Submitted:

27 September 2024

Posted:

29 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Experimental Layout and Treatments

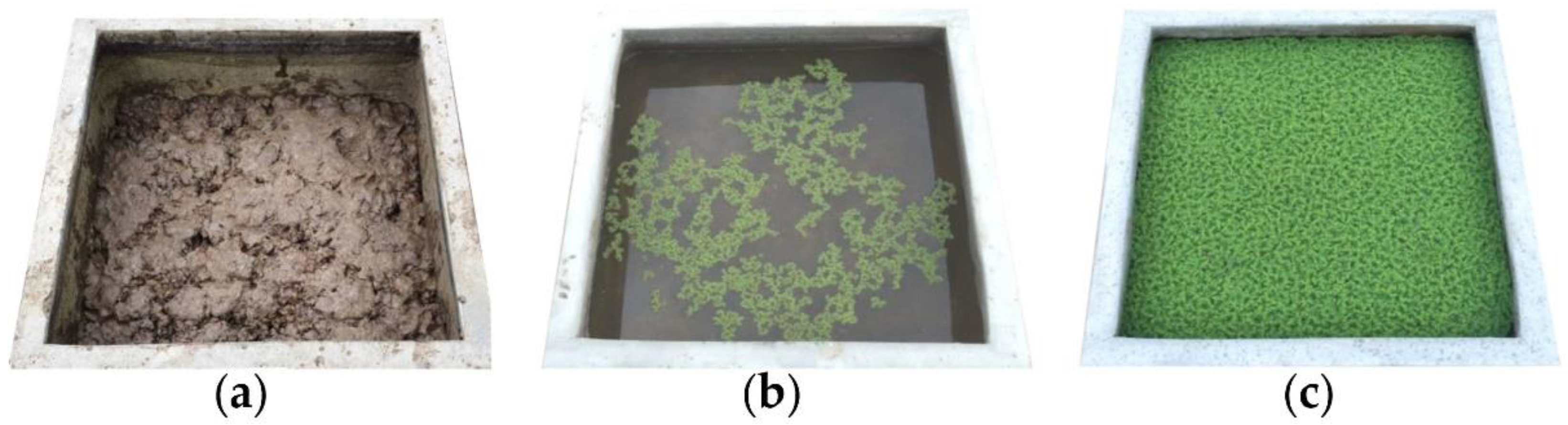

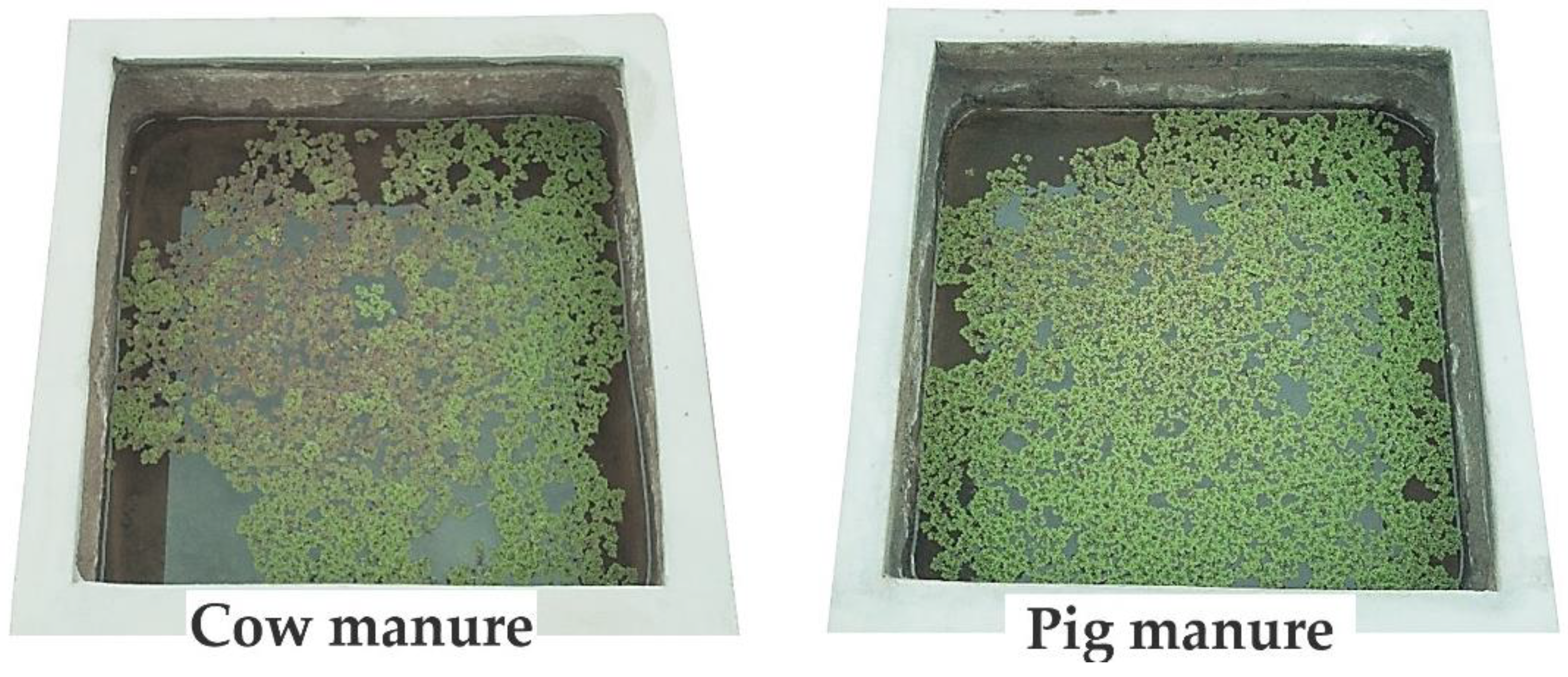

2.1.1. Effect of different manure types on growth development and chemical compositions of A. microphylla

2.1.2. Effect of different manure application rates on growth development and chemical compositions of A. microphylla

2.1.3. Effect of different shading levels on growth development and chemical compositions of A. microphylla

2.1.4. Comparison between the developed method and the conventional method

2.2. Data Collection and Analysis

2.2.1. Growth rate analysis

2.2.2. Chemical analysis of A. microphylla

2.3. Statistical Analysis

3. Results

3.1. Effect of Different Manure Types on Growth Development and Chemical Compositions of A. microphylla

3.2. Effect of Different Manure Application Rates on Growth Development and Chemical Compositions of A. microphylla

3.3. Effect of Different Shading Levels on Growth Development and Chemical Compositions of A. microphylla

3.4. Comparison Between the Developed Method and the Conventional Method

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trindade, C.R.T.; Albertoni, E.F.; Palma-Silva, C. Temporal variation in the biomass and nutrient status of Azolla filiculoides Lam. (Salviniaceae) in a small shallow dystrophic lake. Acta Limnol. Bras. 2011, 23, 368–375. [Google Scholar] [CrossRef]

- Azab, E.; Soror, A.-F.S. Physiological behavior of the aquatic plant Azolla sp. in response to organic and inorganic fertilizers. Plants 2020, 9, 924. [Google Scholar] [CrossRef]

- Pathak, J.; Rajneesh; Maurya, P. K.; Singh, S.P.; Häder, D.-P.; Sinha, R.P. Cyanobacterial farming for environment friendly sustainable agriculture practices: Innovations and perspectives. Front. Environ. Sci. 2018, 6, 7. [Google Scholar] [CrossRef]

- Banach, A.; Kuźniar, A.; Mencfel, R.; Wolińska, A. The study on the cultivable microbiome of the aquatic fern Azolla filiculoides L. as new source of beneficial microorganisms. Appl. Sci. 2019, 9, 2143. [Google Scholar] [CrossRef]

- Jumadi, O.; St. Hiola, F.; Hala, Y.; Norton, J.; Inubushi, K. Influence of Azolla (Azolla microphylla Kaulf.) compost on biogenic gas production, inorganic nitrogen and growth of upland kangkong (Ipomoea aquatica Forsk.) in a silt loam soil. Soil Sci. Plant Nutr. 2014, 60, 722–730. [Google Scholar] [CrossRef]

- Santhiya, B.; Sahaya Adlin, M.; Ayun Vinuba, A.; Jeeva, S. Azolla as a source of biofertilizer for sustainable crop production – A literature review. Int. J. Food Sci. Nutr. 2022, 11, 1959–1973. [Google Scholar]

- Sanginga, N.; Van Hove, C. Amino acid composition of azolla as affected by strains and population density. Plant Soil 1989, 117, 263–267. [Google Scholar] [CrossRef]

- Watanabe, I.; Ramirez, C. Phosphorus and nitrogen contents of azolla grown in the Philippines. Soil Sci. Plant Nutr. 1990, 36(2), 319–333. [Google Scholar] [CrossRef]

- Watanabe, I.; Espinas, C.R.; Berja, N.S.; Alimagno, B.V. Utilization of Azolla–Anabaena Complex as a Nitrogen Fertilizer for Rice; IRRI Research Paper Series; no. 11; International Rice Research Institute: Manila, Philippines, 1977; pp. 1–15. [Google Scholar]

- Widiastuti, D.; Davis, J.G. Optimization of the nutrient growing solution and inoculation rate for Azolla mexicana production and use as fertilizer. J. Plant Nutr. 2020, 44, 1404–1419. [Google Scholar] [CrossRef]

- Sadeghi, R.; Zarkami, R.; Sabetraftar, K.; Van Damme, P. Application of genetic algorithm and greedy stepwise to select input variables in classification tree models for the prediction of habitat requirements of Azolla filiculoides (Lam.) in Anzali wetland, Iran. Ecol. Model. 2013, 251, 44–53. [Google Scholar] [CrossRef]

- Bairagi, A.; Ghosh, K.S.; Sen, S.K.; Ray, A.K. Duckweed (Lemna polyrhiza) leaf meal as a source of feed stuff in formulated diets for rohu (Labeo rohita Ham.) fingerings after fermentation with a fish intestinal bacterium. Bioresour. Technol. 2002, 85, 17–24. [Google Scholar] [CrossRef]

- Biswas, M.; Parveen, S.; Shimozawa, H.; Nakagoshi, N. Effects of Azolla species on weed emergence in a rice paddy ecosystem. Weed Biol. Manag. 2005, 5, 176–183. [Google Scholar] [CrossRef]

- Serag, M.S.; El-Hakeem, A.; Badway, M.; Mousa, M.A. On the ecology of A. filiculoides Lam. in Damietta district, Egypt. Limnologica 2000, 30, 73–81. [Google Scholar] [CrossRef]

- Wagner, G.M. Azolla: a review of its biology and utilization. Bot. Rev. 1997, 63, 1–26. [Google Scholar] [CrossRef]

- Pabby, A.; Prasanna, R.; Singh, P.K. Azolla-Anabaena symbiosis from traditional agriculture to biotechnology. IJBT 2003, 2, 26–37. [Google Scholar]

- Kathirvelan, C.; Banupriya, S.; Purushothaman, M.R. Azolla-An alternate and sustainable feed for livestock. Int. J. Sci. Environ. Technol. 2015, 4(4), 1153–1157. [Google Scholar]

- Cary, P.R.; Weerts, P.G.J. Growth and nutrient composition of A. pinnata R. Brown and A. filiculoides Lam. as affected by water temperature, nitrogen and phosphorus supply, light intensity and pH. Aquat. Bot. 1992, 43, 163–180. [Google Scholar] [CrossRef]

- Naksomphan, P.; Kaewsuralikhit, S.; Phavaphutanon, L.; Saradhuldhat, P. Effects of pH and concentration of molybdenum on growth of Azolla microphylla. Agricultural. Sci. J. 2018, 49 (suppl. 2), 349–352. [Google Scholar]

- Costa, M.L.; Santos, M.C.R.; Carrapico, F.; Pereirac, A.L. Azolla–Anabaena's behaviour in urban wastewater and artificial media – Influence of combined nitrogen. Water Resour. Res. 2009, 43, 3743–3750. [Google Scholar] [CrossRef]

- Liu, X.; Min, C.; Xia-shi, L.; Chungchu, L. Research on some functions of Azolla in CELSS system. Acta Astronaut. 2008, 63, 1061–1066. [Google Scholar] [CrossRef]

- Costa, M.L.; Santos, M.C.R.; Carrapico, F. Biomass characterization of A. filiculoides grown in natural ecosystems and wastewater. Hydrobiologia 1999, 415, 323–327. [Google Scholar] [CrossRef]

- EL Katony, T.M.; Serao, M.S.; Badway, A.M.; Mousa, M.A. Effect of phosphorus on growth and uptake of nutrients by A. filiculoides Lam. J. Environ. Sci. 1996, 12, 69–88. [Google Scholar]

- Handajani, H. Optimation of nitrogen and phosphorus in Azolla growth as biofertilizer. Makara J. Technol. 2011, 15(2), 142–146. [Google Scholar] [CrossRef]

- Sadeghi, R.; Zarkami, R.; Sabetraftar, K.; Van Damme, P. Use of support vector machines (SVMs) to predict distribution of an invasive water fern Azolla filiculoides (Lam.) in Anzali wetland, southern Caspian Sea, Iran. Ecol. Model. 2012, 244, 117–126. [Google Scholar] [CrossRef]

- Setiawati, M.R.; Damayani, M.; Herdiyantoro, D.; Suryatmana, P.; Anggraini, D.; Khumairah, F.H. The application dosage of Azolla pinnata in fresh and powder form as organic fertilizer on soil chemical properties, growth and yield of rice plant. AIP Conf. Proc. 2018, 1927, 030017. [Google Scholar]

- Rayne, N.; Aula, L. Livestock manure and the impacts on soil health: A review. Soil Syst. 2020, 4, 64. [Google Scholar] [CrossRef]

- Hendarto, E. Application of cattle manure compost enriched with Azolla microphylla on morphology, production and quality of king grass (Pennisetum purpoides). Ann. For. Res. 2022, 65(1), 4527–4535. [Google Scholar]

- Utomo, R.; Noviandi, C.T.; Umami, N.; Permadi, A. Effect of composted animal manure as fertilizer on productivity of Azolla pinnata grown in earthen ponds. Online J. Biol. Sci. 2019, 19(4), 232–236. [Google Scholar] [CrossRef]

- Potdukhe, S.R.; Gatole, A.U. ; Damayanti Guldekar; Gavade, V.S.; Kajal Mane; Raut, A.M.; Bhombe, R.P. Utilization of different organic matter in the production of Azolla microphylla. J. Soil. Crop. 2020, 30(1), 159–164.

- Triyono, S.; Putra, A.M.; Amin, M.; Haryanto, A. The utilization of wastewater from catfish pond to culture Azolla microphylla. IJASEIT 2022, 12(1), 423–430. [Google Scholar] [CrossRef]

- Tokhun, N.; Chuleemas, B.I.; Ta-Oun, M. Wastewater treatment from piggery farm by using Azolla (Azolla microphylla). Khon Kaen Agr. J. 2011, 39, 269–273. [Google Scholar]

- Hechler, W.D.; Dawson, J.O. Factors affecting nitrogen fixation in Azolla caroliniana. Trans. Ill. State Acad. Sci. 1995, 88, 97–107. [Google Scholar]

- Aparna, M.B.; Yusuf, A. Biochemical and morphological changes in Azolla-Anabaena Azollae symbiotic system under gradient concentrations of NH4NO3. Int. J. Dev. Res. 2017, 7, 17977–17984. [Google Scholar]

- Thepsilvisut, O.; Chutimanukul, P.; Sae-Tan, S.; Ehara, H. Effect of chicken manure and chemical fertilizer on the yield and qualities of white mugwort at dissimilar harvesting times. PLoS ONE 2022, 17(4), e0266190. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis. In AOAC Official Methods of Analysis, 18th ed.; AOAC International: Wasington, DC, USA, 2005. [Google Scholar]

- Walkley, A.; Black, I.A. An examination of Degtjareff method for determining organic carbon in soils: Effect of variations indigestion conditions and of inorganic soil constituents. Soil Sci. 1934, 63, 251–263. [Google Scholar] [CrossRef]

- Herath, B.M.M.D.; Karunarathna, S.C. ; Ishaq, M; Wariss, H.M.; Yapa, P.N. Azolla as the multifunctional, fern in organic agriculture: Prospects and challenges:, IJAT. 2023, 19(1), 63–82. 2023. [Google Scholar]

- Marzouk, S.H.; Semoka, J.M.; Amuri, N.A.; Tindwa, H.J. Rice straw incorporation and Azolla application improves agronomic nitrogen-use efficiency and rice grain yields in paddy fields. Front. Soil Sci. 2024, 4, 1378065. [Google Scholar] [CrossRef]

- Fernández-Zamudio, R.; García-Murilloa, P.; Cirujano, S. Germination characteristics and sporeling success of A. filiculoides Lam., an aquatic invasive fern, in a Mediterranean temporary wetland. Aquat. Bot. 2010, 93, 89–92. [Google Scholar] [CrossRef]

- da Silva, M.E.J.; Mathe, L.O.J.; van Rooyen, I.L.; Brink, H.G.; Nicol, W. Optimal growth conditions for Azolla pinnata R. brown: impacts of light intensity, nitrogen addition, pH control, and humidity. Plants 2022, 11, 1048. [Google Scholar] [CrossRef]

- Korsa, G.; Alemu, D.; Ayele, A. Azolla plant production and their potential applications. Int. J. Agron. 2024, 1716440. [Google Scholar] [CrossRef]

- Temmink, R.J.M.; Harpenslager, S.F.; Smolders, A.J.P.; van Dijk, G.; Peters, R.C.J.H.; Lamers, L.P.M.; van Kempen, M.M.L. Azolla along a phosphorus gradient: Biphasic growth response linked to diazotroph traits and phosphorus-induced iron chlorosis. Sci Rep. 2018, 8, 4451. [Google Scholar] [CrossRef]

- Lumpkin, T.A.; Plucknett, D.L. Azolla as a green manure: Use and management in crop production; Westview Press: Boulder, Colorado, USA, 1982. [Google Scholar]

- Marschner, H. Mineral nutrition of higher plants, 3rd ed.; Academic Press, London, UK, 1986.

- Kushari, D.P.; Watanabe, I. Differential responses of Azolla to phosphorus deficiency. Soil Sci. Plant Nutr. 1991, 37, 271–282. [Google Scholar] [CrossRef]

- Arora, A.; Singh, P.K. Comparison of biomass productivity and nitrogen fixing potential of Azolla spp. Biomass and Bioenergy. 2003, 24, 175–178. [Google Scholar] [CrossRef]

- Tung, H.F.; Shen, T.C. Studies of the Azolla pinnata-Anabaena azollae Symbiosis: Growth and Nitrogen Fixation. Source New Phytol. 1981, 87, 743–749. [Google Scholar] [CrossRef]

- Singh, A.; Srivastava, N. Effect of light intensity on the growth of Azolla pinnata R. Brown at Ranchi, India. Hydrobiologia 1985, 126, 49–52. [Google Scholar] [CrossRef]

- Sarkar, A. Effects of light intensity on growth of Azolla pinnata ta cultured in effluent collected from the Banka stream in West Bengal, India. Aquat. Bot. 1986, 26, 189–194. [Google Scholar] [CrossRef]

- Effendi, I.; Pranata, A. ; Feliatra. The Effect of sun light intensity on the growth of Azolla Microphylla and its symbiont Anabeana Azollae in brackish water. J. Phys.: Conf. Ser. 2019, 1351, 012096.

- Abduh, M.Y.; Ono, J.M.; Khairani, M.; Manurung, R. The influence of light intensity on the protein content of Azolla Microphylla and pre-treatment with saccharomyces cerevisiae to increase protein recovery. J. Appl. Sci. Res. 2017, 13(8), 16–23. [Google Scholar]

- Hanafy, A.; El-Emary, G.A. Role of Azolla pinnata biofertilizer extract in producing healthy tomatoes. Asian J. Res. Biochem. 2018, 56, 1–8. [Google Scholar] [CrossRef]

- Marzouk, S.H.; Tindwa, H.J.; Amuri, N.A.; Semoka, J.M. An overview of underutilized benefits derived from Azolla as a promising biofertilizer in lowland rice production. Heliyon 2023, 9, e13040. [Google Scholar] [CrossRef]

- Maswada, H.F.; Abd El-Razek, U.A.; El-Sheshtawy, AN.A.; Mazrou, Y.S.A. Effect of Azolla filiculoides on growth, physiological and yield attributes of maize grown under water and nitrogen deficiencies. J. Plant Growth Regul. 2021, 40, 558–573. [Google Scholar] [CrossRef]

- Tejaswini, G.S.; Mahadevakumar, S.; Janardhana, G.R. Effect of Azolla pinnata on seed germination, vigour index, biomass and yield of French bean (Phaseolus vulgaris). Curr. Agri. Res. Jour. 2015, 3(2), 137–141.

- Bharali, A.; Baruah, K.; Bhattacharya, S.S.; Kim, K.-H. The use of Azolla caroliniana compost as organic input to irrigated and rainfed rice ecosystems: Comparison of its effects in relation to CH4 emission pattern, soil carbon storage, and grain C interactions. J. Clean. Prod. 2021, 313, 127931. [Google Scholar] [CrossRef]

- Setyaningrum, A.; Amrullah, N.; Yuwono, P. Physiological conditions of decomposition process and quality of compost based on beef cattle feces enriched with Azolla sp. In The 1st Animal Science and Food Technology Conference (AnSTC), Proceeding of IOP Conf. Series: Earth and Environmental Science, Montreal, Canada, –22, 2005. 18 May.

- Singh, P.K.; Panigrahi, B.C.; Satapathy, K.B. Comparative efficiency of Azolla, blue-green algae and other organic manures in relation to N and P availability in a flooded rice soil. Plant Soil 1981, 62, 35–44. [Google Scholar] [CrossRef]

- Seleiman, M.F.; Elshayb, O.M.; Nada, A.M.; El-leithy, S.A.; Baz, L.; Alhammad, B.A.; Mahdi, A.H.A. Azolla compost as an approach for enhancing growth, productivity and nutrient uptake of Oryza sativa L. Agronomy 2022, 12, 416. [Google Scholar] [CrossRef]

- Zaman, M.; Cameron, K.C.; Di, H.J.; Inubushi, K. Changes in mineral N, microbial biomass and enzyme activities in different soil depths after surface applications of dairy shed effluent and chemical fertilizer. Nutr. Cyc. Agroecosys. 2002, 63, 275–290. [Google Scholar] [CrossRef]

- Novair, S.B.; Hosseini, H.M.; Etesami, H.; Razavipour, T. Rice straw and composted azolla alter carbon and nitrogen mineralization and microbial activity of a paddy soil under drying–rewetting cycles. Appl. Soil Ecol. 2020, 154, 103638. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and the editor(s). MDPI and the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Treatment | Relative Growth Rate (g g-1 day-1) | Doubling time (day) |

Fresh Weight (g month-1) |

Dry Weight (g month-1) |

Dry Matter (%) |

|---|---|---|---|---|---|

| T1: Control (no fertilizer) | 0.09 b1 | 12.79 a | 229.83 d | 13.56 c | 6.13 a |

| T2: Cow manure, 100% | 0.11 a | 7.61 b | 301.65 c | 16.06 ab | 5.62 ab |

| T3: Pig manure, 100% | 0.13 a | 5.86 b | 360.16 a | 16.98 a | 4.89 c |

| T4: Cow manure: Pig manure, 25:75% w/w | 0.12 a | 6.56 b | 305.09 bc | 16.02 ab | 5.37 bc |

| T5: Cow manure: Pig manure, 50:50% w/w | 0.12 a | 7.83 b | 312.71 b | 15.48 b | 5.19 bc |

| T6: Cow manure: Pig manure, 75:25% w/w | 0.11 a | 8.50 b | 297.25 c | 15.29 b | 5.48 bc |

| Significance | ** | ** | ** | ** | ** |

| C.V. (%) | 9.58 | 18.91 | 1.58 | 3.97 | 5.88 |

| Treatment | Total N (%) |

Total P (%) |

Total K (%) |

Organic Matter (%) |

C:N Ratio |

|---|---|---|---|---|---|

| T1: Control (no fertilizer) | 2.30 | 0.09 | 0.79 b1 | 59.32 | 14.95 |

| T2: Cow manure, 100% | 2.55 | 0.10 | 1.02 a | 60.37 | 13.86 |

| T3: Pig manure, 100% | 2.43 | 0.14 | 1.14 a | 60.12 | 14.38 |

| T4: Cow manure: Pig manure, 25:75% w/w | 2.38 | 0.10 | 0.54 c | 61.94 | 15.10 |

| T5: Cow manure: Pig manure, 50:50% w/w | 2.52 | 0.12 | 0.50 c | 61.72 | 14.36 |

| T6: Cow manure: Pig manure, 75:25% w/w | 2.49 | 0.10 | 0.33 d | 61.71 | 14.55 |

| Significance | ns | ns | ** | ns | ns |

| C.V. (%) | 7.51 | 15.07 | 9.58 | 3.24 | 13.86 |

| Treatment | Relative Growth Rate (g g-1 day-1) | Doubling time (day) |

Fresh Weight (g month-1) |

Dry Weight (g month-1) |

Dry Matter (%) |

|---|---|---|---|---|---|

| T1: Control (no fertilizer) | 0.14 b1 | 5.06 a | 375.73 b | 20.67 b | 5.46 a |

| T2: Pig manure 20.16 gN m-2 | 0.22 a | 3.22 b | 792.06 a | 32.49 a | 4.18 b |

| T3: Pig manure 30.16 gN m-2 | 0.22 a | 3.15 b | 834.08 a | 33.60 a | 4.05 b |

| T4: Pig manure 40.16 gN m-2 | 0.22 a | 3.10 b | 865.32 a | 35.07 a | 4.07 b |

| Significance | ** | ** | ** | ** | ** |

| C.V. (%) | 3.33 | 5.42 | 6.69 | 7.61 | 3.33 |

| Treatment | Total N (%) |

Total P (%) |

Total K (%) |

Organic Matter (%) |

C:N Ratio |

|---|---|---|---|---|---|

| T1: Control (no fertilizer) | 2.67 b1 | 0.09 b | 2.11 b | 57.75 | 12.60 a |

| T2: Pig manure 20.16 gN m-2 | 3.69 a | 0.84 a | 4.21 a | 55.05 | 8.75 b |

| T3: Pig manure 30.16 gN m-2 | 3.90 a | 0.96 a | 4.34 a | 55.94 | 8.36 b |

| T4: Pig manure 40.16 gN m-2 | 3.32 ab | 1.01 a | 4.33 a | 57.85 | 10.31 ab |

| Significance | * | ** | ** | ns | * |

| C.V. (%) | 11.26 | 19.74 | 5.62 | 17.20 | 13.07 |

| Treatment | Relative Growth Rate (g g-1 day-1) | Doubling time (day) |

Fresh Weight (g month-1) |

Dry Weight (g month-1) |

Dry Matter (%) |

|---|---|---|---|---|---|

| T1: Control (no shading) | 0.23 | 3.12 ab1 | 903.80 ab | 39.15 a | 4.44 a |

| T2: Shading 20% | 0.22 | 3.07 ab | 890.47 b | 36.63 b | 4.14 b |

| T3: Shading 40% | 0.23 | 3.00 b | 922.13 a | 37.51 ab | 4.10 b |

| T4: Shading 60% | 0.22 | 3.18 a | 806.68 c | 32.91 c | 4.10 b |

| Significance | ns | * | ** | ** | ** |

| C.V. (%) | 2.86 | 1.98 | 1.58 | 2.66 | 2.10 |

| Treatment | Total N (%) |

Total P (%) |

Total K (%) |

Organic Matter (%) |

C:N Ratio |

|---|---|---|---|---|---|

| T1: Control (no shading) | 3.27 | 0.30 c1 | 1.56 b | 62.29 | 11.09 a |

| T2: Shading 20% | 3.40 | 0.75 a | 2.11 a | 63.66 | 10.92 a |

| T3: Shading 40% | 3.81 | 0.67 a | 1.88 a | 59.92 | 9.20 b |

| T4: Shading 60% | 3.80 | 0.44 b | 2.06 a | 60.81 | 9.29 b |

| Significance | ns | ** | ** | ns | * |

| C.V. (%) | 8.43 | 11.68 | 7.07 | 3.01 | 8.41 |

| Parameters | Conventional Method * | Developed Method | Compared (%) |

|---|---|---|---|

| Relative growth rate (g g-1 day-1) Doubling time (day) Fresh weight (g month-1) |

0.24 | 0.25 | +4.17 |

| 2.95 | 2.77 | -6.10 | |

| 1,589.94 | 1842.60 | +15.89 | |

| Dry weight (g month-1) | 74.64 | 71.27 | -4.52 |

| Dry matter (%) | 4.65 | 3.87 | -16.77 |

| Total N (%) | 4.89 | 4.92 | +0.61 |

| Total P (%) | 1.05 | 0.75 | -28.57 |

| Total K (%) | 3.18 | 4.08 | +28.30 |

| Protein (%) | 30.58 | 30.72 | +0.46 |

| Organic matter (%) | 63.10 | 67.42 | +6.85 |

| C:N ratio | 7.50 | 7.96 | +6.13 |

| Parameters | A. microphylla | Compost Specifications of Thai Agricultural Standard: Compost (TAS 9503-2005), Thailand |

|---|---|---|

| Organic matter (%) | 67.42 | ≥ 30.0 |

| C:N ratio | 7.96 | ≤ 20:1 |

| Total Nitrogen (%) | 4.92 | ≥ 1.0 |

| Total Phosphorus (%) | 0.75 | ≥ 0.5 |

| Total Potassium (%) | 4.08 | ≥ 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).