1. Introduction

The performance of GFRP Reinforced Concrete (RC) specimens at four-point bending investigation is carried out for normal strength simply supported concrete beams in which three replicate beams were cast and tested. Six different over reinforced samples are designed and fabricated among which all of them were observed to fail under diagonal- tension shear. The results thus obtained are then compared with the analytical estimates and compared the results with that of the steel reinforced concrete beams. The authors also recommended equation to predict the shear strength of GFRP reinforced bars. It was also determined that, the ACI standards overestimate the flexural members that are strengthened with GFRP bars. GFRP bars were found not to influence the shear strength of the concrete beams. And altogether, a much-simplified mathematical equation was developed to determine the shear performance of GFRP RC specimens, [

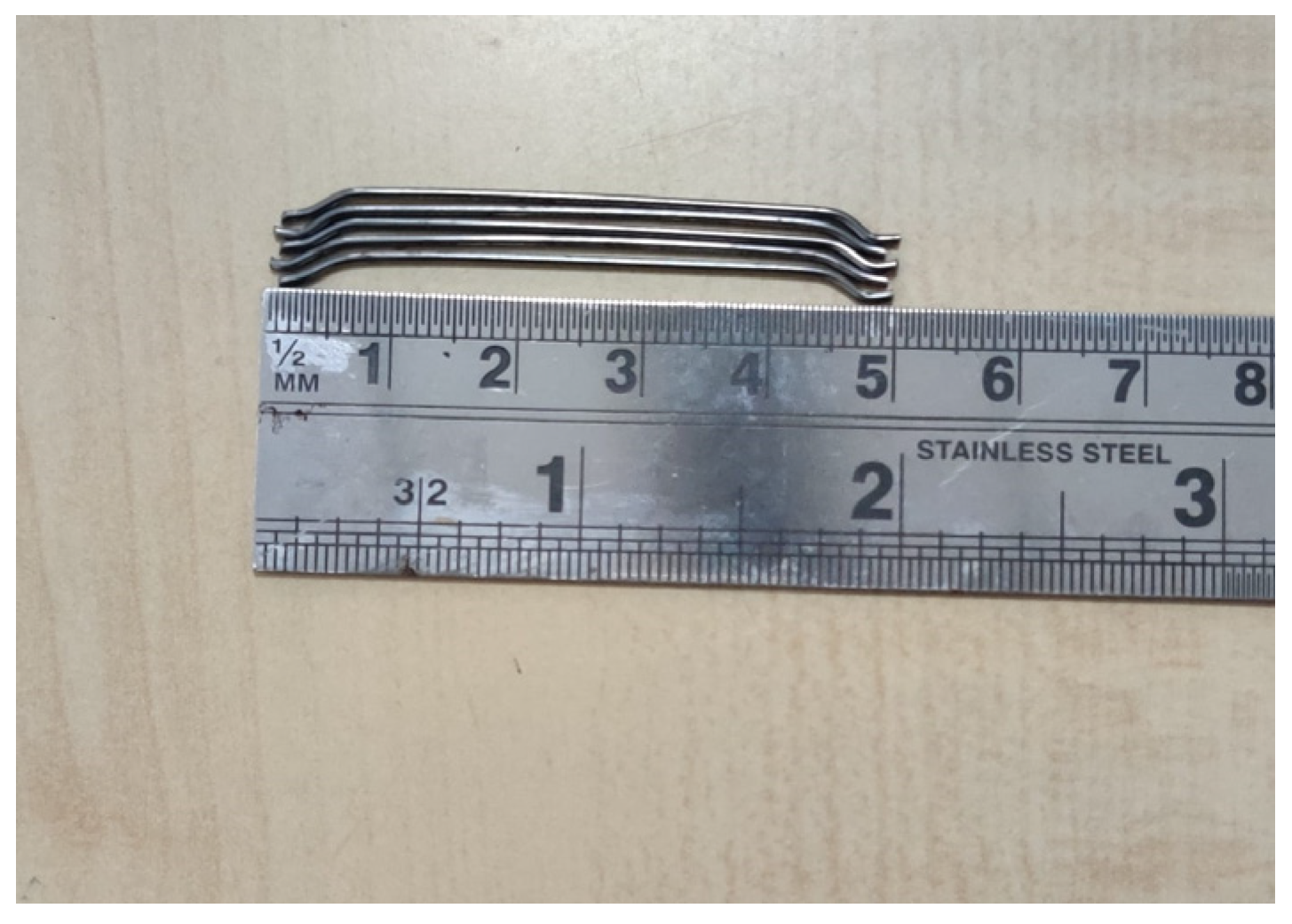

1]. The shear performance in concrete specimens s with steel fibers was studied by, (Ali et al., 2018)[

2]. This investigation was an effort to study shear of concrete specimens fabricated with hooked end steel fibers without incorporating the traditional shear reinforcement. The cast beams were studied under two-point loading till failure is achieved. Steel fibers were included in the concrete matrix and were observed to showcase adequate performance upon usage of 1% of hooked steel fibers as shear reinforcement. Strain, energy absorption, shear behaviour and post stiffness of the concrete beam specimens thus fabricated were noted to be better compared to the steel fibers in the conventional RC beams.

(Ali Amin et al., 2016) found enhanced performance of the concrete specimens by including steel fibers along with stirrups while analysing the shear performance of the simulated concrete beams [

3]. Simply supported rectangular beams developed with varying percentage of steel fibers are considered for the characterization of the materials as well as the post cracking behavior. The results thus obtained in this study are also compared with the predictions observed in the earlier studies.

(Ehsan et al., 2019) detailed the shear performance of the GFRP RC beams with fibers as single along with hybrid fibers [

4]. Macro steel fibers, micro polypropylene fibers and glass fibers are incorporated in the lightweight concrete beams to analyse the shear behavior in various combinations when embedded in lightweight GFRP reinforced concrete. The ultimate load carrying capacity of these specimens are observed to improve up to 233 % in this study. The authors also proposed a correction factor for the GRRP reinforced light weight concrete alone without the addition of any of these fibers. This correction factor is developed by conducting a comparative study of four different codal standards.

(Abathar et al., 2017) experimentally investigated the performance of basalt fiber RC beams with basalt fibers in two different volume fractions [

5]. The ratio of reinforcement, the dosage of the fibers and the span to depth proportion were considered as varying parameters for this study. The reinforcement ratio is observed to be directly proportionate to shear performance of concrete beams fabricated in this study. Also elevated shear strength is observed for lower span to depth proportion. By increasing dosage of basalt fiber, shear capacity and ductility behavior were improved whereas the beam deflection as well as the propagation of cracks were noted to decline.

(C.E. Chalioris, E. F Sfiri, 2011), found the influence of steel fibres on RC beams subjected to cyclic and monotonic loads by investigating in an experimental research.The conventional beam prepared without steel fibers was compared with seven other beams with incorporation of steel fibers with same dimensions and flexural reinforcement of control specimen [

6]. Load is given constantly with gradual increase and the load versus deflection behavior and the crack width was noted. The results are show that, steel fiber reinforced specimens behaved better in shear with high shear performance with improved dissipation of energy thus show lesser crack width.

(M. S. Alam and A. Hussein, 2013), found for various sizes, carbon fiber reinforced plastics, glass fiber reinforced plastics were used as cross-sectional reinforcement in beams, and steel bars are incorporated as longitudinal reinforcement [

7]. Twelve numbers of large size simply supported beams of varying depth were analyzed to measure the shear strength. The effective depth varies from 300 to 750 mm and it was noted that the depth of beams is indirectly proportional to shear strength at failure irrelevant to type of reinforcements. Finally, the findings are compared with four different codes and the results were found to be more moderate with large disperse, particularly for the beams with lesser effective depth.

(M. P. Karthik and D. Maruthachalam, 2015) carried out investigational research to detail the shear cracks in hybrid fiber reinforced concrete beams prepared with the combination of synthetic fiber (recycled polyethylene therephthalate, polypropylene) and scrim bled steel fiber with the volume fraction of 0.5 % [

8]. The mechanical and shear parameters were studied with the M40 grade concrete specimens using different hybrid combinations. Five different dosages of fibers were used. The result states that addition of steel and synthetic fibers helps in bridging action and delaying micro crack formation respectively. The shear performance was found to be good in steel fiber – polypropylene combination than steel fiber - recycled polyethylene therephthalate and the same result was found in finite element analysis carried out using ANSYS 12. The optimum results were obtained for the specimen cast with 75-25% of steel fiber and polypropylene fiber combination.

The shear strength of SFRC beams with and without shear reinforcement was investigated in a study by (Deepa et al., 2017), with the fiber volume varied from 1 to 5% [

9]. The research is based on effect of steel fibers and beam size on mid-span deflection and shear stress in three-dimensional beams. The steel fibers provided in concrete specimens were observed to minimise the deformation along with improving the shear strength of the beam. The same study is also corroborated by simulating the model using ANSYS 15 which is noted to obtain the results in par with the experimental results.

The effect of presence of opening in the web portion of deep beams with and without the provision of web reinforcement is summarized by (Haleem K. Hussain, 2018) [

10]. The size of the opening, the shear span ratio and the presence of web reinforcement were considered for the non-linear finite element analysis using ANSYS 12. The load carrying capacity was observed to get reduced, whereas the propagation of cracks increased in the beam models simulated with opening in the web portion. These parameters were also noted to get decreased with the addition of vertical stirrups. The same observation was then verified experimentally too in which diagonal shear cracks were observed upon failure. (Guray and Riza, 2015) conducted a numerical study on the crack patterns and shear strength based on the flexural reinforcement ratio in RC beams in the absence of stirrups [

11]. The flexural reinforcement percentage is varied from 0.5 to 2.2 by applying load in the mid span. Similar results were obtained for both experimental and analytical approach by the authors. The results also signify that, the shear strength and mid span deflection is highly influenced by the flexural reinforcement ratio.

Another attempt is carried out by (Sudheer et al., 2011) to compare the behaviour of high strength deep beams without shear reinforcement under shear loading [

12]. The study was implemented both experimentally as well as analytically. Data base obtained from previous literature and finite element modelling by non-linear analysis using ANSYS software has enabled the authors to create a simple equation to forecast the shear behaviour of high strength deep beams. The equation thus obtained can be used to evaluate the shear capacity of beams, without the necessity of providing shear reinforcement for high strength deep beams with shear span ratio ranging from 1 to 4.

(Ahmed T.W.,2020) studied the behaviour of high strength concrete containing polypropylene fiber and recycled aggregate by using the demolished waste from war at Mosul city of Iraq. The inclusion of these fibers improved the hardened properties of recycled aggregates (RA) concrete for 0.6%. The response surface method (RSM) was used to obtain the optimum design parameters that maximized the mechanical properties of the concrete while minimizing the fiber percentage and utilizing the RA to the fullest [

13].

(Khan M. et al., 2020) carried out the experiments to check the effectiveness of using multi-scale hybrid fibers in concrete to enhance its resistance to cracking. The basalt fiber content was varied to determine its effect on the mechanical properties of the concrete. The study established the reinforcing index for hybrid fibers and developed empirical equations to predict the strength properties of the concrete based on the reinforcing index. The obtained empirical equations showed satisfactory results in predicting the strength properties of concrete [

14].

(Qin Y et al., 2019) incorporated polypropylene spun-bonded materials produced from used clothes to make concrete specimens. The energy absorption and destruction characteristics of the waste fiber fabric-reinforced concrete were enhanced compared to PC and PPFRC [

15].

(Alwesabi E.A et al., 2022) found the effect of PF, MSF, and PF-MSF hybrid fibres on various properties of FRC, including density, water absorption, voids, compressive strength, compressive toughness, and toughness index. Hybrid FRC achieved more significant improvements in compressive toughness characteristics compared with mono MSFs or PFs inclusion indicating a positive effect of these hybrid fibers [

16].

(Vakili S.E et al., 2019) found the impact of various fiber types and hybrid fibers on the shear strength of glass fiber-reinforced polymer bar-reinforced lightweight concrete beams. When fibers and hybrid fibers were added, lightweight concrete beams’ shear strength and ultimate load carrying capability increased by 55% to 233%. As a result, the authors advise combining the use of various methods, including LWC, fibres, and FRP bars for efficiency [

17].

(Mohamed Firdows et al., 2023) found FRC can enhance the flexural strength of GFRP-reinforced beams. This study examines the flexural strength of plain and polypropylene FRC beams and the impact of GFRP reinforcing bars on fracture breadth. Adding 1% volume of fibers to weathered and un-weathered beams increased flexural strength and reduced fractures by 28-30% compared to plain concrete beams [

18].

(Bingyan Wei et al., 2024) found adding PP to Hybrid-PFRC beams improved ductility but did not significantly improve flexural bearing capacity or cracking moment. Furthermore, PP effectively controls crack propagation in beams [

19].

(Uomoto, T et al., 2002) investigated composites made of GFRP possess outstanding non-magnetic characteristics, high tensile strength and strong corrosion resistance. Concrete buildings reinforced with GFRP systems will be more durable and less prone to repair and maintenance than those reinforced with traditional steel bars [

20].

3. Results and Discussion

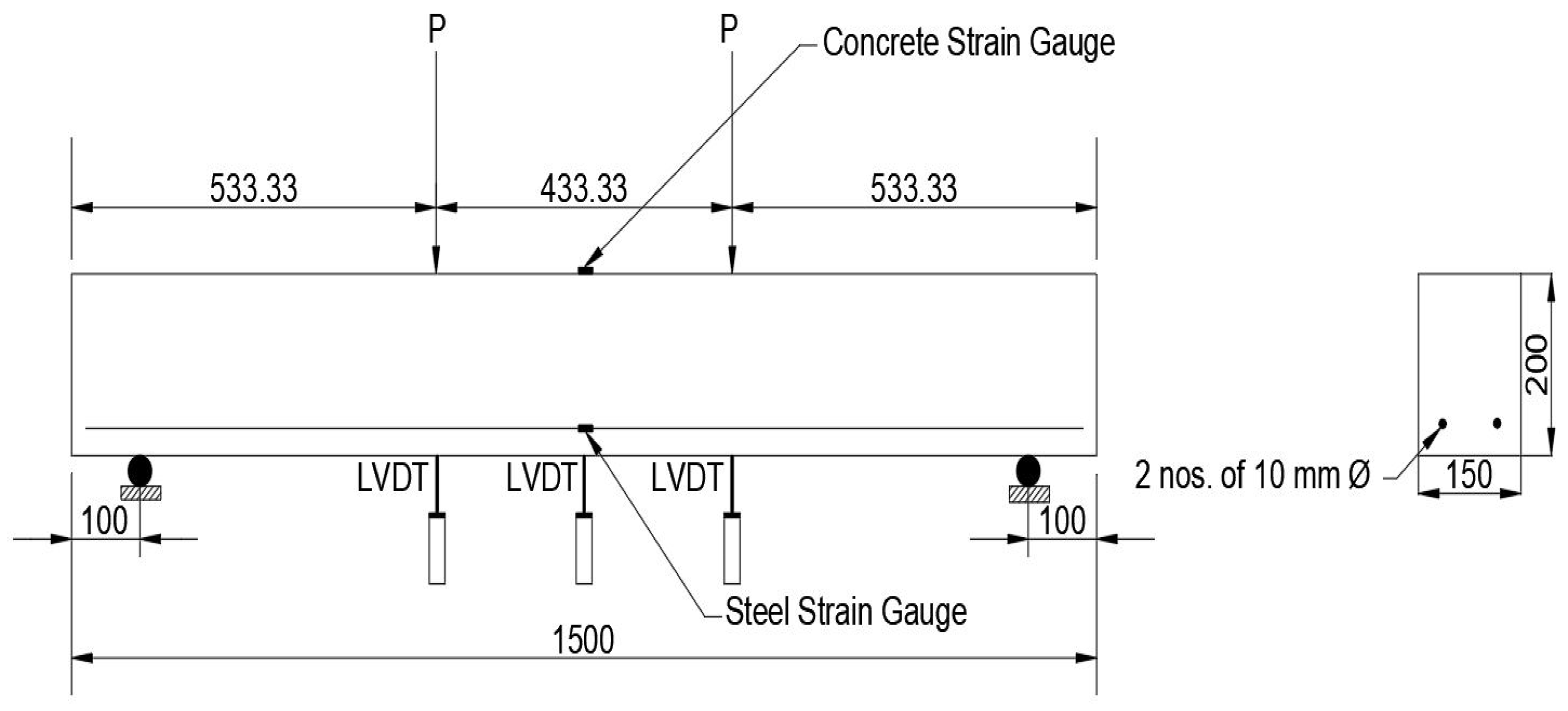

The current study includes testing of shear behaviour of twenty-four steel and GFRP Reinforced Concrete (RC) beams cast with different combination of concrete of grades M30, M60 and M80 and volume fraction of fibers such as 0, 0.5, 1.5 and 2.5%. The parameters considered were, the form of reinforcement material (steel and GFRP), compressive strength of concrete and fiber percentage. Failure mode, initial crack and ultimate load, mid-span deflection, strain in concrete, steel and GFRP reinforcement of steel and GFRP Reinforced Concrete (RC) beams have been reported. The results obtained from the experimental investigation are shown in

Table 1.

3.1. Failure Mode of Steel and GFRP RC Beams

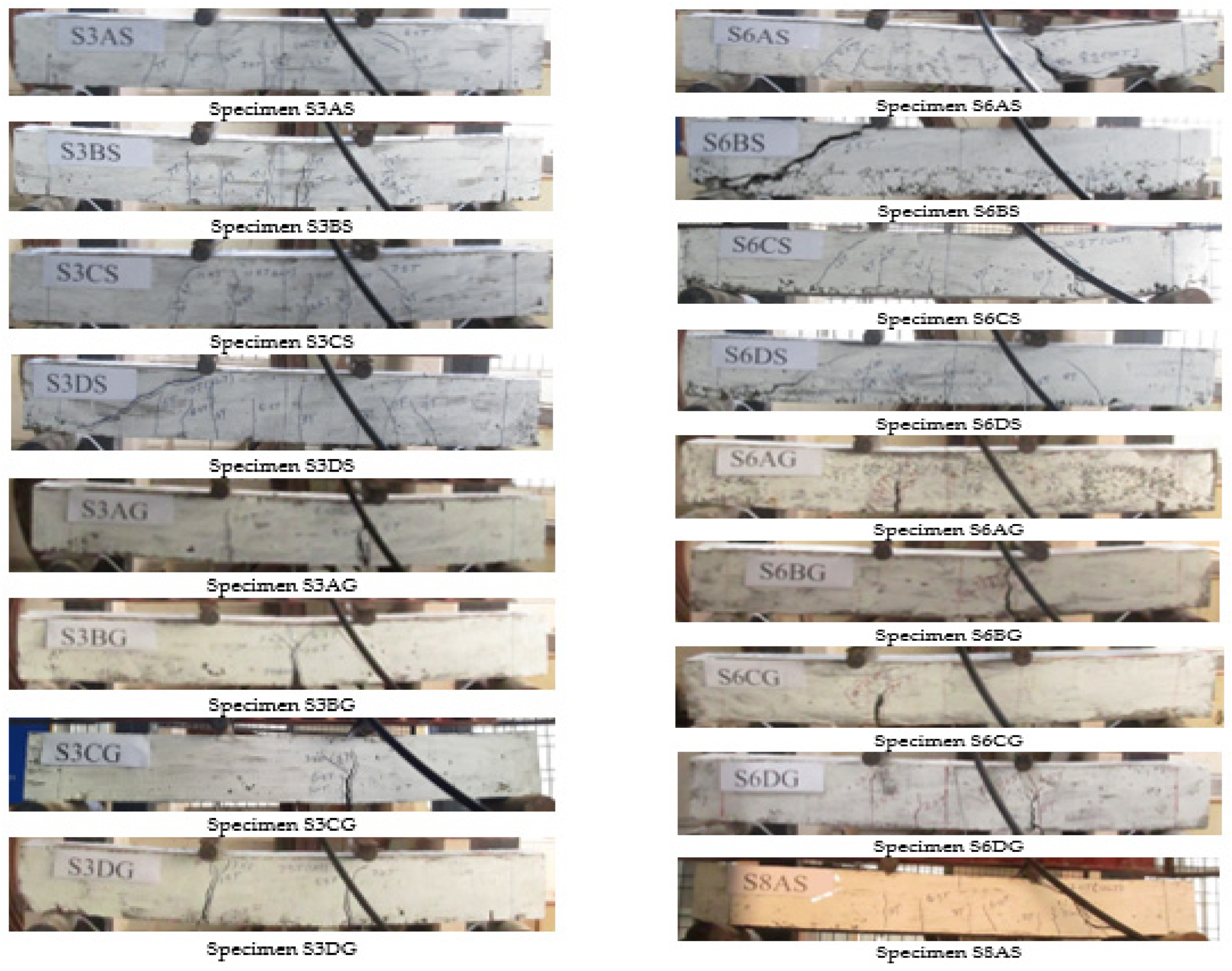

Failure mode of some of steel and GFRP RC beams is shown in

Figure 6. The observed failure mechanisms indicate flexural failure or diagonal tension failure of RC beams. The formation of crack initiated from tension region of beams of negligible shear stress and observed to grow in vertical direction. These are identified as flexural cracks and with the increase in load, flexural-shear cracks started appearing and progressed in an inclined direction towards loading point. The occurrence of flexural-shear cracks leads to the failure of beams in diagonal tension type of shear failure. Since web reinforcement is absent, beams failed immediately after the occurrence of diagonal cracks.

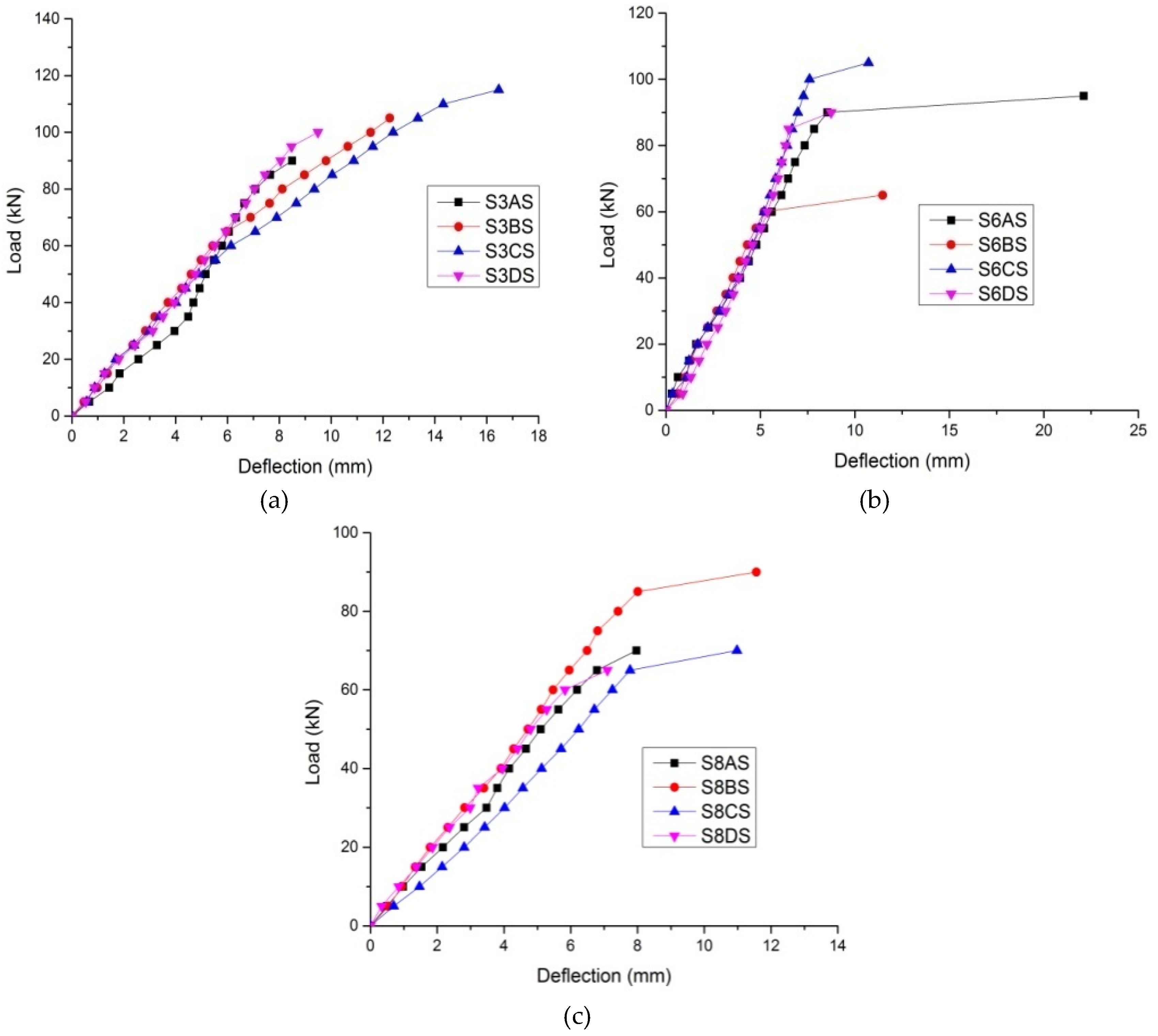

3.2. Load versus Deflection Behaviour of Steel RC Beams

To analyse the shear behaviour of steel RC beams, M30, M60 and M80 grades of RC beams were developed with 0, 0.5, 1.5 and 2.5% of fibers. All RC beams exhibited bilinear behaviour, linear up to first crack when the deflections were small with a relatively large slope. After cracking, the deflections became high and due to reduction in effective concrete area and moment of inertia along with reduction in slope, led to reduction in stiffness as well. The curves revealed that initial stiffness before first crack remained almost the same for all beams while post cracking stiffness of the load response showed small differences between beams. The first linear portion of the curve was identical up to approximately 37% of failure load. For M30 grade RC beams, the initial cracks were observed at a load of 20, 45, 50 and 35 kN for S3AS, S3BS, S3CS and S3DS respectively. The maximum deflection observed of concrete beams reinforced with conventional steel S3CS (16.46 mm) was greater than that of S3AS beam (8.5 mm), by about 93.65%. A maximum load of 115 kN in S3CS which is greater than that of S3AS (90kN) by about 27.77% in M30 grade of concrete. This can be attributed to the improved stiffness of the RC beams developed within by the higher concentration of fibers. A minimum load of 65kN was observed in S6AS and S8DS beams. The post cracking behaviour of S3CS is comparatively better with a fiber volume fraction of 1.5 %.

For M60 grade RC beams, the initial cracks were observed at 40, 30, 40 and 40kN for S6AS, S6BS, S6CS and S6DS respectively. A maximum deflection of 22.11 mm was observed in S6AS. A maximum load carrying capacity of 105 kN is visualized in S6CS which is greater than that of S6AS (95kN) by about 10.52%. The post cracking performance of the S6CS beams was observed to be better when compared to other specimens. A minimum load of 65kN in S6BS beams was observed. As compared to S3AS, the deflection was considerably reduced for S6BS, S6CS, S6DS with 48.25, 51.51 and 60.47% respectively. For M80 grade RC beams, the initial cracks were observed at 20, 35, 30 and 30kN for S8AS, S8BS, S8CS and S8DS respectively The failure of beams after initial cracking is observed to be higher for S8BS when compared to other RC beams of M80 grade concrete with a load carrying capacity of 90kN which is greater than that of S8AS (70kN) by about 28.57%. A mid-span deflection of 7.10 mm was observed in S8DS which is smaller than that of S8AS (7.97 mm) by about 10.91%. A minimum load of 65kN in S8DS beams was observed. Thus, S3CS RC beam reinforced by steel and fibers is noted to exhibit maximum load carrying capacity among other beams. The load versus deflection behaviour of steel RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 7a, 7b and 7c respectively. It was found that adding fiber, to steel RC beams will increase the load carrying capacity thereby reducing the deflection considerably.

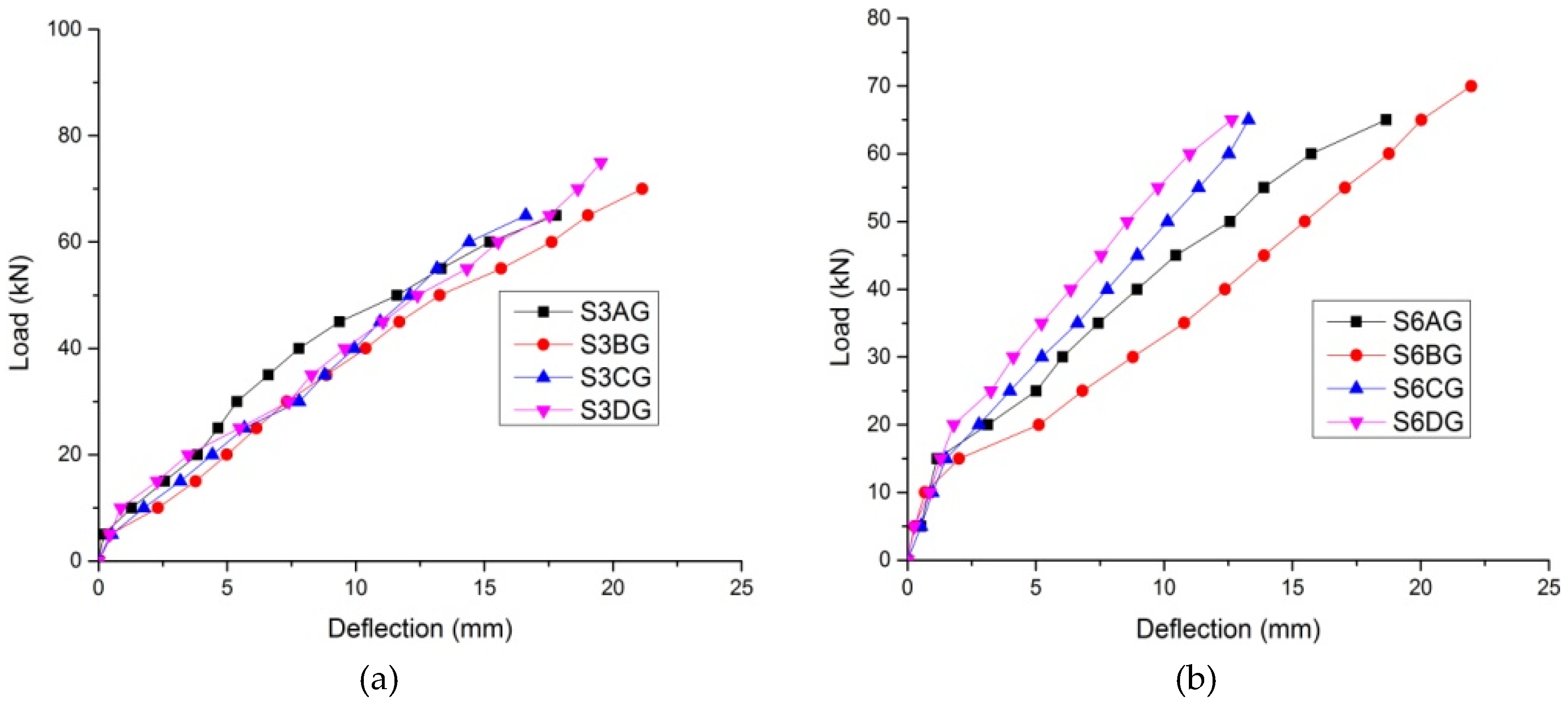

3.3. Load versus Deflection Behaviour of GFRP RC Beams

To analyse the shear behaviour of GFRP RC beams, M30, M60 and M80 grades of RC beams were developed with 0, 0.5, 1.5 and 2.5% of fibers. All RC beams exhibited bilinear behaviour, linear up to first crack when the deflections were small with a relatively large slope. After cracking, the deflections became high which led to reduction in stiffness. For M30 grade RC beams, the initial cracks were observed at almost the same load of 20 kN for S3AG, S3BG, S3CG and S3DG respectively. S3CG specimen showcased a load carrying capacity similar to that of the control specimen, S3AG whereas, S3DG beam exhibited the maximum load carrying capacity of 75kN which is greater than that of control specimen by about 15.38%. The deflection in RC beam reinforced with GFRP bar and 1.5% fiber ie. S3CG (16.61mm) was smaller than that of GFRP RC beam provided without fiber, i.e S3AG (17.79 mm), by about 6.52%. The increased deflection was found in S3BG (21.14 mm) which is greater than that of S3AG (17.79) by about 18.83%. For M60 grade RC beams, the initial cracks were observed at almost the same load of 20 kN for S6AG, S6BG, S6CG and S6DG respectively. Load carrying capability is observed to be same for all four GFRP RC beams. The deflection of RC beams reinforced with GFRP bars and 1.5% fiber ie. S6DG (12.63 mm) was observed to be smaller than that of GFRP RC beams provided without fiber ie S6AG (18.65 mm), by about 32.27%. The increase in deflection was found in S6BG (21.97 mm) which is greater than that of S6AG (18.65) by about 17.80%. The maximum mid-span deflection is found to be reduced for GFRP RC beams provided with higher percentage of fibers. From the observed results, it is evident that addition of fibers at 1.5 and 2.5% improved the shear behaviour of GFRP reinforced RC beams owing to the achievement of a stiff concrete matrix upon addition of fibers. For M80 grade RC beams, the initial cracks were observed at 15, 20, 25, and 25 kN for S8AG, S8BG, S8CG and S8DG respectively. Load carrying capability is observed to be almost the same for all four GFRP RC beams in this category. A mid-span deflection of 17.22 mm was observed in S8BG which is smaller than that of S8AG (18.20 mm) by 5.38%. It was found that adding fibers to GFRP RC beams will reduce the mid-span deflection of the beam specimens. The load versus deflection behaviour of GFRP RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 8a, 8b and 8c respectively.

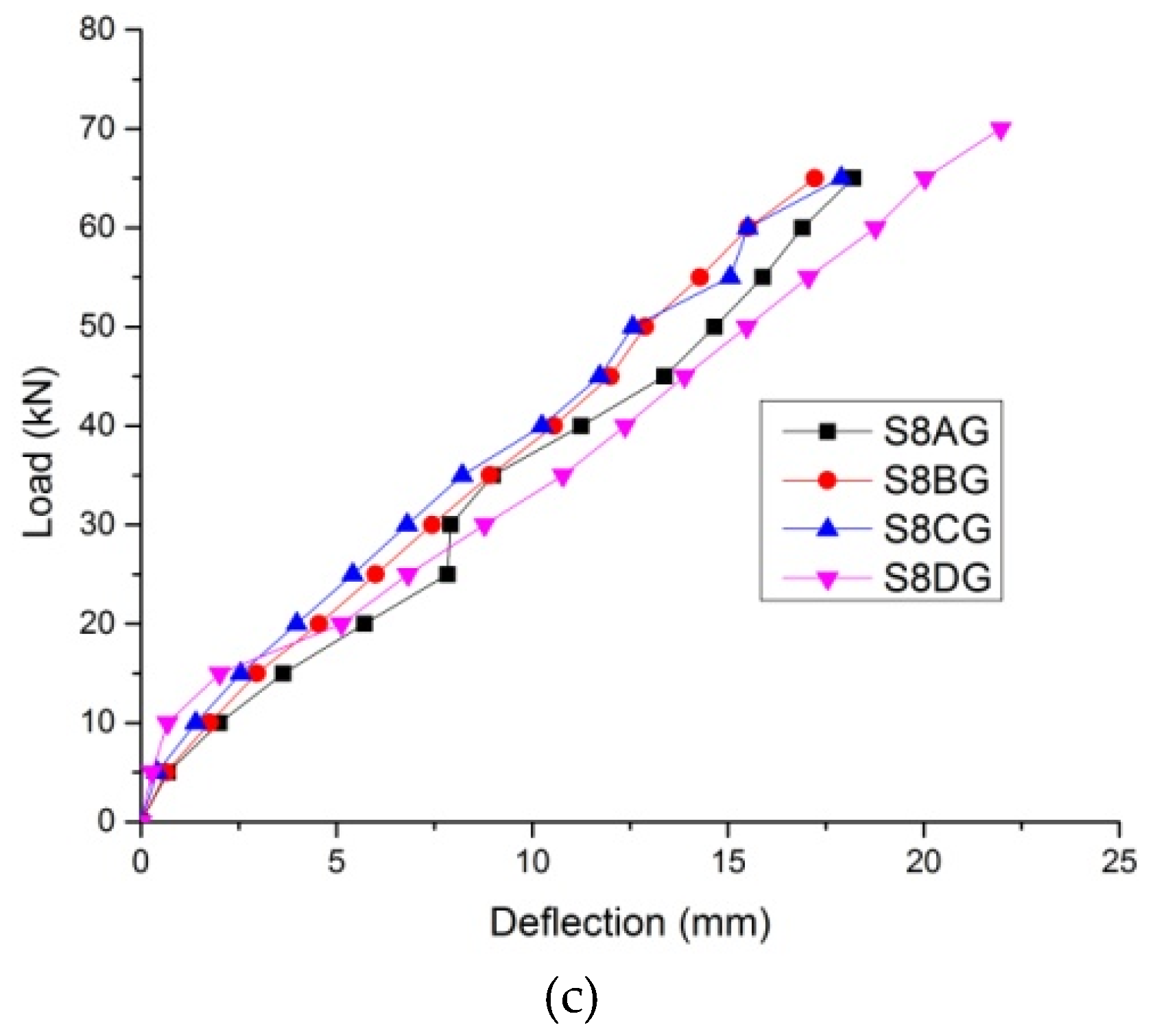

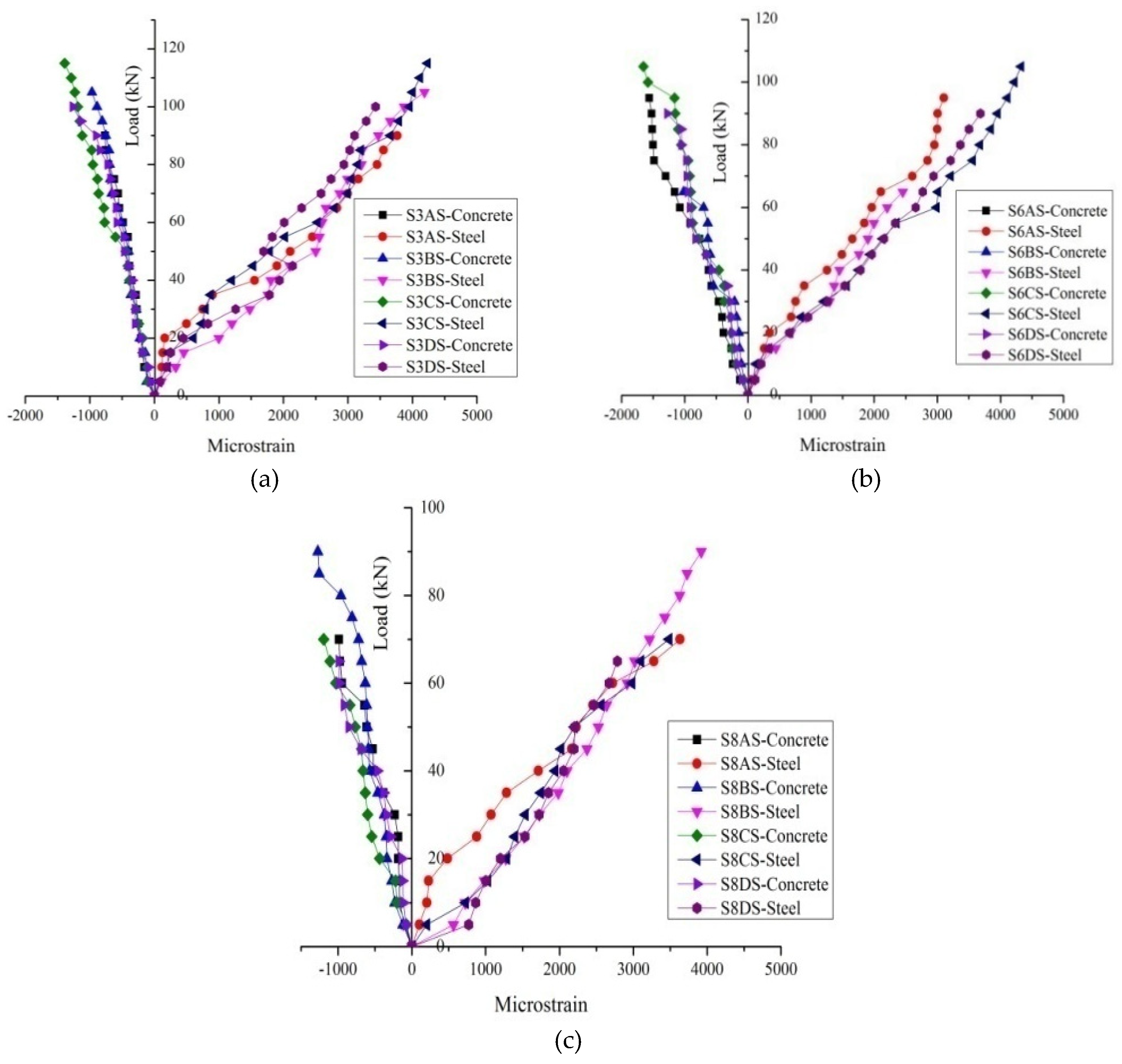

3.4. Load versus Strain of Steel RC Beams

The load versus strain behaviour of steel RC beams made of M30, M60 and M80 grade of concrete and developed with 0, 0.5, 1.5 and 2.5% of fibers was explored.

3.5. Load versus Concrete Strain Behaviour

The load versus concrete strain behaviour of steel RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 9a, 9b and 9c respectively. The ultimate strain of concrete was in the range of 0.000765-0.001389, 0.001018-0.001653 and 0.000986- 0.001273 for steel RC beams of M30, M60 and M80 grade concrete respectively. The change in concrete compressive strain at mid-spans till the formation of first crack was minimal. After this stage, strain values increased and reached the maximum. This quick rise in concrete strain caused by the development of the diagonal tension crack indicates the failure of beams.

3.6. Load versus Steel Strain Behaviour

The load versus steel strain behaviour of steel RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 9a, 9b and 9c respectively. The ultimate strain of steel rebars was in the range of 0.003763-0.004234, 0.002452-0.004324 and 0.002783-0.003920 for steel RC beams of M30, M60 and M80 grade concrete respectively. The change in tensile strain of longitudinal steel reinforcement till the formation of first crack was minimal. After this stage, strain values increased and reached the maximum. This sudden increase in strain in steel reinforcement caused by the development of the diagonal tension crack led to failure of beams. It was found that there is considerable increase in strain occurred after cracking, since concrete stress is transferred to the reinforcement, resulting in large strains.

3.7. Load versus Strain of GFRP RC Beams

The load versus strain behaviour of GFRP RC beams made of M30, M60 and M80 grade of concrete and developed with 0, 0.5, 1.5 and 2.5% of fibers was explored.

3.8. Load versus Concrete Strain Behaviour

The load versus concrete strain behaviour of GFRP RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 9a, 9b and 9c respectively. The ultimate strain of concrete was in the range of 0.000491-0.000782, 0.000563-0.000978 and 0.000762- 0.001354 for GFRP RC beams of M30, M60 and M80 grade concrete respectively. The change in concrete compressive strain at mid-spans till the formation of first crack was minimal. After this stage, strain values increased and reached the maximum. The abrupt rise in concrete strain is initiated by the development of the diagonal tension crack which causes the failure of beams.

3.9. Load versus GFRP Strain Behaviour

The load versus GFRP strain behaviour of GFRP RC beam specimens of M30, M60 and M80 concrete grade is shown in

Figure 10a, 10b and 10c respectively. The ultimate strain of GFRP rebars was in the range of 0.004620-0.005123, 0.003659-0.005731 and 0.003160-0.005024 for GFRP RC beams of M30, M60 and M80 grade concrete respectively. The change in tensile strain of longitudinal GFRP reinforcement till the formation of first crack was minimal. After this stage, strain values increased and reached the maximum. This sudden increase in strain in GFRP reinforcement caused by the development of the diagonal tension crack led to failure of beams. It was found that there is considerable increase in strain occurred post cracking, since concrete stress is transmitted to the reinforcement, resulting in large strains. Strains were comparatively larger since modulus of elasticity is less.

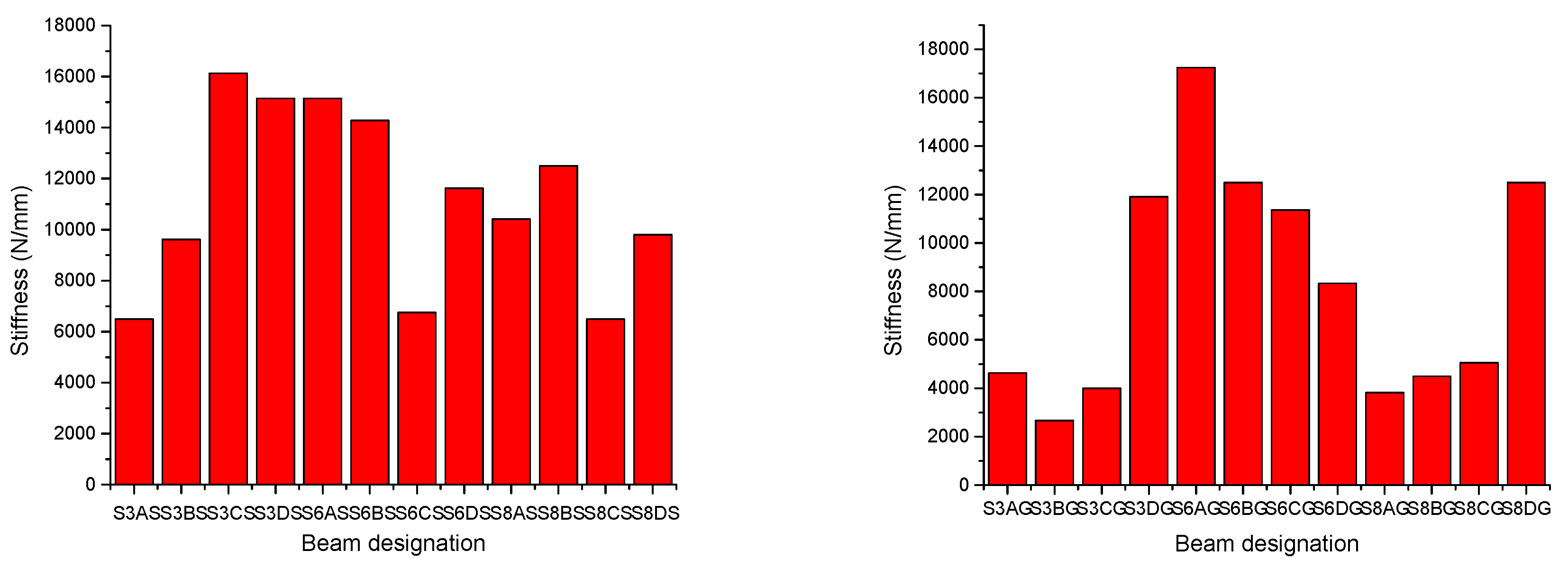

3.10. Stiffness of Steel and GFRP RC Beams

The stiffness of steel and GFRP RC beams made of M30, M60 and M80 grade of concrete and developed with 0, 0.5, 1.5 and 2.5% of fibers was explored and is shown in

Figure 11a and 11b respectively. It can be identified that increasing volume fraction of fibers and concrete compressive strength improves stiffness of RC beams to a greater extent.

While examining the effect of using fibers, it is found that for steel RC beams, the improvement of stiffness of beams is upto a maximum of 148% for 1.5% fiber content compared to beams cast without fiber, with a minimum increase of 20% for the case of 0.5% fiber content. For GFRP RC beams, the improvement in stiffness of beams is upto a maximum of 227% for 2.5% fiber content compared to beams cast without fiber, with a minimum increase of 18% for the case of 0.5% fiber content.

Similarly, while examining the effect of increasing concrete compressive strength, it is found that for steel RC beams, the improvement of stiffness of beams is upto a maximum of 133% for using concrete of M60 grade compared to that of beams cast with M30 grade, with a minimum increase of 30% for the case of M80 compared to that of M30. For GFRP RC beams, the improvement of stiffness of beams is upto a maximum of 367% for using concrete of M60 grade compared to that of beams cast with M30 grade, with a minimum increase of 5% for the case of M80 compared to that of M30.

From the above observations, it can be concluded that, the effect of using fibers and higher grade of concrete is more pronounced in improving stiffness of GFRP RC beams compared to steel RC beams.