1. Introduction

In the context of today's interconnected global business sphere, companies face numerous risks that impact their operations. These risks often emerge from the supply chain, especially involving suppliers [

11]. As crucial components of the business infrastructure, disruptions or failures linked to suppliers can lead to financial damages, create inefficiencies, and diminish a firm's competitive edge. Consequently, organizations need to prioritize supplier risk management. As noted by [

2,

15,

28], supplier risk management entails an orderly process of identifying, evaluating, and managing supplier-associated risks to preserve the resilience and continuity of a business.

In the challenging global business landscape, supplier risk and its multifaceted nature pose a considerable challenge to operational efficiency and business growth. Economic, social, and logistical factors create a complex network of suppliers, making businesses vulnerable to uncertainties linked to supplier pitfalls. Supplier risk encompasses a wide range of potential issues, including production delays, unexpected problems, poor quality, and financial challenges among crucial suppliers [

22]. These risks can significantly impact the overall performance and stability of the supply chain, leading to disruptions and potential losses for organizations [

26]. Effective management of supplier risks is essential for companies to navigate the complexities of global competition and ensure the smooth flow of materials and information within the supply chain [

4]. Identifying and mitigating these risks through methods like risk assessment and monitoring suppliers can enhance their resilience and maintain operational efficiency even in the face of uncertainties and challenges in the supply chain [

7]. Stakeholder perspectives also play a vital role in understanding and addressing supplier risks, highlighting the importance of collaboration and communication among all parties involved in the supply chain.

Supply chain management studies have given limited attention to the fundamental causes of disruptions, such as supplier financial instability, quality issues, and delivery delays, to scrutinize the impact of how supplier evaluation, payment terms, contract duration, and buyer and supplier collaboration influence risk mitigation and control towards effective supplier risk management. Through an examination of the interplay between supplier evaluation, payment terms, contract duration, buyer-supplier collaboration, information transparency, and supplier risk management, this review offers fresh insights into proactive measures, transcending a mere reactive stance. It establishes an insight for more resilient supply chain, by leveraging supplier evaluation, payment terms, contract duration, and buyer and supplier collaboration, that could lead to noticeable enhancements in operational efficiency and the quality of goods and services.

2. Broader Concept

Supplier Risk Management

Supplier risk management is essential for companies to navigate the complexities of global supply chains and ensure operational resilience. The process involves identifying, assessing, and mitigating risks associated with suppliers [

9]. [

14] emphasize the importance of proactively identifying potential risks and developing contingency plans as essential strategies for successful supplier risk management.

Supplier Risk Management involves collaboration with partners in the supply chain to implement risk management processes, as highlighted in a study on Supply Chain Risk Management [

21]. Supplier risk evaluation and monitoring are essential in operations management, considering various factors such as supplier financial performance, geopolitical risks, news sentiments, judicial filings, and regulatory compliance [

5]. The complexity and frequency of risk events in supply chains have heightened the need for objective risk assessment methods to mitigate subjectivity biases among auditors. This evolving discipline caters to a wide range of industries, including manufacturers, retailers, financial services companies, and government agencies, all reliant on suppliers to achieve their business objectives [

5].

Various studies emphasize the importance of managing risks within the supply chain to ensure operational efficiency and mitigate disruptions. [

7] highlights the need for companies to identify and manage supplier risks to succeed in a competitive environment. Additionally, [

6,

8], and underscore the significance of risk identification, mitigation, and control in global supply chains to enhance performance and sustainability. Supplier risk management is a crucial process in both private and public procurement contexts. [

1] emphasize that it involves evaluating risks within the supply chain to enhance procurement performance.

With effective management of supplier risks, organizations can reduce the likelihood of disruptions, ensure timely deliveries, maintain product quality, and ultimately enhance overall procurement efficiency and effectiveness. This process not only contributes to cost reduction but also plays a significant role in achieving value for money, supporting complex procurement processes, and maximizing social welfare in the economy. Previous research has demonstrated that effective supplier risk management yields several positive outcomes, including improved organizational performance, enhanced supply chain visibility, reduced occurrence and adverse effects of risks, effective supply chain integration, and the recognition of managing supplier risks as a critical capability for long-term competitiveness.

3.0. Specific Concepts

A. Supplier Evaluation

Supplier Evaluation is the process of assessing the capabilities and performance of suppliers. This process involves gathering information about suppliers' financial stability, quality management systems, production capacity, and delivery performance. Various studies emphasize the significance of supplier evaluation in supply chain management [

19], as it aids in assessing suppliers' capabilities and potential risks. Supplier evaluation plays an important role in assessing and approving potential suppliers based on their ability to meet a company's needs, ensuring the procurement of quality materials and services at competitive prices. Supplier evaluation is a critical process in selecting vendors and suppliers for products or materials, focusing on criteria that align with the organization's business goals [

28]. Its role in supplier risk management involves assessing and selecting suppliers based on their capacity to meet organizational requirements, leading to improved performance, responsiveness, and supply chain resilience.

[

5] highlight the significance of systematically evaluating suppliers based on various criteria to select low-risk suppliers effectively. Additionally, [

24] discuss the importance of selecting qualified suppliers to ensure product quality and control procurement costs. From these insights, it is evident that supplier evaluation serves as a critical tool for identifying and reducing supply chain risks to improve procurement performance and overall supply chain effectiveness. Similarly, supplier evaluation serves as an analysis of inherent supply chain risks, aiming to develop strategies for risk mitigation. [

18] emphasizes the role of supplier evaluation in achieving sustainable risk management in the manufacturing sector by mitigating adverse impacts on the manufacturing process. [

10] identify supplier evaluation as the process of recognizing and validating key supply chain risks in Ghanaian companies, proposing effective risk management strategies, and investigating their impact on performance.

While effective supplier evaluation has been linked to improved organizational performance, challenges remain, such as the need for a better understanding of regulatory impacts and concerns about methodological rigor. Further research is warranted to address these inconsistencies and enhance the efficacy of supplier evaluation in enhancing organizational resilience and performance. Evaluating delivery capabilities helps mitigate delivery-related risks, while service evaluation verifies that suppliers can provide necessary support services. Delivery analysis evaluates suppliers based on key performance indicators such as lead time and on-time delivery rates, and service analysis gauges suppliers' service capabilities and customer service routines [

25].

B. Payment Terms

Payment terms in business transactions refer to the contractual clauses that outline the period and method for the settlement of financial obligations between a buyer and a supplier. These terms have a significant impact on various aspects of supplier risk, including financial risk, credit risk, currency risk, market risk, counterparty risk, and settlement risk. Synchronizing payments with the delivery of products or services can indeed help mitigate risks and ensure consistent cash flows for suppliers.

Timely payment of suppliers is indeed fundamental in managing supplier risk, as highlighted by [

31]. By ensuring prompt payments, companies can mitigate financial uncertainties for suppliers, reducing the likelihood of disruptions in the supply chain. [

32] emphasizes that such measures are essential for preventing suppliers from facing undue financial risks, ultimately contributing to the stability and reliability of the supply chain. This practice not only fosters stronger relationships with suppliers but also enhances overall supply chain resilience and competitiveness, particularly in industries like pharmaceuticals where disruptions can have significant societal impacts. Therefore, prioritizing timely payments is a strategic approach to proactively manage supplier risks and maintain a sustainable supply chain ecosystem.

The implementation of measures to ensure prompt payment to suppliers can effectively mitigate the risk of cash flow difficulties for the providers, thereby preventing potential non-fulfilment of obligations. Incentivizing suppliers to meet performance criteria, such as offering discounts for prompt settlement or tying remittance to specific quality or delivery criteria, can encourage improved supplier performance.

C. Contract Duration

Contract duration in procurement refers to the period stipulated in an agreement for the provision of goods or services, outlining the timeframe within which the contract is valid and enforceable [

12]. The legal principles governing contract duration emphasize the freedom to contract within legal limits, good faith in negotiations, and the prohibition of life-long obligations. The duration of a contract determines the period during which parties are responsible for fulfilling their contractual duties and considering the objectives, benefits, and risks associated with the contract is essential in determining its duration [

20].

Contract duration, a key element in this management process, impacts the feasibility and profitability of contracts for all parties involved. Longer durations can provide stability and predictability, managing various supplier risks such as quality, delivery, and pricing, while shorter durations offer flexibility to adapt to changing circumstances. A study by [

13] finds that the actual benefits of long-term contracts for suppliers are greater than theoretical predictions, and that long-term contracts result in more stable supply chain performance compared to short-term contracts.

Determining the appropriate contract duration involves a careful consideration of various factors such as the nature of work, associated risks, and opportunities for both parties [

12]. Contract terms, including duration, are jointly determined by various factors such as buyer and supplier characteristics, with larger and more creditworthy buyers receiving longer contract maturities. Therefore, the duration of contracts is a critical element in mitigating supplier default risk and enhancing supply chain coordination, reflecting the complex interplay between contract terms and risk management strategies. Longer contract durations have the potential to cultivate long-term relationships and mutual trust, effectively managing supplier risks like reputational, ethical, and strategic risks. Conversely, shorter contract durations can facilitate competitive bidding, aligning with market dynamics, and offering flexibility and adaptability in the business environment [

13]. Very long contracts can lead to higher agency costs, where companies feel less pressure to innovate because they have already secured their income for a long period, which can be detrimental in highly competitive markets [

17].

D. Buyer-Supplier Collaboration

Buyer and supplier collaboration involves a thorough engagement with suppliers to identify and manage potential risks, focusing primarily on information exchange about production timelines, inventory levels, and quality concerns [

25]. Successful collaboration can boost supply chain transparency and efficiency, subsequently decreasing the likelihood of supplier-related operational risks.

The domain of buyer-supplier collaboration within risk management involves the understanding and mitigation of risks stemming from the interdependencies between buyers and suppliers. These risks encompass disruptions in the supply chain, challenges related to product quality, and instances of financial instability, as highlighted by [

3]. The collaboration between buyers and suppliers involves establishing shared objectives and fostering transparent communication channels to build trust and ensure effective risk management. Risk management through buyer-supplier collaborations is essential for companies, addressing challenges like shortages, supplier-related risks, and inflationary risks [

30].

The benefits of supplier collaboration in supply chain management are significant, including cost savings, quality enhancement, innovation promotion, and increased adaptability for companies. Through fostering collaborative relationships, companies can leverage the expertise, resources, and capabilities of their suppliers, as highlighted by [

29]. This collaboration between stakeholders is instrumental in identifying and mitigating risks associated with suppliers, contributing to the establishment of robust supply chains.

4. Methodology

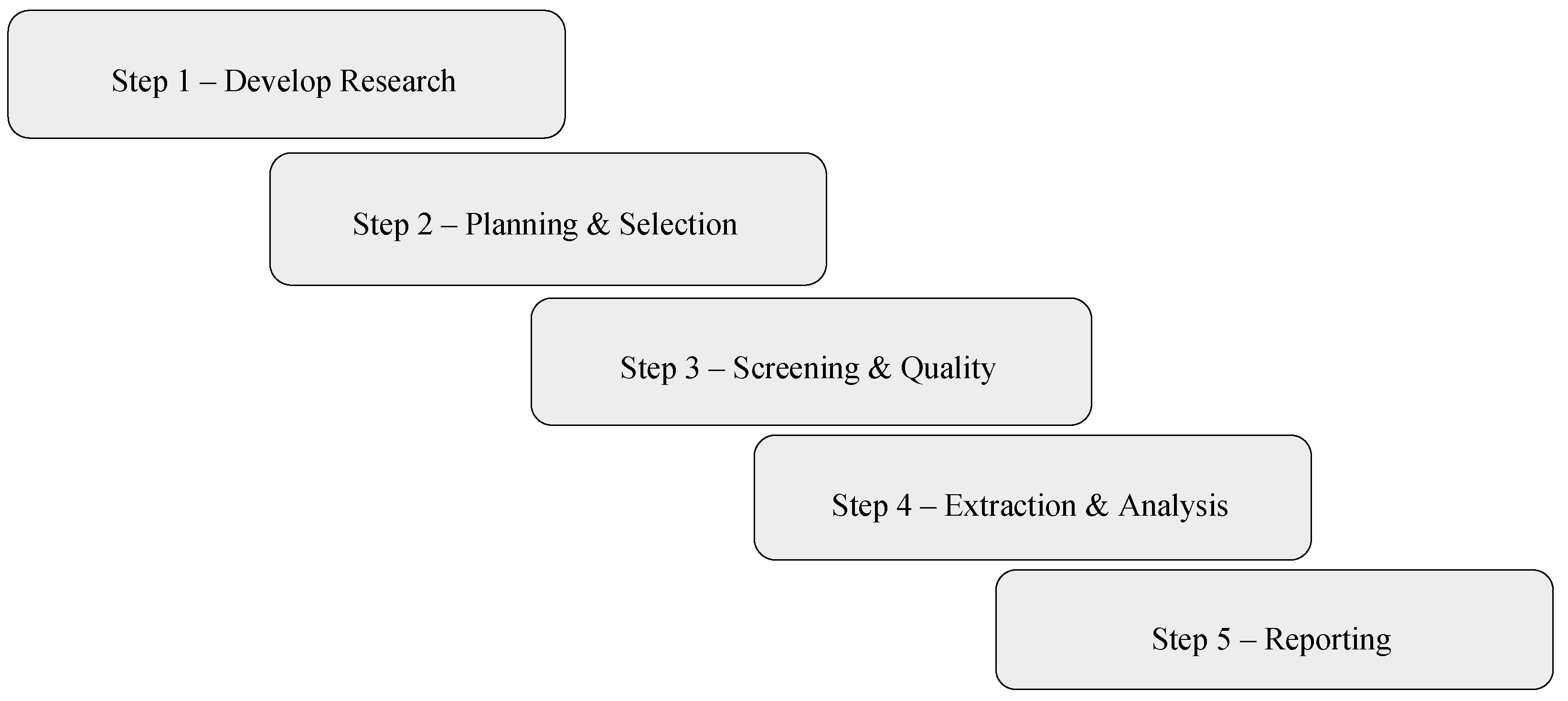

In reviewing the literature on the subject, a systematic literature review approach was adopted. The review aims to establish the supplier risk mitigating and control factors in the procurement of goods and services, and identify gaps in the literature to inform further research. A Systematic Literature Review (SLR) is a rigorous and structured methodology that synthesizes findings from primary research to provide a comprehensive overview of existing knowledge, methodologies, and gaps in a particular field. This process involves systematically searching, selecting, and critically appraising relevant studies to aggregate their results

To accomplish the aims of the review, a rigorous scrutiny of previous studies was undertaken to produce definitive and impartial results. Unlike historical, narrative, and integrative literature reviews, a Systematic Literature Review (SLR) leverages precise and stringent approaches that can be replicated and confirmed by other scholars. The clarity and reproducibility of these approaches bolster the scientific validity of such inquiries. The steps involved in conducting a qualitative Systematic Literature Review (SLR) with established methodologies in qualitative research. The process begins with performing scoping searches, identifying review questions, and writing a protocol for the review, which is crucial for setting a clear direction and scope for the study [

27]. This is followed by literature searching and screening titles and abstracts to ensure that only relevant studies are considered, a step that is essential for maintaining the focus and quality of the review [

23].

Figure 1 shows steps employed to undertake the systematic literature review. This process was designed to address the question: "Does supplier evaluation, payment terms, contract duration, and buyer-supplier collaboration influence supplier risk mitigation and control in the procurement of goods and services?"

To understand the relationship between supplier evaluation, payment terms, contract duration, buyer-supplier collaboration, and supplier risk management, the following specific keywords were used for the literature search: "supplier risk," "supplier evaluation," "payment terms," "contract duration," and "buyer-supplier collaboration." with search syntax: ("supplier risk" AND ("supplier evaluation" OR "payment terms" OR "contract duration" OR "buyer-supplier collaboration")).

The Boolean search syntax used facilitated a check for the key words in multiple databases. The Boolean is a type of search that allows users to combine keywords with operators such as AND, OR, and NOT to produce more relevant results. The databases include Mendeley, Scopus, Emerald, PubMed, Semantic Scholar, Google Scholar, EBSCOhost, ScienceDirect, Springer, and Web of Science.

The assessment was confined to the procurement of goods and services, including works, but not restricted to a specific industry in order to delve into publications that are tailored to the objective of the review. Consequently, the exploration was constrained to current research articles, spanning from 2020 to 2023, as the supply chain has encountered various interruptions within this timeframe.

The search yielded 541 hits representing related documents. Screening and quality procedures involved reviewing all titles, eliminating entries with only abstracts, and removing duplicate papers and unpublished articles. This process resulted in 105 full articles, which were further analyzed. Articles not aligned with the review's objectives were excluded. Following the completion of the screening and quality check, 32 peer-reviewed and published papers were retained for analysis. These 32 papers were analyzed using descriptive and thematic analyses.

5. Findings

A. Descriptive Analysis

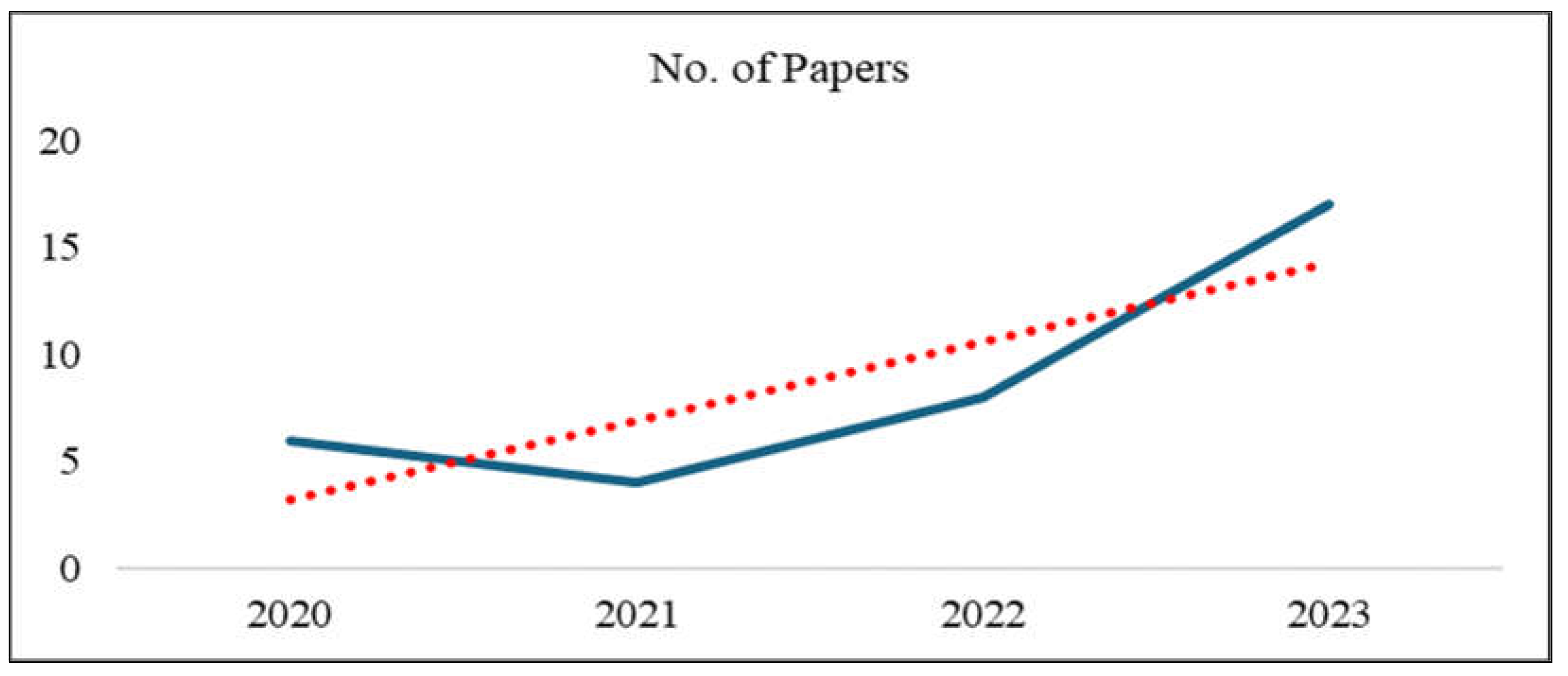

The chosen articles reviewed ranged from 2020 to 2023 (

Figure 2), with a noticeable increase in the number of publications related to the subject of interest starting from 2021 following a decline between 2020 and 2021. The onset of the Covid-19 pandemic was officially announced in late 2019 and exacerbated in 2020, causing disruptions in the global supply chain and constraining the movement of goods and services. By 2021, the effects of the pandemic had diminished, allowing global supply chains to partially return to normalcy, only to face disruptions again in 2022 due to the intensification of the Russia-Ukraine conflict. Since then, there has been a growing interest from both academia and industry in the areas of supply chain risk and supplier risk management. The trends depicted in

Figure 1 serve as a representation of the occurrences within the global supply chains impacting both the purchasing and supplying entities.

The examined articles were sourced from a total of twenty-five distinct academic journals, with merely five originating from a pair of specific journals within this pool. Among these, two articles were derived from publications of conference proceedings, while another article stemmed from a review of existing literature. The variety of journals consulted imparts credibility to the central focus of the topic being evaluated. Significantly, there was at least one article authored by individual(s) hailing from one of the seven major geographical regions across the globe. This phenomenon underscores the widespread interest in the realms of supply chain management and the mitigation of supplier-related risks.

B. Content Analysis

This review on Determinants of Risk Mitigation and Control in Procurement of Goods and Services, it examined the critical components necessary for organizations to navigate global supply chains and ensure resilience and operational efficiency from a Supplier Risk Management perspective. The analysis revealed insights the key themes of interest for this review, including risk identification, assessment, and mitigation strategies. The specific elements delved into are supplier evaluation, payment terms, contract duration, and buyer-supplier collaboration to provide a comprehensive understanding of the field.

Risk Identification and Mitigation

Supplier risk management commences with proactively identifying potential risks and developing contingency plans. This is essential for maintaining supply chain stability, as emphasized by [

9,

14]. The review highlights the importance of collaboration with supply chain partners to implement effective risk management processes. Studies by [

5,

21] stress the need for objective risk assessment methods to mitigate subjectivity biases. Managing supply chain risks is crucial for enhancing performance and sustainability, a point reiterated by [

6,

7,

8].

Supplier Evaluation

Supplier evaluation is critical in assessing and approving suppliers based on their ability to meet organizational needs, this ensures the procurement of quality goods and services at competitive prices. [

19,

28] underscore the significance of this process in SRM. Evaluating suppliers involves criteria such as financial stability, quality management, and delivery performance, helping to identify and mitigate supply chain risks. This is corroborated by [

5,

10,

18,

24].

Payment Terms

Payment terms significantly affect supplier risk, including financial, credit, currency, market, counterparty, and settlement risks. Timely payment settlement is essential for reducing financial uncertainties for suppliers, thus enhancing supply chain stability. [

31,

32] highlight the importance of timely payments in ensuring effective supplier relationships and enhancing the overall resilience of the supply chain.

Contract Duration

The duration of contracts determines the timeframe for fulfilling contractual duties and impacts the feasibility and profitability of contracts. Longer durations provide stability and predictability, managing supplier risks such as quality, delivery, and pricing, while shorter durations offer flexibility. [

12,

13] discuss how contract duration is critical in mitigating supplier default risk and enhancing supply chain coordination. Contrary, [

17], warned that excessively long term contracts can lead to higher agency costs and reduced innovation.

Buyer and Supplier Collaboration

Effective buyer-supplier collaboration involves the exchange of information about production timelines, inventory levels, and quality concerns to manage potential risks. This collaboration fosters supply chain transparency, efficiency, and trust, thereby reducing operational risks. [

3,

25] highlighted the importance of collaboration between the buying and supplying organization to leverage supplier capabilities to contribute to resilient supply chains. [

29,

30] underscored the benefits of collaboration in enhancing supplier risk management capabilities.

6. Conclusion

The review underscored the essential role of effective supplier risk management in reducing disruptions, ensuring timely deliveries, maintaining product quality, and enhancing overall procurement efficiency. The review highlighted the importance of proactive risk identification, comprehensive supplier evaluation, strategic payment terms, appropriate contract durations, and robust buyer-supplier collaboration. Despite the evident benefits, challenges persist in understanding regulatory impacts and ensuring methodological consistency. Further research is needed to address these challenges and enhance supplier risk management practices.

The evolving status of supplier risk management is evident, and its critical role in achieving long-term competitiveness and resilience in global supply chains cannot be overstated. The review hope to contribute to the ongoing discourse on supplier risk management and provide insights for future research and practical applications.

References

- Afoakwah, E.; Kemevor, H. The impact of supplier selection and monitoring on the effectiveness of public procurement in Ghana: Cost reduction point of view. International Journal of Engineering, Technology, Management and Sciences (IJETMS) 2023, 7(3), 103–110. [Google Scholar] [CrossRef]

- Andenæs, E.; Time, B.; Torp, O.; Kvande, T.; Lohne, J. Risk Management in Procurement of Blue-Green Roofs—Supplier Perspective. In Collaboration and Integration in Construction, Engineering, Management and Technology: Proceedings of the 11th International Conference on Construction in the 21st Century; Springer International Publishing: London, 2019; pp. 111–111. [Google Scholar]

- Bag, S.; Choi, T.-M.; Rahman, M.; Srivastava, G.; Singh, R. Examining collaborative buyer-supplier relationships and social sustainability in the 'new normal' era: The moderating effects of justice and big data analytical intelligence. Annals of Operations Research 2022. [CrossRef] [PubMed]

- Brooks, R.; Gherghina, C.; Richert, M.; Dudek, M. Risk Mapping: Ranking and Analysis of Selected, Key Risk in Supply Chains. J. Risk Financial Manag. 2023, 16(71). [Google Scholar] [CrossRef]

- Burstein; Guy; Zuckerman, I. Deconstructing Risk Factors for Predicting Risk Assessment in Supply Chains Using Machine Learning. Journal of Risk and Financial Management 2023, 16, 97. [Google Scholar] [CrossRef]

- Çanakkale Onsekiz, M.; Avci, M.G. An integrated risk management framework for global supply chains. Journal of Advanced Research in Natural and Applied Sciences 2022, 8(4), 624–640. [Google Scholar] [CrossRef]

- Çullu, B.; Bircan, K. Tedarikçi risk değerlendirmesi üzerine örnek bir uygulama. Aydin Adnan Menderes University Journal of Institute of Social Sciences 2022, 9(1), 16–34. [Google Scholar] [CrossRef]

- Handayani, W.; Syahda, E.; Rabihah. Risk mitigation in supply chain management process: Procurement using house of risk method at PT. Pertamina EP Asset 4. Jurnal Siasat Bisnis 2022, 26(1), 70-84. [CrossRef]

- Hamin, H.; Rosenbaum, D.; More, E. Risk and Financial Management. Journal of Risk and Financial Management 2023, 16(134).

- Ganiyu, S.A.; Yu, D.; Xu, C.; Providence, A.M. The impact of supply chain risks and supply chain risk management strategies on enterprise performance in Ghana. Open Journal of Business and Management 2020, 8(4), 1491–1507. [Google Scholar] [CrossRef]

- Hoek, R.V. Responding to COVID-19 supply chain risks—Insights from supply chain change management, total cost of ownership and supplier segmentation theory. Logistics 2020, 4(4), 23. [Google Scholar] [CrossRef]

- Humadi, M.R.; Hassan, H.F. Legal rules governing the duration of the contract in its Period of Formation (COMPARATIVE LEGAL STUDY). Russian Law Journal 2023, 11(11s).

- Johnsen, L.; Sadrieh, A.; Voigt, G. Short-term vs. long-term contracting: Empirical assessment of the ratchet effect in supply chain interaction. Production and Operations Management 2021, 30(7), 2252-2272. [CrossRef]

- Kabak, M.; Oztek, G. A multi-criteria approach to sustainable risk management of supplier portfolio: A case study at defense industry. Gazi University Journal of Science 2022, 35(4), 1504–1519. [Google Scholar] [CrossRef]

- Mandal, S. Impact of supplier innovativeness, top management support and strategic sourcing on supply chain resilience. International Journal of Productivity and Performance Management 2021, 70(7), 1561–1581. [Google Scholar] [CrossRef]

- Mpanga Kowet, C.; Ozumba, A. The relationship between procurement strategies and sustainability outcomes: A systematic literature review. 2019. [Google Scholar]

- Nguyen, T.; Nguyen, L.V.; Nguyen Canh, K. Buyer-Supplier Contract Length and the Innovation of Supplier Firms. Journal of Open Innovation: Technology, Market, and Complexity 2020, 6(52).

- Oduoza, C.F. Framework for sustainable risk management in the manufacturing sector. Procedia Manufacturing 2020, 51, 1290–1297. [Google Scholar] [CrossRef]

- Oetama, R.; Armando, F. Supplier Evaluation at Small-Medium Enterprise Using Simple Additive Weighting. Journal of Information Systems and Informatics 2023, 5(2), 467–480. [Google Scholar] [CrossRef]

- Owusu-Asante, M.; Darko, D.; Asamoah-Okyere, K.D.; Asante-Boateng, S.; Kermad, A.; Walker, S.; Salek, S. Evaluation of the Food and Drugs Authority, Ghana Regulatory Review Process: Challenges and Opportunities. Therapeutic Innovation & Regulatory Science 2023, 57(3), 372-385. [CrossRef]

- Popstefanova, N.; Jovanovska, V.; Jankovska, S.; Spirovska Burčevska, J.; Kimovska, V.; Bobevska, O.; Paneva, E.; Karadžinska, T.; Camurovski, K.; Velinovska Brzilova, V. Risk Management and Business Continuity of Alkaloid AD Skopje. Macedonian Pharmaceutical Bulletin 2022, 68 (Suppl 1), 57–58. [Google Scholar] [CrossRef]

- Pham, T.; Testorelli, R.; Verbano, C. Supply chain risk and its impact on performance: A structured literature review. Journal of Industrial Engineering and Management 2020, 13(2), 237–240. [Google Scholar] [CrossRef]

- Sekhon, M.; De Thurah, A.; Fragoulis, G.; Stamm, T.; Vlieland, T.; Esbensen, B.; Lempp, H.; Bearne, L.; Kouloumas, M.; Pchelnikova, P.; Swinnen, T.; Blunt, C.; Ferreira, R.; Carmona, L.; Nikiphorou, E. POS1552-HPR: A synthesis of guidance available for assessing methodological quality and grading of evidence from qualitative research to inform clinical recommendations: A systematic review. Annals of the Rheumatic Diseases 2022, 81, 1120.2–1121. [Google Scholar] [CrossRef]

- Shi, X.Y.; Zhang, W.H. Research on supplier selection, evaluation, and relationship management. Open Journal of Business and Management 2023, 11(3), 1208–1215. [Google Scholar] [CrossRef]

- Susanto, E.; Othman, N.A.; Irfan, A.; Tjaja, S.; Rahayu, S.; Gunawan, S.; Saptari, A. The impact of collaborative networks on supply chain performance: A case study of fresh vegetable commodities in Indonesia. AGRARIS: Journal of Agribusiness and Rural Development Research 2023, 2407-814X, 2527-9238.

- Tang, C.; Xu, H. Risk analysis and research of construction supply chain. Highlights in Business, Economics and Management GAGBM 2023, 11, 156. [Google Scholar] [CrossRef]

- Tebes, G.; Peppino, D.; Becker, P.; Olsina, L. Proceso para revisión sistemática de literatura y mapeo sistemático. Electronic Journal of SADIO (EJS) 2020, 19(2), 94-118. Available online: https://publicaciones.sadio.org.ar/index.php/EJS/article/view/170.

- Urbaniak, M.; Zimon, D.; Madzik, P.; Šírová, E. Risk factors in the assessment of suppliers. Plos one 2022, 17(8), e0272157. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.; Stanbury, P.; Dietrich, T.; Döring, J.; Ewert, J.; Foerster, C.; Freund, M.; Friedel, M.; Kammann, C.; Koch, M.; Owtram, T.; Schultz, H.R.; Voss-Fels, K.; Hanf, J. Developing a sustainability vision for the global wine industry. Sustainability 2023, 15(10487). [CrossRef]

- Wahyono, S. Risk management analysis in international collaborative research. ICoGPASS 2023. [CrossRef]

- Wu, C.; Zou, H.; Barnes, D. A supply risk perspective integrated sustainable supplier selection model in the intuitionistic fuzzy environment. Soft Computing 2023, 27, 15133–15151. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Boggia, A.; Wu, C.-H.; Yuan, Y.-H. Risk Management of Supply Chain Green Finance Based on Sustainable Ecological Environment. Sustainability 2023, 15(7707). [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).