1. Introduction

The investigation of hybrid metal matrix nanocomposites (HMMNCs) has garnered significant attention in recent years due to their potential to develop material performance across various applications, particularly in the aerospace sector. HMMNCs combine the advantageous properties of metal matrix composites (MMCs) with the superior characteristics of nanomaterials, leading to enhanced mechanical, thermal, and wear-resistant properties. The incorporation of nanoparticles, such as silicon carbide (SiC), alumina (Al

2O

3), and carbon nanotubes (CNTs), into a metal matrix like aluminum allows for the tailoring of material properties to meet the demanding requirements of aerospace applications, where weight reduction and performance optimization are critical [

1,

2].

Recent advancements in fabrication techniques, including stir casting, powder metallurgy, and additive manufacturing, have facilitated the production of HMMNCs with improved microstructural characteristics and mechanical performance. For instance, ultrasonic-assisted stir casting has been shown to enhance the dispersion of reinforcements within the matrix, resulting in composites with superior tensile strength and fatigue resistance [

2,

3]. The hybridization of different types of nanoparticles has also demonstrated synergistic effects, leading to composites that exhibit enhanced mechanical and tribological properties compared to conventional materials [

2,

4].

Hybrid nanocomposites based on the aluminum alloy Al6061 have emerged as a promising class of materials due to their ability to combine superior mechanical and functional properties. The Al6061 alloy is widely used in structural applications for its excellent strength-to-weight ratio, corrosion resistance, and good machinability. However, to meet growing industry demands for materials with even more advanced performance, the addition of reinforcing nanoparticles, such as ceramics (SiC, Al2O3, TiO2) and carbon-based materials (graphene, carbon nanotubes), has been explored to produce hybrid nanocomposites. The advantages of Al6061 hybrid nanocomposites include significant improvements in mechanical properties, such as hardness and wear resistance, due to reinforcements that increase the aluminum matrix’s yield strength and fracture resistance. In addition, incorporating nanoparticles can increase thermal stability and improve tribological properties, making these materials ideal for applications in the automotive, aerospace, and defense sectors, where the combination of lightness and high performance is crucial.

Recent advancements in fabrication techniques, such as stir casting and powder metallurgy, have facilitated the production of Al6061 nanocomposites with improved microstructural characteristics and mechanical performance. For instance, studies have demonstrated that the ultrasonic stir-casting method can achieve a uniform distribution of reinforcements within the matrix, resulting in composites with enhanced tensile strength and fatigue resistance [

5,

6]. Additionally, using hybrid reinforcements—combining different types of nanoparticles—has yielded synergistic effects, leading to composites that exhibit superior mechanical and tribological properties compared to unreinforced materials [

7,

8].

Despite the advantages, the production of Al6061 hybrid nanocomposites presents significant challenges. Obtaining a uniform distribution of nanoparticles in the aluminum matrix is complex due to the tendency of nanoparticles to agglomerate, which can lead to a heterogeneous distribution and, consequently, a reduction in the desired mechanical properties. For instance, Kumar et al. [

9] demonstrated that the wear characteristics of Al6061 reinforced with multiwalled carbon nanotubes (MWCNTs) and graphene were significantly influenced by the dispersion of these fillers, which was enhanced through a ball milling process. Similarly, the work by Soni and Thomas [

10] highlighted the importance of nanoparticle dispersion in influencing the mechanical properties of Al6061 matrix composites, emphasizing that poor dispersion can lead to weak interfacial bonding and reduced mechanical performance. This challenge is compounded by the high viscosity of the aluminum matrix during processing, which can hinder the adequate mixing of the nanofillers [

11]. Reddy et al. [

12] utilized ultrasonically assisted stir casting to fabricate Al6061 composites reinforced with silicon carbide and graphite, achieving improved mechanical properties. However, each method has its limitations; for instance, powder metallurgy can lead to difficulties in achieving the desired density and homogeneity of the final product [

13]. Moreover, the processing parameters, including temperature and time, must be carefully controlled to prevent nanofiller degradation, mainly when using thermally sensitive materials like CNTs and graphene [

14].

Additional challenges include optimizing the interface between the matrix and the nanoparticles to maximize load transfer and preventing microstructural defects that could compromise the integrity of the material. Recent studies have focused on functionalizing nanoparticle surfaces and modifying production techniques to improve the dispersion and adhesion of nanoparticles in the aluminum matrix.

Practical applications of these nanocomposites range from lightweight structural components in automotive and aerospace vehicles to sports equipment and consumer electronics, where superior mechanical performance and weight reduction are critical. Research to date has shown progress in improving the properties of nanocomposites but also highlights the need for further studies into the effects of different types of reinforcements and production methods. Continued progress in understanding the mechanisms governing the behavior of these hybrid materials is essential for the development of broader and more effective industrial applications.

In this sense, this work explores the possibility of producing hybrid nanocomposites of Al6061 matrix reinforced with SiC and CNTs. An intense microstructural characterization was carried out to evaluate the effect of the percentage of reinforcement, sintering temperature, and type of reinforcement to obtain nanocomposites with the best balance between microstructure and mechanical properties with high potential for future implementation.

2. Materials and Methods

In the current study, the selected matrix metal was the 6061-aluminum alloy (Al6061) powder. Two different reinforcements were chosen to produce hybrid Al nanocomposites. These include multiwalled carbon nanotubes (MWCNTs) and silicon carbide (SiC) particles. The MWCNTs were obtained from Fibermax Nanocomposites Ltd. (London, UK), and the SiC particles were supplied by Merck (Darmstadt, Germany).

The as-received materials were characterized using optical microscopy (OM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD). The equipment used for this characterization was an optical microscope, M 4000 M, with Leica Application Suite software (version 4.13.0, Leica Microsystems, Wetzlar, Germany) and a Thermo Fisher Scientific QUANTA 400 FEG SEM (Thermo Fisher Scientific, Hillsboro, OR, USA) with an EBSD TSL-EDAX detector unit (EDAX Inc. (Ametek), Mahwah, NJ, USA). The CNTs were analyzed using transmission electron microscopy (TEM, FEI Company, Hillsboro, OR, USA) and high-resolution TEM (HRTEM, JEOL Ltd., Tokyo, Japan).

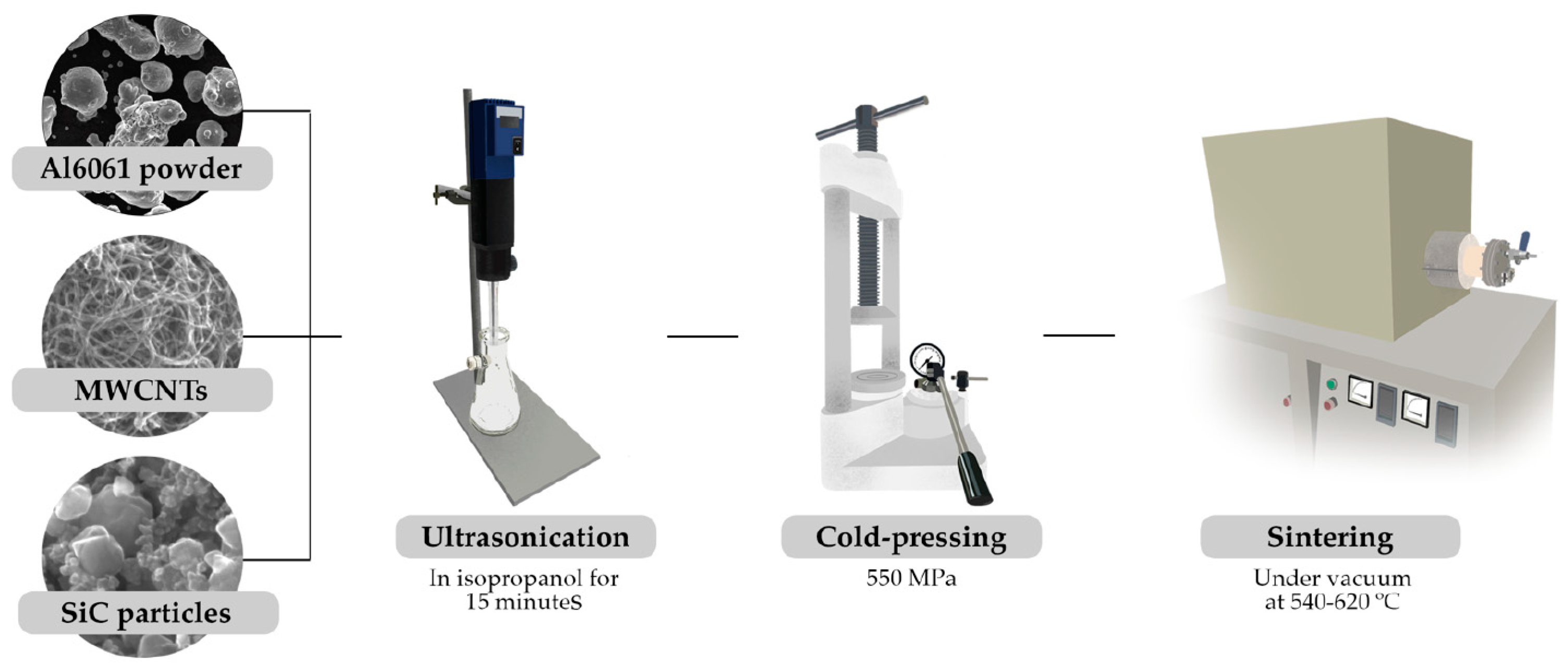

The hybrid nanocomposites were produced via powder metallurgy schematically represented in

Figure 1. The Al6061 powder was first mixed with CNTs and SiC particles using an ultrasonication process in isopropanol for 15 minutes. This method has proven effective and efficient in dispersing nanoparticles while minimizing agglomeration [

15,

16], thus ensuring a homogenous distribution of CNTs and SiC within the Al6061 powder. After ultrasonication, the mixture was dried and cold-pressed at 550 MPa to form cylindrical (⌀ 10 mm) green compacts. Posteriorly, these compacts were sintered in a high-temperature tubular furnace under vacuum (better than 10

-4), with sintering temperatures ranging from 540 to 620 °C, which provokes diffusion and ensures enhanced bonding between the matrix and the reinforcements, thus optimizing the mechanical integrity of the hybrid nanocomposite. Nanocomposites reinforced only with CNTs and SiC at different reinforcement concentrations were also produced to evaluate their fraction’s effect on the nanocomposites’ properties.

The approach to evaluating the densification of the sintered composites resorted to determining both theoretical and experimental densities. The theoretical density was calculated using the rule of mixtures, accounting for the individual densities of Al6061, CNTs, and SiC. In contrast, the experimental density was determined by using the Archimedes principle. Posteriorly, the relative density of the nanocomposites was determined by comparing both densities.

A detailed microstructural analysis was conducted to understand the aluminum matrix’s and reinforcements’ interaction. To do so, optical microscopy (OM), digital microscopy (DM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) were applied to polished cross-sections of the nanocomposites.

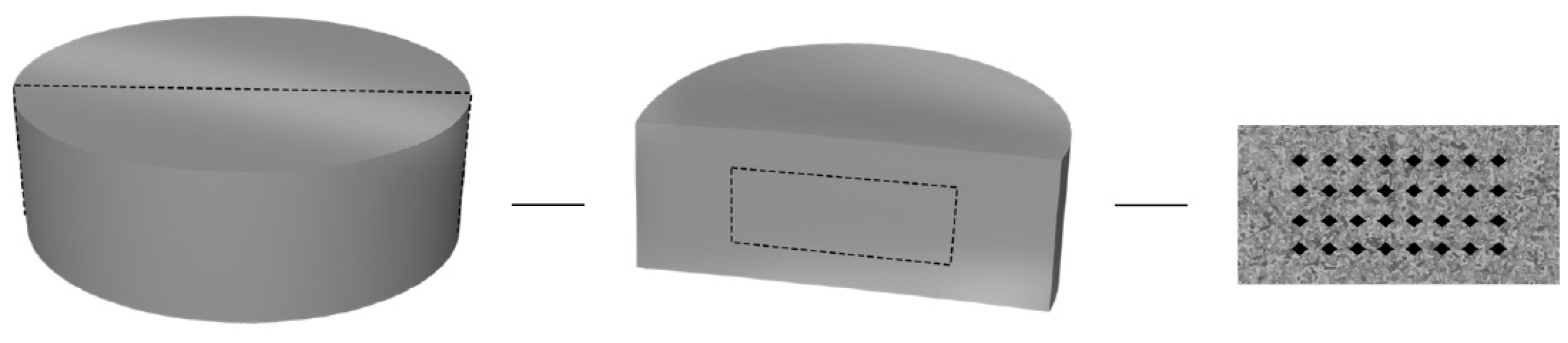

The mechanical characterization of the sintered hybrid nanocomposites was performed through hardness and tensile tests. Thirty Vickers microhardness indentations were taken on polished cross-sections to determine the overall hardness of the samples as schematized in

Figure 2. These were conducted with an application load of 196 mN for 10 seconds, using a FALCON 400 micro/macro-Vickers hardness tester (INNOVATEST Europe BV, Maastricht, The Netherlands). The tensile tests were carried out using a Shimadzu EZ Test machine (Shimadzu Corporation, Kyoto, Japan) at a crosshead speed of 1 mm/s to understand the influence of both reinforcements on the overall strength, ductility, and failure mechanisms of the hybrid nanocomposite.

3. Results and Discussion

In this study, Al6061 hybrid nanocomposites reinforced with CNTs and SiC particles were produced and characterized to evaluate the effects of the reinforcements on the microstructure, phase composition, and mechanical properties of the resulting material. The initial materials have a significant influence on the final properties and microstructure. So, a characterization of the reinforcements and powders used to produce the composites was also carried out initially.

3.1. Powders and Reinforcements Characterization

The initial characterization of the powders and reinforcements used in producing hybrid Al6061 nanocomposites is essential to understand their morphological, structural, and chemical properties before integration into the composite matrix.

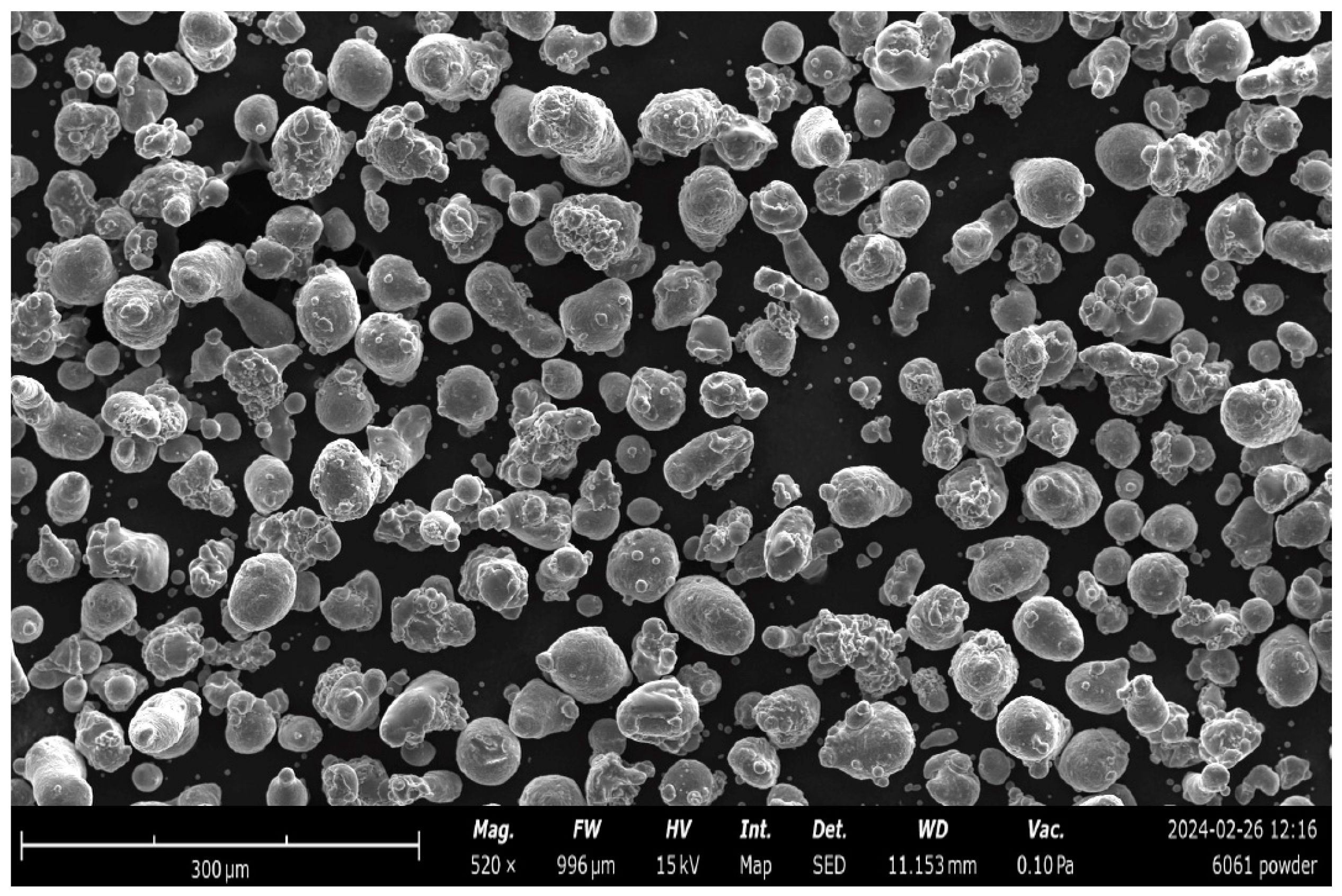

The Al6061 powder, used as the matrix material, was characterized to ensure its suitability for the fabrication of nanocomposites. The particle size distribution was measured, and the results showed that the average particle size was approximately 35 µm, with a narrow distribution, as depicted in

Figure 3. The morphology of the Al6061 powder was examined using scanning electron microscopy (SEM), revealing predominantly spherical particles, which are preferred for uniform mixing and compaction. The spherical shape of the particles is advantageous in reducing the porosity of the sintered composite, thereby improving its mechanical properties.

The chemical composition of the Al6061 alloy powder was analyzed using energy-dispersive X-ray spectroscopy (EDS) to confirm the presence of primary alloying elements such as magnesium (Mg), silicon (Si), and copper (Cu). The results, presented in

Table 1, show that the elemental composition of the Al6061 powder follows the standard composition of the Al6061 alloy, ensuring that the matrix will exhibit the expected mechanical and thermal properties.

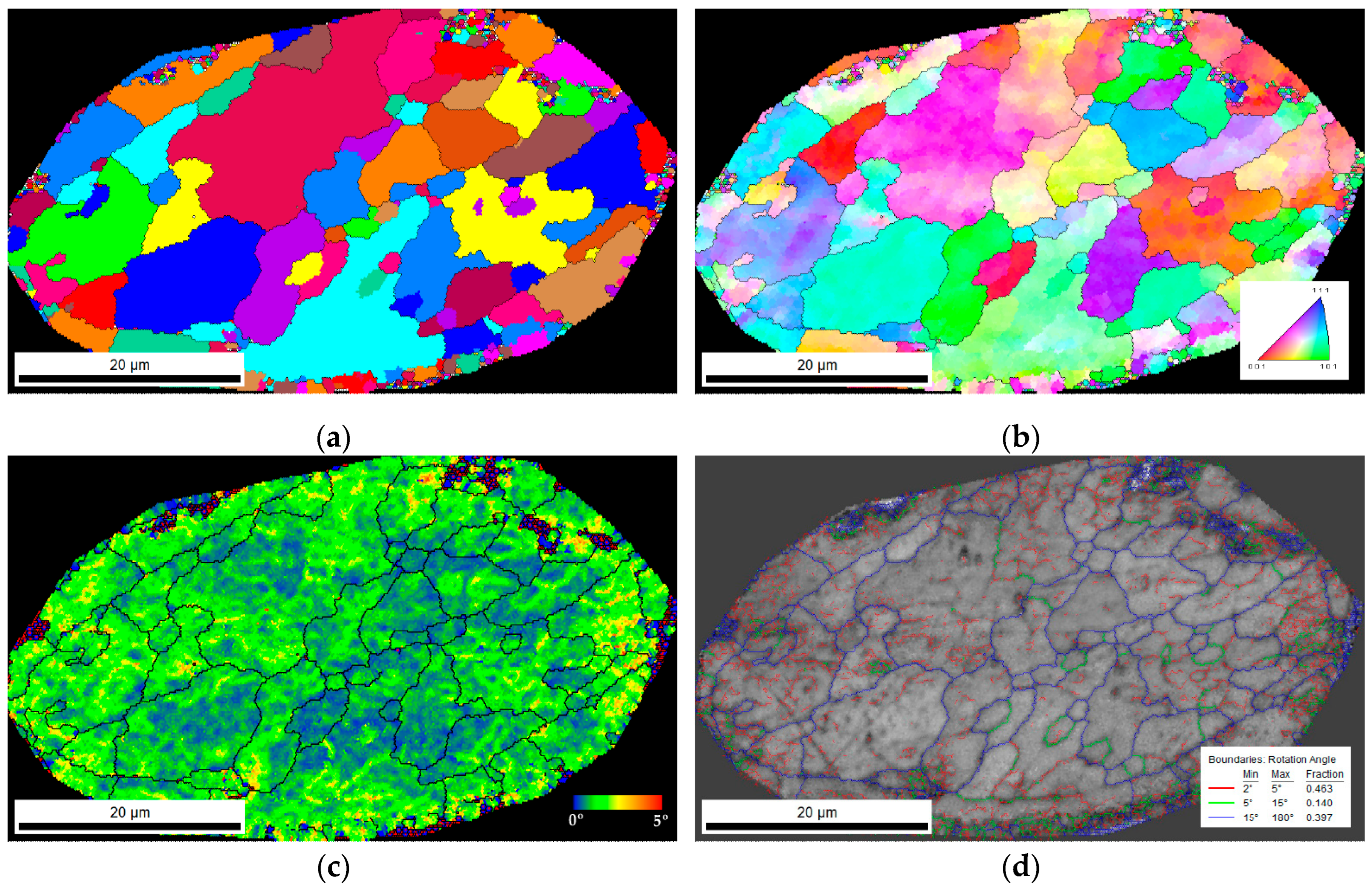

Electron backscatter diffraction (EBSD) was used to map crystallographic information such as grain orientation, phase distribution, and strain in the crystalline of the powder particles.

Figure 4 shows the results of Al6061 powder particles.

Figure 4a shows the unique color map. Each grain is colored differently to represent different sizes, and this map suggests the presence of grains of different sizes in each powder particle. The inverse pole figure (IPF) map of

Figure 4b shows the orientation of individual grains in the powder. Each grain is colored differently to represent its crystallographic orientation. This helps identify the grain structure, size distribution, and how grains are oriented relative to each other. The map suggests the presence of grains of different sizes, and the color variation indicates different crystallographic orientations. In the KAM map presented in

Figure 4c, colors usually represent the magnitude of the misorientation.

Regions with high misorientation, indicated by warmer tones (yellow, orange, or red), may be associated with plastic deformation regions, such as grain or subgrain boundaries, where more dislocation activity has occurred. Green or blue areas, more common in grain centers, indicate lower misorientation, suggesting that these regions are less deformed or subjected to significant internal stresses. In the Al6061 powder, these high-misorientation areas could indicate zones of intense processing, such as during milling, atomization, or rapid solidification, where deformation has accumulated due to internal stresses. They are comparing this map with others (especially orientation maps like (a) or (b)), you can observe how internal misorientation correlates with grain size and crystallographic orientation. Regions of high misorientation, usually at grain boundaries, stand out in the KAM map as expected.

Figure 4d is the image quality map where brighter areas typically correspond to well-ordered crystalline regions with high-quality diffraction patterns.

In comparison, darker areas might indicate defects, poor patterns, or regions where patterns were harder to obtain. This map helps identify regions with strain or defects in the sample and understand the quality of the EBSD results. The lines represent grain boundaries where the crystallographic orientation changes significantly. Blue lines could represent high-angle grain boundaries, while red and green lines represent low-angle boundaries.

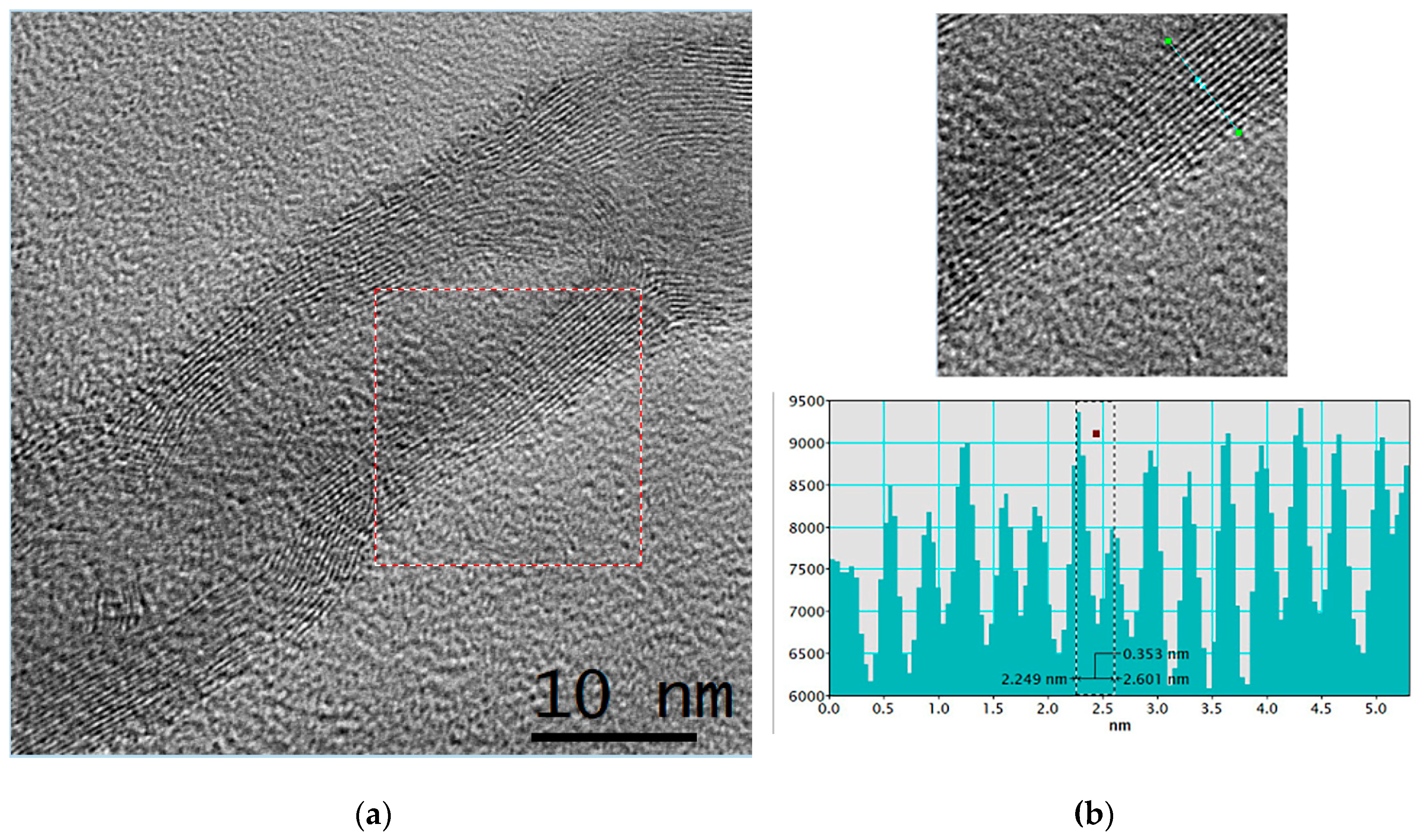

The CNTs, attending as the primary nanoscale reinforcement, were characterized to assess their purity, structure, and dispersion quality. Transmission electron microscopy (TEM) was used to examine the morphology and structural integrity of the CNTs.

Figure 5 shows a TEM image of the CNTs, revealing a multiwalled structure with an average diameter of 10-20 nm and lengths in the micrometer range. The high aspect ratio of CNTs is crucial for improving the load transfer capability within the nanocomposite.

Raman spectroscopy was performed to confirm the structural quality of the CNTs. The Raman spectrum shows distinct D and G bands, corresponding to the disordered carbon (D band) and the graphitic structure (G band). The intensity ratio of these two bands (ID/IG) was calculated to be around 1.01. This value can be attributed to some defects in the CNTs, which is critical for their role as reinforcement in the composite.

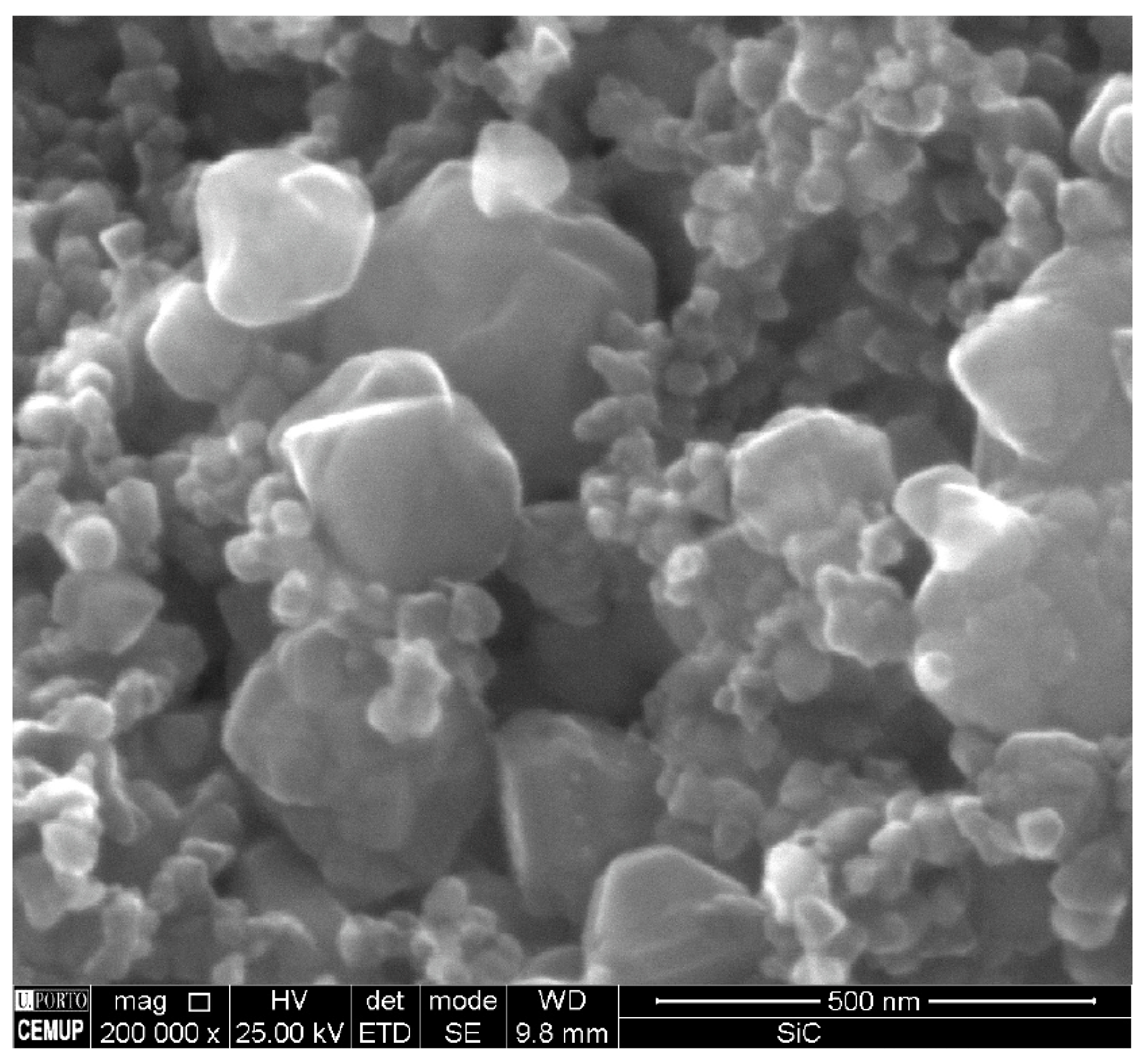

The SiC particles were characterized to ensure their uniformity, size, and morphology before being used as the second reinforcement in the hybrid composite. The SiC powder was analyzed using SEM, and

Figure 6 presents SEM images showing the angular morphology of the SiC particles, with an average particle size of approximately 5 µm. The sharp edges and irregular shape of the SiC particles are expected to enhance mechanical interlocking within the matrix, contributing to improved load-bearing capacity.

In addition, the SiC particles were analyzed using EDS, which confirmed that the powder consists primarily of silicon and carbon, with no detectable impurities, as seen in

Table 2. This high-purity SiC is necessary to prevent unwanted chemical reactions with the Al matrix, such as the formation of aluminum carbide (Al

4C

3), which can degrade the mechanical properties of the composite.

The characterization of the Al6061 matrix powder, CNTs, and SiC particles demonstrated that these materials possess the necessary morphological and structural properties to produce hybrid nanocomposites. The spherical morphology of the Al6061 powder, the high aspect ratio and purity of the CNTs, and the angular, high-purity SiC particles contribute to efficient load transfer, grain refinement, and the overall improvement of the composite’s mechanical properties. The uniform dispersion of CNTs and SiC within the matrix was achieved through ultrasonication to ensure homogeneity, minimizing potential defects in the final nanocomposite and reducing the observed agglomeration of the as-received particles and CNTs.

3.2. Nanocomposites Characterization

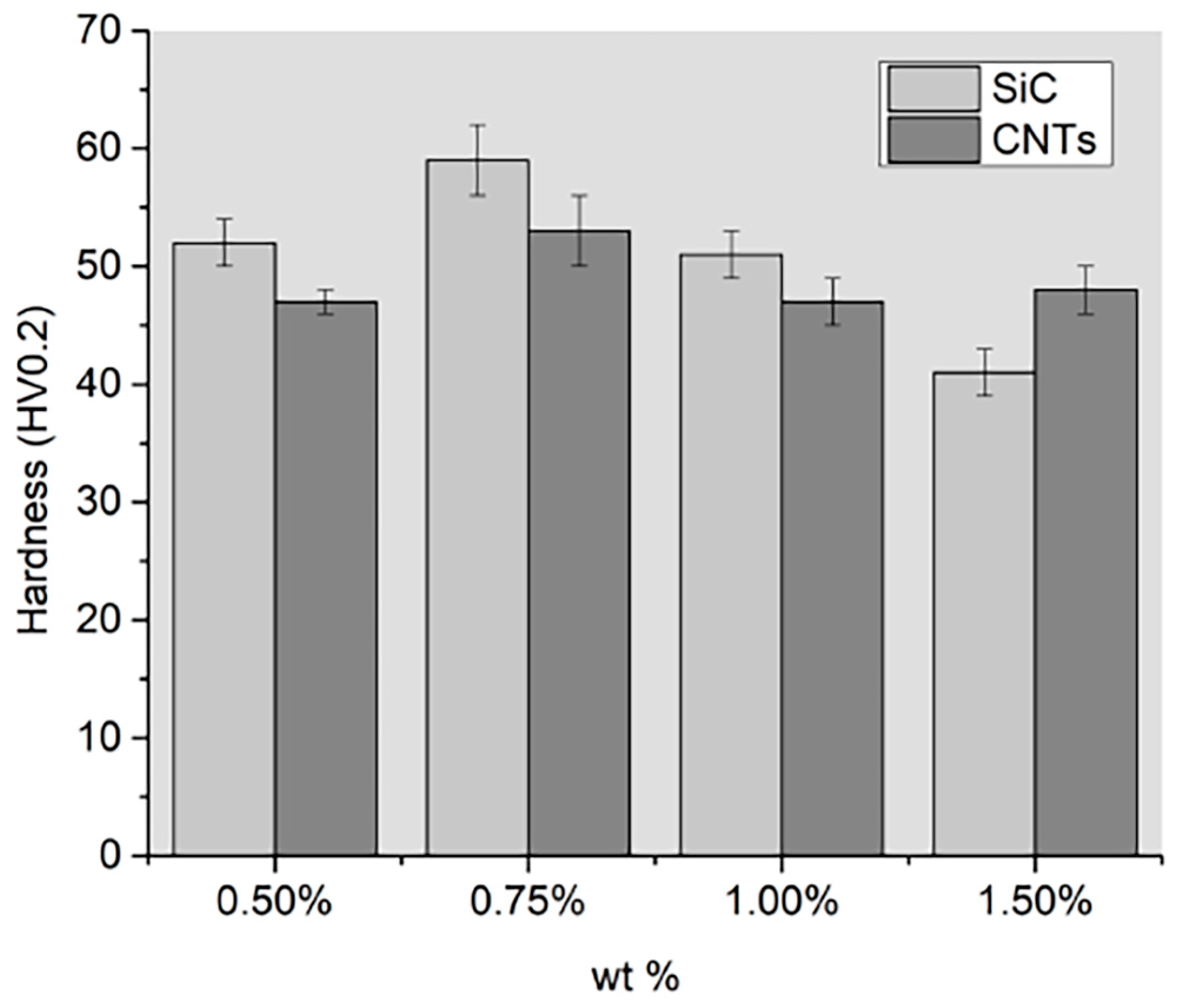

To produce the hybrid nanocomposites, a study was first carried out on the effect of the amount of SiC and CNT reinforcement for producing the nanocomposites. Reinforcement additions of 0.50, 0.75, 1.00, and 1.50wt.% for SiC and CNTs were evaluated.

Figure 7 shows the hardness evolution for Al6061 composites reinforced with varying amounts of SiC and CNTs.

As the amount of SiC increases, a steady or rapid increase in hardness is expected. However, at very high SiC content, the hardness tends to stabilize or slightly decrease due to poor particle distribution or clustering, which can cause defects or porosity. The addition of CNTs to the aluminum matrix improves hardness. However, this increase may be more gradual compared to SiC, due to the challenges of uniformly dispersing the CNTs within the matrix. As the CNT content increases, an improvement in hardness is expected. Nevertheless, if the CNTs are not well dispersed, the agglomeration of the nanotubes may limit the improvement, reducing the overall benefit. For both types of reinforcement, the maximum hardness value was observed for 0.75wt.% reinforcement content.

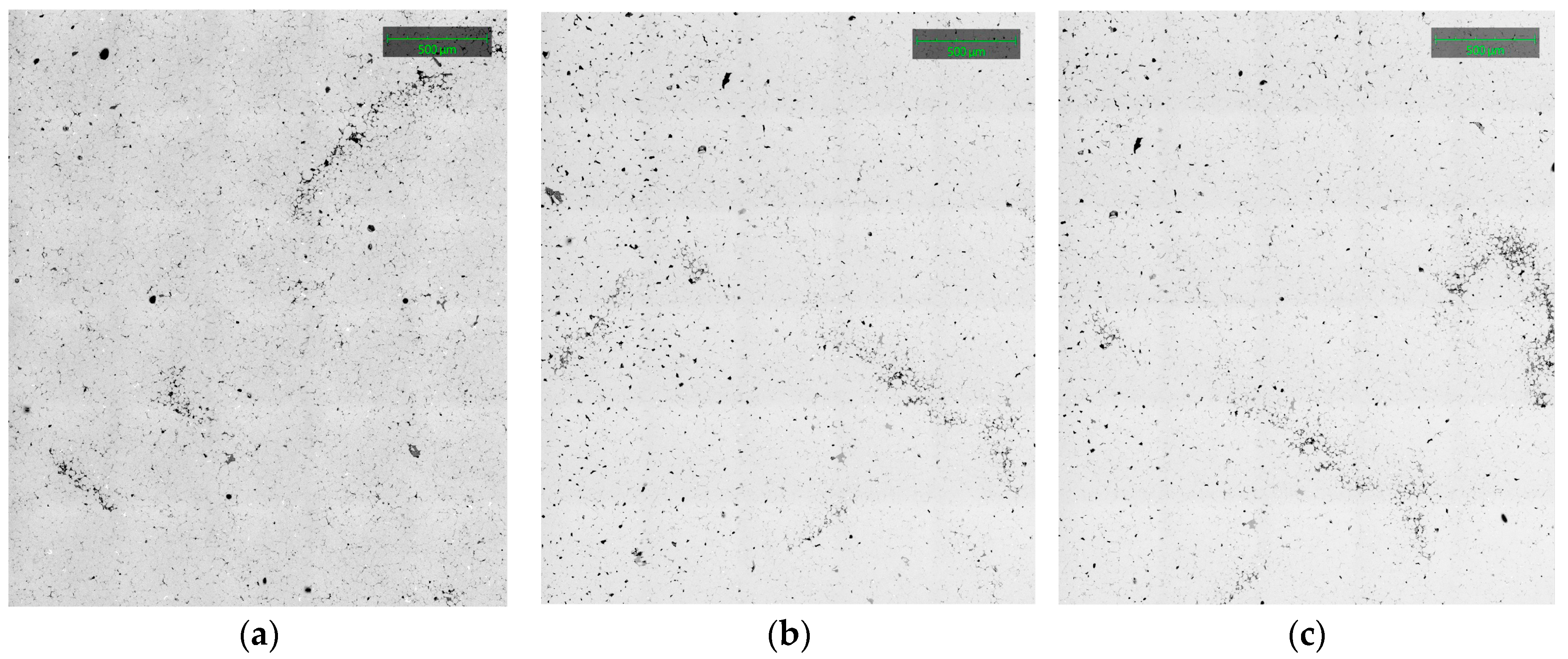

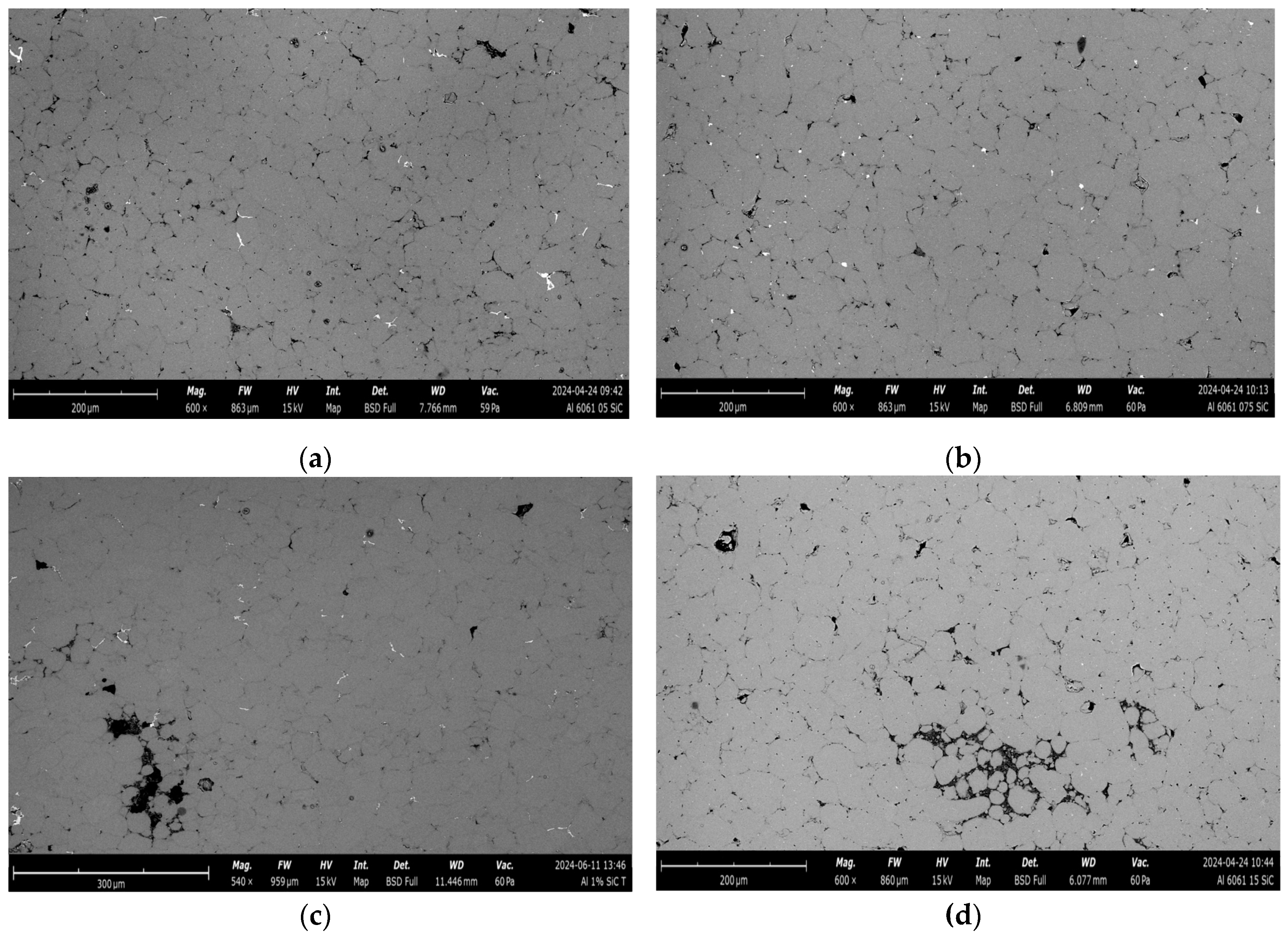

A detailed microstructural characterization was performed in the nanocomposites reinforced with SiC to understand the hardness evolution with the reinforcement amount.

Figure 8 shows the SEM images at a lower magnification of Al6061 nanocomposites reinforced with different amounts of SiC. Each image corresponds to a different SiC reinforcement weight percentage (0.50, 0.75 and 1.00 wt.% of SiC). The images display the distribution of SiC particles within the aluminum matrix. The particles appear as dark spots, while the aluminum matrix appears as a lighter background. Increasing the amount of SiC reinforcement changes the particles’ distribution, agglomeration, and overall interaction within the matrix for the nanocomposite with 0.50 wt.% SiC, the image shows a relatively uniform distribution of SiC particles with some small clusters. The size of the SiC particles appears relatively uniform, with fewer large agglomerates. This amount may result in effective dispersion strengthening as the particles are well-distributed without significant clustering, enhancing the hardness and mechanical properties due to load transfer from the matrix to the particles. The concentration of particles increases for nanocomposite with 0.75 wt.% SiC and there is a slight tendency for more clusters or agglomerations of SiC particles, especially in certain areas. Although there is still relatively good dispersion, the agglomeration of SiC particles could become more pronounced compared to the 0.50 wt.% sample. The presence of agglomerates may act as stress concentrators or weak points in the material, potentially affecting its overall mechanical properties. However, the hardness may continue to increase with the increase in SiC. For 1.00 wt.% SiC, the micrograph reveals a more pronounced agglomeration of SiC particles. The dark spots representing the SiC particles are more clustered and unevenly distributed. Agglomerates are visible across the image, suggesting that, at higher concentrations, it becomes more challenging to maintain a uniform distribution of the reinforcement within the matrix. This agglomeration could lead to reduced mechanical performance, as these clusters may act as points of weakness where failure can initiate. These areas could also introduce voids or other defects, negatively affecting the material’s toughness and ductility.

High-magnification SEM images of the nanocomposites reinforced with different amounts of SiC can be observed in

Figure 9.

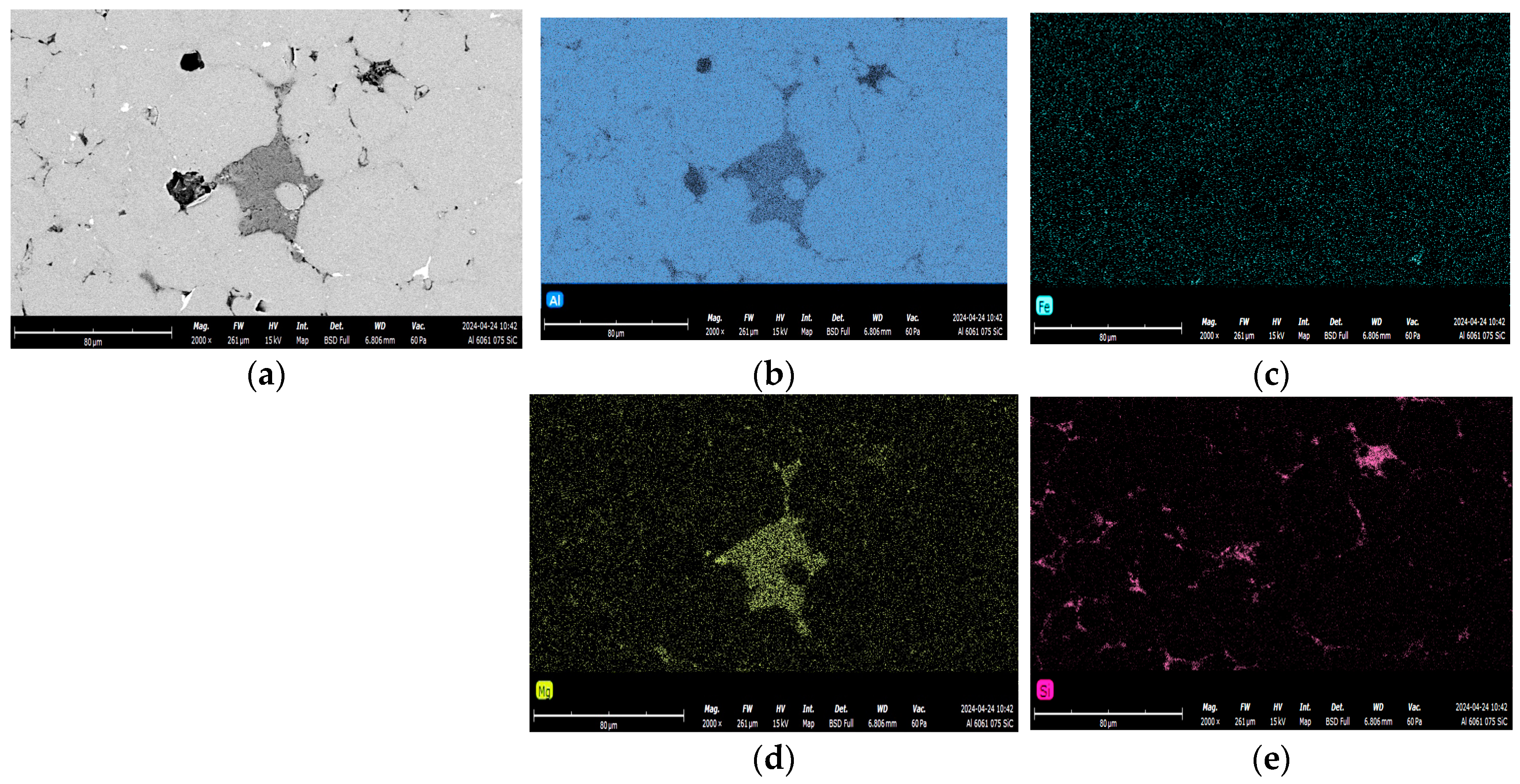

Based on these high magnification images, which correspond to different compositions of SiC-reinforced Al6061 nanocomposites (0.50, 0.75, 1.00, and 1.50 wt.%), it is possible to confirm the evolution of the distribution and agglomeration of SiC particles within the aluminum matrix as the reinforcement concentration increases. As the amount of SiC increases from 0.50% to 1.50%, the images change from a uniform distribution to a highly agglomerated microstructure. At lower concentrations (0.50% and 0.75%), the uniform distribution of particles promotes effective strengthening by dispersion, improving the composite’s mechanical properties without compromising its integrity. However, from 1.00% onwards, the formation of large clusters becomes significant, indicating that the reinforcement exceeds the matrix’s dispersion capacity. At 1.5%, the large agglomerations result in a less homogeneous microstructure with the potential for deterioration in mechanical properties, especially fracture toughness and ductility. These observations suggest an ideal limit for incorporating SiC particles, probably around 0.75% to 1.00%, where there is a balance between increasing hardness and maintaining good mechanical properties. The formation of second-phase particles tends to increase with the concentration of SiC, and their presence strongly impacts the microstructure and mechanical properties of the nanocomposites. These particles are finely dispersed at lower reinforcement concentrations and act beneficially, increasing hardness and wear resistance. At higher concentrations, however, they group together and interact with the SiC agglomerates, introducing stress concentration points and defects that reduce the material’s overall strength, especially under cyclic or impact loads. The quantity and distribution of these particles must be carefully controlled to avoid deteriorating mechanical properties at high reinforcement concentrations. Second-phase particles in aluminum composites often include compounds such as AlFeSi, AlMgSi, or other intermetallic arising from the reaction of alloying elements (such as Mg, Si, Fe) present in Al6061. Their formation is influenced by thermal processing, sintering time and the nature of the reinforcement introduced. These phases are generally harder and more brittle than the pure aluminum matrix and can significantly impact the material’s mechanical and tribological properties. EDS analyses were carried out to predict the nature of these second phases.

Figure 10 shows the EDS maps of the sample reinforced with 0.75 wt.% SiC. The Si element map shows that the element is more concentrated in the points corresponding to the dark particles in the SEM image. This distribution confirms that these dark regions are SiC particles used as reinforcement in the composite. Si is not present in the second phase particle located in the center of the image, suggesting that it is predominantly composed of other elements, such as Al and Mg. The Fe map reveals a significant concentration in the lighter second-phase particles. This suggests that the particle is composed of an Al-Fe intermetallic compound, possibly with Si. EDS analysis reveals the presence of a second-phase particle rich in Al, Fe, and Si, suggesting an intermetallic compound, possibly Al-Fe-Si, formed during the solidification process. These intermetallic particles are generally harder and more brittle than the aluminum matrix and can act as stress concentration points and failure initiators under cyclic or impact loads. However, the formation of large intermetallic particles containing Mg or Si can compromise the material’s overall strength, making it more disposed to fracture.

Table 3 shows the phase percentages of the samples for the different nanocomposites. The addition of reinforcement affects the formation of these second phases typical of the Al6061 alloy. Similar results were reported in previous studies when CNTs were added [

15].

When CNTs are added to the Al6061 matrix, similar results are observed concerning dispersion and the formation of second phases. In this sense, a percentage of 0.75 wt.% was selected for both reinforcements to produce hybrid nanocomposites, considering all the microstructural and mechanical characterization results.

3.3. Hybrid Nanocomposites Characterization

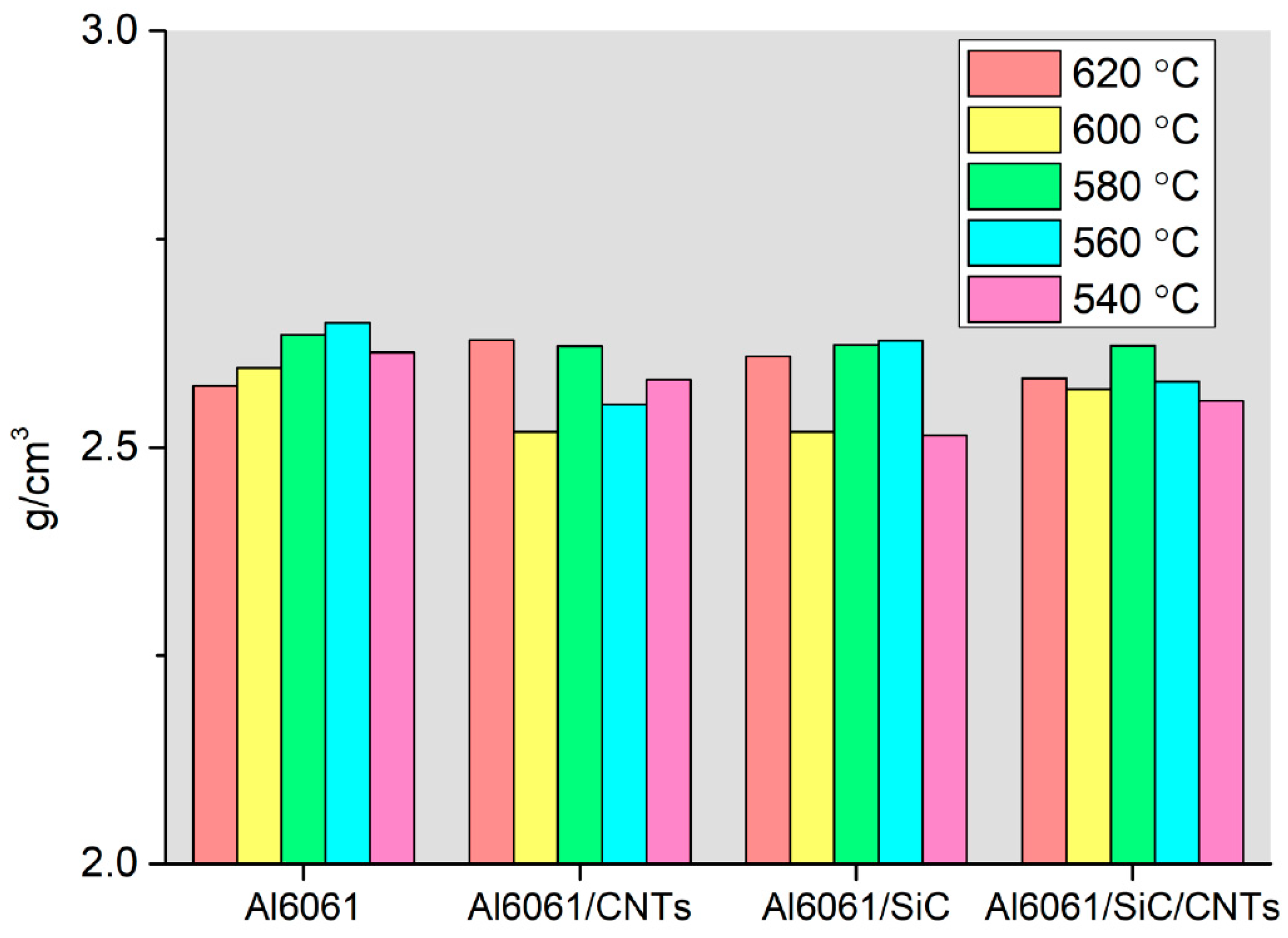

The hybrid nanocomposites were produced at different sintering temperatures.

Figure 11 shows the density of the hybrid nanocomposites for the different sintering temperatures. The density for the matrix and the nanocomposites reinforced only with SiC and CNTs is also shown for comparison purposes. The sintering temperature where the greatest densification is obtained is 580 °C; for this reason, it was selected to produce the hybrid nanocomposites.

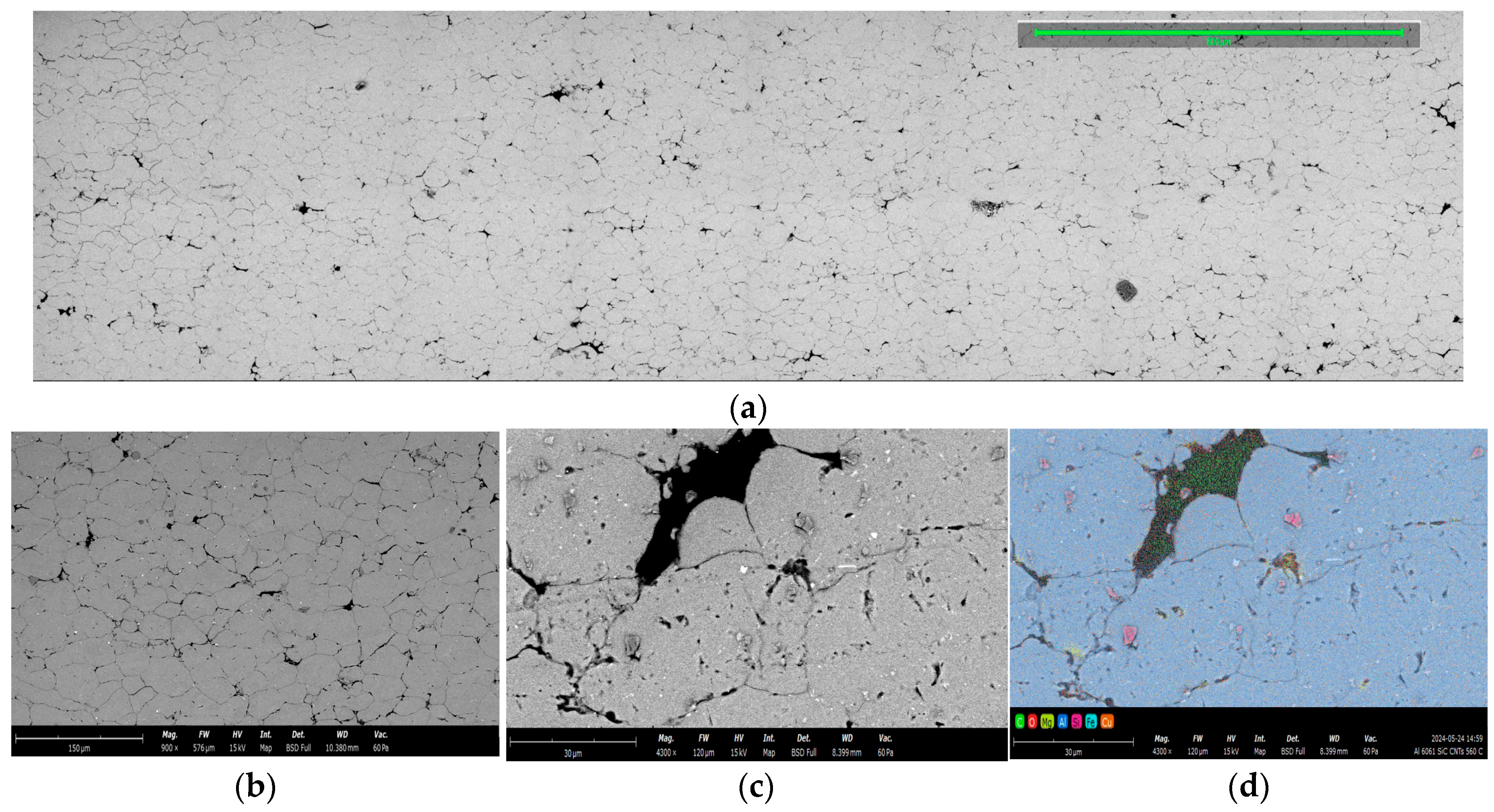

The microstructure of the hybrid nanocomposites was analyzed using SEM, EDS and EBSD.

Figure 12 shows the SEM images of the composite at different magnifications. It can be observed that the SiC particles are uniformly distributed within the matrix, while the CNTs form a network-like structure, reinforcing the matrix along the grain boundaries. No significant agglomeration of CNTs was detected, suggesting that the selected processing technique achieved effective dispersion. The higher magnification SEM image shows that dark spots and regions may correspond to the SiC or CNT clusters. The EDS map reveals the distribution of elements (Al, Fe, Mg, and Si) within the observed microstructure. Each color represents a different element, allowing for a visual correlation between the presence of specific elements and the microstructural features. For example, Si (silicon) might be concentrated around the SiC particles and combined with Fe in secondary phases.

In addition to the mechanical properties, the addition of reinforcements has a significant impact on the microstructure of the matrix. The microstructure of the nanocomposites was investigated in detail using EBSD.

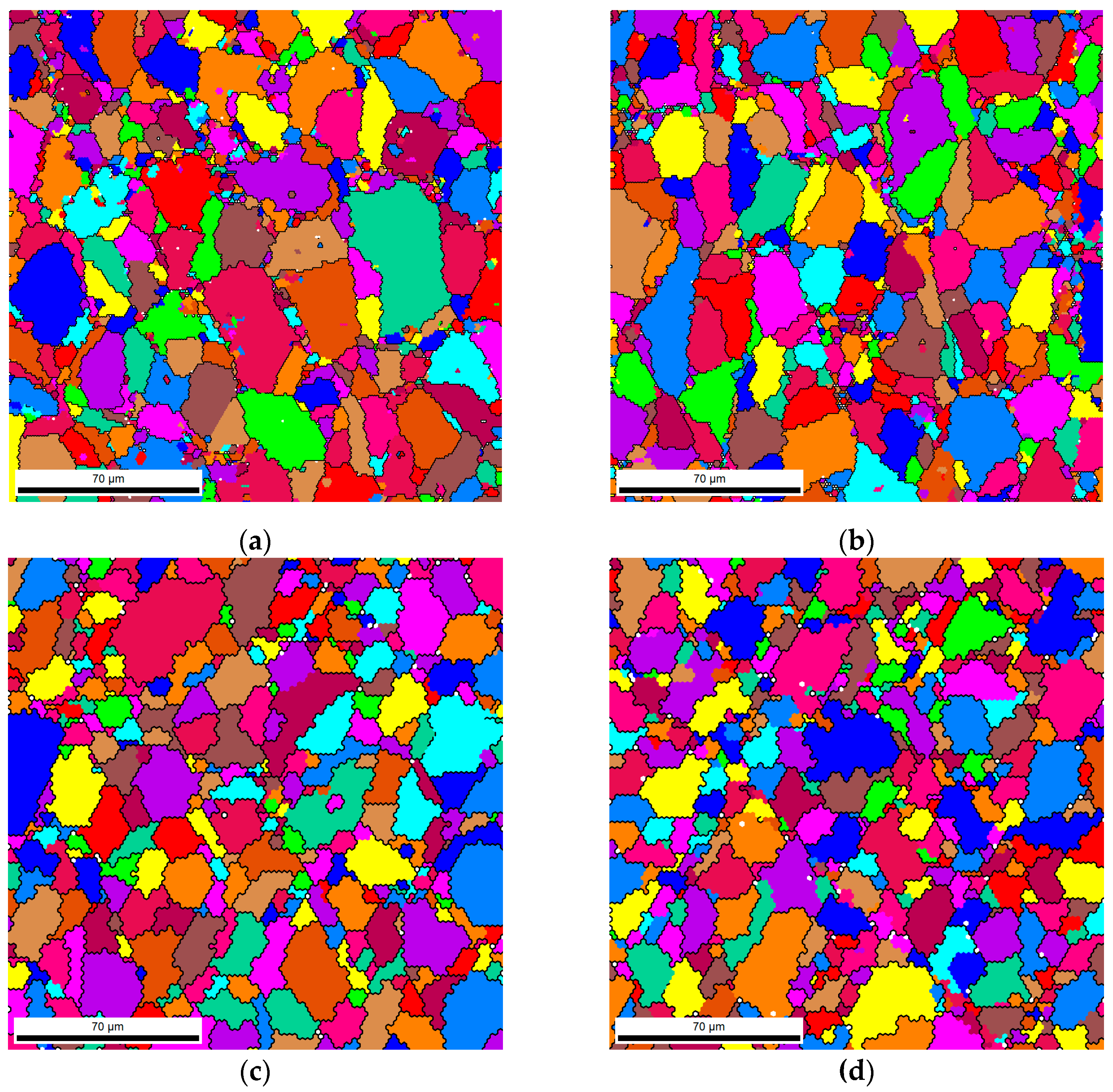

Figure 13 shows the unique color maps for Al6061, Al6061/CNTs, Al6061/SiC, and Al6061/SiC/CNTs. Using the unique color maps to represent grains helps visualize the impact of different reinforcements on grain refinement. The addition of SiC has a stronger effect on grain size reduction than CNTs, and the hybrid Al/SiC/CNTs configuration shows the most refined microstructure. This refined grain structure enhances the resulting nanocomposites’ mechanical performance, such as increased hardness, yield strength, and wear resistance.

Moreover, incorporating SiC particles resulted in grain refinement, as evidenced by the smaller grain sizes in the composite compared to the unreinforced Al6061 alloy. The fine dispersion of SiC likely acted as a barrier to grain growth during solidification, contributing to this observed refinement. CNTs may have further restricted grain boundary movement through a pinning effect, synergistically enhancing the microstructural refinement.

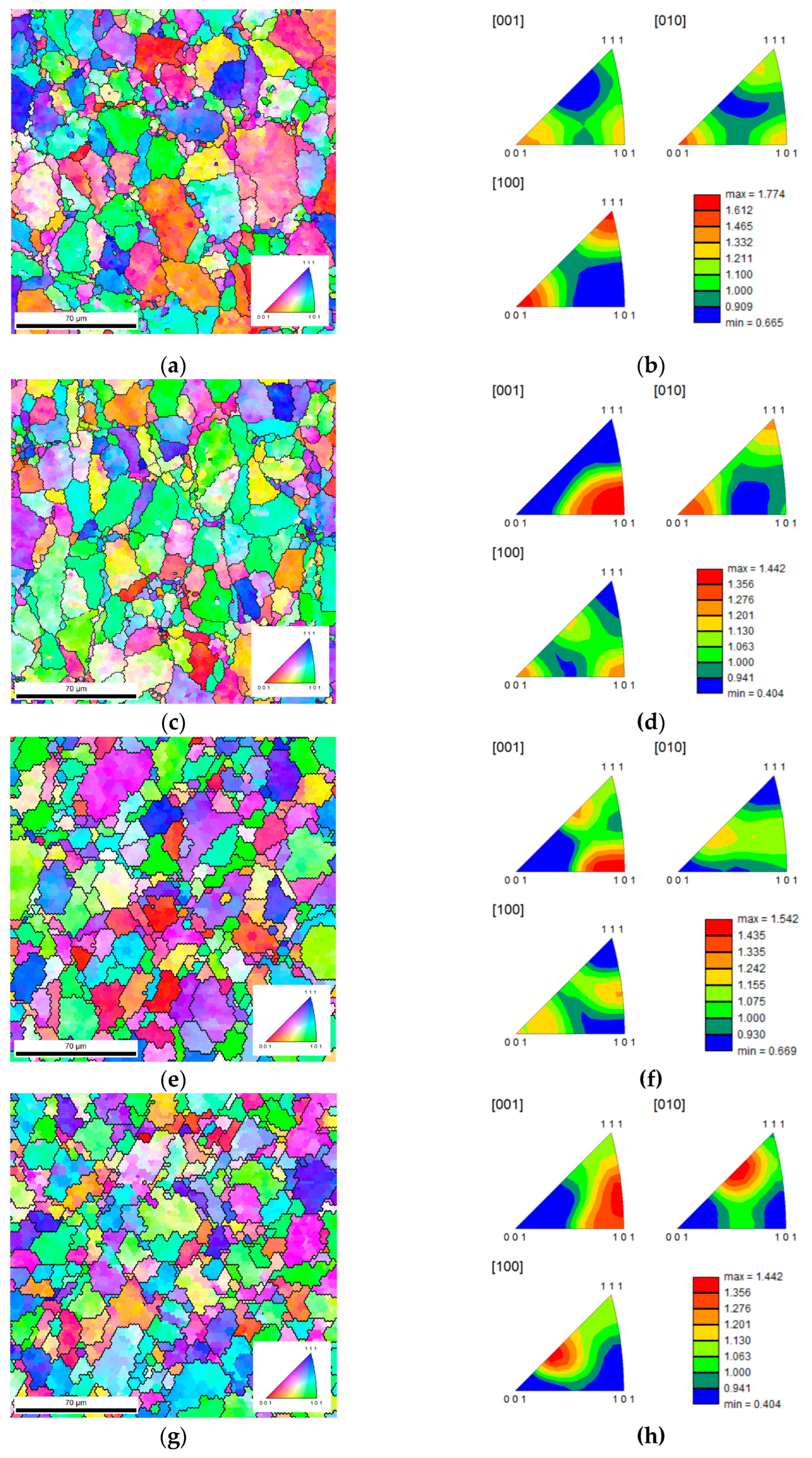

Inverse pole figure (IPF) maps the corresponding IPF orientation distribution function figures of the Al6061 matrix, and the different reinforced nanocomposites with CNTs, SiC, and hybrid are present in

Figure 14. The IPF maps are color-coded to display grain crystallographic orientation in the materials, while figures show the intensity of specific crystallographic orientations within the material. Based on these results, the impact of different reinforcements on the grain orientation and microstructure of the Al6061 matrix is clear. Adding CNTs and SiC particles, individually and in combination, significantly refines the grain structure and modifies the crystallographic texture.

The Al/SiC/CNTs configuration exhibits the most refined microstructure and the strongest texture, suggesting potential for superior mechanical properties, including increased hardness, strength, and possibly improved thermal stability and wear resistance. This influence in the crystallographic orientation of the metallic matrix grains can be explained by reinforcements, which create significant internal stresses in the matrix due to differences in mechanical properties, such as the modulus of elasticity and hardness. These internal stresses alter the distribution of forces within the grains, resulting in crystallographic reorientations to accommodate the local deformation. As a result, the grains near the reinforcements tend to realign, changing their orientations to balance the stress distribution. The high density of dislocations generated by the reinforcement particles can induce the formation of subgrains within the existing grains. These subgrains, which have slight orientation differences, arise to relieve the accumulated stress. Some subgrains may reorganize and reorient as the deformation continues, leading to new crystallographic orientation patterns. This reorientation is more pronounced when a combination of reinforcements, such as CNTs and SiC, synergistically affects the dislocation movement. The distribution of reinforcement particles influences the overall grain orientation in the material.

The reinforcement particles can favor certain crystallographic orientations that minimize interfacial energy, promoting, for example, the formation of preferred textures. Therefore, adding reinforcements can lead to a stronger and more organized texture, especially in hybrid materials that combine different types of reinforcements, such as the Al/SiC/CNTs configuration. The reinforcements act as barriers to the movement of grain boundaries, restricting the ability of grains to freely reorganize under deformation. This restriction leads to the accumulation of deformation energy at the grain boundaries, forcing the grains to change their orientations to relieve this accumulated energy. The result is a significant modification in crystallographic orientation, with an increase in the number of high-angle grain boundaries and greater structural complexity.

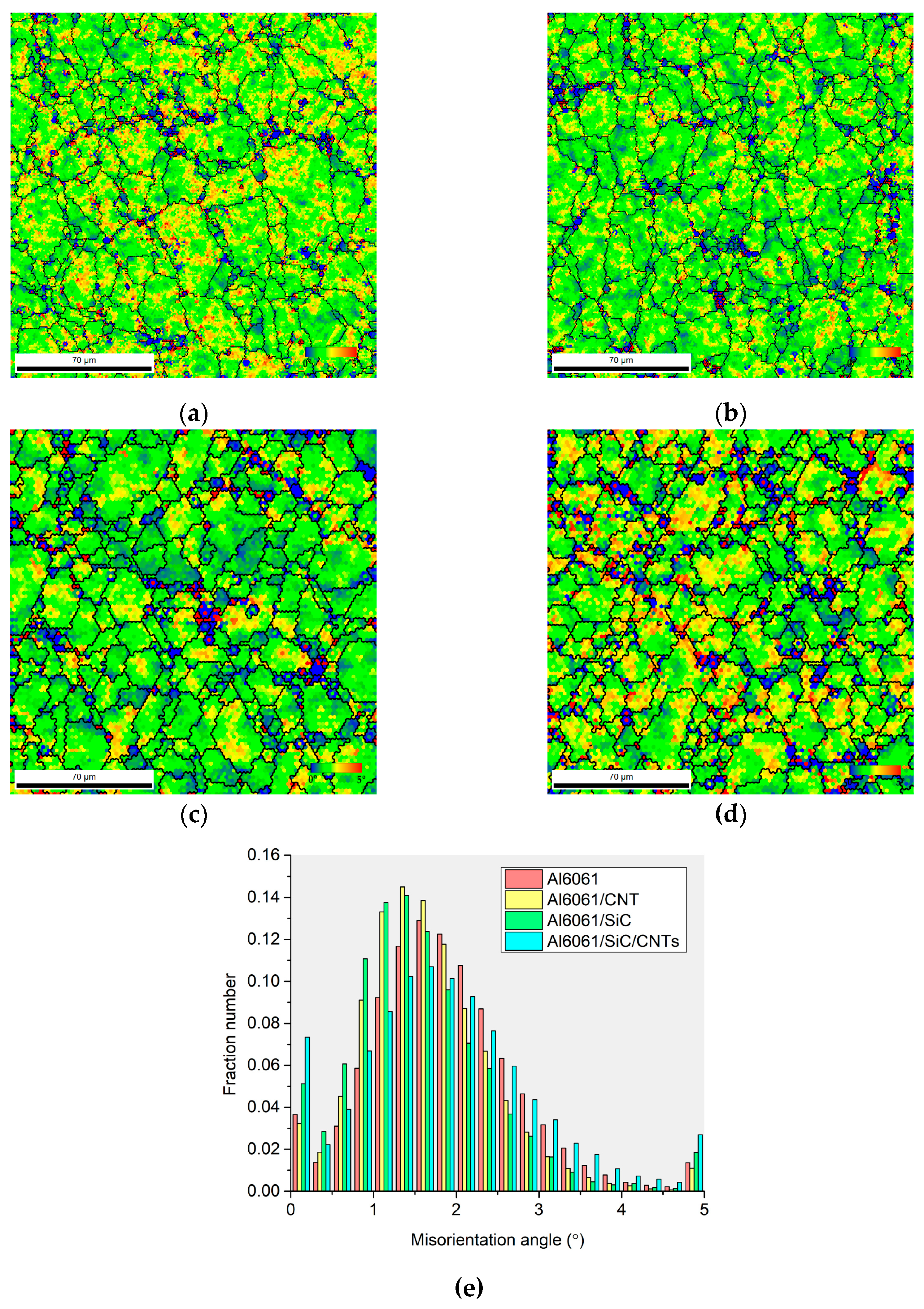

The Kernel average misorientation (KAM) maps of four samples and a histogram showing the distribution of KAM misorientation angles are present in

Figure 15.

For the matrix, the map shows the grain boundaries and internal misorientation, which are primarily green, indicating a relatively homogeneous microstructure. For the nanocomposites reinforced with CNTs, the distribution of colors suggests a slight change in the misorientation pattern, with more blue and red areas, indicating variations in strain or dislocation density compared to the pure Al6061 matrix. The Al6061 matrix reinforced with SiC revealed a KAM map with more prominent red and yellow areas, suggesting a higher misorientation in certain regions, which could indicate increased strain due to the presence of hard SiC particles. For the hybrid nanocomposites, the KAM map shows a more complex distribution of colors, with a mixture of high (red) and low (green) misorientations, indicating that the combination of reinforcements has a notable effect on the internal microstructure. The Al6061 matrix has the highest frequency at lower misorientation angles, while the Al6061/SiC/CNTs hybrid composite has a broader distribution, indicating a more heterogeneous strain distribution. The trend shows how different reinforcements affect the internal strain and dislocation patterns of the Al6061 matrix.

Adding reinforcements in the matrix, such as SiC particles or carbon nanotubes (CNTs), causes a significant increase in dislocations and the average misorientation angle within the grains. This effect can be explained based on the interaction between the reinforcements and the metallic matrix during solidification and subsequent plastic deformation processes. The reinforcements, especially the SiC particles, have much higher elasticity and hardness modulus than the aluminum matrix (Al6061). This generates incompatibility in the regions near the reinforcements, resulting in internal stresses and localized deformations. To accommodate these stresses, additional dislocations form, especially at the matrix-reinforcement interfaces. The reinforcement particles act as physical barriers to the movement of dislocations. When a dislocation encounters a rigid particle, it accumulates, increasing the density of dislocations near these regions. This effect leads to a local buildup of stress, which can be partially relieved by forming new dislocations in the remaining matrix, resulting in a more refined structure.

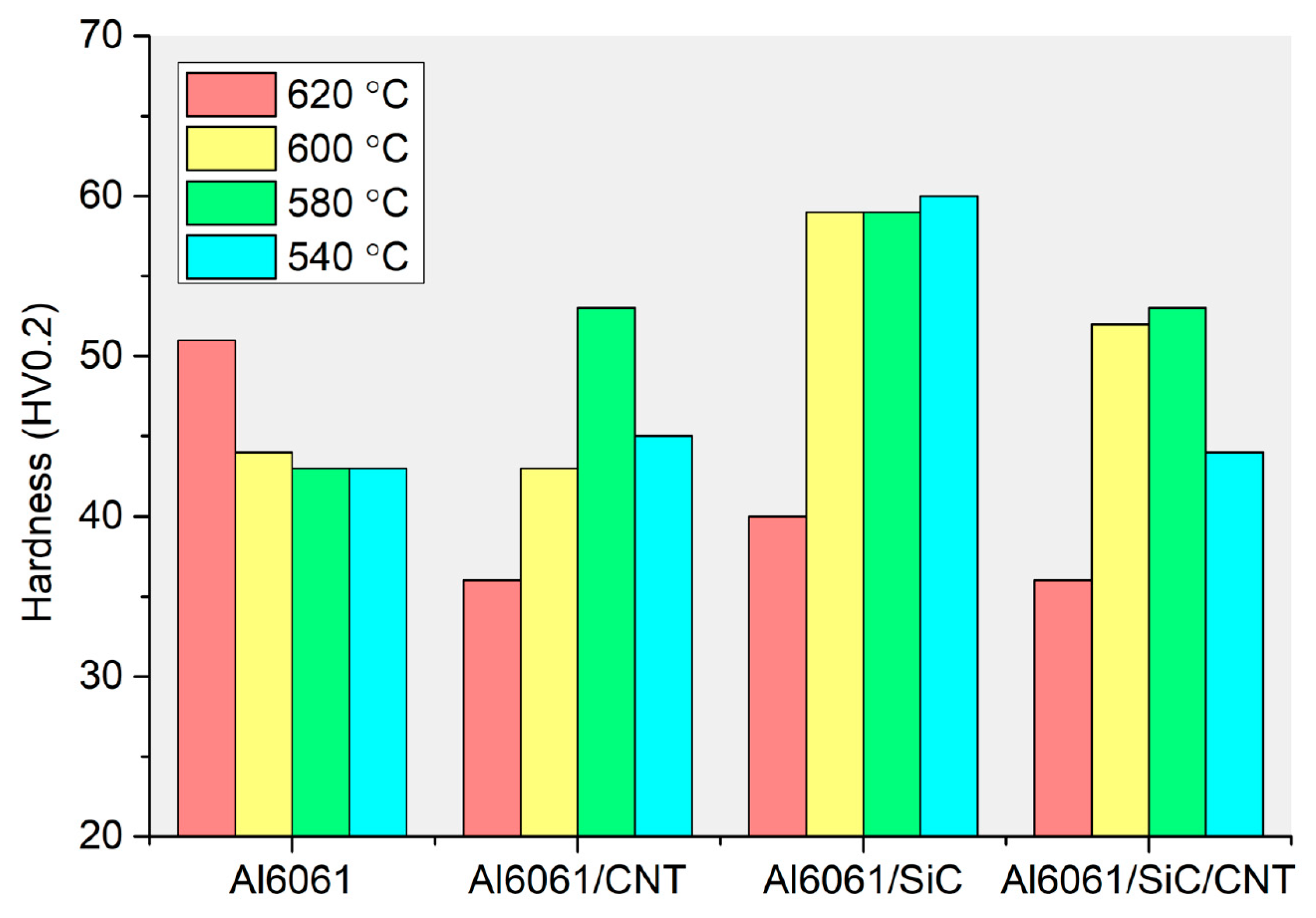

The hardness evolution of Al6061-based composites sintered at different temperatures can be analyzed in

Figure 16 by considering the reinforcing effects of CNTs and SiC particles on the Al6061 matrix. Due to its relatively homogeneous microstructure, the Al6061 matrix typically shows the lowest hardness values across all sintering temperatures. As the sintering temperature increases, the hardness might initially rise due to densification but may decrease at higher temperatures due to grain growth. The addition of CNTs generally improves the hardness of the Al6061 matrix due to the strengthening effect of the nanoscale reinforcement and its ability to hinder dislocation motion. The CNTs can remain well-dispersed at lower sintering temperatures, reinforcing the matrix. However, CNT agglomeration or reaction with the matrix at higher sintering temperatures can reduce their strengthening effect, potentially decreasing hardness. SiC particles significantly enhance the hardness of the Al6061 matrix due to their high hardness and ability to act as barriers to dislocation movement. The improvement in hardness is more pronounced at all sintering temperatures than the CNT reinforcement. SiC particles can maintain their reinforcing effect at high sintering temperatures better than CNTs, as they are less prone to degradation or agglomeration. At lower sintering temperatures, hardness is primarily influenced by the matrix’s distribution and dispersion of reinforcements. As the sintering temperature increases, hardness can increase due to improved bonding and matrix densification. At higher temperatures, grain growth and potential degradation of reinforcements (e.g., CNTs) can decrease hardness.

Table 4 demonstrates the impact of different reinforcements on the mechanical properties of Al6061. The Al6061/CNTs/SiC hybrid composite achieves the best overall strength but at the expense of ductility. Each reinforcement type (CNTs, SiC, and hybrid) improves tensile strength compared to the pure Al6061 matrix but reduces elongation, with the hybrid configuration providing a balance between the two properties. The Al6061 matrix has the lowest tensile strength, measuring 63 MPa. The addition of MWCNTs significantly enhances the tensile strength to 87 MPa, showing the strengthening effect of the carbon nanotubes. Al6061/SiC composite exhibits an even higher tensile strength of 96 MPa, indicating that SiC particles are more effective at improving the load-bearing capacity of the matrix. The hybrid composite (Al6061/CNTs/SiC) shows the highest tensile strength of 104 MPa, suggesting a synergistic effect between CNTs and SiC in strengthening the matrix. The Al6061 matrix shows the highest elongation value of 8.2%, indicating good ductility. Adding MWCNTs decreases the elongation to 4.4%, reflecting the typical trade-off between strength and ductility as CNTs increase tensile strength but reduce flexibility. The Al6061/SiC composite has an even lower elongation of 3.2%, due to the inherent brittleness of SiC particles. The hybrid configuration (Al6061/CNTs/SiC) slightly improved elongation to 3.4% compared to the SiC-only composite, possibly due to the reinforcing effect of CNTs mitigating some of the brittleness introduced by SiC.

5. Conclusions

The production and characterization of hybrid composites based on the Al6061 alloy reinforced with carbon nanotubes (CNTs) and silicon carbide (SiC) particles have demonstrated that incorporating multiple reinforcements leads to significant enhancements in the material’s mechanical properties. Adding individual reinforcements, such as CNTs or SiC, contributed to increased tensile strength and hardness due to the combined effects of grain refinement, load transfer, and barriers to dislocation movement. However, the hybrid configuration (Al6061/CNTs/SiC) exhibited the most pronounced improvements, showcasing superior tensile strength and a more refined microstructure, indicating a synergistic effect between the two reinforcements.

While the increase in strength is evident, a reduction in ductility was observed for all reinforced composites compared to the unreinforced Al6061 matrix, with the hybrid composites displaying a moderate compromise between strength and elongation. This behavior is attributed to the high stiffness and hardness of SiC particles, coupled with the enhanced load transfer capability of the CNTs. The results suggest that the hybrid composites are particularly suitable for applications where high strength and wear resistance are critical, but moderate ductility can be tolerated.

Overall, the successful production of Al6061/CNTs/SiC hybrid composites using powder metallurgy and subsequent characterization indicates that these materials possess great potential for advanced engineering applications. Future work should optimize the dispersion and bonding of reinforcements within the matrix to further enhance mechanical performance and explore the impact of different sintering conditions and reinforcement ratios on the microstructural evolution and overall properties of the composites.

Author Contributions

Conceptualization, SS; methodology, SS; validation, SS..; formal analysis, BM; investigation, BM; writing—original draft preparation, BM; writing—review and editing, SS..; visualization, BM; supervision, SS; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data can be made available upon request to the authors.

Acknowledgments

The authors are grateful to CEMUP—Centro de Materiais da Universidade do Porto—for the expert assistance with SEM.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mattli, M.; Reddy, M.; Khan, A.; Abdelatty, R.; Yusuf, M.; Ashraf, A.; Kotalo, R.; Shakoor, A. Study of microstructural and mechanical properties of Al/SiC/TiO2 hybrid nanocomposites developed by microwave sintering. Crystals 2021, 11, 1078. [Google Scholar] [CrossRef]

- Moustafa, E.; Taha, M. The effect of mono and hybrid additives of ceramic nanoparticles on the tribological behavior and mechanical characteristics of an Al-based composite matrix produced by friction stir processing. Nanomaterials 2023, 13, 2148. [Google Scholar] [CrossRef] [PubMed]

- Anitha, P.; Rao, M. Influence of titanium diboride and graphite on microstructure characteristics and mechanical behaviors of aluminium hybrid nanocomposites. Proc. Inst. Mech. Eng. Part E 2022, 236, 2071–2081. [Google Scholar] [CrossRef]

- Džunić, D.; Pantić, M.; Mitrović, S.; Babic, M.; Savić, S.; Đorđević, A.; Arsić, A. Assessment of tribological behaviour of ZA-27 zincaluminium alloy based nanocomposite. Proc.Eng. Sci. 2019, 1, 145–153. [Google Scholar] [CrossRef]

- Singh, A.; Yadav, G.; Gupta, P. Correlation of structural and mechanical properties for ultrasonically stir casted al6061 reinforced SiC-AlN hybrid metal matrix composites. Ecs J. Solid State Sci Technol 2023, 12, 057008. [Google Scholar] [CrossRef]

- Iyengar, S.; Sethuram, D.; Shobha, R.; Koppad, P. Microstructure, microhardness, and tensile properties of hot-rolled al6061/TiB2/CeO2 hybrid composites. J. South. Afr. Inst. Min. Metall. 2021, 121, 1–6. [Google Scholar] [CrossRef]

- Gireesh, C.; Prasad, K.; Ramji, K. Experimental investigation on mechanical properties of an Al6061 hybrid metal matrix composite. J. Compos. Sci. 2018, 2, 49. [Google Scholar] [CrossRef]

- Kumar, R. Optimizing Al6061-based hybrid metal matrix composites: unveiling microstructural transformations and enhancing mechanical properties through Ni and Cr reinforcements. Evergreen 2023, 10, 2161–2172. [Google Scholar] [CrossRef]

- Kumar, V.; Nagegowda, K.; Boppana, S.; Sengottuvelu, R.; Palanikumar, K. Wear behavior of aluminium 6061 alloy reinforced with coated/uncoated multiwalled carbon nanotube and graphene. J. Met. Mater. Miner. 2021, 31. [Google Scholar] [CrossRef]

- Soni, S.; Thomas, B. Influence of TiO2 and MWCNT nanoparticles dispersion on microstructure and mechanical properties of Al6061 matrix hybrid nanocomposites. Mater. Res. Express 2020, 6, 1265f3. [Google Scholar] [CrossRef]

- Kinloch, I.; Suhr, J.; Lou, J.; Young, R.; Ajayan, P. Composites with carbon nanotubes and graphene: an outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef] [PubMed]

- Reddy, A.; Krishna, P.; Rao, R. Tribological behaviour of Al6061–2SiC-xGr hybrid metal matrix nanocomposites fabricated through ultrasonically assisted stir casting technique. Silicon 2019, 11, 2853–2871. [Google Scholar] [CrossRef]

- Meignanamoorthy, M.; Ravichandran, M.; Mohanavel, V.; Afzal, A.; Sathish, T.; Alamri, S.; Khan, S.; Saleel, C. Microstructure, mechanical properties, and corrosion behavior of boron carbide reinforced aluminum alloy (Al-Fe-Si-Zn-Cu) matrix composites produced via powder metallurgy route. Materials 2021, 14, 4315. [Google Scholar] [CrossRef] [PubMed]

- Rashid, A. Nanotechnology-enhanced fiber-reinforced polymer composites: recent advancements on processing techniques and applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, B.; Simões, S. Optimization of Al6061 Nanocomposites Production Reinforced with Multiwalled Carbon Nanotubes. J. Compos. Sci. 2024, 8, 381. [Google Scholar] [CrossRef]

- Carneiro, Í.; Monteiro, B.; Ribeiro, B.; Fernandes, J.V.; Simões, S. Production and Characterization of Cu/CNT Nanocomposites. Appl. Sci. 2023, 13, 3378. [Google Scholar] [CrossRef]

Figure 1.

Schematic representation of the hybrid nanocomposite production process via powder metallurgy.

Figure 1.

Schematic representation of the hybrid nanocomposite production process via powder metallurgy.

Figure 2.

Schematic representation of the hardness indentation on polished cross-sections of the nanocomposites.

Figure 2.

Schematic representation of the hardness indentation on polished cross-sections of the nanocomposites.

Figure 3.

Scanning electron microscopy (SEM) image in secondary electron mode of the Al6061 as-received powders.

Figure 3.

Scanning electron microscopy (SEM) image in secondary electron mode of the Al6061 as-received powders.

Figure 4.

EBSD results of an Al6061 powder particle (a) unique color map, (b) inverse pole figure map, (c) Kernel average misorientation map, and (d) Image quality map with grain boundaries delimitated.

Figure 4.

EBSD results of an Al6061 powder particle (a) unique color map, (b) inverse pole figure map, (c) Kernel average misorientation map, and (d) Image quality map with grain boundaries delimitated.

Figure 5.

High-resolution (TEM) image of an MWCNT showing details of the number of walls.

Figure 5.

High-resolution (TEM) image of an MWCNT showing details of the number of walls.

Figure 6.

SEM image of the SiC nanoparticles used as reinforcement material.

Figure 6.

SEM image of the SiC nanoparticles used as reinforcement material.

Figure 7.

Evolution of hardness (HV0.2) of the nanocomposites with the different amounts of the reinforcement.

Figure 7.

Evolution of hardness (HV0.2) of the nanocomposites with the different amounts of the reinforcement.

Figure 8.

SEM images of the nanocomposites reinforced with SiC with (a) 0.50%, (b) 0.75%, and (c) 1.00% wt.

Figure 8.

SEM images of the nanocomposites reinforced with SiC with (a) 0.50%, (b) 0.75%, and (c) 1.00% wt.

Figure 9.

SEM images of the nanocomposites of the SiC reinforced with (a) 0.50 wt.%; (b) 0.75 wt.%; (c) 1.00 wt.% and (d) 1.50 wt.%.

Figure 9.

SEM images of the nanocomposites of the SiC reinforced with (a) 0.50 wt.%; (b) 0.75 wt.%; (c) 1.00 wt.% and (d) 1.50 wt.%.

Figure 10.

(a) SEM image of Al6061 matrix and EDS elemental distribution map of: (b) Al; (c) Fe; (d) Mg and (e) Si.

Figure 10.

(a) SEM image of Al6061 matrix and EDS elemental distribution map of: (b) Al; (c) Fe; (d) Mg and (e) Si.

Figure 11.

The density of the Al6061 matrix and Al6061 reinforced with CNTs, SiC, and SiC/CNTs for the different sintered temperatures.

Figure 11.

The density of the Al6061 matrix and Al6061 reinforced with CNTs, SiC, and SiC/CNTs for the different sintered temperatures.

Figure 12.

(a) low magnification SEM image of Al6061/SiC/CNTs produced at 580 ºC; (b, c) higher magnification SEM images and (d) EDS elemental distribution map of Al, Fe; Mg, C, O, Si and Cu.

Figure 12.

(a) low magnification SEM image of Al6061/SiC/CNTs produced at 580 ºC; (b, c) higher magnification SEM images and (d) EDS elemental distribution map of Al, Fe; Mg, C, O, Si and Cu.

Figure 13.

Unique color map of (a) Al6061 matrix (b) Al6061/CNTs; (c) Al6061/SiC; (d) Al6061/SiC/CNTs.

Figure 13.

Unique color map of (a) Al6061 matrix (b) Al6061/CNTs; (c) Al6061/SiC; (d) Al6061/SiC/CNTs.

Figure 14.

Inverse pole figures (IPF) maps and IPF figures of (a, b) Al6061 matrix, (b,c) Al6061/CNTs; (e,f) Al6061/SiC; (g,h) Al6061/SiC/CNTs.

Figure 14.

Inverse pole figures (IPF) maps and IPF figures of (a, b) Al6061 matrix, (b,c) Al6061/CNTs; (e,f) Al6061/SiC; (g,h) Al6061/SiC/CNTs.

Figure 15.

KAM maps of (a) Al6061 matrix, (b) Al6061/CNTs, (c) Al6061/SiC, (d) Al6061/SiC/CNTs, and (e) distribution of KAM misorientation angle for all samples.

Figure 15.

KAM maps of (a) Al6061 matrix, (b) Al6061/CNTs, (c) Al6061/SiC, (d) Al6061/SiC/CNTs, and (e) distribution of KAM misorientation angle for all samples.

Figure 16.

The evolution of hardness of the Al6061 matrix and Al6061 reinforced with CNTs, SiC, and SiC/CNTs for the different sintered temperatures.

Figure 16.

The evolution of hardness of the Al6061 matrix and Al6061 reinforced with CNTs, SiC, and SiC/CNTs for the different sintered temperatures.

Table 1.

Chemical composition (wt.%) of aluminum alloy 6061 as-received powder.

Table 1.

Chemical composition (wt.%) of aluminum alloy 6061 as-received powder.

| Al |

Mg |

Cu |

Si |

| 97.9 |

1.0 |

0.7 |

0.4 |

Table 2.

Chemical composition (wt.%) of SiC powder obtained by EDS.

Table 2.

Chemical composition (wt.%) of SiC powder obtained by EDS.

Table 3.

Phase percentages and pores and SiC agglomerates of the Al6061 matrix and nanocomposites.

Table 3.

Phase percentages and pores and SiC agglomerates of the Al6061 matrix and nanocomposites.

| |

Al8Fe2Si |

(Mg, Si)ss |

Pores+SiC agglomerates |

| Al |

0.5 |

1.3 |

1.3 |

| Al0.5wt.%SiC |

0.4 |

0.4 |

1.7 |

| Al0.75wt.%SiC |

0.8 |

0.7 |

1.6 |

| Al1.00wt.%SiC |

0.5 |

0.7 |

2.6 |

| Al1.50wt.%SiC |

0.3 |

0.7 |

3.2 |

Table 4.

Mechanical properties of matrix and nanocomposites obtained by tensile tests for samples sintered at 580 °C.

Table 4.

Mechanical properties of matrix and nanocomposites obtained by tensile tests for samples sintered at 580 °C.

| |

Tensile Strength (MPa) |

Elongation (%) |

| Al 6061 |

63 |

8.2 |

| Al 6061/MWCNTs |

87 |

4.4 |

| Al6061/SiC |

96 |

3.2 |

| Al6061/CNTs/SiC |

104 |

3.4 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).