1. Introduction

The International Energy Agency (IEA) warns that growing air conditioner use will drive global electricity demand over the next three decades. In its report "The Future of Cooling," the IEA calls for urgent policy actions to improve cooling efficiency. Without new standards, global AC energy demand could triple by 2050 [

1]. Efficiency improvements could cut this growth in half, saving up to

$2.9 trillion and reducing the need for new power plants. Currently, less than a third of global households have air conditioners, with stark regional disparities. Demand is expected to surge, particularly in countries like India, without intervention [

2]. Air conditioning systems are an integral part of modern building environments, providing essential control of temperature, humidity, and indoor air quality. The operational framework of these systems is based on the refrigeration cycle, where the refrigerant undergoes phase changes—alternating between gaseous and liquid states—to absorb and reject heat, thus facilitating the cooling process. The basic components of a typical AC system include a compressor, condenser, evaporator, and expansion valve. The compressor is responsible for compressing the refrigerant, thereby increasing its temperature, and forcing it through the system. The high-temperature, high-pressure refrigerant then enters the condenser, where it releases heat to the surrounding environment and condenses into a liquid state. The refrigerant then passes through the expansion valve, which reduces its pressure and temperature before entering the evaporator. In the evaporator, the refrigerant absorbs heat from the indoor air, evaporates back into a gas, and cools the air, which is then circulated back into the space. Air conditioning systems are classified into several types based on their configuration and application, including window units, split systems, central air conditioning systems, and portable units. Window units are stand-alone systems designed for single-room cooling, while split systems, which consist of separate indoor and outdoor units, are commonly deployed in residential and commercial settings for targeted cooling. Central air conditioning systems are designed for large-scale applications, using a network of ducts to distribute cooled air throughout a building [

3,

4,

5]. Portable units provide flexible and mobile cooling solutions, and are often used as supplements to existing systems. Evaporative cooling cells, also known as cooling pads, are used in refrigeration and air-conditioning systems to enhance energy efficiency by taking advantage of the natural process of evaporation. As warm air passes through these wet cells, water evaporates, cooling the air. This cooled air can then be used directly or to pre-cool the air entering the refrigeration system, reducing the workload on the compressor and saving energy. These systems are particularly effective in hot, dry climates and are commonly used in agricultural storage, greenhouses, and industrial environments. However, their efficiency declines in high-humidity environments, and they require regular maintenance to prevent mineral build-up, microbial growth, and salts. In general, evaporative cooling cells provide a cost-effective and energy-efficient alternative or complement to conventional cooling, especially in specific climatic conditions. This study explores the integration of conventional residential cooling systems with an (ECS) to improve energy efficiency and sustainability. This integration is particularly effective in hot and dry climates, reducing the energy load on compressors. The research focuses on optimizing the system design, including cooling cell placement, air distribution, and control mechanisms to manage different environmental conditions. The goal is to develop a hybrid cooling solution that combines evaporative and mechanical cooling technologies, providing a more efficient and environmentally friendly approach to residential cooling.

2. Experimental Section

Research into air conditioning units, particularly those using evaporative cooling systems, has led to significant advances in our understanding of how different cooling pad materials and system configurations affect overall efficiency and performance. Evaporative cooling systems are highly valued for their energy efficiency and environmental benefits, primarily because they use water rather than refrigerants to cool the air. Consequently, a large body of research has focused on improving the design and materials used in cooling pads, as these components play a pivotal role in determining the effectiveness of the system. For example, the “Performance Study of Cooling Pads” provides a detailed analysis of different cooling pad materials, including curtain fabric and raw cotton, under different operating conditions such as different blowing speeds and water flow rates [

6]. The results from this study indicate that cooling pads made from curtain fabric exhibit higher saturation efficiencies compared to those made from raw cotton. Specifically, curtain fabric pads were found to be more effective at reducing air temperature and increasing humidity levels in the air passing through the pads. This suggests that material selection is critical in the design of effective evaporative cooling systems. Furthermore, other studies in this area have explored the cooling efficiency of alternative materials such as jute, loofah, and recycled high-density polyethylene (HDPE), further underscoring the potential environmental benefits of these systems. These studies highlight that evaporative coolers, using various innovative materials, can offer significant reductions in electricity consumption and reduce reliance on conventional refrigerants, making them a more sustainable option compared to conventional vapor-compression cooling systems. In addition to material studies, research has also delved into the structural aspects of evaporative cooling systems, particularly the configuration and number of cooling pads used. For example, the paper titled “Effect of the Number of Cooling Pads on Outdoor Air Conditioner and Air Cooler Efficiency” examines how the amount of cooling pads affects the cooling performance of the system. The study shows that increasing the number of cooling pads generally results in lower dry air temperatures and higher outdoor relative humidity, which in turn improves the cooling efficiency of the system. Notably, the research suggests that using six cooling pads results in the lowest possible dry air temperature and highest efficiency, with the air outlet reaching almost full saturation (close to 100% relative humidity). However, it is also noted that after a certain point, adding more cooling pads does not lead to further significant improvements, as the benefits tend to level off [

7]. The study titled "Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation" enhancing air conditioning performance using direct evaporative cooling (DEC), showing a 10-20% increase in cooling capacity, a 6-10°C reduction in outlet temperature, and a 3% decrease in energy consumption [

8]. Despite extensive research on stand-alone evaporative cooling systems, there is a significant gap in the integration of these systems with conventional air conditioning units. This study advances the current body of knowledge by investigating the integration of (ECPs) with conventional split air conditioning systems. The primary goal of this integrated approach is to enhance the cooling efficiency and reduce the electricity consumption of air conditioning systems by pre-cooling the air before it enters the unit. By pre-positioning the air conditioning cooling pads, the hybrid system reduces the workload on the air conditioning compressor, thereby improving the overall energy efficiency. This hybrid approach represents an important innovation in refrigeration technology, as it combines the environmental benefits and energy savings of evaporative cooling with the reliability and performance of conventional mechanical air conditioning systems. The integration of these technologies addresses a critical gap in current research, which has largely focused on the stand-alone application of evaporative cooling systems. By exploring this integrated approach, the study opens up new avenues for enhancing energy efficiency in residential and commercial cooling applications, especially in hot and dry climates where evaporative cooling is more effective. In addition, this hybrid system has the potential to provide a more sustainable air conditioning solution, reducing operating costs and environmental impact3. Results

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation as well as the experimental conclusions that can be drawn.

3. Methodology

In this study, the methodology was designed to evaluate the performance improvement of an LG split air conditioner, with a capacity of 18,000 Btu and equipped with an inverter compressor, by incorporating (ECP). The study was conducted in Riyadh, Saudi Arabia, which is characterized by its hot and dry climate, to take advantage of these conditions to improve the efficiency of the air conditioning system. This experiment was conducted on the hottest summer days in the region, which are July 7 and July 8, and while ensuring that the air conditioning temperature was set to 25°C. 1. Equipment selection: The LG split air conditioner model was selected for continuous compressor operation, which allows for continuous cooling and facilitates accurate calculation of operating costs. The unit specifications were considered appropriate for the environmental conditions and objectives of the study. 2. Design and fabrication: A custom L-shaped galvanized steel structure was designed to cover all sides of the air conditioner condenser unit. The aim of this design was to maximize the exposure of the condenser to the cooled air generated by the (ECP). The structure is designed to house 20cm wide (ECP), chosen to balance the cooling of the incoming air to the condenser and the cooling of the internal components of the air conditioner. 3. Evaporative Cooling Pads (ECP): Evaporative cooling pads are strategically installed before the air enters the condenser unit of the air conditioner. The (ECP) are connected to the water supply via a pump installed to lift the water to the top of the (ECP), ensuring that the water is evenly distributed across the surface. The cooling pads work by evaporating water, which reduces the temperature of the air passing through them before it reaches the condenser. A fan built into the outdoor unit of the air conditioner aids in this process by distributing the cooled air to the condenser coils. 4. Electrical integration: To achieve operational efficiency, the electricity supply to the water pump was integrated with the air conditioner control unit, with the addition of a device that can be used to turn the pump on and off manually via a mobile phone. We can also set the program used for a specific time to turn the pump on and off, but in this experiment, the pump was operated throughout the air conditioner operation period, thus improving consumption efficiency so that we can operate the pump only during the air conditioner operation time and not operate all the time. 5. Testing and data collection: The performance of the air conditioning system, with or without the integrated (ECS), was monitored and recorded over a specified period. Key performance indicators included temperature drop on the condenser, overall cooling efficiency, and energy consumption of the air conditioning unit. Data on operating costs were also collected to evaluate the economic benefits of the enhanced cooling system. 6. Analysis: The collected data was analyzed to determine the effectiveness of the (ECS) in improving the performance of the air conditioner. The focus was on reducing the thermal load on the condenser, enhancing the resulting cooling capacity, and improving overall energy efficiency. Comparisons were made between the baseline performance of the air conditioner and its performance after incorporating an (ECS) to measure the impact of this hybrid cooling approach.

4. Experimental Setup

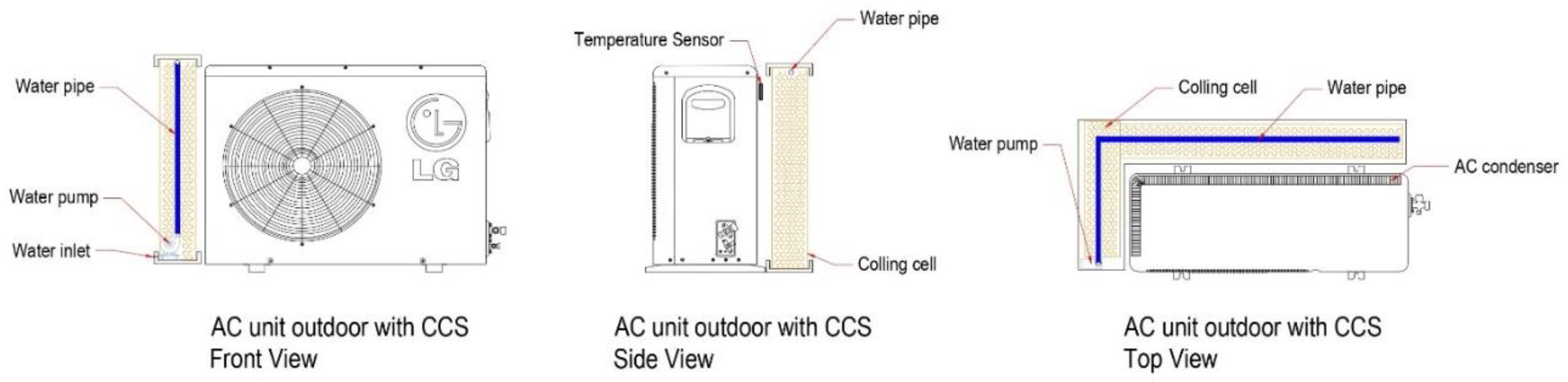

In this study, an LG NC182H3 60Hz, 230V, 6.1A, EER 13.10 (Btu/h)/w split air conditioner with 18,000 Btu/h UK capacity, 5.28kW capacity and inverter type compressor was selected for analysis due to the continuous compressor operation, which ensures a constant cooling effect and prevents the building occupants from being exposed to temperature fluctuations typically caused by the compressor cycle. Continuous operation also allows for accurate calculations of operating costs throughout the life of the air conditioner. The primary focus of this study was to improve the performance of the air conditioner by incorporating an (ECS) into a conventional air conditioner, specifically targeting the condenser unit in an outdoor setting. Given the hot and dry climate of Riyadh, Saudi Arabia, where this experiment was conducted, the (ECPs) were strategically placed before the air enters the condenser. The aim was to take advantage of the ambient conditions to maximize the cooling effect on the condenser, thereby improving the overall efficiency of the air conditioning unit. The cooling pad basin was filled with water, which when evaporated, effectively lowered the temperature of the air passing between the condenser coils, with the help of the fan located inside the outdoor unit. To implement this setup, a custom L-shaped galvanized steel frame was fabricated to encase all sides of the condenser

Figure 1,

Figure 2 and

Figure 3.

Within this design, the maximum surface area of the condenser is exposed to the cooled air from the (ECP). In addition, a water pump was installed to lift the water to the top of the (ECP), ensuring a constant flow and even distribution across the cells through holes drilled in the water pipe. To achieve operational efficiency, the electrical supply to the water pump was integrated with the air conditioner control unit, allowing the pump to operate seamlessly alongside the air conditioner operation. We can control the pump’s on and off manually via a mobile phone program and we can also set the program used to a specific time when the pump is turned on and off. The (ECP) used in this setup were 20 cm wide, chosen due to their wide availability in the local market and to provide optimum cooling efficiency for the condenser. This dimension was chosen to ensure sufficient surface area for air cooling while maintaining a compact form factor that does not interfere with the normal operation of the outdoor unit. The integration of these cooling cells aims to enhance the cooling performance of the air conditioning unit, especially in harsh climates, by reducing the thermal load on the condenser, thus improving the overall energy efficiency of the system. This approach not only improves the cooling capacity of the air conditioner, but also has the potential to reduce energy consumption and operating costs, making it a viable solution for improving air conditioning performance in hot and dry environments. A thermometer was also used, where it was added between the condenser in the outdoor unit and the (ECP),

Figure 4, to measure the temperature passing through the condenser, with the aim of reaching the lowest possible temperature passing through the condenser. To calculate the energy consumed (power, voltage and current), a device,

Figure 5, was used and connected through a laptop to read and record the consumption data.

As for the temperature and humidity of the atmosphere, they were taken based on what was mentioned on the Arab Weather website and time and date, as they were the reference in this study, and these websites indicate that the temperature during the experiment was from 44 °C to 45 °C, and the humidity ranged between 7% to 9% during the two days in which this experiment was conducted [

8,

9].

5. Results and Discussion

In this experiment, a precise comparison was made between the performance of the air conditioner using the ECS evaporative cooling system and the conventional air conditioning system, with the aim of determining the differences in energy consumption and operational efficiency. I will review the results obtained using specialized measuring devices and present them in tables and graphs to provide a comprehensive and accurate analysis of the data. In

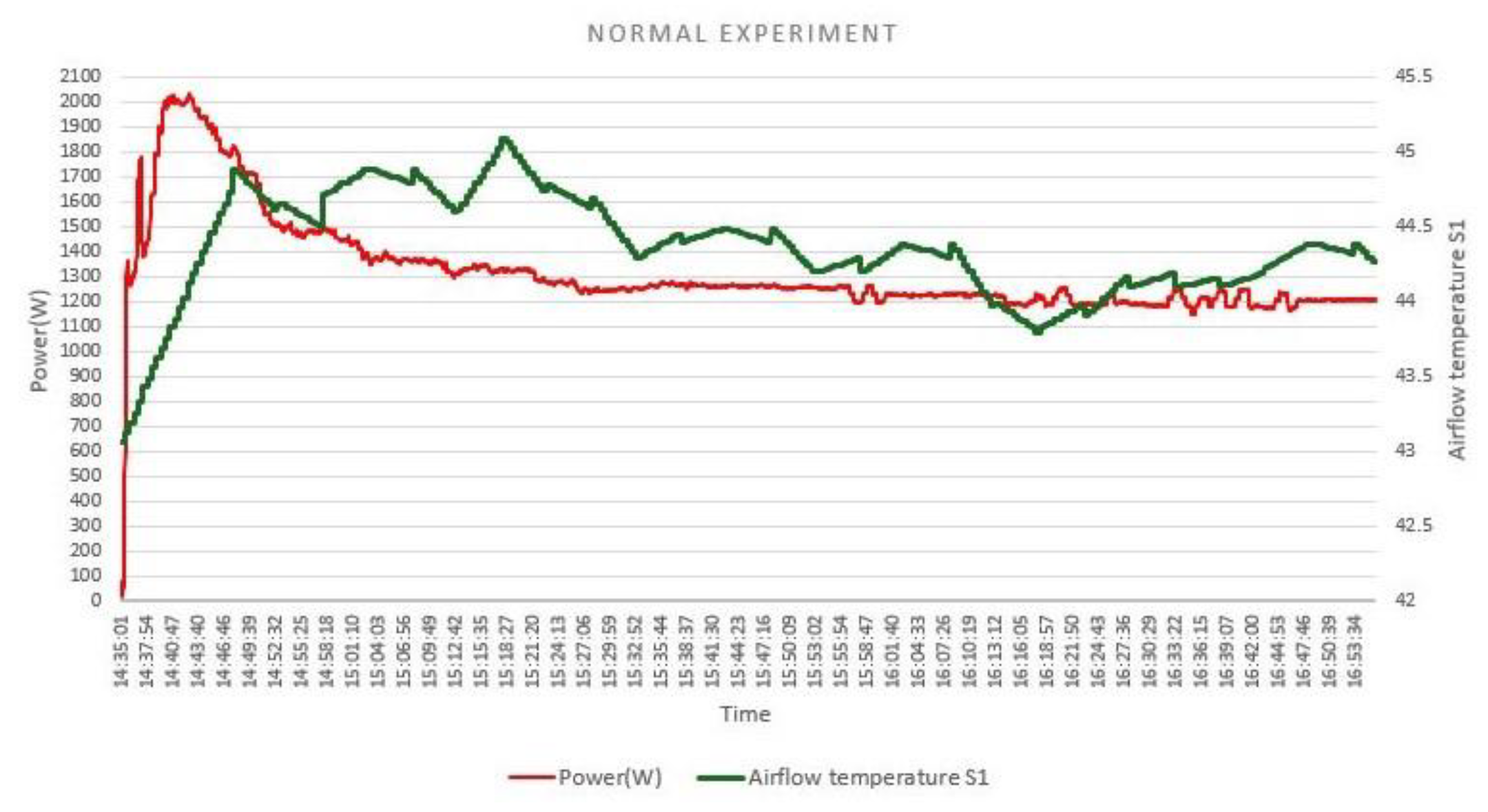

Figure 6, the horizontal axis (X) shows the time in seconds, where the data was recorded over the course of the experiment. While the vertical axis (Y) displays two important variables: the electrical power consumed by the air conditioner during operation, which is represented in red, and the temperature of the air passing through the condenser, indicated in green.

6. Results and Discussion

In this experiment, a precise comparison was made between the performance of the air conditioner using the ECS evaporative cooling system and the conventional air conditioning system, with the aim of determining the differences in energy consumption and operational efficiency. I will review the results obtained using specialized measuring devices and present them in tables and graphs to provide a comprehensive and accurate analysis of the data. In

Figure 6, the horizontal axis (X) shows the time in seconds, where the data was recorded over the course of the experiment. While the vertical axis (Y) displays two important variables: the electrical power consumed by the air conditioner during operation, which is represented in red, and the temperature of the air passing through the condenser, indicated in green.

Through this data, the lowest temperature reached the condenser was recorded at 43.06 °C. In

Table 1, the data shows that the maximum electrical power consumed by the air conditioner during operation reached 2034.6 W, while the maximum electrical current reached 9.42 A. The average electrical power consumption of the air conditioner was calculated over the experiment period and the result was 1318.6 W, while the average current was 6.07 A.

The experiment took two hours and twenty minutes, during which all variables were accurately measured. Moving to the second experiment, where the (ECS) was used,

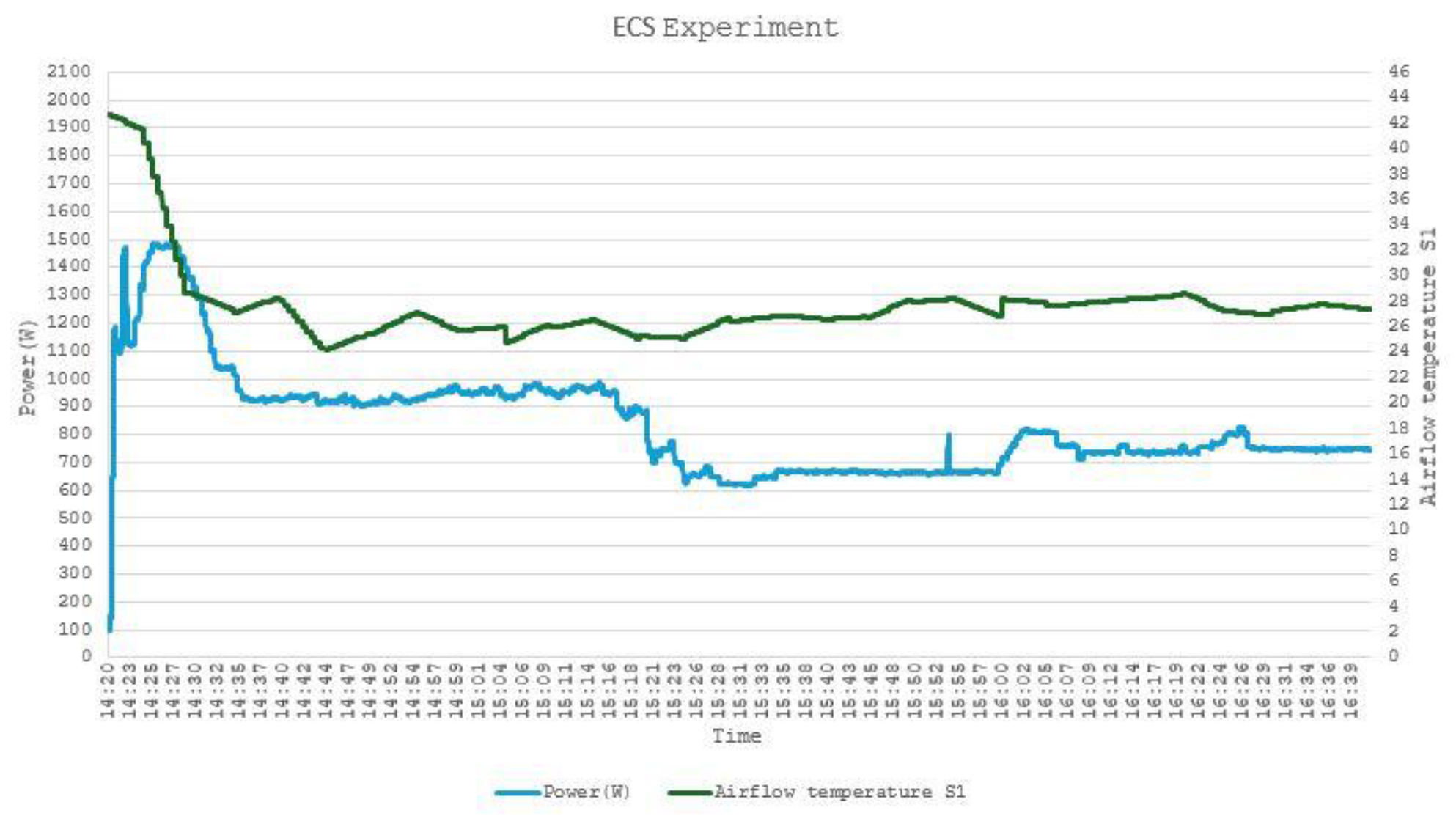

Figure 7 shows the same X and Y axes, but with a clear decrease in energy consumption after one hour from the start of the experiment.

The data indicate that the reason for this decrease is due to the effect of the (ECS) on the condenser, as the decrease in the condenser temperature led to a decrease in the speed of the external air conditioner fan, which in turn reduces energy consumption. In

Table 2, the maximum electrical power consumed by the air conditioner with the evaporative cooling system (ECS) was monitored and was 1484.9 W, while the maximum current was 9.58 A. If we calculate the average over the entire experiment, we find that the operating power was 831.6 W, while the average current was 6.05 A. The lowest temperature that reached the condenser was recorded and was 24.20 °C.

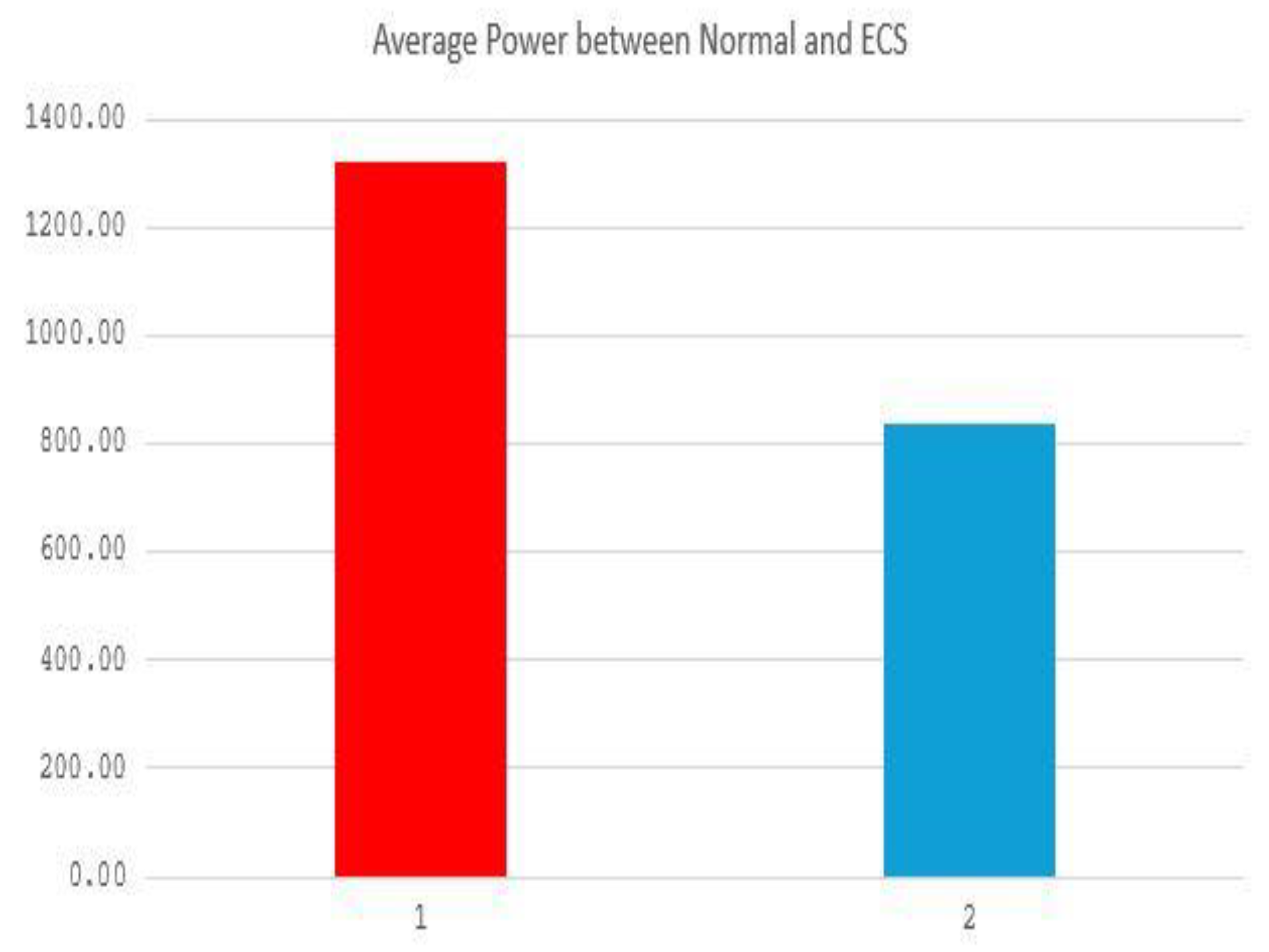

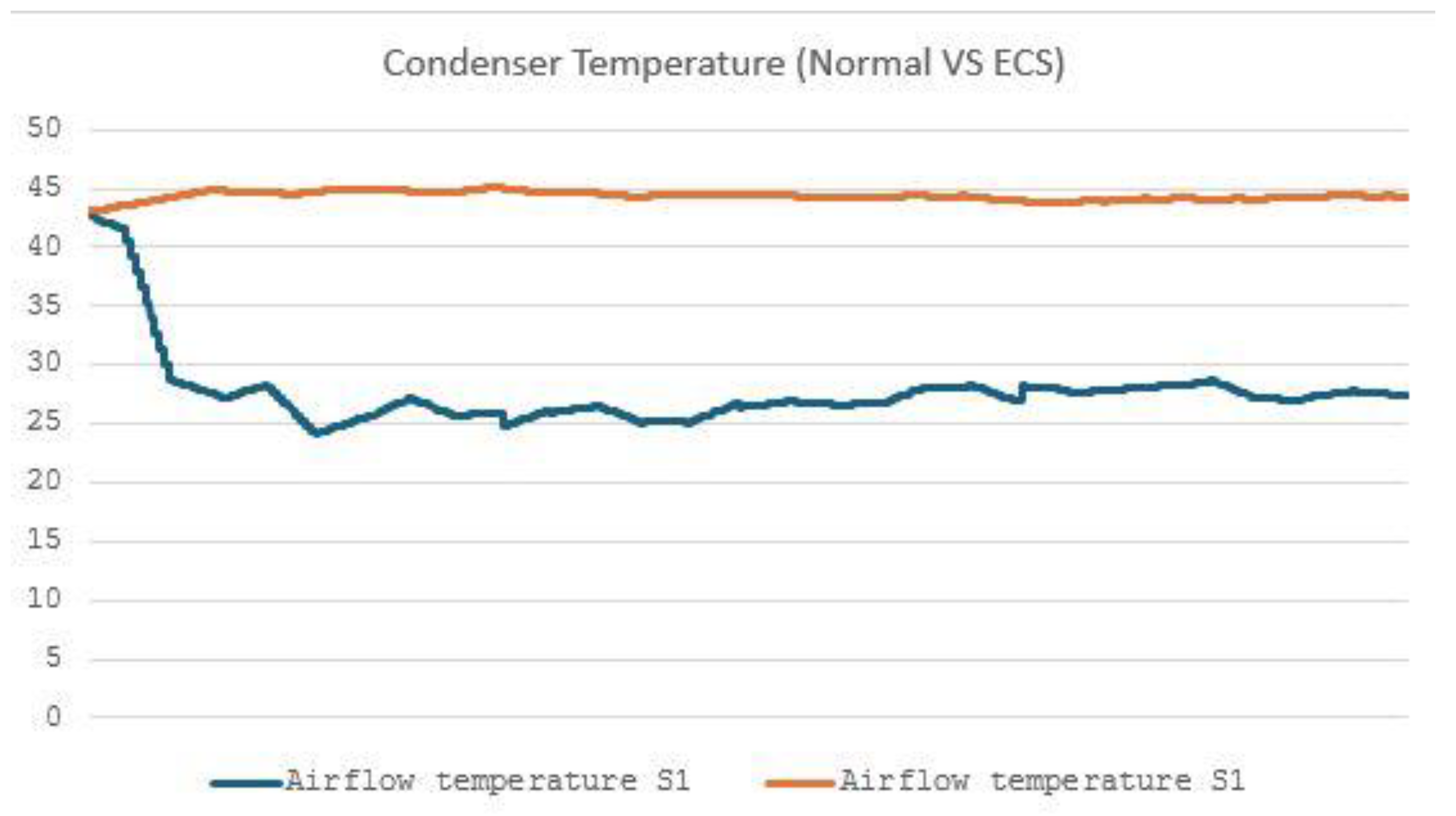

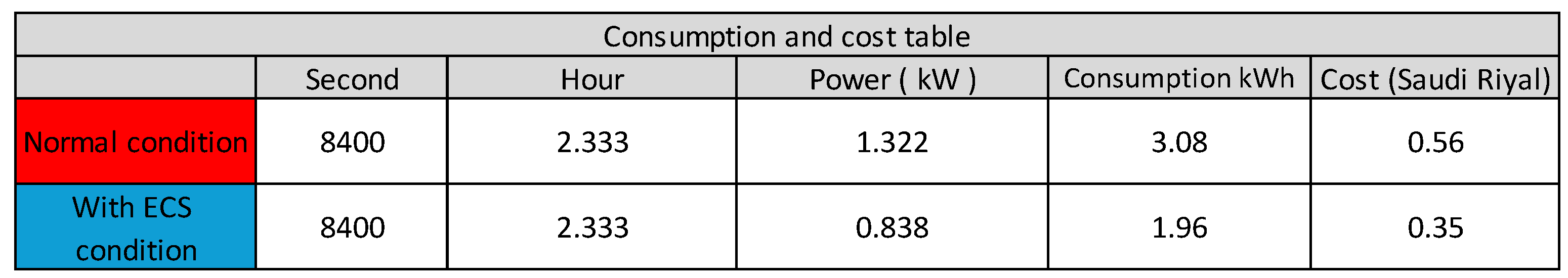

In addition, the consumption of the water pump used with the (ECS) was calculated, which amounted to 120 W during its operation period. The duration of this experiment was also two hours and twenty minutes. When comparing the results between the two experiments, as shown in

Table 3 and

Figure 8 and

Figure 9, we find that there is a significant saving in power consumption between the two systems by 36.9%.

As for the average electrical current, the difference was in favor of the conventional system, as the current was higher in the (ECS) by a slight difference.

Figure 10 shows an accurate comparison between the temperatures reaching the condenser in both systems, which shows the effect of the (ECS) on improving the cooling efficiency and reducing the temperature of the air entering the condenser.

In terms of energy consumption, the data in

Table 4 showed that the conventional system consumed 3.08 kWh, compared to 1.96 kWh when using the (ECS), which shows a difference of 1.13 kWh.

Financially, the operating cost was calculated based on the price of a kilowatt per hour in Saudi Arabia, which is 0.18 Saudi riyals per kilowatt, for the conventional system and was found to be 0.56 Saudi riyals for the trial period, while the operating cost with the (ECS) was 0.35 Saudi riyals, which shows a financial saving of 0.20 riyals during the trial period that lasted for two hours and twenty minutes. The air coming out of the external air conditioner fan can also be used to cool open spaces such as sitting areas or others, as the air temperature coming out of the external air conditioning unit is approximately 24 °C. Finally, this experiment clearly shows that the use of the (ECS) provides tangible benefits in improving cooling efficiency and reducing electricity consumption. However, among the challenges associated with this system is the need for large amounts of water due to the evaporation process, in addition to the need for periodic maintenance to prevent the accumulation of salts in the water basin, which are aspects that must be taken into account when considering the adoption of this system on a large scale.

5. Conclusions

This study clearly demonstrates the significant benefits that can be achieved by integrating an (ECS) with conventional air conditioning systems. The most notable results include a significant saving in electrical power consumption of 36.9%, and improved cooling efficiency by effectively lowering the temperature of the air passing through the condenser, with the data recording a decrease in the condenser temperature to 24.20°C when using the ECS, compared to 43.06°C in the conventional system. In addition, the results showed a significant reduction in electricity consumption, with energy consumption dropping from 3.08 kWh in the conventional system to 1.96 kWh when using the ECS. This reduction in energy consumption translates into a financial saving of SAR 0.20 for every two hours and twenty minutes of operation. The implications for the design and use of the air conditioning unit when integrating an (ECS) include the need to reconsider the design of the outdoor units of the air conditioners to provide sufficient space to strategically install the (ECS). This simple modification can lead to significant improvements in system efficiency and reduced energy consumption. Integrating the water pump with the air conditioning control system also enhances operational efficiency, as the pump operation can be controlled automatically based on the system’s need, reducing both water and energy consumption. However, the results indicate that there are challenges that need to be considered when adopting this system on a large scale. The most important of these challenges is the need for large amounts of water to operate the ECS, which requires effective management of water resources, especially in areas suffering from water scarcity. In addition, the ECS requires periodic maintenance to prevent the accumulation of salts and mineral deposits, which is essential to maintain the system’s efficiency in the long term. This study recommends further investigation into the effect of the ECS on indoor cooling efficiency in closed spaces, as a significant difference in room coolness was observed when using the ECS, but the indoor cooling efficiency was not accurately calculated. This point deserves more attention in future studies, as it can provide accurate data on the temperature difference inside rooms when using hybrid systems, which enhances our understanding of how these systems can be optimized to achieve maximum energy efficiency. We also recommend investigating the possibility of developing evaporative cooling cell materials to improve their water efficiency, and reduce the need for frequent maintenance. Innovative designs for outdoor air conditioning units that better integrate with evaporative cooling cells can also be explored, which reduces the complexity of installation and operation. We also recommend finding a suitable method to prevent water from leaking out of the water box, as in this experiment a lot of water leaked due to the internal curvature of the (ECP). Ultimately, this study opens the door to the development of hybrid cooling solutions based on integrating evaporative cooling systems with conventional systems, which provides a more efficient and environmentally friendly approach to residential and commercial cooling in hot and dry regions. However, realizing the full benefits of this approach requires continued research and innovation in this area to ensure improved performance and long-term sustainability.

Nomenclature

| EER |

Energy Efficiency Ratio |

| Btu |

British Thermal Unit |

| cm |

Centimeter |

| W |

Watt |

| A |

Ampere |

| V |

Volt |

| Hz |

Hertz |

| ECS |

Evaporative Cooling System |

| ECP |

Evaporative Cooling Pads |

| °C |

Degrees Celsius |

References

- International Energy Agency. (2018). The Future of Cooling: Opportunities for energy-efficient air conditioning. OECD/IEA. Retrieved from https://www.iea.org.

- International Energy Agency. (2018). Air conditioning use emerges as one of the key drivers of global electricity demand growth. Retrieved from https://www.iea.org/news/air-conditioning-use-emerges-as-one-of-the-key-drivers-of-global-electricity-demand-growth.

- ASHRAE. (2021). ASHRAE Handbook - Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

- Dossat, R. J., & Horan, T. J. (2001). Principles of Refrigeration (5th ed.). Pearson..

- Watt, J. R. (1986). Evaporative Air Conditioning Handbook (2nd ed.). The Fairmont Press, Inc.

- Niyomvas, B., & Potakarat, B. (2013). Performance Study of Cooling Pads. Advanced Materials Research, 664, 931-935. [CrossRef]

- Kusbandono, W. (2022). The Effect of the Number of Cooling Pads on the Output Air Condition and Effectiveness of Air Cooler. International Journal of Applied Sciences and Smart Technologies, 4(2), 255-266. [CrossRef]

- Hashim, R. H., Hammdi, S. H., & Eidan, A. A. (2023). Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation. Open Engineering, 13, 20220415. [CrossRef]

- ArabiaWeather. (n.d.). Weather forecast for Riyadh, Saudi Arabia. Retrieved from https://www.arabiaweather.com/en/weather-forecast/riyadh/344/sa.

- Time and Date. (n.d.). Weather in Riyadh, Saudi Arabia. Retrieved from https://www.timeanddate.com/weather/saudi-arabia/riyadh.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).