1. Introduction

Polyethylene (PE) stands as the predominant plastic in today’s market, accounting for 70% of the global plastic commodity market share [

1,

2,

3,

4]. As one of the five major synthetic resins, it boasts the largest production capacity and highest import volume among such materials in China [

5,

6,

7]. Polyethylene serves as a widely utilized and cost-effective general-purpose plastic due to its exceptional malleability, low melting temperature, and excellent fluidity making it well-suited for a wide range of polymer material forming and processing techniques [

8,

9]. Presently, there exists a diverse array of PE resin options to choose from including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), medium-density polyethylene (MDPE), high-density polyethylene (HDPE) and ultra-high molecular weight polyethylene (UHMW- PE) — all enjoying significant popularity.

XLPE is a polymer material with high molecular weight that has undergone cross-linking of its polyethylene structure through chemical or physical methods. Polyethylene, widely used in packaging, piping, and cabling across various industries, has limited stability in high-temperature, high-pressure, and chemical environments [

10]. To address these limitations, scientists have developed cross-linked polyethylene to significantly enhance the material’s heat resistance, strength, and chemical stability through the cross-linking process. As a result, cross-linked polyethylene has found extensive applications in construction for plumbing systems due to its improved resistance to hot water and chemicals; water supply systems for its flexibility and corrosion resistance; radiant floor heating systems (underfloor heating) for its durability under varying temperatures; cable insulation for telecommunications and power distribution networks due to enhanced electrical properties; as well as medical applications owing to its biological compatibility and sterilization ability [

11].

The research on XLPE is of significant scientific and societal importance, primarily manifested in the following seven aspects. Firstly, in terms of enhancing material performance, the process of cross-linking significantly improves the properties of original polyethylene, including high temperature resistance, high pressure resistance, chemical corrosion resistance, and aging resistance. These enhancements enable the application of XLPE in extreme environments and expand its utility across various fields. Secondly, with regard to industrial applications, the use of XLPE in sectors such as construction, hydraulic engineering, energy production, cable manufacturing [

12] and medical technology effectively enhances product safety standards while also improving reliability and service life. This provides a dependable material foundation for industrial development [

13,

14,

15,

16]. Thirdly, XLPE is noted for its favorable recyclability from an environmental sustainability perspective. Research efforts aimed at developing more environmentally friendly synthetic processes and recycling technologies can propel the plastics industry towards sustainable practices by optimizing material life cycle management to reduce environmental impact [

17,

18,

19,

20,

21]. The fourth is to meet market demand. With the acceleration of global urbanization and the improvement of living standards, the demand for high-performance durable materials is increasing. Research into XLPE can help meet this growing need by providing essential support for building modern societies. Fifthly is scientific research & technological innovation: The study of XLPE spans multiple disciplines including materials science, chemical engineering and physics. Through this research progress can be made within these related fields promoting new material development as well as technological innovation [

22,

23,

24,

25]. The fifth aspect pertains to economic development: the production and application chain linked to XLPE encompasses all stages of the process, from raw material supply through manufacturing to sales, thereby fostering economic growth and generating employment opportunities in related industries [

26,

27,

28]. Lastly, we have market competitiveness: In today’s global marketplace research & development focused on XLPE has potential to enhance a country or region’s competitive advantage within modern materials sector thereby driving exportation of related products [

29,

30,

31,

32].

In conclusion, the research on cross-linked polyethylene holds immense significance for the advancement of science and technology, while also playing a pivotal role in fostering economic and social development as well as environmental protection. Further research and development are anticipated to augment the potential value of this material in the future.

2. Classification and Properties of Polyethylene Resins

PE is one of the five major synthetic resins, and even is the most productive and imported variety of synthetic resins in China. PE is a widely used and inexpensive general-purpose plastic. Due to its high plasticity, low melting temperature and good fluidity, it is suitable for most forming and processing methods of high molecular polymer materials.

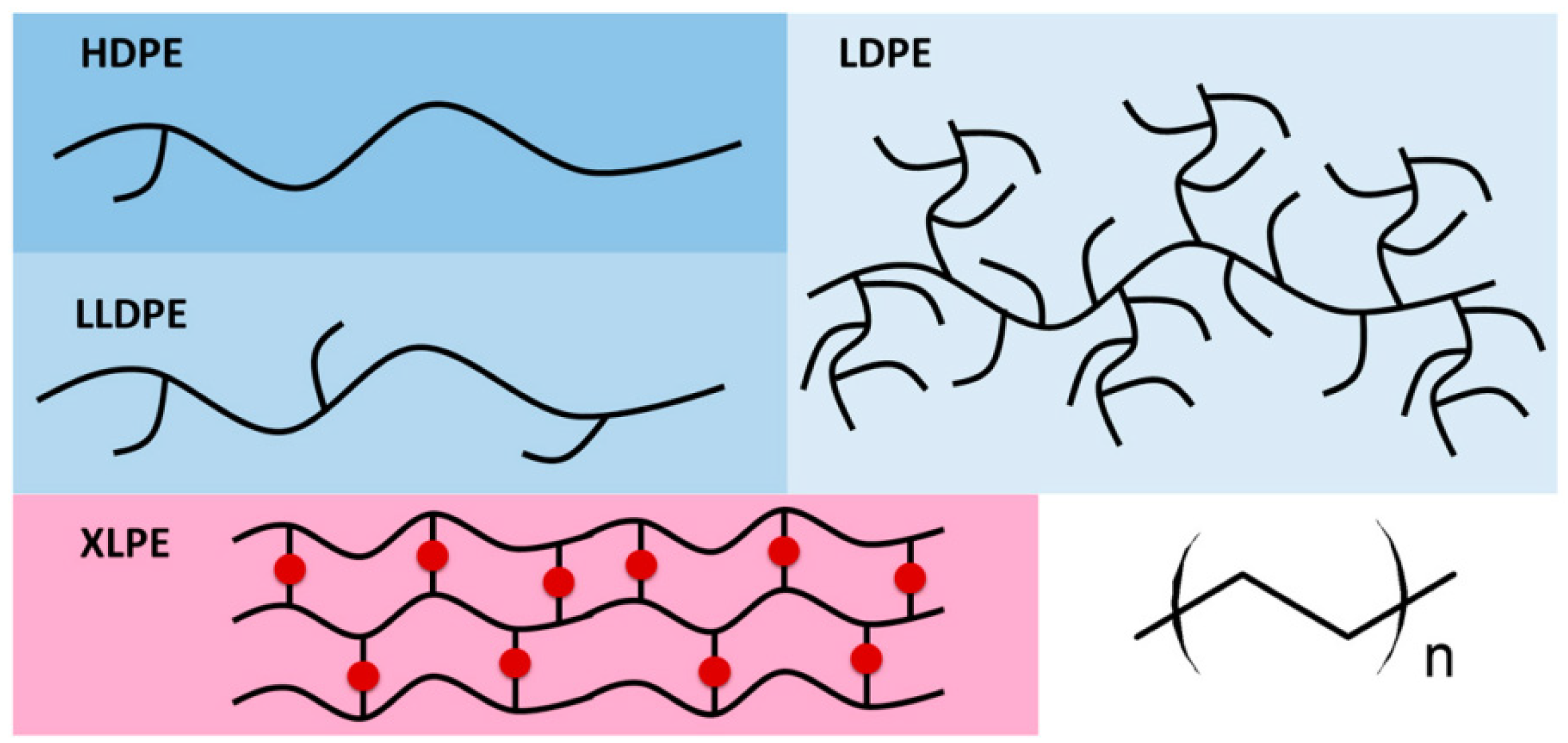

As illustrated in

Figure 1, polyethylene can be divided into HDPE, LDPE, and LLDPE, based on the method of polymerization, molecular weight, and chain structure [

33,

34]. I will introduce these three types of polyethylene from the perspectives of structure, features, and applications. Polyethylene is a high molecular weight compound synthesized through the polymerization of ethylene monomers, characterized by its molecular structure predominantly consisting of repeating units of “-CH

2-”. Various types of polyethylene exhibit distinct molecular architectures. HDPE features linear molecular chains with minimal branching, resulting in a tightly packed arrangement and elevated crystallization [

35]. In contrast, LDPE possesses elongated branches that lead to a less compact molecular configuration and consequently lower crystallization. LLDPE, while also exhibiting branching, has shorter and uniformly distributed branches, yielding an intermediate level of crystallization between HDPE and LDPE.

HDPE is known for its rigidity, hardness, and mechanical strength, as well as excellent heat and cold resistance [

36]. In contrast, LDPE offers remarkable flexibility, outstanding elongation properties, transparency, cold resistance, and great processability [

37,

38,

39]. LLDPE is recognized for its strong environmental stress crack resistance, high impact strength, and superb heat sealing capabilities [

40]. Ultra-high molecular weight polyethylene (UHMWPE) is distinguished by exceptional wear resistance, impact resilience, and chemical stability [

41].

Different types of polyethylene have widespread applications in many fields due to their unique physical and chemical properties. In the packaging industry, due to its good mechanical strength and chemical resistance, HDPE is commonly used to produce various containers, caps, bottles, etc. ; LDPE is commonly used to produce plastic bags, freshness bags, bubble wrap, etc. due to its good flexibility and transparency; and LLDPE is particularly suitable for producing high-strength, high-toughness film products, such as packaging films, due to its excellent resistance to environmental stress cracking and impact strength [

40]. In agriculture, HDPE film is valued for its mechanical strength and durability, allowing it to withstand significant external pressures and environmental conditions. This makes it ideal for crop cultivation areas requiring prolonged coverage. Conversely, LDPE offers flexibility and ductility, enabling it to closely adhere to the soil surface and effectively block water and wind infiltration, creating an optimal environment for plant growth [

42]. Additionally, LLDPE film resists environmental stress cracking well, maintaining structural integrity under challenging conditions while minimizing soil erosion and reducing crop damage [

43]. In the construction industry, HDPE pipes are commonly used for drainage, firefighting, and gas delivery due to their corrosion resistance, wear resistance, low temperature tolerance, and easy installation [

44]. LDPE is suitable for certain waterproof materials; its coating or film can be created by mixing it with specific additives. LLDPE exhibits exceptional resistance to environmental stress cracking, rendering it an optimal material for pipe and cable applications. Furthermore, LLDPE waterproofing membranes are employed in roofing and subterranean waterproofing projects due to their superior weather resistance, chemical stability, and flexibility [

33,

42,

45].

Cross-linking is a process in which linear or branched polymer chains are chemically or physically interconnected to form covalent bonds, resulting in the transformation of the original linear structure into a network structure and thereby significantly augmenting a spectrum of physical and chemical properties [

46,

47].

Figure 1.

Schematic representation of the structure of varying types of PEs [

48].

Figure 1.

Schematic representation of the structure of varying types of PEs [

48].

3. Advantages of Cross-linked Polyethylene Materials

XLPE is derived from linear or branched PE resins by treating with chemical or physical cross-linking modifications [

49]. A high molecular weight PE with a linear molecular structure experiences decreased VDM (Van der Waals’ force) between its linear molecules at a higher temperature (e.g., its temperature of critical deformation is approximately 55°C), leading to deformation of materials. In XLPE, cross-linking bonds are formed between single polymer chains to replace the original weak VDM, creating a stable network structure among molecules. This cross-linking process transforms thermoplastic polyethylene into thermosetting cross-linked polyethylene [

50], resulting in some enhanced properties for XLPE [

51,

52,

53].

XLPE exhibits an enhanced mechanical strength as well as a superior heat resistance, an improved resistance to chemicals, and even a better insulating property. Firstly, in regard to heat tolerance, the interconnected three-dimensional structure endows XLPE with an exceptional resilience, and its deterioration and charring occur only at temperatures above 300 °C. Its sustained operating temperature can reach 90 °C with a thermal longevity extending up to 40 years. Secondly, in terms of insulating performance, XLPE retains the favorable insulating traits of PE while augmenting its insulating capacity. The dielectric loss tangent remains minimal regardless of temperature fluctuations. Regarding mechanical attributes [

54], the formation of fresh chemical bonds among large molecules results in heightened hardness, rigidity, wear-resistance [

55], and impact-resistance within XLPE, countering PE’s susceptibility to cracking under environmental strain. Finally, in relation to chemical endurance, XLPE is insoluble in common solvents, bolstering PE solvent and chemical resilience while exhibiting robust immunity against acids, alkali and oils. Its combustion by-products primarily comprise water and carbon dioxide, minimizing environmental harm and in compliance with contemporary fire safety standards.

4. Cross-linking Methods of Polyethylene

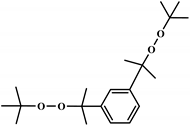

Three primary cross-linking methods have been successfully developed to achieve industrial-scale cross-linked polyethylene: (1) chemical cross-linking using peroxides (e.g., DCP (Dicumyl peroxide) and DTBP (Di-tert-butyl hydrogen peroxide)); (2) chemical cross-linking employing silicone coupling agents (e.g., A171 (silane-ethenyltrimethoxy) and A151 (triethoxyvinylsilane)); and (3) physical cross-linking of polyethylene materials through irradiation with high-energy rays (e.g., electron beam and gamma ray of

60Co). Among these, irradiation cross-linked represents a form of physical cross-linking that enables polyethylene materials to undergo the process without the introduction of large quantities of low-molecular-weight chemicals, rendering it environmentally friendly and non-toxic. This characteristic is expected to significantly broaden the application scope of irradiation cross-linked polyethylene materials. Additionally, irradiation cross-linked offers advantages such as high efficiency, uniformity in cross-linked, and a high degree of cross-linked, all contributing to substantial enhancements in the performance stability of irradiation cross-linked polyethylene materials [

56,

57].

Table 1 describes the advantages, disadvantages and applications of four cross-linking methods: peroxide cross-linking, silica gel cross-linking, irradiation cross-linking and purple cross-linking.

4.1. Peroxide Cross-Linking

In contemporary industrial production, peroxide cross-linking is among the most prevalent methods for achieving cross-linked PE-based materials [

58,

59]. This process involves the introduction of a specific quantity of peroxide and antioxidant into the PE matrix, followed by treating under suitable temperature and pressure conditions to realize the transformation of linear or branched structure into cross-linked structure. Organic peroxide cross-linking agents represent a category of organic compounds characterized by the presence of an oxygen-oxygen (O-O) bond [

60,

61,

62,

63]. These compounds exhibit a tendency to decompose under external conditions such as elevated temperatures or exposure to light, resulting in the generation of free radicals. The high reactivity of these free radicals enables them to initiate cross-linking reactions among polymer molecules, thereby converting linear or slightly branched macro-molecular structures into three-dimensional network architectures and enhancing various properties of the material. The organic peroxides produced within the chemical industry primarily function as polymerization initiators and catalysts for synthetic resins [

64,

65]. In the field of polymer materials, it can serve as radical polymerization initiator, grafting reaction catalyst, cross-linking agent for rubber and plastics, curing agent for unsaturated polyesters, and regulator of molecular weight and distribution in the preparation of high-quality polypropylene suitable for spinning [

66,

67,

68].

Table 2 describes the advantages, disadvantages and applications of the three peroxide cross-linkers (i.e., DCP, DTBP and BIBP).

The peroxide cross-linking process exhibits some advantages over other methods due to the requirement for premixed polyethylene and cross-linking agents prior to extrusion through an extruding machine, resulting in significantly enhanced uniformity and depth of cross-linked products [

69,

70,

71]. In comparison with silicone cross-linking, the peroxide process extends product storage time and reduces production costs [

72]. Furthermore, the utilization of a plunger extruding machine in the peroxide cross-linking process eliminates the need for a post-heating device, leading to a more compact equipment structure and reduced production costs; however, this may limit production efficiency. When conducting peroxide cross-linking, it is crucial to maintain a controlled temperature to prevent carbonation of the cross-linked material due to exceeding the decomposition temperature of the peroxide [

73,

74]. Additionally, it is essential to regulate the extruding machine speed and utilize specialized extruding machine heads and high-pressure connection channels, which may pose limitations on application for medium-sized and small enterprises. Sun et al. developed a novel organic peroxide, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (Bi25) , which effectively initiates the cross-linking process of polyethylene (Bi25-XLPE) [

64]. Bi25-XLPE is characterized by the absence of by-product gases and an extended vulcanization duration. Its non-porous nature, coupled with a higher cross-linking density and crystallization, ensures that the physical and mechanical properties of Bi25-XLPE sheets comply with the insulation standards for 500 kV power cables. Furthermore, COMSOL has developed a 500 kV power cable model to validate the breakdown strength (reaching up to 61.66 kV/mm) and stability of Bi25-XLPE.

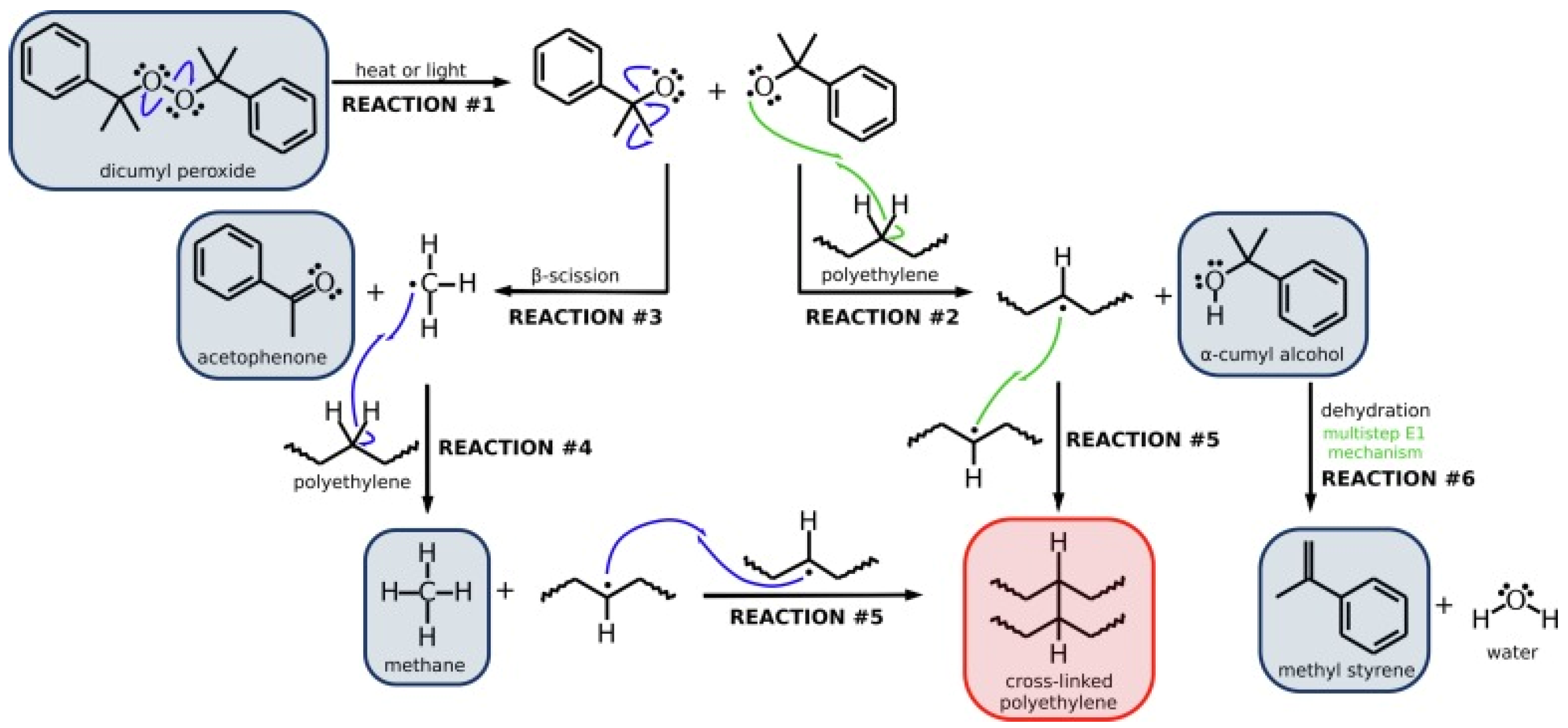

Figure 2 shows the reaction scheme and byproducts generated during DCP induced cross-linking procedure [

75,

76]. As

Figure 2 shows, the main steps in this process are: (1) Generation of free radicals: When PE and a peroxide cross-linking agent are mixed and melted under specific conditions, the peroxide decomposes at high temperatures to produce free radicals; (2) Hydrogen capture : The free radical attacks the PE macro-molecular chain, removing hydrogen atoms and generating a macro-molecular chain free radical; (3) Cross-linking: The highly reactive macro-molecular chain free radical of PE combines with another to form carbon-carbon bonds, resulting in a three-dimensional network structure that significantly enhances the mechanical properties and heat resistance of PE [

54,

77,

78,

79,

80]. Kang and Ha investigated the impact of various parameters, including temperature, shear rate, and cross-linking agent concentration, on the torque value and cross-linking reaction of HDPE that was cross-linked using 2,4-di-tert-butylperoxide [

44]. Their findings indicated that the effect of temperature was significantly more pronounced than that of shear rate. Elevated reaction temperatures facilitated the cross-linking process within the polymer matrix. Di et al. investigated the effects of varying concentrations of DCP on the cross-linking of LDPE. The findings indicated that as the concentration of the cross-linking agent increased, the degree of cross-linking in polyethylene initially rose before subsequently declining. Notably, when DCP content exceeded 1.0 wt%, a similar accumulation of polar space charges was observed. Furthermore, optimal rheological characteristics of processing properties for cross-linked polyethylene were noted within a DCP concentration range of 1.0-1.5 wt% [

81].

4.2. Silicone Cross-Linking

Silicone cross-linking is a chemical method used for the production of insulating materials. Silicone cross-linking is a chemical process that involves the interaction of silicone compounds with polymers under specific conditions to create a three-dimensional network structure material [

82]. This cross-linking technique significantly enhances the performance of materials, resulting in exceptional physical and chemical stability. Silicone cross-linked polyethylene usually exhibits outstanding physical properties, heat resistance, chemical resistance and excellent mechanical properties [

83,

84,

85,

86,

87,

88].

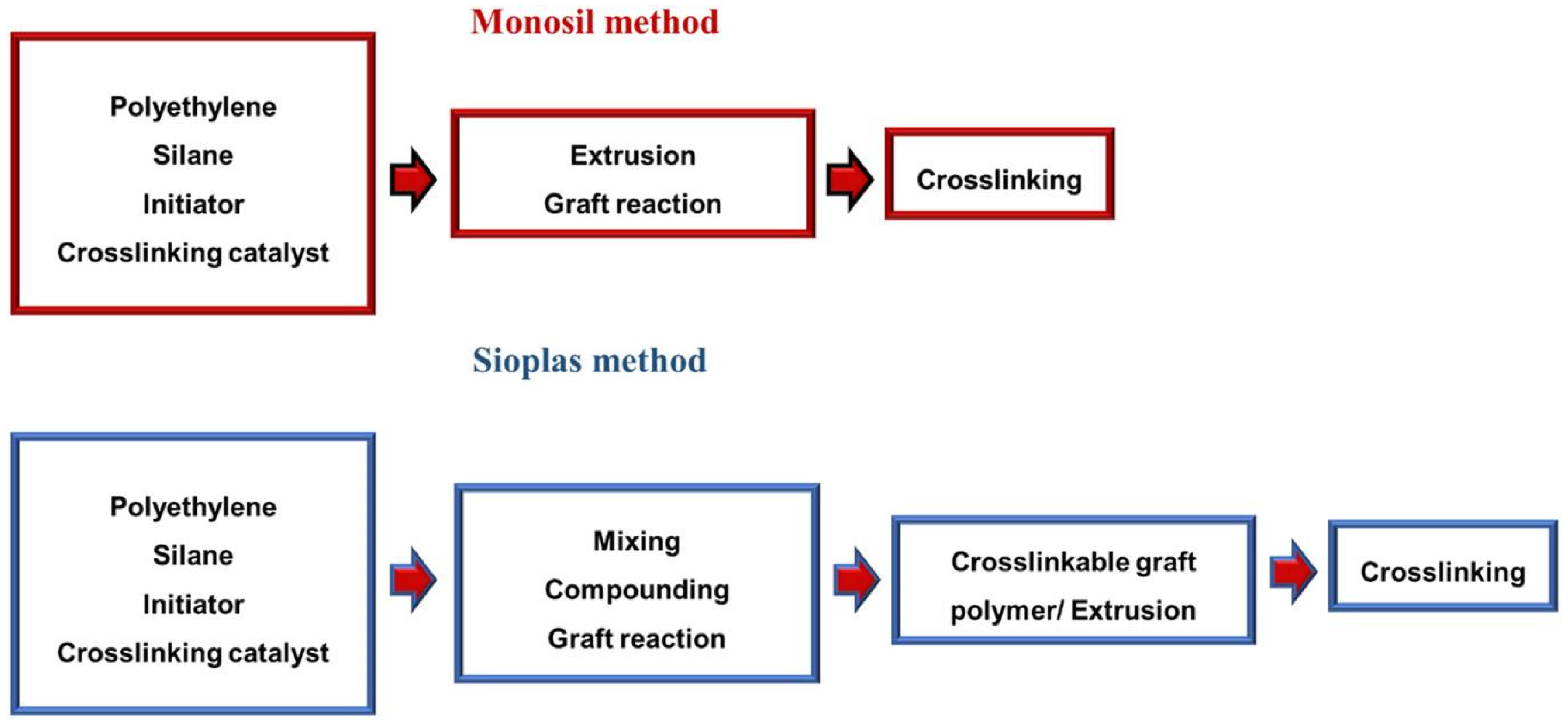

4.2.1. Sioplas Method

The two-step approach, as implied by its name, comprises of a pair of sequential processes. In the first step, peroxide serves as an initiator when PE molecules are exposed to silicone in a molten state. Under high temperature conditions, the peroxide acts as an initiator and decomposes into small molecular free radicals [

89]. These free radicals then combine with hydrogen atoms on the PE molecule to generate large molecular free radicals, which subsequently react with chemical bonds in the silicone. Subsequently, in the second step following this reaction, the linear structure of silicone transforms into a network structure through cross-linking reaction. During this process, water molecules replace silicone bonded to polymer chains via gaps within polymer molecules and undergo reactions with silicone bonded to polymer chains to form Si-O-Si cross-links.

The two-step approach is widely favored in low-voltage cable and small-scale production due to its ability to tailor products according to customer-specific requirements, minimal equipment demands, high insulation material grafting and cross-linked degree, simple process and low investment. However, this method has several drawbacks during the production process, such as susceptibility to impurity contamination, short product shelf life, premature cross-linking with air exposure, and they ultimately limit its applicability. Chen et al. conducted a comprehensive investigation into the thermal and mechanical properties of silicone-water cross-linked LLDPE in hot water, alongside an analysis of surfactant effects [

90]. Their findings indicated a reduction in crystallization, which was attributed to the increased concentration of silicone and the establishment of a silicone cross-linking network. Furthermore, variations in the silicone component’s content were found to significantly influence both tensile strength and elongation at break values.

4.2.2. Monosil Method

The one-step process has rapidly developed on the basis of the two-step process. Its basic principle is simple: to directly input basic materials into an extruding machine and produce electric wires and cables in a single step.

Figure 3 illustrates the procedural steps involved in one-step and two-step silane cross-linking. Compared to the two-step process, the one-step process offers numerous advantages, such as lower impurity levels and suitability for both low-voltage and medium-voltage cables. However, with advantages come disadvantages; this method demands high technical requirements and significant investment.

For example, BP (a British company) utilizes a hydrolysis type catalyst with high activity to yield an excellent performance of resulting cross-linked products. The quality of the produced goods depends on a key technology of the one-step process—grafting. A higher grafting rate leads to better product quality, while a lower rate results in inferior product quality [

91]. Yussuf et al. investigated the effects of varying silicone concentrations and the incorporation of nanoclay fillers on the degree of cross-linking, as well as the mechanical, thermal, rheological, and morphological properties [

85]. The findings indicated that an increase in silane concentration corresponded to a rise in gel content and degree of cross-linking. Notably, the gel content of XLPE containing MMT nanoclay reached an impressive 84%. Regarding mechanical properties, elevating the silicone concentration from zero to 2.0 phr resulted in an approximate increase of 2 MPa in tensile strength for native LLDPE; furthermore, incorporating MMT nanoclay into XLPE enhanced its tensile strength by approximately 3 MPa compared to pure LLDPE.

4.2.3. Precipitation Polymerization Approach

The precipitation polymerization method was developed by leveraging the advantages of both the two-step and one-step methods [

92]. In the 1980s, international researchers aimed to produce cross-linked polyethylene by directly introducing vinyl silicone into a high-pressure reactor. This approach entails a random precipitation polymerization reaction of ethylene and silicone units within the high-pressure reactor, without the use of peroxides during experimentation to prevent bubble formation, as no volatile substances are generated during the reaction [

93]. Similar to both the two-step and one-step methods, this precipitation polymerization technique utilizes silicone as its monomer. However, it diverges in process technology by integrating silicone directly into the monomer polymerization process instead of grafting it onto a silicone chain. Consequently, the resulting co-polymer is facile to process and exhibits wet-curing properties [

94].

The cross-linked polyethylene produced using this advanced and unique precipitation polymerization method offers numerous benefits such as high stability, prolonged durability, ease of shaping and shortened production time. The cross-linked material ensures high cleanliness while mitigating pollution issues stemming from peroxide residues during grafting [

95]. Notably, with this approach, injecting silicone co-polymer monomers once achieves uniform distribution of cross-linked crystals with lower required silicone content compared to that in silicone grafting compounds—resulting in improved product performance especially in terms of electrical properties [

96]. It can be utilized as an insulating material with a voltage rating of up to 33kV, and possesses inherent flame-retardant properties, rendering it suitable for use as a flame-retardant sheath [

97]. Camalov et al. investigated the breakdown strength of XLPE samples incorporating peroxides and silicone, revealing that at elevated voltage rise rates, both sample types exhibited enhanced breakdown strength values [

98]. Notably, the maximum increases in breakdown strength for the two XLPE samples were 17.96% and 23.80%, respectively. Additionally, the findings indicated that the silicone cross-linked sample consistently demonstrated superior breakdown strength across all tested conditions.

4.3. Irradiation Cross-Linking

Irradiation cross-linking, as a commonly used method of cross-linking, was first proposed by the Dole team in experiments with heavy water reactors. Subsequently, with further research, irradiation cross-linking technology of polyethylene has been primarily applied in the production of electric wires and cables, pipes, foam materials, films and gel materials [

99]. Cassidy et al. investigated the effects of gamma irradiation on HDPE [

100]. They examined the increase in intensity, noting that the material becomes brittle at a radiation dose of 60 kGy. Additionally, they analyzed the enhancement in ultimate strength, reduction in elongation, and increase in Rockwell hardness. Alsabbagh et al. conducted a comprehensive investigation into the effects of gamma irradiation on the mechanical and structural properties of polylactic acid (PLA) and HDPE [

101]. The samples were subjected to irradiation using a

60Co gamma-irradiation facility under ambient conditions, within a dose range of 0 to 175 kGy. The experimental findings revealed that gamma irradiation significantly influenced polymer properties through mechanisms such as cross-linking, chain scission, and oxidative degradation.

During the process of irradiation cross-linking, free radicals in polymers are generated through the irradiation of high-energy rays such as electron beams and neutron beams. In laboratory experiments, the rays are typically produced by a 60Co isotope irradiation source [

43]. In industrial settings, polymer cross-linking is commonly achieved using electron beams generated by large-scale electron accelerators [

102]. The principle of irradiation cross-linking [

103] is as follows: (1) High-energy irradiation acts on the bond energy of PE, breaking the C-H bonds and C-C bonds in PE to form free radicals and hydrogen atoms; (2) Hydrogen atoms are energized during the irradiation process and react with other C-H bonds and C-C bonds to generate secondary free radicals. In this process, hydrogen atoms undergo transformations and exist in a different state; (3) When the free radicals generated by irradiation encounter the secondary free radicals, they undergo cross-linked reactions. The issue of sensitization irradiation in polyethylene is currently a primary focus of research in the production of cross-linked polyethylene using the irradiation cross-linking method. Addressing this concern typically involves incorporating sensitizing agent or altering the irradiation atmosphere within the polyethylene [

104,

105]. Commonly used sensitizing agent include 2, 4-dimethyl-2,4-pentanediol acetate and trimethylol propane tris-(3-hydroxypropyl) acid ester while common sensitizing agent options include silicon tetrachloride, carbon tetrachloride, sodium fluoride and carbon black.

The use of the irradiation cross-linking method for cross-linked polyethylene offers several advantages [

106]: separate processes for cross-linking and extrusion allow for easy control over product quality, high production efficiency and low waste rates; no additional free radical initiator is required during the cross-linking process, maintaining material cleanliness and enhancing electrical properties [

107]; it is particularly suitable for producing small-sectioned, thin-walled insulated cables that are challenging to cross-link using chemical methods. This method avoids high-temperature peroxide-based cross-linking by utilizing shaping processing on a standard extruding machine followed by water-boiling cross-linking in warm water. As a result, degree of crystallization and density remain essentially unchanged [

108]. However, irradiation cross-linking also presents some drawbacks such as the requirement of an increased electron beam acceleration voltage for thick materials, the requirement of rotation or employing multiple electron beams for circular objects like electrical wires and cables to achieve uniform irradiation, substantial initial investment costs, complex operational and maintenance technology requirements and stringent safety protection measures during operation.

4.4. Ultraviolet Cross-Linking

The UV irradiation cross-linking technology represents a newly developed technique, and it provides an effective technical pathway for upgrading and replacing traditional products in the cable industry. Its application prospects are extensive, particularly in the manufacturing of various high-voltage cross-linked polyethylene insulated cable products, where UV cross-linking technology offers irreplaceable advantages [

109]. Zhang et al. synthesized functionalized SiO

2/XLPE nanocomposites by chemically grafting an auxiliary crosslinking agent onto the surface of nanoscale silica [

110]. Trihydroxymethyltrimethylolpropane triacrylate (TMPTA) served as an effective auxiliary crosslinking agent for polyethylene, which was successfully grafted onto the surface of nanoscale silica through a chemical reaction involving the thiol group of the coupling agent between sulfur silane and 3-mercaptopropyl trimethoxysilane (MPTMS).The findings indicate that the polar groups present on the surface of modified nanoscale silica inhibit the proliferation of electrical trees, while simultaneously introducing deep traps that hinder charge injection, thereby significantly enhancing both resistance and dielectric breakdown strength in electrical trees. This study proposes a strategy for developing high-resistance cross-linked polyethylene materials through the integration of surface functionalization and nanodielectric technology. Zhao et al. synthesized XLPE grafted with maleic anhydride (MAH) (denoted as XLPE-g-MAH) utilizing a photocatalyst under ultraviolet irradiation, and conducted a systematic investigation of its dielectric properties in comparison to pure XLPE [

111]. The fundamental mechanism underlying space charge suppression was elucidated through the analysis of the trapping energy level distribution within XLPE-g-MAH, which accounted for the observed enhancement in electrical breakdown performance.

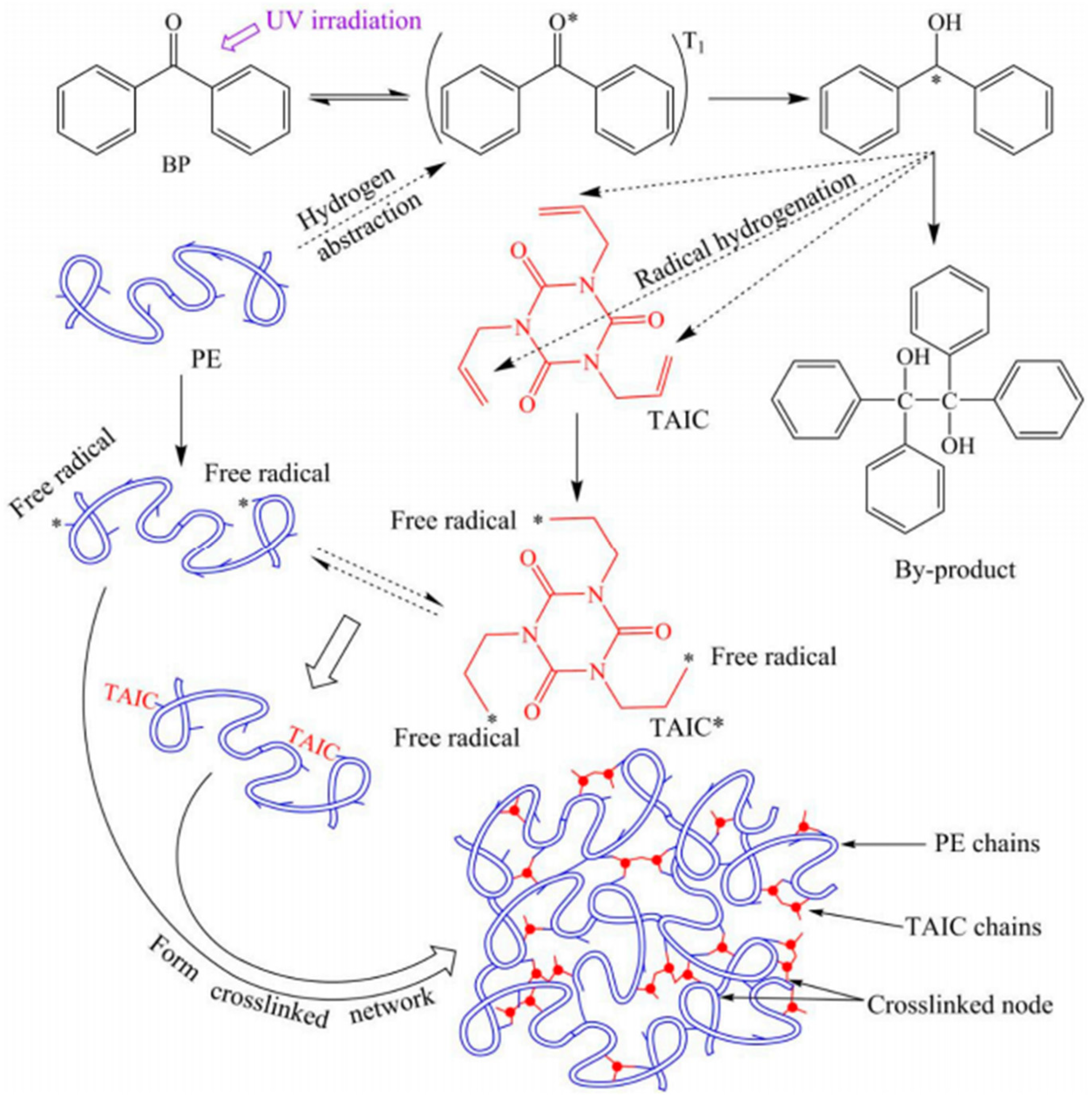

Previously, the utilization of photosensitive chemical cross-linking techniques entailed the activation of a photo-sensitizer by ultraviolet light to induce cross-linking reaction in polyethylene materials [

112]. The UV cross-linkable photo-initiator system comprises two key components: photo-initiators and cross-linking agents [

113,

114,

115]. Photo-initiators are compounds that selectively absorb UV light energy to generate free radicals. They can be categorized into cleavage-type photo-initiators and hydrogen abstraction-type photo-initiators. The role of the cross-linking agent is primarily manifested in three aspects: enhancing the quantum efficiency of the photo-initiator, accelerating the rate of cross-linking reaction, and improving the uniformity of cross-linking [

116]. cross-linking agents typically contain two or more unsaturated structures and mainly participate in UV cross-linking reactions by forming allylic free radicals [

117,

118]. In contrast, monomers or homo-polymer forms of auxiliary cross-linking agents demonstrate a greater capacity to participate in the formation of polyethylene cross-linked nodes, thereby increasing the likelihood of cross-linking and enhancing photon-induced cross-linking efficiency [

118]. Ye Lei et al. examined the thermodynamic properties of flame-retardant materials based on UV cross-linked polyethylene vinyl acetate (EVA), demonstrating enhancements in thermal stability and mechanical strength in these samples [

119].

The lack of progress in UV cross-linking is primarily due to the utilization of low-energy UV radiation as the irradiation source and the inherent technical limitations [

120]. The constraints of UV cross-linking technology can be observed from two perspectives. Firstly, with regard to penetration power, UV light has limited the depth of penetration and is only suitable for thin and low-voltage samples; it cannot uniformly cross-link thicker samples. Secondly, in terms of speed, the cross-linking process with UV light is slow and often fails to meet industrial production requirements [

121,

122].

Cross-linked polyethylene insulated cables have a wide range of potential applications in the high-voltage and extra-high-voltage fields. The ultraviolet (UV) light-induced cross-linking technology for cross-linked polyethylene shows promise in addressing the limitations of peroxide cross-linking technology in high-voltage applications, enabling the production of long-length, high-voltage grade insulated cables. The UV light-induced cross-linking technology offers several advantages for manufacturing high-voltage cross-linked polyethylene cables: (1) Rapid production speed without causing insulation defects [

111,

123]: By absorbing specific wavelengths of UV light through a photo-initiator, polymerization reactions can occur within an extremely short time frame [

124]. Additionally, the polyethylene-based material containing a photo-initiator system undergoes cross-linking reactions only under UV light irradiation. As a result, materials trapped in mold dead corners during cable insulation extrusion do not form any cross-linking defects; (2) Reduced material cost and lower production energy consumption; (3) Minimal infrastructure investment: The mixing process of the photo-initiator system (non-thermally sensitive materials) can be synchronized with the melt filtration process used to produce high-purity cable raw materials for high-pressure cables, thereby eliminating the need to introduce DCP as a separate peroxide chemical-cross-linking agent via liquid-phase diffusion [

121]. Therefore, UV light-induced cross-linking technology for cross-linked polyethylene is anticipated to meet the demand for long-length submarine cables at higher voltage levels while reducing equipment investment and production costs associated with these types of cables [

109].

In practical experiments and in the production of UV-cross-linked polyethylene, a fluid mixture comprising LDPE, photo-initiator, and auxiliary cross-linking agent is directly exposed to ultraviolet light above the melting point temperature [

125,

126]. This process facilitates the ultraviolet-induced molecular cross-linking of polyethylene. The cross-linking mechanism (

Figure 4) can be delineated into three steps [

127,

128,

129]. Initially, during the chain initiation stage, the photo-initiator absorbs ultraviolet light and transitions from the ground state to the singlet excited state. It then undergoes inter-system crossing to form a triplet excited state and abstracts hydrogen atoms from both polyethylene and cross-linked agents to generate corresponding alkyl free radicals P· and T·. Subsequently, in the chain growth stage, molecules with chain free radicals P· and T· respectively bond with cross-linking agent molecules. Finally, during the chain termination stage, the longer chain free radicals are formed. Polyethylene molecules containing these chain free radicals undergo reactions such as bi-molecular coupling or bi-molecular disproportion termination to form various cross-linked structures by bonding together long macro-molecular chains of polyethylene. Without an auxiliary cross-linking agent, polyethylene macro-molecules can only form cross-linked nodes through the chemical bonds of their own free radicals.

4.5. Other Cross-Linking Methods for PE-Based Materials

4.5.1. Salt Cross-Linking/Ion Cross-Linking

Salt cross-linking, also known as ion cross-linking, has similar principles to silicone cross-linking, but it solves the problem of resin recycling compared to silicone cross-linking [

130]. This establishes a foundation for the future advancement of resin production technology. The fundamental principle of salt cross-linking involves grafting reactive functional groups onto the chemical bonds of the resin monomer PE, such as -COOH or -SO

3H. Zinc hydroxide is employed for neutralization, leading to the formation of ionic salt bridges along the molecular chain, such as -COOZn

2+OOC- or -SO

3HZn

2+O

3S-. This results in a transition from a linear to a network structure.

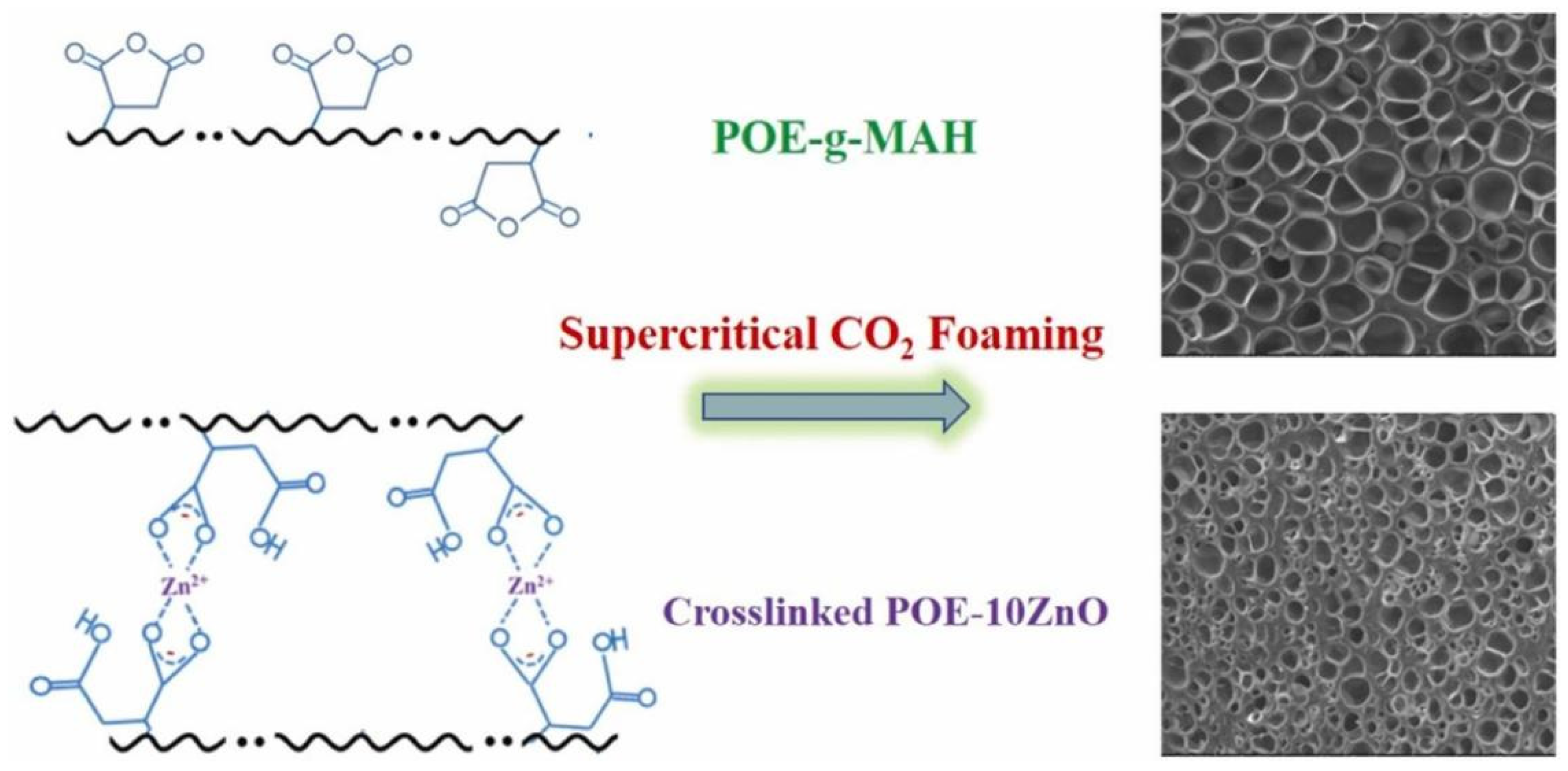

Figure 5 illustrates the successful synthesis of ionically cross-linked poly(ethylene oxide) (POE) via the incorporation of zinc oxide (ZnO) and stearic acid (StAc), resulting in a cross-linked POE that demonstrates improved tensile strength and enhanced anti-creep characteristics. Zhang et al. successfully grafted maleic anhydride (MAH) onto polyolefin elastomer (POE), resulting in POE-g-MAH, which was subsequently combined with ZnO and StAc to fabricate ionically cross-linked POE/ZnO composite materials through a straightforward melt mixing technique. The results showed that the POE-10ZnO foam exhibited good rebound resilience and high compressive strength [

131].

4.5.2. Azoic Cross-Linking

This method [

132]entails incorporating a azoic compound into PE and extruding it at a temperature below the decomposition point of the azoic compound. The extrusion objects then traverse through a high-temperature salt bath, where the azoic compound decomposes to generate free radicals, which in turn initiate cross-linking of PE. Azo compounds, such as aliphatic azo esters (2,2′-azobis [2-ethoxypropane]), are used as initiators for cross-linked PE. This technique is limited practical utility for plastics. Compounds featuring azobenzene motifs, frequently employed as initiators for free radical polymerization, exhibit a propensity for facile thermal degradation, photo-irradiation, or mechanical incorporation into polymers. Such derivatives containing azobenzene groups often function as macro-initiators in the synthesis of well-defined block co-polymers or the development of thermally degradable materials [

133].

5. Applications of Cross-Linked Polyethylene

Cross-linked polyethylene demonstrates superior mechanical properties, heat resistance, chemical resistance, and insulation compared to standard polyethylene. It is employed as an insulating material and coating for high-pressure and heat-resistant applications such as rockets, missiles, motors, transformers, among others. Furthermore, it is utilized in the production of heat-shrinkable tubing, various heat-resistant pipes and tubes, foam plastic products, corrosion-resistant chemical equipment components and containers, as well as flame-retardant building materials. The products of cross-linked polyethylene encompass pipes and cable materials. Currently, its most significant application areas lie within wires and cables, pipes and tubes, and foam plastics.

5.1. Wire and Cable Insulation Materials

In high-voltage cables, the electrical insulation performance is of paramount importance [

1,

13,

134,

135,

136]. The multiple layers of insulation surrounding typical high-voltage cables serve various crucial functions and possess important properties. The outer layer typically consists of polymers such as polyvinyl chloride or polyethylene [

137], providing excellent mechanical resistance at a low cost. As current is transmitted through high-voltage cables, the conductor temperature rises. Therefore, cross-linked polyethylene cables can transmit more power than non-cross-linked ones. Currently, XLPE, due to its simple extrusion manufacturing process and good electrical performance including thermal stability and mechanical properties, serves as the primary insulating material for HVAC power cables [

138].

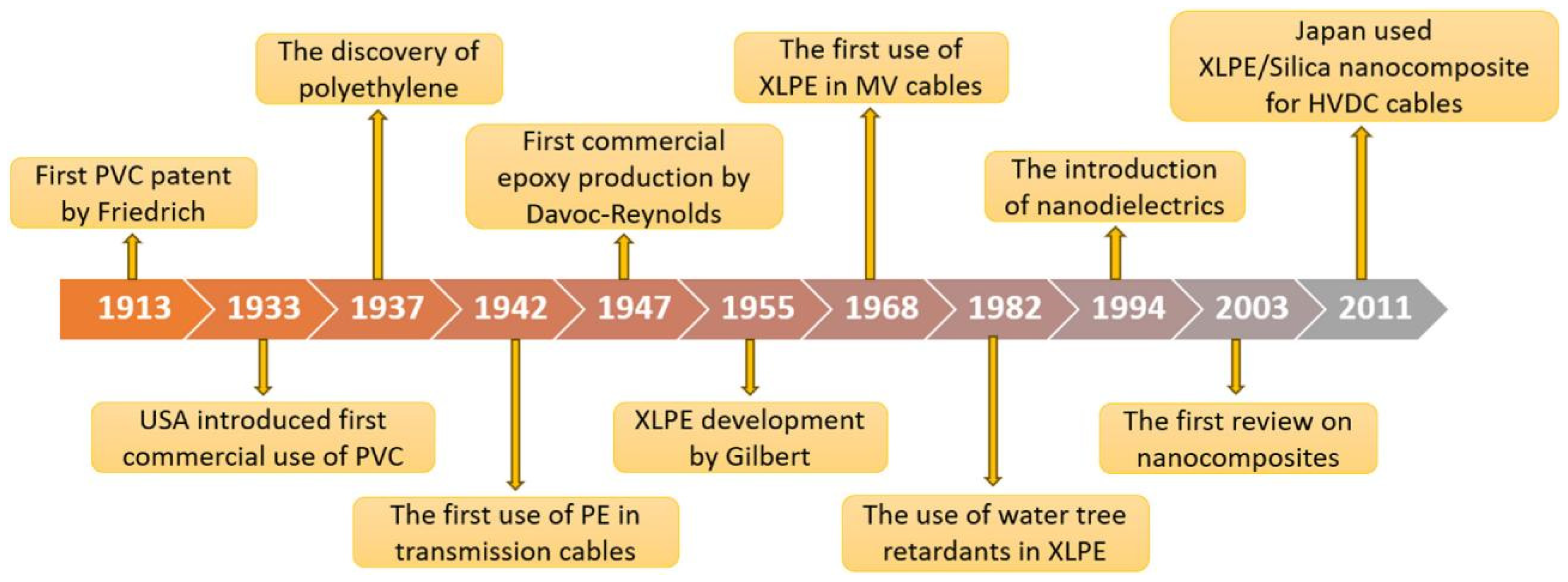

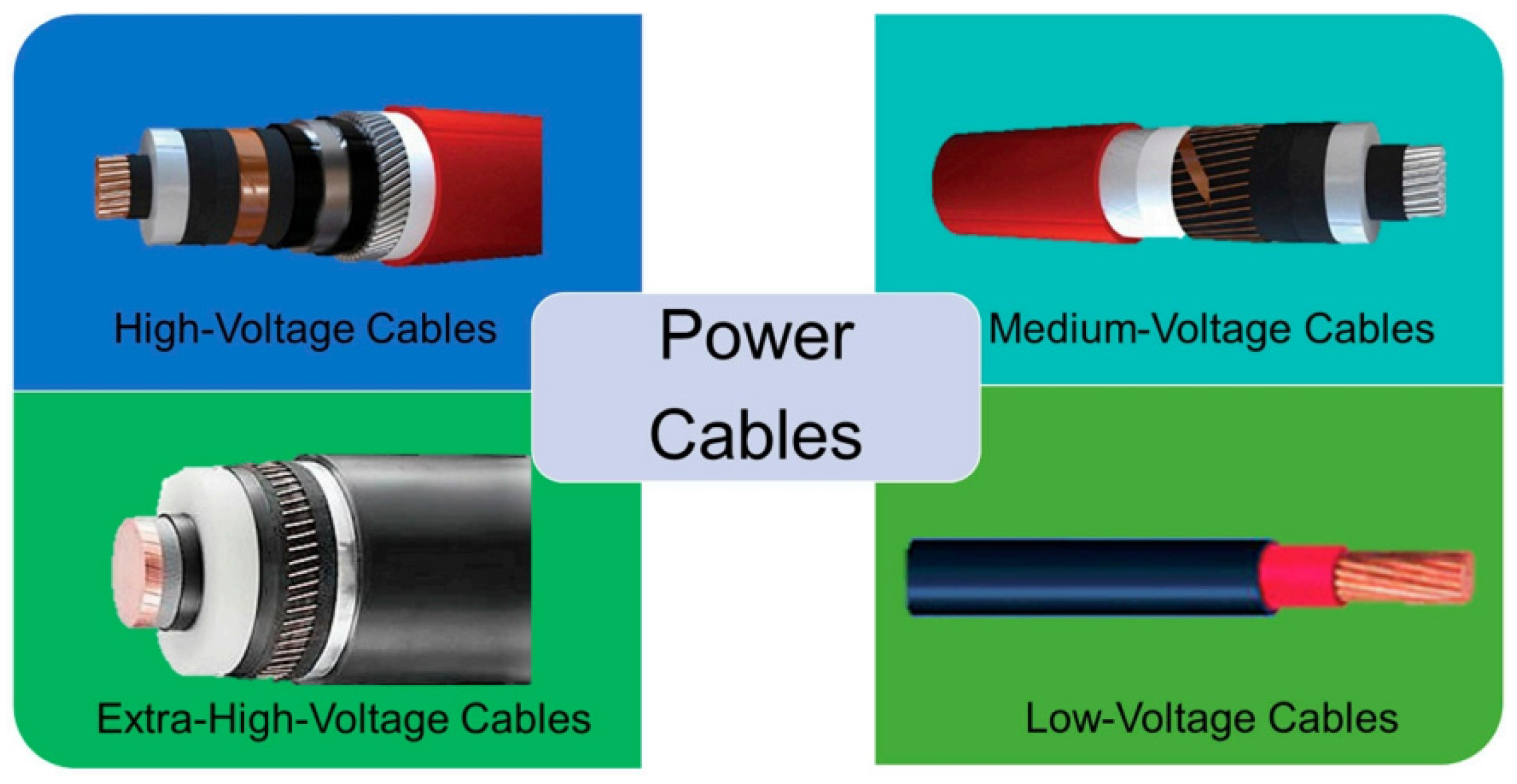

Figure 6 depicts the development history of insulated cables. It can be seen that the development of insulated cables has experienced a number of important milestones, which have not only promoted the progress of power, communications and other industries, but also greatly enriched people’s lives.

The cross-linked polyethylene cable material (

Figure 7) offers several advantages, including excellent wear resistance, environmental stress cracking resistance, high insulation resistance, and lightweight properties [

48]. It is primarily utilized as an overlay material [

140,

141] for electric wires and cables. The polyethylene cable sheath material serves as the protective sheath layer of cables, providing protection for optical cables, power cables, communication cables, etc. This material is available in LLDPE, HDPE, and MDPE variants-all of which are black to provide UV protection [

142]. Power cable sheaths can be made from either polyethylene or PVC materials [

143,

144]. The production process for polyethylene sheath materials does not require specialized equipment and can be achieved using twin-screw extruding machines and kneaders. Liu et al. developed a series of innovative halogen-free flame-retardant poly(vinyl chloride) composite insulating materials utilizing organic-inorganic flame-retardant blend agents [

145]. They incorporated CP-Allyl, a compound exhibiting both flame-retardant and radiation-sensitizing properties, into a matrix composed of low-density polyethylene and ethylene-vinyl acetate co-polymer through melt blending techniques. Furthermore, by subjecting the composite material to electron beam irradiation at doses ranging from 100 to 190 kGy, they facilitated cross-linking of the material and established correlations between the irradiation dose, degree of cross-linking, and resultant material properties. The findings indicate that the radiation cross-linking composite containing functional cyclotriphosphazene derivatives exhibits exceptional mechanical strength, flame resistance properties, and electrical insulation characteristics. Specifically, the mechanical strength exceeds 14.5 MPa, the limiting oxygen index ranges from 28.2% to 32.4%, and resistance surpasses 2.47×10

12 Ω, rendering it highly promising for applications in electrical wires and cables.

Cross-linked polyethylene forms a three-dimensional network structure, resulting in significantly enhanced heat resistance. Moreover, it exhibits shape memory functionality [

146,

147], enabling it to return to its pre-cross-linked state when heated. By harnessing these post-cross-linked characteristics, cross-linked PE products are widely utilized in applications such as heat shrink tubing, cables, heat-resistant pipes, and shrinkable films. The application of PE-based heat shrinkable materials in cable accessories encompasses indoor flame-retardant, outdoor, semi-conductive, stress control, and underground insulation heat shrink materials [

148,

149]. These materials have diverse requirements and formulations but all exhibit shape memory functionality. They are currently widely utilized and hold promising prospects for further development [

14].

5.2. Piping System

Compared to traditional plastic pipe materials, XLPE pipe materials offer numerous advantages, including extended service life, corrosion resistance, excellent heat resistance, strong impact performance, high creep strength, non-toxicity, and good pressure resistance [

150]. They are considered a new generation of environmentally friendly pipe materials [

151] and can be utilized for fluid transport pipelines in the petroleum industry and household water heater systems [

152,

153]. The raw materials used to produce peroxide-XLPE heat shrinkable tube products include PE, peroxide cross-linked agents, and antioxidants [

154]. XLPE polyethylene pipe materials demonstrate superior heat resistance and aging properties as well as exceptional corrosion resistance and mechanical performance compared to other cross-linked methods [

155,

156,

157,

158]. They are widely employed both domestically and internationally for the conveyance of gas, hot water, and other fluids with promising prospects for practical application.

XLPE, commonly used in many hot and cold water pipe systems, is typically produced from HDPE [

151,

159]. When utilizing various sizes of metal tubes, insert them into the heat shrink tubing and apply hot water or hot air to contract and secure it [

13]. This method is commonly employed for insulating and protecting internal wiring connections, wire terminals, and waterproofing communication cable joints. The use of shape memory heat-shrink materials in manufacturing cable accessories not only facilitates easy and quick installation but also ensures reliable performance at a low cost [

160,

161].

Due to the outstanding performance and complete non-toxic hygiene of cross-linked polyethylene pipe materials, they are regarded as a new generation of environmentally friendly pipes [

162]. They are primarily utilized in the following applications: 1) cold and hot water supply systems for buildings and potable water distribution systems [

163]; 2) air conditioning chilled water systems for buildings; 3) residential heating systems; 4) ground heating systems; 5) piping for domestic hot water heater systems [

10]; 6) fluid transport pipelines for beverages, alcoholic drinks, milk, etc., in the food industry; 7) fluid transport pipelines for chemical and petroleum industries; 8) pipelines for refrigeration systems and water treatment systems [

164]. Al-Malaika et al. examined the effectiveness of synthesized reactive antioxidants (r-AOs) with blocked phenolic and amine groups for grafting onto polyethylene, as well as their retention and stabilizing capabilities in peroxide-cross-linked polyethylene (PEX

a) pipes [

155]. The results revealed that adding graftable antioxidants did not affect the cross-linking density of PEX

a pipes, which consistently demonstrated a high level of cross-linking (>85%) and significant retention after solvent extraction from PEX

a materials. Additionally, the distribution of these antioxidants was notably uniform throughout both the length and thickness of the PEX

a pipes. The stabilizing performance of r-AOs was compared to that of conventional PEX

a materials stabilized with similar antioxidant functionalities produced through analogous methods. Across all testing conditions utilized in this research, the retention rates and long-term stabilization efficacy of graftable antioxidants within the pipes were markedly superior to those seen with traditional antioxidants.

5.3. Packing Material

Cross-linked technology has been demonstrated to be effective in the field of polyethylene materials foaming, as it functions to stabilize bubbles throughout the foaming process, enhance thermal resistance, and improve mechanical properties [

165,

166]. The performance of cross-linked polyethylene foam depends on both the cross-linked process (whether chemical or physical) and the extrusion process (also whether chemical or physical). Polyurethane foam demonstrates exceptional resistance to low temperatures, weathering, abrasion, chemicals, and thermal transfer. It also offers excellent insulation properties, buoyancy, and cushioning effects while remaining odorless and non-toxic [

167]. Moreover, it exhibits favorable secondary processing capabilities including cutting, thermoforming, embossing, vacuum-forming, and compatibility with other materials.

The closed-cell cross-linked polyethylene foam exhibits excellent mechanical properties, making it well-suited for a diverse range of applications such as providing insulation and protection for pipes, ducts, containers, and process equipment to prevent condensation, conserve energy, and block sound transmission [

168]. Additionally, the application of an aluminum sheet covering ensures both its mechanical and thermal properties are maintained, rendering it ideal for roof insulation. However, closed-cell foam is not suitable for applications requiring high gas or vapor permeability or selective permeability or absorption and damping of sound. In contrast, open-cell cross-linked polyethylene foam possesses these characteristics and may be more suitable for applications such as filters, separation membranes, diapers [

169].

Polyethylene materials thermal shrinkable films exhibit the unique ability to contract both longitudinally and transversely when exposed to heat [

170,

171,

172]. Once properly sized and applied to the surface of the product, they are passed through a hot air tunnel. Upon reaching an optimal temperature, the film undergoes significant contraction in both length and width, tightly enveloping the product’s surface to create a secure packaging layer. The resulting packages boast excellent sealing and moisture-proof properties, making them suitable for packaging metal parts and food items. The materials utilized in the production of thermal shrink film include PE [

173], polyvinyl chloride (PVC) [

174,

175,

176], polyester (PET) [

174,

177,

178], and polypropylene (PP) [

179,

180,

181] among others. Polyolefins foam (POE) [

182]is utilized in medical applications such as fillers for prosthetics and sports padding within plastic surgery. Additionally, it may serve as an alternative to EPDM foam material aviation, aerospace, and military contexts.

Cross-linked polyethylene foam offers diverse utility. In construction, it functions as both heat preservation and insulation and cushioning material for roof insulation, frost-resistant sheets, and related uses [

183]. In industry, it serves as thermal insulating material for cold storage and pipe installations [

184,

185,

186,

187]. Automotive aspects, it finds application in interior ceiling decoration, luggage compartments, floor mats, thermal insulation pads, sidewall panels, and waterproof curtains for car doors. Furthermore, in packaging, it acts as cushioning and protective materials within the realms of household appliances, medical equipment, glassware, and fruit. Additionally, these versatile materials employed as an insulating agent within agriculture. Xia et al. created two controllable cross-linked polyethylene foam systems by employing 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane as the cross-linking agent, TEMPO to inhibit cross-linking, azodicarbonamide (AC) for foaming purposes, and citric acid as a promoter [

166]. They examined the density, expansion rate, cell structure, and mechanical properties of these two materials with controllable characteristics. The findings reveal that both systems display comparable performance trends: an increase in either the quantity of cross-linking inhibitor or foaming promoter results in larger pore sizes and higher expansion rates while simultaneously reducing density and mechanical strength. A comparative assessment indicates that the polyethylene foam system enhanced with citric acid as a foaming aid exhibits superior performance. Hong et al. chemically modified lignin using poly(ethylene-methacrylate) (PEGMA) to synthesize PEGMA-g-lignin (PEGMA-g-Lignin) [

188]. Both the original lignin and PEGMA-g-lignin were effectively integrated into the LDPE matrix. The analysis of thermal behavior and mechanical properties of the resulting biocomposite materials demonstrated that enhanced mechanical characteristics could be achieved without compromising the thermal properties of the LDPE matrix. Moreover, the foaming characteristics of these biocomposite materials, in conjunction with azodicarbonamide (a chemical blowing agent) and diaminodiphenylamine (a cross-linking agent), were investigated. The incorporation of 20 wt% PEGMA-g-lignin resulted in a high-quality lignin-reinforced LDPE biocomposite foam, which exhibited a uniform distribution of pore size frequency, comparable pore density, and an expansion rate akin to that observed in pure LDPE foam.

5.4. Other Materials

Cross-linked polyethylene is widely used in various applications, such as electric wires and cables, pipes, automotive components, foam materials, sports equipment, and packaging materials. In conclusion, the study of cross-linked polyethylene holds significant importance for advancing science and technology while also making substantial contributions to economic and social development as well as environmental protection.

5.4.1. Auto Parts

Polyethylene materials elastomer (POE), a novel thermoplastic elastomer (TPE), finds extensive applications in the automotive sector [

13]. Stringent environmental regulations call for lightweight [

189,

190], halogen-free, and recyclable materials in automotive manufacturing. Consequently, cross-linked POE can serve as an alternative to PVC for producing decorative materials used on automotive surfaces or interiors. cross-linked POE demonstrates exceptional heat resistance and resistance to permanent compression set deformation, which can be further improved through compounding and incorporating fillers [

34]. In thermoplastic blends containing tire rubber, the interaction of free radicals generated by organic peroxides provides a possibility for molecular cross-linking between rubber and matrix phases. For example, Li et al. ‘s research shows that combining DCP with other organic compatibilizers in polyethylene-tire rubber composites can obtain excellent impact strength and elongation at break [

191]. However, the mechanical properties of polythylene-tire rubber composites are poor in terms of tensile strength and hardness [

192].

5.4.2. Sport Equipment

Modified polyethylene is distinguished by its exceptional wear resistance, low coefficient of friction, water resistance, excellent impact resistance, chemical corrosion resistance, and outstanding low-temperature and electrical insulation properties. It finds extensive application in the manufacturing of sports equipment. In the realm of sports equipment, a variety of modified polyethylene products are widely utilized in ball sports, water sports, and ice sports. The use of modified polyethylene can enhance the impact resistance [

193,

194], heat resistance [

195,

196], and shock absorption [

183,

197] of sports equipment. This not only enhances athletes’ comfort during exercise but also safeguards them while prolonging the service life of sports equipment and reducing costs. Modified polyethylene exhibits superior wear resistance which further improves with increasing relative molecular mass [

132,

198]. Compared to unmodified polyethylene, modified polyethylene has a lower coefficient of friction making it an ideal lubricating plastic. Additionally, it absorbs minimal water with one of the lowest rates among most engineering plastic products; even when soaked in rainwater it does not swell.

The modified polyethylene has specific applications in the sports equipment field as follows: 1) Applying modified polyethylene to the fireproof layer of artificial grass can render the grass fiber soft, enhance its wear and chemical resistance, thereby improving the safety of artificial turf. 2) Sports equipment crafted from modified polyethylene exhibits excellent flexibility [

199] and robust shock absorption [

200], offering protection for athletes and suiting high-intensity sports such as football and American football. 3) Modified polyethylene fibers are utilized to laminate the surface, core, and base of a snowboard sequentially [

201]. In certain high-performance ski boards, a surface material made of cross-linked polyethylene may be utilized to optimize glide performance and enhance durability. By integrating a variety of materials such as wood, carbon fiber, or alternative plastics, cross-linked polyethylene can enhance the structural integrity of ski boards and improve their ability to withstand impacts [

202]. Furthermore, its exceptional water resistance effectively protects against material deterioration in slippery conditions, ultimately extending the overall lifespan of the ski board [

203]. Tomin et al. conducted a comprehensive study on various densities of XLPE foam, which is widely recognized as one of the most prevalent foam types in the sports and packaging sectors due to its superior heat resistance and enhanced recovery from mechanical loads attributed to its relatively weak cross-linked structure [

193]. The research involved compression tests alongside two dynamic mechanical assessments performed on closed-cell XLPE foam with densities ranging from 30 to 70 kg/m³ and thicknesses between 10 and 60 mm. The findings indicate that the thickness of the foam significantly influences its impact damping performance, while the energy absorption capacity is primarily determined by both the structural characteristics and density of the material. Excessive compaction can lead to irreversible micro-structural deformation; consequently, repeated impacts may compromise both impact damping and energy absorption capabilities of the foam material. These insights have valuable implications across various industries, including sports equipment manufacturing and packaging solutions.

5.4.3. Food Packaging

The metal content in polyethylene materials elastomer (POE) is minimal, and it boasts a high level of purity, rendering it highly suitable for applications in medical equipment and food packaging [

204,

205,

206]. The majority of polyethylene is utilized for film products, with most being employed for packaging purposes. Additionally, a portion is used as agricultural film and building film. Polyethylene packaging film finds extensive use in the food industry for wrapping candies, vegetables, frozen foods, etc., while also serving as inner lining film, shrink packaging film, elastic packaging film, and heavy-duty packaging film for non-food items [

207]. Manukumar et al. developed a novel stable antibacterial packaging film by using a new photo-cross-linking technology to cross-link cinnamaldehyde (Cin-C) onto LDPE. This new approach is highly promising for developing food packaging containing natural antibacterial agents targeting cell membrane components [

208].

6. Challenges and Limitations

Cross-linked polyethylene is a commonly employed material, especially in the fields of pipe and cable insulation; however, it also faces significant challenges [

92]. The primary challenge for cross-linked polyethylene lies in the fact that the insulated cable is subjected to various stresses, including heat, electricity, and mechanical forces during operation. These factors interact with one another, resulting in space charge accumulation, accelerating the aging of the cable insulation, and posing a threat to the stability of cable operation. The aging process [

209,

210,

211] of cross-linked polyethylene materials typically takes place under various environmental factors such as electric fields, thermal conditions, oxygen exposure, moisture ingress, mechanical stress, light exposure, chemical substances, and microbial presence encountered during use. These factors can cause irreversible damage to the insulation material and even lead to power accidents, presenting incipient fault to the power grid’s operation. Similar to pipelines, cable materials are poor conductors of heat and electricity, yet due to the existence of micro-cavities, gas particles, and conductive particles, water-tree formation occurs. Water trees do not necessarily result in medium failure, but in certain cases, it can directly lead to electric tree development. The incorporation of hydrophilic clusters can effectively inhibit the formation of water trees, but improper addition may compromise the dielectric strength. Therefore, it is imperative to develop strategies for mitigating water tree formation without compromising dielectric performance. Cross-linked polyethylene cables and pipes encounter substantial challenges in resisting moisture and corrosive chemicals due to their inherent nature. Introducing self-healing properties has been necessitated by difficulties in detecting and rectifying damages sustained by these cables and pipes [

212].

An additional obstacle confronting both cross-linked polyethylene itself as well as its products pertains to waste disposal and recycling issues. The complexities associated with recycling this material contribute significantly towards environmental pollution [

213,

214]. Moreover, when compared to traditional materials, the initial cost of cross-linked polyethylene may be higher, especially when assessing its cost-effectiveness on a large scale of deployment. Considering these limitations, what trajectory can be anticipated for cross-linked polyethylene? Let’s observe and analyze.

7. Research Trend

The development trend of cross-linked polyethylene primarily focuses on three areas: nanocomposites, biodegradability, and recycling. These research directions not only enhance the performance and application range of cross-linked polyethylene but also stimulate the creation of new products and market expansion. As science and technology advance, the cross-linked polyethylene industry will continue to innovate, leading to broader prospects for development.

7.1. Nanocomposite Material

Materials of polyethylene nanocomposite with enhanced high-voltage direct current (HVDC) performance are crucial for the research and development of new insulating materials [

48]. This approach holds great promise for expanding applications in high-voltage direct current transmission cables. The incorporation of small amounts of inorganic nanoparticles [

215] into insulating materials can effectively enhance their electrical properties, including improving dielectric strength, volume resistivity, and modifying spatial charge behavior [

216,

217,

218,

219].When nanoparticles are functional modification with polyethylene materials, the resulting material demonstrates significant enhancements in terms of strength, toughness, and elongation. Various types of nano reinforcements have been documented so far, including grapheme [

220], layered silicates [

221], nanoscale silica, carbon nanotubes (CNTs), and polyhedral oligomeric silsesquioxane [

160,

222] (POSS). The primary techniques for fabricating polyethylene materials nanocomposites [

223] involve blending, embed [

224], and in-situ polymerization.

The research into enhancing the electrical insulation performance of polyethylene insulating materials through the incorporation of grapheme oxide (GO) has emerged as a burgeoning area of study. Research indicates that the introduction of GO into the LDPE matrix can create numerous deep traps within the matrix, impeding the movement of charge carriers and thereby restraining the injection and accumulation of space charges. The grapheme nanoparticles establish multiple interaction regions in the nanocomposite material, elevating the trapping energy level of cross-linked polyethylene [

225]. Grapheme nanoparticles create numerous interconnected zones within nanocomposite materials, resulting in a significant increase in breakdown strength, minimal accumulation of space charge, and improved electrical conductivity in cross-linked polyethylene/GO nanocomposites [

226]. Han et al. found that adding nano-graphene oxide to the XLPE could effectively suppress the space charge accumulation and increase its breakdown strength [

227].

Boron nitride (BN) filler not only has excellent thermal conductivity and insulation properties but also demonstrates thermal stability, strong mechanical attributes, and resistance to both corrosion and oxidation. Li et al. utilized a melt blending method to create XLPE/BN nanocomposites with different concentrations of fillers, incorporating boron nitride nanoparticles (BNNP) and boron nitride nanoflakes (BNNS) as the nanofillers, while XLPE, designed for high-voltage direct current (HVDC) cable applications, acted as the matrix material. The introduction of BNNS and BNNP enhances the dielectric constant of the composite materials [

228]. The peak relative permittivity is observed at a concentration of 1 wt%, measuring 2.35 for XLPE/BNNSs and 2.32 for XLPE/BNNP—an increase of approximately 11% and 9%, respectively, compared to that of the pure XLPE matrix. For both BNNSs and BNNP composites, the breakdown strength initially rises before declining as BN concentration increases; it reaches its highest value at a concentration of 0.5 wt%. Specifically, these values are recorded at 403.8 kV/mm for XLPE/BNNSs and 349.2 kV/mm for XLPE/BNNP—representing enhancements of about 33% and 13% over that of the unmodified XLPE matrix.

Carbon nanotubes (CNTs) exhibit good dispersion and compatibility within the HDPE matrix; their incorporation enhances the yield strength and tensile modulus of the composite material, while also improving processing performance [

229].

Cross-linked polyethylene composite silica nanomaterials have a wide range of applications. In the construction industry, these materials can be used for thermal insulation of building walls, roofs, floors, and other components, effectively reducing energy consumption and enhancing the energy-saving performance of buildings. In industrial equipment applications, this material is suitable for thermal insulation in various industrial equipment such as petrochemical facilities, boilers, pipelines, etc., thereby improving equipment insulation and reducing energy loss. For automotive manufacturing purposes, this material can be employed for soundproofing, heat preservation, and sound absorption to enhance in-car comfort and reduce noise levels [

230]. In cold chain logistics scenarios, it is applicable to the cold chain logistics industry by providing effective thermal insulation in cold storage and freezing environments to maintain product quality and freshness [

231]. Cross-linked polyethylene composite silica nanomaterials demonstrate exceptional thermal insulation, high strength, temperature resistance, corrosion resistance, and aging resistance, as well as environmental sustainability [

110]. As a result, they have extensive applications in these fields. Additionally, the material also possesses environmentally sustainable characteristics that align with current requirements for environmental protection and sustainable development [

232]. In summary, cross-linked polyethylene composite silica nanomaterials hold promising prospects for broad application in construction, industry, automobiles, etc [

233]. Liu et al. developed composite materials (PE-Al-Si) exhibiting enhanced thermal conductivity and mechanical properties by melt blending LDPE, aluminum oxide (Al

2O

3), and nano-silica (SiO

2). The resulting material was subsequently modified through electron beam irradiation. When the mass fraction of nano-SiO

2 was 1% and the electron beam irradiation dose reached 120 kGy, the thermal conductivity of PE-Al-Si attained 0.759 W/(m·K), representing a 22% increase compared to the composite material (PE-Al) devoid of SiO

2. Furthermore, the tensile strength of PE-Al-Si improved from 21.6 MPa to 26.2 MPa, marking a 17% enhancement relative to PE-Al. This demonstrates that SiO

2 not only augments the mechanical properties of the composite but also enhances its radiation efficiency and thermal conductivity [

234].

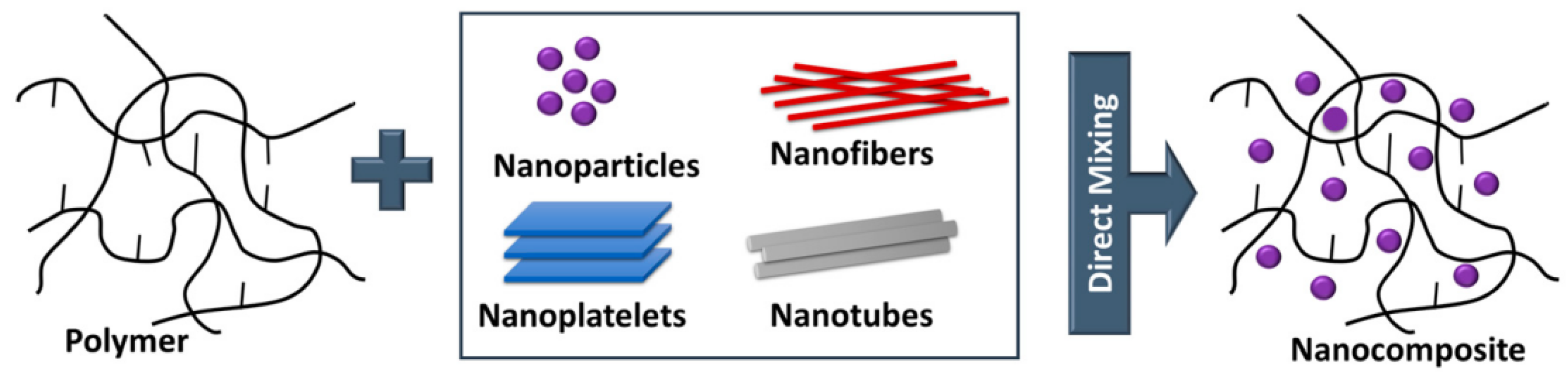

In order to enhance the electrical insulation properties of polyethylene materials insulating materials, two main technologies are primarily utilized: ultrapure technology and composite material technology. However, ultrapure technology is associated with high industrial costs and is constrained by the maximum direct current breakdown strength of polyethylene materials insulating materials. On the other hand, composite material technology (

Figure 8) is predominantly restricted to blending polyethylene materials with polymers and doping polyethylene materials with nanoparticles. Moreover, it is challenging for modified nanoparticles to effectively interact with non-polar polyethylene materials. Consequently, novel technologies are urgently required for enhancing the electrical insulation properties of polyethylene materials insulating materials in high-voltage direct current power transmission systems and reducing China’s long-term reliance on imported insulating materials for high-voltage direct current cables [

216].

7.2. Restoration

XLPE has undergone significant enhancements in its physical and chemical properties due to cross-linking modifications. XLPE cables are extensively utilized in urban and industrial power supply system owing to their advantages of flexible spatial configuration, excellent electrical and mechanical properties, and high reliability in power delivery. However, during practical applications, the material is inevitably subjected to various external factors such as mechanical stress, chemical corrosion, and temperature fluctuations, which can lead to a deterioration in performance or even structural damage. Through advanced repair technologies, it is possible to restore the original performance of cross-linked polyethylene, thereby extending its service life and reducing both replacement frequency and associated costs.

Currently, repair systems are classified into two categories: endogenous and exogenous [

235,

236,

237]. Endogenous repair primarily leverages the material’s inherent properties for restoration, utilizing reversible valence bond alterations and chemical reactions to modify the intrinsic chemical structure of the material, thereby facilitating damage repair. However, the application of intrinsic repair systems to insulating materials poses challenges due to valence bond reactions that can alter the substrate’s chemical structure and significantly impair its fundamental properties. Exogenous repair materials are composite substances composed of foreign elements and a matrix, aimed at restoring the integrity of the matrix. Exogenous repair systems primarily encompass micro-capsules, bio-mimetic blood vessels, and hollow fibers [

238].

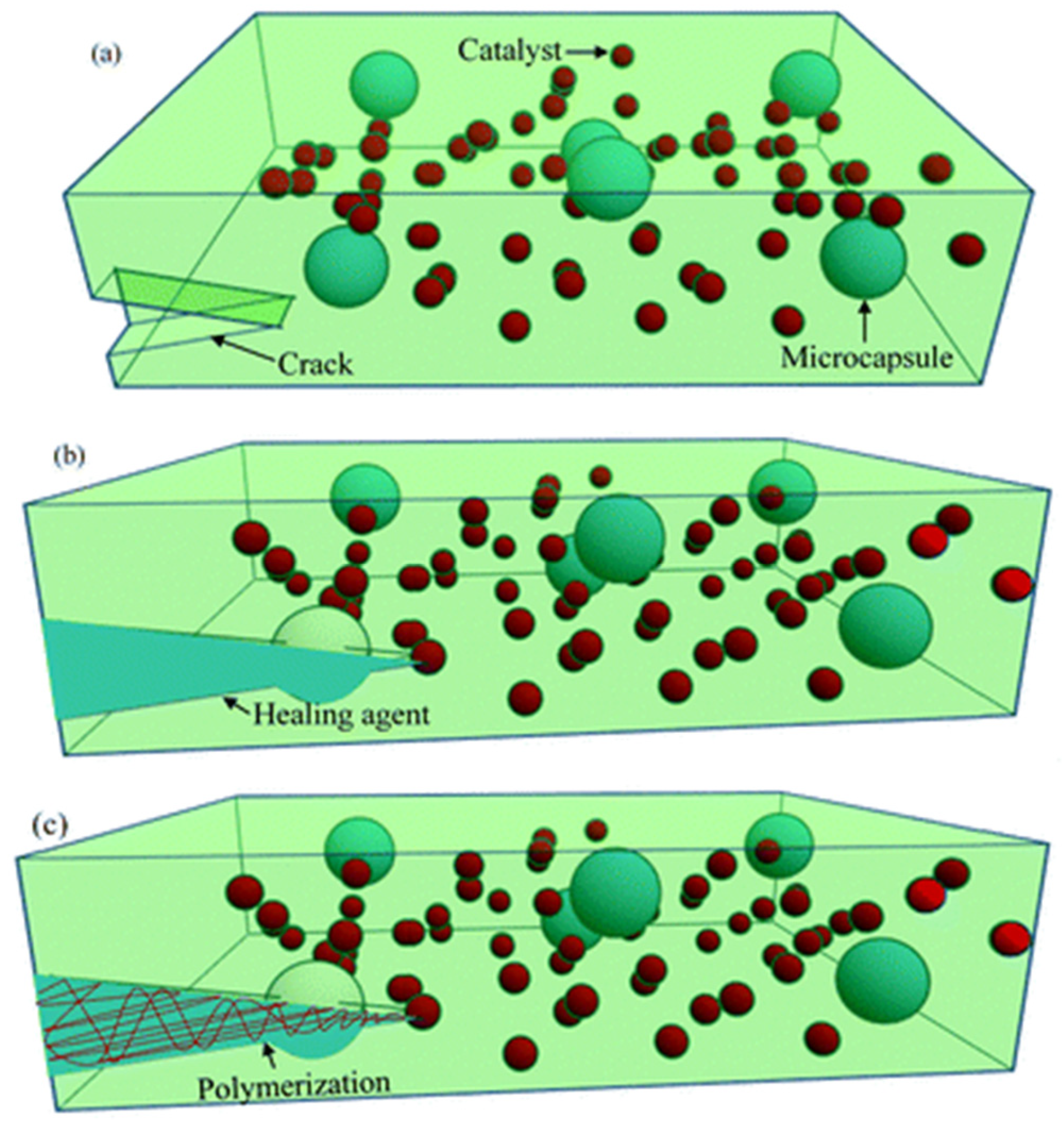

The micro-capsule repair system not only exhibits excellent stability and a high repair efficiency but also exerts minimal influence on the properties of the matrix [

239]. This innovative micro-capsule repair technology was initially introduced by White et al. [

240], involving encapsulating the repair material within specialized micro-capsules that are integrated into the matrix material. Upon damage to the matrix, stress concentration at the affected site induces rupture of the micro-capsule. In response to external stimuli, the internal reparative agent rapidly solidifies and fills in the compromised region, thereby facilitating the material’s restoration process.

Figure 9 illustrates the mechanism underlying micro-capsule repair. Zhu et al. proposed a micro-capsule-based XLPE repair material to address the degradation of insulation performance caused by water tree aging in XLPE. UF@SiO

2, modified with nano-silica dioxide (SiO

2), was utilized as the wall material, while octadecyl trimethoxysilane (DTMS) and linear alkylbenzenesulfonic acid (LABSA) were selected as core materials [

241]. The three-layer shell-core structure micro-capsules were synthesized through interfacial polymerization. The preparation method for the three-layer shell microcapsule/XLPE composite material was investigated. Results indicate that an increased doping concentration of the three-layer shell-core micro-capsules leads to a significant decline in the electrical performance of the composite compared to XLPE without microcapsules. At a doping concentration of 1.0 wt%, there is no substantial change in breakdown strength or dielectric loss factor; however, spatial charge density decreases significantly, resulting in markedly improved space charge performance. Furthermore, during water tree aging tests, the composite demonstrated effective inhibition of water tree growth and notable repair capabilities post-aging due to the presence of micro-capsules. Additionally, nanoscale SiO

2 on the surface of these micro-capsules enhances their adhesion to the matrix, preventing common issues related to capsule aggregation when incorporated into composites and thereby improving repair efficiency. Zhou et al. investigated the impact of a novel repair solution on the restoration of aging cables affected by water tree phenomena [

242]. The repair solution incorporated long-chain siloxanes and voltage stabilizers, and the long-term anti-aging performance against water tree degradation in the repaired cables was evaluated through a secondary water tree aging test. Concurrently, a comparative analysis was conducted to assess the effects of both repaired and unrepaired conditions on the initiation and growth of electrical trees, elucidating the operational mechanisms of the repair solution as well as examining the degradation trends associated with voltage stabilizers.

7.3. Reutilization

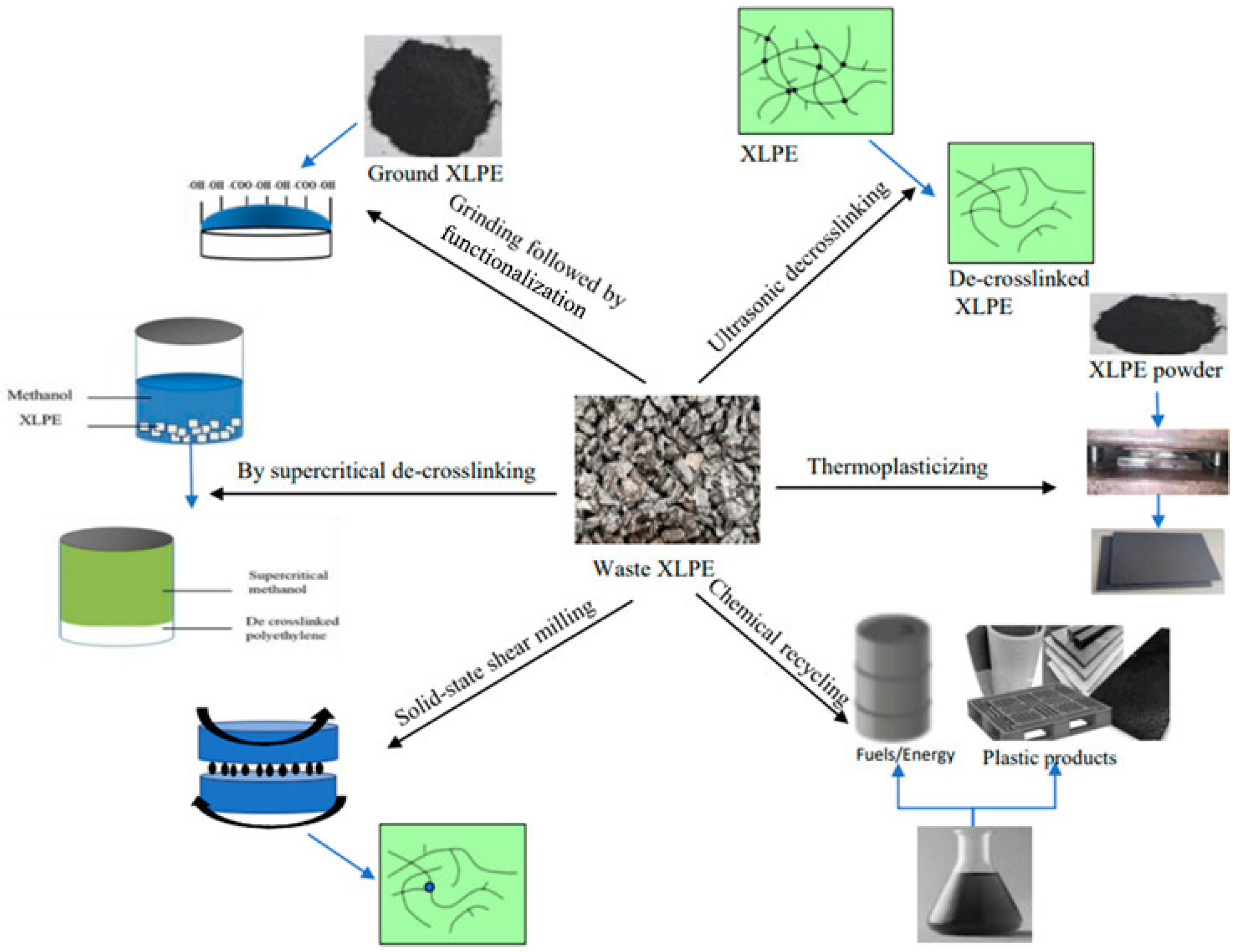

The significance of plastic waste recycling cannot be overstated in addressing global environmental issues (

Figure 10) [

244]. By processing discarded waste and utilizing it as a new energy source, recycled products are created. Cross-linked polyethylene is widely utilized as a thermosetting plastic due to its cost-effectiveness, lightweight nature, and exceptional insulation properties against electricity and heat [

244]. It is commonly used as an insulating material for wires and cables. As a thermosetting plastic, cross-linked polyethylene exhibits limited fluidity and poor plasticity. Additionally, chemical bonds exist between its molecular chains, causing the molecular structure to transition from linear to three-dimensional, resulting in a thermosetting material that does not melt upon heating and is difficult to dissolve in most solvents [

245]. Consequently, recycling cross-linked polyethylene presents significant challenges but holds great importance. The irreversible covalent cross-linking in cross-linked polyethylene makes its recycling a highly challenging task. An energy-efficient, economical, and environmentally friendly recycling process is essential to protect our ecosystem.

Disposal of cross-linked polyethylene through landfill dumping poses environmental concerns due to the material’s stable properties that prevent decay over extended periods. This not only occupies limited land resources but also contributes to soil and water pollution. Incineration releases toxic and harmful gases that can adversely impact the ecological environment. Therefore, research into scientific and effective technological methods for the recycling and reuse of waste cross-linked polyethylene and other thermosetting plastics holds significant implications for resource regeneration and environmental protection [

159,

246]. Recycling methods for cross-linked polyethylene include grinding [

247], thermal-assisted shearing, supercritical fluid processing, ultrasonic-assisted single-screw extrusion, as well as solid-state mechanical-chemical grinding.

7.3.1. Powdered Filler Recovery Method

This approach primarily entails employing basic recycling techniques to recover discarded cross-linked polyethylene edge trim through sorting, cleaning, and crushing it into powdered fillers [

248]. Subsequently these fillers undergo direct processing via blending with other thermoplastic polymers [

249]. The recycled powdered filler regeneration technology offers a streamlined process with low costs and minimal investment requirements; however product quality cannot be assured as they fail to match those derived from pure materials in terms of strength, elasticity, toughness, durability or any other aspect, resulting in significant limitations on their applications [

250]. Hence, it is anticipated that leveraging more efficient grinding equipment and compatibility technology will enhance the performance characteristics of this blended system. White et al. systematically investigated the viability of utilizing recycled XLPE cable material as a powder filler through three perspectives: separation techniques, granule refinement methods, and molding processes [

67].

7.3.2. Hot Shear Plasticizing Recovery Technology

The core of the hot shear plastic recycling process lies in the thermal oxidation and mechanical action that result in the breakdown of the cross-linked three-dimensional structure. Specifically, at certain temperatures and under mechanical shear force, some carbon-carbon bonds and cross-linked carbon-carbon bonds within the main chain of cross-linked polyethylene molecules are partially disrupted, leading to a shift away from a three-dimensional molecular structure and an increase in material thermal plasticity [

251]. Xie et al. examined how roll temperature and the duration of plasticization affect the degradation of waste XLPE scrap using a twin-roll calender, maintaining constant roll speed and gap settings [

252,