Submitted:

08 October 2024

Posted:

09 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Manufacturing Processes

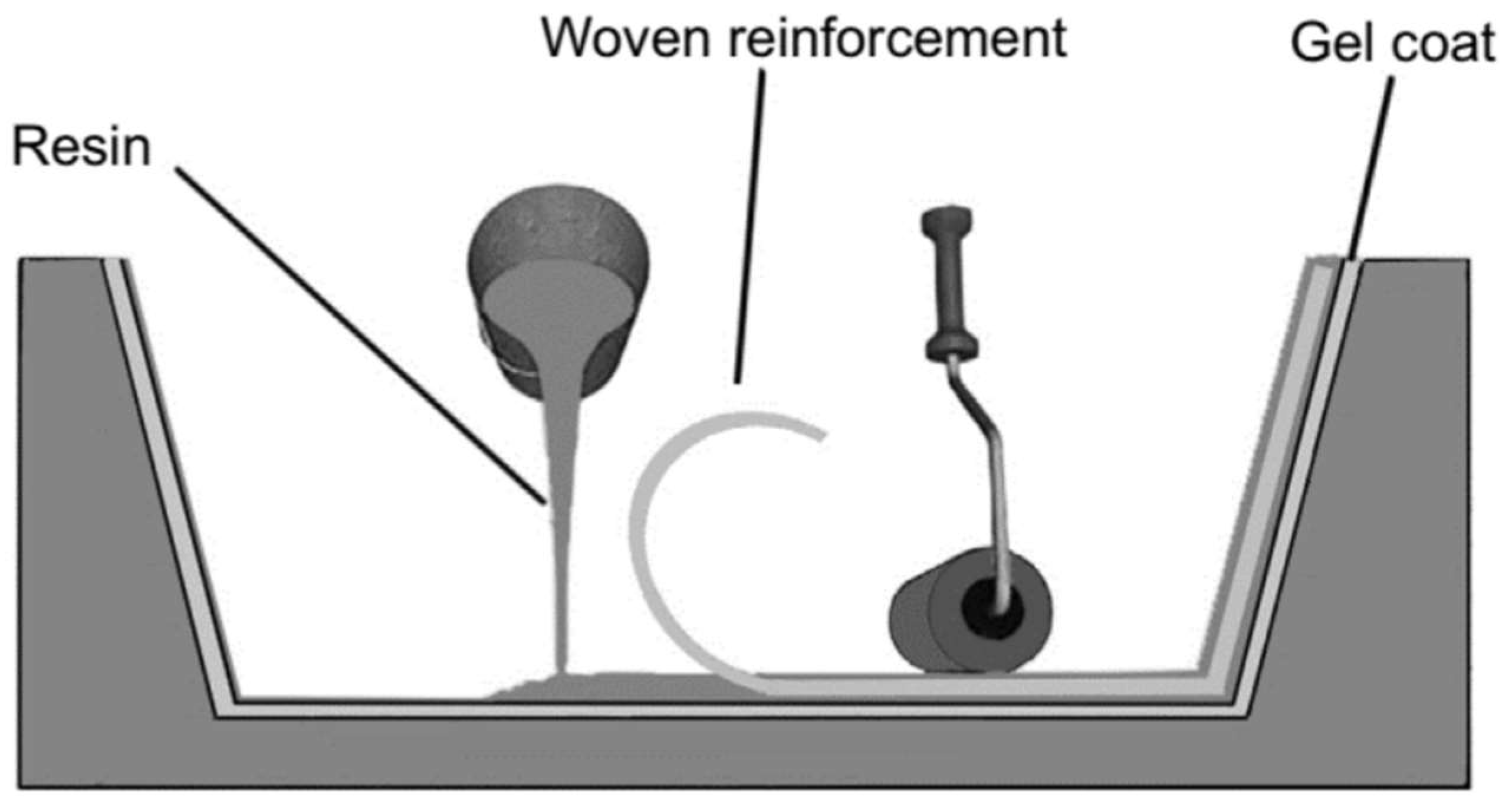

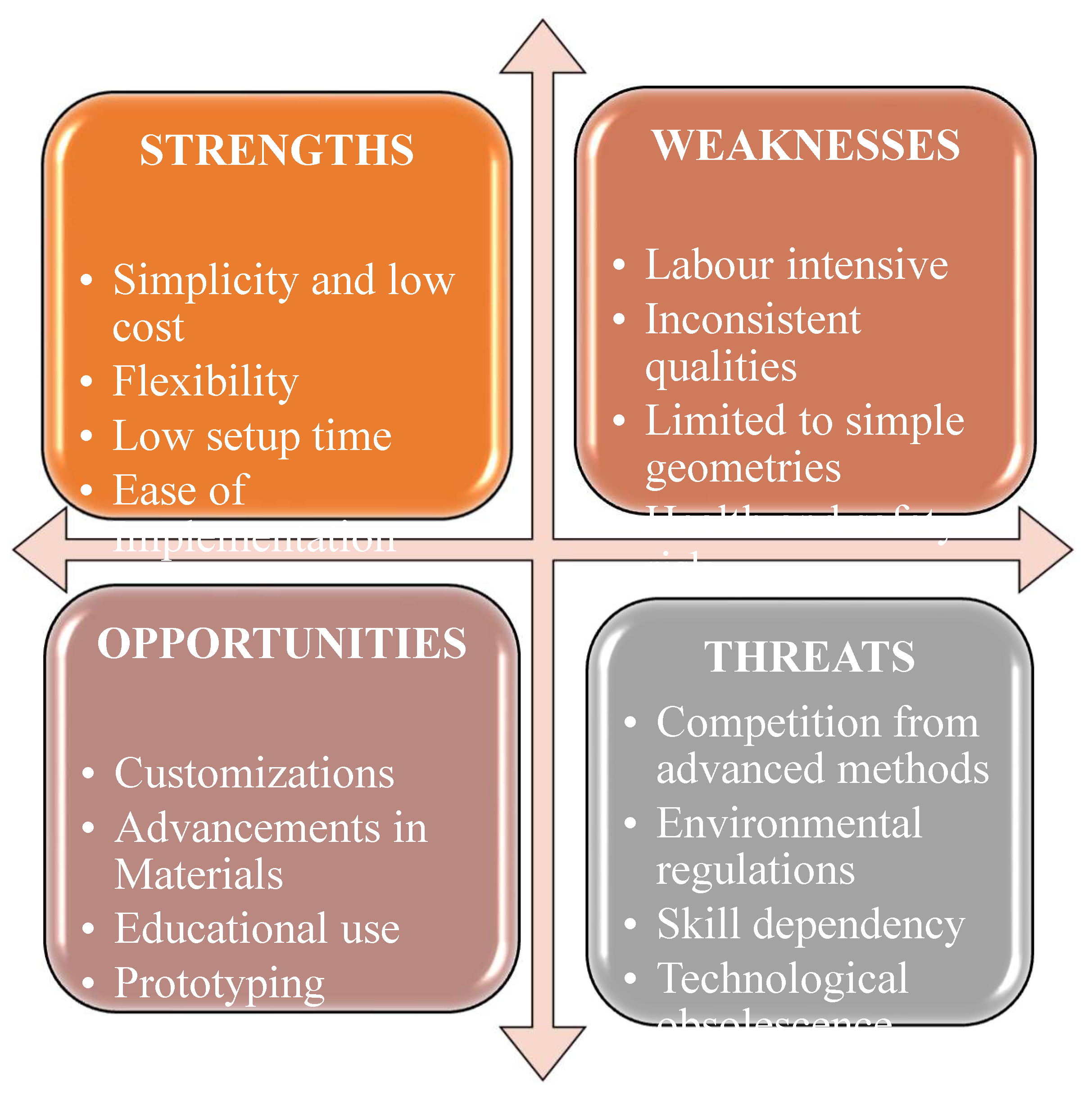

2.1. Hand Lay-up Method

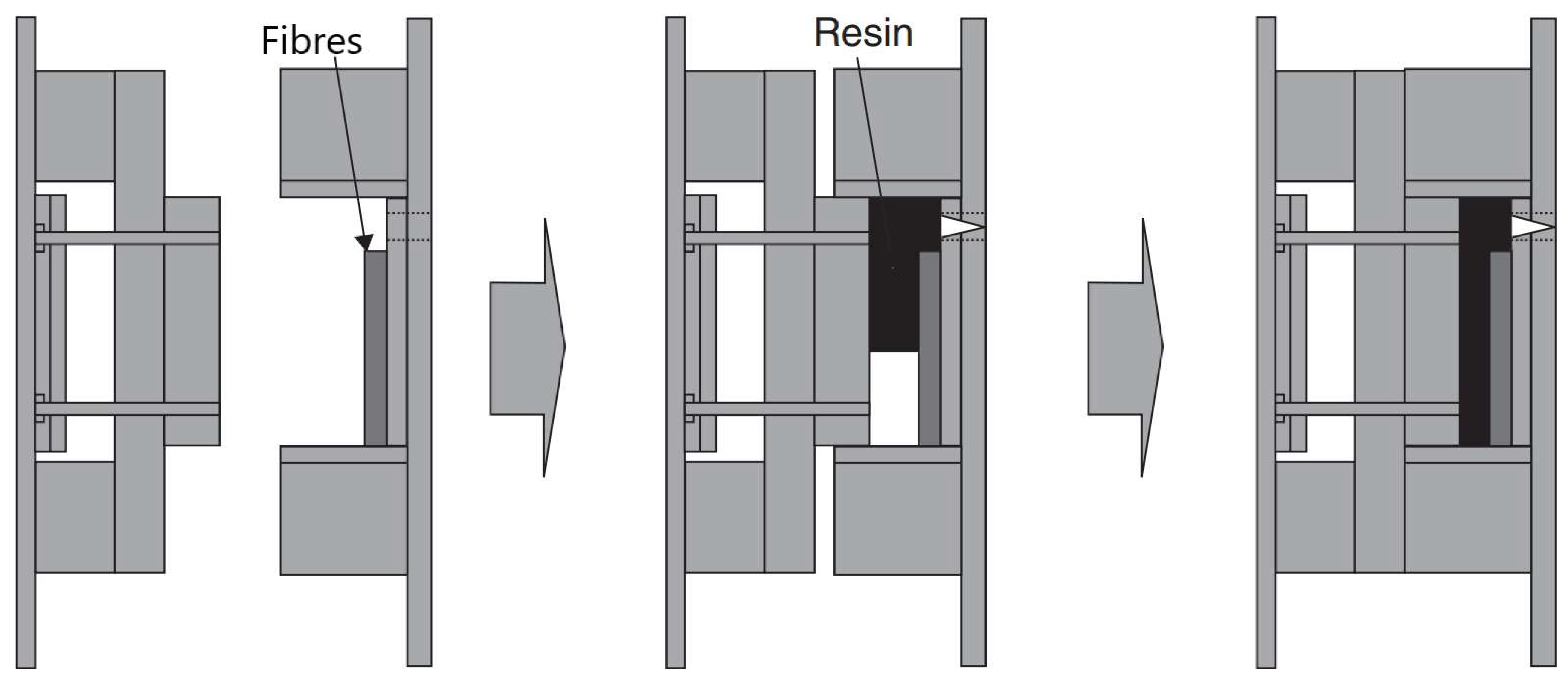

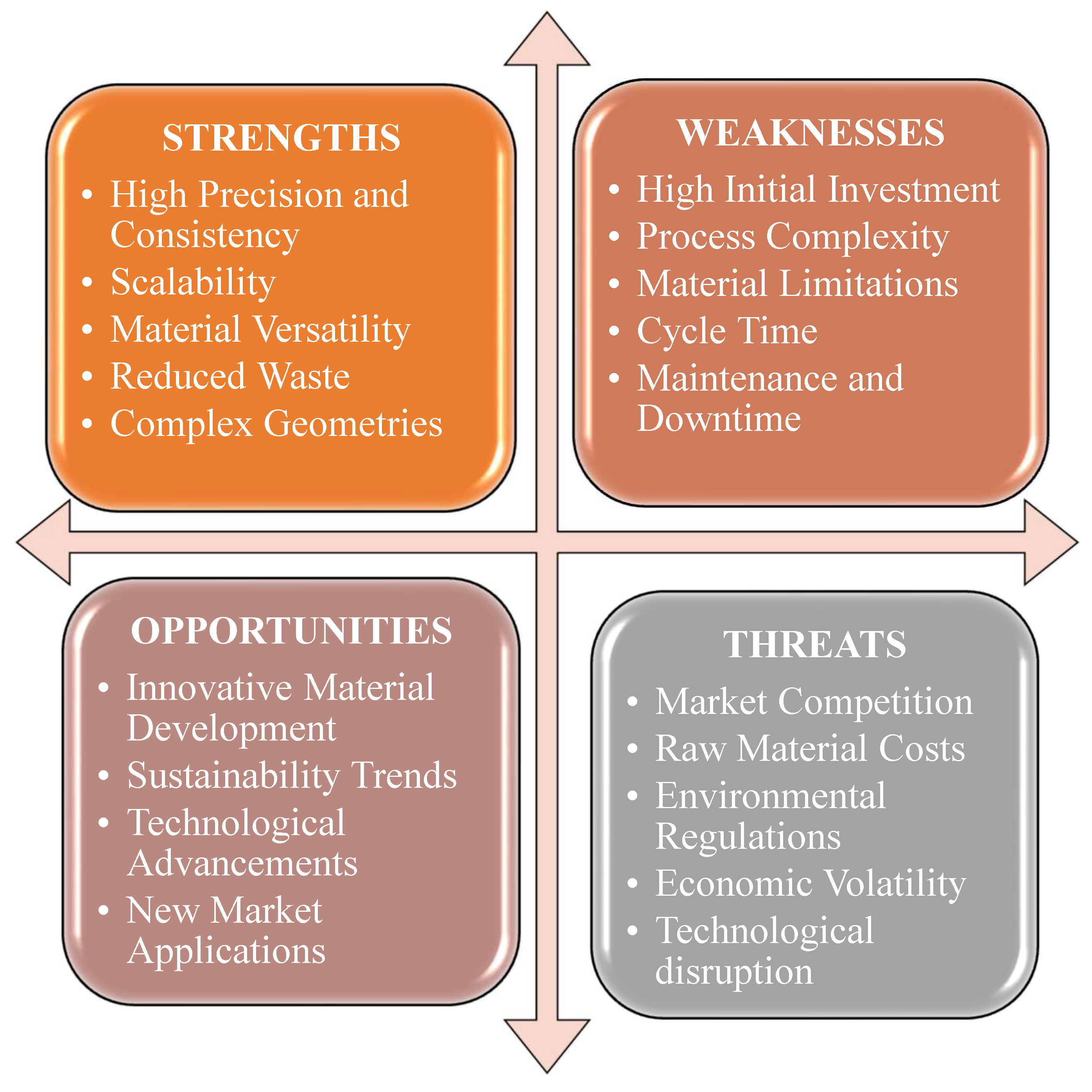

2.2. Injection Molding Method

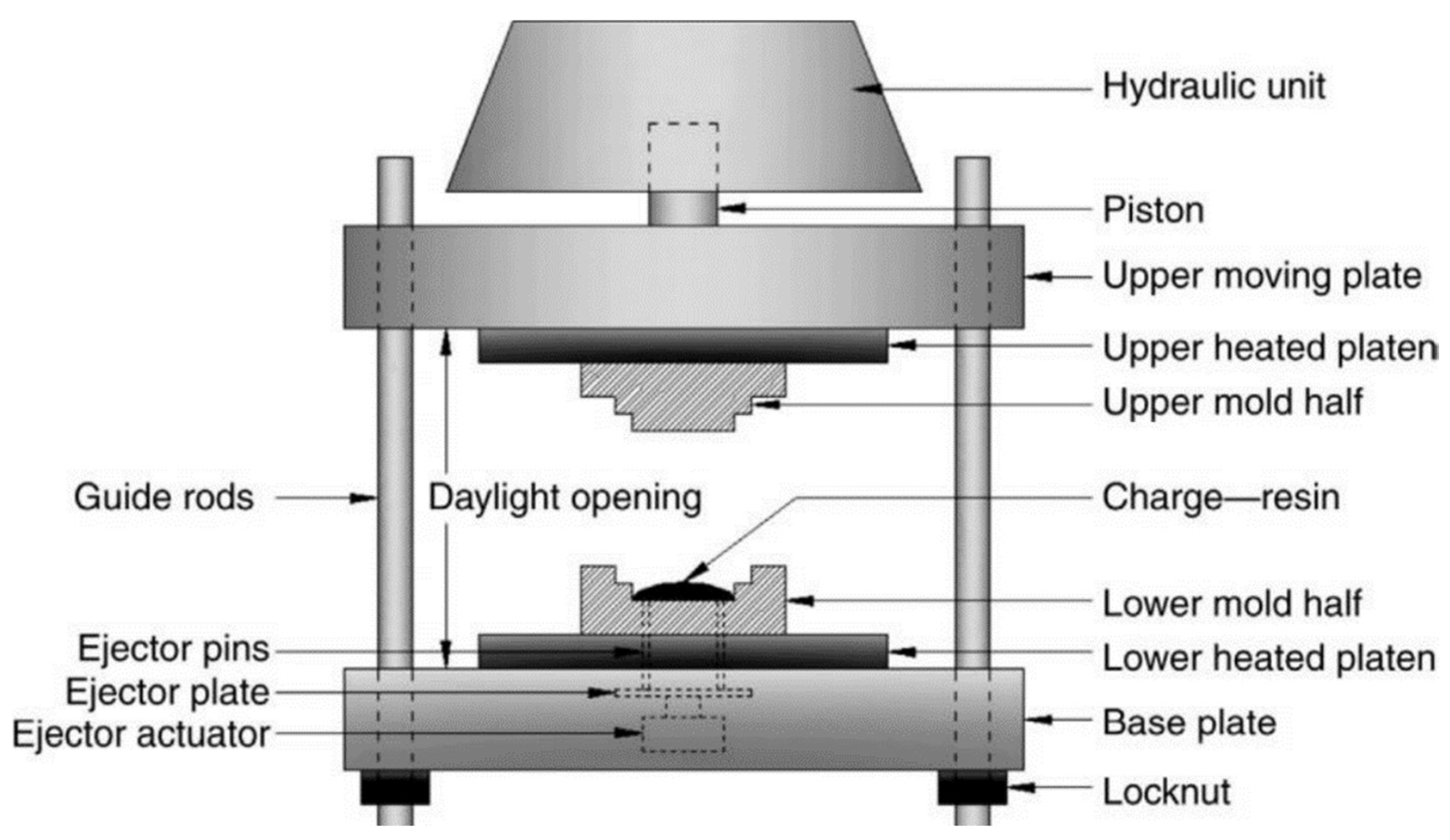

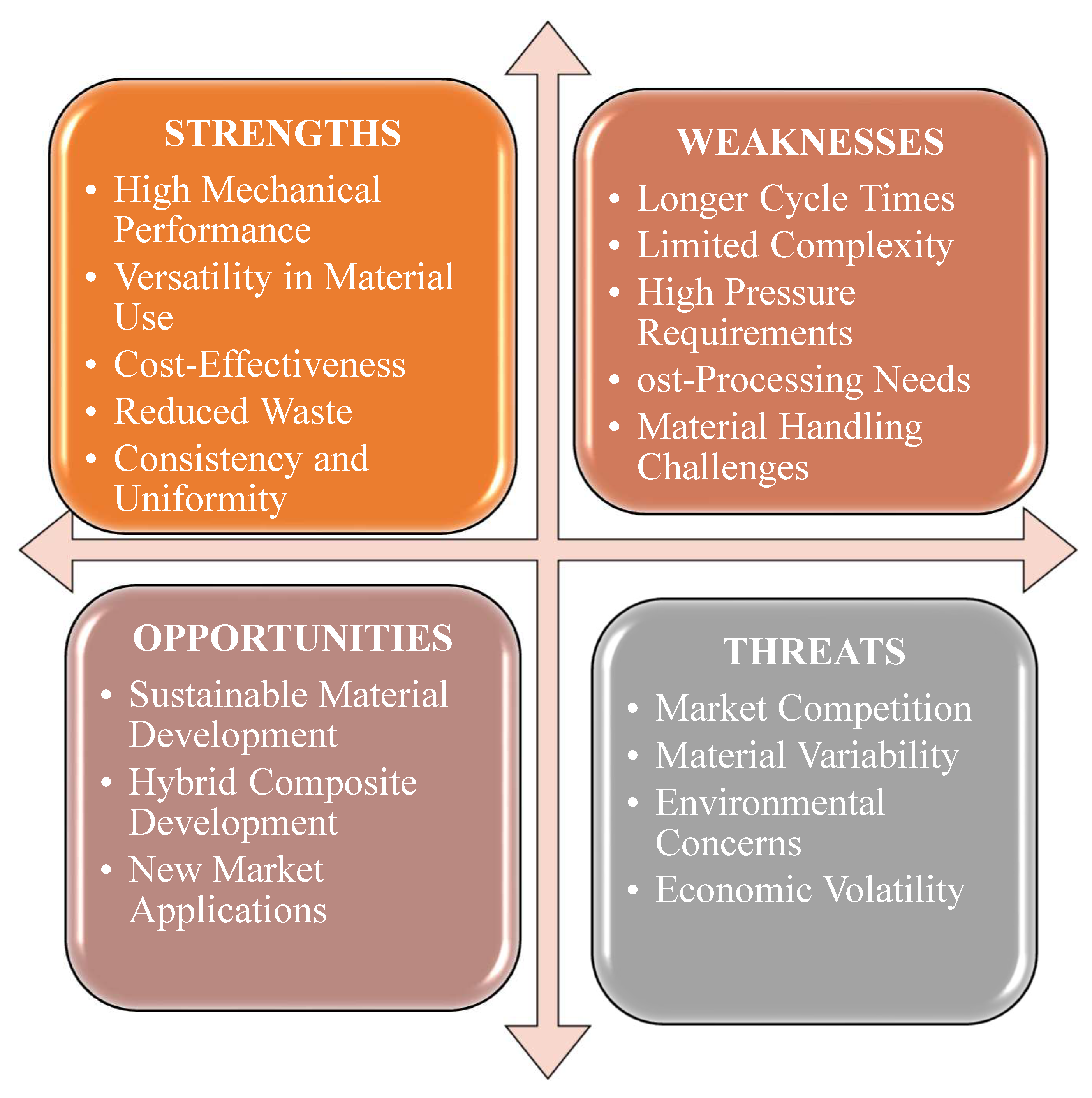

2.3. Compression Molding Method

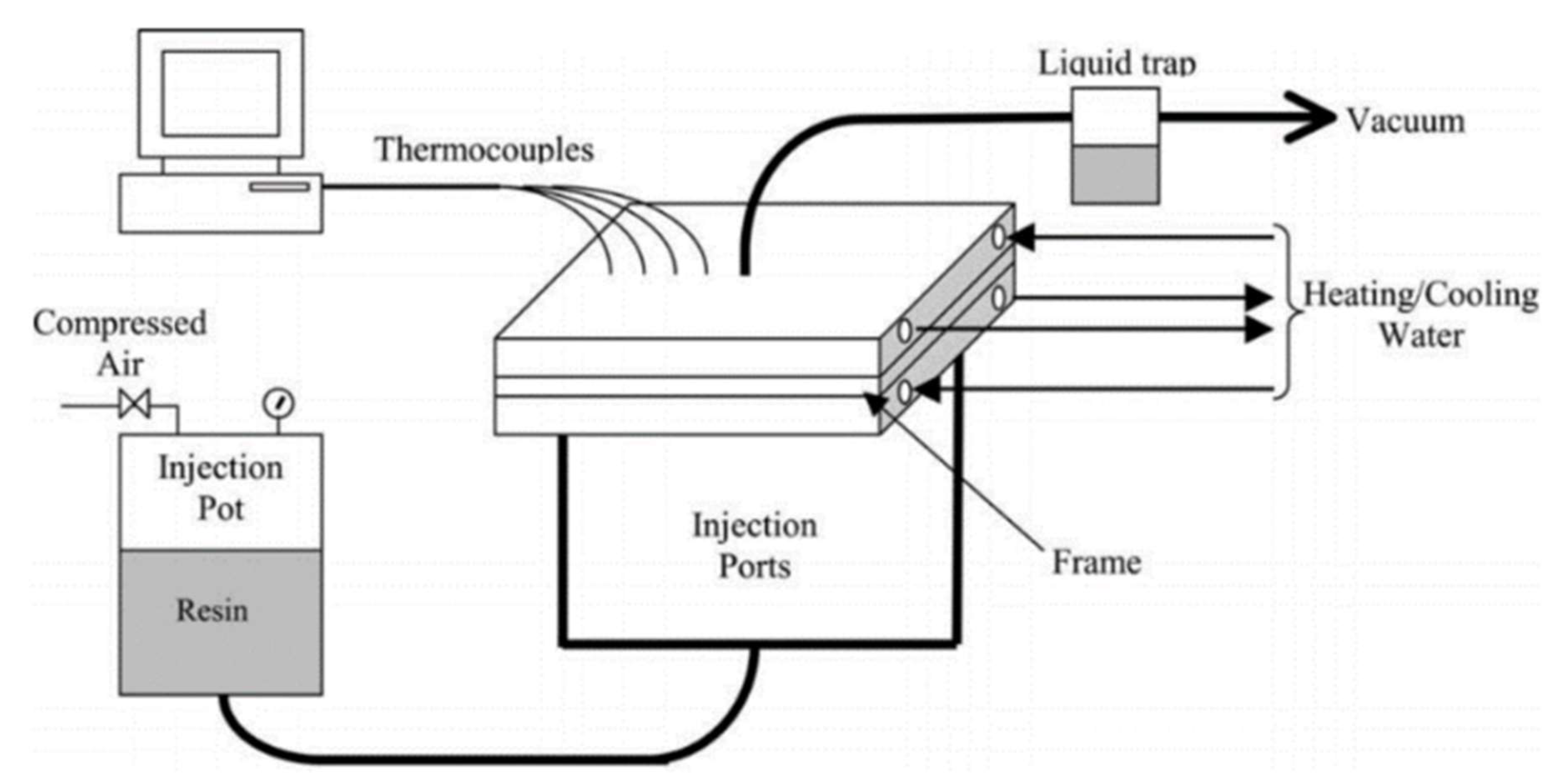

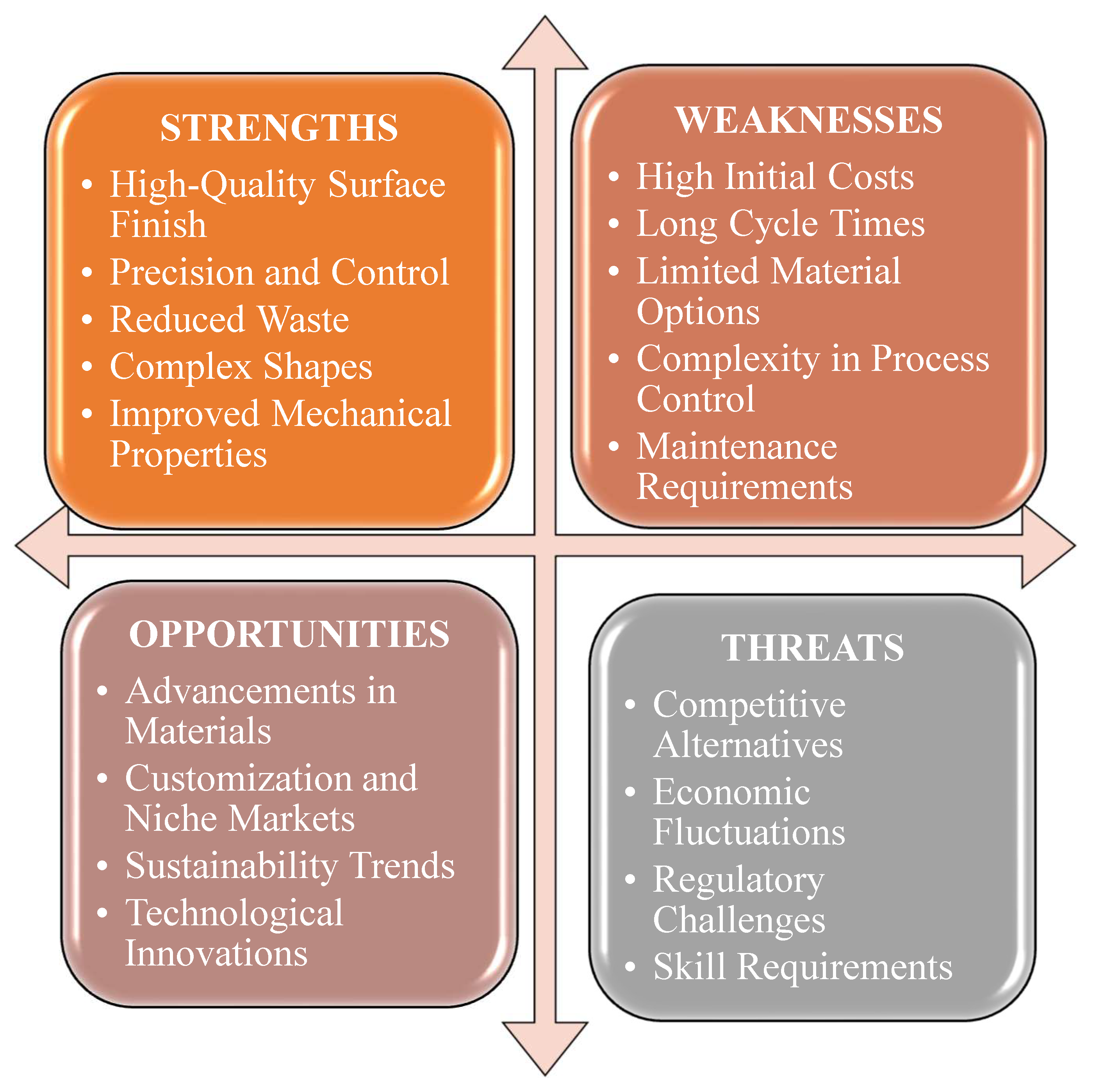

2.4. Resin Transfer Molding Method

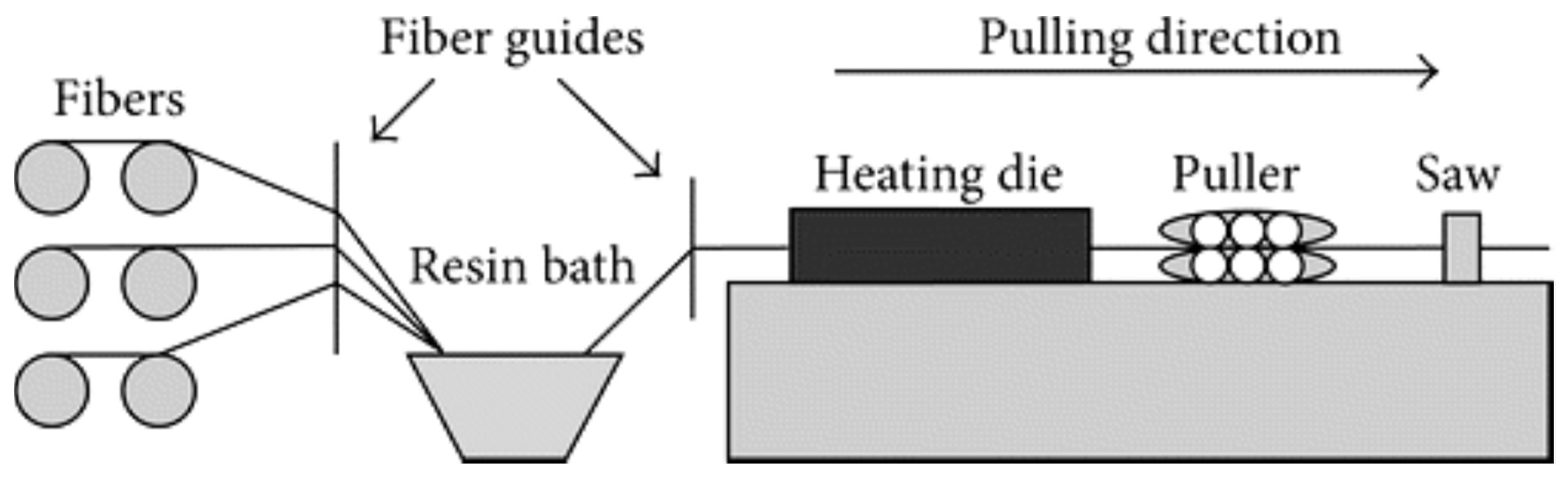

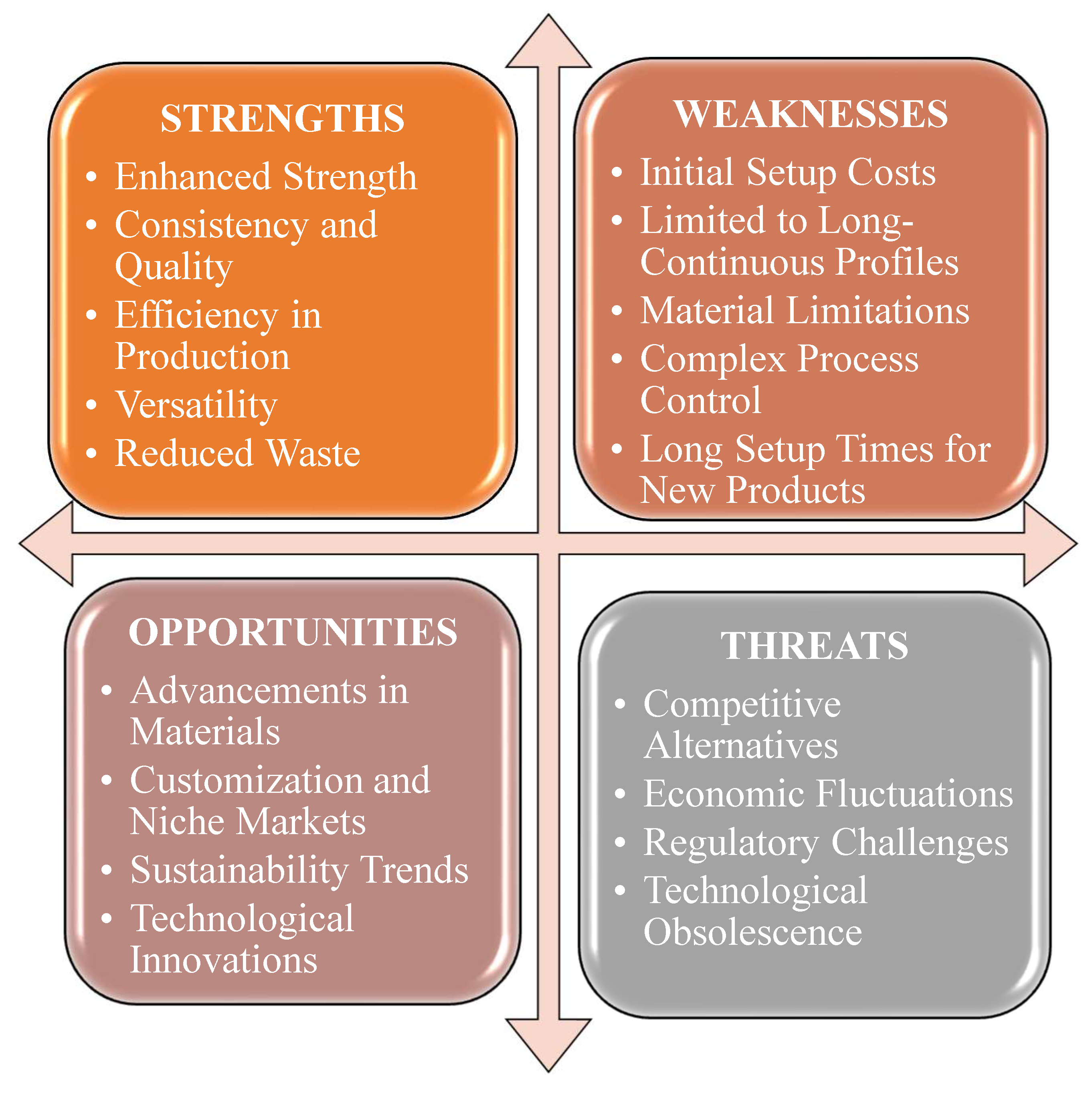

2.5. Pultrusion Method

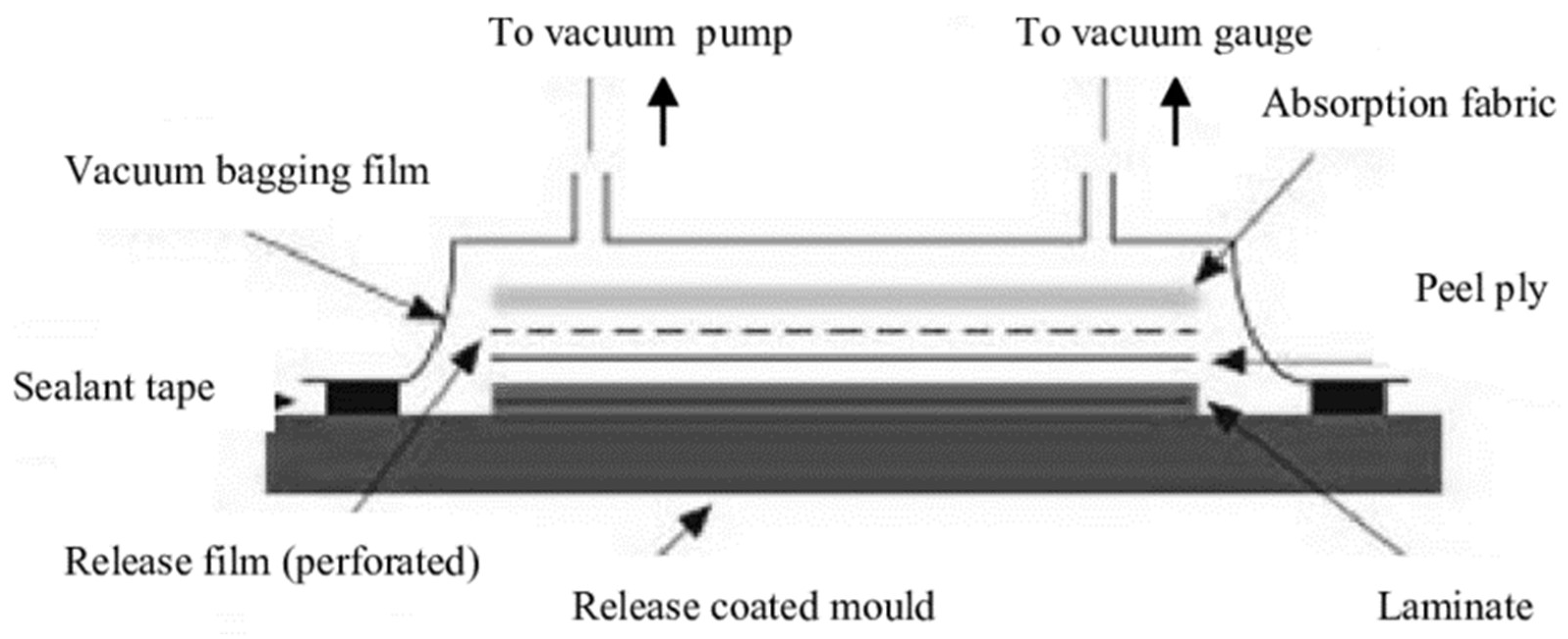

2.6. Vacuum Molding Method

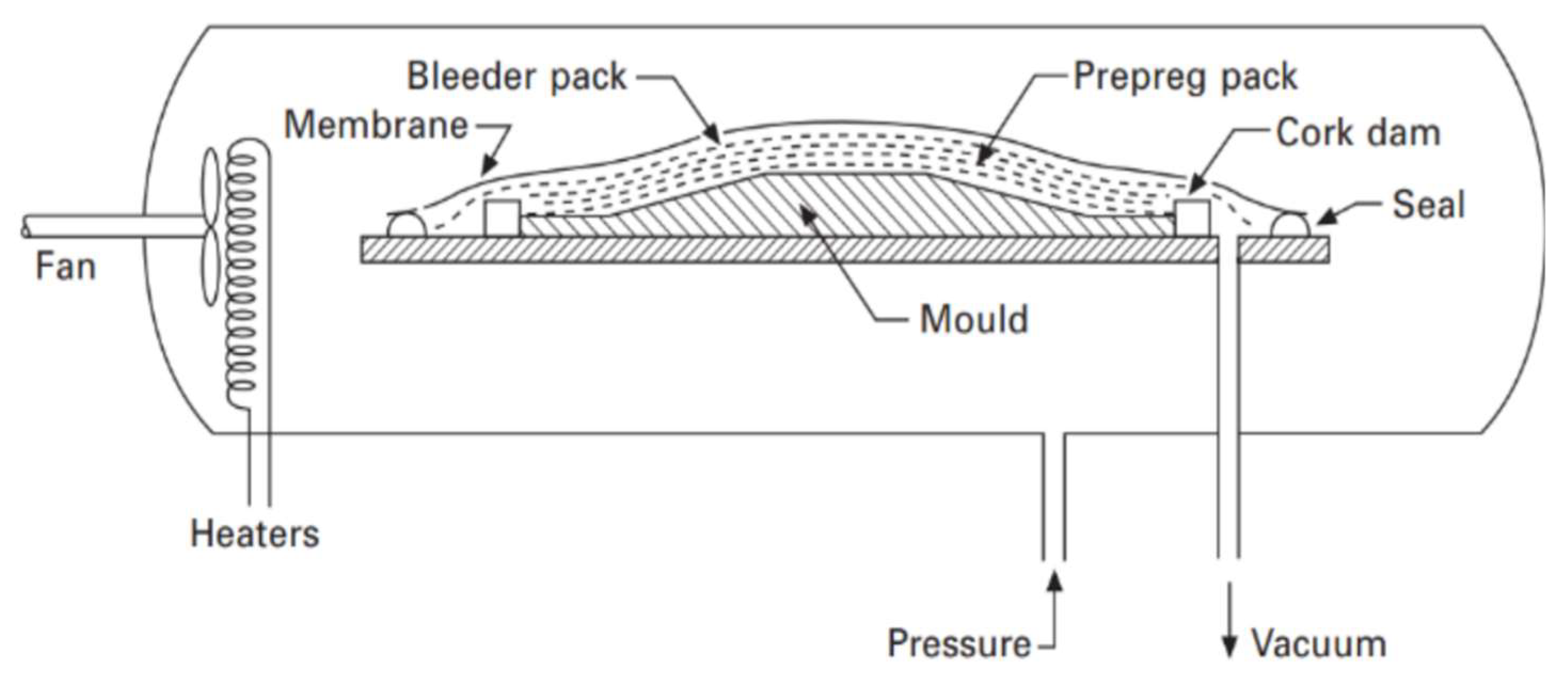

2.7. Autoclave Molding Method

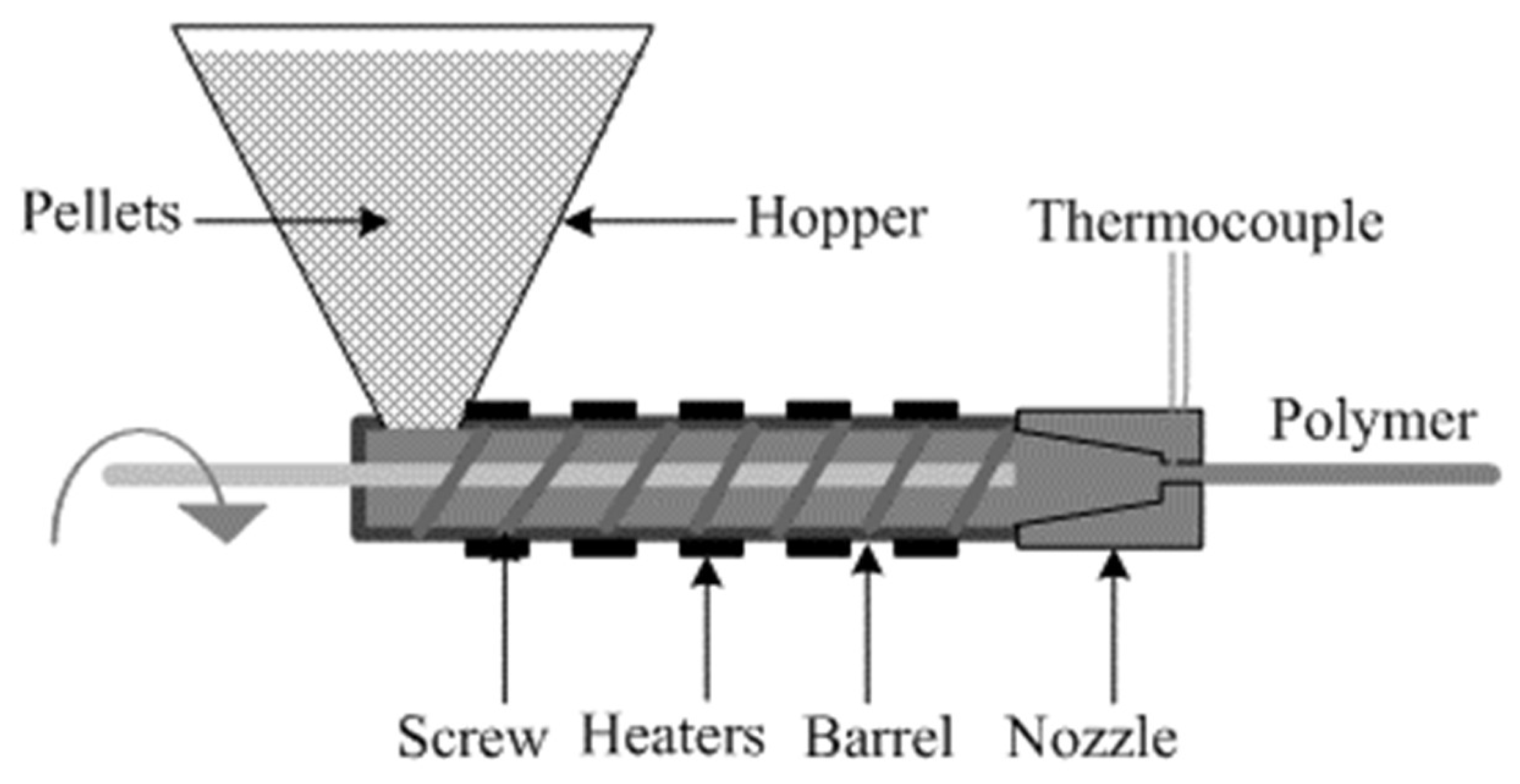

2.8. Extrusion Molding Method

2.9. Palsule Process

2.10. Heating in Hollow Cylindrical Glass Tube

3. Mechanical Properties

3.1. Hand Lay-up Process

3.1.1. Tensile properties

3.1.2. Compressive Properties

3.1.3. Flexural Properties

3.1.4. Impact Properties

3.1.5. Hardness

3.2. Vacuum Molding

3.2.1. Tensile Properties

3.2.2. Flexural Properties

3.2.3. Impact Properties

3.3. Palsule Process

3.3.1. Tensile Properties

3.3.2. Flexural Properties

3.4. Heating in Hollow Cylindrical Glass

3.4.1. Flexural Properties

3.4.2. Impact Properties

3.5. Extrusion Method

3.5.1. Tensile Properties

3.5.2. Impact Properties

3.6. Injection Molding Method

3.6.1. Tensile Properties

3.6.2. Flexural Properties

3.6.3. Impact Properties

3.6.4. Thermal Properties

3.6.5. Hardness

3.6.6. Water Absorption Properties

3.7. Hot Press Method/ Compression Molding Method

3.7.1. Tensile Properties

3.7.2. Flexural Properties

3.7.3. Impact Properties

3.7.4. Water Absorption Test

3.7.5. Thermal Properties

3.7.6. Compression Properties

4. Recommendation and Future Research Direction

4.1. Fiber Treatment and Surface Alteration Techniques

4.2. Fiber Hybridization

4.3. Manufacturing Process Optimization

4.4. Utilization of Bio-based Resins

4.5. Exploration of Nanotechnology in JFRCs

4.6. Assessment of Life Cycle and Studies on Environmental Impact

4.7. Development of Smart JFRCs

4.8. Customization for Particular Applications

5. Concluding Remarks

- The mechanical properties of JFRCs are greatly influenced by fiber treatment, matrix type, fiber orientation, and the particular production technique employed. Experimental research shows that alkali treatment enhances jute fibers' affinity for the polymer matrix, which improves mechanical properties of the composites. However, careful regulation of alkali treatment is essential to prevent fiber degradation.

- Manufacturing processes have a significant role in determining the quality and performance of JFRCs. Each process, including hand lay-up, compression molding, injection molding, and RTM, has unique benefits and constraints. Although the hand layup process is economical and adaptable, it is labor-intensive and susceptible to variations that may lead to flaws such as voids and inadequate fiber or matrix distribution.

- Compression molding and RTM shows better fiber dispersion and resin impregnation. Nevertheless, these processes need meticulous regulation of processing parameters, and any deviations might result in substantial material defects. Improvements in automated and scalable production methods are essential for improving the industrial feasibility of JFRCs.

- Although JFRCs have vast potential, they encounter several obstacles that must be resolved to enable their broader implementation in industrial applications. The major obstacles are the absorption of moisture, the quality of fibers, and the significant duration of the production process cycle. Moisture absorption is a major concern, as it can result in the degradation of the composite material over time. These obstacles can be mitigated by using proper treatment or hybridization with other fibers or particles.

- In order to save production time without sacrificing the mechanical and thermal properties of the composites, future studies should focus on the optimization of the process parameters.

References

- Shah, S.S.; Shaikh, M.N.; Khan, M.Y.; Alfasane, A.; Rahman, M.M.; Aziz, A. Present Status and Future Prospects of Jute in Nanotechnology: A Review. Chem. Rec. 2021, 21, 1631–1665. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Liu, J.; He, K.; Ahmad, W. A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- Bambach, M.R. Direct Comparison of the Structural Compression Characteristics of Natural and Synthetic Fiber-Epoxy Composites: Flax, Jute, Hemp, Glass and Carbon Fibers. Fibers 2020, 8, 62. [Google Scholar] [CrossRef]

- Dev, B.; Rahman, A.; Repon, R.; Rahman, M.M.; Haji, A.; Nawab, Y. Recent progress in thermal and acoustic properties of natural fiber reinforced polymer composites: Preparation, characterization, and data analysis. Polym. Compos. 2023, 44, 7235–7297. [Google Scholar] [CrossRef]

- Kumar, T.S., S. S. Kumar, and L.R. Kumar, Jute fibers, their composites and applications, in Plant fibers, their composites, and applications. 2022, Elsevier. p. 253-282.

- Wang, Y.; Du, T.; Ma, W.; Song, P.; Chen, Y. Research on mechanics and acoustic properties of Jute fiber composite material. Heliyon 2024, 10, e33869. [Google Scholar] [CrossRef]

- Gonzalez, V.; Lou, X.; Chi, T. Evaluating Environmental Impact of Natural and Synthetic Fibers: A Life Cycle Assessment Approach. Sustainability 2023, 15, 7670. [Google Scholar] [CrossRef]

- Tariq, M. , et al., Fiber crops in changing climate, in Global Agricultural Production: Resilience to Climate Change. 2023, Springer. p. 267-282.

- Elseify, L.A.; Midani, M.; El-Badawy, A.; Jawaid, M. Manufacturing Automotive Components from Sustainable Natural Fiber Composites; Springer Nature: Dordrecht, GX, Netherlands, 2021; ISBN 9783030830243. [Google Scholar]

- Natrayan, L. , et al., Dynamic Mechanical and Thermal Properties of Polymer-Coated Jute Fibers for Enhanced Automotive Parts. 2024, SAE Technical Paper.

- Parra, J.A.V.; Valencia, B.A.R.; Espinosa, W.J.M. Mechanical characterization of jute fiber based biocomposite to manufacture automotive components. J. Appl. Res. Technol. 2021, 19, 472–491. [Google Scholar] [CrossRef]

- Affan, M.; Ali, M. Experimental investigation on mechanical properties of jute fiber reinforced concrete under freeze-thaw conditions for pavement applications. Constr. Build. Mater. 2022, 323, 126599. [Google Scholar] [CrossRef]

- Majumder, A. , et al. Sustainable building material: recycled Jute fiber composite mortar for thermal and structural retrofitting. in International Conference on Computational Science and Its Applications. 2022. Springer.

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Mancusi, G.; Martinelli, E. Jute fiber-reinforced mortars: mechanical response and thermal performance. J. Build. Eng. 2023, 66. [Google Scholar] [CrossRef]

- Ali, H.T.; Alghtani, A.H.; Felemban, B.F.; El-Aziz, K.A.; Saber, D.; Ahmed, E.M.; Megahed, M.; Fotouhi, M. Multivariable analysis for selection of natural fibers as fillers for a sustainable food packaging industry. Mater. Res. Express 2021, 8, 095504. [Google Scholar] [CrossRef]

- Hamouda, T.; Aly, N.M. Circular Economy of Composite Materials Using Waste Jute Fibers and Recycled Polyester Fibers as a Reinforcement for Packaging Applications. Egypt. J. Chem. 2022, 65, 81–93. [Google Scholar] [CrossRef]

- Turjo, S.K.S.; Hossain, F.; Rana, M.S.; Ferdous, S. Mechanical characterization and corrosive impacts of natural fiber reinforced composites: An experimental and numerical approach. Polym. Test. 2023, 125. [Google Scholar] [CrossRef]

- Gogna, E. , et al., A comprehensive review on jute fiber reinforced composites. Advances in industrial and production engineering: select proceedings of FLAME 2018, 2019: p. 459-467.

- Pradeep, P. , et al., Mechanical Characterization of jute fiber over glass and carbon fiber reinforced polymer composites. International Journal of Applied Engineering Research, 2015. 10(11): p. 10392-10396.

- Alves, C.; Ferrão, P.; Silva, A.; Reis, L.; Freitas, M.; Rodrigues, L.; Alves, D. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2009, 18, 313–327. [Google Scholar] [CrossRef]

- de Queiroz, H.F.M.; Banea, M.D.; Cavalcanti, D.K.K. Adhesively bonded joints of jute, glass and hybrid jute/glass fibre-reinforced polymer composites for automotive industry. Appl. Adhes. Sci. 2021, 9, 1–14. [Google Scholar] [CrossRef]

- Gon, D. , et al., Jute Composites as Wood Substitute. International Journal of Textile Science, 2012. 1: p. 84-93.

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Gopinath, A.; Kumar, M.S.; Elayaperumal, A. Experimental Investigations on Mechanical Properties Of Jute Fiber Reinforced Composites with Polyester and Epoxy Resin Matrices. Procedia Eng. 2014, 97, 2052–2063. [Google Scholar] [CrossRef]

- Das, S.C.; Paul, D.; Fahad, M.M.; Das, M.K.; Rahman, G.M.S.; Khan, M.A. Effect of Fiber Loading on the Dynamic Mechanical Properties of Jute Fiber Reinforced Polypropylene Composites. Adv. Chem. Eng. Sci. 2018, 08, 215–224. [Google Scholar] [CrossRef]

- RAO, P.R.T.M.Y.P. , Study the Mechanical Properties of Jute and Sisal fiber reinforced Hybrid Composite Materials. International Research Journal of Engineering and Technology (IRJET), 2019. 6(10): p. 741 - 749.

- Rezaur Rahman, M. , et al., Physico-Mechanical Properties of Jute Fiber Reinforced Polypropylene Composites. Journal of Reinforced Plastics and Composites, 2009. 29(3): p. 445-455.

- Singhal, P. and S. K. Tiwari. Effect of Various Chemical Treatments on the Damping Property of Jute Fibre Reinforced Composite. 2014.

- RAO, P.R.T.M.Y.P. , Study the Mechanical Properties of Jute and Sisal fiber reinforced Hybrid Composite Materials. International Research Journal of Engineering and Technology (IRJET), 2019. 6(10): p. 741 - 749.

- Davidovits, J. , Geopolymer Chemistry and Applications. Vol. 171. 2008.

- Sanjay; Yogesha, B. Studies on Natural/Glass Fiber Reinforced Polymer Hybrid Composites: An Evolution. Mater. Today: Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- Billah, M.; Rabbi, S.; Hasan, A. A Review on Developments in Manufacturing Process and Mechanical Properties of Natural Fiber Composites. J. Eng. Adv. 2021, 2, 13–23. [Google Scholar] [CrossRef]

- Raji, M. , et al., Prediction of the cyclic durability of woven-hybrid composites, in Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites. 2019, Elsevier. p. 27-62.

- Khanam, P.N.; Reddy, M.M.; Raghu, K.; John, K.; Naidu, S.V. Tensile, Flexural and Compressive Properties of Sisal/Silk Hybrid Composites. J. Reinf. Plast. Compos. 2007, 26, 1065–1070. [Google Scholar] [CrossRef]

- Kornmann, X.; Rees, M.; Thomann, Y.; Necola, A.; Barbezat, M.; Thomann, R. Epoxy-layered silicate nanocomposites as matrix in glass fibre-reinforced composites. Compos. Sci. Technol. 2005, 65, 2259–2268. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Sreekumar, P.; Joseph, K.; Unnikrishnan, G.; Thomas, S. A comparative study on mechanical properties of sisal-leaf fibre-reinforced polyester composites prepared by resin transfer and compression moulding techniques. Compos. Sci. Technol. 2007, 67, 453–461. [Google Scholar] [CrossRef]

- Jatmiko, A.; Handayani, I.P.; Suhendi, A. Speed Controlled Composite Fabrication Using DC Motor. J. Meas. Electron. Commun. Syst. 2021. [Google Scholar] [CrossRef]

- Arslan, E.; Ayaz, E. The Usage of a Force Controlled Delta Manipulator for Composite Hand Lay-Up Fiber Placement Process. 2023 5th International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA). LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE; pp. 01–06.

- Gambardella, A.; Esperto, V.; Tucci, F.; Carlone, P. Defects Reduction in the Robotic Layup Process. Key Eng. Mater. 2022, 926, 1437–1444. [Google Scholar] [CrossRef]

- Barletta, M.; Vesco, S.; Puopolo, M.; Tagliaferri, V. Graphene reinforced UV-curable epoxy resins: Design, manufacture and material performance. Prog. Org. Coatings 2016, 90, 414–424. [Google Scholar] [CrossRef]

- Cooley, J. , An introduction to common hand-layup methods with composite materials. 2018, Brigham Young University-Idaho.

- Elkington, M. , et al., Studying effects of preshearing on hand layup. Advanced Manufacturing: Polymer & Composites Science, 2015. 1(2): p. 80-93.

- Collinson, M.; Bower, M.; Swait, T.J.; Atkins, C.; Hayes, S.; Nuhiji, B. Novel composite curing methods for sustainable manufacture: A review. Compos. Part C: Open Access 2022, 9. [Google Scholar] [CrossRef]

- Elkington, M. , et al., Hand layup: understanding the manual process. Advanced manufacturing: polymer & composites science, 2015. 1(3): p. 138-151.

- Kikuchi, T.; Koyanagi, T.; Hamada, H.; Nakai, A.; Takai, Y.; Goto, A.; Fujii, Y.; Narita, C.; Endo, A.; Koshino, T. Biomechanics Investigation of Skillful Technician in Hand Lay Up Fabrication Method. ASME 2012 International Mechanical Engineering Congress and Exposition. LOCATION OF CONFERENCE, USADATE OF CONFERENCE; pp. 533–539.

- Abdurohman, K. , et al. A comparison process between hand lay-up, vacuum infusion and vacuum bagging method toward e-glass EW 185/lycal composites. in Journal of Physics: Conference Series. 2018. IOP Publishing.

- Leong, Y.W. , et al., 8 - Compression and injection molding techniques for natural fiber composites, in Natural Fibre Composites, A. Hodzic and R. Shanks, Editors. 2014, Woodhead Publishing. p. 216-232.

- Geethamma, V.G., R. Joseph, and S. Thomas, Short coir fiber-reinforced natural rubber composites: Effects of fiber length, orientation, and alkali treatment. Journal of Applied Polymer Science, 1995. 55(4): p. 583-594.

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Sarasook, P.; Uawongsuwan, P.; Memon, A.; Hamada, H. Jute Fiber Reinforced Thermoplastic Composites Fabricated by Direct Fiber Feeding Injection Molding (DFFIM) Process. Key Eng. Mater. 2020, 856, 268–275. [Google Scholar] [CrossRef]

- He, L.; Xia, F.; Chen, D.; Peng, S.; Hou, S.; Zheng, J. Optimization of molding process parameters for enhancing mechanical properties of jute fiber reinforced composites. J. Reinf. Plast. Compos. 2022, 42, 446–454. [Google Scholar] [CrossRef]

- Pailoor, S.; Murthy, H.N.N.; Hadimani, P.; Sreenivasa, T.N. Effect of chopped/continuous fiber, coupling agent and fiber ratio on the mechanical properties of injection-molded jute/polypropylene composites. J. Nat. Fibers 2017, 16, 126–136. [Google Scholar] [CrossRef]

- Gong, G.; Chen, J.C.; Guo, G. Enhancing tensile strength of injection molded fiber reinforced composites using the Taguchi-based six sigma approach. Int. J. Adv. Manuf. Technol. 2017, 91, 3385–3393. [Google Scholar] [CrossRef]

- Fujiura, T. , et al., A study on preparation and mechanical properties of long jute fiber reinforced polylactic acid by the injection molding process. WIT Trans. Built Environ, 2008. 97: p. 231-240.

- Fu, H.; Xu, H.; Liu, Y.; Yang, Z.; Kormakov, S.; Wu, D.; Sun, J. Overview of Injection Molding Technology for Processing Polymers and Their Composites. ES Mater. Manuf. 2020. [Google Scholar] [CrossRef]

- Rabbi, M.S.; Islam, T.; Islam, G.M.S. Injection-molded natural fiber-reinforced polymer composites–a review. Int. J. Mech. Mater. Eng. 2021, 16, 1–21. [Google Scholar] [CrossRef]

- Singh, G.; Verma, A. A Brief Review on injection moulding manufacturing process. Mater. Today: Proc. 2017, 4, 1423–1433. [Google Scholar] [CrossRef]

- Boros, R.; Rajamani, P.K.; Kovacs, J.G. Combination of 3D printing and injection molding: Overmolding and overprinting. Express Polym. Lett. 2019, 13, 889–897. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. 3D Printed Injection Molds Using Various 3D Printing Technologies. Mater. Sci. Forum 2020, 1005, 150–156. [Google Scholar] [CrossRef]

- Fuenmayor, E.; O'Donnell, C.; Gately, N.; Doran, P.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Mass-customization of oral tablets via the combination of 3D printing and injection molding. Int. J. Pharm. 2019, 569, 118611. [Google Scholar] [CrossRef] [PubMed]

- Adekunle, K.; Åkesson, D.; Skrifvars, M. Biobased composites prepared by compression molding with a novel thermoset resin from soybean oil and a natural-fiber reinforcement. J. Appl. Polym. Sci. 2010, 116, 1759–1765. [Google Scholar] [CrossRef]

- Mallick, P.K. , Fiber-Reinforced Composites: Materials, Manufacturing and Design. iii ed. 2007, Boca Raton: CRC Press. 638.

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Tatara, R.A. , 14 - Compression Molding, in Applied Plastics Engineering Handbook (Second Edition), M. Kutz, Editor. 2017, William Andrew Publishing. p. 291-320.

- Barocio, E. , et al., FIBER REINFORCED THERMOPLASTICS: Compression Molding of Hybrid Continuous and Discontinuous Fiber Reinforced Thermoplastics for Enhancing Strength Characteristics. SAMPE Journal, 2023. 59(5).

- Alam, M.J. , et al., Investigation of jute and glass fibre reinforced hybrid composites manufactured through compression molding process. International Journal of Engineering Materials and Manufacture, 2022. 7(1): p. 35-46.

- Khalid, M.Y.; Arif, Z.U.; Sheikh, M.F.; Nasir, M.A. Mechanical characterization of glass and jute fiber-based hybrid composites fabricated through compression molding technique. Int. J. Mater. Form. 2021, 14, 1085–1095. [Google Scholar] [CrossRef]

- Reddy, S.R.T.; Prasad, A.R.; Ramanaiah, K. Tensile and flexural properties of biodegradable jute fiber reinforced poly lactic acid composites. Mater. Today: Proc. 2021, 44, 917–921. [Google Scholar] [CrossRef]

- Yallew, T.B.; Kassegn, E.; Aregawi, S.; Gebresias, A. Study on effect of process parameters on tensile properties of compression molded natural fiber reinforced polymer composites. SN Appl. Sci. 2020, 2, 338. [Google Scholar] [CrossRef]

- Jaafar, J.; Siregar, J.P.; Tezara, C.; Hamdan, M.H.M.; Rihayat, T. A review of important considerations in the compression molding process of short natural fiber composites. Int. J. Adv. Manuf. Technol. 2019, 105, 3437–3450. [Google Scholar] [CrossRef]

- Tatara, R.A. , Compression molding, in Applied plastics engineering handbook. 2024, Elsevier. p. 389-424.

- Park, C. and W.I. Lee, Compression molding in polymer matrix composites, in Manufacturing techniques for polymer matrix composites (PMCs). 2012, Elsevier. p. 47-94.

- Verma, N.; Singh, M.K.; Zafar, S.; Pathak, H. Comparative study of in-situ temperature measurement during microwave-assisted compression-molding and conventionally compression-molding process. CIRP J. Manuf. Sci. Technol. 2021, 35, 336–345. [Google Scholar] [CrossRef]

- Rouison, D.; Sain, M.; Couturier, M. Resin-transfer molding of natural fiber-reinforced plastic. I. Kinetic study of an unsaturated polyester resin containing an inhibitor and various promoters. J. Appl. Polym. Sci. 2003, 89, 2553–2561. [Google Scholar] [CrossRef]

- Francucci, G.; Rodríguez, E.S.; Vázquez, A. Experimental study of the compaction response of jute fabrics in liquid composite molding processes. J. Compos. Mater. 2011, 46, 155–167. [Google Scholar] [CrossRef]

- Idicula, M.; Sreekumar, P.; Joseph, K.; Thomas, S. Natural fiber hybrid composites—A comparison between compression molding and resin transfer molding. Polym. Compos. 2009, 30, 1417–1425. [Google Scholar] [CrossRef]

- Richardson, M.; Zhang, Z. Experimental investigation and flow visualisation of the resin transfer mould filling process for non-woven hemp reinforced phenolic composites. Compos. Part A: Appl. Sci. Manuf. 2000, 31, 1303–1310. [Google Scholar] [CrossRef]

- Rodriguez, E.; Giacomelli, F.; Vazquez, A. Permeability-Porosity Relationship in RTM for Different Fiberglass and Natural Reinforcements. J. Compos. Mater. 2004, 38, 259–268. [Google Scholar] [CrossRef]

- Karacor, B.; Özcanli, M. Characterization Of Jute/Aramid Hybrid Composite Materials with Using Different Resins. Sak. Univ. J. Sci. 2022, 26, 915–930. [Google Scholar] [CrossRef]

- Plateau, T.P. Evaluation of Tensile Strength of Jute Fiber Reinforced Polypropylene Composite. Adv. Mater. 2017, 6, 149. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Kovács, J.G. A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation. Polymers 2019, 11, 1555. [Google Scholar] [CrossRef]

- Okabe, T.; Oya, Y.; Yamamoto, G.; Sato, J.; Matsumiya, T.; Matsuzaki, R.; Yashiro, S.; Obayashi, S. Multi-objective optimization for resin transfer molding process. Compos. Part A: Appl. Sci. Manuf. 2017, 92, 1–9. [Google Scholar] [CrossRef]

- Crawford, B.; Rashif, K.M.S.; Rashidi, A.; Sadiq, R.; Milani, A.S. A Bayesian belief approach to quality control of resin transfer molding process. Int. J. Adv. Manuf. Technol. 2020, 109, 1953–1968. [Google Scholar] [CrossRef]

- Campos, B.M.; Bourbigot, S.; Fontaine, G.; Bonnet, F. Thermoplastic matrix-based composites produced by resin transfer molding: A review. Polym. Compos. 2022, 43, 2485–2506. [Google Scholar] [CrossRef]

- Baran, I.; Akkerman, R.; Hattel, J.H. Modelling the pultrusion process of an industrial L-shaped composite profile. Compos. Struct. 2014, 118, 37–48. [Google Scholar] [CrossRef]

- Carlone, P.; Baran, I.; Hattel, J.H.; Palazzo, G.S. Computational Approaches for Modeling the Multiphysics in Pultrusion Process. Adv. Mech. Eng. 2013, 5. [Google Scholar] [CrossRef]

- Han, C.D.; Lee, D.S.; Chin, H.B. Development of a mathematical model for the pultrusion process. Polym. Eng. Sci. 1986, 26, 393–404. [Google Scholar] [CrossRef]

- Gutowski, T.G. , Advanced Composites Manufacturing. Vol. i. 1997, New York: Wiley New York.

- Liu, X.L.; Crouch, I.; Lam, Y. Simulation of heat transfer and cure in pultrusion with a general-purpose finite element package. Compos. Sci. Technol. 2000, 60, 857–864. [Google Scholar] [CrossRef]

- Tipboonsri, P.; Pramoonmak, S.; Uawongsuwan, P.; Memon, A. Optimization of Thermoplastic Pultrusion Parameters of Jute and Glass Fiber-Reinforced Polypropylene Composite. Polymers 2023, 16, 83. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Rajeshkumar, L.; Sanjay, M.R.; Siengchin, S.; Thakrishnan, N.; Rajeshkumar, G. Improving the mechanical properties of jute fiber woven mat reinforced epoxy composites with addition of zinc oxide filler.CONFERENCE NAME, LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE; p. 02006.

- ElMessiry, M., S. El Tarfawy, and R. El Deeb, Mechanical performance of cementitious composites reinforced with pultruded jute/polymeric matrix fabric. J Material Sci Eng, 2015. 4(173): p. 2169-0022.1000173.

- Gupta, A.; Singh, H.; Walia, R.S. Hybrid filler composition optimization for tensile strength of jute fibre-reinforced polymer composite. Bull. Mater. Sci. 2016, 39, 1223–1231. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Talabi, S.I.; Tobin, J.; Strom, B.; Brownstein, I.; Kunc, V.; Hassen, A.A. Recent and future developments in pultrusion technology with consideration for curved geometries: A review. Compos. Part B: Eng. 2024, 283. [Google Scholar] [CrossRef]

- Volk, M.; Yuksel, O.; Baran, I.; Hattel, J.H.; Spangenberg, J.; Sandberg, M. Cost-efficient, automated, and sustainable composite profile manufacture: A review of the state of the art, innovations, and future of pultrusion technologies. Compos. Part B: Eng. 2022, 246. [Google Scholar] [CrossRef]

- Correia, J.R. , Pultrusion of advanced composites, in Advanced fiber-reinforced polymer (FRP) composites for structural applications. 2023, Elsevier. p. 137-177.

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- Yenilmez, B.; Senan, M.; Sozer, E.M. Variation of part thickness and compaction pressure in vacuum infusion process. Compos. Sci. Technol. 2009, 69, 1710–1719. [Google Scholar] [CrossRef]

- Yang, J.; Xiao, J.; Zeng, J.; Jiang, D.; Peng, C. Compaction Behavior and Part Thickness Variation in Vacuum Infusion Molding Process. Appl. Compos. Mater. 2011, 19, 443–458. [Google Scholar] [CrossRef]

- Hammami, A.; Gebart, B.R. Analysis of the vacuum infusion molding process. Polym. Compos. 2000, 21, 28–40. [Google Scholar] [CrossRef]

- Yunus, S.; Salleh, Z.; Aznan, M.; Berhan, M.; Kalam, A.; Rashid, A.; Wong, F.R. Impacted of Vacuum Bag Woven Kenaf/Fiberglass Hybrid Composite. Appl. Mech. Mater. 2014, 660, 572–577. [Google Scholar] [CrossRef]

- Govignon, Q.; Bickerton, S.; Kelly, P. Simulation of the reinforcement compaction and resin flow during the complete resin infusion process. Compos. Part A: Appl. Sci. Manuf. 2009, 41, 45–57. [Google Scholar] [CrossRef]

- Simacek, P.; Heider, D.; Gillespie, J.W.; Advani, S. Post-filling flow in vacuum assisted resin transfer molding processes: Theoretical analysis. Compos. Part A: Appl. Sci. Manuf. 2009, 40, 913–924. [Google Scholar] [CrossRef]

- Yang, J.; Xiao, J.; Zeng, J.; Jiang, D.; Peng, C. Compaction Behavior and Part Thickness Variation in Vacuum Infusion Molding Process. Appl. Compos. Mater. 2011, 19, 443–458. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Huang, J.-T. VARTM process of composites using double-bag air cushion method. Trans. Can. Soc. Mech. Eng. 2023, 47, 131–142. [Google Scholar] [CrossRef]

- Bhatt, A.T.; Gohil, P.P.; Chaudhary, V. Degassing and layers variation effect on composite processing by vacuum assisted resin transfer moulding. J. Eng. Res. 2021, 9, 184–192. [Google Scholar] [CrossRef]

- Shen, R.; Liu, T.; Liu, H.; Zou, X.; Gong, Y.; Guo, H. An Enhanced Vacuum-Assisted Resin Transfer Molding Process and Its Pressure Effect on Resin Infusion Behavior and Composite Material Performance. Polymers 2024, 16, 1386. [Google Scholar] [CrossRef]

- Shen, R.; Liu, T.; Liu, H.; Zou, X.; Gong, Y.; Guo, H. An Enhanced Vacuum-Assisted Resin Transfer Molding Process and Its Pressure Effect on Resin Infusion Behavior and Composite Material Performance. Polymers 2024, 16, 1386. [Google Scholar] [CrossRef]

- Valášek, P. and M. Müller. Tensile characteristics of epoxy/jute biocomposites prepared by vacuum infusion. in Innovation, Engineering and Entrepreneurship. 2019. Springer.

- Halley, P.J. , 4 - Rheology of thermosets: the use of chemorheology to characterise and model thermoset flow behaviour, in Thermosets, Q. Guo, Editor. 2012, Woodhead Publishing. p. 92-117.

- Purslow, D.; Childs, R. Autoclave moulding of carbon fibre-reinforced epoxies. Composites 1986, 17, 127–136. [Google Scholar] [CrossRef]

- What is the Difference between Injection Molding & Extrusion? 2020 [cited 2023 ]; Available from: http://www.veejayplastic.com/blog/top-5-key-difference-between-extrusion-injection-molding/#:~:text=Injection%20molding%20is%20suitable%20for,can%20be%20achieved%20by%20extrusion. 1 April.

- Kopeliovich, D. Extrusion of polymers. 2014 [cited 2023 ]; Available from: https://www.substech.com/dokuwiki/doku.php?id=extrusion_of_polymers#:~:text=Extrusion%20is%20a%20process%20of,an%20extruder%20through%20a%20hopper. 1 April.

- Kulkarni, G.S. , 1 - Introduction to Polymer and Their Recycling Techniques, in Recycling of Polyurethane Foams, S. Thomas, et al., Editors. 2018, William Andrew Publishing. p. 1-16.

- Singh, A.A.; Palsule, S. Jute fiber reinforced chemically functionalized polypropylene self-compatibilizing composites by Palsule process. J. Compos. Mater. 2015, 50, 1199–1212. [Google Scholar] [CrossRef]

- Biswas, K.; Palsule, S. Bamboo Fibre-reinforced Self-compatibilizing Functionalized Polypropylene Composites by Palsule Process. Polym. Polym. Compos. 2016, 24, 663–674. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.; Bose, N. Impact fatigue behaviour of vinylester resin matrix composites reinforced with alkali treated jute fibres. Compos. Part A: Appl. Sci. Manuf. 2002, 33, 233–241. [Google Scholar] [CrossRef]

- Mishra, V.; Biswas, S. Physical and Mechanical Properties of Bi-directional Jute Fiber Epoxy Composites. Procedia Eng. 2013, 51, 561–566. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A. Mechanical and water absorption properties of woven jute/banana hybrid composites. Fibers Polym. 2012, 13, 907–914. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Strengthening of RC beams in flexure using natural jute fibre textile reinforced composite system and its comparative study with CFRP and GFRP strengthening systems. Int. J. Sustain. Built Environ. 2013, 2, 41–55. [Google Scholar] [CrossRef]

- Chandramohan, D. , et al., Mechanical, Moisture Absorption, and Abrasion Resistance Properties of Bamboo–Jute–Glass Fiber Composites. Journal of Bio- and Tribo-Corrosion, 2019. 5(3): p. 66.

- Das, S. and M. Bhowmick, Mechanical Properties of Unidirectional Jute-Polyester Composite. Journal of Textile Science & Engineering, 2015. 05.

- Manik, M.K.; Gajghat, R.H.; Joseph, A. Mechanical Properties of Epoxy Resin Matrix Composites Reinforced with Jute Fiber, Coconut Coir and Human Hair. Int. J. Eng. Adv. Technol. 2019, 9, 1270–1275. [Google Scholar] [CrossRef]

- Dieu, T.V.; Phai, L.T.; Ngoc, P.M.; Tung, N.H.; Thao, L.P.; Quang, L.H. Study on Preparation of Polymer Composites Based on Polypropylene Reinforced by Jute Fibers. JSME Int. J. Ser. A 2004, 47, 547–550. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Miah, S.; Ali, A. Effect of Jute Fiber Modification on Mechanical Properties of Jute Fiber Composite. Materials 2019, 12. [Google Scholar] [CrossRef]

- Bambach, M. Compression strength of natural fibre composite plates and sections of flax, jute and hemp. Thin-Walled Struct. 2017, 119, 103–113. [Google Scholar] [CrossRef]

- Dobah, Y.; Bourchak, M.; Bezazi, A.; Belaadi, A.; Scarpa, F. Multi-axial mechanical characterization of jute fiber/polyester composite materials. Compos. Part B: Eng. 2016, 90, 450–456. [Google Scholar] [CrossRef]

- Boopalan, M.; Niranjanaa, M.; Umapathy, M. Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos. Part B: Eng. 2013, 51, 54–57. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Dhawan, V.; Singh, S.; Jangid, K. Study of Effect of Surface Treatment on Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today: Proc. 2017, 4, 2793–2799. [Google Scholar] [CrossRef]

- Boopalan, M.; Umapathy, M.J.; Jenyfer, P. A Comparative Study on the Mechanical Properties of Jute and Sisal Fiber Reinforced Polymer Composites. Silicon 2012, 4, 145–149. [Google Scholar] [CrossRef]

- Mache, A.; Deb, A.; Gupta, N. An experimental study on performance of jute-polyester composite tubes under axial and transverse impact loading. Polym. Compos. 2019, 41, 1796–1812. [Google Scholar] [CrossRef]

- Cavalcanti, D.K.K.; Banea, M.D.; Neto, J.S.S.; Lima, R.A.A.; da Silva, L.F.M.; Carbas, R.J.C. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part B Eng. 2019, 175, 107149. [Google Scholar] [CrossRef]

- Joseph, B.G.; Rajan, J.A.; Jeevahan, J.; Mageshwaran, G. Influence of Alkaline Treatment on Improving Mechanical Properties of Jute Fiber-Reinforced Epoxy (LY556) Composites. FME Trans. 2019, 47, 83–88. [Google Scholar] [CrossRef]

- Gupta, M. Investigations on jute fibre-reinforced polyester composites: Effect of alkali treatment and poly(lactic acid) coating. J. Ind. Text. 2018, 49, 923–942. [Google Scholar] [CrossRef]

- Pawar, M.J.; Patnaik, A.; Nagar, R. Investigation on mechanical and thermo-mechanical properties of granite powder filled treated jute fiber reinforced epoxy composite. Polym. Compos. 2015, 38, 736–748. [Google Scholar] [CrossRef]

- Singh, S.P.; Dutt, A.; Hirwani, C.K. Mechanical, Modal and Harmonic Behavior Analysis of Jute and Hemp Fiber Reinforced Polymer Composite. J. Nat. Fibers 2022, 20. [Google Scholar] [CrossRef]

- Kakati, N.; Assanvo, E.F.; Kalita, D. Synthesis and Performance Evaluation of Unsaturated Polyester Blends of Resins and Its Application on Non-woven/Fabric Jute Fibers Reinforced Composites. J. Polym. Environ. 2019, 27, 2540–2548. [Google Scholar] [CrossRef]

- Kabir, M.; Islam, M.; Wang, H. Mechanical and Thermal Properties of Jute Fibre Reinforced Composites. J. Multifunct. Compos. 2013, 1, 71–76. [Google Scholar] [CrossRef]

- Biswas, S.; Shahinur, S.; Hasan, M.; Ahsan, Q. Physical, Mechanical and Thermal Properties of Jute and Bamboo Fiber Reinforced Unidirectional Epoxy Composites. Procedia Eng. 2015, 105, 933–939. [Google Scholar] [CrossRef]

- Rodriguez, E.S.; Stefani, P.M.; Vazquez, A. Effects of Fibers' Alkali Treatment on the Resin Transfer Molding Processing and Mechanical Properties of Jute—Vinylester Composites. J. Compos. Mater. 2007, 41, 1729–1741. [Google Scholar] [CrossRef]

- Cabral, H.; Cisneros, M.; Kenny, J.M.; Vazquez, A.; Bernal, C.R. Structure–Properties Relationship of Short Jute Fiber-reinforced Polypropylene Composites. J. Compos. Mater. 2005, 39, 51–65. [Google Scholar] [CrossRef]

- Khan, M.A.; Ganster, J.; Fink, H.-P. Hybrid composites of jute and man-made cellulose fibers with polypropylene by injection moulding. Compos. Part A: Appl. Sci. Manuf. 2009, 40, 846–851. [Google Scholar] [CrossRef]

- Zhong, Z.; Li, M.; Liao, Z.; Lu, L. The impact of adhesive resin solution on carbon fibers cloth and jute-reinforced epoxy resin matrix composites. J. Text. Inst. 2015, 107, 1264–1267. [Google Scholar] [CrossRef]

- Rahman, M.R. , et al., Improvement of physico-mechanical properties of jute fiber reinforced polypropylene composites by post-treatment. Composites Part A: Applied Science and Manufacturing, 2008. 39(11): p. 1739-1747.

- Hong, C.; Hwang, I.; Kim, N.; Park, D.; Hwang, B.; Nah, C. Mechanical properties of silanized jute–polypropylene composites. J. Ind. Eng. Chem. 2008, 14, 71–76. [Google Scholar] [CrossRef]

- Nabila, S.; Juwono, A.L.; Roseno, S. Effect of Weight Fractions of Jute Fiber on Tensile Strength and Deflection Temperature of Jute Fiber/Polypropylene Composites. IOP Conf. Series: Mater. Sci. Eng. 2017, 196, 012029. [Google Scholar] [CrossRef]

- Das, S.C.; Paul, D.; Fahad, M.M.; Das, M.K.; Rahman, G.M.S.; Khan, M.A. Effect of Fiber Loading on the Dynamic Mechanical Properties of Jute Fiber Reinforced Polypropylene Composites. Adv. Chem. Eng. Sci. 2018, 08, 215–224. [Google Scholar] [CrossRef]

- Khan, G.A.; Terano, M.; Gafur, M.; Alam, M.S. Studies on the mechanical properties of woven jute fabric reinforced poly(l-lactic acid) composites. J. King Saud Univ. - Eng. Sci. 2016, 28, 69–74. [Google Scholar] [CrossRef]

- Chatterjee, A.; Kumar, S.; Singh, H. Tensile strength and thermal behavior of jute fibre reinforced polypropylene laminate composite. Compos. Commun. 2020, 22, 100483. [Google Scholar] [CrossRef]

- Shen, J.; Li, X.; Yan, X. Mechanical and Acoustic Properties of Jute Fiber-Reinforced Polypropylene Composites. ACS Omega 2021, 6, 31154–31160. [Google Scholar] [CrossRef]

- Keya, K.N.; Kona, N.A.; Khan, R.A. Comparative Study of Jute, Okra and Pineapple Leaf Fiber Reinforced Polypropylene Based Composite. Adv. Mater. Res. 2019, 1155, 29–40. [Google Scholar] [CrossRef]

- Miah, M.; Ahmed, F.; Hossain, A.; Khan, A.; Khan, M. Study on Mechanical and Dielectric Properties of Jute Fiber Reinforced Low-Density Polyethylene (LDPE) Composites. Polym. Technol. Eng. 2005, 44, 1443–1456. [Google Scholar] [CrossRef]

- Plateau, T.P. Evaluation of Tensile Strength of Jute Fiber Reinforced Polypropylene Composite. Adv. Mater. 2017, 6, 149. [Google Scholar] [CrossRef]

- Sudha, S.; Thilagavathi, G. Analysis of electrical, thermal and compressive properties of alkali-treated jute fabric reinforced composites. J. Ind. Text. 2017, 47, 1407–1423. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Regenerated cellulose fibers as impact modifier in long jute fiber reinforced polypropylene composites: Effect on mechanical properties, morphology, and fiber breakage. J. Appl. Polym. Sci. 2014, 132. [Google Scholar] [CrossRef]

- Rashed, H.; Islam, M.; Rizvi, F. Effects of Process Parameters on Tensile Strength of Jute Fiber Reinforced Thermoplastic Composites. J. Nav. Arch. Mar. Eng. 1970, 3, 1–6. [Google Scholar] [CrossRef]

- Sajin, J.; Aurtherson, P.B.; Binoj, J.; Manikandan, N.; Saravanan, M.S.; Haarison, T. Influence of fiber length on mechanical properties and microstructural analysis of jute fiber reinforced polymer composites. Mater. Today: Proc. 2020, 39, 398–402. [Google Scholar] [CrossRef]

- Easwara Prasad, G., B. Megha, and B. Keerthi Gowda. Study of mechanical characteristics of banana and jute fiber reinforced polyester composites. in Mechanics of Composite, Hybrid and Multifunctional Materials, Volume 5: Proceedings of the 2018 Annual Conference on Experimental and Applied Mechanics. 2019. Springer.

- Liu, J.; Xue, Y.; Dong, X.; Fan, Y.; Hao, H.; Wang, X. Review of the surface treatment process for the adhesive matrix of composite materials. Int. J. Adhes. Adhes. 2023, 126. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115. [Google Scholar] [CrossRef]

- Mylsamy, B.; Shanmugam, S.K.M.; Aruchamy, K.; Palanisamy, S.; Nagarajan, R.; Ayrilmis, N. A review on natural fiber composites: Polymer matrices, fiber surface treatments, fabrication methods, properties, and applications. Polym. Eng. Sci. 2024, 64, 2345–2373. [Google Scholar] [CrossRef]

- RajuAhammad, M.A. and M.S. Isalm, Effect of Alkali Treatment on Mechanical Properties of Non-woven Jute Fiber Reinforced Epoxy Composite.

- Seisa, K.; Chinnasamy, V.; Ude, A.U. Surface Treatments of Natural Fibres in Fibre Reinforced Composites: A Review. Fibres Text. East. Eur. 2022, 30, 82–89. [Google Scholar] [CrossRef]

- Ivanovska, A.; Milošević, M.; Obradović, B.; Svirčev, Z.; Kostić, M. Plasma Treatment as a Sustainable Method for Enhancing the Wettability of Jute Fabrics. Sustainability 2023, 15, 2125. [Google Scholar] [CrossRef]

- Naik, R.; Allu, S.G.; Purnima, D. PP/Jute Fiber Composites: Effect of Biological Route of Surface Treatment and Content of Jute on Composites. Appl. Biochem. Biotechnol. 2023, 196, 2869–2880. [Google Scholar] [CrossRef]

- Alshahrani, H.; A Sebaey, T.; Allah, M.M.A.; El-Baky, M.A.A. Jute-basalt reinforced epoxy hybrid composites for lightweight structural automotive applications. J. Compos. Mater. 2023, 57, 1315–1330. [Google Scholar] [CrossRef]

- Kurien, R.A.; Arshad, A.; Joseph, A.; Sunil, A.; Cherian, B.T.; Rangappa, S.M.; Suttiruengwong, S.; Kannan, G.; Siengchin, S. Agave-jute fiber–reinforced hybrid composite for lightweight applications: effect of hybridization. Biomass- Convers. Biorefinery, 14. [CrossRef]

- Kurien, R.A.; Biju, A.; Raj, A.K.; Chacko, A.; Joseph, B.; Koshy, C.P.; Paul, C. Comparative Mechanical Properties of Duck Feather–Jute Fiber Reinforced Hybrid Composites. Trans. Indian Inst. Met. 2023, 76, 2575–2580. [Google Scholar] [CrossRef]

- Prasad, M.; Maneengam, A.; Siddique, M.J.; Selvaraj, R. Static and dynamic characteristics of jute/glass fiber reinforced hybrid composites. Structures 2023, 50, 954–962. [Google Scholar] [CrossRef]

- Ahmed, K.; Qin, X.; Yuqiu, Y.; Yu, L.; Hamada, H. Physiochemical and thermodynamic mechanical behavior of injection molded sized and de-sized CF/PP composites. Compos. Interfaces 2022, 30, 123–145. [Google Scholar] [CrossRef]

- G. , V.; Chohan, J.S.; A., M.A.S.; R., S.; S., S.M.; M., N.; S., S.K.; V., S.S.; D., E.R. Investigation of Nano SiO2 Filler Loading on Mechanical and Flammability Properties of Jute-Based Hybrid Polypropylene Composites. Silicon 2023, 15, 7247–7263. [Google Scholar] [CrossRef]

- Dejene, B.K. Exploring the Potential of ZnO Nanoparticle-Treated Fibers in Advancing Natural Fiber Reinforced Composites: A Review. J. Nat. Fibers 2024, 21. [Google Scholar] [CrossRef]

- Rashid, A.B. , et al., Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon, 2024.

- Tasnim, T.; Rabbi, M.S.; Adil, M.; Hasib, A. An experimental study on jute/banana fiber reinforced poly(vinyl alcohol) composites with nanofiller. J. Vinyl Addit. Technol. 2024. [Google Scholar] [CrossRef]

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation | ||

| [25] | Fiber length 5-6 mm |

Polyester | 5% NaOH | 18% wt. | 9.24 | 0.811 | 1.14 mm | ||

| 10% NaOH | 7.92 | - | - | ||||||

| Epoxy | 5% NaOH | 12.46 | 1.064 | 1.17 mm | |||||

| 10% NaOH | 10.5 | - | - | ||||||

| [121] | Bi-directional jute fiber mat | Epoxy | Untreated | 12% wt. | 71.67 | 0.96 | - | ||

| 24% wt. | 88.87 | 3.03 | - | ||||||

| 36% wt. | 97.99 | 3.81 | - | ||||||

| 48% wt. | 110 | 4.45 | - | ||||||

| [122] | Woven fabric | Epoxy | Untreated | 25% wt. | 26.53 | 6.32 | - | ||

| [123] | Main and cross directional Woven textile | Epoxy | Heat treatment | 189.479 | |||||

| [124] | Continuous jute fibers (5 layers) | Polyester | Dry | 50% wt. | 34.87 | 1.989 | - | ||

| Wet - water | 35.23 | 2.23 | - | ||||||

| [125] | Raw jute fiber reed | Un-saturates polyester |

30% jute batching oil in water emulsion | 25% wt. | 80 ± 13.39 | 3.68 ± 0.48 | 4.5 ± 0.55 % | ||

| 35% wt. | 106 ± 16.30 | 4.83 ± 0.63 | 5.2 ± 0.83 % | ||||||

| 44% wt. | 122 ± 31.11 | 5.56 ± 0.67 | 4.8 ± 0.54 % | ||||||

| Jute silver | 25% wt. | 71 ± 11.93 | 3.24 ± 0.65 | 4.8 ± 0.59 % | |||||

| 35% wt. | 89 ± 9.74 | 4.46 ± 0.45 | 5.4 ± 0.48 % | ||||||

| 44% wt. | 109 ± 16 | 4.89 ± 0.55 | 4.7 ± 0.54 % | ||||||

| [126] | Long jute fibers | Epoxy | Untreated | 70% wt. | 419 | - | - | ||

| [127] | Plain weave jute fabrics | Poly-propylene | 0.4% NaOH | 30% wt. | 16.73 | - | - | ||

| 40% wt. | 22.31 | - | - | ||||||

| 45% wt. | 24.21 | - | - | ||||||

| 50% wt. | 21.55 | - | - | ||||||

| 60% wt. | 20.15 | - | - | ||||||

| 65% wt. | 18.50 | - | - | ||||||

| [128] | Unidirectional jute fiber | Epoxy | Untreated | 8% wt. | 45.28 ± 0.45 | 3.18 ± 0.40 | - | ||

| 10% wt. | 54.35 ± 4.88 | 5.66 ± 0.65 | - | ||||||

| 12% wt. | 78.38 ± 1.01 | 9.9 ± 1.61 | - | ||||||

| Chemically treated | 8% wt. | 51.25 ± 4.88 | 11.9 ± 0.55 | - | |||||

| 10% wt. | 67.97 ± 2.99 | 12.38 ± 1.38 | - | ||||||

| 12% wt. | 84.46 ± 4.99 | 13 ± 0.67 | - | ||||||

| [129] | Bi-axial woven jute fabric | Epoxy | Untreated | 44.3 ± 2.2 % vol. | 52.1 | 5.184 | 1.6% | ||

| [130] | Woven jute fiber plies | Polyester | Untreated | 20% vol. | Uni | 42.236 | 3.973 | 0.011 m/m | |

| Multi | 21.685 | - | 0.529 m/m | ||||||

| [131] | Cross-plied | Epoxy | Untreated | - | 16.62 | 0.664 | - | ||

| [132] | Combed unidirectional | Epoxy | Untreated | 40% vol. | 179 | - | - | ||

| 5% NaOH | 432 | - | - | ||||||

| [133] | Matted Jute fabric | Epoxy | Untreated | - | 46.7 | - | - | ||

| 20% NaOH | 97.5 | - | - | ||||||

| [134] | Bidirectional woven jute | Polyester | Untreated | 30% vol. | 30 | 2.1 | - | ||

| 33% vol. | 35 | 2.5 | - | ||||||

| 37% vol. | 46 | 3 | - | ||||||

| 40% vol. | 60 | 4 | - | ||||||

| [135] | Twine form fabric weaved in bidirectional mat | Epoxy | Untreated | 30% vol. | 39.75 ± 0.97 | 39.75 ± 0.97 | - | ||

| Alkalized | 39.08 ± 3.35 | 3.60 ± 0.24 | - | ||||||

| Alkalized + Silanized | 43.07 ± 3.80 | 3.77 ± 0.23 | - | ||||||

| [136] | Jute fabric | Epoxy | Untreated | 30% vol. | 45.628 | - | - | ||

| Alkalized | 50.19 | - | - | ||||||

| [137] | Short jute fibers | Polyester | Untreated | 16% wt. | 30.6 ± 2.30 | 3.368 ± 0.18 | 1.209 ± 0.08 % | ||

| 5% NaOH | 34.2 ± 2.91 | 3.946 ± 0.22 | 1.221 ± 0.09 % | ||||||

| PLA-coated | 31.6 ± 2.83 | 3.489 ± 0.19 | 1.212 ± 0.07 % | ||||||

| Alkalized + PLA-coated | 36.6 ± 3.12 | 3.991 ± 0.23 | 1.324 ± 0.08 % | ||||||

| [138] | Matted jute | Epoxy | 5% wt. NaOH | 10% wt. | 28.33 ± 1.05 | 0.6246 ± 0.0325 | - | ||

| 20% wt. | 31.71 ± 2.11 | 0.8486 ± 0.0516 | - | ||||||

| 30% wt. | 33.04 ± 0.46 | 1.0453 ± 0.0379 | - | ||||||

| 40% wt. | 33.72 ± 1.73 | 1.2284 ± 0.0846 | - | ||||||

| 50% wt. | 34.26 ± 2.59 | 1.1785 ± 0.1085 | - | ||||||

| [139] | Long Jute fiber | Epoxy | Untreated | 1 layer | 11.02 | 0.90 | - | ||

| 2 layers | 42.73 | 1.06 | - | ||||||

| 3 layers | 53.69 | 1.40 | - | ||||||

| [140] | Non-woven + Fabric + non-woven fibers with Unsaturated polyester, Soy Flour Resin | no Alkyd Resin | Un-treated | - | 2.83 | - | 1.57% | ||

| 5% Alkyd Resin | 24.87 | - | 3.46% | ||||||

| 10% Alkyd Resin | 25.79 | - | 5.27% | ||||||

| Ref. | Jute fiber/ fabric type | Resin | Treatment | Percentage of Fiber in Composite | Compressive Strength, MPa | Compressive Modulus, GPa | Strain, % |

|---|---|---|---|---|---|---|---|

| [129] | Bi-axial woven | Epoxy | Untreated | 44.3 ± 2.2 % vol. | 40.2 | 3.523 | - |

| [141] | Woven jute fabric | Un-saturated polyester | Untreated | 25% wt. | 56.09 | 0.75 | 4.72 |

| 4% NaOH | 57.42 | 0.44 | 12.97 | ||||

| 5% NaOH | 69.01 | 0.88 | 7.77 | ||||

| 7% NaOH | 55.63 | 0.65 | 8.59 | ||||

| [134] | Bi-directional woven jute | Polyester | Untreated | 30% vol. | 58 | - | - |

| 33% vol. | 54 | - | - | ||||

| 37% vol. | 49 | - | - | ||||

| 40% vol. | 40 | - | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

| [25] | Fiber length 5-6 mm | Polyester | 5% NaOH | 18% wt. | 44.71 | 1.91 | 5.5 mm |

| 10% NaOH | 40.5 | - | - | ||||

| Epoxy | 5% NaOH | 39.08 | 3.08 | 2.1 mm | |||

| 10% NaOH | 32.5 | - | - | ||||

| [121] | Bi-directional jute fiber mat | Epoxy | Untreated | 12% wt. | 28.61 | 0.59 | - |

| 24% wt. | 34.79 | 0.73 | - | ||||

| 36% wt. | 51.22 | 1.24 | - | ||||

| 48% wt. | 55.8 | 3.02 | - | ||||

| [122] | Woven fabric | Epoxy | Untreated | 25% wt. | 66.67 | 5.78 | - |

| [123] | Main and cross directional Woven textile | Epoxy | Heat treatment | 208.705 | - | - | |

| [124] | Continuous Jute fibers (5 layers) | Polyester | Dry | 50% wt. | 67.56 | 2.59 | - |

| Wet by water | 68.89 | 3.121 | - | ||||

| [125] | Raw jute fiber reed | Un-saturates polyester |

30% jute batching oil in water emulsion | 25% wt. | 102 ± 16.23 | 9.42 ± 1.31 | 2.27 ± 0.15 % |

| 35% wt. | 124 ± 17.97 | 11.6 ± 1.65 | 3.49 ± 0.28 % | ||||

| 44% wt. | 145 ± 21.94 | 15.41 ± 2.22 | 3.18 ± 0.31 % | ||||

| Jute silver | 25% wt. | 85 ± 20.16 | 7.56 ± 1.36 | 2.61 ± 0.60 % | |||

| 35% wt. | 103 ± 14.64 | 10.64 ± 1.41 | 2.66 ± 0.57 % | ||||

| 44% wt. | 112 ± 17.30 | 13.24 ± 2.12 | 2.57 ± 0.48 % | ||||

| [127] | Plain weave jute fabrics | Poly-propylene | 0.4% NaOH | 30% wt. | 34.75 | - | - |

| 40% wt. | 42.49 | - | - | ||||

| 45% wt. | 44.26 | - | - | ||||

| 50% wt. | 39.31 | - | - | ||||

| 60% wt. | 38.05 | - | - | ||||

| 65% wt. | 36.14 | - | - | ||||

| [141] | Woven jute fabric | Un-saturated polyester | Untreated | 25% wt. | 39.63 | 1.56 | 2.52% |

| 4% NaOH | 47.91 | 1.77 | 2.70% | ||||

| 5% NaOH | 57.16 | 1.49 | 3.81% | ||||

| 7% NaOH | 56.75 | 2.13 | 2.66% | ||||

| [131] | Cross-plied | Epoxy | Untreated | - | 57.22 | 8.956 | |

| [132] | Combed unidirectional | Epoxy | Untreated | 40% vol. | 85 | - | - |

| 5% NaOH | 89 | - | - | ||||

| [133] | Matted Jute fabric | Epoxy | Untreated | - | 62.4 | - | - |

| 20% NaOH | 80.1 | - | - | ||||

| [135] | Twine form fabric weaved in bidirectional mat | Epoxy | Untreated | 30% vol. | 64.30 ± 5.50 | 4.63 ± 0.42 | - |

| Alkalized | 56.31 ± 5.68 | 3.53 ± 0.34 | - | ||||

| Alkalized + Silanized | 50.62 ± 2.31 | 3.53 ± 0.34 | - | ||||

| [136] | Jute fabric | Epoxy | Untreated | 30% vol. | 81.12 | - | - |

| Alkalized | 90.89 | - | - | ||||

| [137] | Short jute fibers | Polyester | Untreated | 16% wt. | 58.17 ± 3.14 | 3.931 ± 0.17 | 1.861 ± 0.11 % |

| 5% NaOH | 78.27 ± 4.12 | 5.872 ± 0.25 | 2.414 ± 0.12 % | ||||

| PLA-coated | 67.68 ± 3.26 | 4.420 ± 0.19 | 2.090 ± 0.12 % | ||||

| Alkalized + PLA-coated | 79.76 ± 4.67 | 6.231 ± 0.31 | 2.512 ± 0.14 % | ||||

| [138] | Matted jute | Epoxy | 5% wt. NaOH | 10% wt. | 44.2 ± 2.65 | 0.7363 ± 0.0458 | - |

| 20% wt. | 49.6 ± 4.32 | 1.0248 ± 0.0276 | - | ||||

| 30% wt. | 68.8 ± 4.49 | 1.2906 ± 0.0241 | - | ||||

| 40% wt. | 81.8 ± 6.78 | 1.2583 ± 0.0546 | - | ||||

| 50% wt. | 97.8 ± 5.25 | 1.0133 ± 0.179 | - | ||||

| [139] | Long Jute fiber | Epoxy | Untreated | 1 layer | 31.3 | 1.42 | - |

| 2 layers | 56.32 | 2.03 | - | ||||

| 3 layers | 76.52 | 3.02 | - | ||||

| [140] | Non-woven + Fabric + non-woven fibers with Unsaturated polyester, Soy Flour Resin | no Alkyd Resin | Un-treated | - | 2.83 | - | - |

| 5% Alkyd Resin | 24.87 | - | - | ||||

| 10% Alkyd Resin | 25.79 | - | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Type of Impact Test | Impact strength |

| [25] | Fiber length 5-6 mm | Polyester | 5% NaOH | 18% wt. | Charpy | 3.25 J |

| 10% NaOH | 2.75 J | |||||

| Epoxy | 5% NaOH | 2.63 J | ||||

| 10% NaOH | 2 J | |||||

| [121] | Bi-directional jute fiber mat | Epoxy | Untreated | 12% wt. | - | 3.048 J |

| 24% wt. | 3.929 J | |||||

| 36% wt. | 4.528 J | |||||

| 48% wt. | 4.875 J | |||||

| [122] | Woven fabric | Epoxy | Untreated | 25% wt. | 80 J/m2 | |

| [124] | Continuous Jute fibers (5 layers) | Polyester | Dry | 50% wt. | Charpy | 6.14 J |

| Wet by water | 7.23 J | |||||

| [126] | Long jute fibers | Epoxy | Untreated | 70% wt. | Charpy | 3 J |

| Izod | 2 J | |||||

| [127] | Plain weave jute fabrics | Poly-propylene | 0.4% NaOH | 30% wt. | Charpy | 54.42 kJ/m2 |

| 40% wt. | 61.27 kJ/m2 | |||||

| 45% wt. | 61.78 kJ/m2 | |||||

| 50% wt. | 51.62 kJ/m2 | |||||

| 60% wt. | 49.09 kJ/m2 | |||||

| 65% wt. | 44.39 kJ/m2 | |||||

| [131] | Cross-plied | Epoxy | Untreated | - | Izod | 13.44 kJ/m2 |

| [132] | Combed unidirectional | Epoxy | Untreated | 40% vol. | Charpy | 480.76 kJ/m2 |

| 5% NaOH | 76.92 kJ/m2 | |||||

| [135] | Twine form fabric weaved in bidirectional mat | Epoxy | Untreated | 30% vol. | - | 143.06 ± 22.39 J/m |

| Alkalized | 171.68 ± 18.28 J/m | |||||

| [136] | Jute fabric | Epoxy | Untreated | 30% vol. | Izod | 69.5 J/cm2 |

| Alkalized | 88.5 J/cm2 | |||||

| [137] | Short jute fibers | Polyester | Untreated | 16% wt. | Izod | 5.10 ± 0.32 kJ/m2 |

| 5% NaOH | 2.29 ± 0.16 kJ/m2 | |||||

| PLA-coated | 3.95 ± 0.21 kJ/m2 | |||||

| Alkalized + PLA-coated | 5.30 ± 0.29 kJ/m2 | |||||

| [138] | Matted jute | Epoxy | 5% wt. NaOH | 10% wt. | - | 20.35 ± 0.2 kJ/m2 |

| 20% wt. | 20.98 ± 0.24 kJ/m2 | |||||

| 30% wt. | 21.84 ± 0.05 kJ/m2 | |||||

| 40% wt. | 22.65 ± 1.1 kJ/m2 | |||||

| 50% wt. | 23.87 ± 1.36 kJ/m2 |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Rockwell hardness Value | |

|---|---|---|---|---|---|---|

| [25] | Fiber length 5-6 mm | Polyester | 5% NaOH | 18% wt. | 44 | |

| 10% NaOH | 41.67 | |||||

| Epoxy | 5% NaOH | 42 | ||||

| 10% NaOH | 41 | |||||

| [121] | Bi-directional jute fiber mat | Epoxy | Untreated | 12% wt. | 70.68 | |

| 24% wt. | 74.01 | |||||

| 36% wt. | 78.54 | |||||

| 48% wt. | 85.5 | |||||

| [126] | Long jute fibers | Epoxy | Untreated | 70% wt. | 40 | |

| [140] | Non-woven + Fabric + non-woven fibers with Unsaturated polyester, Soy Flour Resin | no Alkyd Resin | Un-treated | - | 44.6 | |

| 5% Alkyd Resin | 63 | |||||

| 10% Alkyd Resin | 66.60 | |||||

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation |

|---|---|---|---|---|---|---|---|

| [142] | Unidirectional | Epoxy | - | 52% wt. | 216 ± 1.02 | 31 ± 1.34 | 0.78 ± 0.05 %. |

| [143] | Bi-directional woven | Epoxy vinylester | Untreated | - | 505 ± 165 | 30 ± 14 | - |

| 5% NaOH | 326 ± 150 | 12.2 ± 5.2 | - |

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

|---|---|---|---|---|---|---|---|

| [142] | Unidirectional longitudinal | Epoxy | - | 52% wt. | 158 ± 18.90 | 18 ± 1.92 | - |

| Unidirectional transverse | 25.7 ± 2.17 | 2.73 ± 0.28 | - | ||||

| [143] | Bi-directional woven | Epoxy vinylester | Untreated | - | 103 ± 6 | 6.6 ± 0.5 | - |

| 5% NaOH | 83 ± 6 | 5.5 ± 0.02 | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation |

|---|---|---|---|---|---|---|---|

| [118] | 3 - 6 mm chopped jute | Poly-propylene | Untreated | 10% wt. | 43.03 | 1.27 | 6.9% |

| 20% wt. | 46.58 | 1.46 | 6.1% | ||||

| 30% wt. | 56.71 | 1.82 | 5.2% |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

|---|---|---|---|---|---|---|---|

| [118] | 3 - 6 mm chopped jute | Poly-propylene | Untreated | 10% wt. | 61.85 | 2.72 | - |

| 20% wt. | 69.21 | 3.27 | - | ||||

| 30% wt. | 77.32 | 4.34 | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

|---|---|---|---|---|---|---|---|

| [120] | White jute fibers | Vinyl-ester | Untreated | 35% vol. | 199.10 ± 7.6 | 11.89 ± 0.62 | - |

| 5% NaOH for 4 hours | 238.90 ± 17.60 | 14.69 ± 0.85 | - | ||||

| 5% NaOH for 8 hours | 204.20 ± 1.20 | 12.32 ± 0.35 | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Type of Tester | Toughness |

|---|---|---|---|---|---|---|

| [120] | White jute fibers | Vinyl-ester | Untreated | 35% vol. |

Charpy |

22.10 ± 2.79 kJ/m2 |

| 5% NaOH for 4 hours | 21.92 ± 3.84 kJ/m2 | |||||

| 5% NaOH for 8 hours | 19.97 ± 0.78 kJ/m2 |

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation |

|---|---|---|---|---|---|---|---|

| [144] | Uniaxial jute yarn | Poly-propylene | - | 6% vol. | 28.11 | 1.32 | - |

| 12% vol. | 29.24 | 1.61 | - | ||||

| 18% vol. | 27.31 | 1.87 | - | ||||

| 23% vol. | 27.98 | 2.04 | - | ||||

| 29% vol. | 33.12 | 2.03 | - | ||||

| 34% vol. | 33.56 | 2.18 | - | ||||

| 45% vol. | 34.46 | 2.28 | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Type of Impact Test | Impact strength |

|---|---|---|---|---|---|---|

| [144] | Uniaxial jute yarn | Poly-propylene | - | 6% vol. | Izod | 25.77 kJ/m2 |

| 12% vol. | 28.40 kJ/m2 | |||||

| 18% vol. | 29.33 kJ/m2 | |||||

| 23% vol. | 17.89 kJ/m2 | |||||

| 29% vol. | 17.47 kJ/m2 | |||||

| 34% vol. | 13.19 kJ/m2 | |||||

| 45% vol. | 11.46 kJ/m2 |

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation |

|---|---|---|---|---|---|---|---|

| [145] | Yearned Jute | Poly-propylene | Untreated | 25 % wt. | 71.9 ± 0.4 | 3.18 ± 0.05 | - |

| Maleic Acid Anhydride | 71 ± 0.6 | 3.39 ± 0.06 | - | ||||

| [146] | Jute fiber | Epoxy, Polyamide Resin, | Untreated | - | 192.65 -225.89 | - | - |

| [147] | Chopped jute fibers | Poly-propylene | Untreated | 20% wt. | 25.726 | 1.682 | - |

| 25% wt. | 25.359 | 1.71 | - | ||||

| 30% wt. | 24.18 | 2.137 | - | ||||

| 35% wt. | 23.536 | 2.221 | - | ||||

| Oxidized | 20% wt. | 27.092 | 1.714 | - | |||

| 25% wt. | 26.374 | 1.999 | - | ||||

| 30% wt. | 25.158 | 2.234 | - | ||||

| 35% wt. | 24.33 | 2.313 | - | ||||

| Oxidized & post-treated | 20% wt. | 29.473 | 1.864 | - | |||

| 25% wt. | 29.365 | 2.03 | - | ||||

| 30% wt. | 28.998 | 2.29 | - | ||||

| 35% wt. | 27.201 | 2.398 | - | ||||

| [148] | Short jute fiber | Poly-propylene | Untreated | 1% wt. | 26.778 | 0.807 | 5.429 mm |

| 5% wt. | - | 1.189 | - | ||||

| 10% wt. | - | 1.766 | - | ||||

| 15% wt. | 35.856 | 2.153 | 2.102 mm | ||||

| Silanized | 1% wt. | 29.162 | 0.844 | 5.811 mm | |||

| 5% wt. | - | 1.158 | - | ||||

| 10% wt. | - | 1.819 | - | ||||

| 15% wt. | 37.049 | 2.193 | 1.957 mm |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

|---|---|---|---|---|---|---|---|

| [145] | Yearned Jute | Poly-propylene | Untreated | 25 % wt. | 68.5 ± 1.5 | 2.72 ± 0.05 | - |

| Maleic Acid Anhydride | 71.5 ± 0.4 | 2.77 ± 0.04 | - | ||||

| [146] | Jute fiber | Epoxy, Polyamide Resin, | Untreated | - | 196.26 - 236.19 | 1.640 - 1.992 | - |

| [147] | Chopped jute fibers | Poly-propylene | Untreated | 20% wt. | 45.499 | 1.928 | - |

| 25% wt. | 47.145 | 2.136 | - | ||||

| 30% wt. | 47.191 | 2.246 | - | ||||

| 35% wt. | 45.515 | 2.404 | - | ||||

| Oxidized | 20% wt. | 49.459 | 2.406 | - | |||

| 25% wt. | 49.665 | 2.487 | - | ||||

| 30% wt. | 49.689 | 2.521 | - | ||||

| 35% wt. | 47.175 | 2.553 | - | ||||

| Oxidized & post-treated | 20% wt. | 53.979 | 2.532 | - | |||

| 25% wt. | 54.385 | 2.766 | - | ||||

| 30% wt. | 54.350 | 2.995 | - | ||||

| 35% wt. | 45.499 | 3.101 | - |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber | Type of Impact Test | Impact strength |

|---|---|---|---|---|---|---|

| [145] | Yearned Jute | Poly-propylene | Untreated | 25 % wt. | Charpy | 79 ± 0.2 kJ/m2 |

| Maleic Acid Anhydride | 47.2 ± 4.2 kJ/m2 | |||||

| [146] | Jute fiber | Epoxy, Polyamide Resin, | Untreated | - | - | 1.6038 - 1.9262 MPa |

| [147] | Chopped jute fibers | Poly-propylene | Untreated | 20% wt. | Charpy | 18.513 MPa |

| 25% wt. | 31.199 MPa | |||||

| 30% wt. | 31.245 MPa | |||||

| 35% wt. | 19.307 MPa | |||||

| Oxidized | 20% wt. | 23.426 MPa | ||||

| 25% wt. | 34.435 MPa | |||||

| 30% wt. | 34.480 MPa | |||||

| 35% wt. | 23.261 MPa | |||||

| Oxidized & post-treated | 20% wt. | 39.243 MPa | ||||

| 25% wt. | 48.694 MPa | |||||

| 30% wt. | 48.379 MPa | |||||

| 35% wt. | 31.11 MPa |

| Ref. | Jute Fiber/ Fabric type | Resin | Treatment | Percentage of Fiber in Composites | Tensile Strength, MPa | Tensile Modulus, GPa | Tensile Elongation | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [149] | Matted Jute | Poly-propylene | 5% NaOH | 30 % in weight | 33.5 | 2.8 | 3.09 % | |||||||

| 40% in weight | 38.2 | 3.2 | 2.95 % | |||||||||||

| 50 % in weight | 36.38 | 3.17 | 2.84 % | |||||||||||

| [150] | Woven Jute Fabric | Poly-propylene | Untreated | 40 % in weight | 53.12 | 2.51 | - | |||||||

| 45 % in weight | 58.40 | 2.79 | - | |||||||||||

| 50 % in weight | 68.27 | 2.94 | - | |||||||||||

| 55 % in weight | 56.29 | 2.77 | - | |||||||||||

| [151] |

Uni-directional | Poly L-lactic acid |

- | - | 55 ± 11.5 | 0.867 ± 0.02 | 6.01% | |||||||

| Woven jute fabric-Wrap |

Un-treated | 52 yarns per 100 mm | 81 ± 13.5 | 1.12 ± 0.034 | 3.8% | |||||||||

| Treated | 87 ± 8.5 | 1.42 ± 0.047 | 5.1% | |||||||||||

| Woven jute fabric- Weft | Un-treated | 44 yarns per 100 mm | 71 ± 8.7 | 0.78 ± 0.063 | 4.1% | |||||||||

| Treated | 79.2 ± 9 | 0.91 ± 0.057 | 4.2% | |||||||||||

| [152] | Chopped-3 cm-1 Ply | Poly-propylene | Un-treated | 5% | 10.44 ± 0.62 | - | - | |||||||

| Chopped-3 cm-2 Ply | 12.01 ± 1.66 | - | - | |||||||||||

| Chopped-3 cm-4 Ply | 11.54 ± 2.86 | - | - | |||||||||||

| Chopped-6 cm-1 Ply | 10.09 ± 1.34 | - | - | |||||||||||

| Chopped-6 cm-2 Ply | 11.88 ± 2.51 | - | - | |||||||||||

| Chopped-6 cm-4 Ply | 10.16 ± 2.8 | - | - | |||||||||||

| Chopped-9 cm-1 Ply | 9.68 ± 2.48 | - | - | |||||||||||

| Chopped-9 cm-2 Ply | 11.36 ± 2.73 | - | - | |||||||||||

| Chopped-9 cm-4 Ply | 10.34 ± 3.40 | - | - | |||||||||||

| Chopped-3 cm-1 Ply | 10% | 10.23 ± 1.61 | - | - | ||||||||||

| Chopped-3 cm-2 Ply | 17.86 ± 0.62 | - | - | |||||||||||

| Chopped-3 cm-4 Ply | 12.47 ± 3.05 | - | - | |||||||||||

| Chopped-6 cm-1 Ply | 10.21 ± 1.61 | - | - | |||||||||||

| Chopped-6 cm-2 Ply | 13.48 ± 1.48 | - | - | |||||||||||

| Chopped-6 cm-4 Ply | 12.16 ± 2.30 | - | - | |||||||||||

| Chopped-9 cm-1 Ply | 9.92 ± 2.22 | - | - | |||||||||||

| Chopped-9 cm-2 Ply | 13.65 ± 2.16 | - | - | |||||||||||

| Chopped-9 cm-4 Ply | 11.93 ± 4.12 | - | - | |||||||||||

| [153] | Chopped Jute Fiber | Poly-propylene | NaOH | 5% wt. | 23.08 ± 0.94 | - | - | |||||||

| 20% wt. | 26.78 ± 0.64 | - | - | |||||||||||

| 35% wt. | 27.42 ± 0.59 | - | - | |||||||||||

| 50% wt. | 24.96 ± 0.3 | - | - | |||||||||||

| [154] | Bleached jute fabric | Poly-propylene | Untreated | 45% wt. | 45 | 2.2 | 11% | |||||||

| [155] | Jute fabric | low-density poly-ethylene | Untreated | 10% wt. | 15.05 | - | 30.51 % | |||||||

| 15% wt. | 17.23 | - | 33.02 % | |||||||||||

| 20% wt. | 19.05 | - | 35.38 % | |||||||||||

| 25% wt. | 20.05 | - | 36.06 % | |||||||||||

| 30% wt. | 19.09 | - | 26.02 % | |||||||||||

| 3% 2-hydroxyl ethyl methacrylate & 2% benzol peroxide treated | 10% wt. | 17.11 | - | 32.17 % | ||||||||||

| 15% wt. | 21.26 | - | 35.23 % | |||||||||||

| 20% wt. | 23.68 | - | 41.32 % | |||||||||||

| 25% wt. | 25.12 | - | 50 % | |||||||||||

| 30% wt. | 23.43 | - | 48.10 % | |||||||||||

| [156] | Chopped jute fibers- 1 mm long | Poly-propylene | Untreated | 5% wt. | 23.5 | - | - | |||||||

| 10% wt. | 26 | |||||||||||||

| 15% wt. | 20.4 | |||||||||||||

| Treated 20% NaOH |

5% wt. | 19 | ||||||||||||

| 10% wt. | 25 | |||||||||||||

| 15% wt. | 24 | |||||||||||||

| Chopped jute fibers- 2 mm long | Untreated | 5% wt. | 33 | - | - | |||||||||

| 10% wt. | 26 | |||||||||||||

| 15% wt. | 26.4 | |||||||||||||

| 20% NaOH | 5% wt. | 30 | ||||||||||||

| 10% wt. | 32.4 | |||||||||||||

| 15% wt. | 26 | |||||||||||||

| Chopped jute fibers- 4 mm long | Untreated | 5% wt. | 26 | - | - | |||||||||

| 10% wt. | 25.04 | |||||||||||||

| 15% wt. | 25.04 | |||||||||||||

| 20% NaOH | 5% wt. | 33 | ||||||||||||

| 10% wt. | 28 | |||||||||||||

| 15% wt. | 27 | |||||||||||||

| [157] | Plain woven Jute fibers | Vinyl-ester resin | Untreated | 4.5 ± 0.2 | - | - | ||||||||

| 5% NaOH | = 8.3 ± 0.6 | - | - | |||||||||||

| [158] | Twisted Jute Yarn | Poly-propylene | Untreated | 30% in wt. | 29.1 ± 1.1 | 2.7 ± 0.103 | 3.3 ± 1.0% | |||||||

| [159] | Chopped jute fiber- 1 mm | Poly-propylene | Untreated | 5% wt. | 23.29 ± 0.34 | - | - | |||||||

| 10% wt. | 26.39 ± 0.34 | - | - | |||||||||||

| 15% wt. | 22.13 ± 0.34 | - | - | |||||||||||

| 20% NaOH | 5% wt. | 18.99 ± 0.11 | - | - | ||||||||||

| 10% wt. | 25.24 ± 0.11 | - | - | |||||||||||

| 15% wt. | 24.42 ± 0.11 | - | - | |||||||||||

| Chopped jute fiber- 2 mm | Untreated | 5% wt. | 26.55 ± 0.34 | - | - | |||||||||

| 10% wt. | 31.71 ± 0.34 | - | - | |||||||||||

| 15% wt. | 27.05 ± 0.34 | - | - | |||||||||||

| 20% NaOH | 5% wt. | 30.52 ± 0.11 | - | - | ||||||||||

| 10% wt. | 33.15 ± 0.11 | - | - | |||||||||||

| 15% wt. | 26.58 ± 0.11 | - | - | |||||||||||

| Chopped jute fiber- 4 mm | Untreated | 5% wt. | 25.13 ± 0.34 | - | - | |||||||||

| 10% wt. | 26.11 ± 0.34 | - | - | |||||||||||

| 15% wt. | 25.13 ± 0.34 | - | - | |||||||||||

| 20% NaOH | 5% wt. | 32.77 ± 0.11 | - | - | ||||||||||

| 10% wt. | 28.05 ± 0.11 | - | - | |||||||||||

| 15% wt. | 27.41 ± 0.11 | - | - | |||||||||||

| [160] | Chopped jute fiber- 5 mm | Polyester | Untreated | 30% wt. | 29 | - | - | |||||||

| Chopped jute fiber- 10 mm | 9.46 | - | - | |||||||||||

| Chopped jute fiber- 15 mm | 8.68 | - | - | |||||||||||

| Chopped jute fiber- 20 mm | 2.08 | - | - | |||||||||||

| Chopped jute fiber- 25 mm | 1.675 | - | - | |||||||||||

| [161] | Chopped jute fiber- 3 mm | Polyester | - | 5% wt | 17.09 | - | - | |||||||

| 10% wt. | 22.49 | - | - | |||||||||||

| 15% wt. | 23.45 | - | - | |||||||||||

| 20% wt. | 35.15 | - | - | |||||||||||

| 25% wt | 43.94 | - | - | |||||||||||

| Chopped jute fiber- 5 mm | 5% wt | 10.68 | - | - | ||||||||||

| 10% wt. | 14.93 | - | - | |||||||||||

| 15% wt. | 16.59 | - | - | |||||||||||

| 20% wt. | 24.88 | - | - | |||||||||||

| 25% wt. | 39.28 | - | - | |||||||||||

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Flexural Strength, MPa | Flexural Modulus, GPa | Flexural Elongation |

| [150] |

Woven Jute Fabric |

Poly-propylene |

untreated |

40 % in weight | 74.83 | ||

| 45 % in weight | 78.77 | ||||||

| 50 % in weight | 94.43 | ||||||

| 55 % in weight | 77.32 | ||||||

| [151] |

Uni-directional | Poly L-lactic acid |

- | 67 ± 8.4 | 2.83 ± 1.1 | ||

| Woven jute fabric-Wrap |

Un-treated | 52 yarns per 100 mm | 82 ± 12.0 | 4.3 ± 0.10 | |||

| Treated | 121 ± 13.4 | 5.3 ± 0.10 | |||||

| Woven jute fabric- Weft | Un-treated | 44 yarns per 100 mm | 81 ± 9.4 | 3.62 ± 0.08 | |||

| Treated | 111 ± 8.1 | 4.72 ± 0.05 | |||||

| [153] | Chopped jute fiber | Poly-propylene | NaOH | 5% wt. | 31.16 ± 1.89 | - | - |

| 20% wt. | 35.46 ± 0.78 | - | - | ||||

| 35% wt. | 36.40 ± 0.12 | - | - | ||||

| 50% wt. | 35.02 ± 0.78 | - | - | ||||

| [154] | Bleached jute fabric | Poly-propylene | Untreated | 45% wt. | 54 | 4.1 | - |

| [155] | Jute fabric | low-density poly-ethylene | Untreated | 10% wt. | 22.23 | - | - |

| 15% wt. | 39.81 | - | - | ||||

| 20% wt. | 48.62 | - | - | ||||

| 25% wt. | 48.01 | - | - | ||||

| 30% wt. | 47.14 | - | - | ||||

| 3% 2-hydroxyl ethyl methacrylate & 2% benzol peroxide treated | 10% wt. | 27.07 | - | - | |||

| 15% wt. | 61.14 | - | - | ||||

| 20% wt. | 77.07 | - | - | ||||

| 25% wt. | 73.05 | - | - | ||||

| 30% wt. | 20.15 | - | - | ||||

| [158] | Twisted Jute Yarn | Poly-propylene | Untreated | 30% in wt. | 47.1 ± 7.1 | = 5.269 ± 0.482 | - |

| [160] | Chopped jute fiber- 5 mm | Polyester | Untreated | 30% wt. | 64.66 | - | - |

| Chopped jute fiber- 10 mm | 30.46 | - | - | ||||

| Chopped jute fiber- 15 mm | 25.56 | - | - | ||||

| Chopped jute fiber- 20 mm | 22.86 | - | - | ||||

| Chopped jute fiber- 25 mm | 21.5 | - | - | ||||

| [161] | Chopped jute fiber- 3 mm | Polyester | - | 5% wt. | 15.75 | - | - |

| 10% wt. | 26.16 | ||||||

| 15% wt. | 42.51 | ||||||

| 20% wt. | 55.89 | ||||||

| 25% wt. | 53.65 | ||||||

| Chopped jute fiber- 5 mm | - | 5% wt. | 12.12 | - | - | ||

| 10% wt. | 21.90 | ||||||

| 15% wt. | 24.87 | ||||||

| 20% wt. | 41.23 | ||||||

| 25% wt. | 38.15 |

| Ref. | Fiber type | Resin | Treatment | Percentage of Fiber in Composites | Type of Impact Test | Impact strength |

|---|---|---|---|---|---|---|

| [150] | Woven Jute Fabric |

Poly-propylene |

untreated |

40 % in weight | Not specified | 8.997606253 |

| 45 % in weight | 13.07566584 | |||||

| 50 % in weight | 14.59758961 | |||||

| 55 % in weight | 11.92773381 | |||||

| [151] |

Uni-directional | Poly L-lactic acid |

- | Charpy | 12.98 ± 1.1 kJ/m2 | |

| Woven jute fabric-Wrap |

Un-treated | 52 yarns per 100 mm | 16.4 ± 1.8 kJ/m2 | |||

| Treated | 18.1 ± 2.3 kJ/m2 | |||||

| Woven jute fabric- Weft | Un-treated | 44 yarns per 100 mm | 14.3 ± 1.5 kJ/m2 | |||

| Treated | 16.6 ± 1.8 kJ/m2 | |||||

| [154] | Bleached jute fabric | Poly-propylene | Untreated | 45% wt. | Izod | 0.61 kJ/m2 |

| [158] | Twisted Jute Yarn | Polypropylene | Untreated | 30% in wt. | Izod | 24.4 ± 3.1 J/m |

| [160] | Chopped jute fiber- 5 mm | Polyester | Untreated | 30% wt. | Izod |

0.61 J |

| Chopped jute fiber- 10 mm | 0.51 J | |||||

| Chopped jute fiber- 15 mm | 0.48 J | |||||

| Chopped jute fiber- 20 mm | 0.45 J | |||||

| Chopped jute fiber- 25 mm | 0.39 J |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).