1. Introduction

Additive manufacturing (3D printing) is fast becoming the choice of manufacturing technique due to its flexibility and adaptability [

1,

2] in prototyping. Several technological innovations which are physical models are first tested with additively manufactured models as proof of concepts before actual production. It is therefore important to painstakingly select the suitable method and parameters that suit the desired performance of the prototype [

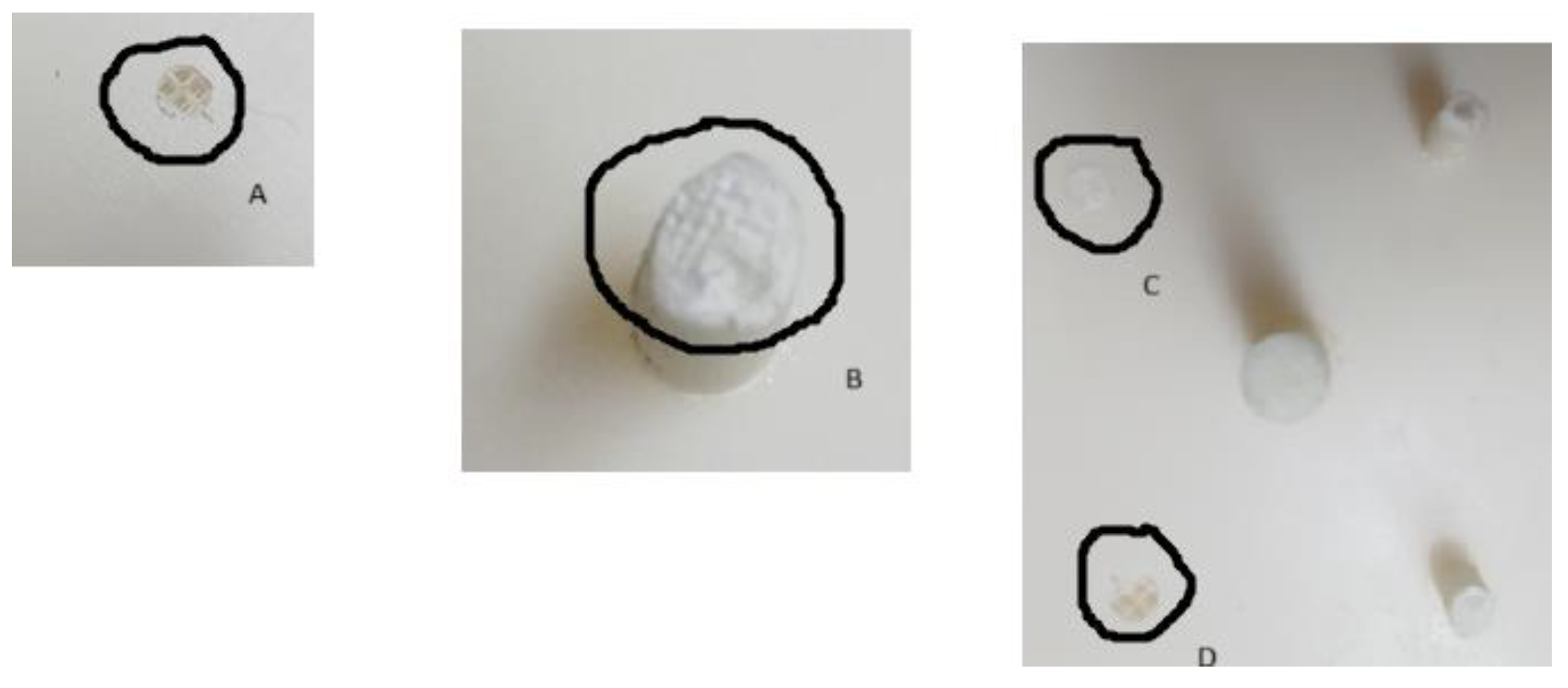

3]. Additive Manufacturing (AM) is important in optimizing composite materials for improved mechanical properties. Mechanical tests are prerequisites to validate the suitability of a material for aerospace, medical, automobile, and product development applications. Infill density, printing speed, and layer thickness are parameters to interchange to influence the quantity of materials used and the cost of printing. However, these three have not been keenly investigated to determine their influence on the mechanical properties of materials, especially PLA. Many failures have been recorded while developing prototypes due to inappropriate printing parameters as seen in

Figure 1. The infill density, layer thickness, and printing speed have been examined individually or combined with other parameters such as infill pattern, build orientation, and rafter angle to investigate their influence on the mechanical properties of selected additive manufacturing materials [

4,

5].

Layer thickness is a parameter that affects the print quality and properties of a 3D-printed material. The effect of layer thickness has been studied on the water absorption characteristics of 3D printed PLA based on four layers of 0.05 mm, 0.1 mm, 0.2mm, and 0.3 mm [

6]. This parameter has been considered for its influence on flexural strength [

7], bond and tensile strength [

8], hardness[

9], and the accuracy of a printed specimen [

10]. Layer thickness and binder properties were varied to determine their impact, and it was discovered that an increase in layer thickness reduces the tensile strength but increases the flexural strength [

11]. This method was also performed for the ABS [

12], bone tissues [

13].

Printing speed plays an important role in the outcome of printed materials as a measure of the rate of building up the materials in layers. It is influential, especially for continuous fiber composite printing based on its role in the morphology output [

14]. In another study, the influence of printing speed on the morphology and mechanical properties of wood polylactic acid composite was evaluated [

15]. The effect of printing speed and extrusion temperature on the tensile strength and dimensional quality was investigated. It was observed that the printing speed increases the tensile strength, but it is inversely proportional to the printing time [

16]. High print speed produces high-quality and high-performance thermosetting polymers [

17]. The morphology and print quality can be improved by optimizing the extrusion speed. Furthermore, the print speed can be improved by optimizing the extrusion diameter thereby eliminating the inconsistencies in the extrusion process [

18].

Fernandes et al., 2018 [

19] explored the effect of four printing parameters on the mechanical properties of Polylactic acid material. The parameters considered were infill density, extrusion temperature, raster angle, and layer thickness and it was discovered that the infill density had a progressive influence on the mechanical properties. In another work, infill pattern and density, shell thickness, and printing temperature were considered for ABS additive manufacturing to investigate their contribution to the material properties. The result of this experiment was to assist in decision-making for the type of printing element to be considered for parts and prototype development [

20]. The print speed and raster layer up were accessed for their influence on PLA's tensile strength and stiffness [

21].

It is important to consider the contribution of infill density to the mechanical properties, quality, and properties of additively manufactured parts [

22]. Infill density and infill patterns are very influential to the energy absorption characteristics of the material [

23]. It was discovered that an increase in infill density, wall perimeter, and layer height has a positive impact on the tensile strength of printed material [

24]. In ASTM standard testing, variations were noticed in the tensile strength and modulus by varying the infill density and orientation angle while also affecting the position and angle of the fracture [

25]. In an impact test to determine the influence of infill density on the tensile strength and impact strength of printed materials, an increase in infill density increases the tensile strength but a reduction in the impact strength [

26]. Printing time is also impacted by varying the infill properties such as infill pattern and, infill density [

27].

Analysis of variance is a tool used to investigate the impact and degree of influence and behaviour of individual variables on a set of objectives. In addition, it is often used to evaluate the influence of printing parameters on mechanical properties such as ultimate tensile strength, yield strength, modulus of elasticity, load at maximum strength, and the load at break [

19,

28,

29]. It is important to determine the parameters suitable to 3D print models with the required mechanical toughness in human and machine interfaces for haptic manipulation.

Having drawn inferences from the studies above, it became evident that the three major parameters that affect print quality should be closely evaluated. The evaluation of the mechanical properties of additively manufactured parts with varying parameters is necessary to ascertain the printing conditions to produce suitable parts for required applications [

8,

20,

30]. Judging from experience and previous investigations, the infill density, layer thickness, and printing speed significantly affect the durability of printed parts. In this work, 3D printed tensile test samples are based on varying infill properties, print speed, and layer thickness to select a suitable combination of parameters that will not fail under operation. Similar works that investigated the effect of printing speed, layer thickness, and infill density on the mechanical properties of 3D printed parts, chose a wide range of values up to 100% for the infill density and layer thickness [

28,

31,

32,

33,

34,

35] as summarized in

Table 1. These combinations only present a wide range of mechanical properties but do not serve as a specific guide for parameter selection. Some of these combinations result in significant differences in the printing time. The negative impact reflects time loss and increased power consumption. Selecting close-range parameters has less effect on the printing time but can give the desired mechanical properties. This work was set out to create a guide for easy access to parameter combinations that ensures the appropriate parameters are easily accessible for intended results.

2. Materials and Methods

In determining the materials to be used for the ongoing research in robotics and haptic feedback mechanisms, an investigation was launched into determining the printing parameters for the additively manufactured parts. Three printing parameters were varied: layer thickness, infill density, and printing speed. These three parameters directly influence the print quality, because an alteration in any of these results in a change in the printing time and quantity of materials to print. The layer thickness range depends on the manufacturing specifications for each FDM printer. However, the Creator Pro 2 used for this experiment has a layer thickness range between 0.1 mm and 0.33 mm. Three levels of thickness were used: 0.1 mm, 0.2 mm, and 0.3 mm.

Printing speed is the rate at which the nozzle moves along the X and Y axes while depositing molten filament onto the platform, which also dictates the movement of the z-axis. The printing speed also affects surface finish, accuracy, and strength. Like the layer thickness, the range of values for the printing speed depends on the manufacturer's specifications. The default printing speed for the Creator Pro used is 70 mm/s, but the three levels of printing speed used for this experiment are 60 mm/s, 70 mm/s, and 80 mm/s.

The third parameter is the infill density which relates to the amount of material between the surface layers of the printed part. It is very critical to the strength of the part, and it determines the weight, the strength, and the durability of the part. Like the other two parameters, its range of values depends on the printer type. The three levels used for the experiment are 15%, 17.5%, and 20%. The choice of this range was based on previous prints which shows there is little variation in printing time and material usage when this parameter is changed. However, in some literature, a wide range of this parameter is used, it does not reflect the exact influence of this parameter because the wide range values are bogus to track the effect of the infill density.

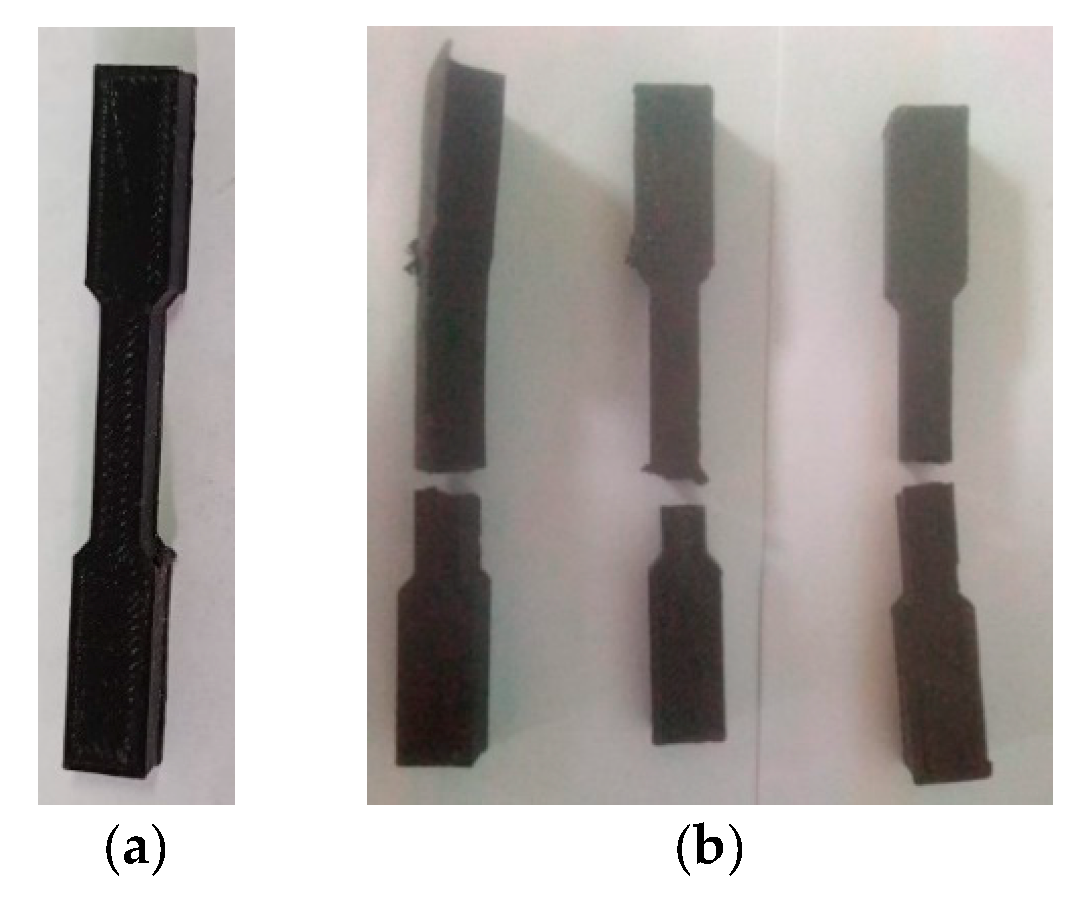

The Taguchi L9 orthogonal array was adopted to create 27 experimental samples by varying the parameters on 3 levels as in equation (1): infill density (15%, 17.5%, and 20%), printing speed (60 mm/s, 70 mm/s, and 80 mm/s), and layer thickness (0.1 mm, 0.2 mm, and 0.3 mm). Plastic Tensile tests according to the ASTM D638 were conducted using the Inspiron Series 3369 Tensile testing machine (

Figure 2) because it is known for its precision and reliability in conducting tension tests according to various international standards, ensuring consistent and repeatable results. The data recorded were analyzed using Taguchi and ANOVA to determine the significance of each parameter on the Maximum tensile strength equation (2), Modulus of elasticity of the material equation (3), and Load at maximum tensile strength measured directly from the machine. The test samples before the experiment and the samples after the experiments are shown in

Figure 3a,b.

Table 1.

Related works on ANOVA and Printing Parameters.

Table 1.

Related works on ANOVA and Printing Parameters.

| Author |

Methodology |

Properties |

Material |

ANOVA |

Parameters |

| [31] |

Numerical |

Warpage deformation |

PEI

ABS

PA 6 |

81 samples |

PT, PS, BT, ID, LT, IP |

| [32] |

Experimental |

Flexural strength |

ABS |

25 samples |

ID 15-100

RA 0-90

NT 20-60

LT 0.1-0.3

BT 90-110 |

| [33] |

Experimental |

Tensile strength

Maximum load

Elongation

Elastic modulus |

Wood-PLA |

9 samples |

LT 0.1-0.3

ID 50-100

PS 10-20

NT 180-190 |

| [34] |

Numerical |

Residual stress |

ABS |

27 samples |

PO H,S,V

RA 0 -90

IP 0,Z,90 |

| [35] |

Experimental |

Compressive strength |

TPU

PLA |

9 samples |

PS 40-60

LT 0.1-0.3

ID 50 75 100 |

| Current work |

Experimental |

Toughness

Max. Tensile Strength

Elastic Modulus

Load @ Max Tensile Strength. |

PLA |

27 samples |

PS 60-80

LT 0.1-0.3

ID 15 17.5 20 |

3. Results

In this section, the mechanical properties evaluated were presented, and the effect of the infill density and layer thickness on the mechanical properties was also presented. Subsequently, the experimental analysis and the evaluations were reported and discussed.

3.1. Experimental and Analysis of the Mechanical Properties

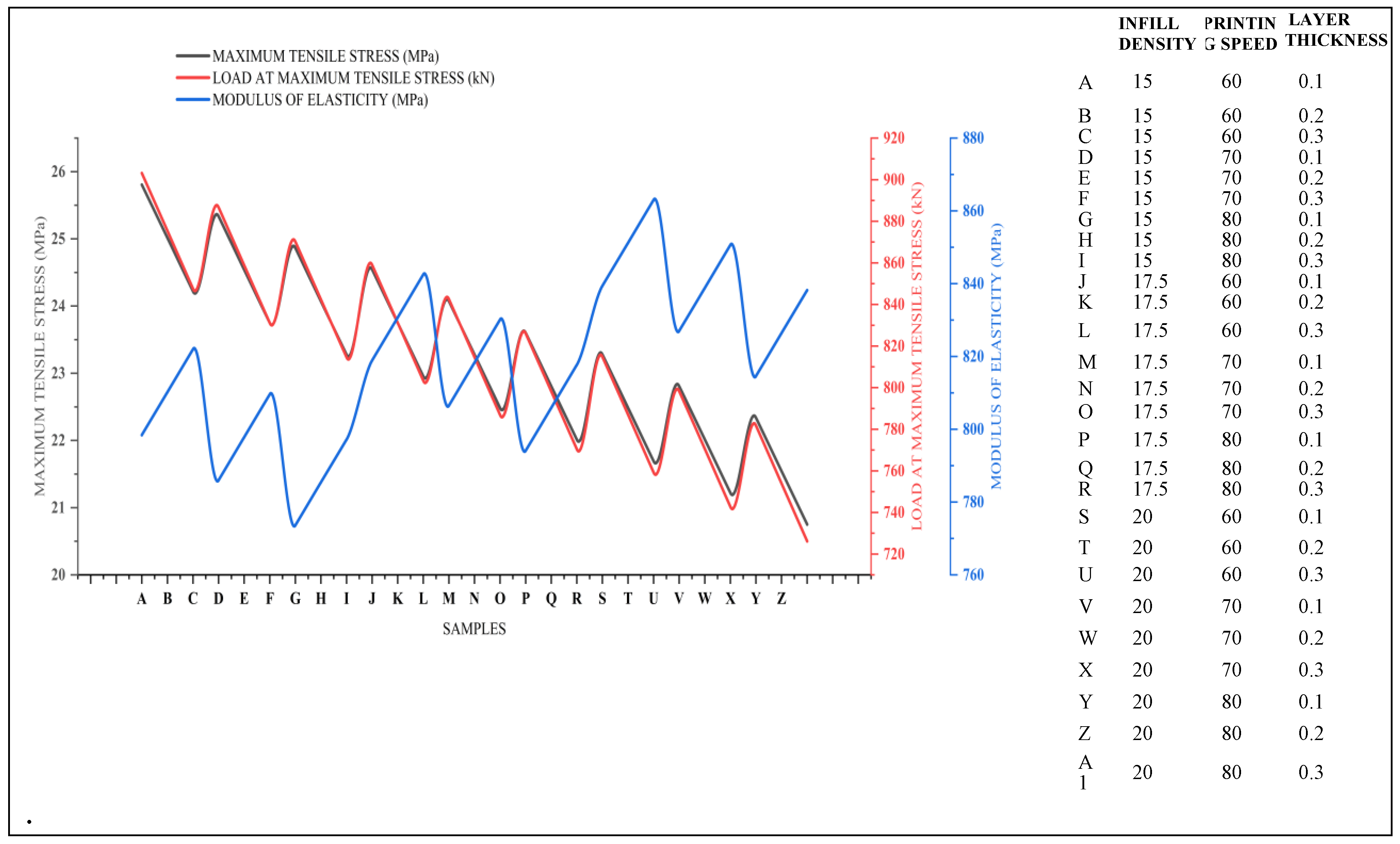

The experimental results of the testing were recorded as force and extension. These results were used to calculate the Maximum tensile strength, Load at maximum tensile strength, and the Modulus of elasticity as presented in

Table 2.

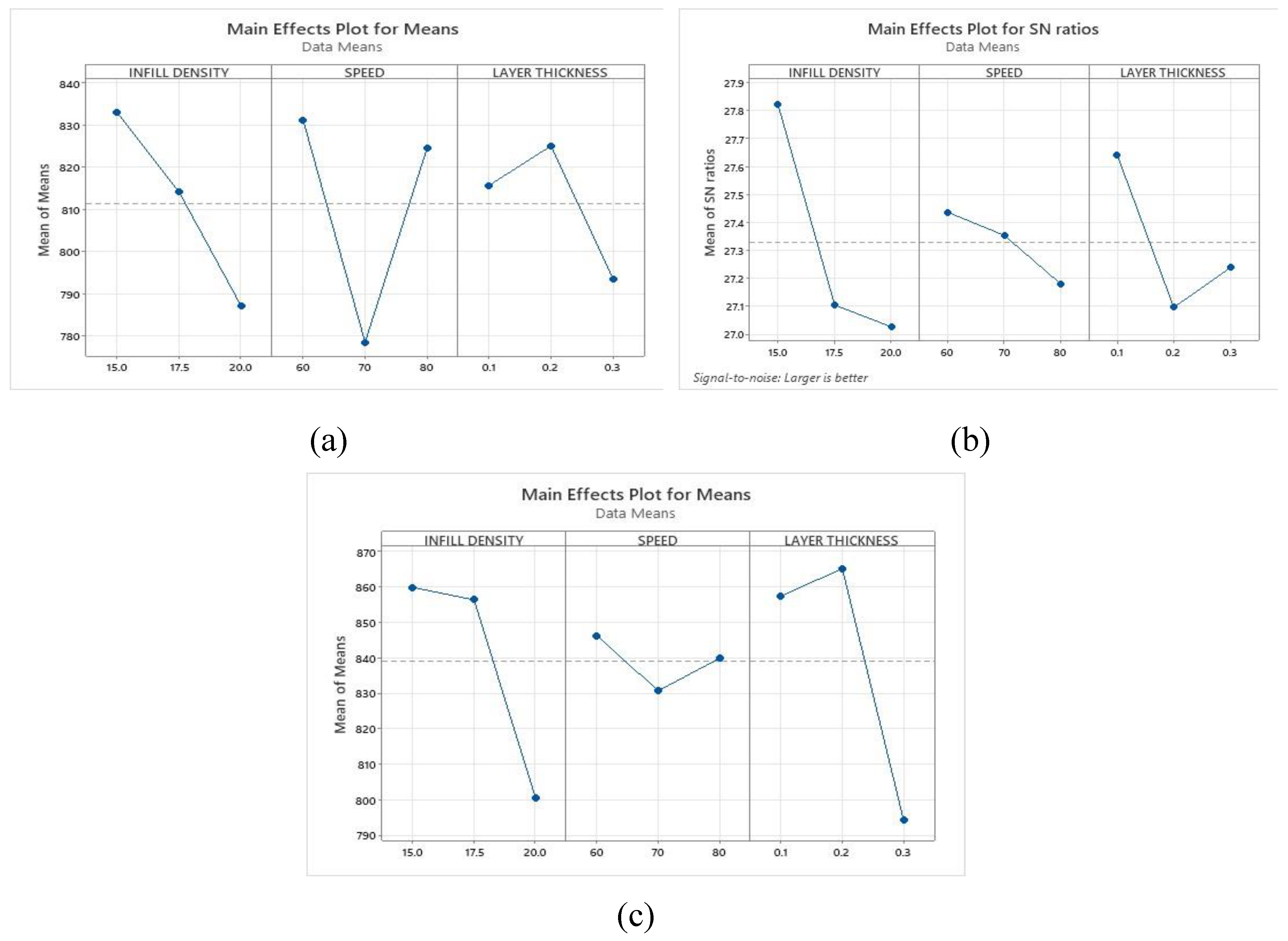

3.2. Influence of Infill Density on the Material Properties

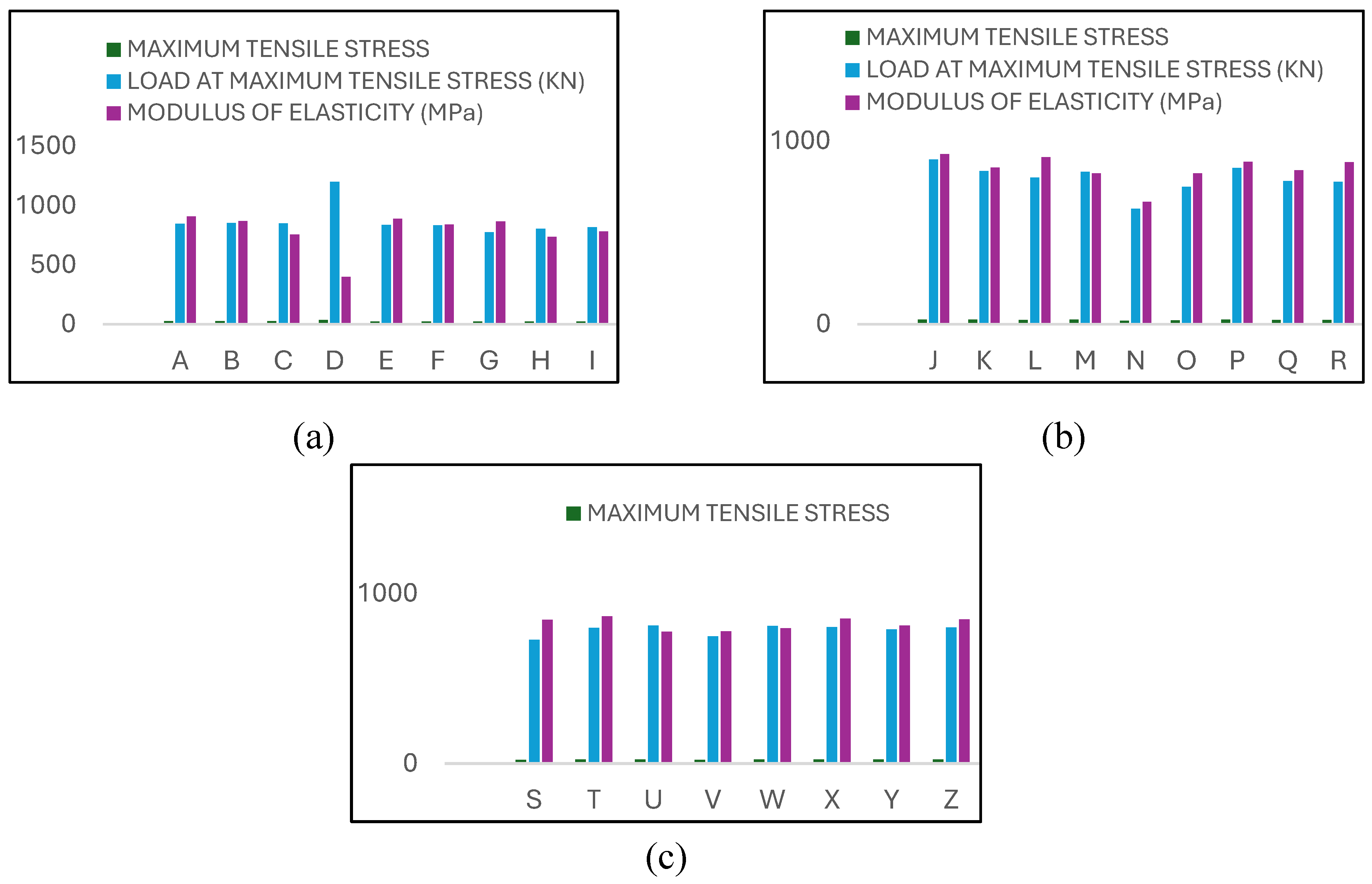

In

Figure 4a–c; Specimen D has the highest maximum load with a low tensile strength but the lowest modulus of elasticity since the tensile strength is proportional to Young’s modulus. Modulus of elasticity is the measure of the stiffness of a material, hence specimen D with the configuration 15 infill density, 70 mm/s speed, and 0.1 mm layer thickness is tougher than other configurations. All the values loads are above 800 kN. All the moduli are above 800 MPa, but more peak loads here are below 800 MPa. This group seems more ductile. The modulus variations here tend to be like the first group, but the load is lower (all below 800 kN).

3.3. Influence of Layer Thickness on the Properties of the Printed Samples

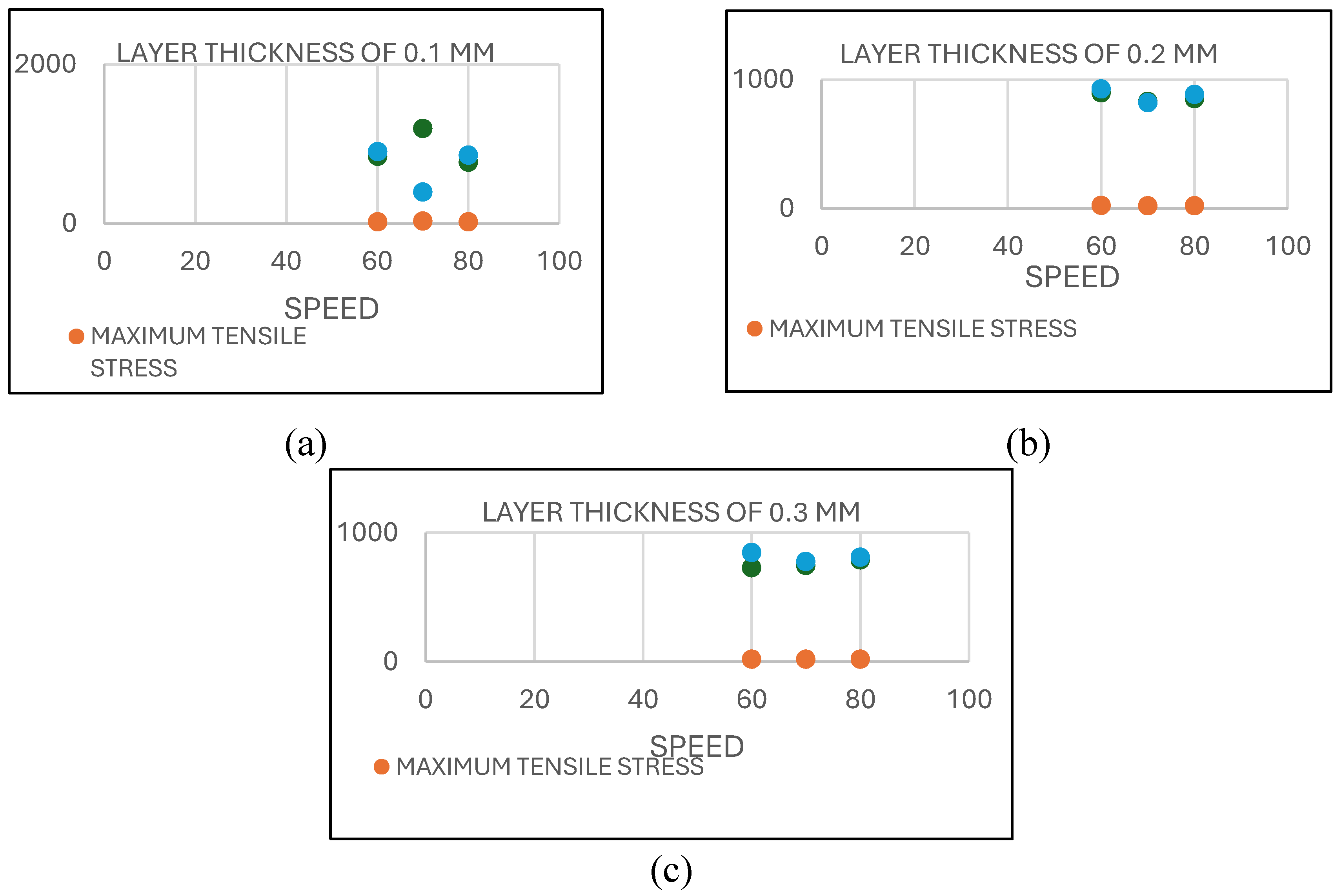

From

Figure 5a, it was observed that at 70 printing speed, sample 4 has the lowest modulus of elasticity at 17.5mm infill density when the layer thickness was 0.1 mm. The modulus of elasticity had the best performance at the 0.2 mm layer thickness as seen in

Figure 5b. The modulus of elasticity is closest. However, there is a peculiarity with the 0.3 mm layer thickness plot (

Figure 5c), the modulus of elasticity has very close Figures, which means they exhibit the same behaviour. It is thus safe to say that the layer thickness becomes less significant at this thickness irrespective of the other parameters.

Table 3 shows that the infill density significantly impacts the properties of the samples. There is a large deviation for all the samples with 15 mm infill density but moderate for those with 17.5 mm infill density. However, little disparity exists when the infill density increases. This shows that the infill density is a major influence on the properties of these samples.

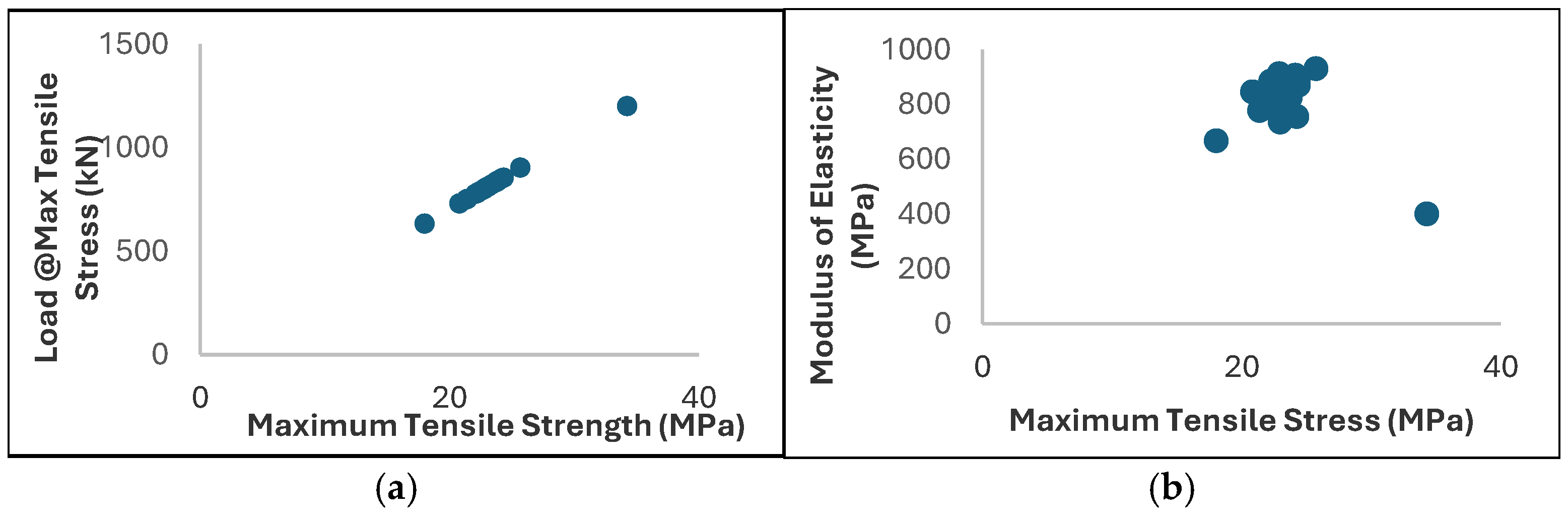

From

Figure 6a,b, the load at the highest tensile stress increases with the maximum tensile strength. There is no significant influence on the content variation. The modulus of elasticity varies between 650 MPa to 900 MPa for most of the specimen. The variation is observed when the maximum tensile strength is highest, and the modulus of elasticity is lowest.

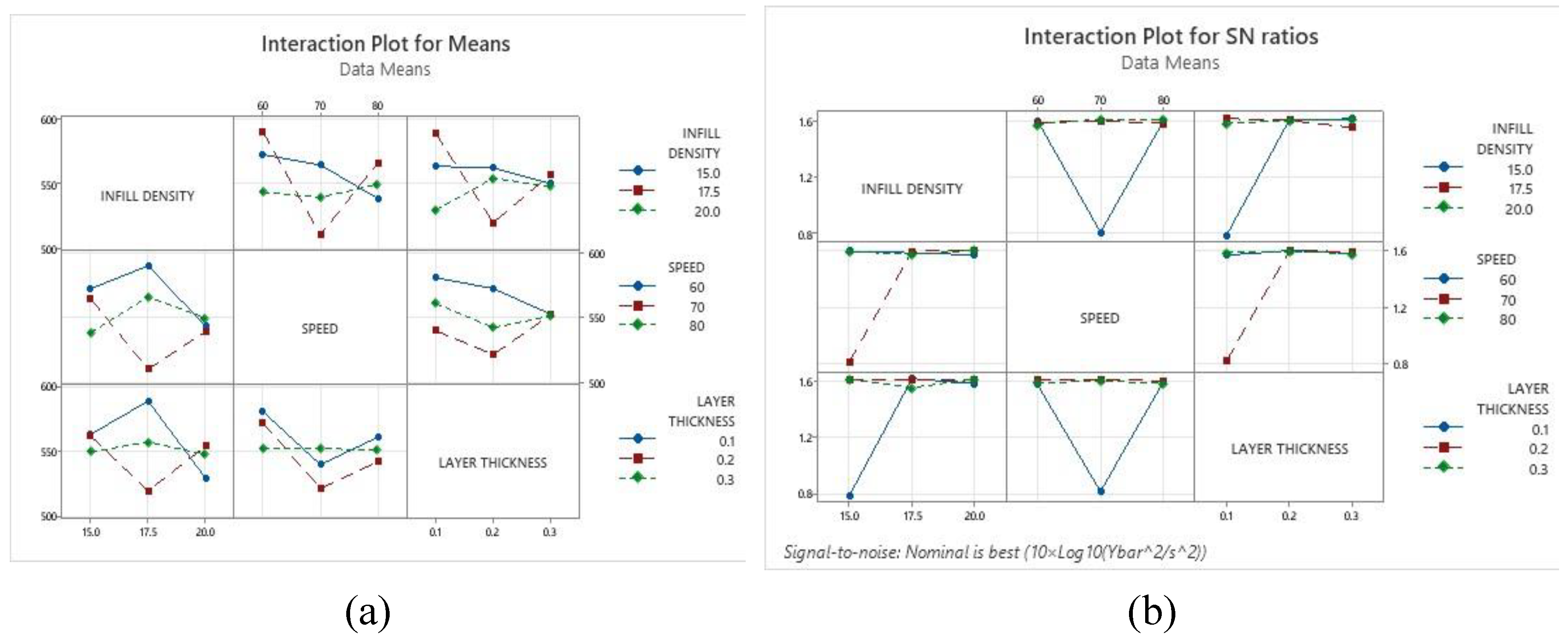

From

Figure 7, the highest tensile strength was observed when the infill density and printing speed were lowest corresponding to 15 and 60 mm/s. It can also be observed that the combination of infill density of 20 and 0.3 mm layer thickness is not desirable. The printing speed was insignificant when the infill density was 17.5 and the layer thickness was 0.2 mm. Despite these variations in the impact of the parameters, the three parameters impact the tensile strength. However, the infill density is more influential.

Figure 8a highlights the significance of the infill density. It can be seen that the infill density of 17.5 mm is most significant when the speed is 60 mm/s and the layer thickness is 0.1 compared to other values. At 20 infill density, the speed is significant for all the values of infill density and layer thickness. When the layer thickness is 0.2 mm, the infill density shows significance at 17.5 succeeded by layer thickness at 0.1 for a printing speed of 60 mm/s.

According to

Figure 8b, the speed and layer thickness significantly influenced the maximum load at higher infill densities. This means that higher infill densities can assist the printed materials to withstand more load applications, hence it is a critical factor to consider when selecting printing parameters for these applications. It was also discovered in Figure 14 that low and high printing speeds influence the modulus of the material such that lower printing speeds result in high modulus of elasticity while faster printing speeds reduce the material toughness. However, the case of the layer thickness is like that of the infill density in that higher layer thickness has a significant influence on the modulus increasing the porosity of the material [

6].

3.4. ANOVA Results and Discussions

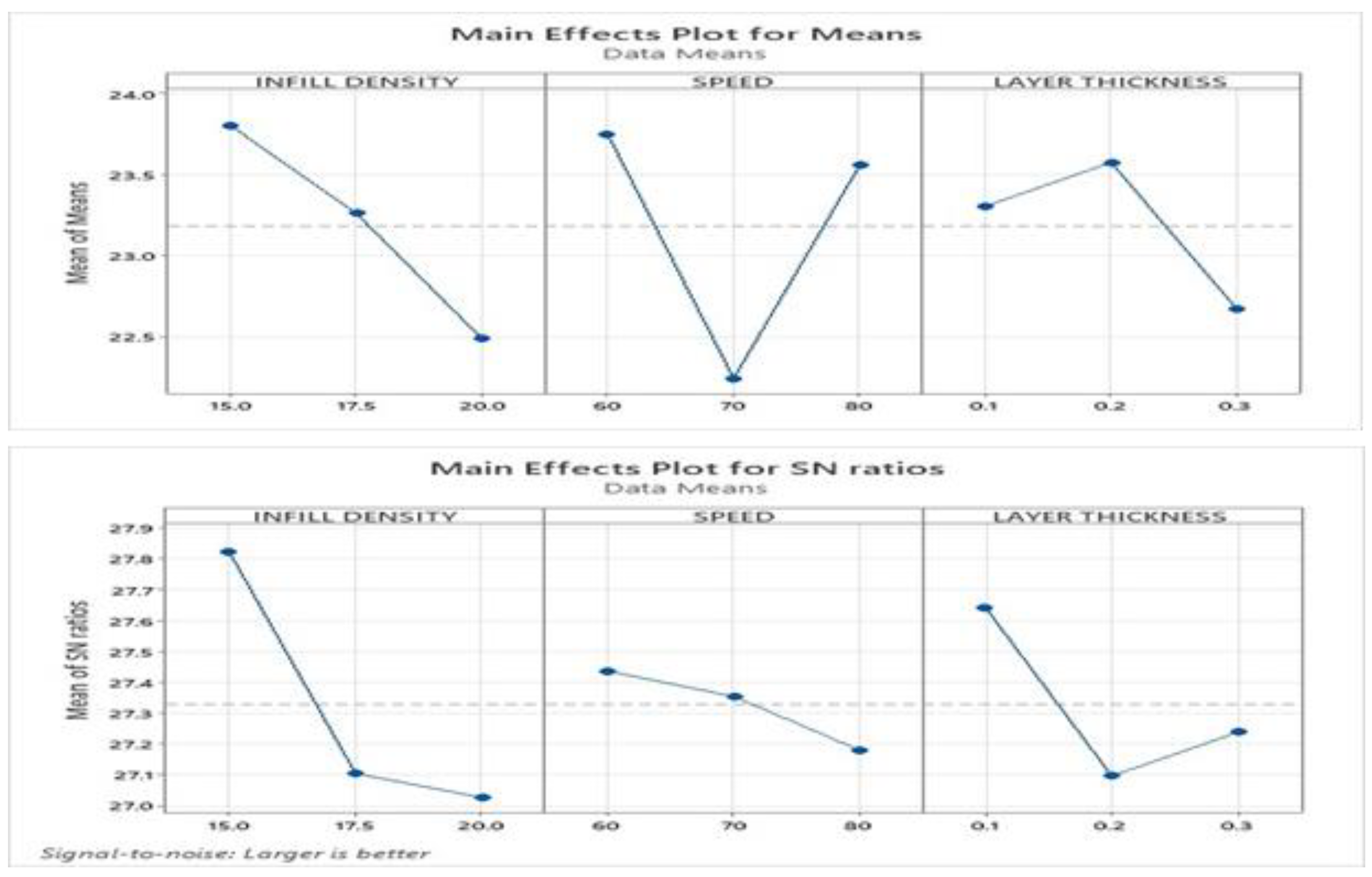

The results obtained from the testing were first analyzed using the Taguchi approach since the experiment was designed based on the Taguchi DOE (Design of Experiment). This result showed the most desirable level of each factor as it gave the Main Effect plots of each factor. The results of the Taguchi analysis are seen in

Figure 9a–c.

In

Figure 9a, the highest tensile strength occurred when the infill density and printing speed were lowest at 15 and 60 mm/s respectively. When the infill density was 20 and the layer thickness 0.3 mm, the material properties were poor regardless of the printing speed. This can be interpreted as reducing the elastic property of the material, hence introducing hardness instead of toughness to the material. Meanwhile in

Figure 9b, when the infill density was 17.5 and the layer thickness was 0.2 mm, the printing speed had no significant effect. This can mean that the medium parameters of infill density and layer thickness will produce a tough material irrespective of the printing speed.

In

Figure 9c showing the main effects plot for the modulus, the infill density of 15 had the greatest influence on the modulus of elasticity. Like earlier observations, the lower values for infill density and the layer thickness have greater significance than the highest values. For the printing speed, the influence is on the average significant, hence it is a major factor to consider regarding the modulus. Specifically, the combination of infill density of 15, printing speed of 60 mm/s, and layer thickness of 0.1 mm had the greatest effect on the modulus in the main effects plot for the modulus.

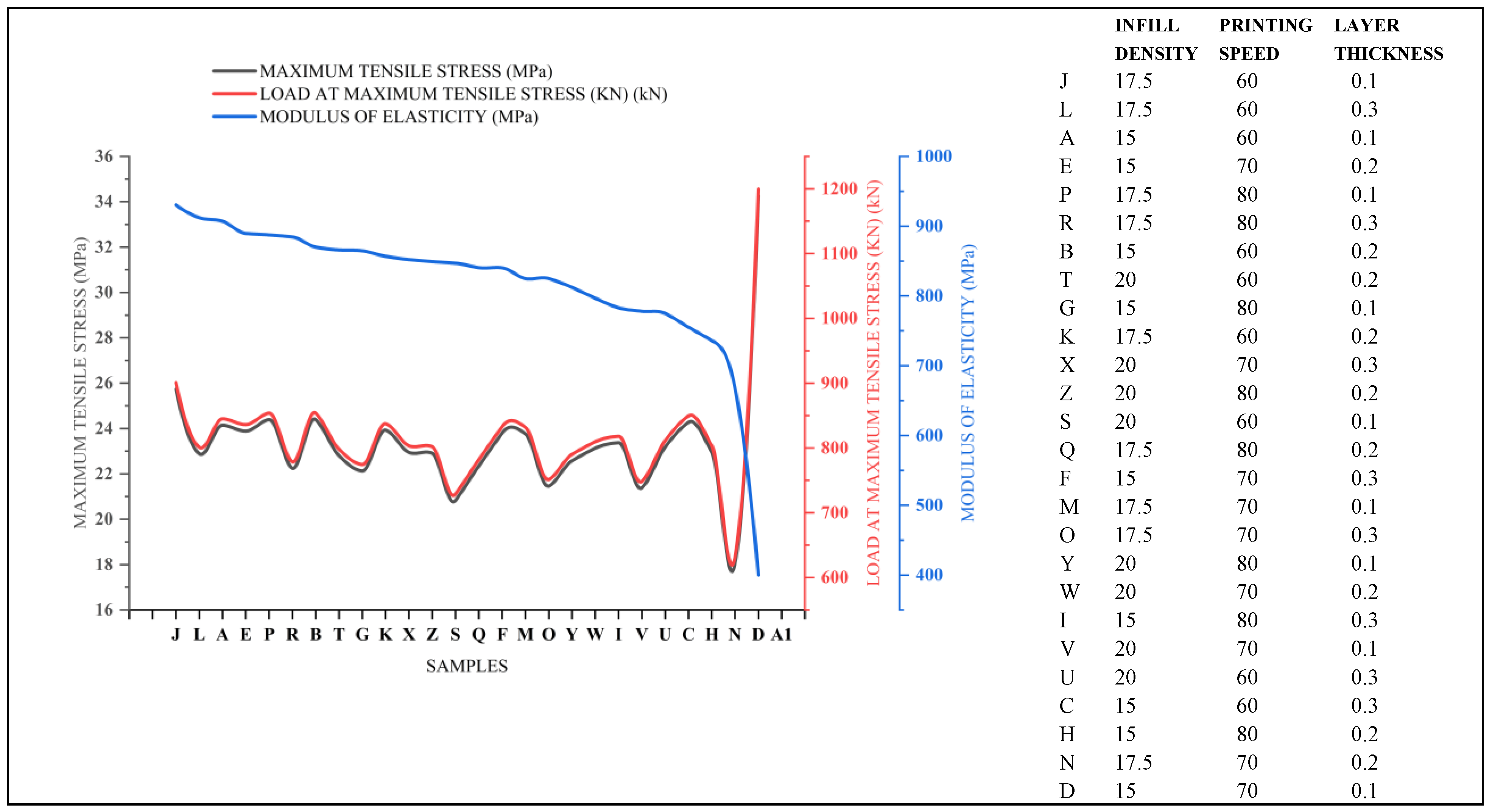

3.5. Regression Analysis and Look-Up Chart

It is important to establish a relationship between the mechanical properties discussed in this work and create a chart of printing parameters and possible mechanical properties. Regression was performed on the experimental data in Microsoft Excel. The Excel regression generated the equations to develop the values within the range of the commonly used printing parameters. Equations iv – vi represent the regression equations for the maximum tensile stress, load at maximum tensile stress, and the modulus of elasticity. These equations can be used to optimize the parameters for customized slicer and printing software. Some developers and researchers have developed AI software for customized printing which does not follow the conventional vertical layer-by-layer printing.

The chart of the mechanical properties calculated from equations iv to vi is presented in

Figure 10 with the plot of the properties to the left and the configurations on the right-hand side. After this, the properties were sorted according to the degree of toughness (

Figure 11) with the highest first. This look-up table is a quick reference for selecting printing parameters based on toughness requirements.

This chart serves as a lookup chart where the properties desired are matched with the corresponding printing materials. For example, if 680 MPa modulus is required, the point is drawn from the left-hand side to touch the curves and the point on the curve is traced to the x-axis to choose the closest sample. To get the other properties, the trace is extended to the chart of the required property. After which this sample is checked on the right-hand side for the corresponding configuration. This method can be replicated for any other known property and the printing parameters can be determined. The look-up chart is vital as it assists the designer in estimating the cost and time for the printing desired, corresponding to the mechanical properties suitable for the parts.

4. Conclusions

The experimental design presented twenty-seven samples with three variables for each printing parameter considered. The experimental procedure was carried out according to the ASTM 2450 standard. The Tensile strength, load at maximum tensile strength, and Modulus of elasticity were determined through the relationship between the force, stress, and strain. The effects of infill density and layer thickness were assessed to see how they influenced the mechanical properties. An analysis of the distinction of each parameter was carried out to investigate how each parameter influences the mechanical properties of each sample. Regression analysis as models for customized printing was also presented. Lastly, charts of the mechanical properties were plotted, and the lookup chart for mechanical properties where the printing parameters suitable for a desired mechanical property was presented.

The data presented here is suitable for use in research laboratories where products are developed. The chart of printing parameters will assist in selecting appropriate parameters to achieve the printing of durable parts and prototypes. The goal is for the prototypes to withstand the testing and for the proof-of-concept and prototype to attain performance close to real application. In many research endeavours, records of broken parts have been reported because little or no consideration was given to the properties of the materials used for the experiments. This study presents a methodology to be adopted by researchers who make prototypes for their proofs-of-concept, to reduce wastage while presenting durable and test-worthy prototypes. In addition, the regression analysis is a model that can be adopted to integrate artificial intelligence in 3D printing.

Author Contributions

S.D is the principal investigator of the haptic research. O.K.A. coordinates the mechanical designs and developments which led to this work. O.K.A and S.D supervised and prepared the manuscript. T.A.O and O.B produced the samples and carried out the experiments under the supervision of O.K.A. O.K.A., T.A.O., and O.B. collated and analyzed the results. O.K.A. interpreted and discussed the results and provided the charts.

Competing interest

The authors declare no competing interests.

References

- T. J. Suteja and A. Soesanti, “Mechanical Properties of 3D Printed Polylactic Acid Product for Various Infill Design Parameters: A Review,” J Phys Conf Ser, vol. 1569, no. 4, pp. 0–6, 2020. [CrossRef]

- J. A. Travieso-Rodriguez, R. Jerez-Mesa, J. Llumà, O. Traver-Ramos, G. Gomez-Gras, and J. J. R. Rovira, “Mechanical properties of 3D-printing polylactic acid parts subjected to bending stress and fatigue testing,” Materials, vol. 12, no. 23, 2019. [CrossRef]

- Y. L. Song, N. Yu, B. P. T. Danny, and M. T. Chew, “A pilot study on three-dimensional printing of stainless steel arch bars for orthognathic segmental jaw surgeries,” Annals of 3D Printed Medicine, vol. 6, p. 100055, 2022. [CrossRef]

- M. Doshi, A. Mahale, S. K. Singh, and S. Deshmukh, “Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects,” Mater Today Proc, vol. 50, pp. 2269–2275, 2021. [CrossRef]

- B. Jackson, K. Fouladi, and B. Eslami, “Multi-Parameter Optimization of 3D Printing Condition for Enhanced Quality and Strength,” Polymers (Basel), vol. 14, no. 8, 2022. [CrossRef]

- N. Ayrilmis, M. Kariz, J. H. Kwon, and M. Kitek Kuzman, “Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials,” International Journal of Advanced Manufacturing Technology, vol. 102, no. 5–8, pp. 2195–2200, 2019. [CrossRef]

- A. Nugroho, R. Ardiansyah, L. Rusita, and I. L. Larasati, “Effect of layer thickness on flexural properties of PLA (PolyLactid Acid) by 3D printing,” J Phys Conf Ser, vol. 1130, no. 1, pp. 0–10, 2018. [CrossRef]

- Y. Liu et al., “Effects of printing layer thickness on mechanical properties of 3D-printed custom trays,” Journal of Prosthetic Dentistry, vol. 126, no. 5, pp. 671.e1-671.e7, 2021. [CrossRef]

- A. Alshamrani, R. Raju, and A. Ellakwa, “Effect of Printing Layer Thickness and Postprinting Conditions on the Flexural Strength and Hardness of a 3D-Printed Resin,” Biomed Res Int, vol. 2022, 2022. [CrossRef]

- Z. chen Zhang, P. lun Li, F. ting Chu, and G. Shen, “Influence of the three-dimensional printing technique and printing layer thickness on model accuracy,” Journal of Orofacial Orthopedics, vol. 80, no. 4, pp. 194–204, 2019. [CrossRef]

- M. Vaezi and C. K. Chua, “Effects of layer thickness and binder saturation level parameters on 3D printing process,” International Journal of Advanced Manufacturing Technology, vol. 53, no. 1–4, pp. 275–284, 2011. [CrossRef]

- S. T. Dwiyati, A. Kholil, R. Riyadi, and S. E. Putra, “Influence of layer thickness and 3D printing direction on tensile properties of ABS material,” J Phys Conf Ser, vol. 1402, no. 6, pp. 0–6, 2019. [CrossRef]

- Farzadi, V. Waran, M. Solati-Hashjin, Z. A. A. Rahman, M. Asadi, and N. A. A. Osman, “Effect of layer printing delay on mechanical properties and dimensional accuracy of 3D printed porous prototypes in bone tissue engineering,” Ceram Int, vol. 41, no. 7, pp. 8320–8330, 2015. [CrossRef]

- Akhoundi, M. Nabipour, O. Kordi, and F. Hajami, “Calculating printing speed in order to correctly print PLA/continuous glass fiber composites via fused filament fabrication 3D printer,” Journal of Thermoplastic Composite Materials, vol. 36, no. 1, pp. 162–181, 2023. [CrossRef]

- T. C. Yang and C. H. Yeh, “Morphology and mechanical properties of 3D printed wood fiber/polylactic acid composite parts using Fused Deposition Modeling (FDM): The effects of printing speed,” Polymers (Basel), vol. 12, no. 6, p. 1334, 2020. [CrossRef]

- A. Ansari and M. Kamil, “Effect of print speed and extrusion temperature on properties of 3D printed PLA using fused deposition modeling process,” Mater Today Proc, vol. 45, pp. 5462–5468, 2021. [CrossRef]

- X. Kuang, Z. Zhao, K. Chen, D. Fang, G. Kang, and H. J. Qi, “High-Speed 3D Printing of High-Performance Thermosetting Polymers via Two-Stage Curing,” Macromol Rapid Commun, vol. 39, no. 7, pp. 1–8, 2018. [CrossRef]

- P. Geng et al., “Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament,” J Manuf Process, vol. 37, no. November 2018, pp. 266–273, 2019. [CrossRef]

- J. Fernandes, A. M. Deus, L. Reis, M. F. Vaz, and M. Leite, “Study of the influence of 3D printing parameters on the mechanical properties of PLA,” Proceedings of the International Conference on Progress in Additive Manufacturing, vol. 2018-May, pp. 547–552, 2018. [CrossRef]

- G. Ćwikła, C. Grabowik, K. Kalinowski, I. Paprocka, and P. Ociepka, “The influence of printing parameters on selected mechanical properties of FDM/FFF 3D-printed parts,” IOP Conf Ser Mater Sci Eng, vol. 227, no. 1, pp. 0–10, 2017. [CrossRef]

- M. R. Khosravani and T. Reinicke, “Effects of raster layup and printing speed on strength of 3D-printed structural components,” Procedia Structural Integrity, vol. 28, pp. 720–725, 2020. [CrossRef]

- S. Sriya Ambati and R. Ambatipudi, “Effect of infill density and infill pattern on the mechanical properties of 3D printed PLA parts,” Mater Today Proc, vol. 64, pp. 804–807, 2022. [CrossRef]

- P. K. Mishra, P. Senthil, S. Adarsh, and M. S. Anoop, “An investigation to study the combined effect of different infill pattern and infill density on the impact strength of 3D printed polylactic acid parts,” Composites Communications, vol. 24, no. April 2020, p. 100605, 2021. [CrossRef]

- M. A. Mazlan, M. A. Anas, N. A. Nor Izmin, and A. H. Abdullah, “Effects of Infill Density, Wall Perimeter and Layer Height in Fabricating 3D Printing Products,” Materials, vol. 16, no. 2, pp. 1–11, 2023. [CrossRef]

- M. W. Alhazmi and A. H. Backar, “Influence of Infill density and Orientation on the Mechanical Response of PLA+ Specimens Produced using FDM 3D Printing,” International Journal of Advanced Science and Technology, vol. 29, no. 6, pp. 3362–3371, 2020.

- M. Q. Tanveer, A. Haleem, and M. Suhaib, “Effect of variable infill density on mechanical behaviour of 3-D printed PLA specimen: an experimental investigation,” SN Appl Sci, vol. 1, no. 12, pp. 1–12, 2019. [CrossRef]

- J. Suteja, “Effect of Infill Pattern, Infill Density, and Infill Angle on the Printing Time and Filament Length of 3D Printing,” Jurnal Rekayasa Mesin, vol. 12, no. 1, p. 145, 2021. [CrossRef]

- M. N. Ahmad et al., “Application of Taguchi Method to Optimize the Parameter of Fused Deposition Modeling (FDM) Using Oil Palm Fiber Reinforced Thermoplastic Composites,” Polymers (Basel), vol. 14, no. 11, Jun. 2022. [CrossRef]

- M. M. Tünçay, “An Investigation of 3D Printing Parameters on Tensile Strength of PLA Using Response Surface Method,” J Mater Eng Perform, vol. 33, no. 12, pp. 6249 – 6258, 2024. [CrossRef]

- H. Tetsuka and S. R. Shin, “Materials and technical innovations in 3D printing in biomedical applications,” J Mater Chem B, vol. 8, no. 15, pp. 2930–2950, 2020. [CrossRef]

- H. Alzyod and P. Ficzere, “Material-Dependent Effect of Common Printing Parameters on Residual Stress and Warpage Deformation in 3D Printing: A Comprehensive Finite Element Analysis Study,” Polymers (Basel), vol. 15, no. 13, Jul. 2023. [CrossRef]

- J. D. Kechagias, “3D printing parametric optimization using the power of Taguchi design: an expository paradigm,” Materials and Manufacturing Processes, vol. 39, no. 6, pp. 797–803, 2024. [CrossRef]

- J. Sultana, M. M. Rahman, Y. Wang, A. Ahmed, and C. Xiaohu, “Influences of 3D printing parameters on the mechanical properties of wood PLA filament: an experimental analysis by Taguchi method,” Progress in Additive Manufacturing, vol. 9, no. 4, pp. 1239–1251, Aug. 2024. [CrossRef]

- H. Alzyod, L. Borbas, and P. Ficzere, “Rapid prediction and optimization of the impact of printing parameters on the residual stress of FDM-ABS parts using L27 orthogonal array design and FEA,” in Materials Today: Proceedings, Elsevier Ltd, 2023, pp. 583–588. [CrossRef]

- N. Dixit and P. K. Jain, “Effect of Fused Filament Fabrication Process Parameters on Compressive Strength of Thermoplastic Polyurethane and Polylactic Acid Lattice Structures,” J Mater Eng Perform, vol. 31, no. 7, pp. 5973–5982, Jul. 2022. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).