1. Introduction

Nowadays, the rapid development of remote and contactless sensing applied in a plethora fields is increasingly promoting the advancement of wireless sensing technology and, accordingly, improving the functionality and utility of sensor system. However, in terms of the deployment of wired sensor and sensing system, the drawback and limitation are also evident, laying in the necessity of power supplied by the battery on board that always occupy a large amount of space with much difficulty and inconvenience in maintenance and battery replacement[

1,

2,

3]. Instead, the wireless sensor and sensing system can break the free from this constraint, appropriating for long-term or even permanent deployment in especially some extreme situation or the environments full of danger and hazard. In addition, compared with the active sensor embedded with integrated circuits (IC) on board, the passive sensor is functionalized by IC without battery power or IC powered by wireless transfer that can sense and transmit the sensed signal in the scenario that the active can’t and avoid the necessity of battery renew in terms of real-time real-field monitor and sensing application[

4,

5,

6]. Basically, a passive wireless sensor system is composed of sensors and externally equipped interrogators. The interrogators transmit the interrogating signals to sensors, the interrogating signals will be received and then scattered backwardly. The interrogators can then receive these backscattered signals, reading and identifying them owing that the sensed information will be borne by these signals with different formula or different modulation[

7].

Up to now, the passive wireless sensor technology and application have attracted a lot attention. Along with the progress of the technology of micro electromechanical systems (MEMS) and integrated circuit, the passive wireless sensors can be innovated to be more appropriate for the application that are tediously required for constraint size, dimension and power consumption[

8,

9], regarding simpler architecture, wider environmental suitability, lower cost, and easier utilization. However, the passive wireless sensors have inherent disadvantage need to be overcome, in especially the comparatively lower information capacity compared with the active counterparts.

So, in this paper, an enhanced multiple bits passive wireless sensor based on UWB spectral-temporal joint coding and modulation is designed and developed based on the uniqueness of super-narrow electromagnetic pulse that is possessed of ultra-wide band in frequency band. The proposed sensor has such feature:1) the sensor unit is a planar patch covering UWB standardized bandwidth from 3.1GHz~10.6GHz;2)the patch is etched by a U-slot that bring about a specific bandgap frequency in frequency domain;3) the patch is fed by a meander microstrip line that bring about pulse in time domain;4)a sensor node is embedded and located in the middle of U-slot, the node’s status and the length of the U-slot is used to modulate the bandgap frequency to realize digital coding in frequency domain; 5)a sensor node is equipped at the terminal of meander microstrip line, the node’s status and the length of the meander line is used to modulate the pulse’s amplitude to realize digital coding in time domain;6)Four such kind of sensor units with different length of U-slot and meander microstrip line are combined cubically to configure sensor architecture with total 8 bits capacity.

2. Theoretical Model

The UWB technology is a formula used in specific for the short-range wireless communication that, as extremely wide band employed, show much outstanding features as of low spectrum occupation, low power consumption and strong anti-interference. In commercial use, the 3.1GHz~10.6GHz band is specifically allocated for promoting short-range communication with large capacity. In principle, what we call the UWB has two definitions, the first is the relative bandwidth that is equal to or greater than 20%, as shown equation (1).

And, the second is the absolute bandwidth, denoting bandwidth exceeding up to 500MHz, as shown equation (2).

where,

,

and

represent the lowest, the highest, and the center frequency respectively.

In time domain accordingly, the UWB signal is a very short pulse shortened by approximating nanosecond level between 0.2 and 1.5 nanosecond. Since being very short in time domain whilst high tier temporal resolution, the UWB system is able to adopt periodic pulse to carry and transmit data with low duty cycle that, as a result, can reduce power consumption greatly. Moreover, due to the extreme narrow pulse it has, the multipath effect is not very much easier to be overlapped in the time axial that can enable receiver to separate multipath signals effectively so as to improve the resolution of multipath effects.

On the contrary, in frequency domain, the bandwidth of UWB spectrum can be awfully extended to be extremely high energy dispersion, and since it has relatively lower power spectral density, the UWB can enable the interference interfering to other wireless system to be minimum to improve spectral efficiency of utilization.

Therefore, the UWB system is regarded as the optimal architecture for wireless sensor system that usually equipped by passive sensor node, chipless or battery free. Upon both the research and application issue, the small size, low profile and high efficiency passive sensor structure is always the hot subject, for example, the UWB is applied to a printed microstrip antenna with an etched ground plane to extend its operating frequency covering overall UWB band[

10], and compact ultra-wideband (UWB) printed monopole antenna with higher gain and efficiency that is light-weight, low-cost, easy to be manufacturing and better integrating with other systems to provide solution for short-range communication with large capacity and traffic[

11].

3. Sensor Unit

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

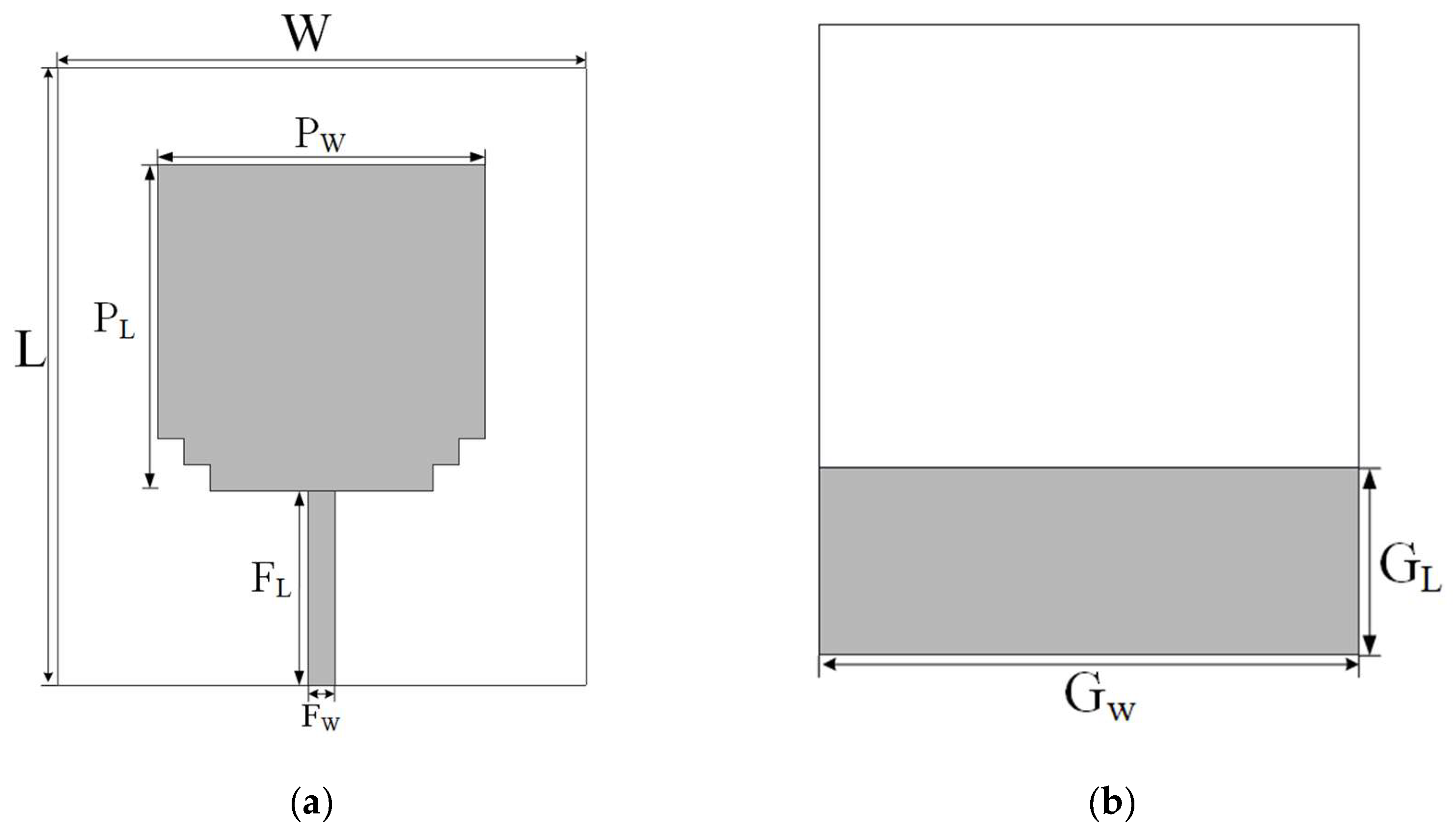

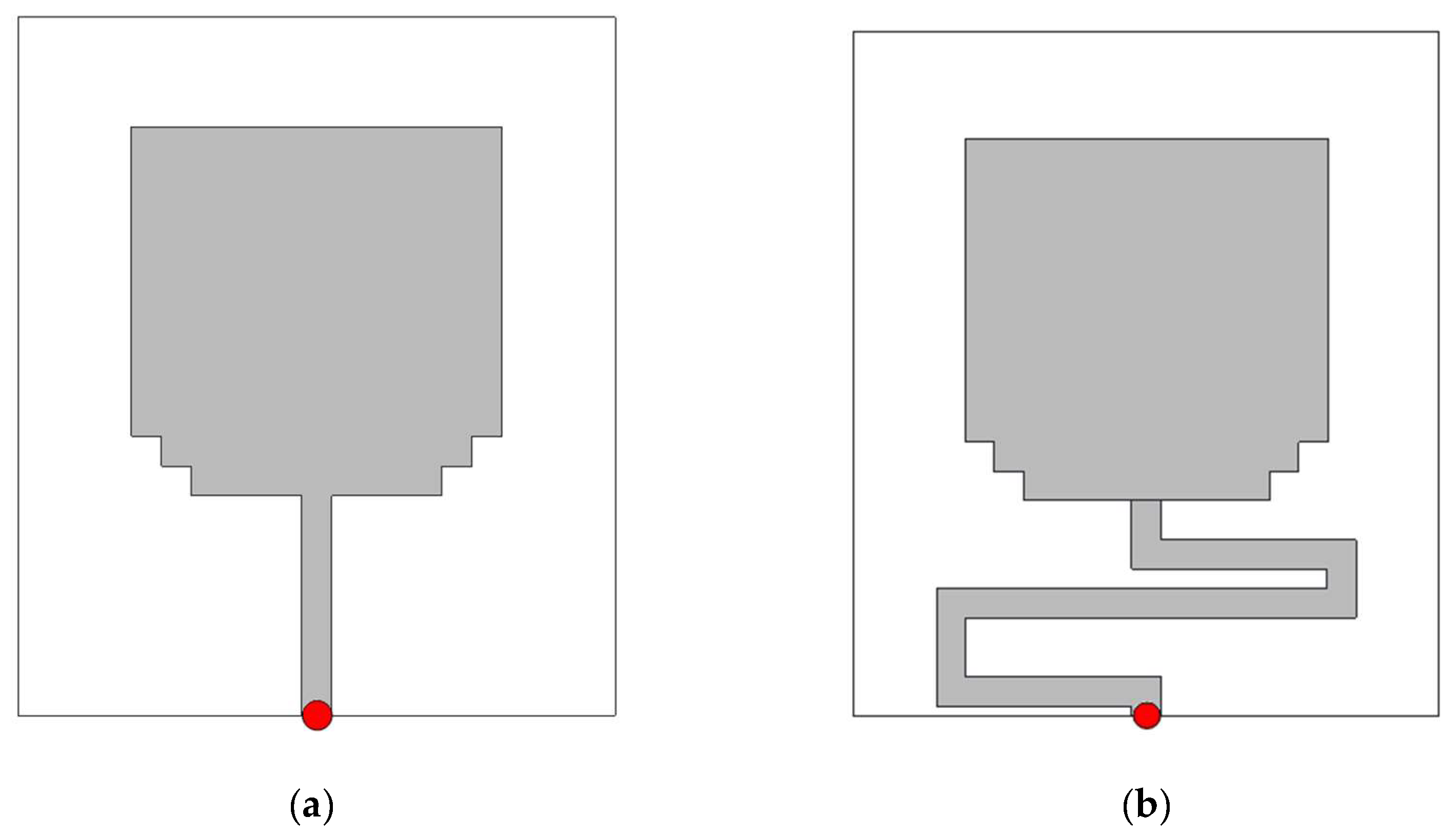

The sensor unit is designed and shown in

Figure 1, illustrated by a metallic planar printed on the surface of PCB board fed by a microstrip line with grounding plane printed on bottom side. The PCB board is the RF4 type with dielectric constant of 2.33. The size of the sensor unit is 30mm long(W), 35mm wide(L)and 0.5 mm thick(H). The size of the metallic patch is 18.6mm long (PW) ,18.5mm wide (PL), the two bottom edges are specifically designed by two level staircases in order to widen bandwidth as much as possible. The metallic patch is fed by a microstrip line that is 11mm long(FL)and 1.5 mm wide(FW), as shown in

Figure 1(a). As microstrip line, the grounding plate is 30mm long (Gw)and 10.4 mm wide (GL), printed on the bottom side of PCB board, as shown in

Figure 1(b).

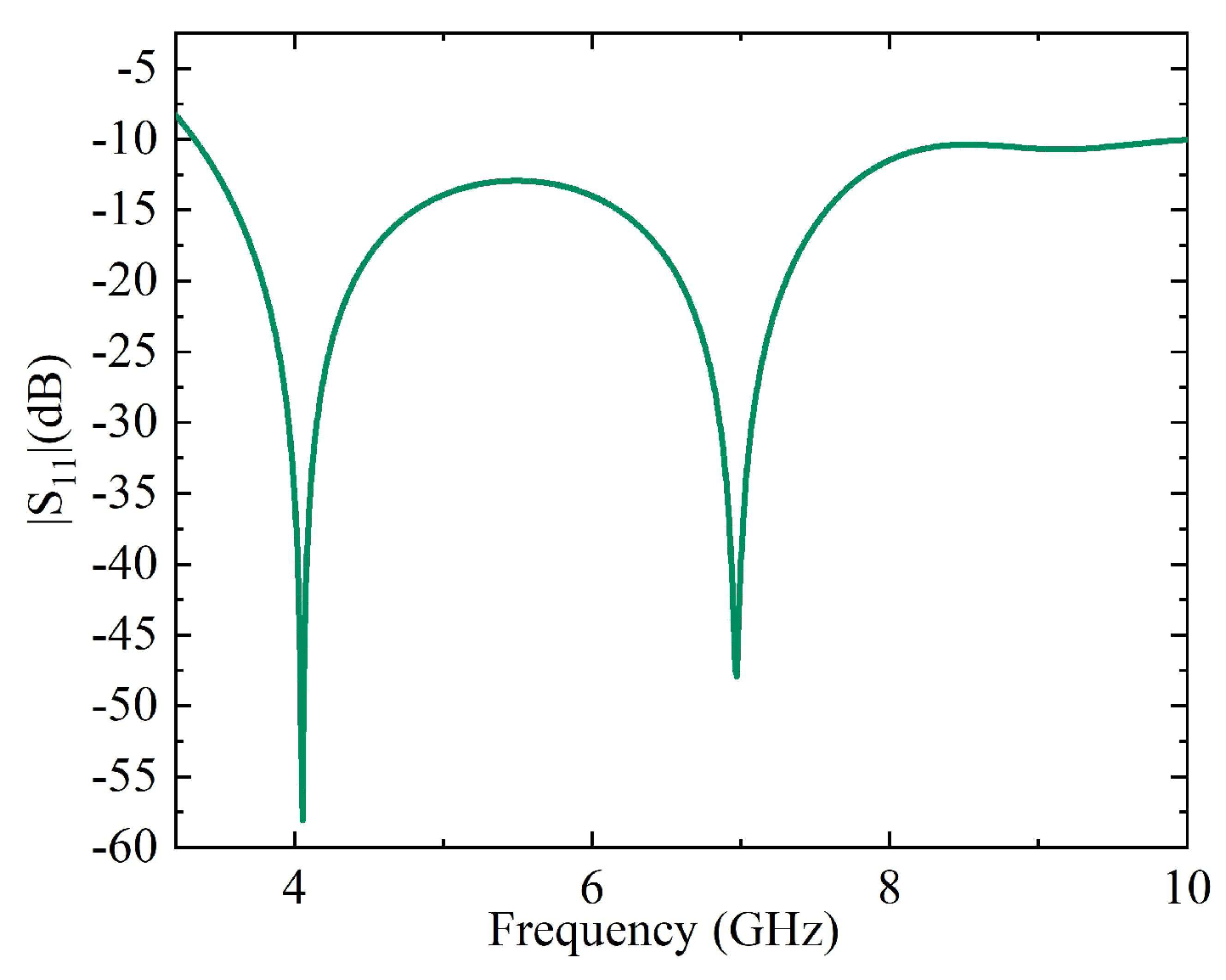

Simulation is conducted to verify the performance of the proposed sensor unit by CST MWS. As shown in

Figure 2, the S11 parameter is achieved by lower than the threshold level of -10dB that can consistently cover the entire bandwidth from 3.1GHz~10.6GHz. This result show that the sensor unit is a qualified architecture working well in UWB band.

3.1. Sensor Unit with Frequency Domain Coding and Modulation

The ultra-wide band characteristic of the sensor unit can also provide a large span of spectrum that make it possible to be manipulated by sensed information. One effective way is to bring about bandgap in assigned frequency slot and the magnitude of it, compared with the threshold level, is an ostensive signature modulated or coded by digital way.

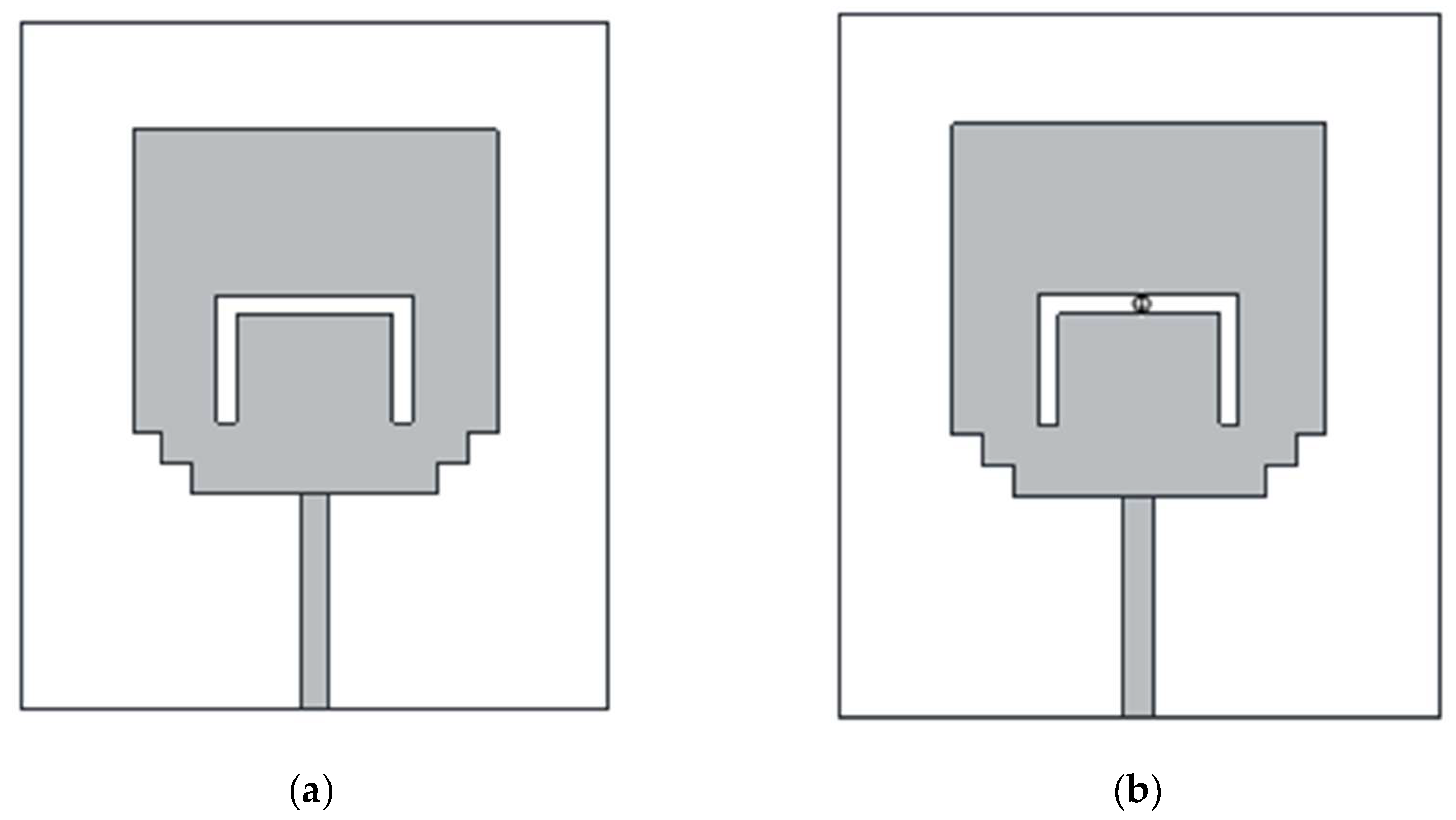

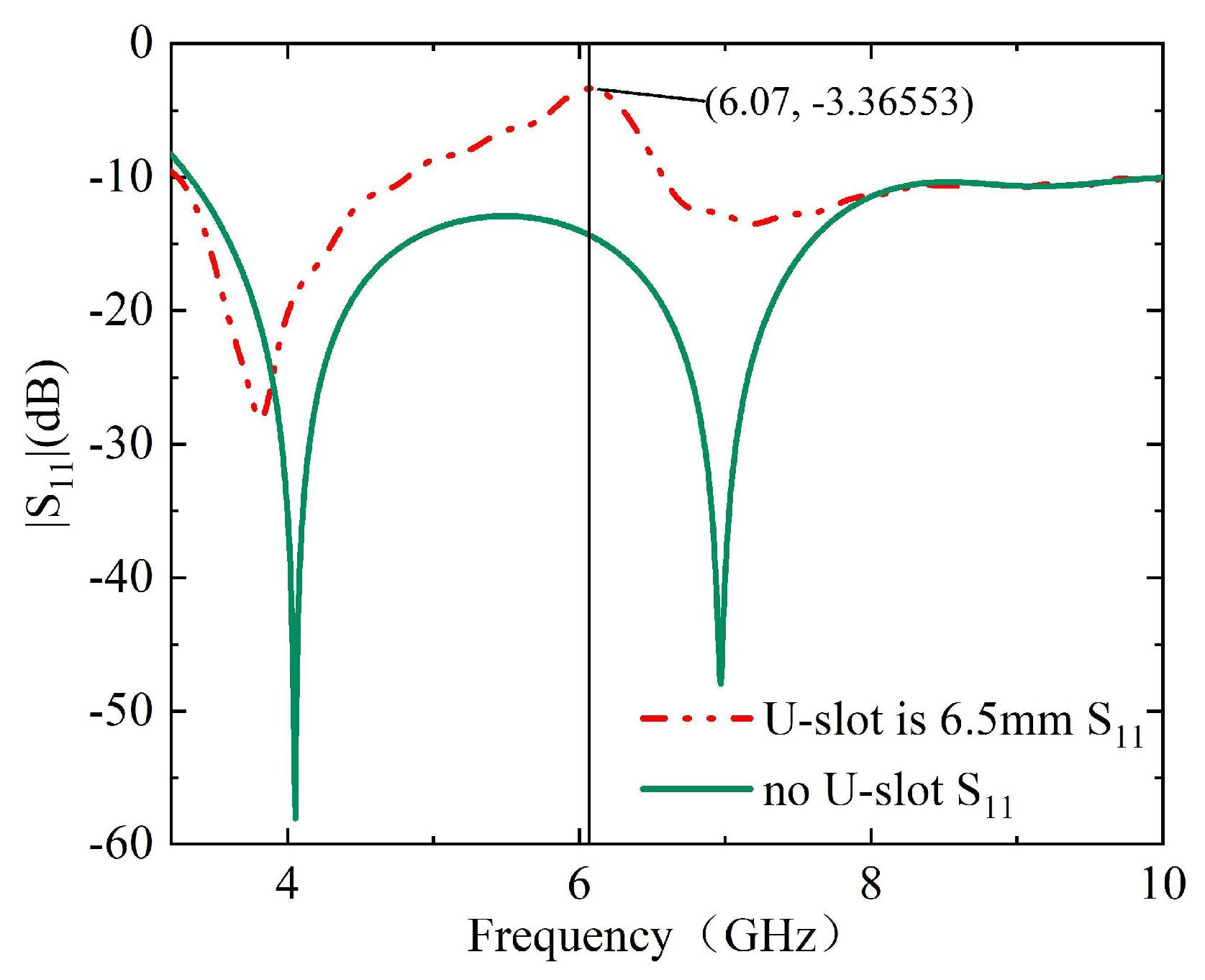

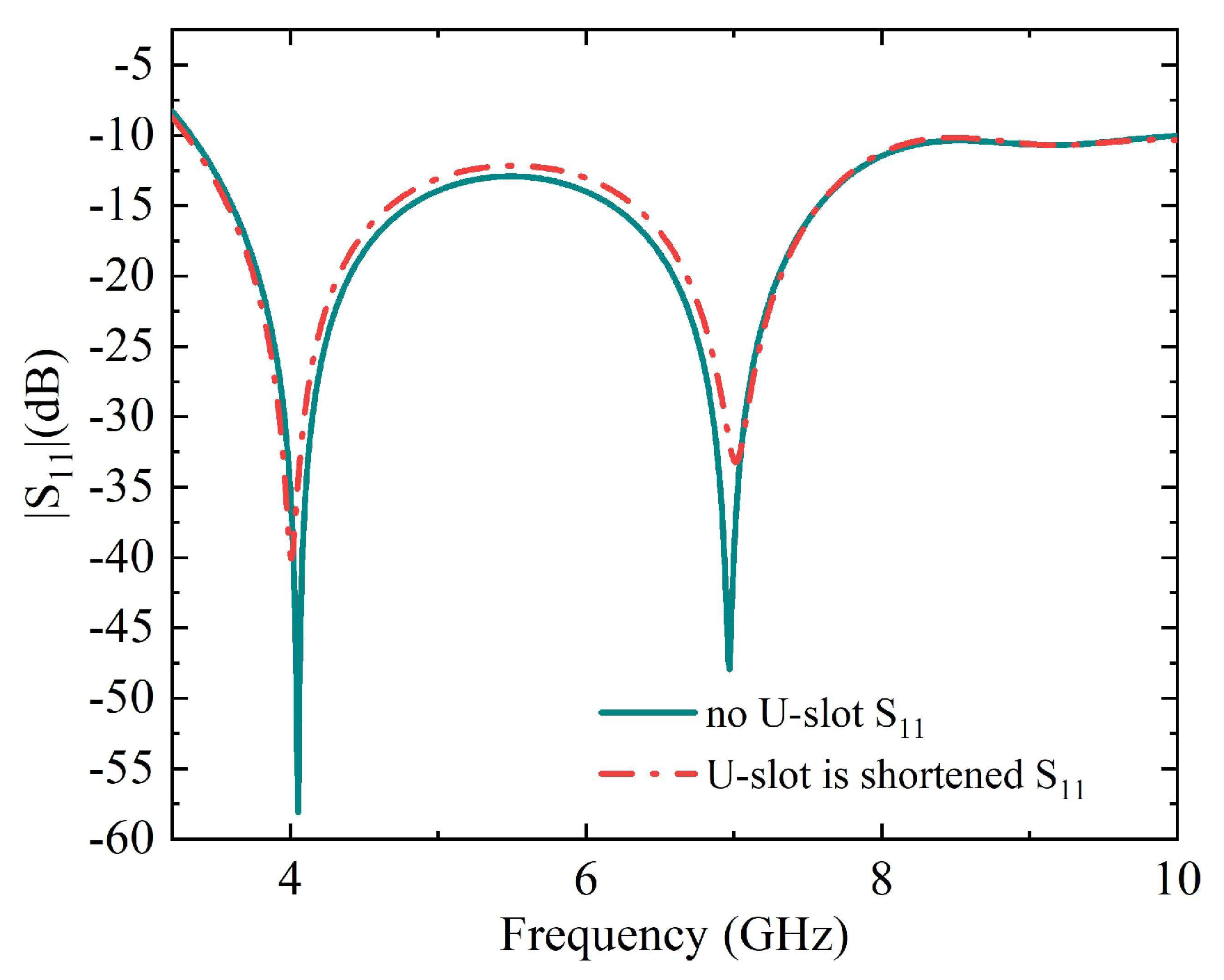

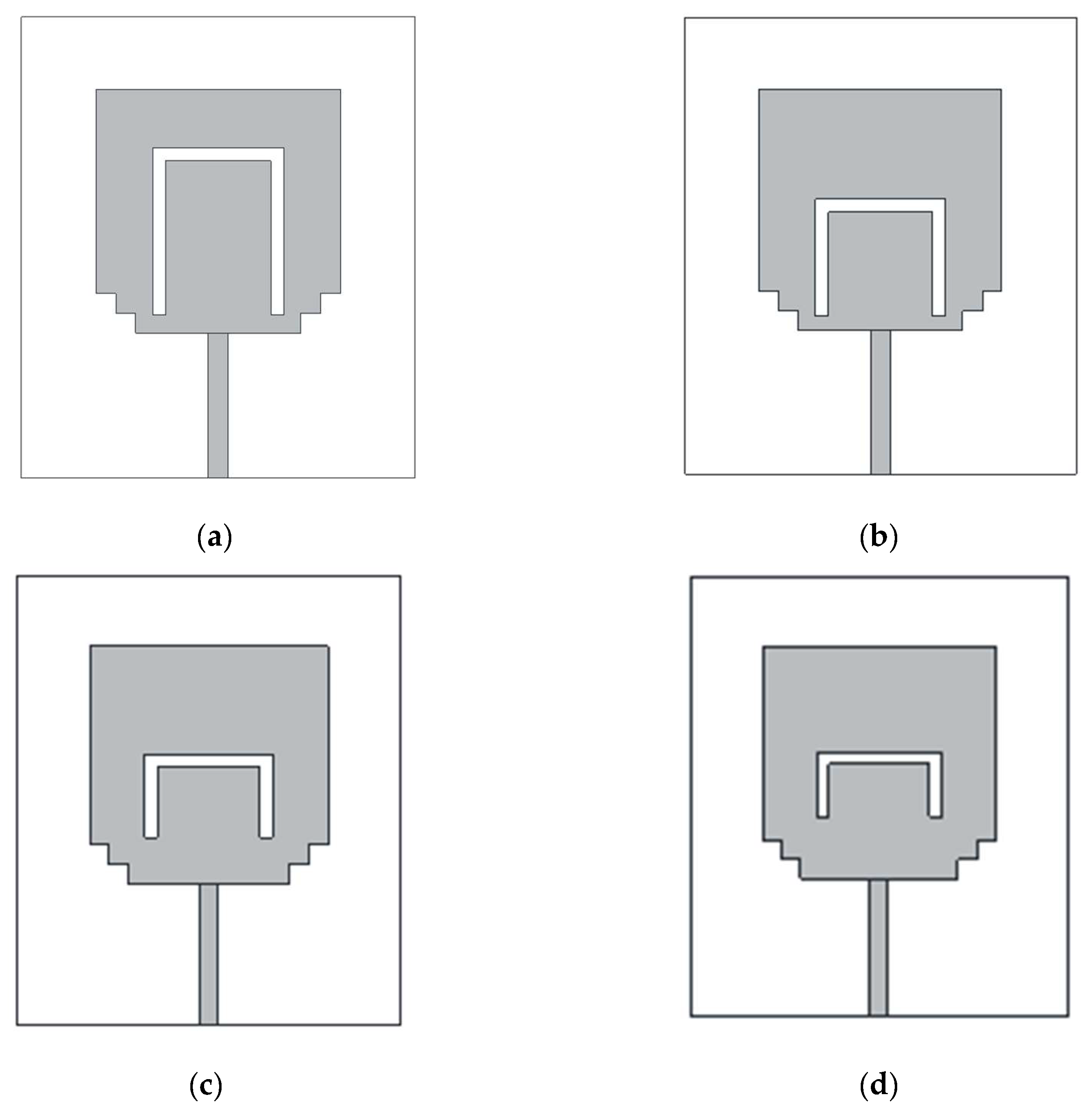

For that, a U-slot is etched on the metallic patch, as shown in

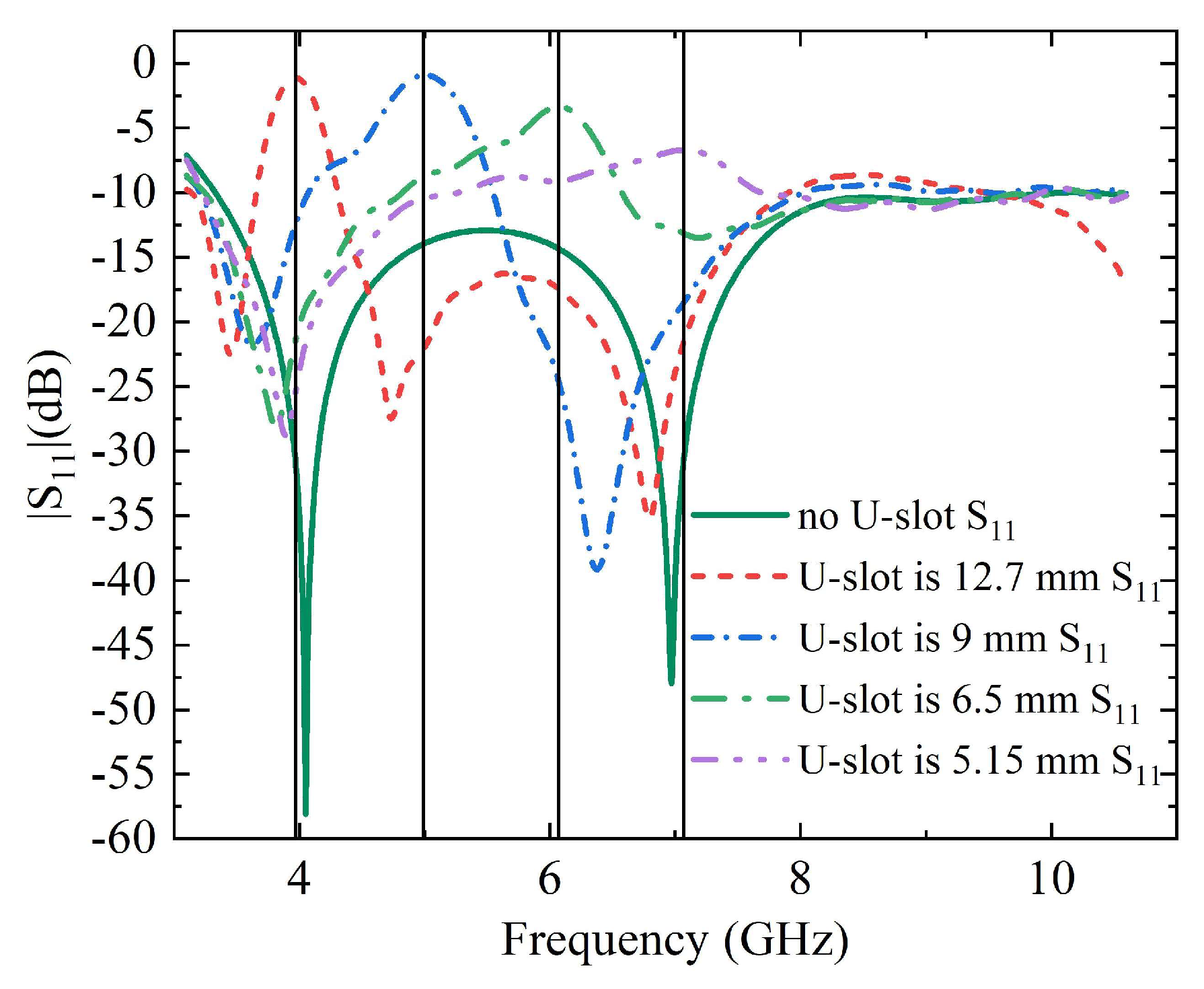

Figure 3. When the length of U-slot is 6.5mm,the study show that there is a bandgap at the frequency slot of 6.07GHz, shown in

Figure 4.

This result indicates that the behavior of the sensor unit can be reconfigured by U-slot, that is: there is a U-slot, there is a band-gap in assigned frequency slot; there is not a U-slot, there is not a band-gap in assigned frequency slot accordingly. So, band-gap frequency slot can be set as sensor’s signature modulated in frequency domain by U-slot or coded with digital bit 1 or 0.

Simulation also shows that when the U-slot is shortened, the band-gap at the assigned frequency slot will disappear, as shown in

Figure 5.

Therefore, if U-slot is manipulated by a sensor head that function as a diode performance along with the variation of the information aimed for sensing, the sensor unit can be borne with the sensed information at frequency domain in the assigned band-gap. If the threshold level of S11 is set by -10dB, the sensed information can be determined by digital bit 1/0, for example, 1 denoting U-slot have, and 0 denoting U-slot haven’t.

3.2. Sensor Unit with Time Domain Coding and Modulation

The ultra-wide band characteristic of sensor unit, as shown in

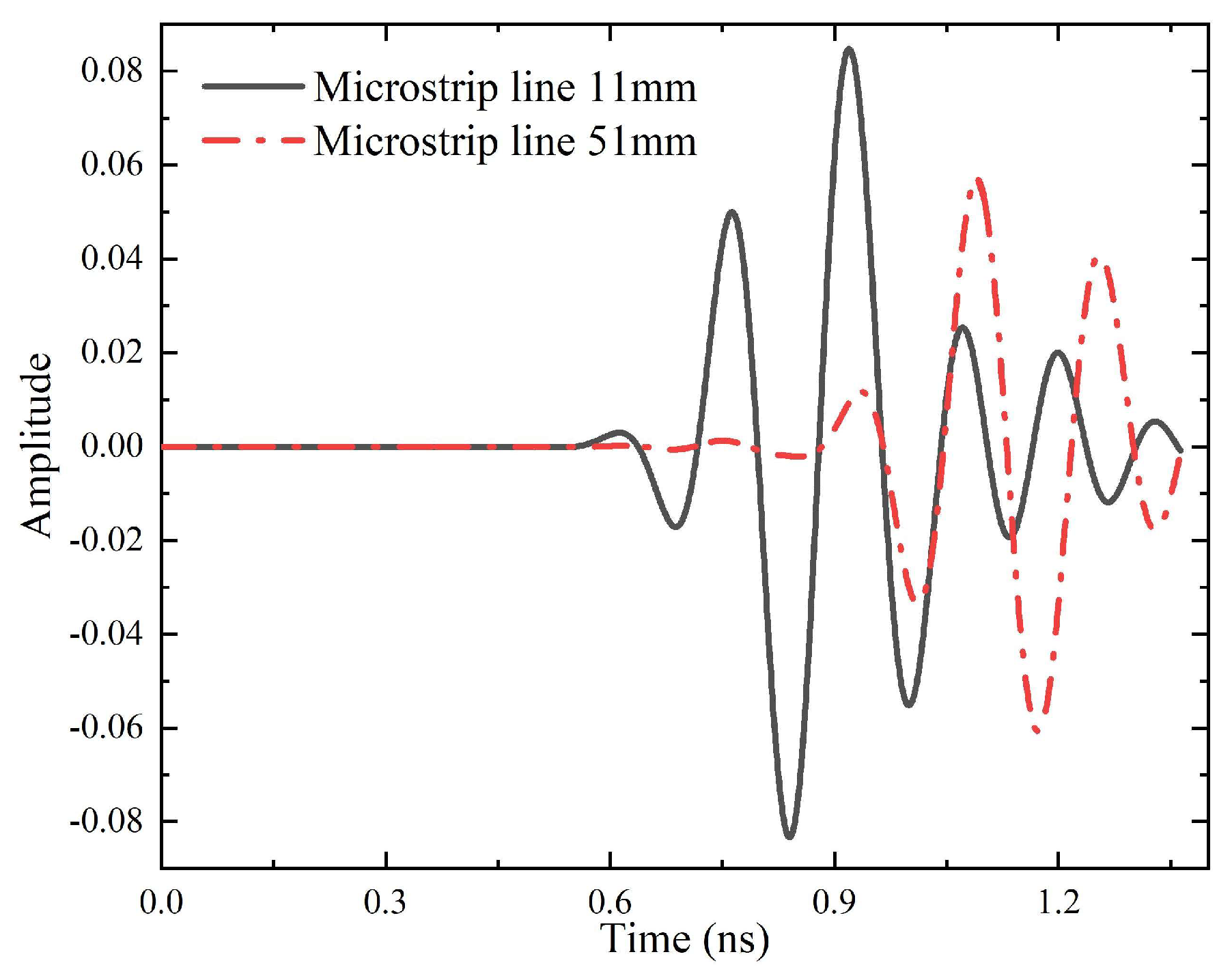

Figure 1,provide a very short pulse in time domain that can be manipulated by the information aiming for sensing. One effective way is to bring about a microstrip line long at a assigned time slot, the magnitude of pulse is an ostensive signature that can be modulated in time axial.

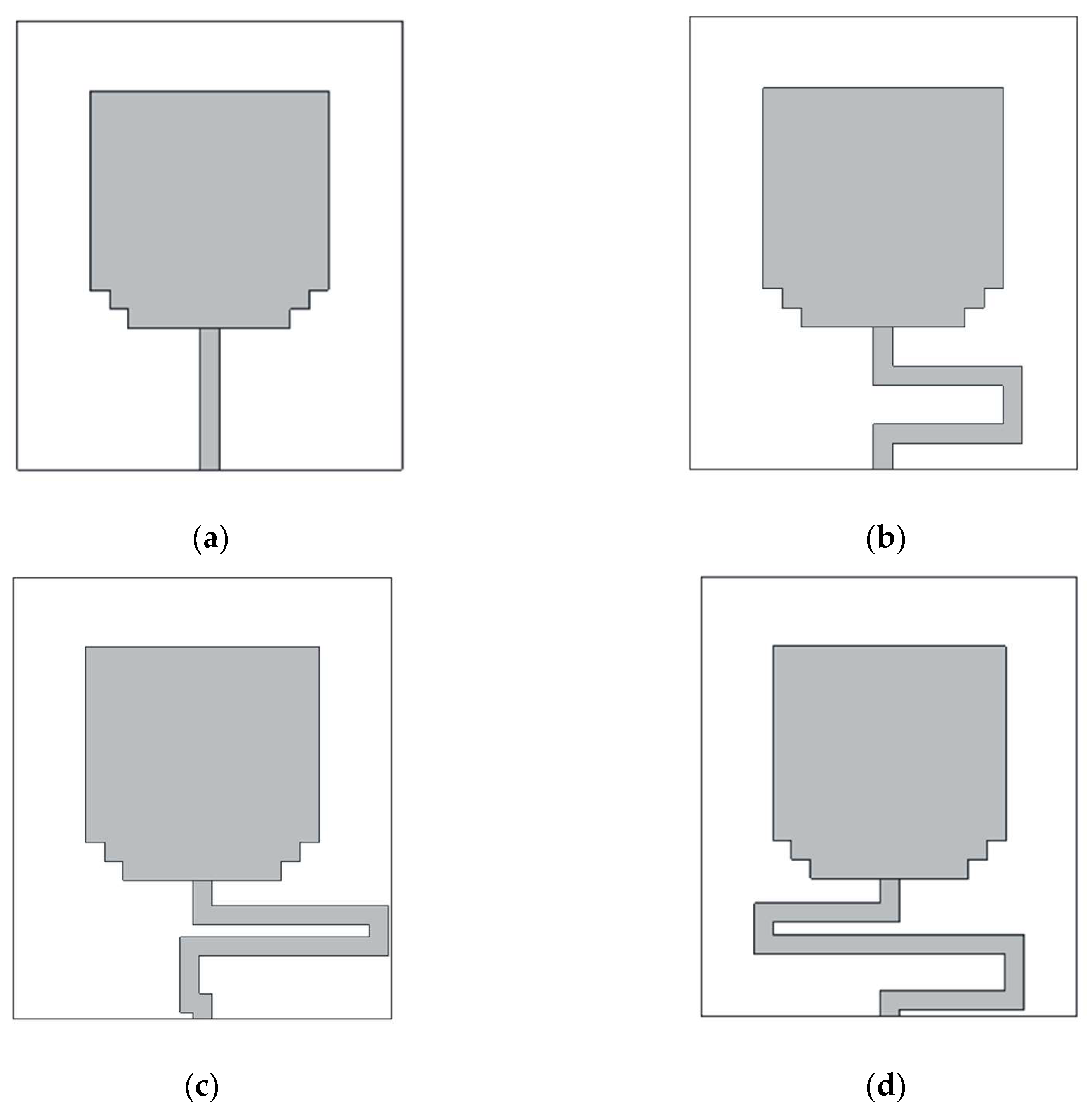

or that, a meander line is specified as the microstrip line, as shown in

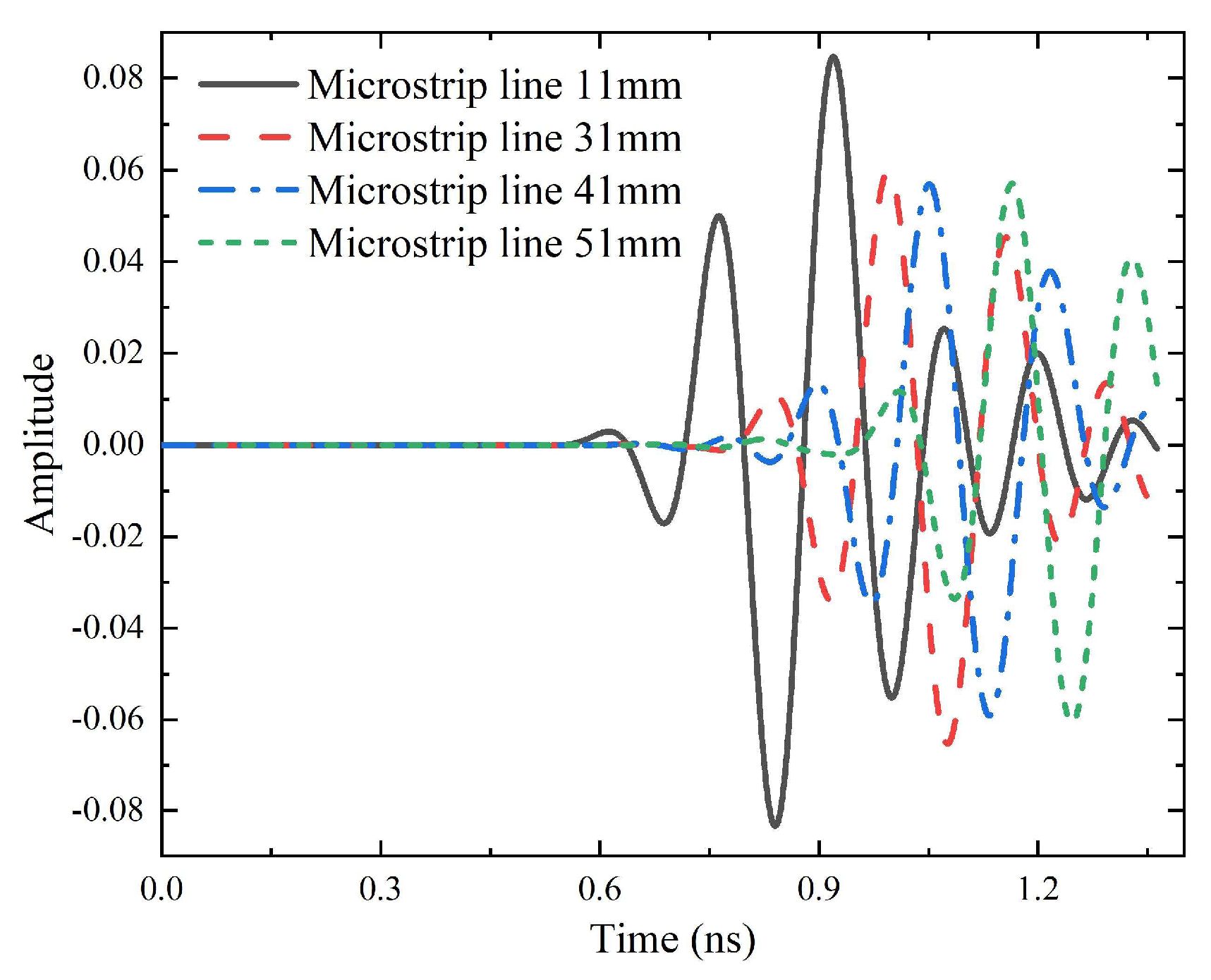

Figure 6. When the total length of meander microstrip line is 11mm,pulse appears at near 0.6ns in time axial. When the total length of meander microstrip line is extended to 51mm, the pulse, reversed due to being reflected by the short end at the terminal of microstrip line, appears at 0.9ns at time axial, as shown in

Figure 7.

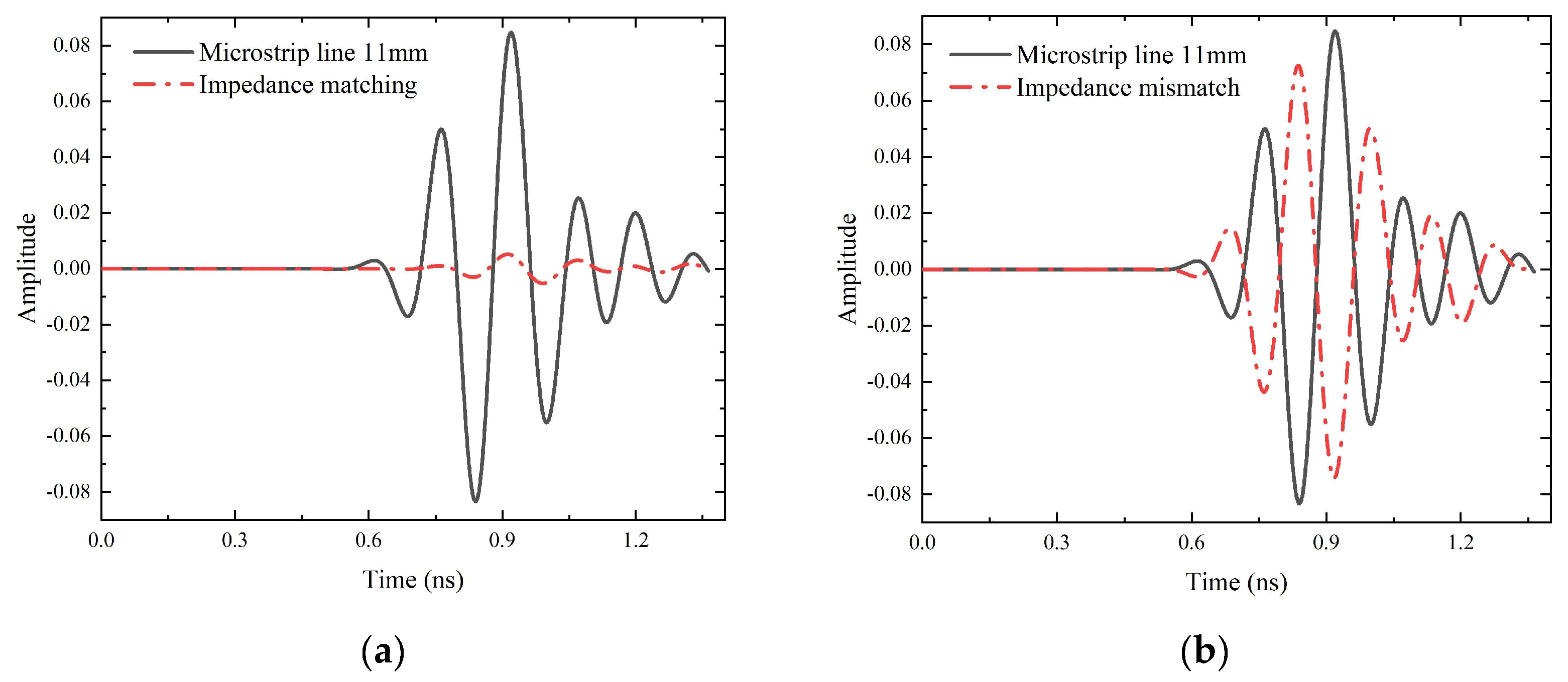

Result show that pulse reflected by sensor unit has two highlighted signatures used to carry the sensed information. One is the time slot at which the reflected pulse appears at the time axial determined by the length of meander microstrip line; Two is the amplitude and the phase of the reflected pulse compared with the amplitude and the phase of the pulse disseminated by interrogator. If the terminal of the meander microstrip line is equipped by an open end, the phase of the pulse is 0 degree in contrast; and if the terminal of the meander microstrip line is equipped by a short end, the phase of the pulse is 180 degree in reverse; and if the terminal is impedance matching to the impedance of the meander microstrip line, the amplitude of the pulse, in theory, is 0, as shown in

Figure 8.

4. Sensor with Spectral-Temporal Joint Coding and Modulation

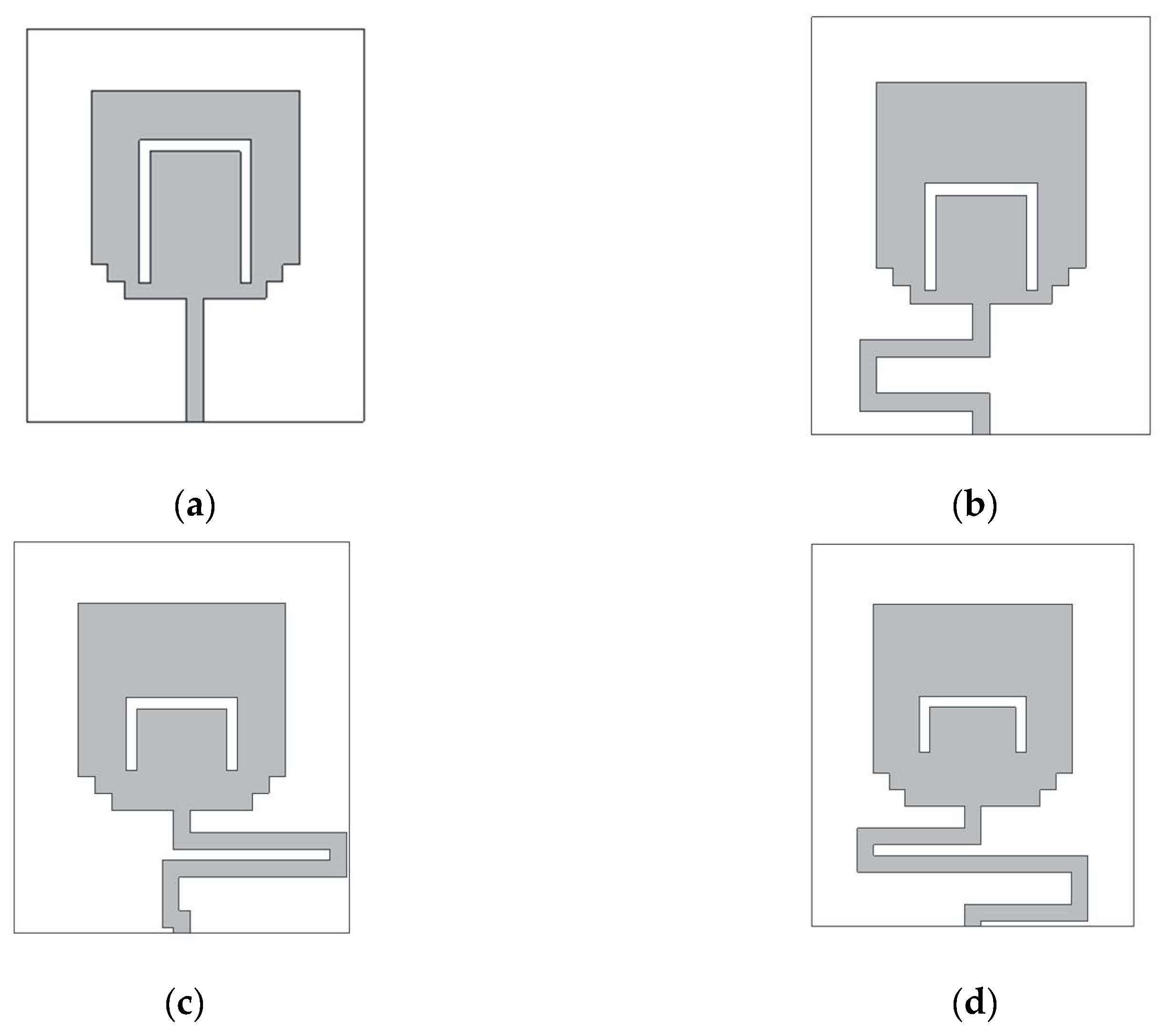

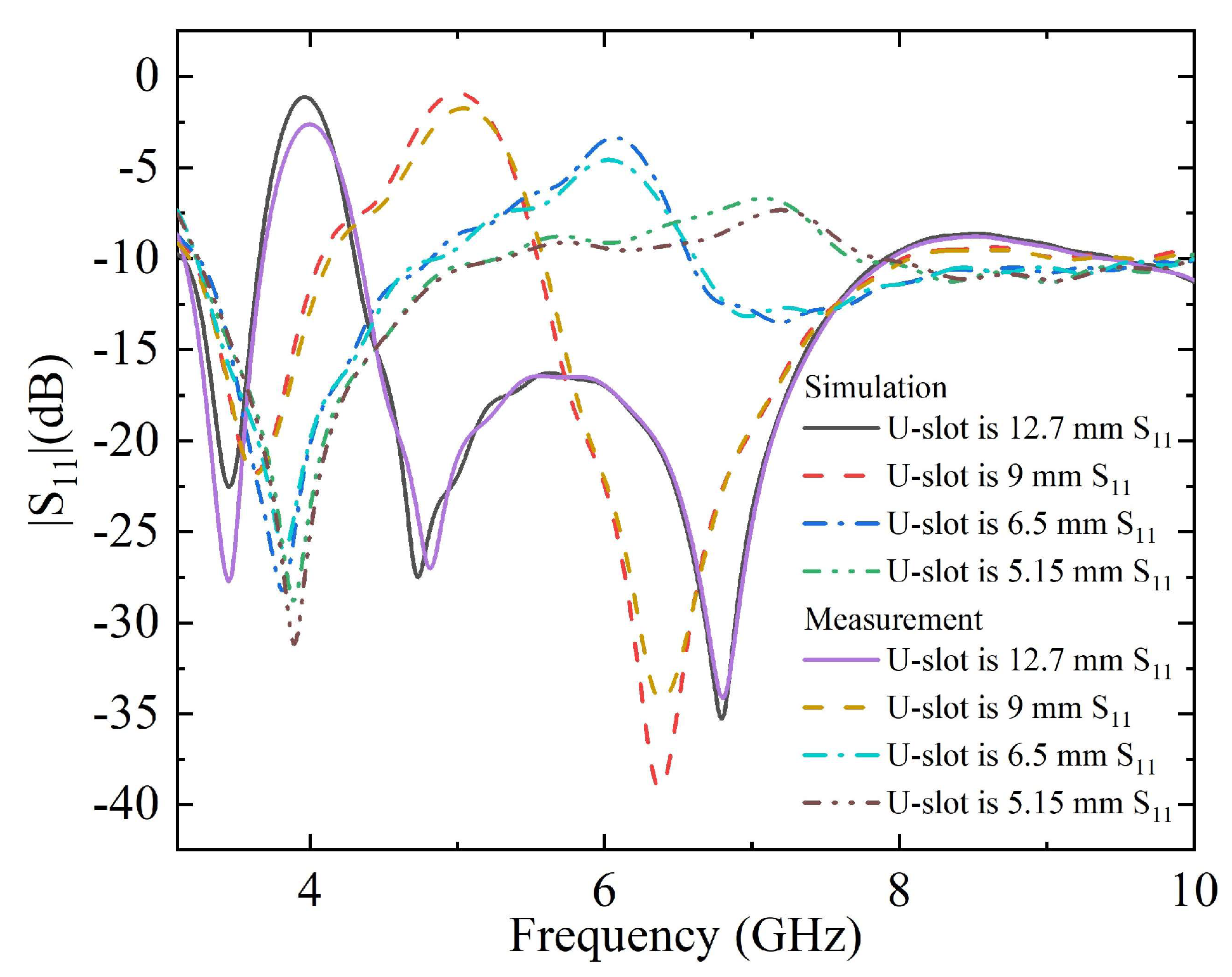

As discussed above, it is concluded that by etching different length of U slot on sensor unit, the band-gap characteristic can be obtained at different frequency slot that render us to bear different sensed information, the capacity of the sensed information can then be increased, known as the spectral modulation or spectral coding in terms of digital way. Simulation shows that the longer the length of U-slot is, the lower the band-gap frequency slot it has. Thus, by changing the length of U-slot with 12.7 mm, 9 mm, 6.5 mm, 5.15 mm, respectively, as shown in

Figure 9, there are band-gap frequency slot at 3.96 GHz, 4.99GHz, 6.07GHz and 7.07GHz accordingly.

The band-gap characteristics at the assigned four frequency slot mentioned above are compared in

Figure 10.

It is evident that these four sensor units, for digital coding, can provide 1 bits each in frequency domain. If the four sensor units are combined in somewhat reasonable form, there are total 4 bits digital capacity available for sensing and transmitting the information that are about to be sensed and transmitted.

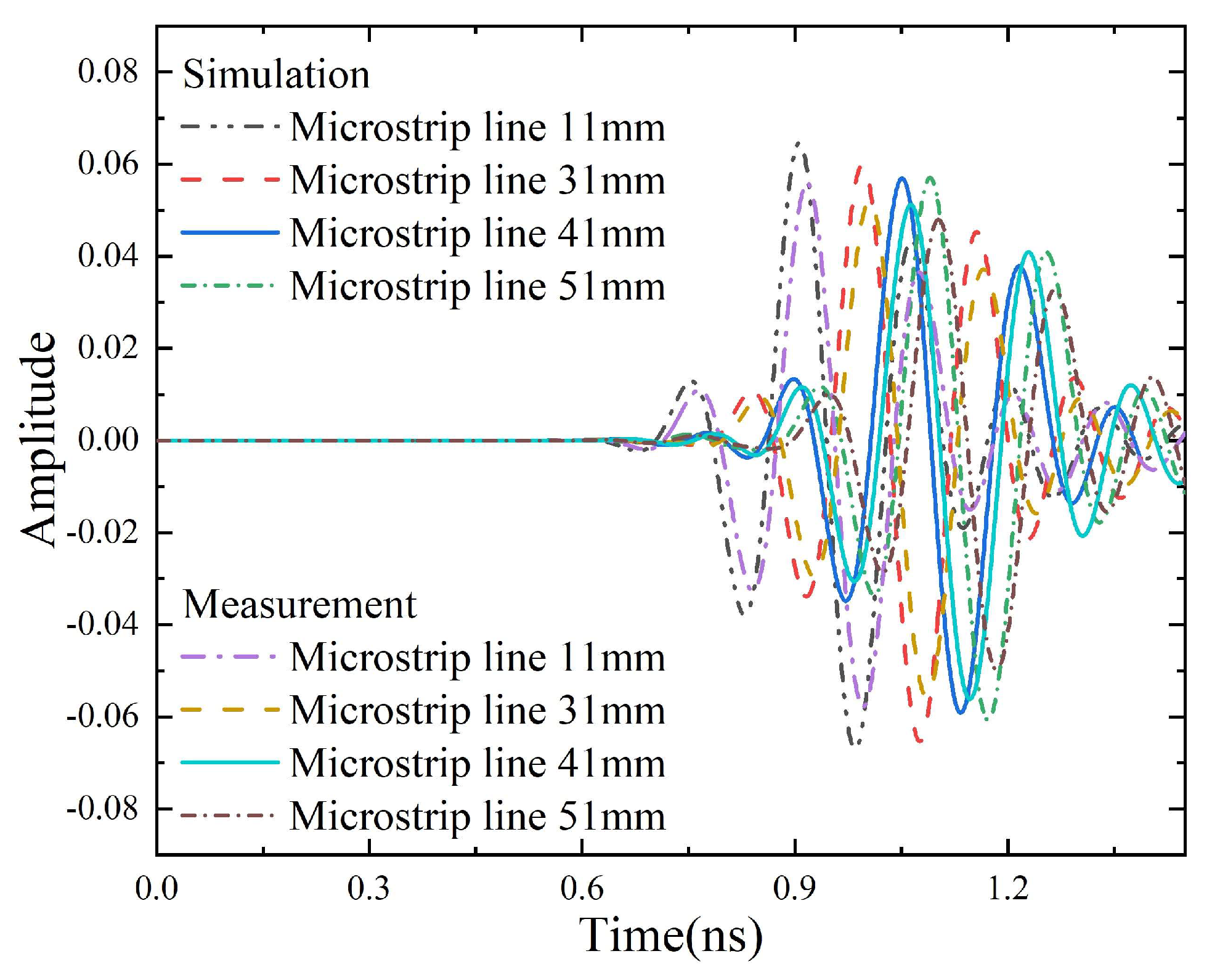

When other conditions are not changed, the microstrip line of these sensor units is extended in meander way, the time delay of the reflected pulse can be observed in time axial. When the length of meander microstrip line is longer, the delay of the pulse will be increased according to the length of microstrip line. Thus, the sensor unit with different microstrip line lengths is configured, as shown in

Figure 11.

When the lengths of meander microstrip line are 11mm, 31mm, 41mm and 51mm respectively, four pulses will appear at time axial in different time slot, as shown in

Figure 12. According to the different length of microstrip line, the reflected pulse is received at a fixed time slot that can be defined to carry different sensed information. Therefore, these four sensor units, for digital coding, will have 1 bits each in the time domain, the four sensor units are combined in somewhat reasonable form, there are total 4 bits digital capacity available for sensing the information that are about to be sensed.

5. Prototype of The Enhanced Multi-Bits Sensor

According to the discussion above, it is a reasonable way to combine these sensor units with different length of U-slot and different length of meander microstrip line for increasing sensing signature designated to enhance information capacity by joint spectral and temporal modulation. For a real embodiment of such sensor, it is possible to embed sensor head with one across the U-slot and another connected at the end of meander microstrip line. This sensor head can be function as the ON/OFF switch that determine the availability of band-gap frequency and the status phase of reflected pulse (0

o or 180

o), which enable one combined sensor unit have digital bits by 2 bits. And if four different these sensor units are configured in cubic way, the sensor can have digital capacity totally up to 8 bits. The designed sensor units used to combine sensor is shown in

Figure 13, where(a)represents that the U-slot length is 12.7 mm combined with the microstrip line length of 11 mm;(b)represents that the U-slot length is 9 mm combined with the microstrip line length of 31 mm;(c)represents that the U-slot length is 6.5 mm combined with the microstrip line length of 11 mm; and(d)represent that the U-slot length is 5.15 mm combined with the microstrip line length of 51 mm.

6. Sensor Fabrication and Performance Verification

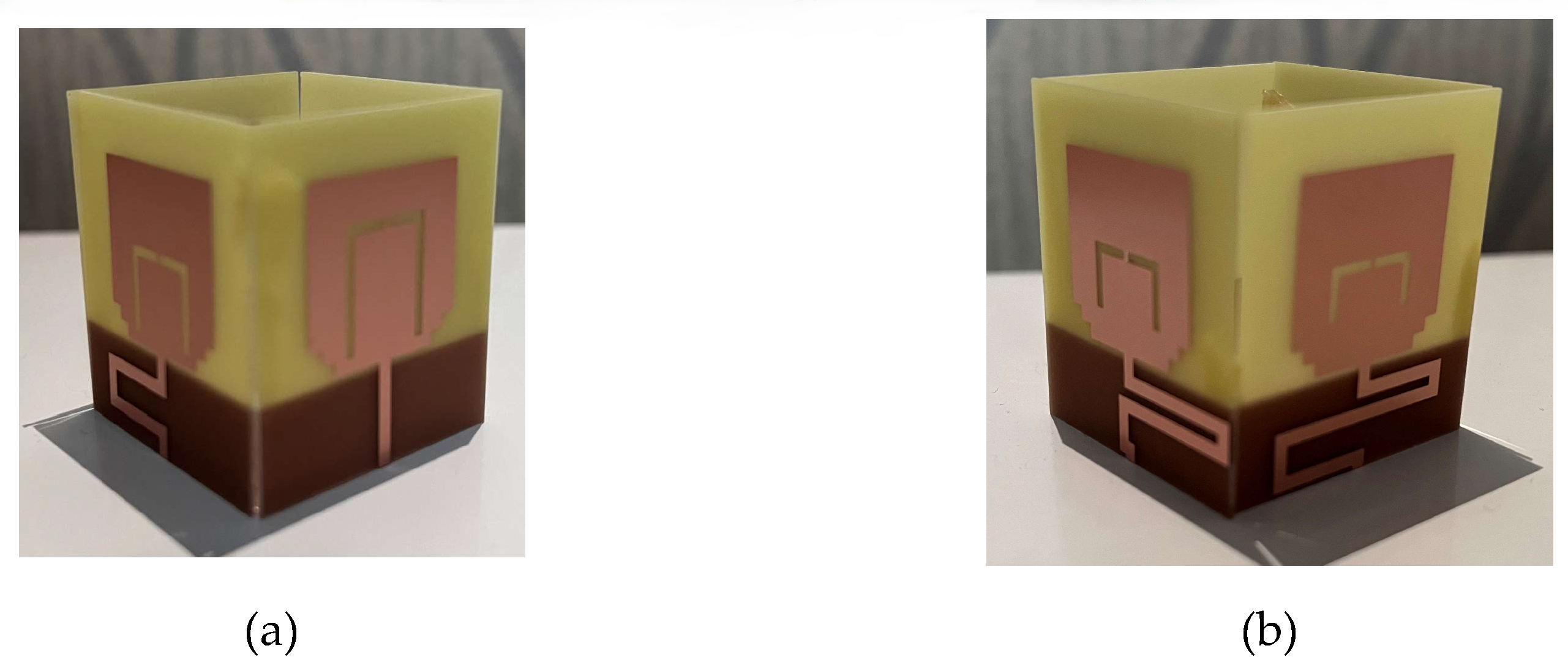

The sensor units illustrated in

Figure 13 is combined and fabricated, as shown in

Figure 14.The performance of the sensor is verified by measurement in chamber, as shown in

Figure 15. The results of the performance of the band-gap frequency for modulation and coding in spectrum domain, and the results of performance of the reflected pulses for modulation and coding in time domain are shown in

Figure 16 and in

Figure 17. The simulation and measurement are in agreement, indication after decision that the U-slot in a and c unit are equal to be the state of shorting, coded in spectral domain by 0; the end of the meander microstrip lines in a and c unit are equal to be the state of opening, coded in the temporal domain by 1; The U-slot in b and d unit are equal to be the state of opening, coded in spectral domain by 1; the end of meander microstrip lines in b and d unit are equal to be the state of shorting, coded in temporal domain by 0, The code that the sensor has can be enhanced by 8 bits in the sequence of spectral temporal joint coding, denoting 01-10-01-10.

7. Conclusions

The UWB signal can render plentiful signature for UWB sensor with enhanced information capacity. For that, this paper design and develop a passive wireless sensor through the combination of multiple sensor units operated in the principle of spectral-temporal joint coding and modulation. A prototype of the proposed sensor is configured by four UWB sensor units, each of them is specified by joint modulation upon the UWB pulse in the time domain and, simultaneously, the UWB spectrum in the frequency domain, coded by 1/0 data delivering totally the enhanced capacity up to 8 bits. Simulation and measurement verify the validation of the UWB sensor with effectiveness of digital data delivery whenever the scenario of remote, contactless and battery-free applications are necessity.

References

- Booth B.M.; Mundnich K.; Feng T.; Nadarajan A.; Falk T.H.; Villatte J.L.; Ferrara E.; Narayanan S. Multimodal Human and Environmental Sensing for Longitudinal Behavioral Studies in Naturalistic Settings: Framework for Sensor Selection, Deployment, and Management. J. Med. Internet Res. 2019. [CrossRef]

- Kondo M.; Melzer M.; Karnaushenko D.; Uemura T.; Yoshimoto S.; Akiyama M.; Noda Y.; Araki T.; Schmidt O.G.; Sekitani T. Imperceptible magnetic sensor matrix system integrated with organic driver and amplifier circuits. Sci. Adv. 2020. [CrossRef]

- Zhang Y., Li Y.; Cheng R.; Shen S.; Yi J.; Peng X.; Ning C.; Dong K.; Wang Z.L. Underwater Monitoring Networks Based on Cable-Structured Triboelectric Nanogenerators. Research. 2022;2022:9809406.

- Darwish A.; Hassanien A.E. Wearable and implantable wireless sensor network solutions for healthcare monitoring. Sensors. 2011;11:5561–5595. [CrossRef]

- Schwiebert L.; Gupta S.K.; Weinmann J.Research challenges in wireless networks of biomedical sensors; Proceedings of the 7th Annual International Conference on Mobile Computing and Networking; Rome, Italy. pp. 151–165. 16 July 2001.

- Tan E.L.; Ng W.N.; Shao R.; Pereles B.D.; Ong K.G. A wireless, passive sensor for quantifying packaged food quality. Sensors. 2007;7:1747–1756.

- He D.; Cui Y.; Ming F. Advancements in Passive Wireless Sensors, Materials, Devices, and Applications[J].Sensors,2023,23(19).

- Verma G.; Mondal K.; Gupta A. Si-based MEMS Resonant Sensor: A Review from Microfabrication Perspective. Microelectron. J. 2021;118:105210. [CrossRef]

- Zhao G.; Xue Y.; Wang Y.; Yin Y.; Chen Q.; Li J. Electroplating process and its application in MEMS technology. Telem. Remote Control. 2022;43:12.

- Rao.; G. Sasibhushana.; Kumar.; S. Srinivasa.; Pillalamarri; Ramu (2015). Printed planar circular radiating patch ultra wideband antennas. Microsystem Technologies, 21(11), 2321–2325. [CrossRef]

- He D,; Cui Y,; Ming F. et al.Advancements in Passive Wireless Sensors, Materials, Devices, and Applications[J].Sensors,2023,23(19). [CrossRef]

Figure 1.

Illustration of Sensor Unit (a) top view (b) Bottom view.

Figure 1.

Illustration of Sensor Unit (a) top view (b) Bottom view.

Figure 2.

Sensor Unit’s S11 parameter.

Figure 2.

Sensor Unit’s S11 parameter.

Figure 3.

Sensor Unit with U-slot (a) without sensor head (b) with sensor head.

Figure 3.

Sensor Unit with U-slot (a) without sensor head (b) with sensor head.

Figure 4.

Sensor Unit’s S11 parameter with and without U-slot.

Figure 4.

Sensor Unit’s S11 parameter with and without U-slot.

Figure 5.

Sensor Unit’s S11 parameter when U-slot is shortened.

Figure 5.

Sensor Unit’s S11 parameter when U-slot is shortened.

Figure 6.

Sensor Unit with meander line (a) open end (b) end with sensor head.

Figure 6.

Sensor Unit with meander line (a) open end (b) end with sensor head.

Figure 7.

Pulse at time domain.

Figure 7.

Pulse at time domain.

Figure 8.

Pulse at time domain (a) impedance match end (b) impedance mismatch end by short.

Figure 8.

Pulse at time domain (a) impedance match end (b) impedance mismatch end by short.

Figure 9.

Structure of four frequency-domain modulation(a)The length of U-slot 12.7 mm (b) The length of U-slot 9 mm(c)The length of U-slot 6.5 mm(d)The length of U-slot 5.15mm.

Figure 9.

Structure of four frequency-domain modulation(a)The length of U-slot 12.7 mm (b) The length of U-slot 9 mm(c)The length of U-slot 6.5 mm(d)The length of U-slot 5.15mm.

Figure 10.

Comparison of band-gap characteristics at four assigned frequencies(U-SLOT).

Figure 10.

Comparison of band-gap characteristics at four assigned frequencies(U-SLOT).

Figure 11.

Sensor units of four time-domain modulation(a)The length of microstrip line 11mm(b)The length of microstrip line 31mm(c)The length of microstrip line 41mm(d)The length of microstrip line 51mm.

Figure 11.

Sensor units of four time-domain modulation(a)The length of microstrip line 11mm(b)The length of microstrip line 31mm(c)The length of microstrip line 41mm(d)The length of microstrip line 51mm.

Figure 12.

Comparison of reflected pulse received by four different lengths of microstrip line.

Figure 12.

Comparison of reflected pulse received by four different lengths of microstrip line.

Figure 13.

Schematics of sensor unit with enhanced multiple Bit Based on UWB Spectral-Temporal Joint Coding and Modulation.

Figure 13.

Schematics of sensor unit with enhanced multiple Bit Based on UWB Spectral-Temporal Joint Coding and Modulation.

Figure 14.

The Fabrication of sensor (a) front side, (b) back side.

Figure 14.

The Fabrication of sensor (a) front side, (b) back side.

Figure 15.

Sensor measurement and performance verification.

Figure 15.

Sensor measurement and performance verification.

Figure 16.

The performance of band-gap frequency for modulation and coding in spectrum domain.

Figure 16.

The performance of band-gap frequency for modulation and coding in spectrum domain.

Figure 17.

The performance of the reflected pulses for modulation and coding in time domain.

Figure 17.

The performance of the reflected pulses for modulation and coding in time domain.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).