Submitted:

13 October 2024

Posted:

15 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Test materials

2.2. Specimen preparation and test scheme

3. Results and Discussion

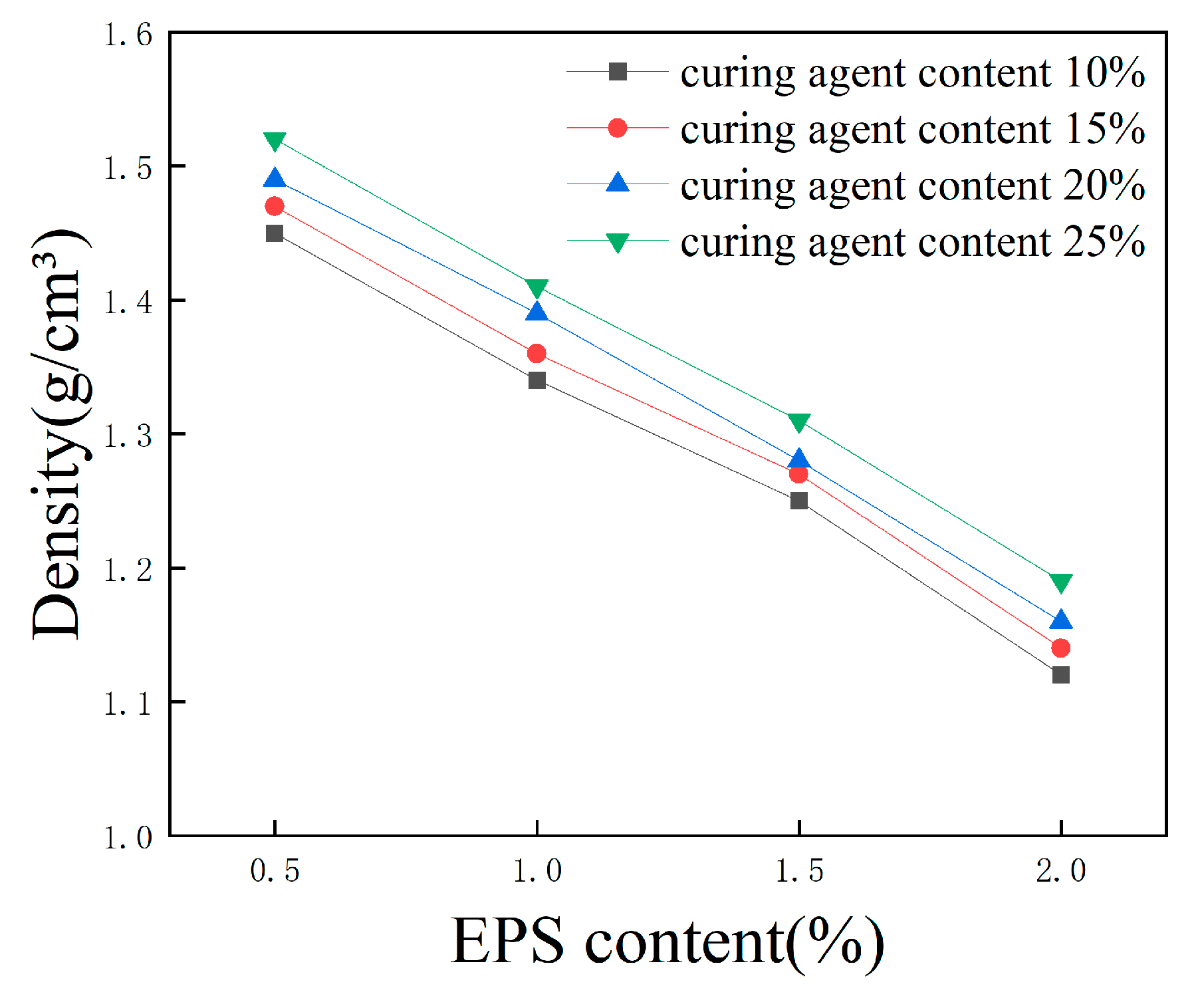

3.1. Effect of EPS content on density of lightweight soil

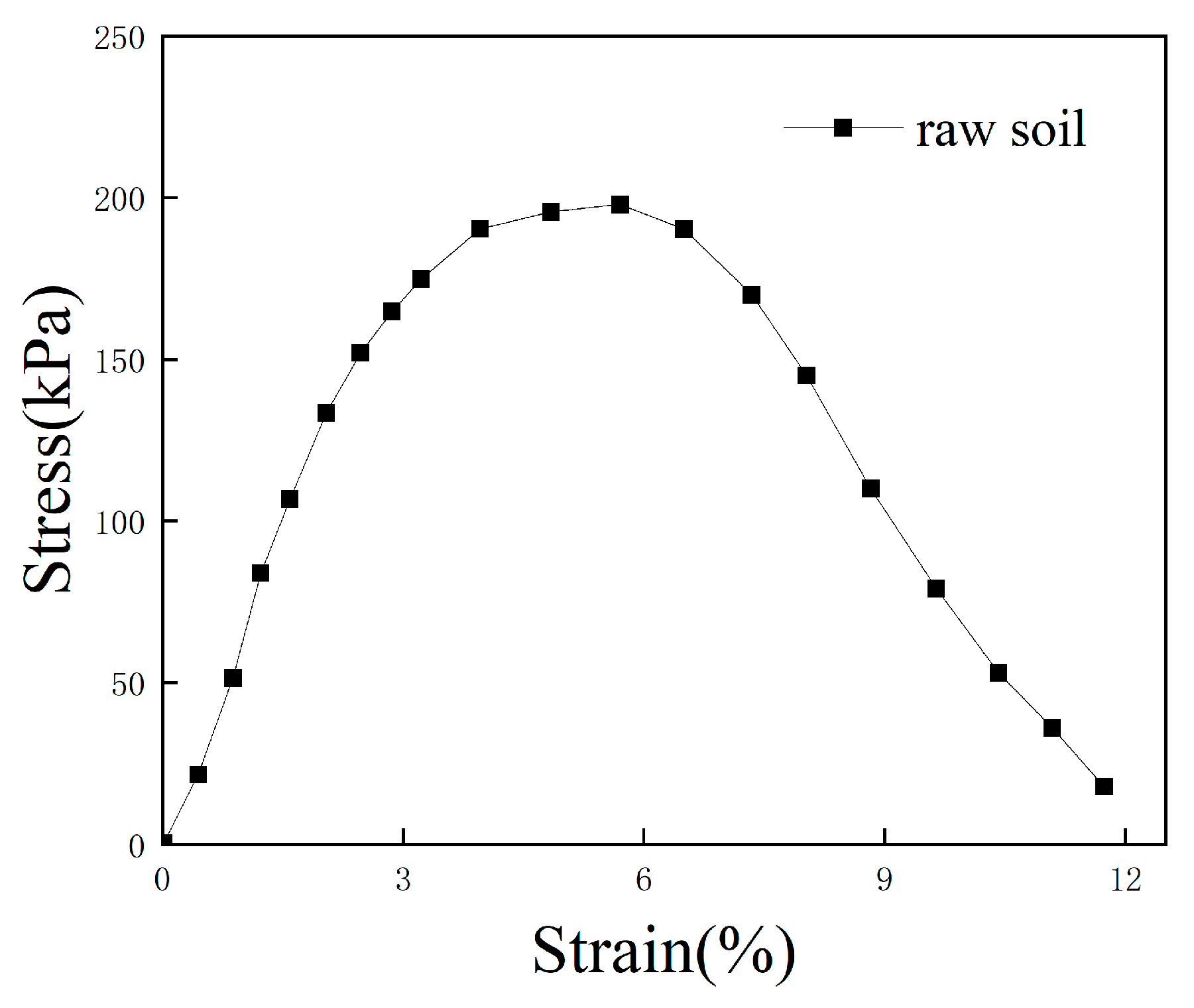

3.2. Stress-Strain Characteristics of raw soil

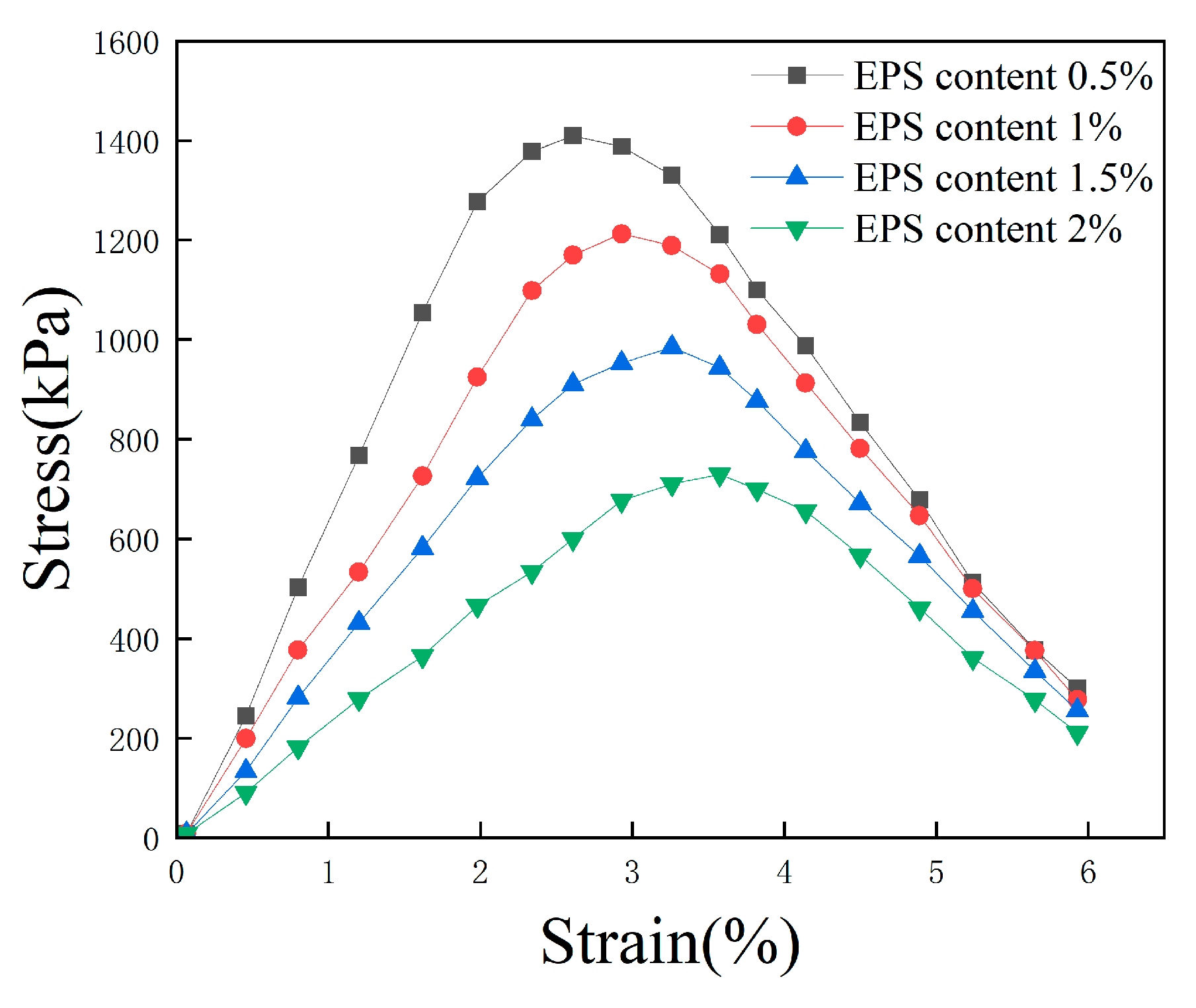

3.3. Effect of EPS content on stress-strain curves

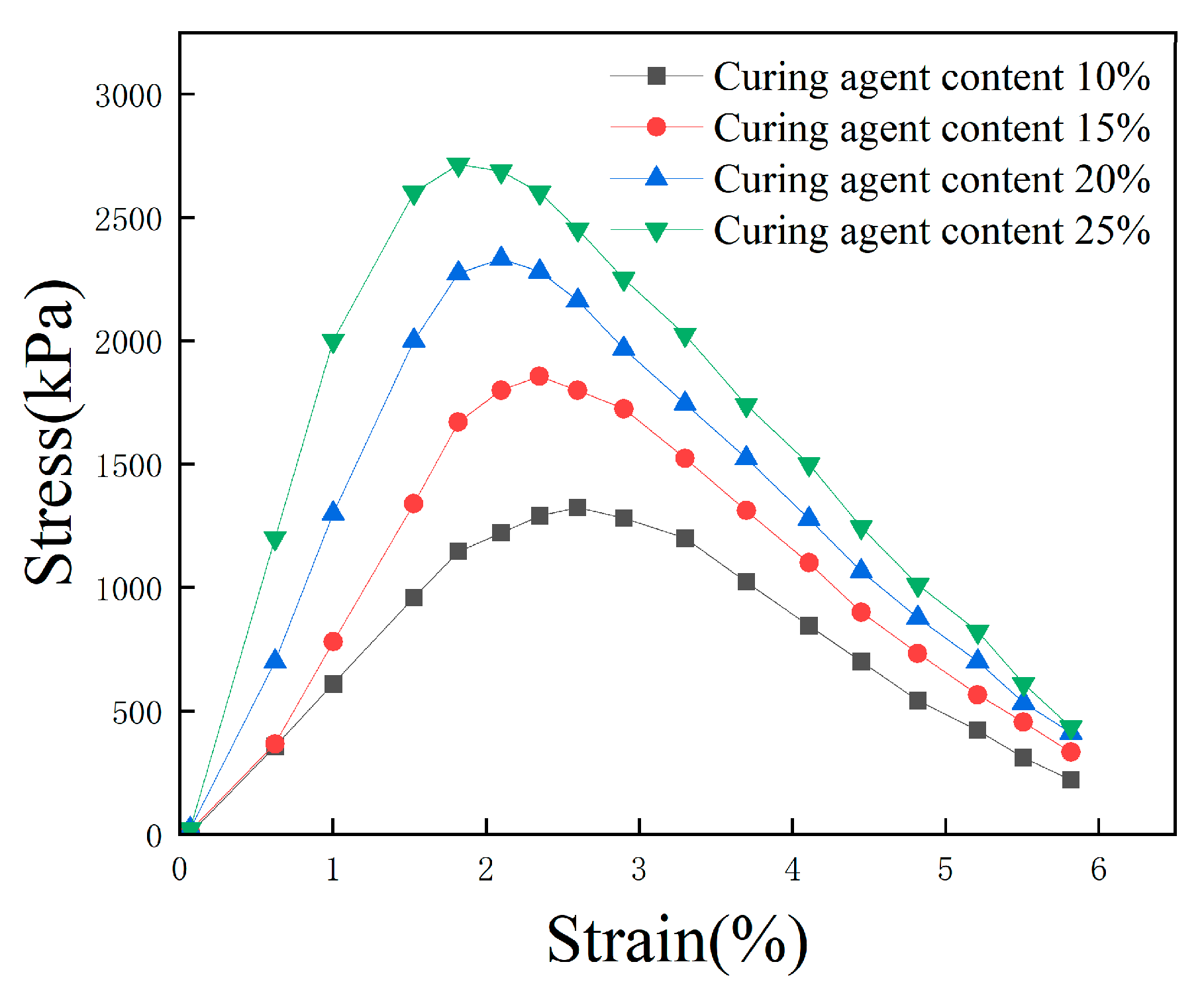

3.4. Effect of total curing agent content on stress-strain curves

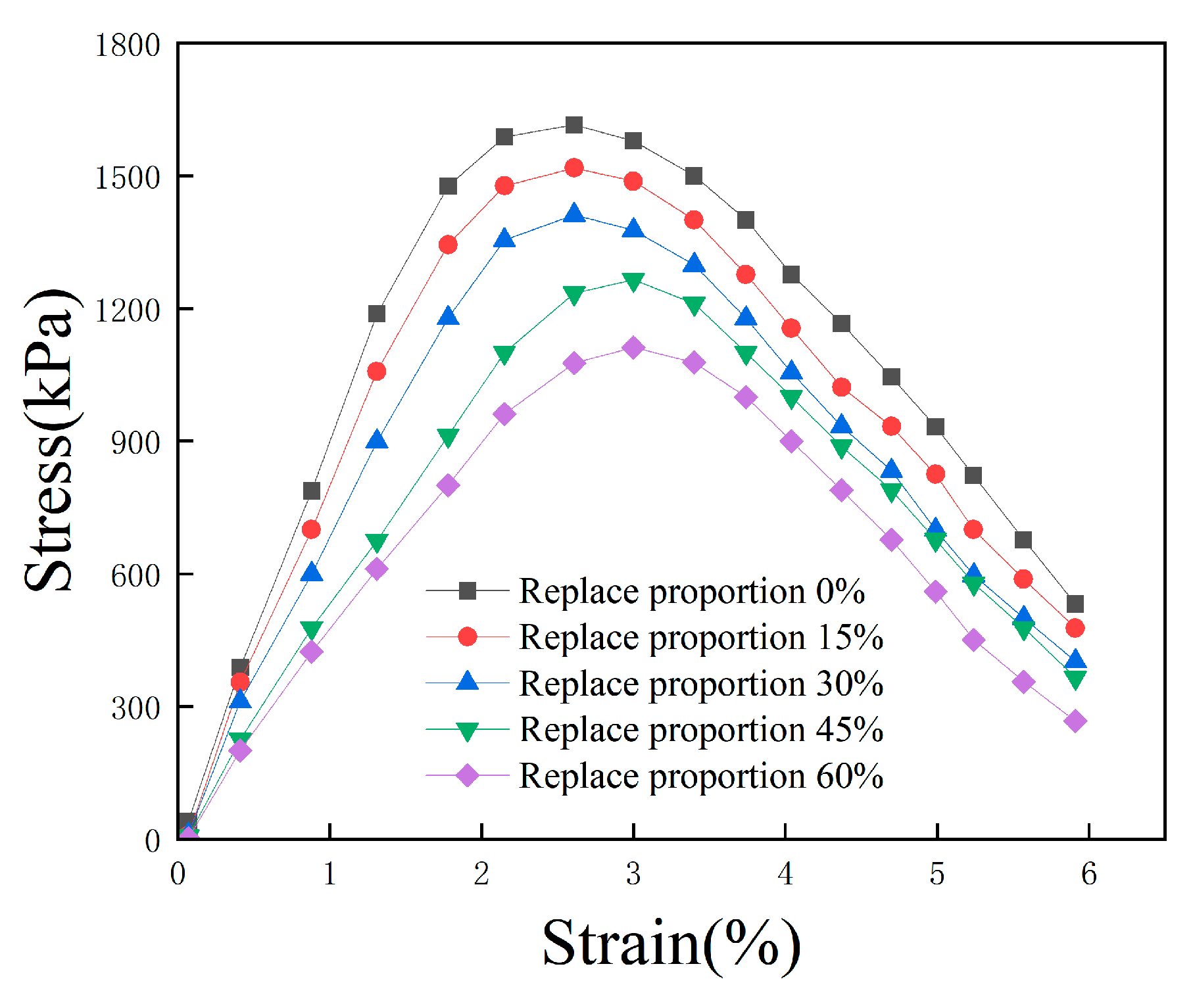

3.5. Effect of fly ash on stress-strain curves

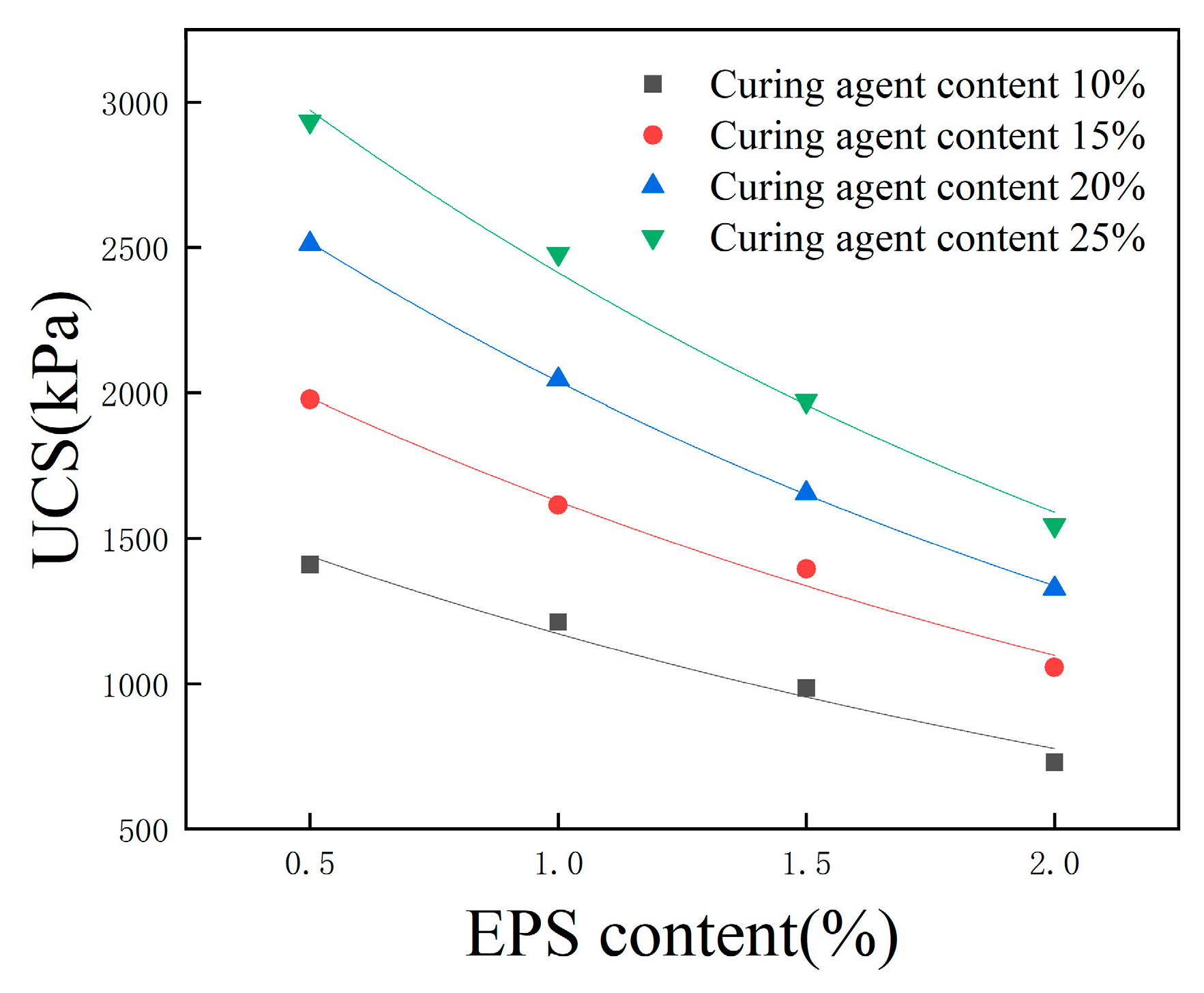

3.6. Effect of EPS content on unconfined compressive strength

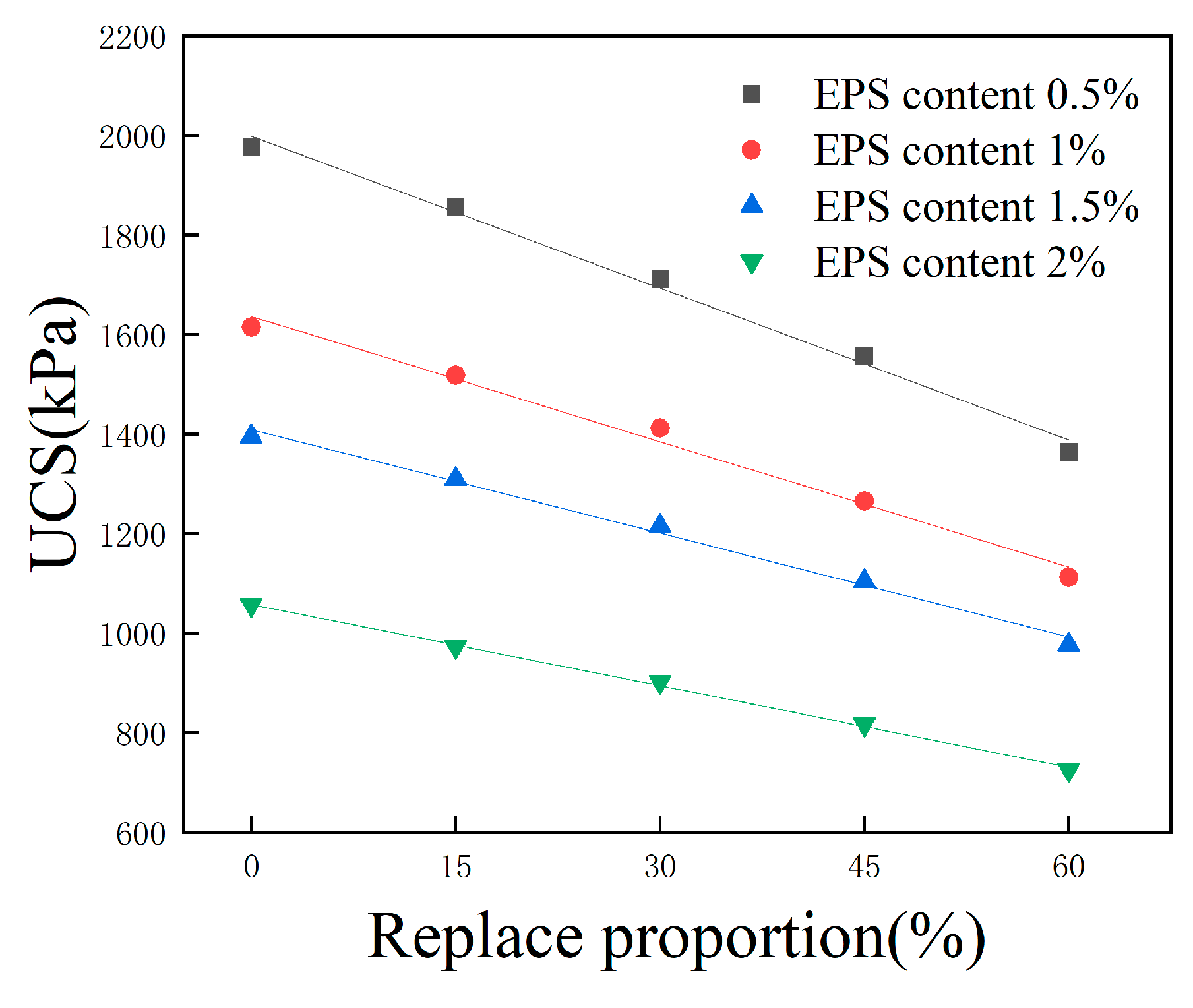

3.7. Effect of total curing agent content on unconfined compressive strength

3.8. Effect of fly ash on unconfined compressive strength

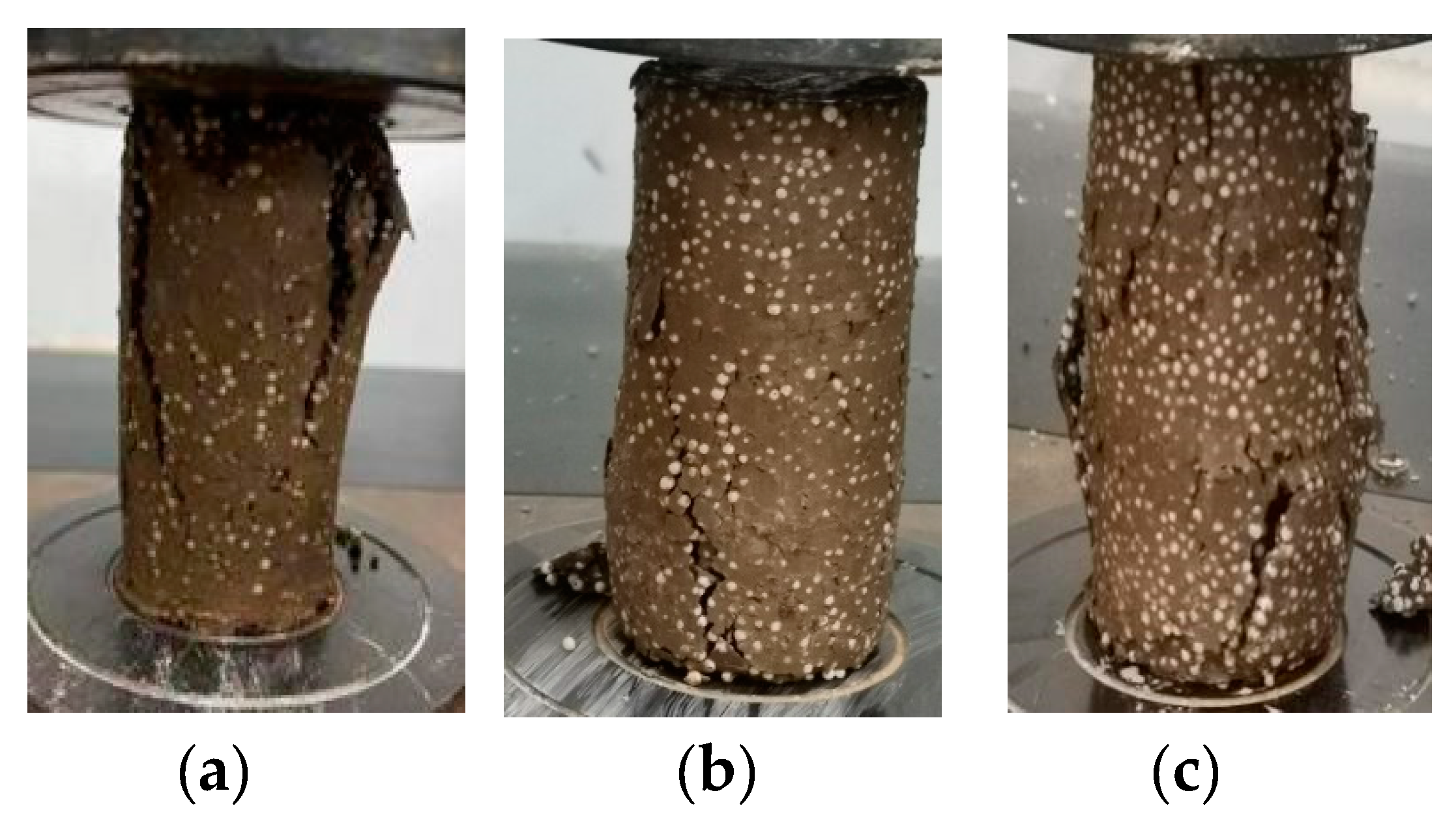

3.9. Unconfined compression failure patterns

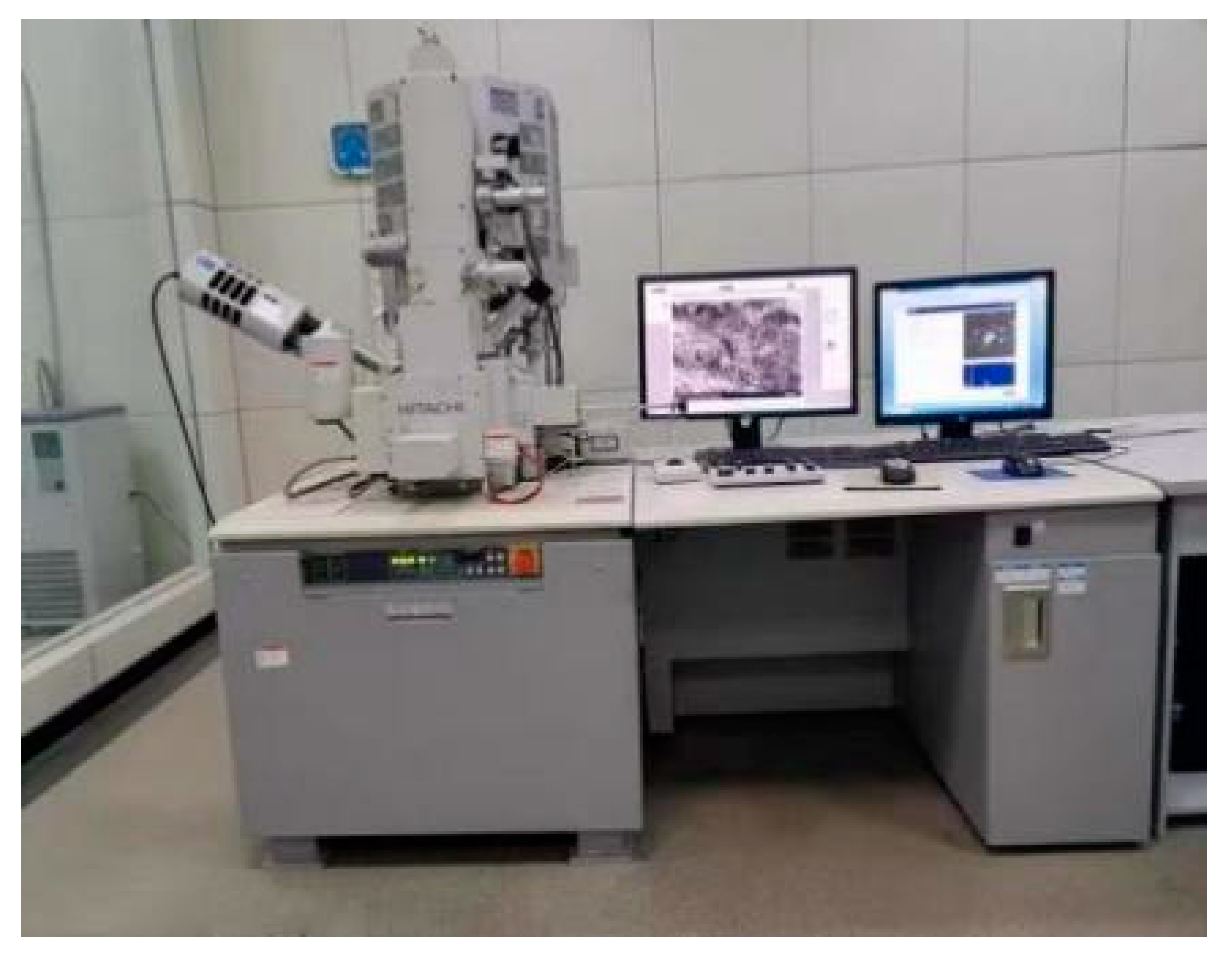

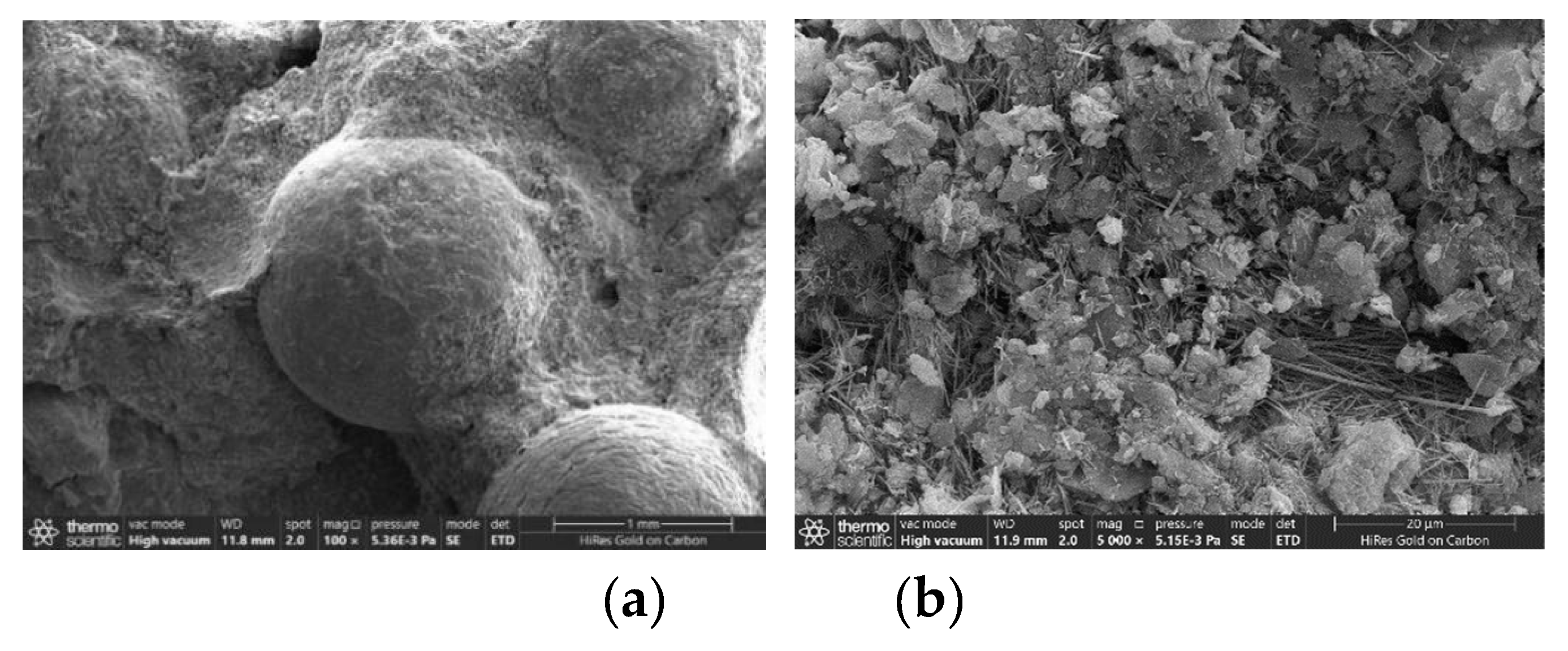

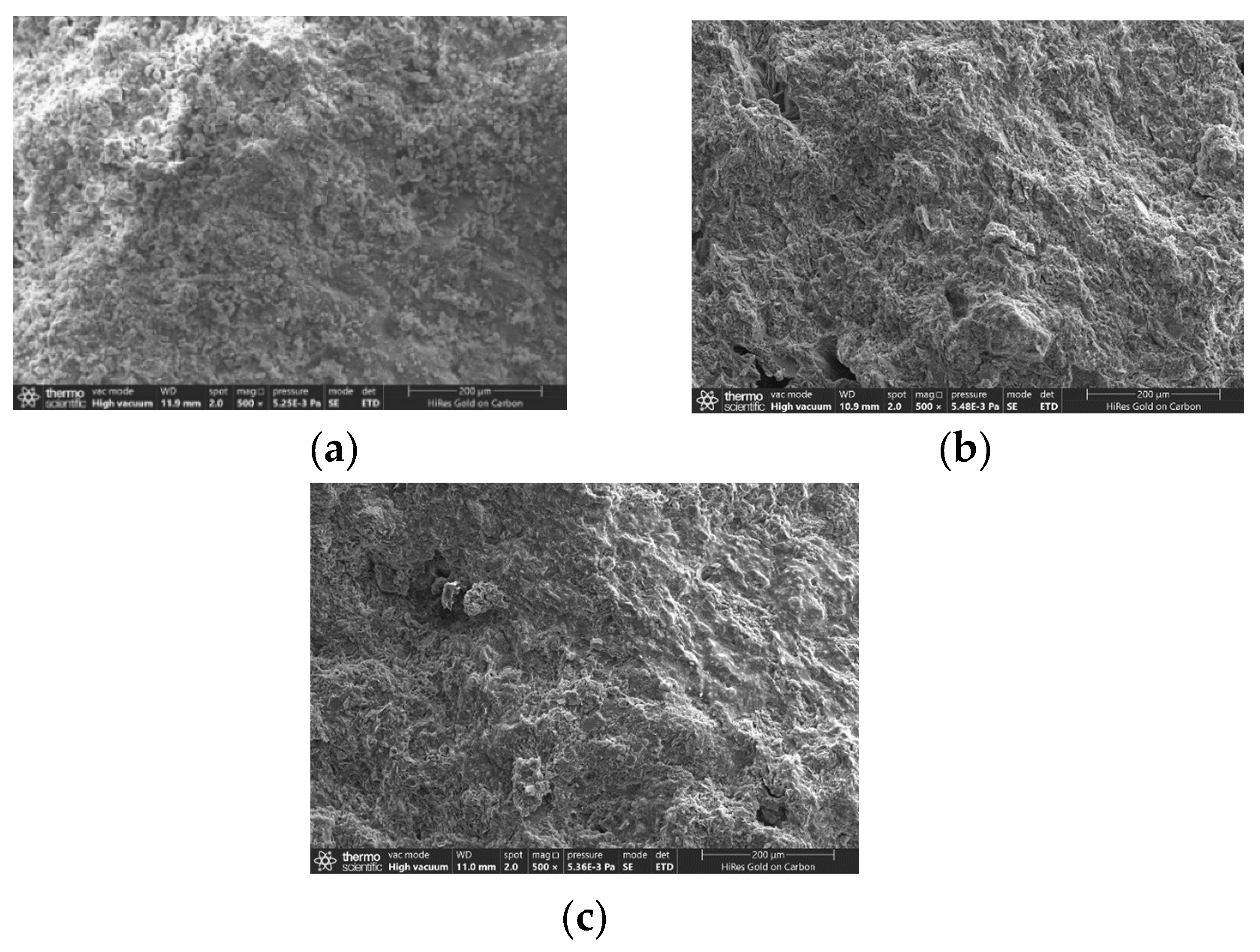

3.10. Micro mechanism

4. Conclusions

- The density of fly ash EPS lightweight soil is mainly affected by EPS beads content. With an increase in the EPS beads content, the density of lightweight soil decreases, and the curing agent on the density of lightweight soil is not significant.

- When other conditions are the same, the unconfined compressive strength of fly ash EPS lightweight soil decreases with an increase in the EPS beads content, increases with an increase in the total curing agent content, and decreases with an increase in the proportion of cement replaced by fly ash. The unconfined stress-strain curve pattern of lightweight soil is related to the EPS beads content, the total curing agent content, and the proportion of cement replaced by fly ash.

- The failure patterns of lightweight soil mainly include splitting failure, oblique shear failure and bulging failure, which are related to the material mix ratio.

- The reticular cementation structure formed by the hydration reaction of the curing agent is the main source of strength of lightweight soil, which directly affects the mechanical properties of lightweight soil. EPS beads are filled between the pores of the cured soil, which reduces the strength of the lightweight soil. After replacing cement with fly ash, the pores and cracks on the surface of the cured soil increase, so the strength of the lightweight soil decreases. When the proportion of cement replaced by fly ash is not too high, the strength of lightweight soil decreases less, and its performance can still meet the engineering needs. At the same time, it can also consume fly ash and reduce environmental pollution. EPS lightweight soil mixed with fly ash still has advantages, and it is recommended that the proportion of cement replaced by fly ash is controlled to less than 30%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Praetorius, A. Integrating a Chemicals Perspective into the Global Plastic Treaty. Environmental Science & Technology Letters 2022, 9, 1000–1006. [Google Scholar] [CrossRef]

- Nguyen, T.T.A.; Ta, Y.T.; Dey, P.K. Developing a plastic cycle toward circular economy practice. Green Processing and Synthesis 2022, 11, 526–535. [Google Scholar] [CrossRef]

- Law, K.L. Plastics in the Marine Environment. Annual Review of Marine Science 2017, 9, 205–229. [Google Scholar] [CrossRef] [PubMed]

- Amadei, A.M.; Rigamonti, L.; Sala, S. Exploring the EU plastic value chain: A material flow analysis. Resources, Conservation and Recycling 2023, 197. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Plastic Debris in the Marine Environment: History and Future Challenges. Global Challenges 2020, 4. [Google Scholar] [CrossRef]

- Apriadi, B.F.; Setiawan, R.P.; Firmansyah, I. Policy scenario of plastic waste mitigation in Indonesia using system dynamics. Waste Management & Research: The Journal for a Sustainable Circular Economy 2024. [Google Scholar] [CrossRef]

- Ono, S.; Hewage, H.T.S.A.; Visvanathan, C. Towards Plastic Circularity: Current Practices in Plastic Waste Management in Japan and Sri Lanka. Sustainability 2023, 15, 7550. [Google Scholar] [CrossRef]

- Ding, Q.; Zhu, H. The Key to Solving Plastic Packaging Wastes: Design for Recycling and Recycling Technology. Polymers 2023, 15, 1485. [Google Scholar] [CrossRef]

- Miao, Y.; von Jouanne, A.; Yokochi, A. Current Technologies in Depolymerization Process and the Road Ahead. Polymers 2021, 13, 449. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.P.; da Costa, J.P.; Mouneyrac, C.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. Solutions and Integrated Strategies for the Control and Mitigation of Plastic and Microplastic Pollution. International Journal of Environmental Research and Public Health 2019, 16, 2411. [Google Scholar] [CrossRef]

- Ali, S.; Yong, F.; Jamil, F.; Mehmood, M. Evaluation of Deformation and Settlement Properties of Cement-Stabilized Silt Mixed with EPS Beads of Various Sizes. Buildings 2024, 14, 334. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhao, J. Experimental Study of the Dynamic Characteristics and Microscopic Mechanism of Lightweight Soil Modified with Expanded Polystyrene and Sisal Fibre. Applied Sciences 2023, 13, 11502. [Google Scholar] [CrossRef]

- Tao, H.; Zheng, W.; Zhou, X.; Zhou, L.; Li, C.; Yu, Y.; Jiang, P. Study on Dynamic Modulus and Damping Characteristics of Modified Expanded Polystyrene Lightweight Soil under Cyclic Load. Polymers 2023, 15, 1865. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Wen, K.; Tong, R.; Li, M. Dynamic Shear Strength Characteristics of Lightweight Sand-EPS Soil. Sustainability 2022, 14, 7397. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, Y.W.; Li, N.; Zhou, L.; Pu, S.Y.; Wang, W. Strength properties and microscopic mechanism of lime and fly ash modified expandable poly styrene lightweight soil reinforced by polypropylene fiber. Case Studies in Construction Materials 2022, 17. [Google Scholar] [CrossRef]

- Jili, Q.; Huan, T.; Weiqing, Q.; Guoqi, H.; Hongmei, L.; Abulimiti, P.; Maimaitiyusupu, S.; Batugin, A. Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene. Science and Engineering of Composite Materials 2022, 29, 37–49. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Wojtasik, A.; Duda, A.; Florkiewicz, A.; Park, D. Failure and Remedy of Column-Supported Embankment: Case Study. Journal of Geotechnical and Geoenvironmental Engineering 2018, 144. [Google Scholar] [CrossRef]

- Puppala, A.J.; Ruttanaporamakul, P.; Congress, S.S.C. Design and construction of lightweight EPS geofoam embedded geomaterial embankment system for control of settlements. Geotextiles and Geomembranes 2019, 47, 295–305. [Google Scholar] [CrossRef]

- Mohajerani, A.; Ashdown, M.; Abdihashi, L.; Nazem, M. Expanded polystyrene geofoam in pavement construction. Construction and Building Materials 2017, 157, 438–448. [Google Scholar] [CrossRef]

- Mei, L.; Gu, H.; He, J.; Cheng, T. Physical and Mechanical Properties of Expanded Polystyrene (EPS) Particle Lightweight Soil under Freeze-Thaw Cycles. ACS Omega 2023, 8, 31365–31372. [Google Scholar] [CrossRef]

- Liang, C.; Wu, Y.; Liu, J.; Wu, H.; Chen, D.; Liu, H.; Song, Y.; Zhang, Y. Effect of Expanded Polystyrene Particle Size on Engineering Properties of Clayey Soil. Advances in Civil Engineering 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Yaghoobzadeh, S.; Azizkandi, A.S.; Salehzadeh, H.; Hasanaklou, S.H. Effect of EPS Beads on the Behavior of Sand–EPS and Slope Stability Using Triaxial and Centrifuge Tests. International Journal of Civil Engineering 2021, 19, 1269–1282. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Kumar Shukla, S. An experimental study on micro-structural and geotechnical characteristics of expansive clay mixed with EPS granules. Soils and Foundations 2020, 60, 705–713. [Google Scholar] [CrossRef]

- Silveira, M.V.; Calheiros, A.V.; Casagrande, M.D.T. Applicability of the Expanded Polystyrene as a Soil Improvement Tool. Journal of Materials in Civil Engineering 2018, 30. [Google Scholar] [CrossRef]

- Mei, L.; Cheng, T.; He, J.; Zhuang, X.; Gu, H. Dynamic properties of EPS beads lightweight soil mixed with polypropylene fiber. Case Studies in Construction Materials 2023, 19. [Google Scholar] [CrossRef]

- Hagemeyer, A.N.; Sears, C.G.; Zierold, K.M. Respiratory Health in Adults Residing Near a Coal-Burning Power Plant with Coal Ash Storage Facilities: A Cross-Sectional Epidemiological Study. International Journal of Environmental Research and Public Health 2019, 16. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Huang, Y.; Liao, X.; Xu, W.; Zhang, T. A comprehensive review of toxicity of coal fly ash and its leachate in the ecosystem. Ecotoxicology and Environmental Safety 2024, 269. [Google Scholar] [CrossRef]

- Fidanchevski, E.; Angjusheva, B.; Jovanov, V.; Murtanovski, P.; Vladiceska, L.; Aluloska, N.S.; Nikolic, J.K.; Ipavec, A.; Šter, K.; Mrak, M.; et al. Technical and radiological characterisation of fly ash and bottom ash from thermal power plant. Journal of Radioanalytical and Nuclear Chemistry 2021, 330, 685–694. [Google Scholar] [CrossRef]

- Buha Marković, J.Z.; Marinković, A.D.; Savić, J.Z.; Mladenović, M.R.; Erić, M.D.; Marković, Z.J.; Ristić, M.Đ. Risk Evaluation of Pollutants Emission from Coal and Coal Waste Combustion Plants and Environmental Impact of Fly Ash Landfilling. Toxics 2023, 11. [Google Scholar] [CrossRef]

- Yadav, V.K.; Gacem, A.; Choudhary, N.; Rai, A.; Kumar, P.; Yadav, K.K.; Abbas, M.; Khedher, N.B.; Awwad, N.S.; Barik, D.; et al. Status of Coal-Based Thermal Power Plants, Coal Fly Ash Production, Utilization in India and Their Emerging Applications. Minerals 2022, 12. [Google Scholar] [CrossRef]

- Chen, H.-J.; Shih, N.-H.; Wu, C.-H.; Lin, S.-K. Effects of the Loss on Ignition of Fly Ash on the Properties of High-Volume Fly Ash Concrete. Sustainability 2019, 11. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash. Sustainability 2018, 11. [Google Scholar] [CrossRef]

- Huang, C.-H.; Lin, S.-K.; Chang, C.-S.; Chen, H.-J. Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash. Construction and Building Materials 2013, 46, 71–78. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Yakub, H.I.; Csetenyi, L.J. Impact of fly ash production and sourcing changes on chemical and physical aspects of concrete durability. Construction and Building Materials 2022, 342. [Google Scholar] [CrossRef]

- Wu, C.-H.; Huang, C.-H.; Kan, Y.-C.; Yen, T. Effects of Fineness and Dosage of Fly Ash on the Fracture Properties and Strength of Concrete. Applied Sciences 2019, 9. [Google Scholar] [CrossRef]

- Jha, A.K.; Sivapullaiah, P.V. Potential of fly ash to suppress the susceptible behavior of lime-treated gypseous soil. Soils and Foundations 2018, 58, 654–665. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R.; Russo, G. Effects of Fly Ash Inclusion and Alkali Activation on Physical, Mechanical, and Chemical Properties of Clay. Materials 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Turan, C.; Javadi, A.A.; Vinai, R.; Beig Zali, R. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability 2022, 14. [Google Scholar] [CrossRef]

- Hu, B.; Hu, Q.; Liu, Y.; Tao, G. Research on the Improvement of Granite Residual Soil Caused by Fly Ash and Its Slope Stability under Rainfall Conditions. Applied Sciences 2024, 14. [Google Scholar] [CrossRef]

- Li, N.; Zhu, Q.; Wang, W.; Song, F.; An, D.; Yan, H. Compression Characteristics and Microscopic Mechanism of Coastal Soil Modified with Cement and Fly Ash. Materials 2019, 12. [Google Scholar] [CrossRef]

- Cheng, Z.; Cui, G.; Yang, Z.; Gang, H.; Gao, Z.; Zhang, D.; Xi, C. Improvement of the Salinized Soil Properties of Fly Ash by Freeze-Thaw Cycles: An Impact Test Study. Sustainability 2021, 13. [Google Scholar] [CrossRef]

| Natural water content (%) | Optimum water content (%) | Natural density (g/cm³) | Maximum dry density (g/cm³) | plastic limit (%) |

liquid limit (%) |

|---|---|---|---|---|---|

| 24.8 | 16.2 | 1.99 | 1.804 | 17.2 | 31.1 |

| Composition | CaO | Fe2O3 | SiO2 | Al2O3 | MgO | SO3 | Loss |

|---|---|---|---|---|---|---|---|

| cement | 60.2% | 3.3% | 22.6% | 6.3% | 2.3% | 1.7% | 1.0% |

| fly ash | 5.6% | 2.5% | 43% | 23% | 0.95% | 0.8% | 3.1% |

| scheme | EPS content (%) | Total curing agent content (%) | Replace proportion (%) |

|---|---|---|---|

| 1 | 0.5, 1, 1.5, 2 | 10, 15, 20, 25 | 0 |

| 2 | 0.5, 1, 1.5, 2 | 10, 15, 20, 25 | 15 |

| 3 | 0.5, 1, 1.5, 2 | 15 | 0, 15, 30, 45, 60 |

| Total curing agent content | ||

| 10% | 1768.17 | 0.41 |

| 15% | 2415.61 | 0.39 |

| 20% | 3108.61 | 0.42 |

| 25% | 3662.59 | 0.42 |

| EPS content | ||

| 0.5% | 92.96 | 429.7 |

| 1% | 79.1 | 326 |

| 1.5% | 59.5 | 358.5 |

| 2% | 51.1 | 190 |

| EPS content | ||

| 0.5% | -10.2 | 1998 |

| 1% | -8.4 | 1636.2 |

| 1.5% | -6.9 | 1408.8 |

| 2% | -5.5 | 1057.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).