1. Introduction

The topic concerns the dangerous phenomenon of bubble effect (b.e.) occurring in power transformers. The bubble effect consists in the rapid release of water vapor bubbles from the wet fibrous insulation immersed in the liquid dielectric after exceeding the critical temperature. The result is an increase in pressure in the transformer tank, and may lead to unsealing the tank, and its fire or even explosion. On the other hand, when bubbles are formed, there is also a risk of partial discharges appearing [

1,

2].

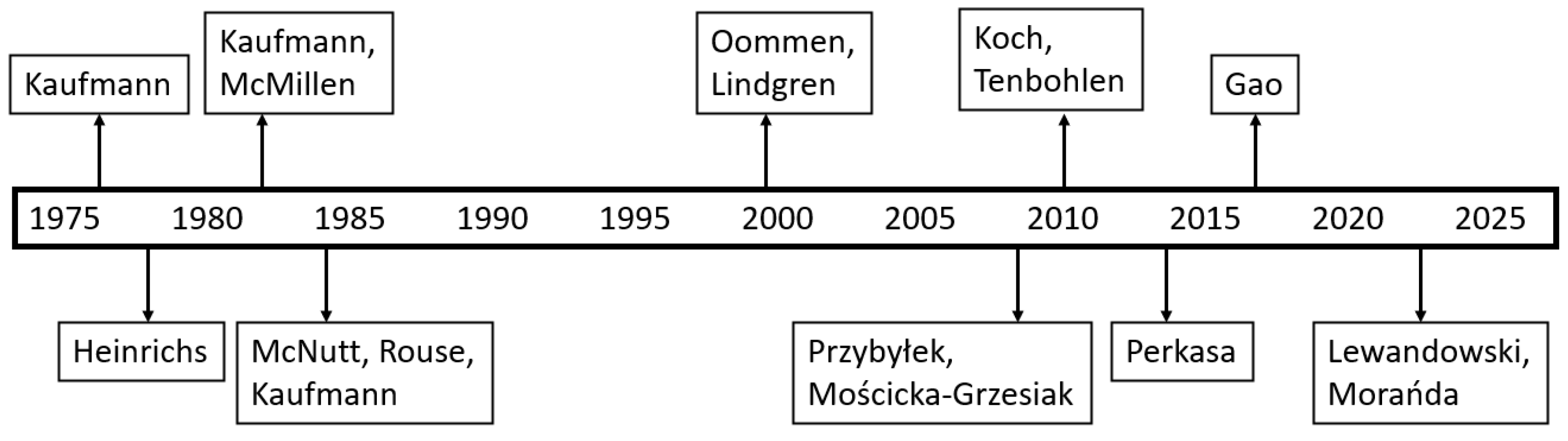

Research on the bubble effect in transformer insulation has been going on for almost 50 years (

Figure 1), and it is still not fully recognized phenomenon. The first article on b.e. was published by Kaufmann in 1977, who observed this phenomenon on distribution transformer windings and on models of coils. He concluded that a transformer which reaches high temperature during overload may be very vulnerable to failure caused by the presence of bubbles, and while insulation temperatures exceeded 200 °C the insulation strength decreased to almost half of its value at rated load [

3]. Heinrich, who also studied the b.e. phenomenon on overload transformers windings, recommended reducing the maximum Hot Spot temperature to 140 °C [

4]. Kaufmann with McMillen also investigated gas bubble evolution on coils model of transformer during loading it above nameplate rating. They observed that it took about 25 minutes for the coil interstices to fill to capacity with gas bubbles. No major difference was observed between unaged and aged coils [

5]. Next, Kaufmann et al. in [

6] presented the basic mechanism of bubble formation. Their research showed that a transformer continuously loaded near nameplate rating has a higher critical temperature for bubbles formation than a lightly loaded one, and the bubble effect starts at temperatures above 150 °C. He also noticed that in transformers the moisture content of the cellulose insulation on the hottest spot of conductor has a minor influence on the initial temperature for bubbles formation.

In 2001 Oommen and Lindgren presented fundamental work [

7] concerns b.e. in paper insulation immersed in mineral oil. Their research was conducted on a winding’s insulation model of overloaded transformer, in which the temperature of the upper oil layer can reach 240 °C, and the temperature of the Hot Spot even 360 °C. Ommenn determined the b.e. initiation temperature depending on the water content in the cellulose and also noted that this temperature can be even 50°C lower when the oil contains dissolved gas. The fact that the presence of gas in oil has a great influence on the b.e. initiation temperature was also shown in [

8].

Studies on bubble effect implicitly assumed that the phenomenon could occur in paper on windings in overloaded transformers. In the article [

9] the situation of the appearing of the b.e. in 30 years old transformer 160 MVA was presented. There were several reasons of it: the planned repair of another transformer forced its load to be increased, the air temperature had been at 26-30 ˚C for many days, and one of its cooling system fans had failed. The bubbling phenomenon resulted atypical – in a few hundreds of liters of oil being forced out of the transformer through its tap changer dehumidifier (the barrier separating oil in the tap changer from the oil in the rest of the transformer was damaged by high difference in its pressure). Such a large amount of forced out oil cannot be explained by appearing of b.e. in paper insulation only. The water content in its cellulose insulation (determined after the incident) with the use of RVM and PDC methods was 3.2%. In accordance with IEEE standard 62-1995 [

10] the insulation was qualified to the “wet” group (2-4% moisture content). Due to the unprofitability of drying, the transformer was scrapped. This case indicates that the bubble effect may appears not in insulation paper in the Hot Spot area only but also in pressboard, whose mass in transformers is many times greater.

Research on bubble effect in aged moistened cellulose insulation immersed in mineral oil presented in [

11,

12,

13,

14] shows that inception temperature of the phenomenon for aged paper is lower than for new ones. Unfortunately, there are a relatively large number of such transformers, as shown results of research carried out for example in Poland, Germany and Sweden [

30].

As shown in the

Figure 1, research on b.e. has been conducted by other researchers. Koch and Tenbohlen in [

16] concluded that this phenomenon depends on: moisture content in paper, paper quality, and paper and oil ageing.

Recently research on b.e. is also being conducted for materials other than cellulose and mineral oil. For example, Perkasa in his research [

17] investigated the bubble effect in vegetable oil, and publications [

18,

19,

20] presents investigation results for aramid-based materials immersed in mineral oil and natural/synthetic ester. Moreover, similar studies on this phenomenon are carried out in bushing insulators [

21,

22,

23].

Summarizing, literature review on b.e. one may get the impression that this phenomenon can occur in overloaded transformers only. In other words, the bubble effect, known today, generally occurs in the hottest places (Hot Spots) of the insulation system. These are the areas of winding metal in contact with the insulation paper. In overloaded transformer with a distinct temperature distribution, Hot Spot may appear in the upper area of the unit, where the insulation moisture is the lowest, but temperature may have an absolutely high, dangerous value. In a transformer without a clear temperature distribution, the most dangerous area may be in its lower part, with the highest value of cellulose moisture. Moisture of cellulose insulation in a lower part of transformer can be event two times higher than in its higher part [

24]. And it should not be forgotten that the inception temperature of b.e. in old insulation is reduced. For this reason, in old and very moistened transformers b.e. may appear even when they are loaded with rated power only [

25].

The assessment of the risk of b.e. appearing in a given transformer is difficult. It depends on two most important factors: moistening of the cellulose and its temperature. In transformers there are usually no equilibrium state – there is a radial and axial distribution of moisture. For this reason (but not only), different methods of moisture content in solid insulation assessment (DFR, RVM, PDC) may give different results. Moreover, the values of the b.e. inception temperatures determined by different authors varies by even several °C (

Table 1) [

26]. Taking all this into account, sometimes the risk of b.e. appearing in a given transformer may be assessed as low, but the phenomenon can start at a much lower temperature than expected – especially in an old unit.

Bubble effect causes a rapid desorption of water, thus drying the insulation. It is also a strongly endothermic process, which causes a significant decrease in temperature in the place where the b.e. appears [

27,

28]. This applies especially to paper insulation, which is much thinner than pressboard barriers. As a result, the phenomenon can be locally extinguished, and may appear in neighboring places. Because the development of this phenomenon in paper is not very dynamic, and it does not generate a huge volume of bubbles, the Buchholz relay sufficiently protects the transformer against a failure. The thesis was put forward that there is another, hitherto unknown, mechanism of the b.e. development, not related to the Hot Spots of the system. It develops in a mass of cellulose heated by circulating oil. This mass consists of insulating barriers between the windings of the lower and upper voltage, usually made as pressboard sleeves with a thickness of several millimeters. In these sleeves, the temperature is 20-30 °C lower than in the Hot Spot and it may be surprising that they can be a source of extremely high pressure in transformer tank, growing very dynamically. This phenomenon may occur, for example, as a result of a failure of the oil cooling system in an old transformer with relatively high moisture in its insulation, as presented in this article.

Under the conditions of long-term emergency load, specified in the standard [

29], at a high Hot Spot temperature, but lower than the b.e. initiation temperature, in the winding insulation there will be an intensive phenomenon of water migration against the temperature gradient, which causes significant drying of the winding paper insulation. At the same time, the moisture content in the pressboard sleeve will decrease slightly because its temperature is much lower than the temperature of the windings. In addition, there is a small temperature gradient which doesn't lead to significant water migration. As a result, there may be a situation where the oil is heated enough to start b.e. from a pressboard sleeve. Most of the volume of the pressboard sleeve is at the same temperature provided by the oil circulating in the transformer, resulting b.e. initiation in a large volume of insulating material. This, in turn, makes the phenomenon very intense, so that the pressure in the tank can dynamically increase and can be extremely dangerous. The reconnaissance experiment confirmed the thesis. The bubble effect occurred in the modeled pressboard sleeve and caused a rapid unsealing of the test chamber as a result of a large increase in pressure.

The aim of the research was to demonstrate the possibility of the b.e. start not in the Hot Spot area, but in a large mass of pressboard insulation at a relatively low temperature. The consequence of this is a catastrophic pressure increase in the test chamber (modeling the transformer tank) leading to its explosion.

2. Water in Cellulose Insulation

The water in the cellulose insulation, which is the cause of the bubble effect, comes mainly from the chemical decomposition of the cellulose. In real insulation systems, after about 50 years of transformer operation, insulation reaches even 4.5% of moisture which we demonstrated during implementation of international project [

30]. The results of transformer insulation moisture research in Poland, Germany and Sweden are presented in publication [

15].

Water in cellulose can exist in three different physical forms depending on its percentage. If the water content of the cellulose product is up to 9%, the water molecules are bound to the cellulose fibers by physical adsorption. In the range of 9-18% of water, the phenomenon of capillary sorption occurs. At a moisture content above 18%, free water occurs [

31]. Under real conditions, in the insulation system of a transformer, water is bound to cellulose only by physical adsorption. In turn, the process of releasing water from solid insulation is described by the laws of physical desorption.

Understanding the phenomenon of water adsorption to cellulose and its consequences requires understanding the structure of cellulose. Long chains of cellulose molecules link together to form microfibrils. The microfibrils, in turn, join together to form macrofibrils. Macrofibrils are arranged counter-twistingly in successive layers, forming a capillary inside, as shown in

Figure 2 [

31]. The created capillaries are used by plants to transport water, even very high. Macrofibrils have a very extensive surface area. Therefore, they can accommodate a significant amount of water in just a few packed monomolecular layers. The binding energy of the next layer of water decreases with the third power of the distance of this layer from the cellulose fiber [

32]. The desorption energy is different for each layer, but since there are only few layers, the desorption temperature range can be several °C. This may be a characteristic of cellulose. In comparison, an alkaline glass fiber in an air atmosphere with 90% humidity has more than 20 monomolecular layers of adsorbed water and consequently the range of desorption temperature is very wide.

3. Experimental Research

The first experiment was to demonstrate the possibility of initiating the bubble effect in pressboard heated with oil, without the appearing of this phenomenon in the Hot Spot area in the winding.

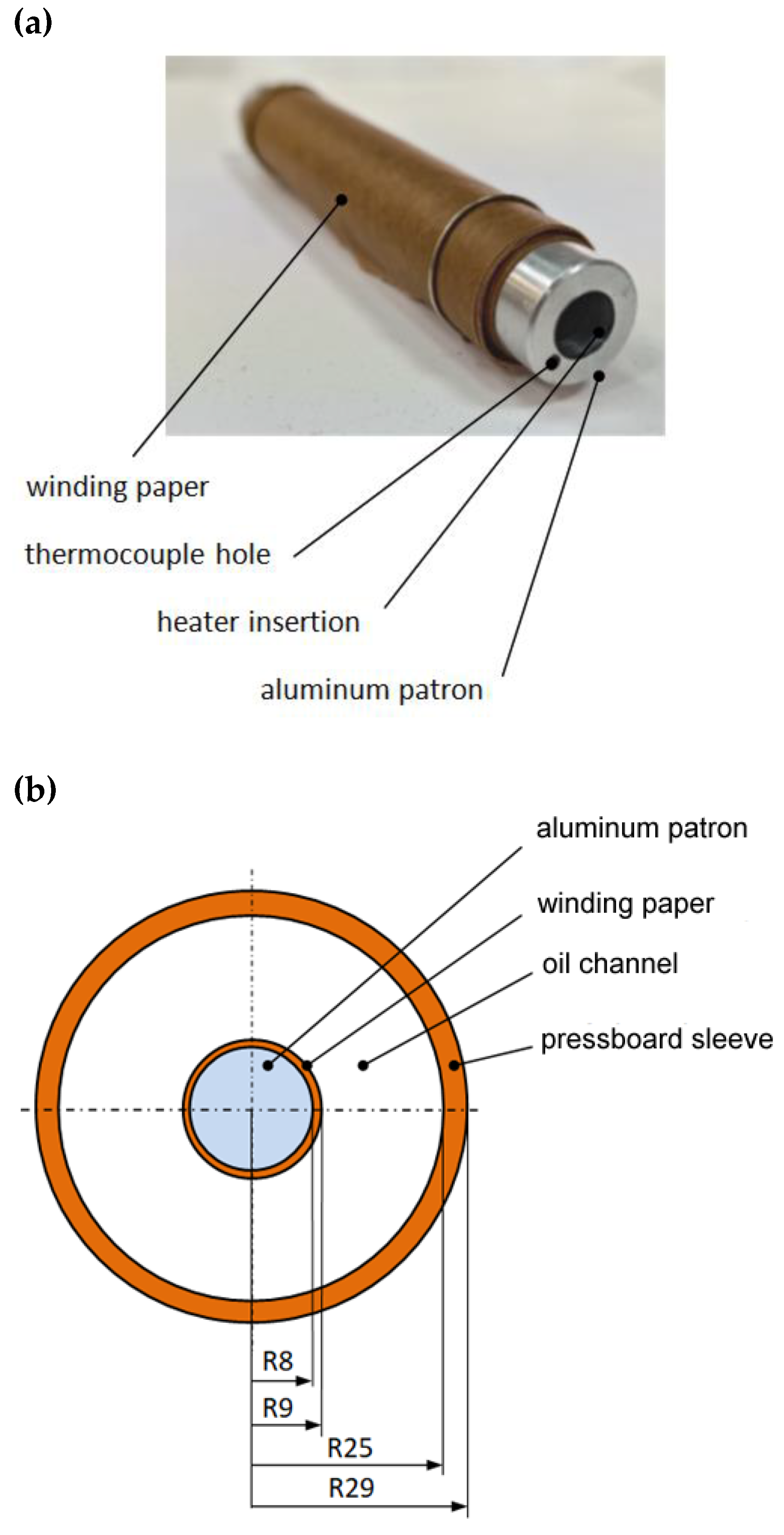

The test object was made taking into account the average geometrical parameters of the transformer insulation system. The transformer winding lead was modeled with a barrel (so called patron) made of aluminum (

Figure 3a). Inside the patron, a heater was placed, the temperature of which was regulated using an autotransformer. In the material of the patron a narrow channel was drilled, along its axis, in which a thermocouple was placed. Hot Spot temperature is defined as the temperature of the hottest spot in windings or other metal parts in contact with insulating materials. Of course, the temperature of the wound paper in contact with Hot Spot will be slightly lower due to its thermal conductivity.

In accordance with the transformer insulating system design principles, the total thickness of the winding paper was assumed to be 1 mm, which was obtained by winding 20 layers of transformer paper with a thickness of 0.05 mm. The width of the oil channel in the model is 16 mm. This corresponds to the average dimensions of the transformer insulation system.

The insulating sleeve, which in the transformer is designed to insulate the low and high voltage windings, is made of 1 mm thick rolled pressboard. Four layers of pressboard were wound, which corresponds to the average thickness of the barrier. Between the layers of pressboard, a thermocouple was placed. Another two thermocouples were placed in the upper and lower layers of oil. The cross-section of the test object is shown in

Figure 3b. The test object was placed in an aluminum test chamber filled with mineral oil. Under the bottom of the chamber, a heater with temperature controlled by an autotransformer was installed.

During the experiment, for 4 days, the aluminum patron was cyclically heated to a temperature below the temperature of initiation of the bubble effect phenomenon. The cartridge was heated in the following cycles: 2.5 h of heating (100 °C) and 21.5 h of cooling, 2.5 h of heating (144 °C) and 45.5 h of cooling, and 4.5 h of heating (144 °C). This procedure was intended to simulate the cyclic loading of the transformer.

After the oil had cooled down, samples of winding paper and pressboard were taken to determine their moisture content using the Karl Fisher method. Before the experiment, the moisture content of the winding paper and pressboard was the same (3.40%), while after cyclic heating and cooling, the moisture content of the paper decreased to 2.81%, and that of the pressboard to 3.12%. The weight ratio of cellulose to oil was 1:27. It corresponds to the ANER3E 160 000/220 PN transformer, manufactured in Poland by Elta in 2000.

This part of the experiment showed that cyclic heating of the windings causes the paper insulation on these windings to dry out much faster than pressboard insulation.

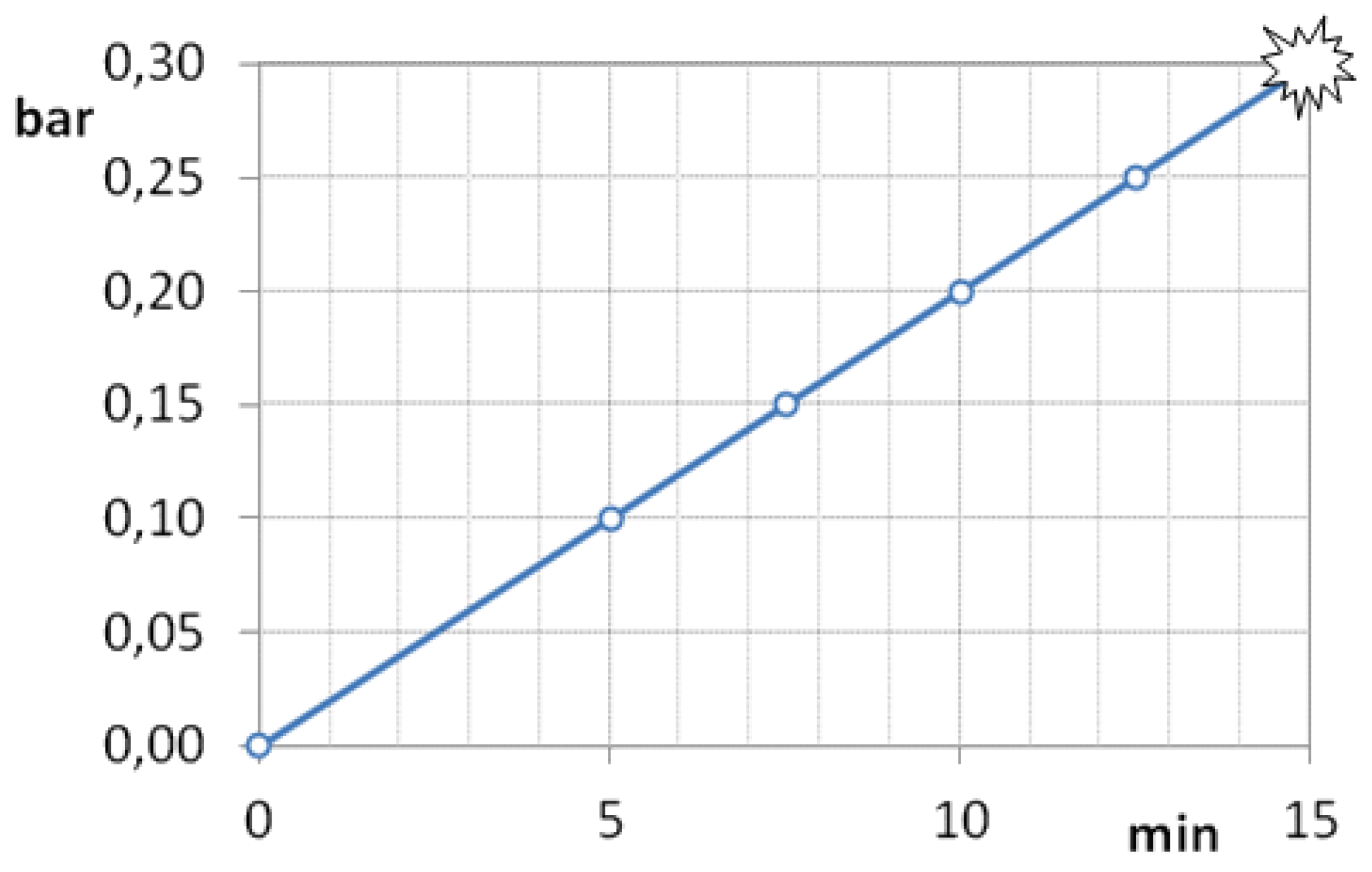

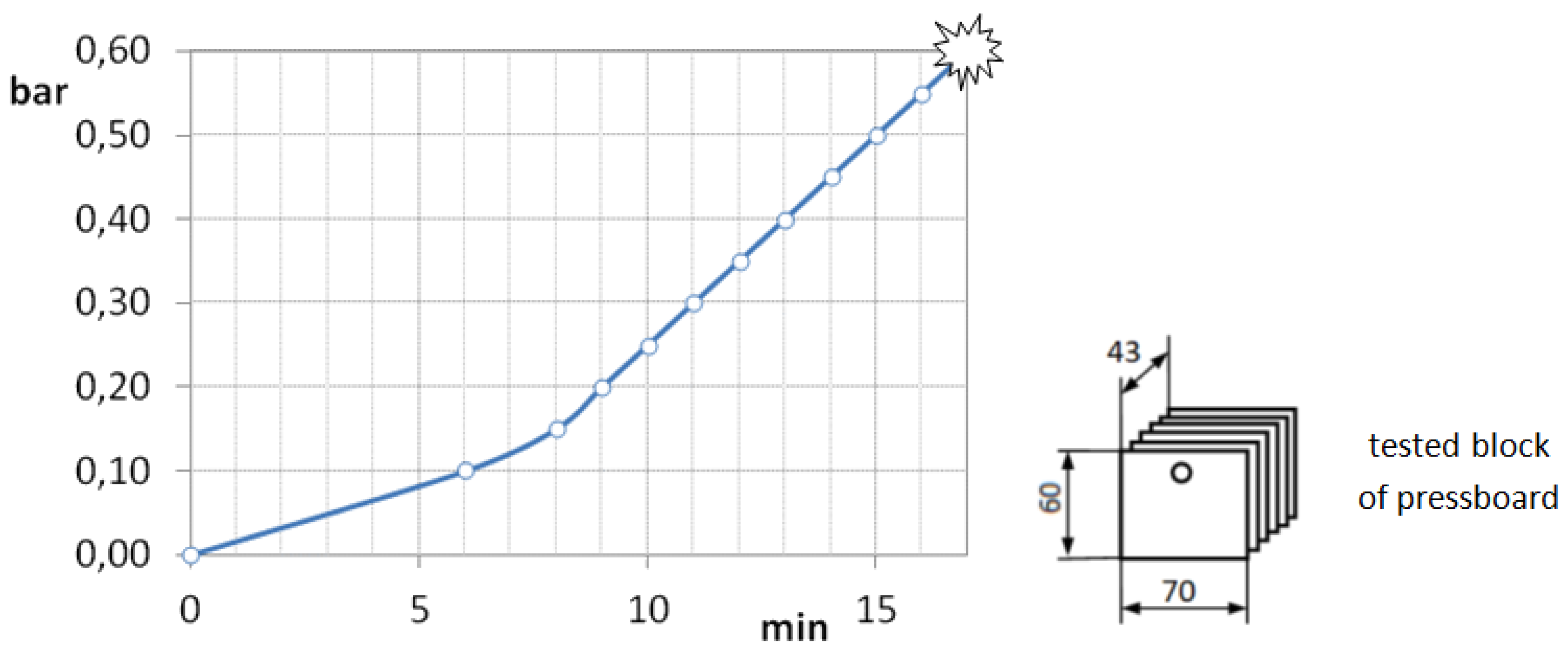

In the second phase of the experiment, the oil was heated only by means of a heater placed under the bottom of the test chamber. The temperature of the upper and lower layers of oil was the same, which resulted from the natural circulation of oil (convection). Bubble effect was found in pressboard at 112 °C and no b.e. was observed in winding paper. The oil temperature was maintained at approx. 115 °C. At that temperature b.e. was intensified, as a result of which within several minutes the pressure in the test chamber increased to 0.3 bar above atmospheric and the test chamber exploded (its seal was damaged). The dependence of the pressure in the air cushion above the oil on time, measured from the b.e. initiation, is shown in

Figure 4.

A very dangerous phenomenon should be noted: the intensity of b.e. observed at increased pressure in the test chamber increased significantly after it was unsealed. This was due to the threefold reduction of pressure in the chamber, which resulted in a threefold increase in the volume of bubbles. This phenomenon can be extremely dangerous in the event of a damage of sealing of the transformer tank caused by b.e. appearing.

In the next experiment, the influence of the ratio of the mass of cellulose to the mass of oil on the dynamics of the pressure increase in the air cushion above the oil in the test chamber was checked. The test object was made in the form of a pressboard block with dimensions of 70x60x43 mm. It was suspended inside the research chamber on a tripod. The highest ratio of cellulose mass to oil mass was assumed, equal to 1:11.6. It corresponds to the transformer ANSR3Ha 450000/400 PN, 160 MVA, produced by Elta, Poland, in 2010. Comparing the results in

Figure 4 and

Figure 5, a much greater dynamics of pressure increase can be seen with a higher ratio of cellulose mass to oil mass value.

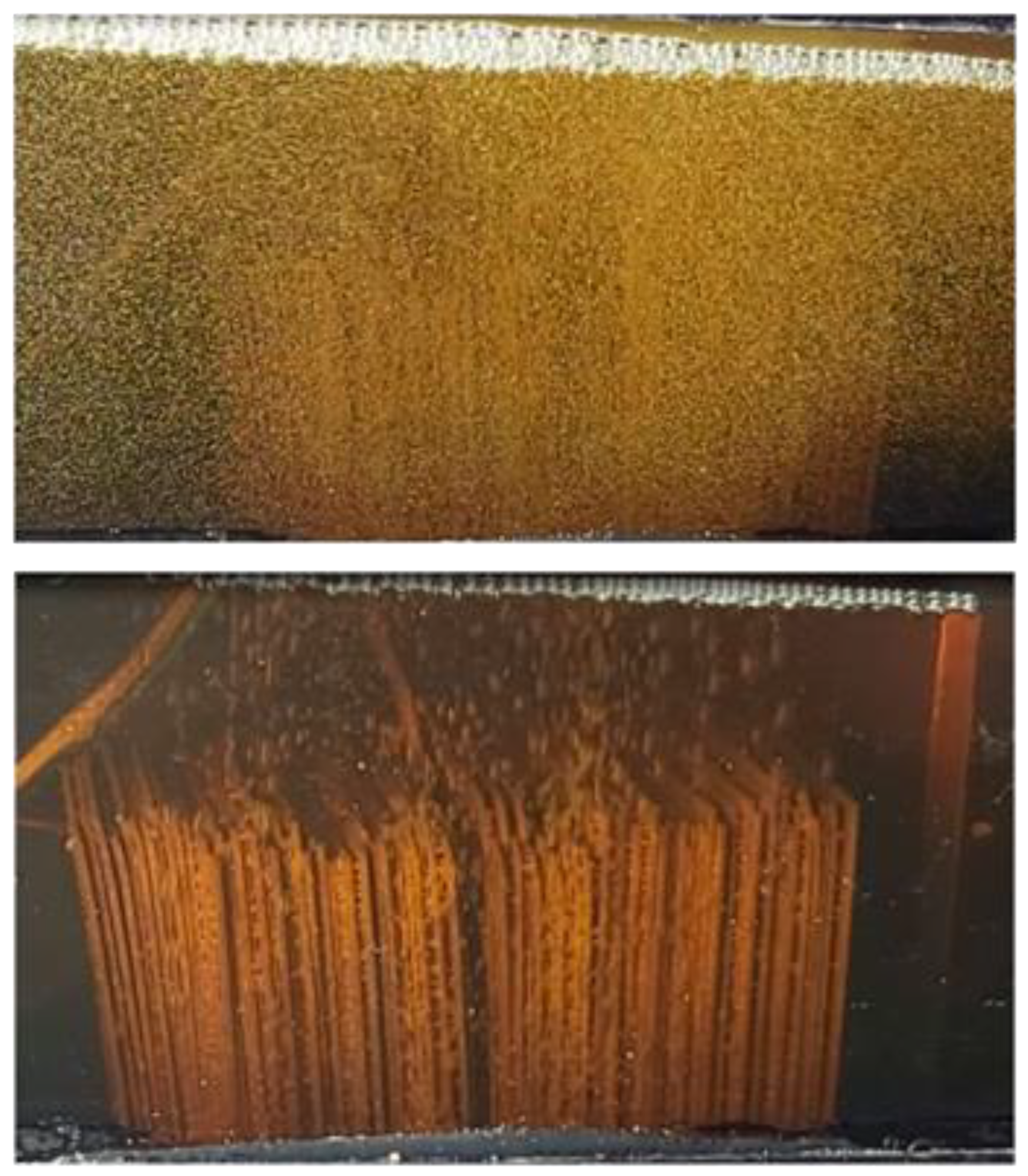

Figure 6 shows selected frames from the film presenting the bubble effect in pressboard sample heated with mineral oil. The sample was made in the form of a block of many layers of pressboard.

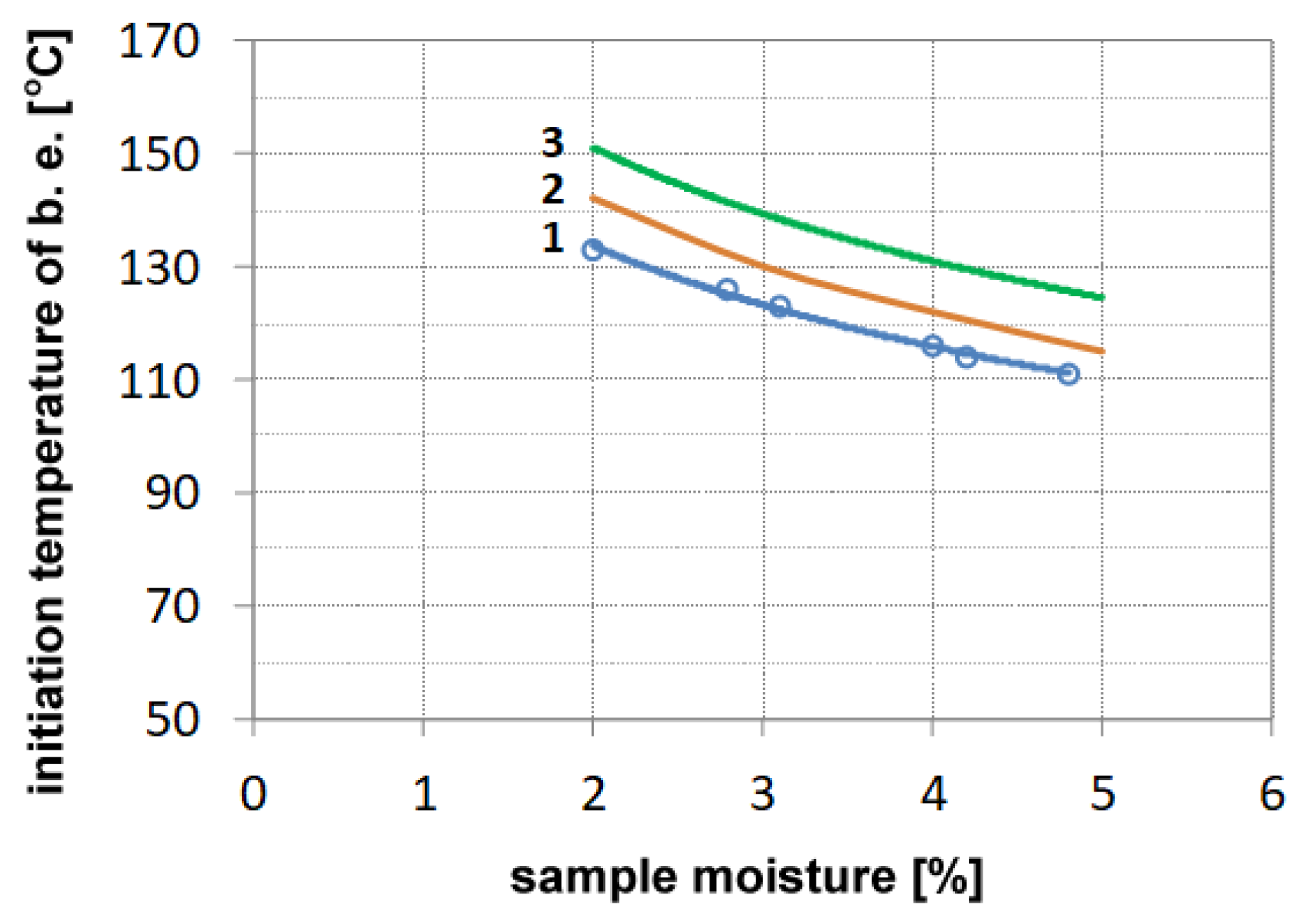

The next experiment consisted in determining the characteristics of the bubble effect initiation temperature depending on the moisture content of the pressboard. Preparing pressboard samples for testing consisted in drying them in a vacuum dryer and then in a controlled moistening in a climatic chamber. The moisture content of the pressboard samples ranged from 2.0 to 4.8%. The tested pressboard had the form of a block with dimensions of 60x70x4.3 mm. The temperature was measured between the pressboard layers and in the oil in its upper and lower layers. It was found that with a slow increase in the oil temperature, equal to 1 °C/min, the temperature of the pressboard is equal to the temperature of the oil in its upper layer with an accuracy of 0.1 °C.

Characteristic 1 on

Figure 7 shows the dependence of the b.e. initiation temperature on pressboard moisture obtained during experiment. For comparison, two characteristics of b.e. initiation temperature in the wound paper in the Hot Spot area have been added. Characteristic 2 comes from the Oommen [

7], while characteristic 3 comes from works [

27,

28]. All these characteristics are similar. As you can see, the course of the curves is the same, regardless of whether the bubbles were formed in paper or pressboard insulation. The difference visible in initiation temperature of b.e. in the pressboard block and in the winding paper in Hot Spot area should not be surprising. This is due to the fact that the paper temperature was measured not directly on the winding, but between the first and second layer of the paper. Due to its thermal conductivity, the measured initiation temperature b.e. will always be slightly higher compared to the actual one.

The experiment showed that the b.e. phenomenon proceeds in the same way, regardless of whether it occurs in insulation in the Hot Spot area or in the pressboard sleeve.

4. Conclusions

Research has shown that there is a hitherto unrecognized bubble effect in a large mass of cellulose heated by mineral oil. This phenomenon can occur in oil transformers in pressboard insulating barriers between the windings of the upper and lower voltage. The fact that a large mass of cellulose with a significant water content may be involved in the process the phenomenon is extremely dangerous. The high dynamics of water desorption causes an extreme increase in pressure in the tank, which can lead even to its explosion. In the model tests, the test chamber exploded twice. This process is fundamentally different from the well-known and described bubble effect occurring in the hottest places of the transformer.

In the first part of the research, the transformer insulation system was modeled, taking into account the appropriate thickness of the winding paper, the thickness of the barrier and the width of the oil channel. The paper insulation was heated intermittently, which corresponded to the cyclical load of the transformer. As a result, the threat of a bubble effect in the Hot Spot area disappeared, while b.e. occurred in the pressboard barrier, which led to the explosion of the test chamber.

In the next experiment, it was found that the bubble effect in pressboard with moisture content encountered in many transformers (approx. 3%) occurs at a temperature of 112 °C, while the standard [

29] allows 115 °C in upper layer of oil. In this situation, the provisions of the standard should be looked at critically – particularly to older transformers, for which the inception temperature of b.e. is reduced.

It was found that the increase in the mass of cellulose products in relation to the mass of oil, when bubble effect appearing, resulted in an increase in the pressure in the air cushion of the test chamber.

If the b.e. appears in large mass of pressboard insulation, what happens suddenly and with very high intensity, and if Buchholz relay will not have time to turn off the transformer in an emergency, the high pressure in the tank may lead to its unsealing, which increase rapidly the volume of bubbles. This will make the situation much worse.

In the future, similar studies are planned for aramid-based materials and alternative insulating liquids.

Funding

This research was funded by the Ministry of Science and Higher Education, grant number 0711/SBAD/4616.

Conflicts of Interest

The authors declare no conflicts of interest. The funder had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-Paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Tyuftyaev, A.S.; Gadzhiev, M.K.; Sargsyan, M.A.; Akimov, P.L; Demirov, N.A. The effect of gas bubbles on electrical breakdown in transformer oil. Journal of Physics: Conference Series 2016, 774, 012202. [Google Scholar] [CrossRef]

- Kaufmann, G. Gas bubbles in distribution transformers. IEEE Transactions on Power Apparatus and Systems 1977, 96, 1596–1601. [Google Scholar] [CrossRef]

- Heinrichs, F.W. Bubble Formation in Power Transformer Windings at Overload Temperatures. IEEE Transactions on Power Apparatus and Systems 1979, 98, 1576–1582. [Google Scholar] [CrossRef]

- Kaufmann, G.; McMillen, C. Gas bubble studies and impulse tests on distribution transformers during loading above nameplate rating. IEEE Transactions on Power Apparatus and Systems 1983, 2531–2542. [Google Scholar] [CrossRef]

- McNutt, W.; Rouse, T.; Kaufmann, G. Mathematical modelling of bubble evolution in transformers. IEEE Transactions on Power Apparatus and Systems 1985, PAS-104, 477-487. [CrossRef]

- Oommen, T.V.; Lindgren, S.R. Bubble evolution from transformer overload. In Proceedings of the 2001 IEEE/PES Transmission and Distribution Conference and Exposition. Developing New Perspectives (Cat. No. 01CH37294), Atlanta, USA, 02-02 November 2001; pp. 137–142. [Google Scholar] [CrossRef]

- Gao, M.; Ding, Y.; Wang, T.; Wen, T.; Zhang, Q. Study on bubble evolution in oil-paper insulation during dynamic rating in power transformers, In Proceedings of the 2016 IEEE International Power Modulator and High Voltage Conference (IPMHVC), San Francisco, CA, USA, 6–9 July 2016. [CrossRef]

- Gielniak, J.; Moranda, H.; Neumann, S.; Ossowski, M.; Przybylek, P.; Walczak, K; Moscicka-Grzesiak, H. Warunki wystapienia "bubble effect" w transformatorze o izolacji papierowo-olejowej (Conditions for the occurrence of the "bubble effect" in a paper-oil insulated transformer). Energetyka 2005, Oficyna Wydawnicza Energia, Katowice, Poland, vol. 6, pp. 120–122.

- IEEE Std. 62-1995, Guide for Diagnostic Field Testing of Electric Power Apparatus, Part 1: Oil Filled Power Transformers, Regulators, and Reactors, New York, USA, March 16, 1995. [CrossRef]

- Przybylek, P.; Moscicka-Grzesiak, H. Influence of oil-paper insulation aging processes on temperature of bubble effect initiation, Prace Naukowe Instytutu Podstaw Elektrotechniki i Elektrotechnologii Politechniki Wroclawskiej. Konferencje 2007, Oficyna Wydawnicza Politechniki Wroclawskiej, Wroclaw, Poland, vol. 46, no. 19, pp. 213–216.

- Przybylek, P. The influence of cellulose insulation aging degree on its water sorption properties and bubble evolution. IEEE Transactions on dielectrics and electrical insulation 2010, 17, 906–912. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H. Zjawisko "bubble effect" w izolacji papierowo-olejowej o różnym stopniu zawilgocenia i zestarzenia. Pomiary Automatyka Kontrola 2009, 55, 44–46. [Google Scholar]

- Przybylek, P.; Nadolny, Z.; Moscicka-Grzesiak, H. Bubble Effect as a Consequence of Dielectric Losses in Cellulose Insulation. IEEE Transactions on Dielectrics and Electrical Insulation 2010, 17, 913–919. [Google Scholar] [CrossRef]

- An international European Commission Research Project FP5, Reliable diagnostics of HV transformer insulation for safety assurance of power transmission system, acronym REDIATOOL, NNE5-2001-472, consortium: Poznan University of Technology, Poland, University of Stuttgart, Germany, Chalmers University of Technology, Sweden, Polish Power Grids – West, Poland, Zaklady Produkcyjno-Remontowe Energetyki – Czerwonak, Poland, RWE Net Aktiengesellschaft, Germany, realization: 01 February 2003-31 January 2006.

- Koch, M.; Tenbohlen, S. Evolution of bubbles in oil-paper insulation influenced by material quality and ageing. IET Electric Power Applications 2011, 5, 168–174. [Google Scholar] [CrossRef]

- Perkasa, C.Y.; Lelekakis, N.; Czaszejko, T.; Martin, D.; Saha, T. Moisture-bubbling of vegetable oil impregnated paper at transformer overload temperatures. In Proceedings of the 2015 IEEE 11 International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, NSW, Australia, 19–22 July 2015; pp. 76–79. [Google Scholar] [CrossRef]

- Lewandowski, K.; Moranda, H.; Szewczyk, R. Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids. Energies 2023, 16, 5297. [Google Scholar] [CrossRef]

- Przybylek, P. A comparison of bubble evolution temperature in aramid and cellulose paper. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 1–4. [Google Scholar] [CrossRef]

- Zhao, T.; Tong, Y.; Zheng, Y.; Zhang, Z.; Liu, Y.; Chao, N. Experimental study on bubble effect of oil–paper insulation in natural ester. IEEE Transactions on Dielectrics and Electrical Insulation 2022, 29, 2387–2393. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. Can the bubble effect occur in an oil impregnated paper bushing? IEEE Transactions on Dielectrics and Electrical Insulation 2012, 19, 1879–1883. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. The bubble effect in bushings – investigations on models. IEEE Transactions on Dielectrics and Electrical Insulation 2015, 22, 3405–3412. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H. Bubble effect in bushing insulators with insulation manufactured from different material. In Proceedings of the XVII International Symposium on High Voltage Engineering (ISH 2011), Hannover, Germany, 22–26 August 2011; p. (on DVD) F-004. [Google Scholar]

- CIGRE Working Group A2.30. Moisture equilibrium and moisture migration within transformer insulation systems. Technical Brochure CIGRE 2008, no. 349.

- Moscicka-Grzesiak, H.; Moranda, H.; Gielniak, J.; Graczkowski, A.; Przybylek, P.; Walczak, K. Ograniczenia obciazalnosci transformatorow o zawilgoconej izolacji (Load capacity limits for transformers with wet insulation). Pomiary Automatyka Kontrola 2009, 55, 47–49. [Google Scholar]

- Hill, J.; Wang1, Z.; Liu1, Q.; Krause, C.; Wilson, G. Analysing the power transformer temperature limitation for avoidance of bubble formation. High Voltage 2019, 4, 210–216. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. Efekt endotermiczny towarzyszacy rozwojowi bubble effect (in Polish, Endothermic effect accompanying the development of the bubble effect). In Proceedings of the International Conference Transformator ‘15, Gdansk, Poland, 12–14 May 2015; pp. 111–115. [Google Scholar]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. Bubble effect w ukladach izolacyjnych papier-ester syntetyczny oraz papier-olej mineralny (in Polish, Bubble effect in paper-synthetic ester and paper-mineral oil insulation systems). Przeglad Elektrotechniczny 2013, 296–299. [Google Scholar]

- IEC 60076-7: 2018 Power transformers – Part 7: Loading guide for mineral-oil-immersed power transformers, Geneva, Switzerland.

- Gielniak, J.; Graczkowski, A.; Moranda, H.; Przybylek, P.; Walczak, K.; Nadolny, Z.; Moscicka-Grzesiak, H.; Feser, K.; Gubanski, S.M. Moisture in cellulose insulation of power transformers – statistics. IEEE Trans. on Dielectrics and Electrical Insulation 2013, 20, 982–987. [Google Scholar] [CrossRef]

- Prosinski, S. Chemia drewna (in Polish, Wood chemistry), Publisher: Panstwowe Wydawnictwo Rolnicze i Lesnicze, Warszawa, Poland, 1984.

- Young, D.M.; Cromwell, A.D. Fizyczna adsorpcja gazow (in Polish, Physical adsorption of gases), PWN, Warszawa, Poland, 1968.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).