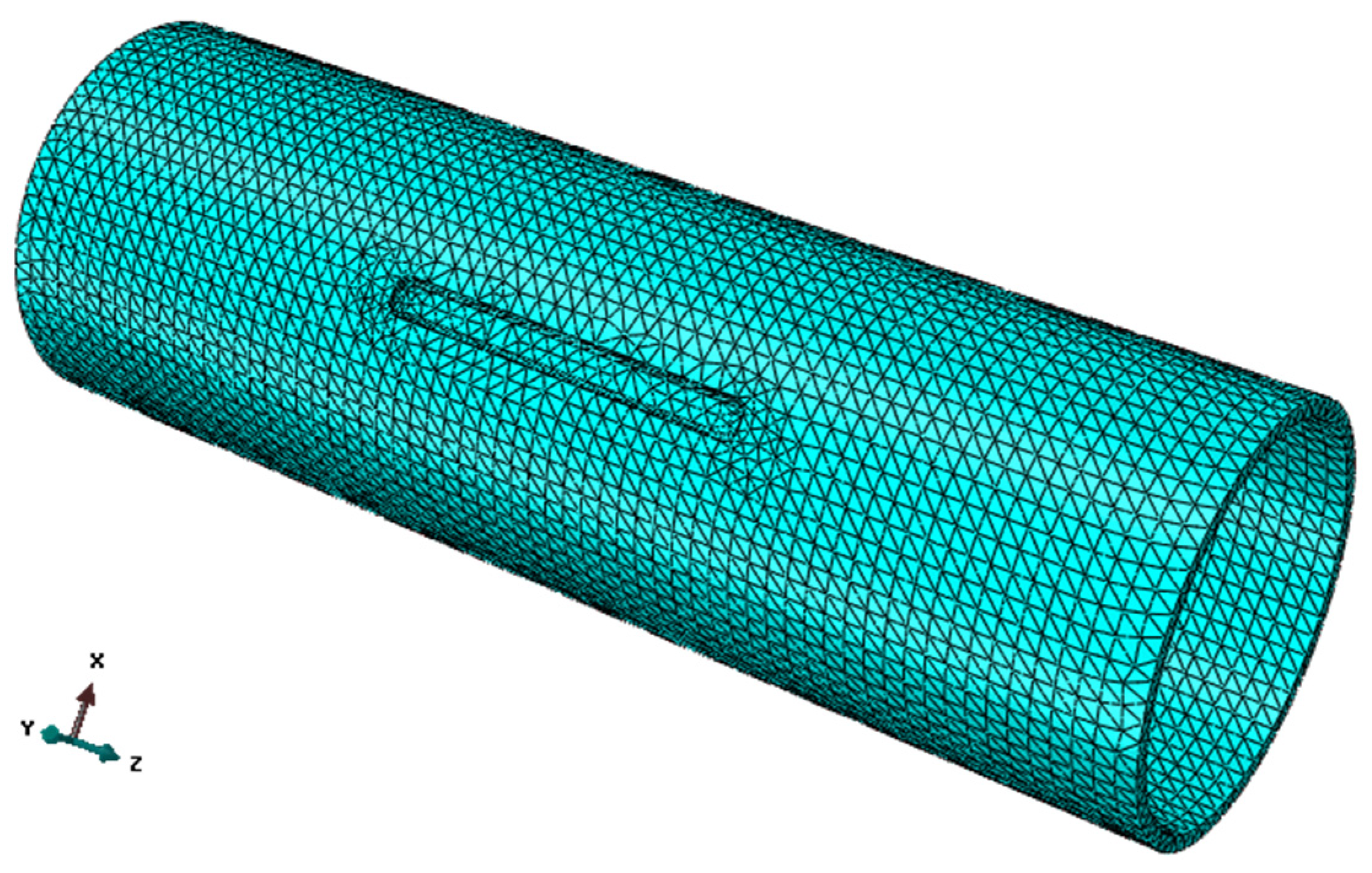

The 3D pipeline model constructed in SolidWorks was imported into ABAQUS. A second-order reduced-integration tetrahedral mesh type was employed, and the basic material properties and true stress-strain curve data of the API 5L X65 pipeline were assigned to the simulation model. A free meshing method was used for the pipeline areas without corrosion defects, with a mesh element size set to 6mm. For the areas with corrosion defects, the mesh was refined and encrypted, with the mesh element size set to 4mm to enhance the simulation accuracy of the stress levels in the corroded regions. The pipeline model and its mesh division are shown in

Figure 4. As the simulation focused solely on the pipeline segments with corrosion defects, axial displacement constraints were applied to one end of the pipeline model, while the other five degrees of freedom were left unconstrained to avoid stress concentration at the constrained end. A continuous uniformly distributed pressure load was applied to the inner wall of the pipeline.

In this study, the primary objective was to investigate the influence of boundary conditions on the stress in the corroded regions of the pipeline to determine the optimal length of the 3D pipeline model for subsequent numerical simulations. Based on this model length, finite element simulation experiments were conducted to minimize the computational cost as much as possible. Therefore, simulation experiments were performed on four full-scale 3D pipeline models of varying lengths. These four models had identical corrosion defect parameters, with the defects located at the mid-length of each pipeline model, but the overall lengths differed. In the simulation experiments, an internal pressure load of 10MPa was applied to observe the stress levels in the corroded regions of the four models. The geometric parameters of the pipeline models and the applied internal pressure load are shown in

Table 4.

2.4. Establishment of Data Sets for Simulation Experiments

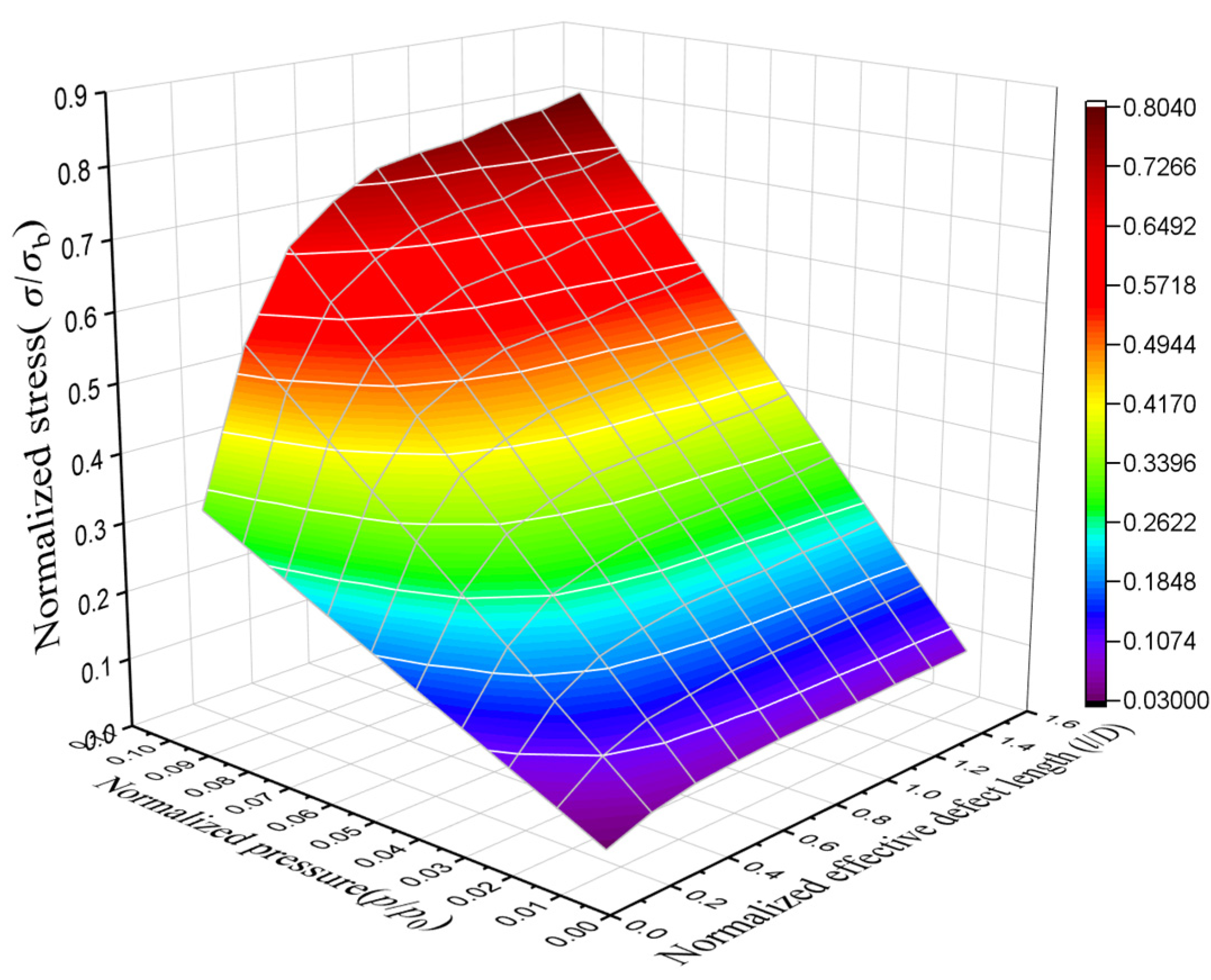

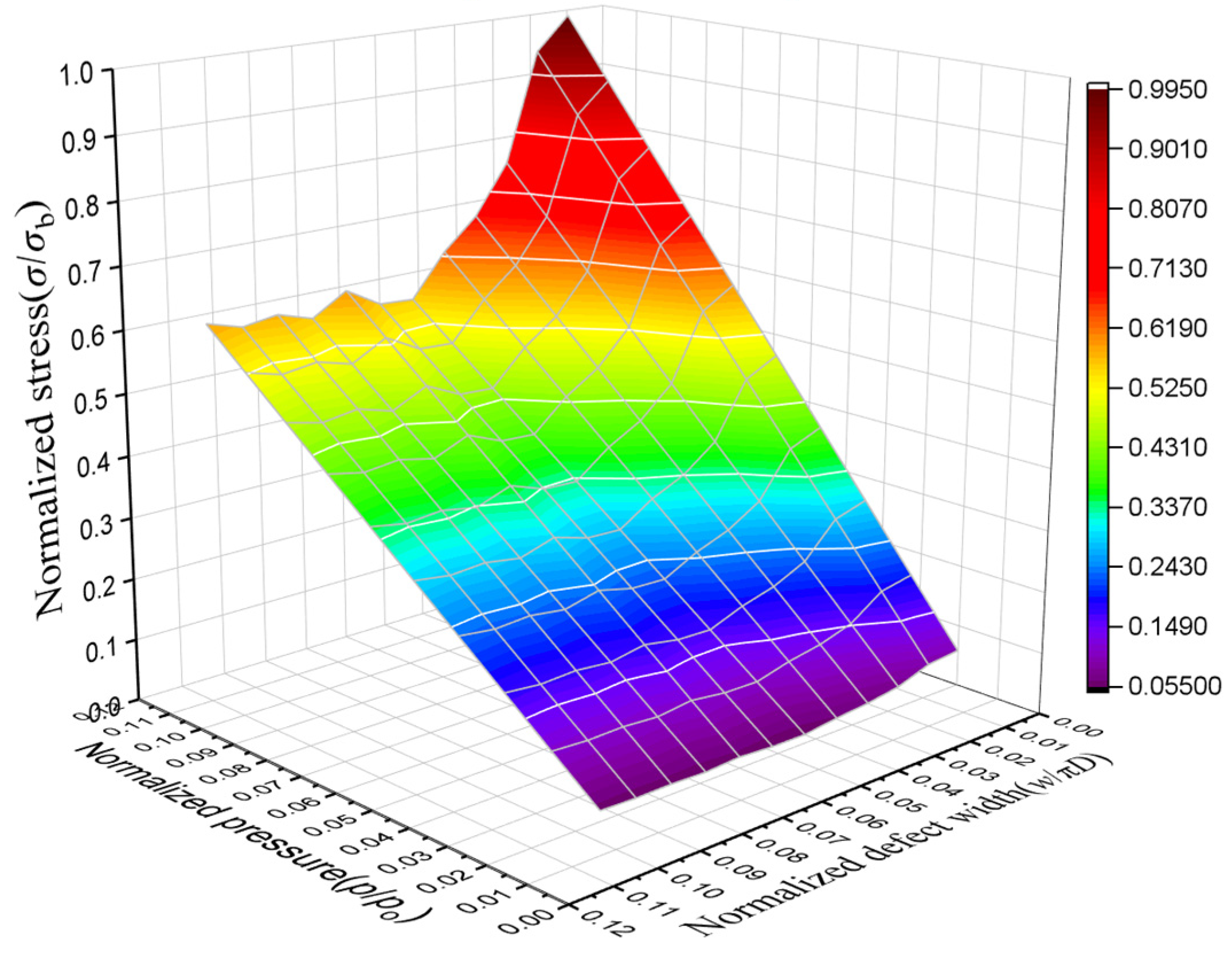

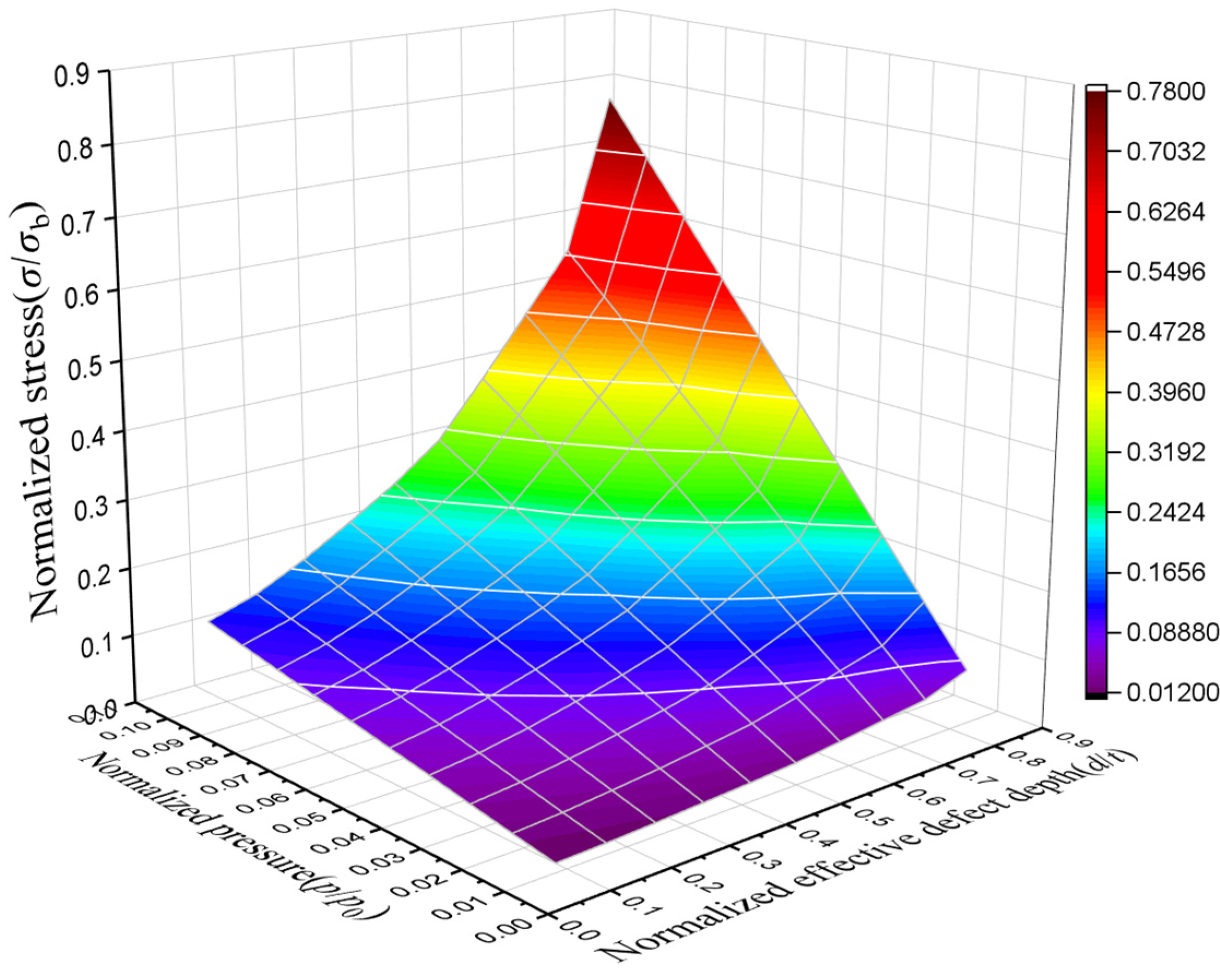

Using ABAQUS, the failure pressure of an API 5L X65 pipeline with localized uniform corrosion defects was simulated, taking into account the nonlinear behavior of the API 5L X65 pipeline material, including plastic deformation and variations in the stress-strain relationship. The failure pressure of corroded pipelines is often influenced by multiple parameters. Through sensitivity analysis, the degree to which the failure pressure is affected by changes in defect parameters can be determined. Parameters with high sensitivity can be considered essential in calculating the failure pressure of corroded pipelines. Based on literature review and numerical simulation results, corrosion length, corrosion width, and corrosion depth are identified as the primary factors affecting failure pressure. Initially, we investigated the impact of defect parameters on stress distribution at the corrosion site. If a change in a particular parameter leads to increased stress concentration at the defect, it significantly affects the failure stress. Therefore, this study conducts a parametric sensitivity analysis of the pipeline’s stress, yield pressure, and failure pressure under corrosion defects with normalized corrosion length (0.1538≤l/D≤1.5385), normalized corrosion width(0.0118≤w/πD≤0.1195), and normalized corrosion depth values (0.0833≤d/t≤ 0.8333). The selected range of corrosion defect parameters adequately covers the defect scales that may appear during the safe service life of the pipeline.

In the simulation experiments, a continuous internal pressure load was applied to the corroded pipeline, and the stress variations in the corroded regions were observed. When the maximum stress in the corroded region reaches the yield strength of the pipeline material, the internal pressure load is defined as the yield pressure of the corroded pipeline, which provides crucial guidance for the design pressure during the pipeline's safe service period. When the maximum stress in the corroded region reaches the tensile strength of the pipeline material, the internal pressure load is defined as the failure pressure of the corroded pipeline. The simulated failure pressure data from the experiments were used as a dataset to develop a nonlinear regression equation capable of predicting the failure pressure of pipelines with localized uniform corrosion.

2.5. Experimental Setup

2.5.1. Design of Test Pipelines

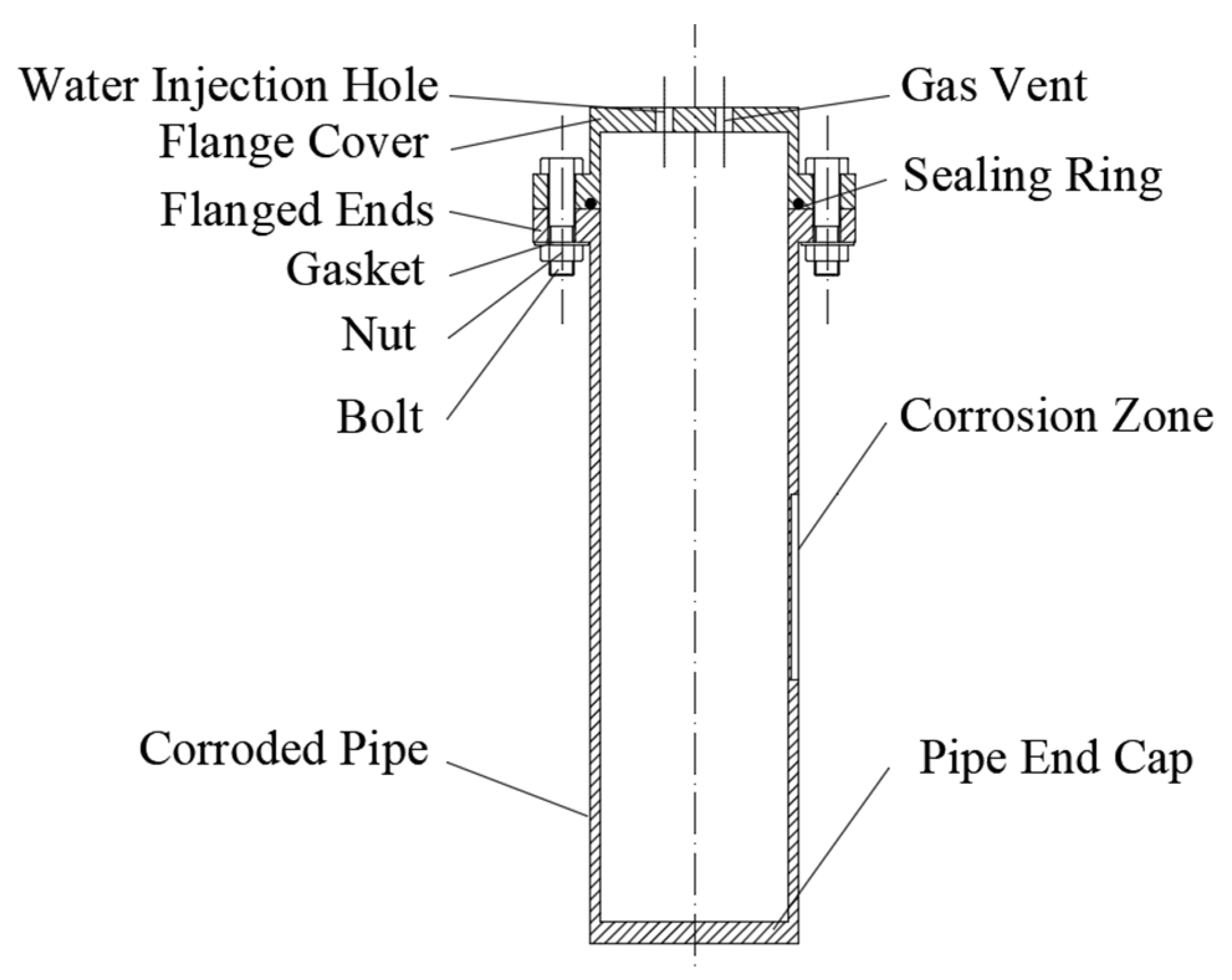

To effectively evaluate and revise the predictive equation for pipeline failure pressure, this study conducted full-scale hydrostatic tests on corroded pipelines. API 5L X65 pipelines were used to design and manufacture the test pipelines for these hydrostatic experiments. Through mechanical processing methods, square grooves were machined onto the outer wall of the API 5L X65 pipelines to simulate localized uniform corrosion. A flat-bottom pipe end cap was welded to one end of the test pipeline, while a flange was welded to the other end to serve as a connecting device with a flange cover. The flange and flange cover were secured with eight bolts and sealed with an O-ring. Two through holes were set on the flange cover’s end surface for pressurized water injection and air venting. A schematic diagram of the pipeline structure used in the hydrostatic test is shown in

Figure 5.

In total, four test pipelines were manufactured, and four hydrostatic failure tests were conducted on these corroded pipelines to obtain data on the stress, failure pressure, and burst pressure of the corroded regions. The structural dimensions of the pipelines used in the hydrostatic tests and the parameters of the corrosion defects are shown in

Table 5, with the defect parameters representing the actual measured values after machining the corroded pipelines.

4. Conclusions

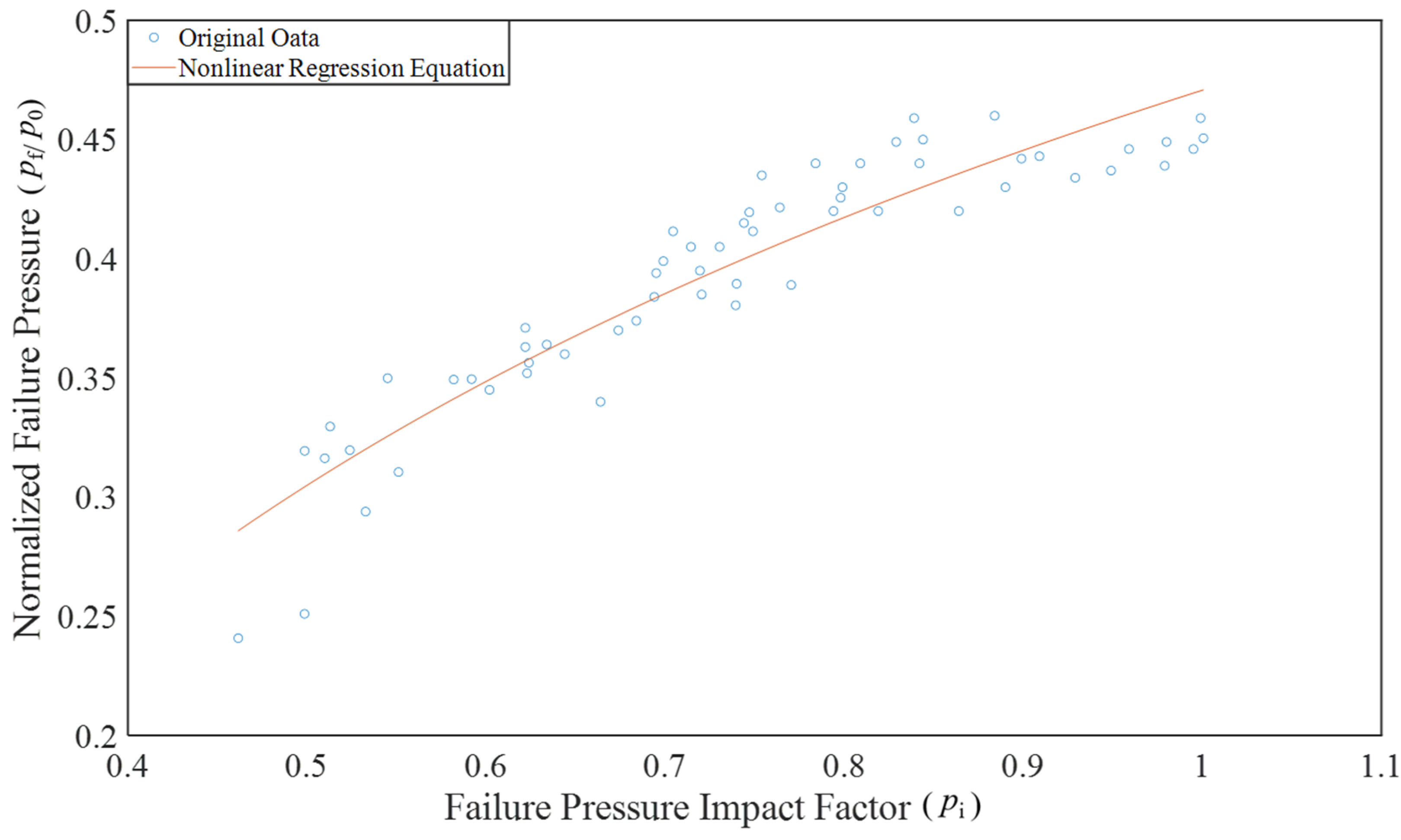

The study utilized finite element numerical simulation to investigate the influence of defect parameters in API 5L X65 corroded pipelines on stress and failure pressure. The simulation results were used to generate a dataset of failure pressures, from which a multivariate nonlinear regression equation was developed to predict failure pressure. This equation, which is a function of the ultimate bearing pressure of an intact pipeline, as well as normalized corrosion length, width, and depth, was validated through experimental testing. Within the range of defect parameters considered in this study, the maximum deviation between the predictions from the regression equation and the simulation results was 8.71%, with a minimum deviation of 2.27%. Similarly, the maximum deviation between the equation's predictions and the experimental results was 8.39%, and the minimum deviation was 6.96%.

This study also analyzed the sensitivity of pipeline failure pressure to defect parameters and integrated this sensitivity into the nonlinear regression equation. The analysis results were further validated through experiments. The research revealed that an increase in corrosion length and depth leads to a decrease in pipeline failure pressure, while an increase in corrosive width results in an increase in pipeline failure pressure. Corrosion depth has the most significant impact on failure pressure; as corrosion depth increases, the reduction in failure pressure becomes more pronounced. Corrosion length has the second-largest effect on failure pressure, with its influence stabilizing once corrosion length reaches a certain threshold. Corrosion width has the least effect on failure pressure, and its influence also stabilizes once corrosive width reaches a specific level.

Author Contributions

Conceptualization, H.Z. and Z.Y.; methodology, H.Z.; software, H.Z.; validation, B.Z., H.Z. and Z.Y.; formal analysis, H.Z.; investigation, H.Z.; resources, X.L.; data curation, H.Z.; writing—original draft preparation, H.Z.; writing—review and editing, P.H.; visualization, P.H.; supervision, P.H.; project administration, H.Z.; funding acquisition, X.L. All authors have read and agreed to the published version of the manuscript.

Figure 1.

Causes for oil and gas pipelines failure

Figure 1.

Causes for oil and gas pipelines failure

Figure 2.

Structural illustration of the corrosion depth of pipe

Figure 2.

Structural illustration of the corrosion depth of pipe

Figure 3.

True stress–strain curve for API 5L X65 steel pipe [

39]

Figure 3.

True stress–strain curve for API 5L X65 steel pipe [

39]

Figure 4.

Simulation model of corroded pipeline

Figure 4.

Simulation model of corroded pipeline

Figure 5.

Structural illustration of pipe for hydraulic test

Figure 5.

Structural illustration of pipe for hydraulic test

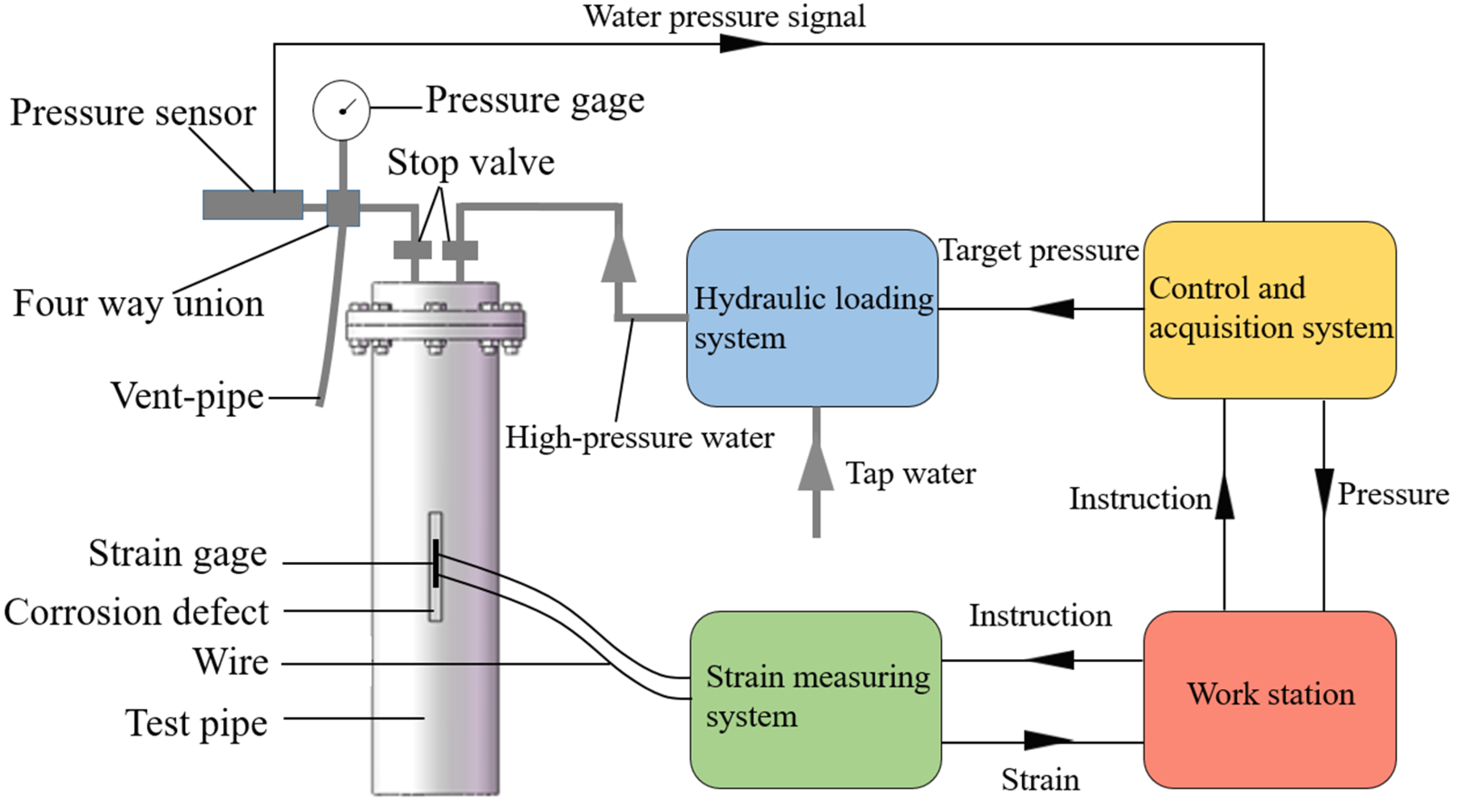

Figure 6.

Architecture illustration of hydraulic test platform

Figure 6.

Architecture illustration of hydraulic test platform

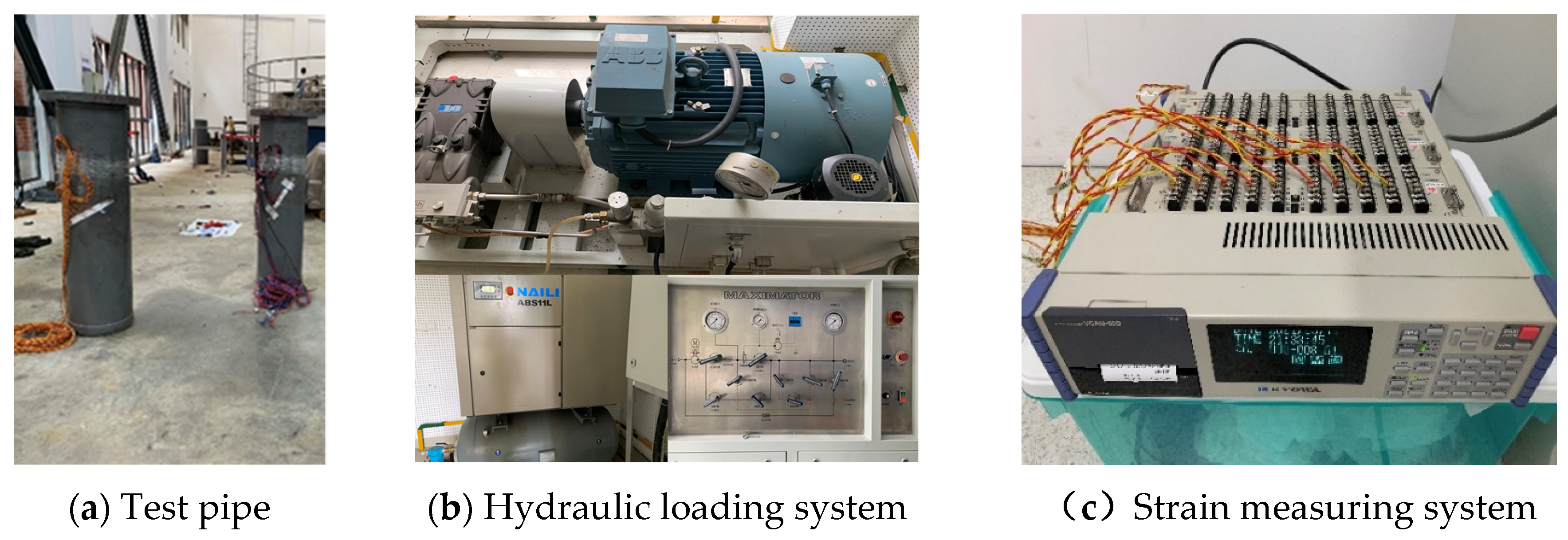

Figure 7.

The main equipment of hydraulic test platform

Figure 7.

The main equipment of hydraulic test platform

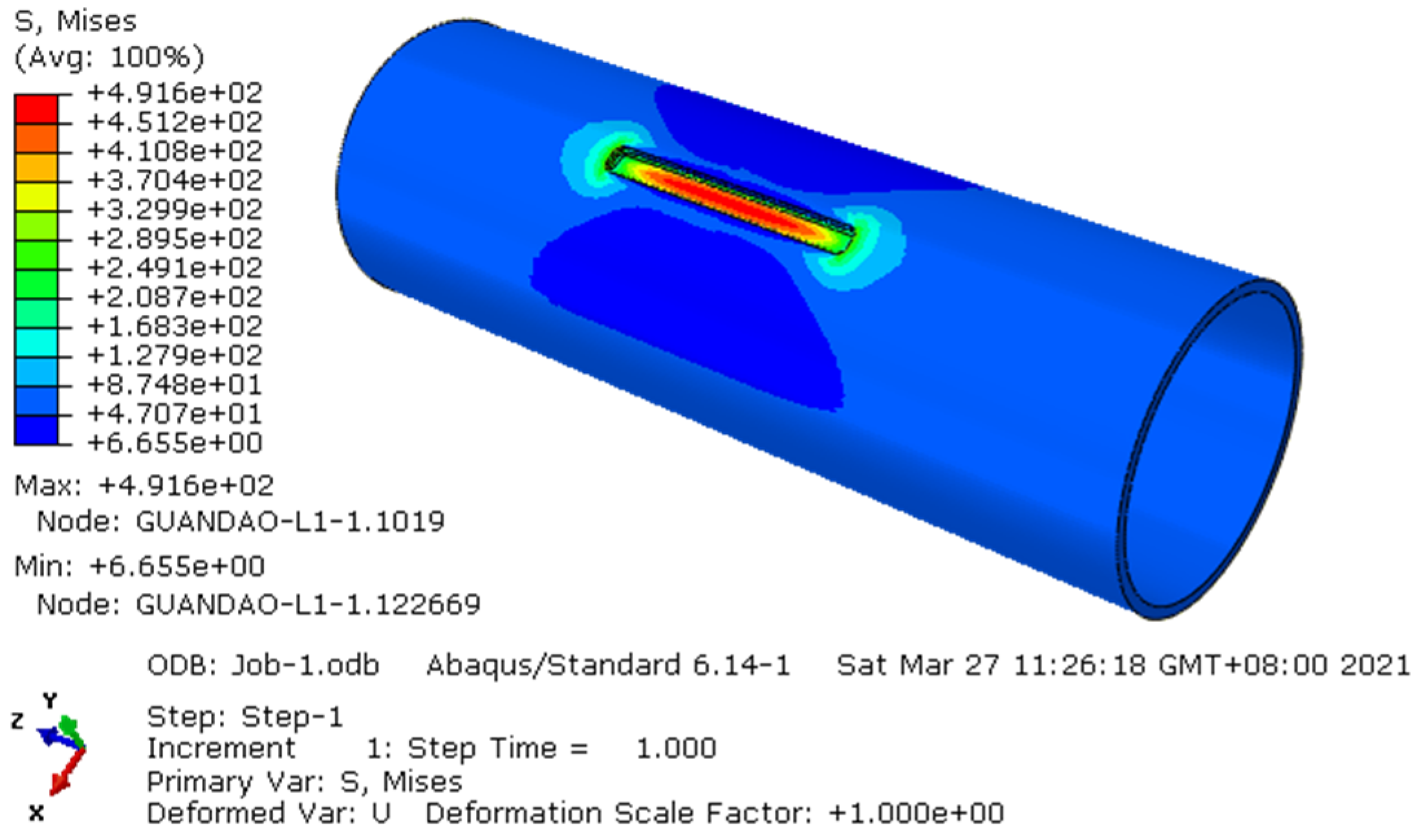

Figure 8.

Stress distribution of Model 1

Figure 8.

Stress distribution of Model 1

Figure 9.

Relation between maximum equivalent stress and corrosion length.

Figure 9.

Relation between maximum equivalent stress and corrosion length.

Figure 10.

Relation between maximum equivalent stress and corrosion width

Figure 10.

Relation between maximum equivalent stress and corrosion width

Figure 11.

Relation between maximum equivalent stress and corrosion depth

Figure 11.

Relation between maximum equivalent stress and corrosion depth

Figure 12.

The fitting of normalized failure pressure and influence factor

Figure 12.

The fitting of normalized failure pressure and influence factor

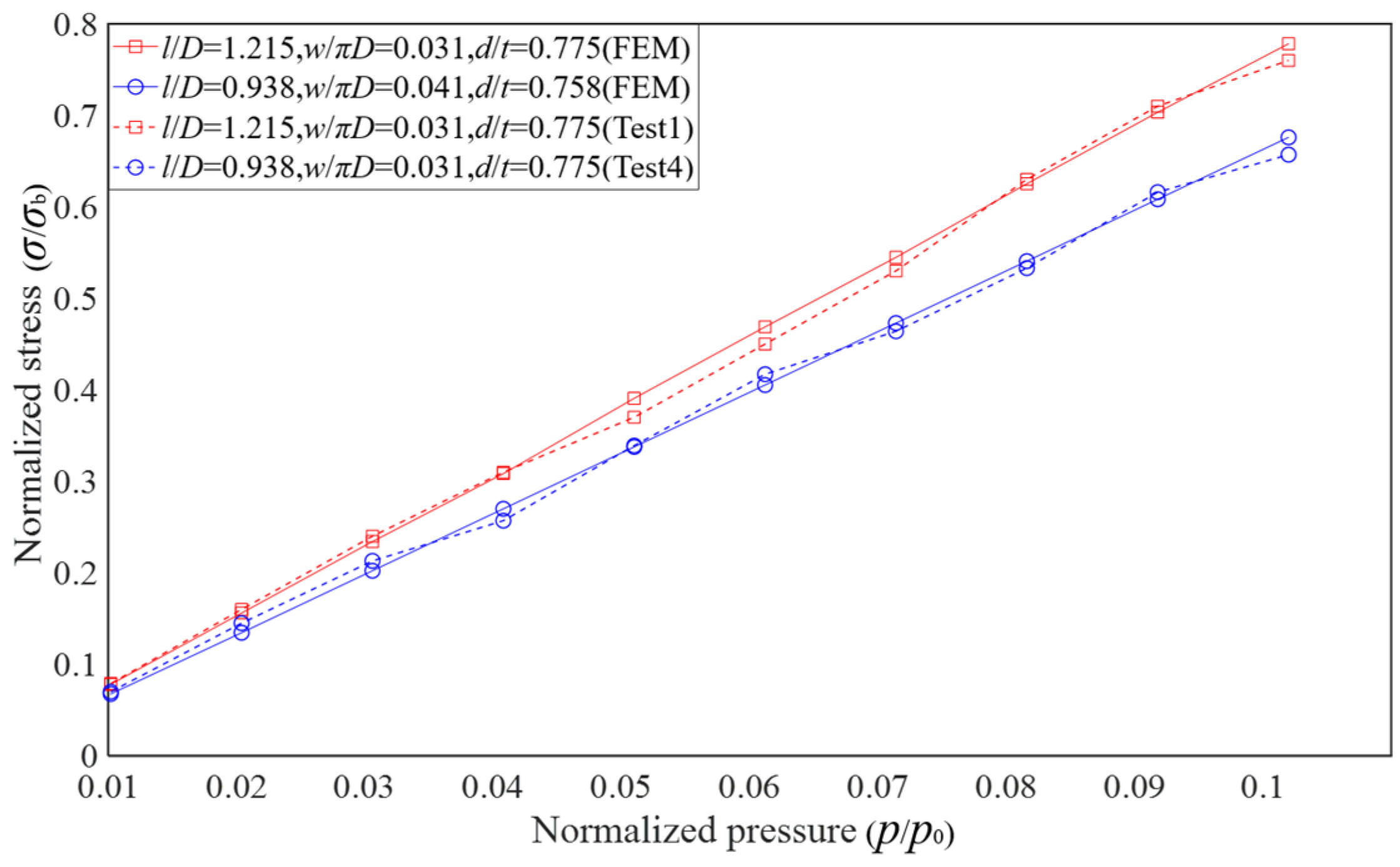

Figure 13.

Comparison of test and simulation results for stress at corrosion defects

Figure 13.

Comparison of test and simulation results for stress at corrosion defects

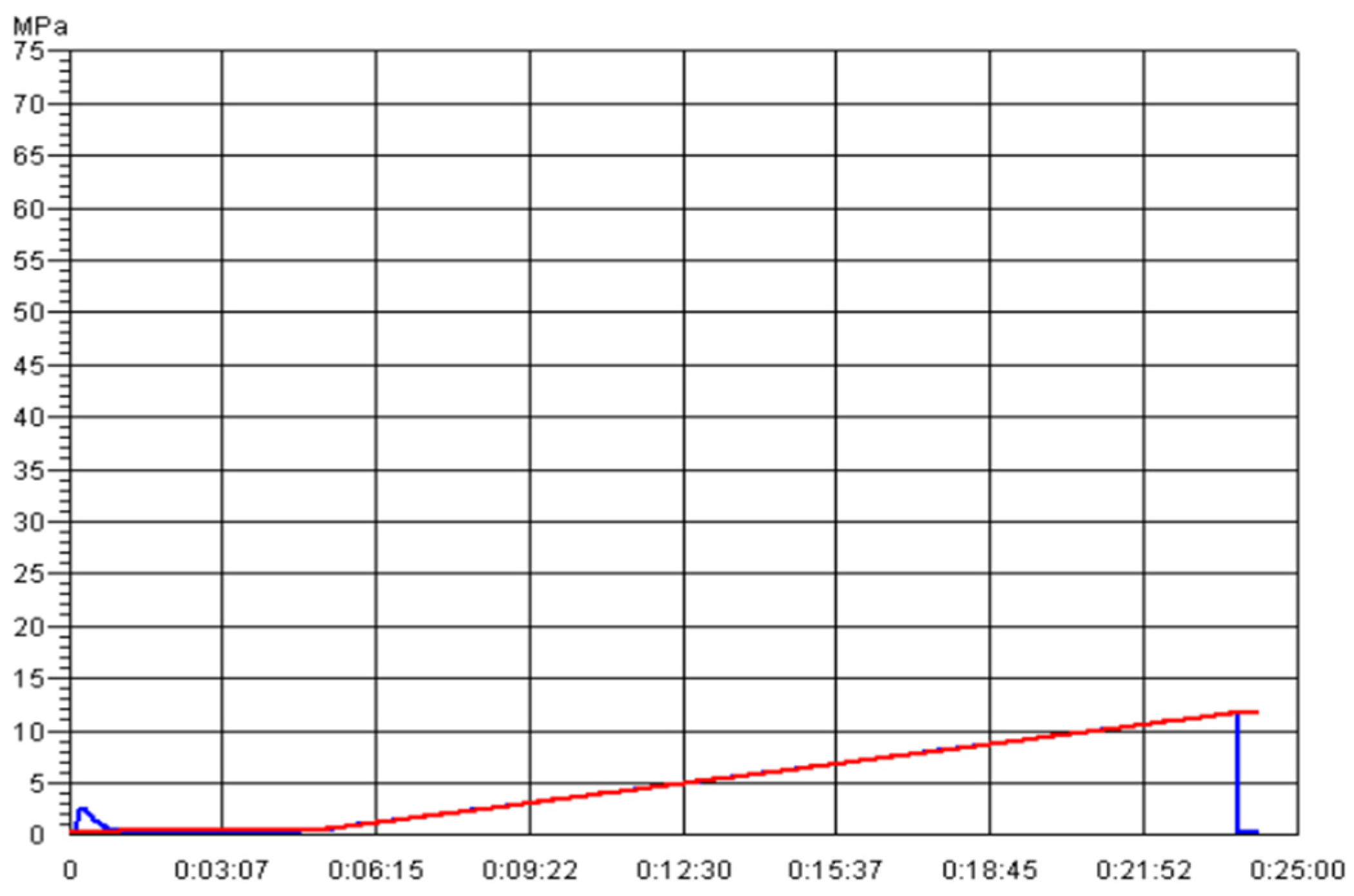

Figure 14.

Pressure curve of test 1

Figure 14.

Pressure curve of test 1

Table 1.

List of assessment methods of the corroded pipeline [

18,

19,

20,

21,

22,

23,

24,

25]

Table 1.

List of assessment methods of the corroded pipeline [

18,

19,

20,

21,

22,

23,

24,

25]

| Calculation Rules Methodology |

Unit or Author |

Date of Submission |

| ASME-B31G |

American Society of Mechanical Engineering |

1984 |

| Amended B31G(0.85dL) |

Kiefer, Vieth |

1989 |

| RSTRENG |

Kiefer, Vieth |

1989 |

| CAS-Z184-M86 |

Canadian Standards Association |

1999 |

| BS-7910 |

British Standards Institution |

1999 |

| API-579 |

American Petroleum Institute |

2000 |

| DNV-RP-F101 |

Det Norske Veritas |

2000 |

| PCORRC |

Stephens, Leis |

2000 |

| CPS |

Waterloo, Canada |

2000 |

| FITNET FFS |

Cicero |

2009 |

Table 2.

Material properties of the pipe grades used in this study

Table 2.

Material properties of the pipe grades used in this study

| Properties |

Values |

| Pipe name |

API 5L X65 pipe |

| Densities, ρ(kg/m3) |

7850 |

| Modulus of elasticity, E(MPa) |

2.06×105 |

| Poisson’s ratio, v

|

0.3 |

| Yield strength,σy (MPa) |

545 |

| Tensile strength,σb (MPa) |

665 |

| Yield ratio, σy/σb

|

0. 82 |

Table 3.

Geometric parameters of the corroded pipe models

Table 3.

Geometric parameters of the corroded pipe models

| Input Parameters |

Values |

| Outer diameter of pipe, D (mm) |

325 |

| Wall thickness, t (mm) |

12 |

| Length of pipe, L (mm) |

600~2400 |

| Ultimate pressure of intact pipe, p0 (MPa) |

49.1 |

| Normalized effective defect length, (l/D) |

0.15~1.54 |

| Normalized defect width, (w/πD) |

0.012~0.12 |

| Normalized effective defect depth, (d/t) |

0.08~0.92 |

| Normalized failure press,(pf/p0) |

0~1 |

Table 4.

Geometric parameters and internal pressure of corroded pipe models

Table 4.

Geometric parameters and internal pressure of corroded pipe models

| Input Parameters |

Values |

| Model 1 |

Model 2 |

Model 3 |

Model 4 |

| Outer diameter of pipe, D (mm) |

325 |

325 |

325 |

325 |

| Wall thickness, t (mm) |

12 |

12 |

12 |

12 |

|

| Length of pipe, L (mm) |

600 |

1200 |

1800 |

2400 |

| Defect length, l (mm) |

300 |

300 |

300 |

300 |

| Defect width, w (mm) |

32 |

32 |

32 |

32 |

| Defect depth, d (mm) |

9 |

9 |

9 |

9 |

| Pipe internal pressure, p(MPa) |

10 |

10 |

10 |

10 |

Table 5.

Geometric parameters of four test pipes

Table 5.

Geometric parameters of four test pipes

| Input Parameters |

Values |

| Test 1 |

Test 2 |

Test 3 |

Test 4 |

| Outer diameter of pipe, D (mm) |

325 |

325 |

325 |

325 |

| Wall thickness, t (mm) |

12 |

12 |

12 |

12 |

|

| Length of pipe, L (mm) |

1200 |

1200 |

1200 |

1200 |

| Normalized effective defect length, (l/D) |

1.215 |

0.938 |

0.938 |

0.938 |

| Normalized defect width, (w/πD) |

0.031 |

0.031 |

0.031 |

0.041 |

| Normalized effective defect depth, (d/t) |

0.775 |

0.775 |

0.758 |

0.758 |

| Normalized failure press,(pf/p0) |

0~1 |

0~1 |

0~1 |

0~1 |

Table 6.

Comparison of stress simulation results of 4 pipe models

Table 6.

Comparison of stress simulation results of 4 pipe models

| Pipe models |

Maximum stress(MPa) |

Maximum

deviation |

Minimum stress(MPa) |

Maximum

deviation |

| Model 1 |

491.6 |

1.7 % |

6.655 |

27% |

| Model 2 |

484.1 |

9.121 |

| Model 3 |

483.4 |

8.175 |

| Model 4 |

483.1 |

7.285 |

Table 7.

Comparison of yield pressure simulations and test results for corroded pipelines

Table 7.

Comparison of yield pressure simulations and test results for corroded pipelines

| (l/D) |

(w/πD) |

(d/t) |

(py/p0) |

Percentage Difference |

| FEM |

Test |

| 1.215 |

0.031 |

0.775 |

0.1975 |

0.1824 |

8.27 |

| 0.938 |

0.031 |

0.775 |

0.2058 |

0.1925 |

6.91 |

| 0.938 |

0.031 |

0.758 |

0.2410 |

0.2243 |

7.45 |

| 0.938 |

0.041 |

0.758 |

0.2594 |

0.2393 |

8.4 |

Table 8.

Comparison of the failure pressure obtained using FEM, the empirical equation and hydraulic test

Table 8.

Comparison of the failure pressure obtained using FEM, the empirical equation and hydraulic test

| (l/D) |

(w/πD) |

(d/t) |

(pf/ p0) |

Percentage Difference |

| FEM |

Equation |

Test |

| 1.215 |

0.031 |

0.775 |

— |

0.2408 |

0.2224 |

8.26 |

| 0.938 |

0.031 |

0.775 |

— |

0.2510 |

0.2347 |

6.96 |

| 0.938 |

0.031 |

0.758 |

— |

0.2939 |

0.2735 |

7.46 |

| 0.938 |

0.041 |

0.758 |

— |

0.3163 |

0.2918 |

8.39 |

| 0.9231 |

0.0314 |

0.75 |

0.3245 |

0.3105 |

— |

4.31 |

| 0.9231 |

0.0608 |

0.75 |

0.3804 |

0.3194 |

— |

5.52 |

| 0.9231 |

0.0608 |

0.5833 |

0.4936 |

0.4506 |

— |

8.71 |

| 0.9231 |

0.0608 |

0.6667 |

0.4507 |

0.4115 |

— |

8.69 |

| 0.6154 |

0.0314 |

0.75 |

0.3765 |

0.3564 |

— |

5.34 |

| 0.7692 |

0.0314 |

0.75 |

0.3574 |

0.3493 |

— |

2.27 |