Submitted:

21 October 2024

Posted:

22 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

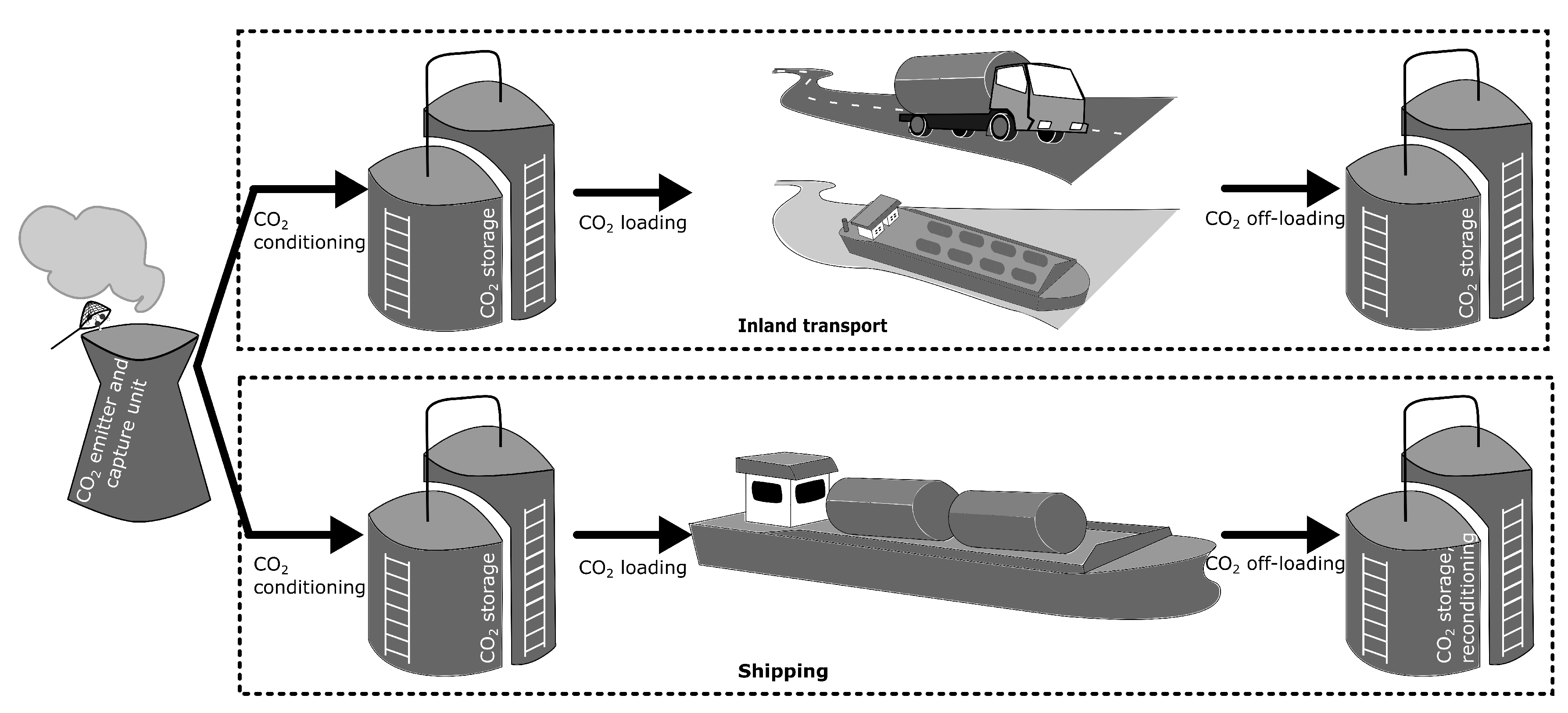

2.1. Shipping

2.2. Inland Transport

3. Results and Discussions

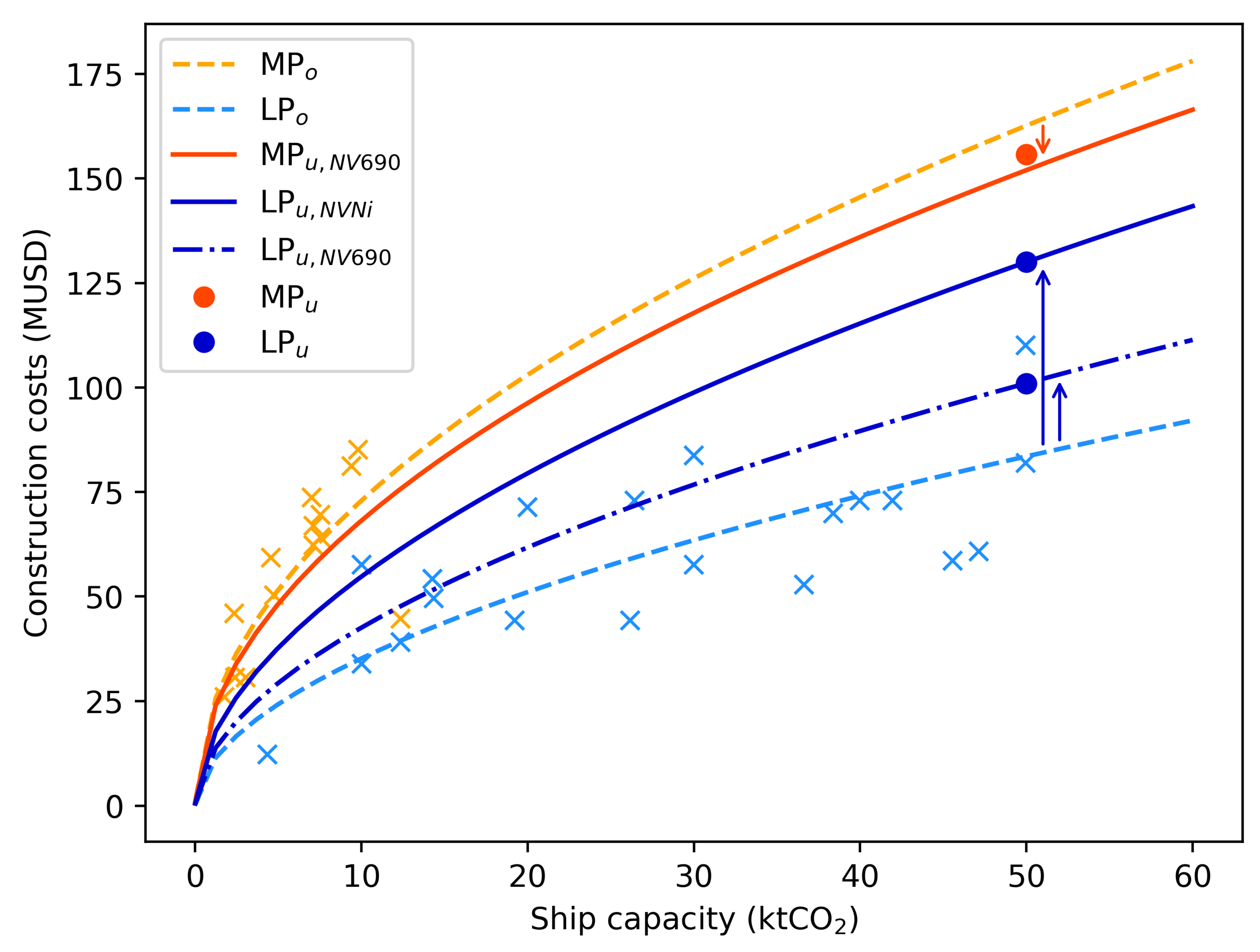

3.1. Shipping

3.1.1. Impact of Tank Material in Shipping

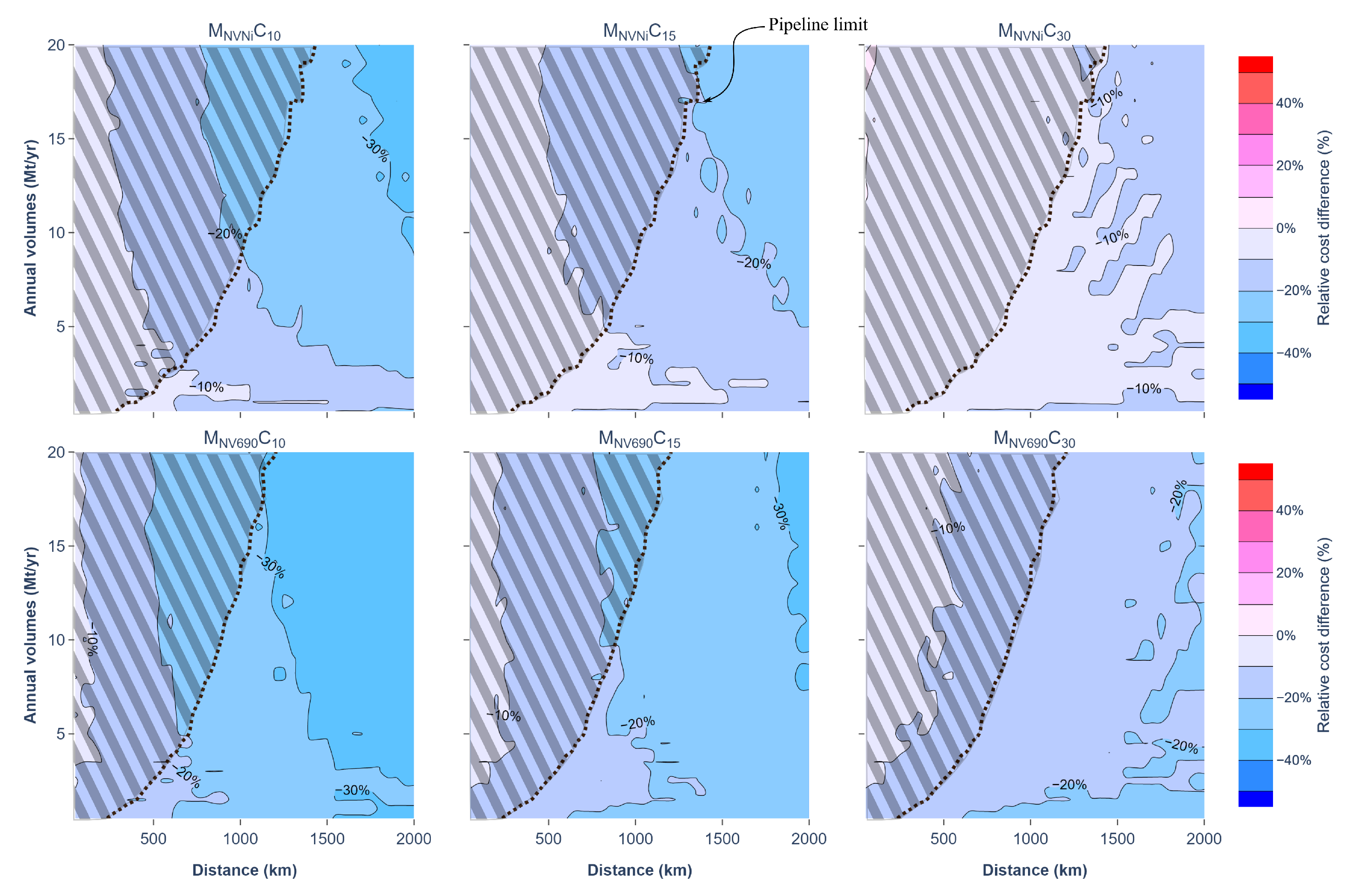

3.1.2. Impact of the Maximal Capacity for Medium Pressure Ship’s Cargo

3.2. Inland Transport

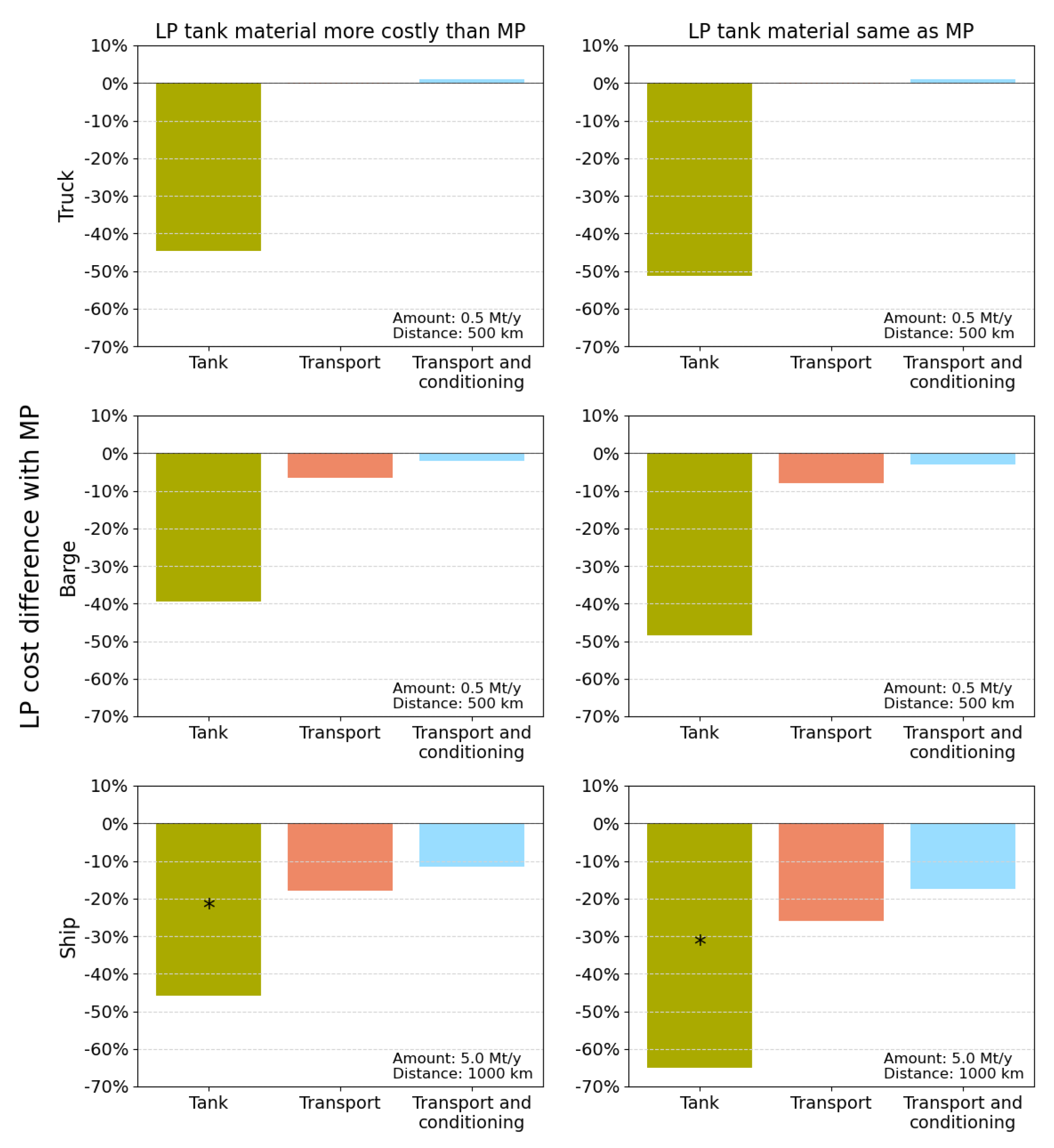

3.2.1. Truck Transport

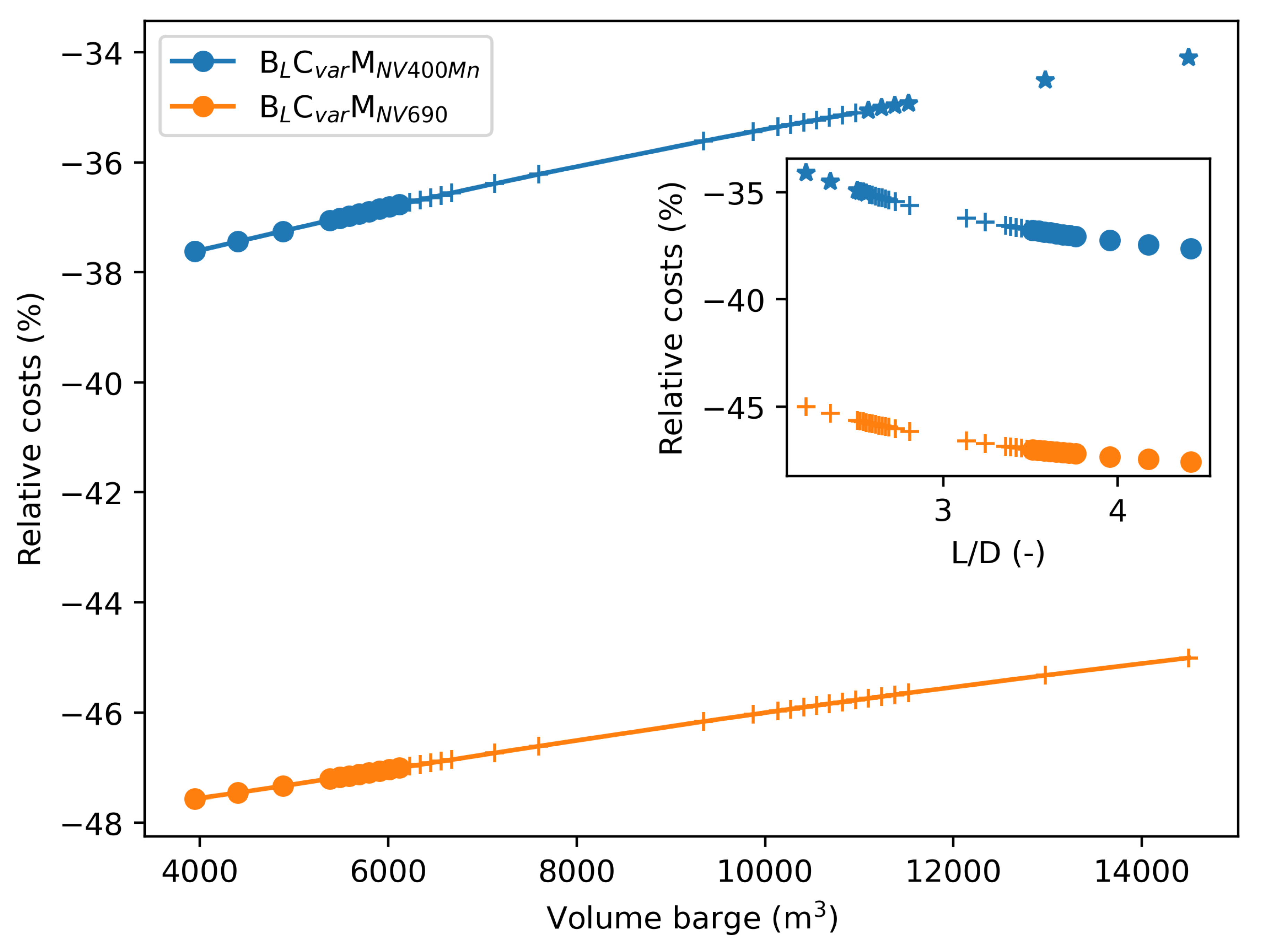

3.2.2. Barge Transport

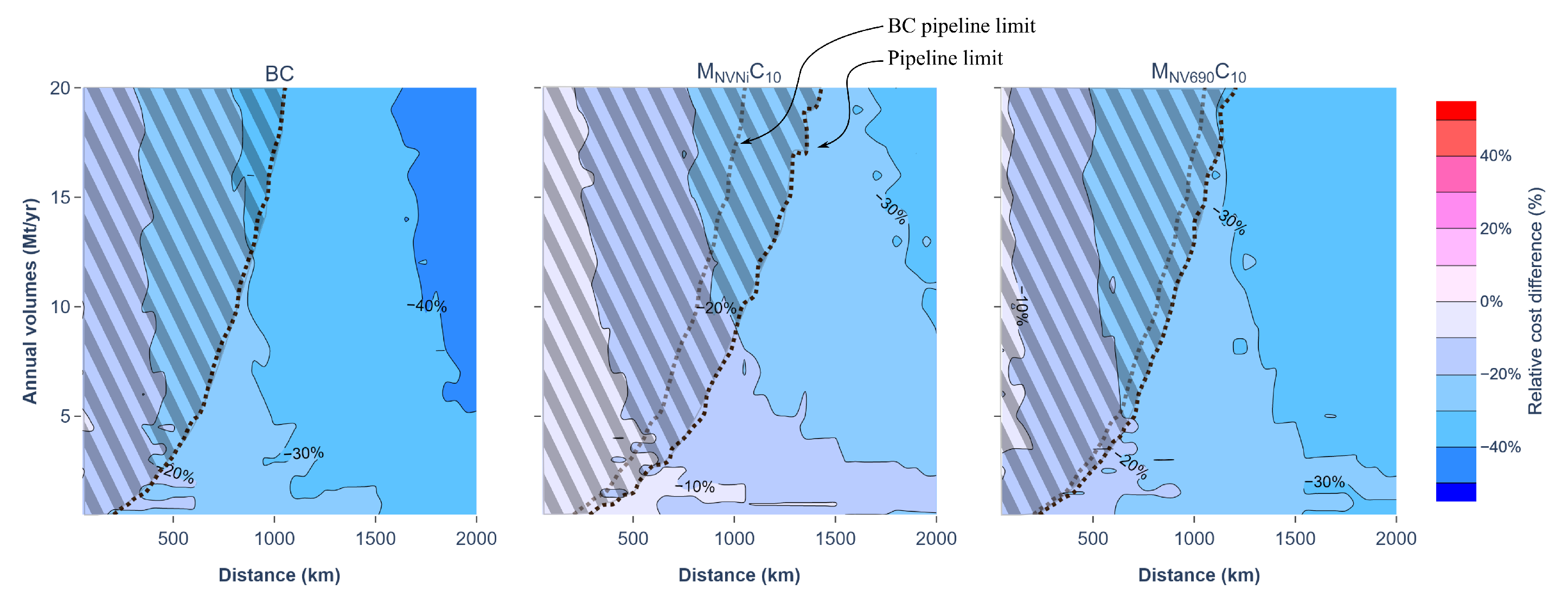

3.3. Implications on the Transport Chains from Capture to Storage

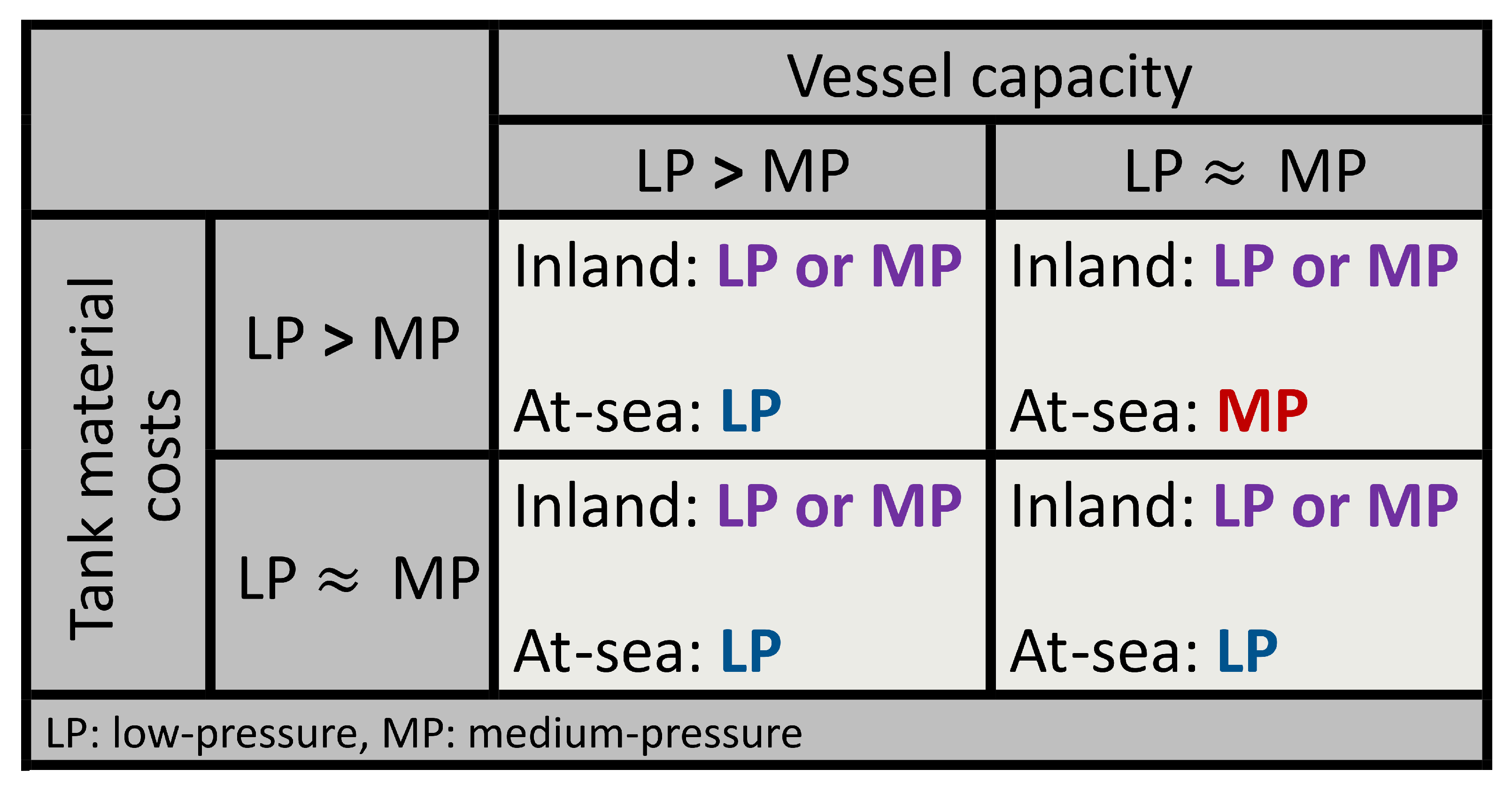

- Firstly, MP continues to be used for both at-sea and inland transport. This could be the case if large MP ships can be manufactured and cost-efficient materials for LP shipping are not qualified, or if experience with and trust in currently commercial technologies prevail over the cost reduction potential of the novel technologies.

- Secondly, both inland and at-sea tank-based transport move from MP to LP. This would correspond to a situation in which at-sea shipping moves to low-pressure due to significant cost savings and inland-based transport transitions to similar conditions to ease the overall transport integration as the transport pressure has little bearing on the cost.

- Finally, another possibility is that at-sea transport transitions to LP shipping due to the significant associated cost savings, whereas inland-based transport continues to operate at MP. This could especially be the case if different actors are involved for the at-sea and inland planning and operations or if both systems (LP at-sea and MP inland) can be smoothly integrated together.

3.3.1. Integration MP Inland and LP at-Sea Transport: How to Design Safe, Reliable and Cost-Efficient Hubs

3.3.2. Handling of Impurities in Combined Low- and Medium Pressure Transport Chains

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CCS | Carbon Capture and storage |

| EU | European Union |

| LCO2 | Liquid CO2 |

| LP | Low-Pressure |

| MP | Medium-Pressure |

Appendix A. Tank Geometry and Cost Calculations

Appendix B. Impact of Changing Tank Sizes and Configurations on the Inland Transport Assessments

Appendix B.1. Methodology

- The wall thickness of the tanks, calculated using Equation (A5), must be less than 50 mm [41].

- The minimum vapour pressure, calculated using Equation (A2), must not exceed the design pressure set to 10 and 22 bar for LP and MP tanks, respectively.

Appendix B.2. Results and Discussions

Appendix B.2.1. With Barge Capacity Constraint

Appendix B.2.2. Without Barge Capacity Constraint

References

- Butnar, I.; Cronin, J.; Pye, S. Review of Carbon Capture Utilisation and Carbon Capture and Storage in future EU decarbonisation scenarios Final report prepared for. Technical report, UCL Energy Institute, 2020.

- Budinis, S.; Fajardy, M.; Greenfield, C. Tracking Clean Energy Progress 2023. Technical report, IEA, 2023.

- Gallego Dávila, J.; Aagesen, M. How to accelerate CCS deployment in the Cement Industry? Assessing impacts of uncertainties on the business case. International Journal of Greenhouse Gas Control 2024, 137, 104197. [CrossRef]

- Kearns, A.; Liu, H.; Consoli, C. Technology Readiness and Costs of CCS Technology. Technical report, Global CCS Institute, 2021.

- Lu, G.; Wang, Z.; Bhatti, U.H.; Fan, X. Recent progress in carbon dioxide capture technologies: A review. Clean Energy Science and Technology 2023, 1. [CrossRef]

- Chowdhury, S.; Kumar, Y.; Shrivastava, S.; Patel, S.K.; Sangwai, J.S. A Review on the Recent Scientific and Commercial Progress on the Direct Air Capture Technology to Manage Atmospheric CO <sub>2</sub> Concentrations and Future Perspectives. Energy & Fuels 2023, 37, 10733–10757. [CrossRef]

- Yang, B.; Shao, C.; Hu, X.; Ngata, M.R.; Aminu, M.D. Advances in Carbon Dioxide Storage Projects: Assessment and Perspectives. Energy & Fuels 2023, 37, 1757–1776. [CrossRef]

- Coussy, P.; Roussanaly, S.; Bureau–Cauchois, G.; Wildenborg, T. Economic CO2 network optimization model COCATE European Project (2010-2013). Energy Procedia 2013, 37, 2923–2931. [CrossRef]

- Roussanaly, S.; Bureau-Cauchois, G.; Husebye, J. Costs benchmark of CO2 transport technologies for a group of various size industries. International Journal of Greenhouse Gas Control 2013, 12, 341–350. [CrossRef]

- Weihs, G.F.; Kumar, K.; Wiley, D. Understanding the Economic Feasibility of Ship Transport of CO2 within the CCS Chain. Energy Procedia 2014, 63, 2630–2637. [CrossRef]

- Roussanaly, S.; Jakobsen, J.P.; Hognes, E.H.; Brunsvold, A.L. Benchmarking of CO2 transport technologies: Part I—Onshore pipeline and shipping between two onshore areas. International Journal of Greenhouse Gas Control 2013, 19, 584–594. [CrossRef]

- Roussanaly, S.; Brunsvold, A.L.; Hognes, E.S. Benchmarking of CO 2 transport technologies: Part II – Offshore pipeline and shipping to an offshore site. International Journal of Greenhouse Gas Control 2014, 28, 283–299. [CrossRef]

- Oeuvray, P.; Burger, J.; Roussanaly, S.; Mazzotti, M.; Becattini, V. Multi-criteria assessment of inland and offshore carbon dioxide transport options. Journal of Cleaner Production 2024, 443. [CrossRef]

- Al Baroudi, H.; Wada, R.; Ozaki, M.; Patchigolla, K.; Iwatomi, M.; Murayama, K.; Otaki, T. Real-scale investigation of liquid CO2 discharge from the emergency release coupler of a marine loading arm. International Journal of Greenhouse Gas Control 2022, 118, 103674. [CrossRef]

- Chen, F.; Morosuk, T. Exergetic and Economic Evaluation of CO2 Liquefaction Processes. Energies 2021, 14, 7174. [CrossRef]

- Trædal, S.; Stang, J.H.G.; Snustad, I.; Johansson, M.V.; Berstad, D. CO2 Liquefaction Close to the Triple Point Pressure. Energies 2021, 14. [CrossRef]

- Lee, J.; Son, H.; Oh, J.; Yu, T.; Kim, H.; Lim, Y. Advanced process design of subcooling re-liquefaction system considering storage pressure for a liquefied CO2 carrier. Energy 2024, 293, 130556. [CrossRef]

- Bjerketvedt, V.S.; Tomasgard, A.; Roussanaly, S. Optimal design and cost of ship-based CO2 transport under uncertainties and fluctuations. International Journal of Greenhouse Gas Control 2020, 103, 103190. [CrossRef]

- Calvillo, C.; Race, J.; Chang, E.; Turner, K.; Katris, A. Characterisation of UK Industrial Clusters and Techno-Economic Cost Assessment for Carbon Dioxide Transport and Storage Implementation. International Journal of Greenhouse Gas Control 2022, 119, 103695. [CrossRef]

- Roussanaly, S.; Holm, S.E.; Subramanian, A. Can subsea shuttles be a cost-competitive solution for CO2 transport? Carbon Capture Science & Technology 2024, 13, 100246. [CrossRef]

- Imran Abdul-Majid.; Chris Armes.; Trevor Crowe.; Jeff Davison.; Baris Dolek.; Martin Edwards.; Kathryn Emmett.; Yunzhe He.; Jasper Heikens.; Phil Hinton.; Tomoki Inoue.; Anton Malakhov.; Clément Merat.; Stavros Niotis.; Gabriel Otaru.; Ian Phillips.; Alistair Tucker.; Luke Warren.; Matt Wilson.; Aaron Wu. Achieving a European market for CO2 transport by ship. Technical report, ZEP, 2024.

- Burger, J.; Nöhl, J.; Seiler, J.; Gabrielli, P.; Oeuvray, P.; Becattini, V.; Reyes-Lúa, A.; Riboldi, L.; Sansavini, G.; Bardow, A. Environmental impacts of carbon capture, transport, and storage supply chains: Status and the way forward. International Journal of Greenhouse Gas Control 2024, 132, 104039. [CrossRef]

- d’Amore, F.; Bezzo, F. Economic optimisation of European supply chains for CO 2 capture, transport and sequestration. International Journal of Greenhouse Gas Control 2017, 65, 99–116. [CrossRef]

- d’Amore, F.; Romano, M.C.; Bezzo, F. Carbon capture and storage from energy and industrial emission sources: A Europe-wide supply chain optimisation. Journal of Cleaner Production 2021, 290, 125202. [CrossRef]

- Frattini, L.; Becattini, V.; Mazzotti, M. Main current legal and regulatory frameworks for carbon dioxide capture, transport, and storage in the European Economic Area. International Journal of Greenhouse Gas Control 2024, 136, 104172. [CrossRef]

- Weber, V. Are we ready for the ship transport of CO2 for CCS? Crude solutions from international and European law. Review of European, Comparative & International Environmental Law 2021, 30, 387–395. [CrossRef]

- Roussanaly, S.; Deng, H.; Skaugen, G.; Gundersen, T. At what Pressure Shall CO2 Be Transported by Ship? An in-Depth Cost Comparison of 7 and 15 Barg Shipping. Energies 2021, 14. [CrossRef]

- Durusut, E.; Joos, M. Shipping CO2 - UK cost estimation study. Technical report, Element Energy, London, 2018.

- Altera Infrastructure.; Moss Maritime.; TGE Marine Gas Eng..; APL Norway.; Sevan SSP.; DNV. Stella Maris Concept Study: Climit-Demo, 2019.

- Altera Infrastructure.; Moss Maritime.; TGE Marine Gas Eng..; APL Norway.; Sevan SSP.; DNV. Stella Maris: Climit-Demo, 2020.

- Gassnova. Feasibility study for full-scale CCS in Norway Contents. Technical report, Ministry of Petroleum and Energy, 2016.

- Equinor.; Gassnova.; Shell.; TotalEnergies. Northern Lights Project Concept report. Technical report, Equinor, 2019.

- Becattini, V.; Gabrielli, P.; Antonini, C.; Campos, J.; Acquilino, A.; Sansavini, G.; Mazzotti, M. Carbon dioxide capture, transport and storage supply chains: Optimal economic and environmental performance of infrastructure rollout. International Journal of Greenhouse Gas Control 2022, 117, 103635. [CrossRef]

- Jakobsen, J.P.; Roussanaly, S.; Brunsvold, A.; Anantharaman, R. A Tool for Integrated Multi-criteria Assessment of the CCS Value Chain. Energy Procedia 2014, 63, 7290–7297. [CrossRef]

- Notaro, G.; Nyseth, H.; Torbergsen, L.E. CETO: Technology Qualification of Low-Pressure CO2 Ship Transportation. Technical report, Equinor Energy AS, Gassco AS, TotalEnergies EP Norge, Shell Global Solutions International, 2024.

- ETH Zurich. DemoUpCARMA, 2021.

- SINTEF Energy. EU Horizon 2020 Project ACCSESS, 2021.

- Sutton, I. Hazards identification. In Process Risk and Reliability Management; Elsevier, 2010; pp. 79–190. [CrossRef]

- Span, R.; Brown, A.; Tlatlik, H. Interoperable CO2 Transport Network-Towards Specifications for the Transport of Impure CO2’. Technical report, Zero Emissions Platform, 2023.

- SONKE, J.; Morland, B.; Moulie, G.; Franke, M. Corrosion and chemical reactions in impure CO2. International Journal of Greenhouse Gas Control 2024, 133, 104075. [CrossRef]

- DNV. Liquefied gas carriers. Technical report, DNV, 2016.

| 1 | |

| 2 | It is worth noting that the material used for the LP truck tanks is different from the LP ship tank. This is due to the different geometries of the tanks, making different LP materials suitable. |

| 3 | As many CO2 emitters are located far from the coast |

| 4 | As CO2 storage take place offshore due to the lack of social acceptability of onshore storage |

| 5 | This means that the tank volume was not maximized relative to the available space on the barge. |

| Scenario | Tank material scenario | Max ship capacity (ktCO2/ship) | ||

|---|---|---|---|---|

| LP | MP | LP | MP | |

| BC | UND [28] | UND [28] | 50 | 10 |

| MNVNiC10 | NVNi | NV690 | 50 | 10 |

| MNVNiC15 | NVNi | NV690 | 50 | 15 |

| MNVNiC30 | NVNi | NV690 | 50 | 30 |

| MNV690C10 | NV690 | NV690 | 50 | 10 |

| MNV690C15 | NV690 | NV690 | 50 | 15 |

| MNV690C30 | NV690 | NV690 | 50 | 30 |

| Transport | Scenario | Capacity ( | Number tanks | LP material | MP material |

| Truck | Truck | 26 t | 1 | NV400Mn | NV690 |

| Truck | 26 t | 1 | NV690 | NV690 | |

| Barge S | 3040 | 8 | NV400Mn | NV690 | |

| 3040 | 8 | NV690 | NV690 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).