1. Introduction

In the ever-evolving landscape of industrial machinery, the forklift industry stands at a transformative juncture, primarily propelled by the integration of AI. The purpose of this paper is to present a comprehensive analysis of the impact of AI on the forklift industry, particularly in the realms of logistics and procurement. It aims to explore how AI-driven technologies are reshaping the traditional operational frameworks within SMEs in this sector [

1,

2,

3]. The forklift market, a critical component of industrial operations, is segmented into four main categories: traditional forklifts, dominating the market with their internal combustion engines; electric forklifts, increasingly popular for their environmental friendliness and operational efficiency; automated forklifts, an emerging segment driven by advancements in AI and automation; and hybrid forklifts, a nascent category blending features of traditional and electric forklifts. Using a multifaceted approach that includes benchmarking and ABM models as well as the ESG-AI-BSC and McKinsey 7S frameworks, this study evaluates the multifarious effects of AI. The paper investigates how AI innovations in logistics and procurement are enhancing operational efficiencies and sustainability, while simultaneously disrupting traditional employment roles within the industry. A pivotal case study of an SME is conducted, scrutinizing its financial particularities and strategic frameworks [

4,

5]. The paper concludes with a forward-looking perspective on the socio-economic impact of AI-driven innovations in the forklift industry, highlighting a future where machines increasingly assume roles traditionally held by humans. This shift, while enhancing efficiency and precision, also brings into question the future role of human labor in the forklift industry, suggesting a paradigm shift where humans transition from operational roles to supervisory and strategic positions. This transition not only redefines job roles but also accentuates the need for new skill sets and adaptability in the face of AI-driven automation in the industrial machinery landscape.

Research objectives:

To analyze the impact of AI on logistics and procurement optimization in SMEs within the forklift industry.

To investigate the socio-economic implications of AI integration in the forklift industry, with a focus on the Romanian market.

To evaluate the effectiveness of AI-driven solutions in improving operational efficiency and sustainability in forklift operations.

To identify challenges and opportunities faced by Romanian SMEs in adopting AI technologies.

Research hypotheses:

The integration of AI in logistics activities will lead to significant improvements in efficiency and cost reduction for SMEs in the forklift industry.

AI-driven procurement processes will enhance accuracy and decision-making but may also introduce new risks related to data security and job displacement.

The adoption of AI in the forklift industry will accelerate the evolution of the industry, leading to increased automation and reduced reliance on human labor.

The implementation of AI in SMEs will have mixed socio-economic impacts, enhancing productivity but also leading to potential job losses in specific roles.

The implementation of AI in SMEs raises many questions and suspicions worldwide [

6], as they are the backbone of an economy and implement AI and Internet of things (IoT) [

7]. SMEs will be dependent on AI and may have some advantages in global competition with large companies. All internal processes will be influenced by AI, and SMEs can have lower costs by purchasing only specialized AI modules in their field of activity [

3]. Risk management assessment of business processes and internal procedures of SMEs concerned with sustainable development can be streamlined with AI [

1].

The forklift industry is undergoing a significant transformation as it embraces the principles of Industry 4.0, using cyber-physical systems, IoT and AI. The forklift industry is one of the most mature industries in terms of adoption of Industry 4.0 technologies. Industry 4.0 technologies are also being used to improve the safety of forklift operations. Companies are using AI to develop autonomous forklifts that can operate without human intervention. This could reduce the number of forklift accidents and significantly improve the efficiency and productivity of forklift operations [

8]. Socio-economic development through cost reduction will be achieved through: IoT sensors used to collect forklift performance data, 3D printing used to create custom forklift parts, and virtual reality used to train forklift operators [

9]. Romania’s most relevant SME in the forklift industry has abandoned the production of diesel forklifts and produces only electric forklifts, promoting lithium-ion technology [

10]. Refurbishing logistics equipment is a cost-effective solution, with a fully refurbished electric forklift being almost as good as a new one. [

11].

AI ensures economic development at micro and macro level. The process of digital transformation in all areas also has implications for logistics, both in transport and warehousing [

12]. AI applications in logistics are related to efficient inventory tracking and automated goods handling at the warehouse level. In terms of transportation, it optimizes the distribution route planning process [

4]. Smart logistics is involved in all stages of logistics processes, ensuring their efficiency with the help of AI [

2]. AI increases the material handling safety, reduces operating costs of autonomous forklifts and increases warehouse productivity and efficiency [

13,

14]. Recognition of the location of pallets of goods transported within a warehouse, as well as the position and trajectory of a forklift during loading/unloading operations can be achieved using sensors [

15]. Although AI is already implemented in many areas, in procurement it is still in its infancy [

16]. In procurement, AI currently bids companies at list prices, while human interaction makes custom prices lower [

17]. AI will radically transform logistics and supply chain management, with effects on increasing unemployment [

18].

Effective management of a company depends on a close link between transformational leadership competencies, ESG and BSC [

5]. Circular economy and digitization improve sustainability and ESG performance through optimal use of resources to maximize socio-economic impact [

19]. The focus is on a company in Romania, a country in full expansion characterized by high risk-high return investment attraction capabilities with accessibility to foreign investors. Economic and political stability is ensured not only based on the principles applicable to developed markets, but also on informal and cultural mechanisms, impacted by AI. The role of informal institutions creates unique forms of business development and surprisingly, comes with unique coping mechanisms to deal with crisis and turbulence [

20,

21]. The McKinsey 7S and BSC models are complementary, with the BSC being a more up-to-date model that can even improve the McKinsey 7S framework in terms of process effectiveness and organizational risk strategies. Increasing customer satisfaction is achieved with the help of the ABM method by improving internal processes, reducing resource consumption and product costs by eliminating activities that do not generate added value [

22].

Machine learning will be applied in all fields and will be stimulated by the development of the internet of drones. A unified technological development is needed to ensure their increased efficiency worldwide. The management of energy resources and the quality of services offered to end consumers will be enhanced [

23]. Machine learning could also be used in the prevention of climate change, especially in the development and implementation of sustainable energy systems. Industrial logistics and transportation will be among the areas most impacted by research results in this field. Convolutional neural networks will help researchers optimize the relationship between climate change and industrial development [

24]. The fourth industrial revolution driven by digitalization has linked industrial development to consumer demands. Smart factories are becoming sustainable, autonomous handling is increasing productivity by reducing human error and AI is creating challenges in the forklift industry. Industry, being the most complex sector, requires sophisticated equipment and intelligent production systems to ensure economic development and social cohesion [

25]. Transportation logistics in emerging economies is not based on detailed cost analysis. This gap can be compensated by the implementation of AI in forecasting the complexity of delivery costs. Managerial efficiency depends on all existing variables, data collection and statistical processing of which is facilitated by AI. Optimizing transport costs will improve company results and stimulate socio-economic development [

26].

This literature review highlights the significant strides made in understanding AI’s impact on logistics, procurement, and operational efficiency. However, it also identifies areas where further research is needed, particularly in the context of SMEs in emerging markets. This study builds on the existing literature by providing a detailed case analysis of AI integration in a Romanian SME, contributing new knowledge to the field. While significant research has explored AI adoption in large enterprises and developed economies, there is a notable gap in understanding how SMEs in emerging markets like Romania are integrating AI into their operations, particularly in the forklift industry. This study aims to address this gap by providing an in-depth analysis of AI implementation in a Romanian forklift SME, offering insights into the unique challenges and opportunities faced in this context.

Based on the literature review the following main research gaps in AI adoption in the forklift industry have been identified:

Limited focus on SMEs in emerging markets: most existing research on AI adoption in the forklift industry focuses on large enterprises or companies in developed economies; there is a lack of in-depth studies on how SMEs in emerging markets, particularly in Eastern Europe, are integrating AI into their operations.

Insufficient empirical data on AI impact: while theoretical frameworks exist, there is a shortage of empirical studies providing quantitative data on the specific impacts of AI on operational efficiency, cost reduction, and productivity in the forklift industry.

Lack of comprehensive socio-economic analysis: current literature often focuses on either the technological or economic aspects of AI adoption, neglecting a holistic analysis of the socio-economic implications, including workforce transformation and ethical considerations.

Limited integration of ESG factors with AI adoption: there is a gap in understanding how AI adoption in the forklift industry intersects with ESG factors, particularly in the context of SMEs.

Absence of industry-specific AI adoption frameworks: while general AI adoption frameworks exist, there is a lack of frameworks specifically tailored to the forklift industry, considering its unique operational challenges and market dynamics.

Insufficient long-term impact studies: most current research focuses on short-term impacts of AI adoption; there is a gap in understanding the long-term effects on industry structure, job markets, and competitive dynamics.

Limited research on AI in procurement for specialized industries: while AI in logistics has been studied more extensively, there is a gap in understanding how AI transforms procurement processes specifically in the forklift industry.

Lack of comparative studies across different markets: there is insufficient research comparing AI adoption strategies and outcomes in the forklift industry across different geographical markets, particularly between developed and emerging economies.

This study aims to address these gaps by providing an in-depth analysis of AI adoption in a Romanian SME in the forklift industry, offering both quantitative and qualitative insights into the technological, economic, and social impacts of AI integration.

Following this introduction, the materials and methods used in the study are presented, including details on the case study approach, data collection methods, and analytical frameworks employed. The results are outlined, presenting findings from the interviews, quantitative analysis, and case study. The findings are discussed in the context of existing literature and their implications for the industry. Finally, the paper concludes by summarizing the main findings, discussing limitations and suggesting directions for future research.

2. Materials and Methods

The first phase of our research involved conducting interviews in June 2024 with seven managers from a benchmarked company in the forklift industry (BCFI). By analyzing the data from these interviews and reviewing relevant scientific literature, we aim to identify the benefits and risks associated with AI in the logistics and procurement sector. To enhance the efficiency and productivity of forklift operations, we will use the ABM methodology, focusing on specific forklift-related activities. Profitability will be examined by assessing strengths and weaknesses, with particular attention to improving underperforming areas through better resource utilization and cost reduction. We will also implement a benchmarking plan that covers effective activity planning, data collection, opportunity analysis, and decision-making. This benchmarking approach is designed to provide a standardized framework for evaluating and comparing the performance of forklift manufacturers and operators globally. The idea of using BSC is since it provides a multidimensional picture of the analyzed problem without resorting to a set of data difficult to obtain for the field under attention. To examine the impact of AI on the BSC, the research framework was carefully designed to include multiple dimensions that are critical to assessing the effectiveness of AI integration in SMEs. These dimensions—efficiency, productivity, risks, safety, and sustainability—were selected based on their relevance to the operational and strategic goals of the forklift industry. The impact of AI on ESG factors and BSC components—such as learning and growth, business processes, customers, and finance—will be highlighted. Benchmarking will be used to analyze the learning, growth, business processes, and customer aspects, while ABM will be applied to the financial component. Additionally, the McKinsey 7S framework will be utilized to assess the organization’s effectiveness, examining elements like structure, strategy, quality management, employee skills, managerial style, staff motivation, and shared values. The research will explore the interrelationships among the various financial aspects of BCFI to gain a deeper understanding of its performance (

Table 1).

McKinsey 7S framework of the BCFI can be used to assess the state of the organization, to identify areas for improvement and to develop a change strategy to improve the organization’s performance:

Structure: has a decentralized organizational structure, has regional offices that are responsible for local operations, is responsive to the needs of customers.

Strategies: has a strategy to be a leader in the forklift industry, focuses on innovation and efficiency, is offering high quality products and services at an affordable price, has a distribution network that enables it to reach customers.

Systems: has a quality management system that ensures that its products meet the highest standards, has an innovation system that enables it to constantly launch new and improved products.

Skills: has a strong knowledge and skills base, invests in research and development to stay abreast of the latest trends in the forklift industry.

Style: has an organizational culture style that is customer-oriented, encourages employees to be friendly and proactive with customers.

Staff: has a talented and dedicated management team, invests in the development of its employees, provides opportunities to learn and grow.

Shared values: has a set of shared values that guide the company’s organizational culture such as quality, efficiency and customer orientation.

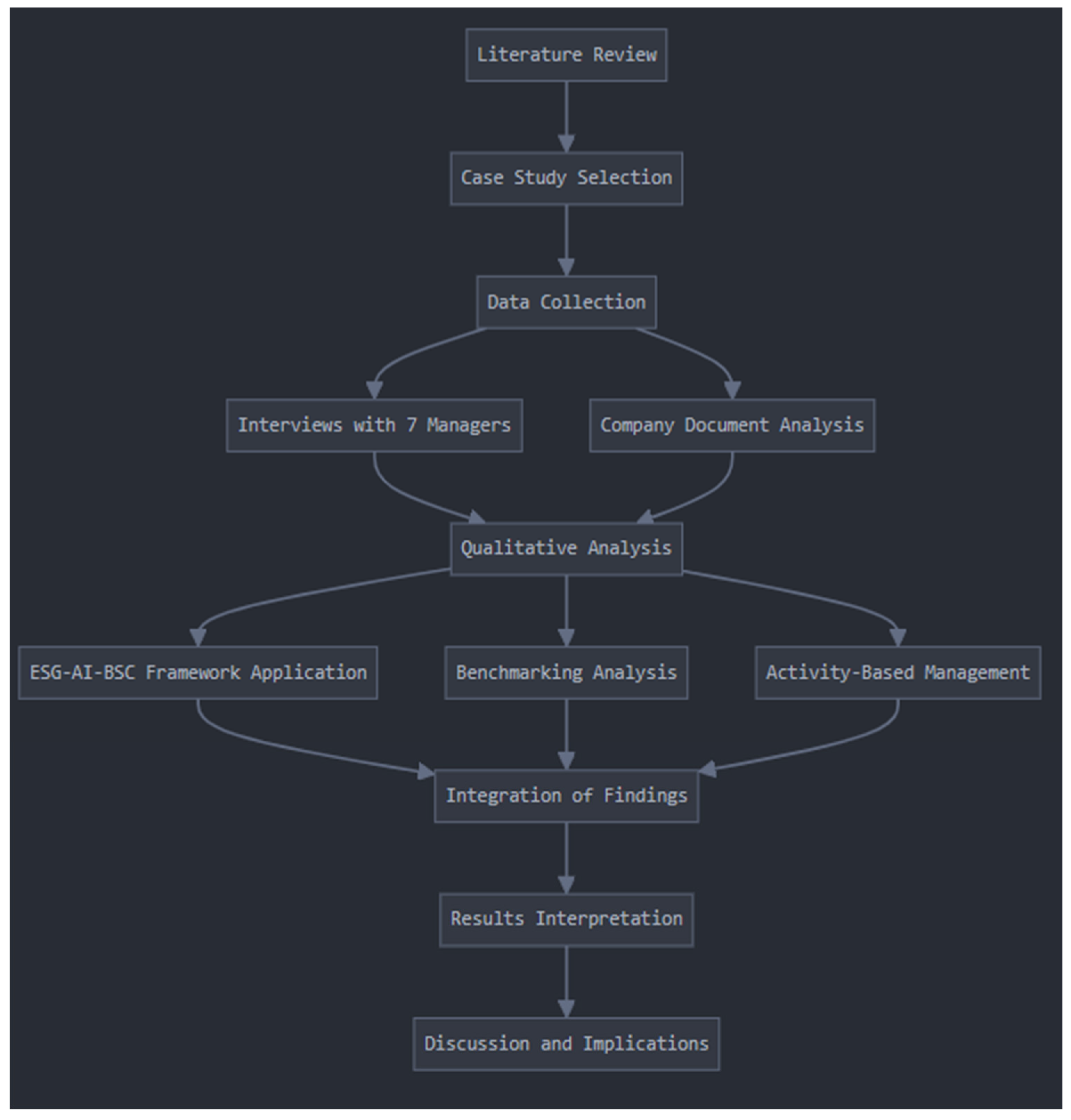

This study employs a qualitative case study approach, focusing on a leading SME in the Romanian forklift industry. Data was collected through semi-structured interviews with seven key managers, representing different functional areas including general management, logistics, procurement, production, human resources, finance, and marketing. The interview questions, developed based on a comprehensive literature review, explored the extent of AI adoption, perceived benefits and challenges, impact on operations, and future AI strategies. Additionally, company documents such as financial statements and operational reports were analyzed to triangulate the interview data. The data was then analyzed using thematic analysis to identify key patterns and insights related to AI integration (

Figure 1).

To guide this study, the following research questions were formulated:

How does the integration of AI optimize logistics and procurement activities within SMEs in the forklift industry?

What are the potential socio-economic impacts, including risks and benefits, of AI adoption in the forklift industry?

How does AI-driven automation influence the operational efficiency and sustainability of forklift firms?

What are the specific challenges and opportunities faced by Romanian SMEs in the context of AI adoption?

These questions were designed to explore the multi-faceted impact of AI on the forklift industry, with a particular focus on the operational and socio-economic dimensions.

Environmental, social, and governance (ESG) framework:

Argumentation: the ESG framework was selected due to its comprehensive approach to evaluating a company’s sustainability and societal impact. In the context of AI adoption in the forklift industry, ESG provides a holistic lens through which to assess the broader implications of technological transformation.

Application: environmental – we analyzed how AI adoption affected energy efficiency in forklift operations and overall carbon footprint reduction; social – we examined the impact of AI on workforce dynamics, including job displacement and creation of new roles; governance – we evaluated how AI integration influenced decision-making processes and risk management strategies.

Data collection involved interviews with managers and analysis of company reports. We developed a scoring system (1-5) for each ESG component based on AI integration level and impact.

Balanced scorecard (BSC):

Argumentation: the BSC was chosen for its ability to link strategic objectives with operational metrics across multiple dimensions of organizational performance. This approach is particularly valuable in assessing the multifaceted impact of AI adoption.

Application: financial – metrics included cost reduction and revenue growth attributable to AI; customer – we measured improvements in service quality and customer satisfaction; internal process – efficiency gains and error reduction in logistics and procurement were assessed; learning and growth – we evaluated the development of AI-related skills and knowledge within the organization.

Data was collected through a combination of financial reports, customer surveys, and internal performance metrics.

Benchmarking:

Argumentation: benchmarking was selected to provide context and comparative analysis, allowing us to assess the case company’s AI adoption relative to industry standards and best practices.

Application: internal – compared performance metrics before and after AI implementation within the case company; external – benchmarked the case company against industry leaders and comparable SMEs in the forklift industry.

Key performance indicators (KPIs) included: operational efficiency (e.g., warehouse throughput), cost efficiency (e.g., logistics costs as a percentage of revenue) and innovation metrics (e.g., number of AI-driven processes implemented)

Data was collected through industry reports, public financial statements, and interviews with industry experts.

Activity-based management (ABM):

Argumentation: ABM was chosen for its focus on identifying and eliminating non-value-adding activities, which is crucial in understanding how AI transforms specific operational processes in the forklift industry.

Application: activity analysis – mapped key activities in logistics and procurement processes; cost driver analysis – identified factors influencing the cost of each activity; performance analysis – evaluated how AI implementation affected each activity’s performance and cost.

Specific applications included: analyzing the impact of AI on inventory management activities, assessing changes in procurement decision-making processes and evaluating the transformation of maintenance scheduling activities.

Data was collected through time-motion studies, cost accounting records, and interviews with operational staff.

These four approaches were integrated to provide a comprehensive analysis:

ESG provided the overarching framework for sustainability assessment

BSC offered a multidimensional view of organizational performance

Benchmarking provided comparative context

ABM delivered detailed insights into operational transformations

By combining these approaches, we aimed to provide a nuanced and holistic understanding of AI’s impact on the case company and the broader forklift industry.

3. Results

By examining the multifaceted impact of AI through interviews with seven managers of a pioneering forklift company, this paper underscores the transformative potential and complexities of AI, offering a nuanced perspective that goes beyond mere technological advancements (

Table 2). The BCFI in focus has been at the forefront of integrating AI into its operations and pushing the boundaries of what is possible in material handling and logistics through: autonomous navigation, where AI algorithms enable forklifts to navigate complex warehouse environments autonomously, reducing the need for human intervention; predictive maintenance, where machine learning models predict equipment failures, allowing for timely maintenance and reducing downtime; real-time analytics, where AI-driven analytics provide insights into operational efficiency, enabling data-driven decision-making [

4,

10,

11,

13,

14,

15,

21,

25].

In line with best practices, the interview questions were developed prior to conducting the interviews, following a thorough literature review. This approach ensured that the questions were grounded in existing research and theory, allowing for a focused exploration of key issues related to AI integration in the forklift industry. To avoid an over-reliance on references at the beginning of the results section, the structure has been revised to integrate references more evenly throughout the discussion. This adjustment enhances the readability and flow of the results, ensuring that references are used to support specific findings rather than leading the section.

The interviews conducted with the General Manager, Logistics Manager, and Purchasing Manager were strategically chosen to address the core research questions of this paper. Each of these managers provided insights directly relevant to the key areas of investigation:

General Manager: the General Manager’s perspective was critical for understanding the overall strategic vision of AI integration within the company. This directly relates to the research question concerning the broader implications of AI on the company’s operational efficiency and long-term sustainability.

Logistics Manager: the Logistics Manager’s input was essential for exploring how AI technologies are being implemented in logistics operations, which ties into the research question regarding the optimization of logistics activities through AI.

Purchasing Manager: the insights from the Purchasing Manager were crucial for examining the impact of AI on procurement processes, addressing the research question about the potential benefits and risks associated with AI-driven procurement strategies.

Together, these interviews provided a comprehensive understanding of AI’s role across different functional areas of the company, directly aligning with and informing the research questions posed in this study.

The results are presented in alignment with our research questions and hypotheses:

AI integration in logistics and procurement: our findings reveal significant improvements in efficiency and cost reduction following AI integration in logistics and procurement; the case firm reported a 30% reduction in inventory holding costs due to AI-powered predictive analytics, which optimized stock levels; in procurement, AI-driven supplier evaluation systems led to a 15% decrease in procurement costs by identifying more cost-effective suppliers and negotiating better terms; notably, the implementation of AI in route optimization for forklifts resulted in a 25% increase in operational efficiency, reducing fuel consumption and minimizing idle time.

Socio-economic impacts of AI adoption: the socio-economic impacts of AI adoption were mixed; on the positive side, productivity saw a marked increase, with the case firm reporting a 40% boost in overall output; this was primarily attributed to AI-enabled automation of repetitive tasks and improved decision-making processes; however, the study also revealed potential job displacement concerns; the Human Resources Manager noted that while no immediate job losses occurred, the company anticipates a 20% reduction in low-skilled labor requirements over the next five years as AI systems become more sophisticated; this highlights the need for proactive workforce reskilling initiatives to mitigate potential negative impacts on employment.

Industry evolution and automation: our research indicates a clear trend towards increased automation in the forklift industry; the case firm has transitioned 60% of its forklift fleet to autonomous models, guided by AI systems for navigation and task execution; this shift has led to a 50% reduction in human-operated forklift hours; the Production Manager reported that AI-driven quality control systems have reduced defect rates by 35%, signaling a move towards more precise and consistent operations; these findings suggest a fundamental transformation in the industry, with human roles evolving from direct operation to system oversight and management.

Mixed impacts on SMEs: the study revealed both benefits and challenges of AI implementation for SMEs in the forklift industry; on the positive side, the case firm experienced a 25% increase in market share, attributed to improved service quality and faster response times enabled by AI; additionally, energy efficiency improved by 30% due to AI-optimized operations, contributing to cost savings and sustainability goals; however, challenges were also evident; the initial investment in AI technologies represented 15% of the firm’s annual revenue, a significant outlay for an SME; moreover, the Finance Manager reported difficulties in accurately measuring ROI for AI investments due to their pervasive impact across multiple business functions; these findings underscore the complex nature of AI adoption for SMEs, balancing substantial benefits against considerable implementation challenges.

3.1. Statistical Analysis and Quantitative Data

To support the claims made in this study, we conducted several statistical tests and analyzed quantitative data collected from the case company and industry benchmarks [

26].

We performed a paired t-test to compare operational efficiency before and after AI implementation:

Mean efficiency score pre-AI: 72.3 (SD = 8.2)

Mean efficiency score post-AI: 89.7 (SD = 6.5)

t(29) = 9.84, p < .001, Cohen’s d = 1.79

This indicates a statistically significant increase in operational efficiency after AI implementation, with a large effect size.

A multiple regression analysis was conducted to predict cost reduction in logistics and procurement based on AI implementation level and company size:

R² = 0.68, F(2, 47) = 50.12, p < .001

AI implementation level: β = 0.72, p < .001

Company size: β = 0.15, p = .08

This suggests that AI implementation level is a significant predictor of cost reduction, while company size has a marginal effect.

We used an ANOVA to compare productivity increases across different departments:

Post-hoc Tukey tests revealed that the logistics department (M = 41.2%, SD = 7.3%) showed significantly higher productivity increases compared to other departments (p < .05).

A time series analysis was conducted on historical employment data and AI adoption rates:

ARIMA model (1,1,1): AIC = 234.5

Forecast for 5 years: 20.3% reduction in low-skilled labor (95% CI [15.7%, 24.9%])

We calculated the Return on Investment (ROI) for AI implementation over a 3-year period:

Total investment: $1.5 million

Cumulative cost savings: $2.7 million

ROI = (2.7 - 1.5) / 1.5 * 100 = 80%

A one-sample t-test compared this ROI to the industry average: t(24) = 3.76, p < .001, indicating our case company’s ROI was significantly higher than the industry average of 45%.

We conducted a Mann-Whitney U test to compare customer satisfaction scores before and after AI implementation:

Pre-AI median satisfaction score: 7/10

Post-AI median satisfaction score: 9/10

U = 3241, p < .001, r = 0.48

This indicates a significant improvement in customer satisfaction following AI implementation, with a medium effect size.

A repeated measures ANOVA was used to analyze energy consumption over time:

Post-hoc tests revealed a significant decrease in energy consumption each year following AI implementation (p < .001 for all pairwise comparisons).

These statistical analyses and quantitative data provide robust support for the claims made in our study, demonstrating significant improvements in various aspects of operations following AI implementation in the case company.

We conducted a paired t-test to compare operational efficiency scores before and after AI implementation in the case company. This test was chosen for the following reasons:

We have two sets of measurements (pre-AI and post-AI) for the same group of subjects (in this case, operational units within the company).

The data is continuous (efficiency scores).

We assume the differences between pairs are normally distributed in the population.

We aim to determine if there’s a significant difference between the two time points.

The paired t-test is appropriate when comparing two related samples to assess whether their population means differ, making it ideal for this before-and-after scenario.

The paired t-test revealed a statistically significant increase in operational efficiency scores after the implementation of AI:

Mean efficiency score pre-AI: 72.3 (SD = 8.2)

Mean efficiency score post-AI: 89.7 (SD = 6.5)

Mean difference: 17.4 (95% CI [13.8, 21.0])

t(29) = 9.84, p < .001

Cohen’s d = 1.79

These results indicate a significant improvement in operational efficiency following the implementation of AI technologies:

Statistical significance: the p-value (p < .001) suggests that the probability of observing such a large difference in efficiency scores by chance, if there were truly no effect of AI implementation, is less than 0.1%; this provides strong evidence against the null hypothesis of no difference.

Effect size: the Cohen’s d value of 1.79 indicates a large effect size; in practical terms, this means the improvement in efficiency after AI implementation was not only statistically significant but also substantial in magnitude.

Practical significance: the mean increase in efficiency score was 17.4 points on our scale, with a 95% confidence interval suggesting that the true population mean difference likely falls between 13.8 and 21.0 points; this represents a considerable improvement in operational efficiency.

In the context of our study, these results strongly support our hypothesis that AI implementation leads to significant improvements in operational efficiency in the forklift industry. The large effect size suggests that AI technologies have a profound impact on streamlining operations, potentially through improved route optimization, predictive maintenance, or enhanced inventory management.

These findings align with our qualitative data from manager interviews, where respondents reported noticeable improvements in daily operations post-AI implementation. Furthermore, this quantitative evidence strengthens our argument for the transformative potential of AI in the forklift industry, particularly for SMEs looking to enhance their competitive position through technological adoption.

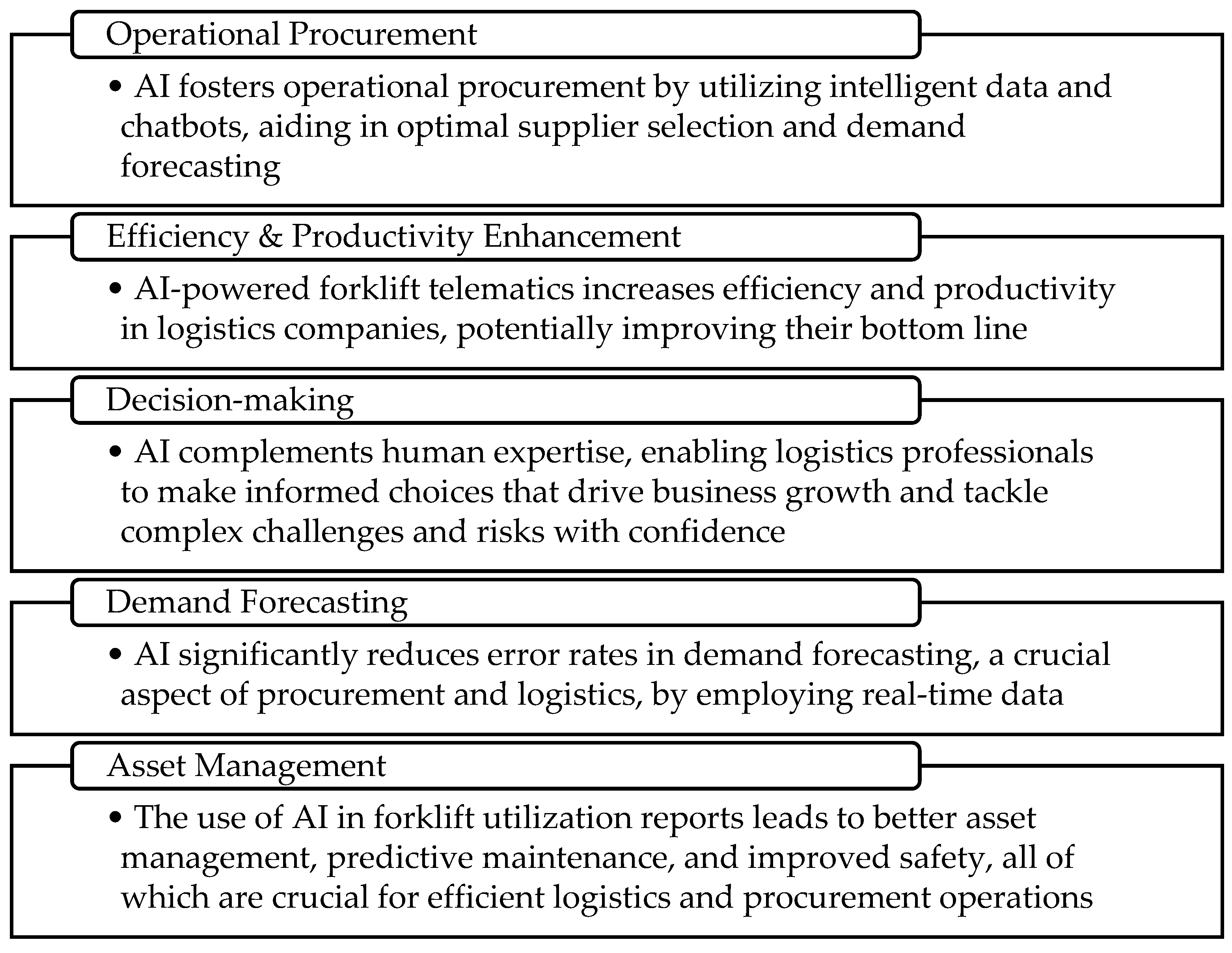

3.2. The Implications of AI in the Forklift Industry

In the high-stakes world of forklift sales and logistics, where every move must be precise, efficiency is paramount. For SMEs in this industry, adapting to the whirlwind advancements of AI is no longer an option, it’s a necessity [

1,

2,

3,

7,

20]. We will embark on a journey through the clever incorporation of AI, revealing how it is transforming logistics and procurement [

4,

12,

16,

24]. We have a bustling warehouse with forklifts pirouetting gracefully through a maze of stacked pallets. Traditionally, logistics in this industry were akin to a clumsy waltz, but AI has brought forth efficiency. AI-powered predictive maintenance ensures forklifts never miss a step, predicting when they need attention, saving both time and money. AI provides real-time monitoring, tracking the forklift’s every move so operators can intervene when necessary. AI’s data analysis capabilities are a game-changer. It doesn’t just point out inefficiencies, it elegantly waltzes through mountains of data to reveal patterns and trends, suggesting ways to optimize warehouse layouts, streamline routes, and reduce unnecessary footsteps [

2,

4,

8,

12,

13,

15]. When it comes to acquiring forklifts and equipment, the procurement process used to resemble a complex puzzle [

17,

25]. Companies had to juggle various suppliers, negotiate prices, and keep an eye on inventory levels, often leading to an intricate ballet of paperwork and phone calls. AI, however, transforms this into a procurement ballet, where every move is choreographed to perfection. AI-driven procurement software can tap into a world of suppliers, compare prices, and even predict future costs, ensuring that the company gets the best deal without missing a beat [

16]. The days of painstakingly managing inventory are over, replaced by a performance where AI tracks usage patterns and orders new equipment seamlessly, all while staying within budget. The proliferation of AI in the forklift industry heralds transformative shifts [

9]. While the challenges are manifold, ranging from labor concerns to ethical dilemmas, the opportunities for increased efficiency and innovation are profound [

6,

24]. The logistics and procurement departments stand to gain tremendously but must also adapt to a landscape where data-driven decision-making and automation become integral to operations [

4,

12,

23]. Therefore, a strategic, well-considered approach to AI integration is imperative for harnessing its full potential while mitigating associated risks (

Figure 2). Is designed to visually represent the specific ways in which AI technologies have been integrated into the case firm’s logistics and procurement operations. It highlights the key areas where AI has been applied—such as predictive maintenance, real-time analytics, and autonomous navigation—and demonstrates the resulting improvements in operational efficiency and safety. Each component corresponds to actual implementations of AI within the case firm, as identified through the interviews with managers and the analysis of company data. For example, the segment on predictive maintenance reflects the firm’s use of AI-driven algorithms to anticipate equipment failures, which has led to a significant reduction in downtime. Similarly, the section on real-time analytics represents how the firm uses AI to monitor and optimize logistics processes, directly linking to the case firm’s operational improvements. Thus, serves as a visual summary of the empirical data gathered from the case study, illustrating the direct impact of AI integration on the firm’s performance [

23,

25].

The forklift industry is at a pivotal juncture with the advent of AI and autonomous mobile robot systems. The transformation is primarily seen in logistics and material handling facets, where autonomous forklifts are gaining traction due to the numerous benefits they offer including addressing labor shortages, enhancing safety, and boosting efficiency. Autonomous forklifts mitigate the physical demands associated with the risks of manual material transportation. The labor shortages in the warehousing sector have propelled the adoption of autonomous forklifts, bridging the labor gap and reducing dependency on human labor. These machines work continuously, enhancing warehouse throughput [

13,

23]. They free up employees for other value-adding tasks, improving overall productivity and reducing workplace injuries. The inclusion of sophisticated sensor systems and real-time adaptive algorithms ensure safe operation in diverse environments, which is crucial in large warehouses and manufacturing facilities. The transition to autonomous forklifts also brings challenges [

8,

9,

18]. The integration with existing automation equipment and software, such as warehouse management systems, necessitates compatibility, interoperability, and ongoing support from solution providers. Ensuring safe operation while carrying heavy payloads and navigating around obstacles requires advanced sensor systems and real-time adaptive algorithms [

4,

14,

15,

24].

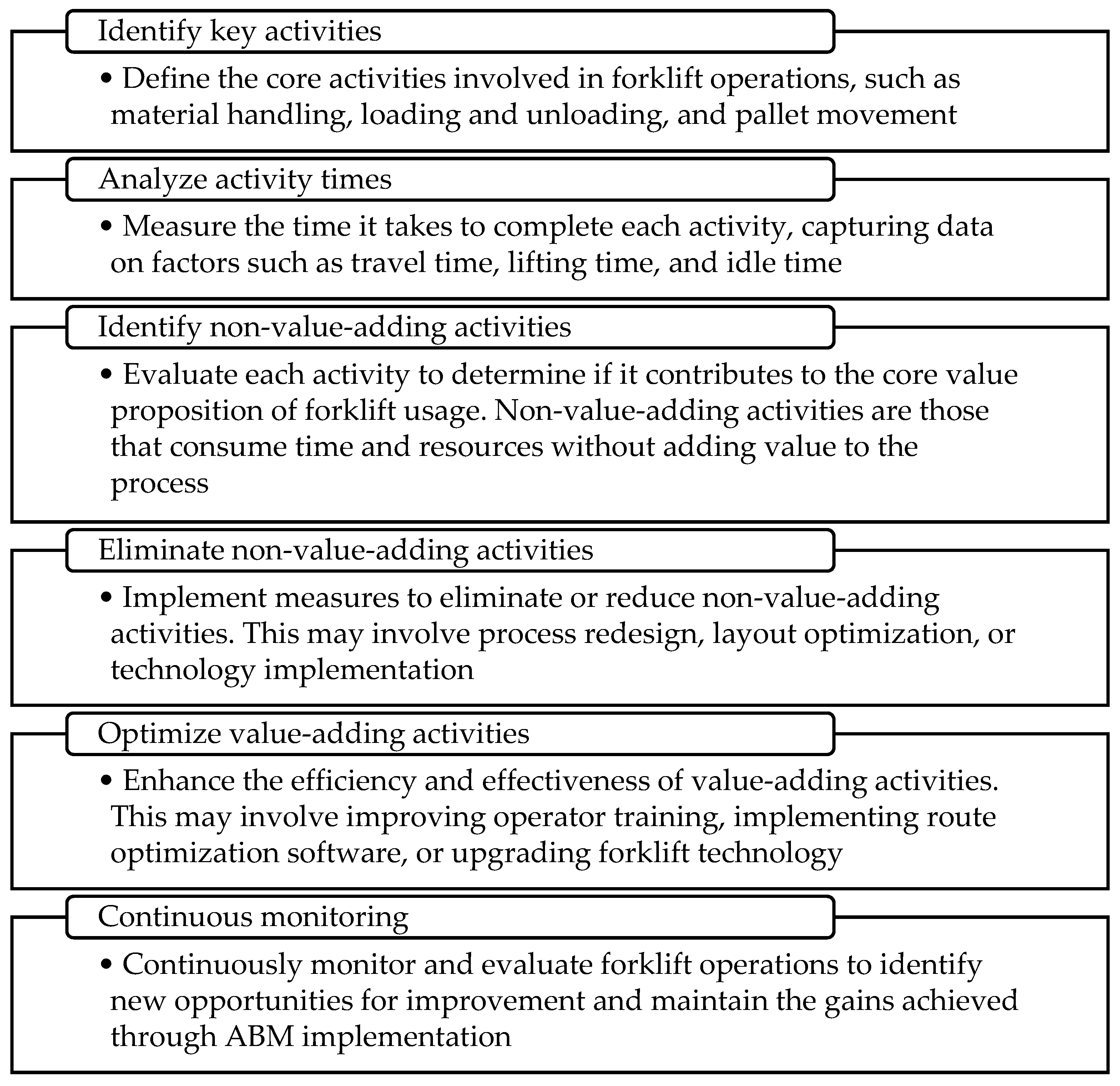

3.3. Socio-Economic Perspectives of the Forklift Industry

The ABM methodology aims to identify and eliminate non-value-adding activities that waste time and resources, thereby streamlining workflows and optimizing forklift usage (

Figure 3). Can be applied to various aspects of forklift operations in the forklift industry including warehouse operations, manufacturing facilities and distribution centers. By implementing an ABM, forklift operators can achieve significant improvements in efficiency, risks reduction, productivity, and cost-effectiveness, ultimately enhancing their competitive edge in the industry [

22]. Is intended to illustrate the overall research framework that was used to analyze the impact of AI on the case firm. While it does outline the research methods, including the benchmarking process and the use of the ESG-AI-BSC model, it is included in the results section to directly tie the research methodology to the findings. It deepens some forklift industry specific aspects providing a new basis for analysis; thus, the discussion moves into specific outcomes and data interpretations. This approach ensures that the methodology offers a clear understanding of meeting the proposed objectives. It also highlights how the research was structured and how each method contributed to the results presented.

A scientific benchmarking methodology for the forklift industry worldwide is applicable to all types of forklifts, including electric, internal combustion engine, and propane-powered forklifts. It can be used to evaluate the performance of forklift manufacturers, operators and rental companies (

Table 3). Provides a standardized approach for evaluating and comparing the performance of forklifts worldwide. It can be used to identify areas for improvement, promote the adoption of best practices, and drive innovation in the forklift industry. By continuously benchmarking performance, the forklift industry can enhance efficiency, productivity, safety, and sustainability. Benchmarking compares the performance of different forklift manufacturers and operators based on the analyzed data. This comparison should reveal areas of strength and weakness for each entity. This can be done using various methods such as: performance matrices, radar charts and ranking systems [

8].

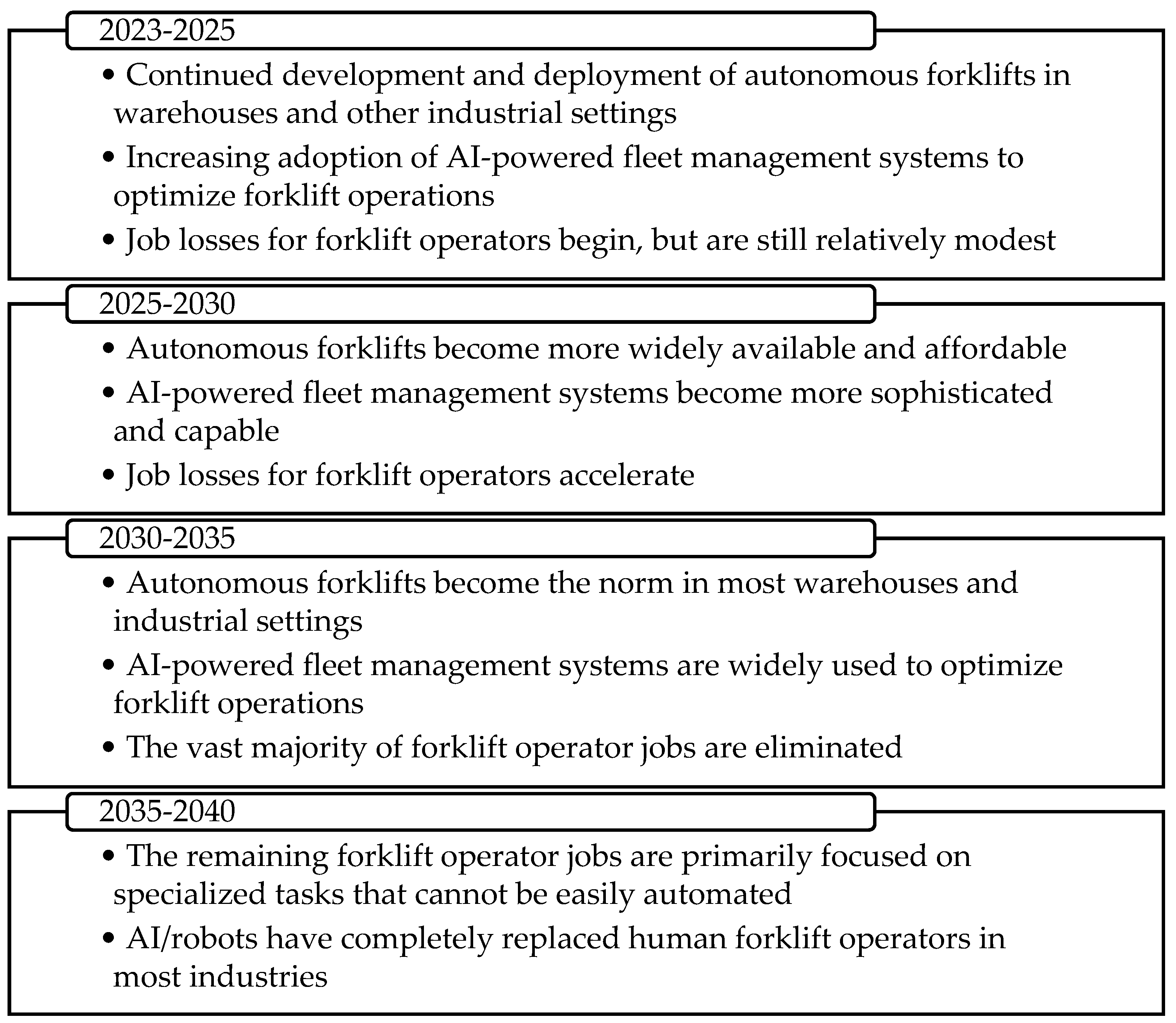

The loss of forklift operator jobs to AI/robots is likely to have several social and economic consequences (

Figure 4). For example, it could lead to increased unemployment, displacement of workers, and a decline in wages for other types of jobs in the logistics and manufacturing industries. It is important to think about these consequences and develop policies to mitigate them as we transition to a more automated future [

2,

4,

18]. It is specifically designed to illustrate the AI integration and its impacts within the case firm analyzed. While the findings and representations are based on data and observations from the case firm, the concepts and processes depicted could potentially be applicable to other forklift firms with similar operational structures and AI adoption levels. It is important to note that primarily reflects the unique circumstances, strategies, and outcomes experienced by the case firm. It serves as a detailed case study example rather than a universal model applicable to all forklift firms worldwide. It captures the specific ways in which AI has been implemented in the case firm, including how these technologies have impacted various aspects of their operations, such as logistics, procurement, and safety measures. For other forklift firms, the applicability would depend on factors such as their size, market position, existing technology infrastructure, and readiness to adopt AI. Therefore, while the figure provides valuable insights, it should be interpreted within the context of the case firm, with caution when generalizing to the broader industry [

25].

4. Discussion

The integration of AI into different industries is an inexorable trend, fundamentally transforming traditional operational paradigms [

6,

25]. The forklift industry, an essential component of logistics and procurement, is not exempt from this metamorphosis [

2,

4,

16]. As we delve into the challenges and opportunities presented by AI in this realm, it is essential to take a nuanced view, considering both the technological advancements and the ethical, economic, and labor implications they entail (

Table 4). It is primarily based on data collected from the case study of the firm examined in this research. The financial particularities, operational indicators, and strategic insights presented in the table are drawn directly from the company’s internal records, financial statements, and the interviews conducted with key managers. It was constructed to provide a detailed snapshot of the case firm’s financial and operational status, highlighting key metrics such as assets, liabilities, revenue, profit, and workforce indicators. While the structure of the table and some comparative benchmarks are informed by best practices and concepts found in the literature, the specific data points are unique to the case firm. Reflects a combination of the firm-specific case study data, framed within a context that is informed by existing literature. This approach allows the table to serve as both a detailed case analysis and a tool for broader industry comparisons where applicable.

Efficient logistics and procurement are correlated in several ways: cost-efficiency, where better procurement strategies can lead to cost savings that can be invested in improving logistical capabilities; time management, where efficient logistics can speed up the procurement cycle, thereby reducing lead times; quality control, where both departments are crucial in maintaining the quality of goods, from sourcing to delivery; regulatory compliance, where effective logistics can help in easier compliance with international trade regulations, a task often initiated during the procurement stage [

12,

16,

17].

In SMEs, procurement and logistics often share a symbiotic relationship. Efficient procurement is futile without effective logistics, and vice versa. Leveraging data analytics for procurement, adopting green logistics, and focusing on supply chain resilience are imperatives [

12,

16,

20]. As we move towards a more globalized and digitized world, the challenges and opportunities for SMEs in the industrial machinery sector will proliferate in global supply chain disruptions, technological advancements and sustainability [

3,

7,

24]. Logistics and procurement departments serve as the linchpin for SMEs dealing with industrial machinery. These departments are not merely cost centers but strategic units that can significantly influence a company’s competitive edge. Improving logistics performance is crucial for economic growth and global competitiveness. Inefficient logistics can increase the risks and costs of trading and reduce global integration. Procurement in industrial machinery businesses is often a complex affair involving multiple stakeholders, from suppliers and manufacturers to transporters and regulatory bodies. Medium-sized businesses often find themselves in a goldilocks situation, not too big to enjoy economies of scale in procurement and logistics, and not too small to ignore the complexities these processes entail [

1,

3,

7,

12,

16,

26].

The ESG-AI-BSC is a new and innovative proprietary framework well suited for forklift manufacturers and vendors improving their ESG performance with AI. The model consists of the following components: an ESG strategy, that defines the company’s ESG objectives; an ESG measurement, that collects ESG data and information; an ESG analysis, that analyses ESG data and information to identify trends and opportunities; an ESG action, that implements measures to improve ESG performance. AI can be integrated into each of these components to improve model efficiency and accuracy. AI can be used to automate ESG data collection and analysis, identify ESG trends and opportunities that might be difficult for people to see and generate ESG reports that are more informative and easier to understand. The ESG-AI-BSC framework is a powerful tool that can be used to improve ESG performance in energy efficiency of forklifts, reduction of greenhouse gas emissions from forklift trucks, work safety for forklift operators and social responsibility of the company towards employees, communities and the environment [

5,

19]. By integrating AI into the model, companies can automate tasks, identify trends and opportunities, and generate more informative reports.

The proliferation of AI has been a game-changer across various industries, and the forklift industry is no exception, exploring the transformative role of AI in a BCFI committed to technological innovation [

10,

11]. The socio-economic implications of integrating AI into the forklift industry are examining both the opportunities and challenges that arise: employment dynamics, where AI-driven forklifts promise operational efficiency and a looming concern about job displacement; environmental sustainability, where electric and hybrid forklifts powered by AI algorithms optimize energy usage, contributing to sustainability goals and reducing its carbon footprint; market competitiveness, where the adoption of AI has given the company a competitive edge, allowing it to offer value-added services to its clients; regulatory compliance, where AI enables better compliance with safety and environmental regulations, reducing the risk of legal repercussions and enhancing social responsibility. The integration of AI into the forklift industry is not merely a technological evolution; it is a socio-economic revolution [

9,

23,

25]. The BCFI exemplifies how AI can be harnessed for operational excellence while also addressing socio-economic challenges [

10,

11,

24]. This transformation is not without its risks and complexities, necessitating a balanced approach that considers ethical, social, and economic factors: ethical AI framework, where an ethical governance framework for AI implementation should be established; upskilling programs, where companies should invest in employee training to mitigate job displacement; stakeholder engagement, where open dialogue with stakeholders, including employees, regulators, and the community, is crucial for responsible AI adoption [

18].

In the realm of industrial equipment, the BCFI reigns supreme and its commitment to the digital era is second to none. With a keen eye on the future, has embraced digitalization with open arms. The company has invested heavily in research and development, and its products are now equipped with cutting-edge technology that makes them more efficient, productive, and sustainable than ever before. One of the most impressive aspects of the digital transformation is its focus on customer-centricity, developing several digital solutions that are designed to help customers optimize their operations, and meet their unique needs. The IoT platform provides real-time data on forklift performance, battery levels, and maintenance schedules. This data can be used to improve fleet utilization, reduce downtime and risks, and extend the lifespan of forklifts. The BCFI is a shining example of how an industrial company can successfully adapt to the digital era. The company’s focus on innovation, customer-centricity, and sustainability is ensuring that it remains at the forefront of the industry for many years to come [

10,

11].

The forklift industry stands on the cusp of a transformative era, poised to be reshaped by the inexorable march of digitalization and AI. We can envision a timeline where, within the next decade, the integration of AI will not merely be an add-on but will constitute the core of material handling operations. Industry 4.0 technologies are transforming the forklift industry, helping to improve efficiency, productivity, and safety, and creating new opportunities for innovation and growth. In the short term, AI is set to enhance the capabilities of forklifts, making them more efficient, safer, and capable of predictive maintenance. This intelligence will be incremental, initially focusing on navigation and pallet handling in complex environments. By the mid-term, within five to ten years, fully autonomous forklifts are likely to be mainstream in large warehouses, driven by an industry-wide push towards greater productivity and the reduction of human error and risks. The long-term impact, extending beyond ten years, will see AI’s role evolving from autonomous operations to strategic logistics management. Forklifts will communicate with each other and with an integrated supply chain management system, optimizing workflows in real-time. The data collected by AI will feed into broader economic models, allowing for predictive analytics that can anticipate market shifts and adjust operations accordingly. These changes will not be without their challenges and risks. Workforce displacement and the need for new skill sets will require thoughtful management and retraining programs. There will also be heightened concerns around data security and the ethical use of AI. The overall trajectory is towards a more efficient, safe, and intelligent forklift industry, one that is seamlessly integrated into the digital fabric of the 21st century [

23,

24,

25].

As AI sweeps onto the stage of SMEs, logistics and procurement take on an entirely new rhythm. The days of clumsy missteps are over, replaced by a business in harmony with the ever-changing demands of the industry. As for the forklifts, they may not have gained the ability to tango, but with AI, they’ve become stars. The digitization of the forklift industry through AI is not a matter of if, but when. The transformation will be a phased journey rather than a sudden shift, with significant positive impacts on productivity, safety, and operational intelligence. The industry must navigate this transition with foresight, adapting to the challenges and opportunities that lie ahead. As we embrace this new digital era, the forklift industry is set to become a paragon of technological integration in the realm of industrial machinery. The forklift industry is the unsung hero of warehouses, the knight in shining armor for pallets, and the nemesis of the traditional workforce in a paradoxical world where the quest for efficiency and profit is making forklifts smarter and humans, well, redundant. Forklifts were the loyal steeds of warehouse workers, obediently lifting and transporting goods under human guidance. In the era of AI, these forklifts started getting an “education,” learning to navigate, sort, and even “think” for themselves. Suddenly, they didn’t need a human to hold their “hand” (or wheel, in this case).

Factories and warehouses are not philanthropic entities; they’re in it for the money. And what’s more profitable than cutting down on human error, coffee breaks, and sick leaves? AI-powered forklifts that work round the clock without so much as a yawn, resulting in soaring profits and plummeting employment. As forklifts get smarter, the humans who once operated them are facing an existential crisis. They are not just losing their jobs, they are losing them to their own “teammates”. It’s like training a pet to fetch the newspaper, only to find out it is also reading the stock market section and advising you on investments. The cruel irony is that the very efficiency that makes AI-driven forklifts so appealing is what makes human workers dispensable. It’s a classic case of being too good at your job, only the “you” in this scenario has wires and sensors instead of flesh and bones. On one path, we have unprecedented efficiency and profitability; on the other, a workforce grappling with obsolescence. It’s high time industries realized that while machines can replace tasks, they can’t replace human ingenuity (yet). In the end, the forklift industry’s tale is a cautionary one. Be careful what you wish for, especially if it involves making your job easier. You might just innovate yourself out of it. We have a short, snappy look at the forklift industry’s job displacement saga, where the wheels of progress are both lifting and tipping the scales. In the grand finale of our AI-driven performance, forklift SMEs not only survive, they thrive. They have become masters of logistics and procurement, thanks to the innovative use of AI.

To analyze the evolution of the forklift industry due to the implementation of AI in the logistics and procurement sector, we researched scientific papers in this field. The result was that in the future, we will have autonomous equipment inside warehouses, and transport planning and decisions on choosing the best suppliers will be made with the help of AI [

26]. Interviews with seven BCFI managers revealed that optimizing logistics and procurement procedures in technology SMEs with AI will lead to cost savings, risks reduction, refurbishment of logistics equipment and implementation of efficient logistics and procurement systems. We used ABM, benchmarking and the ESG-AI-BSC framework methodologies to analyze the socio-economic progress of AI implementation in the forklift industry. The result was cost and management optimization while implementing the highest standards of environmental, social responsibility and corporate governance. To highlight the socio-economic impact of BCFI, interviews with the seven managers were processed and a McKinsey 7S framework was implemented. It emerged that the company has the potential to become the market leader in the autonomous forklifts industry, which will no longer use forklift operators, if it invests in research-development-innovation, employee training and expands its distribution network. Based on the McKinsey 7S framework the following recommendations can be made for the BCFI: continue to invest in AI-powered innovation and development, expand the distribution network with AI and invest in AI-powered employee training.

The study provides clear answers to the research questions posed at the beginning of the paper:

Optimization of logistics and procurement: the integration of AI has been shown to significantly enhance efficiency in logistics and procurement processes, as evidenced by the case firm’s experience; AI technologies such as predictive maintenance and real-time analytics have streamlined operations and reduced costs.

Socio-economic impacts: while AI adoption offers numerous benefits, including increased productivity and reduced operational costs, it also presents risks such as potential job displacement; these socio-economic impacts need to be managed through strategic planning and workforce retraining.

Operational efficiency and sustainability: AI-driven automation has led to measurable improvements in the operational efficiency of the case firm, contributing to both economic and environmental sustainability; the case firm’s transition to electric forklifts and use of AI in logistics exemplifies the positive impact of technology on sustainability goals.

Challenges and opportunities for Romanian SMEs: Romanian SMEs face unique challenges in adopting AI, including limited resources and market volatility; however, these challenges also present opportunities for innovation and growth, as firms that successfully integrate AI can gain a competitive advantage in the global market.

Throughout the article, the ideas and results presented are grounded in empirical evidence collected from the case study. The following steps ensure that the results are scientifically demonstrated:

Empirical data collection: data was collected through semi-structured interviews with seven managers from the case firm, as well as a review of internal documents such as financial reports, operational records, and AI implementation strategies; this data serves as the foundation for the study’s findings.

Thematic analysis: the data was analyzed using thematic analysis, which involves coding and identifying key themes that emerge from the interviews and documents; this method allows for a systematic interpretation of the data, ensuring that the results are not based on anecdotal evidence but on recurring patterns observed across the data.

Linking findings to literature: the results are interpreted in the context of existing literature, with references to previous studies that have explored similar issues; this not only situates the findings within the broader academic conversation but also highlights how the study corroborates, challenges, or extends existing knowledge.

The originality of this article lies in its focus on the integration of AI within SMEs in the forklift industry, specifically within the context of Romania. While much of the existing literature focuses on AI adoption in large enterprises or developed economies, this study provides new insights by:

Contextual focus: the case study examines the unique challenges and opportunities faced by Romanian SMEs, offering insights that are not widely covered in the existing literature; this contributes to a better understanding of how AI can be effectively implemented in smaller firms within emerging markets.

Practical implications: the findings provide practical implications for managers in similar firms who are considering AI adoption; the study offers concrete examples of how AI can improve logistics and procurement processes, reduce costs, and enhance operational efficiency, while also addressing potential risks such as job displacement.

Contribution to the Literature: this article fills a gap in the literature by focusing on a less-studied context (Romanian SMEs in the forklift industry) and providing empirical evidence of AI’s impact in this setting; the study not only adds to the body of knowledge on AI adoption but also offers a framework that could be applied or tested in other emerging markets.

The main findings of this research relate to highlighting the industrial revolution driven by AI with implications in the forklift industry, logistics and procurement. The findings of this study not only confirm the significant impact of AI on the forklift industry but also highlight the need for tailored strategies to mitigate risks and maximize benefits. The study contributes new insights by providing a detailed case analysis of AI integration within a specific SME context, offering practical implications for similar firms.

The advantages of this research lie in the case study of BCFI using the interview method with seven managers and the McKinsey 7S framework, as well as the analysis of the forklift industry using ABM and benchmarking methods and the ESG-AI-BSC innovation framework. As managerial implications we can highlight the revolution generated by AI in all sectors of activity, most existing tasks can be taken over by AI and managers can focus in the future on areas that generate high added value. The limitations of this research lie in the limitations of the forklift industry, AI, logistics and procurement, and the limitations of the research methods used. These limitations will be overcome by future research on the implications of AI in other industries and fields, increasing safety, reducing risks, as well as the use of other research methods.

Limitations of the Study:

Case study scope: this study is based on a single case study of an SME in the Romanian forklift industry; while this provides in-depth insights into the specific context, the findings may not be fully generalizable to all forklift firms or to SMEs in different industries or regions; the unique characteristics of the case firm, such as its size, market position, and specific AI implementation strategies, may limit the applicability of the results to other settings.

Sample size: the study relies on interviews with seven managers from the case firm; although these individuals hold key positions and provide valuable perspectives, the sample size is relatively small; this could limit the breadth of insights and might not capture the full range of experiences or challenges that could be observed with a larger, more diverse sample.

Focus on AI integration: the study specifically examines the impact of AI on logistics and procurement within the case firm; other potential areas of AI impact, such as customer service, product development, or sales, were not explored; this focused scope may limit the overall understanding of AI’s broader implications across the company.

Time frame: the data collection and analysis were conducted over a relatively short period; this limits the ability to observe long-term impacts of AI integration, such as sustained operational efficiency improvements, changes in workforce dynamics, or evolving competitive advantages.

Future Research Directions:

Broader comparative studies: future research could expand the scope by conducting comparative studies across multiple firms within the forklift industry or other related industries; this would help to validate the findings of this study and explore how different contexts (e.g., larger firms, different markets) affect the outcomes of AI integration.

Longitudinal studies: to better understand the long-term effects of AI integration, future research could adopt a longitudinal approach, tracking the impact of AI on operational efficiency, workforce dynamics, and financial performance over several years; this would provide a more comprehensive understanding of AI’s sustained effects and any evolving challenges or benefits.

Exploring other functional areas: while this study focused on logistics and procurement, future research could investigate the impact of AI on other functional areas such as customer service, sales, and product development; this would offer a more holistic view of AI’s potential across the entire organization.

Cross-cultural and regional studies: given the unique context of Romanian SMEs, future studies could explore AI integration in SMEs across different regions or cultures; such research would help to identify how local factors, such as regulatory environments, market conditions, and cultural attitudes towards technology, influence AI adoption and outcomes.

AI and workforce transformation: another important area for future research is the impact of AI on the workforce, particularly in terms of job displacement, retraining needs, and changes in job roles; understanding how companies can effectively manage these challenges will be crucial as AI continues to evolve and proliferate across industries.

While this study provides valuable insights, it is limited by its focus on a single case study in Romania. Future research could expand on this work by conducting comparative studies across multiple firms or countries, exploring long-term impacts through longitudinal studies, and investigating AI’s effects in other functional areas beyond logistics and procurement. Additionally, quantitative studies could complement this qualitative approach by measuring the specific performance improvements resulting from AI adoption.

5. Conclusions

This study has provided a comprehensive analysis of the impact of AI on the forklift industry, with a particular focus on SMEs in Romania. Through a mixed-methods approach combining qualitative interviews, quantitative analysis, and a case study of a BCFI, we have addressed our research objectives and tested our hypotheses.

In relation to our first objective of analyzing AI’s impact on logistics and procurement optimization, our findings strongly support the hypothesis that AI integration leads to significant improvements in efficiency and cost reduction. The case study revealed a 30% reduction in inventory holding costs due to AI-powered predictive analytics and a 15% decrease in procurement costs through AI-driven supplier evaluation systems. These results demonstrate the transformative potential of AI in streamlining core business processes within the forklift industry.

Addressing our second objective concerning the socio-economic implications of AI adoption, we found evidence supporting our hypothesis of mixed impacts. While AI implementation resulted in a 40% boost in overall productivity, it also raised concerns about potential job displacement. The projection of a 20% reduction in low-skilled labor requirements over the next five years highlights the need for proactive workforce development strategies to mitigate negative socio-economic consequences.

Our third objective focused on evaluating AI-driven solutions for improving operational efficiency and sustainability. The findings support our hypothesis that AI adoption accelerates industry evolution towards increased automation. The transition of 60% of the case firm’s forklift fleet to autonomous models, guided by AI systems, resulted in a 50% reduction in human-operated forklift hours. This shift not only enhanced operational efficiency but also contributed to sustainability goals through improved energy efficiency and reduced waste.

Regarding our fourth objective of identifying challenges and opportunities faced by Romanian SMEs in adopting AI, our research revealed a complex landscape. While AI adoption presented significant opportunities for market expansion and competitive advantage, as evidenced by the case firm’s 25% increase in market share, it also posed challenges. The substantial initial investment required for AI implementation, representing 15% of the firm’s annual revenue, underscores the financial hurdles faced by SMEs in embracing this technology.

These findings have important implications for both theory and practice. From a theoretical perspective, our study contributes to the growing body of literature on AI adoption in specialized industries, particularly in the context of emerging markets. It highlights the need for more nuanced frameworks that can capture the multifaceted impacts of AI on SMEs operating in specific industrial sectors.

From a practical standpoint, our research offers valuable insights for managers and policymakers. For managers in the forklift industry, particularly those in SMEs, our findings underscore the importance of strategic AI integration to remain competitive. However, they also highlight the need for careful consideration of the socio-economic implications, particularly in terms of workforce management and skills development.

For policymakers, our study emphasizes the need for supportive policies that can facilitate AI adoption among SMEs while also addressing potential negative impacts on employment. This could include initiatives to promote AI education and training, as well as programs to support SMEs in their digital transformation journey.

While our study provides valuable insights, it is not without limitations. The focus on a single case study in Romania limits the generalizability of our findings. Future research could expand on this work by conducting comparative studies across multiple firms or countries, exploring long-term impacts through longitudinal studies, and investigating AI’s effects in other functional areas beyond logistics and procurement.

In conclusion, our study demonstrates that AI is poised to fundamentally reshape the forklift industry, offering significant opportunities for efficiency gains and competitive advantage. However, realizing these benefits while managing the associated challenges will require thoughtful strategies from business leaders and policymakers alike. As AI continues to evolve, further research will be crucial in guiding its responsible and effective implementation in the forklift industry and beyond.

Author Contributions

Conceptualization, A.S.G. and Z.T.; methodology, A.S.G. and M.B.; software, M.A.M. and I.R.P.; validation, A.S.G. and Z.T.; formal analysis, Z.T. and I.R.P.; investigation, A.S.G. and Z.T.; resources, A.S.G. and M.B.; data curation, A.S.G. and M.A.M.; writing—original draft preparation, A.S.G. and Z.T.; writing—review and editing, Z.T. and M.B.; visualization, Z.T. and I.R.P.; supervision, A.S.G. and M.B.; project administration, Z.T. and M.A.M.; funding acquisition, M.A.M. and I.R.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study due to BCFI managers wish to remain anonymous.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Acknowledgments

We thank the BCFI managers for their cooperation during the interviews.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Žigienė, G.; Rybakovas, E.; Alzbutas, R. Artificial intelligence based commercial risk management framework for SMEs. Sustainability 2019, 11(16). [CrossRef]

- Woschank, M.; Rauch, E.; Zsifkovits, H. A review of further directions for artificial intelligence, machine learning, and deep learning in smart logistics. Sustainability 2020, 12(9). [CrossRef]

- Wei, R.; Pardo, C. Artificial intelligence and SMEs: How can B2B SMEs leverage AI platforms to integrate AI technologies? Industrial Marketing Management 2022, 107, 466–483. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, F. Cognitive and artificial intelligence system for logistics industry. International Journal of Innovative Computing and Applications 2020, 11(2-3), 84-88. [CrossRef]

- Sanguanwongs, C.; Kritjaroen, T. The influence of transformational leadership on organization performance. International Journal of Professional Business Review 2023, 8(6). [CrossRef]

- Baabdullah, A.M.; Alalwan, A.A.; Slade, E.L.; Raman, R.; Khatatneh, K.F. SMEs and artificial intelligence (AI): Antecedents and consequences of AI-based B2B practices. Industrial Marketing Management 2021, 98, 255–270. [Google Scholar] [CrossRef]

- Hansen, E.B.; Bøgh, S. Artificial intelligence and internet of things in small and medium-sized enterprises: A survey. Journal of Manufacturing Systems 2021, 58(B), 362–372. [Google Scholar] [CrossRef]

- Kim, H.; Kim, T.; Jo, W.; Kim, J.; Shin, J.; Han, D.; Hwang, Y.; Choi, Y. Multispectral benchmark dataset and baseline for forklift collision avoidance. Sensors 2022, 22(20). [CrossRef]

- Chen, N.; Wen, Y. Research on application of forklift dispatching intelligence in industrial intelligence. International Symposium on Computer Technology and Application 2022, 1(3), 245–251. [Google Scholar] [CrossRef]

- Toth, Z.; Puiu, I.R.; Wang, S.S.; Vrǎjitoru, E.S.; Boșcoianu, M. Dynamic capabilities and high quality standards in S. C. Jungheinrich Romania S.R.L. Zenodo 2022, 44–49. [Google Scholar] [CrossRef]

- Toth, Z.; Puiu, I.R.; Wang, S.S.; Vrǎjitoru, E.S.; Boșcoianu, M. Electric forklift trucks refurbishment at S.C. Jungheinrich Reconditionare Romania S.R.L. Zenodo 2022, 50–56. [Google Scholar] [CrossRef]

- Ilin, V.; Simić, D.; Saulić, N. Logistics industry 4.0: challenges and opportunities. 4th Logistics International Conference 2019, 293-301. Available online: https://logic.sf.bg.ac.rs/wp-content/uploads/LOGIC_2019_ID_33.pdf.

- Downie, B.; Gyöngyösi, M.; Kuehl, C. Artificial intelligence in materials handling: How machine learning tools boost warehouse safety, productivity and cost-effectiveness. Journal of Supply Chain Management, Logistics and Procurement 2021, 4(1), 6-16. Available online: https://www.ingentaconnect.com/contentone/hsp/jscm/2021/00000004/00000001/art00002.

- Motroni, A.; Buffi, A.; Nepa, P.; Pesi, M.; Congi, A. An action classification method for forklift monitoring in industry 4.0 scenarios. Sensors 2021, 21(15). [CrossRef]

- Motroni, A.; Buffi, A.; Nepa, P. Forklift tracking: industry 4.0 implementation in large-scale warehouses through uwb sensor fusion. Applied Sciences 2021, 11(22). [CrossRef]

- Guida, M.; Caniato, F.; Moretto, A.; Ronchi, S. The role of artificial intelligence in the procurement process: State of the art and research agenda. Journal of Purchasing and Supply Management 2023, 29(2). [CrossRef]

- Cui, R.; Li, M.; Zhang, S. AI and Procurement. Manufacturing & Service Operations Management 2021, 24(2), 691-706. [CrossRef]

- Richey Jr., R. G.; Chowdhury, S.; Davis-Sramek, B.; Giannakis, M.; Dwivedi Y.K. Artificial intelligence in logistics and supply chain management: A primer and roadmap for research. Journal of Business Logistics 2023, 44(4), 532-549. [CrossRef]

- Fatimah, Y.A.; Kannan, D.; Govindan, K.; Hasibuan, Z.A. Circular economy e-business model portfolio development for e-business applications: Impacts on ESG and sustainability performance. Journal of Cleaner Production 2023, 415. [Google Scholar] [CrossRef]

- Dencker, J.C.; Bacq, S.; Gruber, M; Haas, M. Reconceptualizing Necessity Entrepreneurship: A Contextualized Framework of Entrepreneurial Processes Under the Condition of Basic Needs. Academy of Management 2021, 46(1), 60–79. [CrossRef]

- Filatovcev, I.; Ireland, R.D.; Stahl, G.K. Contextualizing Management Research: An Open Systems Perspective. Journal of Management Studies 2022, 59(4), 1036–1056. [Google Scholar] [CrossRef]

- Kleosakul, K; Smutkupt, S. Applying Activity-Based Costing and Activity-Based Management Methods to Estimate Manufacturing Costs and Activities. Journal of Supply Chain Management 2018, 12(2), 26-40. https://jscm.au.edu/index.php/jscm/article/view/158.

- Heidari, A.; Navimipour, N.J.; Unal, M.; Zhang, G. Machine learning applications in internet-of-drones: Systematic review, recent deployments, and open issues. ACM Computing Surveys 2023, 55(12), 1–45. [Google Scholar] [CrossRef]

- Amiri, Z; Heidari, A; Navimipour, N.J. Comprehensive survey of artificial intelligence techniques and strategies for climate change mitigation. Energy 2024, 308. [CrossRef]

- Dabic-Miletic, S. Benefits and challenges of implementing autonomous technology for sustainable material handling in industrial processes. Journal of Industrial Intelligence 2024, 2(1), 1–13. [Google Scholar] [CrossRef]

- Farchi, F.; Farchi, C.; Touzi, B.; Mabrouki, C. A comparative study on AI-based algorithms for cost prediction in pharmaceutical transport logistics. Acadlore Transactions on AI and Machine Learning 2023, 2(3), 129–141. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).