Submitted:

06 October 2024

Posted:

08 October 2024

You are already at the latest version

Abstract

Keywords:

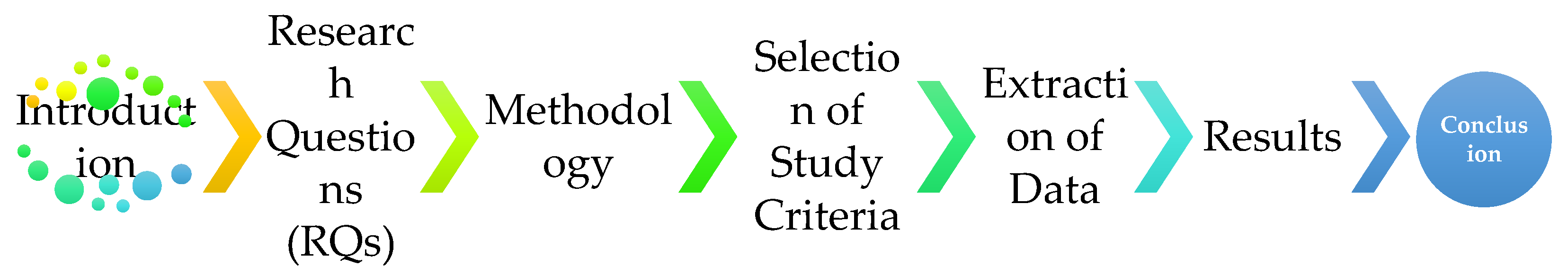

1. Introduction

1.1. Research Question

- What role do emerging technologies (AI, Industry 4.0) play in enhancing manufacturing operations in SMEs?

- How do advanced manufacturing technologies influence SME productivity and profitability across different industry sectors?

- How does effective supply chain management influence key performance indicators (KPIs) in SME manufacturing operations, such as lead time, inventory turnover, and cost efficiency?

- What are the quantifiable effects of lean manufacturing on the operational efficiency of SMEs in developing economies?

- What measurable effects does manufacturing process optimization have on customer satisfaction scores and product quality indicators in SMEs?

1.2. Rationale

1.3. Objectives

- To analyze the different manufacturing operations in their impact on general performances of SMEs. Specific aspects of manufacturing operations, such as efficiency, quality control, and production process, that are related to SME performance measures like financial performance, productivity, and operational efficiency, will be elaborated within the aim.

- The main manufacturing practices enhance the level of productivity and profitability within the SMEs. The objective here is aimed at revealing how such a specific manufacturing practice-lean production or optimization of processes-may be relevant in improving the financial performance and competitive advantage level of an SME.

- Therefore, the study will explore how manufacturing operations contribute to the scalability of SMEs. To this end, the research will try to understand how manufacturing operations enable the SMEs to become strong in growth and expansion-especially regarding market share and sustaining themselves over time.

- The impact the manufacturing operation has in terms of customer satisfaction and market performance in general could be measured. This will thus serve as an indication of how the quality of the manufacturing process contributes to customer satisfaction, market standing, and overall success of the SME, giving special emphasis on product quality and competitiveness within the market.

- Assess the role of new and emergent technologies in improving manufacturing operations within SMEs. This objective will set out the ways in which emerging technologies, such as automation, AI, and Industry 4.0 solutions, have been adopted by the SMEs to drive manufacturing performance and competitive advantage within their marketplace.

1.4. Research Contribution

- We have made an in-depth review of varied manufacturing practices that have affected SME performance, focusing on those aspects dealing with the optimization of production, efficiency of supply chains, and management of resources. This review has highlighted how strategies dealing with increasing productivity, profitability, and sustainability within SMEs can be developed through providing relevant information to decision-makers to develop operational improvements.

- In this paper, we synthesize current research on SME manufacturing operations and identify existing gaps, especially about how these practices collectively impact overall business success. Addressing such knowledge gaps, we show areas where further investigation and innovation are needed, deepening the understanding of operational performance in the SMEs.

- We investigate the role of new manufacturing technologies, including automation and sustainable practices, in possibly enhancing operational effectiveness for SMEs. The contribution underlines the critical need for modern technologies adoption by the SMEs for them to stay competitive, especially in the case of resource scarcity.

1.5. Research Novelty

- Our study represents a comprehensive examination of manufacturing operations in SMEs encompassing key practices associated with the spheres of production efficiency, supply chain coordination, and resource management. Such an approach captures several dimensions of manufacturing operations that are seldom studied together in the context of SMEs.

- We review new trends in manufacturing technologies, including automation and sustainable practices, assessing the impacts on SMEs. This review is unique because most of the past research has focused either on larger organizations or more generalized industry-wide contexts, whereas this one focuses on the impact of advancements on SMEs.

- We also identify some of the fundamental operational issues of SMEs and put forward potentially successful strategies for overcoming such challenges through better management of their manufacturing processes. These results represent a significant gap in existing literature and provide useful lessons that could be applied to enhance SMEs’ performance.

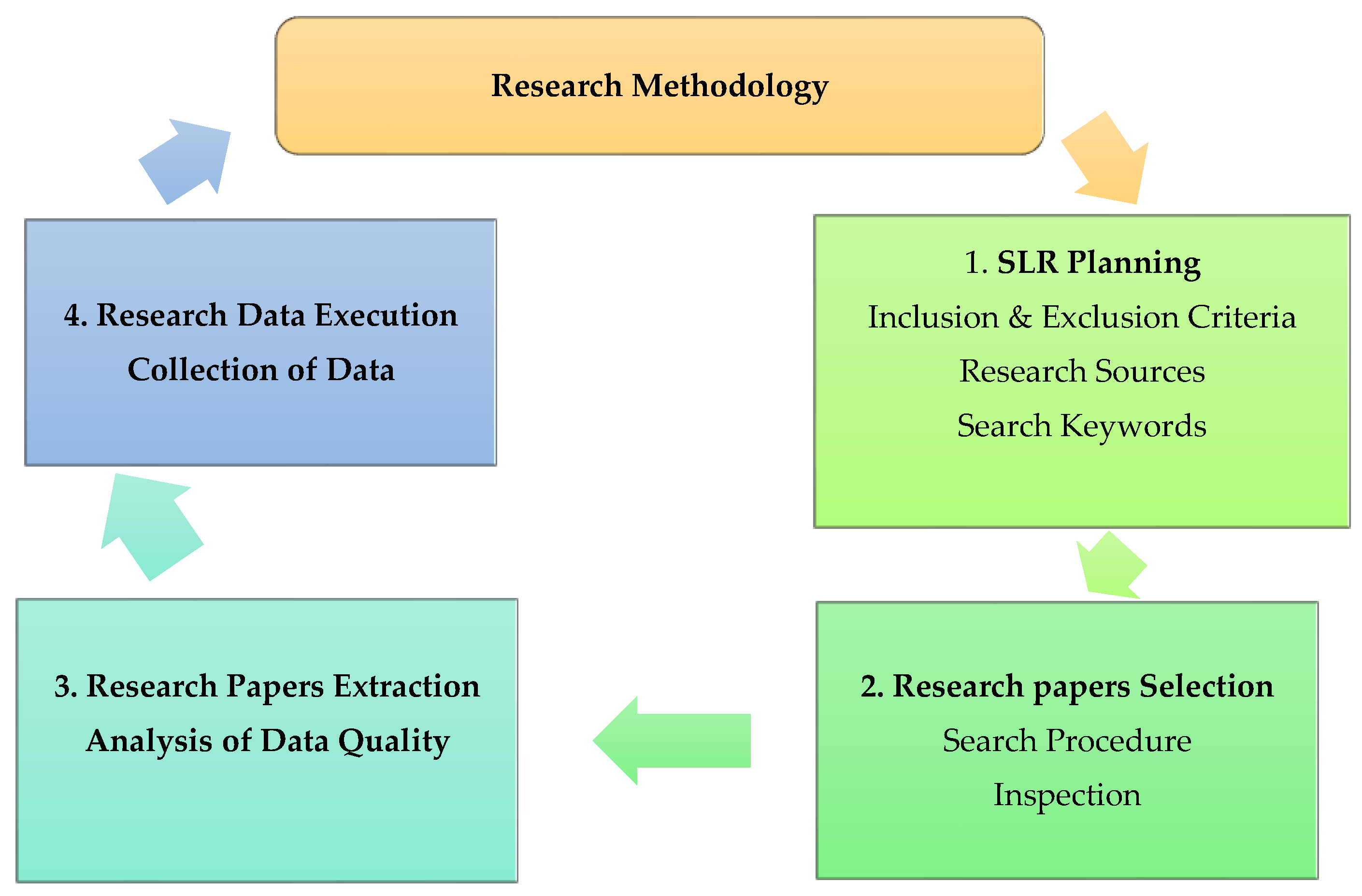

2. Materials and Methods

2.1. Eligibility Criteria

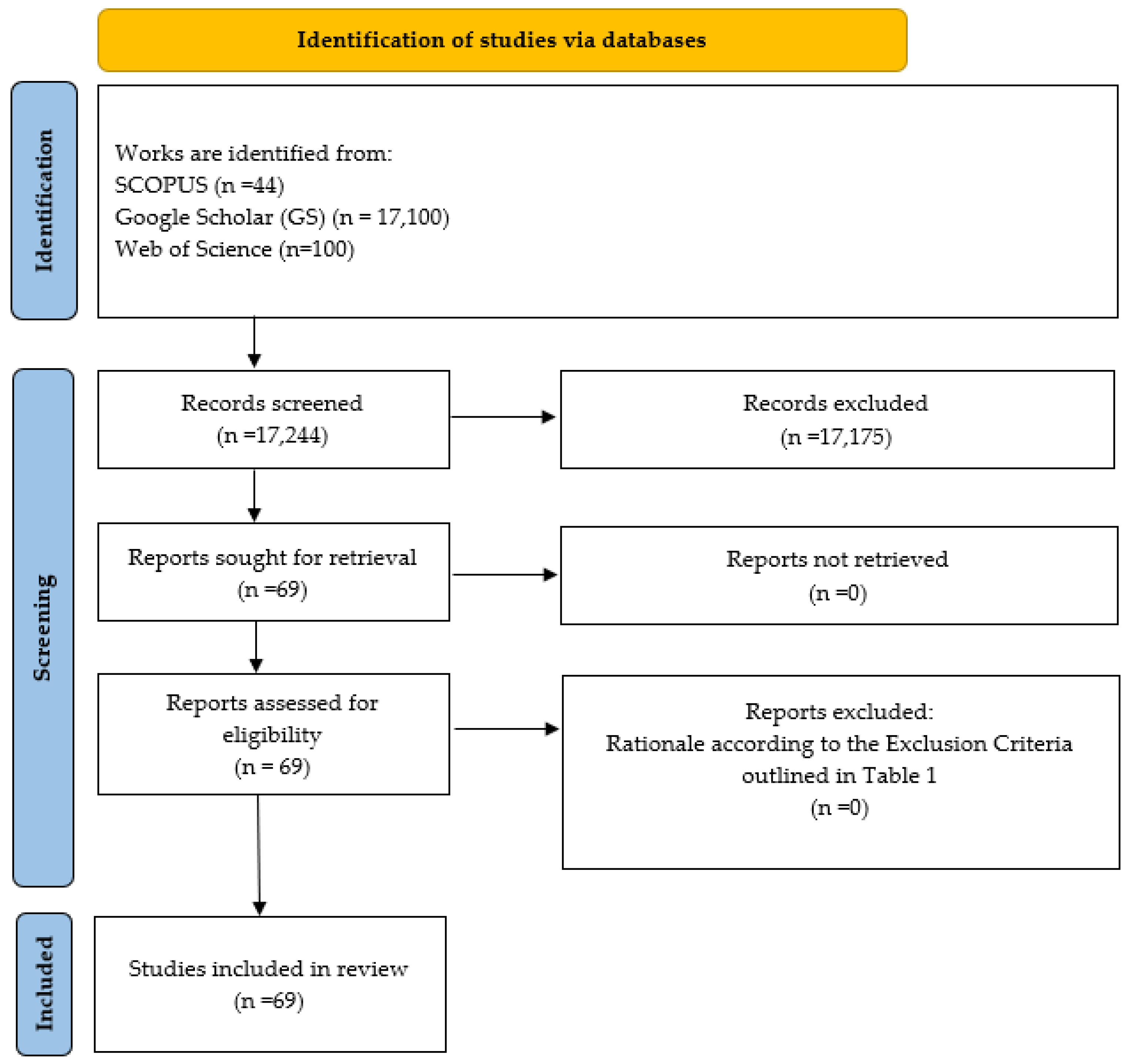

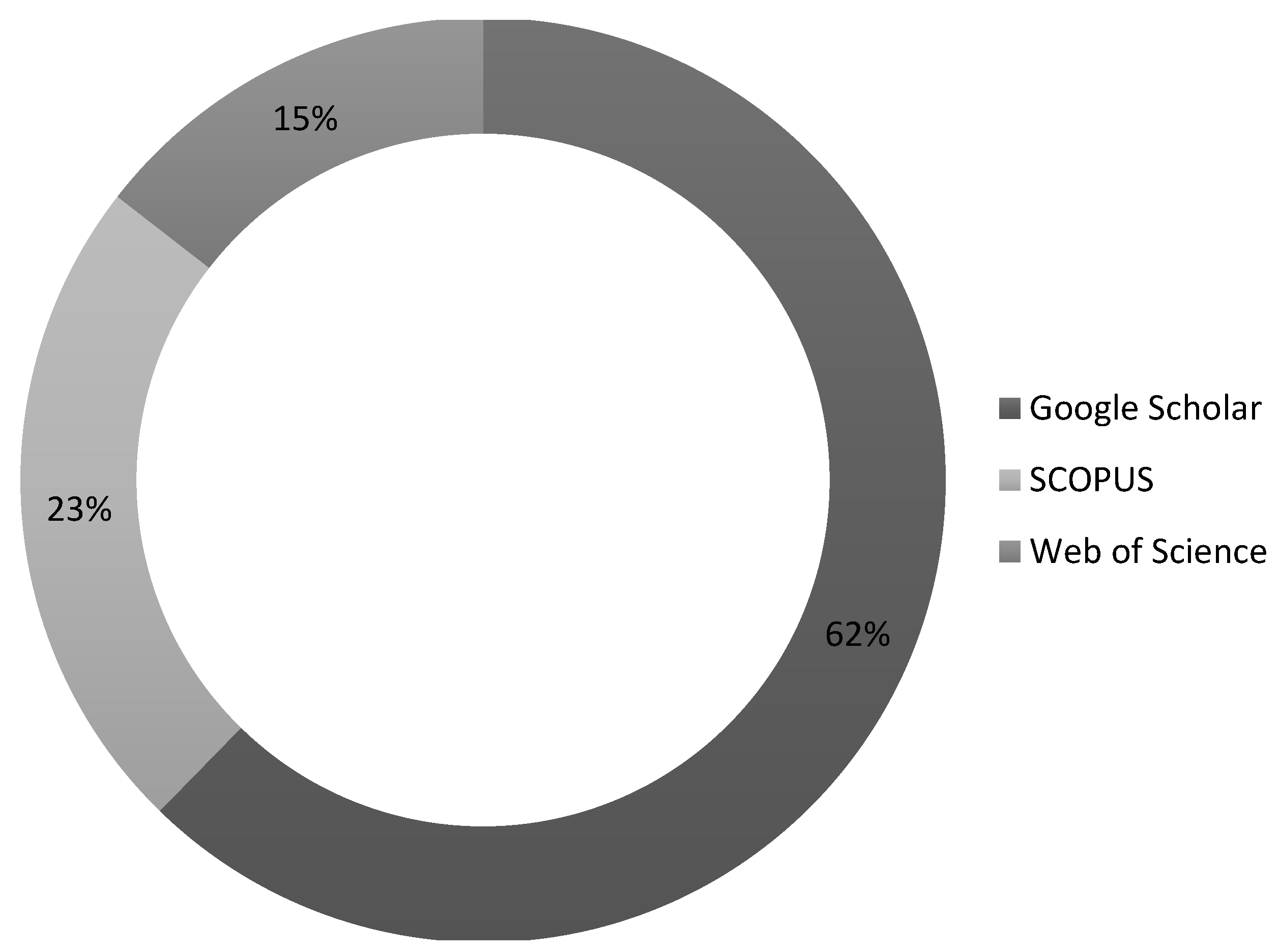

2.2. Information Sources

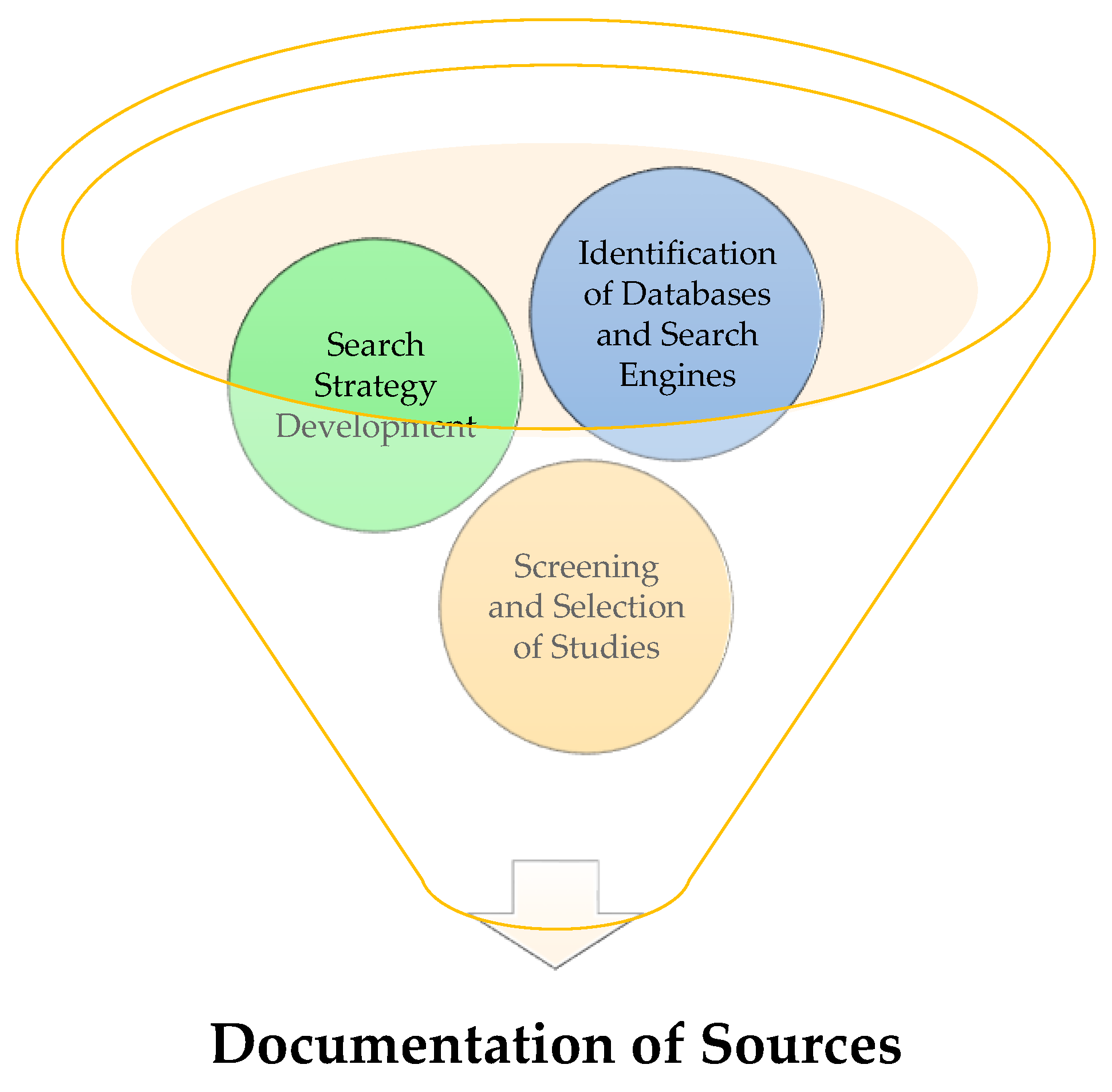

2.3. Search Strategy

2.4. Selection Process

2.5. Data Collection Process

2.6. Data Items

2.6.1. Results and Data Connection

2.6.2. Contributor Characteristics

2.7. Study Risk of Bias Assessment

2.8. Effect Measures

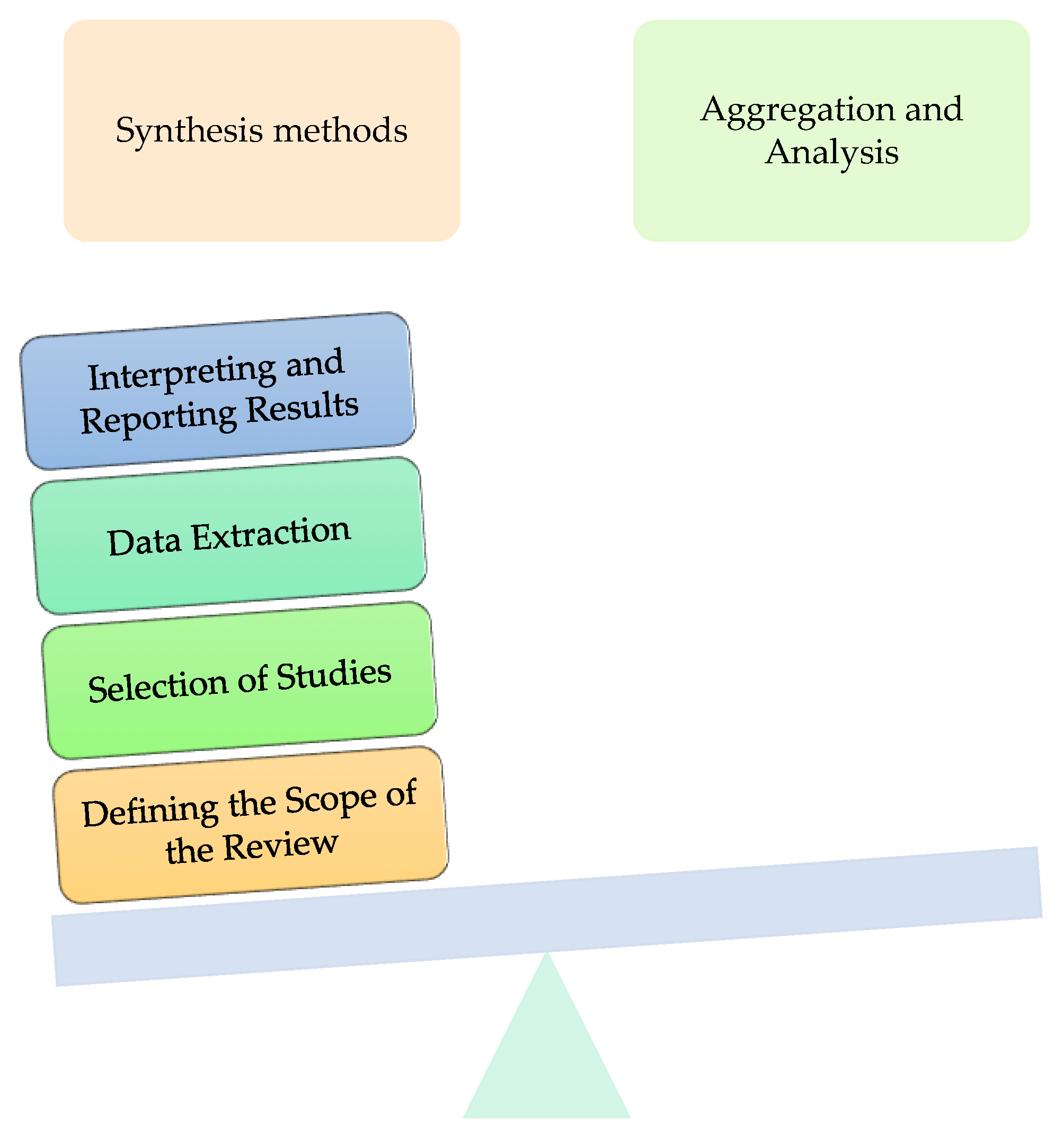

2.9. Synthesis Methods

2.9.1. Study Eligibility Criteria

2.9.2. Data Preparation for Synthesis

2.9.3. Data Visualization and Tabulation Methods

2.9.4. Synthesis Methodology

2.9.5. Exploration of Heterogeneity Causes

2.9.6. Sensitivity Analysis

2.10. Reporting Bias Assessment

2.11. Certainty Assessment

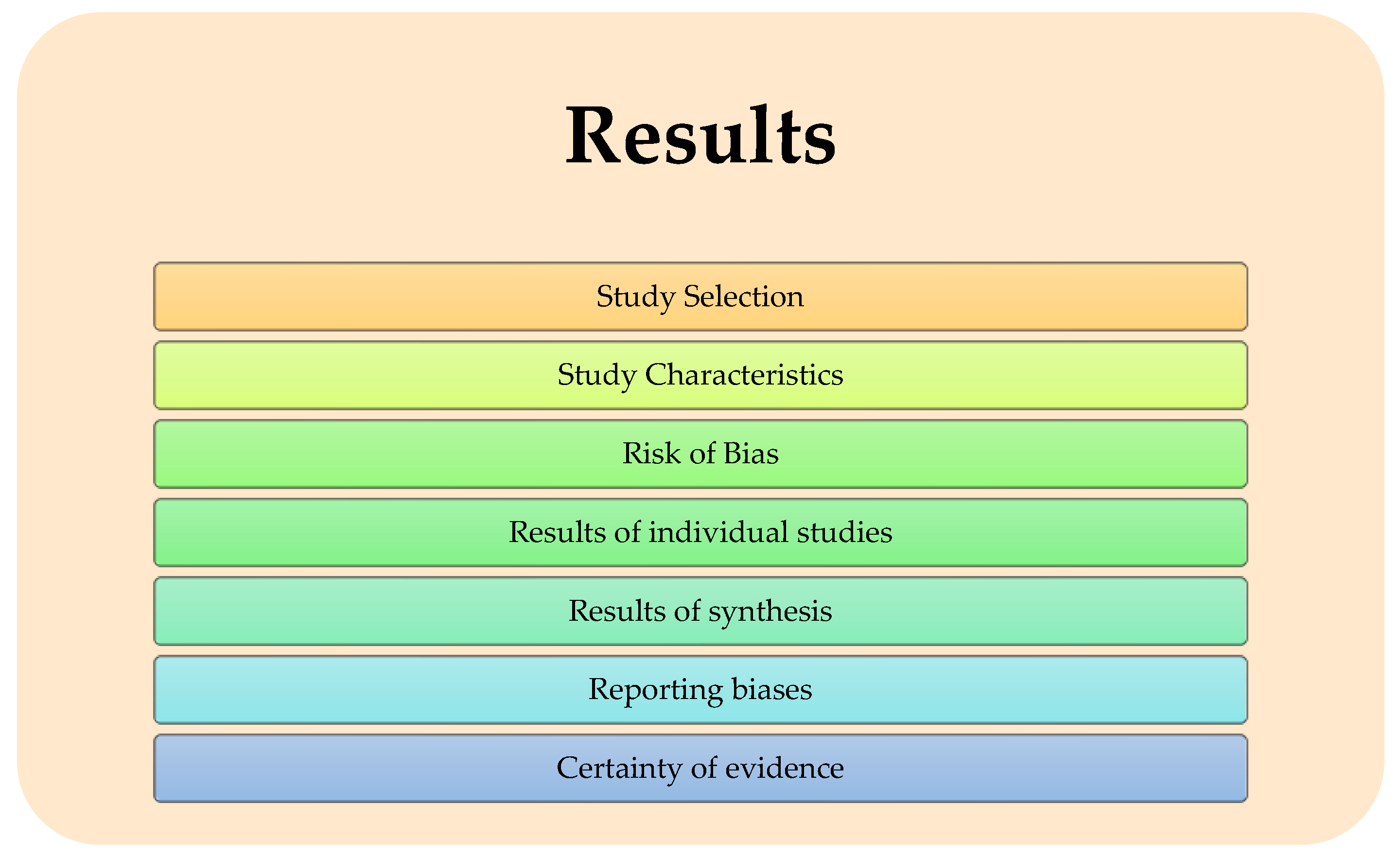

3. Results

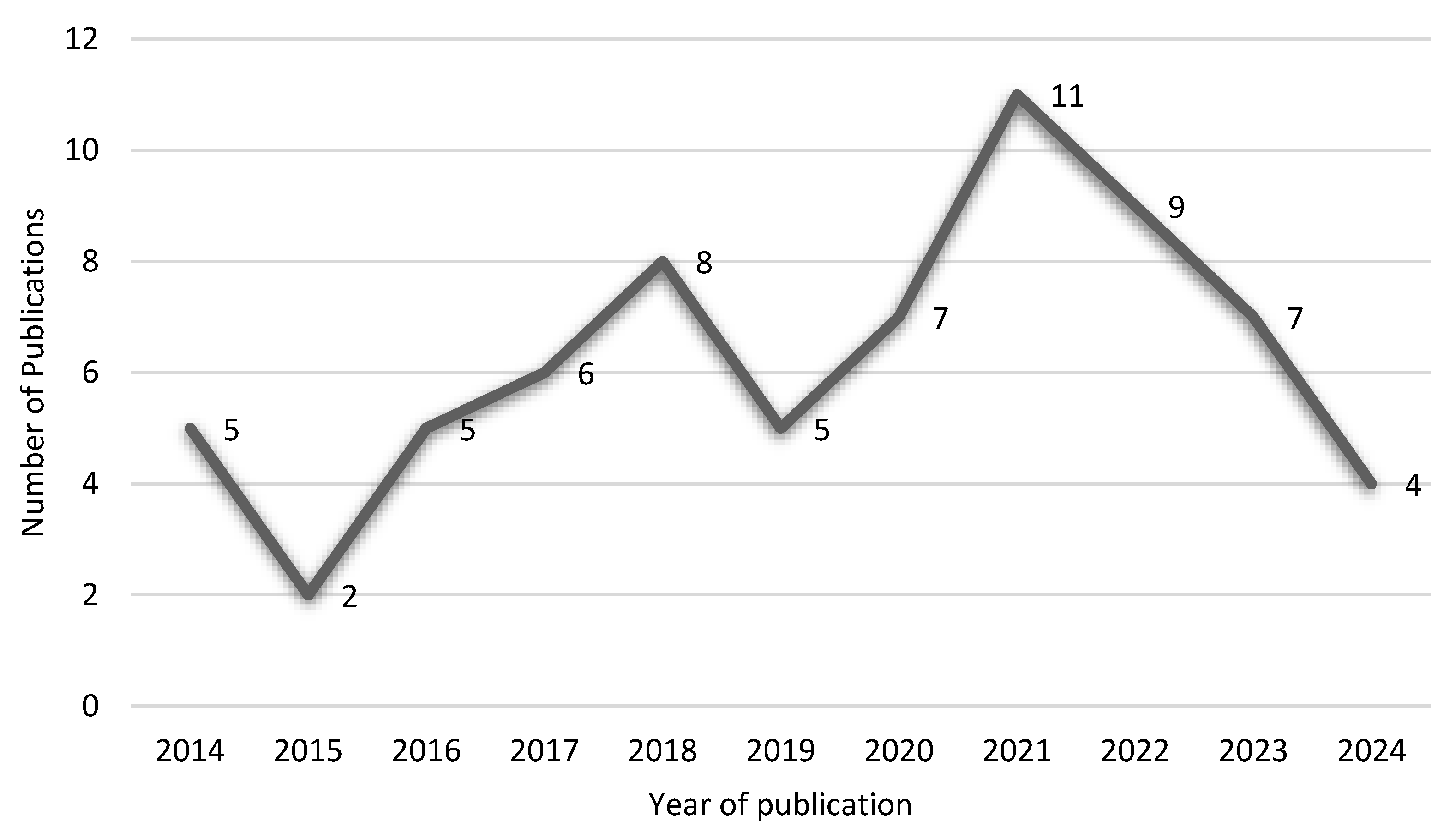

3.1. Study Selection

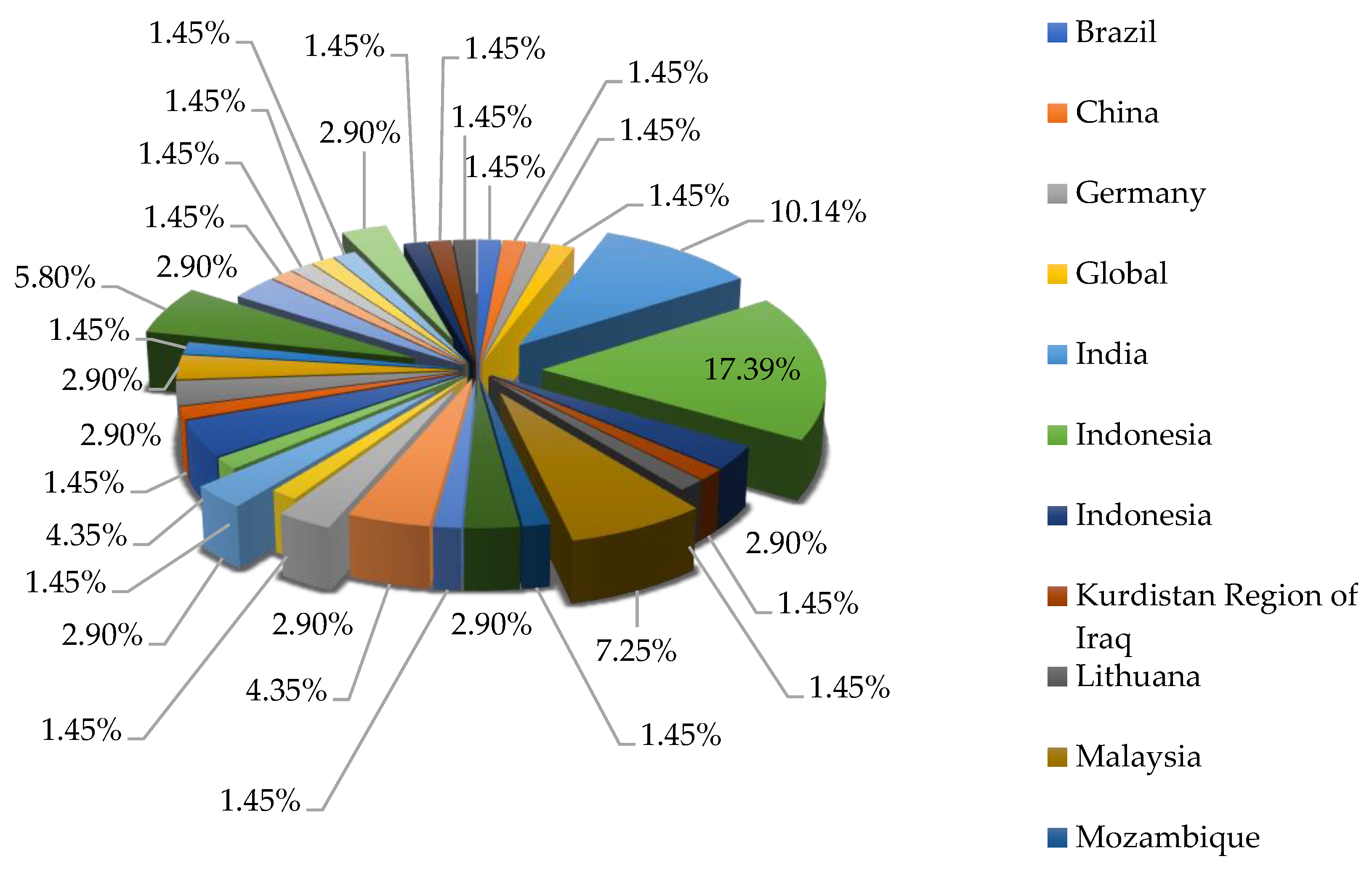

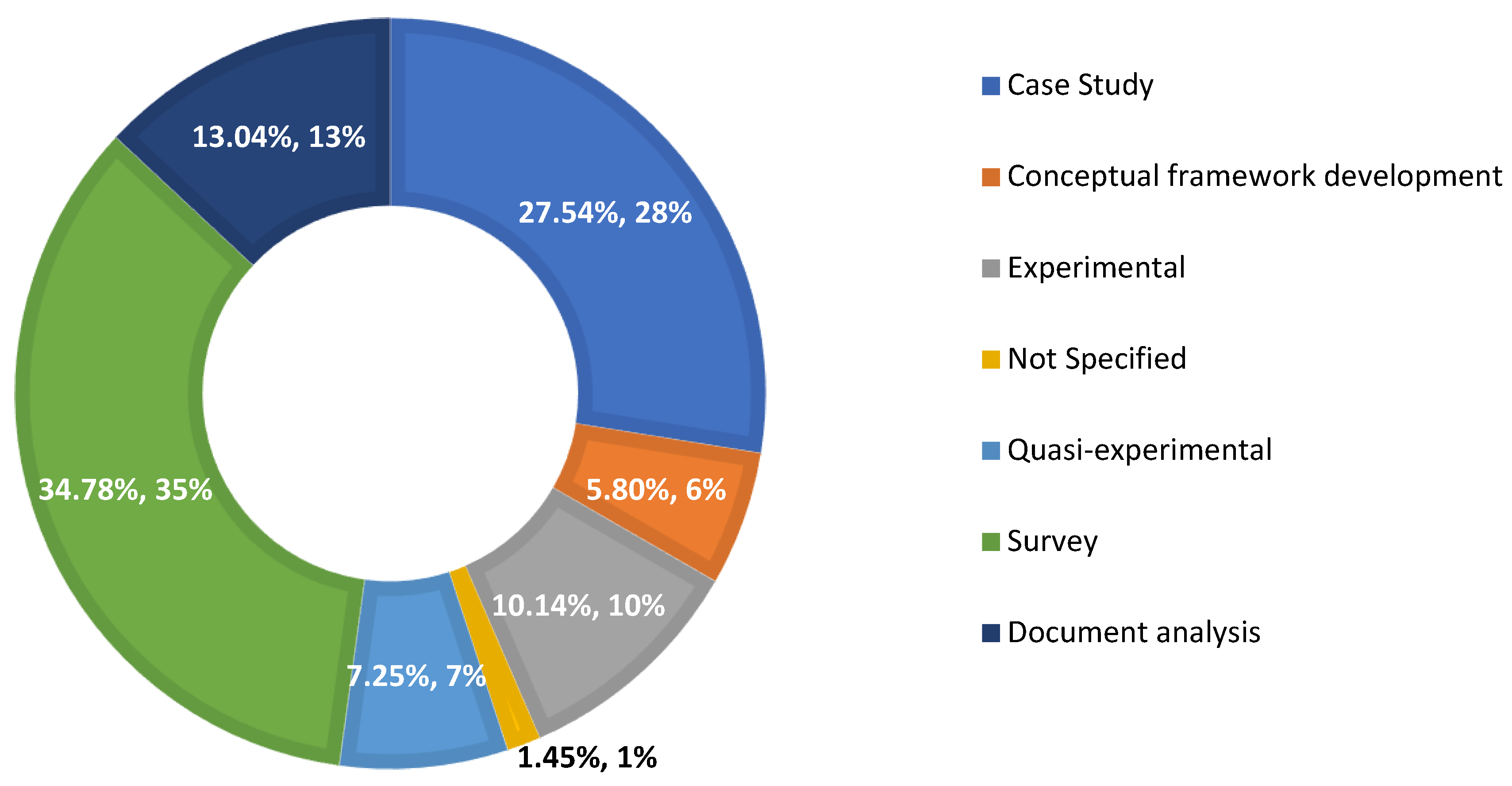

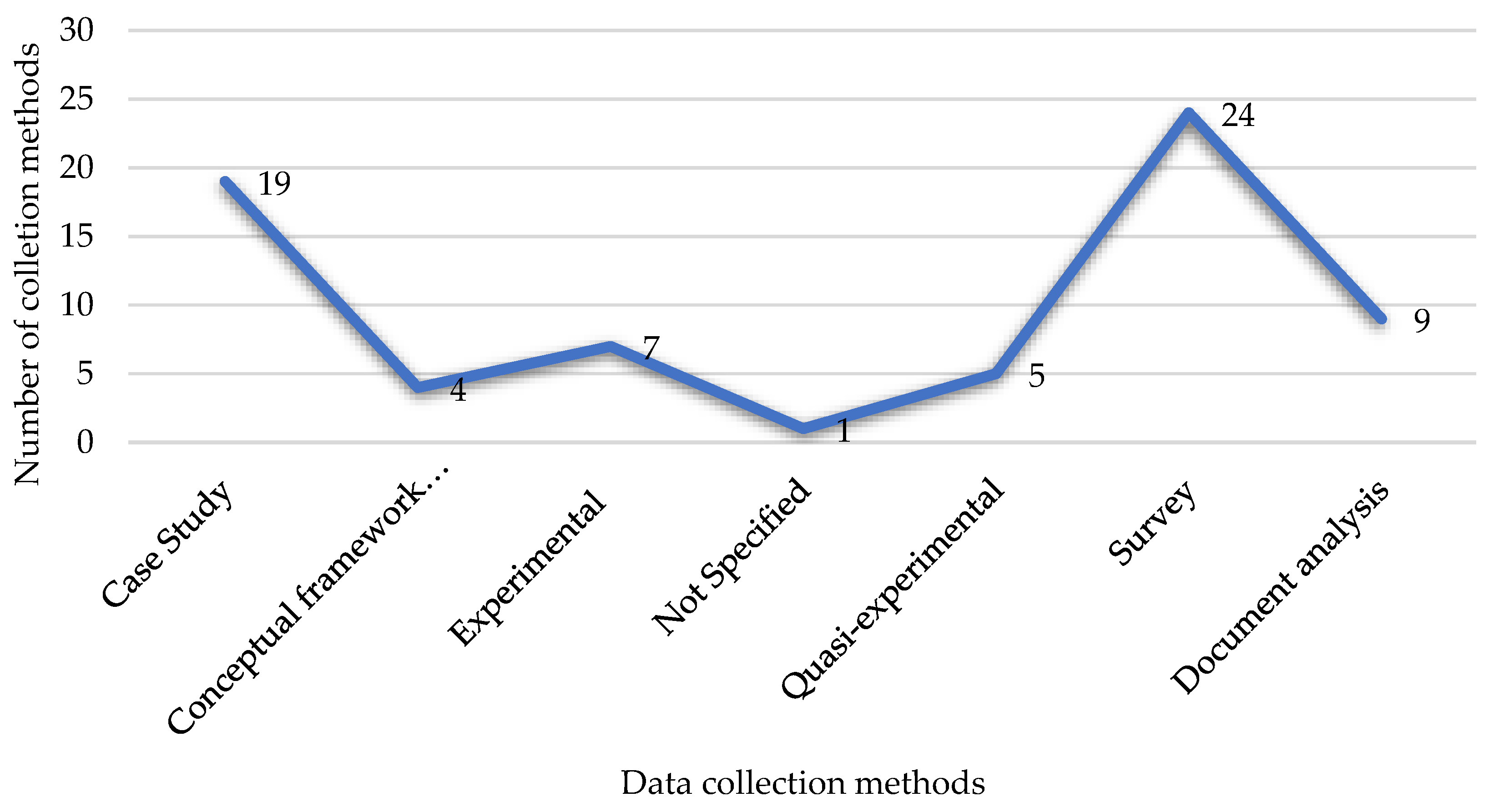

3.2. Study Characteristics

3.3. Risk of Bias in Studies

3.4. Results of Individual Studies

3.5. Results of Synthesis

3.5.1. Study Characteristics and Bias Assessment

3.5.2. Statistical Synthesis Results

3.5.3. Factors Contributing to Result Variability

3.5.4. Sensitivity Analyses

3.6. Reporting Biases

3.7. Certainty of Evidence

4. Key Findings and Strategic Implications for Business Leaders

5. Proposed Decision-Making Framework for Implementation

6. Proposed Best Practices for Successful Implementation

7. Proposed Metrics and KPIs for Measuring Performance

9. Related Real Case Studies

10. Proposed Roadmap for SMEs Businesses and Policy Recommendations

7. Discussion

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- N. Ndiaye, L. Abdul Razak, R. Nagayev, and A. Ng, “Demystifying small and medium enterprises’ (SMEs) performance in emerging and developing economies,” Borsa Istanb. Rev., vol. 18, no. 4, pp. 269–281, 2018. [CrossRef]

- J. U. Eziashi, “Manufacturing strategy of firms in emerging economy: the study of Nigerian manufacturing SMEs,” 2017. [CrossRef]

- A.. Tarutė and R. Gatautis, “ICT impact on SMEs performance,” Procedia Soc. Behav. Sci., vol. 110, pp. 1218–1225, 2014. [CrossRef]

- O. Niyi Anifowose, M. Ghasemi, and B. R. Olaleye, “Total quality management and small and medium-sized enterprises’ (SMEs) performance: Mediating role of innovation speed,” Sustainability, vol. 14, no. 14, p. 8719, 2022. [CrossRef]

- Growingscience.com. [Online]. Available: https://growingscience.com/beta/uscm/6561-the-influence-of-crisis-management-and-management-tools-on-firm-performance-evidence-from-manufacturing-smes-in-thailand.html. [Accessed: 20-Sep-2024]. [CrossRef]

- M. K. Anser et al., “How to unleash innovative work behavior of SMEs’ workers through knowledge sharing? Accessing functional flexibility as a mediator,” Eur. J. Innov. Manag., vol. 25, no. 1, pp. 233–248, 2022. [CrossRef]

- B. E. Narkhede, “Advance manufacturing strategy and firm performance: An empirical study in a developing environment of small- and medium-sized firms,” Benchmarking, vol. 24, no. 1, pp. 62–101, 2017. [CrossRef]

- M. Kharub, R. S. Mor, and S. Rana, “Mediating role of manufacturing strategy in the competitive strategy and firm performance: evidence from SMEs,” Benchmarking, vol. 29, no. 10, pp. 3275–3301, 2022. [CrossRef]

- A. K. Akgul, S. Gozlu, and E. Tatoglu, “Linking operations strategy, environmental dynamism and firm performance: Evidence from Turkish manufacturing companies,” Kybernetes, vol. 44, no. 3, pp. 406–422, 2015. [CrossRef]

- H. Singh and R. Mahmood, “Aligning manufacturing strategy to export performance of manufacturing small and medium enterprises in Malaysia,” Procedia Soc. Behav. Sci., vol. 130, pp. 85–95, 2014. [CrossRef]

- Petra Christian University, Jl. Siwalankerto 120-131, Surabaya, Indonesia, H. Siagian, H. Semuel, and W. G. Widjaja, “The effect of organizational culture and manufacturing strategy on firm performance through business process re-engineering,” Int. J. e-Educ. e-Bus. e-Manag. e-Learn., vol. 7, no. 3, pp. 191–201, 2017. [CrossRef]

- J. M. Serumaga-Zake and J. A. van der Poll, “Addressing the impact of fourth industrial revolution on South African manufacturing Small and Medium enterprises (SMEs),” Sustainability, vol. 13, no. 21, p. 11703, 2021. [CrossRef]

- A. Mohammad Khashman, “The effect of business process re-engineering on Organizational Performance: The mediating role of information and communications technology,” Int. J. Bus. Manag., vol. 14, no. 9, p. 132, 2019. [CrossRef]

- W. Lee, S.-K. Rhee, and J. Oh, “The relationships between manufacturing strategy process, manufacturing-marketing integration, and plant performance: an empirical study of Korean manufacturers,” Oper. Manag. Res., vol. 7, no. 3–4, pp. 117–133, 2014. [CrossRef]

- M. Enis Bulak and A. Turkyilmaz, “Performance assessment of manufacturing SMEs: a frontier approach,” Ind. Manag. Data Syst., vol. 114, no. 5, pp. 797–816, 2014. [CrossRef]

- Ellitan, L. The role of business enviromental and strategy alignment in the optimization of business performance of small scale manufacturing companies in indonesia. World J. Res. Rev. 2017, 5, 262762. [Google Scholar]

- Lestari, R. Kurniawan, J. Arifin, M. Yasir, M. Muhammad Saleh, and Akbarizan, “An integrated framework for the measurement of halal good manufacturing practices on the case of SMEs in the food sector,” J. Islam. Mark., vol. 14, no. 1, pp. 82–105, 2023. [CrossRef]

- A. Anwar, K. Jamil, M. Idrees, M. Atif, and B. Ali, “An empirical examination of SMEs sustainable performance through lean manufacturing,” Knowl. Proc.management, vol. 30, no. 3, pp. 289–299, 2023. [CrossRef]

- Susanty, L. S. Sumiyati, S. Syaiful, and Z. Nihlah, “The impact of lean manufacturing practices on operational and business performances at SMES in the wooden furniture industry,” Int. J. Lean Six Sigma, vol. 13, no. 1, pp. 203–231, 2022. [CrossRef]

- L. Alayón, K. Säfsten, and G. Johansson, “Barriers and enablers for the adoption of sustainable manufacturing by manufacturing SMEs,” Sustainability, vol. 14, no. 4, p. 2364, 2022. [CrossRef]

- S. Gamache, G. Abdul-Nour, and C. Baril, “Evaluation of the influence parameters of Industry 4.0 and their impact on the Quebec manufacturing SMEs: The first findings,” Cogent Eng., vol. 7, no. 1, p. 1771818, 2020. [CrossRef]

- H. M. Naeem and P. Garengo, “The interplay between industry 4.0 maturity of manufacturing processes and performance measurement and management in SMEs,” Int. J. Product. Perform. Manag., vol. 71, no. 4, pp. 1034–1058, 2022. [CrossRef]

- L. Driouach, K. Zarbane, and Z. Beidouri, “Literature review of lean manufacturing in small and medium-sized enterprises,” IJTech, vol. 10, no. 5, p. 930, 2019. [CrossRef]

- Sajan, Shalij, Ramesh, and B. Augustine, “Lean manufacturing practices in Indian manufacturing SMEs and their effect on sustainability performance,” J. Manuf. Technol. Manag., vol. 28, no. 6, pp. 772–793, 2017. [CrossRef]

- Sajan and Shalij, “A multicase study approach in Indian manufacturing SMEs to investigate the effect of Lean manufacturing practices on sustainability performance,” Int. J. Lean Six Sigma, vol. 12, no. 3, pp. 579–606, 2021. [CrossRef]

- Giyanti, A. Indrasari, W. Sutopo, and E. Liquiddanu, “Halal standard implementation in food manufacturing SMEs: its drivers and impact on performance,” J. Islam. Mark., vol. 12, no. 8, pp. 1577–1602, 2021. [CrossRef]

- “Linking dynamic capability, supply chain and raw material uncertainty to Indonesian SMEs manufacturing operational performance,” Quality - Access to Success, vol. 24, no. 193, 2023. [CrossRef]

- P. Bhatia and N. Diaz-Elsayed, “Facilitating decision-making for the adoption of smart manufacturing technologies by SMEs via fuzzy TOPSIS,” Int. J. Prod. Econ., vol. 257, no. 108762, p. 108762, 2023. [CrossRef]

- S. B. Ahmad and H. I. Ramadan, “The relationship among distinctive capabilities, business strategy, environment and performance: a proposed model of manufacturing SMEs in Palestine,” J Glob. Bus. Adv., vol. 11, no. 5, p. 610, 2018. [CrossRef]

- A. S. Ibidunni, A. I. Kolawole, M. A. Olokundun, and M. E. Ogbari, “Knowledge transfer and innovation performance of small and medium enterprises (SMEs): An informal economy analysis,” Heliyon, vol. 6, no. 8, p. e04740, 2020. [CrossRef]

- C. L. Niemeyer, I. Gehrke, K. Müller, D. Küsters, and T. Gries, “Getting Small Medium Enterprises started on Industry 4.0 using retrofitting solutions,” Procedia Manuf., vol. 45, pp. 208–214, 2020. [CrossRef]

- S. Kot, “Sustainable supply chain management in small and medium enterprises,” Sustainability, vol. 10, no. 4, p. 1143, 2018. [CrossRef]

- Effendi, Widjanarko, and Sugandini, J. Asian Finance Econ. Bus., vol. 8, no. 4, pp. 909–916, 2021. Available online: http://data.doi.or.kr/qr/10.13106/jafeb.2021.vol8.no4.0909.

- A. P. H. Wong and D. M. H. Kee, “Driving factors of industry 4.0 readiness among manufacturing SMEs in Malaysia,” Information (Basel), vol. 13, no. 12, p. 552, 2022. [CrossRef]

- Ulas, “Digital transformation process and SMEs,” Procedia Comput. Sci., vol. 158, pp. 662–671, 2019. [CrossRef]

- Purwaningsih, M. Muslikh, S. Suhaeri, and B. Basrowi, “Utilizing blockchain technology in enhancing supply chain efficiency and export performance, and its implications on the financial performance of SMEs,” Uncertain Supply Chain Manag., vol. 12, no. 1, pp. 449–460, 2024. [CrossRef]

- S. U. Saima, R. Badaruddin, R. B. R. Firdaus, and Sarjiyanto, “Challenges and ways forward for the Malaysian SMEs in the Halal food industry: a systematic review,” Potravinarstvo Slovak Journal of Food Sciences, vol. 18, 2024. [CrossRef]

- P. Jaiswal and A. Kumar, “Assessment of drivers to implement integrated lean green manufacturing system in Indian SMEs through IF-TOPSIS approach,” Int. J. Manag. Decis. Mak., vol. 17, no. 2, p. 224, 2018. [CrossRef]

- U. M. Godswill, O. T. Oyedepo, and S. O. Willie, “Effects of Innovation on Performance of Manufacturing SMEs in Nigeria: An empirical study,” Cloudfront.net. [Online]. Available online: https://d1wqtxts1xzle7.cloudfront.net/90425783/879-Effects-of-Innovation-on-Performance-of-Manufacturing-SMEs--libre.pdf?1661800758=&response-content-disposition=inline%3B+filename%3DInnovations_Competitive_Advantage_and_Pe.pdf&Expires=1726844882&Signature=ci9RlPdcoF8b~9tsqPGMCVITf3OSsxICLn0yvDCP4cLcjDr5Dzca-WGcYq~jwP7xRoycFTQfKchmz-sQiFI7PNzcNO2HGM17iylzczjOkYf~WsKz2OLMrhYTqIEVy8fI81335Cb5Zcg4ERaG-dBRC1VlXh9LxbqWVbToVqzP38079aTxR1AVhVz6~FItToklT17AQeABchc~6LxF2klpE810afL0~sTPoWUI9RYSVHHb1STCSt0Odif5SNo9tpfBitA62dCZkRCPv-Ah70p3fzdiXHUztN7Xz3UXmTKwIQoqvy2jWHduEufUg6X1k4amBCLdB2A1aW6enOXLMGho7g__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA. (accessed on 20 September 2024).

- Z. Tanasić, G. Janjić, and B. Kosec, “Lean concept in small and medium enterprises,” Mater. Geoenvironment, vol. 66, no. 2, pp. 129–137, 2019. [CrossRef]

- Researchgate.net. [Online]. Available online: https://www.researchgate.net/profile/Isaac-Nketsiah/publication/329529076_Financial_Management_Practices_and_Performance_of_SMEs_in_Ghana_The_Moderating_Role_of_Firm_age/links/5c0e3ff792851c39ebe252c5/Financial-Management-Practices-and-Performance-of-SMEs-in-Ghana-The-Moderating-Role-of-Firm-age.pdf (accessed on 20 September 2024).

- A. Thomas, W. Morris, C. Haven-Tang, M. Francis, and P. Byard, “Smart systems and collaborative innovation networks for productivity improvement in SMEs,” J. Open Innov., vol. 7, no. 1, p. 3, 2021. [CrossRef]

- Awheda, M. N. Ab Rahman, R. Ramli, and H. Arshad, “Factors related to supply chain network members in SMEs,” J. Manuf. Technol. Manag., vol. 27, no. 2, pp. 312–335, 2016. [CrossRef]

- Researchgate.net. [Online]. Available online: https://www.researchgate.net/profile/Alen-Sawaya/publication/319939464_Weakness_of_manufacturing_SMEs_in_employment_creation_for_the_youth_in_Mozambique/links/59c27d5aa6fdcc69b92fff85/Weakness-of-manufacturing-SMEs-in-employment-creation-for-the-youth-in-Mozambique.pdf (accessed on 20 September 2024).

- “Research portal,” Uj.ac.za. [Online]. Available online: https://ujcontent.uj.ac.za/esploro/outputs/graduate/Exploring-the-impact-of-quality-management/9918309907691 (accessed on 20 September 2024).

- P. Gashi, I. Hashi, and G. Pugh, “Export behaviour of SMEs in transition countries,” Small Bus. Econ., vol. 42, no. 2, pp. 407–435, 2014. [CrossRef]

- M. A. Al-Hakimi, M. M. Goaill, H. M. Al-Hattami, M. A. Murshid, M. H. Saleh, and S. A. M. Moghalles, “Improving operational performance of manufacturing SMEs: the interactive effect of technical and human lean practices,” Int. J. Qual. Reliab. Manag., vol. 40, no. 4, pp. 1092–1110, 2023. [CrossRef]

- E. Okwute, “The use of Virtual Reality in promoting industry 4.0 in manufacturing SMEs,” University of Wales Trinity Saint David, 2024.

- M. E. Bulak, A. Turkyilmaz, M. Satir, M. Shoaib, and M. Shahbaz, “Measuring the performance efficiency of Turkish electrical machinery manufacturing SMEs with frontier method,” Benchmarking, vol. 23, no. 7, pp. 2004–2026, 2016. [CrossRef]

- Muangmee, N. Kassakorn, B. Khalid, R. Bacik, and S. Kot, “Evaluating competitiveness in the Supply Chain Management of small and medium scale enterprises,” J. Competitiveness, vol. 14, no. 3, pp. 93–112, 2022. [CrossRef]

- S. Singh, E. U. Olugu, and S. N. Musa, “Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises,” Procedia CIRP, vol. 40, pp. 608–613, 2016. [CrossRef]

- M. Mulyana and W. Wasitowati, “The improvement of collaborative networks to increase small and medium enterprises (SMEs) performance,” Serbian J. Manag., vol. 16, no. 1, pp. 213–229, 2021. [CrossRef]

- A. Moeuf, R. Pellerin, S. Lamouri, S. Tamayo-Giraldo, and R. Barbaray, “The industrial management of SMEs in the era of Industry 4.0,” Int. J. Prod. Res., vol. 56, no. 3, pp. 1118–1136, 2018. [CrossRef]

- S. Mohammad and C. F. Oduoza, “Lean-excellence business management for manufacturing SMEs focusing on KRI,” Int. J. Product. Perform. Manag., vol. 69, no. 3, pp. 519–539, 2019. [CrossRef]

- M. Yunus Amar, “The influence of product differentiation strategy on operational performance at Small and Medium Enterprises (SMEs) in South Sulawesi, Indonesia,” J. Econ. Bus. Account. Ventura, vol. 18, no. 3, p. 343, 2015. [CrossRef]

- A. Dresch, D. R. Veit, P. N. de Lima, D. P. Lacerda, and D. C. Collatto, “Inducing Brazilian manufacturing SMEs productivity with Lean tools,” Int. J. Product. Perform. Manag., vol. 68, no. 1, pp. 69–87, 2019. [CrossRef]

- M. Soroush, M. Baldea, and T. F. Edgar, Smart Manufacturing: Concepts and methods. Elsevier, 2020.

- A. Memari, H. R. Panjehfouladgaran, A. R. Abdul Rahim, and R. Ahmad, “The impact of lean production on operational performance: a case study,” Asia-Pac. J. Bus. Adm., vol. 16, no. 3, pp. 530–552, 2024. [CrossRef]

- T. Hassel, N. Murray, G. Klimov, and A. Beniyash, “Cutting and welding of high-strength steels using non-vacuum electron beam as a universal tool for material processing,” 2016. [CrossRef]

- M. Johansson and J. Olhager, “Manufacturing relocation through offshoring and backshoring: the case of Sweden,” J. Manuf. Technol. Manag., vol. 29, no. 4, pp. 637–657. [CrossRef]

- N. A. Daniel, R. Kumar, R. Sindhwani, and K. Mathiyazhagan, “Implementation of sustainable manufacturing practices in Indian SME: A case study,” in Lecture Notes in Mechanical Engineering, Singapore: Springer Nature Singapore, 2023, pp. 309–322. [CrossRef]

- Researchgate.net. [Online]. Available online: https://www.researchgate.net/profile/Abror-Hoshimov-2/publication/360464412_Implementation_of_Lean_Manufacturing_tools_in_emerging_countries_evidence_from_Uzbek_SMEs/links/6278f7d4973bbb29cc6e0737/Implementation-of-Lean-Manufacturing-tools-in-emerging-countries-evidence-from-Uzbek-SMEs.pdf (accessed on 20 September 2024).

- Anggrahini, Y. Prasetyawan, and S. Indriyani Diartiwi, “Increasing production efficiency using karakuri principle (A case study in Small and Medium Enterprise),” IOP Conf. Ser. Mater. Sci. Eng., vol. 852, no. 1, p. 012117, 2020. [CrossRef]

- A. Thomas, C. Haven-Tang, R. Barton, R. Mason-Jones, M. Francis, and P. Byard, “Smart Systems implementation in UK food manufacturing companies: A sustainability perspective,” Sustainability, vol. 10, no. 12, p. 4693, 2018. [CrossRef]

- Huamán, J. Llontop, C. Raymundo, and F. Dominguez, “Production management model based on lean manufacturing focused on the human factor to improve productivity of small businesses in the metalworking sector,” in Advances in Intelligent Systems and Computing, Cham: Springer International Publishing, 2020, pp. 847–853. [CrossRef]

- S. Tsai, “When shadow banking can be productive: Financing small and medium enterprises in China,” J. Dev. Stud., vol. 53, no. 12, pp. 2005–2028, 2017. [CrossRef]

- V. Majstorovic, S. Stojadinovic, S. Zivkovic, D. Djurdjanovic, Z. Jakovljevic, and N. Gligorijevic, “Cyber-physical manufacturing metrology model (CPM 3 ) for sculptured surfaces – turbine blade application,” Procedia CIRP, vol. 63, pp. 658–663, 2017. [CrossRef]

- A. Sohal, A. A. Nand, P. Goyal, and A. Bhattacharya, “Developing a circular economy: An examination of SME’s role in India,” J. Bus. Res., vol. 142, pp. 435–447, 2022. [CrossRef]

- S. Blose and O. E. Okeke-Uzodike, “Pre-fourth industrial revolution : challenges for small, medium and micro enterprises in a transforming economy,” Journal of Contemporary Management, vol. 17, no. se1, pp. 67–90, 2020. [CrossRef]

- Tsiu, S.; Ngobeni, M.; Mathabela, L.; Thango, B. Applications and Competitive Advantages of Data Mining and Business Intelligence in SMEs Performance: A Systematic Review. Preprints 2024, 2024090940. [Google Scholar] [CrossRef]

- Mkhize, A.; Mokhothu, K.; Tshikhotho, M.; Thango, B. Evaluating the Impact of Cloud Computing on SMEs Performance: A Systematic Review. Preprints 2024, 2024090882. [Google Scholar] [CrossRef]

- Kgakatsi, M.; Galeboe, O.; Molelekwa, K.; Thango, B. The Impact of Big Data on SME Performance: A Systematic Review. Preprints 2024, 2024090985. [Google Scholar] [CrossRef]

- Molete, O. B.; Mokhele, S. E.; Ntombela, S. D.; Thango, B. A. The Impact of IT Strategic Planning Process on SME Performance: A Systematic Review. Preprints 2024, 2024091024. [Google Scholar] [CrossRef]

- Mothapo, M.; Thango, B.; Matshaka, L. Tracking and Measuring Social Media Activity: Key Metrics for SME Strategic Success – A Systematic Review. Preprints 2024, 2024091757. [Google Scholar] [CrossRef]

- Ngcobo, K.; Bhengu, S.; Mudau, A.; Thango, B.; Matshaka, L. Enterprise Data Management: Types, Sources, and Real-Time Applications to Enhance Business Performance - A Systematic Review. Preprints 2024, 2024091913. [Google Scholar] [CrossRef]

- Mohlala, T. T.; Mehlwana, L. L.; Nekhavhambe, U. P.; Thango, B.; Matshaka, L. Strategic Innovation in HRIS and AI for Enhancing Workforce Productivity in SMEs: A Systematic Review. Preprints 2024, 2024091996. [Google Scholar] [CrossRef]

- Chabalala, K.; Boyana, S.; Kolisi, L.; Thango, B. A.; Matshaka, L. Digital Technologies and Channels for Competitive Advantage in SMEs: A Systematic Review. Preprints 2024, 2024100020. [Google Scholar] [CrossRef]

- Ndzabukelwako, Z.; Mereko, O.; Sambo, T. V.; Thango, B. The Impact of Porter’s Five Forces Model on SMEs Performance: A Systematic Review. Preprints 2024, 2024100119. [Google Scholar] [CrossRef]

- Maswanganyi, N. G.; Fumani, N. M.; Khoza, J. K.; Thango, B. A.; Matshaka, L. Evaluating the Impact of Database and Data Warehouse Technologies on Organizational Performance: A Systematic Review. Preprints 2024, 2024100059. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, A. Operational Efficiency and Quality Management in SMEs: A Review. Production Planning & Control 2015, 26, 678–690. [Google Scholar]

| Ref. | Cites | Year | Contribution | Pros | Cons |

|---|---|---|---|---|---|

| [16] | 85 | 2014 | The paper uses Melitz’s dynamic model to explore the export behaviors of SMEs in Transition Countries (TCs). It highlights the importance of human and technology-related factors, productivity-enhancing spillovers, firm size, ownership type, activity type, external finance availability, networking, and market share. | Provides a comprehensive understanding of SME internationalization and export behaviors in TCs. Identifies a broad range of influencing factors. | Limited to SMEs in Transition Countries; may not be generalizable to other regions. |

| [17] | 0 | 2016 | Explores the role of shadow banking in financing SMEs in China, focusing on informal finance and non-banking financial institutions. Highlights how regulated NBFIs could support SMEs. | Provides a detailed analysis of various shadow banking forms and their implications for SME financing. Offers insights into how regulated NBFIs can serve SMEs effectively. | May not fully capture the risks associated with informal financial intermediation. Limited to the Chinese context, which might not be applicable elsewhere. |

| [18] | 720 | 2018 | Reviews applied research on Industry 4.0 in SMEs, highlighting performance objectives, managerial capacities, and technology adoption. | Provides a framework for classifying Industry 4.0 applications; emphasizes flexibility and cost-effectiveness of new technologies compared to traditional systems. | SMEs primarily adopt Cloud Computing and IoT; limited application in production planning; many projects are cost-driven with minimal business model transformation. |

| [19] | 103 | 2018 | The paper analyzes five performance indicators for SMEs using World Bank Enterprise Survey data. It identifies how factors like firm characteristics, finance, infrastructure, and regulation impact SME performance differently for small and medium enterprises in emerging economies. | Comprehensive analysis of internal and external drivers for SME performance. Highlights the importance of infrastructure and formalization in SMEs’ growth. | Limited scope regarding the impact of informal SMEs. Some conclusions on financing require further empirical testing in various regions. |

| [20] | 0 | 2018 | Examines the moderating effect of firm age on the relationship between financial management practices and performance in SMEs. Utilizes a sample of 200 SMEs in Sekondi-Takoradi. | Highlights the importance of financial management practices (e.g., receivable, cash, inventory, and asset management) on SME performance. Identifies firm age as a significant moderating factor. | Limited to SMEs in Sekondi-Takoradi; results may not be generalizable to other regions. Study relies on self-reported data which could be biased. |

| [21] | 0 | 2018 | Examines the moderating effect of firm age on the relationship between financial management practices and performance in SMEs. Utilizes a sample of 200 SMEs in Sekondi-Takoradi. | Highlights the importance of financial management practices (e.g., receivable, cash, inventory, and asset management) on SME performance. Identifies firm age as a significant moderating factor. | Limited to SMEs in Sekondi-Takoradi; results may not be generalizable to other regions. Study relies on self-reported data which could be biased. |

| [22] | 2 | 2019 | This paper presents a production management model based on lean manufacturing, focusing on the human factor, to improve productivity in small metalworking businesses. The model integrates lean tools with a focus on the human aspect to address informality and lack of standardization. |

- Addresses the human factor, which is critical in small businesses. - Demonstrates a significant productivity increase (70%) through lean manufacturing. - Provides practical insights into implementing lean in resource-constrained environments. |

- Limited generalizability due to focus on small businesses in the metalworking sector. - Results are specific to the company studied and may not apply to other contexts. - The model’s effectiveness depends heavily on the human factor, which can be variable. |

| [23] | 0 | 2019 | Explores how distinctive capabilities, business strategy, and environmental uncertainty affect the performance of manufacturing SMEs in Palestine. Develops a model showing the relationship between distinctive capabilities, strategy, environment, and performance. | Provides a context-specific model for SME performance in Palestine, offering insights for policymakers, business owners, and educators. Includes critical capabilities such as marketing, HR, and operations. | Limited generalizability to other regions and sectors due to its focus on Palestine. Lack of broader application and empirical testing across different industries. |

| [24] | 0 | 2020 | Discusses retrofitting solutions for helping German SMEs adopt Industry 4.0. Highlights the role of employee training, digital assistance, and retrofitting of existing machinery. Presents the Digital Capability Center (DCC) Aachen’s learning factory concept to assist SMEs with digital transformation. | Focuses on practical, hands-on solutions like mobile sensor kits and IoT platforms. Provides a structured learning process and emphasizes competence-building to overcome digitization challenges. | Primarily focused on German SMEs, limiting global generalizability. Barriers such as high investment costs and lack of skilled labor remain challenges even with retrofitting. |

| [25] | 12 | 2020 | The paper explores effective methods for digital transformation in Quebec’s manufacturing SMEs by evaluating factors influencing digital performance and identifying critical Industry 4.0 technologies and practices. It uses a model of digital performance and hypothesis testing to guide digital transformation efforts. | - Provides actionable insights for SMEs on digital transformation. - Uses a detailed methodology including questionnaires and interviews. - Focuses on affordable and easy-to-integrate digital tools. |

- Limited to Quebec SMEs, which may not generalize to other regions. - Based on a specific experience-based methodology that may not cover all scenarios |

| [26] | 24 | 2021 | Investigates the drivers of halal standard implementation and its impact on SME performance in Indonesia. Finds that internal motivation and organizational commitment positively affect halal standard implementation, leading to improved operational, market, and financial performance. | Provides empirical evidence on the positive effects of halal standards on SME performance. Highlights the role of internal motivation in overcoming external pressures. | Limited to food manufacturing SMEs in Indonesia, with a small sample size. Subjectivity in performance evaluation may affect results. |

| [27] | 13 | 2022 | Proposes an SME-oriented Industry 4.0 maturity framework linking manufacturing processes’ maturity with performance measurement and management (PMM) practices. | Highlights the need for assessing SMEs’ current manufacturing processes and PMM interplay, offering an actionable framework for improvement towards Industry 4.0 adoption. | Limited by its exploratory nature and the need for further validation across different SME sectors. Does not provide detailed solutions for overcoming I4.0 adoption challenges. |

| [28] | 5 | 2022 | Explores the relationship between lean manufacturing and sustainable performance (SP) of SMEs in Pakistan. Identifies significant impacts of lean practices like process and equipment, product design, supplier and customer relationships on SP. | Provides a modern approach for SMEs to minimize material wastage; identifies green supply chain management (GSCM) as a mediator between lean practices and SP. | Limited verification of the impact of planning, control, and HR practices; regional focus on SMEs in Pakistan may limit generalizability. |

| [29] | 5 | 2022 | A systematic review that identifies and categorizes barriers and enablers for the adoption of sustainable manufacturing by SMEs, focusing on the triple bottom line (environmental, social, and economic) sustainability. | Offers a comprehensive categorization of barriers and enablers with actionable insights for SMEs to leverage enablers to mitigate barriers. Emphasizes “critical enablers” for sustainability adoption. | Focuses primarily on the European SME context, which may limit the generalizability to other regions. The study’s findings are largely based on existing literature, without empirical validation through direct field data. |

| [30] | 0 | 2022 | Proposes a multi-criteria decision-making model using fuzzy TOPSIS to aid SMEs in selecting smart manufacturing technologies tailored to their needs. A case study evaluates smart technologies for SMEs considering performance, cost, and sustainability. | Provides a clear roadmap for SMEs to transition to Industry 4.0 by ranking technologies and criteria. Involves all levels of personnel in decision-making, ensuring holistic adoption. | Limited to a specific case study, which may affect generalizability to other SMEs or industries. Lacks real-world application on a larger scale. |

| [31] | 29 | 2022 | Investigates the mediating role of innovation speed in the relationship between total quality management (TQM) and SME performance. Focuses on Nigerian SMEs using PLS-SEM modeling. | Highlights the positive impact of TQM on operational performance and the role of innovation speed. Provides insights into the relationship in developing countries, contributing to the scarce literature. | Limited generalizability due to focus on Nigerian SMEs. The use of judgmental sampling could introduce bias. Lack of longitudinal data to confirm findings over time. |

| [32] | 1,089 | 2022 | Examines the impact of lean manufacturing (LM) practices on operational performance (OP) and business performance (BP) in SMEs within the wooden furniture industry in Jepara. Utilizes PLS regression to analyze data. | Provides empirical evidence on the effectiveness of collective LM practices and their impact on OP and BP. Offers practical insights for SME managers in improving performance. | Limited to SMEs in the wooden furniture industry in Jepara, Indonesia. Uses Likert scale, which may introduce bias. Results may not be generalizable beyond this context. |

| [33] | 644 | 2022 | This paper investigates the impact of lean manufacturing principles on operational efficiency in a Malaysian SME, focusing on waste elimination. The study uses process activity mapping to identify and address inefficiencies. | -Demonstrates significant reduction in waiting times and cycle time. -Provides practical insights for lean implementation in SMEs with volatile demand patterns. -Uses a real case study, enhancing the applicability of findings. |

-Limited to a single case study, which may affect generalizability. - Results are specific to a particular SME in Malaysia. -Mixed success of lean implementation noted in the literature, highlighting the need for more research. |

| Proposed Systematic review | Integrates findings from diverse studies to provide a comprehensive understanding of how effective manufacturing operations contribute to enhancing SME performance. It also examines the challenges SMEs face in adopting and optimizing manufacturing practices, and it offers insights into best practices and strategies for achieving operational excellence. | It offers valuable insights and recommendations for future research, helping SMEs to enhance their manufacturing operations and improve performance outcomes. |

- | ||

| Criteria | Inclusion | Exclusion |

|---|---|---|

| Topic | Articles focusing on The Role of Manufacturing Operations in SMEs Performance | Articles not related to The Role of Manufacturing Operations in SMEs Performance |

| Research Framework | This article must include a research framework or methodology for The Role of Manufacturing Operations in SMEs Performance | Articles lacking clear research framework related to The Role of Manufacturing Operations in SMEs Performance |

| Language | Must be written in English | Articles published in languages other than English |

| Period | Articles between 2014 and 2024 | Articles outside 2014 and 2024 |

| Search Terms | Database | Fields | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (“Manufacturing operations” AND “SMEs” AND “performance”) | OR | (“Lean manufacturing” AND “small and medium-sized enterprises” AND “productivity”) | OR | (“Advanced manufacturing technologies” AND “small businesses” AND “financial performance”) | OR | (“Production management” AND “SMEs” AND “competitive advantage”) | OR | (“Operations management” AND “small firms” AND “efficiency”). | Google Scholar Web of Science SCOPUS |

Title Abstract Keywords |

| Fields | Description | Selection |

|---|---|---|

| Title | The name of the research article or paper. | None |

| Year | The publication year of the study. | None |

| Online database | The database where the article was sourced. | Google Scholar, SCOPUS, Web of Science |

| Journal name | Represents data as slices of a whole, ideal for showing proportional or percentage distribution of categories. | None |

| Research type | Shows parts of a whole, allowing multiple variables to be represented in the same category for easier comparison. | Article Journal, Doctoral Thesis, Research paper, Conference paper, Review, Thesis, Book chapter |

| Cites | Plots individual data points on an X and Y axis to explore relationships or correlations between two variables. | None |

| Discipline or subject area | Uses color coding to represent data intensity or frequency, useful for spotting patterns in large datasets. | SME Performance, Manufacturing operations, Industry 4.0, Business strategy, Financial Management |

| Industry Context | The industry or sector the research is focused on | General SMEs, Manufacturing SMEs, ICT |

| Geographic location | The region or country where the study was conducted or focused. |

None |

| Economic context | The economic environment of the study | Developed, developing |

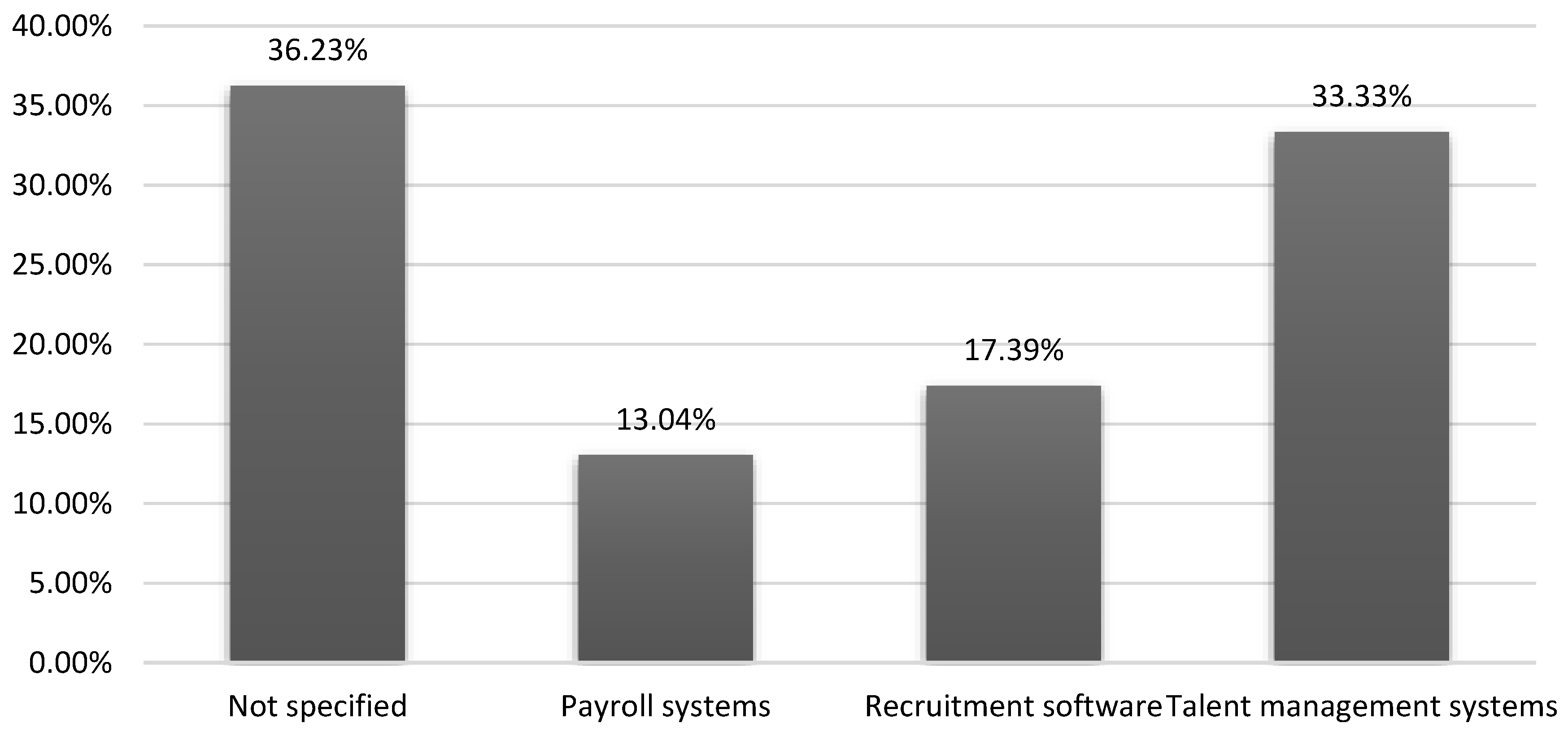

| Types of HRIS Technologies | The specific Big Data technologies used in the research. |

Various, Quality, Cost, Delivery, Flexibility |

| Research design | The design of the study | Experimental, quasi-experimental, case study, survey |

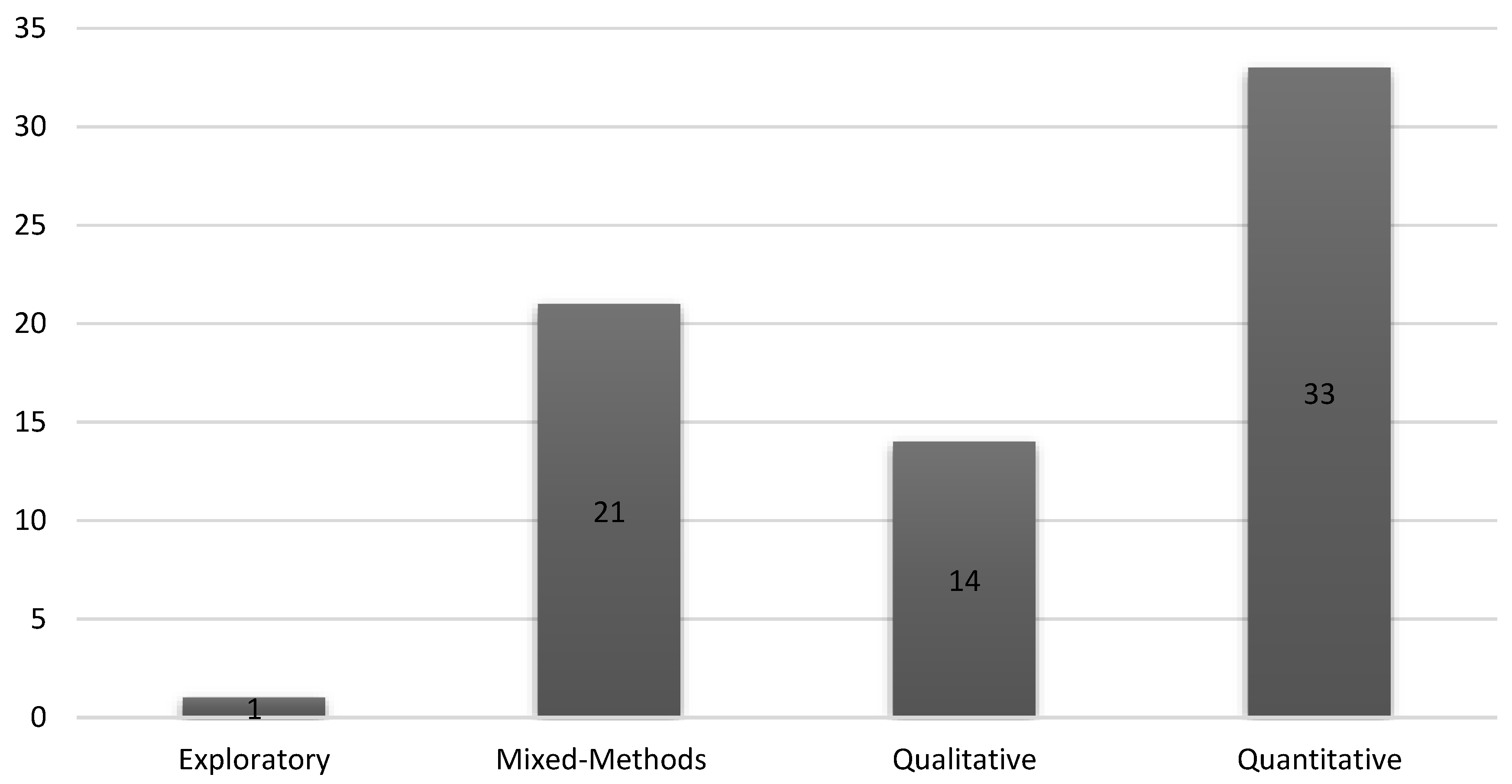

| Types of study | The methodology used | Qualitative, quantitative, and Mixed methods |

| Sample size | The number of participants or entities involved in the study. | None |

| Sample Characteristics | Demographic or specific features of the Sample |

SMEs, Manufacturing manages, policymakers |

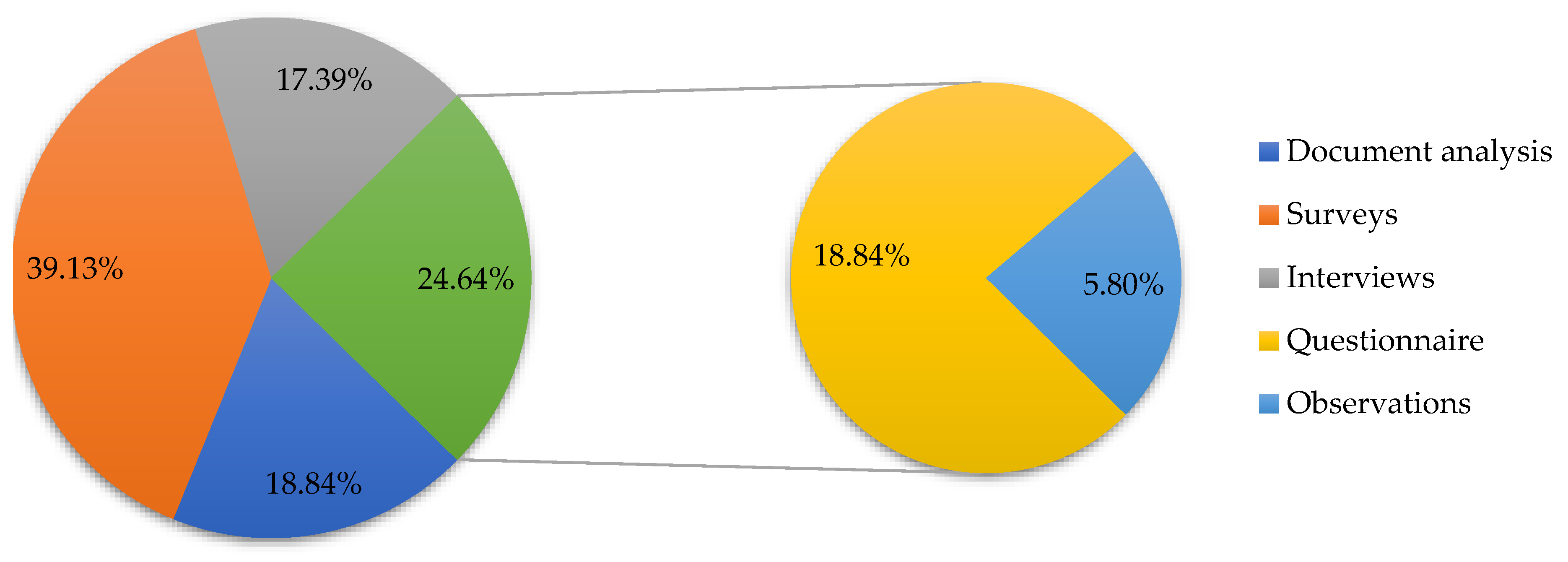

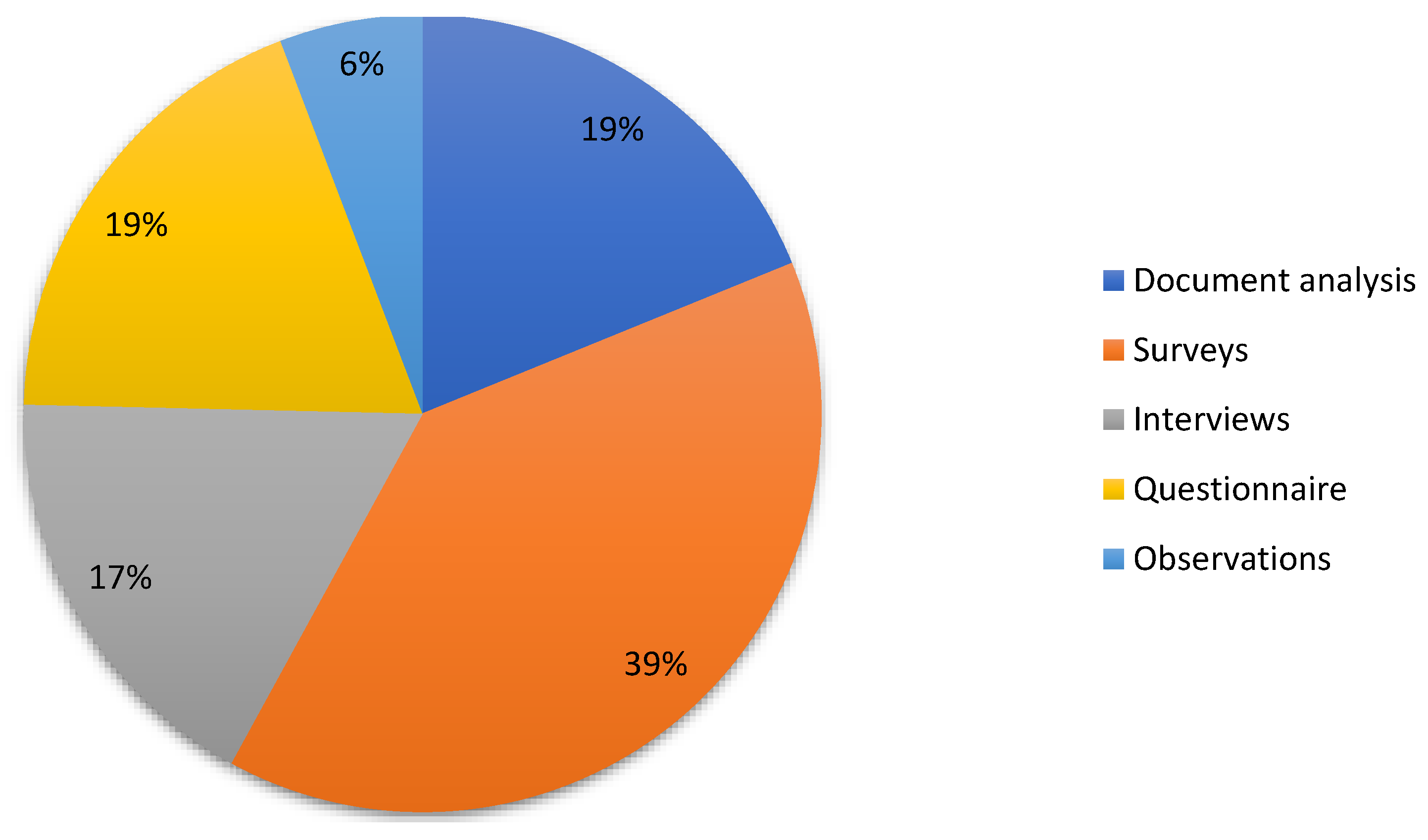

| Data Collection Methods | Techniques used to gather data | Interviews, surveys, observations, document Analysis |

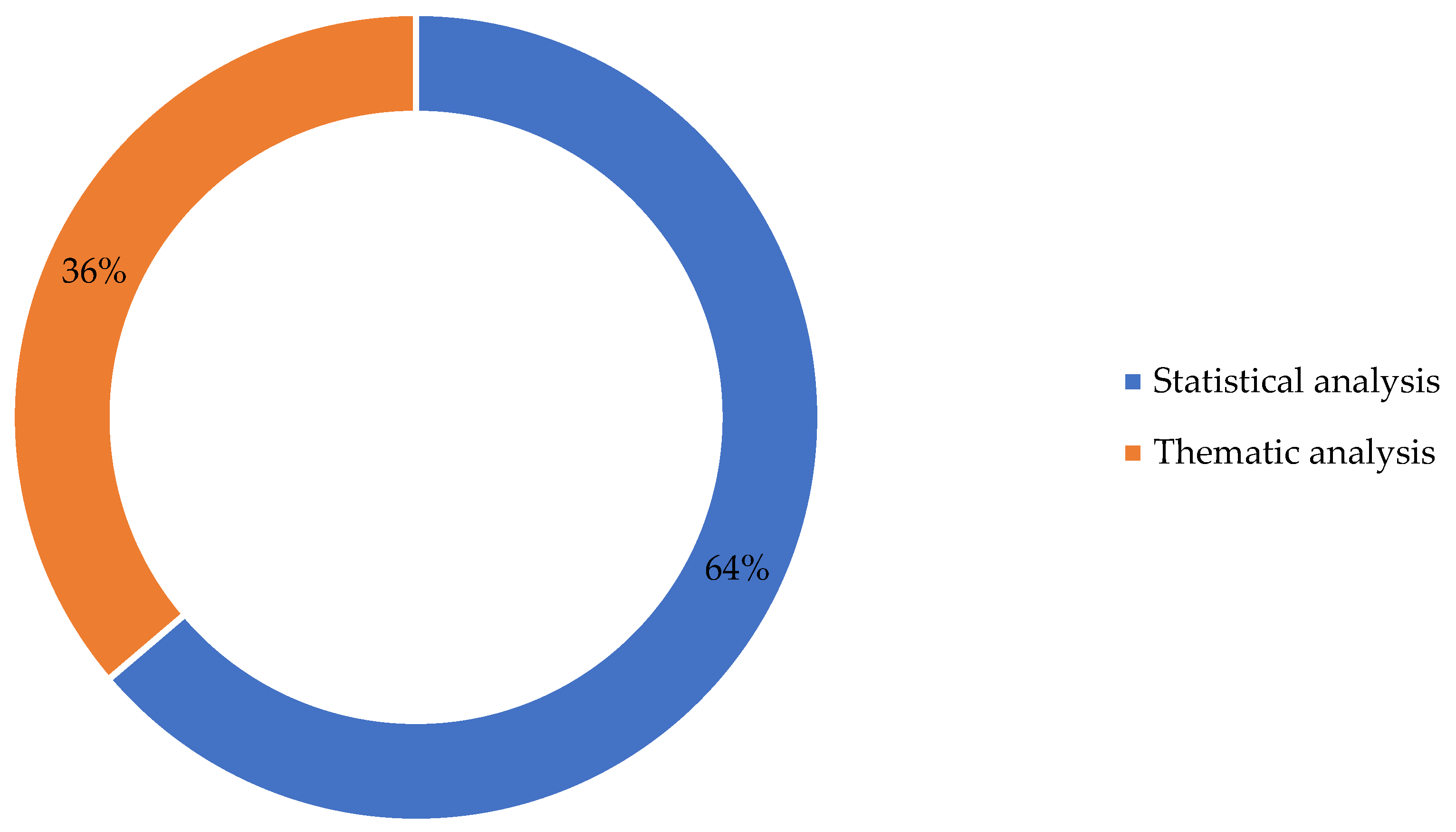

| Data analysis techniques | Methods used to analyze the data | statistical analysis, thematic analysis |

| Workforce productivity metrics | Identify performance improvement areas. | Firm performance, Production efficiency, profitability |

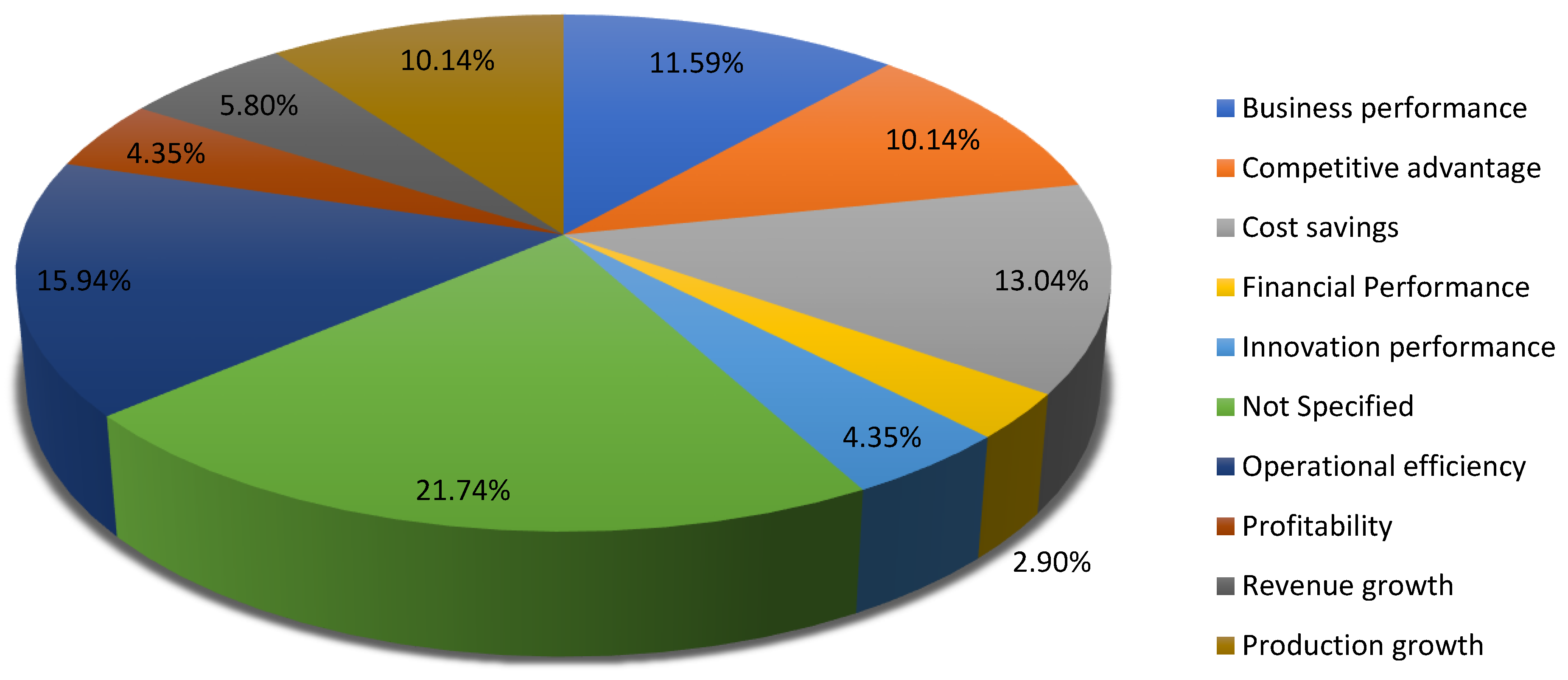

| Business performance metrics | Measures of business outcomes Operational efficiency, | operational efficiency, revenue growth, cost savings |

| Organizational outcomes | Results related to the organization | employee satisfaction, engagement, retention |

| Long-term impacts | The extended effects of the study findings | business sustainability, competitive advantage |

| Ref. | Selection (0-4 stars) | Comparability (0-2 stars) | Outcome/Exposure (0-3) | TotalStars | Quality Rating |

|---|---|---|---|---|---|

| [36,44,57,60] | ★ | ★ | ★★ | 4 | Low |

| [34,41,42,47,58,63] | ★★ | ★★ | ★★ | 6 | Low Moderate |

| [39,43,50,51,55,66,67] | ★★ | ★★ | ★★ | 6 | Low Moderate |

| [38,45,46,49,53,54,56,61,62] | ★★★ | ★★ | ★★★ | 8 | Moderate High |

| [35,37,40,48,52,59,64,65,68,69] | ★★★★ | ★★ | ★★★ | 9 | High |

| Chart Type | Purpose | Data Representation Format |

|---|---|---|

| Bar chart | Displays data using rectangular bars, where the length of each bar represents the value of the variable being measured | Numbers |

| Column chart | Like a bar chart, but the bars are presented vertically. It is used to compare values | Numbers |

| Line chart | Connects data points with a continuous line, making it ideal for showing trends over time. This type of chart is commonly used to track changes | Numbers |

| Pie chart | Circular chart divided into slices to represent proportions of a whole. It is useful for showing the relative contribution of different categories to a total | Percentages (%) |

| Scatter plot | Displays data points on a two-dimensional graph to show relationships between two variables. Each point represents an observation with coordinates based on the values of the two variables being compared. | Numbers |

| No. | Online Repository | Number of results |

|---|---|---|

| 1 | Google Scholar | 17 100 |

| 2 | Web of Science | 100 |

| 3 | Scopus | 44 |

| Total | 17 244 |

| Questions(Q) | Research Quality Questions |

|---|---|

| Q1 | Are the research objectives clearly articulated and precisely defined? |

| Q2 | Is the research methodology thoroughly explained and detailed? |

| Q3 | Is the analysis of the role of manufacturing operations in SME performance comprehensive and well-structured? |

| Q4 | Are the data collection methods clearly detailed and suitable for the research objectives? |

| Q5 | Do the research findings contribute significantly to the existing body of knowledge on the topic? |

| Ref. | Q1 | Q2 | Q3 | Q4 | Q5 | Total | % Grading |

|---|---|---|---|---|---|---|---|

| [36,39,40,41,47,49,52,53,58,59,60,64,66,69] | 1 | 1 | 1 | 1 | 1 | 5 | 100% |

| [42,43,48,50,51,55,57,61,65] | 1 | 1 | 0,5 | 1 | 1 | 4,5 | 90% |

| [34,37,44,56,62,68] | 1 | 0,5 | 1 | 0,5 | 1 | 4 | 80% |

| [45,47,54,63] | 1 | 1 | 0,5 | 0,5 | 0,5 | 3,5 | 75% |

| [46,67] | 1 | 0,5 | 0 | 0 | 1 | 2,5 | 50% |

| Published Year | Book Chapter | Conference paper | Thesis | Research paper | Thesis | Article Journal |

|---|---|---|---|---|---|---|

| 2014 | 0 | 1 | 0 | 1 | 0 | 3 |

| 2015 | 0 | 0 | 0 | 1 | 0 | 1 |

| 2016 | 0 | 1 | 0 | 1 | 0 | 3 |

| 2017 | 0 | 0 | 1 | 0 | 0 | 6 |

| 2018 | 0 | 1 | 0 | 0 | 0 | 7 |

| 2019 | 0 | 1 | 0 | 0 | 0 | 2 |

| 2020 | 1 | 3 | 0 | 1 | 0 | 3 |

| 2021 | 0 | 1 | 0 | 0 | 1 | 8 |

| 2022 | 0 | 0 | 0 | 1 | 0 | 9 |

| 2023 | 0 | 2 | 0 | 0 | 0 | 5 |

| 2024 | 0 | 0 | 0 | 0 | 1 | 3 |

| Industry | Key Finding | Strategic Implications for Business Leaders | Opportunities | Challenges | Relevance to Proposed Systematic Review | Strategic Drivers | Expected Outcome |

|---|---|---|---|---|---|---|---|

| Manufacturing | Optimization of Production Processes | Adopt lean manufacturing and automation technologies to improve efficiency and reduce waste. | Increased productivity and cost reduction through streamlined processes. | High initial investment in automation technology, potential resistance to change. | Aligns with findings that production process optimization enhances efficiency and competitiveness in SMEs. | Lean manufacturing, automation adoption. | Enhanced operational efficiency, reduced waste, and increased production quality. |

| Automotive | Adoption of Advanced Manufacturing Technologies (AMTs) | Invest in Industry 4.0 technologies like IoT, AI, and robotics to drive innovation and responsiveness. | Ability to quickly adapt to market changes, enhancing product customization and innovation. | High costs and the need for a skilled workforce to manage and maintain advanced technologies. | Highlights the role of AMTs in enhancing product innovation and flexibility across various industries. | Industry 4.0, AI integration, IoT and robotics. | Increased flexibility, faster response times, and improved product innovation. |

| Textiles | Effective Supply Chain Management | Build strong supplier relationships and implement JIT inventory management to minimize costs and improve efficiency. | Reduced lead times, lower inventory costs, and better supplier coordination can lead to higher profit margins. | Complexity in managing supplier networks, reliance on external partners, and global supply chain disruptions. | Demonstrates how supply chain improvements can positively affect SME performance, especially in resource-constrained environments. | Supplier collaboration, JIT systems, inventory management. | Streamlined supply chain, reduced costs, and improved production and delivery times. |

| Electronics | Integration of Sustainable Manufacturing Practices | Adopt sustainability measures such as waste reduction, energy efficiency, and eco-friendly production techniques. | Expanding into green markets, attracting eco-conscious customers, and reducing operational costs in the long term. | Upfront costs of implementing sustainable practices, balancing sustainability with profitability. | Reflects the growing importance of sustainability in modern manufacturing and its direct influence on business performance. | Sustainability, green production, energy efficiency. | Increased sustainability, reduced environmental impact, and long-term cost savings. |

| Food & Beverage | Product Quality and Safety Management | Enhance quality control and food safety standards to increase customer satisfaction and meet regulatory requirements. | Higher customer trust and loyalty, potential for premium pricing due to enhanced quality. | Regulatory compliance costs, maintaining consistent quality across diverse product lines. | Consistent with research showing that quality improvements drive customer retention and market competitiveness in SMEs. | Quality management, compliance with food safety standards. | Improved customer satisfaction, better regulatory compliance, and higher product quality. |

| Pharmaceuticals | Leveraging Data Analytics for Decision-Making | Use data analytics to optimize production schedules, inventory management, and demand forecasting. | Improved decision-making accuracy, reduced stockouts, and optimized production cycles to meet demand. | Need for specialized skills in data analytics, potential data security concerns. | Reiterates the importance of data-driven decisions in streamlining manufacturing operations and improving SME performance. | Data analytics, demand forecasting, inventory optimization. | Enhanced decision-making, better demand management, and more efficient production cycles. |

| Industry | Step | Framework Focus | Key Features | Strategic Drivers | Expected Outcome | Ties to Proposed Study |

| Manufacturing | 1. Assessment | Evaluating current operational and technological state | Data Collection, Operational Audits, Technology Assessment | Baseline understanding of resource constraints | Clear identification of inefficiencies and gaps in technology | Links with the study’s focus on optimizing SME operations through lean manufacturing and agile processes |

| 2. Planning | Strategic process optimization | Objective Setting, Timeline Setup, Risk Assessment | Prioritizing critical processes | Roadmap for implementing lean manufacturing and AMTs | Aligns with research focus on planning improvements for operational efficiency and cost management | |

| 3. Resource Allocation | Financial, human, and technological resource allocation | Budget Forecasting, Skills Mapping, Procurement | Efficient use of limited resources | Balanced distribution of necessary tools, skills, and funds | Supports study themes on optimizing resources in developing economies | |

| 4. Execution | Implementation of planned strategies | Employee Training, Process Monitoring, System Deployment | Operational Alignment, Monitoring Progress | Timely deployment of optimized manufacturing processes | Enhances study focus on executing strategies and measuring real-time results using data | |

| 5. Evaluation | Performance assessment post-implementation | KPI Monitoring, Feedback Loops, Reporting | Continuous progress measurement | Identification of successful strategies and areas for improvement | Ties into the study’s evaluation of performance through quantitative and qualitative measures | |

| 6. Continuous Improvement | Long-term sustainability through iterative processes | Process Refinement, Regular Audits, Upgrades | Agile adaptation to market changes and tech updates | Continuous improvement in operational processes | Links to study conclusions on sustained improvements and market adaptation | |

| Automotive | 1. Assessment | Evaluation of production line efficiency | Technological Audit, Equipment Performance Review | Identifying inefficiencies in the production line | Clear understanding of automation gaps and opportunities for improvement | Aligns with research focus on industry-specific technology adaptation challenges |

| 2. Planning | Planning for automated production systems | Robotics, AI-based processes, Timeline Setup | Prioritization of automation processes | Efficient integration of robotics and AI systems | Supports strategic planning of resource-heavy sectors like automotive | |

| 3. Resource Allocation | Allocating funding and technical resources | Capital Investment, Talent Acquisition, Procurement | Ensuring balanced distribution of capital for automation | Successful acquisition and implementation of advanced systems | Ties to resource allocation strategies in the study for large-scale production sectors | |

| 4. Execution | Deployment of advanced production technologies | Employee Training, Automation Setup, Process Monitoring | Aligning operations with automation strategies | Efficient deployment of robotic and AI systems | Reflects on successful execution strategies tailored to capital-intensive industries | |

| 5. Evaluation | Monitoring production line improvements | KPI Measurement, Production Output Analysis | Tracking efficiency gains through automation | Data-driven identification of improvements | Enhances study’s focus on evaluating post-implementation performance metrics | |

| 6. Continuous Improvement | Iterative refinement of automated processes | Process Optimization, Regular Equipment Upgrades | Adapting to ongoing technological advancements | Continuous operational efficiency through automation | Ties into study’s emphasis on continuous improvement for long-term industry sustainability | |

| Textiles | 1. Assessment | Reviewing operational efficiency and material usage | Operational Audits, Textile Quality Assessments | Identifying areas of waste reduction | Identification of high-waste areas and quality issues | Supports the study’s goal to assess efficiency and material optimization in SMEs |

| 2. Planning | Streamlining textile production processes | Process Mapping, Production Scheduling, Resource Planning | Enhancing efficiency through streamlined processes | Effective scheduling and resource management | Aligns with research focus on improving textile production through planning | |

| 3. Resource Allocation | Allocating labor, machinery, and materials | Workforce Planning, Material Procurement, Budgeting | Effective use of workforce and materials | Reduced waste and improved production efficiency | Reflects on the importance of resource allocation strategies to optimize production | |

| 4. Execution | Implementing lean production techniques | Employee Training, Process Monitoring, Resource Use | Minimizing production delays and waste | Timely and efficient production with reduced waste | Supports execution of lean manufacturing techniques for higher textile production quality | |

| 5. Evaluation | Evaluating production efficiency post-implementation | KPI Monitoring, Material Usage Review, Production Output | Assessing reductions in material waste and delays | Increased efficiency and reduced material waste | Reflects the study’s focus on using evaluation metrics to track success | |

| 6. Continuous Improvement | Ongoing refinement of production processes | Regular Audits, Lean Refinement, Technology Upgrades | Maintaining competitive advantage through innovation | Continuous improvement in production efficiency | Ties to the study’s focus on continuous optimization of manufacturing processes | |

| Electronics | 1. Assessment | Evaluating technology integration within production | Technological Gap Analysis, Process Audits | Understanding current tech limitations and identifying opportunities | Clear understanding of technology gaps | Aligns with the study’s emphasis on technological integration in SMEs |

| 2. Planning | Integrating advanced manufacturing technologies | Robotics, IoT, AI, Process Mapping | Identifying and prioritizing key tech adoption areas | Roadmap for technology integration | Reflects on planning for Industry 4.0 adoption in electronics production | |

| 3. Resource Allocation | Allocating capital and technical resources | Budgeting for Robotics and AI, Skills Development | Balanced distribution of capital and human resources | Successful integration of IoT and AI technologies | Supports study focus on the allocation of capital and human resources for tech-heavy sectors | |

| 4. Execution | Implementation of Industry 4.0 technologies | Employee Training, Process Monitoring, System Deployment | Aligning operations with technological strategies | Successful deployment of smart technologies | Ties into the study’s focus on execution efficiency and real-time monitoring for electronics sectors | |

| 5. Evaluation | Assessing technological impact on performance | KPI Monitoring, Production Output Analysis | Evaluating the performance of new technologies | Data-driven insights into tech-based efficiency gains | Enhances the study’s focus on evaluating tech-driven results for SMEs | |

| 6. Continuous Improvement | Iterative refinement of technology integration | Process Optimization, Regular Technology Audits | Staying up to date with rapid technological changes | Continuous efficiency improvements through technology | Ties into the study’s conclusion on continuous refinement and technological adaptation | |

| Food & Beverage | 1. Assessment | Evaluating production and supply chain efficiency | Operational Audits, Quality Control Reviews | Identifying inefficiencies and areas for cost reduction | Clear identification of quality control and supply chain inefficiencies | Supports study focus on assessing SME supply chain and quality control challenges |

| 2. Planning | Planning for lean production and quality control | Process Mapping, Resource Planning, Timeline Setup | Enhancing operational efficiency and maintaining quality | Efficient production planning and resource management | Reflects on strategic planning to balance production efficiency with quality control | |

| 3. Resource Allocation | Allocating human, material, and technical resources | Workforce Planning, Equipment Procurement, Budgeting | Effective use of workforce and equipment | Balanced resource distribution for high-quality production | Ties into study’s focus on optimizing resources for food and beverage production | |

| 4. Execution | Implementing lean production and quality control | Employee Training, Process Monitoring, Equipment Setup | Ensuring timely production and maintaining quality | Efficient production and high-quality output | Enhances study focus on executing lean strategies for food and beverage SMEs | |

| 5. Evaluation | Evaluating quality control and supply chain processes | KPI Monitoring, Quality Output Review, Supply Chain Analysis | Assessing improvements in quality control and cost savings | Data-driven insights into supply chain and quality improvements | Reflects on the study’s focus on evaluating quality control and operational efficiency in SMEs | |

| 6. Continuous Improvement | Ongoing refinement of quality control processes | Regular Audits, Process Optimization, Tech Upgrades | Maintaining long-term quality control and cost efficiency | Continuous improvement in quality and supply chain efficiency | Ties into the study’s conclusion on continuous refinement for long-term competitive advantage | |

| Pharmaceuticals | 1. Assessment | Evaluating compliance and operational efficiency | Regulatory Audits, Operational Reviews | Ensuring regulatory compliance and identifying inefficiencies | Clear understanding of compliance gaps and operational challenges | Links with study’s focus on compliance and operational efficiency for SMEs |

| 2. Planning | Planning for regulatory compliance and operational improvement | Process |

| Industry | Focus Areas | Opportunities | Challenges | Strategic Drivers | Expected Outcome |

|---|---|---|---|---|---|

| Manufacturing | Lean manufacturing, Kaizen, waste reduction | Improved operational efficiency, reduced waste | Resistance to change, lack of employee buy-in | Process optimization, cost savings | Higher productivity, reduced costs, minimized waste |

| Automotive | Process standardization, Six Sigma, automation | Increased production consistency, reduced defects | High cost of technological upgrades, supply chain integration | Quality management, process consistency | Enhanced product quality, reduced defects, faster production |

| Textiles | Sustainable manufacturing, lean supply chains | Reduced environmental impact, faster response to market trends | High investment in sustainable technologies | Sustainability, waste reduction | Increased sustainability, lower waste, improved efficiency |

| Electronics | Agile manufacturing, real-time data monitoring | Faster time-to-market, improved product customization | Rapid technological changes, complex global supply chains | Agility, innovation, technological adoption | Shorter lead times, greater flexibility, improved innovation |

| Food & Beverage | Quality control, supply chain transparency | Increased food safety, improved customer trust | Compliance with regulatory standards, perishable goods management | Quality assurance, regulatory compliance | Improved product quality, enhanced customer satisfaction |

| Pharmaceuticals | GMP (Good Manufacturing Practices), risk management | Enhanced product safety, faster regulatory approvals | Stringent compliance requirements, high R&D costs | Compliance, risk management, quality control | Improved compliance, faster time-to-market, higher product quality |

| Industry | Best Practice | SME Type | Operational Challenge | Strategic Drivers | Expected Impact | Ties to Systematic Review Findings |

|---|---|---|---|---|---|---|

| Manufacturing | Lean Manufacturing, Total Quality Management (TQM) | Small Manufacturing Enterprises | Waste reduction, quality consistency | Cost savings, operational efficiency | Reduced waste, higher productivity, improved quality | Review findings emphasize lean manufacturing as a top strategy for operational efficiency and waste reduction. |

| Automotive | Six Sigma, Robotics Process Automation (RPA) | Medium Automotive Enterprises | Process consistency, defect reduction | Precision engineering, process optimization | Improved process quality, reduced defect rates | Automation and Six Sigma are highlighted for ensuring high precision and reducing production defects. |

| Textiles | Sustainable Manufacturing, Green Supply Chains | Small Textile Enterprises | Sustainability, resource conservation | Environmental compliance, resource management | Reduced environmental impact, lower resource costs | Sustainability is key in textiles, aligning with systematic review insights on green manufacturing. |

| Electronics | Agile Manufacturing, Digital Twin Technology | Medium Electronics Enterprises | Production flexibility, real-time monitoring | Innovation, agility, technological advancements | Enhanced flexibility, improved time-to-market | Systematic review supports agile manufacturing to improve flexibility and responsiveness in dynamic industries like electronics. |

| Food & Beverage | HACCP (Hazard Analysis Critical Control Point), Automated Quality Control | SMEs in Perishable Goods | Food safety, inventory management | Regulatory compliance, customer satisfaction | Enhanced food safety, reduced spoilage, better inventory control | Review findings stress automated quality control and regulatory compliance as critical to this sector. |

| Pharmaceuticals | Good Manufacturing Practices (GMP), Process Analytical Technology (PAT) | Small Pharmaceutical Enterprises | Compliance, product safety | Regulatory compliance, risk management | Improved product quality, faster regulatory approvals | Pharmaceutical industry benefits from GMP and PAT as confirmed by the review’s focus on stringent compliance and quality. |

| Industry | Key Metrics/KPIs | Measurement Focus | Strategic Drivers | Expected Outcome | Ties to Systematic Review Findings | Priority (1 = Highest) |

|---|---|---|---|---|---|---|

| Manufacturing | - Overall Equipment Effectiveness (OEE) - Defect Rate - Cycle Time |

Machine productivity, quality, and efficiency | Cost reduction, operational efficiency | Increased equipment uptime, lower defects, faster production | Systematic review highlights OEE and defect rate as critical in evaluating lean manufacturing and automation efforts. | 1: OEE 2: Defect Rate 3: Cycle Time |

| Automotive | - First Pass Yield (FPY) - Scrap Rate - Downtime |

Product quality, resource utilization, and downtime | Process optimization, cost savings | Reduced scrap, increased product quality, less production downtime | Metrics like FPY and downtime closely align with the review’s focus on improving efficiency through process control and automation. | 1: FPY 2: Scrap Rate 3: Downtime |

| Textiles | - Yield Efficiency - Energy Consumption per Unit - Order Lead Time |

Resource utilization, energy use, and supply chain responsiveness | Environmental sustainability, operational efficiency | Higher resource efficiency, faster lead times, reduced energy costs | Sustainability metrics and lead time reduction are key recommendations from the systematic review for textile SMEs. | 1: Yield Efficiency 2: Energy Consumption 3: Order Lead Time |

| Electronics | - Time to Market - Inventory Turnover - Product Return Rate |

Innovation speed, supply chain efficiency, product quality | Agility, responsiveness, technological advancement | Faster time-to-market, reduced returns, optimized inventory levels | The review highlights agility and inventory management as crucial for electronics SMEs adopting advanced technologies. | 1: Time to Market 2: Inventory Turnover 3: Product Return Rate |

| Food & Beverage | - Compliance with Regulatory Standards (e.g., FDA) - Waste per Production Unit - On-Time Delivery Rate |

Compliance, waste reduction, and supply chain reliability | Regulatory compliance, customer satisfaction | Reduced waste, higher compliance rates, timely deliveries | Review findings emphasize regulatory compliance and waste reduction as critical KPIs in the food and beverage industry. | 1: Compliance 2: Waste per Production Unit 3: On-Time Delivery |

| Pharmaceuticals | - Right First Time (RFT) - Batch Cycle Time - Regulatory Audit Findings |

Product quality, process efficiency, and compliance | Risk management, regulatory adherence | Reduced rework, faster batch processing, improved compliance | The review highlights the importance of compliance and efficiency in pharmaceutical operations. | 1: RFT 2: Batch Cycle Time 3: Audit Findings |

| Industry | Case Study | Implementation | Outcome | Reference |

| Manufacturing | Siemens – PCB production with AI and automation | AI-enhanced automation and robotics for more efficient production control in PCB manufacturing. | Significant reductions in production time and waste, enhanced flexibility. | [Link] |

| Automotive | Bosch – Smart factories and AI in automotive manufacturing | Integration of AIoT for production and logistics automation, predictive analytics, and robotics. | Higher product quality, reduced production errors, and increased flexibility. | [LINK] |

| Textiles | Levi’s – Advanced manufacturing with lasers for textile finishing | Laser technology for sustainable textile finishing, reducing chemical use and improving speed. | Decreased production time, reduction in environmental impact. | [LINK] |

| Electronics | Samsung – AI-driven automation in electronics assembly | Automation of assembly lines using AI for better precision and reduced human error. | Enhanced precision, reduced assembly time, and improved product consistency. | [LINK] |

| Food & Beverage | Coca-Cola – Use of IoT and AI for supply chain and production optimization | AI and IoT to optimize bottling operations and supply chain efficiency. | Optimized production scheduling, reduced downtime, and improved quality. | [LINK] |

| Pharmaceuticals | Pfizer – Advanced data analytics and AI for drug manufacturing | AI-powered drug formulation and predictive analytics for efficient drug production. | Reduced R&D time, increased efficiency in drug production and quality control. | [LINK] |

| Industry | Roadmap Focus | Policy Framework | Strategic Link | Strategic Drivers | Expected Outcome | Ties to Proposed Study |

| Manufacturing | Adoption of Lean Manufacturing and IoT | South Africa’s National Industrial Policy Framework (NIPF) | NIPF supports industrial growth through increased productivity, enabling lean manufacturing and IoT adoption for efficiency improvements. | Innovation, Tech Adoption, Operational Efficiency | Improved operational efficiency, cost savings | Aligns with lean manufacturing and IoT application findings from the review, focusing on SME growth. |

| Automotive | Automation and Robotics Integration | Automotive Production and Development Programme (APDP) | The APDP incentivizes the adoption of robotics and automation by providing subsidies for technology upgrades to increase productivity. | Automation, Robotics, Competitive Advantage | Increased productivity, reduced costs, improved vehicle quality | Automation links with advanced technology adoption in SMEs, particularly in highly competitive industries. |

| Textiles | Digitalization and Sustainable Practices | Sustainable Development Goals (SDGs)(UN) - Goal 12 (Responsible Consumption) | Aligns with SDG 12, which promotes sustainable production and the adoption of clean technology to reduce environmental impact. | Sustainability, Digital Transformation, Clean Production | Enhanced market positioning, reduction in waste | Supports the systematic review’s focus on sustainable manufacturing in developing economies. |

| Electronics | AI-Enhanced Quality Control and Automation | National Development Plan (NDP) - Chapter 5 (Environmental Sustainability) | Supports digital and AI advancements to ensure high-quality production while maintaining compliance with environmental policies. | AI Integration, Quality Control, Tech-Driven Growth | Improved product quality, compliance with environmental standards | Direct correlation with advanced manufacturing technology findings, including AI for SMEs. |

| Food & Beverage | AI for Inventory and Supply Chain Optimization | Agriculture and Agro-Processing Master Plan (AAMP) | AAMP promotes the use of AI and digital tools in managing supply chains to reduce food wastage and optimize production cycles. | AI, Supply Chain Management, Inventory Optimization | Reduced wastage, improved supply chain efficiency | Related to supply chain management and its impact on performance metrics in SMEs, per review findings. |

| Pharmaceuticals | AI and Automation for Drug Production | Medicines and Related Substances Act | The regulatory framework promotes the use of AI to enhance drug development and production efficiency, in line with compliance standards. | Automation, AI for Production, Compliance | Increased drug production efficiency, cost reductions | Reinforces findings around advanced manufacturing and regulatory alignment in pharmaceuticals. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).