Submitted:

16 September 2024

Posted:

17 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3.1. Matrix Material

2.2. Reinforcement Material

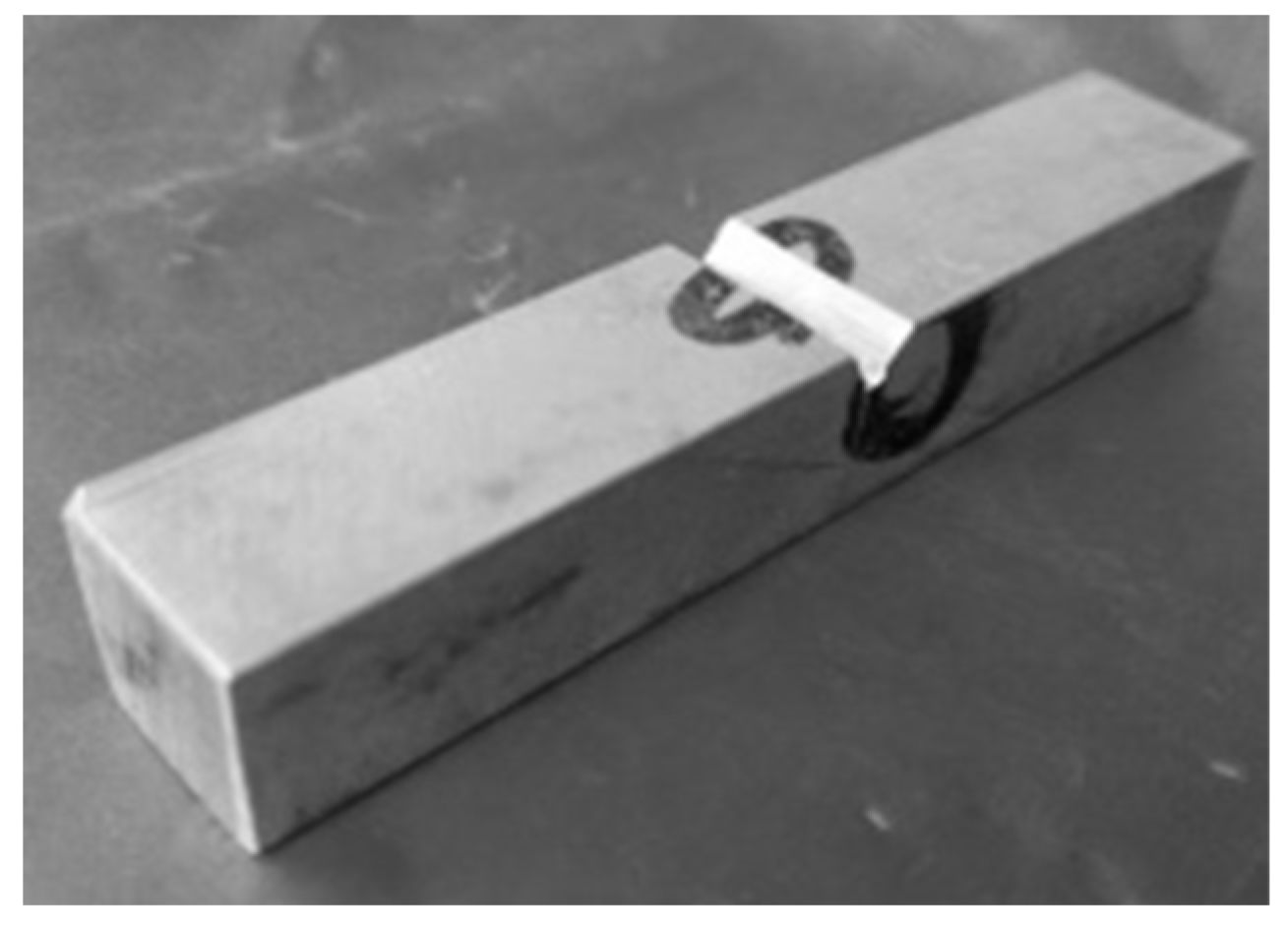

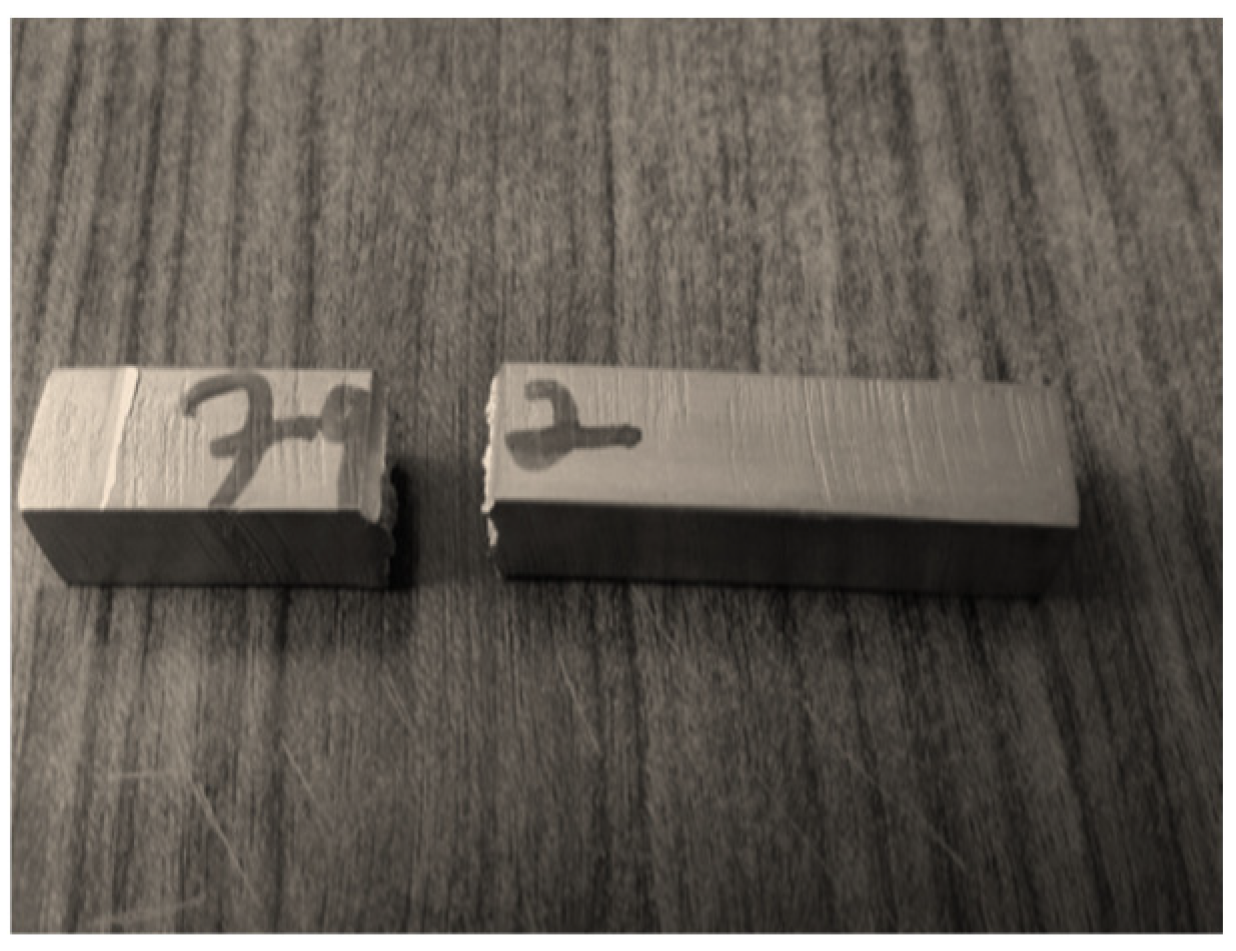

2.3. Fabrication of Al7475-Zirconium Carbide Composites

2.4. Heat Treatment Process

2.5. Testing of Al7475-Zirconium Carbide Composites

3. Results and Discussion

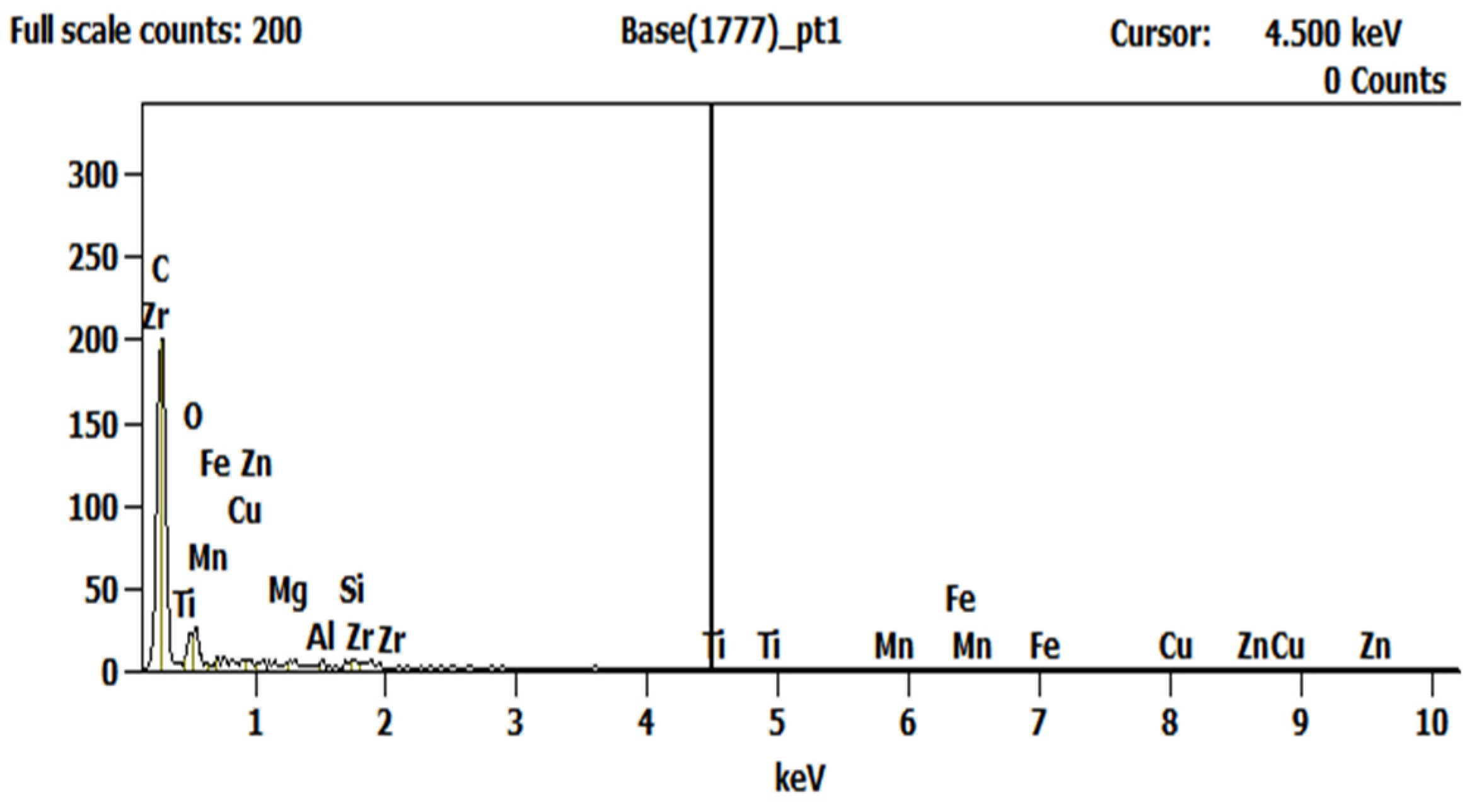

3.1. EDX Study of Al7475-Zirconium carbide Composites

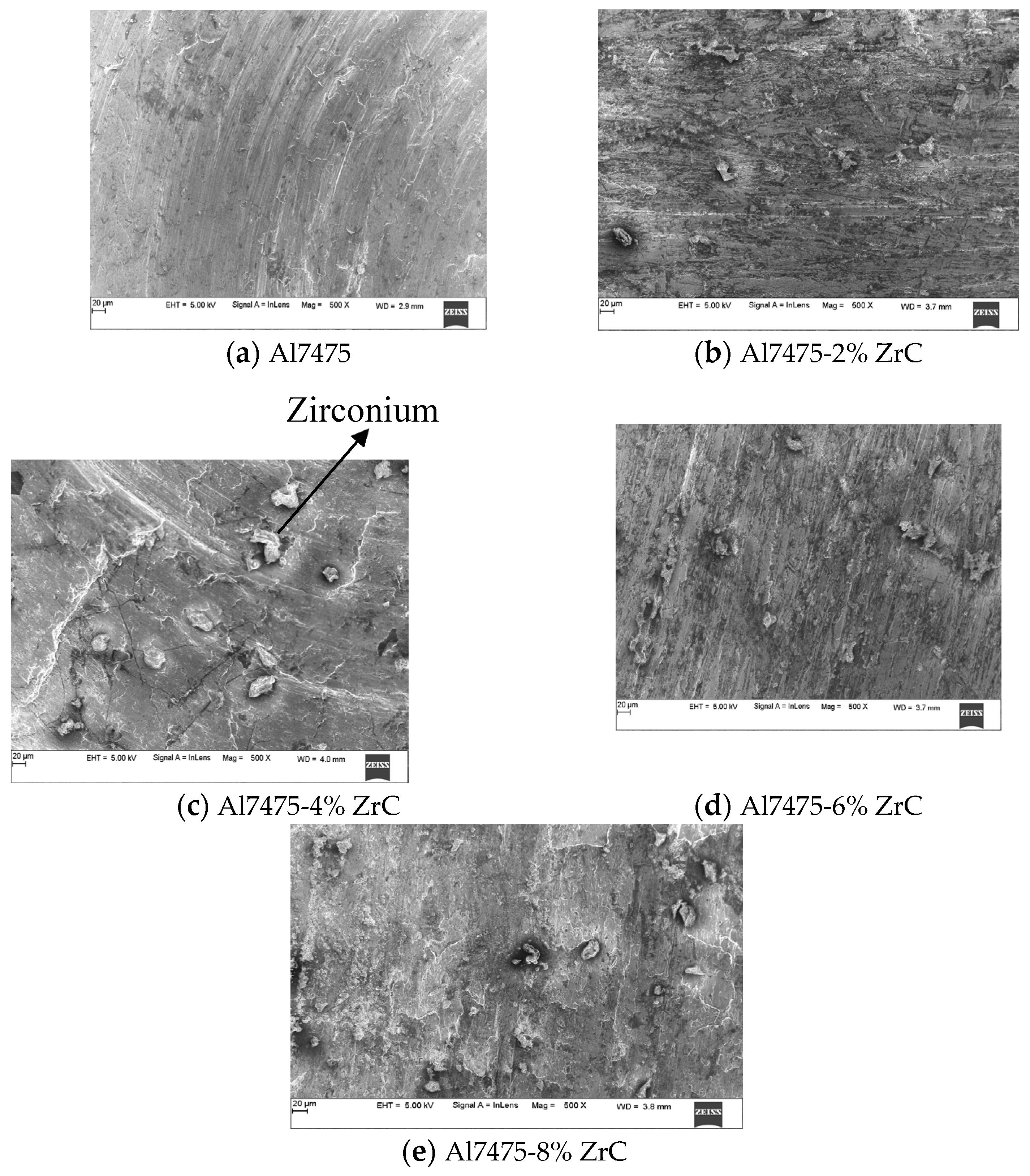

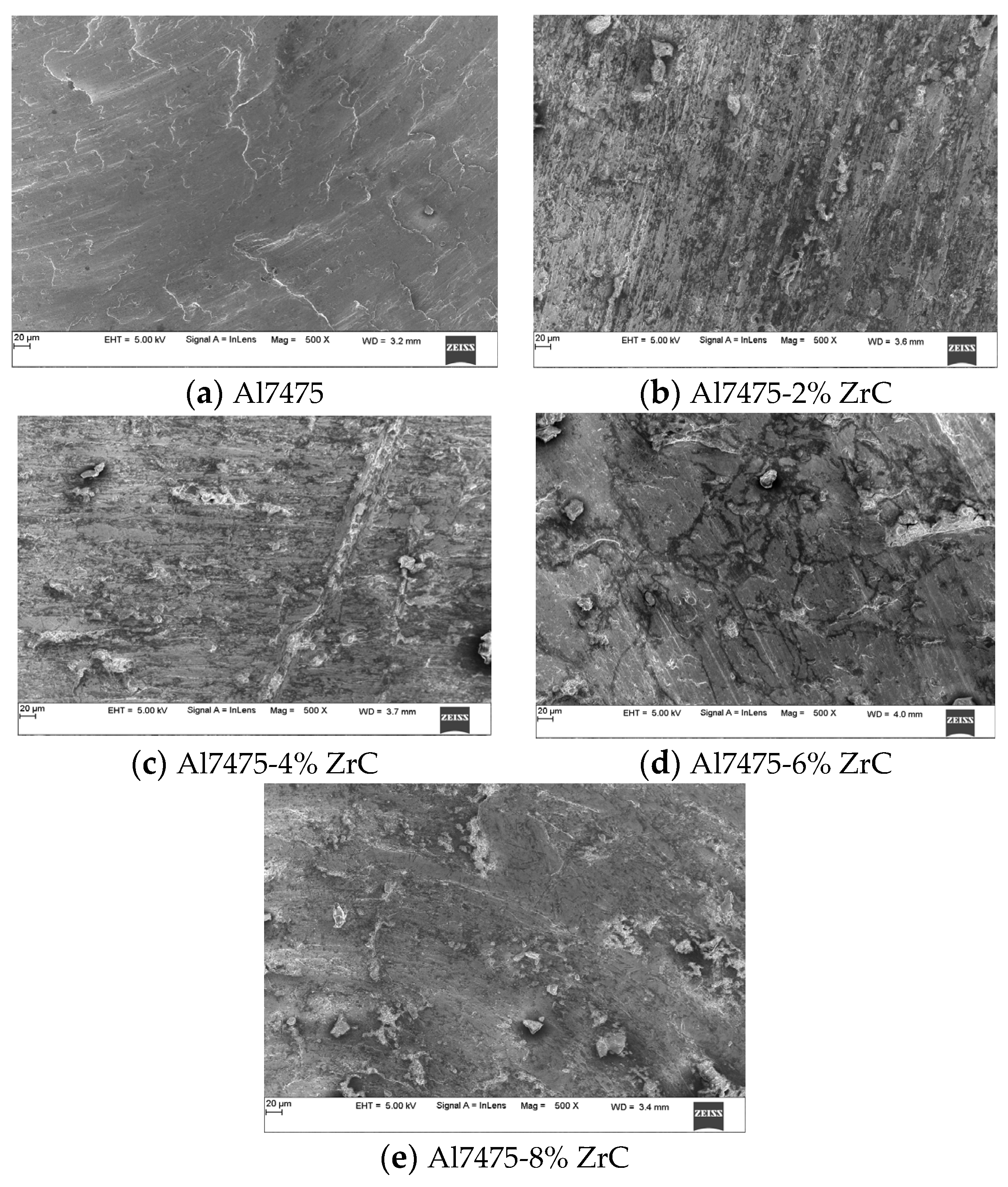

3.2. SEM Characterization of As-cast Al7475-ZrC Composites

3.3. SEM Characterization of Heat Treated Al7475-ZrC Composites

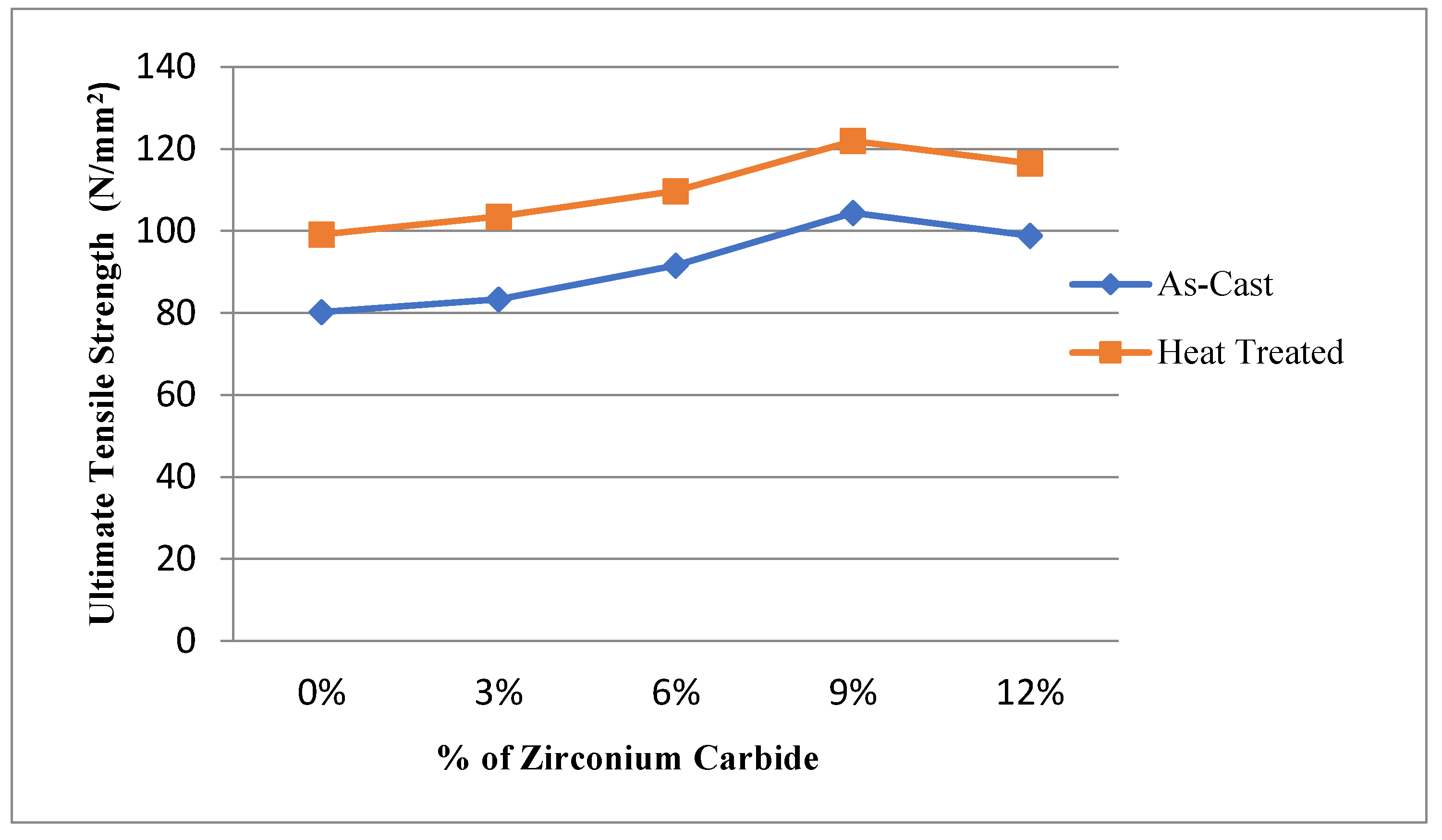

3.4. Tensile Strength Test Comparison between As-Cast and Heat Treated Al7475-ZrC Composites

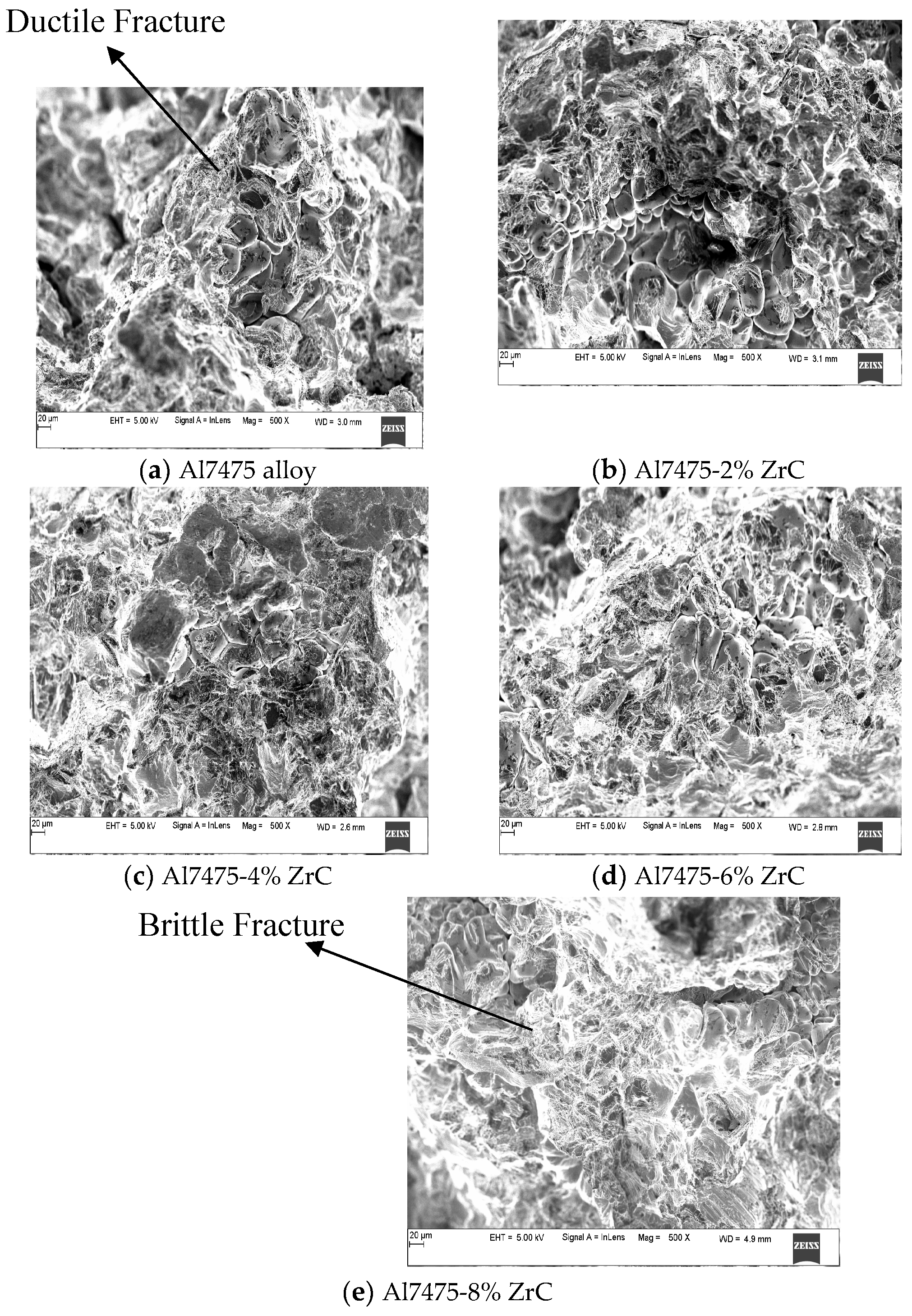

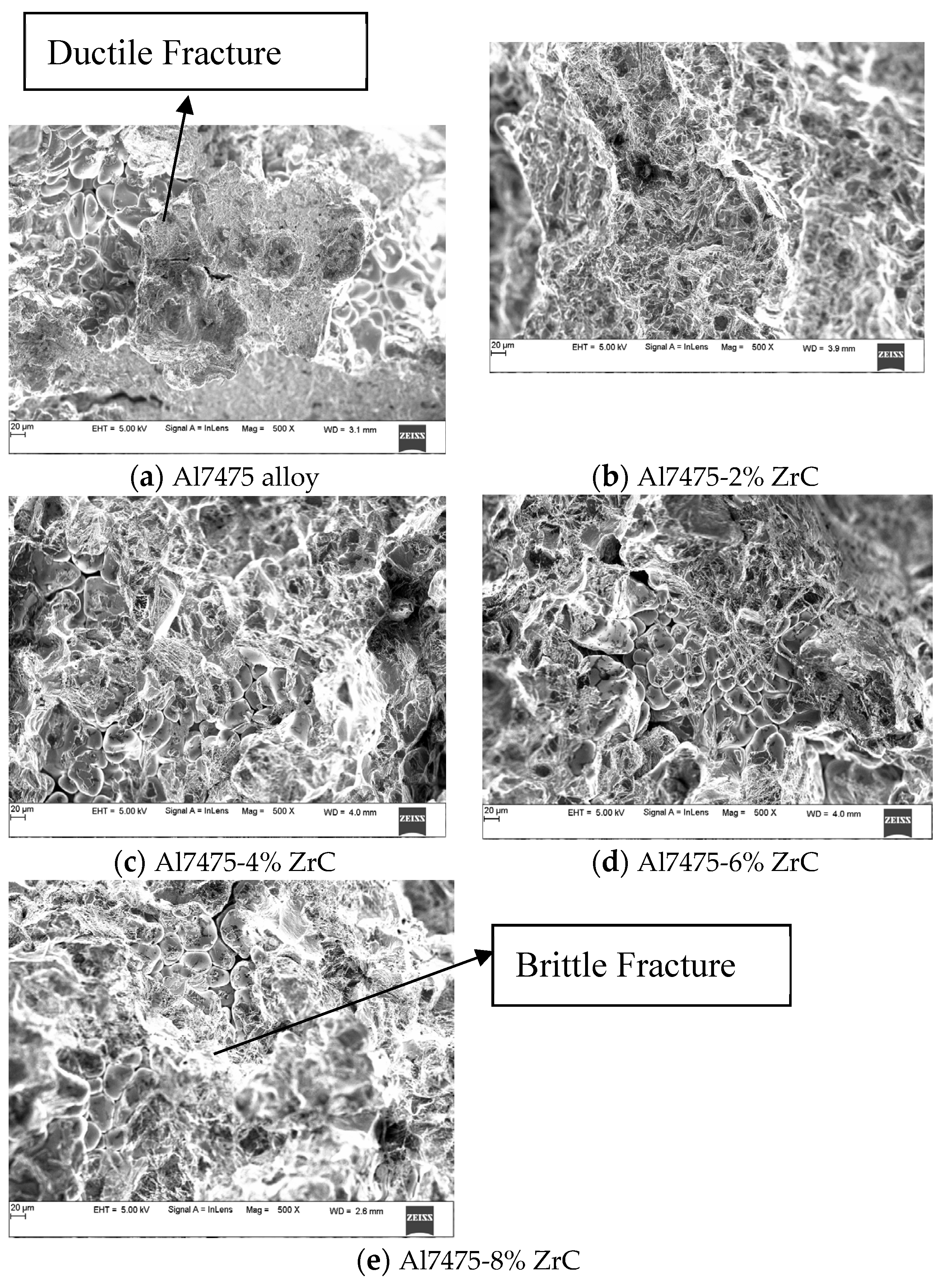

3.4.1. Tensile Fracture Study of As-Cast Al7475-Zirconium Carbide Composites Using SEM

3.4.2. Tensile Fracture Study of Heat Treated Al7475-ZrC Composites Using SEM

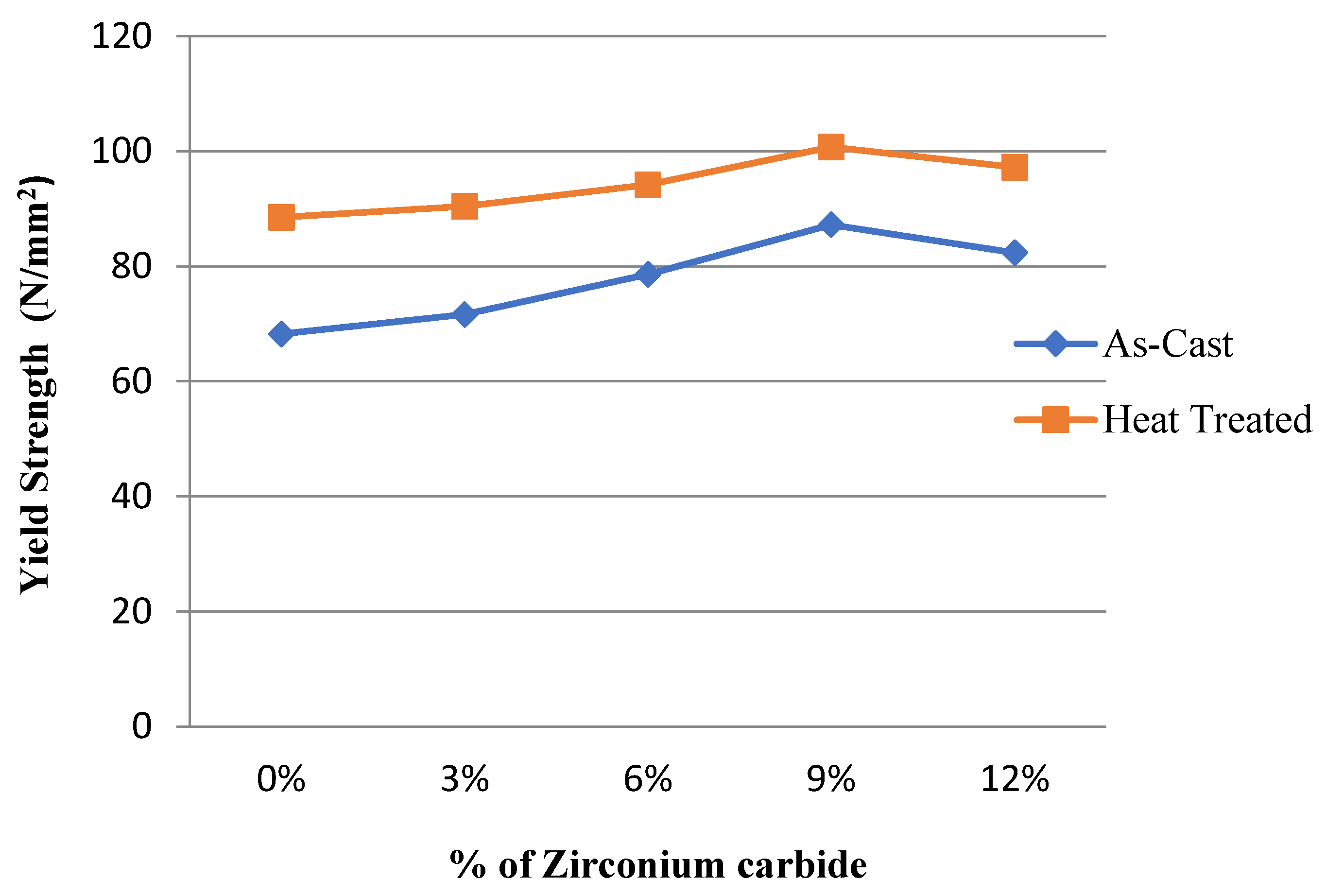

3.5. Yield Strength Comparison of Al7475-ZrC Composites in As-Cast and Heat Treated Condition

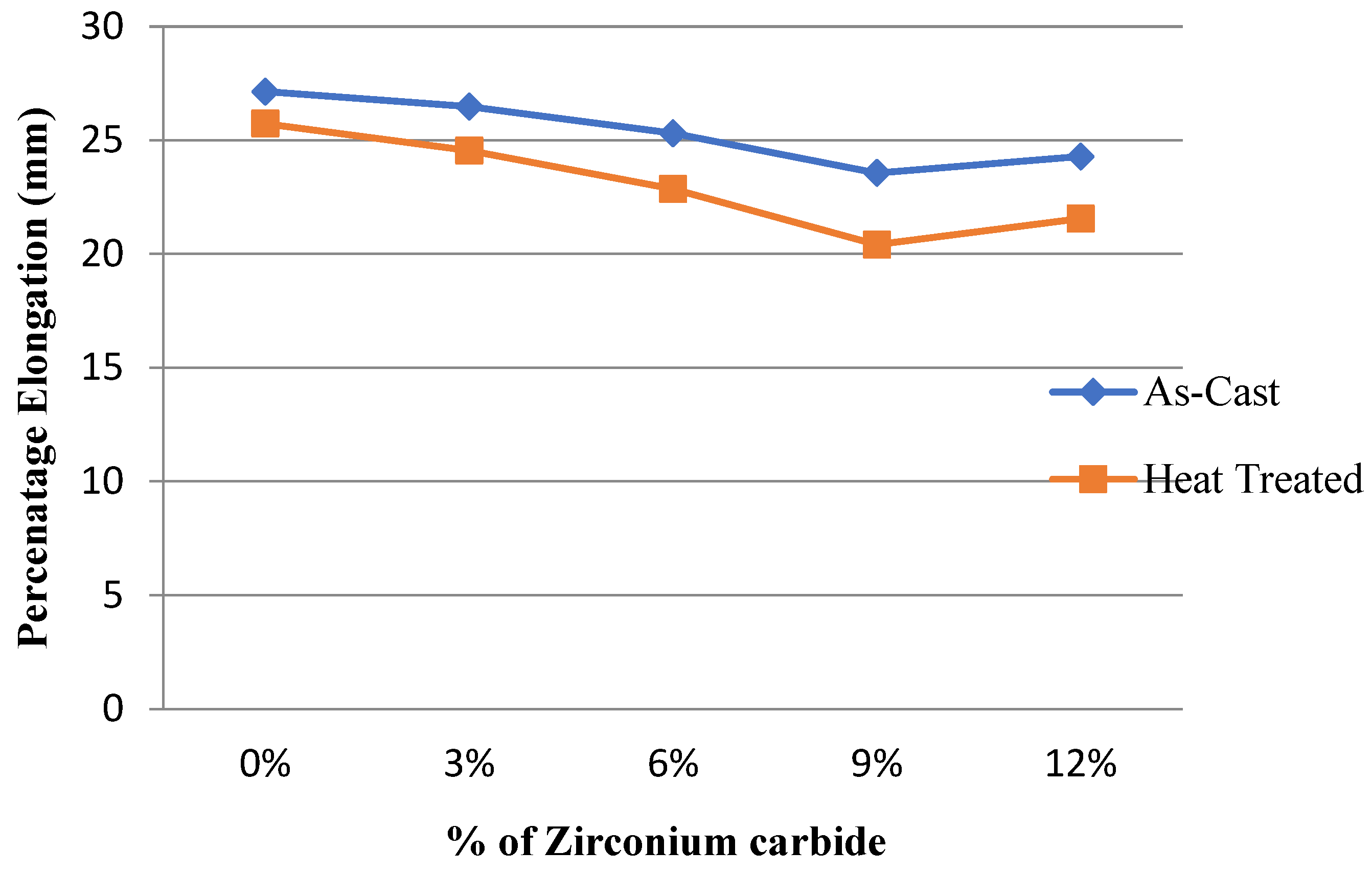

3.6. Percentage Elongation of Al7475-ZrC Composites in As-Cast and Heat Treated Condition

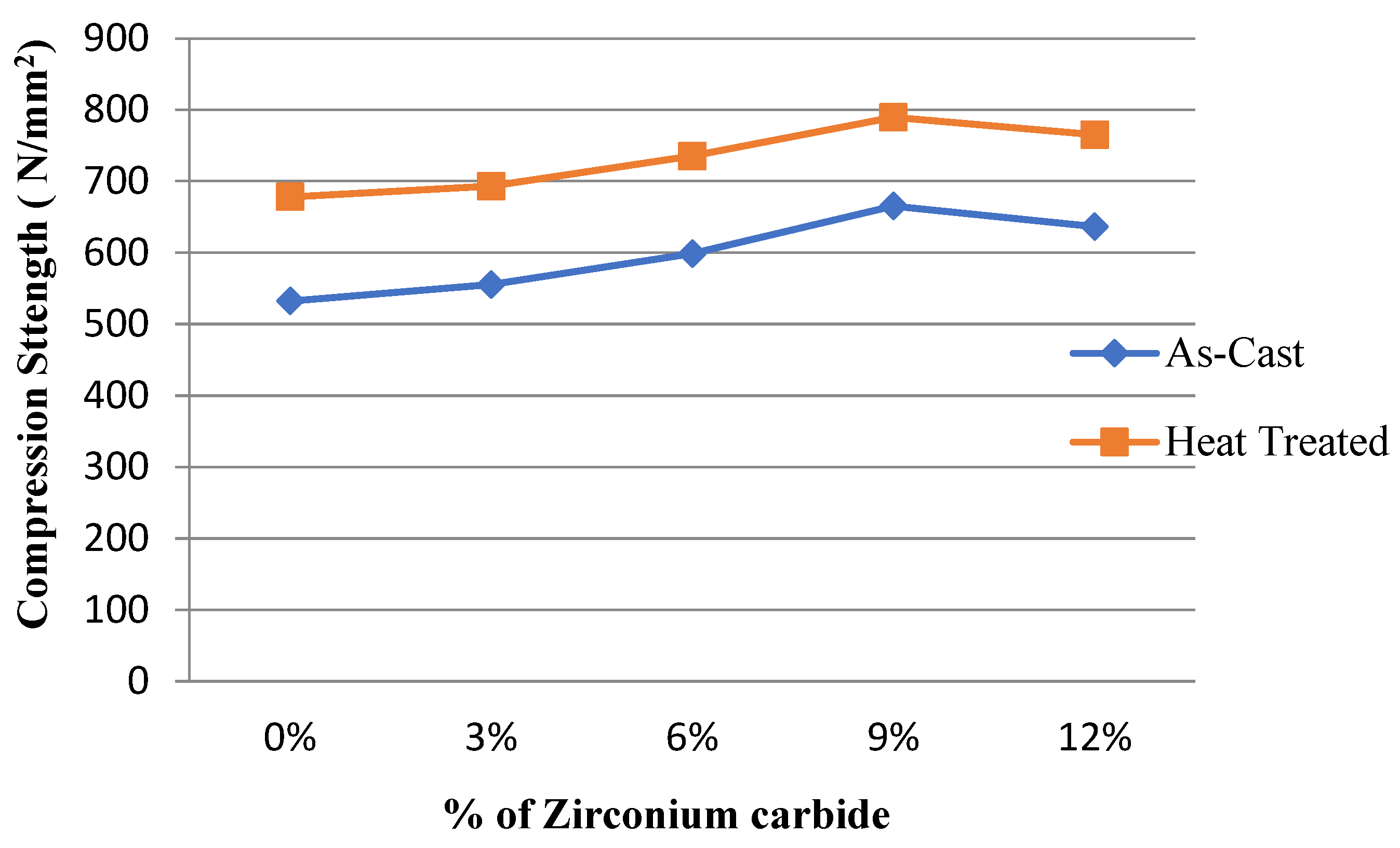

3.7. Compression Strength of Al7475-ZrC composites in As-Cast and Heat Treated Condition

| Sl. No. | Composition | Compression Strength (N/) | |

| As-Cast | Heat Treated | ||

| 01 | Al7475+ 0% ZrC |

532.35 | 678.25 |

| 02 | Al7475+ 2% ZrC |

555.42 | 693.23 |

| 03 | Al7475+ 4% ZrC |

598.67 | 735.44 |

| 04 | Al7475+ 6% ZrC |

665.43 | 789.68 |

| 05 | Al7475+ 8% ZrC |

636.38 | 765.13 |

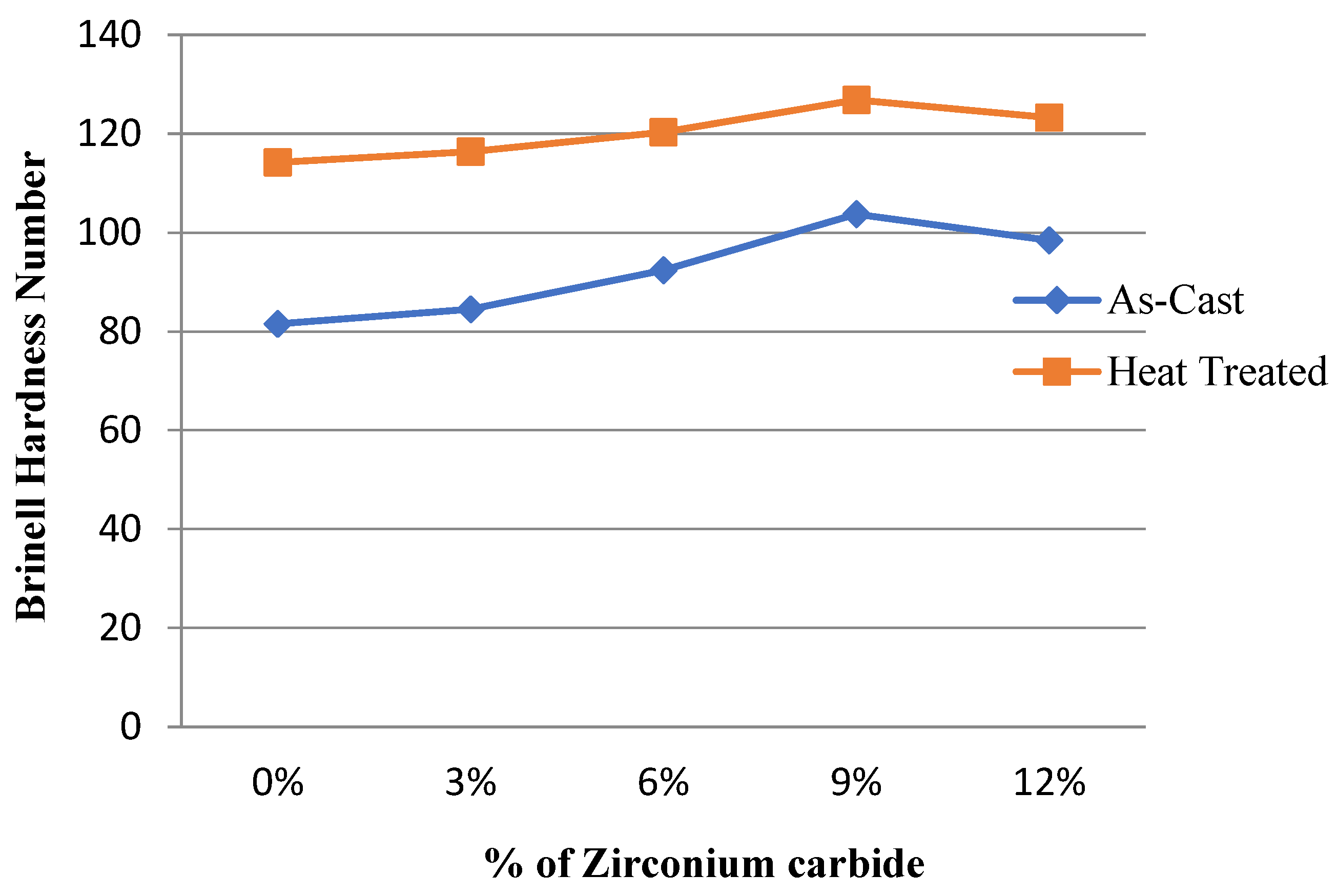

3.8. Hardness Test of Al7475-Zirconium Carbide Composites in As-Cast and Heat Treated Condition

| Sl. No. | Composition | Brinell Hardness Number | |

| As-Cast | Heat Treated | ||

| 01 | Al7475+ 0% ZrC |

81.53 | 114.21 |

| 02 | Al7475+ 3% ZrC |

84.48 | 116.35 |

| 03 | Al7475+ 6% ZrC |

92.35 | 120.29 |

| 04 | Al7475+ 9% ZrC |

103.74 | 126.86 |

| 05 | Al7475+ 12% ZrC |

98.41 | 123.24 |

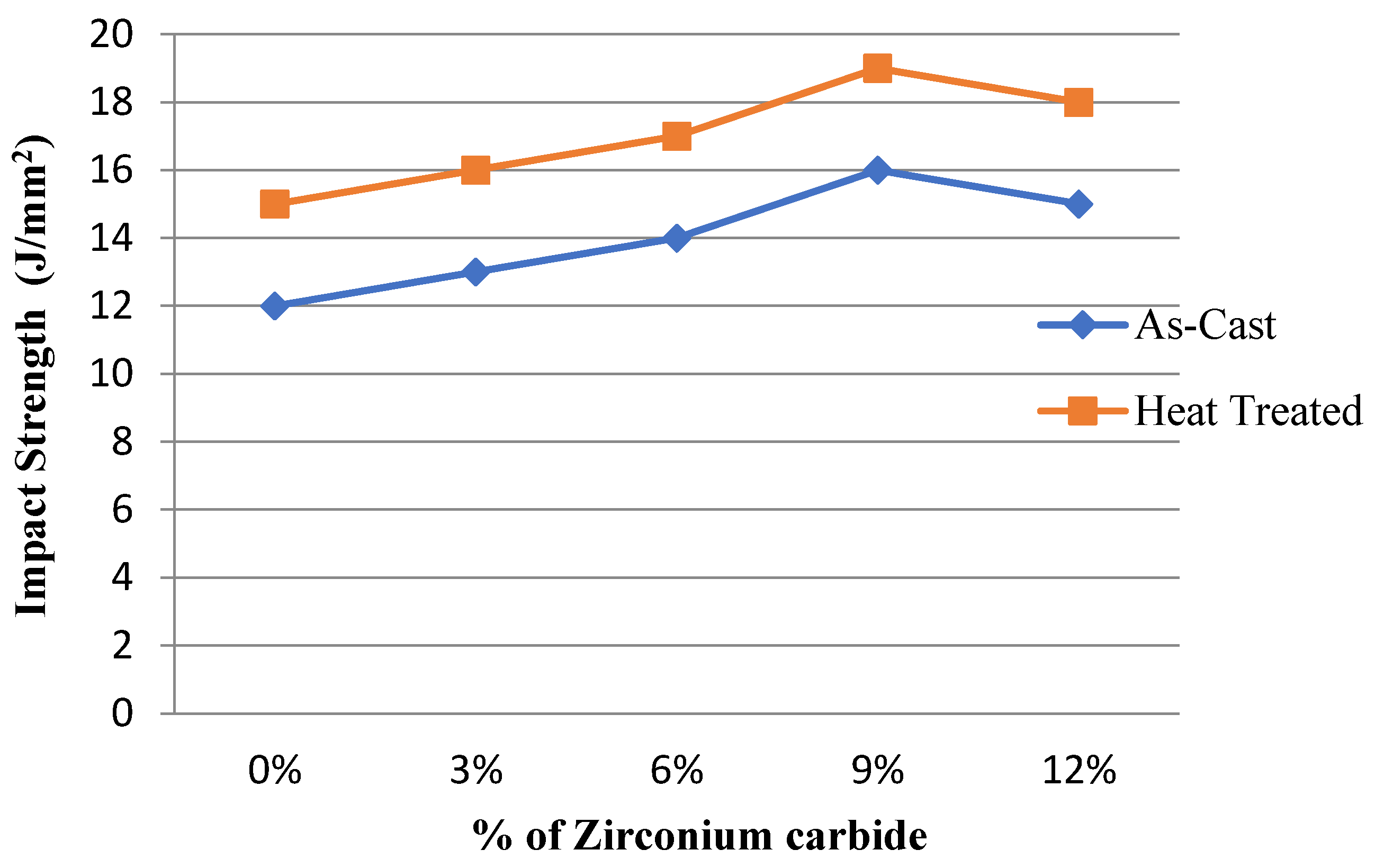

3.9. Impact Strength Test of Al7475-Zirconium Carbide Composites in As-Cast and Heat Treated Condition

5. Conclusions

- The Al7475-ZrC composites were prepared by stir casting process. This was accomplished by adjusting the weight percentage of Zirconium carbide particles in increments of two weight percent, ranging from 0 to 8 wt.%.

- The EDX spectrum of the composite material Al7475-6% ZrC reveal the existence of aluminium, Zirconium and carbon.

- The microstructure of the as-cast and heat treated Al7475-ZrC composites, revealed that the matrix of Al7475 alloy consisted of Zirconium carbide particles uniformly distributed throughout the matrix.

- The SEM images of heat-treated composite reveal that the grain size decreased as a result of the heat treatment effect, which in turn results in improvement in the strength of the Al7475-ZrC composites.

- The mechanical characteristics of the heat-treated Al7475-ZrC composites have been observed to be superior to those of the as-cast composites. These properties include Ultimate Tensile Strength, compressive strength, Brinell Hardness, and impact strength. When compared to as-cast composites, T6 heat treated Al7475-ZrC composites exhibit a 16.78% increase in Ultimate Tensile Strength.

- Composites that have been heat treated with T6 have a yield strength that is 15.46% higher than composites that have been cast.

- There is a 22.28% increase in the Hardness in composites that have been heat treated to T6 compared to composites that have been as-cast.

- The compression strength of heat treated composites is 18.67% higher than that of as-cast composites.

- When compared to as-cast composites, the impact strength of heat treated composites is 18.75% higher than that without heat treatment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Bawa, M. A., Umaru, O. B., Abur, B. T., Salako, I., & Jatau, J. S. Effect of locust bean pod ash on the hardness and wear rate of heat treated A356 alloy metal matrix composite for production of automobile brake rotor. International Journal of Research Publication (IJRP.ORG) 2020, 57, 36–43. [CrossRef]

- Ikumapayi, O. M., Afolalu, S. A., Bodunde, O. P., Ugwuoke, C. P., Benjamin, H. A., & Akinlabi, E. T.. Efficacy of heat treatment on the material properties of aluminium alloy matrix composite impregnated with silver nano particle/calcium carbonate Al. International Journal of Advanced Technology and Engieering Exploration 2022, 9, 523–535. [CrossRef]

- Khan, A. H., Shah, S. A. A., Umar, F., Noor, U., Gul, R. M., Giasin, K., & Aamir, M. Investigating the microstructural and mechanical properties of novel ternary reinforced AA7075 hybrid metal matrix composite. Materials 2022, 15, 5303. [CrossRef]

- Lakshmikanthan, A., Prabhu, T. R., Babu, U. S., Koppad, P. G., Gupta, M., Krishna, M., & Bontha, S., The effect of heat treatment on the mechanical and tribological properties of dual size SiC reinforced A357 matrix composites. Journal of Materials Research and Technology 2020, 9, 6434–6452. [CrossRef]

- Manda, C. S., Babu, B. S., & Ramaniah, N, Effect of heat treatment on mechanical properties of aluminium metal matrix composite (AA6061/MoS2). Advances in Materials and Processing Technologies 2021, 8, 205–222. [CrossRef]

- Nagaraja, S., Kodandappa, R., Ansari, K., Kuruniyan, M. S., Afzal, A., Kaladgi, A. A., Aslfattahi, N., Saleel, C. A., Gowda, A. C., & Anand, P. B, Influence of heat treatment and reinforcements on tensile. Materials 2021, 14, 5261. [CrossRef]

- Rajaram, S., Subbiah, T., Mahali, P. K., & Thangara, M, Effect of age-hardening temperature on mechanical and wear behavior of furnace-cooled al7075-Tungsten Carbide compositer. Materials 2022, 15, 5344. [CrossRef]

- Sam, M., Radhika, N., & Sai, K. P, Effect of heat treatment on mechanical and tribological properties of aluminum metal matrix composites. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 2020, 234, 4493–4504. [CrossRef]

- V.M.R. Muthaiah, S.R. Meka, and B.V.M. Kumar. “Processing of heat-treated silicon carbide-reinforced aluminum alloy composites”. Meter. Manuf. Process. 2019, 34, 320–321.

- Krishna Mohan Singh and Akhilesh Kumar Chauhan, Fabrication, Characterization, and Impact of Heat Treatment on Sliding Wear Behaviour of Aluminium Metal Matrix Composites Reinforced with B4C. Hindawi Advances in Materials Science and Engineering 2021, 2021, 5554837. [CrossRef]

- B.M. Viswanatha, M. Prasanna Kumar, S. Basavarajappa, Effect of heat treatment and ageing on microstructure for hypoeutectic Al-7Si alloy and hybrid metal matrix composites. International Journal of Engineering, Science and Technology 2021, 13, 1–11. [CrossRef]

- Hamid, M. Mahan, S.V. Konovalov, Irina Panchenko, Effect of heat treatment on the mechanical properties of the aluminium alloys AA2024 with nanoparticles. International Journal of Applied Science and Engineering 2023, 20, 2022324. [CrossRef]

- Gurumurthy B M, Jamaluddin Hindi, Achutha Kini U, Investigation and analysis of aging behavior and tensile fracture study on precipitation hardened al7075-white cast iron particulate reinforced composites. Cogent Engineering 2021, 8, 1920093. [CrossRef]

- Raj Kumar. R. G. Deshpande. B. Gopinath, Mechanical Fractography and Worn Surface Analysis of Nanographite and ZrO2-Reinforced Al7075 Alloy Aerospace Metal Composites. Journal of Failure Analysis and Prevention 2020, 1-12. [CrossRef]

- V. Bharath, V. Auradi, G. B. Veeresh Kumar, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites. Materials 2022, 15, 4244. [CrossRef]

- Shengqing Hu, KaiWang, Simu Ma, Effects of Heat Treatment on the Interface Microstructure and Mechanical Properties of Friction-Stir-Processed AlCoCrFeNi/A356 Composites. Materials 2023, 16, 2234. [CrossRef]

- Xin Li, Hong Yan, Zhi-Wei Wang, Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles. Metals 2019, 9, 1205. [CrossRef]

- Gopal Krishna U B, Manoj Kumar D, Naveen A, Microstructure and Wear Behaviour of Matrix Al7075 Reinforced with Micro Wc-Co particulate composite processed by stir casting method. IOP Publishing. IOP Conf. Series: Materials Science and Engineering 2021, 1013012020, 1–8. [CrossRef]

- Siddesh Matti, B. P. Shivakumar, Suresh Holi, Effect of Heat Treatment on Mechanical Behavior of Al7075-Based Hybrid Composites. Advances in Modern Machining Processes, Lecture Notes in Mechanical Engineering 2022, 345–359. [CrossRef]

- N. Ramadoss, K. Pazhanivel, G. Anbuchezhiyan, Synthesis of B4C and BN reinforced Al7075 hybrid composites using stir casting method. Journal of materials research and technology. [CrossRef]

- H. Alrobei, “Effect of different parameters and ageing time on wear resistance and hardness of SiC-B4C reinforced AA6061 alloy”. J. Mech. Sci. Technol. 2020, 34, 2027–2034. [CrossRef]

- Clement, C.D., Masson, J., Kabir, A.S, Effects of heat treatment on microstructure and mechanical properties of alsi10mg fabricated by selective laser melting process. Journal of Manufacturing and Materials Processing 2022, 6, 52. [CrossRef]

- Kilic, S., Kacar, I., Sahin, M., Ozturk, F., Erdem, O, Effects of aging temperature, time, and pre-strain on mechanical properties of AA7075. Materials Research 2019, 22, 1–9.

- Zhao, K., Gao, T., Yang, H., Hu, K., Liu, G., Sun, Q., Nie, J. Liu, X. Enhanced grain refinement and mechanical properties of a high–strength Al–Zn–Mg–Cu–Zr alloy induced by TiC nano–particles. Materials Science and Engineering: A 2021, 806, 140852. [CrossRef]

- Anantha Padmanabham, K.C.; Mruthunjaya, M. Microstructure Studies and Mechanical Characterisation of T6 Heat Treated Aluminium and Copper Based Alloy Reinforced with Zircon and Graphite Composite. J. Eng. Sci. Technol. 2019, 14, 2063–2073. [Google Scholar]

- Hu, Y.; Wu, T.; Guo, Y.; Wang, W.; Song, M.; Qian, L.; Zhao, H.; Wang, M. Effects of T6 Treatment, Tensile Temperature, and Mass Fraction of SiC on the Mechanical Properties of SiCp/6061Al Composites. Materials 2019, 12, 1602. [Google Scholar] [CrossRef] [PubMed]

- Hussein, S.G.; Al-Shammari, M.; Takhakh, A.M.; Al-Waily, M. Effect of Heat Treatment on Mechanical and Vibration Properties for 6061 and 2024 Aluminum Alloys. J. Mech. Eng. Res. Dev. 2020, 43, 48–66. [Google Scholar]

- Tayyebi, M.; Adhami, M.; Karimi, A.; Rahmatabadi, D.; Alizadeh, M.; Hashemi, R. Effects of strain accumulation and annealing on interfacial microstructure and grain structure (Mg and Al3Mg2 layers) of Al/Cu/Mg multilayered composite fabricated by ARB process. J. Mater. Res. Technol. 2021, 14, 392–406. [Google Scholar] [CrossRef]

- Tayyebi, M.; Rahmatabadi, D.; Karimi, A.; Adhami, M.; Hashemi, R. Investigation of annealing treatment on the interfacial and mechanical properties of Al5052/Cu multilayered composites subjected to ARB process. J. Alloy. Compd. 2021, 871, 159513. [Google Scholar] [CrossRef]

- S. Sharma, T. Nanda, and O.P. Pandey, Investigation of T4 and T6 Heat Treatment on the Wear Properties of Sillimanite Reinforced LM30 Aluminium Alloy Composites. Wear 2019, 426–427(Part A), 27–36.

- Gökme¸se H, Ta¸sci U, Bostan B, Investigation of microstructure and hardness properties of aged AA 7075 matrix B4C/SiC reinforced composite-hybrid materials. J Boron 2020, 5, 73–82.

- T. Velmurugan, R. Subramanian, G. Sugunya Priyadharshini, and R. Raghu, “Experimenetal investigation of microstructure, mechanical and wear characteristics of Cu-Ni/ZrC composites synthesized through friction stir processing”. Arch. Metall. Mater 2020, 2, 565–574.

- M.K. Pireyousefan, R. Rahmanifard, L. Orovcik, P. Švec, V. Klemm, “Application of a novel method for the fabrication of graphene reinforced aluminum matrix nanocomposites: Synthesis, microstructure, and mechanical properties”. Mater. Sci. Eng. A 2020, 772, 138820. [CrossRef]

- P. Ranjitha, T. Hemanth Raju, S. Udayashankar, Study of Wear Behavior of Silicon Carbide and Boron Carbide Reinforced Alumiium Alloy (Al6061) Matrix Composites. J. Inst. Eng. India Ser. D 2023, 1-8. 2023. [CrossRef]

- R. Vijayakumar, T. Hemanth Raju, S. Udayashankar, Synthesis and Characteristics of Heat Treated Al6061-Zirconium Dioxide Metal Matrix Composites. J. Inst. Eng. India Ser. D 2022, 1-10. [CrossRef]

- P. Ranjitha, T. Hemanth Raju, S. Udayashankar, Investigation of Mechanical Properties of Al6061–SiC–B4C Composites Produced by Using Stir Casting Method. J. Inst. Eng. India Ser. D 2024, 1-13. [CrossRef]

- R. Vijaya Kumar, T. Hemanth Raju, S. Udayashankar, Experimental Investigation of Al6063 Alloy with Zirconium Silicate Composite. J. Inst. Eng. India Ser. D 2024, 1-10. [CrossRef]

| Element | Al | Zn | Mg | Cu | Cr | Fe | Si | Mn | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Quantity (wt.%) | Balance | 5.5 | 2.2 | 1.4 | 0.2 | 0.1 | 0.08 | 0.04 | 0.04 |

| Sl. No. | Composition | Ultimate Tensile Strength (N/) | |

| As-Cast | Heat Treated | ||

| 01 | Al7475+ 0% ZrC |

80.25 | 99.13 |

| 02 | Al7475+ 2% ZrC |

83.34 | 103.54 |

| 03 | Al7475+ 4% ZrC |

91.57 | 109.71 |

| 04 | Al7475+ 6% ZrC |

104.42 | 121.95 |

| 05 | Al7475+ 8% ZrC |

98.81 | 116.46 |

| Sl. No. | Composition | Yield Strength (N/) | |

| As-Cast | Heat Treated | ||

| 01 | Al7475+ 0% ZrC |

68.26 | 88.52 |

| 02 | Al7475+ 2% ZrC |

71.62 | 90.42 |

| 03 | Al7475+ 4% ZrC |

78.60 | 94.17 |

| 04 | Al7475+ 6% ZrC |

87.23 | 100.72 |

| 05 | Al7475+ 8% ZrC |

82.34 | 97.20 |

| Sl. No. | Composition | Percentage Elongation (mm) | ||

| As-Cast | Heat Treated | |||

| 01 | Al7475+ 0% ZrC |

27.14 | 25.73 | |

| 02 | Al7475+ 2% ZrC |

26.47 | 24.54 | |

| 03 | Al7475+ 4% ZrC |

25.31 | 22.86 | |

| 04 | Al7475+ 6% ZrC |

23.56 | 20.41 | |

| 05 | Al7475+ 8% ZrC |

24.28 | 21.55 | |

| Sl. No. | Composition | Impact Strength (J/mm2) | ||

| As-Cast | Heat Treated | |||

| 01 | Al7475+ 0% ZrC |

12 | 15 | |

| 02 | Al7475+ 2% ZrC |

13 | 16 | |

| 03 | Al7475+ 4% ZrC |

14 | 17 | |

| 04 | Al7475+ 6% ZC |

16 | 19 | |

| 05 | Al7475+ 8% ZrC |

15 | 18 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).