1. Introduction

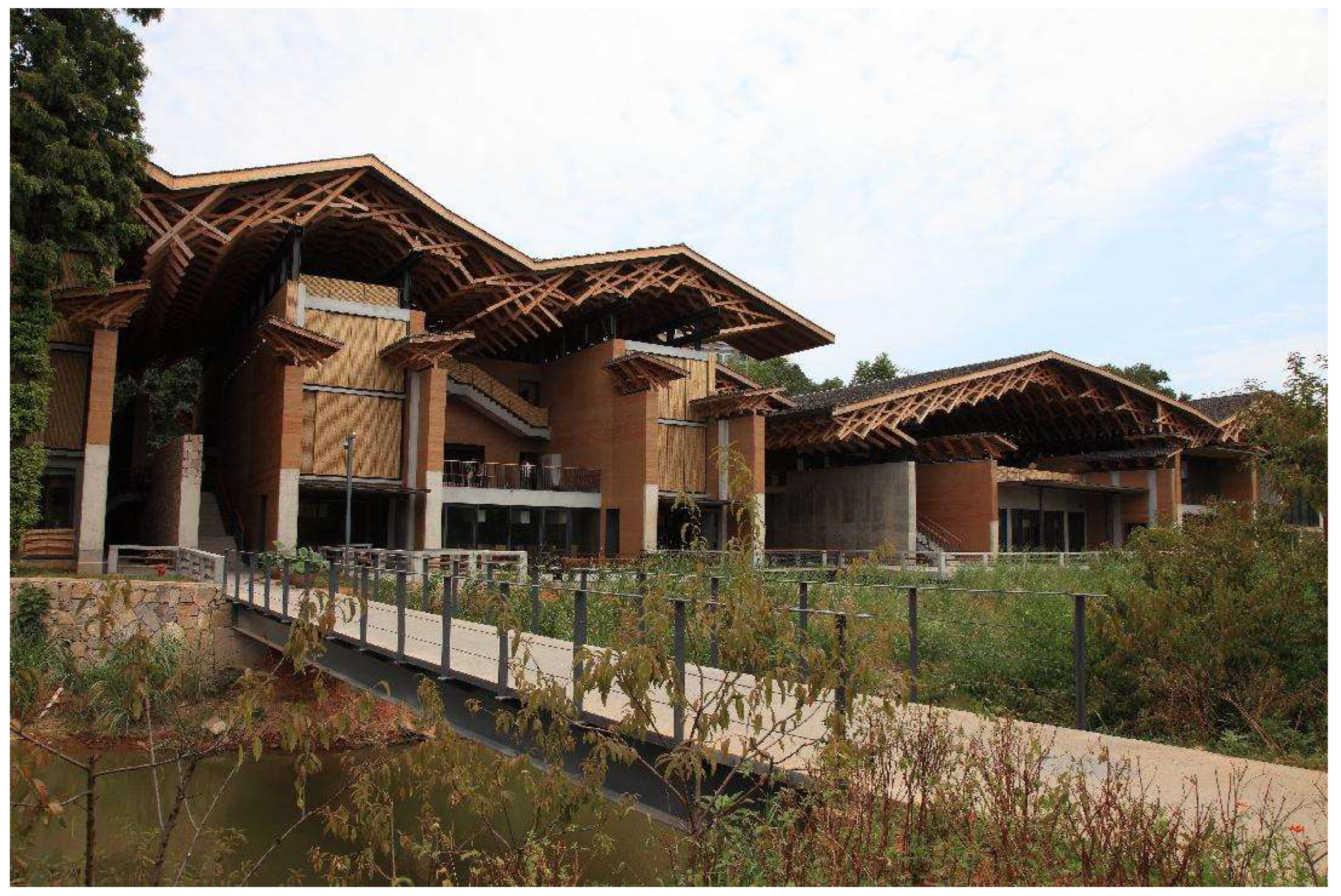

Rammed earth, as an ancient construction technique, has long been a vital component of traditional Chinese building methods. However, with the development of modern construction materials and technologies, traditional rammed earth techniques gradually receded from the historical stage. Despite this, the values it embodies—its connection with nature and its cyclically sustainable principles—continue to play a unique role. Therefore, a significant area of research lies in how to revitalize this craft within modern construction frameworks and integrate it into sustainable development models. Against this backdrop, since 2001, Wang Shu's team at School of Architecture in China Academy of Art has been consistently exploring rammed earth techniques. In 2011, the school established its own Sustainable Construction Laboratory to further advance research in this field. The author of this article is a member of Wang Shu’s team, and through the discussion and analysis of the "Tiles Hill — New Reception Center for the Xiangshan Campus" project [

1], we demonstrate how our team has explored and applied rammed earth techniques within contemporary construction systems (

Figure 1).

Before the project formally commenced, the team first conducted experiments in the laboratory to construct a rammed earth test wall, which led to the establishment of a template production and installation system suited to modern rammed earth techniques. As the project progressed, they gradually refined the rammed earth technology, resolving issues such as outward wall inclination, vertical settlement cracking, and horizontal expansion cracking through the rational design of structural nodes. Finally, after improving the rammed earth process, they achieved the recycling and reuse of excavated earth materials and controlled the texture of mixed-color earth materials.Through this practice, the team not only completed the first large-scale rammed earth project in China but also initiated a profound exploration and study of traditional earthen construction techniques.

2. Experimentation and Exploration of Rammed Earth Techniques in This Project

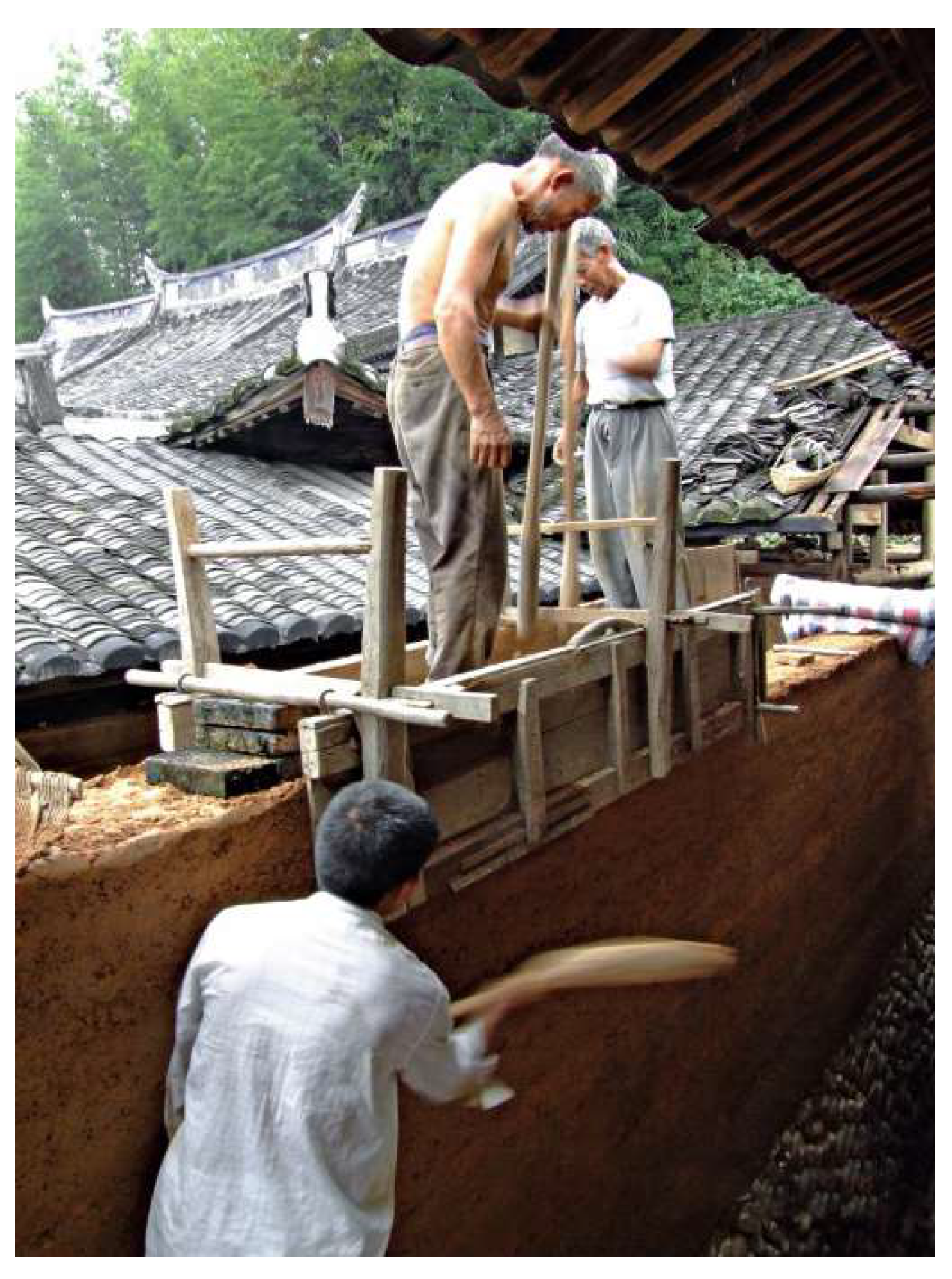

Before the construction of the "Tiles Hill — New Reception Center for the Xiangshan Campus" project commenced, the Sustainable Construction Laboratory, with assistance from the CRAterre International Centre for Earthen Architecture in France, initiated an experimental project focused on rammed earth test walls. Two French researchers, Marc Auzet and Juliette Goudy, aided in the preparation of the test walls and provided technical training to the team. Prior to the official start of on-site construction, a complete rammed earth test wall was already built in the laboratory (

Figure 2). The experiments included soil property analysis, the design, and optimization of rammed earth formwork. Through these experiments, the laboratory established a rammed earth construction process suited to modern building conditions.

In the research on the fundamental materials for rammed earth construction, the laboratory conducted soil analysis while building the rammed earth test walls, using samples collected from the excavation site. Through extensive data analysis, the team determined whether the soil was suitable for constructing rammed earth walls or whether adjustments to the proportions of sand, stone, and clay were needed to meet the demands of large-scale construction. This data-driven analytical method not only provided a scientific basis for subsequent construction but also revealed the valuable labor wisdom inherent in traditional rammed earth techniques[

2]. For our ancestors, soil not only served as a building material to meet basic housing needs, but after the houses collapsed, it could be reused for growing crops, fulfilling fundamental survival needs. The use of soil sourced from leveled or cultivated land at the construction site reflects the wisdom of living in harmony with nature and represents a highly sustainable method of construction.

The dimensions of the formwork for the rammed earth walls were determined after multiple trials by the Sustainable Construction Laboratory. To prevent the formwork from expanding, cedar wood beams were used to create a reinforcing frame on its back. Horizontal scaffold steel pipes were placed outside this reinforcement, and several tie rods running through the wall were tightly secured to hold everything in place. These layers of reinforcement ensured that the formwork frame used for rammed earth construction was extremely sturdy. Additionally, a tongue-and-groove system was designed between the upper and lower formwork layers to allow for quick installation and dismantling. This formwork arrangement closely resembles the "pouring-like" method used in concrete construction, where continuous formwork is used for single-stage molding[

3]. The primary purpose of using large-scale formwork in this manner was twofold: first, to accelerate the construction process, and second, to ensure the integrity of the surface texture of the rammed earth walls after completion (

Figure 3). In contrast to the "pouring-like" method, the traditional rammed earth construction in the villages of Zhejiang, Jiangsu, and Fujian regions employed a "bricklaying-like" approach. This method used a very small "wall bucket" formwork to complete the entire rammed earth construction of a house, where the ramming was limited to the size of the "wall bucket." For the walls, each section of the wall was rammed into large earthen blocks, which were then staggered and stacked, much like bricks in masonry. Using only one "wall bucket" formwork, the construction proceeded along the length of the wall, ramming from one end to the other in a bricklaying fashion (

Figure 4). Moreover, due to the time difference in the formation of the upper and lower layers during the ramming process, the lower rammed earth blocks were exposed to air, accelerating their hardening and preparing them to support the next layer of rammed earth. This technique, passed down through generations of practical experience, reflects the ancestors' wisdom in developing a highly efficient and economical method of rammed earth construction.

During the team's research in the mountainous regions of southern Zhejiang, they discovered a particularly important aspect of traditional rammed earth techniques: the surface of the walls after ramming was not considered the final finish. Both the interior and exterior sides of the walls would typically undergo an additional layer of earth plaster. After each section of the rammed earth was completed and the formwork removed, a craftsman would follow up with a specialized wooden clapper to flatten a layer of very fine earth over the rammed surface (

Figure 5). This process would be applied to both sides of the wall, resulting in a very smooth finished surface.This practice also explains why the "wall bucket" formwork used in traditional rammed earth construction was often quite simple. There was no need for high precision in the rammed surface once the formwork was removed, as achieving a perfectly smooth surface with such basic formwork was nearly impossible. The ancestors' understanding of rammed earth was primarily focused on fulfilling the structural needs of insulation, heat retention, theft prevention, and spatial enclosure, while the external appearance was left to be enhanced by subsequent finishing layers [

4]. This approach aligns with the principles of traditional rammed earth construction in the Jiangsu, Zhejiang, and Fujian regions, where cost-saving and ease of operation were prioritized. The use of small, modular formwork for section-by-section assembly was a key factor in this approach.

Once the rammed earth construction method was determined, the overall dimensions and structural mechanics of the rammed earth walls became crucial topics of study. Previously, assessments of the structural integrity of rammed earth walls relied entirely on the accumulation of traditional knowledge, as this material had never been formally used in new buildings within China, leaving no established formulas or methods for reference. The traditional villages that still employ rammed earth construction served as the best data samples for our team’s research and learning.In the traditional villages of the southern Zhejiang mountainous region, the height-to-thickness ratio of rammed earth walls typically ranges from 1:10 to 1:12, with most residential walls not exceeding two stories. However, there are exceptions, such as in the village of Maozhuyuan in Taishun County, near the Fujian border. This village features small, square earthen towers, designed with three bays both horizontally and vertically, yet reaching a height of up to five stories, approximately 13 meters tall (

Figure 6). The walls of these towers employ a stepped design that tapers upward, presenting a slightly trapezoidal profile, which enhances stability[

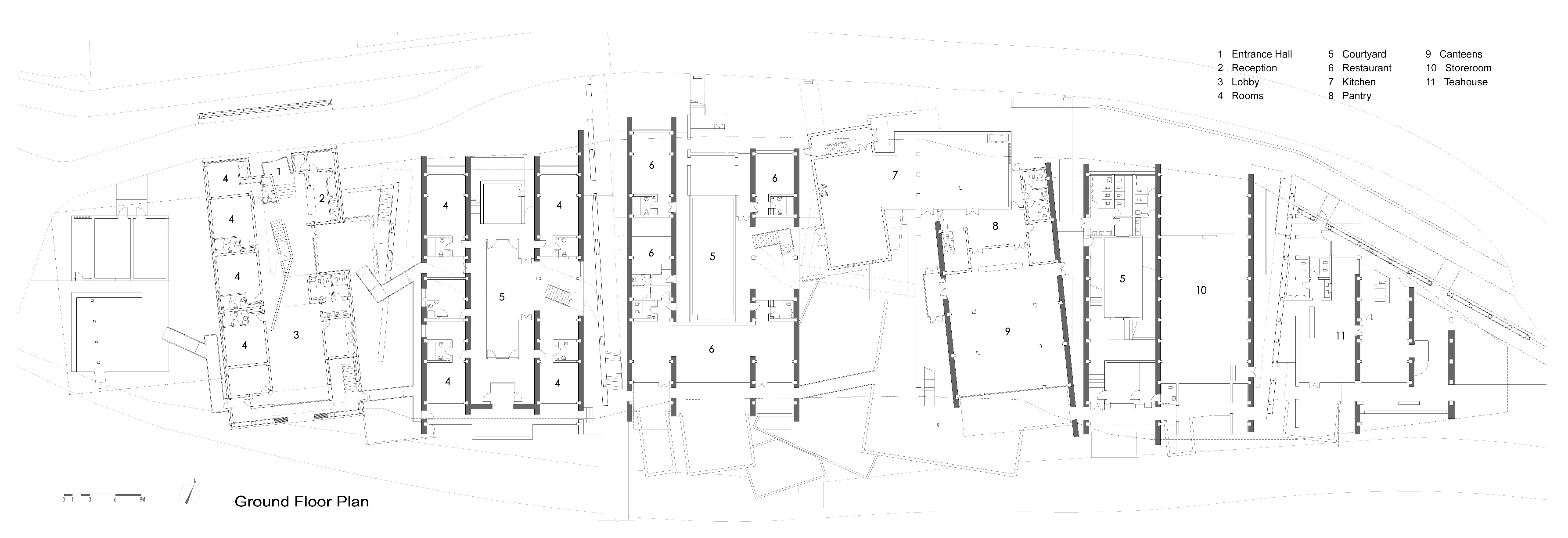

5]. Additionally, the four-sided enclosed layout further reinforces the integrity of the structure。 In contrast, the current project involves a total of 16 independent north-south oriented rammed earth walls (

Figure 7), which presents a significantly greater risk to stability compared to the typical four-sided enclosed structures found in traditional villages, thereby introducing substantial safety concerns.

3. Problems Encountered and Measures Taken in the Ramming Process

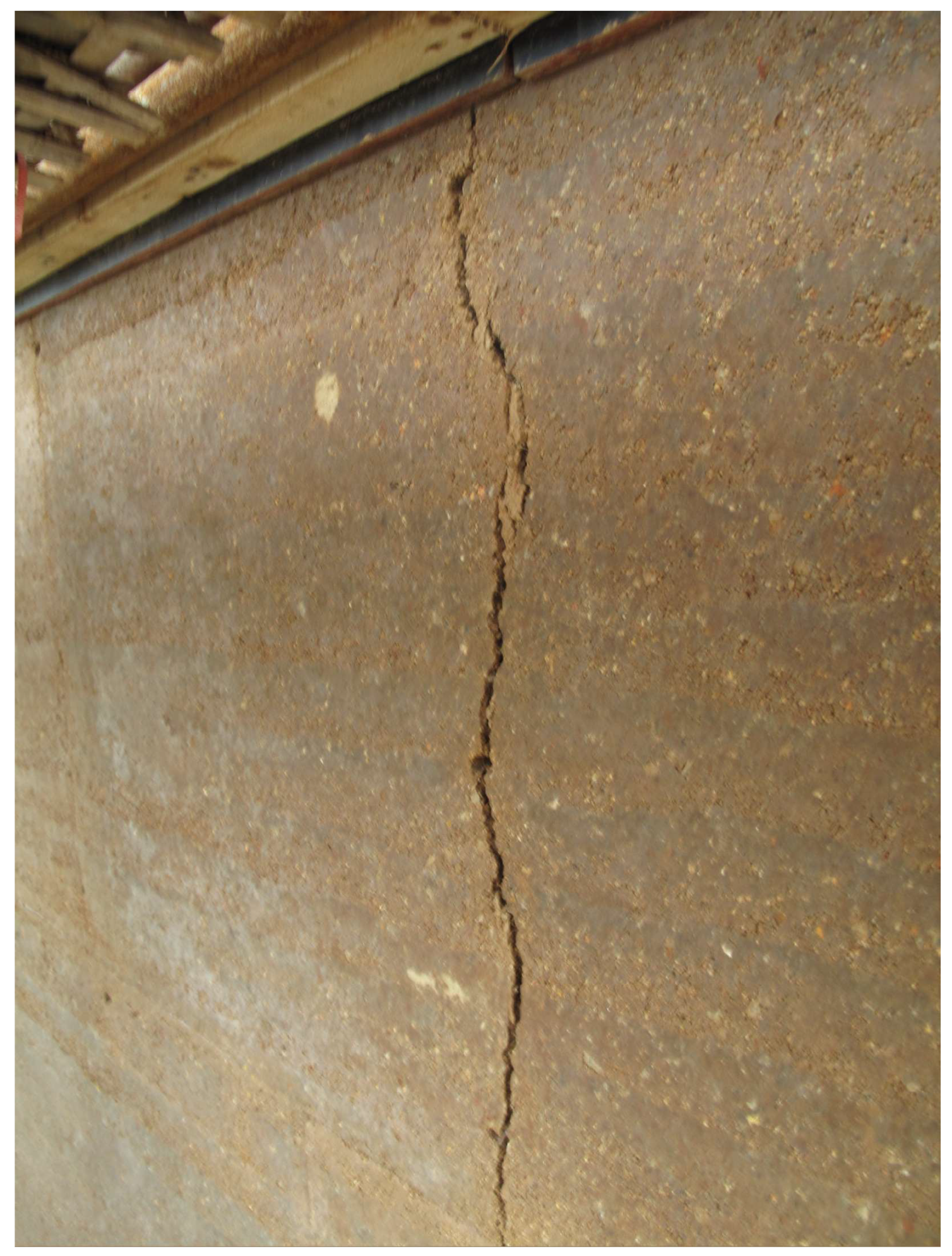

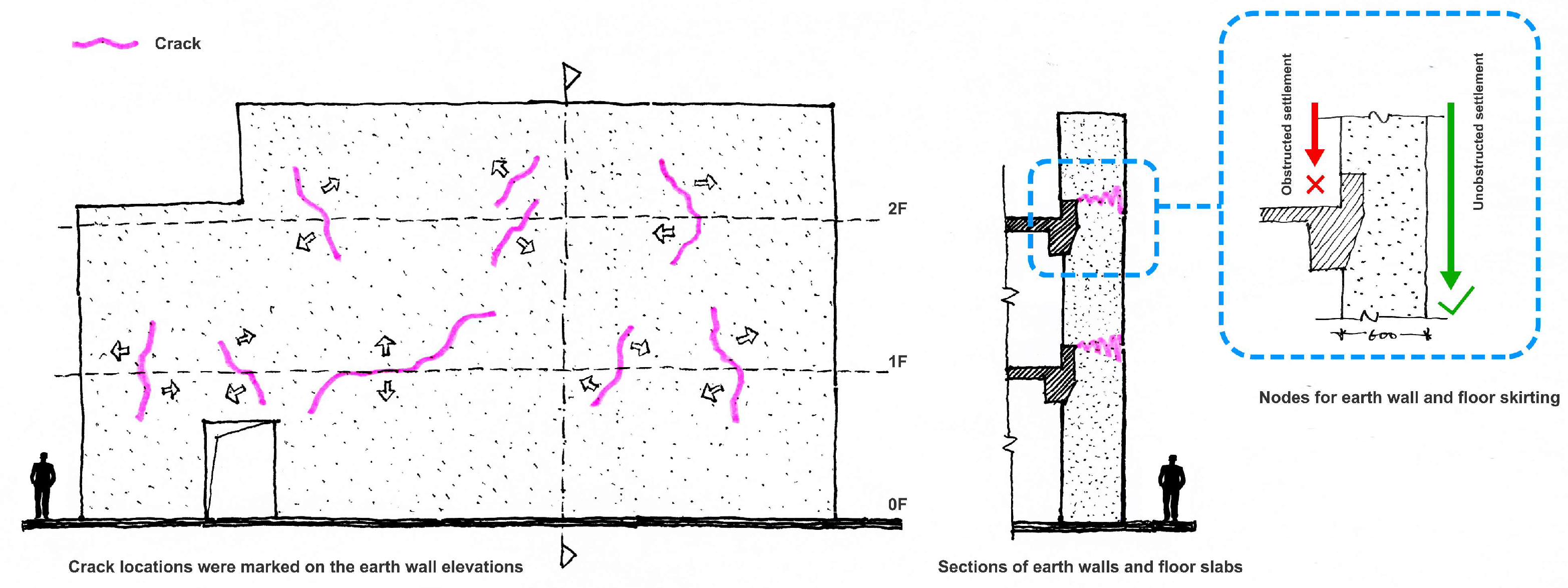

Before proceeding with large-scale rammed earth construction, Wang Shu insisted on conducting a test ramming on one of the site's larger walls. This wall was structurally representative, measuring over 30 meters in length and more than 10 meters in height. The wall was rammed as quickly as possible, while the speed of construction on the other walls was controlled to await the results of this trial. However, when ramming reached above the third floor level, issues of wall leaning and cracking became apparent. First, a large diagonal crack appeared near the second and third floor positions, with the lower part of the crack showing a tendency to bulge outward (

Figure 8). This crack was structurally deep, posing a significant risk to the stability of the wall. Secondly, several small vertical cracks were observed on the wall surface between the floor slabs (

Figure 9). The edges of these cracks were clean, with no outward bulging on either side, leading to the preliminary conclusion that these fine cracks were likely caused by shrinkage due to the excessive length of the wall. These smaller cracks were judged to have no impact on the overall structural stability of the wall.

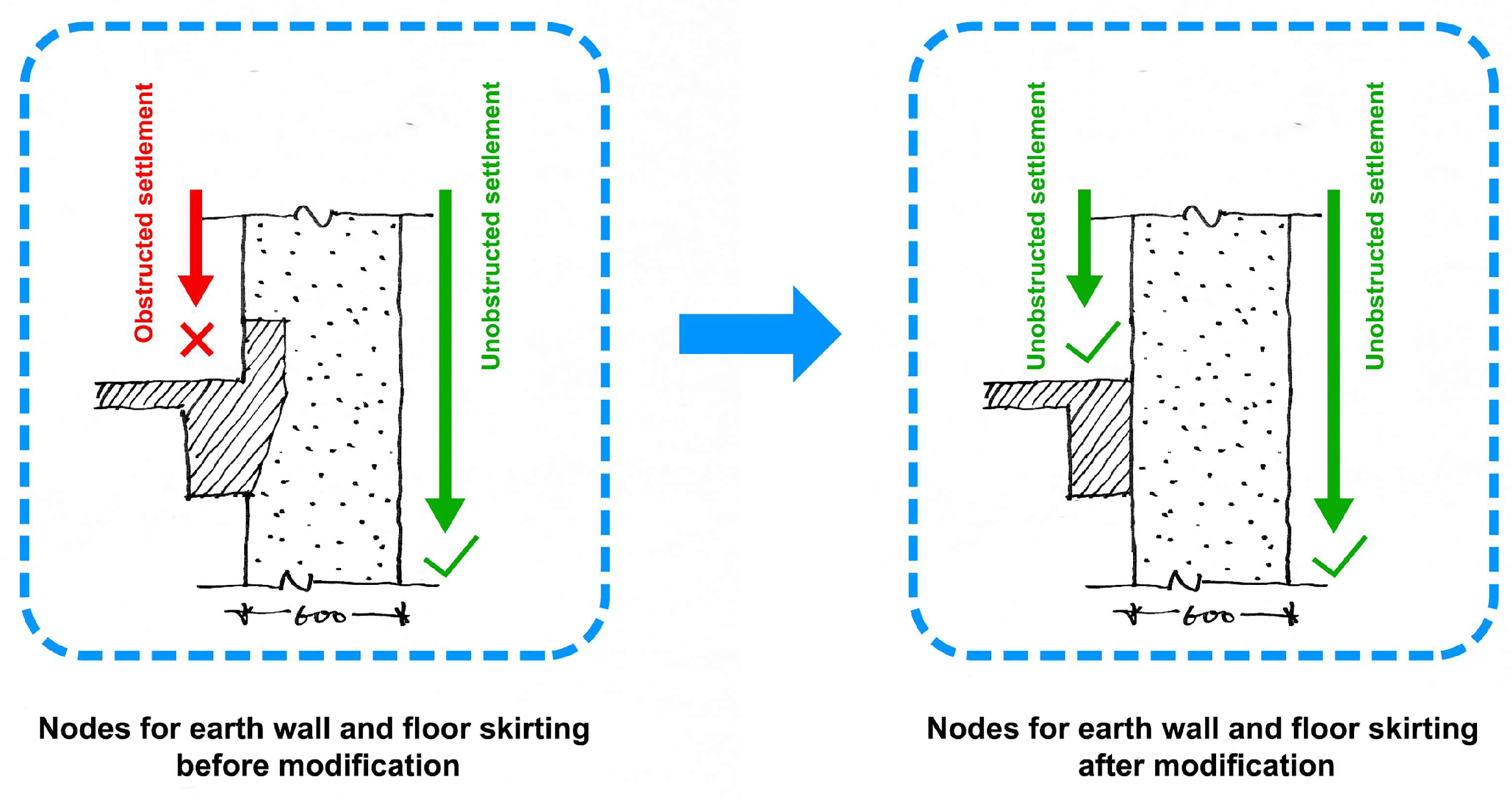

To make a more precise assessment, the team carefully marked the locations of all cracks on the elevation drawings of the wall. It became evident that the cracks showing signs of outward leaning were primarily concentrated around the second floor and third floor slabs. Based on the detailed drawings of the wall-slab joints, we speculated that the problem might stem from the kickplate (baseboard) edging at the floor-slab interface (

Figure 10). This recessed kickplate design, which the team had discussed extensively before construction, was intended to prevent water from the interior floor from seeping into the earthen wall and to ensure that the kickplate and the wall would be flush after completion. However, during the actual construction process, it became apparent that when the rammed earth wall settled, the settlement on the side with the kickplate was restricted, causing the wall to lean towards the side without the kickplate. If not addressed in time, this could eventually lead to wall collapse. The small cracks between the floor slabs, on the other hand, were primarily shrinkage cracks caused by the excessive length of the wall[

6]. Observations from the site indicated that the lower level exhibited fewer shrinkage cracks than the second level, likely due to the greater pressure exerted by the wall’s own weight, which reduced the potential for shrinkage. We concluded that these natural shrinkage cracks did not affect the stability of the wall, and the issue could be resolved by introducing expansion joints at intervals along the wall.

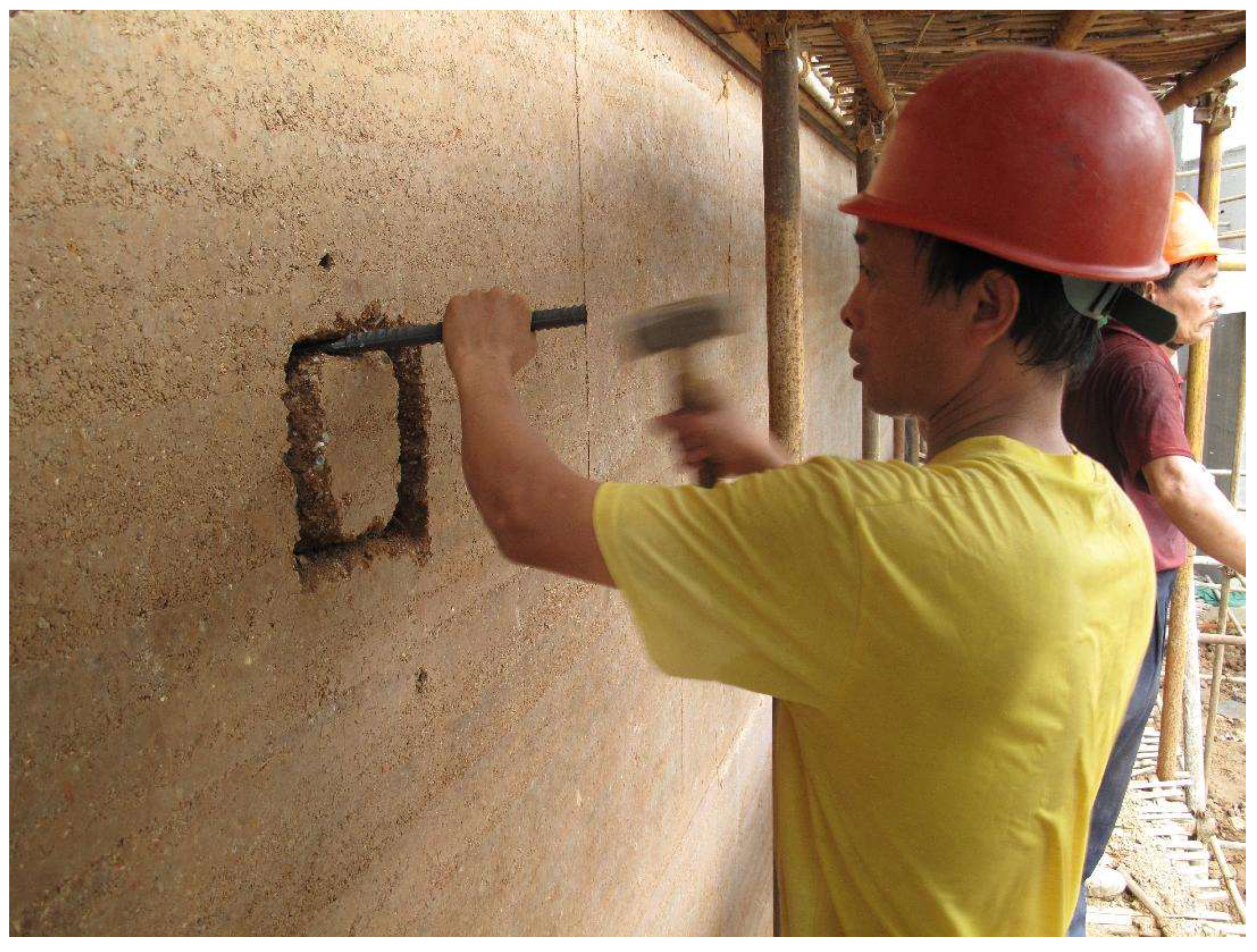

Before completely dismantling the outward-leaning wall, the laboratory took samples of the rammed earth blocks to test their compressive strength, ensuring that the leaning and cracking were not caused by inadequate material grading (

Figure 11). After several rounds of testing, the results confirmed that there were no issues with the material composition, conclusively pointing to the kickplate design as the source of the problem. The next step was to remove the recessed kickplate that was connected to the main structural framework, allowing the rammed earth wall to be decoupled from the frame, thus preventing interference between the two structures and allowing the wall to settle naturally (

Figure 12). However, this solution raised a new challenge: how to prevent the wall from leaning outward once it was detached. According to Wang Shu's design, the wall was over 10 meters high but only 0.6 meters thick, resulting in a height-to-thickness ratio of 1:17. Additionally, one side of the wall was entirely exposed, making it difficult to balance detaching the wall from the structural frame while ensuring it wouldn’t lean or collapse. This presented a particularly tricky problem at the time.

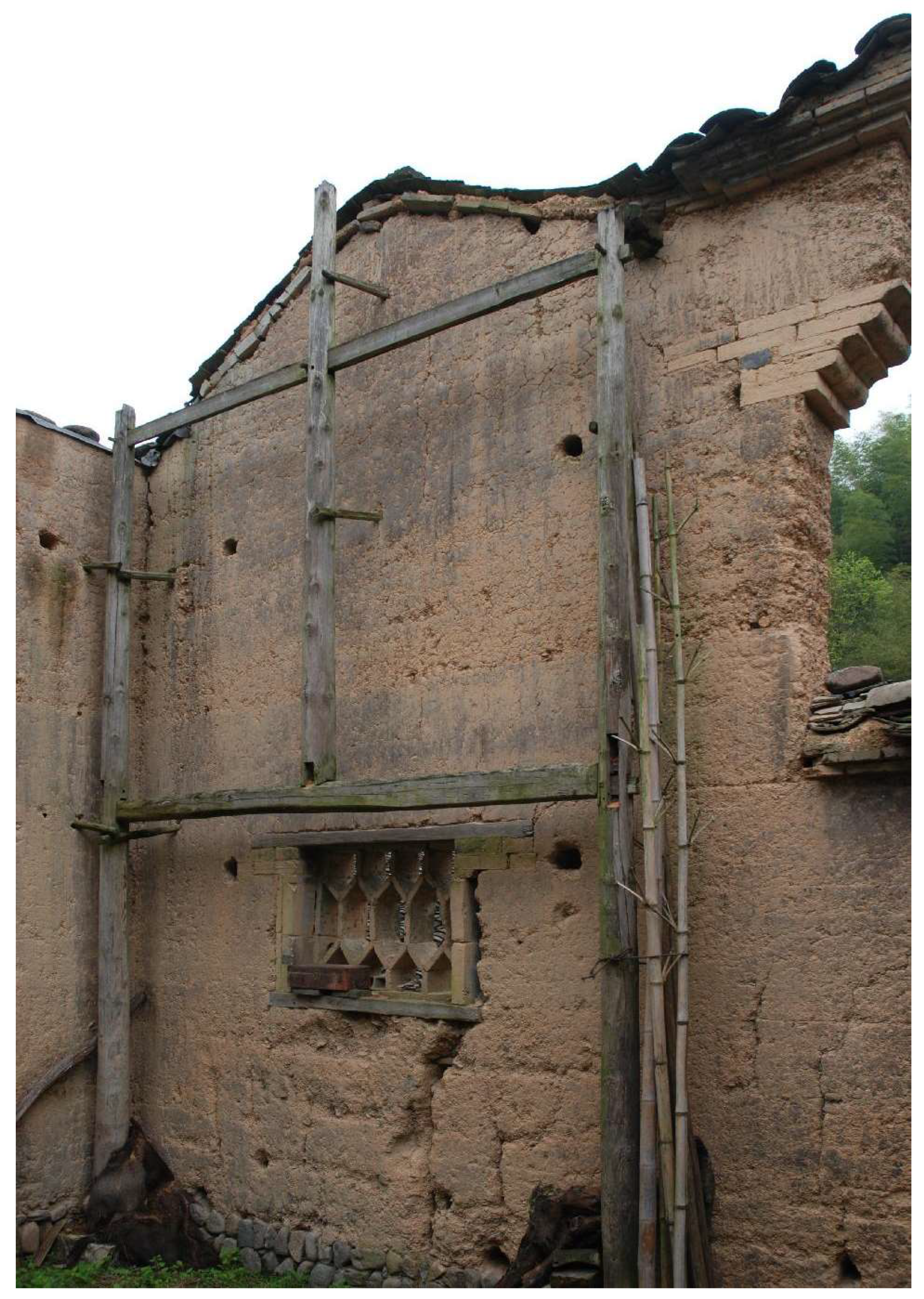

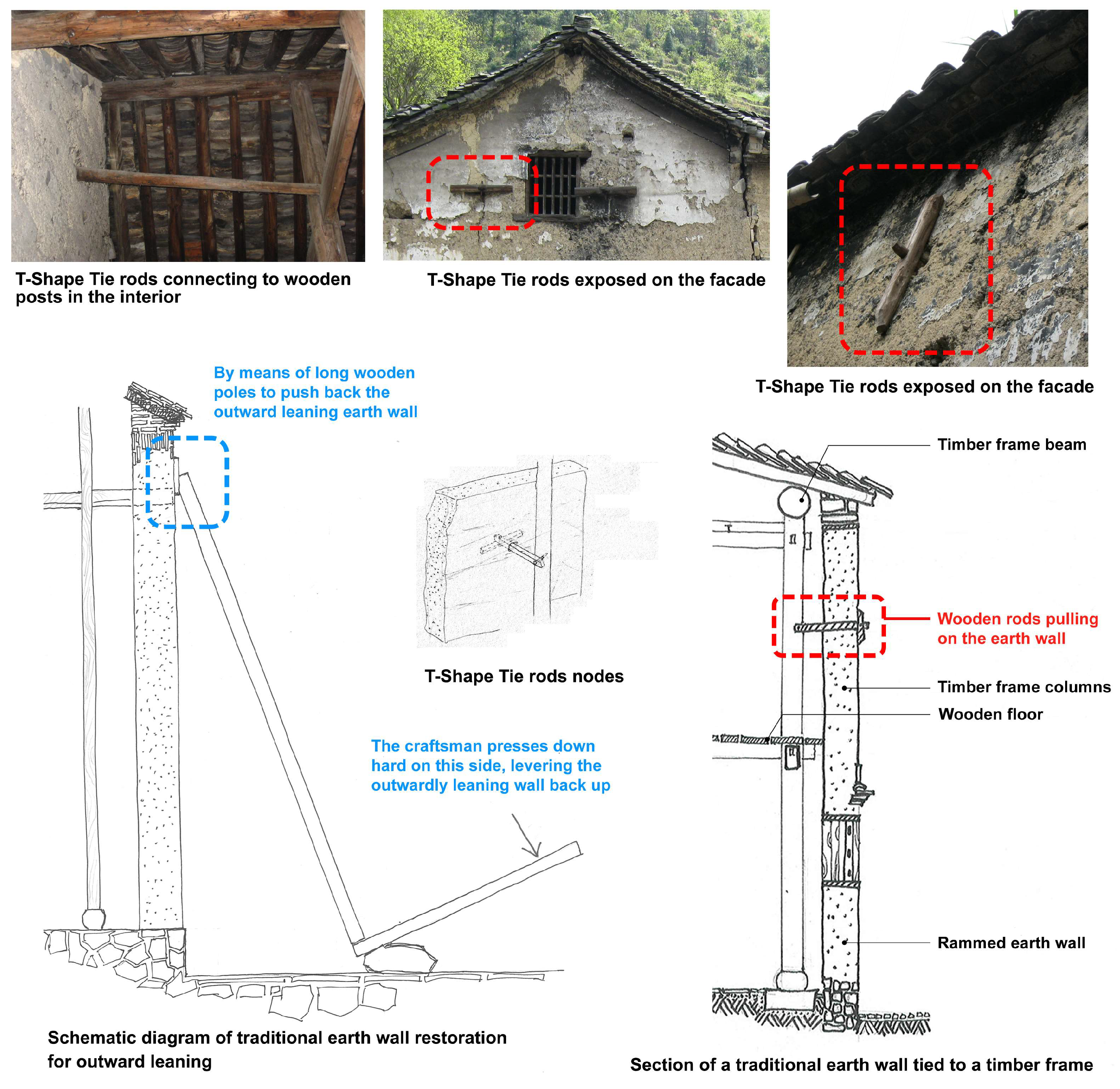

To solve this problem, our team turned once again to the traditional villages in the mountainous regions of southern Zhejiang for inspiration. In the village of Shanxia Bao in Wuyi County, Jinhua, we found a collapsed house with a hybrid structure of rammed earth and timber. On the remaining two-story rammed earth gable wall, parts of the timber frame were still visible, with several wooden tie rods extending from the wall to securely anchor it to the main timber structure (

Figure 13). The connection points between the timber rods and the main framework had a certain degree of flexibility, allowing the rammed earth wall to settle slightly without causing damage. This offered us an ingenious solution to our problem. Additionally, some of the more sophisticated nodes in the village design featured tie rods that extended entirely through the rammed earth wall, where a long, flat wooden beam would be inserted horizontally or vertically, forming a mortise-and-tenon structure. This created a "T-shaped" tie component that provided an anchor for the wall. With this external tie structure in place, the wall could be adjusted to correct any outward leaning. An elderly carpenter in the village shared with us a fascinating method for repairing rammed earth walls: when they noticed a wall leaning outward, they would position a long, slanted pole against the head of the "T-shaped" tie component, providing a ground support for the pole. Using a lever, they would slowly push the leaning wall back into place. After the wall returned to its original position and had stabilized, they would hammer a fixed pin into the outside of the "T" structure (

Figure 14), completing the correction. This process highlighted another important aspect of rammed earth—it is a relatively flexible material that can be repaired and adjusted over time.

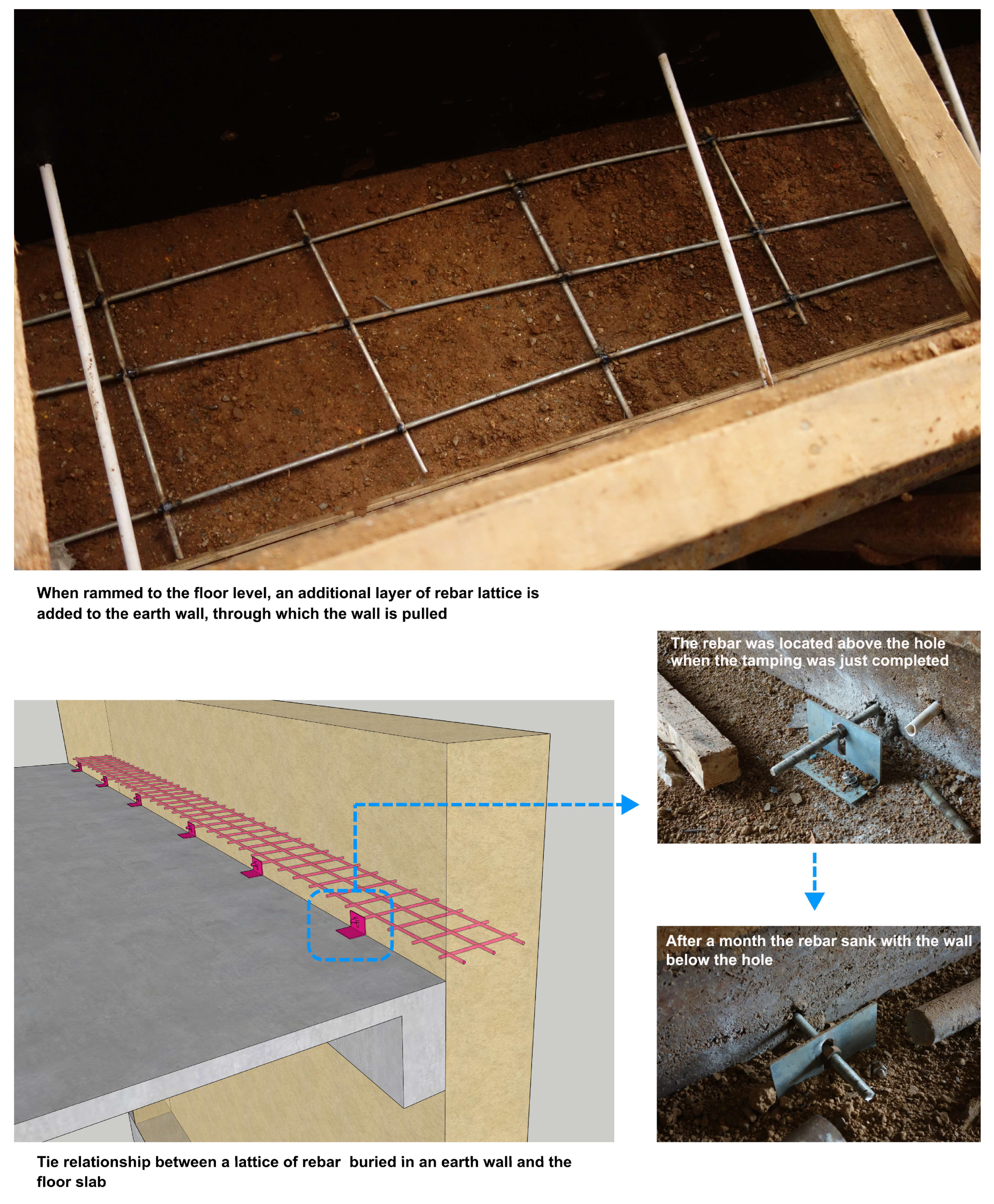

So our team came up with the idea of making exposed tensioned structural components by borrowing traditional methods, and after consulting with the project management engineers on site, We absorbed their suggestions and decided to use another, more subtle approach to tie rods. The revised solution involved embedding a mesh structure of steel bars, arranged both horizontally and vertically, at the level of the floor slabs during the ramming process. The horizontal steel bars extended outward and were anchored to the floor slab at an adjustable fixed point, with sufficient room for the bars to move vertically to accommodate settlement. This design effectively addressed the problem of the wall's outward leaning while allowing for the natural settlement of the rammed earth wall. At the same time, it preserved the integrity of the exposed side of the earthen wall, maintaining its aesthetic and structural coherence (

Figure 15).

Once it became clear that uneven settlement was causing the cracks and outward leaning in the earthen walls, our team assigned a group of diligent workers to monitor and record the settlement displacement of the newly rammed walls daily. The goal was to determine the "optimal time period"—the amount of time required for each section of the wall, based on the proportions provided by our Sustainable Laboratory, to transition from completion of ramming to initial solidification. This data was critical for both the construction of the building and for our research in the laboratory. As mentioned earlier, to ensure the precision and texture of the rammed earth finish, we employed a “pouring-like” method, which differs from traditional techniques. This method involved using a single layer of formwork that spanned the entire length of the wall for each section. The "optimal time period" was crucial for controlling the timing of the formwork removal between the upper and lower layers, the degree of soil hardening, and the overall construction progress. Analyzing the material properties of the rammed earth, which has a dispersed particle structure, it became evident that once the formwork was removed, the evaporation of moisture created voids that led to settlement, marking the wall's solidification process. This settlement was clearly linked to the solidification of the wall[

7], and once complete, the internal settlement of the wall should cease. By monitoring the settlement displacement at the top of the wall—where displacement is most noticeable—we could estimate the time required for the wall to solidify. This data was used to guide the timing for completing each section of the wall. The process required meticulous timing: it couldn’t be too fast or too slow. Precisely controlling this aspect of the construction was key to ensuring successful execution.

After dismantling the trial rammed earth wall, a significant amount of leftover soil was scattered at the site. The workers gathered this material for reuse in the subsequent ramming process. However, these dismantled earth blocks varied in size and couldn’t be directly mixed with water for ramming. Therefore, they were first processed through a crusher to be ground into a fine powder (

Figure 16). This powder was a mixture of soil and sand. The sand content could be divided into two parts: first, the sand that was part of the original mix, and second, gravel from the original mixture that had been crushed into sand by the machine. Our team tested this soil and sand mixture in the laboratory using specialized instruments, which allowed us to adjust the internal composition ratios to make this recycled material suitable for reuse[

8]. This process highlights the most essential characteristic of rammed earth construction—its recyclability. This recyclability holds two significant implications: first, the materials can be reused repeatedly. Even after a wall is dismantled, the materials can be repurposed for construction elsewhere, a quality that most modern building materials lack. It is also the centerpiece of the nature-oriented vernacular construction system, aligned with traditional philosophical views on eternity. The concept of endless cycles, epitomized in Daoist thought and texts such as the I Ching, reflects the belief in continuous renewal—"cyclical regeneration, eternal life”. If we think about it today, this sustainable construction method is also a strategy to resist the gradual scarcity of resources caused by the rough use of materials under the current mainstream construction system. Second, the composition of the rammed earth itself is naturally recyclable. It consists entirely of materials sourced directly from nature, with no added chemicals like lime. This means that when these materials eventually return to the earth, they cause no environmental pollution or damage. They originate from the earth and will, in time, seamlessly return to it[

9].

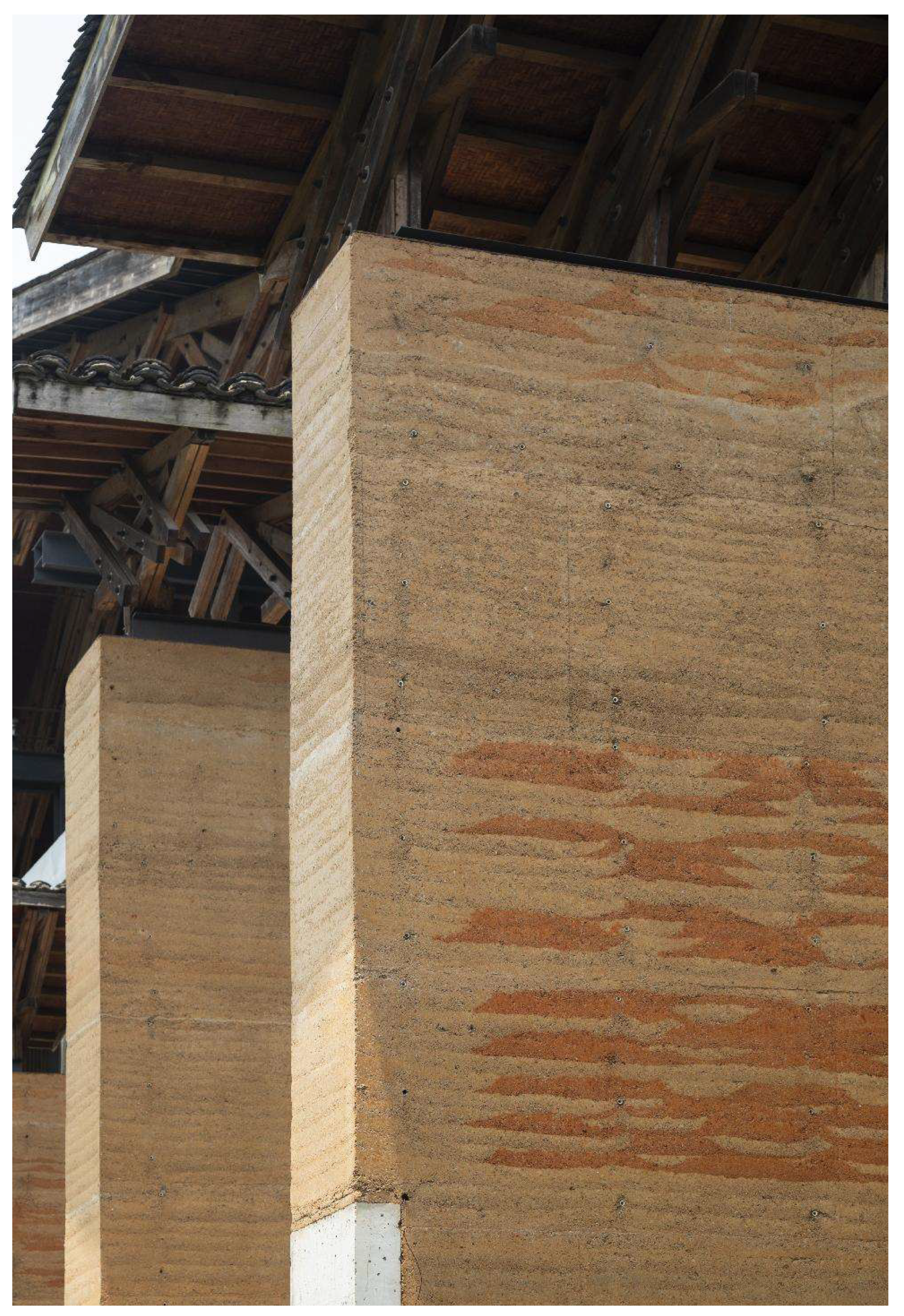

After learning from the previous setbacks, the subsequent rammed earth construction work gradually progressed smoothly. Once the ramming was completed and the formwork was removed, the exterior surface of the walls revealed a fine, horizontal layered texture. Within each compacted layer, there were subtle differences in texture from top to bottom. The upper parts, being more compacted by the vertical blows of the ramming hammer, had a denser surface than the lower parts. This stratification is reminiscent of the depiction of layered mountains in traditional Chinese landscape paintings. It's a fascinating characteristic of the material, as the construction process leaves visible traces of craftsmanship. However, due to the constraints of the formwork on both sides, these delicate variations are difficult to control during construction [

10], much like the traditional firing process of ceramics. In ceramic production, the final appearance of the glaze is only roughly predictable based on experience, since the transformation in color and shape occurs out of sight in the kiln. When the kiln is opened, there is a sense of anticipation—one can generally control the outcome, but the finer details are always uncertain. This concept applies to the control of texture and color in rammed earth walls as well. From the soil excavated at the site, we identified two distinct color types: a yellowish soil near the foot of the mountain, and a red soil found beneath the cultivated layers on the slopes. After laboratory testing, we selected the yellow soil as the primary source for the ramming, but Wang Shu requested that some areas of the walls exhibit a mixed effect with red soil. During the construction process, the workers were instructed to follow the design plans, which marked the locations for incorporating red soil into the walls (

Figure 17). Although the team carefully mapped the precise locations, shapes, and sizes of the red soil areas on both sides of each wall, the presence of the formwork prevented the workers from seeing the surface as they worked. As a result, they had to rely largely on their experience and intuition, rather than direct observation, when executing the design. Consequently, when the formwork was removed, the final result differed somewhat from the intended design in the drawings. However, this outcome, though unintended, reflects a kind of serendipitous craftsmanship that is both lively and rich with character, a hallmark of traditional building methods where "objective chance" plays a significant and creative role.

4. Conclusions

"Manual labor" is an especially precise word to describe the kind of construction activities within the vernacular architecture system. In our laboratory, there is a photograph on the wall depicting villagers from a Tibetan area in northwest China building a house (

Figure 18). Both men and women participate in the rammed earth construction, their faces glowing with the joy of a festive occasion. I can vividly imagine them chanting rhythmically, working together in unison, layer by layer, ramming the earth to raise the structure. This collective activity, imbued with a strong sense of ritual, allowed everyone, regardless of skill level, to participate. It is an experience that rapid industrial production cannot provide—an experience that only exists within traditional labor, deeply tied to the bodily imagination. The philosophical separation of body and mind has caused modern architectural theory to overlook the tangible experiences of building[

11]. Architecture is often discussed in terms of symbols and meanings, focusing so heavily on conceptual understanding that the actual experience of constructing buildings is ignored. Experience, while linked to cognition, is reduced to visual records of coded information. As a result, the eye can detach from the material existence of the architecture, with written descriptions serving as substitutes. Even when the body is considered in architectural theory, it is unfortunately reduced to a collection of needs and constraints, awaiting solutions derived from behavioral studies and ergonomics. Consequently, the body’s real, lived experience is excluded from the construction and meaning of architecture. This intellectual approach ignores the richness of the labor experience embodied in traditional building practices.

It was much the same in the villages of central and southern Zhejiang. I recall a visit to the village of Ku in the Taishun Mountains of Wenzhou, where an elderly villager proudly shared with us that the house he lived in had been built by himself, along with a few of his relatives and brothers, when he was younger. Despite having been repaired many times due to the wear and tear of wind and rain, the house remains in good condition, and he still lives in it today. Perhaps this is the essence of these structures—they are in a constant state of reconstruction and renewal, never fully finished, but always evolving. The "Tiles Hill — New Reception Center for the Xiangshan Campus" project is similar. Though it took nearly two years to build, our team feels that the house is still far from being in its ideal finished state. There remain many traditional techniques and methods that require further exploration and deeper research. While the building has been completed and delivered for use in terms of engineering, for Wang Shu and our team, this does not signify the end of anything. Rather, it marks only the beginning of our journey into the exploration and practice of traditional rammed earth construction techniques.

Figure 1.

Tiles Hill — New Reception Center for the Xiangshan Campus (Authors).

Figure 1.

Tiles Hill — New Reception Center for the Xiangshan Campus (Authors).

Figure 2.

Construction of the first experimental earth wall at the Sustainable Construction Laboratory of China Academy of Art(©Chaochao Wei).

Figure 2.

Construction of the first experimental earth wall at the Sustainable Construction Laboratory of China Academy of Art(©Chaochao Wei).

Figure 3.

A rammed earth wall formwork technique akin to concrete pouring methods(Authors).

Figure 3.

A rammed earth wall formwork technique akin to concrete pouring methods(Authors).

Figure 4.

The traditional rammed earth wall formwork still in use in the village(Authors).

Figure 4.

The traditional rammed earth wall formwork still in use in the village(Authors).

Figure 5.

In the traditional practice, specialized craftsmen patted down the finished rammed walls(Authors).

Figure 5.

In the traditional practice, specialized craftsmen patted down the finished rammed walls(Authors).

Figure 6.

A small earthen building in a mountainous village in southern Zhejiang, constructed to a height of five stories(Authors).

Figure 6.

A small earthen building in a mountainous village in southern Zhejiang, constructed to a height of five stories(Authors).

Figure 7.

The floor plan of the "Tiles Hill — New Reception Center for the Xiangshan Campus" Project.

Figure 7.

The floor plan of the "Tiles Hill — New Reception Center for the Xiangshan Campus" Project.

Figure 8.

The wall has developed an outward tilt, leading to a large crack(Authors).

Figure 8.

The wall has developed an outward tilt, leading to a large crack(Authors).

Figure 9.

The wall exhibits vertical fine cracks(Authors).

Figure 9.

The wall exhibits vertical fine cracks(Authors).

Figure 10.

Analyzing the structural joints to determine the cause of the cracks in the earth wall(Authors).

Figure 10.

Analyzing the structural joints to determine the cause of the cracks in the earth wall(Authors).

Figure 11.

Specimen blocks in walls(Authors).

Figure 11.

Specimen blocks in walls(Authors).

Figure 12.

Modification of the construction details for cracked joints(Authors).

Figure 12.

Modification of the construction details for cracked joints(Authors).

Figure 13.

Connection between traditional rammed earth walls and the main wood structure(Authors).

Figure 13.

Connection between traditional rammed earth walls and the main wood structure(Authors).

Figure 14.

epairing the outward leaning of earth walls through clever nodal constructions in traditional techniques(Authors).

Figure 14.

epairing the outward leaning of earth walls through clever nodal constructions in traditional techniques(Authors).

Figure 15.

tructural joints used in modern construction systems to prevent outward tilting of earth walls(Authors).

Figure 15.

tructural joints used in modern construction systems to prevent outward tilting of earth walls(Authors).

Figure 16.

Earth blocks, after being crushed, await reuse(Authors).

Figure 16.

Earth blocks, after being crushed, await reuse(Authors).

Figure 17.

The textured effect of the colored rammed earth wall(©Chaochao Wei).

Figure 17.

The textured effect of the colored rammed earth wall(©Chaochao Wei).

Figure 18.

A scene of villagers in the Tibetan region engaged in the rammed earth construction process[

12].

Figure 18.

A scene of villagers in the Tibetan region engaged in the rammed earth construction process[

12].