1. Introduction

Concrete, a fundamental component of modern construction, consists of cement, fine aggregates, and coarse aggregates, each contributing to the overall structural integrity of buildings and infrastructure. The strength of concrete is primarily influenced by the quality and characteristics of its aggregates, which include factors such as the water-cement ratio, aggregate gradation, particle size and shape, and curing practices. In the pursuit of sustainability, there is growing interest in identifying alternative materials that can replace traditional aggregates without compromising the mechanical properties of concrete. Among these alternatives, coconut shells and bamboo strips have emerged as promising candidates.

The present study, titled "Compressive Strength Variation of Concrete with Coconut Shell & Bamboo Strips," delves into the potential of these eco-friendly materials to serve as substitutes for conventional aggregates. This research is driven by the need for sustainable construction practices that reduce environmental impact while maintaining or enhancing the performance of concrete. By investigating the compressive strength of concrete incorporating coconut shells and bamboo strips, the study aims to provide insights into their suitability and effectiveness as alternative materials.

The incorporation of coconut shells and bamboo strips into concrete mixes represents a significant step towards environmentally responsible construction. These materials not only offer the potential to improve the sustainability of concrete but also contribute to waste reduction by utilizing by-products that might otherwise be discarded. The study specifically examines the effects of replacing traditional aggregates with varying percentages of coconut shells and bamboo strips, assessing their impact on the compressive strength of concrete.

Through this investigation, the research contributes to the field of structural engineering by exploring new methods to enhance the eco-friendliness of building materials. It aligns with the broader mission of advancing sustainable construction practices and fostering a more resilient and environmentally conscious future for the construction industry. By evaluating the viability of coconut shells and bamboo strips as sustainable alternatives, this study provides valuable data that can inform future applications and encourage further innovation in green building technologies.

2. Aim

The aim of this study is to investigate the variation in compressive strength of traditional concrete when partially incorporating coconut shells and bamboo strips as alternative aggregates.

3. Objectives

The objectives of this research encompass a comprehensive investigation into the compressive strength variation of traditional concrete with the partial inclusion of coconut shell and bamboo strips. Firstly, the study aims to elucidate the behavior of conventional concrete, devoid of any alternative aggregates, in both C20 [1:1.5:3] and C30 [1:0.75:1.5] formulations. Following this, the research delves into assessing the impact of incorporating solely 10% coconut shell as a replacement for coarse aggregate in the aforementioned concrete types. Similarly, the investigation extends to analyzing the behavior of traditional concrete when 10% of the coarse aggregate is substituted with bamboo strips. Additionally, the study scrutinizes the effects of incorporating a combination of 5% coconut shell and 5% bamboo strips into the concrete mix. Through these objectives, the research seeks to evaluate the compressive strength variations in C20 and C30 concrete types, offering insights into the individual and combined influences of coconut shell and bamboo strips on traditional concrete. Ultimately, this endeavor contributes to advancing sustainable and innovative construction practices by understanding the potential of these alternative materials.

4. Literature Review

4.1. Introduction to Alternative Materials in Construction

-Highlight the importance of exploring alternative materials in construction to address cost challenges and promote low-cost housing solutions.

-Emphasize the need for innovative approaches to traditional construction practices.

4.1.1. Impact of Coconut Shell in Concrete

-Discuss research findings on replacing conventional aggregates with coconut shells in concrete at various proportions.

-Explore how this substitution affects compressive strength, indicating a critical threshold for coconut shell incorporation.

-Reference the study that demonstrates a significant decrease in concrete strength when the coconut shell replacement exceeds 10% [

3].

4.1.2. Potential of Bamboo in Structural Concrete

-Present findings on the promise of bamboo chips in structural concrete, highlighting its eco-friendly nature.

-Discuss insights into bamboo's mechanical properties in concrete and recommendations for further investigation into optimal inclusion ratios and treatment methods [

4].

4.1.3. Bamboo and Quarry Dust in Concrete

-Outline research on concrete incorporating bamboo and quarry dust as replacements for coarse and fine aggregates.

-Highlight the optimal 15% replacement ratio for each material, yielding comparable flexural strength to control concrete.

-Discuss the practical solution offered for managing secondary cementitious waste and enhancing construction materials [

5].

4.1.4. Bamboo Strips for Tensile Strength Improvement

-Examine the use of bamboo strips as partial replacements for coarse aggregate in concrete.

-Discuss how the fibrous nature of bamboo improves tensile strength, enhancing cracking resistance and toughness in concrete.

-Emphasize the importance of these findings in structural applications and advancing sustainable construction practices [

6].

5. Methodology

Compressive Strength Variation of Concrete with Coconut Shell and Bamboo Strips.

The study is conducted to analyze the compressive strength of concrete when the natural coarse aggregate is partially replaced with waste coconut shells & bamboo strips respectively.

5.1. Material Preparation

5.1.1. Coconut Shell Processing

Clean and process coconut shells to remove husk and moisture. Crush them into suitable coarse aggregate sizes.

5.1.2. Bamboo Strips Preparation

Cut bamboo strips into standardized lengths for use as additional strength enhance. [Using Coarse aggregate size ≥4.75mm]

5.1.3. Material Selection (Cement)

The commercially available Nippon Ordinary Portland Cement is packaged in 50kg packs and is manufactured by Tokyo Cement Co. (Lanka) PLC. This cement product holds the SLS107 certificate in Sri Lanka, ensuring compliance with the national standards set forth by the Sri Lanka Standards Institution. Specifically, it meets the strength specifications outlined in SLS107:2008, with a grade designation of 42.5N. This certification signifies that the cement meets the required quality and performance standards, providing assurance to consumers and builders regarding its reliability and suitability for various construction applications.

5.1.4. Concrete Mix Design

The process of finding right proportions of cement, sand and coarse aggregates for concrete to achieve target strength in structures. So concrete mix can be stated as concrete mix = cement: sand (fine aggregate) : coarse aggregates.

The grade of concrete which I adopted, C-20 & C-30. The concrete mix proportions cement: sand: coarse aggregates are following 1:1.5:3 & 1:0.75:1.5 by volume and a water cement ratio of 0.50

5.1.5. Acquire Molds of Standard Dimensions

The concrete specimens were fabricated using molds measuring 150mm × 150mm × 150mm and made of cast iron material. Each specimen had a weight ranging between 13 to 14 kilograms. These standardized dimensions and materials ensured uniformity and consistency in the testing process, allowing for accurate evaluation of the concrete's properties. By employing these specifications, the study aimed to maintain repeatability and reliability in the experimental procedures, facilitating precise analysis of the concrete's compressive strength and other mechanical characteristics. Before casting cubes, applying grease or oil inside the mold is essential to prevent mold absorption, facilitate easy demolding, and extend the mold's lifespan.

5.1.6. Sample Cubes Casting

Planned to cast a total of 24 concrete cubes, with each set consisting of 3 samples of C20 and C30 grades. Casted six cubes without using coconut shells and bamboo strips. However, it's important to note that there were two different strength values for C20 and C30 grades.

In conventional C20 and C30 concrete mixes, replaced only 10% of the coarse aggregate with coconut shells. (6Cubes). Similar way 10% bamboo strips replaced the coarse aggregate (6Cubes).

Replaced 5% of the coarse aggregate with both coconut shells and bamboo strips (6Cubes).

5.1.7. Cubes Curing

All the cubes were submerged in water for a curing period of 28 days as part of the process.

5.1.8. Compressive Strength Testing

The compressive strength test for concrete blocks evaluates their capacity to endure pressure, typically using a universal testing machine. This assessment, conducted after a 28-day curing period, get the weights of samples & provides critical information about the blocks' quality and their suitability for their intended purpose. The compressive strength of a concrete cube is determined by dividing the maximum load at failure (measured in N or kN) by the cube's cross-sectional area (in square millimeters), resulting in a value typically expressed in megapascals (MPa).

6. Results Analysis

Test results are the foundation of research, serving as the means to answer research questions, validate methods, and derive valuable insights. They have implications for decision-making, problem-solving, and the advancement of knowledge practices in fields.

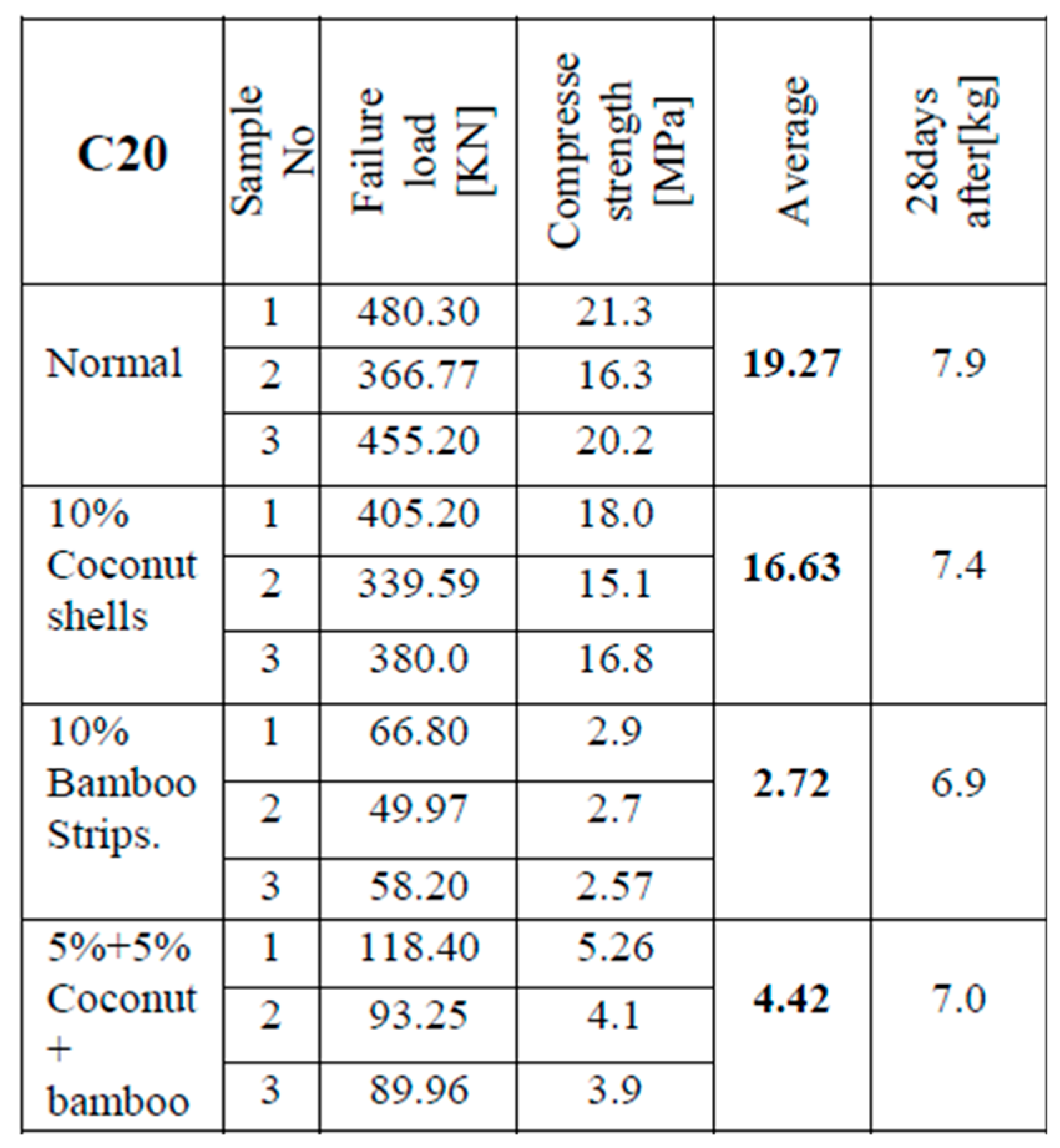

The following two tables present the results for this topic.

Table 1.

-[C20, Cube samples Results].

Table 1.

-[C20, Cube samples Results].

In this result of C20, the control concrete with no replacement exhibited a robust compressive strength of 19.27 MPa after 28 days, serving as the reference point. When 10% of the aggregates were replaced with coconut shells, the compressive strength decreased to 16.63 MPa, remaining suitable for various applications. However, a 10% replacement with bamboo strips led to a substantial strength reduction to 2.72 MPa, rendering bamboo unsuitable as a primary aggregate replacement. Combining 5% coconut shell and 5% bamboo strips improved strength to 4.42 MPa but remained significantly lower than the control and coconut shell replacements.

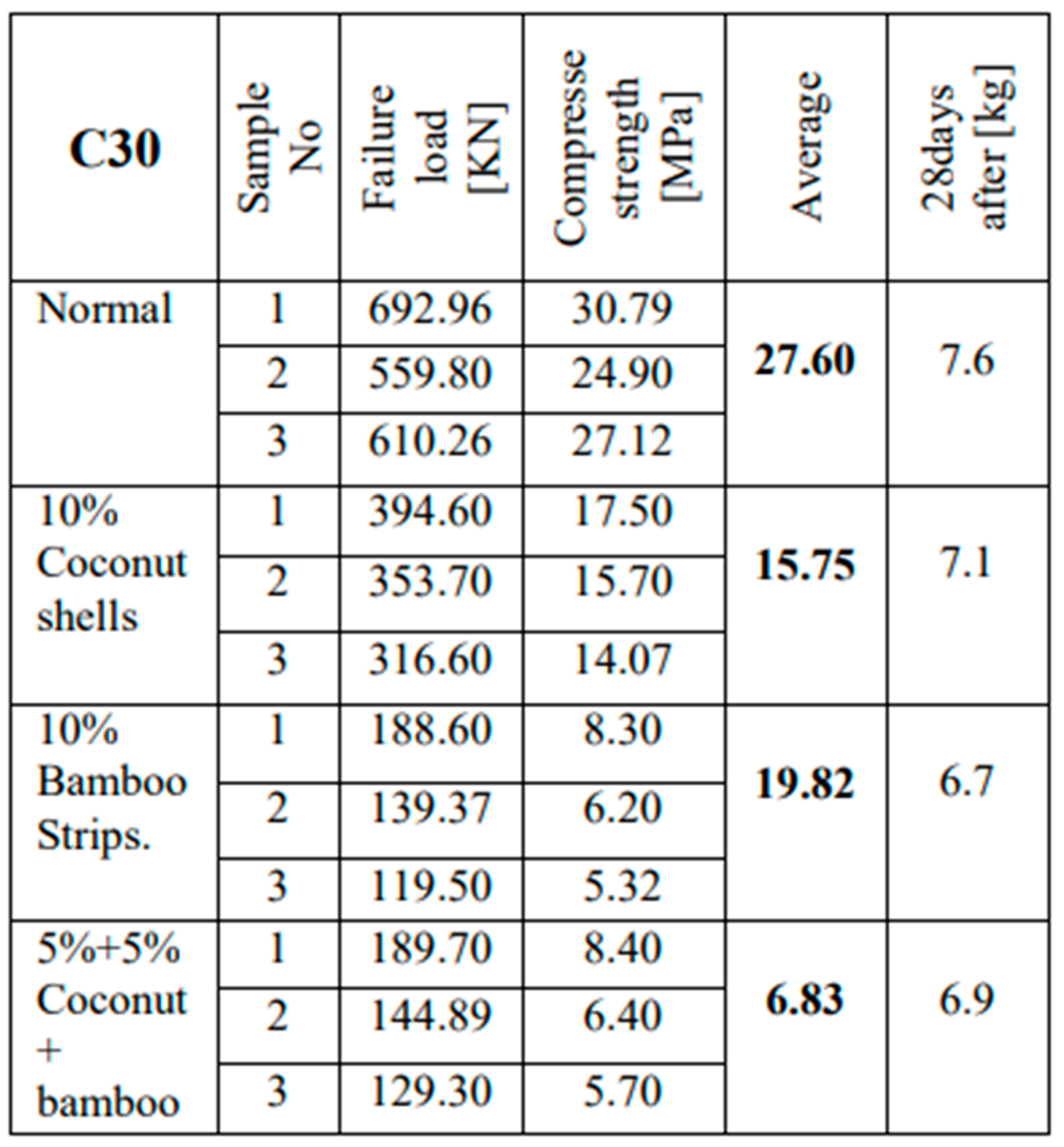

Table 2.

-[C30, Cube samples Results].

Table 2.

-[C30, Cube samples Results].

In the C30 concrete, the control group exhibited substantial compressive strength, with an average of 27.60 MPa after 28 days. However, when 10% of the aggregates were replaced with coconut shells, the compressive strength decreased to 15.75 MPa. Similarly, a 10% replacement with bamboo strips resulted in a significantly lower strength of 19.82 MPa, making it unsuitable as a primary aggregate. Combining 5% coconut shell and 5% bamboo strip replacements improved strength to 6.83 MPa, though it remained relatively lower than the control group. These findings underscore the importance of careful material selection to meet specific structural requirements in C30 concrete.

7. Discussion

C2O - This Research assessed the impact of substituting conventional aggregates with coconut shells, bamboo strips, and a combination in C20 concrete. Notably, the control group with 100% conventional aggregates showed robust compressive strength at 19.27 MPa. Replacing 10% of the aggregates with coconut shells resulted in an acceptable reduction to 16.63 MPa. However, a 10% bamboo strip replacement led to a substantial drop to 2.72 MPa, indicating their unsuitability. Combining 5% coconut shells and 5% bamboo strips improved strength to 4.42 MPa but remained lower than the control and coconut shell replacements.

These findings underscore the significance of thoughtful material selection in concrete, balancing sustainability and structural needs. Coconut shells present a reasonable alternative, while bamboo strips, even when combined, exhibit significant strength reductions.

C30 - The study examined the impact of substituting traditional aggregates in C30 concrete with coconut shells, bamboo strips, and a combination. The control group displayed robust compressive strength (27.60 MPa), while a 10% coconut shell replacement maintained adequate strength (15.75 MPa) for various applications. However, a 10% bamboo strip substitution resulted in unsuitable strength (19.82 MPa). Combining 5% coconut shells and 5% bamboo strips improved strength (6.83 MPa) but remained below the control and coconut shell alternatives, underlining the significance of material selection for structural and sustainability considerations. Coconut shells offer a viable alternative.

8. Conclusions

Comparing the data from Table-1 (C20) and Table-2 (C30) reveals critical insights for this research:

Compressive Strength Variation: -In both C20 and C30 concrete, the control groups with 100% conventional aggregates displayed significantly higher compressive strengths, emphasizing their load-bearing capacity.

Coconut Shell Replacement (10%): -The 10% replacement with coconut shells resulted in a reduction in compressive strength in both C20 and C30. However, it remained within acceptable limits for construction purposes.

Bamboo Strip Replacement (10%): -Replacing 10% of the aggregates with bamboo strips led to a substantial decrease in compressive strength in both C20 and C30 concrete. This highlights the inappropriateness of bamboo strips as the primary aggregate.

Combined Coconut and Bamboo (5%+5%): -The combination of 5% coconut shells and 5% bamboo strips improved strength but remained lower than the control and coconut shell replacements in both C20 and C30.

Finally, this research delved into the intricate realm of failure, shedding light on its underlying causes and effects. The outcomes provide valuable insights for addressing and mitigating failure, paving the way for future studies to explore deeper aspects of this complex phenomenon.

References

- Compressive strength of concrete by using coconut shell - research gate. https://www.researchgate.net/publication/271250375_Compressive_Strength_of_Concrete_by_Using_Coconut_Shell (Accessed: 27 October 2023).

- A comprehensive study of waste coconut shell ... - research gate. https://www.researchgate.net/publication/346870465_A_comprehensive_study_of_waste_coconut_shell_aggregate_as_raw_material_in_concrete (Accessed: 27 October 2023).

- Coconut shell as a substitute for coarse aggregate in concrete. https://www.researchgate.net/publication/327765985_Coconut_Shell_as_a_Substitute_for_Coarse_Aggregate_in_Concrete (Accessed: 27 October 2023).

- Bamboo as partially replacement for coarse aggregate (no date) PPT. https://www.slideshare.net/nischithapu/bamboo-as-partially-replacement-for-coarse-aggregate (Accessed: 27 October 2023).

- Experimental study on partial replacement of coarse aggregate by bamboo. https://www.researchgate.net/publication/319479571_Experimental_study_on_partial_replacement_of_coarse_aggregate_by_bamboo_and_fine_aggregate_by_quarry_dust_in_concrete (Accessed: 27 October 2023).

- Park, S.-S. et al. (2019) Mechanical properties of concrete with bamboo chips, MDPI. https://www.mdpi.com/2076-3417/9/16/3367 (Accessed: 28 October 2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).