Submitted:

08 October 2024

Posted:

09 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Modeling of the Elastic Behaviour of MN Nanosheets

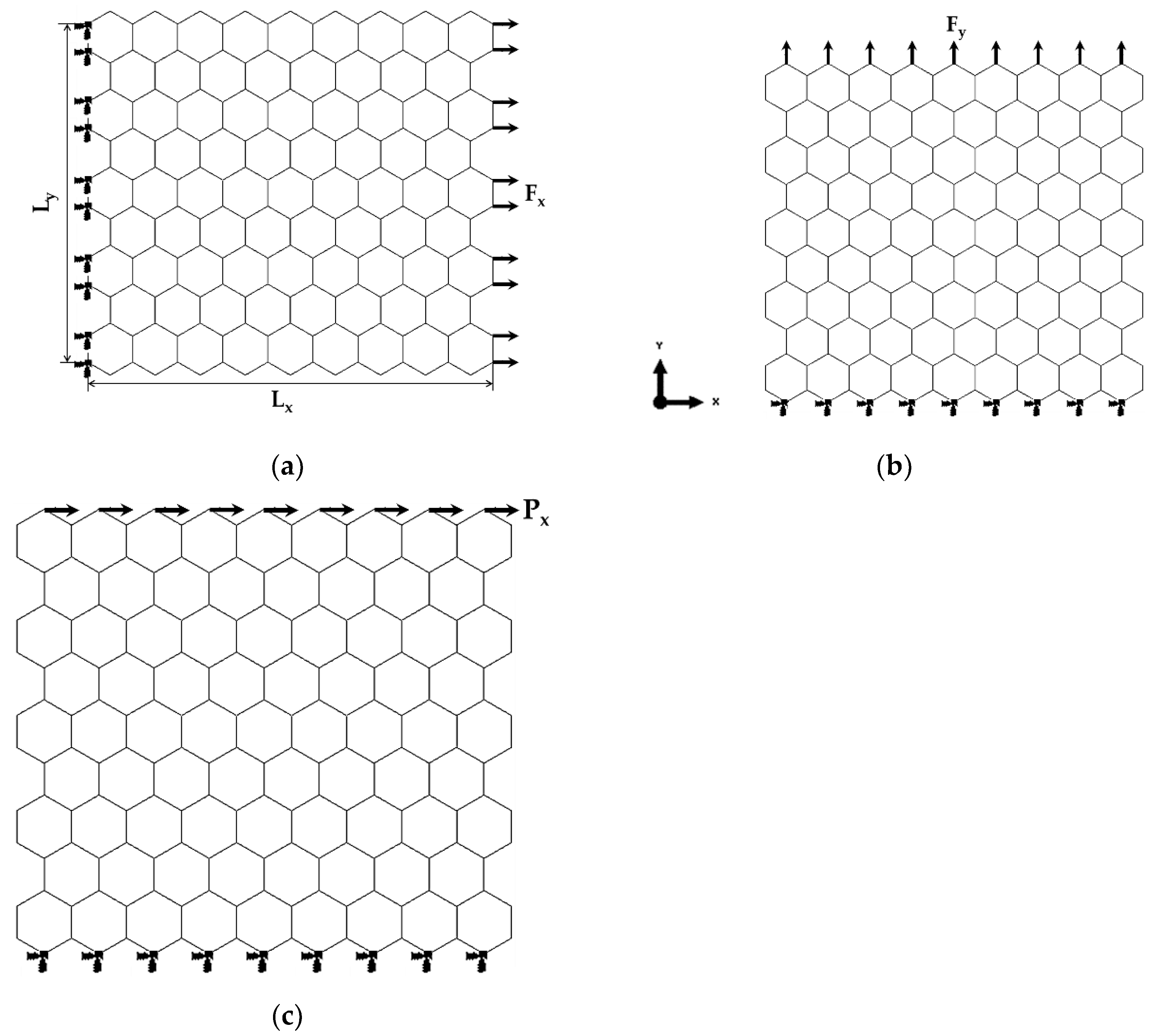

2.2. Finite Element Analysis and Elastic Properties of MN Nanosheets

3. Results and Discussion

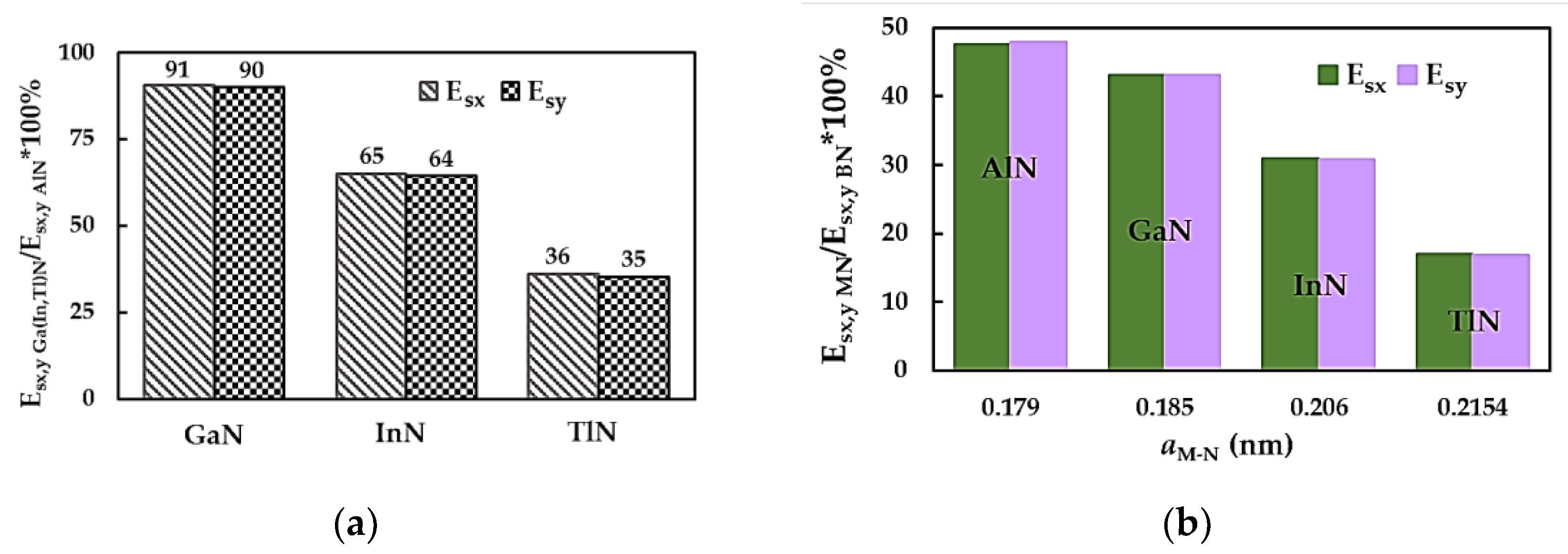

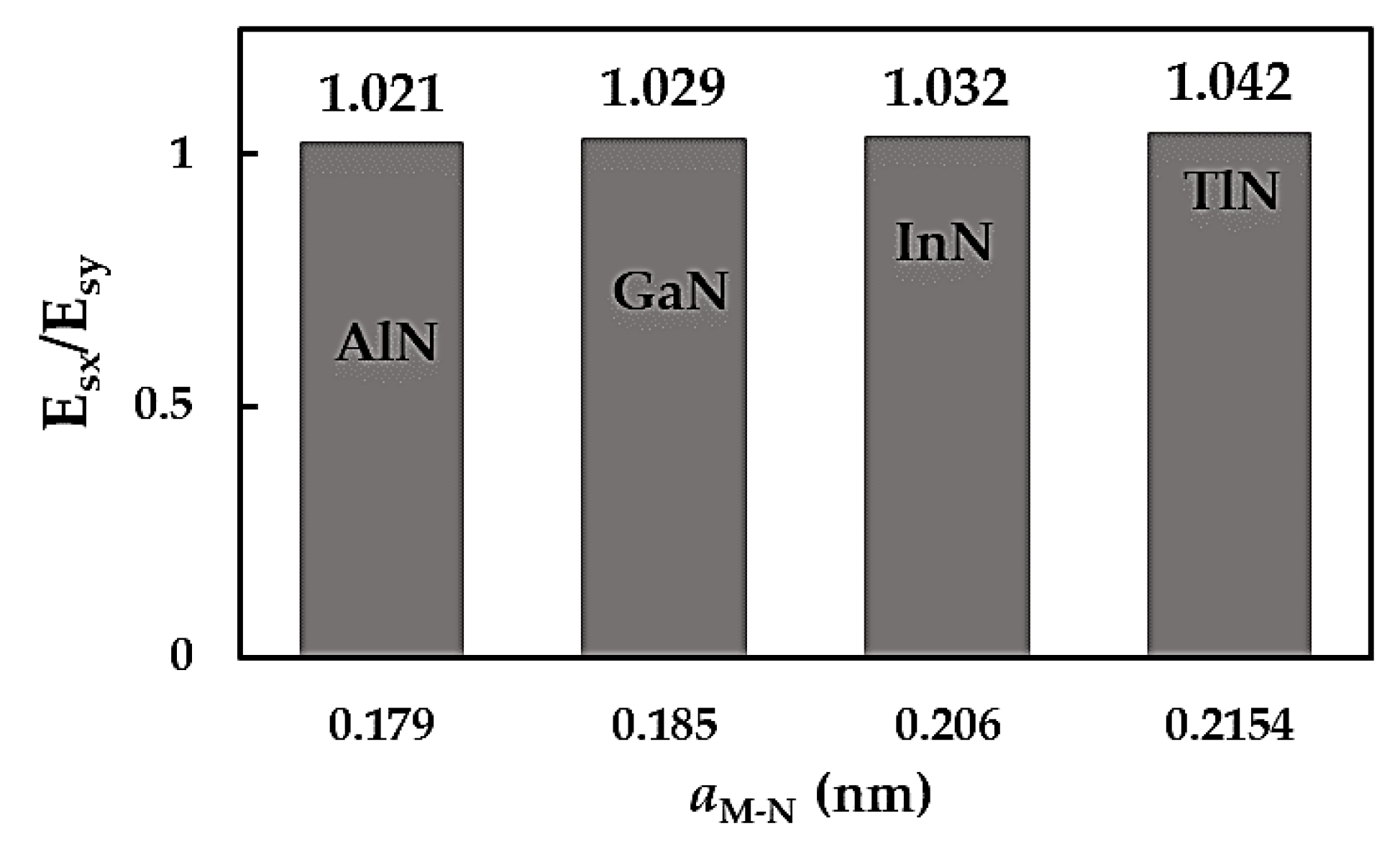

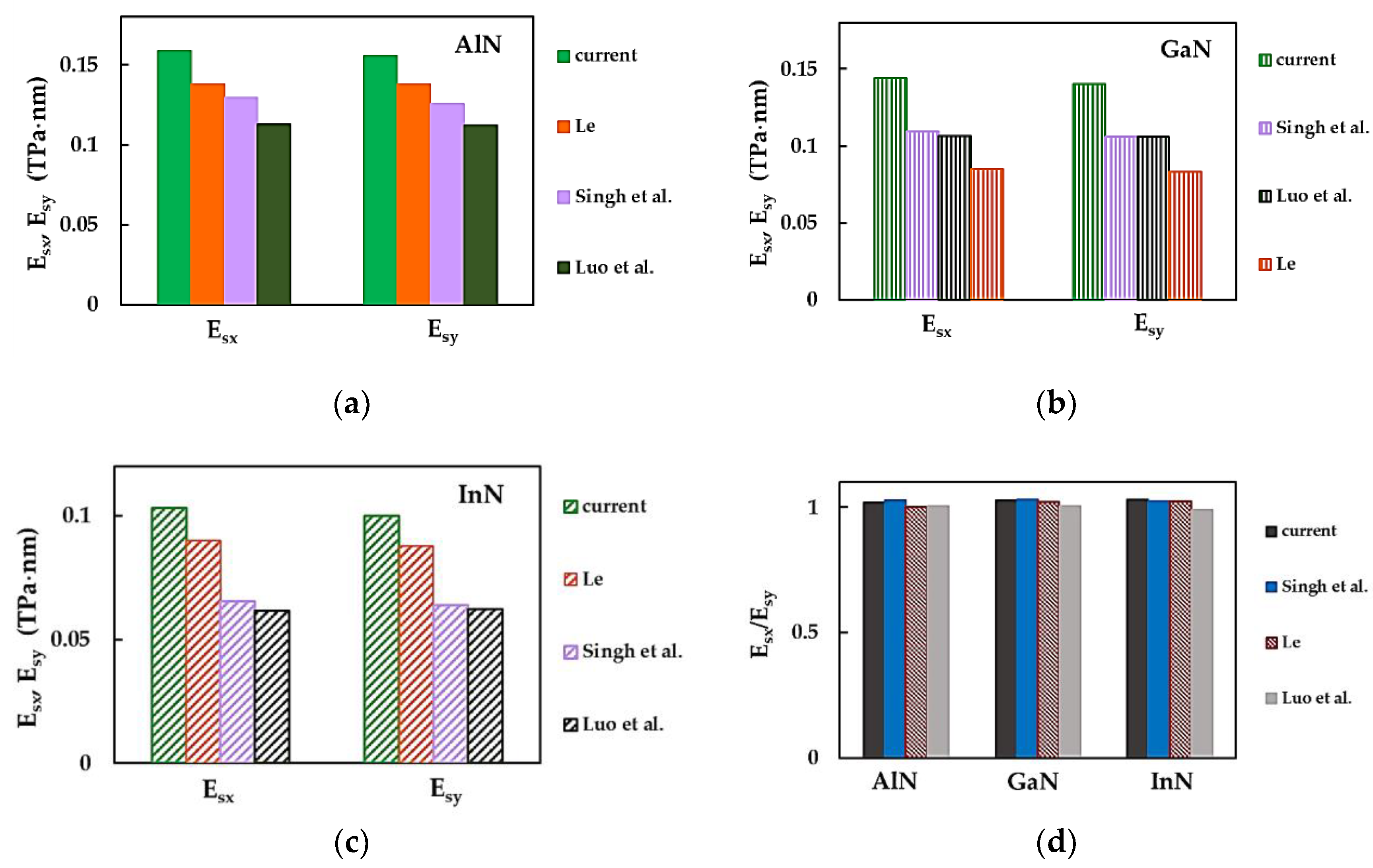

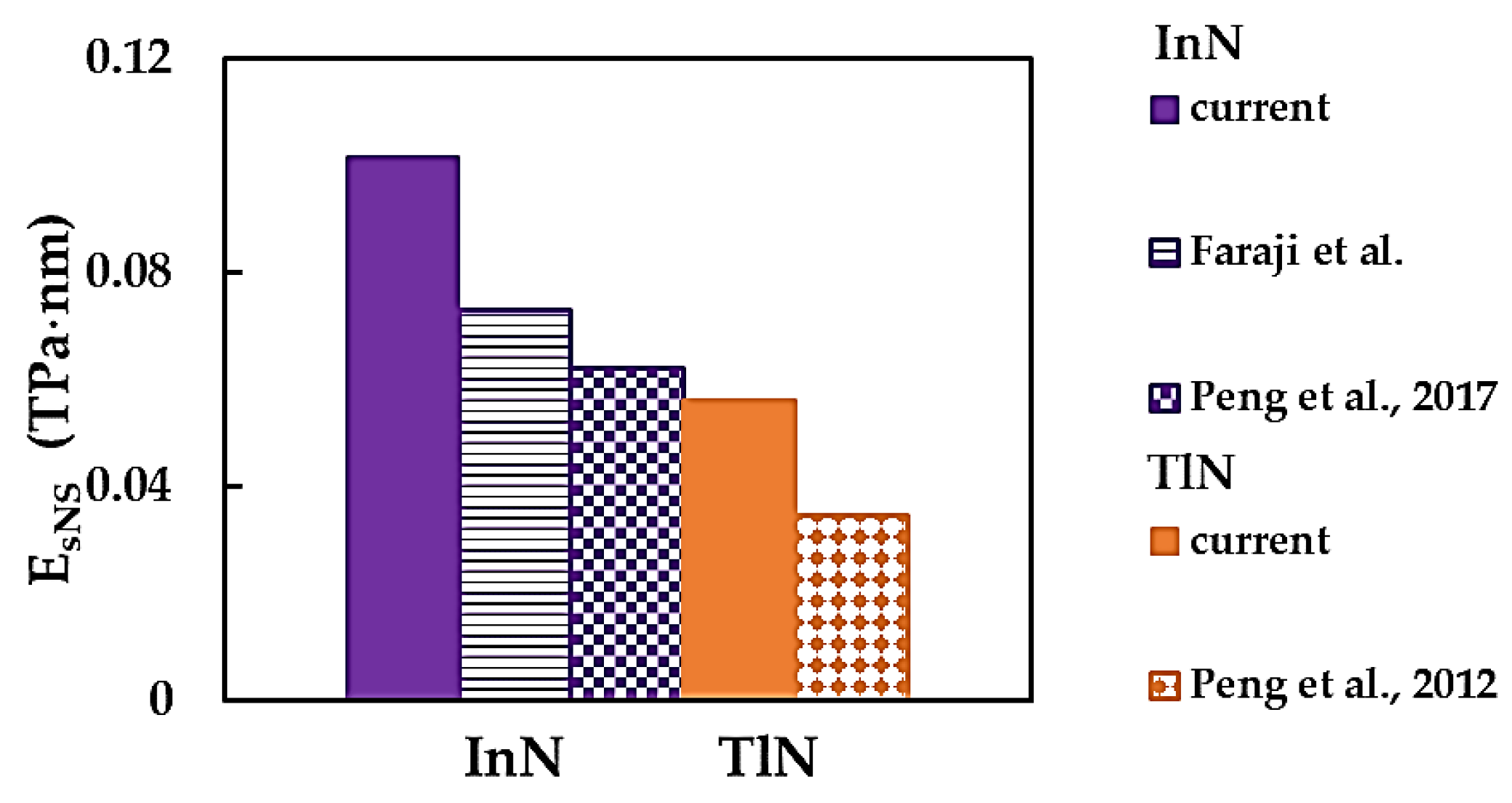

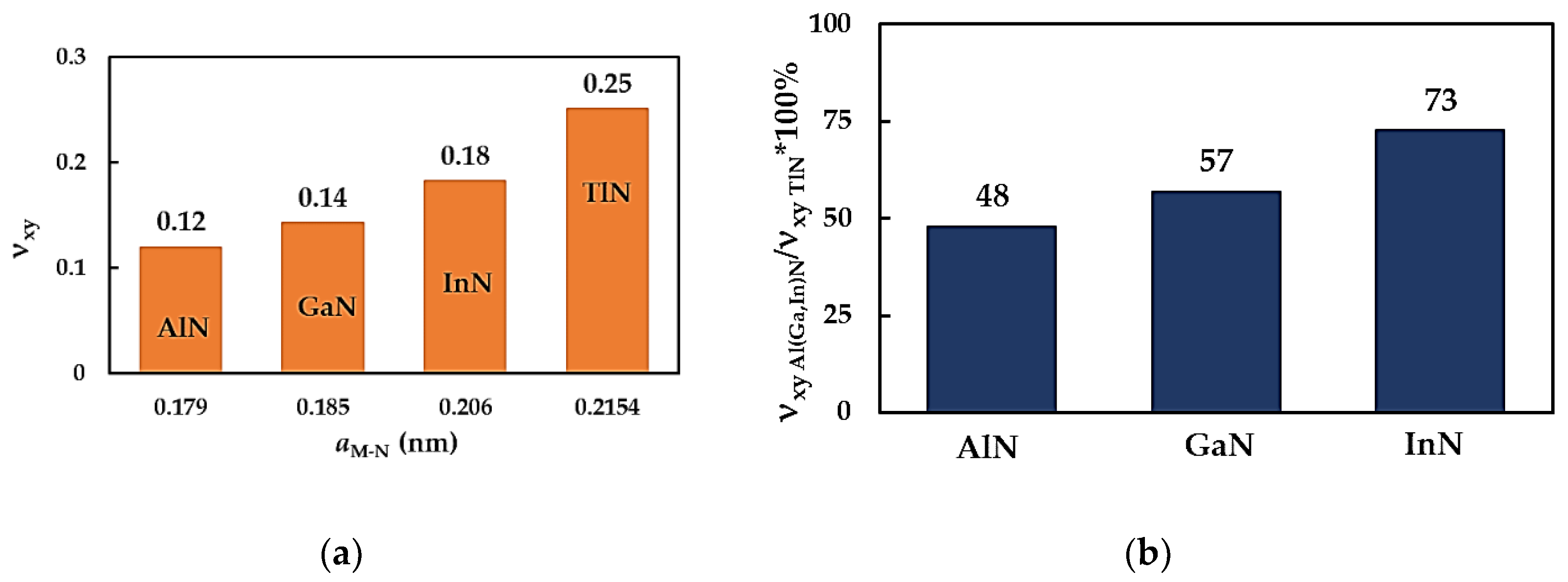

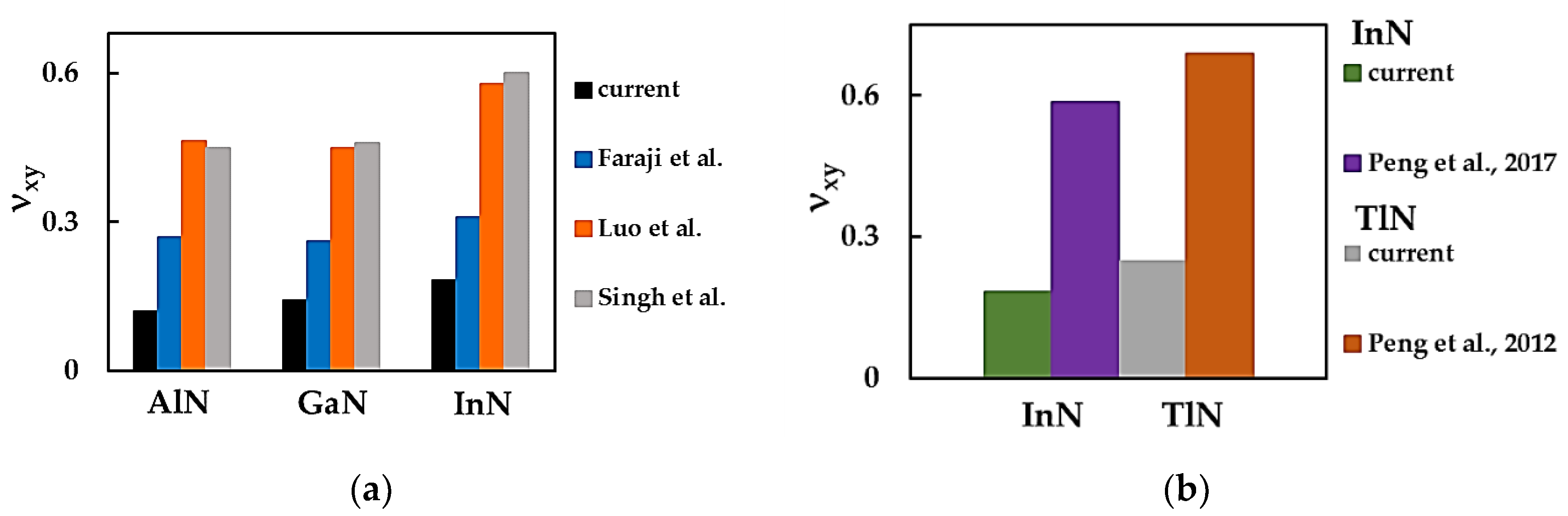

3.1. SurfaceYoung´s Moduli and Poisson´s Ratio of MN Nanosheets

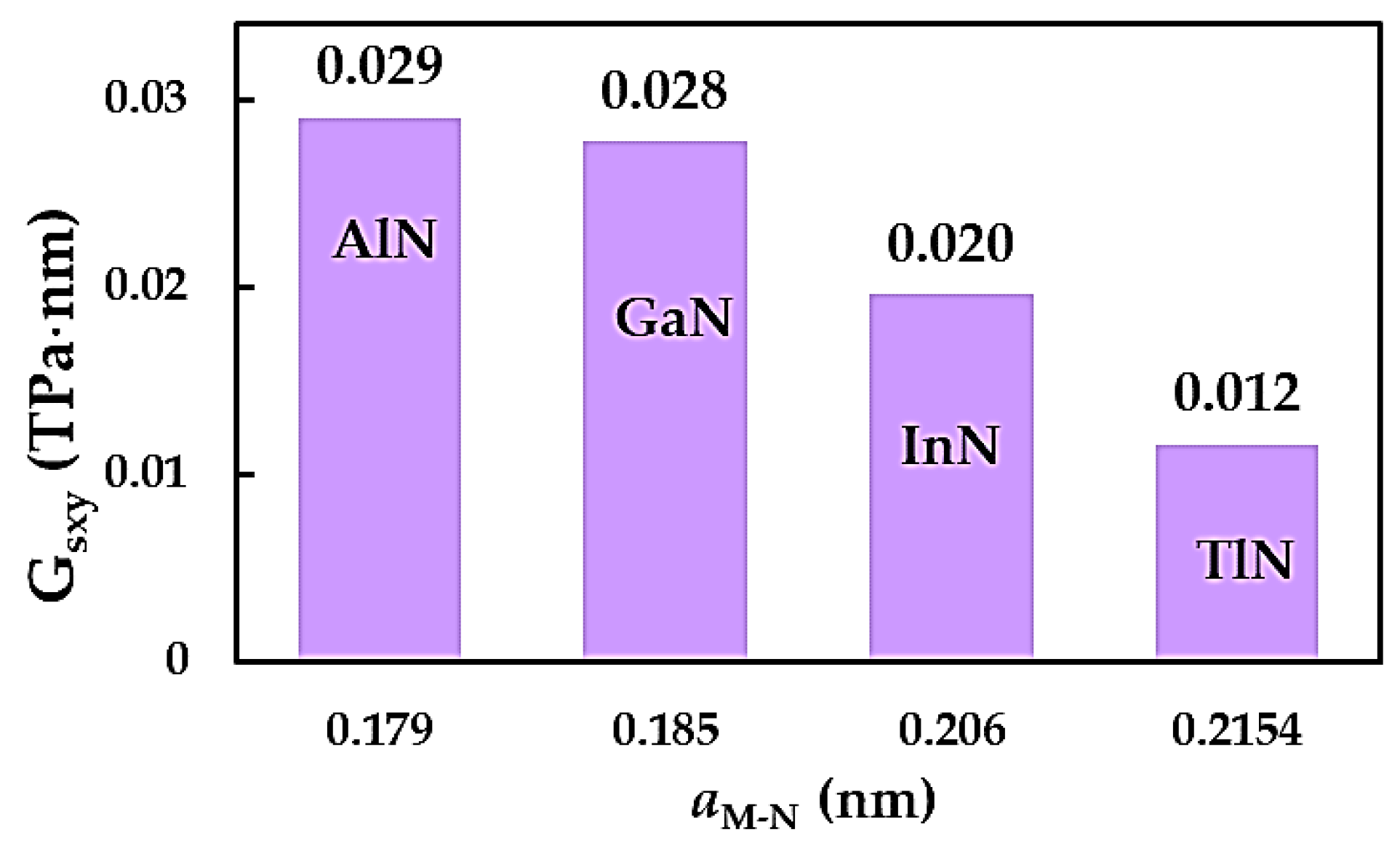

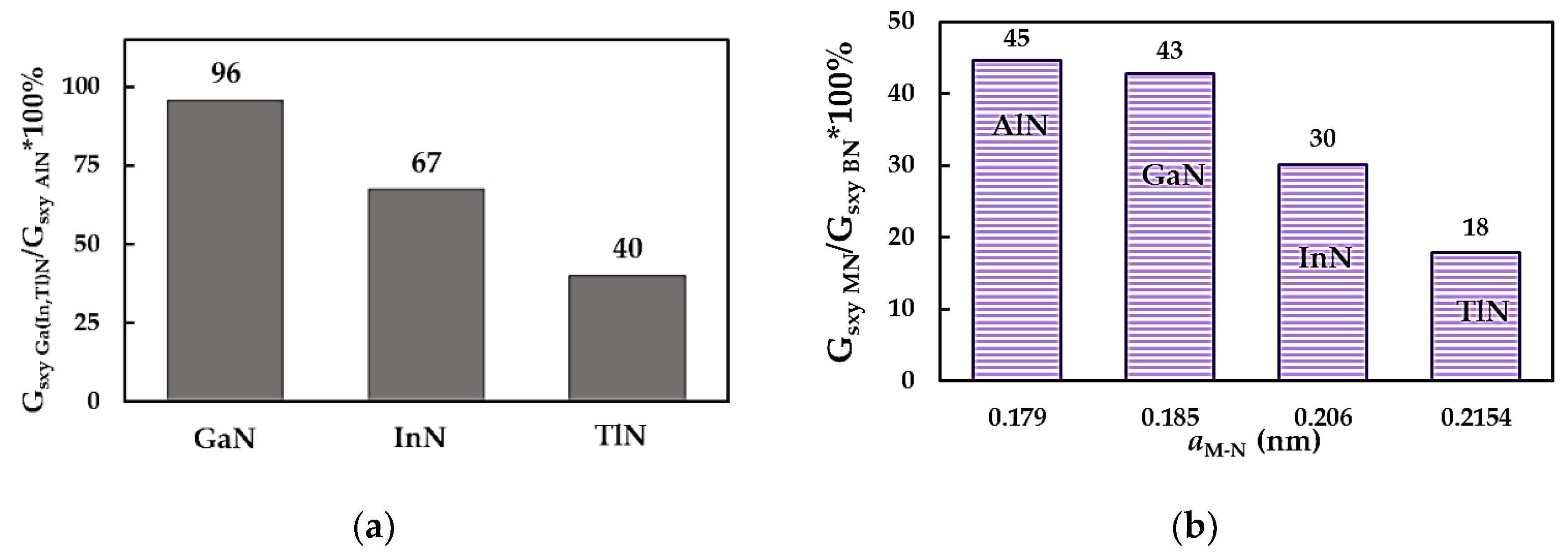

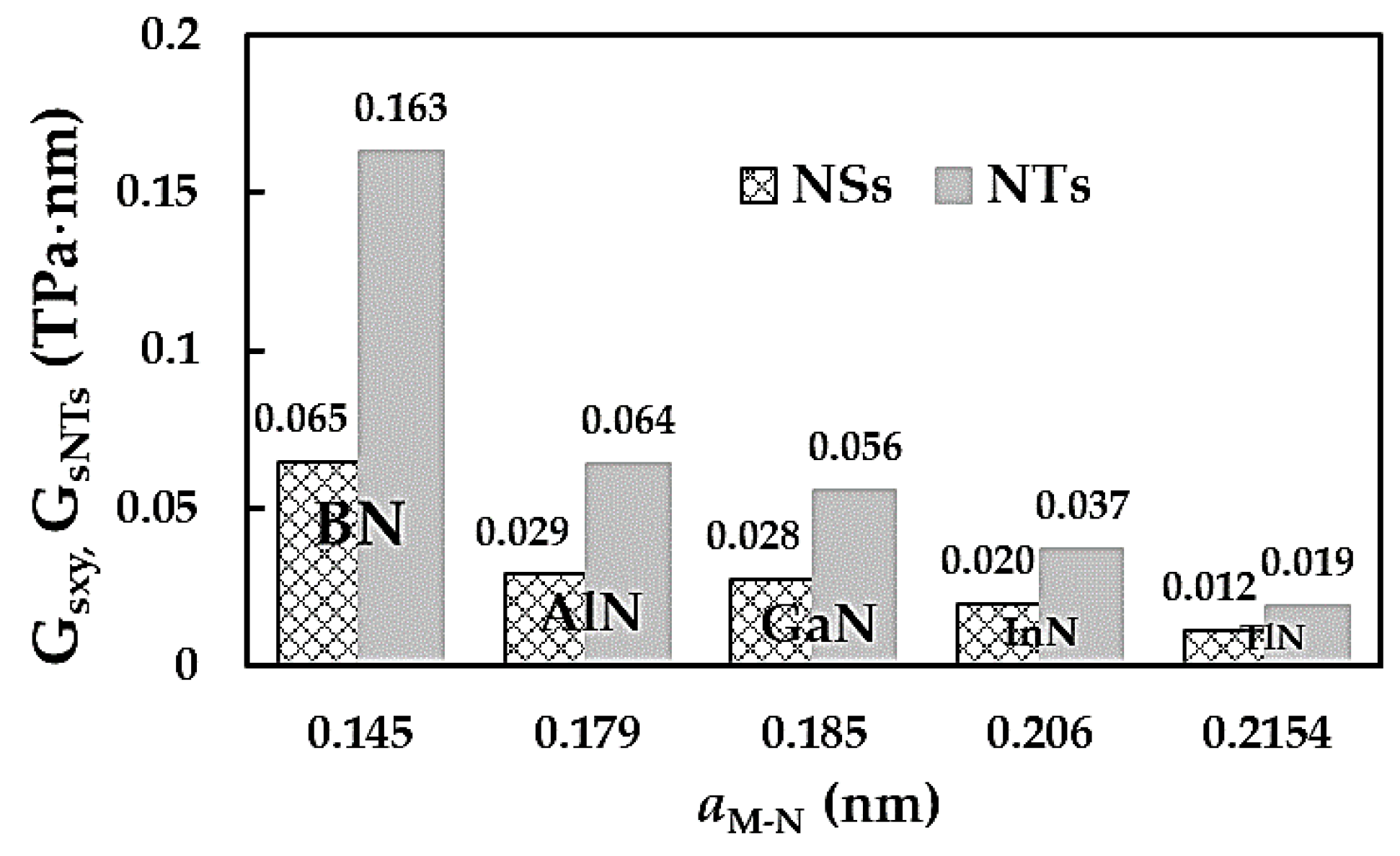

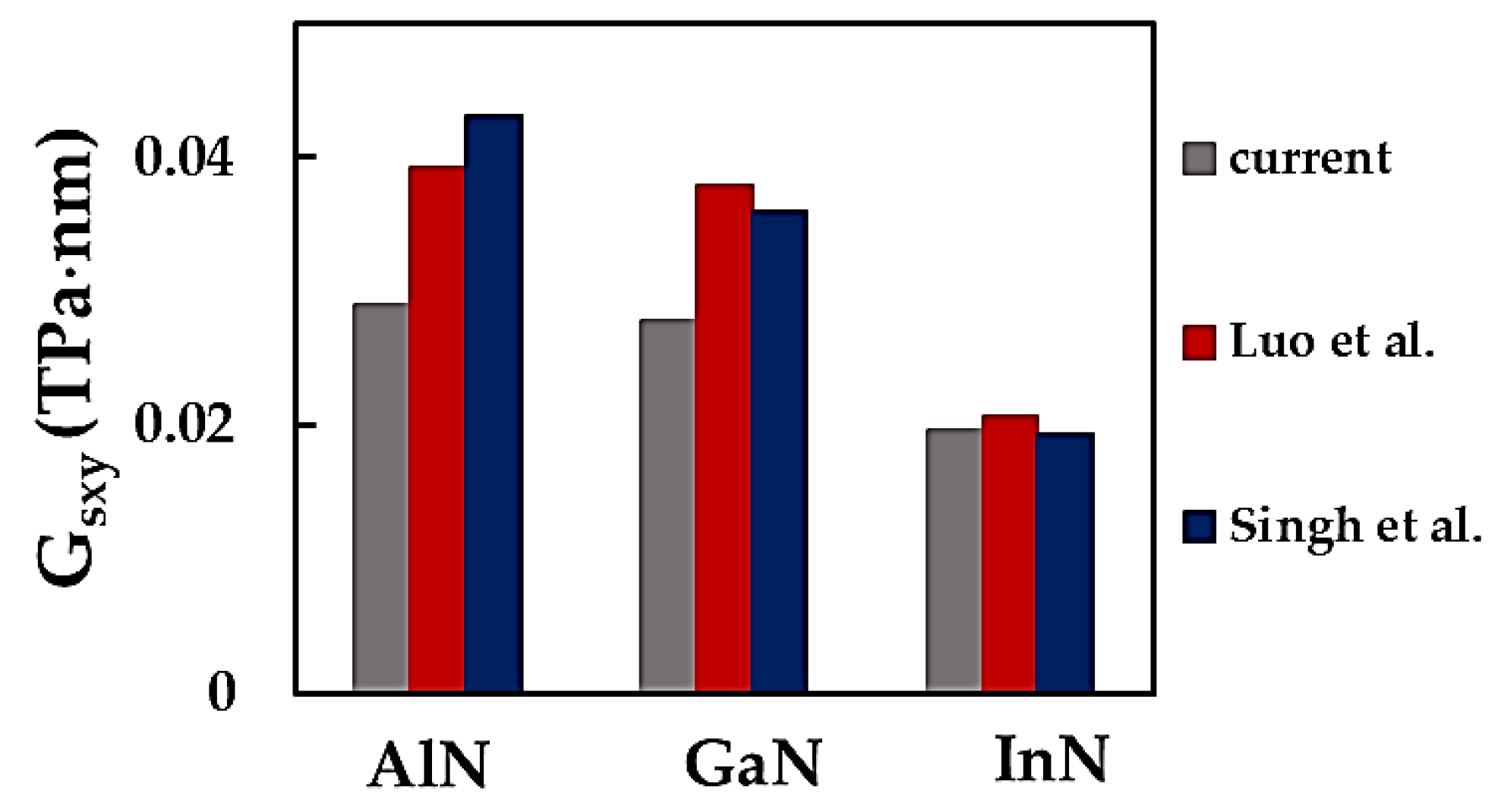

3.2. Surface Shear Modulus of MN Nanosheets

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, F.; Xiao, X.; Xie, J.; Zhou L.; Li, Y.; Dong, H. Structures, properties and applications of two-dimensional metal nitrides: from nitride MXene to other metal nitrides. 2D Mater. 2022, 9, 022001. [CrossRef]

- Ben, J.; Liu, X.; Wang, C.; Zhang, Y.; Shi, Z.; Jia, Y.; Zhang, S.; Zhang, H., Yu, W.; Li D.; Sun, X. 2D III-Nitride Materials: Properties, Growth, and Applications. Adv. Mater. 2021, 33, 2006761.

- Şahin, H.; Cahangirov, S.; Topsakal, M.; Bekaroglu, E.; Akturk, E.; Senger, R.T.; Ciraci, S. Monolayer honeycomb structures of group-IV elements and III-V binary compounds: First-principles calculations. Phys. Rev. B 2009, 80, 155453. [CrossRef]

- Ye, C.; Peng, Q. Mechanical Stabilities and Properties of Graphene-like 2D III-Nitrides: A Review. Crystals 2023, 13, 12. [CrossRef]

- Elahi, S.M.; Farzan, M.; Salehi, H.; Abolhasani, M.R. An investigation of electronic and optical properties of TlN nanosheet and compare with TlN bulk (Wurtzite) by first principle. Optik 2016, 127, 9367 – 9376. [CrossRef]

- Vurgaftman, I.; Meyer, J.R. Band parameters for nitrogen-containing semiconductors. J. Appl. Phys. 2003, 94, 3675 – 3696. [CrossRef]

- Wu, K.; Huang, S.; Wang W.; Li, G. Recent progress in III-nitride nanosheets: properties, materials and applications. Semicond. Sci. Technol. 2021, 36, 123002. [CrossRef]

- Wang, Z.; Wang, G.; Liu, X.; Wang, S.; Wang, T.; Zhang, S.; Yu, J.; Zhao G.; Zhang, L. Two-dimensional wide band-gap nitride semiconductor GaN and AlN materials: properties, fabrication and application. J. Mater. Chem. C 2021, 9, 17201–17232. [CrossRef]

- Zaoui, A. Plane wave pseudopotential study of ground state properties and electrochemical description of thallium nitride. Mater. Sci. Eng.B 2003, 103, 258 – 261. [CrossRef]

- Abdullah, N.R..; Abdullah, B.J.; Gudmundsson, V. Electronic and optical properties of metallic nitride: A comparative study between the MN (M = Al, Ga, In, Tl) monolayers. Solid State Commun. 2022, 346, 114705. [CrossRef]

- Zhang, X.; Liu, Z.; Hark, S. Synthesis and optical characterization of single-crystalline AlN nanosheets. Solid State Commun. 2007, 143, 317–320. [CrossRef]

- Borisenko, D.P.; Gusev, A.S.; Kargin, N.I.; Komissarov, I.V.; Kovalchuk N.G.; Labunov, V.A. Plasma assisted-MBE of GaN and AlN on graphene buffer layers. Jpn. J. Appl. Phys. 2019, 58, SC1046. [CrossRef]

- Yang, F.; Jin, L.; Sun, L.; Ren, X.; Duan, X.; Cheng, H.; Xu, Y.; Zhang, X.; Lai, Z.; Chen, W.; Dong H.; Hu, W. Free-standing 2D hexagonal aluminum nitride dielectric crystals for high-performance organic field-effect transistors. Adv. Mater. 2018, 30, 1801891. [CrossRef]

- Wang, W.L.; Zheng, Y.L.; Li, X.C.; Li, Y.; Zhao, H.; Huang, L.G.; Yang, Z.C.; Zhang X.N.; Li, G.Q. 2D AlN layers sandwiched between graphene and Si substrates. Adv. Mater. 2019, 31, 1803448. [CrossRef]

- Chen, Y.X.; Liu, K.L.; Liu, J.X.; Lv, T.R.; Wei, B.; Zhang, T.; Zeng, M.Q.; Wang Z.C.; Fu, L. Growth of 2D GaN single crystals on liquid metals. J. Am. Chem. Soc. 2018, 140, 16392–16395. [CrossRef]

- Wang, W.L.; Li, Y.; Zheng, Y.L.; Li, X.C.; Huang L.G.; Li, G.Q. Lattice structure and bandgap control of 2D GaN grown on graphene/Si heterostructure. Small 2019, 15, 1802995. [CrossRef]

- Zhang, Z.; Zhang, S.; Zhang, L.; Liu, Z.; Zhang, H.; Chen, J.; Zhou, Q.; Nie, L.; Dong, Z.; Pan, G. Honeycomb-like gallium nitride prepared via dual-ion synergistic etching mechanism using amino acid as etchant. Chem. Phys. Lett. 2021, 773, 138588. [CrossRef]

- ElAfandy, R.T.; Majid, M.A.; Ng, T.K.; Zhao, L.; Cha, D.; Ooi, B.S. Exfoliation of threading dislocation-free, single-crystalline, ultrathin gallium nitride nanomembranes. Adv. Funct. Mater. 2014, 24, 2305–2311. [CrossRef]

- Syed, N.; Zhang, Y.; Zheng, G.; Wang, L.; Russo, S.P.; Esrafilzadeh, D.; McConville, C.F.; Kalantar-Zadeh, K.; Daeneke, T. Wafer-Sized Ultrathin Gallium and indium nitride nanosheets through the ammonolysis of liquid metal derived oxides. J. Am. Chem. Soc. 2019, 141, 104 – 108. [CrossRef]

- Wang, X, Che, S.-B.; Ishitani, Y.; Yoshikawa, A.; Sasaki, H.; Shinagawa, T., Yoshida, S. Polarity inversion in high Mg-doped In-polar InN epitaxial layers. Appl. Phys. Lett. 2007, 91, 081912. [CrossRef]

- Pécz, B.; Nicotra, G., Giannazzo, F., Yakimova, R., Koos, A.; Georgieva, A.K. Indium Nitride at the 2D Limit. Adv. Mater. 2021, 33, 2006660. [CrossRef]

- Singh, A.K.; Zhuang, H.L.; Hennig, R.G. Ab initio synthesis of single-layer III-V materials. Phys. Rev. B 2014, 89, 245431.

- Jafari, H.; Ravan, B.A.; Faghihnasiri, M. Mechanical and electronic properties of single-layer TiN and AlN under strain. Solid State Commun. 2018, 282, 21–27. [CrossRef]

- Peng, Q.; Chen, X.-J. Liu, S.; De, S. Mechanical stabilities and properties of graphene-like aluminium nitride predicted from first-principles calculations. RSC Adv. 2013, 3, 7083–7092.

- Kourra, M.H.; Sadki, K.; Drissi, L.B.; Bousmina, M. Mechanical response, thermal conductivity and phononic properties of group III-V 2D hexagonal compounds. Mater. Chem. Phys. 2021, 267, 124685. [CrossRef]

- Lv, S.-J.; Yin, G.-X.; Cui, H.-L.; Wang, H.-Y. Electronic, vibrational, elastic, and piezoelectric properties of H-, F-f Functionalized AlN sheets. Phys. Status Solidi B 2021, 258, 2100216.

- Tuoc, V.N.; Lien, L.T.H; Huan, T.D.; Trung, N.N. Structural, electronic and mechanical properties of few-layer GaN nanosheet: A first-principle study. Mater. Trans. 2020, 61, 1438–1444. [CrossRef]

- Fabris, G.S.L.; Paskocimas, C.A.; Sambrano, J.R.; Paupitz, R. One- and two-dimensional structures based on gallium nitride. J. Solid State Chem. 2021, 303, 122513. [CrossRef]

- Ahangari, M.G.; Fereidoon, A.; Mashhadzadeh, A.H. Interlayer interaction and mechanical properties in multi-layer graphene, Boron-Nitride, Aluminum-Nitride and Gallium-Nitride graphene-like structure: A quantum-mechanical DFT study. Superlattices Microstruct. 2017, 112, 30–45. [CrossRef]

- Peng, Q.; Sun, X.; Wang, H.; Yang, Y.; Wene, X.; Huang, C.; Liu, S.; De, S. Theoretical prediction of a graphene-like structure of indium nitride: A promising excellent material for optoelectronics. Appl. Mater. Today 2017, 7, 169 – 178. [CrossRef]

- Peng, Q.; Liang, C.; Ji, W.; De, S. A First Principles Investigation of the Mechanical Properties of g-TlN. Model. Numer. Simulat. Mater. Sci. 2012, 2, 76–84.

- Luo, Z.J.; Yang, Y.F.; Yang, X.Z.; Lv, B.; Liu, X.F. The mechanical properties and strain effect on the electronic properties of III-nitride monolayers: ab-initio study. Mater. Res. Express 2019, 6, 115915. [CrossRef]

- Faraji, M.; Bafekry, A.; Fadlallah, M.M.; Jappor, H.R.; Nguyen, C.V.; Ghergherehchi, M. Two-dimensional XY monolayers (X = Al, Ga, In; Y = N, P, As) with a double layer hexagonal structure: A first-principles perspective. Appl. Surf. Sci. 2022, 590, 152998. [CrossRef]

- Rouhi, S.; Pourmirzaagha, H.; Bidgoli, M.O.; Molecular dynamics simulations of gallium nitride nanosheets under uniaxial and biaxial tensile loads. Int. J. Mod. Phys. B 2018, 32, 1850051. [CrossRef]

- Singh, S.; Raj, B.M.R.; Mali, K.D.; Watts, G. Elastic Properties and nonlinear elasticity of the noncarbon hexagonal lattice nanomaterials based on the multiscale modelling. J. Eng. Mater. Technol. 2021, 143, 021006. [CrossRef]

- Le, M.-Q. Atomistic Study on the tensile properties of hexagonal AlN, BN, GaN, InN and SiC sheets. J. Comput. Theor. Nanosci. 2014, 11, 1458–1464. [CrossRef]

- Sarma, J.V.N.; Chowdhury, R.; Jayaganthan, R. Mechanical behavior of gallium nitride nanosheets using molecular dynamics. Comput. Mater. Sci. 2013, 75, 29–34. [CrossRef]

- Sakharova, N.A.; Antunes, J.M.; Pereira, A.F.G.; Fernandes, J.V. Developments in the evaluation of elastic properties of carbon nanotubes and their heterojunctions by numerical simulation. AIMS Mater. Sci. 2017, 4, 706 – 737. [CrossRef]

- Sakharova, N.A.; Antunes, J.M.; Pereira, A.F.G.; Chaparro, B.M.; Fernandes, J.V. On the Determination of Elastic Properties of Single-Walled Boron Nitride Nanotubes by Numerical Simulation. Materials 2021, 14, 3183. [CrossRef]

- Tapia, A.; Cab, C.; Hernández-Pérez, A.; Villanueva, C.; Peñuñuri, F.; Avilés, F. The bond force constants and elastic properties of boron nitride nanosheets and nanoribbons using a hierarchical modeling approach. Physica E 2017, 89, 183–193. [CrossRef]

- Georgantzinos, S.K.; Kariotis, K.; Giannopoulos, G.I.; Anifantis, N.K. Mechanical properties of hexagonal boron nitride monolayers: Finite element and analytical predictions. Proc. IMechE C J. Mech. Eng. Sci. 2020, 234, 4126–4135. [CrossRef]

- Le, M.-Q. Prediction of Young’s modulus of hexagonal monolayer sheets based on molecular mechanics. Int. J. Mech. Mater. Des. 2015, 11, 15 – 24. [CrossRef]

- Giannopoulos, G.I.; Georgantzinos, S.K. Tensile behavior of gallium nitride monolayer via nonlinear molecular mechanics. Eur. J. Mech. A Solids. 2017, 65, 223–232. [CrossRef]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M.; Chaparro, B.M.; Fernandes, J.V. On the determination of elastic properties of indium nitride nanosheets and nanotubes by numerical simulation. Metals 2023, 13, 73. [CrossRef]

- Sakharova, N.A.; Antunes, J.M.; Pereira, A.F.G.; Chaparro, B.M.; Parreira, T.G.; Fernandes, J.V. Numerical Evaluation of the Elastic Moduli of AlN and GaN Nanosheets. Materials 2024, 17, 799. [CrossRef]

- Li, C.; Chou, T.W. A structural mechanics approach for the analysis of carbon nanotubes. Int. J. Solids Struct. 2003, 40, 2487 – 2499. [CrossRef]

- Genoese, A.; Genoese, A.; Rizzi, N. L.; Salerno, G. Force constants of BN, SiC, AlN and GaN sheets through discrete homogenization. Meccanica 2018, 53, 593 – 611.

- Mayo, S.L.; Barry D. Olafson, B.D.; Goddard, W.A. DREIDING: A generic force field for molecular simulations. J. Phys. Chem. 1990, 94, 8897 – 8909. [CrossRef]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M. A Study of the mechanical behaviour of boron nitride nanosheets using numerical simulation. Nanomaterials 2023, 13, 2759. [CrossRef]

- Zeng, H.; Zhi, C.; Zhang, Z.; Wei, X.; Wang, X.; Guo, W.; Bando, Y.; Golberg, D. “White Graphenes”: Boron Nitride Nanoribbons via Boron Nitride Nanotube Unwrapping. Nano Lett. 2010, 10, 5049 – 5055.

- Nadeem, A.; Ali Raza, M.; Maqsood, M.F.; Ilyas, M.T.; Westwood, A.; Rehman, Z.U. Characterization of boron nitride nanosheets synthesized by boron-ammonia reaction. Ceram. Int. 2020, 46, 20415 – 20422. [CrossRef]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M.; Chaparro, B.M.; Parreira, T.G.; Fernandes, J.V. On the Determination of Elastic Properties of Single-Walled Nitride Nanotubes Using Numerical Simulation. Materials 2024, 17, 2444. [CrossRef]

| Compound | , nm [3] | Es, nN/nm [3] | ν [3] | , nN/nm | , nN⋅nm/rad2 | , nN⋅nm/rad2 |

|---|---|---|---|---|---|---|

| AlN | 0.179 | 116 | 0.46 | 372 | 0.451 | 0.625 |

| GaN | 0.185 | 110 | 0.48 | 366 | 0.445 | |

| InN | 0.206 | 67 | 0.59 | 283 | 0.296 | |

| TlN | 0.2154* | 34.5* | 0.689* | 192 | 0.151 |

| Compound | diameter, d, nm |

Formulation | Young´s modulus, Eb, GPa |

Formulation | shear modulus, Gb, GPa |

Formulation | |

|---|---|---|---|---|---|---|---|

| AlN | 0.1392 | 4374 | 3032 | 0.46 [3] | |||

| GaN | 0.1395 | 4437 | 3113 | 0.48 [3] | |||

| InN | 0.1294 | 4432 | 4674 | 0.59 [3] | |||

| TlN | 0.1120 | 4200 | 8712 | 0.689 [4] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).