Submitted:

29 September 2024

Posted:

30 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

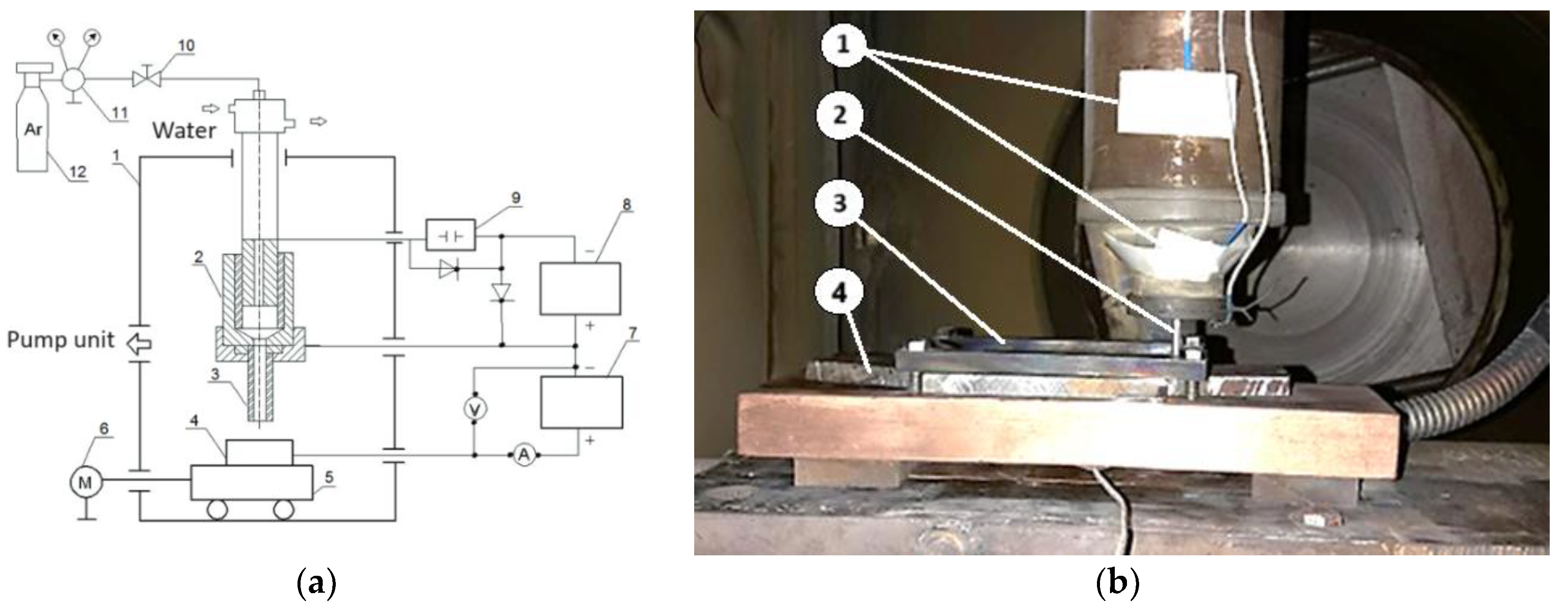

2.1. Experiments

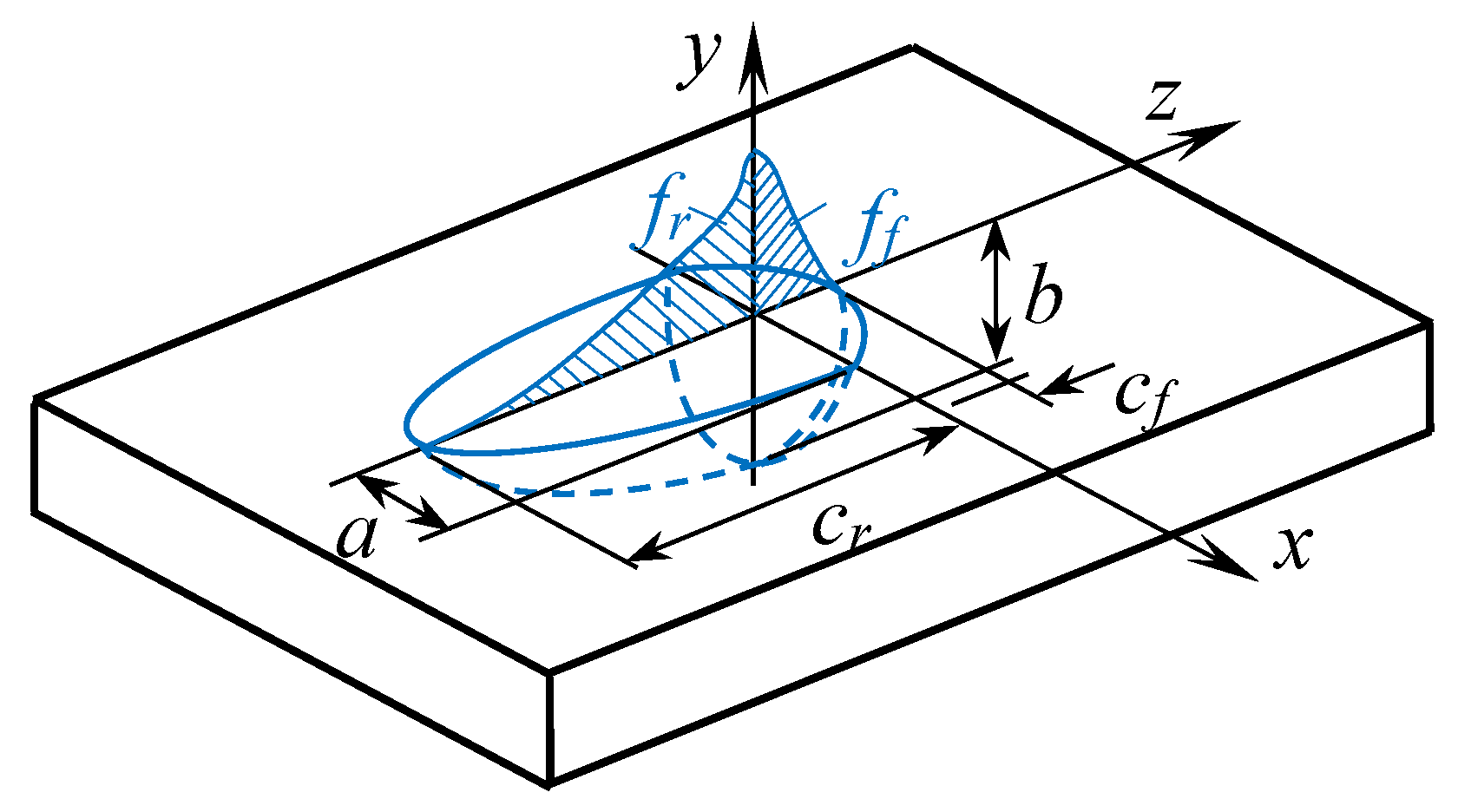

2.2. Thermo-Mechanical Model

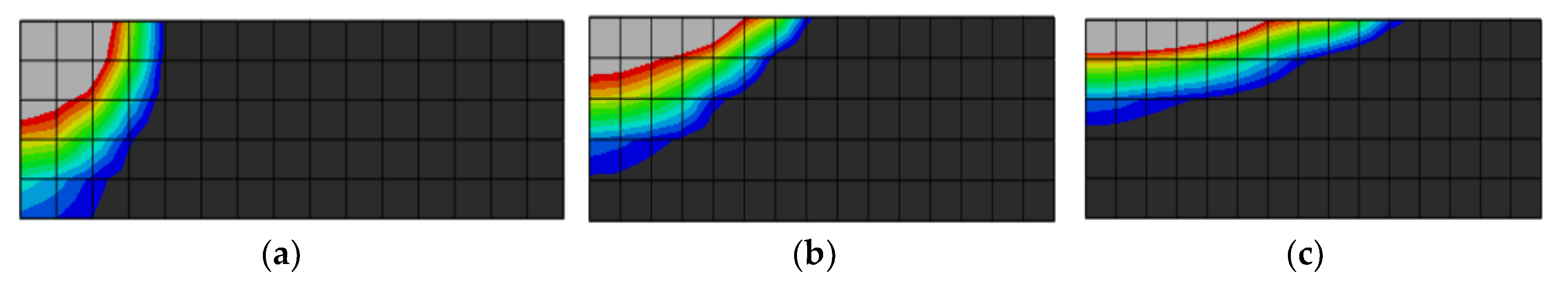

2.3. Finite Element Desription

2.4. Computer Model

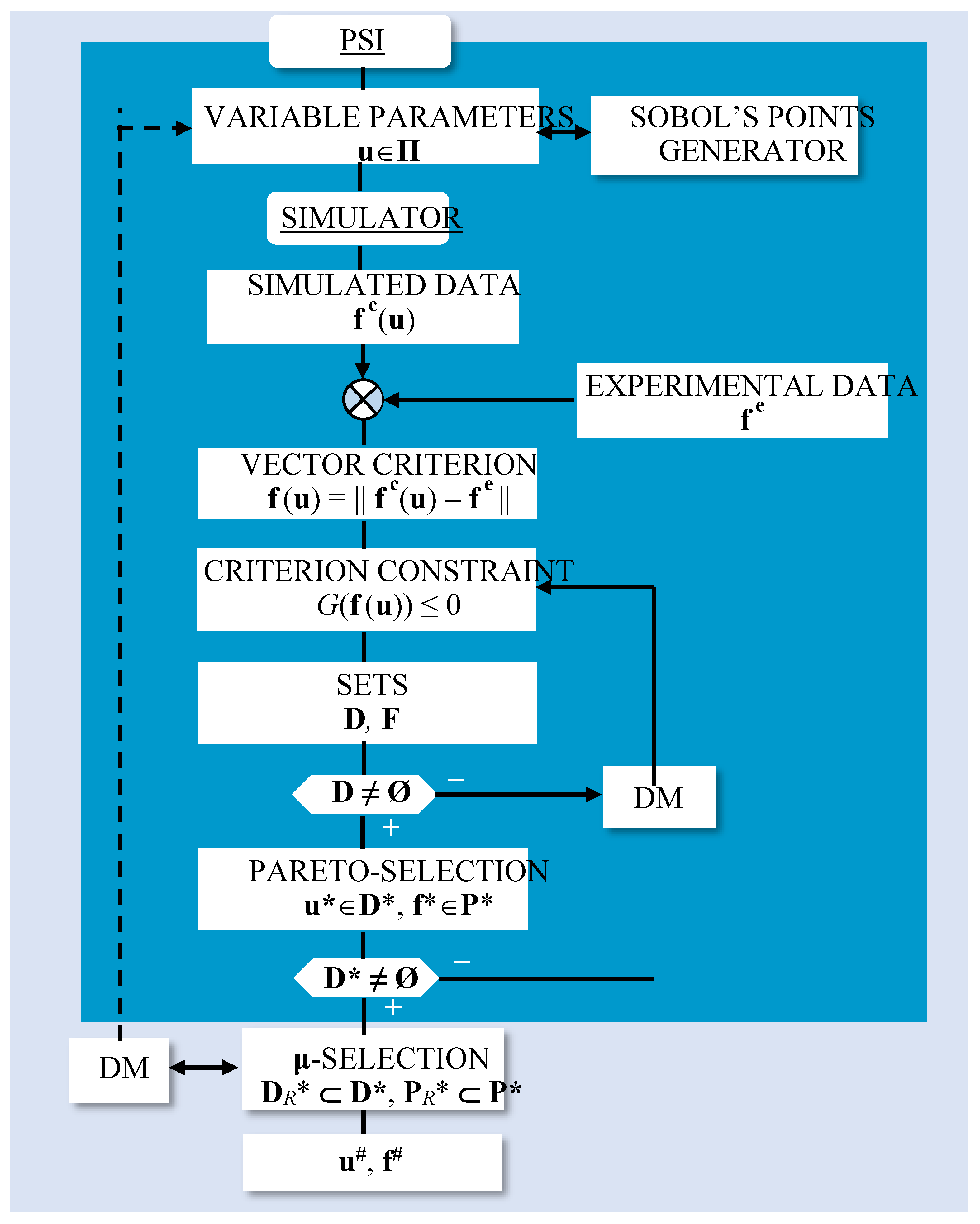

2.5. Optimization Model

f c(u) = [ f1c(u), f2c(u), … , fvc(u), … , f4c(u) ],

f е = [ f1е, f2е, … , fvе, … , f4е ].

D = {u∈Е5: G (f (u)) ≤ 0, u∈П},

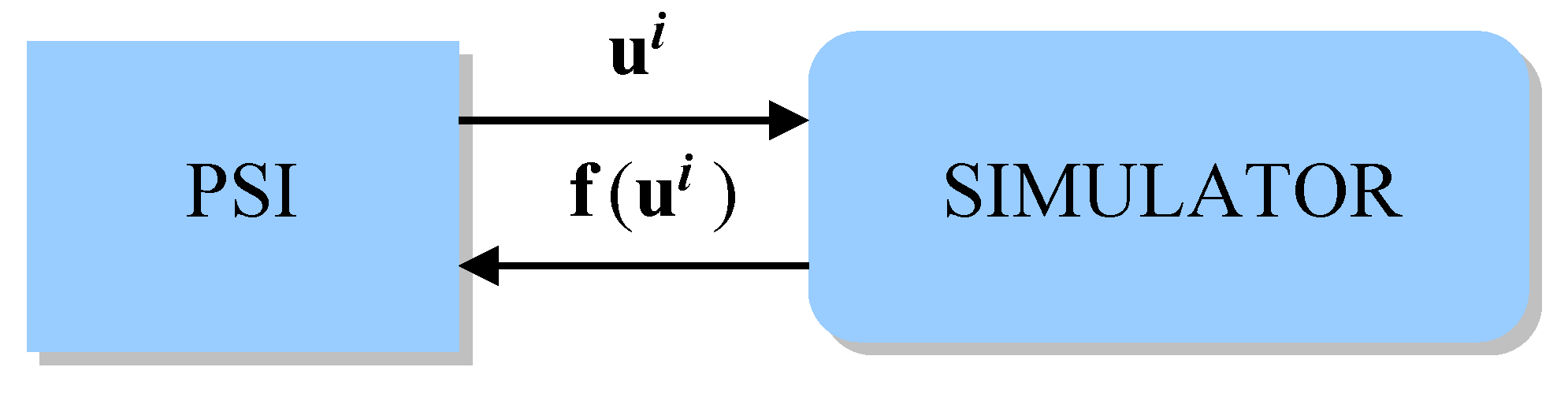

2.6. Calculation Procedure

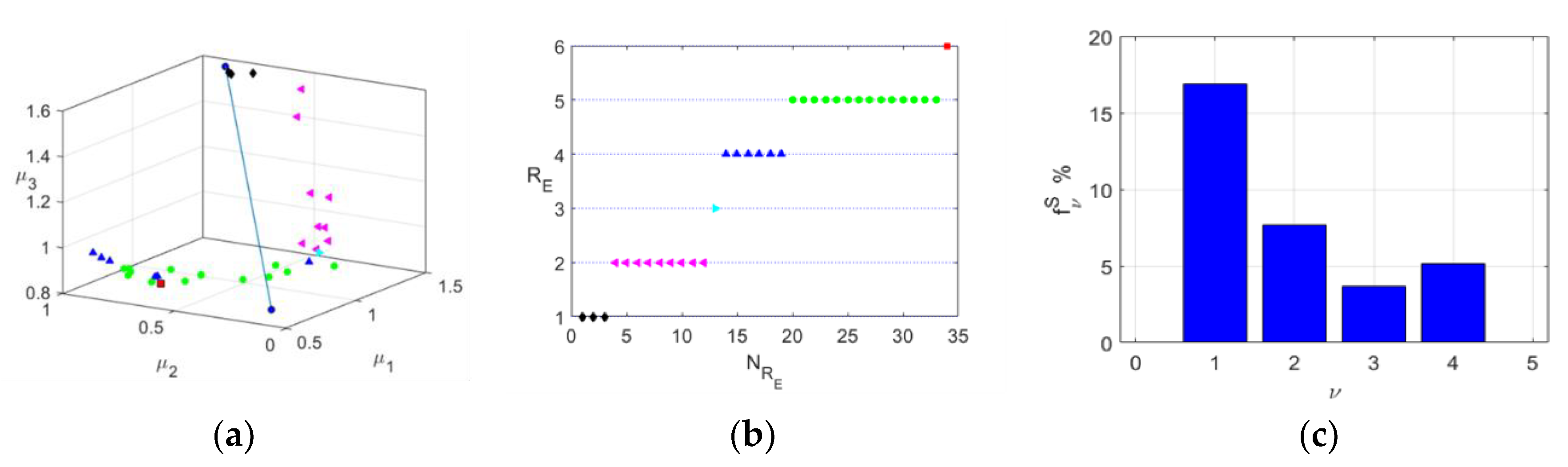

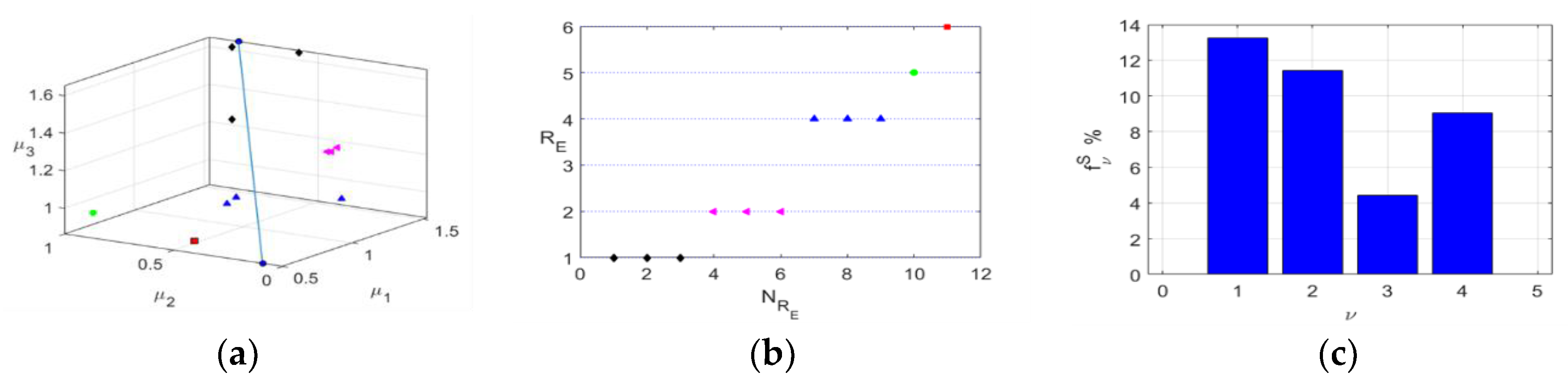

3. Results

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Arata, Y.; Abe, N.; Oda, T.; Tsujii, N. Fundamental Phenomena during Vacuum Laser Welding; ASME: Boston, Massachusetts, USA, 1984; pp 1–7. [CrossRef]

- Miller, H. C. A Review of Anode Phenomena in Vacuum Arcs. IEEE Transactions on Plasma Science 1985, Vol. 13, (No. 5), pp 242–252. [CrossRef]

- Toya, H.; Hieda, K.; Saitou, T. Preliminary Study on Arc Welding in Vacuum; Matsue, Japan, 2006; pp 762–765. [CrossRef]

- Ferdinandov, N.; Gospodinov, D.; Ilieva, M.; Dimitrov, S. Effect of the process parameters on mechanical properties of titanium alloy Ti-6Al-4V welds; Proceedings of University of Ruse; Ruse, Bulgaria, 2017, Vol. 56, book 2, pp 58-65.

- Hibbitt, H.; Marcal, P. A Numerical, Thermo-Mechanical Model for the Welding and Subsequent Loading of a Fabricated Structure. Comuters & Structures 1973, Vol. 3, pp 1145–1174.

- Friedman, E. Thermomechanical Analysis of the Welding Process Using the Finite Element Method. Trans. ASME 1975, Vol. 97 (No. J3), pp 206–213.

- Goldak, J.; Chakravarti A.; Bibby M. A New Finite Element Model for Welding Heat Sources. Metallurgical Transactions B 1984, Vol. 15B, pp 299–305.

- Michaleris, P.; Debiccari, A. Prediction of Welding Distortion. AWS Annual Convention 1996, pp 172–181.

- Han, Y.; Lee, K.; Han, M.; Chang, H.; Choi, K.; Im, S. Finite Element Analysis of Welding Processes by Way of Hypoelasticity-Based Formulation. Journal of Engineering Materials and Technology 2011, Vol. 133, pp 1–13. [CrossRef]

- Fadaei, A.; Mokhtari, H. Finite Element Modeling and Experimental Study of Residual Stress in Repair Butt Weld of St-37 Plates. IJST, Transactions of Mechalical Engineering 2015, Vol. 39, (No. M2), pp 291-307.

- Nezamdost, M.; Efahani, M.; Hashemi, S.; Mirbozorgi, S. Investigation of Temperature and Residual Stresses Field of Submerged Arc Welding by Finite Element Method and Experiments. Int. J. Adv. Manuf. Technol. 2016, Vol. 87, pp 615–624. [CrossRef]

- Kik, T.; Górka, J. Numerical Simulations of Laser and Hybrid S700MC T-Joint Welding. Materials 2019, Vol. 12, (No. 3), 516. [CrossRef]

- Murthy, K.K.R.; Akyel, F.; Reisgen, U.; Olschok, S.; Mahendran, D. Modelling the Evolution of Phases during Laser Beam Welding of Stainless Steel with Low Transformation Temperature Combining Dilatometry Study and FEM. J. Manuf. Mater. Process. 2024, Vol. 8, 50. [CrossRef]

- Akrivos, V.; Muransky, O.; Depradeux, L.; Smith, M.C.; Vasileiou, A.; Deaconu, V.; Kapadia, P. On the Accurate Prediction of Residual Stress in a Three-Pass Slot Nickel-Base Repair Weld by Numerical Simulations. J. Manuf. Mater. Process. 2022, Vol. 6, 61. [CrossRef]

- Sumanlal, M. S.; Sarin, P.; Varghese, V. J. Three-Dimensional Finite Element Optimization of Bead Shape Developed during Tig Welding of Mild Steel. International Journal of Applied Engineering Research 2018, Vol. 13, (No. 3), pp 104–109.

- Bag, S.; Trivedi, A.; De, A. Use of a Multivariate Optimization Algorithm to Develop a Self-Consistent Numerical Heat Transfer Model for Laser Spot Welding. The International Journal of Advanced Manufacturing Technology 2008, Vol. 38, (No. 5), pp 575–585.

- Fu, G.; Gu J.; Lourenco, M. I.; Duan, M.; Estefen, S. F. Parameter Determination of Double-Ellipsoidal Heat Source Model and Its Application in the Multi-Pass Welding Process. Ships and offshore structures 2015, Vol. 10, (No. 2), pp 204–217.

- Belitzki, A.; Marder, C.; Huissel, A.; Zaeh, M.F. Automated Heat Source Calibration for the Numerical Simulation of Laser Beam Welded Components. Production Engineering 2016, Vol. 10, (No. 2), pp 129-36. [CrossRef]

- Walker, T. R.; Bennett, C. J. An Automated Inverse Method to Calibrate Thermal Finite Element Models for Numerical Welding Applications. Journal of Manufacturing Processes 2019, Vol. 47, pp 263–283. [CrossRef]

- Escribano-García, R.; Álvarez, P.; Marquez-Monje, D. Calibration of Finite Element Model of Titanium Laser Welding by Fractional Factorial Design. J. Manuf. Mater. Process. 2022, Vol. 6, (No. 6), 15 p. [CrossRef]

- Hartwig, P.; Bakir, N.; Scheunemann, L.; Gumenyuk, A.; Schröder, J.; Rethmeier, M. A. Physically Motivated Heat Source Model for Laser Beam Welding. Metals 2024, Vol. 14, (No. 4), 430. [CrossRef]

- Statnikov, R. B.; Matusov, I. B. Solved tasks of multi-criteria identification and refinement of experimental samples. Problems of mechanical engineering and machine reliability 2012, No. 5, pp 20–29.

- ISO/TS 18166 Numerical Welding Simulation — Execution and Documentation.

- Strychek, Y.; Antoniak, P.; Lurie, Z. Y.; Solovyov, V. M. Determination of unknown parameters of a gear pump external gearing by solving the inverse problem of multi-criteria identification. Industrial hydraulics and pneumatics 2017, No. 2, pp 57–69. https://repository.kpi.kharkov.ua/server/api/core/bitstreams/1d1bf4c3-f772-49fb-ab78-fbef39f079e6/content .

- Kovalenko, D. V.; Pavlyak, D. A.; Sudnik, V. A.; Kovalenko, I. V. Adequacy of the thermo-hydrodynamic model of through penetration in TIG and A-TIG welding of Nimonic-75 nickel alloy. Automatic Welding 2010, No. 10, pp 5–9.

- Yadaiah, N.; Bag, S. Effect of Heat Source Parameters in Thermal and Mechanical Analysis of Linear GTA Welding Process. ISIJ International 2012, Vol. 52, (No. 11), pp 2069–2075. [CrossRef]

- Bradáč, J. Calibration of Heat Source Model in Numerical Simulations of Fusion Welding. Machines, Technologies, Materials 2013, No. 11, pp 9–12. https://mech-ing.com/journal/Archive/2013/11/76_Bradac.pdf .

- Yakimenko, O. A.; Statnikov, R. B. Multicriteria Parametrical Identification of the Parafoil-Load Delivery System. 18th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Munich, Germany, AIAA 2005 – 1664, 12 р. [CrossRef]

- Sobol, I. M.; Statnikov, R. B. Selection of optimal parameters in tasks with many criteria.; Drofa: Moscow, 2006, (in Russ.).

- Statnikov, R. B.; Statnikov, A. R. The Parameter Space Investigation Method Toolkit.; Artech House: Boston/ London, 2011.

- Lu, Y.; Blal, N.; Gravouil, A. Space-Time POD Based Computational Vademecums for Parametric Studies: Application to Thermo-Mechanical Problems. Advanced Modeling and Simulation in Engineering Sciences 2018, Vol. 5, (No. 3), pp 1–27. [CrossRef]

- Chinesta, F.; Leygue, A.; Bordeu, F.; Aguado, J.; Cueto, E.; Gonzalez, D.; Alfaro, I.; Ammar, A.; Huerta, A. PGD-Based Computational Vademecum for Efficient Design. Optimization and Control. Archives of Computational Methods in Engineering 2013, Vol. 20, (No. 1), pp 31–59. [CrossRef]

- EN 10025-2:2005 Hot Rolled Products of Structural Steels - Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels.

- Draganov, I.; Ferdinandov, N.; Gospodinov, D.; Radev, R.; Mileva, S.; Angelov, Y. Numerical modeling and calibration of steel plate welding in vacuum; Ruse, Bulgaria, 2019; Vol. 58, book 2.1, pp 65-73.

- Bergheau, J-M.; Fortunier R. Finite Element Simulation of Heat Transfer. Hoboken: John Wiley & Sons, Inc., NJ, 2008.

- ABAQUS. Analysis User’s Manual. Ver. 6.14, Providence, RI, USA.

- Milkowska-Piszczek, K.; Korolczuk-Hejnak, M. An Analysis of The Influence of Viscosity on The Numerical Simulations of Temperature Distribution as Demonstrated The CC Process. Archives of Metallurgy and Materials 2011, Vol. 58 (No. 4), pp 1267–1274. [CrossRef]

- Muhtarov, I. Residual stresses in thin stainless steel plates subject to TIG welding; Sozopol, Bulgaria, 2011, pp 246–249.

- Miettinen, K. Nonlinear Multiobjective Optimization, 2nd ed., Springer: New York, 2012.

- Yordanov, Y. T.; Vitliemov, V. G. Optimization with MATLAB. A pragmatic approach.; “Angel Kanchev” University Publishing House: Ruse, Bulgaria, 2013, (in Bulg.).

- Cheshankov, B. I.; Ivanov, I. V.; Vitliemov, V. G.; Koev, P. A. PSI-Method Multi-Criteria Optimization Contracting the Set of Trade-Off Solutions. Proceedings of the 15th International Conference on Systems Science, Wrozlaw, Poland, 2004, Vol. 1, pp 281–288,.

- Salukvadze, M. E. Vector-Valued Optimization Problems in Optimal Control Theory, 2nd ed., Academic Press: New York, 2012.

- Huang, H.; Murakawa, H. A. Selective Integration-Based Adaptive Mesh Refinement Approach for Accurate and Efficient Welding Process Simulation. J. Manuf. Mater. Process. 2023, Vol. 7, (No. 6), 206. [CrossRef]

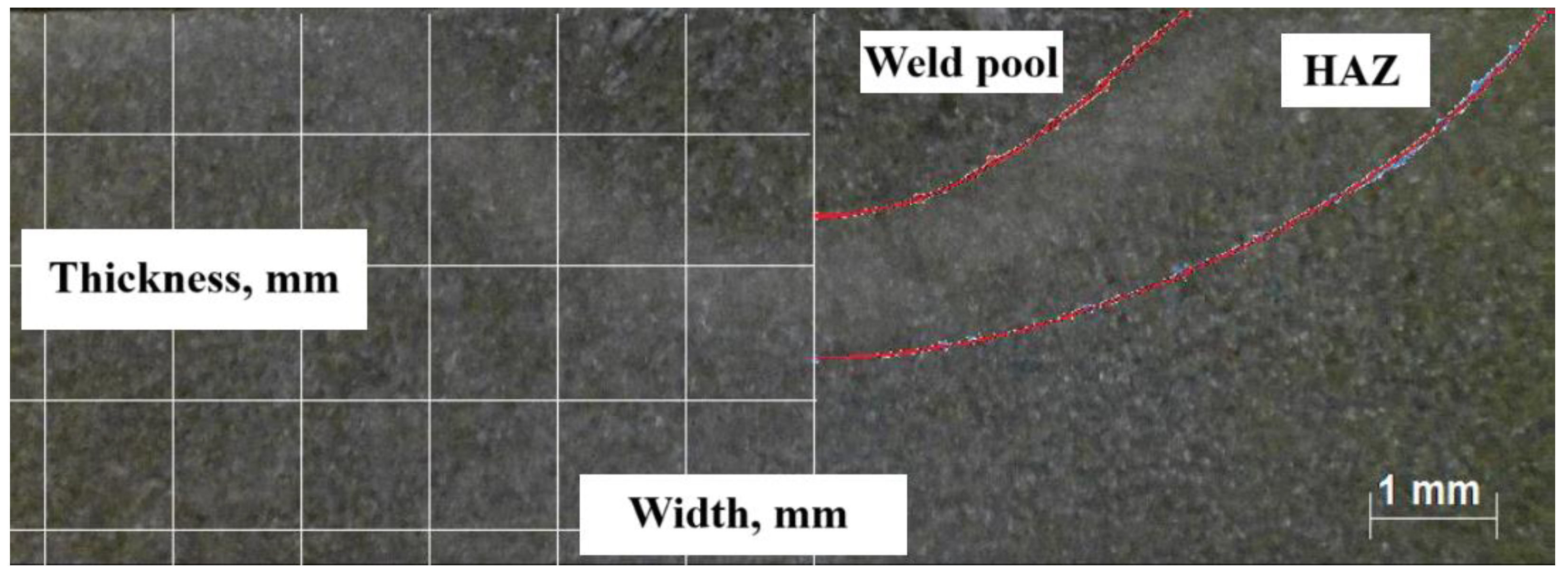

| Dimensions | Designation | Value, mm |

|---|---|---|

| Width of the WP | f1е | 4.30 |

| Depth of WP | f2е | 1.65 |

| Width of HAZ | f3е | 8.40 |

| Depth of HAZ | f4е | 2.80 |

| Material Properties | Temperature, °C | Value |

|---|---|---|

| Thermal conductivity, W/mK | 20 | 40 |

| 1300 | 30 | |

| 1600 | 120 | |

| Specific heat capacity, J/kgK | 20 | 400 |

| 1540 | 600 | |

| Modulus of elasticity, GPa | 20 | 210 |

| 1500 | 5 | |

| Poisson’s ratio, – | 20 … 1600 | 0.27 |

| Coefficient of temperature expansion, K – 1 | 20 | 1.25×10–6 |

| 1500 | 1.65×10–6 | |

| Yield strength, MPa | 20 | 235 |

| 500 | 100 | |

| 1000 | 50 |

| Phase Transformations | Latent Heat, kJ | Lower Limit, °C | Upper Limit, °C |

|---|---|---|---|

| (α – γ) transition | 55 | 700 | 800 |

| Solid phase – liquid phase | 150 | 1450 | 1650 |

| uj | Designation | Values | ||

|---|---|---|---|---|

| uj– | uj° | uj+ | ||

| u1 | Depth-related calibration parameter – k | 3.00 | 5.00 | 8.00 |

| u2 | Calibration parameter related to the width – l | 1.00 | 2.00 | 3.00 |

| u3 | Calibration parameter related to length – m | 3.00 | 5.00 | 8.00 |

| u4 | Arc density factor in front of the center of the HF | 1.00 | 1.20 | 1.60 |

| u5 | Arc efficiency | 0.40 | 0.46 | 0.52 |

| Variant | δfv +, % |

|---|---|

| V1 | 20 |

| V2 | 15 |

| V3 | 13 |

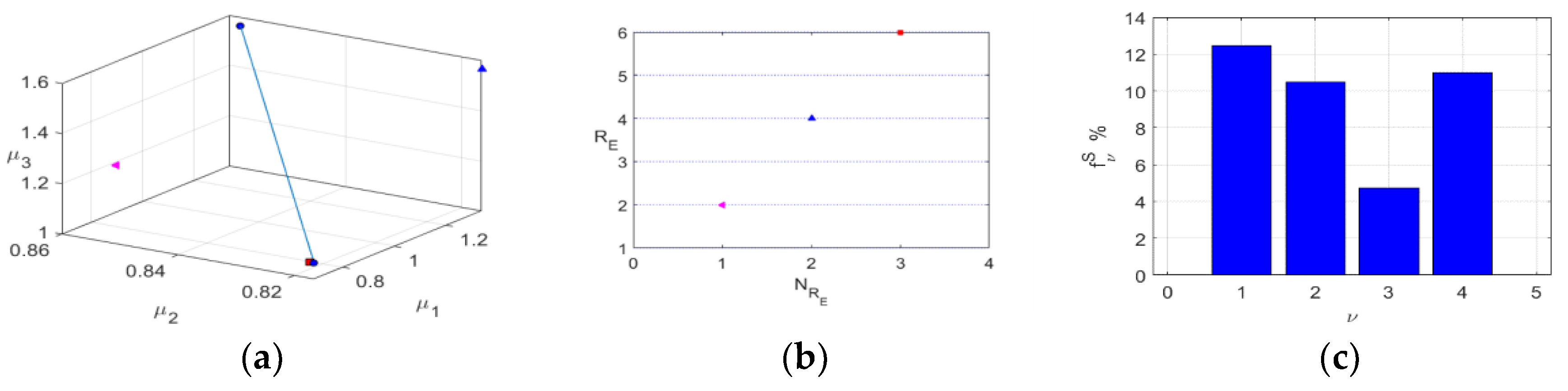

| RE | f1*R | f2*R | f3*R | f4*R |

| 6 | 12.471 | 10.487 | 4.746 | 11.017 |

| 4 | 9.738 | 12.169 | 5.203 | 11.827 |

| 2 | 11.601 | 12.988 | 4.758 | 10.537 |

| RE | u1*R | u2*R | u3*R | u4*R | u5*R |

| 6 | 3.469 | 1.938 | 7.219 | 1.244 | 0.434 |

| 4 | 5.734 | 2.531 | 3.547 | 1.047 | 0.424 |

| 2 | 5.383 | 2.391 | 7.961 | 1.098 | 0.438 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).