Submitted:

10 October 2024

Posted:

11 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

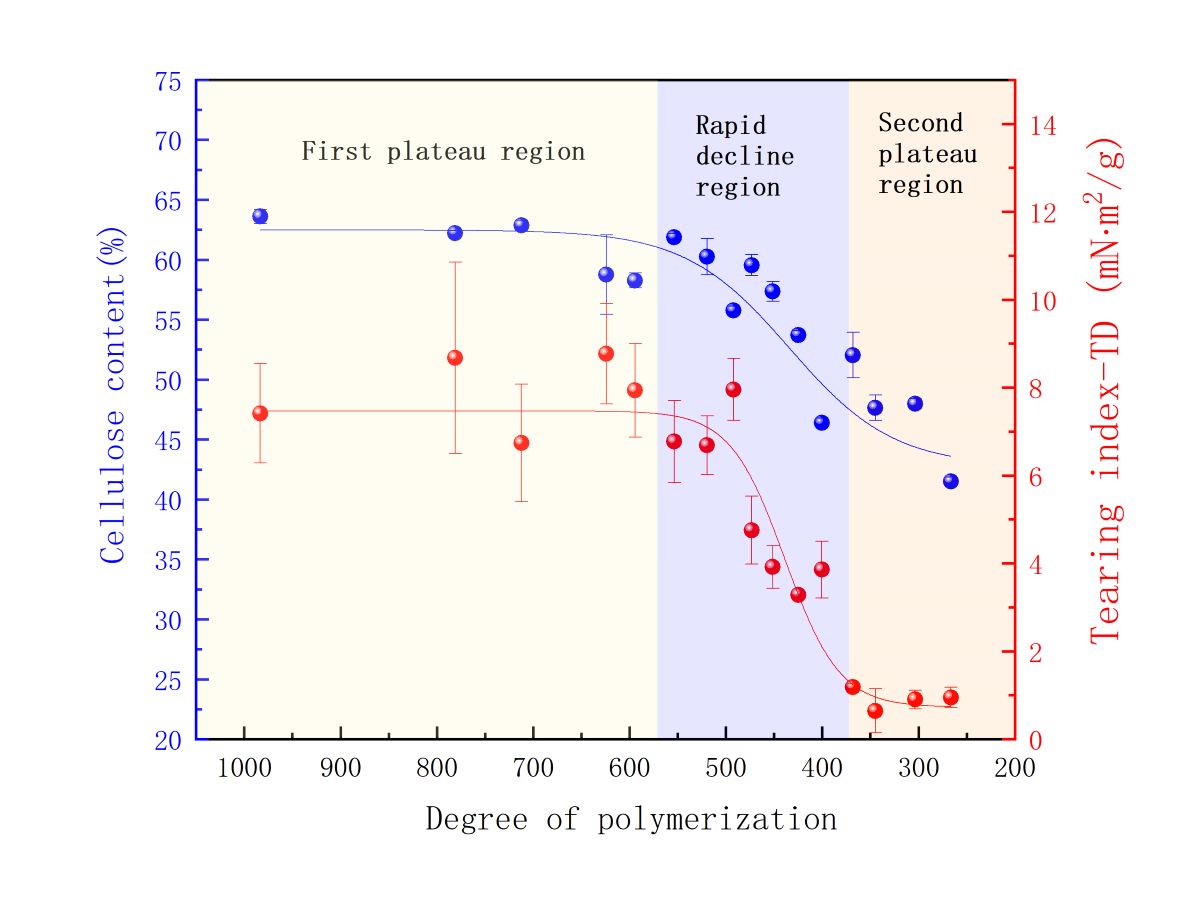

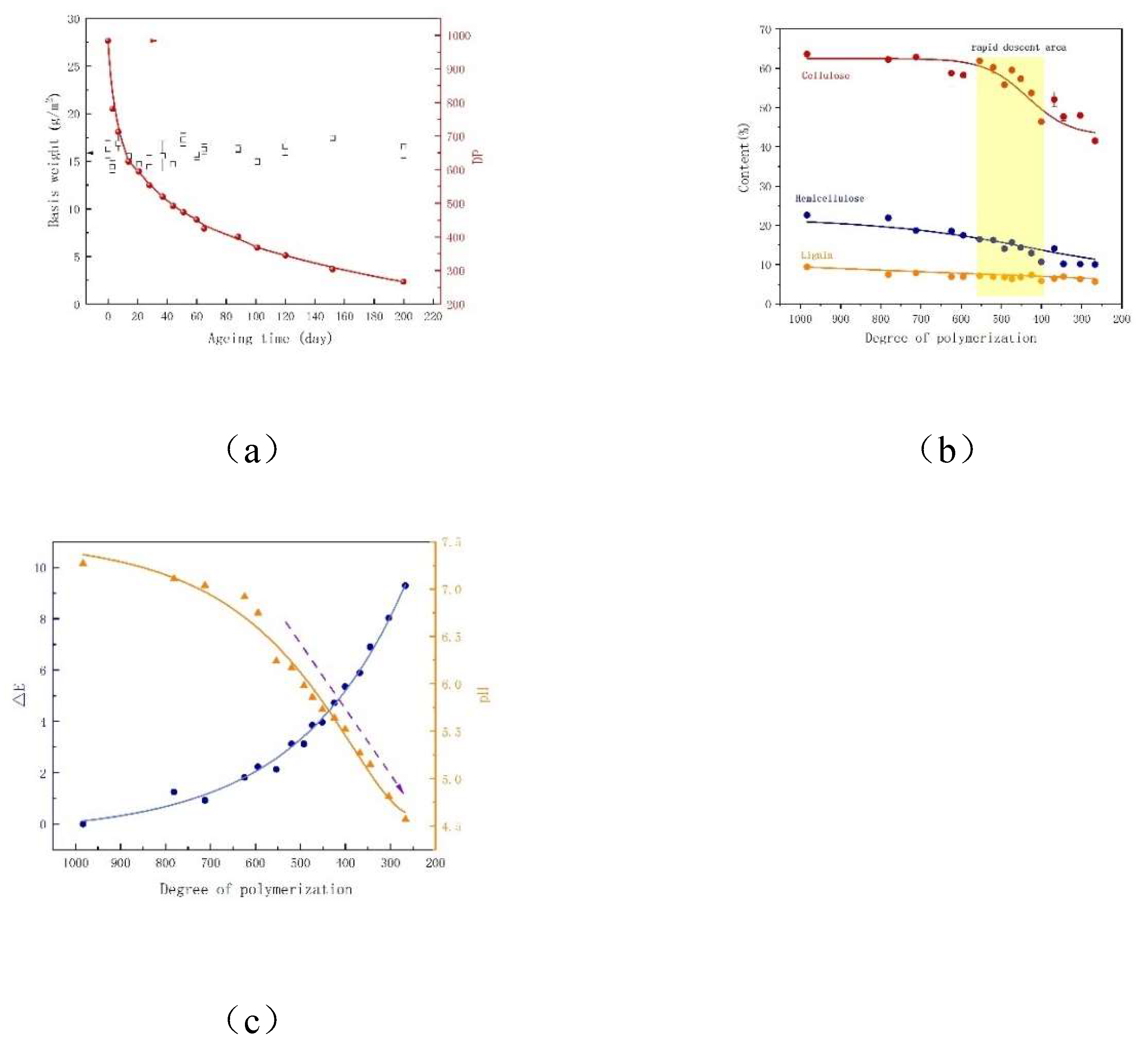

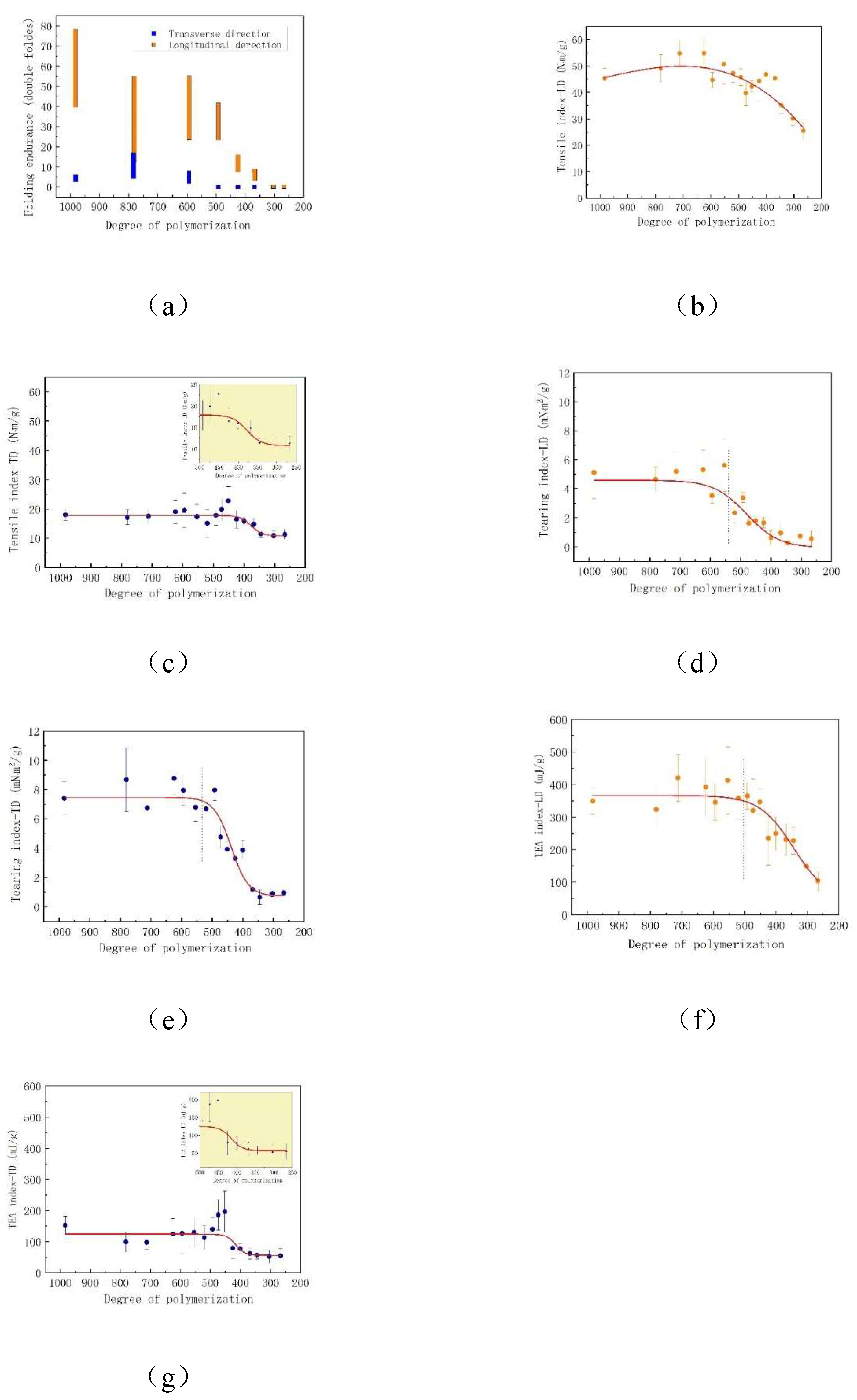

2.1. Mechanical properties

2.2. DP and Component Contents

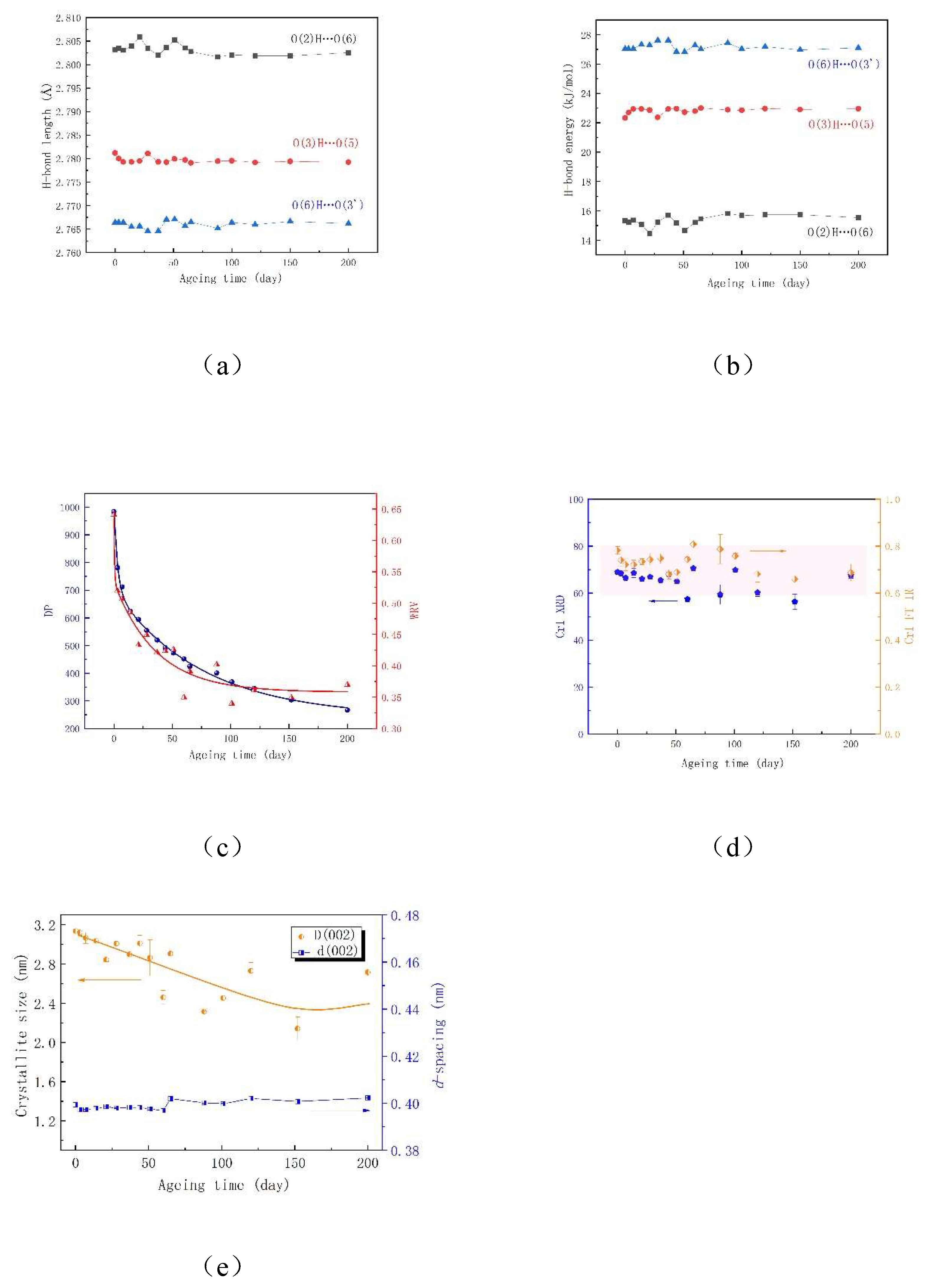

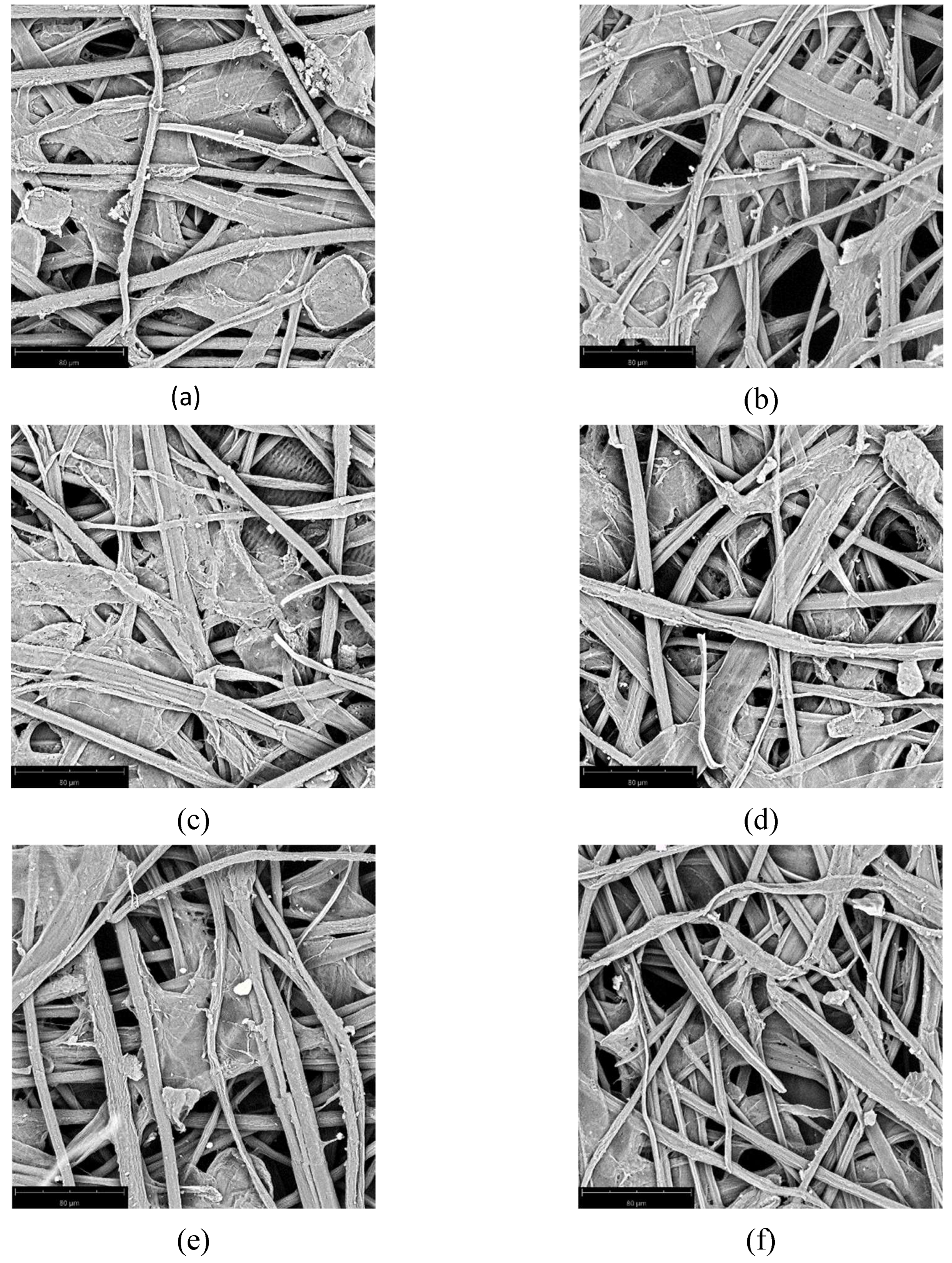

2.3. Microstructures

3. Materials and Methods

3.1. Materials

3.2. Accelerated Ageing

3.3 Analysis of Chemical Components

3.4. Viscosity Determination

3.5. Mechanical Properties Tests

3.6. Infrared Analysis

3.7 Water Retention Value Measurement

3.8 Chromaticity test

3.9 X-ray Diffraction measurement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Liu, P.; Yan, Y.; Yao, J.; Tang, Y.; Yang, Y. , Degradation of Chinese handmade papers with different fiber raw materials on molecular and supramolecular structures. Polymer Degradation and Stability 2023, 211, 110330. [Google Scholar] [CrossRef]

- Hubbe, M. A.; Bowden, C. , Handmade paper: a review of its history, craft, and science. BioResources 2009, 4, 1736–1792. [Google Scholar] [CrossRef]

- Jain, P.; Gupta, C. , A sustainable journey of handmade paper from past to present: A review. Problemy Ekorozwoju 2021, 16, 234–244. [Google Scholar] [CrossRef]

- Baty, J. W.; Maitland, C. L.; Minter, W.; Hubbe, M. A.; Jordan-Mowery, S. K. , Deacidification for the conservation and preservation of paper-based works: A review. BioResources 2010, 5, 1955–2023. [Google Scholar] [CrossRef]

- Ahn, K.; Hennniges, U.; Banik, G.; Potthast, A. , Is cellulose degradation due to β-elimination processes a threat in mass deacidification of library books? Cellulose 2012, 19, 1149–1159. [Google Scholar] [CrossRef]

- Ahn, K.; Rosenau, T.; Potthast, A. , The influence of alkaline reserve on the aging behavior of book papers. Cellulose 2013, 20, 1989–2001. [Google Scholar] [CrossRef]

- Xu, Z.; Yueer, Y.; Jingjing, Y.; Shutong, J.; Yi, T. , Chemistry directs the conservation of paper cultural relics. Polymer Degradation and Stability 2023, 207. [Google Scholar]

- Zervos, S.; Moropoulou, A. , Methodology and criteria for the evaluation of paper conservation interventions: A literature review. Restaurator 2006, 27, 219–274. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Lu, J. , Exploring the relationship between air pollution and meteorological conditions in China under environmental governance. Scientific Reports 2020, 10, 14518. [Google Scholar] [CrossRef]

- Łojewska, J.; Miśkowiec, P.; Łojewski, T.; Proniewicz, L. M. , Cellulose oxidative and hydrolytic degradation: In situ FTIR approach. Polymer Degradation and Stability 2005, 88, 512–520. [Google Scholar] [CrossRef]

- Łojewski, T.; Zięba, K.; Knapik, A.; Bagniuk, J.; Lubańska, A.; Łojewska, J. , Evaluating paper degradation progress. Cross-linking between chromatographic, spectroscopic and chemical results. Applied Physics A 2010, 100, 809–821. [Google Scholar] [CrossRef]

- Piantanida, G.; Bicchieri, M.; Coluzza, C. , Atomic force microscopy characterization of the ageing of pure cellulose paper. Polymer 2005, 46, 12313–12321. [Google Scholar] [CrossRef]

- Zervos, S. , Characterization of changes induced by ageing to the microstructure of pure cellulose paper by use of a gravimetric water vapour adsorption technique. Cellulose 2007, 14, 375–384. [Google Scholar] [CrossRef]

- Zou, X.; Uesaka, T.; Gurnagul, N. , Prediction of paper permanence by accelerated aging I. Kinetic analysis of the aging process. Cellulose 1996, 3, 243–267. [Google Scholar] [CrossRef]

- Fan, Y.; Han, B.; Ge, M.; Jiang, R.; Shi, J. , Development process and reserch status of handmade bamboo paper. World bamboo and rattan 2024, 22, 100–106. [Google Scholar]

- Gang, C. , Current Situation and Questions of Archives and Ancient Books Restoration in Bamboo Paper. Archives science study 2012, (1), 80–84. [Google Scholar]

- Lv, S. , A research on the characteristics of Chinese ancient paper aging. Ancient books conservation study 2020, 2, 73–88. [Google Scholar]

- Xu, W. , Research on the aging performance of paper used for the restoration of calligraphy and painting cultural relics. China cultural heritage scienctific research 2021, 2, 68–72. [Google Scholar]

- Tian, Z.; Long, K.; Ren, S.; Zhang, M. , A study on in study on influence of storage environment on paper properties. China Pulp & Paper Industry 2016, 37, 31–33. [Google Scholar]

- Chen, B.; Tan, J.; Huang, J.; Lu, Y.; Gu, P.; Han, Y.; Ding, Y. , Research on the aging-resistance properties of four kinds of Fuyang bamboo paper. Journal of Forestry Engineering 2021, 6, 121–126. [Google Scholar]

- Tan, J.; Lu, Y.; Fu, X.; Chen, B.; Ding, Y. , Effects of micro-structural changes on properties of aged bamboo paper. Chinese Science Bulletin 2022, 67, 4429–4438. [Google Scholar] [CrossRef]

- Chen, B.; Tan, J.; Fu, X.; Lu, Y.; Zhu, Y.; Huang, J.; Di, Y.; Ding, Y. , Study on Pyrolysis Characteristics of Bamboo Paper After Aging and Quantitative Evaluation of Its Aging Degree. Materials Reports 2022, 36, 213–217. [Google Scholar]

- Yi, X.; Li, Y.; Lei, X. , Study on Performance Difference of Handmade Bamboo Paper Between Traditional Uncooked Process and Cooking Process. Transactions of China Pulp and Paper 2022, 37, 78–85. [Google Scholar]

- Stephens, C. H.; Whitmore, P. M. , Comparison of the degradation behavior of cotton, linen, and kozo papers. Cellulose 2013, 20, 1099–1108. [Google Scholar] [CrossRef]

- KATO, K. L.; CAMERON, R. E. , Structure–Property Relationships in Thermally Aged Cellulose Fibers and Paper. Journal of Applied Polymer Science 1999, 74, 1465–1477. [Google Scholar] [CrossRef]

- Vizárová, K.; Kirschnerová, S.; Kačík, F.; Briškárová, A.; Šutý, Š.; Katuščák, S. , Relationship between the decrease of degree of polymerisation of cellulose and the loss of groundwood pulp paper mechanical properties during accelerated ageing. Chemical Papers 2012, 66, 1124–1129. [Google Scholar] [CrossRef]

- Ding, H. Z.; Wang, Z. D. , On the degradation evolution equations of cellulose. Cellulose 2008, 15, 205–224. [Google Scholar] [CrossRef]

- Vibert, C.; Dupont, A.-L.; Dirrenberger, J.; Passas, R.; Ricard, D.; Fayolle, B. , Relationship between chemical and mechanical degradation of aged paper: fibre versus fibre–fibre bonds. Cellulose 2024, 31, 1855–1873. [Google Scholar] [CrossRef]

- Zou, X.; Gurnagul, N.; Uesaka, T.; Bouchard, J. , Accelerated aging of papers of pure cellulose: mechanism of cellulose degradation and paper embrittlement. Polymer Degradation and Stability 1994, 43, 393–402. [Google Scholar] [CrossRef]

- Gurnagul, N.; Howard, R. C.; Zou, X.; Uesaka, T.; Page, D. H. , Mechanical permanence of paper: A literature review. Journal of Pulp and Paper Science 1993, 19, 160–166. [Google Scholar]

- Jin, C.; Wu, C.; Liu, P.; Yu, H.; Yang, Y.; Zhang, H. , Kinetics of cellulose degradation in bamboo paper. Nordic Pulp & Paper Research Journal 2022, 37, 480–488. [Google Scholar]

- Jeong, M.-J.; Kang, K.-Y.; Bacher, M.; Kim, H.-J.; Jo, B.-M.; Potthast, A. , Deterioration of ancient cellulose paper, Hanji: evaluation of paper permanence. Cellulose 2014, 21, 4621–4632. [Google Scholar] [CrossRef]

- Rychlý, J.; Matisová-Rychlá, L.; Bukovský, V.; Pleteníková, M.; Vrška, M. , The Progress of Ageing of Lignin-containing Paper Induced by Light and its Relation to Chemiluminescence – Temperature Runs. Macromolecular Symposia 2005, 231, 178–192. [Google Scholar] [CrossRef]

- Małachowska, E.; Dubowik, M.; Boruszewski, P.; Łojewska, J.; Przybysz, P. , Influence of lignin content in cellulose pulp on paper durability. Scientific Reports 2020, 10, 19998. [Google Scholar] [CrossRef]

- Fu, H.; Gao, W.; Wang, B.; Zeng, J.; Cheng, Z.; Xu, J.; Chen, K. , Effect of lignin content on the microstructural characteristics of lignocellulose nanofibrils. Cellulose 2020, 27, 1327–1340. [Google Scholar] [CrossRef]

- Fayolle, B.; Richaud, E.; Colin, X.; Verdu, J. , Review: degradation-induced embrittlement in semi-crystalline polymers having their amorphous phase in rubbery state. Journal of Materials Science 2008, 43, 6999–7012. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. , Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angewandte Chemie International Edition 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Yi, T.; Zhao, H.; Mo, Q.; Pan, D.; Liu, Y.; Huang, L.; Xu, H.; Hu, B.; Song, H. , From Cellulose to Cellulose Nanofibrils—A Comprehensive Review of the Preparation and Modification of Cellulose Nanofibrils. In Materials, 2020; Vol. 13.

- Park, S.; Baker, J. O.; Himmel, M. E.; Parilla, P. A.; Johnson, D. K. , Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnology for Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- Medhekar, N. V.; Ramasubramaniam, A.; Ruoff, R. S.; Shenoy, V. B. , Hydrogen Bond Networks in Graphene Oxide Composite Paper: Structure and Mechanical Properties. ACS Nano 2010, 4, 2300–2306. [Google Scholar] [CrossRef]

- Toba, K.; Yamamoto, H.; Yoshida, M. , Crystallization of cellulose microfibrils in wood cell wall by repeated dry-and-wet treatment, using X-ray diffraction technique. Cellulose 2013, 20, 633–643. [Google Scholar] [CrossRef]

- Lin, Q.; Huang, Y.; Yu, W. , An in-depth study of molecular and supramolecular structures of bamboo cellulose upon heat treatment. Carbohydrate Polymers 2020, 241, 116412. [Google Scholar] [CrossRef] [PubMed]

- Leng, E.; Gong, X.; Zhang, Y.; Xu, M. , Progress of cellulose pyrolysis mechanism: cellulose evolution based on intermediate cellulose. CIESC Journal 2018, 69, 239–248. [Google Scholar]

- Kato, K. L.; Cameron, R. E. , A Review of the Relationship Between Thermally-Accelerated Ageing of Paper and Hornification. Cellulose 1999, 6, 23–40. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, D.; Chen, Q.; Chen, P.; Song, G.; Chang, C. , Reversible Surface Engineering of Cellulose Elementary Fibrils: From Ultralong Nanocelluloses to Advanced Cellulosic Materials. Advanced Materials 2024, 36, 2312220. [Google Scholar] [CrossRef]

- Wohlert, M.; Benselfelt, T.; Wågberg, L.; Furó, I.; Berglund, L. A.; Wohlert, J. , Cellulose and the role of hydrogen bonds: not in charge of everything. Cellulose 2022, 29, 1–23. [Google Scholar] [CrossRef]

- Wan, J.; Wang, Y.; Xiao, Q. , Effects of hemicellulose removal on cellulose fiber structure and recycling characteristics of eucalyptus pulp. Bioresource Technology 2010, 101, 4577–4583. [Google Scholar] [CrossRef]

- Mo, W.; Chen, K.; Yang, X.; Kong, F.; Liu, J.; Li, B. , Elucidating the hornification mechanism of cellulosic fibers during the process of thermal drying. Carbohydrate Polymers 2022, 289, 119434. [Google Scholar] [CrossRef] [PubMed]

- Sjöstrand, B.; Karlsson, C.-A.; Barbier, C.; Henriksson, G. , Hornification in Commercial Chemical Pulps: Dependence on Water Removal and Hornification Mechanisms. BioResources 2023, 18, 3856–3869. [Google Scholar] [CrossRef]

- Heinze, T. , Cellulose: Structure and Properties. In Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials, Rojas, O. J., Ed. Springer International Publishing: Cham, 2016; pp 1-52.

- Yao, J.; Zhang, R.; Luo, C.; Yan, Y.; Bi, N.; Tang, Y. , Deterioration of Kaihua handmade paper: Evolution of molecular, supermolecular and macroscopic structures. Polymer Degradation and Stability 2022, 195, 109773. [Google Scholar] [CrossRef]

- Turki, A.; El Oudiani, A.; Msahli, S.; Sakli, F. , Investigation of OH bond energy for chemically treated alfa fibers. Carbohydrate Polymers 2018, 186, 226–235. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).