Submitted:

04 October 2024

Posted:

07 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Background and Hypotheses Development

2.1. Circular Business Models in the Agri-Food Sector

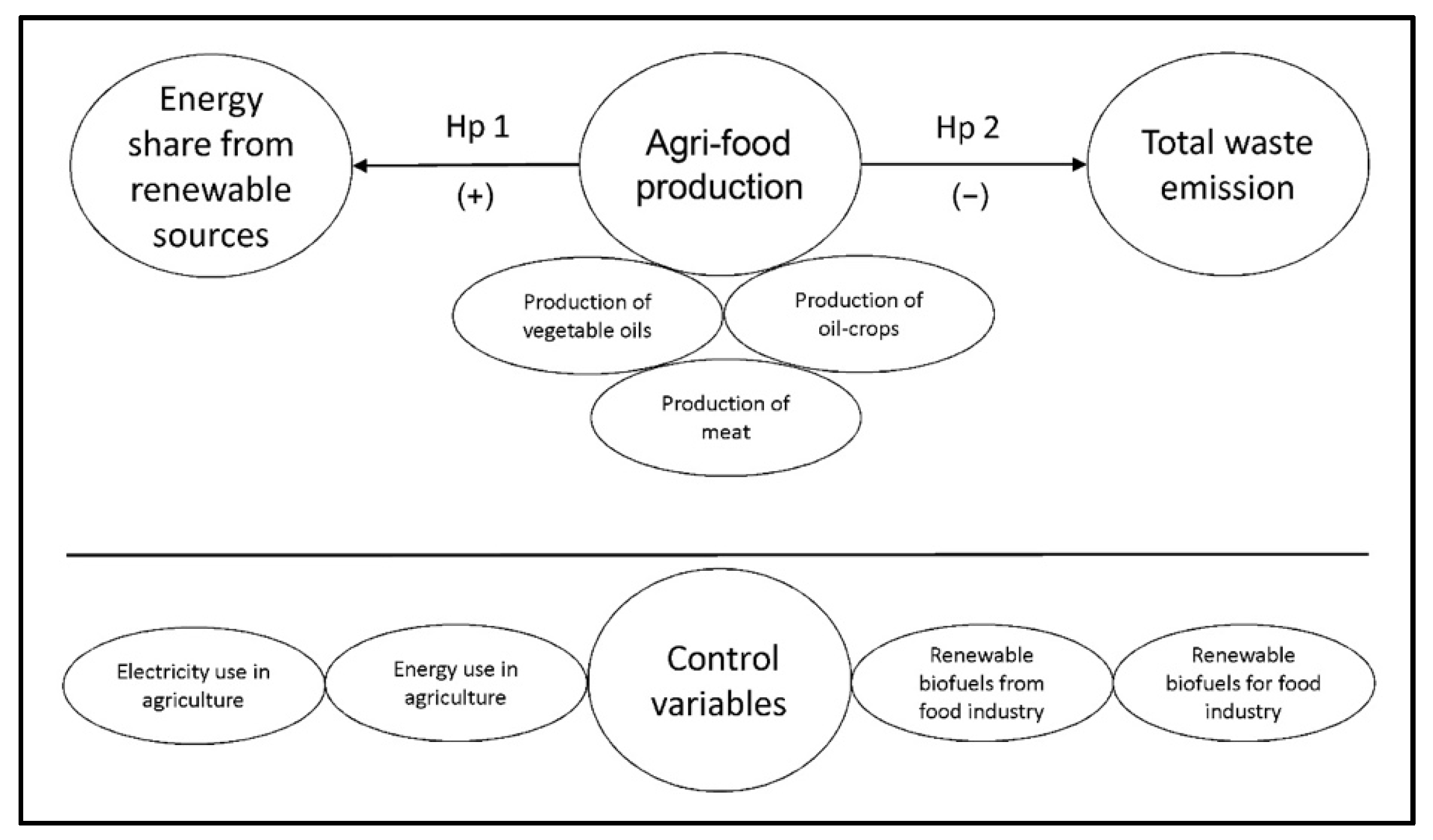

2.2. Hypotheses Development

3. Materials and Methods

3.1. Data Preparation

3.2. Data Analysis

4. Results

4.1. Data Description

4.2. Panel Data Analysis

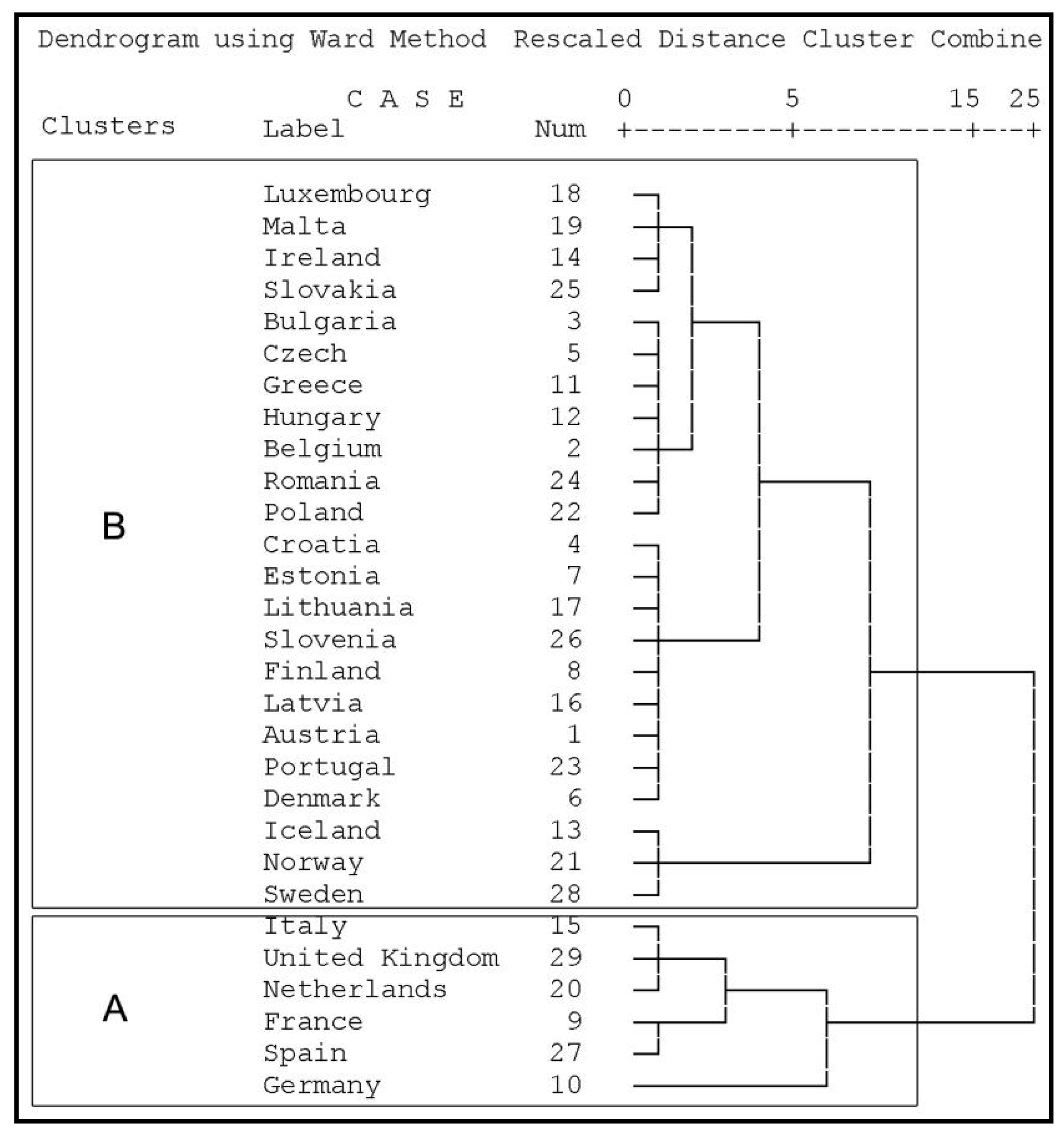

4.3. Hierarchical Clustering

5. Discussion

5.1. Circular Economy Implementation Level in the Agri-Food System in European Countries

5.2. Fostering the Circular Economy Implementation in the Agri-Food in European Countries

- Enhancing durability of agri-food products [EP]. Lifetime of the agri-food production from farm to fork should be extended to optimize the processes and reduce the losses (Bressanelli et al. 2018; Ingemarsdotter et al. 2020).

- Innovative transport tracking and service management [IP]. This offers new transport routes should be offered together with new service tracking in the context of sustainable waste management (Parida et al. 2019; Geissdoerfer et al. 2020).

- Digitalization to generate end-of-life packing process [DP]. Digital technologies can be adopted and used to facilitate and initiate the generation of end-of-life packing processes in the food sector (Reike et al. 2018, Uçar et al. 2020).

- Biodegradable materials in agri-food packing [RP]. This suggests the use of materials for packing with a return capacity in the environment and without the harmful effects and toxic chemicals (Rabnawaz et al. 2017; Jafarzadeh et al. 2020). Biodegradable materials are greatly contributed to returning the resources contained in the agri-food system to the environment (Luttenberger 2020). Similar propositions need to be innovative in the agri-food system to decrease system costs and increase added value (Hamam et al. 2021).

- Cascading reuse to organic feedstock farms [EW]. Cascading biomass can be reused in organic feedstock farms, resulting in new products or applications of the agri-food system and low emission of waste (Lüdeke-Freund et al. 2019).

- Advanced system for handling agri-food waste [IW]. An advanced system can be used for monitoring and handling and variability of agri-food systems to create values from agri-food waste (Donner et al. 2020).

- Consumer education and demand rationalization [DW]. Consumers’ awareness should be changed to rationalize their demand and their acceptance of dematerialized agri-food packing products (Perito et al. 2019).

- Zero-waste bio-refineries process [RW]. The bio-refinery process attempts to use a variety of technologies to recover marketable energy during agri-food production, consumption, and waste management, such as bio-fuels and bio-materials (Donner et al. 2020).

- Refurbishing and retrofitting bio-fuel plants [EE]. It entails a transition from traditional behaviors to sustainable ways using zero-waste biofuel plants (Donner et al. 2020).

- Retailing energy from the agri-food system [IR]. This proposition offers retailing of stored energy during the innovative agri-food processes (Ingemarsdotter et al. 2020).

- Technologies to create marketable renewable energy [DE]. Technologies to create renewable energy from agri-food systems, particularly in the production process, with value addition and marketable capabilities (Donner et al. 2020).

- Integrating biomass, bio-fuel, biomaterials, and bio-energy cycles [RE]. This proposition offers to integrate the biological and technical approaches in the CE of the agri-food system to retain successful implementations (Kanda et al. 2021). For instance, a bio-refinery proposition for the agri-food process is a variety of technologies to produce biofuels, food and feed ingredients, organic feedstock, biomaterials, and energy from biomass materials to maximize the added value along three pillars of sustainability: environment, economy, and society (Donner et al. 2020)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrade, E.P.; Bonmati, A.; Esteller, L.J.; Brunn, S.; Jensen, L.S.; Meers, E.; Anton, A. Selection and application of agri-environmental indicators to assess potential technologies for nutrient recovery in agriculture. Ecol. Indic. 2021, 134, 108471. [Google Scholar] [CrossRef]

- Baltagi, B.H. Panel Data and Difference-in-Differences Estimation. Encycl. Health Econ. 2014, 425–433. [Google Scholar] [CrossRef]

- Barakat, A.; de Vries, H.; Rouau, X. Dry fractionation process as an important step in current and future lignocellulose biorefineries: A review. Bioresour. Technol. 2013, 134, 362–373. [Google Scholar] [CrossRef] [PubMed]

- Bocken, N.M.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Bocken, N.; Ritala, P. Six ways to build circular business models. J. Bus. Strat. 2021, 43, 184–192. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Bruins, M.E.; Sanders, J.P. Small-scale processing of biomass for biorefinery. Biofuels, Bioprod. Biorefining 2012, 6, 135–145. [Google Scholar] [CrossRef]

- Christensen, C.M. The Innovator’s Dilemma: When New Technologies Cause Great Firms to Fail; Harvard Business Review Press: Boston, MA, USA, 2013. [Google Scholar]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Corrado, S.; Sala, S. Food waste accounting along global and European food supply chains: State of the art and outlook. Waste Manag. 2018, 79, 120–131. [Google Scholar] [CrossRef]

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- Dogan, E.; Chishti, M.Z.; Alavijeh, N.K.; Tzeremes, P. The roles of technology and Kyoto Protocol in energy transition towards COP26 targets: Evidence from the novel GMM-PVAR approach for G-7 countries. Technol. Forecast. Soc. Chang. 2022, 181. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total. Environ. 2020, 716, 137065. [Google Scholar] [CrossRef] [PubMed]

- Dora, M. Collaboration in a circular economy: Learning from the farmers to reduce food waste. J. Enterp. Inf. Manag. 2019, 33, 769–789. [Google Scholar]

- Esposito, M.; Tse, T.; Soufani, K. Introducing a Circular Economy: New Thinking with New Managerial and Policy Implications. Calif. Manag. Rev. 2018, 60, 5–19. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- European Commission (2021). European Agri-Food Data Archived by European Commission. https://agridata.ec.europa.eu/extensions/DataPortal/home.html.

- FAO (2017). The Future of Food and Agriculture—Trends and Challenges. UN Food and Agriculture Organization, Rome.

- FAO—Food and Agriculture Organization of the United Nations. The State of Food and Agriculture 2019. Moving forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019; Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 5 September 2020).

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Business models for industrial symbiosis: A taxonomy focused on the form of governance. Resour. Conserv. Recycl. 2019, 146, 114–126. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Henry, R.C.; Engström, K.; Olin, S.; Alexander, P.; Arneth, A.; Rounsevell, M.D.A. Food supply and bioenergy production within the global cropland planetary boundary. PLoS ONE 2018, 13, e0194695. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, F.; Erben, M.J. Organizational transition management of circular business model innovations. Bus. Strategy Environ. 2019, 29, 2770–2788. [Google Scholar] [CrossRef]

- Huho, J.M.; Kosonei, R.C.; Musyimi, P.K. Sociodemographic Determinants of Households’ Food Wastein Garissa Sub County, Kenya. Bp. Int. Res. Crit. Inst.-J. 2020, 3, 932–946. [Google Scholar]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation—A case study. Resour. Conserv. Recycl. 2020, 16, 105047. [Google Scholar] [CrossRef]

- Jafari-Sadeghi, V.; Garcia-Perez, A.; Candelo, E.; Couturier, J. Exploring the impact of digital transformation on technology entrepreneurship and technological market expansion: The role of technology readiness, exploration and exploitation. J. Bus. Res. 2020, 124, 100–111. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M.; Salehabadi, A.; Nafchi, A.M.; Kumar, U.S.U.; Khalil, H.A. Biodegradable green packaging with antimicrobial functions based on the bioactive compounds from tropical plants and their by-products. Trends Food Sci. Technol. 2020, 100, 262–277. [Google Scholar] [CrossRef]

- Kanda, W.; Geissdoerfer, M.; Hjelm, O. From circular business models to circular business ecosystems. Bus. Strat. Environ. 2021, 30, 2814–2829. [Google Scholar] [CrossRef]

- Khatami, F.; Scuotto, V.; Krueger, N.; Cantino, V. The influence of the entrepreneurial ecosystem model on sustainable innovation from a macro-level lens. Int. Entrep. Manag. J. 2021, 18, 1419–1451. [Google Scholar] [CrossRef]

- Kostakis, I.; Tsagarakis, K.P. The role of entrepreneurship, innovation and socioeconomic development on circularity rate: Empirical evidence from selected European countries. J. Clean. Prod. 2022, 348. [Google Scholar] [CrossRef]

- Kyriakopoulos, G.L.; Kapsalis, V.C.; Aravossis, K.G.; Zamparas, M.; Mitsikas, A. Evaluating Circular Economy under a Multi-Parametric Approach: A Technological Review. Sustainability 2019, 11, 6139. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2018, 23, 36–61. [Google Scholar] [CrossRef]

- Luttenberger, L.R. Waste management challenges in transition to circular economy – Case of Croatia. J. Clean. Prod. 2020, 256, 120495. [Google Scholar] [CrossRef]

- Moktadir, A.; Kumar, A.; Ali, S.M.; Paul, S.K.; Sultana, R.; Rezaei, J. Critical success factors for a circular economy: Implications for business strategy and the environment. Bus. Strat. Environ. 2020, 29, 3611–3635. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of Eco-Efficiency of Two Alternative Agricultural BiogasPlants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef]

- Palmié, M.; Boehm, J.; Lekkas, C.-K.; Parida, V.; Wincent, J.; Gassmann, O. Circular business model implementation: Design choices, orchestration strategies, and transition pathways for resource-sharing solutions. J. Clean. Prod. 2020, 280, 124399. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef]

- Perito, M.A.; Di Fonzo, A.; Sansone, M.; Russo, C. Consumer acceptance of food obtained from olive by-products: A survey of Italian consumers. Br. Food J. 2019, 122, 212–226. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Poponi, S.; Arcese, G.; Pacchera, F.; Martucci, O. Evaluating the transition to the circular economy in the agri-food sector: Selection of indicators. Resour. Conserv. Recycl. 2021, 176, 105916. [Google Scholar] [CrossRef]

- Potting j, Hekkert M, Worrell E, HanemaaijerA (2017). Circular economy: measuring innovation in the product chain. Policy Report of Netherlands Environmental Assessment Agency, PBL publication number: 2544.

- Rabnawaz, M.; Wyman, I.; Auras, R.; Cheng, S. A roadmap towards green packaging: the current status and future outlook for polyesters in the packaging industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3. 0? — Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar]

- Richardson, J. The business model: an integrative framework for strategy execution. Strat. Chang. 2008, 17, 133–144. [Google Scholar] [CrossRef]

- Ratner, B. The correlation coefficient: Its values range between +1/−1, or do they? J. Target. Meas. Anal. Mark. 2009, 17, 139–142. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Smith, D.; Reams, H.; Hair, J. F, Jr. Partial least squares structural equation modeling (PLS-SEM): A useful tool for family business researchers. J. Fam. Bus. Strategy 2014, 5, 105–115. [Google Scholar] [CrossRef]

- Sewpersadh, N.S. An examination of CEO power with board vigilance as a catalyst for firm growth in South Africa. Meas. Bus. Excel. 2019, 23, 377–395. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef]

- Tariq Majeed, M.; Luni, T. Renewable Energy, Circular Economy Indicators and Environmental Quality: A Global Evidence of 131 Countries with Heterogeneous Income Groups, Pakistan Journal of Commerce and Social Sciences 2022, 14, 866–912.

- Uçar, E.; Le Dain, M.-A.; Joly, I. Digital Technologies in Circular Economy Transition: Evidence from Case Studies. Procedia CIRP 2020, 90, 133–136. [Google Scholar] [CrossRef]

- Urbinati, A.; Franzò, S.; Chiaroni, D. Enablers and Barriers for Circular Business Models: an empirical analysis in the Italian automotive industry. Sustain. Prod. Consum. 2021, 27, 551–566. [Google Scholar] [CrossRef]

- Vermeulen, W. Self governance for sustainable global supply chains: Can it deliver the impacts needed? Business Strategy and the Environment 2015, 24, 73–85. [Google Scholar] [CrossRef]

- Verstraete, W.; Clauwaert, P.; Vlaeminck, S.E. Used water and nutrients: Recovery perspectives in a “pantarhei” context. Bioresour. Technol. 2016, 215, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Weerawardena, J.; McDonald, R.E.; Mort, G.S. Sustainability of nonprofit organizations: An empirical investigation. J. World Bus. 2010, 45, 346–356. [Google Scholar] [CrossRef]

- World Bank (2020). World development indicators Archived by online public web resource of World Data Dank. https://data.worldbank.org/indicator/AG.PRD.FOOD.XD.

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strat. Environ. 2018, 28, 274–285. [Google Scholar] [CrossRef]

- Zuin VG, Ramin LZ (2018). c: Review: green and sustainable separation of natural products from agro-industrial waste.

| Variable Country |

Production of meat (K tonnes) |

Production of oil crops (K tonnes) |

Production of vegetable oils (K tonnes) | Total waste emission (K tonnes) |

Renewable energy sharing (%) | |||||

| 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | |

| Austria | 900 | 910 | 390 | 387 | 219 | 255 | 185.95 | 186.16 | 33.55 | 33.81 |

| Belgium | 1814 | 1825 | 66 | 54 | 989 | 1205 | 116.33 | 116.39 | 8.04 | 9.48 |

| Bulgaria | 206 | 233 | 2547 | 2411 | 398 | 536 | 6.92 | 6.96 | 18.05 | 20.59 |

| Croatia | 210 | 231 | 315 | 548 | 54 | 54 | 65.58 | 65.73 | 27.82 | 28.05 |

| Czech | 519 | 515 | 1644 | 1511 | 463 | 592 | 28.34 | 28.52 | 15.07 | 15.14 |

| Denmark | 1889 | 1876 | 709 | 489 | 221 | 249 | 13.41 | 13.41 | 29.32 | 35.41 |

| Estonia | 71 | 75 | 167 | 114 | 57 | 58 | 47.29 | 47.57 | 26.14 | 29.99 |

| Finland | 384 | 393 | 62 | 71 | 111 | 76 | 22.38 | 22.39 | 38.78 | 41.16 |

| France | 5520 | 5551 | 7486 | 6829 | 2878 | 2721 | 984.03 | 983.25 | 14.42 | 16.44 |

| Germany | 8351 | 8189 | 6329 | 3778 | 4521 | 4145 | 1823.34 | 1824.39 | 14.39 | 16.67 |

| Greece | 428 | 446 | 3278 | 3461 | 488 | 605 | 174.81 | 174.25 | 15.68 | 18.05 |

| Hungary | 888 | 1032 | 2440 | 3039 | 625 | 848 | 44.33 | 44.53 | 14.62 | 12.54 |

| Iceland | 32 | 34 | 0 | 0 | 0 | 0 | 0.25 | 0.26 | 73.08 | 76.69 |

| Ireland | 1024 | 1165 | 34 | 41 | 25 | 40 | 26.32 | 26.72 | 8.57 | 10.89 |

| Italy | 3378 | 3661 | 3591 | 3633 | 1139 | 1154 | 627.44 | 626.68 | 17.08 | 17.80 |

| Latvia | 85 | 92 | 187 | 238 | 65 | 59 | 29.46 | 29.57 | 38.63 | 40.03 |

| Lithuania | 227 | 251 | 506 | 444 | 83 | 89 | 17.45 | 17.52 | 23.59 | 24.70 |

| Luxembourg | 21 | 24 | 16 | 11 | 0 | 0 | 18.63 | 18.68 | 4.47 | 8.97 |

| Malta | 13 | 12 | 0 | 0 | 0 | 0 | 0.17 | 0.17 | 4.74 | 7.97 |

| Netherlands | 2800 | 3012 | 161 | 65 | 1790 | 1765 | 592.21 | 592.77 | 5.42 | 7.34 |

| Norway | 345 | 359 | 10 | 7 | 89 | 93 | 12.43 | 12.37 | 68.21 | 71.80 |

| Poland | 4197 | 5260 | 3326 | 2170 | 1202 | 1278 | 188.62 | 189.14 | 11.61 | 11.48 |

| Portugal | 791 | 852 | 496 | 781 | 396 | 451 | 106.83 | 107.03 | 29.51 | 30.21 |

| Romania | 1054 | 1152 | 3476 | 5161 | 755 | 810 | 23.25 | 23.42 | 24.85 | 23.88 |

| Slovakia | 138 | 151 | 739 | 795 | 99 | 118 | 25.72 | 25.76 | 11.71 | 11.90 |

| Slovenia | 123 | 137 | 22 | 21 | 5 | 3 | 19.35 | 19.41 | 22.46 | 21.38 |

| Spain | 5722 | 7028 | 5728 | 11066 | 2228 | 3363 | 290.28 | 290.65 | 16.16 | 17.45 |

| Sweden | 530 | 570 | 334 | 222 | 129 | 146 | 98.97 | 98.80 | 51.82 | 54.65 |

| United Kingdom | 3694 | 4086 | 2504 | 2061 | 1017 | 1048 | 935.41 | 933.18 | 6.74 | 11.14 |

| Variables | PM | PO | PV |

| Renewable energy sharing: RE | -5.33 | -23.87 | 7.95 |

| 10.83 | 18.55 | 12.18 | |

| Energy use in agriculture: EN | 0.02* | 0.01 | 0.00 |

| 0.00 | 0.01 | 0.00 | |

| Electricity use in agriculture: EL | 0.04* | 0.03 | 0.00 |

| 0.01 | 0.04 | 0.02 | |

| Renewable bio-fuels from food industry: R from F | 0.04 | -0.02 | -0.06* |

| 0.03 | 0.08 | 0.03 | |

| Renewable bio-fuel for food industry: R for F | 0.07 | 0.17 | 0.11 |

| 0.07 | 0.19 | 0.08 | |

| Tests | |||

| R2 | 0.81 | 0.46 | 0.07 |

| F-test | 0.00 | 0.00 | 0.49 |

| p value | 0.00 | 1.44 | 0.00 |

| Hausman test | (Fixed) | (Random) | (Fixed) |

| Observations | 145 | 145 | 145 |

| Groups | 29 | 29 | 29 |

| Variables | PM | PO | PV |

| Total waste emission: WE | 1.56* | 1.15 | 1.60* |

| 0.51 | 1.28 | 0.35 | |

| Energy use in agriculture: EN | 0.02* | 0.01* | 0.01* |

| 0.00 | 0.01 | 0.00 | |

| Electricity use in agriculture: EL | 0.03* | 0.02 | 0.01 |

| 0.01 | 0.04 | 0.01 | |

| Renewable bio-fuels from food industry: RfromF | 0.05* | -0.07 | -0.02 |

| 0.02 | 0.08 | 0.02 | |

| Renewable bio-fuel for food industry: RforF | 0.02 | 0.19 | 0.05 |

| 0.06 | 0.19 | 0.05 | |

| Tests | |||

| R2 | 0.85 | 0.41 | 0.80 |

| F-test | 0.00 | 0.00 | 0.00 |

| p value | 1.11 | 1.57 | 1.15 |

| Hausman test | (Random) | (Random) | (Random) |

| Observations | 145 | 145 | 145 |

| Groups | 29 | 29 | 29 |

| Country Name | Value |

| Austria | 3.55 |

| Belgium | 3.91 |

| Bulgaria | 3.42 |

| Croatia | 3.64 |

| Czech | 3.61 |

| Denmark | 3.58 |

| Estonia | 3.81 |

| Finland | 4.56 |

| France | 12.06 |

| Germany | 26.61 |

| Greece | 3.22 |

| Hungary | 3.57 |

| Iceland | 12.35 |

| Ireland | 4.27 |

| Italy | 5.07 |

| Latvia | 4.45 |

| Lithuania | 3.68 |

| Luxembourg | 5.00 |

| Malta | 5.03 |

| Netherlands | 4.95 |

| Norway | 10.79 |

| Poland | 4.40 |

| Portugal | 3.38 |

| Romania | 3.40 |

| Slovakia | 4.11 |

| Slovenia | 3.87 |

| Spain | 10.08 |

| Sweden | 6.36 |

| United Kingdom | 7.29 |

| Aspects | Production Process [P] | Waste Emission [W] | Renewable Energy Sharing [E] | |

| Strategies | ||||

| Extending [E] | EP: Enhancing durability of the agri-food products | EW: Cascading reuse to organic feedstock farms | EE: Refurbishing and retrofitting bio-fuel plants | |

| Intensifying [I] | IP: Innovative transport tracking and service management | IW: Advanced system for handling agri-food waste | IE: Retailing energy from agri-food system | |

| Dematerializing [D] | DP: Digital capabilities to generate end-of-life packing process | DW: Consumer education and demand rationalization | DE: Technologies to create marketable renewable energy | |

| Recycling [R] | RP: Biodegradable materials in agri-food packing | RW: Zero-waste bio-refineries process | RE: Integrating biomass, bio-fuel, biomaterials, and bio-energy cycles | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).