1. Introduction

Artificial intelligence (AI) is changing many industries, and now has a great deal of influence on the logistics and parcel delivery industries. The complexity and amount of data that this industry needs, along with the demand for much leaner processes than in the past, have led individuals to increasingly consider AI systems. For example, transportation systems are supported with AI technology for route optimization at different levels, from route and rideshare services, to predict the exact day and time that users will receive their packages. (Hu et al., 2020).

Many new issues have also become of interest because, as AI technology progresses to address new challenges, many paradigms developed during the AI and logistics revolution have required reassessment of conventional solutions. This review seeks to provide an audience of both scholars and industrial professionals in the areas of logistics and AI with contextualized information concerning the current developments in AI in logistics. This study focuses on the use of AI in the logistics industry. The term logistics has developed and evolved tremendously in the past few years. It primarily centers on the management and integration of products, services, and information from supplier checkpoints to the consumer's doorstep. Efficient management and optimization of the logistics system throughout the supply chain are the main concerns of this enterprise. The evolution and acceptability of emerging technologies have transformed existing dynamic systems with their numerous latest applications. (Ghiani et al., 2022).

The UPS has implemented artificial intelligence technology in its logistics operations to improve its efficiency and accuracy. One example is the use of AI-powered route optimization algorithms to reduce delivery times and fuel consumption. For instance, in the logistics industry, AI has been used to predict demand more accurately, leading to better inventory management and reduced costs (Modgil et al.2022).

2. Methodology

Artificial intelligence has had a notable impact on the logistics sector as of late. Many businesses have harnessed the power of AI technology to significantly enhance their processes and increase their overall productivity. In this comprehensive article, we delve into various innovative methodologies utilized to evaluate and measure the profound influence of AI in the realm of logistics. These methodologies include in-depth case studies, thorough data analyses, and meticulous simulation models. One of the cornerstone techniques employed in the study of AI's impact of AI is the implementation of cutting-edge machine-learning algorithms. These algorithms have proven to be highly effective not only in analyzing vast amounts of data but also in providing valuable insights and predictions that optimize logistical processes. Additionally, optimization methods play a pivotal role in understanding the extent of AI capabilities in the logistics industry. By employing advanced optimization techniques, businesses can further streamline operations, reduce costs, and maximize efficiency. Another significant aspect of this study is the use of predictive analytics. This powerful analytical tool grants businesses the ability to anticipate future trends and behaviors, thereby empowering them to make informed decisions with utmost precision. The seamless integration of predictive analytics into the logistics sector has resulted in profound advancements and has revolutionized the decision-making process. Notably, recent advancements in AI technologies have indisputably transformed the logistics industry on a global scale. These advancements have not only propelled the industry forward, but have also paved the way for enhanced efficiency, cost savings, and better decision-making capabilities. The profound and positive impact of machine-learning technologies, as well as robotics, cannot be overstated. These technologies have facilitated a shift towards a more automated and efficient logistics process, thereby optimizing resource allocation and ensuring seamless operations. In conclusion, this study sheds light on the remarkable influence of artificial intelligence in the logistics sector. Through the utilization of numerous methods, such as case studies, data analysis, and simulation models, we have come to understand the extent of AI's impact on the industry. Machine learning algorithms, optimization techniques, and predictive analytics have played indispensable roles in improving efficiency, reducing costs, and enhancing decision-making abilities. The integration of AI technologies, including machine learning and robotics, has resulted in a new era of automation and efficiency in the logistics process. The future holds immense potential for AI advancements, and it is evident that this technology will continue to revolutionize and shape the logistics industry.

3. AI Applications in Supply Chain Management

The agility and intelligence that AI brings in reaction to the increasing complexity and dynamics of demand are now considered a competitive advantage for logistics. There is strong interest in the latest cutting-edge developments in AI and how they can be applied to logistics and supply chain management to facilitate and optimize their operations. Logistics has frequently been cited as an area that stands to benefit substantially from advances in AI. Here, the potential contributions of AI to logistics are explored on three levels: developing new AI techniques for logistics (M Remondino, A Zanin 2022)determining how AI can itself be treated as a logistics operation, and identifying the broader implications of AI for logistics and related problems such as pricing.

AI applications in the supply chain are divided into various areas such as demand forecasting, inventory optimization, route optimization, fleet management, and warehouse automation( DN Dwivedi -2024). In each of these areas, the current state-of-the-art and main technical approaches are presented. AI is used to build models that predict the demand by integrating a multitude of internal and external data. An AI-based approach can address this complexity and take full advantage of this wealth of information. AI also provides a way to solve classical optimization models to replenish inventories in real time after the occurrence of random events. Typically, classical models are not recalculated after each delivery. In the context of tree-based AI models, this approach leverages regularized linear models to enable rapid inference at runtime. AI has also been shown to provide significant improvements in dispatching decisions compared to rule-based approaches( SP Singh, J Rawat, M Mittal, I Kumar 2022). It trains an AI model to obtain the results of a classical modeling simulation. By contrast, AI forecasts are updated in real time and benefit from more detailed information. Finally, AI-based techniques can optimize the stock level of newly available products based on virtually any vector of customer characteristics including previously hidden or unknown characteristics. This is accomplished by training the model on a combination of a product's general characteristics and its first customers. In addition, unlike other AI models, this model directly integrates business rules directly( R Sharma, A Shishodia, A Gunasekaran 2022). In the remainder of this paper, we provide a brief overview of the classical method used in inventory management and the AI models used for each inventory optimization task.

4. Demand Forecasting and Inventory Optimization

The performance of supply chain operations is highly dependent on the quality of predictions of future demand for goods or services, which is directly proportional to the level of randomness and unpredictability of customers’ buying behavior of customers (M Seyedan, F Mafakheri 2020). With the global logistics network expanding its reach to a greater share of businesses, the task of efficient planning and coordination becomes increasingly difficult, owing to the increased uncertainty within the chain. However, the advent of artificial intelligence (AI) is steadily changing how operations are handled and managed( CC Wang, CH Chien 2021), thereby leaving a mark on the consequent effect of such advanced technologies on activities carried out in logistics. In this chapter, we focus mostly on the use of AI analytics to solve dynamic inventory problems(QS Ren, K Fang, XT Yang, JW Han 2022).

Managing inventory is critical for firms. Overinvestment may lead to poor use of available resources and affect a company's liquidity(PD Sumo, X Ji, L Cai 2023). Conversely, underinvestment may result in production and revenue losses owing to stock-out situations. The solution for performance lies in planning for an optimal investment, also known as inventory optimization(SMH Bamakan, N Faregh 2021). Because correctly forecasting demand can help organize such processes, certain decision problems have been attractive to several researchers. In the past, researchers addressed demand forecasting problems for some industries. However, few articles discuss transport and logistics forecasting; therefore, an AI literature overview in this field will examine such papers when possible. For instance, we discuss some articles on demand forecasting to demonstrate different state-of-the-art AI techniques. Cognitive techniques have been observed to be the best approach. For example, integrating an Adaptive Neuro-Fuzzy Inference System (ANFIS) with Data Envelopment Analysis (DEA) has been shown to provide more accurate results, allowing improved business decisions (A Puente-Castro, D Rivero, A Pazos2022).

4.1. Route Optimization and Fleet Management

An increasing number of artificial intelligence (AI) algorithms and tools have been developed to calculate the best delivery routes given local traffic congestion patterns. Logistics companies use available tools to manage their fleets more efficiently, reduce fuel expenses, and reduce the overall cost of the logistics supply chain. Route optimization is defined by reducing the time and cost required to deliver goods, which in turn can potentially increase customer satisfaction(K Meduri, GS Nadella, H Gonaygunta 2023). The authors combined the decision tree and optimization algorithms tailored for logistics, such as genetic algorithms, to develop an optimization model that many logistics companies are currently using. Develop a classical intelligence algorithm that can organize big data. This algorithm has been used for many years to develop a route optimization tool for logistics companies(P Nowakowski, K Szwarc 2020).

The largest proportion of logistics costs are associated with transportation; therefore, there is an urgent need for research in logistics engineering. Supply Chain Management encompasses planning and optimization solutions as important components for successful logistics processes, and one of the most frequently addressed and high-impact solutions is transportation planning(M Jalolova, L Amirov, M Askarova 2022). In general, Fleet Management refers to managing a fleet of motor vehicles such as cars and planes. Effective Fleet Management can optimize the actual costs of logistics operations, thereby reducing both fuel consumption and vehicle wear. Road freight transportation costs are also increasing. Routing algorithms can solve the road freight transportation problem quickly, and the paths they determine can help manage fleets and resize delivery routes. Investigate the influence of three variables: 4PL/2PL partnership in logistics, use of route optimization solutions, and fleet management (task assignment) in logistics management(M Hurskainen, J Ihonen 2020). found that the total number of computations increases linearly with problem size (numbers of products and order locations). Package, product, order, and resource capacity in logistics networks have a moderately positive influence on the number of physical evaluations of delivery solutions. The strength of evidence against the null hypothesis is moderate to confirm that fleet management under the linear-division operating condition is faster than that under the linear-trained operating condition. Software diagnostics are used in operation(A Gohar, G Nencioni 2021).

4.2. Warehouse Automation:

AI is revolutionizing warehouse and distribution center operations, enabling organizations to streamline shipping and receiving functions and minimize the clerical and throughput time associated with both processes(V Antonoglou 2022). Advanced robotics is making inroads in warehouse automation, and various reports have indicated that robots are responsible for transporting a parcel between 25% and 75% of the distance required to fulfill an order in e-commerce fulfillment centers. In addition, companies are developing robots that can pick and pack items from warehouse storage to help in the order fulfillment process(B Himstedt, F Meisel 2023). A recent development is the distribution of machine learning to edge devices, which enables them to make decisions much more quickly without having to connect to the cloud. This reinforcement of machine learning systems has been used in pick-by-robot systems to decrease the cost of latencies and improve picking times by an average of 5% and a maximum of 20%( H Kalkha, A Khiat, A Bahnasse, H Ouajji 2023).

Firms also remain interested in more traditional types of robots, particularly drones, for the optimization of supply chains and logistics. Research is converging towards the aim of using teams of drones for warehouse management tasks rather than singular drones, both through path optimization and management tasks such as cycle counting(A Rejeb, K Rejeb, SJ Simske 2023). Developments in AI-driven inventory management have emerged. Recently, authors have proposed an AI-driven inventory management model based on reinforcement learning that prefers items that have higher velocity or items to be restocked imminently over those that have not yet been restocked, leading to better replenishment performance in certain situations. Much of the academic work in inventory management focuses on the impact of the accuracy of AI and machine learning models on the supply chain, rather than specifically the use of AI for inventory management(A Rhiat, L Chalal, A Saadane 2022).

5. AI in Last-Mile Delivery

The final delivery stage of the logistics chain is called last-mile delivery. Many consider last-mile delivery the most necessary, expensive, time-consuming, and complex part of the supply chain. Enabling last-mile deliveries has also become a significant issue with the rapid growth of e-commerce (F Borghetti, C Caballini 2022), while it allows sellers to reach a larger number of consumers during lockdowns and social distancing. This has put logistic companies in a very tough spot, as they must adhere to social distancing as well as fulfill orders at the same time. In such a situation, it becomes important for them to explore all types of support technologies and systems, such as those run on AI, which would help them complete their services faster and more efficiently (M Suguna, B Shah, SK Raj, M Suresh 2021).

The AI industry has provided logistics companies with many different kinds of tools over the years that have been revolutionizing their operations. It has helped them take on difficult challenges, such as those concerning last-mile delivery. AI solutions, for example, applying machine learning, streamline route scheduling processes. AI tools help logistics companies gather and analyze data loads over a period (DN Dwivedi 2024). This includes every step that a product takes from the first mile it covers in the supply chain to the end of delivery. The data at every stage were collected and analyzed in near real time to ensure that all nodes were operating optimally. This includes checking the movement of goods and their storage. AI tools are also directing how goods are handled in the warehouse and what needs to be dispatched to satisfy real-time demands(M Khadem, A Khadem, S Khadem 2023).

6. AI in Freight Transportation and Shipping

Freight transportation. Data-driven AI algorithms support logistics companies in streamlining and optimizing day-to-day freight operations(DN Dwivedi 2024). Research projects use reinforcement learning, a subfield of AI, and work with real-world data to evaluate action policies for routing trucks to picking stations and orchestrating the picking process. The approximation of optimal strategies with AI is challenging because route planning, dispatching trucks, and the picking process are combinatorial optimization problems that are difficult to solve in large instances. It is equally challenging to assess the effectiveness of AI algorithms using partial or full simulations. Addressing these challenges paves the way for industrial adaption and changes in the framework of operational transport logistics(P Whig, A Velu, RR Nadikattu 2024).

Shipping logistics. Autonomous shipping, or intelligent ships, is a concept that drives the need for advanced autonomous navigation systems. Autonomous ships equipped with AI can transform the shipping industry and trade logistics(M Riyadh 2024). Workshops and industry events emphasize the need for data sharing within logistics to improve the sustainability of transport operations. In the context of container logistics, data collected by different stakeholders (shippers, carriers, terminal operators, and forwarders) are leveraged to solve some of the significant challenges that current transportation companies face. For instance, carriers can use predictive analytics to optimize the allocation of shipments to ships and inland transport modalities, while IoT data provide transparency and predictability concerning supply delays through route optimization and monitoring safe delivery conditions. Addressing these challenges in cargo handling is the first step toward fully realizing autonomous shipping(Y Ichimura, D Dalaklis, M Kitada 2022).

7. AI in Reverse Logistics

Introduction:

The Role of AI in Reverse Logistics:

Reverse logistics refers to the management of product returns, including returns for transactions, end-of-life product returns, and recalls. In practice, the increasing use of e-commerce has accelerated the demand for intelligence-based support for managing reverse logistics. Customers generally expect free and easy product return. In June 2020, Narvar found in a survey that 96% of consumers said that the returns process changed how and where they shop for products(K Lysenko-Ryba, D Zimon 2021). The fifth UPS eCommerce Returns Study in March 2021 discovered that UPS assisted a record of 2.5 returns per second in 2020, more than 80 million returns in peak week alone. Innovations in using AI for reverse logistics have been reported for handling a peppier return process for individual customers and managing product recalls. Owing to the omnipresence of reverse logistics, the contribution of AI is broad. Post, Schure, Aftergut, and Sarvary examined which consumer products are returned the most and why. They found that approximately 70% of the customer returns cannot be sold at full price once the item is put back on the shelf, resulting in the need to sell the item at clearance price, process it for resale, dispose of it, or donate the item(S Saxena, V Chawla, J Tähtinen 2022).

Isik, Guide, and Hazzard built on this approach and offered an overview of reverse logistics practices, modeling, and applications, including e-commerce return management. AI for reverse logistics is concerned with improving operational efficiency, operational sustainability, and technology support for product recalls. Product recall is connected to reverse logistics, and Dempsey empirically examined big data-driven monitoring of product recalls with AI(M Javaid, A Haleem, RP Singh 2022). Balakrishnan et al.. reported strategies to improve the sustainability of reverse logistics in agri-food supply chains. Xie et al.. studied the balance between economic and environmental goals in material reuse during reverse supply chain operations and showed how AI can be used to ensure no goals for the mass of the retained material. In our review, we survey recent developments in AI in logistics with a thematic section organized according to various aspects of the logistics industry. In this paper, we discuss findings related to reverse logistics.

8. Benefits of AI in Logistics

The need for ever-faster, customer-oriented delivery services, shipping, and inventory management systems is given today(M Sullivan 2021). AI is powering logistics teams to develop innovative methods with the help of robotics, automating complex processes, and designing intelligent transportation and freight management systems to address these challenges. Use scenarios stretch from the planning of the best pricing and route optimization to predictive maintenance. This leads logistics decisions towards a more demand-driven approach. With the declining costs of technology and the advent of AI, logistics platforms have access to tremendous throughput and storage capabilities(F Firouzi, B Farahani, M Daneshmand 2021).

In this direction, Hackl et al. conducted a case study based on a tool that helps shippers optimize routes and prevent unnecessary accruals in the taxes they must pay. Belopoulou et al. introduced a decision support tool that applies to the domain of geographic information, focusing on the transport of people with special needs using conventional rail. Their research aimed to optimize train movement in the framework of a public transportation system, and it characterized users by various types of reduced mobility onboard the train. AI offers many opportunities to improve operational effectiveness. The effect of combining human labor or cognitive technologies, such as robotics and AI, is an order of magnitude higher. In logistics, the application of AI increases efficiency, generally reduces operational costs, and streamlines the decision process owing to accurate operational status detection and careful planning in the sense of proactive problem resolution(AK Tyagi, SU Aswathy, A Abraham 2020).

8.1. Increased Efficiency and Cost Savings

One of the predominant benefits related to artificial intelligence applications in logistics is increased operational efficiency and the resulting cost savings. Many AI-based technologies analyze large volumes of data related to state-altering events in the supply chain, resource utilization, or shipment status; inform about these events; and drive alerts or take action. Through predictive analytics, managers are informed of what the next step is to keep the business running smoothly(A Dhaliwal 2022). For example, artificial intelligence technology embedded in a transport management system (TMS) or yard management system (YMS) can automatically suggest and select the most efficient carrier for a given move, seek a backhaul given a picked delivery, and propose an efficient pick-up from a nearby node by another company’s assets. Importantly, AI-optimized pick-ups and deliveries maximize the load utilization of the truck used, thereby reducing logistical expenses. AI can suggest the fastest and cheapest delivery method based on the order requirements and available resources. This results in not only cost savings and satisfied customers but also resource savings through efficient resource utilization. Moreover, AI helps companies in decision-making processes; for example, it finds the most profitable route based on the traffic status or fuel cost.

Combining IoT with AI to improve SCM processes results in better performance, as well as cost and time savings. For instance, AI-powered IoT-enabled supply chain management systems with real-time tracking, tracing, and monitoring (TT&M) capabilities for both products and vehicles allow their users to detect goods that are about to spoil earlier than ever. Consequently, managers can prevent potential goods from spoilage or waste at the earliest possible stage.

8.2. Enhanced Decision-Making and Planning

Enhance Decision-Making and Planning

One of the fields most significantly impacted by advances in AI is decision making. AI tools provide logistics managers with predictions and forecasts that can be used to improve business decision-making. This is addressed in the context of strategic and tactical planning. AI's predictive power has been harnessed in a wide range of areas, including demand forecasting, lead-time prediction, and transport planning, and so on(A Belhadi, S Kamble, S Fosso Wamba 2022). AI is expected to contribute to improvements in other areas such as network design, inventory planning, and the design of products, services, and logistical systems. In addition to decision support systems, AI tools are currently being developed to support real-time decision making in logistics. While today, human managers develop and assess different scenarios and make choices, AI systems or people supported by AI are expected to make some of these decisions in real time as a key input to process automation(M Woschank, E Rauch, H Zsifkovits 2020).

While these technologies can bring about performance improvements for individual firms, the main driver behind this development is the large-scale analysis enabled through these techniques, combined with the ability to efficiently integrate various data sources. The results are solutions that can cope more adequately with the high uncertainty, dynamic behavior, and nonlinearity encountered in logistics and provide a better fit to the requirements of complex, dynamic systems such as supply chains. By providing tools to support the analysis of large volumes of unstructured data, AI can enhance the competitiveness of its users. In the context of logistics, AI, especially in the form of Big Data analytics, can support improved decision-making at operational, strategic, and tactical levels. At the operational level, AI can support more efficient responses to demand dynamics, machinery and tool wear, and planning and process operations. Financial transactions, real-time routing solutions, and fleet and crew management in transport are typical use cases where AI finds broad applications. In logistics distribution centers, AI solutions developed for traffic management, predictive maintenance, and staffing are expected to become more important by 2020. In the next five years, logistics companies are expected to integrate AI applications for improved risk management, analyze new partnerships for increased value generation, forecast the lifetime of assets, and optimize their response to chain disruptions and demand variabilities. In freight markets, AI-supported tools will allow for more accurate pricing, carriers to identify potential shippers, and all users to make better decisions about orders and shipments. Artificial intelligence can support the flow of goods by providing real-time insights and supply chain control. Supply chain finance has increased visibility and reduced concerns. At the strategic level, AI contributes to tactical decision making in warehousing, retail, and end-to-end supply chains. Staff management and service improvements are the key areas of focus. Predictive logistics increases the "intelligent" responsiveness of the logistics networks. The benefits of AI-based predictive analytics in logistics centers on customer satisfaction and a reduction in delays and costs. Warehousing, roads, and railways will see an increase in the use of AI for the predictive maintenance of their assets and staff rostering processes. Co-modal door-to-door logistics, co-modal freight, traceability, and transparency of supply chains are seen as beneficiaries of this technology(O Allal-Chérif, V Simón-Moya, ACC Ballester 2021).

9. Challenges and Limitations of AI in Logistics

The efficient uptake of AI technologies in logistics may be impeded by a multitude of factors at various levels. First, there is the issue of data security and privacy, which are frequently cited as the main obstacles impeding the efficient deployment of AI in logistics and other areas. Ensuring the safety and security of data is particularly critical in logistics, where technology often manages information that is crucial for the business, and whose leakage or loss might have significant consequences(T Sobb, B Turnbull, N Moustafa - Electronics, 2020). Given the importance of data protection in logistics, it is not surprising that some companies prefer "homemade" data management solutions, thereby safeguarding sensitive information and minimizing the chances of cyberattack.

Yet another issue that deserves consideration is the lack of knowledge and experience concerning new AI tools, such as machine learning (ML), deep learning (DL), or natural language processing (NLP). While numerous studies confirm the positive effect of implementing AI algorithms, such as predictive algorithms or recommendation engines, into supply chain processes, logistics operators do not seem to be eager to invest in properly trained analysts. Compatibility between AI technologies and older technologies is yet another issue. The road to the total replacement of outdated logistics systems is long, and what is seamless to implement in a start-up may be unachievable for an enterprise relying on legacy systems. Research suggests that the incompatibility between artificial general intelligence and specific legacy systems is a major obstacle to the uptake of AI(LS Iyer, 2021).

9.1. Data Security and Privacy Concerns

Although the potential benefits of AI for the logistics sector are significant, several concerns must be addressed before organizations are prepared to roll out these types of applications on a larger scale. Data security and privacy are important points of study. In particular, the logistics sector holds a vast amount of data on cargo, fleet movements, and delivery processes, making it a lucrative market for cyberattacks. Major logistics companies are increasingly targeted by data breaches, such as DHL, XPO Logistics, and Kuehne+Nagel, as they become more technologically enabled and could also become more vulnerable(X Xu, Y He -, - Taylor & Francis 2024).

Moreover, if personal data are handled by AI systems, companies will have to navigate new data protection regulations, such as the General Data Protection Regulation (GDPR), which is in place in the EU. This is especially true as the capabilities of AI improve and systems tend to make use of more personal data for riskier use cases. Furthermore, the use of personal data can be seen as unethical, as AI consumer shipments can reveal sensitive information about recipients, even if it is not a standard practice to look beyond the overall movement of freight. One study suggests that people usually dislike the use of AI for data collection and categorization, especially if that data could be used to infer their characteristics and a personal Magnetic Machine Learning algorithm is used(C Kuner, L Bygrave, C Docksey, L Drechsler – 2020).

9.2. Integration with Legacy Systems Enlarged

A further obstacle for both technologies discussed above, and more generally AI-driven implementations, relates to the question of interoperability(A Dhaliwal, 2022). Are well-established systems in logistics compatible with these innovative technologies or do we have to replace a completely established system (other than a part with a more efficient one)? This is not just a question of running them parallel, but involves multiple issues beyond simple system compatibility, such as data and workflow integration, integration of different cultural aspects, machine interfacing, and the associated training needs.

The conversion process is also a significant issue. While it is already quite complex to design algorithms more efficiently than, or even as efficient as, human beings, the process of moving to a completely new system that has different workflows and underlying logic, and which is as reliable as known systems, requires careful planning and design. The shift from known and functioning systems towards AI-driven systems or even just adding these technologies may create significant logistic complexities, from lost goods to an interrupted workflow, and therefore, large fines. This also poses questions about ongoing legal questions that remain open, about whether and how known principles such as workers' rights and protection apply in a context in which we move towards a labor-friendly substitution(I Ramasamy, S Natarajan 2024).

10. Future Trends and Innovations in AI for Logistics

Logistics represents a part of the supply chain in which goods are delivered from a manufacturer or supplier to a customer. AI applications in logistics usually focus on demand forecasting, route optimization, warehouse and inventory management, and last-mile delivery. This study aimed to identify future trends and potential innovations regarding AI applications within logistics(WC Hu, HT Wu, HH Cho, FH Tseng 2020). Further research should concentrate on AI in customer service operations, freight traffic management, and predictions of carriers' and transport indications based on AI. The evolution of datafication and digital transformation has motivated and enabled the application of AI to logistics. In the future, we predict continued developments in AI capabilities, including a growing range of AI applications, further integration throughout the supply chain, and potential collaborations between both AI and logistics companies(EA Abaku, TE Edunjobi 2024).

Several companies are currently involved in the development of cutting-edge innovations with the potential to revolutionize the future of artificial intelligence (AI) in the logistics industry. As AI continues to play an increasingly important role, we anticipate greater emphasis on stringent validation processes to ensure that its deployment is authorized and adheres to the highest standards. Moreover, blockchain technology is rapidly gaining momentum and holds significant promise in the field of AI(H Allioui, Y Mourdi 2023). The potential impact of blockchain on the future of AI in logistics was closely monitored and evaluated. Advancements have been made in AI, particularly in the field of advanced deep learning techniques. Algorithms such as the encoder-decoder, attention mechanism, and transformer networks are being extensively explored, opening up a vast array of innovative applications in the field of logistics. Furthermore, transfer learning, which is a rapidly evolving concept, is gaining popularity and sophistication. This has the potential to enable the development of AI models capable of solving multiple logistics tasks simultaneously, further enhancing the efficiency and effectiveness of logistics operations. In the transportation and logistics sectors, extensive research is being conducted on autonomous transportation technologies to refine and establish detailed plans for the development and implementation of autonomous delivery systems. The goal is to create a seamless and efficient autonomous delivery system that can operate with minimal human intervention, ensuring the smooth and timely delivery of products. In addition to autonomous technologies, conversational agents and intelligent voice assistants (TVS) have emerged as promising tools for understanding customers' needs and expectations. By leveraging natural language processing and artificial intelligence, these conversational agents can interact with customers, analyze their requirements, and efficiently provide them with the right products at the right time and place, thereby enhancing overall customer satisfaction and streamlining the logistics process(G Duft, P Durana, 2020).

Empirical studies:

Practical Case: AI Optimization in Logistics

The combination of Artificial Intelligence (AI) and Internet of Things (IoT) technologies in the logistics sector is expected to result in significant advancements in supply chain management and operational effectiveness. The implementation of AI will lead to a notable improvement in predictive maintenance capabilities, ensuring proactive maintenance and reducing unexpected breakdowns(T Zonta, CA Da Costa 2020). Furthermore, the use of AI will enable more efficient route optimization, leading to streamlined, cost-effective, and time-efficient logistics operations. The fusion of AI and IoT is poised to transform the logistics industry, resulting in greater precision, flexibility, and efficiency. The integration of autonomous vehicles and AI algorithms will further enhance the efficiency and reliability of supply chain operations, resulting in cost reduction and improved customer service. In addition, AI has the potential to enhance supply chain visibility and optimize inventory management(A Theissler, J Pérez-Velázquez, M Kettelgerdes 2021).

A significant future trend in AI for logistics is the use of predictive analytics to optimize inventory management and demand forecasting. This allows companies to anticipate customer needs better and reduce excess inventory. In addition, AI can optimize transportation routes and delivery schedules, leading to more efficient operations.(OS Joel, AT Oyewole, OG Odunaiya 2024).

For example, autonomous vehicles and drones can revolutionize last-mile delivery, thereby reducing carbon emissions and traffic congestion. In addition, AI-powered predictive maintenance can help minimize downtime and optimize the efficiency of logistics operations.

Another emerging trend in AI for logistics is the integration of autonomous vehicles and drones for last-mile delivery, which has the potential to revolutionize the efficiency of supply chain operations. This technology can help reduce delivery times and costs, and improve overall customer satisfaction.

Furthermore, AI can be implemented to enhance predictive maintenance and reduce the risk of unexpected downtimes for vehicles and equipment(I Nurgaliev, Y Eskander, K Lis, 2023).

I will explore several real-life examples that illustrate the significant influence of AI on supply chain management. Amazon's utilization of sophisticated AI algorithms to optimize delivery routes and reduce operational costs represents a major shift in the field of logistics. The incorporation of artificial intelligence has substantially improved productivity and streamlined operations. (Sorooshian et al.2022).

FedEx is another company that has integrated AI technology into its supply chain management system, leading to increased efficiency and lower costs. An instance of FedEx's implementation of AI in supply chain management is the use of predictive analytics to forecast demand and optimize delivery routes.

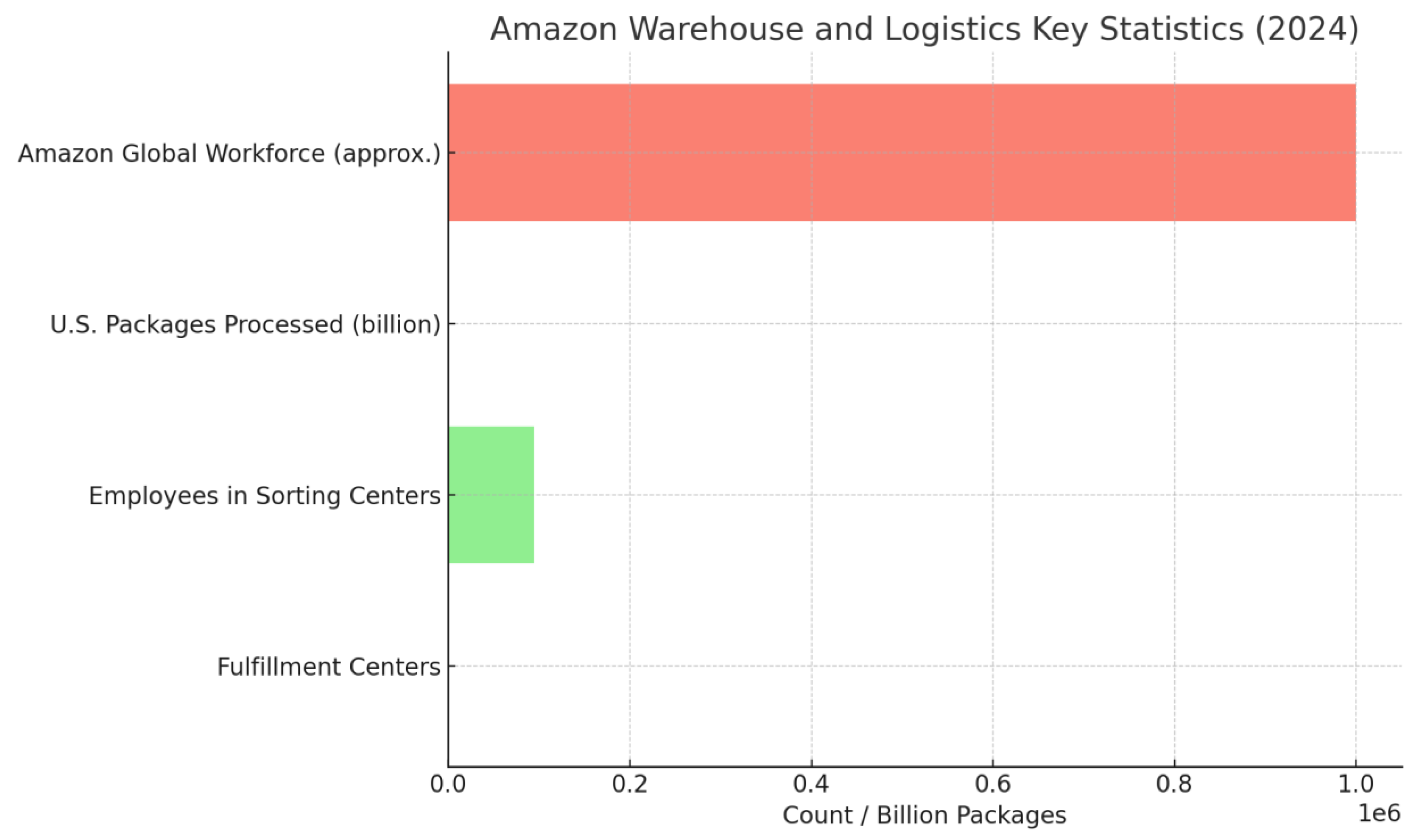

Amazon Warehouse and Logistics Key Statistics (2024):

The

Figure 1 illustrates crucial data on Amazon's warehouse and logistics activities, such as the number of fulfillment centers, staff in sorting centers, packages handled in the U.S., and the worldwide workforce linked to logistics.

These data are significant in comprehending the size and operational capability of Amazon's logistics system, pertinent to conversations regarding AI incorporation into logistics. Statistics display Amazon's expansive logistics network, which supplies substantial infrastructure for the application of AI and automation technologies to further enhance its operations. (SHAIJU, 2023)

Amazon's global logistics workforce, estimated at around one million, is the dominant feature of the graph, illustrating the massive scale of the company's operations. The 21.7 billion packages processed in the U.S. underscore Amazon's substantial presence in the shipping and logistics market, highlighting the need for advanced logistics systems. The 95,000 employees in sorting centers play a key role in Amazon's logistics chain, but their numbers are relatively small compared to the global workforce, indicating a reliance on automation and AI for managing the workload. While 175 fulfillment centers are fewer in number compared to other metrics, they are crucial nodes in Amazon's logistics network. The diagram reveals an efficiency disparity between the fulfillment centers and workforce, as well as the potential for AI and automation to optimize operations. Despite the effective display of category distribution on the chart, the overwhelming value for the global workforce may overshadow other important statistics, potentially leading to skewed interpretation.

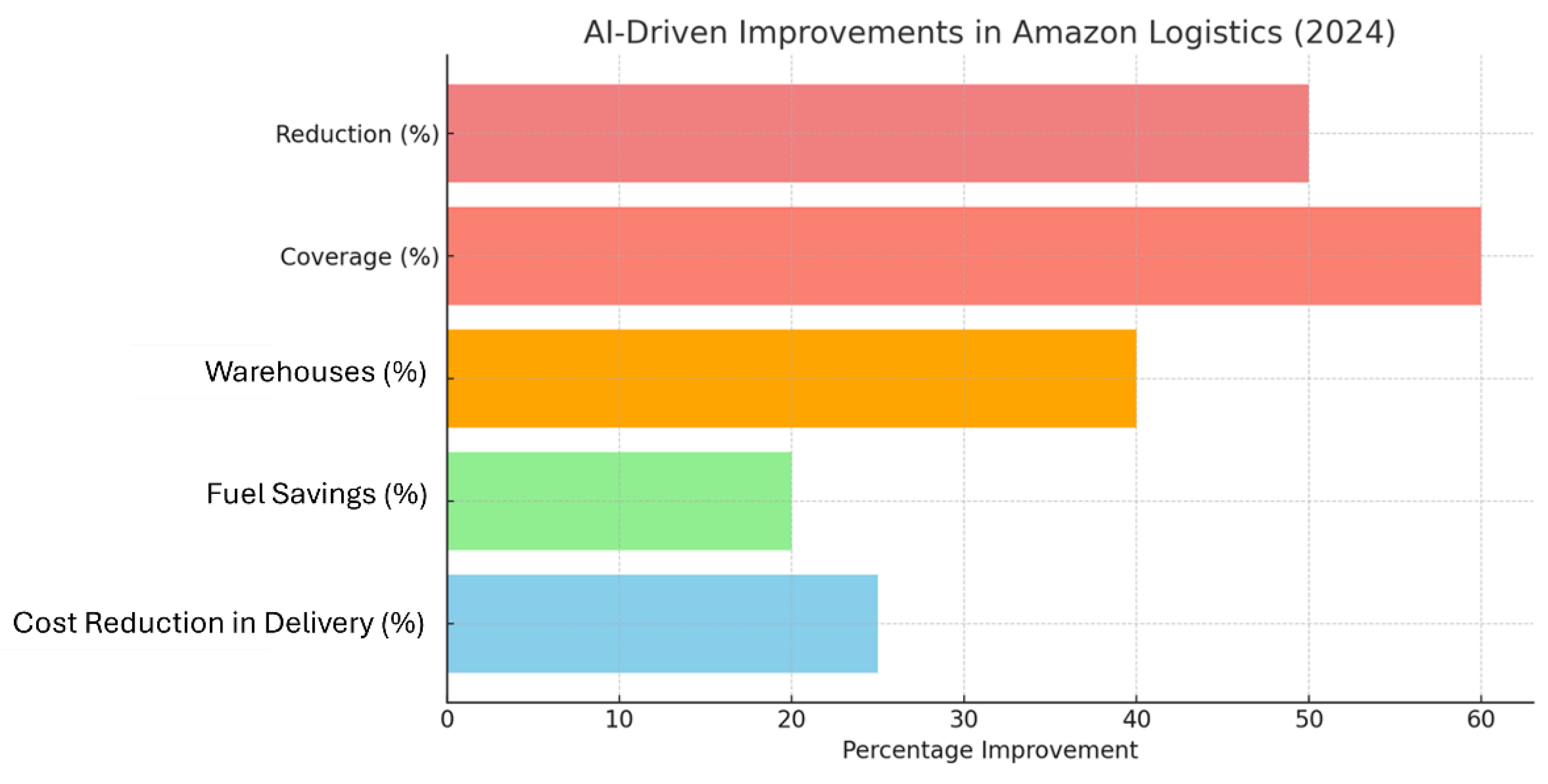

AI-Driven Improvements in Amazon Logistics (2024):

This diagram shows the effects of incorporating AI-driven enhancements into Amazon's logistics operations. These enhancements result in cost reductions, fuel savings, increased productivity, expanded delivery coverage, and shorter package-processing times.

1. Cost Reduction in Delivery: Utilizing AI algorithms has led to the optimization of delivery routes, resulting in a decrease in delivery costs by as much as 25%, particularly because of the ability to predict traffic and make dynamic adjustments to routes.

2. Fuel Savings: AI-driven fleet optimization has led to fuel consumption savings of up to 20%, particularly with the growing use of electric vehicles.

3. Productivity Improvement in Warehouses: Implementation of AI-powered robots and machine learning systems has increased warehouse productivity by 30-40%, significantly accelerating operational processes.

4. Same/Next Day Delivery Coverage: Around 60% of prime orders are now delivered on the same or the next day, largely attributed to AI optimization in route planning and inventory management.

5. Package Processing Time Reduction: AI algorithms reduce the time required to process customer orders by up to 50%, resulting in expedited deliveries and enhanced operational efficiency. (Soori et al., 2023).

AI in Amazon Logistics: Benefits vs. Challenges (2024):

The illustration below outlines a juxtaposition of the advantages and obstacles associated with incorporating AI into Amazon's logistics functions. Although AI has yielded substantial benefits in terms of reducing costs, enhancing productivity, and improving delivery efficiency, there are also hindrances related to safeguarding data, integrating existing systems, and adapting the workforce.

Figure 3.

AI in Amazon Logistics: Benefits vs. Challenges (2024).

Figure 3.

AI in Amazon Logistics: Benefits vs. Challenges (2024).

1. Cost Reduction in Delivery (benefit): Optimization algorithms powered by AI have resulted in a reduction in delivery costs by up to 25%, leading to substantial savings, particularly in terms of fuel consumption and effective vehicle usage.

2. Fuel Savings (Benefit): Fleet optimization has contributed to a 20% decrease in fuel expenses, particularly with Amazon's move towards electric vehicles.

3. Productivity Improvement in Warehouses (benefit): Robotics powered by AI boosted warehouse productivity by 40%, automating tasks, such as sorting and packing.

4. Same/Next Day Delivery Coverage (Benefit): AI ensures that almost 60% of prime orders in major cities are delivered on the same day or the next day.

5. Package Processing Time Reduction (Benefit): AI algorithms reduce package processing time by half, enhancing efficiency by 50%.

Challenges:

1. Worries about Data Security and Privacy: AI systems that handle large amounts of sensitive data raise concerns about potential breaches and privacy violations.

2. Complications and costs of integrating AI with legacy systems: Integrating AI with older logistics infrastructure can be complex and expensive, posing a significant challenge.

3. Significant Initial Investment in AI Technologies: Implementing AI involves substantial upfront costs, including acquiring advanced hardware and software.

4. Workforce Displacement and Skills Gap: Automation may displace workers, and there is a growing need for qualified personnel to effectively manage AI systems. 5. Ongoing Maintenance and Upgrades of AI Systems: AI systems require ongoing monitoring, updates, and maintenance, which can strain the resources. (Wan et al.2020).

Discussion

The integration of artificial intelligence (AI) into the logistics industry has led to substantial changes in business operations, resulting in enhanced efficiency, cost savings, and overall operational performance. This article examines the various ways in which AI is utilized in logistics, with a focus on critical areas such as demand forecasting, inventory management, route optimization, and fleet control. Of particular note is AI's impact of AI on demand prediction and inventory management, which has been highly beneficial in accurately forecasting consumer needs, enabling companies to maintain optimal inventory levels and ensure a seamless supply chain. The adoption of AI-driven prediction models has empowered businesses to make well-informed decisions, with notable success stories from companies such as Amazon and FedEx resulting in tangible improvements in efficiency and cost reduction. Additionally, AI's influence of AI on transportation, particularly in route optimization and fleet management, is of utmost importance. AI algorithms are now capable of analyzing traffic patterns and delivery schedules to identify the most efficient routes, thereby reducing fuel consumption and delivery times, which are essential for logistics companies in a competitive environment where timely and precise deliveries are crucial for customer satisfaction. The use of autonomous vehicles and drones for last-mile delivery underscores AI's potential of AI to transform the industry, offering significant reductions in labor costs and improved delivery accuracy. Warehouse automation, another critical area enhanced by AI, has also undergone substantial advancements. AI-powered robots and systems have been implemented to streamline tasks such as sorting, picking, and packing, minimizing errors, increasing throughput, and reducing operational costs, particularly in large-scale operations such as e-commerce fulfillment centers. However, the widespread adoption of AI in logistics presents challenges, including concerns about data security and privacy, difficulties in integrating AI with legacy systems, and shortage of skilled personnel trained in AI technologies.

Conclusion

In recent years, the integration of Artificial Intelligence (AI) into logistics has revolutionized the way supply chains operate, leading to increased efficiency and cost savings. The use of AI applications, such as forecasting demand and automating warehouses, has helped companies meet modern supply chain requirements. Case studies revealed that the adoption of AI has resulted in quicker deliveries, reduced costs, and more satisfied customers. However, there are challenges to address, including data privacy, integration with legacy systems, and shortage of AI experts. The future of logistics will depend heavily on further research and development of AI to overcome these obstacles and to fully leverage AI-driven systems for innovation and competitiveness in the global market.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Ethical Approval

This study did not involve human participants, animals, or sensitive data; therefore, no ethical approval was required.

Data Availability Statement

No additional research data are available for this publication.

References

- Belhadi, A.; Kamble, S.; Wamba, S.F; … Building supply-chain resilience: an artificial intelligence-based technique and decision-making framework. International Journal of … 2022. Taylor & Francis.

- Gohar, A.; Nencioni, G. The role of 5G technologies in a smart city: The case for intelligent transportation system. Sustainability 2021. [CrossRef]

- Dhaliwal, A. Workshop on e-Business. Towards AI-Driven Transport and Logistics; Springer: 2022.

- Puente-Castro, A.; Rivero, D.; Pazos, A; … A review of artificial intelligence applied to path planning in UAV swarms. Neural Computing and … 2022. Springer. [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.J.; … Drones for supply chain management and logistics: a review and research agenda. Journal of Logistics … 2023. Taylor & Francis. [CrossRef]

- Rhiat, A.; Chalal, L.; Saadane, A. A Smart Warehouse Using Robots and Drone to Optimize Inventory Management. Proceedings of the Future Technologies … 2022. Springer.

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; … Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliability engineering & … 2021. Elsevier. [CrossRef]

- Tyagi, A.K.; Aswathy, S.U.; Abraham, A. Integrating blockchain technology and artificial intelligence: Synergies perspectives challenges and research directions. Journal of Information … 2020. softcomputing.net.

- Himstedt, B.; Meisel, F. Parcel delivery systems for city logistics: A cost-based comparison between different transportation technologies. Logistics Research 2023. econstor.eu.

- Kuner, C.; Bygrave, L.; Docksey, C.; Drechsler, L. The EU general data protection regulation: a commentary. 2020. scholar.archive.org.

- Wang, C.C.; Chien, C.H.; Trappey, A.J. On the application of ARIMA and LSTM to predict order demand based on short lead time and on-time delivery requirements. Processes 2021. mdpi.com. [CrossRef]

- Dwivedi, D.N. The use of artificial intelligence in supply chain management and logistics. Leveraging AI and Emotional Intelligence in … 2024. igi-global.com.

- Abaku, E.A.; Edunjobi, T.E.; … Theoretical approaches to AI in supply chain optimization: Pathways to efficiency and resilience. International Journal of … 2024. pdfs.semanticscholar.org.

- Firouzi, F.; Farahani, B.; Daneshmand, M.; … Harnessing the power of smart and connected health to tackle COVID-19: IoT, AI, robotics, and blockchain for a better world. IEEE Internet of … 2021. ieeexplore.ieee.org.

- Duft, G.; Durana, P. Artificial intelligence-based decision-making algorithms, automated production systems, and big data-driven innovation in sustainable industry. Economics, Management and Financial Markets 2020. ceeol.com.

- Ghiani, G.; Laporte, G.; Musmanno, R. Introduction to Logistics Systems Management: With Microsoft Excel and Python Examples. 2022.

- Allioui, H.; Allioui, A.; Mourdi, Y. AI-Based Logistics Solutions to Tackle COVID-19 Pandemic and Ensure a Sustainable Financial Growth. Advanced AI and Internet of Health Things … 2023. Springer.

- Kalkha, H.; Khiat, A.; Bahnasse, A.; Ouajji, H. The rising trends of smart e-commerce logistics. IEEE Access 2023. ieeexplore.ieee.org. [CrossRef]

- Hu, W.C.; Wu, H.T.; Cho, H.H.; Tseng, F.H. Optimal route planning system for logistics vehicles based on artificial intelligence. Journal of Internet Technology 2020.

- Nurgaliev, I.; Eskander, Y.; Lis, K. The Use of Drones and Autonomous Vehicles in Logistics and Delivery. Logistics and Transport 2023. yadda.icm.edu.pl. [CrossRef]

- Ramasamy, I.; Natarajan, S.; … Does disruptive technology and AI (Artificial Intelligence) influence logistics management? Multidisciplinary Science … 2024. malque.pub.

- Lysenko-Ryba, K.; Zimon, D. Customer behavioral reactions to negative experiences during the product return. Sustainability 2021. mdpi.com. [CrossRef]

- Meduri, K.; Nadella, G.S.; Gonaygunta, H.; … Developing a Fog Computing-based AI Framework for Real-time Traffic Management and Optimization. Development in … 2023. ijsdcs.com.

- Mauler, L.; Duffner, F.; Zeier, W.G.; Leker, J. Battery cost forecasting: a review of methods and results with an outlook to 2050. Energy & Environmental … 2021. pubs.rsc.org. [CrossRef]

- Li, B.; Chen, R.S.; Liu, C.Y. Using intelligent technology and real-time feedback algorithm to improve manufacturing process in IoT semiconductor industry. The Journal of Supercomputing 2021. [CrossRef]

- Iyer, L.S. AI enabled applications towards intelligent transportation. Transportation Engineering 2021. Elsevier. [CrossRef]

- Hurskainen, M.; Ihonen, J. Techno-economic feasibility of road transport of hydrogen using liquid organic hydrogen carriers. international journal of hydrogen energy 2020. Elsevier. [CrossRef]

- Jalolova, M.; Amirov, L.; Askarova, M.; … Territorial features of railway transport control mechanisms. Transportation Research … 2022. Elsevier. [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; … Artificial intelligence applications for industry 4.0: A literature-based study. Journal of Industrial … 2022. World Scientific.

- Remondino, M.; Zanin, A. Logistics and agri-food: Digitization to increase competitive advantage and sustainability. Literature review and the case of Italy. Sustainability 2022. mdpi.com. [CrossRef]

- Riyadh, M. Transforming the Shipping Industry with Autonomous Ships and Artificial Intelligence. Maritime Park Journal of Maritime Technology and … 2024. journal.unhas.ac.id. [CrossRef]

- Seyedan, M.; Mafakheri, F. Predictive big data analytics for supply chain demand forecasting: methods, applications, and research opportunities. Journal of Big Data 2020. Springer. [CrossRef]

- Suguna, M.; Shah, B.; Raj, S.K.; Suresh, M. A study on the influential factors of the last mile delivery projects during Covid-19 era. Operations Management … 2021. Springer. [CrossRef]

- Sullivan, M. Demystifying the impacts of the Fourth Industrial Revolution on logistics: An introduction. The digital transformation of logistics: Demystifying … 2021. Wiley Online Library.

- Woschank, M.; Rauch, E.; Zsifkovits, H. A review of further directions for artificial intelligence, machine learning, and deep learning in smart logistics. Sustainability 2020. mdpi.com. [CrossRef]

- Modgil, S.; Singh, R.K.; Hannibal, C. Artificial intelligence for supply chain resilience: learning from Covid-19. The International Journal of Logistics Management 2022, 33(4), 1246-1268. ljmu.ac.uk. [CrossRef]

- Allal-Chérif; Simón-Moya, V.; Ballester, A.C. Intelligent purchasing: How artificial intelligence can redefine the purchasing function. Journal of Business … 2021. Elsevier.

- Joel, O.S.; Oyewole, A.T.; Odunaiya, O.G.; … Leveraging artificial intelligence for enhanced supply chain optimization: a comprehensive review of current practices and future potentials. Journal of Management … 2024. fepbl.com. [CrossRef]

- Nowakowski, P.; Szwarc, K.; Boryczka, U. Combining an artificial intelligence algorithm and a novel vehicle for sustainable e-waste collection. Science of The Total Environment 2020. Elsevier. [CrossRef]

- Whig, P.; Velu, A.; Nadikattu, R.R.; … Role of AI and IoT in Intelligent Transportation. Artificial Intelligence for … 2024. taylorfrancis.com.

- Sumo, P.D.; Ji, X.; Cai, L. Performance prediction of a textile reverse logistics system using DEA and ANFIS hybrid models. Journal of Intelligent & Fuzzy Systems 2023. content.iospress.com. [CrossRef]

- Ren, Q.S.; Fang, K.; Yang, X.T.; Han, J.W. Ensuring the quality of meat in cold chain logistics: A comprehensive review. Trends in Food Science & Technology 2022. Elsevier. [CrossRef]

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; … The role of artificial intelligence in supply chain management: mapping the territory. Journal of Production … 2022. Taylor & Francis. [CrossRef]

- Saxena, S.; Chawla, V.; Tähtinen, J. Dimensions of e-return service quality: conceptual refinement and directions for measurement. Journal of Service Theory and … 2022. emerald.com.

- shaiju, m. the substantial impact of artificial intelligence over e-commerce progress with reference to amazon online shopping. 2023.

- Bamakan, S.M.; Faregh, N.; … Di-ANFIS: an integrated blockchain–IoT–big data-enabled framework for evaluating service supply chain performance. … of Computational Design … 2021. academic.oup.com.

- Soori, M.; Arezoo, B.; Dastres, R. Artificial intelligence, machine learning and deep learning in advanced robotics, a review. Cognitive Robotics 2023. [CrossRef]

- Sorooshian, S.; Khademi Sharifabad, S.; Parsaee, M.; Afshari, A.R. Toward a modern last-mile delivery: Consequences and obstacles of intelligent technology. Applied System Innovation 2022, 5, 82. [CrossRef]

- Singh, S.P.; Rawat, J.; Mittal, M.; Kumar, I.; … Application of AI in SCM or Supply Chain. Artificial Intelligence in … 2022. Springer.

- Sobb, T.; Turnbull, B.; Moustafa, N. Supply chain 4.0: A survey of cyber security challenges, solutions and future directions. Electronics, 2020. mdpi.com. [CrossRef]

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; … Predictive maintenance in the Industry 4.0: A systematic literature review. Computers & Industrial … 2020. Elsevier.

- Antonoglou, V. Last-Mile Delivery Scheduling Using Autonomous Delivery Robots. 2022. search.proquest.com.

- Wan, J.; Li, X.; Dai, H.N.; Kusiak, A.; Martinez-Garcia, M.; Li, D. Artificial-intelligence-driven customized manufacturing factory: key technologies, applications, and challenges. Proceedings of the IEEE 2020, 109, 377-398. [CrossRef]

- Hu, W.C.; Wu, H.T.; Cho, H.H.; Tseng, F.H. Optimal route planning system for logistics vehicles based on artificial intelligence. Journal of Internet Technology 2020. jit.ndhu.edu.tw.

- Xu, X.; He, Y. Blockchain application in modern logistics information sharing: A review and case study analysis. Production Planning & Control 2024. Taylor & Francis. [CrossRef]

- Ichimura, Y.; Dalaklis, D.; Kitada, M.; Christodoulou, A. Shipping in the era of digitalization: Mapping the future strategic plans of major maritime commercial actors. Digital Business 2022. Elsevier. [CrossRef]

- Lv, Z.; Li, Y.; Feng, H.; Lv, H.; Deep learning for security in digital twins of cooperative intelligent transportation systems. … on intelligent transportation systems 2021. ieeexplore.ieee.org. [CrossRef]

- Hu, Y.; Chen, Y.; Zheng, Y.; You, C.; Tan, J.; Hu, L.; ; Ding, L. Factors related to mental health of inpatients with COVID-19 in Wuhan, China. Brain, behavior, and immunity 2020, 89, 587-593.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).