1. Introduction

Freeze-drying, or lyophilization, is widely used to preserve the nutritional qualities of food products. Camel and mare milk, due to their unique chemical composition, present challenges for conventional drying methods. Camel milk contains 3-5% fat and 3-4% protein, while mare milk has higher lactose content, making it prone to caramelization if not carefully processed. The objective of this study is to develop optimized parameters for the freeze-drying process, ensuring minimal nutrient loss while maintaining product quality.

The increasing global demand for sustainable food products has intensified research on non-cattle milk, particularly camel and mare milk, due to their unique nutritional and therapeutic properties. These types of milk have a higher concentration of essential bioactive compounds, such as immunoglobulins, lysozymes, and beneficial fatty acids, making them suitable for both dietary consumption and medicinal use. Camel milk, for example, contains higher protein and fat content than cow’s milk, making it more challenging to process through conventional methods [

1]. Similarly, mare milk has a higher lactose concentration, which can lead to caramelization under standard drying conditions, thereby requiring specialized techniques to maintain its quality during preservation [

2,

3].

Freeze-drying, or vacuum-sublimation drying, offers a solution by removing water content from milk without exposing it to damaging heat, preserving the bioactive components and nutritional properties. This process has been shown to maintain the structural and functional integrity of proteins and other sensitive compounds, which is crucial for products intended for infant nutrition, dietary supplements, and medicinal purposes [

4]. However, the method presents certain challenges, including high energy consumption, prolonged processing time, and the need for precise control over temperature and pressure. Furthermore, traditional freeze-drying protocols may not be optimized for camel and mare milk due to their distinct compositions, necessitating research to identify ideal parameters for efficient drying [

5].

This study aims to optimize the vacuum freeze-drying process for camel and mare milk by determining the optimal temperature, drying time, and layer thickness. Special attention is given to the pre-treatment techniques of ultrasound and homogenization, which have been found to enhance heat and mass transfer, thus potentially reducing drying time and energy consumption [

6]. Additionally, mathematical modeling using Python and Maple was employed to simulate the drying process, helping to predict moisture evaporation rates under varying conditions. This research not only offers practical insights for the dairy industry but also provides a framework for future studies exploring drying technologies for non-cattle milk products.

In summary, this study seeks to bridge the gap in knowledge regarding optimal drying conditions for camel and mare milk by systematically analyzing the effects of temperature, pressure, and pre-treatment techniques on product quality. The results will contribute to improving the efficiency of freeze-drying processes and ensure the production of high-quality powdered milk that retains its nutritional and functional benefits [

7,

8].

2. Materials and Methods

2.1. Milk Samples

Camel Milk: Dromedary camels raised in an arid climate. Fresh camel milk was obtained from healthy camels during lactation.

All collected milk samples were stored at 4°C until processing. Ethics approval was not required as the study involved only milk samples with no direct animal intervention.

2.2. Experimental Setup and Conditions

Drying Equipment:

A vacuum freeze-dryer was used for all trials.

Initial Freezing Temperature: -50°C

Drying Shelf Temperature Range: -50°C to +50°C, with progressive increases throughout the process.

Chamber Pressure: Maintained between 60–100 Pa throughout drying.

Layer Thickness: Two layers were tested — 0.5 cm and 0.9 cm — to determine optimal moisture removal and product uniformity.

Pre-Treatment Techniques:

Ultrasound: 35 kHz, 200 W for 5 minutes before drying.

Homogenization: Samples were homogenized at 1600 bar to ensure uniform particle size, facilitating more efficient moisture transfer.

2.3. Analytical Methods

The following analytical methods were employed to assess the quality of the fresh, dried, and reconstituted milk samples:

Moisture Content: Measured by drying samples at 105°C to constant weight (gravimetric analysis).

Protein Content: Determined by the Kjeldahl method.

Fat Content: Assessed using the Gerber method.

Lactose Content: Measured by enzymatic analysis.

pH and Acidity:

pH: Measured using a pH meter calibrated with standard buffer solutions.

Acidity: Determined via titration, expressed in degrees Turner (°T).

Density: Assessed using a pycnometer at 20°C.

2.4. Process Modeling

Mathematical models for moisture evaporation and drying efficiency were developed using Python and Maple software to predict optimal drying conditions. Key equations include:

Heat Transfer Equation:

where

q is the heat flux (W),

k is the thermal conductivity (0.58 W/m·K),

A is the surface area (0.2 m²),

Ts is the shelf temperature,

Tsub is the sublimation temperature (-45°C), and

d is the layer thickness (m).

m˙ is the rate of sublimation (kg/s) and

Ls is the latent heat of sublimation (2,834,000 J/kg).

2.5. Data Availability

All data generated during this study, including experimental results and Python/Maple codes, are available upon request from the corresponding author.

3. Results

3.1. Optimization of the Drying Process

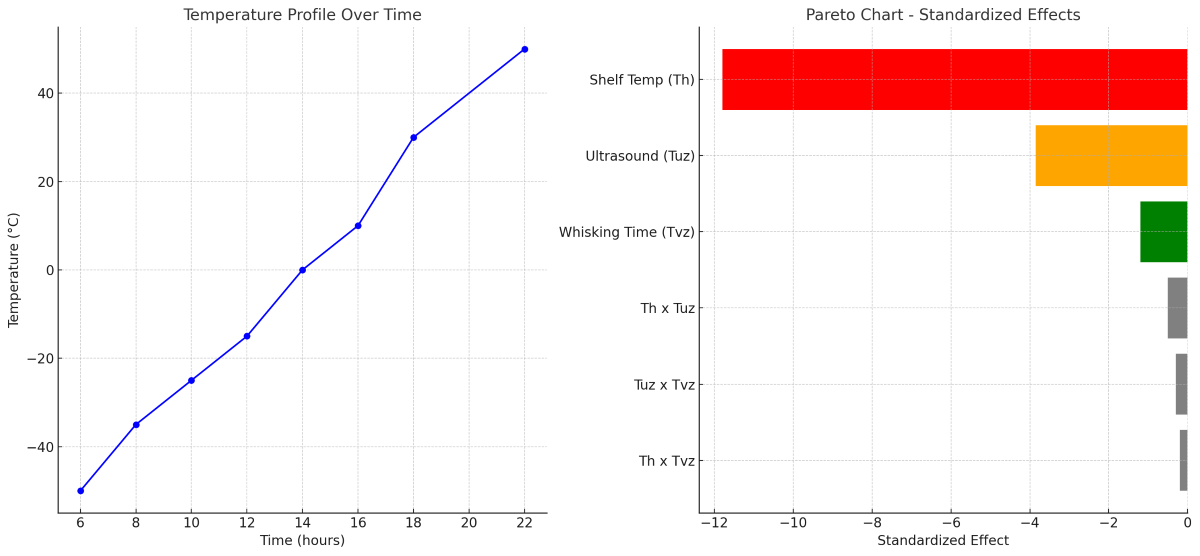

Optimal drying parameters for camel milk:

Total drying time: 22 hours.

Shelf temperature: From -50°C to +50°C with gradual increases to ensure even moisture removal.

Layer thickness: The optimal thickness is 0.9 cm, providing a balance between time and quality. A thinner layer (0.5 cm) leads to over-drying, reducing moisture content to approximately 3%.

Table 1.

Temperature Regime and Drying Duration for Camel Milk.

Table 1.

Temperature Regime and Drying Duration for Camel Milk.

| Temperature (°C) |

Duration (hours) |

| -50°C |

6 hours |

| -35°C |

2 hours |

| -25°C |

2 hours |

| -15°C |

2 hours |

| 0°C |

2 hours |

| 10°C |

2 hours |

| 30°C |

2 hours |

| 50°C |

4 hours |

3.2. Effect of Pre-Treatment

The

ultrasound treatment and

homogenization applied before drying significantly improved the drying process. These methods enhanced moisture transfer, resulting in more uniform drying and better product quality. Below are the key effects observed from the pre-treatments:

| Pre-Treatment Method |

Parameters |

Effects on Drying Process |

| Ultrasound |

35 kHz, 200 W, 5 minutes |

Improved heat and mass transfer, reducing drying time by 15–20%. |

| Homogenization |

1600 bar |

Enhanced particle distribution, promoting even moisture removal. |

- –

Ultrasound promotes uniform heat transfer by reducing the resistance to moisture migration within the milk layer. This significantly shortens the drying time while maintaining product consistency. Studies such as those by [

9,

10] confirm that ultrasound enhances drying efficiency by improving viscosity control and protein stability during processing.

- –

High-pressure homogenization (1600 bar) helped ensure even particle distribution, facilitating uniform moisture removal. This step was crucial, especially for the

1 cm thick layer, to avoid local overdrying. Similar benefits have been reported in[

6], where homogenization improved the texture and quality of dairy powders.

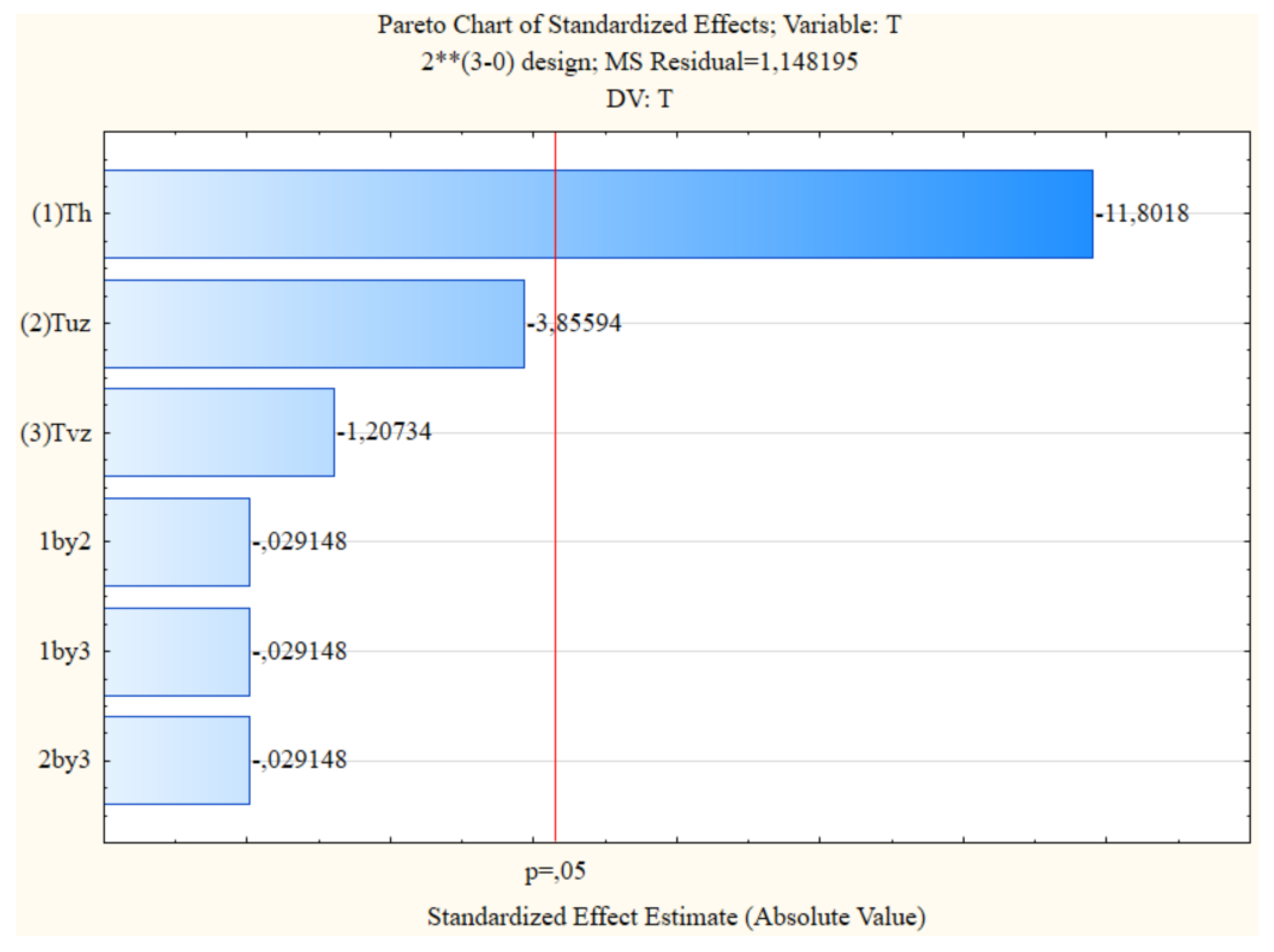

The diagram in

Figure 1 highlights the contribution of ultrasound and homogenization to the efficiency of the drying process.

These pre-treatment techniques, especially when combined, enhanced the overall efficiency of the drying process, ensuring high product quality while reducing drying time.

The Pareto chart (

Figure 1) provides a clear illustration of the standardized effects of various factors on the drying process. On the X-axis, the standardized effects are plotted to indicate the magnitude of each factor's influence on the outcome variable (T – the drying efficiency). The Y-axis lists the factors evaluated in the process:

Th — Influence of homogenization.

Tuz — Influence of ultrasound (UZ) treatment.

Tvz — Influence of whisking time at 1600 bar (UZ).

1by2, 1by3, 2by3 — Interactions between multiple factors.

Key Findings from the Pareto Chart

As shown in

Figure 1, the temperature (Th) has the greatest influence on the process, indicated by the longest bar on the graph with a negative standardized effect of -11.8018. This highlights the critical role of temperature control during the drying process, as it is directly linked to the phase transition during sublimation.

The ultrasound treatment (Tuz) also has a significant effect, with a standardized effect value of -3.85594, but it is less influential compared to homogenization. Ultrasound likely contributes by accelerating moisture removal through mechanical vibrations, which enhances the migration of water molecules to the surface.

The impact of whisking time (Tvz) under high pressure (1600 bar) is comparatively smaller, with a standardized effect of -1.20734. While it plays a role in improving particle distribution and moisture removal, its contribution is not as significant as temperature or ultrasound.

Finally, the interactions between factors (1by2, 1by3, 2by3) show minimal influence, with very low standardized effect values. This suggests that these factors independently affect the drying process without meaningful synergistic interactions.

Based on the Pareto chart, temperature (Th) is the most influential factor in the drying process, which aligns with expectations since temperature is directly associated with sublimation dynamics. The ultrasound treatment (Tuz) also plays a significant role, supporting the theory that mechanical vibrations enhance the drying process by facilitating moisture migration. However, the whisking time (Tvz) and interactions between factors have lesser impacts, indicating that optimizing temperature and ultrasound is key to improving drying efficiency.

3.3. Process Modeling

The drying process was modeled using Python and Maple to determine optimal conditions. The primary equation for heat transfer used in the model is:

where: q = heat flux (W),

k=0.58W/mK (thermal conductivity of milk),

A=0.2 m2 (surface area of the milk layer),

Ts = shelf temperature (°C),

Tsub=−45∘C (sublimation boundary temperature),

d=0.009 m(layer thickness).

Calculations indicated that with q=64.44 W

m˙=2.27×10−5kg/s.

q=64.44W, the sublimation rate was:

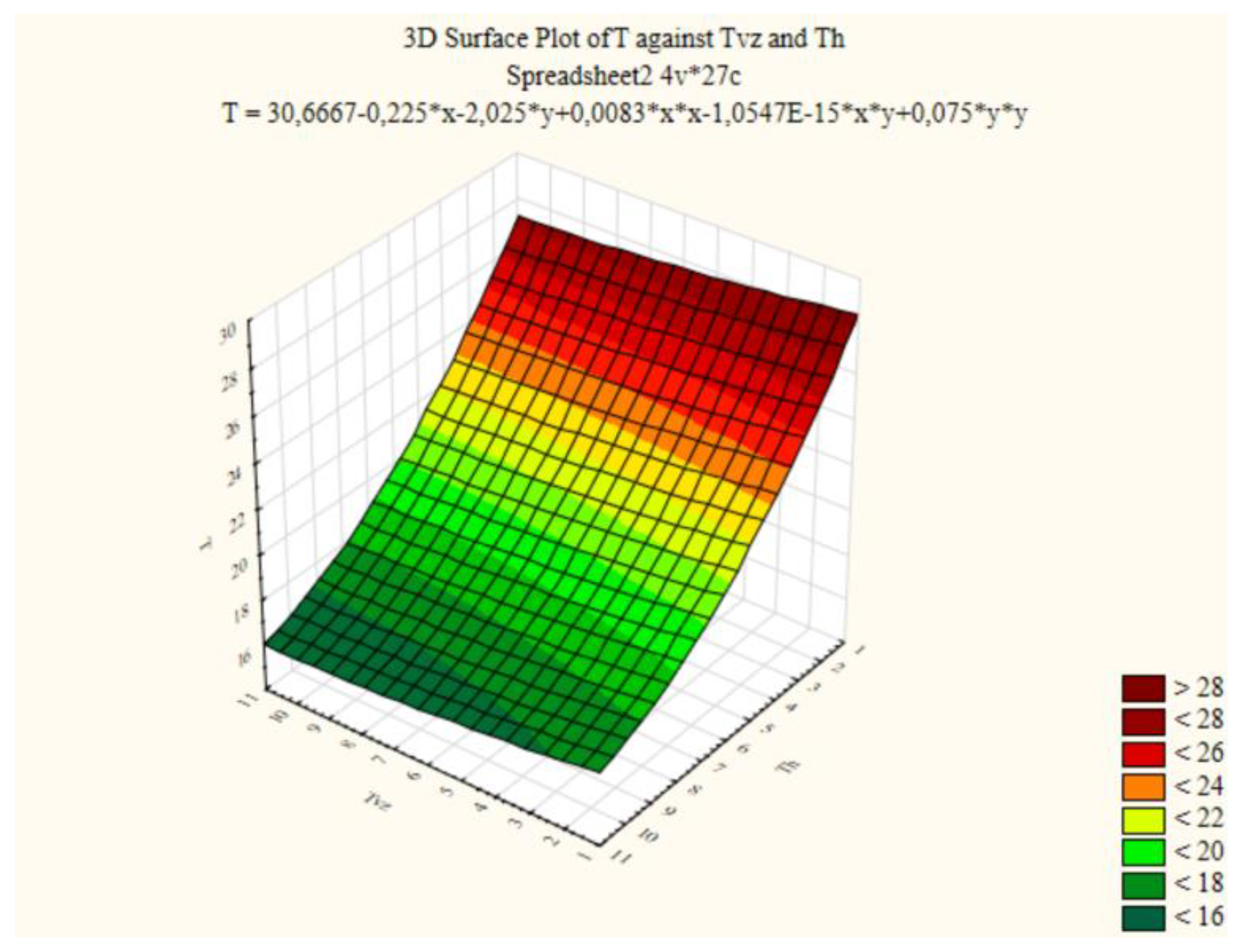

A 3D surface plot (

Figure 2) illustrates the relationship between T (total drying time) and two key factors:

Tvz — Whisking time at 1600 bar (ultrasound).

Th — Duration of homogenization.

The equation modeling the relationship is:

T=30.6667−0.225⋅x−2.025⋅y+0.0083⋅x2−1.0547×10−15⋅x⋅y+0.075⋅y2,

where: x — value of Th (homogenization duration),

y — value of Tvz (whisking time at 1600 bar).

The color scale on the right of the graph ranges from <16 (dark green) to >28 (red). This shows that longer homogenization durations (Th) and shorter whisking times (Tvz) result in longer drying times, indicated by the red areas on the plot.

Gradual temperature increases from -50°C to +50°C ensured stable moisture removal without overheating the product.

Camel milk required more intensive heat treatment during the final stages due to its higher density and protein content.

Total drying time of 22 hours was necessary under these conditions, reflecting the high thermal resistance of camel milk proteins.

A 0.9 cm milk layer resulted in faster and more uniform drying compared to thicker layers, confirming that thinner layers accelerate the drying process. Optimal temperature settings were chosen based on experimental data and previous studies, which confirm that ice sublimates most effectively below -30°C. Increasing the temperature during the final stages accelerates drying without damaging the product.

Ultrasound treatment improved heat transfer by breaking down fat globules and increasing porosity, enhancing the sublimation process. These findings align with previous studies showing that ultrasound enhances drying efficiency and improves product porosity [

10,

11]. Optimal parameters for drying camel milk:

Temperature: -50°C to +50°C

Drying time: 22 hours

Milk layer thickness: 0.9 cm

Ultrasound treatment and homogenization improved the drying process and reduced the drying time by 15–20%.

Modeling results confirmed the optimal parameters, improving process control and efficiency. These results align with previous findings that ultrasound and homogenization enhance drying performance [

9,

10,

11]

4. Discussion

4.1. Optimizing Drying Conditions

This study demonstrates that the optimal drying parameters for camel milk are a 1 cm layer thickness, a 22-hour drying cycle, and temperature increments from -50°C to +50°C. Although theoretical models indicated that a thinner layer of 0.5 cm could be dried within 6 hours, practical experiments showed that this approach led to over-drying, compromising product quality. A layer of 1 cm ensured optimal moisture removal and product stability, highlighting the importance of balancing drying time and thickness to avoid over-drying and brittleness.

These findings align with other studies that emphasize optimized drying processes for milk powder. For example, [

12] demonstrated that microwave vacuum drying significantly reduced drying time while maintaining good solubility, with product temperatures kept below 55°C to preserve quality [

12]. This highlights the potential of using precise heat control to enhance drying efficiency.

4.2. Effect of Pre-Treatment and Temperature Control

The combination of ultrasound and homogenization improved the drying efficiency by 15–20%. Ultrasound treatment promoted better heat transfer by breaking down fat globules and increasing product porosity, as demonstrated by[

10,

11]. Homogenization ensured uniform particle distribution, enabling consistent moisture removal, which is essential for maintaining product quality during drying (

Figure 1).

Studies also show that temperature adjustments can enhance drying processes. [

13] emphasized the importance of inlet and outlet temperature optimization during spray drying to achieve moisture control and product stability [

14,

15]. Similarly, [

13] found that optimizing air temperature and milk flow rate in spouted bed drying reduced drying time without compromising product characteristics.

4.3. 3D Model Analysis

The 3D model analysis confirmed that increasing homogenization duration (Th) while reducing whisking time (Tvz) could extend drying times (

Figure 2). The color-coded 3D plot highlights the relationship between these factors and drying duration, with red areas indicating increased drying time when homogenization is prolonged. This finding aligns with [

16], who reported that increasing microwave power significantly shortened drying time without sacrificing product humidity or quality.

Figure 2. 3D surface plot showing the relationship between drying time, homogenization (Th), and whisking time (Tvz)

4.4. Comparison with Previous Research

The results of this study align with the findings from other alternative drying processes. [

12] identified microwave vacuum drying as a method to optimize drying for concentrated skim milk, reducing drying time while maintaining solubility. Similarly, [

15]demonstrated that higher inlet air temperatures during spray drying reduced moisture content effectively, showing that precise control of drying parameters is key to minimizing time without compromising quality.

4.5. Key Findings

Optimal Drying Parameters for Camel Milk:

Temperature: -50°C to +50°C

Drying Time: 22 hours

Layer Thickness: 1 cm

Pre-Treatment Impact:

Ultrasound and homogenization reduced drying time by 15–20%.

Consistent temperature increases helped preserve protein structure and enhance sublimation.

Model Validation:The model confirmed that layer thickness and precise heat control are essential for optimal drying.

Aligning drying practices with microwave drying techniques from previous studies suggests additional improvements can be achieved through further parameter adjustments [

13].

4.6. Limitations and Future Research

This study highlights several areas for future research:

Energy Optimization: Future work should focus on energy-efficient drying technologies, such as microwave vacuum drying.

Storage Stability: The long-term stability of dried camel milk powder should be evaluated under different storage conditions.

Hybrid Techniques: Exploring hybrid drying methods, like combining vacuum drying with infrared radiation, could further improve efficiency and reduce energy consumption.

5. Conclusions

This study confirmed that the optimal drying parameters for camel milk are a 1 cm layer thickness, a drying cycle of 22 hours, and temperature increments from -50°C to +50°C. Although thinner layers (0.5 cm) could theoretically be dried in 6 hours, practical results showed that this led to over-drying and reduced product quality. The combination of ultrasound and homogenization enhanced the drying process, reducing drying time by 15–20%. These findings align with previous research on optimized drying methods and underscore the importance of precise parameter control for achieving high-quality milk powder.

6. Patents

At present, no patents are associated with this work. However, future patent applications may be submitted regarding the methodology of combined ultrasound treatment and vacuum freeze-drying for dairy products.

Author Contributions

Conceptualization — Ayaulym Rakhmatulina and Fatima Dikhanbayeva; methodology — Ayaulym Rakhmatulina, Dinara Tlevlessova; software — Fatima Dikhanbayeva; validation — Dinara Tlevlessova, Nurbek Aralbayev, and Aidana Yessenova; formal analysis — Ayaulym Rakhmatulina; investigation — Fatima Dikhanbayeva, Altynay Abuova, Dinara Tlevlessova, Akniyet Ibraikhan; resources — Altynay Abuova; data curation — Dinara Tlevlessova; writing — original draft preparation — Fatima Dikhanbayeva, Dinara Tlevlessova; writing — review and editing — Fatima Dikhanbayeva, Aidana Yessenova; visualization — Dinara Tlevlessova, Aidana Yessenova; supervision — Ayaulym Rakhmatulina; project administration — Ayaulym Rakhmatulina, Fatima Dikhanbayeva. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been/was/is funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR21881957).

Data Availability Statement

Data supporting the findings will be made available upon request.

Acknowledgments

In this section, you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments).

Conflicts of Interest

The authors declare that there is no conflict of interest.

References

- Ali, W. et al. "Milk production and composition in camel and its beneficial uses: a review." Turkish Journal of Agriculture-Food Science and Technology, 2019.

- Seifu, E. "Camel milk products: innovations, limitations, and opportunities." Food Production, Processing, and Nutrition, 2023.

- El-Agamy, E. I. "The challenge of cow milk protein allergy." Small Ruminant Research, 2007.

- Kowalski, S. J., & Mierzwa, D. "Ultrasound-Assisted Drying of Milk Products." Drying Technology, 2020.

- Park, Y. W. et al. "Handbook of Milk of Non-Bovine Mammals." Wiley-Blackwell, 2017.

- Alam, M. S. et al. "Effect of Ultrasound and Homogenization on Spray-Dried Milk Powder." Journal of Food Science and Technology, 2019.

- Rakhmatulina, A. et al. "Advancements in Camel Milk Drying Technology: A Comprehensive Review." Dairy, 2024.

- Benedito, J. et al. "Quality control of cheese maturation and defects using ultrasonics." Journal of Food Science, 2001.

- Zisu, B., & Chandrapala, J. (2015). High Power Ultrasound Processing in Milk and Dairy Products. In Advances in Dairy Ingredients (pp. 121–144). Wiley-Blackwell. [CrossRef]

- Carrillo-Lopez, L., Garcia-Galicia, I., Tirado-Gallegos, J., Sánchez-Vega, R., Huerta-Jimenez, M., Ashokkumar, M., & Alarcon-Rojo, A. (2021). Recent advances in the application of ultrasound in dairy products: Effect on functional, physical, chemical, microbiological and sensory properties. Ultrasonics Sonochemistry, 70, 105467. [CrossRef]

- Vadlja, D. (2013). Primjena ultrazvuka i visokih tlakova pri obradi i analizi mlijeka. In Proceedings of the Conference on Food Technology. The paper discusses the impact of ultrasound and high pressure on drying time reduction.

- Dumpler, J., & Moraru, C. I. (2022). Microwave vacuum drying of concentrated skim milk: Process optimization and impact on powder solubility. Journal of Dairy Science, 105(6), 4654–4665. [CrossRef]

- Hamedi, H., Azizi, M. H., & Hosseini, H. (2021). Optimization of spouted bed drying conditions for skimmed milk powder: Effect on physicochemical properties. LWT - Food Science and Technology, 145, 111448. [CrossRef]

- Masum, A. K. M., Dissanayake, M., Ramchandran, L., & Vasiljevic, T. (2020). Spray drying of infant milk formula powders: Optimization of process and storage stability. International Dairy Journal, 104, 104696. [CrossRef]

- Saha, M. S., Chan, E. S., & Zhang, Z. (2019). Effect of air inlet temperature on spray drying of milk powders: Optimization for product quality and energy efficiency. Powder Technology, 353, 237-245. [CrossRef]

- Tultabayeva, A., Kudaybergen, S., Shilibekova, M., & Sarsembayeva, N. (2023). Microwave drying of milk powders: Influence of power level on drying time and product quality. Technological Journal, 2(124), 124-130. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).