Submitted:

11 September 2024

Posted:

11 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

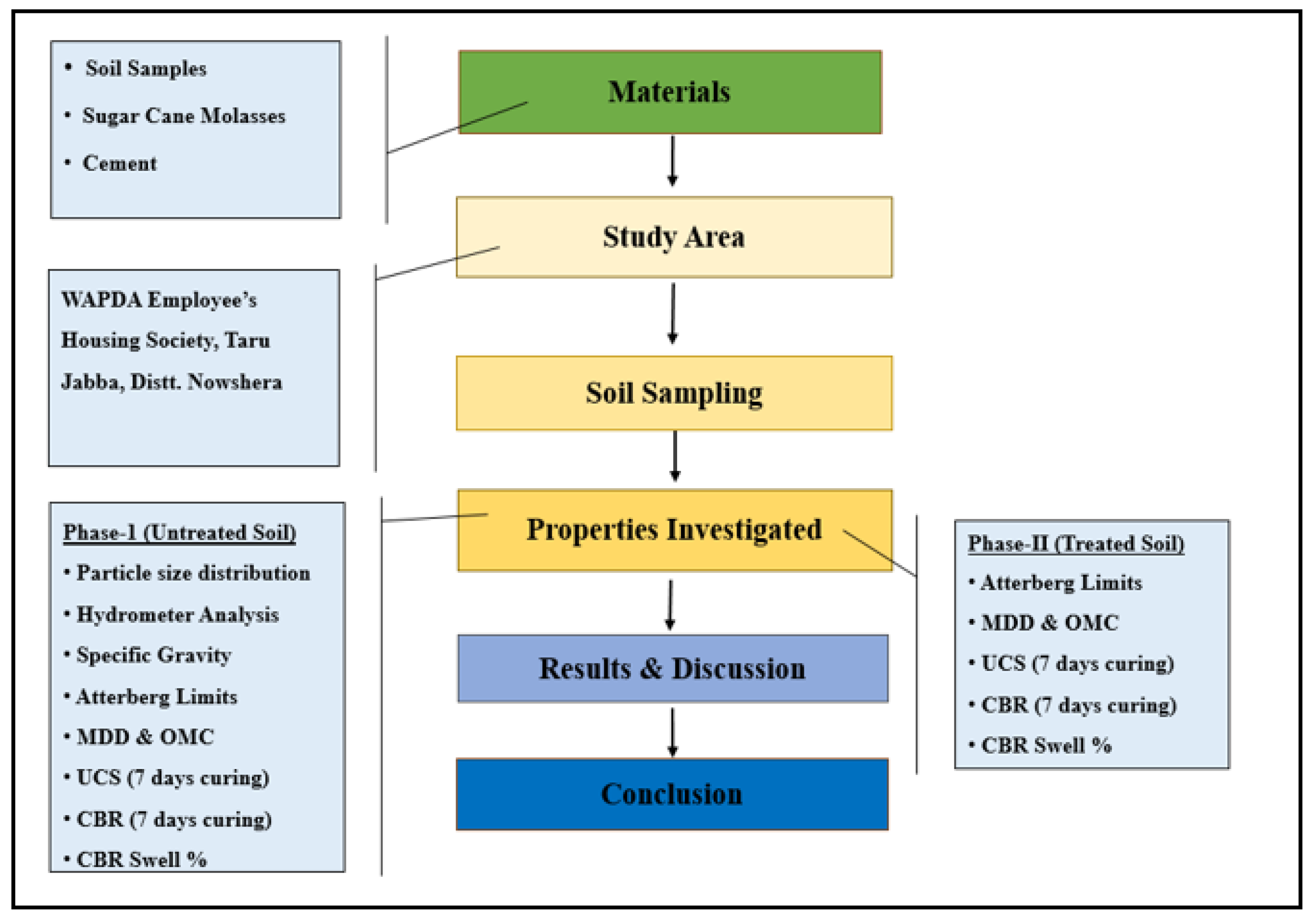

2. Methodology

3. Materials

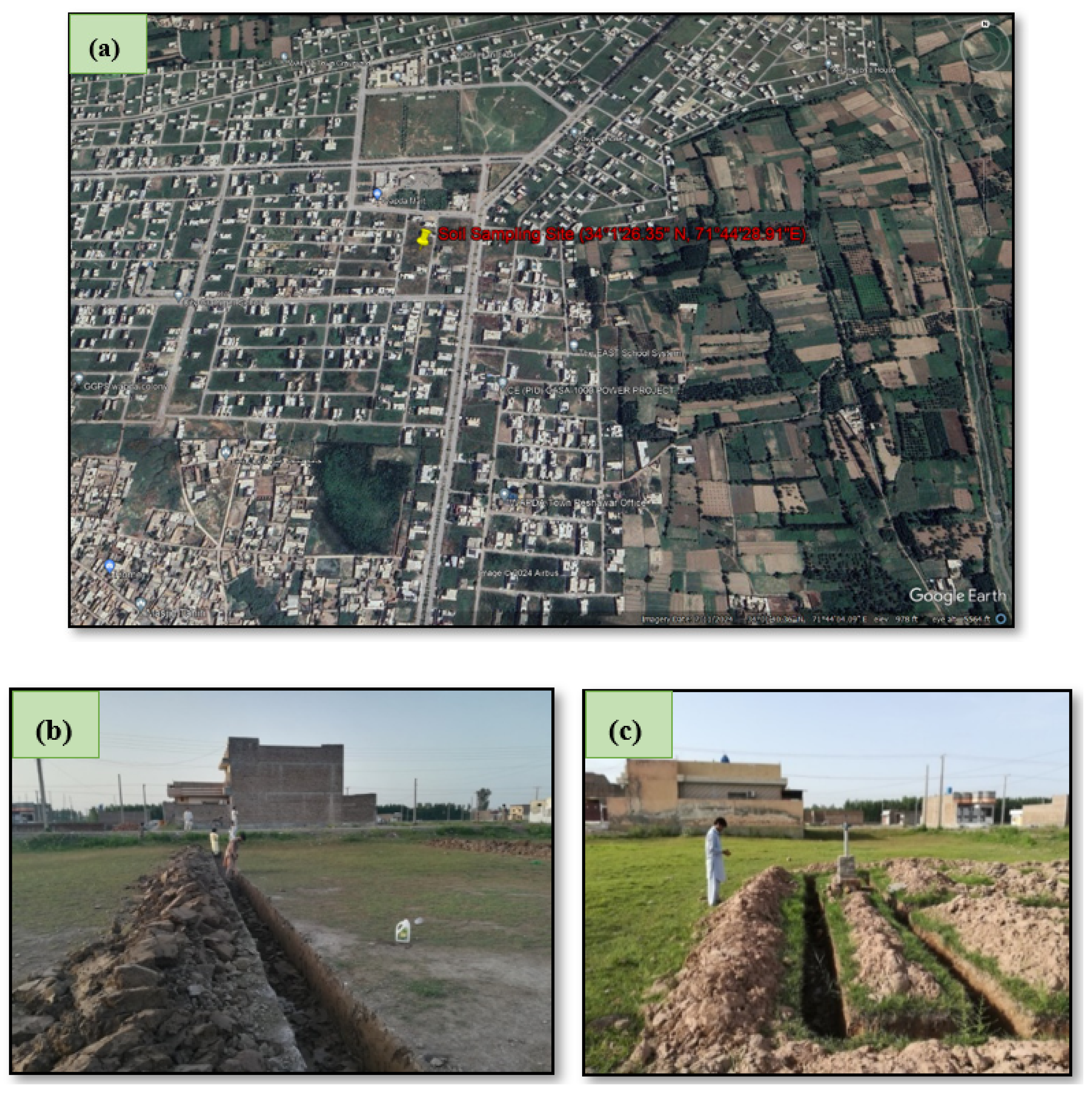

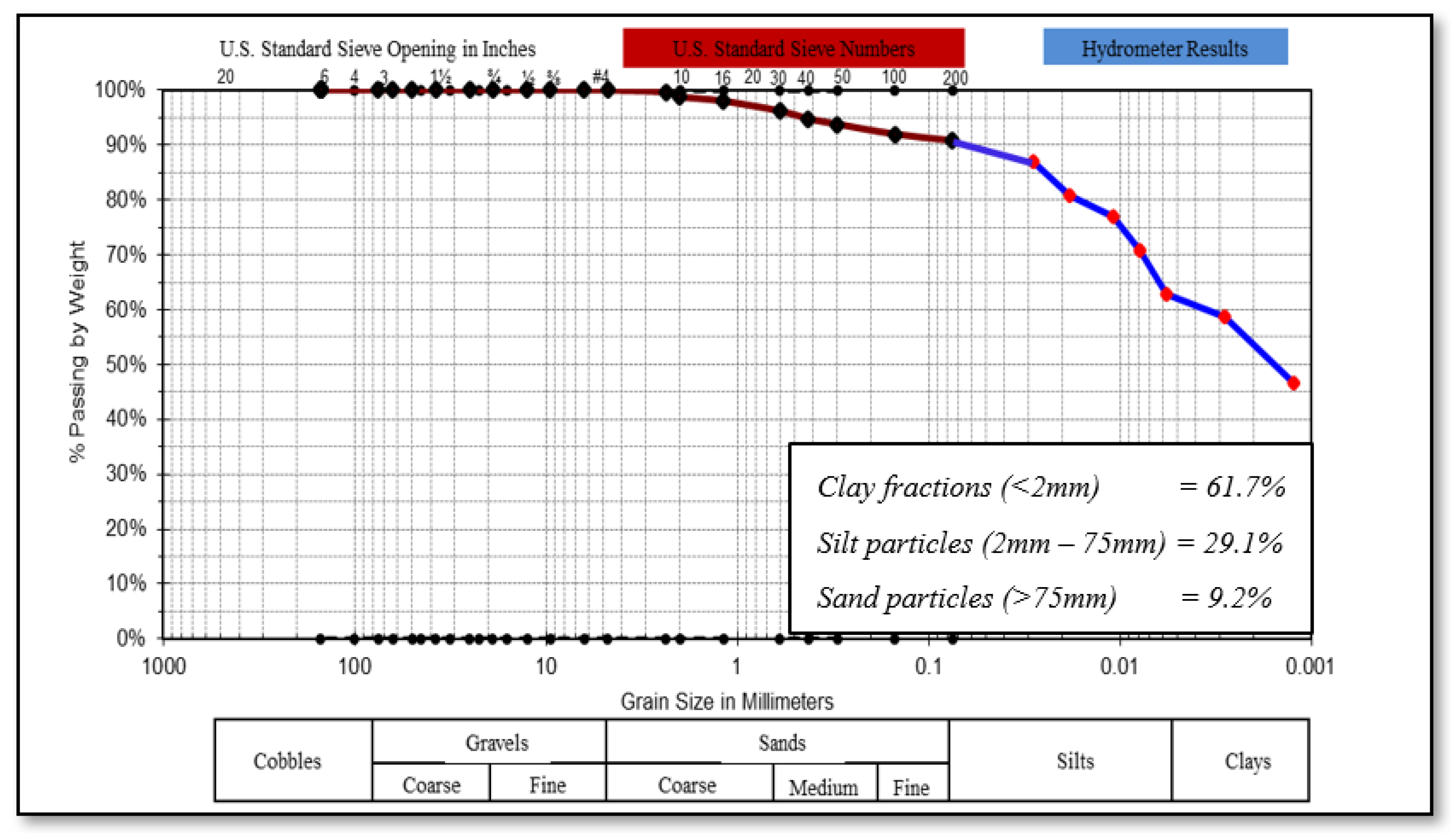

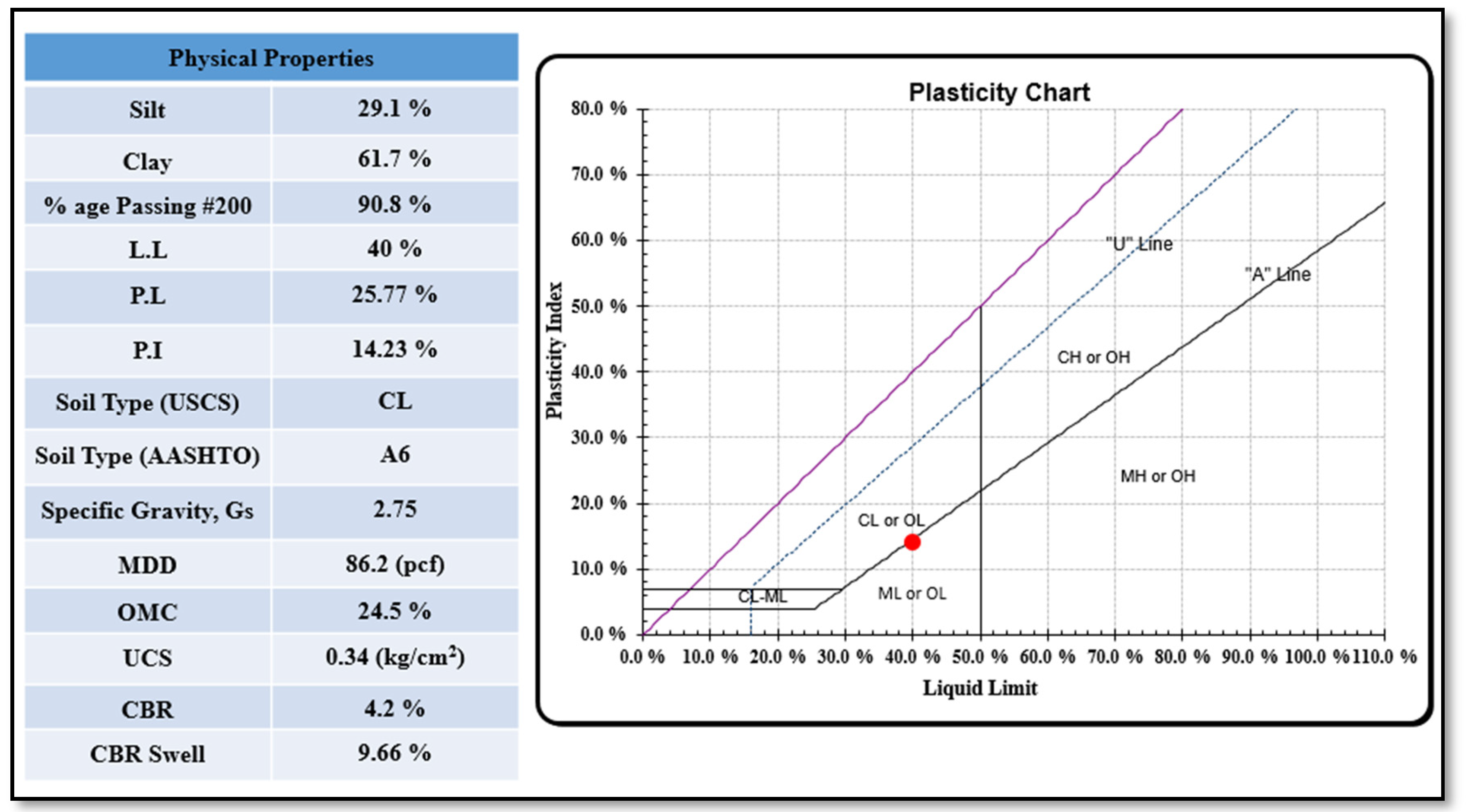

3.1. Expansive Soil

3.2. Sugarcane Molasses

3.3. Ordinary Portland Cement (OPC)

3.4. Soil Consistency

3.5. Compaction Test

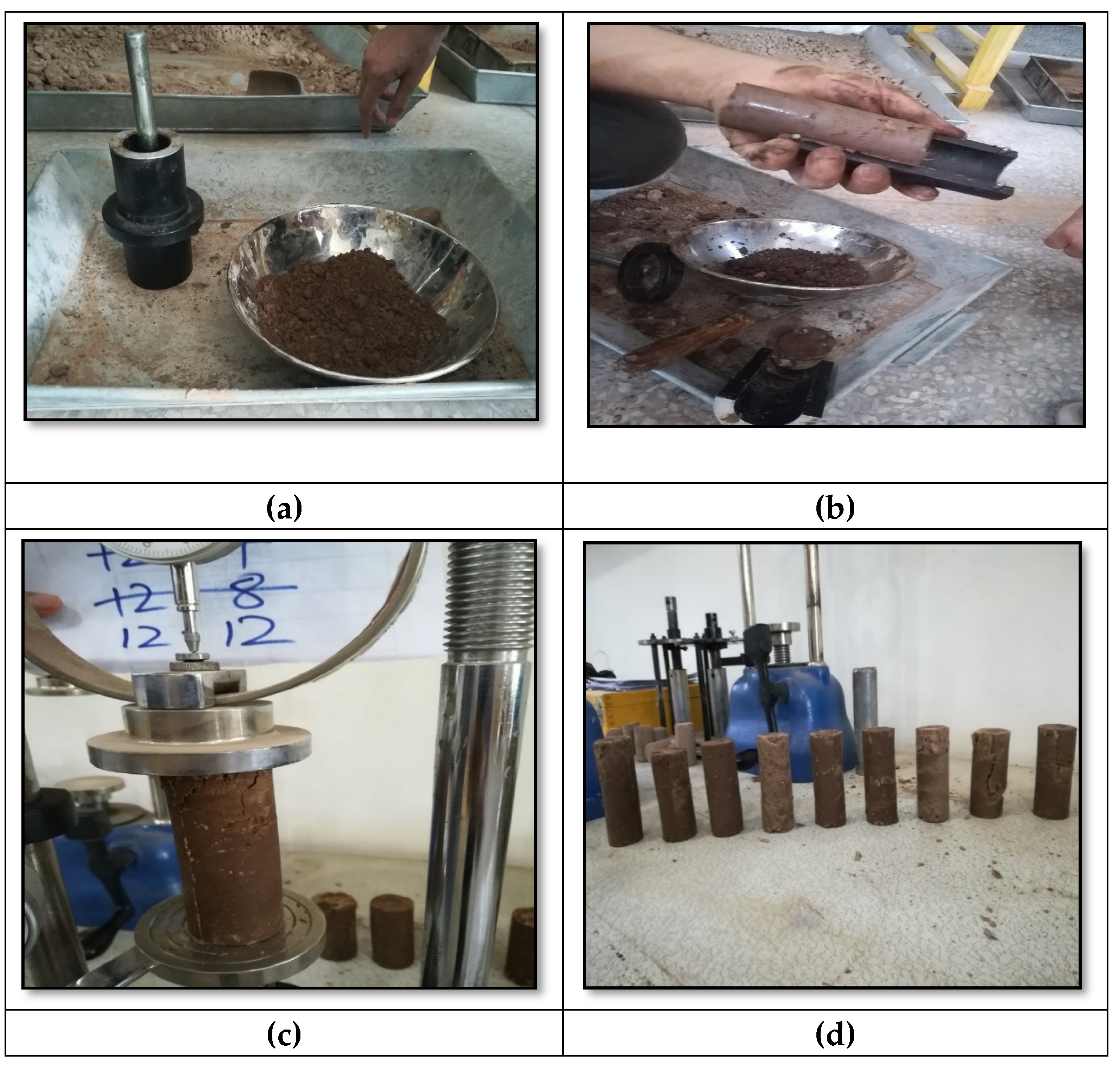

3.6. Unconfined Compressive Strength (UCS)

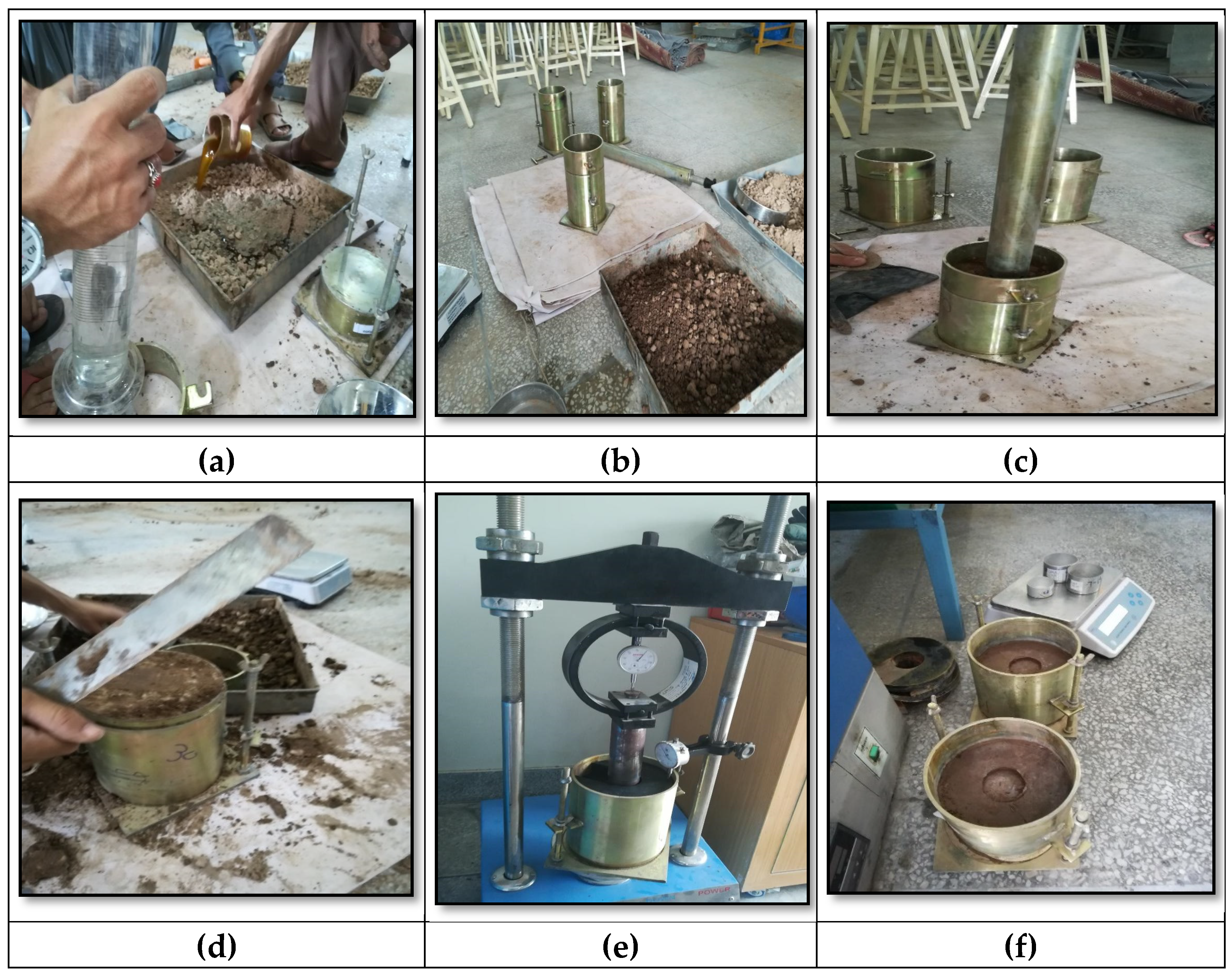

3.7. California Bearing Ratio (CBR)

4. Material Testing

4.1. Sample Preparation

4.2. Planning for Laboratory Tests

5. Results and Discussions

5.1. Effect of Stabilizers on pH values

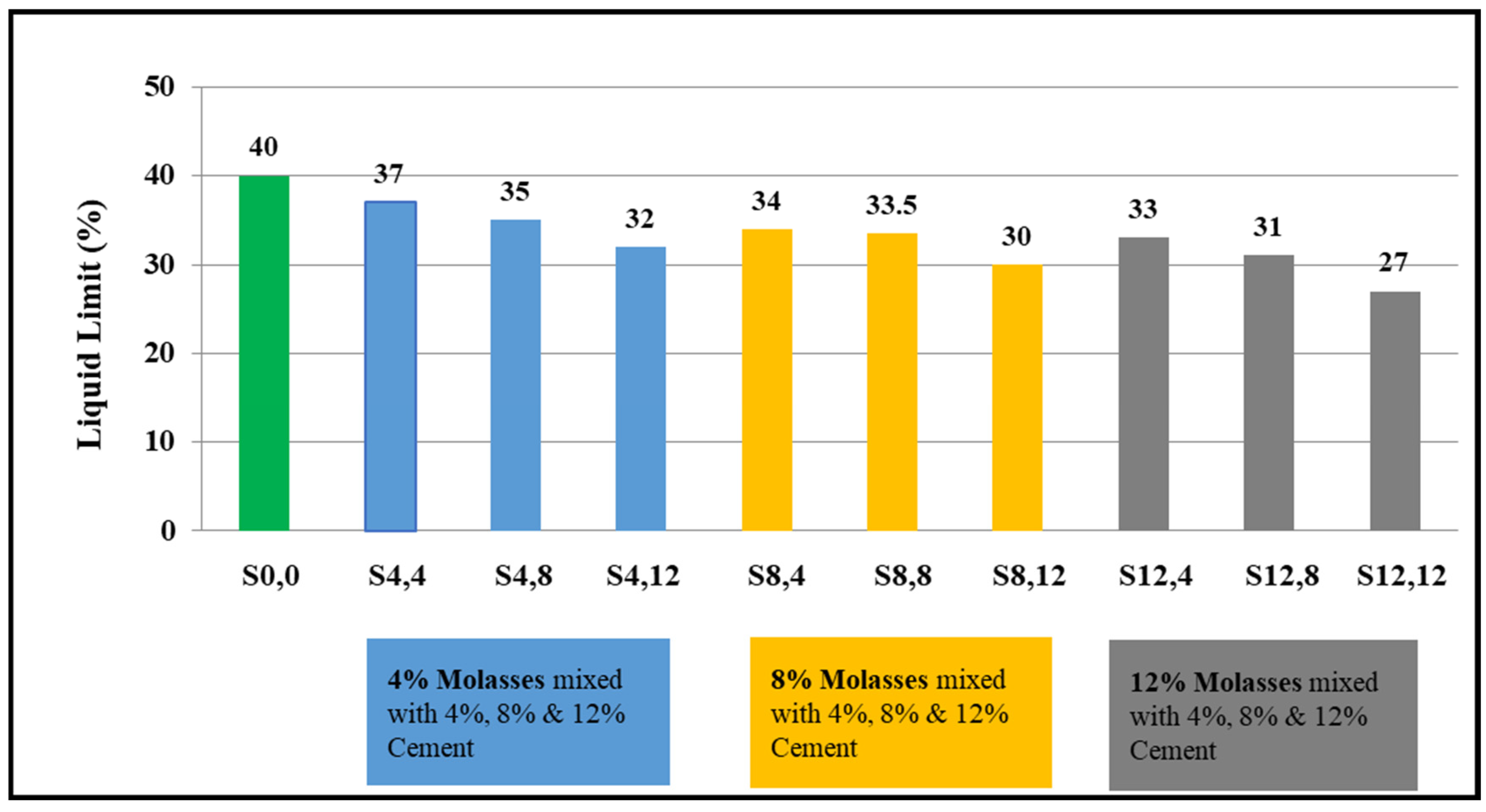

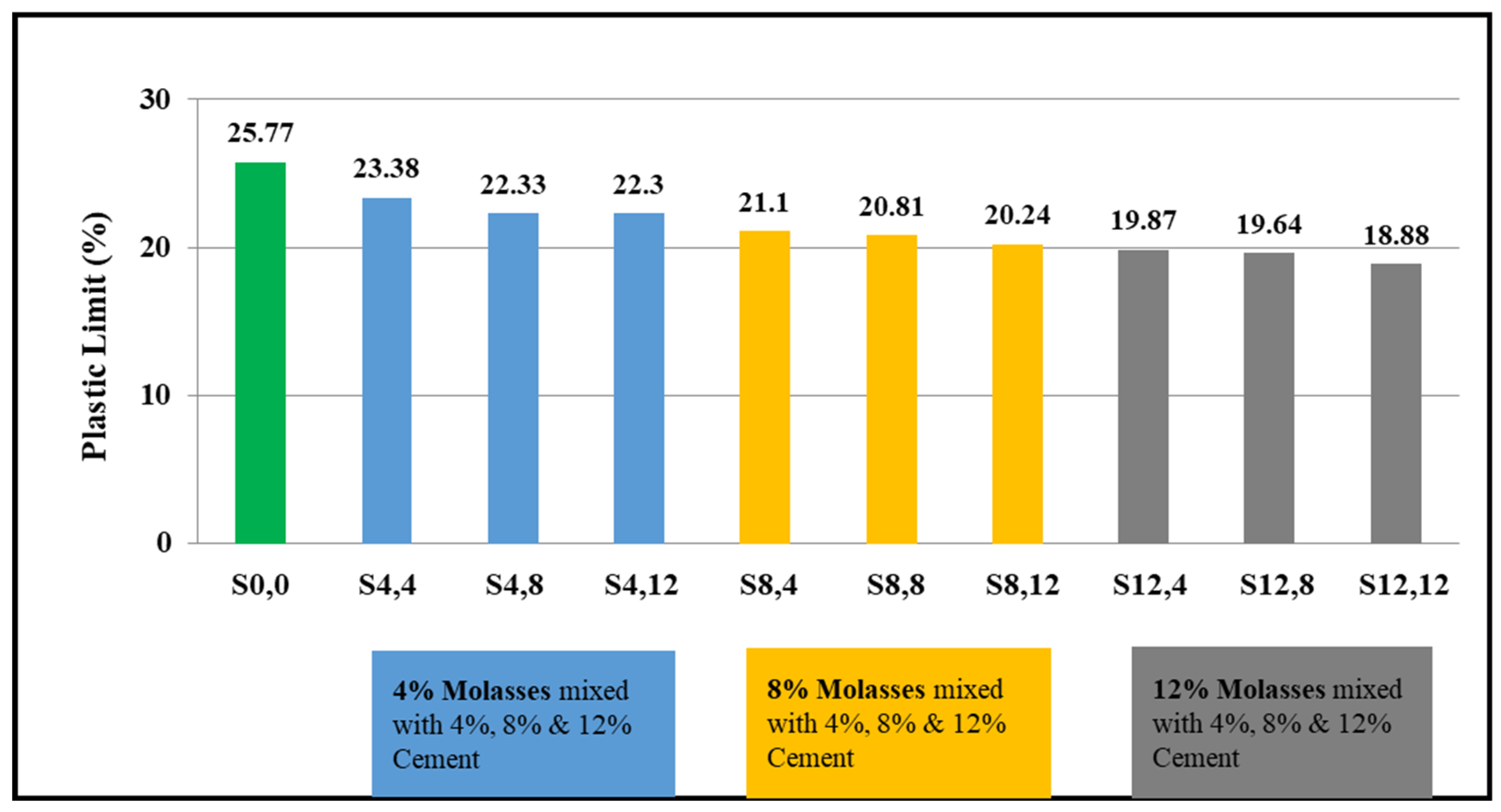

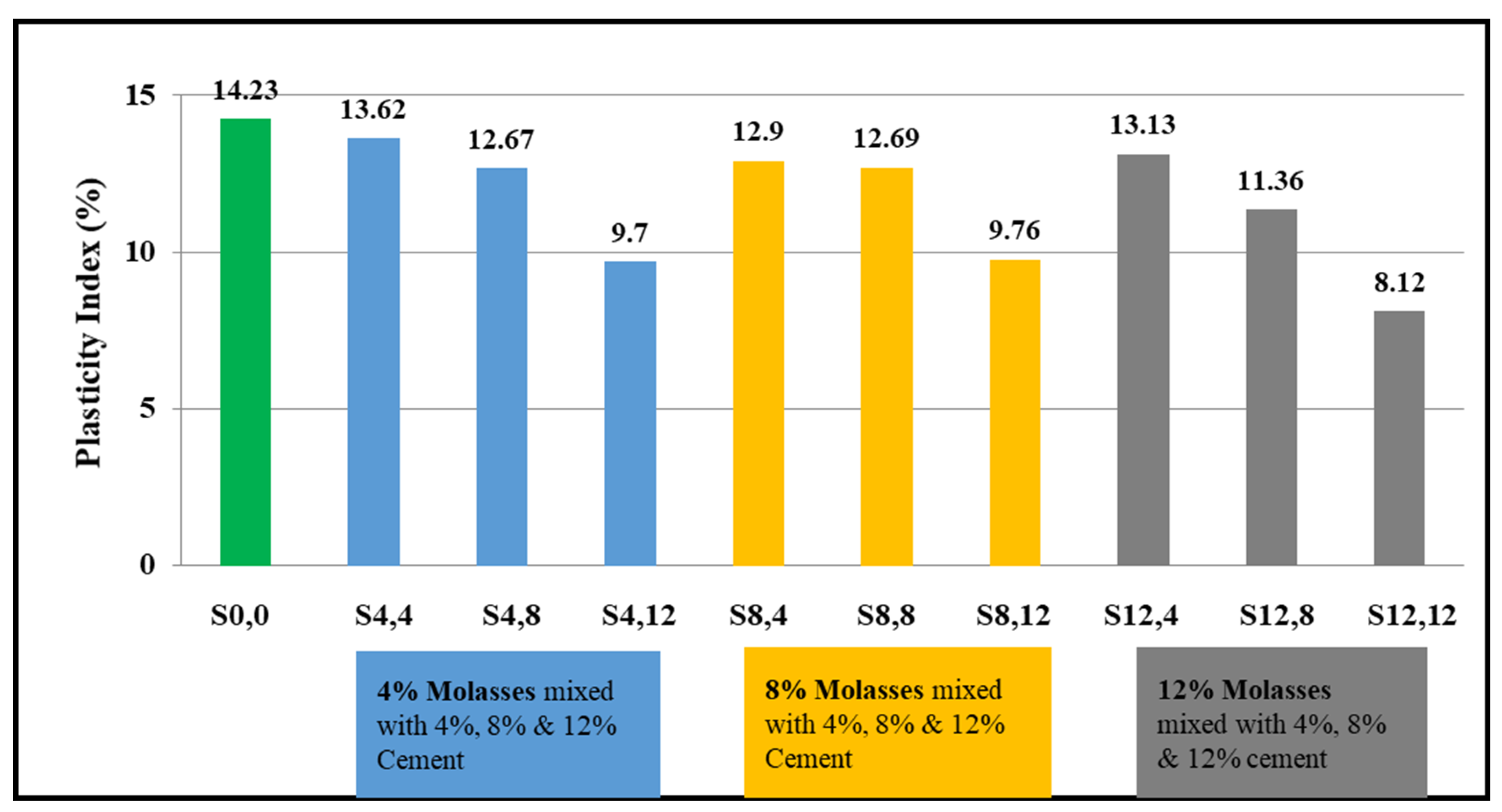

5.2. Effect of Stabilizers on Atterberg Limits

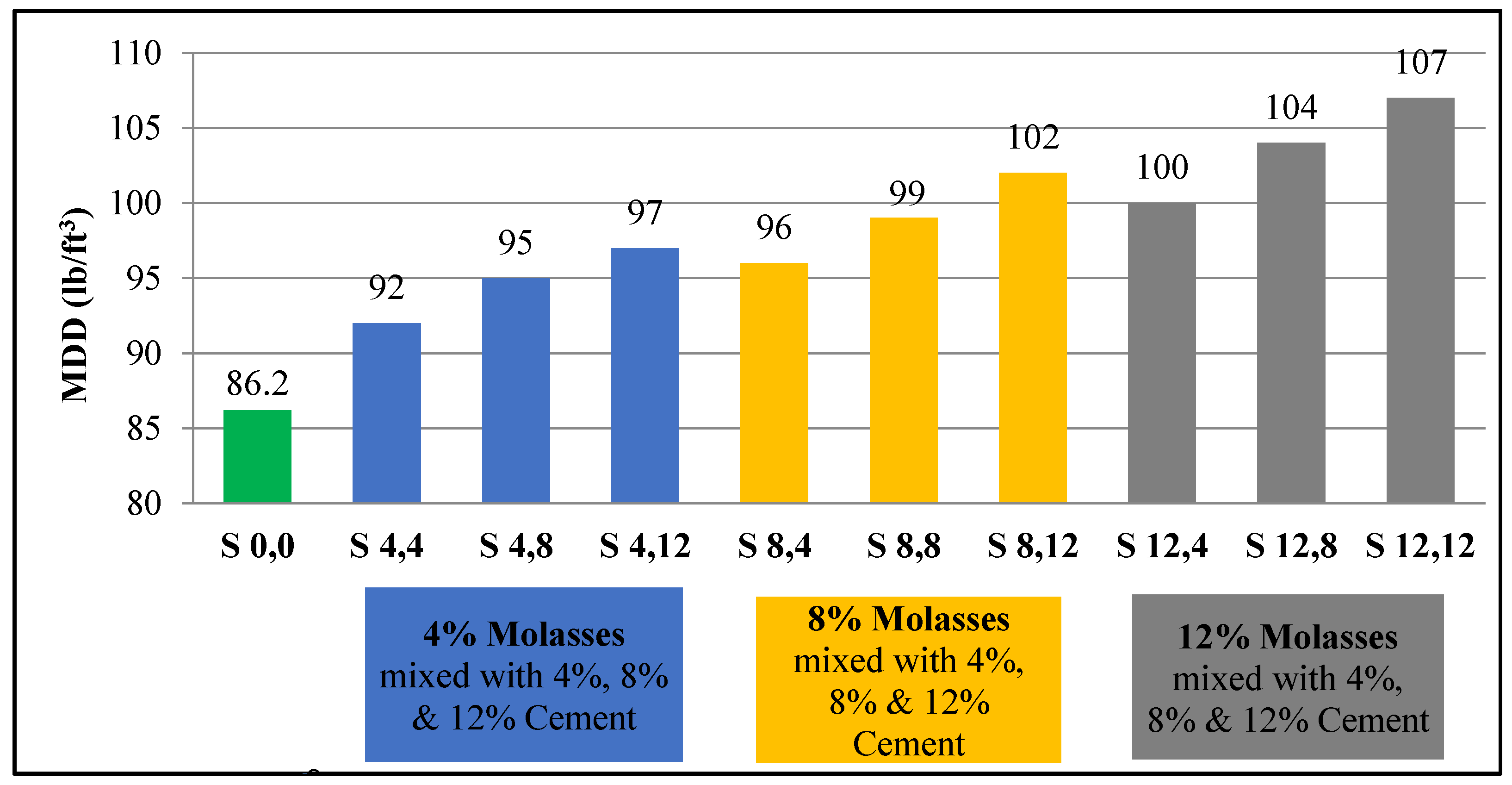

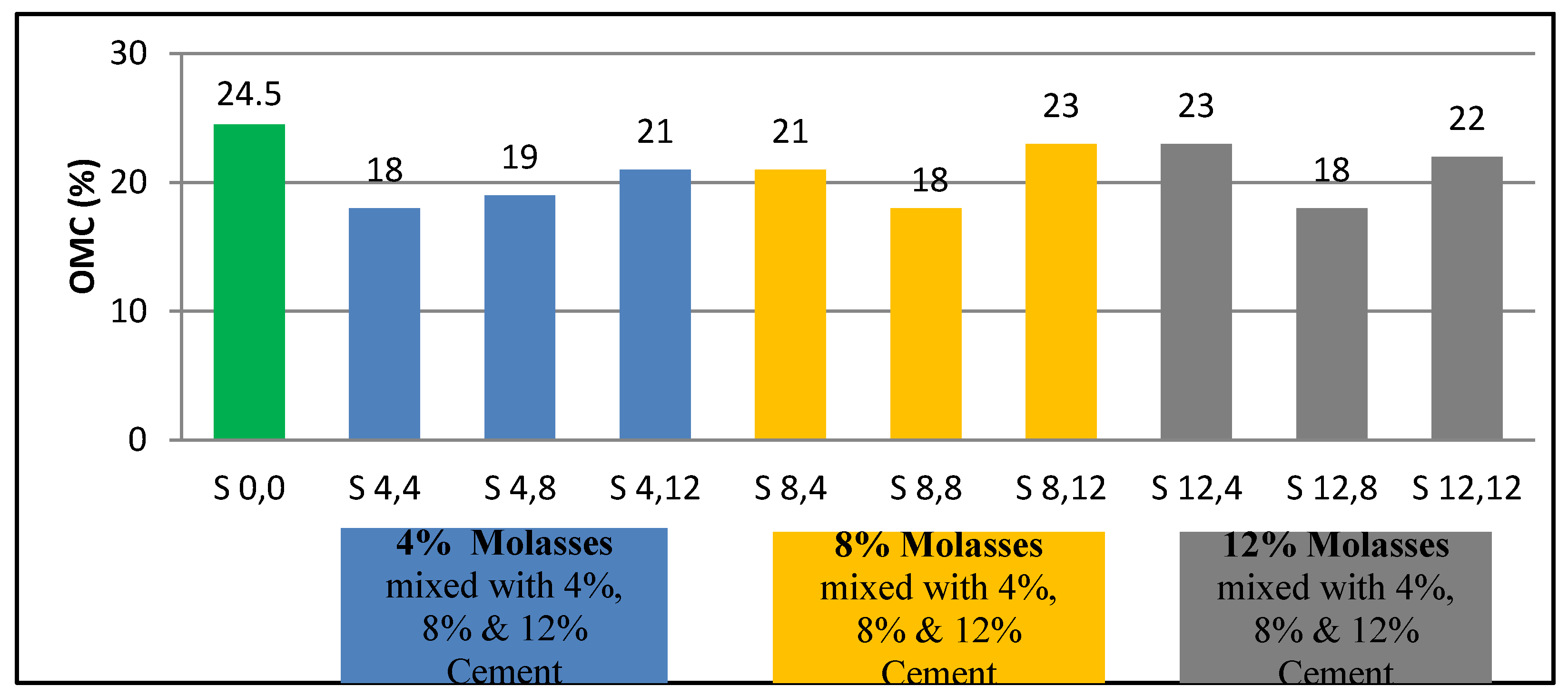

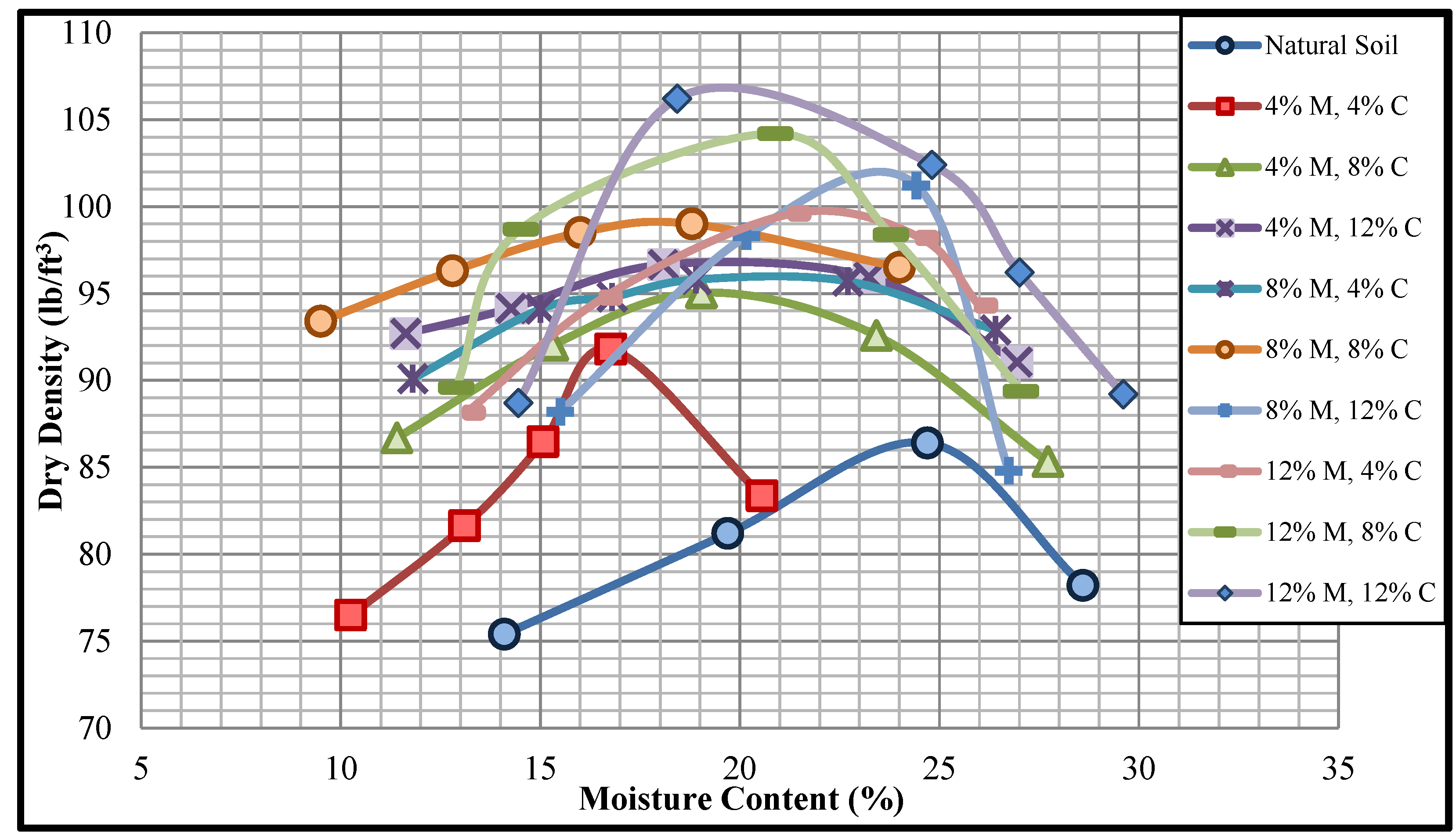

5.3. Effect of Stabilizers on Standard Proctors

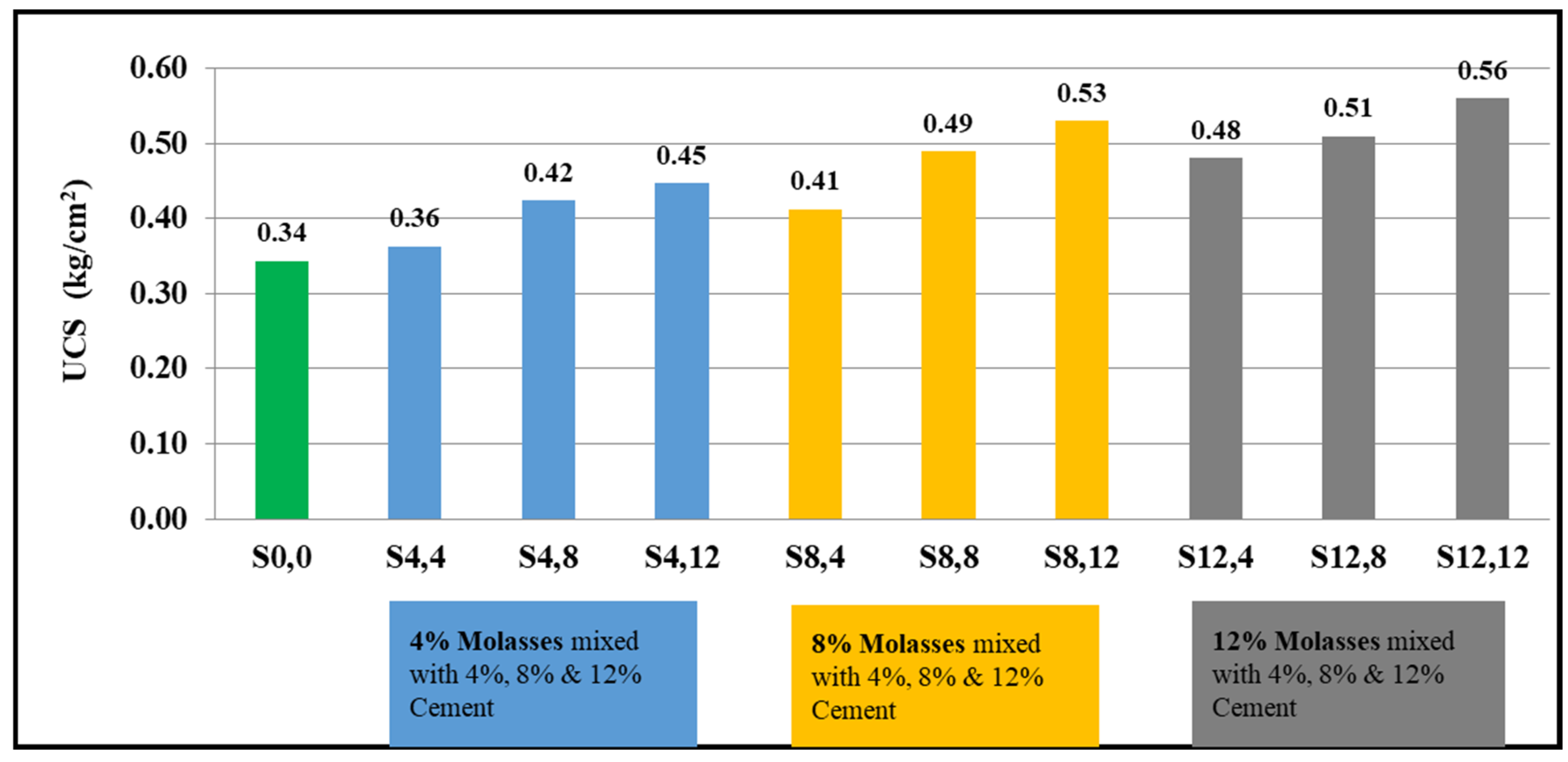

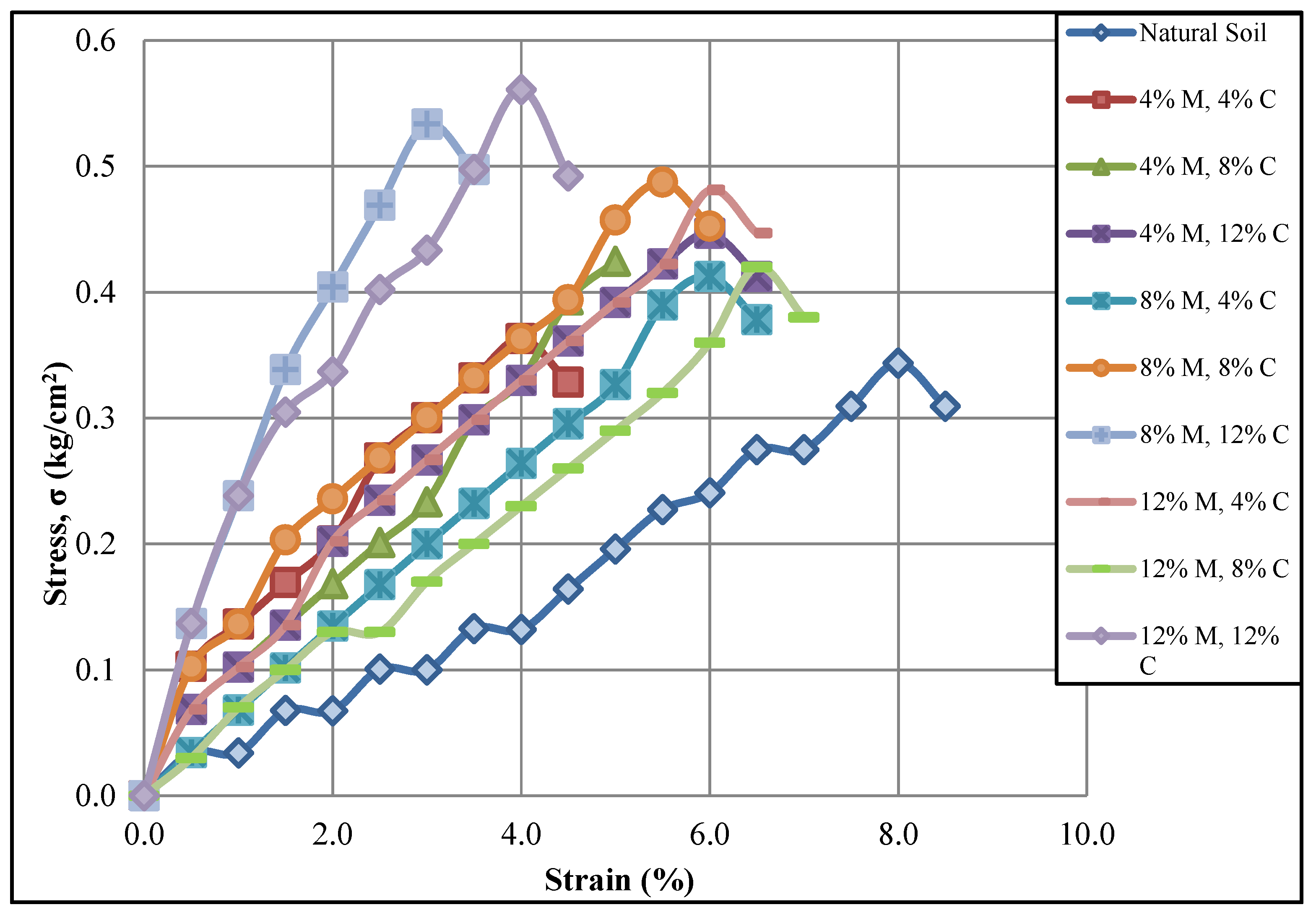

5.4. Effect of Stabilizers on UCS values

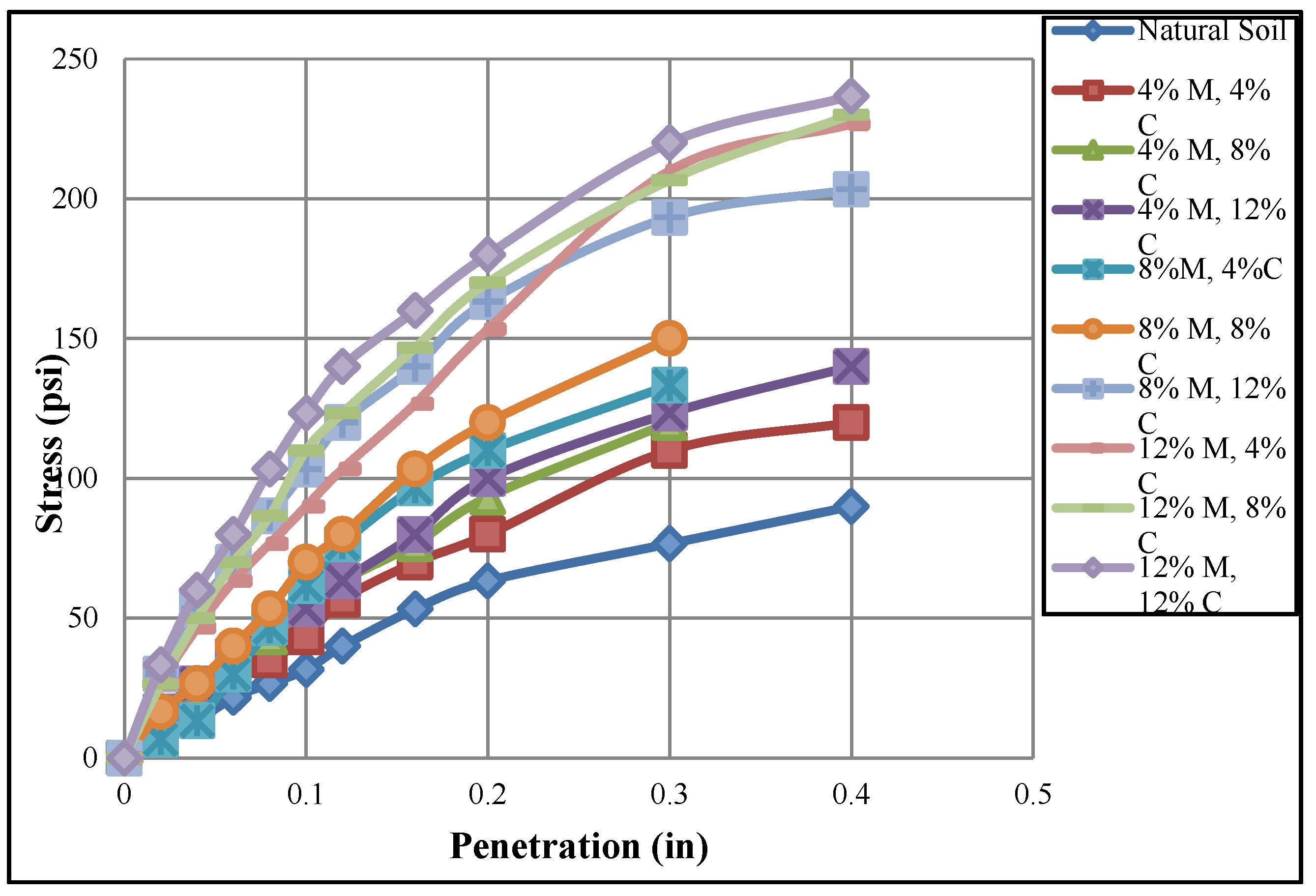

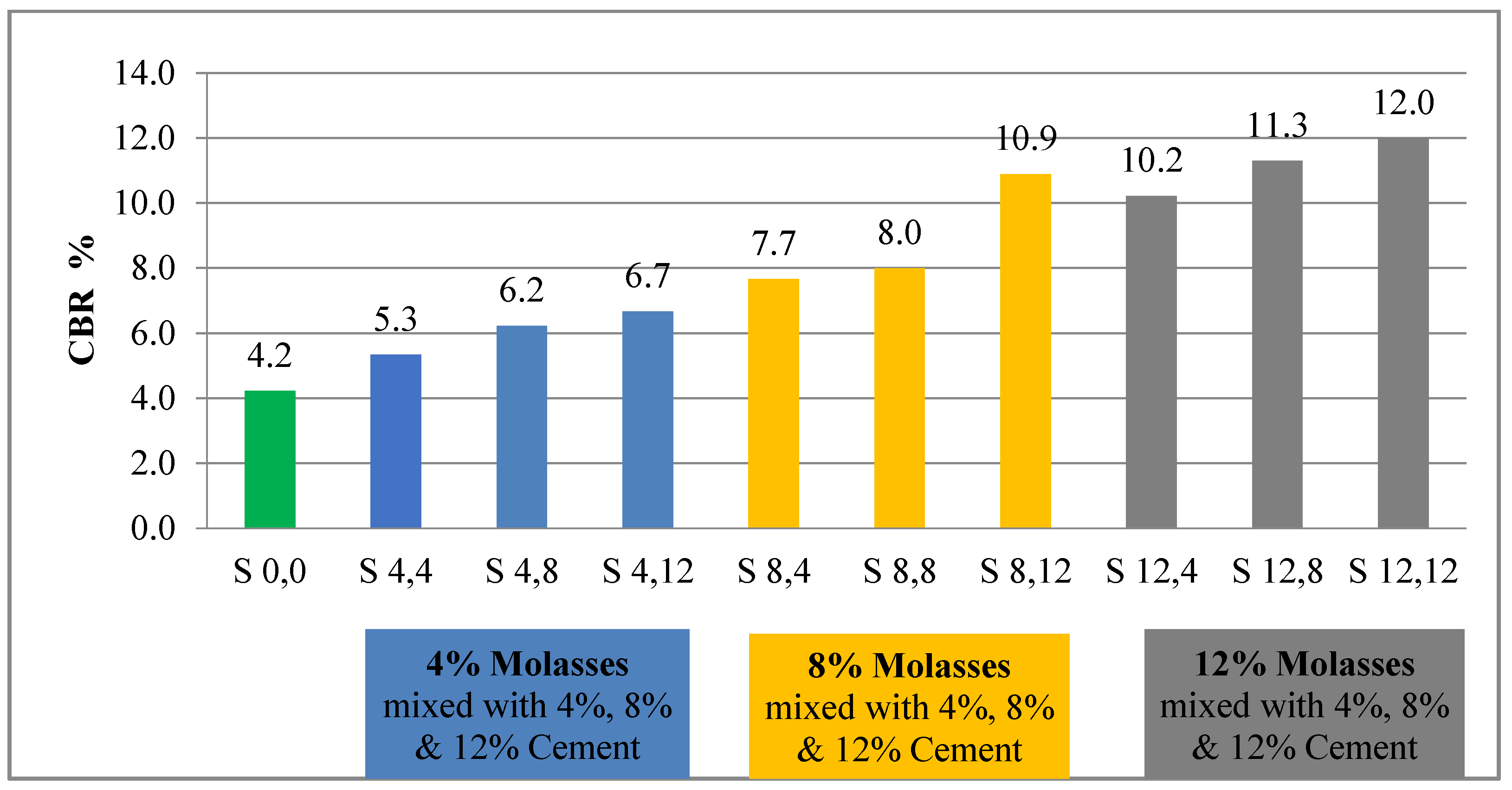

5.5. Effect of Stabilizers on CBR Values

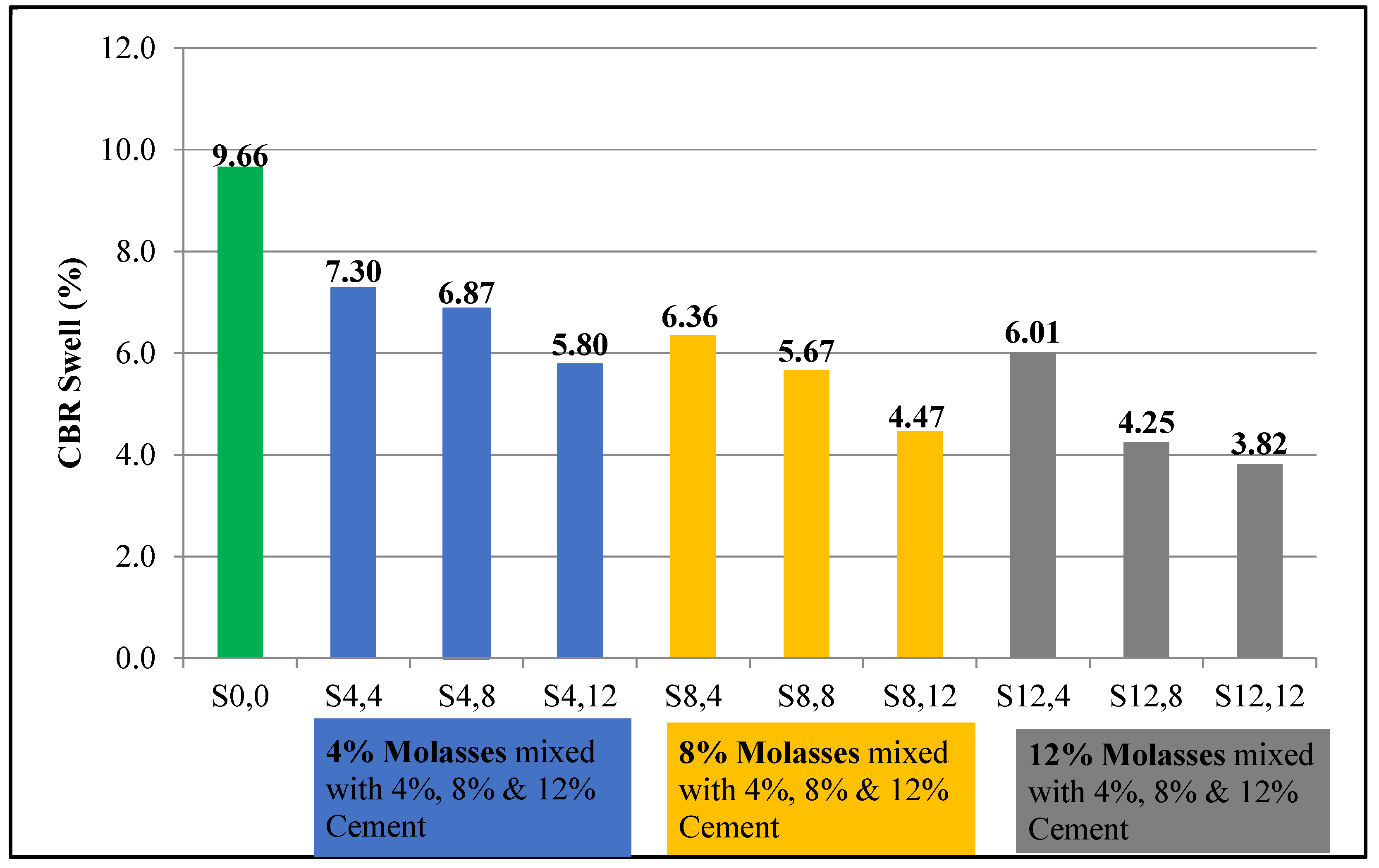

5.6. CBR Swell of Expansive Clay Soils

6. Conclusions and Recommendations

- i

- The values of Liquid Limit decline with the addition of sugar cane molasses and cement up to 12%. For the stabilized soil, the Liquid Limit value decreased from 40% to 27% compared to the unstabilized soil. The values of Plastic Limit also slightly decline with the addition of sugar cane molasses and cement up to 12%. Additionally, the values of the Plasticity Index decrease with the addition of sugar cane molasses and cement.

- ii

- The values of MDD increase with the addition of sugar cane molasses and cement up to 12%, while the values of OMC decrease with the increasing percentages of sugar cane molasses and cement in the soil sample.

- iii

- In the unconfined compression test, it is observed that the compressive strength of the stabilized soil increased by 64.7% with the addition of sugar cane molasses and cement up to 12%, after curing for 7 days, compared to the strength of the native soil. Soil treated with molasses exhibits a plastic nature, while soil treated with cement shows a brittle nature, with shrinkage cracks observed. The addition of molasses to cement reduces the soil’s brittleness.

- iv

- The addition of 12% sugar cane molasses to 12% cement increases the CBR value from 4.2% in the native soil to 12.3% in the stabilized soil and reduces the swell value from 9.66% in the native soil to 3.82% in the stabilized soil, after curing for 7 days. Thus, the geotechnical properties of the soil are improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cai, G.J., Song, D. H., Liu, L. L., Liu, X. Y., & Tian, H. L. , A Comprehensive Review of the Evaluation and Application of Engineering Properties of Expansive Soil Based on Piezocone Penetration Test (CPTU). In IOP Conference Series: Earth and Environmental Science, 2024. Vol. 1337, No. 1: p. p. 012005. [CrossRef]

- Pandey, V.K., Dhiman, S., & Bharti, K. , A Review on the Use of Lime in Soil Stabilization. Latest Trends in Engineering and Technology, 2024: p. 414-421.

- Pokkunuri, G.R., Sinha, R. K., & Verma, A. K. , Field Studies on Expansive Soil Stabilization with Nanomaterials and Lime for Flexible Pavement. Sustainability, 2023: p. 15(21), 15291. [CrossRef]

- Stãnciucu, M., & Dogaru, I., Geotechnical Hazards Induced by Montmorillonite Presence. 2024.

- Ali, L., & Zafar, Z. , Construction on expansive soils in semi arid zone. In Instrumentation, Testing, and Modeling of Soil and Rock Behavior, 2011: p. pp. 256-263.

- Huang, B., Zhang, Y., Shen, J., Li, J., & Xu, J. , Effect of cement modification on expansive soil slope. In Smart Geotechnics for Smart Societies, 2023: p. pp. 1152-1156.

- Pathan, S.B., & Singh, V. V. , Using molasses in concrete as a time retarding admixture. International Journal of Engineering Research & Technology, 2017: p. 6(11), 509-513.

- M’Ndegwa, J.K., The effect of cane molasses on strength of expansive clay soil. Journal of Emerging Trends in Engineering and Applied Sciences, 2011: p. 2(6), 1034-1041.

- Jiménez, J.E., Fontes Vieira, C. M., & Colorado, H. A. , Composite soil made of rubber fibers from waste tires, blended sugar cane molasses, and kaolin clay. Sustainability, 2022: p. 14(4), 2239. [CrossRef]

- Melese, B.E.T.E.L.H.E.M., Review on soil stabilization using bagasse ash with lime and molasses with cement. Addis Ababa Science and Technology University, Addis Ababa, 2018.

- Tiwari, N., Satyam, N., & Sharma, M. , Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method. Scientific Reports, 2021: p. 11(1), 10324. [CrossRef]

- Pooni, J., Giustozzi, F., Robert, D., Setunge, S., & O’Donnell, B. J. T. G. , Durability of enzyme stabilized expansive soil in road pavements subjected to moisture degradation. Transportation Geotechnics, 2019: p. 21, 100255. [CrossRef]

- Bhardwaj, A., & Sharma, R. K. , Effect of industrial wastes and lime on strength characteristics of clayey soil. Journal of Engineering, Design and Technology, 2020: p. 18(6), 1749-1772. [CrossRef]

- Khawaja, M., Study on the Use of Local Additives for Stabilization of Road Subgrade. International Journal for Research in Applied Science and Engineering Technology, 2019. [CrossRef]

- Hussain Sadique, C.S., A Systematic Study to Strengthen the Sub Grade of the Pavement by Stabilisation of Expansive Soil with Molasses and Jute Fibre. Mathematical Statistician and Engineering Applications, 2023: p. 72(1), 668-682. [CrossRef]

- M’Ndegwa, J.K., & Shitote, S. M. , Influence of cane molasses on plasticity of expansive clay soil. International Journal of Current Research, 2012: p. 4(1), 136-141.

- Yu, H., Huang, X., Ning, J., Zhu, B., & Cheng, Y. , Effect of cation exchange capacity of soil on stabilized soil strength. Soils and Foundations, 2014: p. 54(6), 1236-1240. [CrossRef]

- Bhattacharya, M., & Harish, K. V. , An integrated approach for studying the hydration of portland cement systems containing silica fume. Construction and Building Materials, 2018: p. 188, 1179-1192. [CrossRef]

- Estabragh, A.R., Khatibi, M., & Javadi, A. A. , Effect of cement on treatment of a clay soil contaminated with glycerol. Journal of Materials in Civil Engineering, 2016: p. 28(4), 04015157. [CrossRef]

- Paneru, H., Acharya, M. P., & Acharya, I. P. , Cement Stabilization of soft soil subgrade and Cost Analysis. Kathford Journal of Engineering and Management, 2023: p. 2(01), 1-16. [CrossRef]

- Shirsavkar, S.S., & Koranne, S. , Innovation in road construction using natural polymer. Electronic Journal of Geotechnical Engineering, 2010: p. 15(1), 1614-1624.

- Suriadi, A., Murray, R. S., Grant, C. D., & Nelson, P. N. , Structural stability of sodic soils in sugarcane production as influenced by gypsum and molasses. Australian journal of experimental agriculture, 2002: p. 42(3), 315-322. [CrossRef]

- Wahab, N.A., Rashid, A. S. A., Roshan, M. J., Rizal, N. H. A., Yunus, N. Z. M., Hezmi, M. A., & Tadza, M. Y. M. , Effects of cement on the compaction properties of lateritic soil. In IOP Conference Series: Materials Science and Engineering 2021. Vol. 1153, No. 1: p. p. 012015). [CrossRef]

- Roshan, M.J., Rashid, A. S. A., Wahab, N. A., Hezmi, M. A., Jusoh, S. N., Norsyahariati, N. D. N., ... & Roslizayati, R. , EFFECTS OF ORDINARY PORTLAND CEMENT ON THE SOIL-WATER CHARACTERISTICS CURVE OF LATERITIC SOIL. Suranaree Journal of Science & Technology, 2023: p. 30(1). [CrossRef]

- Tsutsumi, T., & Uchida, S. , Effect of Surfactant in Molasses Based Soil Solidification Material to Tensile Strength in Seven Day Material Age. In IOP Conference Series: Earth and Environmental Science, 2022. Vol. 971, No. 1: p. p. 012030. [CrossRef]

- Nabil, M., Mustapha, A., & Rios, S. , Impact of wetting—drying cycles on the mechanical properties of lime-stabilized soils. International Journal of Pavement Research and Technology, 2020: p. 13, 83-92. [CrossRef]

- Kumar, P., Puppala, A. J., Congress, S. S. C., & Tingle, J. S. , Characterization of Cement-Polymer-Treated Soils under Repeated Loading. Journal of Materials in Civil Engineering, 2024: p. 36(4), 04024036. [CrossRef]

- Ndegwa, S.M., The effect of credit risk on the financial performance of commercial banks listed at the Nairobi securities exchange. Doctoral dissertation, University of Nairobi, 2017.

- Taye, B., & Araya, A. A. , Stabilization of expansive clay soil with sugar cane molasess and cement. In Proceedings of the 2nd International Conference on Transportation in Africa (ICTA2015) Majestic Five Hotel, Palapye, Botswana 2015: p. pp. 25-27.

- Bansal, A., Goyal, T., & Sharma, U. , Enhancement of sub-grade soil strength with additives: Cement and molasses. Springer International Publishing, 2021: p. pp. 35-47.

- Yabi, C.P., Agongbe, S. W., Koto Tamou, B. C., Noroozinejad Farsangi, E., Alamou, E., & Gibigaye, M. , Prediction of CBR by Deep Artificial Neural Networks with Hyperparameter Optimization by Simulated Annealing. Indian Geotechnical Journal, 2024: p. 1-17. [CrossRef]

- Amrisha, K., Krishna, Kumar, Patel., Vishwajeet, Pratap, Singh., Volume Change Behavior of Amended Expansive Soil Using Sugarcane Bagasse Ash-Based Geopolymer. Journal of Materials in Civil Engineering, 2024. [CrossRef]

- Liu, C., Lu, K., Wu, Z., Liu, X., Garg, A., Qin, Y., ... & Lv, C. , Expansive soil improvement using industrial bagasse and low-alkali ecological cement. Construction and Building Materials, 2024: p. 423, 135806. [CrossRef]

- Soltani, A., Taheri, A., Khatibi, M., & Estabragh, A. R. , Swelling potential of a stabilized expansive soil: a comparative experimental study. Geotechnical and Geological Engineering, 2017: p. 35, 1717-1744. [CrossRef]

| Sr. No | Constituents | Result |

|---|---|---|

| 1 | Color | Black |

| 2 | Brix | 84.9 |

| 3 | pH(1:1at 200C) | 5.5 |

| 4 | Specific gravity at 20/40 | 1.43181 |

| 5 | Viscosity @ 300c (mPa. s) | 18400 |

| 6 | Viscosity @ 600c (mPa. s) | 6600 |

| 7 | Moisture (%) | 23.78 |

| 8 | Total Sugar (%) | 48.46 |

| 9 | Invert Sugar (%) | 10.53 |

| 10 | Sulphated ash (%) | 14.52 |

| 11 | Ca (%) | 1.60 |

| Sr. No. | Specific Items | Unit | Measured |

|---|---|---|---|

| 1 | Loss on ignition | % | 2.05 |

| 2 | SiO2 (silica) | % | 21.63 |

| 3 | Al203 (alumina) | % | 5.52 |

| 4 | Fe203 (Iron Oxide) | % | 3.42 |

| 5 | CaO (Lime) | % | 61.45 |

| 6 | MgO (Magnesia) | % | 1.86 |

| 7 | S03 (Sulphur Trioxide) | % | 2.71 |

| 8 | C3S (ofClinker)-tri silicate | % | >55.0 |

| 9 | C2S (of Clinker)—dicalcium silicate | % | >14 |

| 10 | C3A (of Clinker)—tricalcium Aluminate | % | <8 |

| 11 | CAF (of Clinker)-tetracalicium alumina-ferrite | % | >10 |

| 12 | Free Lime | % | 0.45-0.80 |

| 13 | Liter Weight | G/Lt | >1310 |

| Mix Types | Soil | Molasses | Cement |

|---|---|---|---|

| S0,0 | 100% | - | - |

| S4,4 | 92% | 4% | 4% |

| S4,8 | 88% | 4% | 8% |

| S4,12 | 84% | 4% | 12% |

| S8,4 | 88% | 8% | 4% |

| S8,8 | 84% | 8% | 8% |

| S8,12 | 80% | 8% | 12% |

| S12,4 | 84% | 12% | 4% |

| S12,8 | 80% | 12% | 8% |

| S12,12 | 76% | 12% | 12% |

| Percent of Stabilizer | pH Value |

|---|---|

| Native | 8.20 |

| S4,4 | 7.84 |

| S4,8 | 8.07 |

| S4,12 | 9.11 |

| S8,4 | 13.19 |

| S8,8 | 13.63 |

| S8,12 | 13.74 |

| S12,4 | 12.75 |

| S12,8 | 13.18 |

| S12,12 | 13.48 |

| Limit | Native soil (%) | Soil treated with molasses and cement (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S4,4 | S4,8 | S4,12 | S8,4 | S8,8 | S8,12 | S12,4 | S12,8 | S12,12 | ||

| LL | 40 | 37 | 35 | 32 | 34 | 33.5 | 30 | 33 | 31 | 27 |

| PL | 25.77 | 23.38 | 22.33 | 22.3 | 21.1 | 20.81 | 20.24 | 19.87 | 19.64 | 18.88 |

| PI | 14.23 | 13.62 | 12.67 | 9.7 | 12.9 | 12.69 | 9.76 | 13.13 | 11.36 | 8.12 |

| Soil Type | Mould Height (mm) | Change in Length in mm during soaking |

CBR Swell (%) | % Change |

|---|---|---|---|---|

| S0,0 | 116.43 | 11.25 | 9.66 | 0.00 |

| S4,4 | 116.43 | 8.5 | 7.30 | -24.43 |

| S4,8 | 116.43 | 8 | 6.87 | -28.88 |

| S4,12 | 116.43 | 6.75 | 5.80 | -39.95 |

| S8,4 | 116.43 | 7.4 | 6.36 | -34.16 |

| S8,8 | 116.43 | 6.6 | 5.67 | -41.30 |

| S8,12 | 116.43 | 5.2 | 4.47 | -53.72 |

| S12,4 | 116.43 | 7 | 6.01 | -37.78 |

| S12,8 | 116.43 | 4.95 | 4.25 | -56.0 |

| S12,12 | 116.43 | 4.45 | 3.82 | -60.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).