Submitted:

19 September 2024

Posted:

22 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

- Poly(lactic acid) – PLA 6202D from NatureWorks (Minneapolis, USA) (d=1.24 cm3/g, MFR=15-30 g/10min and Tm=155-170 oC);

- acrylic acid – C3H4O2 from Sigma-Aldrich (Saint Louis, USA) ( d=1.05 g/cm3, Mn=72.06 g/mol, η=1,06 g/cm³);

- 2,2-dimethoxy-2-phenylacetophenone – C16 H16 O3 from Sigma-Aldrich (Saint Louis, USA) (pure 99%, Mn=256.30 g/mol);

- pentaerythritol triacrylate – C14H18O7 from Sigma-Aldrich (Saint Louis, USA) ( d=1.18 g/cm3, Mn=298.29 g/mol);

- zinc sulfide – ZnS from Sigma-Aldrich (Saint Louis, USA) (nanopowder, <21 μm primary particle size (TEM), ≥99.9% trace metals basis);

- titanium (IV) dioxide – TiO2 from Sigma-Aldrich (Saint Louis, USA) (nanopowder, <25 nm particle size, 99.70% trace metals basis);

- nano-Ag from Amepox Microelectronics (Lodz, Poland) nanopowder, <25 nm particle size, 99.99% trace metals basis).

2.2. Methods

3. Results and Discussion

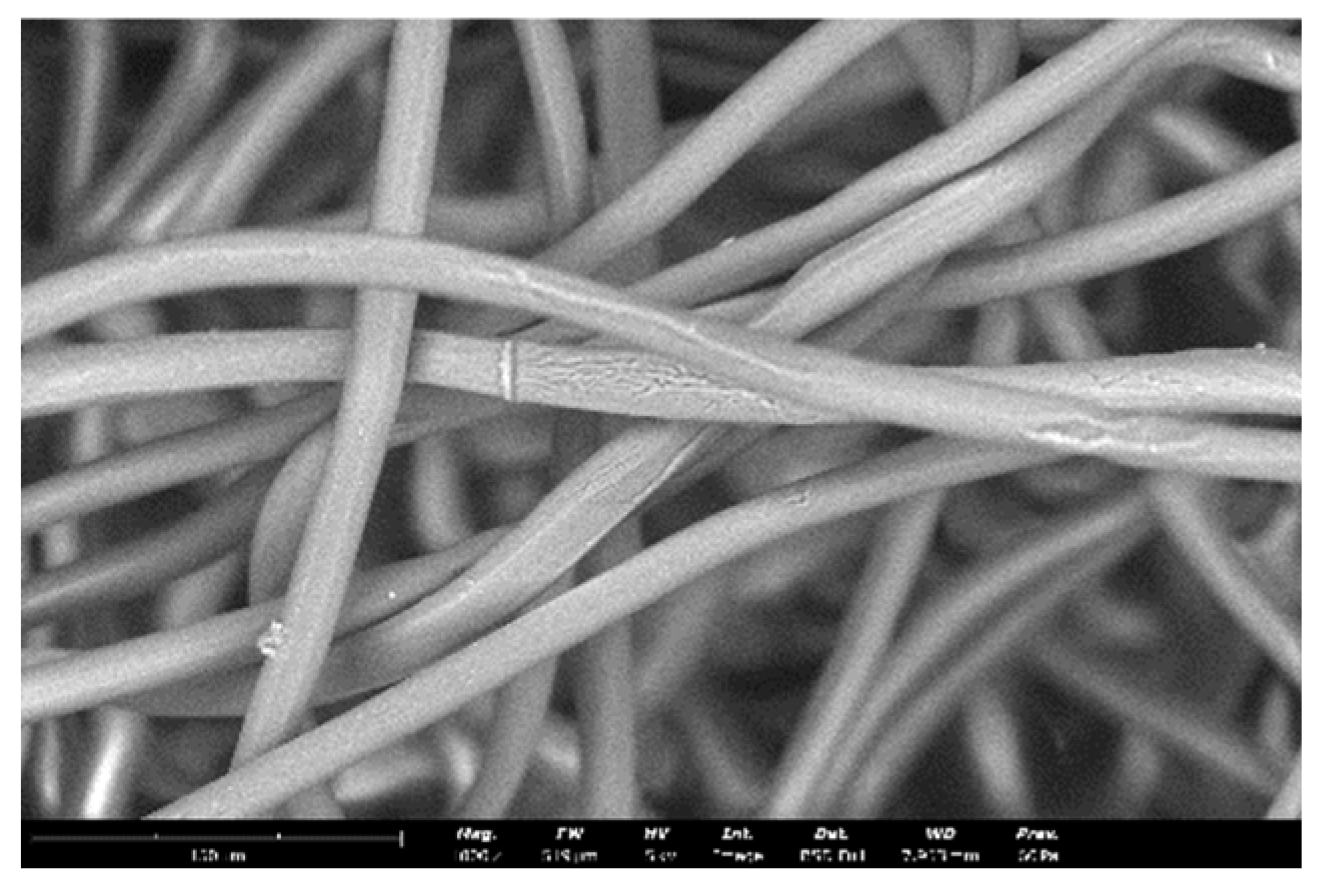

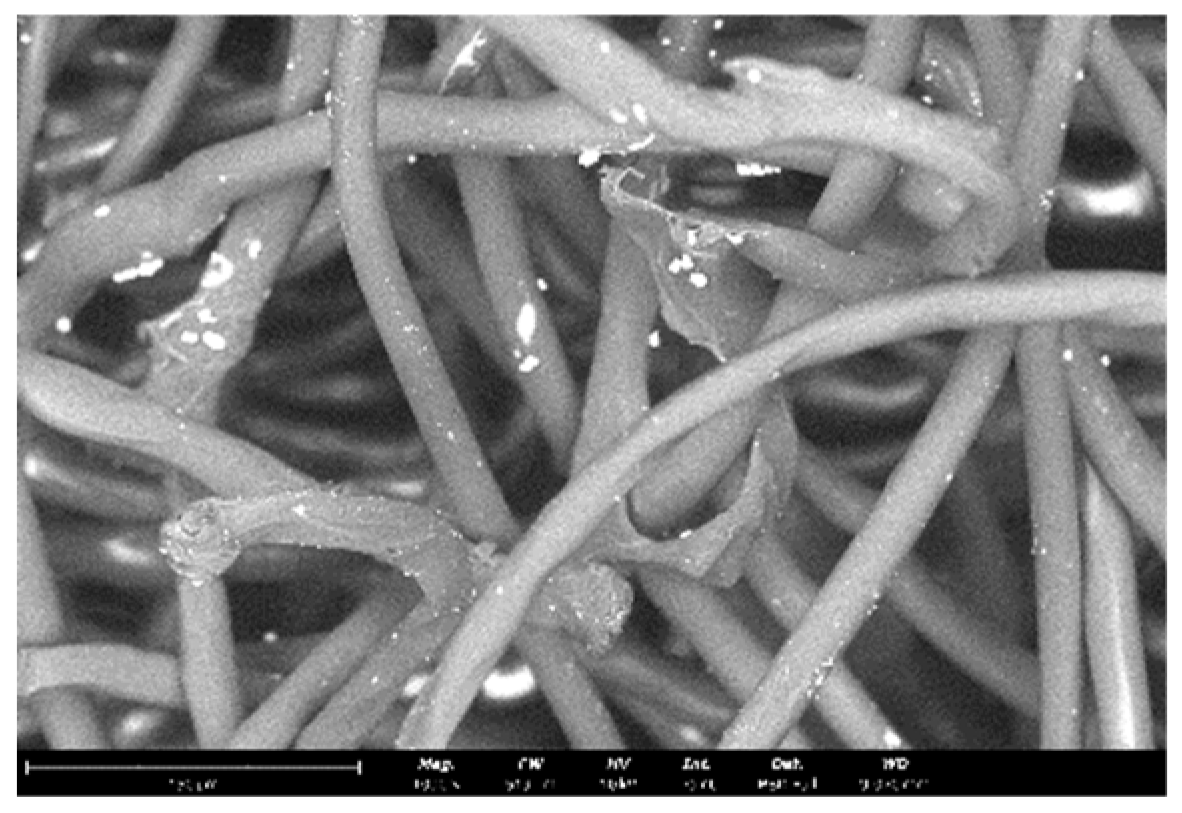

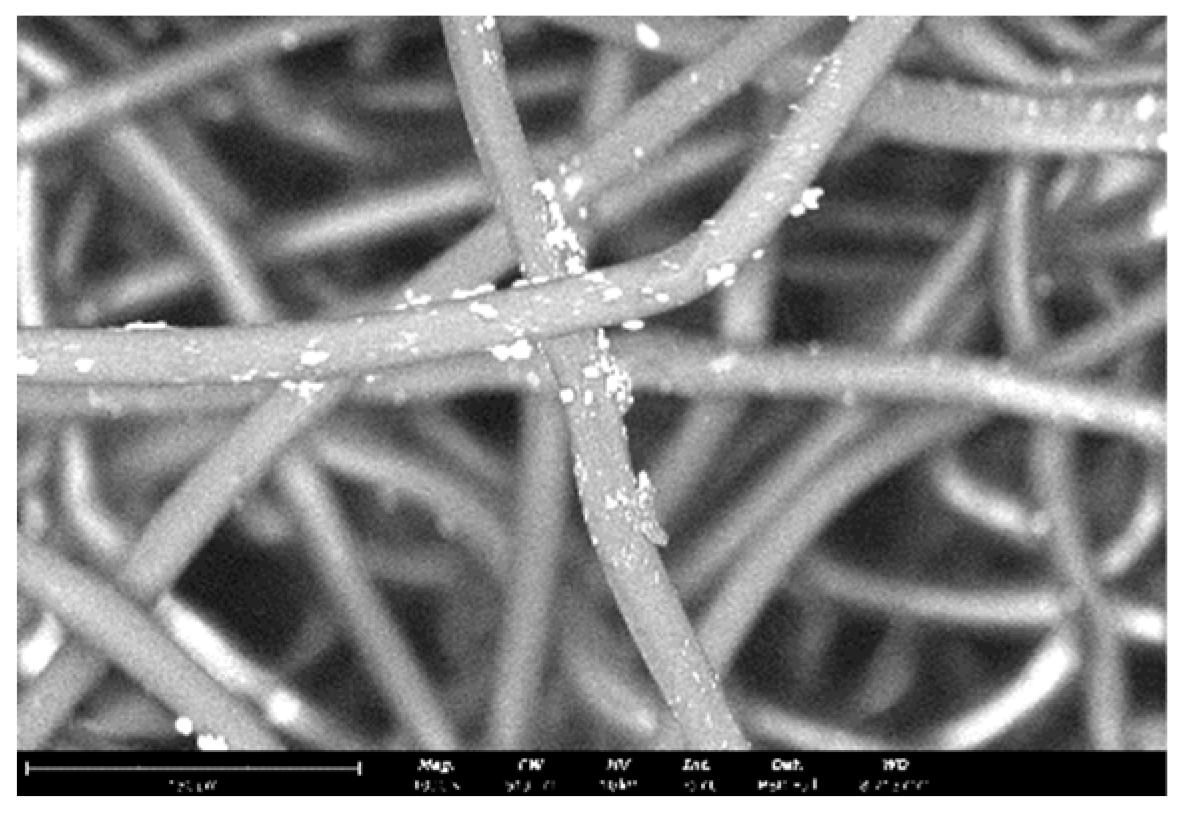

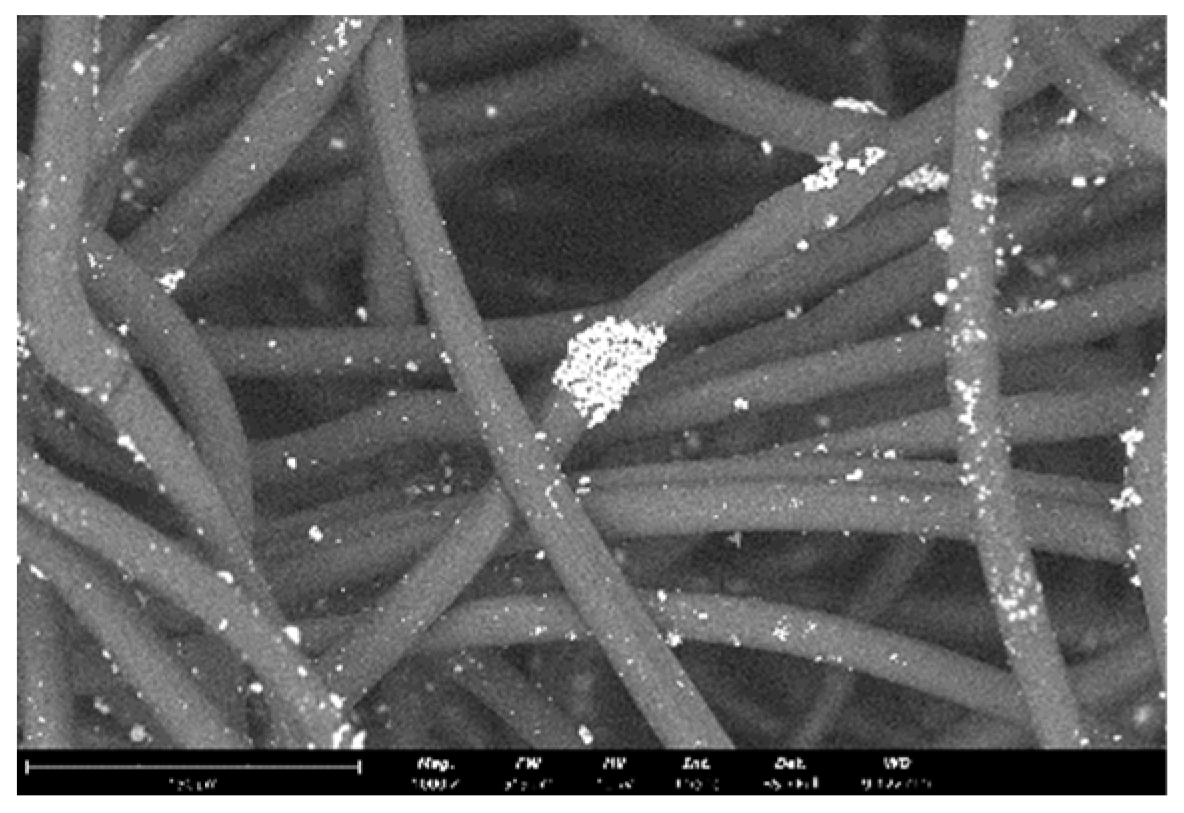

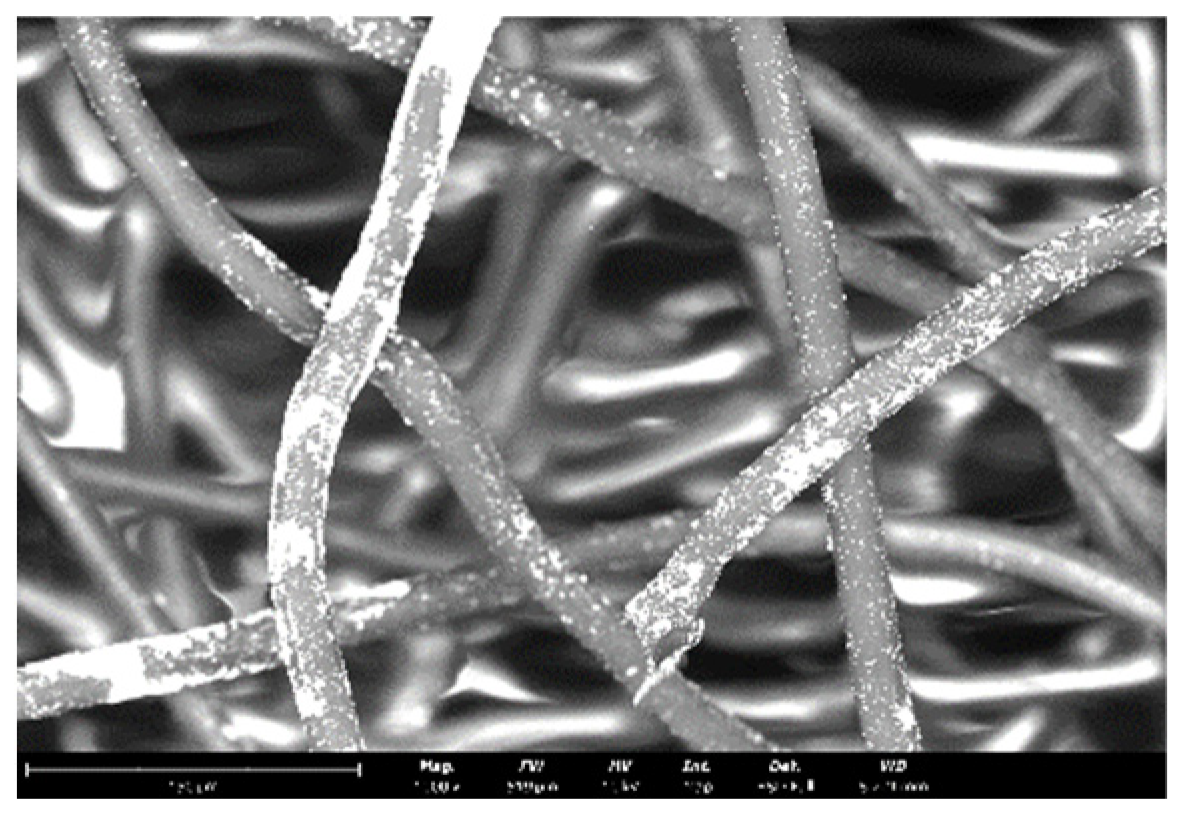

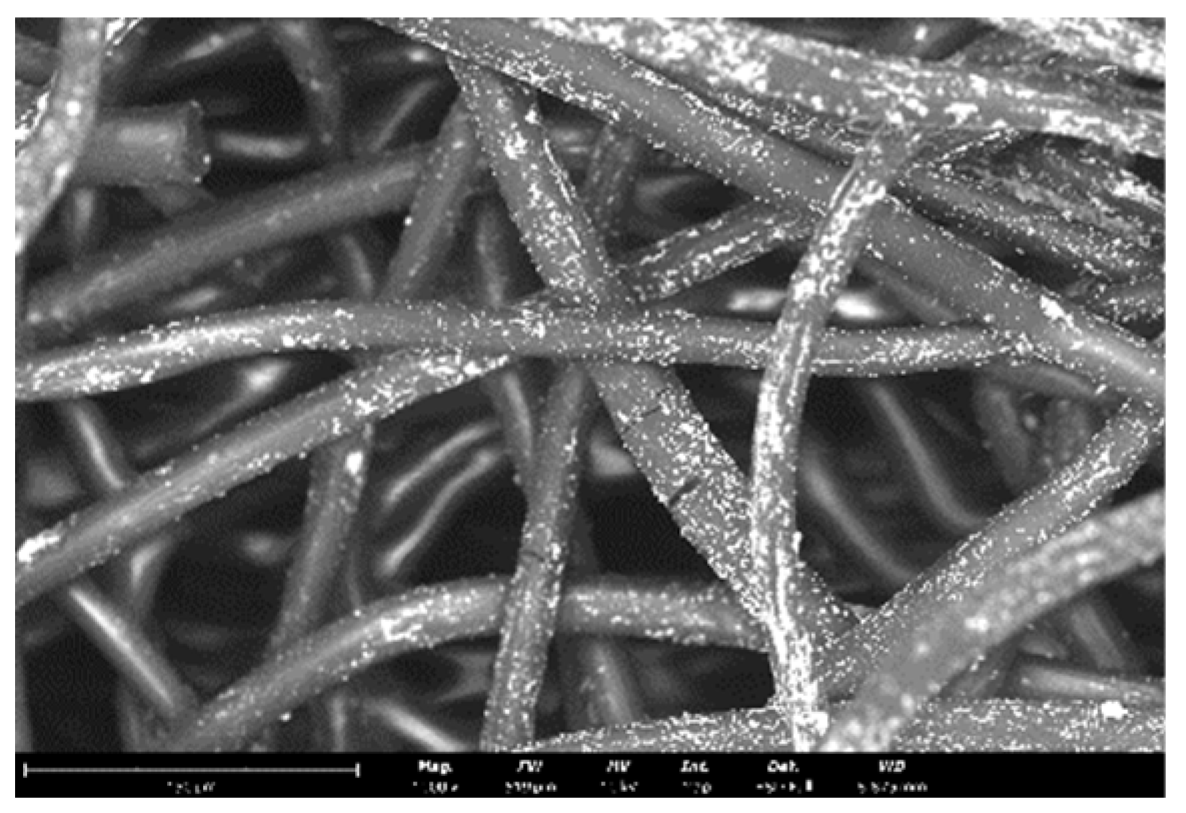

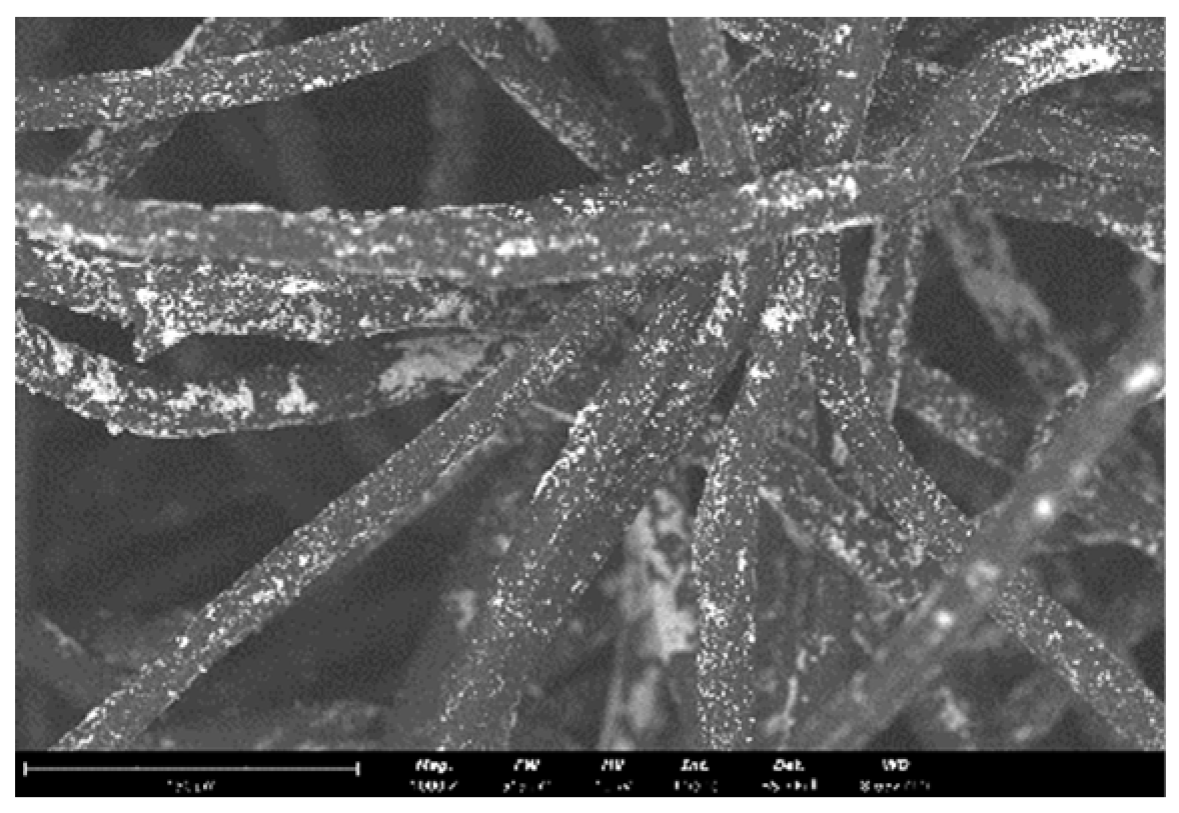

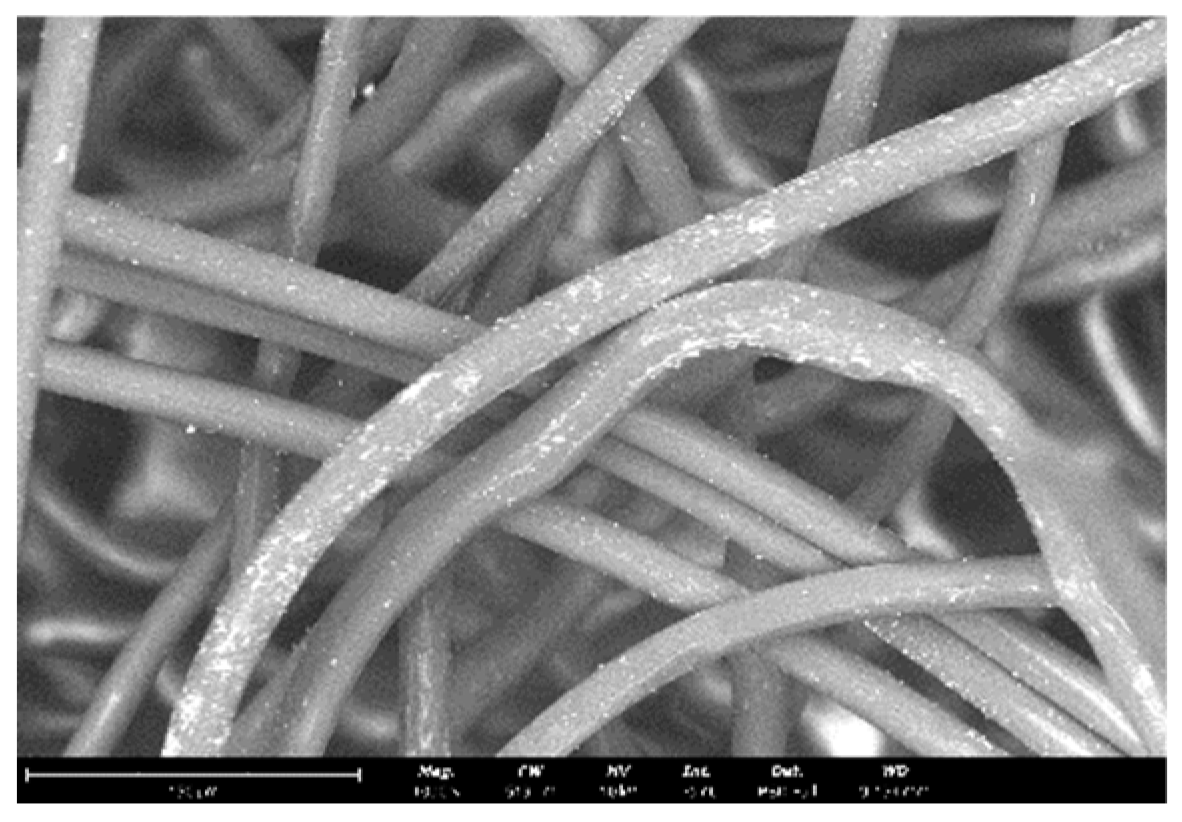

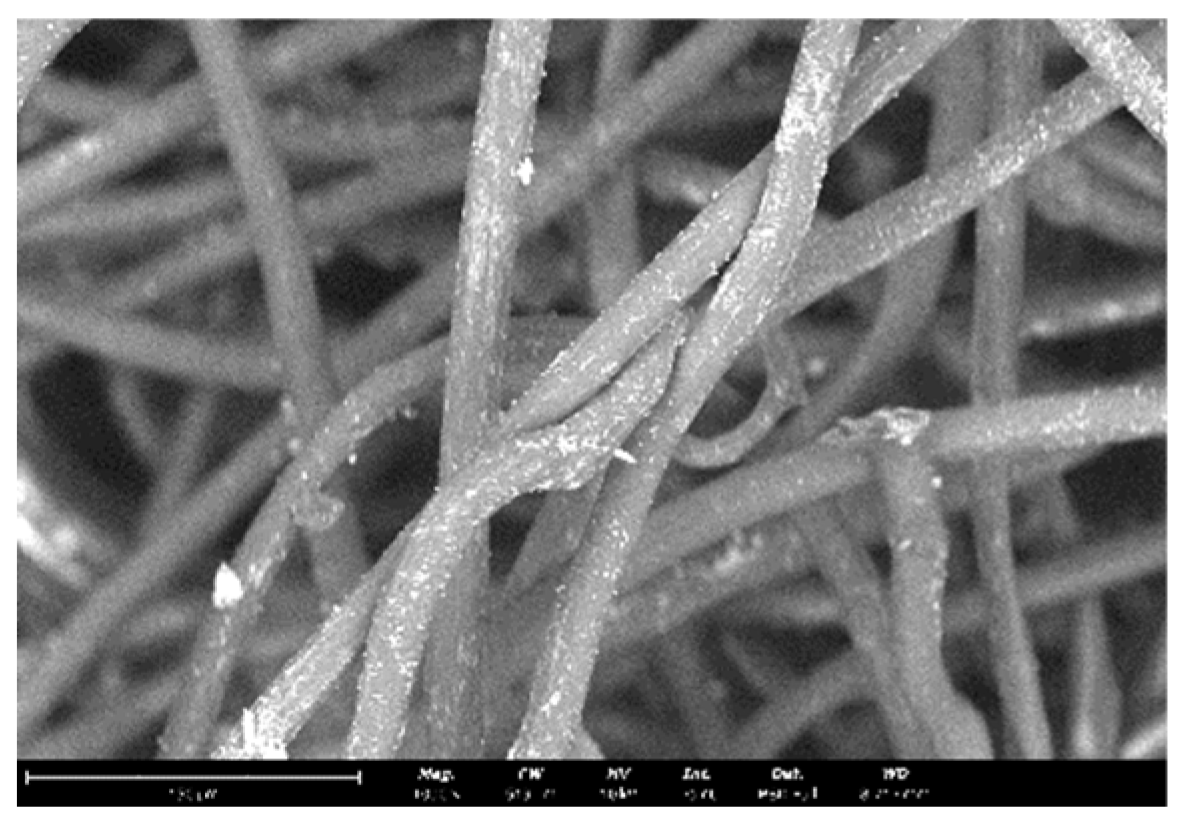

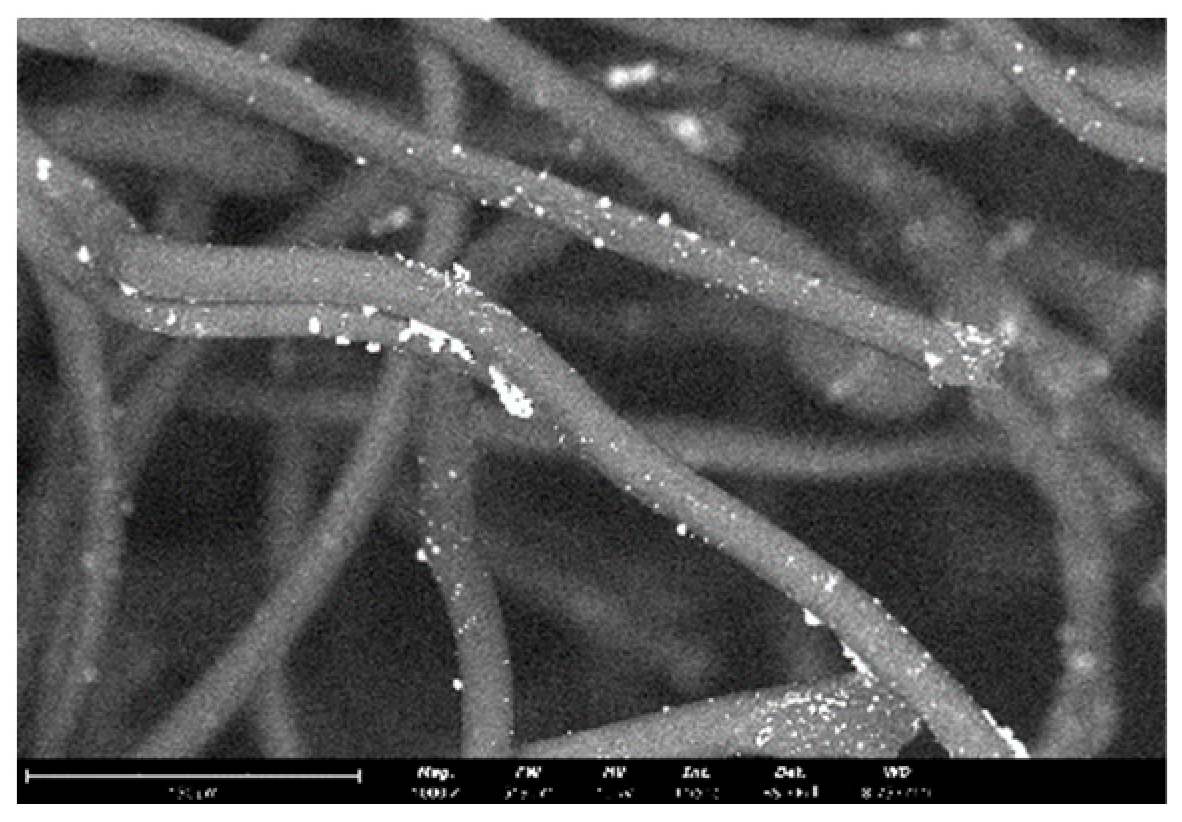

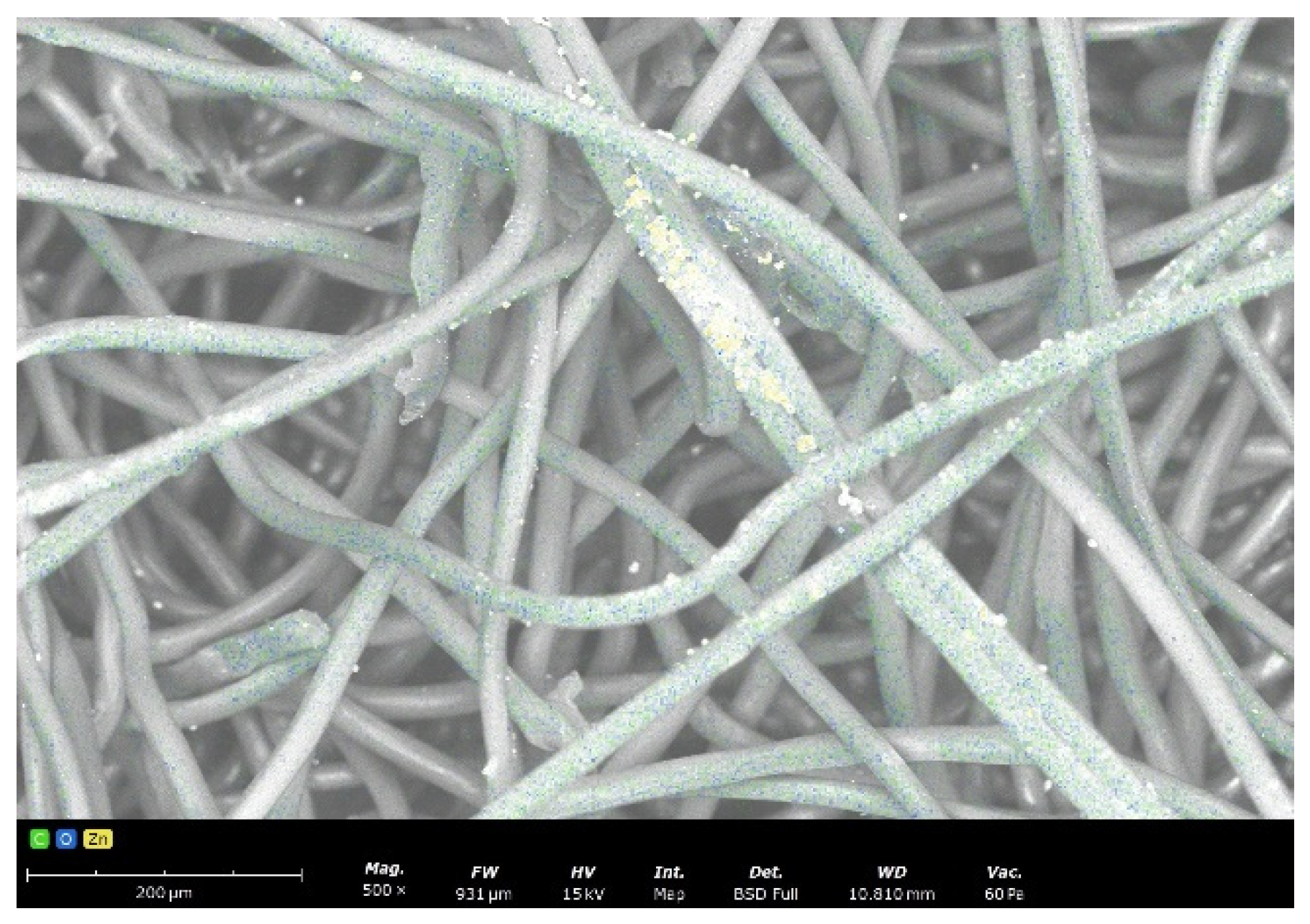

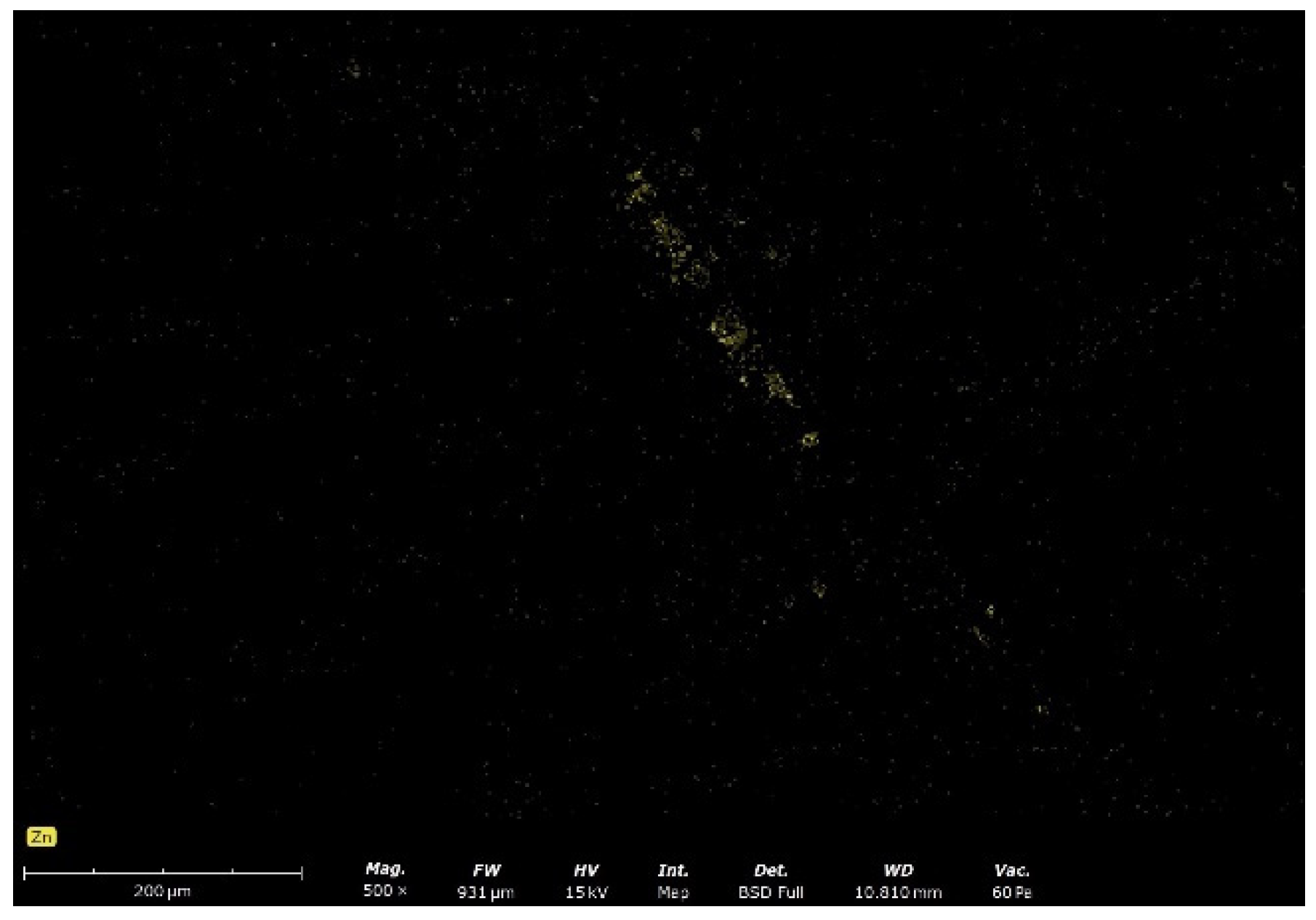

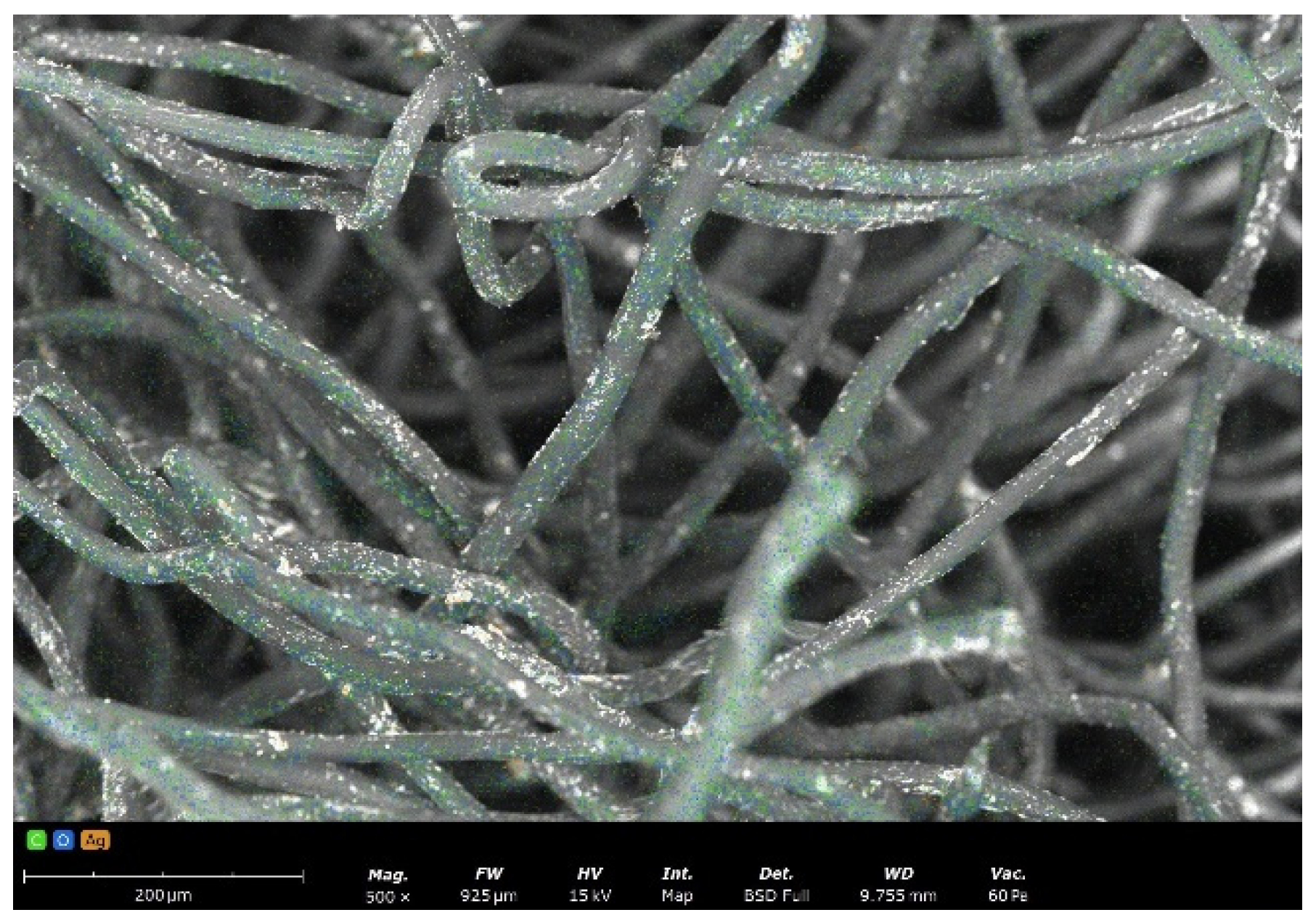

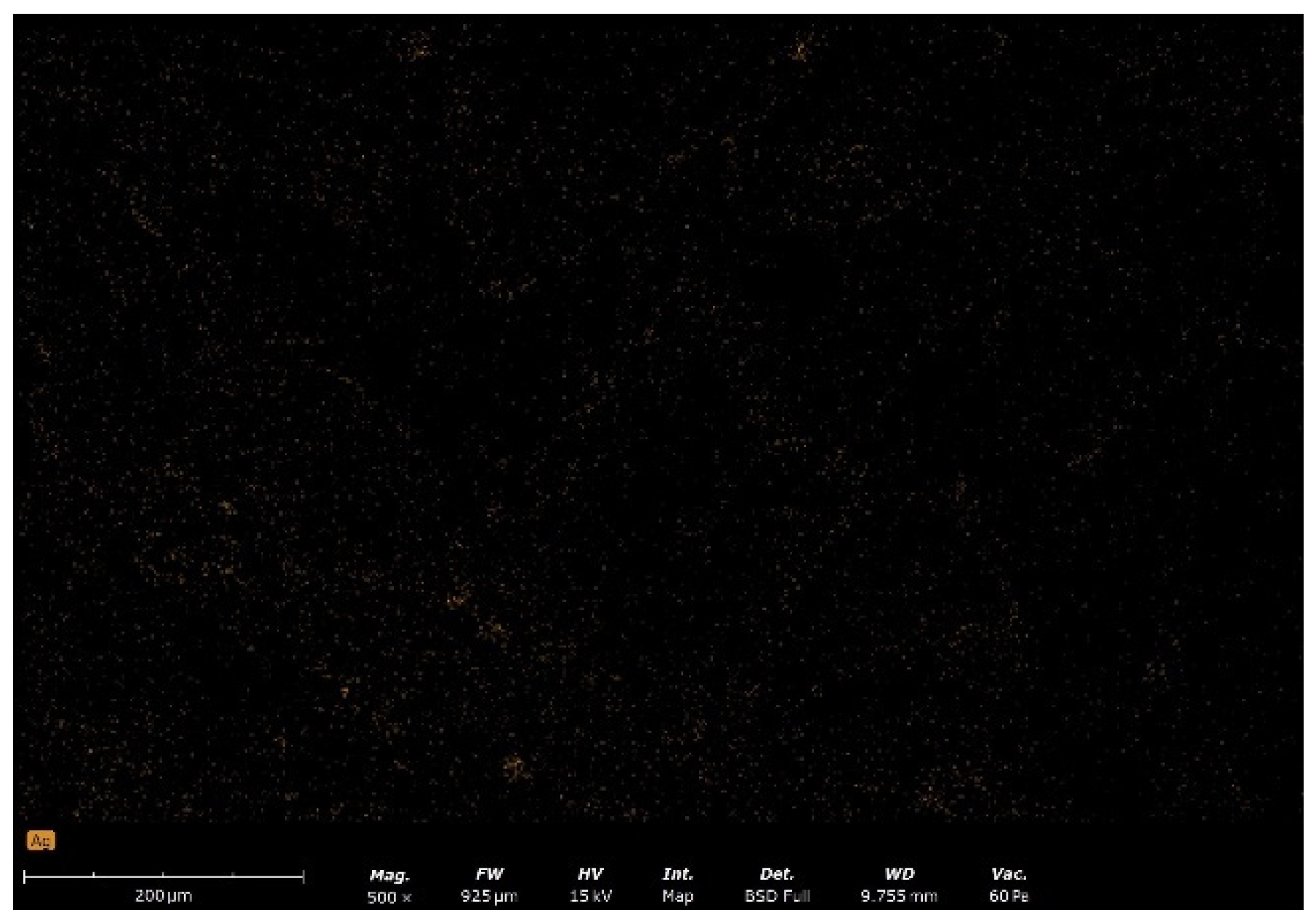

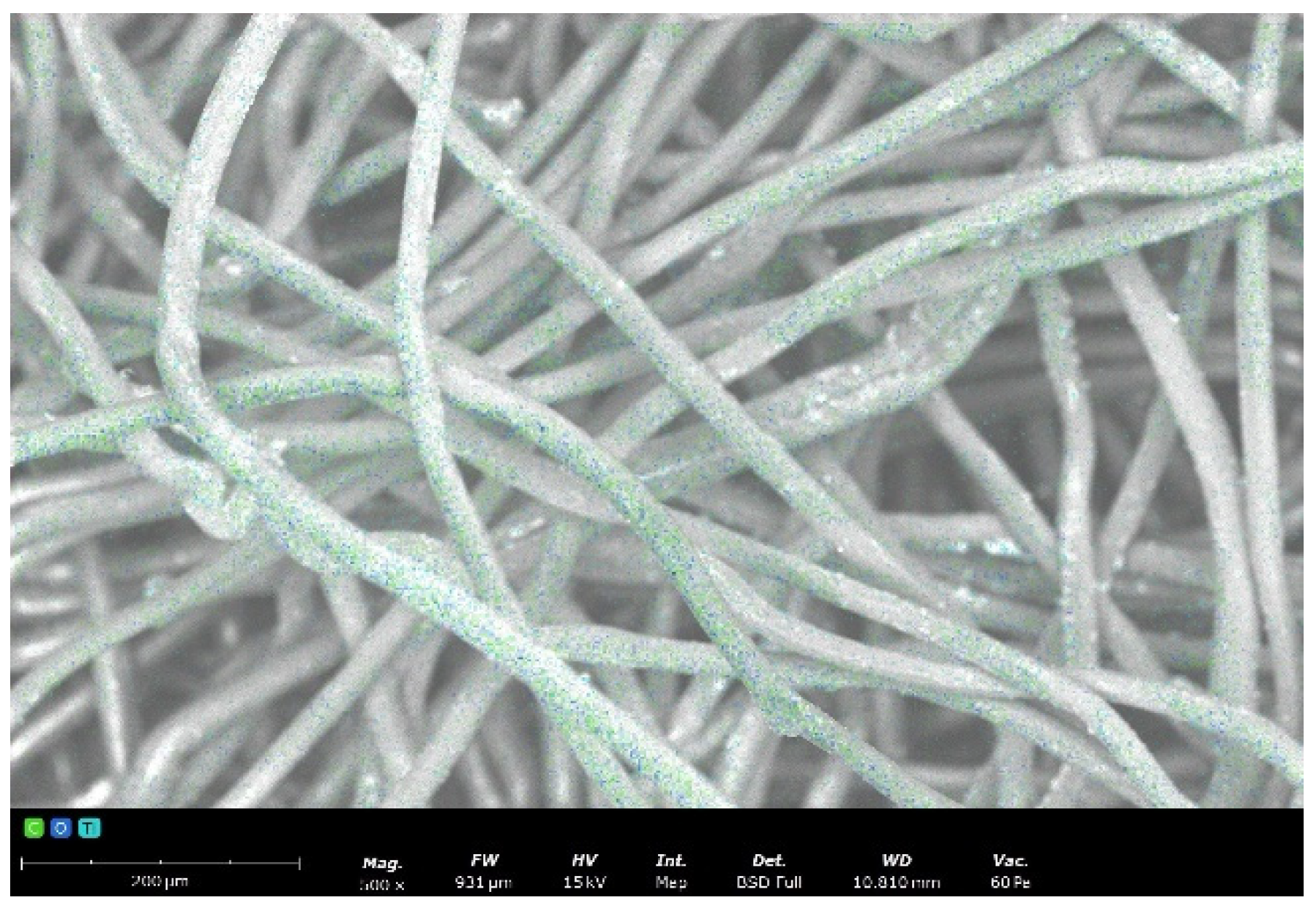

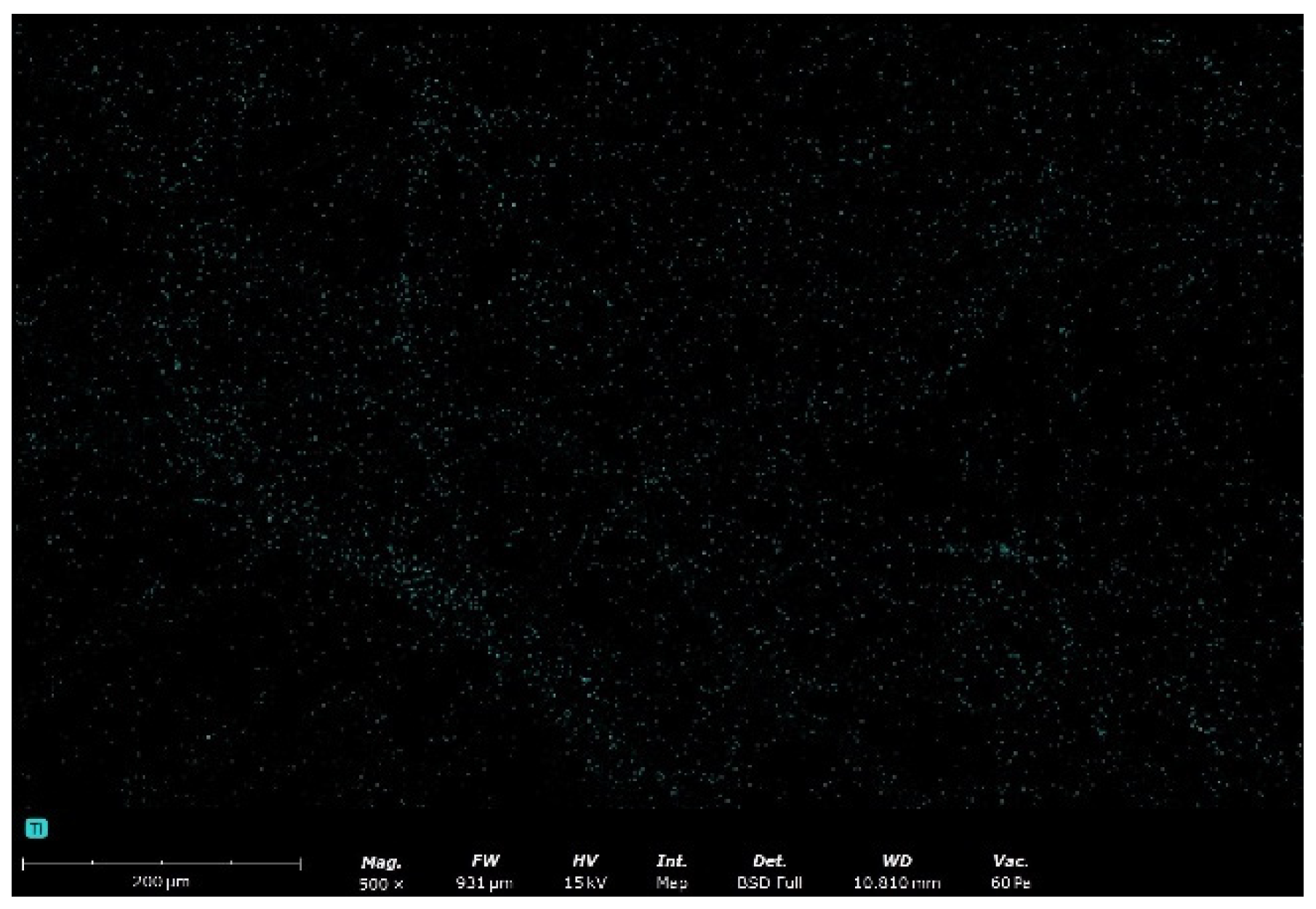

3.1. Scanning Electron Microscopy – SEM/EDS

3.2. Antimicrobial activity studies

- A – the number of cells in flasks containing modified nonwovens after 1 and 24 hours of contact;

- C – the number of cells in flasks with modified nonwovens after 1 and 24 hours of incubation.

4. Conclusions

References

- Kraemer SA, Ramachandran A, Perron GG., Antibiotic Pollution in the Environment: From Microbial Ecology to Public Policy. Microorganisms. 2019 Jun 22;7(6):180. PMID: 31234491; PMCID: PMC6616856. [CrossRef]

- Edberg SC, Rice EW, Karlin RJ, Allen MJ., Escherichia coli: the best biological drinking water indicator for public health protection. Symp Ser Soc Appl Microbiol. 2000; (29): 106S-116S. PMID: 10880185. [CrossRef]

- Leclerc H, Mossel DA, Edberg SC, Struijk CB., Advances in the bacteriology of the coliform group: their suitability as markers of microbial water safety. Annu Rev Microbiol. 2001; 55:201-34. PMID: 11544354. [CrossRef]

- Olańczuk-Neyman, K., Sokołowska A., Bakterie i wirusy w wodzie wodociągowej. Inżynieria i Ochrona Środowiska, 2004, 7(3/4), 259-276.

- Plachta, J., Ranke-Rybicka, B., Wichrowska B., Zycinski, D., Występowanie organizmów wodnych w wodociągach i wynikające stąd problemy dezynfekcji wody do picia. Cześć I. Roczniki Państwowego Zakładu Higieny, 1992, 43(1), 95-100.

- Sobieraj-Garbiak, I. A., Drożdżyńska, M., Wybrane zakażenia bakteryjne–nieuniknione zagrożenia zdrowia i życia człowieka. Pomeranian Journal of Life Sciences, 2015 61(1), 99-107.

- Kim S., Aga D.A., Potential Ecological and Human Health Impacts of Antibiotics and Antibiotic-Resistant Bacteria from Wastewater Treatment Plants, Journal of Toxicology and Environmental Health, Part B:Critical Reviews, 2007 10:8, 559-573. [CrossRef]

- Jahan, I., Zhang, L. Natural Polymer-Based Electrospun Nanofibrous Membranes for Wastewater Treatment: A Review. J Polym Environ 30, 1709–1729, 2022. [CrossRef]

- Brzezińska, A. Emisja zanieczyszczeń z przelewów burzowych w aspekcie wpływu na odbiornik. Inżynieria Ekologiczna, 2016, (48), 17-27.

- Adams J., Whitfield E., Lemley D., 4.16 - Phytoplankton/Seagrass Response to Management Interventions in Eutrophic Estuaries, Academic Press, 2024, Pages 445-473, ISBN 9780323910422. [CrossRef]

- Kesari, K.K., Soni, R., Jamal, Q.M.S. et al. Wastewater Treatment and Reuse: a Review of its Applications and Health Implications. Water Air Soil Pollut 232, 208, 2021. [CrossRef]

- Sundayi Sambaza S., Naicker N., Contribution of wastewater to antimicrobial resistance: A review article, Journal of Global Antimicrobial Resistance, Volume 34, 2023, Pages 23-29, ISSN 2213-7165. [CrossRef]

- Vymazal J., Removal of nutrients in various types of constructed wetlands, Science of The Total Environment, Volume 380, Issues 1–3, 2007, Pages 48-65, ISSN 0048-9697. [CrossRef]

- Li, X., Tabil, L.G. & Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J Polym Environ 15, 25–33, 2007. [CrossRef]

- Ibrahim, M.; Nawaz, M.H.; Rout, P.R.; Lim, J.-W.; Mainali, B.; Shahid, M.K. Advances in Produced Water Treatment Technologies: An In-Depth Exploration with an Emphasis on Membrane-Based Systems and Future Perspectives. Water 2023, 15, 2980. [CrossRef]

- Khraisheh, M.; Elhenawy, S.; AlMomani, F.; Al-Ghouti, M.; Hassan, M.K.; Hameed, B.H. Recent Progress on Nanomaterial-Based Membranes for Water Treatment. Membranes 2021, 11, 995. [CrossRef]

- Hoslett, J., Massara, T. M., Malamis, S., Ahmad, D., van den Boogaert, I., Katsou, E., Jouhara, H., Surface water filtration using granular media and membranes: A review. Science of the Total Environment, 2018, 639, 1268-1282. [CrossRef]

- Chen, H. Surface-Flow Constructed Treatment Wetlands for Pollutant Removal: Applications and Perspectives. Wetlands 31, 805–814 2011. [CrossRef]

- Jaspal D., Malviya A., Composites for wastewater purification: A review, Chemosphere, Volume 246, 2020, 125788, ISSN 0045-6535. [CrossRef]

- Ahmed MdJK, Ahmaruzzaman M., A review on potential usage of industrial waste materials for binding heavy metal ions from aqueous solutions. J Water Process Eng., 2016, 10:39 47. [CrossRef]

- Khoo R.Z., Ismail H., Chow W.S., Thermal and Morphological Properties of Poly (Lactic Acid)/Nanocellulose Nanocomposites, Procedia Chemistry, Volume 19, 2016, Pages 788-794, ISSN 1876-6196. [CrossRef]

- Mathew A. P., Oksman K., Sain, M. The effect of morphology and chemical characteristics of cellulose reinforcements on the crystallinity of polylactic acid. Journal of Applied Polymer Science, 101(1), 2006, 300-310. [CrossRef]

- Gzyra-Jagieła, K.; Sulak, K.; Draczyński, Z.; Podzimek, S.; Gałecki, S.; Jagodzińska, S.; Borkowski, D. Modification of Poly(lactic acid) by the Plasticization for Application in the Packaging Industry. Polymers 2021, 13, 3651. [CrossRef]

- Murariu, Marius, and Philippe Dubois. “PLA composites: From production to properties.” Advanced drug delivery reviews 107, 2016, 17-46. [CrossRef]

- Kumar Trivedi A., Gupta M.K., Singh H., PLA based biocomposites for sustainable products: A review, Advanced Industrial and Engineering Polymer Research, Volume 6, Issue 4, 2023, Pages 382-395, ISSN 2542-5048. [CrossRef]

- Warheit, D.B.; Webb, T.R.; Reed, K.L.; Frerichs, S.; Sayes, C.M. Pulmonary toxicity study in rats with three forms of ultrafine-TiO2 particles: differential responses related to surface properties. Toxicology 2007, 230, 90–104. [CrossRef]

- Pryliński, M.; Limanowska-Shaw, H. Właściwości tytanu i problem nadwrażliwości na ten metal. Implantoprotetyka 2007, 4, 50-52.

- Mazur, M.; Sieradzka, K.; Kaczmarek, D.; Domaradzki, J.; Wojcieszak, D.; Domanowski, P.; Prociów, E. Investigation of physicochemical and tribological properties of transparent oxide semiconducting thin films based on Ti-V oxides. Materials Science-Poland 2013, 31, 434-445. [CrossRef]

- Borkowski, D.; Krucińska, I.; Draczyński, Z. Preparation of Nanocomposite Alginate Fibers Modified with Titanium Dioxide and Zinc Oxide. Polymers 2020, 12, 1040. [CrossRef]

- Ye Z., Kong L., Chen F., Chen Z., Lin Y., Liu Ch., A comparative study of photocatalytic activity of ZnS photocatalyst for degradation of various dyes, Optik, Volume 164, 2018, Pages 345-354,ISSN 0030-4026. [CrossRef]

- Xu, X.; Li, S.; Chen, J.; Cai, S.; Long, Z.; Fang, X. Zasady projektowania i inżynieria materiałowa ZnS dla urządzeń optoelektronicznych i katalizy. Adv. Funct. Mater. 2018, 28. [CrossRef]

- Malarkodi, C., Rajeshkumar, S., Paulkumar, K., Vanaja, M., Gnanajobitha, G., Annadurai, G.,Biosynthesis and Antimicrobial Activity of Semiconductor Nanoparticles against Oral Pathogens, Bioinorganic Chemistry and Applications, 2014, 347167, 10 pages, 2014. [CrossRef]

- Mahendra Rai, Alka Yadav, Aniket Gade, Silver nanoparticles as a new generation of antimicrobials, Biotechnology Advances, Volume 27, Issue 1, 2009, Pages 76-83, ISSN 0734-9750. [CrossRef]

- Duran N, Marcarto PD, De Souza GIH, Alves OL, Esposito E. Antibacterial effect of silver nanoparticles produced by fungal process on textile fabrics and their effluent treatment. J Biomed Nanotechnol 2007;3:203–8. [CrossRef]

- ISO 20743:2021, Textiles — Determination of antibacterial activity of textile products.

| Eschericha coli | Staphylococcus aureus | |||

|---|---|---|---|---|

| log reduction after 1h |

log reduction after 24h |

log reduction after 1h |

log reduction after 24h |

|

| PLA | 0,05 | -0.92 | 1.73 | 1.85 |

| PLA + 1.5% ZnS | 0.28 | 4.23 | 1.46 | 5.50 |

| PLA + 3% ZnS | 0.48 | 4.82 | 1.48 | 3.74 |

| PLA + 4.5% ZnS | 0.35 | 1.94 | 1.24 | 3.80 |

| PLA + 1.5% TiO2 | 0.67 | -1.21 | 1.17 | 1.89 |

| PLA + 3% TiO2 | 0.50 | 2.69 | 1.58 | 3.29 |

| PLA + 4.5% TiO2 | 0.86 | 0.04 | 1.71 | 3.90 |

| PLA + 1.5% Ag | 4.04 | 4.24 | 1.24 | 5.52 |

| PLA + 3% Ag | 3.67 | 4.89 | 1.87 | 5.45 |

| PLA + 4.5% Ag | 4.04 | 4.24 | 1.26 | 5.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).