1. Introduction – Finding the Best Construction Strategy

For some countries without shallow water, floating wind in deep water is the only way to generate a substantial amount of wind energy. Unfortunately, at the moment, floating wind is much more expensive than fixed-bottom offshore wind, particularly due to mass floater production and supply chain challenges [

1]. To achieve cost reductions in line with fixed offshore wind, streamlining mass production and installation of FOWT is necessary.

Hong et al. [

2] made a broad overview of FOWT farm installation challenges and opportunities. They emphasized challenges such as the increasing difficulty of turbine-floater mating (integration), the necessity for installation vessels’ fleet expansion and the refinement of cost estimation models, making use of weather and environmental data. They also identified opportunities for improvement, such as the potential for technological advancements to simplify the integration process and the use of data-driven models to enhance cost estimation accuracy.

Torres et al. [

3] compared FOWT installation strategies for 3 different integration ports in the UK, highlighting the strong influence that port choice exerts on project cost and execution time. Notably, he explored the influence of foreign manufacturing and floater towing time on the project.

The floater assembly and turbine integration concepts were touched upon by Diaz and Soares [

4]; they produced a tool for an economic view of the logistics and installation involved in a FOWT farm design with a TLP floater farm as a case study. They identified numerous parameters as inputs for the tool, including crane capacity, quay space, cable length, etc, providing a good point for comparison. BVG Associates produced a large report, calculating in-detail components and process costs for the whole FOWT farm lifecycle, albeit only for a single strategy [

5].

Previous studies focused on optimising a single floater structural design and mooring system [

6,

7,

8,

9], which will be used as a baseline for this study. The port requirements commonly mentioned in the literature [

4,

5] are quay bearing capacity, crane reach and lifting capacity. This study provides these numbers for a hypothetical 100-floater farm based on the TaidaFloat semi-submersible floater [

7,

10] equipped with NREL’s IEA 15 MW wind turbine [

11].

There are two possible approaches to studying FOWT port operations: (1) use an existing port and tailor operations to its constraints, or (2) devise a perfect port for the most effective operations. Port construction is an immense capital investment, and construction and planning take more than a decade, including planning for FOWT and other types of operations (cargo, passenger, military). Given that, it was decided to focus on an existing port and compare how different installation strategies would affect the requirements.

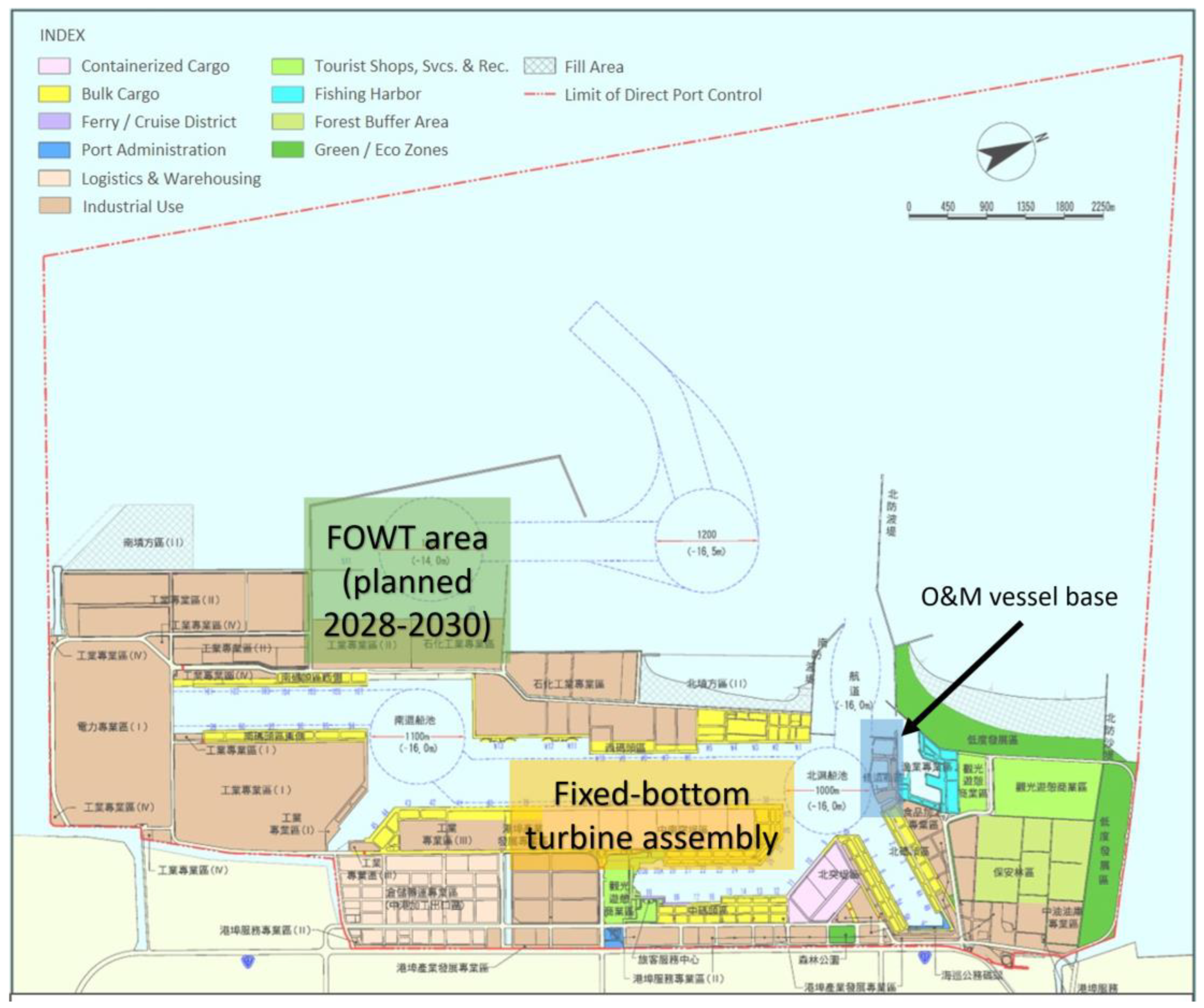

As the wind farm will be in the Taiwan Strait, Taichung port has been chosen for the study. Taichung is one of Taiwan's only two industrial-use harbours without height restrictions due to nearby airports, which ban 15 MW turbines from being installed in other harbours for aeroplane safety reasons (the other being Xingda harbour). The government of Taiwan has already designated Taichung as an offshore wind port, and it’s undergoing an expansion to provide a safe harbour for FOWT and other industrial projects, which includes 2 new quays directly facing the Taiwan Strait and a wave breaker, seen in Figure 1.1 [

12]. Interior quays (those inside the port) currently used for fixed-bottom wind marshalling will not be available for FOWT floaters due to the collision risk of marine traffic. The two new quays will be leased independently to two developers. This study investigates whether the two quay’s space could be used effectively compared to other alternatives.

Figure 1.1.

Future arrangements for accommodating the integration and assembly of floating wind turbines, using Taichung port as an example. Reworked based on a picture from [

13].

Figure 1.1.

Future arrangements for accommodating the integration and assembly of floating wind turbines, using Taichung port as an example. Reworked based on a picture from [

13].

Several strategies were researched and compared in regard to the floater’s construction/assembly and turbine integration. One key conclusion is that floater on-quay assembly in Taichung would be more cost-effective than the construction and towing from a drydock in Kaohsiung or other remote places.

2. Port Operations and Crane Types

Table 2.1 lists the complete list of possible port operations needed for a FOWT project and the necessary equipment. Not all operations are expected to be done in the same port; a port is classified depending on which operations are done in it. Theoretically, all these functions could be separated into different ports. A few concepts have been proposed:

Floater – Floater hull assembly port;

Turbine – Turbine integration port;

F+T – Floater assembly and Turbine integration port;

Moor – mooring and service base port;

All – All-in-one hub port.

The floater, turbine, and mooring components for 15 MW FOWT are all large in size and heavy in weight, so usually, the only viable shipping strategy is by sea; therefore, all of the concepts above need at least a deep enough quay and a crane for loading/offloading operations; however, locally produced components might not need that. This study assumes that floater components are fabricated elsewhere; alternative ways are local manufacturing or delivery in pre-assembled blocks.

Table 2.1.

Port classifications based on capabilities of operation types for a FOWT project.

Table 2.1.

Port classifications based on capabilities of operation types for a FOWT project.

| Floater |

Turbine |

F+T |

Moor |

All |

Operation types |

Quay depth, m |

Crane capacity, t |

Storage, km2 |

| |

|

|

|

|

Components offloading |

4-10 |

< 1000 |

0.02 |

| |

|

|

|

|

Turbine assembly |

- |

< 1600 |

0.03 |

| |

|

|

|

|

Turbine integration |

8-12 |

< 3200 |

0.05 |

| |

|

|

|

|

Turbine comp. storage |

- |

- |

0.06 |

| |

|

|

|

|

Floater comp. storage |

- |

- |

0.2 |

| |

|

|

|

|

Floater assembly |

- |

< 1600 |

0.03 |

| |

|

|

|

|

Floater launch |

8-12 |

- |

0.02 |

| |

|

|

|

|

Mooring comp. storage |

- |

< 200 |

0.04 |

| |

|

|

|

|

Anchor Handling Ves. Base |

4-8 |

< 200 |

- |

| |

|

|

|

|

Service Vessel base |

4-8 |

< 200 |

- |

| |

|

|

|

|

Spare parts storage |

- |

< 200 |

0.04 |

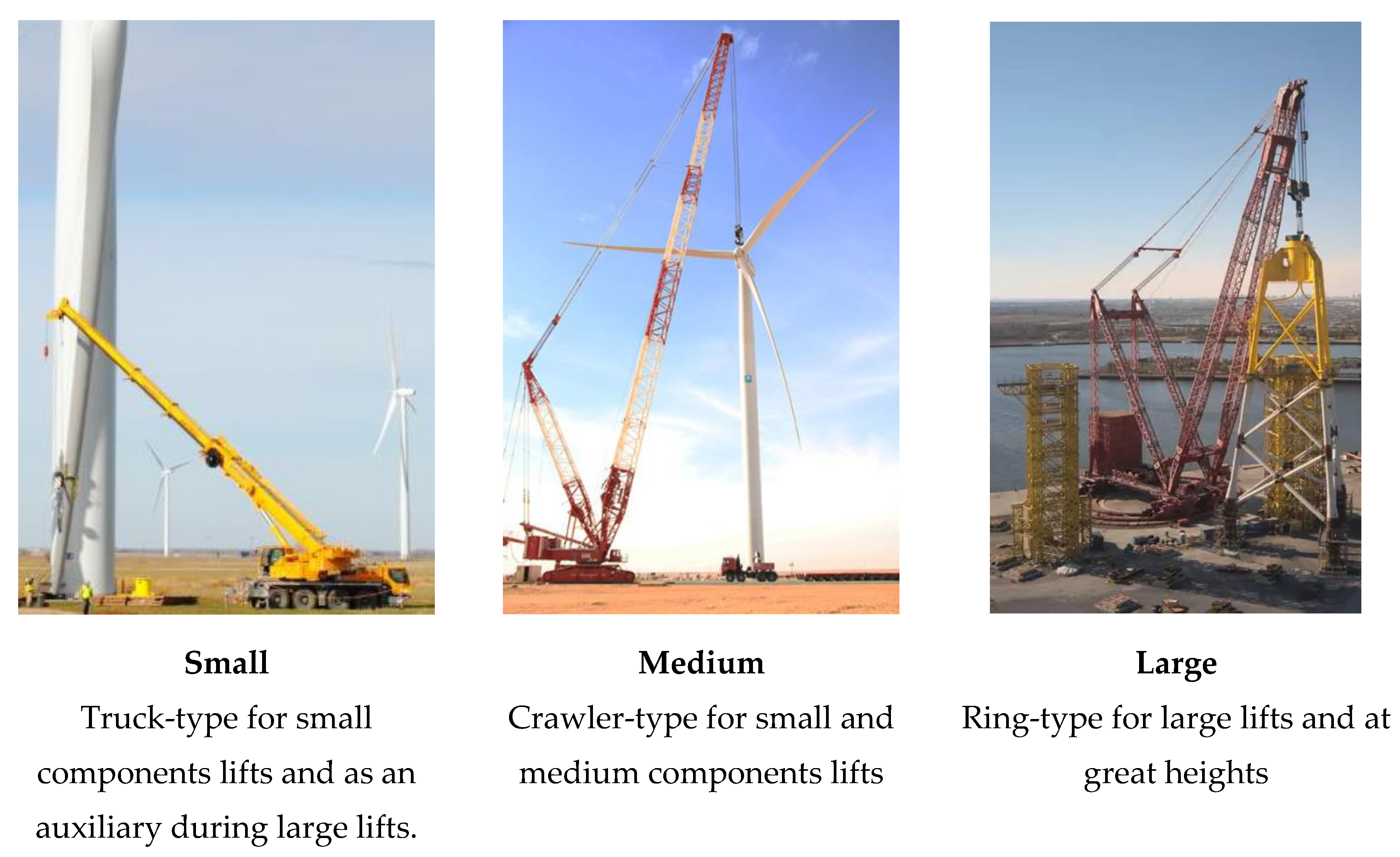

For all the lifting operations involved, cranes are the critical tools. For this study, they are defined as per Figure 2.1. While small and medium cranes can be procured relatively easily, procuring, installing, and operating a large crane (i.e. ring crane) is challenging. Therefore, the latter is discussed in detail here. The large crane may perform heavy lifts during floater assembly, turbine installation, and unloading vessels with incoming equipment. When selecting a crane, not only the lifting capacity needs to be checked, but also the reaching range for a particular component’s weight as defined in crane curves.

Figure 2.1.

Cranes definition. Photo courtesy: CraneHotLine, Liebherr, and Mammoet.

Figure 2.1.

Cranes definition. Photo courtesy: CraneHotLine, Liebherr, and Mammoet.

For example, the CC9800 crane [

14] has a 1600 t lift capacity and 228 maximum height, but upon a close investigation of its specification, at 150 m (nacelle height), it can only lift 355 t. Thus, it is not suitable for nacelle lift. LR 11350 was chosen in Taichung harbour improvement study of 2016 [

12]. LR 11000, LR 11350, LR 12500 and LR 13000 [

15] lifting tables were analysed, and only LR 12500 [

16] was found suitable for a 15 MW nacelle lift (configuration H90 W54 B2). It is noted that without a detailed lifting table analysis, suitability can’t be judged just on maximum capacity, an erroneous assumption often made in the literature.

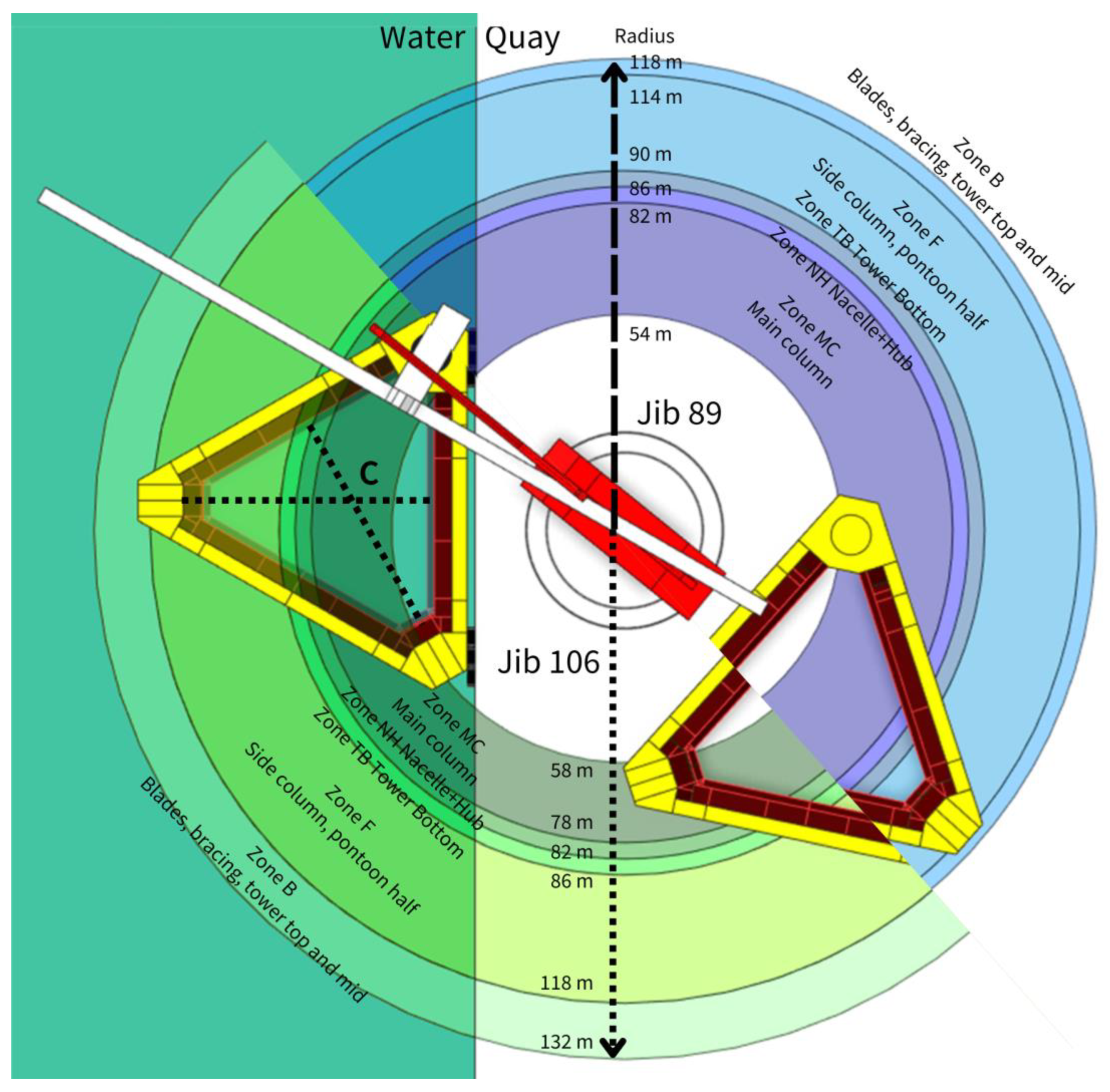

The PTC200-DS mega crane is selected for this study as one of its variants. The mega crane (also known as ring crane) had already been employed recently in a nearby harbour in Taiwan [

17] for lifting jacket foundations. It has sufficient lift capacity to lift a 15 MW nacelle to 150-165 m hub height. It has several configurations of boom and jib length, specification details of the weights that can be lifted at different heights and horizontal reach radii [

18]. In this paper, it is expected that all the operations will be completed by only one main crane, sometimes with the help of a small or medium auxiliary crane. Therefore, the crane should be fit for all operations. One of the most significant constraints from offshore wind experience is the nacelle lift, where height, reach and weight are all pushed to the limit. Due to this requirement, only the maximum boom length configurations are considered, and different jib lengths allow balancing between the required maximum weight, height, and reach, as illustrated in Figure 2.2. All the liftable components' weights are compiled in Table 2.2 to determine which jib length is suitable. The corresponding reach radius for 3 different jibs is found in the crane spec [

18].

Table 2.2.

Summary of components that need to be lifted with weights and the maximum workable radii.

Table 2.2.

Summary of components that need to be lifted with weights and the maximum workable radii.

| Using PTC 200-DS 140 crane |

|

Crane Radius, m |

|

| 15 MW IEA Turbine |

Quantity |

Mass, t |

Jib 106 |

Jib 101 |

Jib 89 |

| Tower top |

1 |

213 |

132 |

132 |

118 |

| Tower mid |

1 |

252 |

132 |

132 |

118 |

| Tower bot |

1 |

796 |

86 |

86 |

90 |

| Nacelle+Hub |

1 |

822 |

82 |

86 |

86 |

| Blade 1x |

3 |

65 |

208 |

200 |

118 |

| Total |

|

2280 |

|

|

|

| |

|

|

|

|

|

| TaidaFloat (ver. 4.1.6A) |

|

|

|

|

|

| Main Column |

1 |

883 |

78 |

82 |

82 |

| Side Column |

2 |

492 |

122 |

118 |

114 |

| Pontoon half |

6 |

521 |

118 |

118 |

114 |

| Brace |

3 |

152 |

132 |

132 |

118 |

| Total |

|

5448 |

|

|

|

A project-specific crane working zone could be developed based on specific floater, turbine and crane configurations, such as the one shown in Figure 2.2. Circular bands co-centred with the crane show what components can be lifted. For example, the blades and bracing are relatively lighter and can be lifted with the furthest reach, giving zone B. The zones are cumulative, so liftable components in a zone can also be lifted in the zones of smaller radius (e.g. blades can be lifted in any zone). However, there is a dead-eye zone near the crane where no lifts can be performed.

As a ring crane can’t be moved and changing configuration is very time-consuming and expensive, a suitable configuration must be chosen to handle floater assembly, turbine integration and components lifts. Therefore, the quay, assembly site and temporary storage areas must be organised inside the corresponding zones.

Figure 2.2.

Working zone of a ring crane shown together with 15 MW TaidaFloat, for 2 jibs.

Figure 2.2.

Working zone of a ring crane shown together with 15 MW TaidaFloat, for 2 jibs.

Different jibs are compared to determine the most suitable for operations described in Part 3. Out of the crane specification, 3 jib lengths were suitable to perform all operations: 106, 101 and 89 metres. It is evident from Figure 2.2 that longer jibs have a farther reach, which is beneficial, but smaller heavy load bands and larger dead zones are detrimental. An unsuccessful attempt was made to optimise the floater assembly strategy by choosing a smaller jib length. Finally, the longest suitable jib (106 m) is chosen, as it allows a larger total working zone, making it easier to access stored components.

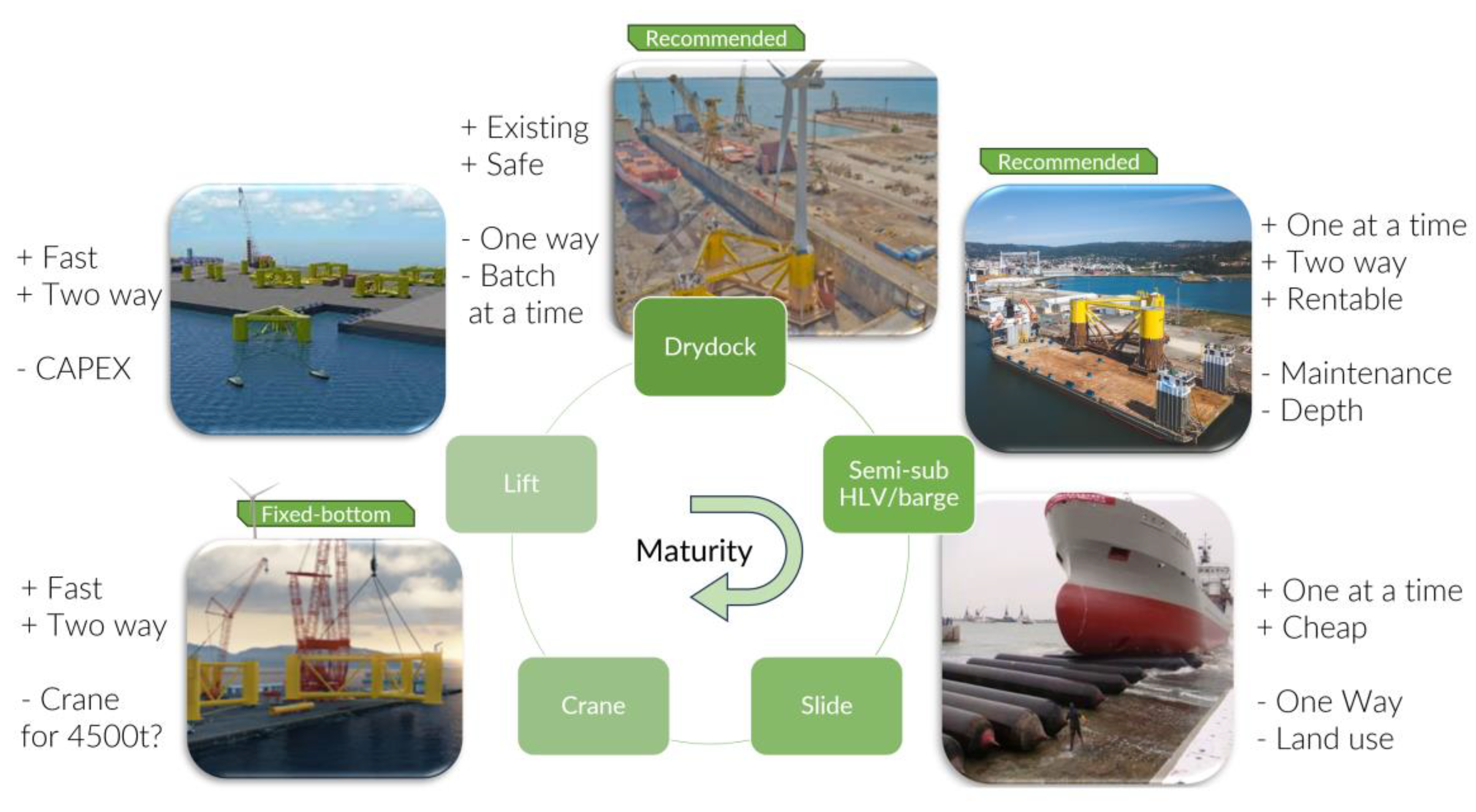

3. Floater Block Assembly and Launching

Next, typical installation procedures are devised, starting with floater block assembly and launch. This is based on the assumption that Taichung port would be the site for assembly and integration. The most challenging part of the procedure is to launch the assembled floater on water after block assembly. Five methods are shown in Figure 3.1. Drydock and semi-sub HLV (heavy lift vessel) are considered more practical among the five. Drydock was used for those semi-submersible platforms for the WindFloat Kincardine and Atlantic projects. Semi-sub HLV has been used many times in the oil and gas industry.

Taichung port doesn’t have such a large infrastructure, i.e. dry dock, slide or lift. Also, a 5448-ton floater can’t be lifted by any crane. The best method may be a semi-submersible barge (e.g. a floating dock) as the most viable launching option. When using this method, port depth is critical, as it must accommodate the floater hull (5 m) and the HLV (2-6 m) draft. However, other solutions are available to utilise the existing infrastructures in Kaohsiung or Taipei ports. A wet tow of the floater to Taichung would be required, which may take two to four days.

Figure 3.1.

Ways to launch a floater. Pictures courtesy of: Principle Power, Ocergy, Bardex.

Figure 3.1.

Ways to launch a floater. Pictures courtesy of: Principle Power, Ocergy, Bardex.

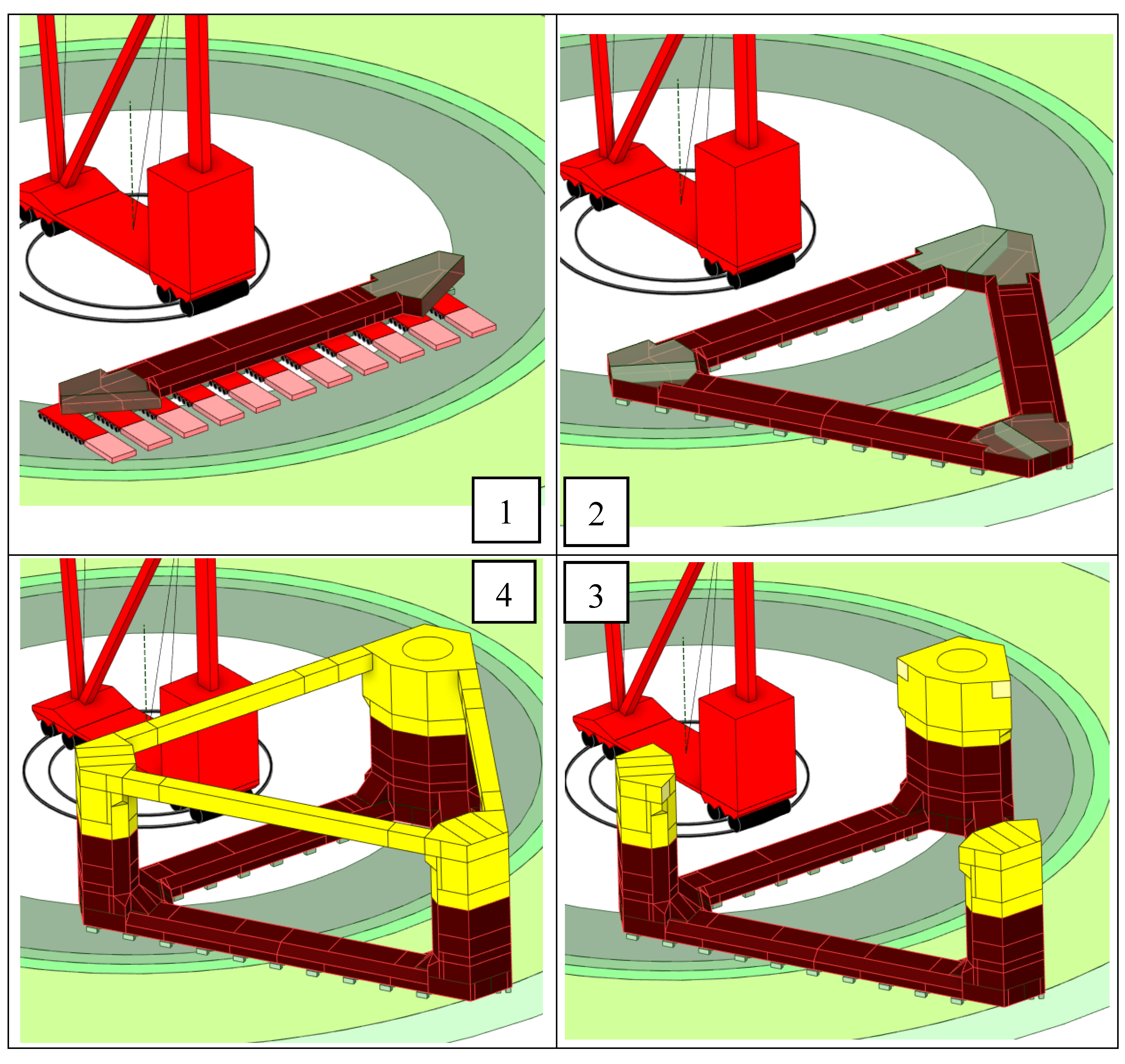

Figure 3.2 shows the quayside block assembly method of the TaidaFloat using a ring crane and SPMTs [

19], of which the four steps are explained below.

The main column is positioned closer to the crane, as the crane can only handle its heavy weight in a particular range (dark green), as explained in Figure 2.2 and Table 2.2. The far side column can’t be too far from the crane (light green). With these constraints, the only possible floater position during assembly is shown in Figure 2.2. This implies that the pontoon closest to the crane must be installed with SPMTs, as it is in its blind zone.

Step 1: The 1st pontoon support blocks are installed, then the first pontoon is placed on blocks using SPMTs.

Step 2: The other support blocks should be correctly placed based on the actual location. The remaining 2 pontoons are installed with the ring crane. After alignment is confirmed, pontoons are welded together.

Step 3: The 3 columns are installed with a ring crane and an auxiliary crane (for upending columns to vertical position). Columns welded to the pontoons.

Step 4: Lift 1 brace with the main crane, weld to columns, and repeat for the other 2 braces.

Figure 3.2.

Floater quayside block assembly, steps 1 to 4.

Figure 3.2.

Floater quayside block assembly, steps 1 to 4.

The complete list of assembly steps is shown in Table 3.1; it is assumed that (i) water tightness tests and (ii) non-destructive weld tests are performed in parallel with the next component assembly. Electro gas manual welding is used as this is a quay environment, and many seams are vertical or slanted. Time for welding operations varies on the thickness of the metal and is calculated according to Table 3.2, adapted from [

20]. Time for lifting operations was approximated from [

21]. A Gantt chart was made, and manpower was identified as a bottleneck. Even though some operations, such as installing the columns, can be performed in parallel, changing the number of skilled workers (welders) during the installation is impractical due to logistical and contractual reasons. Assuming one team of six works one 8-hour shift a day, 2 teams could

assemble the floater in 77 days or three teams in 51 days, which could be impractical due to 3-shift working time during the night. The paper assumes no weekends or holiday breaks, which is true for many Asian enterprises. This may be achieved by hiring more part-time employees, but this is not always the case in real life. It should be noted that there are some floater designs [

22,

23] that promise fast assembly without welding. However, they haven’t been tested yet, and most floaters have historically been welded.

Table 3.1.

Floater assembly procedure and estimated time.

Table 3.1.

Floater assembly procedure and estimated time.

| No. |

Assembly procedure |

Thickness, mm |

Seam length, m |

Time, h |

| 1 |

Pontoon 1 lift |

30 |

|

5.0 |

| 2 |

Pontoon 1 middle weld |

30 |

50.6 |

189.2 |

| 3 |

Pontoon 1 butt weld 1 |

30 |

87.7 |

327.8 |

| 4 |

Pontoon 1 butt weld 2 |

30 |

87.7 |

327.8 |

| 5 |

Pontoon 2 lift |

30 |

|

5.0 |

| 6 |

Pontoon 2 middle weld |

30 |

50.6 |

189.2 |

| 7 |

Pontoon 2 butt weld 1 |

30 |

87.7 |

327.8 |

| 8 |

Pontoon 2 butt weld 2 |

30 |

87.7 |

327.8 |

| 9 |

Pontoon 3 lift |

30 |

|

5.0 |

| 10 |

Pontoon 3 middle weld |

30 |

50.6 |

189.2 |

| 11 |

Pontoon 3 butt weld 1 |

30 |

87.7 |

327.8 |

| 12 |

Pontoon 3 butt weld 2 |

30 |

87.7 |

327.8 |

| 13 |

MC lift 1 |

30 |

|

5.0 |

| 14 |

MC bottom weld |

30 |

170 |

634.0 |

| 15 |

MC lift 2 |

30 |

|

5.0 |

| 16 |

MC mid weld |

30 |

142 |

529.2 |

| 17 |

SC 1 lift |

30 |

|

5.0 |

| 18 |

SC 1 weld |

30 |

124 |

462.1 |

| 19 |

SC 2 lift |

30 |

|

5.0 |

| 20 |

SC 2 weld |

30 |

124 |

462.1 |

| 21 |

Bracing 1 lift |

20 |

|

53.0 |

| 22 |

Bracing 1 weld 1 |

20 |

30 |

52.2 |

| 23 |

Bracing 1 weld 2 |

20 |

30 |

52.2 |

| 24 |

Bracing 2 lift |

20 |

|

53.0 |

| 25 |

Bracing 2 weld 1 |

20 |

30 |

52.2 |

| 26 |

Bracing 2 weld 2 |

20 |

30 |

52.2 |

| 27 |

Bracing 3 lift |

20 |

|

53.0 |

| 28 |

Bracing 3 weld 1 |

20 |

30 |

52.2 |

| 29 |

Bracing 3 weld 2 |

20 |

30 |

52.2 |

| 30 |

Internal systems outfitting |

|

|

72.0 |

| 31 |

Transportation to barge |

|

|

24.0 |

| 32 |

Towing to quay |

|

|

12.0 |

| |

Total |

|

Manhours |

5237 |

Table 3.2.

Estimated welding time by thickness [

20].

Table 3.2.

Estimated welding time by thickness [

20].

| Electro gas manual welding |

| Thickness, mm |

10 |

15 |

20 |

25 |

30 |

35 |

| Hours to weld 5m |

6.8 |

7.6 |

8.7 |

10.3 |

13.1 |

18.7 |

| Hours to weld 1m |

1.36 |

1.52 |

1.74 |

2.06 |

2.62 |

3.74 |

| Weld area preparation, h |

2 |

2 |

2 |

2 |

2 |

2 |

Skilled welders are in shortage in Taiwan [

24,

25], thus foreign teams are invited for the whole project duration; such teams usually comprise about 6 members. If the crane for assembly is rented on a daily basis, crane idle time is of concern. Construction and idle time can be reduced by performing multiple assemblies in parallel. However, an even more significant concern arises: how often a new set of parts can be delivered for assembly. Minimum total time and idle time can be achieved by using many welders in a perfect situation. However, if 11 teams are used (which could prove impossible to hire), new parts must be delivered each week, which might also be unrealistic. More realistic options are procuring a new set of parts every two weeks (36 welders) or three weeks (24 welders).

After assembly, there are two options:

1) The floater will be transported to a semi-submersible barge and lowered to the water, then moored at the quayside and the turbine installed.

2) The turbine will be installed on the floater onshore, and the assembly will be moved to a barge and lowered to the water.

Option 2 allows much easier turbine integration, as the floater and crane are not moving at all, no mooring is needed, and electricity is easily supplied to the turbine for hub rotation. However, if the turbine is installed first, the SMPTs and supports below the main column must withstand turbine weight and the floater. Also, the crane would need ±30 metres of extra lift height (floater height). Additionally, lowering the weight of the barge will lead to deeper draught, which is limited. Overall, Option 1 may be more practical.

Block support configuration was based on the existing projects. Considering SPMT handling, the main column and pontoon under it (20% of pontoon weight) are supported by 17 blocks with a total area of 38.59 m

2. In option 1, these blocks will support 1092 t, requiring a quay bearing capacity of

28.3 t/m2; option 2 supports 3370 t, requiring 87.3 t/ m

2 capacity. Some upper-end standards require quays to be built for 30 t/m2 capacity, making option 1 viable, while option 2 is not. Therefore, it is not investigated further. While supporting the column with SMPTs could increase the supported area, the floater would still have to rest on blocks when submerged on a barge. Unfortunately, the Taichung Harbour improvement study of 2016 [

12] recommended only 15 t/m

2.

4. Cranes for Turbine Assembly

After launching, the next step is to install the turbine on the floater using cranes. First, the floater must be moored to the quay to minimise the wave-induced motions; note that there will be some movement, so this operation introduces a weather constraint. Alternatively, it can be ballasted to sit on the quay if the seabed surface is flat and the floater structure fits.

Then, there are a few ways to install the turbine [

26] — the 3-part tower lift is chosen due to the weight of the turbine tower for floating wind, then the nacelle is lifted separately due to its weight, and the blades will be installed 1 by 1 with an electrical cable connected to rotate the hub.

The turbine can be placed in the central or out-of-centre (side) column of a semi-submersible floater. It is sometimes reasoned that the side turbine location allows smaller-capacity cranes to be used for turbine integration, which is critical as large cranes are in short supply. In contrast, the central turbine location allows hull weight reductions due to improved stability and turbine load distribution. However, Table 2.2 showed that due to the crane jib’s moment capacity, a very large crane is needed even for side-column configuration; this kind of crane is enough to install the turbine in both central (marked C in Figure 2.2) and side locations. How close the crane can be positioned to the quayside is also a factor, but the usual clearance of 5-10 m is not a problem for 3200 t cranes. This giant crane on-site can also handle the floater on-quay assembly, as shown in Figure 3.2. Overall, having a large crane is the best decision. However, a side column arrangement could help if the large crane is impossible to procure due to supply chain constraints. Then, a tandem of two smaller crawler cranes could install the turbine, as with the 15 MW onshore prototype [

27].

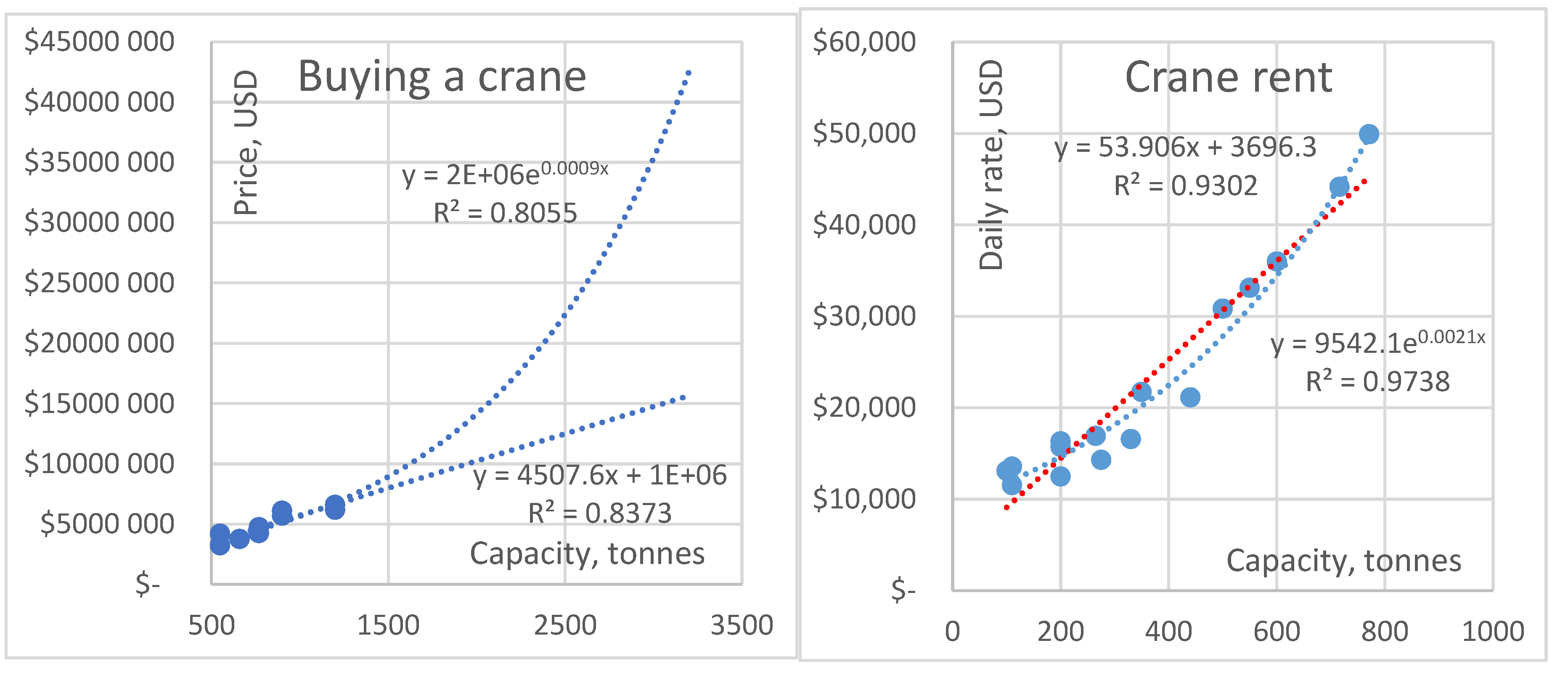

Thus, the crane cost is important in determining the floater configuration in the very early design stage. No data on the cost of large cranes is openly available online; crane manufacturers declined to share due to commercial sensitivity and pricing complexity. Data for the rental [

28] and purchase of small and medium cranes (up to 1200 t) was found on different websites.

These prices were extrapolated to 3200 t using linear and exponential functions for rental and purchase, shown in Figure 4.1. While both approaches yield similar results at small-medium capacity, they give wildly different results when extrapolated to 3500 t.

Data for 600 t and 1000 t cranes from [

4] fits well with extrapolated prices [

28]. Data in BVG associates Floating Wind Guide [

5] doesn’t explain whether cranes are rented or bought and gives a one-number installation cost considering both crane and SPMT lifting operations. SMPT rental prices could not be found online freely and were roughly estimated from a bridge-building report [

29] and sale website

[30]; thus, 10 axle lines of SPMT would cost 90566

$/day (377

$/hour/line). It was concluded that BVG associates assumed buying the crane.

To check the validity of the prices as they came from different sources, the purchase price was divided by the rent to find how many days of rent crane costs — similar numbers (around 100 days) show the validity of the data and also that if you plan to use the crane for longer, it might be cheaper to buy the crane. Based on this, the linear extrapolation gave the best fit to estimate the rental and purchase prices of the 3200 t crane. The rental price of 176 196 $/day is marked up by 50% to 264 293 $/day to account for supply scarcity; the purchase price of 15 424 320 $ is marked up to 23 136 480 $. One-time shipping and installation costs are neglected due to volatile prices on shipments. Buying a crane is not discussed further because of the complexity of depreciation, salary, and other costs.

Figure 4.1.

Crane price extrapolation.

Figure 4.1.

Crane price extrapolation.

No matter the crane, the wind turbine can only be installed when the wind (10-min, 10 m reference height) is slower than 10 m/s [

31]. Table 4.1 shows Taichung port wind statistics [

12]. 6 months from April to September have sufficiently low wind speeds more than 70% of the time. Thus, they are called the installation season. Accounting for the unworkable days, the season duration is 146 days. As the exact dates of strong wind can’t be predicted, for further calculations, it is instead assumed that the installation season is an uninterrupted 146 days from the beginning of May to the late days of September; thus, the timeline is not fragmented, and the total number of workable days is same with statistical data. In reality, the time window is fragmented and relatively unpredictable, so start-up times and decision-making also highly affect the actual workability.

Table 4.1.

Taichung port wind statistics and workability. Adapted from [

12].

Table 4.1.

Taichung port wind statistics and workability. Adapted from [

12].

| Month |

Mean Speed (m/s) |

Max. Wind Speed/Direction |

Wind Speed <5m/s (%) |

Wind Speed 5-10m/s (%) |

Wind Speed 10-15m/s (%) |

Wind Speed >15m/s (%) |

Direction N-E (%) |

Direction E-S (%) |

Direction S-W (%) |

Direction W-N (%) |

|

Wind speed <10m/s |

Days |

Workable days |

| Jan |

13.8 |

28.4/NE |

7.3 |

19.5 |

24.9 |

48.3 |

90.9 |

2.3 |

1.1 |

5.7 |

|

27% |

31 |

8 |

| Feb |

11.7 |

27.8/N |

18.8 |

22.1 |

24.1 |

35 |

82.8 |

3.8 |

6.1 |

7.1 |

|

41% |

29 |

12 |

| Mar |

10.5 |

32.4/NE |

25.2 |

23.9 |

23.5 |

27.5 |

76 |

5 |

10.6 |

8 |

|

49% |

31 |

15 |

| Apr |

7.9 |

30.1/NNE |

32.6 |

37.8 |

18.4 |

11.3 |

58.9 |

7.8 |

22.5 |

10.6 |

|

70% |

30 |

21 |

| May |

7 |

27.6/NE |

35.1 |

44.3 |

15.6 |

5 |

50.5 |

7 |

32.4 |

9.9 |

|

79% |

31 |

25 |

| Jun |

7.1 |

21.1/SW |

28.8 |

51.5 |

17.2 |

2.5 |

27.4 |

10 |

54.9 |

7.6 |

|

80% |

30 |

24 |

| Jul |

6.6 |

37.5/NNE |

34.8 |

53.4 |

8.7 |

3.2 |

21.1 |

10.3 |

54.3 |

14.2 |

|

88% |

31 |

27 |

| Aug |

5.7 |

35.5/NNE |

52.6 |

36 |

8 |

3.4 |

24.5 |

15.3 |

43.4 |

16.6 |

|

89% |

30 |

27 |

| Sep |

7.6 |

36.3/N |

40.4 |

31.8 |

15.8 |

12.1 |

61.4 |

9.5 |

16.6 |

11.2 |

|

72% |

31 |

22 |

| Oct |

12.4 |

40.0/NNE |

15.9 |

21.9 |

21.8 |

40.4 |

88.6 |

3 |

4.2 |

4.1 |

|

38% |

30 |

11 |

| Nov |

12.1 |

32.2/NNE |

19.9 |

19.5 |

19.9 |

40.8 |

87 |

4.3 |

4.1 |

4.7 |

|

39% |

31 |

12 |

| Dec |

12.8 |

30.3/NNE |

16 |

17.3 |

27.1 |

39.7 |

92.2 |

3 |

1.5 |

3.3 |

|

33% |

30 |

10 |

| Mean |

9.6 |

31.6/NNE |

27.3 |

31.6 |

18.7 |

22.4 |

63.4 |

6.8 |

21 |

8.6 |

|

59% |

365 |

215 |

5. Turbine Integration with Floater

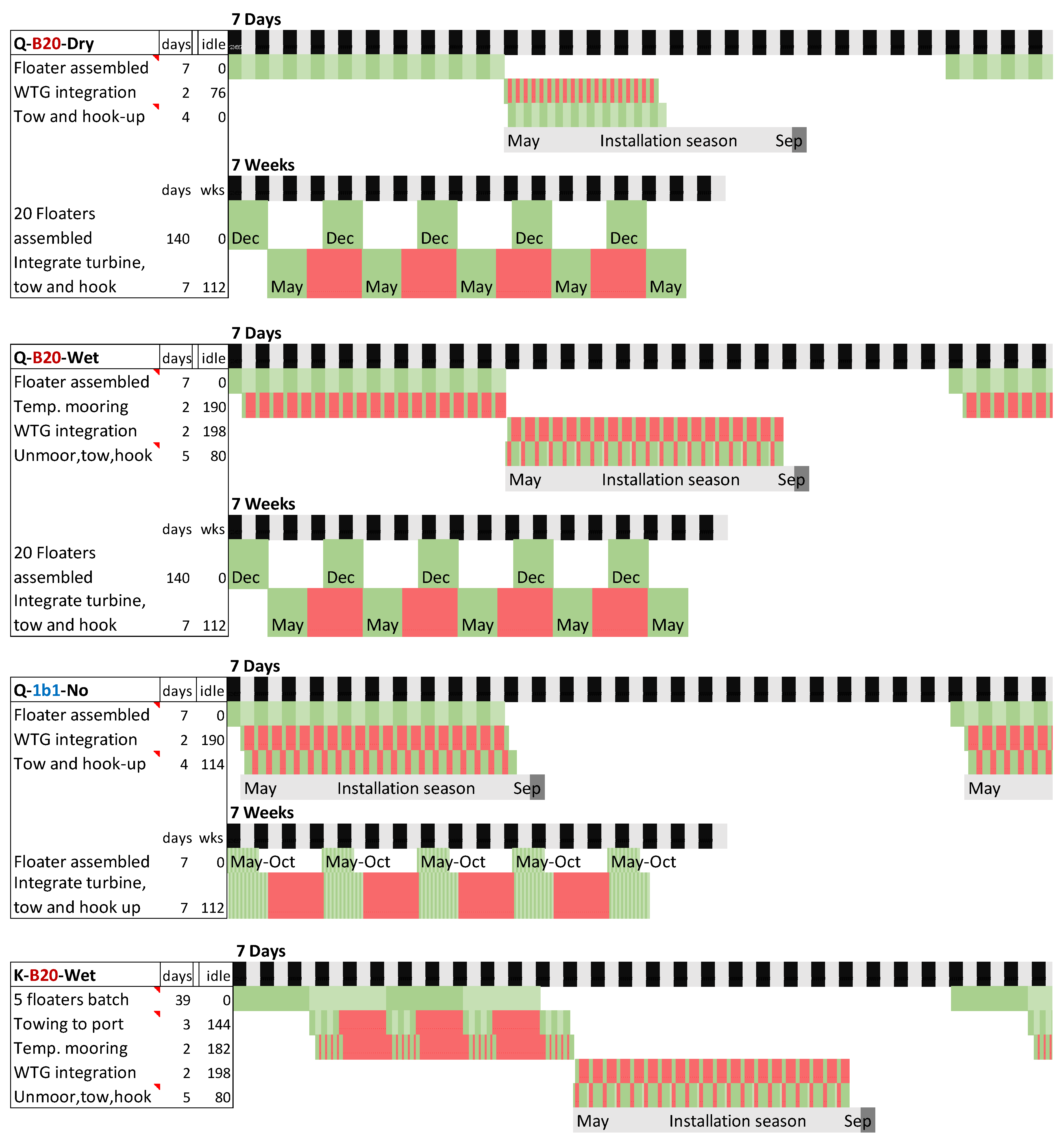

Seven integration strategies are investigated based on ongoing discussions in the industry and a list of port operations in Table 2.1; they are shown in Table 5.1. Floaters are either built on-quay in Taichung port (denoted as Q) or towed from Kaohsiung CSBC shipyard in Taiwan (denoted as K), Nagasaki Oshima Shipyard in Japan (denoted as N) or other places to Taichung. Two turbine integration strategies are compared:

1) One-by-one (1b1): Install the turbine as soon as a floater is ready and then pay for the crane’s idle time before the next installation.

2) Batches of 20 (B20): Wait for a batch of 20 floaters to be ready for integration in one season to minimise the crane idle time.

A crane would be rented each season. In such cases, floaters must be

wet-stored (temporarily moored in the harbour) or

dry-stored on the quay (only for on-quay assembly, as moving floaters up and down the quay is complicated).

No floater storage is required for one-by-one integration. Marine operation time is based on completed projects around the world, compiled by T. Hasumi [

32].

After a cost evaluation under several assumptions, Strategy №1 gives the lowest overall cost. Its low cost mainly comes from the lowest turbine integration cost due to its high crane time efficiency, as the components are located conveniently on-site.

Table 5.1.

Seven FOWT integration strategies.

Table 5.1.

Seven FOWT integration strategies.

|

Strategies№

|

1 Q-B20-Dry

|

2 Q-B20-Wet

|

3 Q-1b1-No

|

4 K-B20-Wet

|

5 K-1b1-N

|

6 N-B20-Wet

|

7 N-1b1-No

|

| Floater Construction |

On-quay |

On-quay |

On-quay |

Kaohsiung |

Kaohsiung |

Nagasaki |

Nagasaki |

| Turbine Integration |

Batches of 20 |

Batches of 20 |

One-by-one |

Batches of 20 |

One-by-one |

Batches of 20 |

One-by-one |

| Storage |

Dry |

Wet |

(n/a) |

Wet |

(n/a) |

Wet |

(n/a) |

20 floaters per batch are chosen, as 25 floaters can’t be installed within the time of the operational season, and in drydock, floaters are manufactured in batches of 5 (assuming full dry dock utilisation). Ships are assumed to be contracted for a minimum of several months of the continuous contract. Thus, the time between installations/tows is paid idle time. 10 assembly teams are working in two 8-hour shifts without holidays in all cases.

In all cases, 20 floaters can be installed during one installation season, but in the N-1b1-No case, only 14 can due to the long towing time from Nagasaki to Taichung, as seen in Figure 5.1. To compare the total time and cost, quay space rent must be estimated first.

Figure 5.1.

FOWT assembly Gantt charts of the 7 strategies. Red denotes rental equipment idle time. To scale, capped at 415 days.

Figure 5.1.

FOWT assembly Gantt charts of the 7 strategies. Red denotes rental equipment idle time. To scale, capped at 415 days.

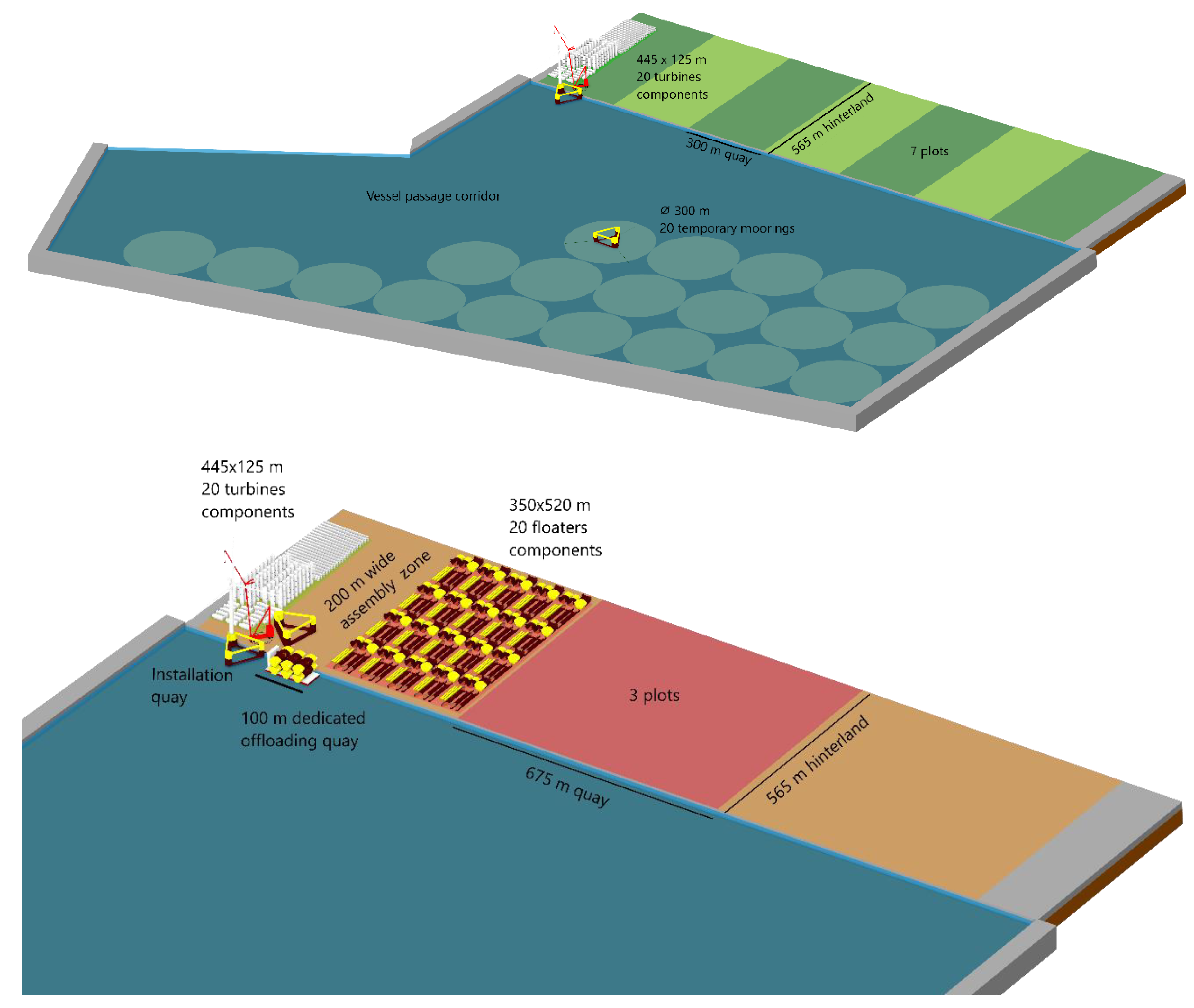

Quay requirements vary depending on the dry or wet storage method; both are shown in Figure 5.2. In both cases, more plots are available than the current Taiwan port authority’s arrangement that divides the quay into 2 plots. However, there is only enough space for wet storage of 1 project’s floaters, so only 1 of the plots could be utilised for a Floating Wind project with wet storage. Possible division configurations are shown in Table 5.2; all 7 developers participating in the Floating Wind auction could be allocated a quay plot, or all 3 winners could be allocated a dry storage plot. Assembly zone dimensions are based on the existing Smulders’ facility in France, where SBM’s TLP and semi-sub WindFloat floaters were assembled successfully [

33].

With storage space requirements calculated, the quay rent price can be estimated using the price known from industry experience — 0.03

$/m

2/day. Dry dock space is valued at 1

$/m

2/day. AHT and tug charter prices from [

34] were doubled to account for installation crew and equipment; 3 small tugs are used for towing and temporary mooring, while an AHT is used for tow-out and hook-up.

It is further assumed that the farm developer rents quay/drydock and employs their own welders and other personnel to perform the assembly works. This assumption is required to eliminate commercial considerations from drydock vs on-quay assembly and compare them fairly. In reality, there will be both revenue margin paid to the shipyard but also savings due to the shipyard’s experience and scale which could not be determined in the scope of this research. It is further assumed that in both quay and dock assembly, individual parts such as columns are sourced at nearby enterprises (1-day sailing distance), delivered by the semi-submersible vessel, and then unloaded by SPMTs.

Table 5.2.

Possible quay division configurations.

Table 5.2.

Possible quay division configurations.

| Floater storage |

Dry+Wet |

Dry+No |

Wet+No |

| Dry storage |

3 |

1 |

0 |

| Wet storage |

1 |

1 |

1 |

| No storage |

0 |

4 |

6 |

| Total projects |

4 |

6 |

7 |

Figure 5.2.

Possible wet (top) and dry (bottom) floater storage arrangements in Taichung port.

Figure 5.2.

Possible wet (top) and dry (bottom) floater storage arrangements in Taichung port.

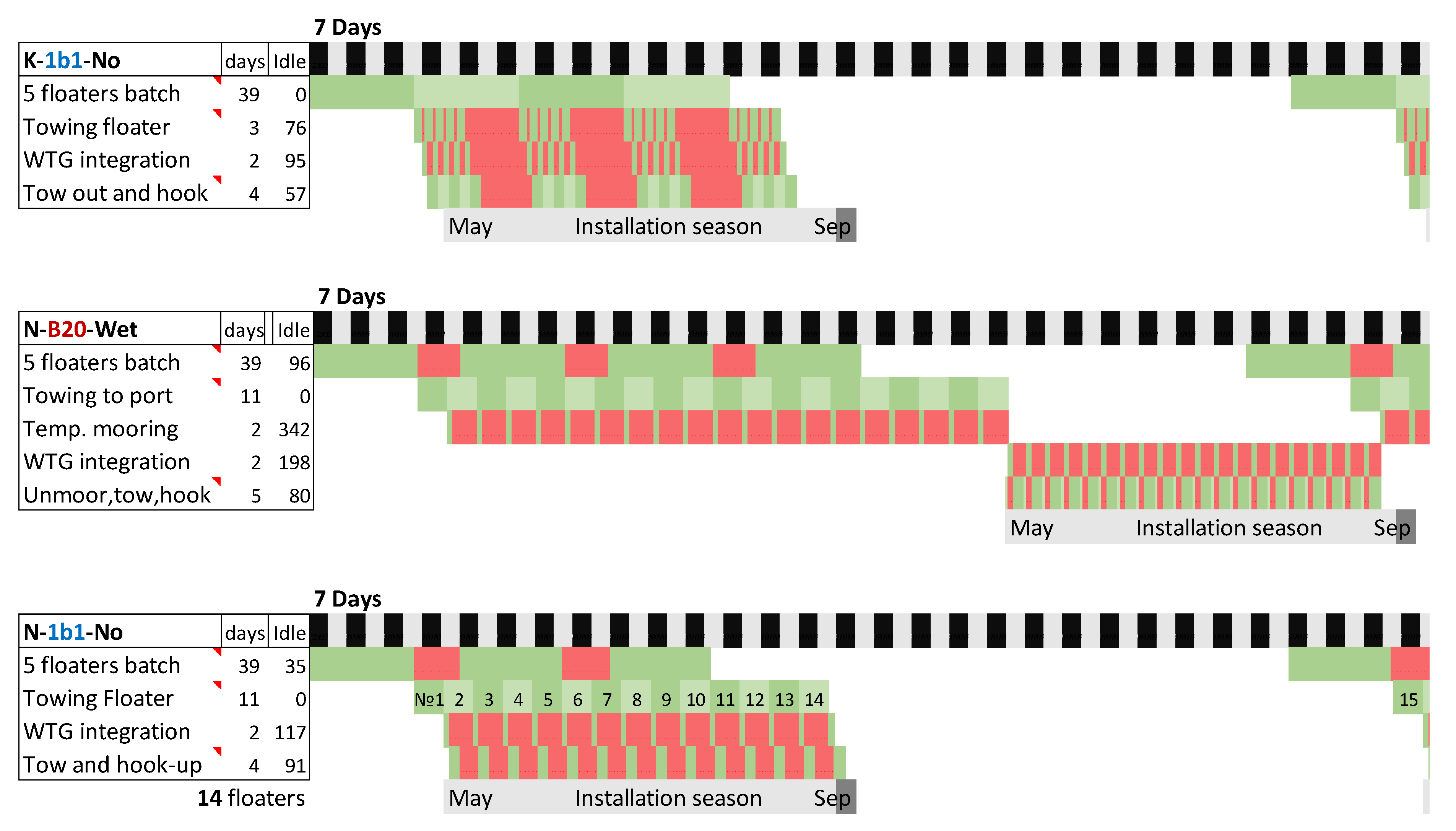

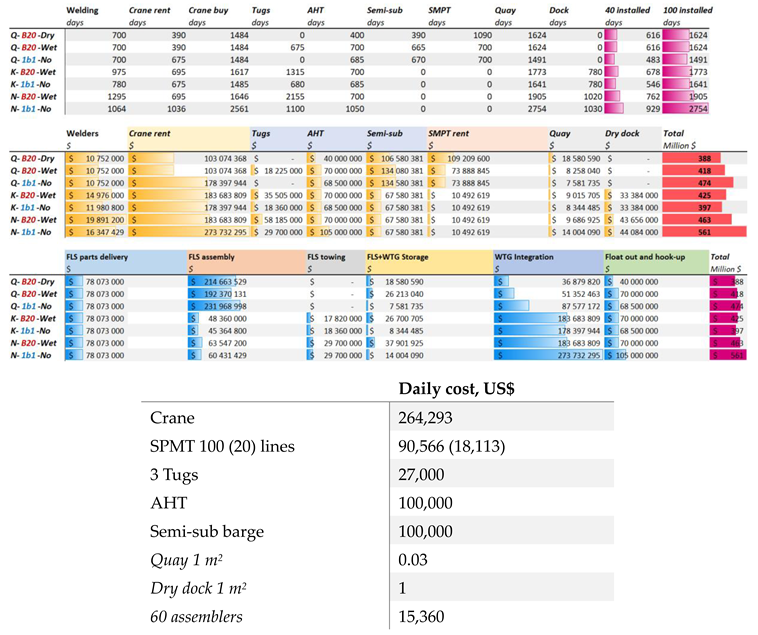

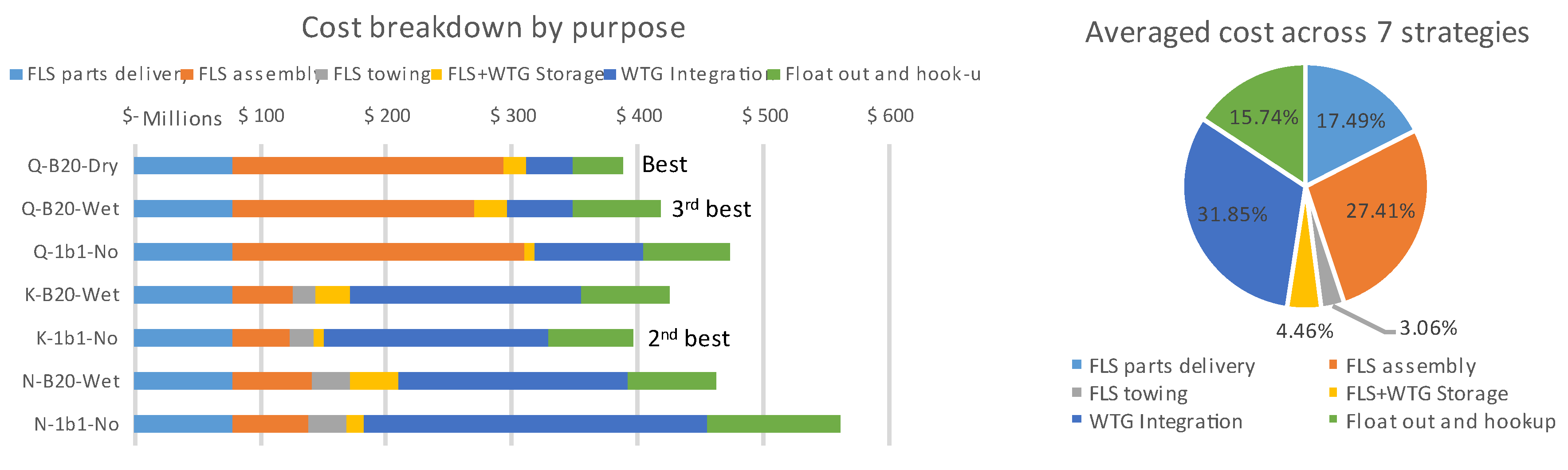

Table 5.3 compares the time and cost of the 7 assembly strategies. Except for case N-1b1-No, which is limited by towing time from Nagasaki to Taichung, it takes a relatively similar time to install 100 floaters. The results are also visualised in Figure 5.3. However, comparison by cost provides the following remarks:

Strategy №1, Q-B20-Dry (Taichung quay, batch 20, and dry storage), gives the lowest overall cost. Its low cost mainly comes from the lowest turbine integration cost, due to its high crane time efficiency, as the components are located conveniently on-site.

Dry dock and towing costs balance out crane costs. Thus, dry dock assembly has a similar cost as an on-quay assembly. Duration is also similar. If a cheaper crane solution can be found (buy 2nd hand, share etc.), on-quay assembly can be made significantly cheaper.

On-quay assembly and immediate turbine integration are as good as on-quay assembly and dry storage, giving choice flexibility based on other factors.

When it comes to wet storage, it’s cost-ineffective if paired with on-quay assembly or if the drydock is close by (Kaohsiung). However, it can be slightly beneficial if the drydock is far (Nagasaki). Combined with a limited wet storage area in the harbour, wet storage is the worst choice overall.

Comparing batch vs one-by-one turbine integration, waiting for a batch helps save costs due to reduced crane hire time, but just-in-time turbine integration generally allows the fastest project execution overall.

Table 5.3.

Assembly strategies rated by time (top), equipment cost (middle) and activity cost (bottom).

Table 5.3.

Assembly strategies rated by time (top), equipment cost (middle) and activity cost (bottom).

In the UK, a project in the Celtic Sea with a methodology similar to case N-1b1-No was investigated [

3]. The floater was towed for 4.5 days (accounting for weather) through 517 nautical miles from a construction site in Ferrol, Spain, to the integration port Milford Haven, UK. In the N-1b1-No case, the floater was towed 9 days through 827 nautical miles (without accounting for weather). Nevertheless, towing 100 floaters were installed in 2754 days in N-1b1-No, very similar to 2700 days (on average) in the Celtic Sea project, confirming the two studies’ methodology is credible and relatable.

Figure 5.3.

Assembly cost breakdown charts, with Q-B20-Dry being the best overall.

Figure 5.3.

Assembly cost breakdown charts, with Q-B20-Dry being the best overall.

6. Discussion

Apart from cost factors, other factors influence strategy choice, including carbon emissions, industrial localisation policies, supply chain risk, supply capacity, and workforce availability. These are briefly reviewed here, but further research by relevant disciplines is needed.

Emissions reduction is a major goal for the wind industry. Even as the power generated by the turbines is clean, a multitude of equipment is used during the installation phase and beyond, including transportation and installation vessels running on heavy fuel oil [

35]. In this study, on-quay manufacturing results in an average 35% reduction in vessel time (thus emissions) compared to manufacturing elsewhere.

Localisation of the supply chain is a goal for many countries [

36]. No matter where the parts come from, on-quay or local drydock manufacturing provides at least 80 welder and crane operator jobs and many further supporting personnel jobs. Local businesses such as turbine components, steel, lifting equipment, vessels and other manufacturers can further benefit if parts are procured locally [

37].

At the same time, Taiwan’s

supply chain for these components is limited [

38] and has a history of underperformance despite government incentives [

24]. This introduces significant supply risk. It is higher in the case of wet-storge, as vessel procurement is another issue [

2]. Foreign manufacturing is also a risk, as facilities worldwide are limited [

37,

39], and countries will probably try to fill their demand before exporting. Supply risk can be identified as a problem for all FOWT assembly strategies [

39].

Workforce availability is a major concern for developing and developed countries alike. Developed countries lack critical personnel such as qualified welders and crane operators. This gap is partially filled by the immigration of such workers from developing countries, leaving their original country also short of supply [

40]. Taiwanese government classified welders and shipbuilding welders in particular as a job with a critical cadre shortage [

24,

25]. This imposes a high risk on local manufacturing.

From these considerations, on-quay manufacturing is a good well-rounded strategy if enough skilled workers can be hired and brought for long-term work in the harbour.

7. Conclusions and Recommendations

This paper analysed different strategies for assembling and integrating floating offshore wind turbines at a port. The context is for a hypothetical 100-floater farm based on the TaidaFloat semi-submersible floater. As TaidaFloat is designed to operate on the Taiwan Strait, Taichung and other nearby ports have been reviewed for the study. Several strategies regarding floater construction/assembly and turbine integration were researched and compared. The following conclusions may be made:

Floater on-quay assembly in Taichung port may be the most cost-effective, compared with remote drydock assembly. After a cost evaluation under several assumptions, the integration strategy (Q-B20-Dry) using Taichung quay, batch of 20 floaters, and dry storage gives the lowest overall cost. Its low cost mainly comes from the lowest turbine integration cost due to its high crane time efficiency, as the components are located conveniently on-site.

A complete list of possible port operations with necessary equipment is summarized for a FOWT project. Regarding selecting a floater launching method, the most viable method may be using a semi-submersible barge (e.g. a floating dock). This is based on the assumption that the hull assembly work will be carried out at Taichung port in an ideal situation. This launching method avoids the long-distance wet tow from a shipyard with a drydock to the port.

A very large crane (e.g. a ring crane) is needed even for floater designs with a turbine on the side column. A large crane may be enough to install the turbine in both central and side columns, making the argument that a side-column turbine may not gain too much advantage. However, the side-column location could show its advantage if the large crane is impossible to procure due to short supply. In that situation, a tandem of two smaller crawler cranes could install the turbine.

The complex work of floater assembly and turbine integration was investigated in this research. It is aimed to guide wind energy developers, port authorities, project contractors, and government agencies. Some of the findings and conclusions may be useful under the stated background and assumptions. The research findings may help in decision making for the future development of wind energy.

Acknowledgments

The authors highly appreciate the funding support from the two government agencies of Taiwan, the National Science & Technology Council, and the Ministry of Education’s Yushan Fellow programme.

References

- Stehly, T., P. Beiter, and P. Duffy, 2019 cost of wind energy review. 2020, National Renewable Energy Lab.(NREL), Golden, CO (United States). Available from: https://www.nrel.gov/docs/fy21osti/78471.pdf.

- Hong, S., et al., Floating offshore wind farm installation, challenges and opportunities: A comprehensive survey. Ocean Engineering, 2024. 304: p. 117793.DOI: https://doi.org/10.1016/j.oceaneng.2024.117793. [CrossRef]

- Torres, E.S., P.R. Thies, and M. Lawless, Offshore Logistics: Scenario Planning and Installation Modeling of Floating Offshore Wind Projects. ASME Open Journal of Engineering, 2023. 2.DOI: 10.1115/1.4056882. [CrossRef]

- Díaz, H. and C. Guedes Soares, Approach for Installation and Logistics of a Floating Offshore Wind Farm. Journal of Marine Science and Engineering, 2023. 11(1): p. 53.

- BVG Associates, Guide to a Floating Offshore Wind Farm. 2023, The Crown Estate and Crown Estate Scotland: Offshore Renewable Energy Catapult. Available from: https://guidetofloatingoffshorewind.com/wp-content/uploads/2023/06/BVGA-16444-Floating-Guide-r1.pdf.

- Hsu, I.-J., et al. Optimization of Semi-Submersible Hull Design for Floating Offshore Wind Turbines. in 41st International Conference on Offshore Mechanics and Arctic Engineering (OMAE 2022). 2022. Hamburg, Germany: American Society of Mechanical Engineers.DOI: https://doi.org/10.1115/OMAE2022-86751. Available from. [CrossRef]

- Ivanov, G., I.-J. Hsu, and K.-T. Ma, Design Considerations on Semi-Submersible Columns, Bracings and Pontoons for Floating Wind. Journal of Marine Science and Engineering, 2023. 11(9): p. 1663.DOI: https://doi.org/10.3390/jmse11091663. [CrossRef]

- Lai, Z.-Y., et al., Mooring Anchor radius and Spread-angle Optimization for a 2 MW Semi-Submersible Floating Wind Turbine in Taiwan Strait, in International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2024). 2024, American Society of Mechanical Engineers: Singapore.

- Chen, C.-A., et al., Design Of Mooring System For a 15mw Semi-Submersible, Taidafloat, in Taiwan Strait, in 42nd International Conference on Ocean, Offshore and Arctic engineering. 2023, ASME: Melbourne, Australia. Available from: https://www.researchgate.net/publication/371856783_OMAE2023-104394_DESIGN_OF_MOORING_SYSTEM_FOR_A_15MW_SEMI-SUBMERSIBLE_TAIDAFLOAT_IN_TAIWAN_STRAIT_Design_Load_Case_EWM_Extreme_Wind_speed_Model_ESS_Extreme_Sea_State_ECM_Extreme_Current_Model_EWLR_Extr.

- Wu, K.-Y., et al., Technology Development of a Floating Offshore Wind Turbine, "TaidaFloat", in Taiwan Wind Energy Conference 2023. 2023, Taiwan Wind Energy Association: Taipei, Taiwan.

- Gaertner, E., et al., IEA wind TCP task 37: definition of the IEA 15-megawatt offshore reference wind turbine. 2020, National Renewable Energy Lab.(NREL), Golden, CO (United States).

- Jensen, M.B., et al., Offshore Wind Port Feasibility Study of Taichung Harbor, Taiwan. 2016.

- Taiwan International Ports Corporation. Port Layouts. 2024 [cited 2024 09/08]; Available from: https://www.twport.com.tw/en/cp.aspx.

- Terex, Terex CC9800 Crawler Crane Specification. 2009. Available from: https://storage.bigge.com/webstorage/crane-charts/Demag-CC9800.pdf.

- Liebherr, Technical Data - LR 13000. 2024. Available from: https://www.liebherr.com/en/int/products/mobile-and-crawler-cranes/crawler-cranes/lr-crawler-cranes/lr-13000.html.

- Liebherr, Game changer for tomorrow's energy. LR12500-1.0 Crawler crane. 2023. Available from: https://www.liebherr.com/external/products/products-assets/68260ca3-3e8d-4366-9019-5413e68d6bf1-10/liebherr-281-lr-12500-1.0-281-00-defisr10-2023.pdf.

- Mammoet. Mammoet-Giant JV supports manufacturing of Taiwan’s first wind turbine jacket foundations. [cited 2024 23/05]; Available from: https://www.mammoet.com/news/mammoet-giant-jv-supports-manufacturing-of-taiwans-first-wind-turbine-jacket-foundations/.

- Mammoet, MAMMOET PTC 200-DS Dimensions. 2015. Available from: https://www.mammoet.com/equipment/cranes/ring-cranes/ptc-200-ds/.

- Mammoet, SPMT Scheuerle Dimensions and Specifications. 2015.

- Tayyar, G.T., Welding in Shipbuilding. 2008, Martin Leduc: www.dieselduck.info. Available from: https://www.dieselduck.info/machine/04%20auxiliary/2008%20Ship%20Welding.pdf.

- Scheid, P., Sailing Cargo Ship | Shipyard Vietnam - Hull block heavy lift & installation | Dop Peter Scheid. 2023, YouTube. Available from: https://www.youtube.com/watch?v=speTKU4Bkcg.

- Ocergy. About OCG-Wind. [cited 2024 23/05]; Available from: https://www.ocergy.com/ocg-wind.

- Stiesdal. Tetra offshore foundations for any water depth. [cited 2024 23/05].

- Ivanov, G., Ukraine – Taiwan Offshore Wind Joint Venture. Promising Cooperation for Achieving Energy Independence. International Journal of Business, 2024. 29(3).

- National Development Council (Taiwan), 2021-2023 Annual survey and estimation of talent supply and demand in key industries. 2021: Taiwan. Available from: https://ws.ndc.gov.tw/Download.ashx?u=LzAwMS9hZG1pbmlzdHJhdG9yLzE4L3JlbGZpbGUvNjAzNy85NTEwLzkxN2I0ZDk4LTRkNzAtNDk0OC1hNDM3LTVhMmI4MGVkNDQ0Ni5wZGY%3D&n=MTEwLTExMuW5tOmHjem7nueUoualreS6uuaJjeS%2Bm%2BmcgOiqv%2BafpeWPiuaOqOS8sCgxMDnlubTovqbnkIbmiJDmnpzlvZnmlbTloLHlkYopLnBkZg%3D%3D&icon=..pdf.

- van der Kaaij, I., Evaluating the workability of On-Site Assembly of a 15MW Wind Turbine Blade on a Semi-Submersible Floating Wind Turbine Using a Crane Vessel, in Offshore and Dredging Engineering, Wind Energy Technology. 2023, Delft University of Technology, Norwegian University of Science and Technology.

- Vestas, Building the V236-15.0 MW™ offshore turbine prototype | Episode 3: The Installation. 2023: YouTube. Available from: https://www.youtube.com/watch?v=xRqwEnb8K68.

- Bigge. Operated & Maintained Crane Rental Rates. [cited 2024 23/05]; Available from: https://www.bigge.com/crane-rental/operated-and-maintained/.

- Ralls, M.L. and R. Newman, Introduction on Use of Self Propelled Modular Transporters (SPMTs) to Move Bridges. 2008, National Highway Institute: USA. Available from: https://www.nhi.fhwa.dot.gov/downloads/other/real_solutions_presentations/real_solutions_presentation_2008_06.pdf.

- Shandong Panda Mechanical Co. For sale: 150 ton 10 axle 12 axle line spmt self propelled modular transporter trailer. 2024 [cited 2024 04/06]; Available from: https://www.alibaba.com/product-detail/150-ton-10-axle-12-axle_1600987143384.html?spm=a2700.7724857.0.0.44cd4d58LXp6Ei.

- Crowle, A. and P. Thies, Floating offshore wind turbines port requirements for construction. Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment, 2022. 236(4): p. 1047-1056.DOI: 10.1177/14750902221078425. [CrossRef]

- Hasumi, T., et al., Estimation For Efficiency Of Offshore Installation Process Of Floating Offshore Wind Turbines In Japan, in 42nd International Conference on Ocean, Offshore and Arctic Engineering. 2023, ASME: Melbourne, Australia.

- Buljan, A., Floaters for French Pilot Wind Farm Taking Shape, in offshoreWind.biz. 2022. Available from: https://www.offshorewind.biz/2022/07/14/floaters-for-french-pilot-wind-farm-taking-shape/.

- Chitteth Ramachandran, R., et al., Floating wind turbines: marine operations challenges and opportunities. Wind Energ. Sci., 2022. 7(2): p. 903-924.DOI: 10.5194/wes-7-903-2022. [CrossRef]

- Arvesen, A., C. Birkeland, and E.G. Hertwich, The Importance of Ships and Spare Parts in LCAs of Offshore Wind Power. Environmental Science & Technology, 2013. 47(6): p. 2948-2956.DOI: 10.1021/es304509r. [CrossRef]

- Ferry, T., Offshore wind industry struggles with localisation, in Euroview. 2022, European Chamber of Commerce Taiwan. Available from: https://euroview.ecct.com.tw/category-inside.php?id=412.

- Uttley, E., et al., Port And Manufacturing Infrastructure Investment Models, in Offshore Renewable Energy Catapult. 2024, Floating Offshore Wind Centre Of Excellence. Available from: https://fowcoe.co.uk/wp-content/uploads/2024/03/FOW-CoE-PR50-Port-Infrastructure-and-Manufacturing-Investment-Models.pdf.

- Metal Industry Intelligence, The Supply Chain Study of Offshore Wind Industry in Taiwan. 2022. Available from: https://www.bcctaipei.com/sites/default/files/2022-03/Taiwan%20Offshore%20Wind%20Supply%20Chain%20Report%200322.pdf.

- Smith, B.M., et al., Mitigation of assembly constraints for floating offshore wind turbines using discrete event simulation. Journal of Physics: Conference Series, 2023. 2626(1): p. 012044.DOI: 10.1088/1742-6596/2626/1/012044. [CrossRef]

- Pronoza, P., UKRAINE SHIPBUILDING AND WORLD: FEATURES AND TRENDS. ECONOMICS, MANAGEMENT, LAW: PROBLEMS AND PROSPECTS, 2015. 215(2): p. 102.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).