1. Introduction

With the rapid advancement of technology, the potential application of autonomous mobile robots is enormous, revolutionizing society’s quality of life by improving human well-being and assisting human activities in general. Some of the mobile robot applications include surveillance, planetary exploration, emergency rescue operations, mining, entertainment, precision agriculture, and transportation. The essential feature of a mobile robot is its capacity to navigate and maneuver efficiently within its surroundings, which primarily depends on its steering systems [

1]. Skid steer mobile robot (SSMR) is one of the widely used ground mobile robots in virtue of its simple mechanical structure, remarkable flexibility, and capability to produce enough traction forces. The concept of planar motion of a rigid body states that the pure rotation of a rigid body occurs around the instantaneous center of rotation (ICR).The application of this principle can also be extended to skid-steer vehicles, where the turning maneuvers are solely dependent on the slipping and lateral skidding of each wheel on the ground. Although these actions are not energy-efficient, they are necessary and crucial for the robot to alter its travel direction. SSMR is steered by initiating lateral skidding, which results from the unequal sideway forces generated on each side of the robot’s wheel. Namely, the robot is laterally skidding due to the moment generated by unequal forces exceeding the frictional moment [

2].

Capturing and incorporating the friction force between the ground and the wheel into the dynamics of SSMR is challenging, thereby making the accurate motion modeling of SSMR difficult due to the diverse nonlinear nature of the coefficients of friction. In recent years, model-free control algorithms have been proposed to improve the performance of SSMR. For instance, a learning-based nonlinear model predictive control is used by formulating disturbances as a Gaussian process in [

3], deep reinforcement learning algorithm for path tracking in [

4] and enhanced self-organizing incremental neural network in [

5]. Model-free approaches don’t require a prior understanding of the robot’s dynamic or kinematic models. However, it requires large amounts of data and computational complexity in real-time application. In a more recent study, in contrast to model-free control, [

6] employed a comparative study of six different control frameworks based on a kinematic model to counteract disturbances associated with unmodelled dynamics of SSMR in outdoor applications. The control architecture of proportional-derivative, sliding mode controller (SMC), control-Lyapunov function, nonlinear model predictive controller (NMPC), tube-based NMPC, and model predictive sliding mode control have been studied. It has been shown that the tube-based NMPC exhibits a more excellent disturbance rejection capability compared to other control architectures. So far, several dynamic-based nonlinear controls have been proposed for SSMR. For example, adaptive control [

7], dynamic control law [

8], etc. A robust tube-based NMPC has been presented in [

9] to regulate the nonlinear tire-ground dynamics of SSMR over deformable terrain. [

10] proposed a tube-based NMPC to mitigate the impact of terrain disturbances originating from traction losses of SSMR. A combined MPC with a fuzzy system has been used in [

11] to adapt the slope angle variation of SSMR during sloppy maneuvering. However, despite its distinctive advantage of handling system constraints, NMPC leads to computational complexity in executing real-time optimization problems.

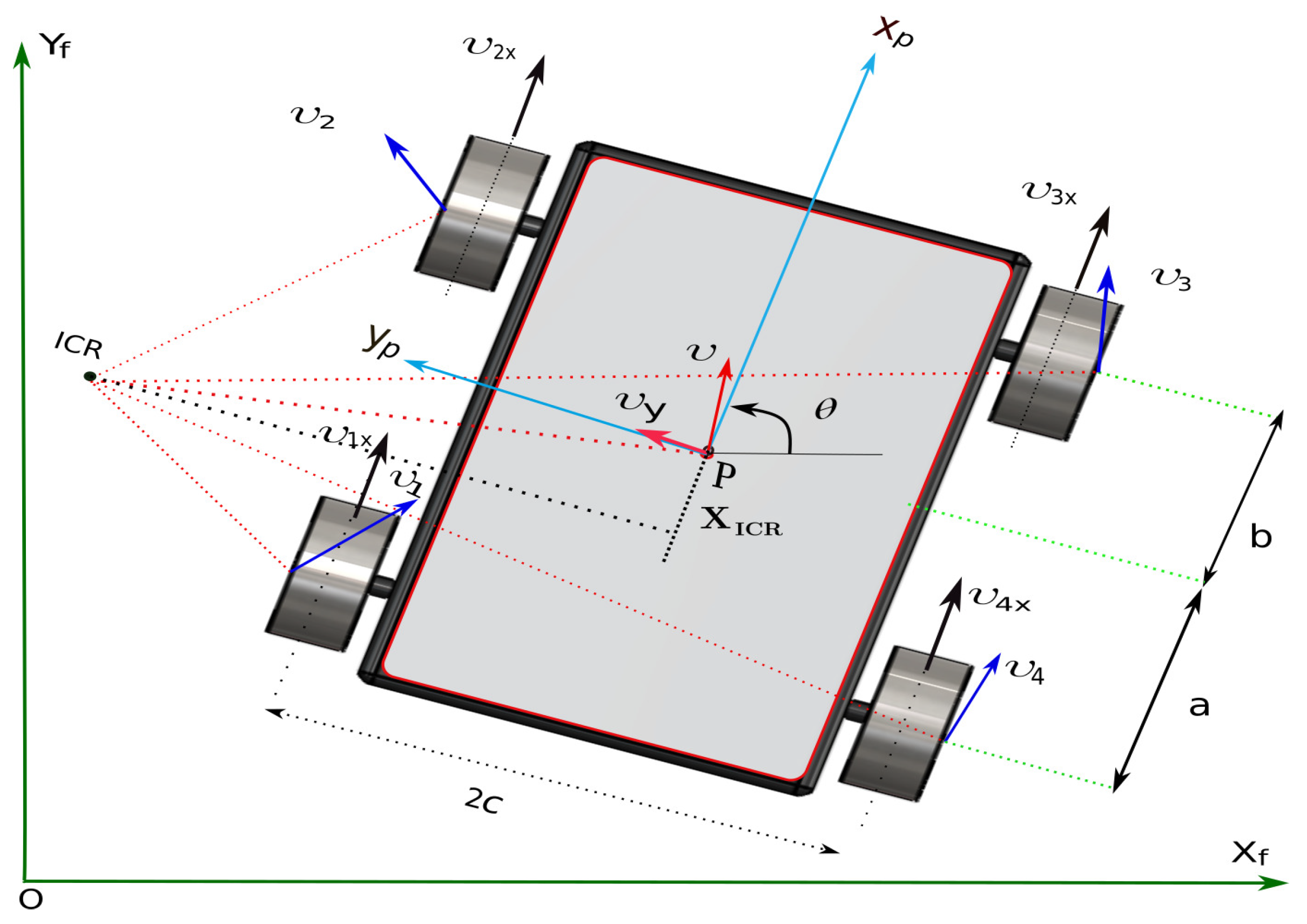

Another critical challenge SSMR faces is the change in the location of ICR during turning maneuvers due to lateral skidding. Depending on the location of

, the distance

swings up and down along

X-direction as shown in

Figure 1. The nonlinear dynamic wheel-terrain interactions, instantaneous lateral velocity, and angular velocity during the curved path motion determine to what extent

shifts along the

X-direction. The worst case scenario occurs if the

extends beyond the robot wheelbase, which can skid laterally and lose motion stability. Incorporating such behavior into SSMR modeling is significantly challenging. Thus, most of the work carried out on SSMR ignores the effect of lateral skidding during turning maneuvers to simplify the modeling and control complexity. So far, however, very few studies have examined the role of lateral skidding, which commonly kept

value to a constant value during turning maneuvers [

8,

12]. The varying nature of

gives rise to alternations in model parameters, which calls for the need of a robust control method dealing with modeling uncertainties.

SMC is one of the most well-known robust control strategies that guarantee robust performance against uncertainties and disturbances. The design of an SMC contains two sequential steps that need to be undertaken. Primarily, a sliding manifold is formulated based on the desired error dynamics. Subsequently, the control input is designed to ensure that the system trajectories remain on the sliding manifold regardless of model uncertainties, nonlinearities and external disturbances [

13,

14,

15]. An important feature of the linear sliding manifold is its simplicity, which guarantees asymptotic stability despite the slower convergence time of the states closer to equilibrium. That means the system states cannot reach the equilibrium in a finite time [

15,

16]. A terminal sliding mode control (TSMC) based on the nonlinear switching manifold has emerged to deal with this problem [

16,

17,

18]. TSMC offers the benefit of a fast finite-time convergence of the states to equilibrium. As indicated by [

18], however, uncertainties can potentially impact the robustness of TSMC. In addition, singularities may occur when the sliding manifold’s time derivative occurs, leading to infinite control input.

To tackle the singularity problem of TSMC, a nonsingular terminal sliding mode control (NTSMC) has been introduced in recent years. An adaptive fast NTSMC has been proposed by [

19] to ensure precise and steady steering performance of a vehicle steer-by-wire system. The effectiveness of the NTSMC is verified via an experimental test, which shows a fast finite convergence and robust performance against different road conditions. [

20] proposed a second-order fast NTSMC combined with ANN for rehabilitation robots to achieve a rapid convergence rate and robustness against uncertain parameters and disturbances, which ANN estimates. A cascaded NTSM-PID controller scheme has been presented in [

21] to achieve robustness against disturbance and improve the tracking accuracy of a four-wheel independently driven skid steer robotic vehicle. In [

17,

22,

23,

24], NTSMC has also been designed for trajectory tracking control of robotic manipulators to obtain finite convergence of states to equilibrium and robust performance against uncertainties and external disturbances. In view of all that has been mentioned so far, some of the challenges associated with SSMR motion modeling and its control arise from the nonlinear behavior of coefficients of friction and change in the location of ICR, which pose modeling uncertainties. Therefore, well-calibrated robust control laws are needed to address these challenges so that SSMR can carry out its assigned tasks appropriately.

The main contributions of this paper are threefold: (a) This study formulated the uncertainties originating from friction forces due to wheel ground interaction, change in location, and external disturbances combined as lumped parametric uncertainties. Subsequently, an adaptive law is designed that tracks the occurrence uncertainties and estimates the lumped parametric uncertainties; (b) A continuous and chattering-free robust nonsingular terminal sliding mode control (NTSMC) based on a back-stepping method is developed; (c) In addition, the finite time stability of the closed-loop system is proven using Lyapunov’s theory.

The remainder of the paper is outlined as follows.

Section 2 and

Section 3 cover the kinematic and dynamic models of the SSMR, respectively.

Section 4 proposes the formulation of robust control and the synthesis of finite-time stability.

Section 5 presents some numerical simulation results. Finally,

Section 6 gives some concluding remarks.

2. Kinematic Model

Typically, SSMR is equipped with wheels that cannot be steered, and it achieves steering by moving one side of the wheels at a faster speed than the other side [

11,

25]. As shown in

Figure 1, two coordinate frames are defined to model the maneuverability of the SSMR: a fixed reference coordinate frame

, and a moving local coordinate frame attached at the robot’s center of mass (COM) as

.

is the heading angle of the robot. The actual robot pose,

, is used to define the robot’s configuration, while the reference (target) pose is represented by

, which defines

. Further details of SSMR modeling are found in [

8,

12]. If we define

as a displacement vector, then

, with

and

representing the velocity and angular velocity of the robot, respectively.

and

are the longitudinal and lateral velocities of the

wheel, respectively.

where

,

, and

are the kinematic parameters of the SSMR shown in

Figure 1.

A velocity constraint for SSMR was introduced in [

12] as:

where

is the lateral velocity.

It is essential to ensure the boundedness of

to maintain lateral stability and reduce the robot’s sideslip angle during sharp turns [

26]. The nonholonomic constraint can be rewritten in the Pfaffian form as follows:

If we let

be a full-rank matrix in which its columns are orthogonal to

, then we can write:

where

is defined in the following equation.

Now, the generalized velocity vector can be written as:

It has been noted from Equation (

6) that the generalized velocity vector is dependent on

. Differentiating both sides of Equation (

6) leads to

3. Dynamic Model

Lateral skidding is an inevitable phenomenon, and determining the exact location of the

is difficult due to the nonlinear dynamic nature of the wheel-ground interaction during turning maneuvers. The unknown lateral skidding and ground interaction forces significantly affect the dynamic model of the SSMR. The dynamic model of the SSMR is formulated as [

8]:

where

,

,

,

,

. Substituting Equation (

7) into Equation (

8) and multiplying both sides by

yields:

The terms

,

,

,

, and

are defined as follows:

,

where m, I and r denote robot mass, moment of inertia, and wheel radius, respectively. It is important to note that , , and , as defined earlier, are entirely dependent on the location of . Any change in the location of results in model parameter variations, thereby introducing model uncertainties to the dynamic system and poses a significant challenge in robot control.

, and

represent the resistive forces in the inertial frame along the longitudinal and lateral directions, respectively, while

denotes the resistant moment around the center of mass. These forces and moments can be computed as follows [

8]:

where

g,

, and

represent the gravity of acceleration, longitudinal, and lateral coefficients of friction forces, respectively,

denoting the signum function. Furthermore, it is essential to emphasize that the robot’s dynamic model of Equation (

9) is also affected by model uncertainty due to the varying coefficients of friction forces, as denoted in Equations (

10)–(

12). These friction force coefficients depend primarily upon the dynamic nature of the surface of the wheel-ground interaction contact point.

4. Control Problem Formulation

For the trajectory tracking problem, the desired reference state vector is generated as follows.

where

and

are the reference velocity and angular velocity, respectively.

To ensure the robot pose to track the intended reference trajectory, the trajectory tracking error can be described in the following equation:

with

,

is the transformation matrix that transforms the local into a fixed reference coordinate frame.

The corresponding tracking error derivative,

, is thus readily obtained:

The popularity of the backstepping control approach has grown among researchers in recent decades due to its application to nonlinear systems. This approach systematically defines the Lyapunov function for stability analysis and the feedback control law design [

27,

28]. Moreover, it has the potential to be integrated with other control techniques, including neural networks [

29], adaptive control [

30], reinforcement learning [

31], sliding mode control [

32], and fuzzy control [

33], to improve the system’s overall performance. By virtue of its distinctive advantages, the backstepping kinematic controller is proposed in this study to eliminate the pose tracking error,

. Subsequently, the control input,

, can also be used as a command velocity to NTSMC. As proposed by [

34],

can be given by

where

,

,

are positive constant numbers.

Assuming that

and

are constant, the time derivative of

can be determined as [

35]:

Definition 1. If we define the signal , the velocity tracking error, , can be defined as the difference between the command velocity control inputs and the true velocity .

with

It has been well-known that the coefficient of friction is highly nonlinear, complex, and difficult to model. Furthermore, accurately determining the

while executing a turning maneuver poses a considerable challenge. The dynamic equation of Equation (

9) can be rewritten as

where

,

and

denote the nominal model parameters and

,

and

are the corresponding uncertainties. If we define the lumped parametric uncertainties as

, then Equation (

20) can be written as:

The parametric uncertainties are upper bound by positive vectors

and

but are assumed to be unknown.

where

,

,

.

Taking the time derivative of Equation (

19) and using Equation (

21) yields the error dynamics as follows:

As discussed above, a nonsingular terminal sliding manifold is selected to avoid the singularity problem [

16] as

where

,

,

, and

,

for i = 1, 2.

To ensure the sliding motion occurs, the derivative of sliding surface

should be satisfied.

where

For the tracking problem, substituting Equation (

23) into Equation (

25) leads to

The design of feedback control is vital to stabilize

to ensure the attractive property of the manifold. According to the sliding mode control design, the control input can be defined as

where

is the equivalent control and

is reaching control to ensure the reachability of the sliding manifold.

can be obtained by setting

and

.

Referring to Equation (

22), let

be the estimation of upper bound, and

the true upper bound assuming that

, for

. The reaching control,

, can be designed as [

36]

where

,

,

, and

,

and

for i=0,1. Therefore, the total NTSMC law for the system is given by:

The

of Equation (

26) is simplified further by substituting Equation (

30) into Equation (

26).

where

and

are defined as

and

.

If

is defined as the state vector, then the Lyapunov function

is expressed as:

where

and

are positive constants. The time derivative of

yields

Substituting Equation (

31) into Equation (

33) yields,

Rearranging Equation (

34) gives

The following inequality holds since

. In addition, the assumption

leads to

.

where

and

. We know that

is assumed to be positive. In order to develop an adaptive law to estimate the lumped parametric uncertainties, Equation (

36) can be written as

where

. Therefore, the estimation adaptive law of

and

can be explicitly defined as:

and

. Note:

and

. Similarly,

and

. Thus, the estimation update rule becomes,

Now, Equation (

37) is simplified as

Substituting Equations (

38)–(4) into Equation (

42) yields,

To achieve a more concise expression, we define that: ,

,

,

,

,

Now,

is rewritten as

where

min

.

It is noteworthy that the subsequent inequality is valid [

37] for

:

Hence, Equation (

44) is simplified as

Lemma 1 ([

38,

39]).

Consider the nonlinear system described by , whose equilibrium is . Suppose there is a (continuously differentiable) function defined in a neighborhood of the origin, and there are real numbers and , such that on D and (along the trajectory) on D. Then the origin of the system is finite-time stable. Moreover, the settling time, depending on the initial slate , is given by

for in some open neighborhood of the origin.

Hence, the finite-time stability criterion of the system is satisfied based on Lemma 1, implying that

V converges from initial

to the origin according to the inequality given by Equation (

46).

Despite uncertainties and disturbances, the sliding surface

,

, and

will converge to the origin within finite time

.

5. Numerical Results

The numerical example is used to implement the proposed control strategy. The SSMR is required to follow a desired circular trajectory path starting from an initial pose of

. The reference circular trajectory is defined in Equation (

13), where the reference velocities are given by

and

. The design parameters were chosen from [

12] to represent a typical SSMR. Referring to

Figure 1, the dimensions of the SSMR are given as:

,

,

, and the wheel radius is

. Additionally, the mass and inertia of SSMR are

, and

, respectively. The nominal friction coefficients for lateral and longitudinal direction are

and

, respectively. As noted in [

8], a fixed coordinate of the

should be selected as

. Hence, the nominal

is selected as

.

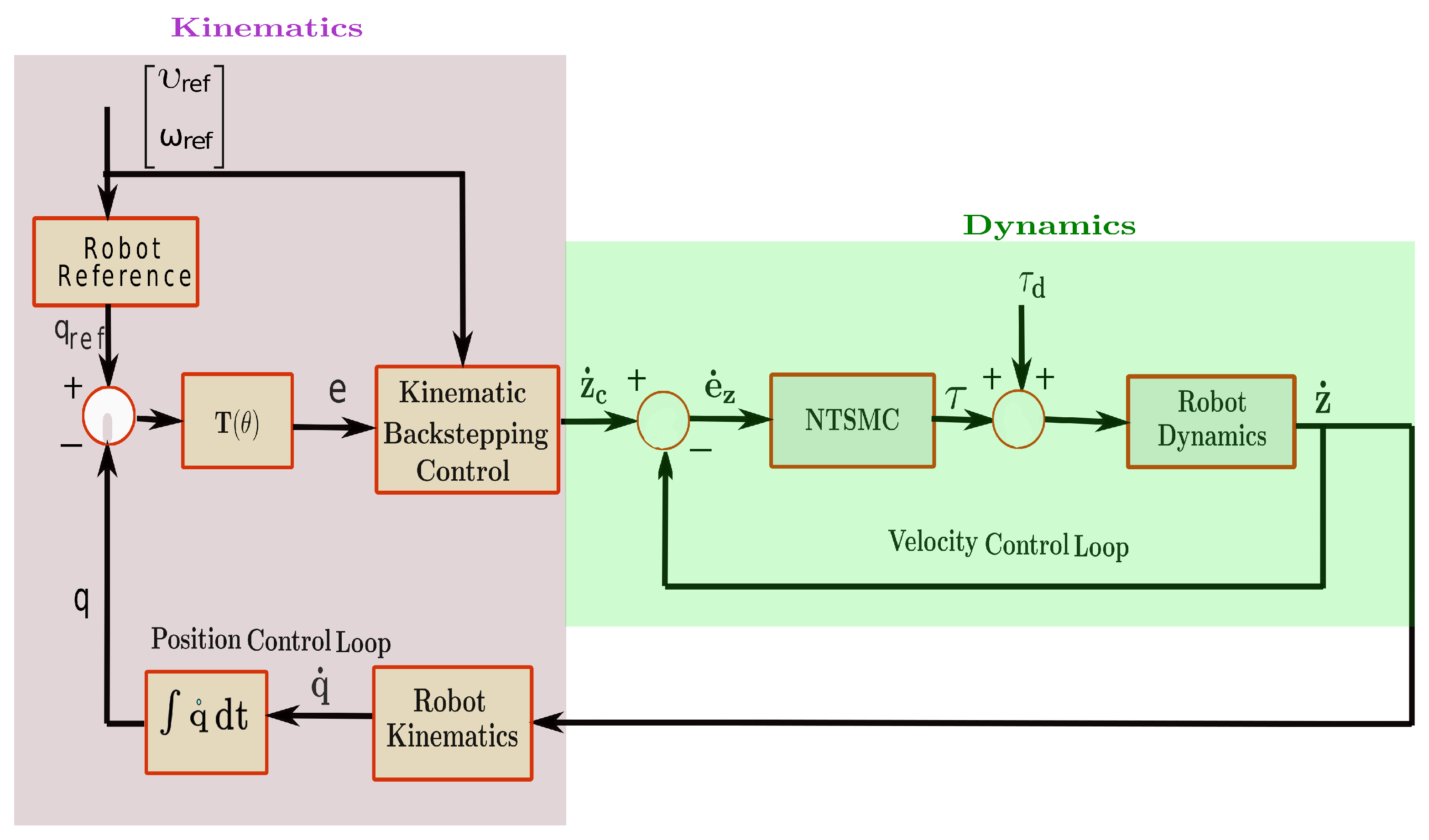

The complete control diagram of the wheeled mobile robot is shown in

Figure 2. It has been noted that the parametric change in

has introduced parametric uncertainties in

,

and

. Moreover, the parametric change in the coefficient of friction has introduced parametric uncertainties in

. In order to validate the performance of robustness against modeling uncertainties, the following uncertainties are considered:

for

,

for

,

for

and

for

. The constant gains undergo tuning in various simulation tests, and the final values are provided as:

,

,

,

,

,

,

,

.

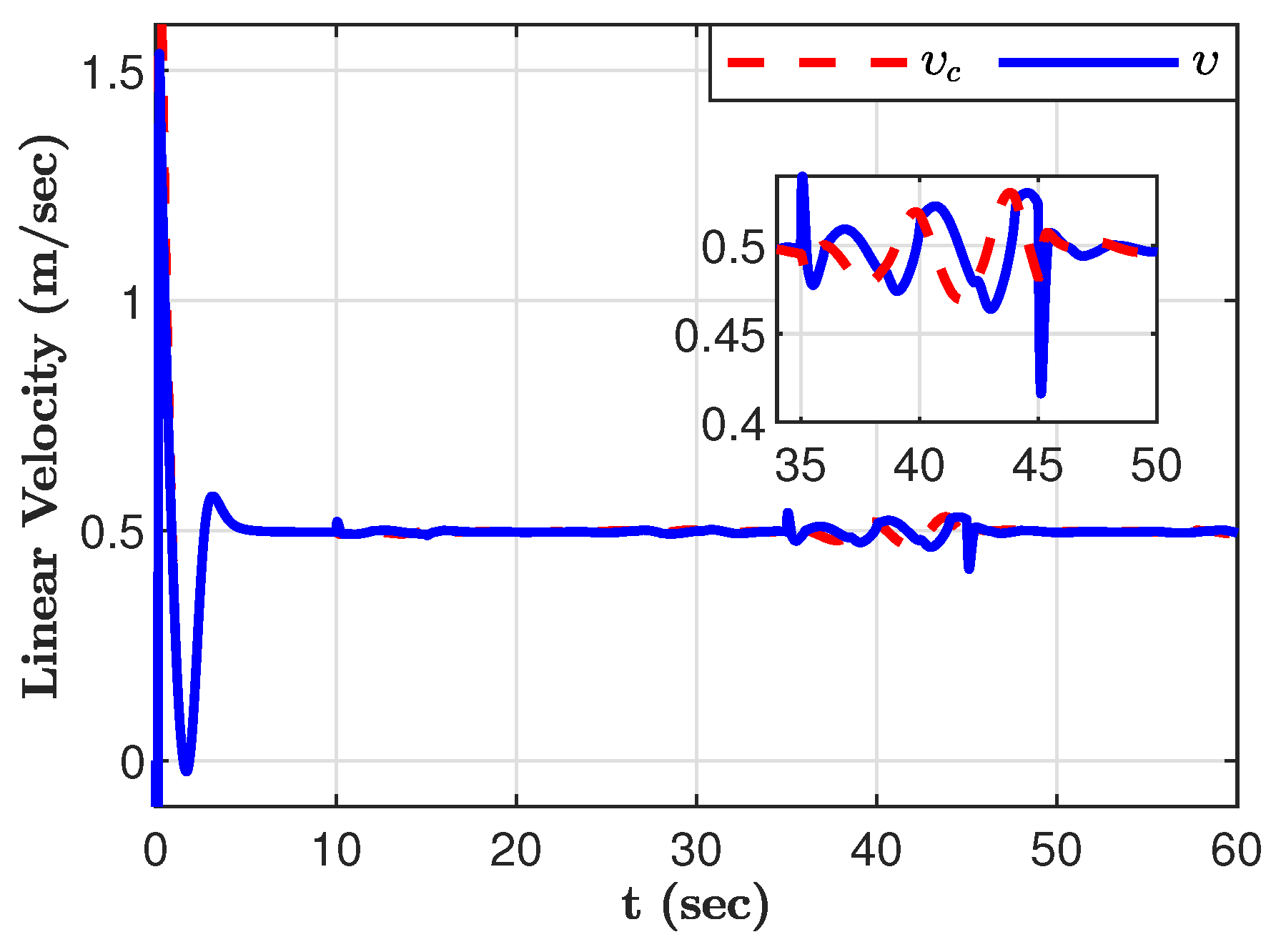

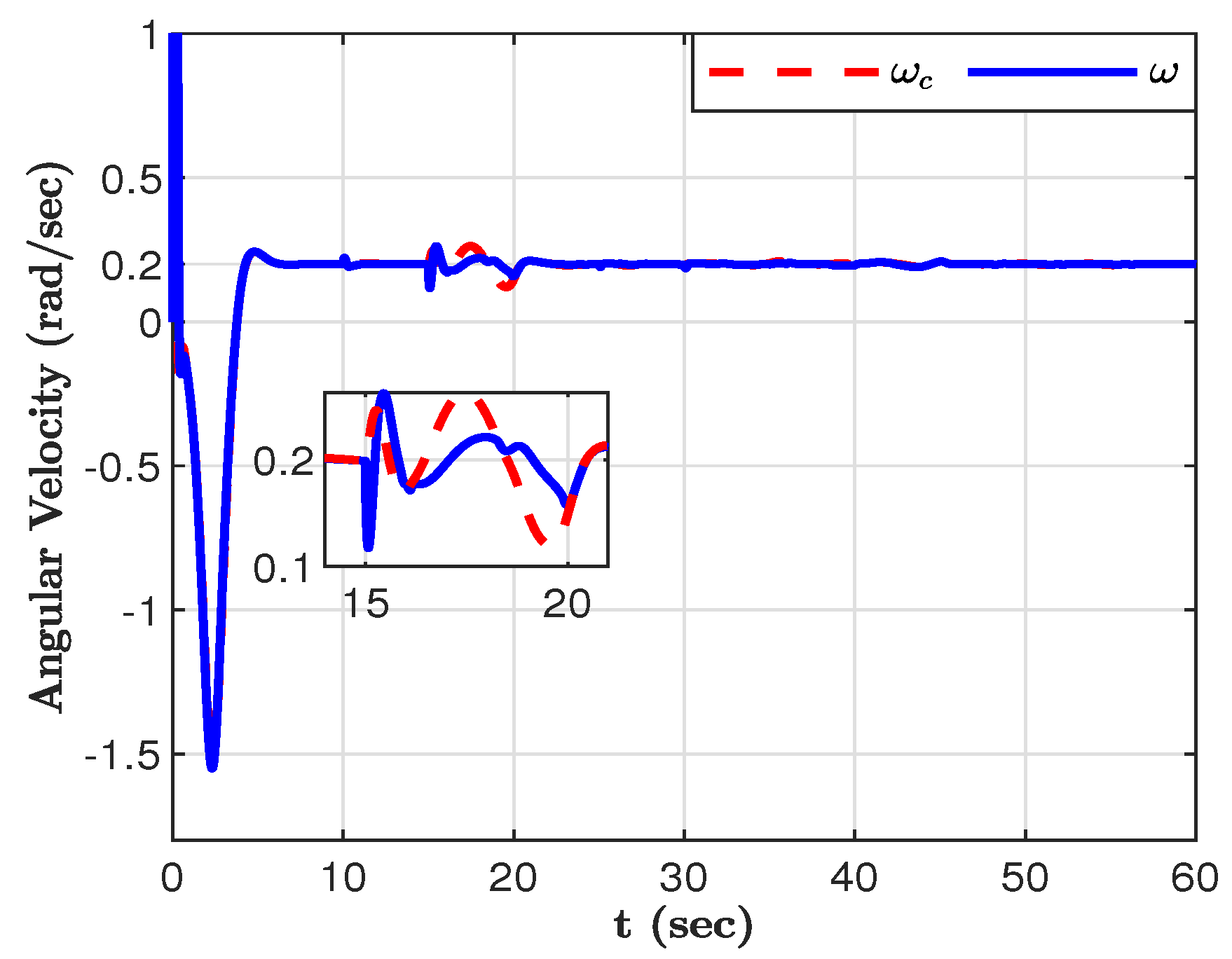

The robustness of NTSMC against model uncertainties and external disturbances is examined by considering time-varying parametric perturbation of

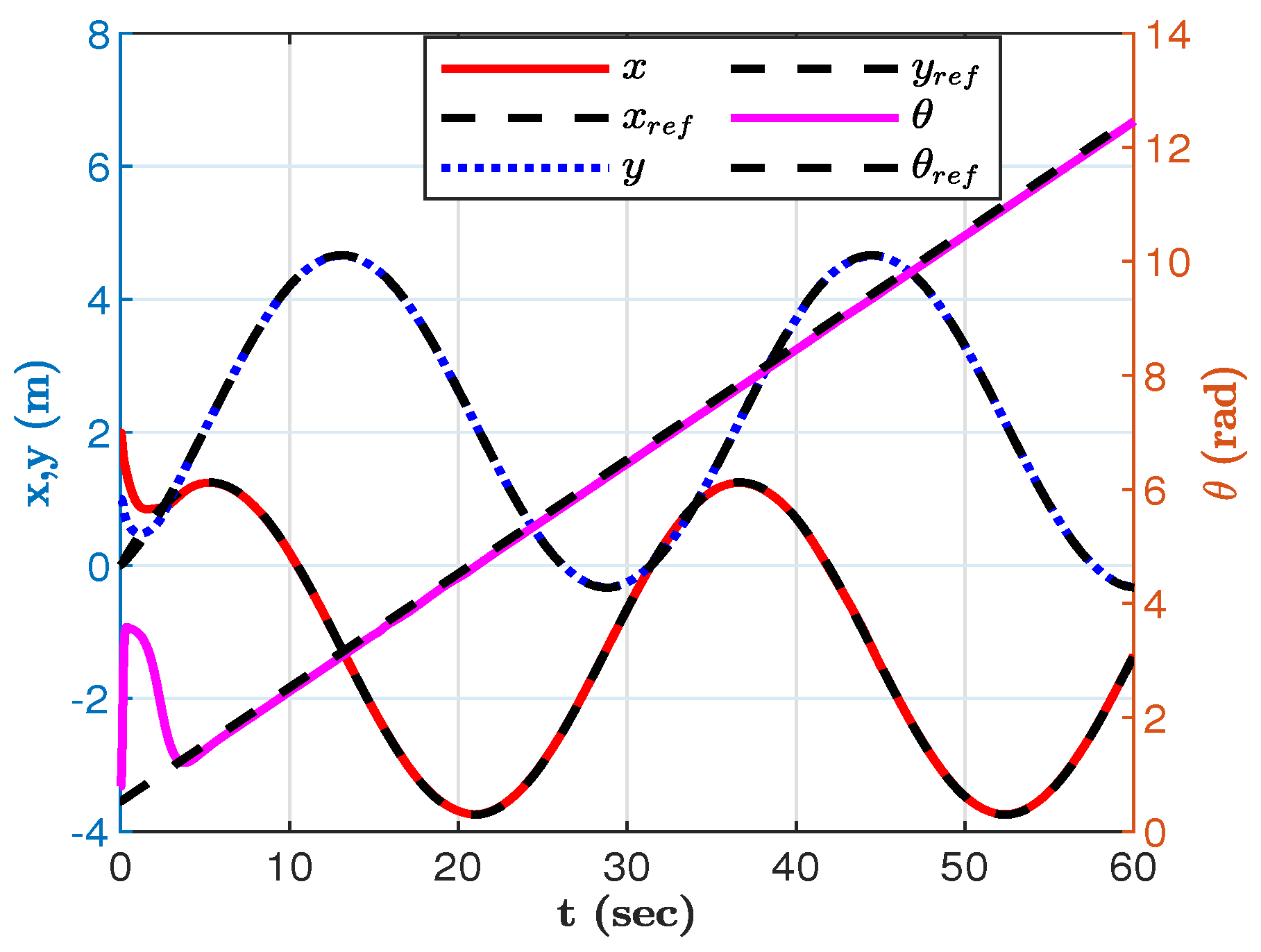

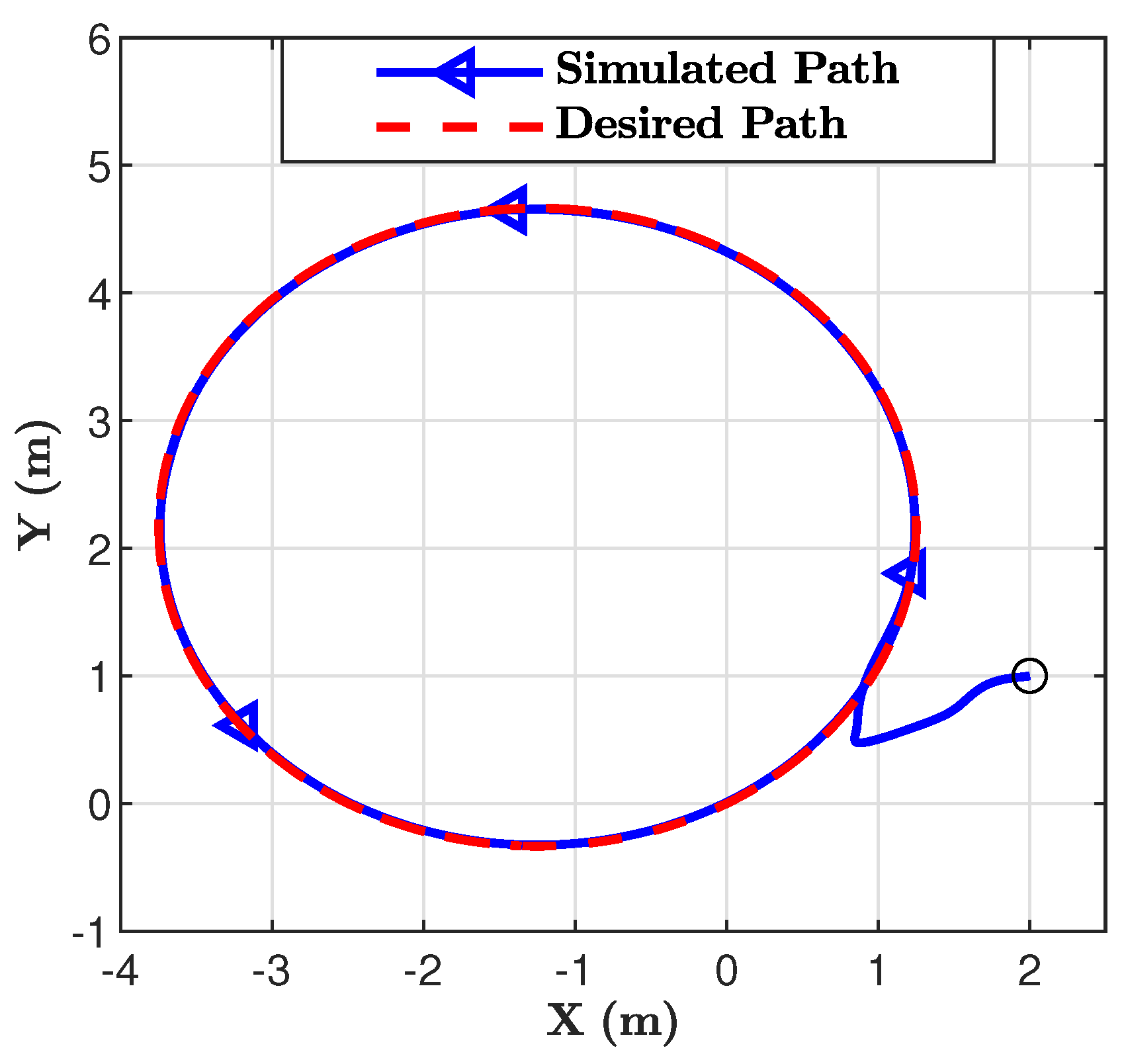

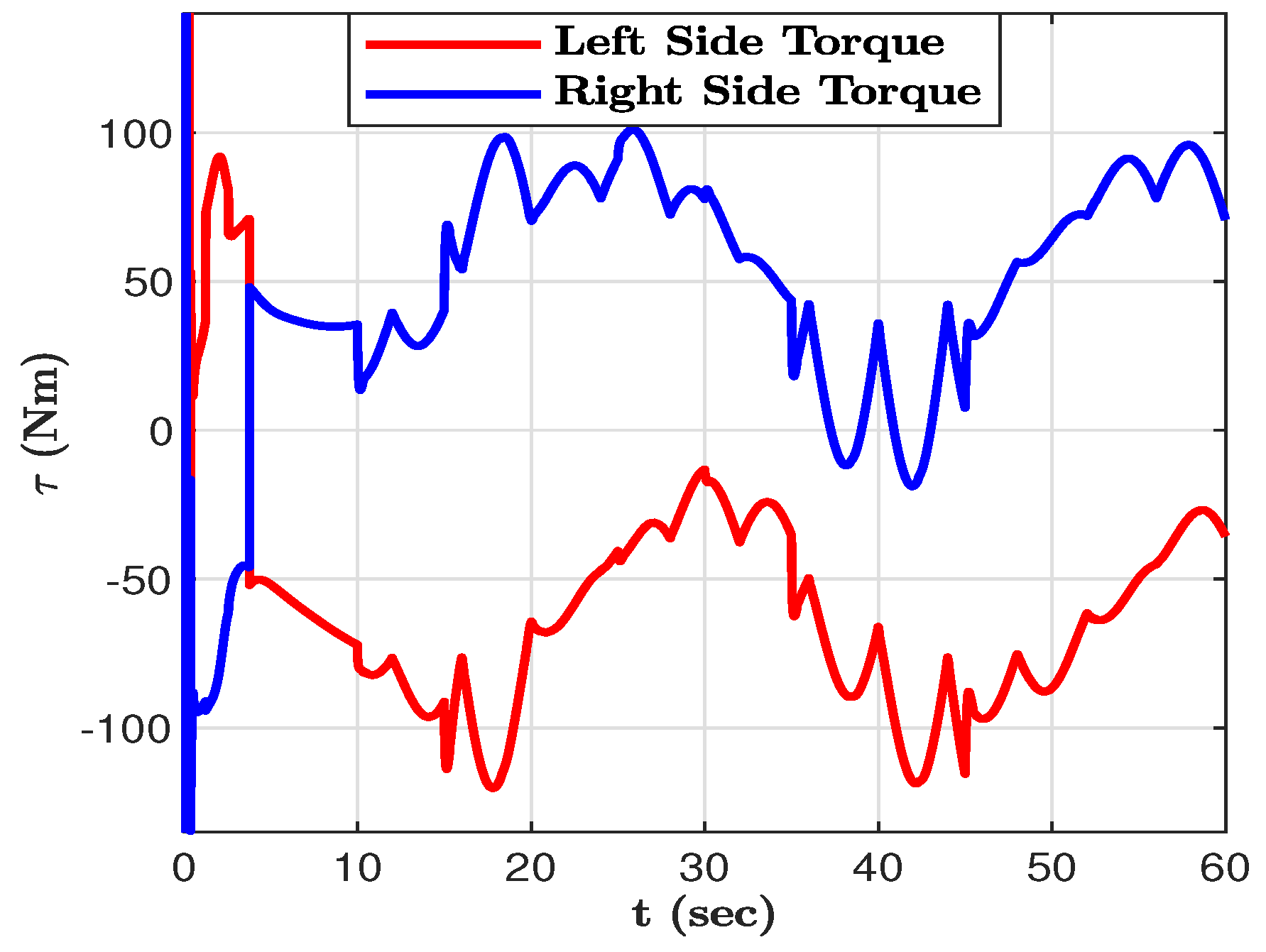

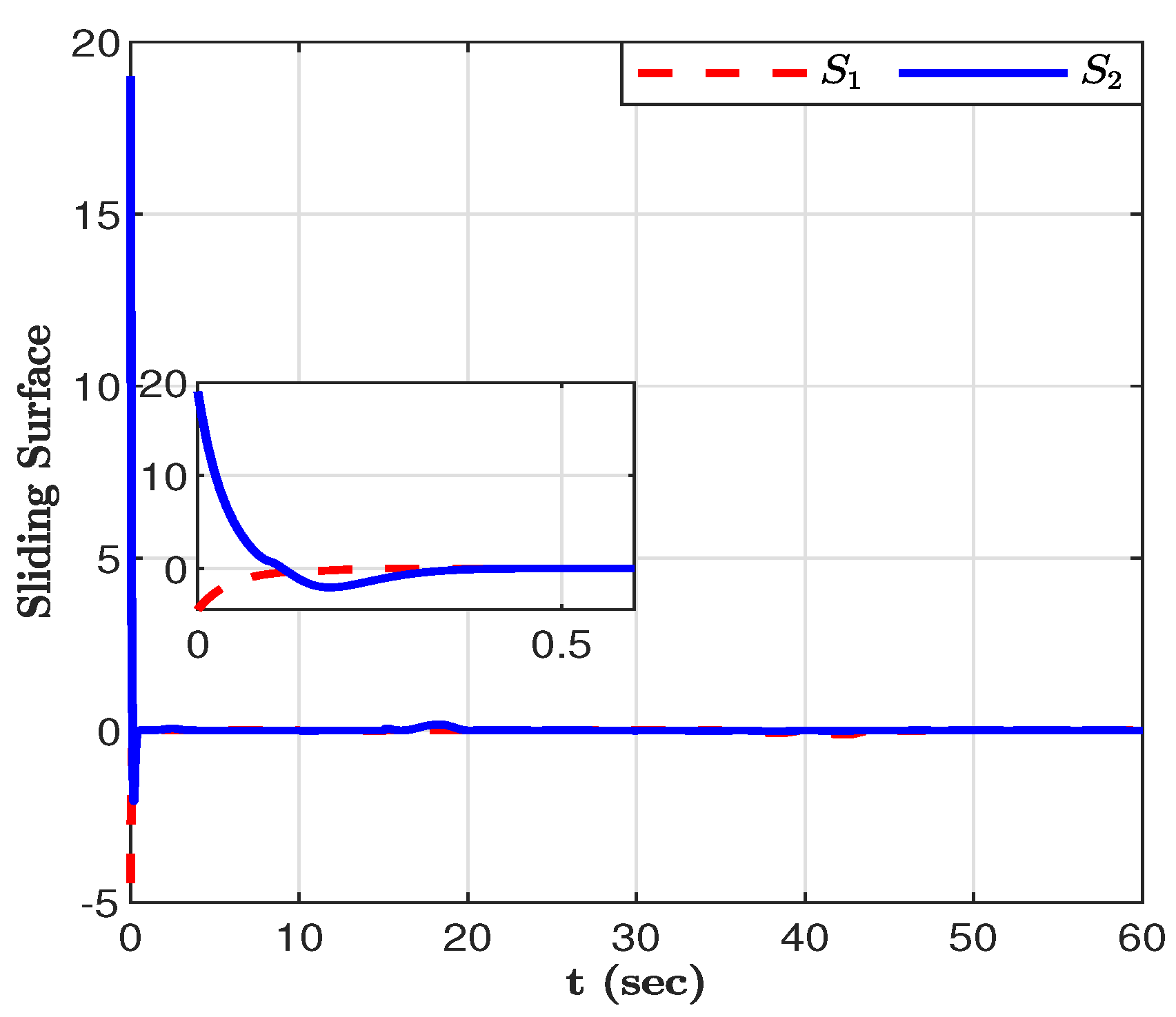

, friction coefficients along the x and y directions during turning maneuvers.

Figure 3 and

Figure 4 illustrate the time history of the velocity and angular velocity of the SSMR, respectively. It is clear that the velocity does not converge near the initial time, which denotes unstable motion; however, it is stabilized for the rest of the simulation time. Compared to other types of uncertainties, the external disturbance has a notable effect on velocity, as shown in

Figure 3. On the other hand, disturbance in lateral friction force has a notable influence on the angular velocity of the robot, as shown in

Figure 4. However, as shown in the time history of the figures, the designed NTSMC eliminates both disturbances and performs better trajectory tracking. The robot poses are plotted in

Figure 5, which shows the SSMR accurately tracks the target pose despite the disturbances. As shown in

Figure 6, the robot follows the desired circular path precisely in spite of the disturbances.

Figure 7 shows that the proposed torque input is a continuous control and does not exhibit a noticeable chattering problem. It has been observed from the simulation results that time-varying parametric perturbation of

during turning maneuvers is successfully compensated by robust NTSMC. Finally, the simulation results shown in

Figure 8 clearly reveal the asymptotically convergent property of NTSMC.