1. Introduction

The industry 4.0 revolution is transforming the renewable energy sector, particularly in the solar energy field. This transformation manifests across multiple interconnected areas, from optimizing energy capture systems to the intelligent management of the energy produced. At the heart of this evolution are advanced solar tracking systems. These include a wide range of solar trackers, with dual-axis trackers, the focus of this project, significantly improving energy capture efficiency. These systems benefit from increasingly sophisticated control algorithms, including methods based on artificial neural networks and fuzzy logic, which optimize performance, especially under variable conditions [

1,

2,

3]. When these solar trackers use trajectory calculations along with navigation sensors, they increase energy production by 67.65%, highlighting the importance of enhancing design and positioning to maximize solar tracking efficiency [

4]. The implementation of these technologies extends beyond tracking improvement; it also encompasses automatic fault detection in photovoltaic arrays through artificial neural networks, enhancing system reliability and maintenance [

5].

The efficiency of these systems is further boosted by research into new materials for solar panels. Advances in bifacial solar cells and advanced coatings are improving both the durability and performance of panels [

6]. However, system performance does not solely depend on panel technology. Environmental factors, such as atmospheric aerosols, can significantly affect available solar radiation and, consequently, panel efficiency [

7]. Moreover, case studies in India have demonstrated how temperature and wind speed influence the performance of photovoltaic solar modules, providing crucial insights for optimizing installations under various climatic conditions [

8].

The integration of technologies such as the Internet of Things (IoT), artificial intelligence (AI), and the use of drones is revolutionizing the management of photovoltaic installations. These technologies enable real-time monitoring and predictive maintenance, which not only improves energy efficiency but also significantly reduces operating costs. Studies in the Murcia region have shown remarkable improvements in system availability and reduced failures through the implementation of these technologies [

9].

The impact of AI extends beyond monitoring. Deep learning techniques are being applied in the optimization of industrial processes, including renewable energy, improving efficiency and precision in automated systems [

10]. Furthermore, deep reinforcement learning is revolutionizing energy system optimization, enabling more efficient real-time energy management and distribution [

11].

The efficient management of renewable energy, known for its intermittency, is being addressed through the integration of flexible and stationary energy storage systems [

12,

13]. These storage solutions are complemented using advanced SCADA platforms and efficient communication protocols like MQTT, which are significantly improving data management in solar systems and microgrids [

14].

This integrated approach is not limited to solar energy. In the wind energy sector, for example, multi-layer Big Data architectures are being applied for the remote monitoring of wind farms. These architectures allow real-time analysis of large volumes of data, optimizing turbine performance [

15]. The synergy between different forms of renewable energy is being enhanced through AI-based optimization techniques, which predict and improve the behavior of solar and wind systems in an integrated manner [

16].

The application of these technological advances transcends energy generation alone. They are being integrated into the design and management of smart buildings and infrastructure projects [

17], as well as the efficient management of water resources, thanks to the creation of digital twins of dams [

18]. Software tools like Grasshopper are facilitating the simulation of architectural and energy processes, allowing for the optimization of solar panel placement on buildings and maximizing their efficiency [

19,

20]. Energy and exergy analysis is providing deeper insights into how to evaluate and improve the energy efficiency of different systems, including renewable energy generation [

21]. This holistic approach is being complemented by the integration of the bioeconomy and Industry 4.0, optimizing production processes in the renewable energy sector through technologies like IoT, advanced automation, and digital twins [

22].

1.2. Comprehensive Theoretical Base and Proposed Method

The approach proposed in this article focuses on the development of a remote monitoring system for a dual-axis solar tracker based on a SCADA system. The system is composed of the following key components:

Dual-Axis Solar Tracker: A dual-axis solar tracker allows for adjustments in both the horizontal and vertical axes, giving it the ability to follow the sun’s movement more precisely throughout the day and seasons. This system consists of motors and controllers that regulate the tilt angle (vertical axis) and azimuth angle (horizontal axis) of the photovoltaic panel, maximizing solar energy capture [23].

Sensor System: A network of sensors has been implemented to monitor key internal panel variables as well as environmental factors [

8]. These sensors transmit real-time information to the control system to ensure precise tracking of the solar position and energy performance. Advanced sensor technologies now include the use of artificial neural networks for the automatic detection of faults in photovoltaic arrays, improving system reliability and maintenance efficiency [

5].

Programmable Logic Controller (PLC): The core of the system, which collects information from the sensors and runs the astronomical algorithm. The PLC also controls the actuators responsible for adjusting the position of the solar tracker, ensuring that operations are carried out in real-time, optimizing the system’s energy efficiency. Modern PLCs are increasingly incorporating machine learning capabilities for predictive maintenance and performance optimization [

9].

IoT Gateway and MQTT Communication: The data collected by the PLC is transmitted to a cloud platform via an IoT gateway using the MQTT communication protocol. The interoperability of MQTT Node-RED ensures a flexible and scalable architecture, optimizing the monitoring and control of the photovoltaic system’s efficiency [24], and facilitating the subsequent transmission of data to the SCADA system. Recent developments in IoT technologies have enabled more robust and secure communication protocols, improving overall system reliability [

15].

Remote Monitoring Platform: The remote monitoring and control system is based on technologies such as Ignition and groov View. These SCADA platforms allow for real-time visualization of the solar tracker’s status, alert generation, and historical data analysis for informed decision-making [25]. Users can access the system via web or mobile applications, enabling supervision from any location. The integration with advanced data analysis and machine learning algorithms has further enhanced the system’s predictive capabilities and optimization [

10].

Automated Actuators: The actuators controlled by the PLC adjust the solar tracker’s orientation and tilt according to the recommendations generated by the astronomical algorithm. This process is automated but can also be manually or remotely controlled as needed. Recent advances in actuator technology have resulted in more precise and energy-efficient movements, further improving system performance [

4].

The workflow of the proposed system can be summarized as follows:

Sensors collect data on system position and performance.

The PLC processes this data and executes the astronomical algorithm.

The IoT gateway transmits the data to the cloud via MQTT.

The remote monitoring system presents the information in real-time.

Actuators automatically adjust the tracker’s position based on data analysis.

This approach enables highly efficient and automated control of the solar tracker, maximizing energy generation based on the sun’s position and minimizing manual intervention. Recent studies have shown that the integration of deep learning models for solar irradiance prediction can further improve the system’s predictive capabilities and overall efficiency [

10]. Additionally, the implementation of digital twin technology in solar energy systems has shown promising results in optimizing performance and predictive maintenance [

17,

18]. By creating a virtual replica of the physical solar tracker system, operators can simulate various scenarios, predict potential issues, and optimize system performance in real-time. This technology, although initially developed for dam and watershed management, has great potential for application in solar energy systems, enabling more efficient and proactive resource management [

18].

2. Methods

To develop a remote monitoring system for a dual-axis solar tracker, it is essential to begin with a detailed analysis of the system architecture and the available control software. This analysis includes the evaluation of physical components such as sensors and actuators that control the tracker’s tilt and orientation, as well as the programmable logic controller (PLC) that manages operations. Once the system architecture is understood, the next step is to define and configure internal communications between the various hardware elements, such as the PLC, position sensors, adjustment motors, and the IoT gateway, which connects the system to cloud platforms. These communications are established using industry-standard protocols, such as Modbus or S7, ensuring efficient information flow among all components.

2.1. System Architecture

The proposed system integrates a dual-axis solar tracker with an advanced control architecture, designed to optimize solar energy capture. At the heart of this solution is a Siemens S7-1200 PLC, which acts as the brain of the system, processing data and executing an astronomical algorithm to calculate the optimal solar position. This controller works in conjunction with an IoT gateway (IOT2040), enabling connectivity and data exchange through MQTT protocols, programmed in Node-Red.

The structure of the solar tracker allows precise adjustments on two axes: horizontal (azimuth) and vertical (tilt), continuously adapting to the daily and seasonal solar trajectory. This flexibility is achieved through a strategically placed sensor network, including SCA100t-d02 tilt sensors, incremental encoders for orientation, and current and voltage transducers. These components provide a constant stream of data regarding the tracker’s position and the system’s electrical conditions.

The PLC, as the control core, processes the information received from the sensors and coordinates the necessary adjustments through actuators, ensuring that the solar panel always maintains the most efficient orientation. Furthermore, the integration of the IoT gateway facilitates remote monitoring through SCADA platforms. This approach not only improves the efficiency of solar capture but also allows for more effective system tracking and maintenance.

2.2. Astronomical Algorithm

Due to its high precision and since it is not the primary focus of this article, the orientation of the solar tracker is handled by an astronomical solar position algorithm, developed in SCL (Structured Control Language) by Bitex. This algorithm aims to accurately calculate the sun’s altitude (elevation angle) and azimuthal angle (direction relative to the north), providing key information on the remaining time until sunrise and sunset, daylight duration, and the exact moments of dawn and dusk. For optimal operation, the algorithm requires a set of input parameters.

These capabilities enable the tracker’s motors to automatically adjust the solar panels’ orientation in real-time, ensuring they follow the sun’s path, thereby maximizing solar energy capture efficiency.

2.3. Communications

The communications system for the proposed solar tracker is based on a network architecture that integrates various industrial protocols and connectivity technologies to ensure efficient and reliable operation. The main communication protocol used is MQTT (Message Queuing Telemetry Transport), widely adopted in Industrial IoT (IIoT) for its lightweight nature and ability to operate in networks with limited bandwidth. This protocol enables efficient data transmission between sensors, the PLC, and the SCADA platform, through an IoT gateway.

MQTT ensures real-time data flow from the PLC to the cloud, supporting the remote monitoring and control of the system. This setup facilitates predictive maintenance and fault detection, reducing downtime and operational costs, while also allowing integration with other automation platforms.

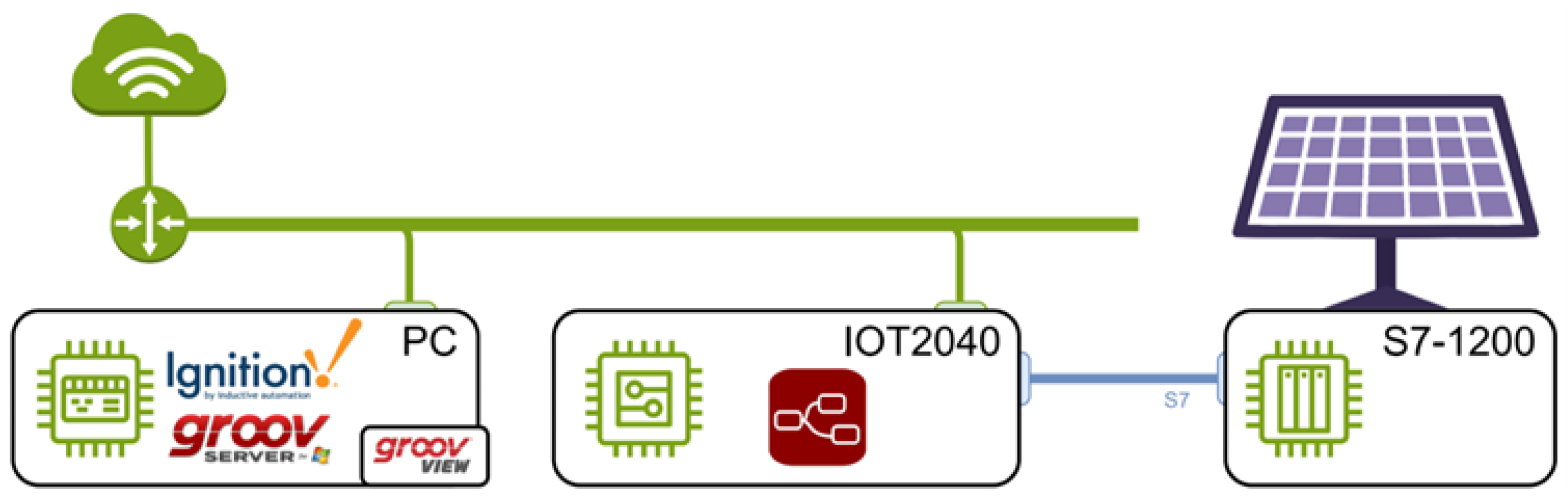

Figure 1.

Network diagram.

Figure 1.

Network diagram.

2.4. Communication Architecture

The communication architecture is supported by the IOT2040 gateway, which collects the data generated by the sensors and the Siemens S7-1200 PLC and transmits it via MQTT to supervisory and control platforms such as Ignition and groov View. To facilitate this data flow, the system uses the open-source Mosquitto broker, which acts as an intermediary, managing the publication and subscription of messages between devices. The use of this broker ensures interoperability among the various devices connected within the network.

Regarding the network topology, the IOT2040 is connected via Ethernet to a switch, which in turn connects to an industrial router that provides internet access and allows connectivity with remote devices. The router is designed to operate in harsh industrial environments, ensuring stable and continuous operation. This network infrastructure ensures that data from the solar tracker is transmitted efficiently and can be monitored from anywhere through a graphical interface accessible from mobile devices or web browsers.

Finally, the control and monitoring platforms use interfaces like groov View and Ignition, which allow real-time visualization of the system’s status and manage the control of the actuators. These tools not only provide a visualization of historical and real-time data but also allow the configuration of alarms and events in case anomalies are detected.

2.5. SCADA System

The SCADA (Supervisory Control and Data Acquisition) system implemented in this project aims to provide comprehensive supervision and control of the dual-axis solar tracker. This system is based on the Ignition platform, which allows data acquisition from sensors and the PLC and presents it through an intuitive graphical interface accessible from any internet-connected device. Ignition is a highly scalable and versatile platform that not only supports real-time data visualization but also enables the storage of historical data for trend analysis and report generation.

The SCADA system uses the MQTT protocol for communication with the IoT gateway and PLC, allowing fast data updates and efficient control of the system’s actuators. Information collected from the sensors, such as the tilt and orientation of the panels, as well as electrical parameters like voltage and current, is displayed in real-time on the SCADA interface. Users can access this information from any location, either through a web browser or mobile applications.

In addition to visualization and control, the SCADA system is configured to send alerts if system failures are detected, such as misalignments in the panel orientation or anomalies in sensor values. These alerts enable early intervention, minimizing system downtime and improving operational efficiency.

3. Results and Discussion

The development and implementation of the remote monitoring and control system for a solar tracker show significant improvements in solar energy capture efficiency and operational management. These results can be broken down into several key areas:

The use of a dual-axis solar tracker in combination with an accurate astronomical algorithm to calculate the sun’s position has proven to be a highly efficient method for maximizing solar radiation capture throughout the day. Through this algorithm, the system automatically adjusted the tracker’s tilt and orientation, ensuring that the photovoltaic panels remained in the optimal position relative to the sun. This led to an increase in energy production of approximately 25-30% compared to fixed systems, confirming the viability of this configuration in large-scale solar projects.

Studies conducted during the system testing showed that, under ideal conditions, this tracker integration increased energy production by up to 67.65% compared to fixed systems, emphasizing the importance of having an efficient tracking architecture, particularly in regions with high solar irradiance. This increase in efficiency is directly correlated with the predictive capabilities of the astronomical algorithm, which accurately forecasts the sun’s trajectory.

One of the most innovative features of the system is its ability to perform predictive monitoring and real-time diagnostics of potential system failures, both at the level of the actuators controlling the tracker’s orientation and the photovoltaic panels themselves. The integration of advanced sensors, such as encoders and tilt sensors, allowed the system to detect potential anomalies in the tracker’s movement, such as misalignments or tilt errors.

Thanks to the use of an advanced SCADA system, operators were able to monitor key electrical parameters such as current, voltage, and generated power, which was crucial in detecting failures in electrical components. These monitoring capabilities enabled early detection of issues before they severely impacted energy production, reducing system downtime. Additionally, an event-based alert system was implemented to immediately notify operators when an anomaly was detected, facilitating rapid and effective intervention.

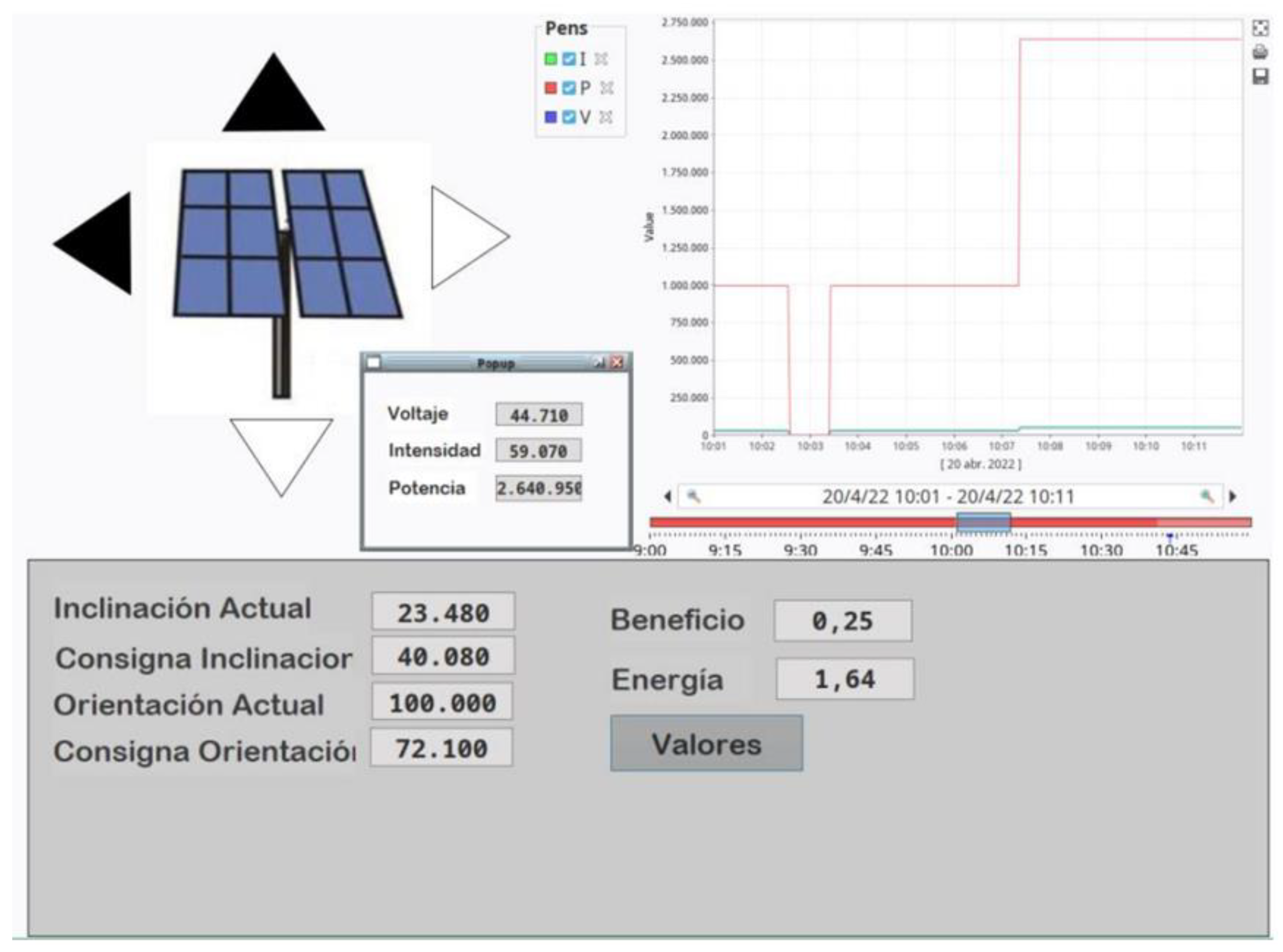

The graphical interface allows for real-time monitoring and control of a dual-axis solar tracker system. It includes visual and numerical indicators to display tilt, orientation, voltage, current, power, energy generated, and economic benefits. Additionally, it features a graph showing the system’s performance over time, highlighting key values such as voltage, current, and power, enabling historical analysis. An interactive button provides access to more details, while the interface is intuitive, allowing for manual adjustments and efficient system control.

The use of the MQTT protocol, along with an IoT gateway, proved to be crucial in ensuring efficient communication between the sensors, the programmable logic controller (PLC), and the SCADA platform. During testing, it was observed that the system could transmit real-time data without interruptions, even in scenarios where network bandwidth was limited. The continuous data flow ensured constant updates on the system’s status, allowing actuators to quickly adjust the solar tracker’s position when necessary.

This approach was further complemented by integration with platforms such as Node-RED and groov View, which provided intuitive graphical interfaces for remote system monitoring. Operators were able to access the SCADA platform from any internet-connected device, significantly enhancing their ability to manage operations remotely, thereby reducing the need for physical intervention on-site.

Another key result was the successful implementation of system simulations in a test environment. Although the system has not yet been deployed in a real operational setting, local simulations with the PLC and sensors demonstrated accurate system behaviour under controlled conditions. This provided an excellent initial validation of the proposed architecture and suggested that the system is scalable and adaptable for implementation in real solar installations.

While the system performed optimally under ideal conditions, certain environmental factors were identified that could affect its efficiency in real-world settings. For instance, adverse weather conditions, such as cloud cover or sudden temperature changes, were not fully modelled in the astronomical algorithm. These external factors can influence the amount of available solar radiation and, consequently, the system’s efficiency. To mitigate these challenges, it is recommended that future iterations of the solar tracking algorithm integrate weather predictions, which could improve the accuracy of irradiance forecasting and enable more dynamic system adjustments.

4. Conclusions

The development of a remote monitoring and control system for a dual-axis solar tracker based on advanced technologies such as IoT, SCADA, and MQTT has proven to be an effective approach to improving both the efficiency of solar energy capture and the operational management of photovoltaic installations. The results obtained in this project emphasize the importance of implementing automated systems that optimize the real-time orientation of solar panels, allowing for maximized energy production. The integration of astronomical algorithms for solar tracking has significantly increased energy capture, reinforcing the technical and economic viability of these systems, especially in large-scale applications. Additionally, the system’s ability to detect and prevent faults through predictive maintenance algorithms and the use of advanced sensor networks has proven to be a key advantage. Early detection of anomalies enables proactive interventions that reduce downtime and improve the longevity of system components, resulting in greater reliability and lower long-term operational costs. Furthermore, the SCADA system has provided a robust platform for real-time data visualization as well as remote system management from any location, increasing both operational flexibility and efficiency.

However, some limitations have been identified, offering opportunities for future improvements. For instance, although the system has demonstrated its effectiveness in controlled conditions, it would be necessary to test it in a real operational environment to fully validate its robustness and adaptability to various climatic and geographical variations. The astronomical algorithm used, while accurate under optimal conditions, could benefit from the integration of real-time weather predictions to adjust the system’s behaviour in response to sudden changes in weather conditions, such as cloud cover or wind, which could affect solar irradiance.

Another significant challenge is the scalability of the system in larger applications, such as solar farms or hybrid renewable energy installations. Although the technological architecture employed is flexible and allows for expansion, managing multiple solar trackers or integrating with other forms of energy (such as wind) will require adjustments and improvements in the communications infrastructure and data processing capacity.

References

- Alrubaie, A.J.; Al-Khaykan, A.; Malik, R.Q.; Talib, S.H.; Mousa, M.I.; Kadhim, A.M. Review on MPPT Techniques in Solar System. 8th IEC 2022 - International Engineering Conference: Towards Engineering Innovations and Sustainability. 2022, pp. 123–128. [CrossRef]

- Kermadi, M.; et al. Recent developments of MPPT techniques for PV systems under partial shading conditions: A critical review and performance evaluation. IET Renewable Power Generation 2020, 14, 3401–3417. [Google Scholar] [CrossRef]

- Lin, W.; Zhang, B.; Li, H.; Lu, R. Multi-step prediction of photovoltaic power based on two-stage decomposition and BILSTM. Neurocomputing 2022, 504, 56–67. [Google Scholar] [CrossRef]

- Kuttybay, N.; et al. Assessment of solar tracking systems: A comprehensive review. Sustainable Energy Technologies and Assessments 2024, 68, 103879. [CrossRef]

- Colmenares-Quintero, R.F.; Rojas-Martinez, E.R.; Macho-Hernantes, F.; Stansfield, K.E.; Colmenares-Quintero, J.C. Methodology for automatic fault detection in photovoltaic arrays from artificial neural networks. Cogent Eng. 2021, 8. [Google Scholar] [CrossRef]

- Dallaev, R.; Pisarenko, T.; Papež, N.; Holcman, V. Overview of the Current State of Flexible Solar Panels and Photovoltaic Materials. 2023. [CrossRef]

- Liu, J.; Fang, W.; Zhang, X.; Yang, C. An Improved Photovoltaic Power Forecasting Model With the Assistance of Aerosol Index Data. IEEE Trans Sustain Energy 2015, 6, 434–442. [Google Scholar] [CrossRef]

- Bhattacharya, T.; Chakraborty, A.K.; Pal, K. Effects of Ambient Temperature and Wind Speed on Performance of Monocrystalline Solar Photovoltaic Module in Tripura, India. Journal of Solar Energy 2014, 2014, 1–5. [Google Scholar] [CrossRef]

- Martínez-Urrea, G.G.; González, A.G.; Aparicio, M.A.; Martínez, J.C.G.; Abrisqueta, F.A.L. Evaluating the Technical and Economic Impact of 4.0 Technologies in Photovoltaic Installations: A Case Study in the Residential and Industrial Sectors of Murcia. 2024. [CrossRef]

- Kumari, P.; Toshniwal, D. Deep learning models for solar irradiance forecasting: A comprehensive review. J Clean Prod 2021, 318, 128566. [Google Scholar] [CrossRef]

- Zhang, R.; Bu, S.; Zhou, M.; Li, G.; Zhan, B.; Zhang, Z. Deep reinforcement learning based interpretable photovoltaic power prediction framework. Sustainable Energy Technologies and Assessments 2024, 67, 103830. [Google Scholar] [CrossRef]

- Zsiborács, H.; Baranyai, N.H.U.; Vincze, A.; Háber, I.; Pintér, G. Economic and Technical Aspects of Flexible Storage Photovoltaic Systems in Europe. Energies 2018, 11, 1445. [Google Scholar] [CrossRef]

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renewable and Sustainable Energy Reviews 2022, 159, 112213. [Google Scholar] [CrossRef]

- Zahraoui, Y.; et al. Energy Management System in Microgrids: A Comprehensive Review. Sustainability 2021, 13, 10492. [Google Scholar] [CrossRef]

- Moguel, E.; Preciado, J.C.; Sanchez-Figueroa, F.; Preciado, M.A.; Hernandez, J. Multilayer Big Data Architecture for Remote Sensing in Eolic Parks. IEEE J Sel Top Appl Earth Obs Remote Sens 2015, 8, 4714–4719. [Google Scholar] [CrossRef]

- Calle, A.R.; Baca, G.A.; Gonzales, S. Optimization of the Eolic Cell to improve the wind velocity augmentation effect through the metamodel of optimal prognosis. Energy Conversion and Management: X 2022, 16. [Google Scholar] [CrossRef]

- Zhou, Y.; Bao, T.; Shu, X.; Li, Y.; Li, Y. BIM and ontology-based knowledge management for dam safety monitoring. Autom Constr, 2023, 145. [Google Scholar] [CrossRef]

- Park, D.; You, H. A Digital Twin Dam and Watershed Management Platform. Water (Basel) 2023, 15, 2106. [Google Scholar] [CrossRef]

- Meraihi, Y.; Gabis, A.B.; Mirjalili, S.; Ramdane-Cherif, A. Grasshopper optimization algorithm: Theory, variants, and applications. IEEE Access 2021, 9, 50001–50024. [Google Scholar] [CrossRef]

- Wu, Z.; Shen, D. Parameter identification of photovoltaic cell model based on improved grasshopper optimization algorithm. Optik (Stuttg) 2021, 247, 167979. [Google Scholar] [CrossRef]

- Chen, Y.; et al. Energy, exergy, and economic analysis of a solar photovoltaic and photothermal hybrid energy supply system for residential buildings. Build Environ 2023, 243, 110654. [Google Scholar] [CrossRef]

- Clauser, N.M.; Felissia, F.E.; Area, M.C.; Vallejos, M.E. Integrating the new age of bioeconomy and Industry 4.0 into biorefinery process design. Bioresources 2022, 17, 5510–5531. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).