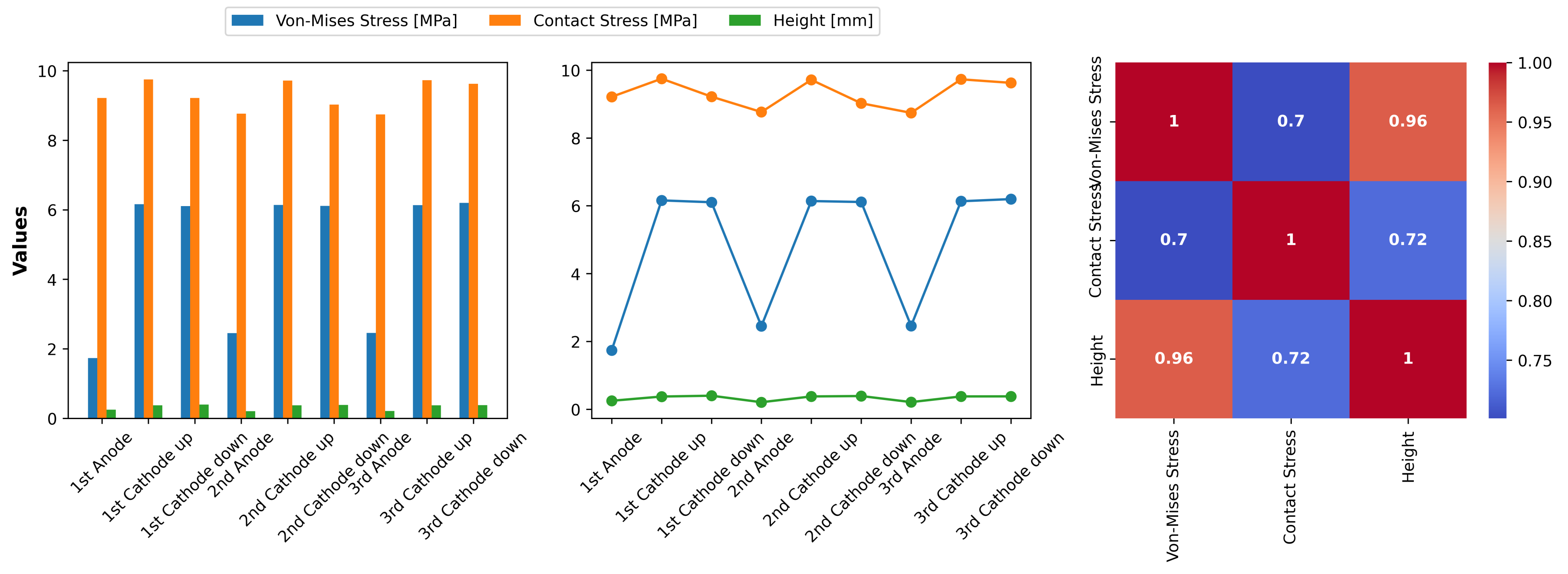

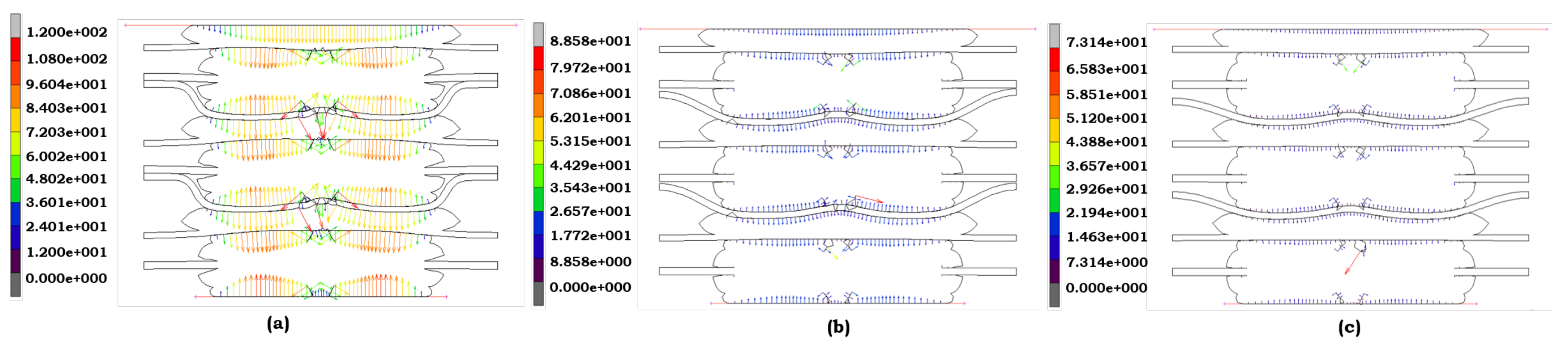

5.1. Contact Stress

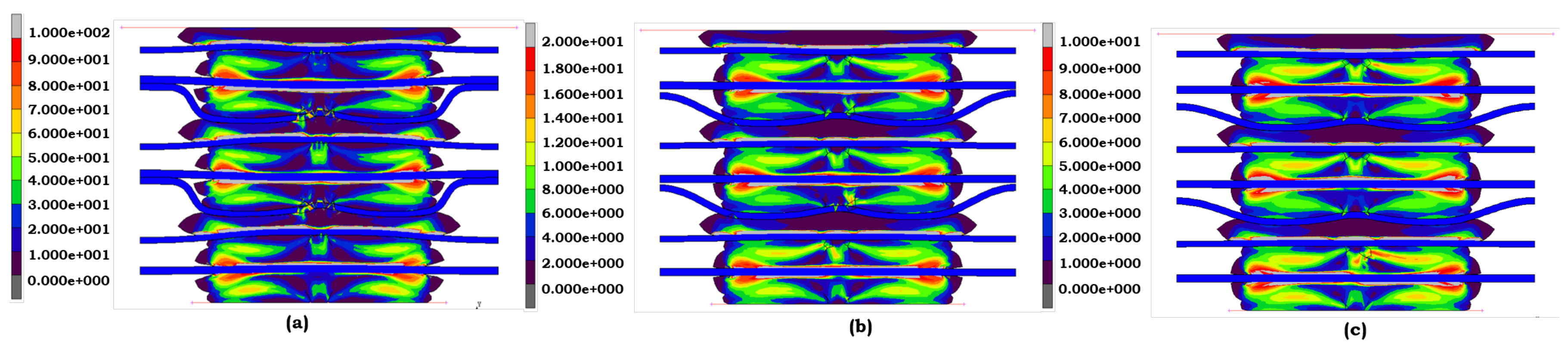

Each model is selected for the EPDM material under different aging conditions based on how effectively it represents its behavior under stress. If the material has not undergone any aging (

Figure 4a), the Ogden model is the most appropriate choice. The contact stress distribution is relatively even, with moderate peaks, indicating that the material retains much of its original elasticity. The Ogden model captures this behavior, reflecting EPDM’s stability without aging factors like heat or acid. When EPDM is subjected to heat (

Figure 4b), the Mooney-Rivlin model comes into play. It effectively portrays the material’s loss of elasticity as the contact stress becomes more concentrated, especially in the central region. The model’s selection for this condition is significant, as it accurately reflects how heat affects the material, resulting in a moderate increase in stress. This portrayal of the material’s behavior under heat is a key aspect of the model’s effectiveness. Regarding combined heat and acid exposure (

Figure 4c), EPDM shows significant peaks in contact stress, indicating substantial structural breakdown. The stress distribution is no longer uniform, with localized peaks pointing to severe material fatigue. The Yeoh model is the best fit here, designed to handle rubber-like materials under large strains. The Yeoh model accurately reflects EPDM’s highly non-linear response when subjected to heat and acid, showing the material’s progressive failure under extreme conditions.

The Mooney-Rivlin model accurately represents its behavior when the LSR material is not aged (

Figure 5a). LSR exhibits a relatively uniform stress distribution, indicating its high elasticity and resilience. The Mooney-Rivlin model captures this stable state, making it the best fit for LSR in its unaged condition, where the material’s elastic properties are fully intact. Stress concentrations appear when LSR is exposed to heat (

Figure 5b). The Ogden model is chosen here because it best represents the slight loss of elasticity due to thermal exposure. Ogden’s capability to manage moderate deformations aligns with the observed behavior, where the material shows localized peaks but continues to perform within acceptable limits. The Yeoh model again proves its worth in the most severe condition, where LSR is exposed to heat and acid (

Figure 5c). It effectively captures the severe structural degradation LSR experiences under these conditions, where the material’s elastic limits are exceeded. The model’s ability to simulate large strains and significant material responses is crucial in this context, as it accurately portrays the substantial deformation and sharp peaks in stress that suggest critical fatigue. The model selection for both EPDM and LSR is grounded in their respective stress responses to different aging conditions. For unaged materials, the Ogden model accurately captures the balanced stress distributions. Under moderate heat exposure, the Mooney-Rivlin model portrays the slight degradation of elasticity. Finally, the Yeoh model is the most suitable for conditions involving combined heat and acid exposure, as it effectively captures the non-linear behavior and material fatigue that both EPDM and LSR exhibit in extreme environments. Each figure complements the discussion by illustrating the distinct stress distributions for the models chosen under each condition.

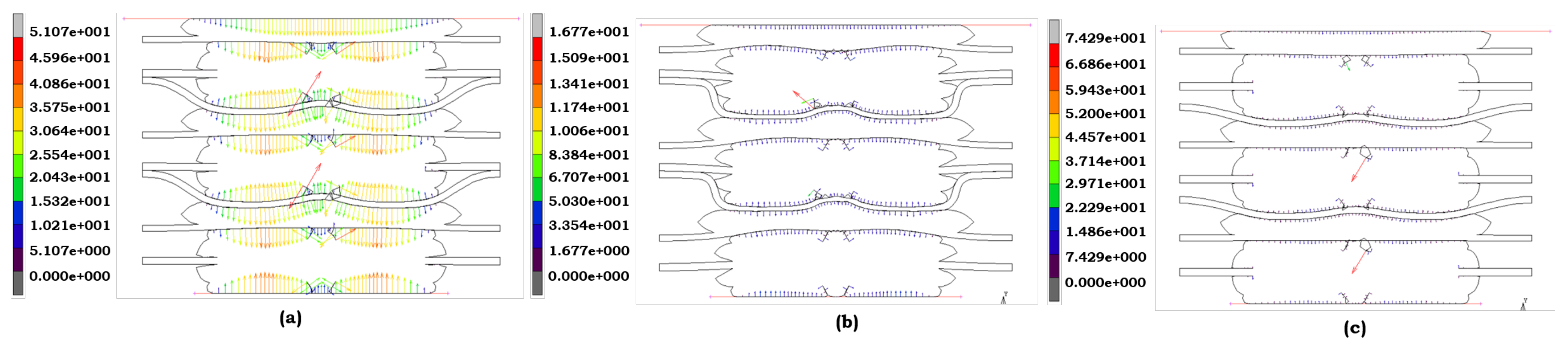

5.2. Von Mises Stress

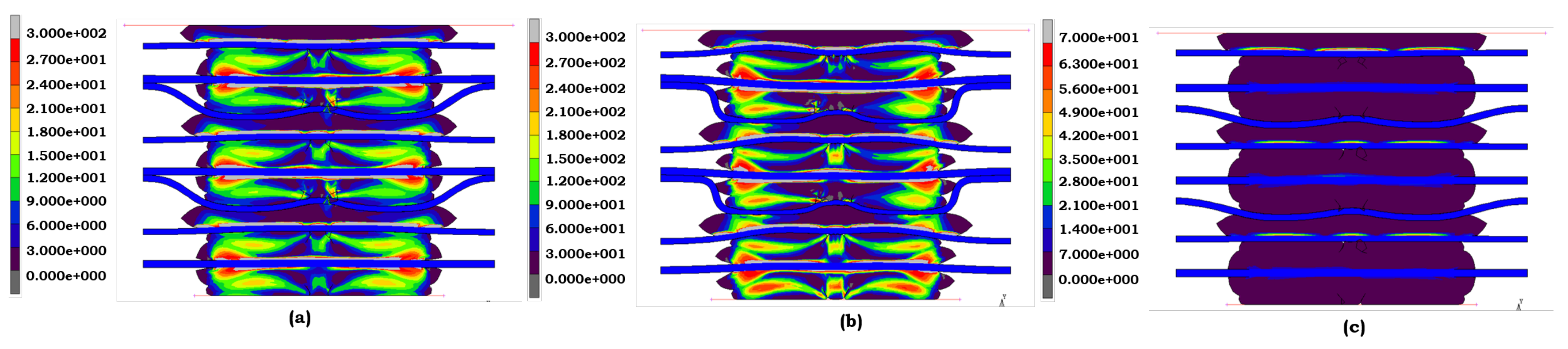

Each model is meticulously chosen for the EPDM material based on its precise representation of its structural response to stress across various aging conditions. This rigorous selection process ensures the accuracy and reliability of our findings. The Ogden model (

Figure 6a) accurately depicts stress distribution in the no-aging condition. EPDM retains much elasticity, and the stress remains evenly distributed. The Ogden model reflects this behavior, capturing EPDM’s stable structural integrity under these conditions, where no significant degradation has occurred. The Mooney-Rivlin model (

Figure 6b) best fits when heat is applied. Under heat exposure, EPDM experiences an increase in stress concentration, particularly in the center regions, indicating some loss of elasticity. The Mooney-Rivlin model effectively portrays this moderate degradation, illustrating how heat impacts the material’s ability to maintain its original mechanical properties. Under combined heat and acid exposure, the Yeoh model (

Figure 6c) is the most appropriate choice. EPDM exhibits highly localized stress peaks, indicating significant structural breakdown. The Yeoh model captures the extreme, non-linear material response under this condition, reflecting the progressive failure as EPDM loses its ability to handle strain effectively.

The selection for the LSR material is similarly grounded in the material’s response to Von Mises stress under different conditions. When LSR is not aged, the Mooney-Rivlin model (

Figure 7a) best represents its stress behavior. LSR exhibits a relatively uniform stress distribution, indicating that the material’s elasticity is intact. The Mooney-Rivlin model accurately captures this stable state, making it the best fit for LSR in its unaged form. The Ogden model (

Figure 7b) is the most suitable under heat exposure. LSR shows the onset of stress concentration, especially in specific localized regions. The Ogden model’s ability to handle moderate deformation makes it well-suited to depict LSR’s performance, where heat causes a slight degradation in elasticity. Finally, when LSR is exposed to heat and acid, the Yeoh model (

Figure 7c) provides the most precise representation of stress behavior. The material undergoes significant deformation, and the Yeoh model’s capacity to capture large strains accurately represents the severe fatigue and degradation of LSR under extreme conditions.

The models selected for both EPDM and LSR under Von Mises stress conditions demonstrate their adaptability to different aging conditions. The Ogden and Mooney-Rivlin models offer the best fit for unaged materials due to their capability to represent balanced and stable stress distributions. Under moderate heat exposure, the Mooney-Rivlin and Ogden models accurately portray the elasticity loss. Finally, the Yeoh model consistently captures the severe degradation and material fatigue for both EPDM and LSR for the combined heat and acid condition. Each model complements the specific aging condition, with the figures provided illustrating the stress distribution that guided the model selection.

5.3. Comparison of EPDM and LSR for Each Aging Condition Using Different Models

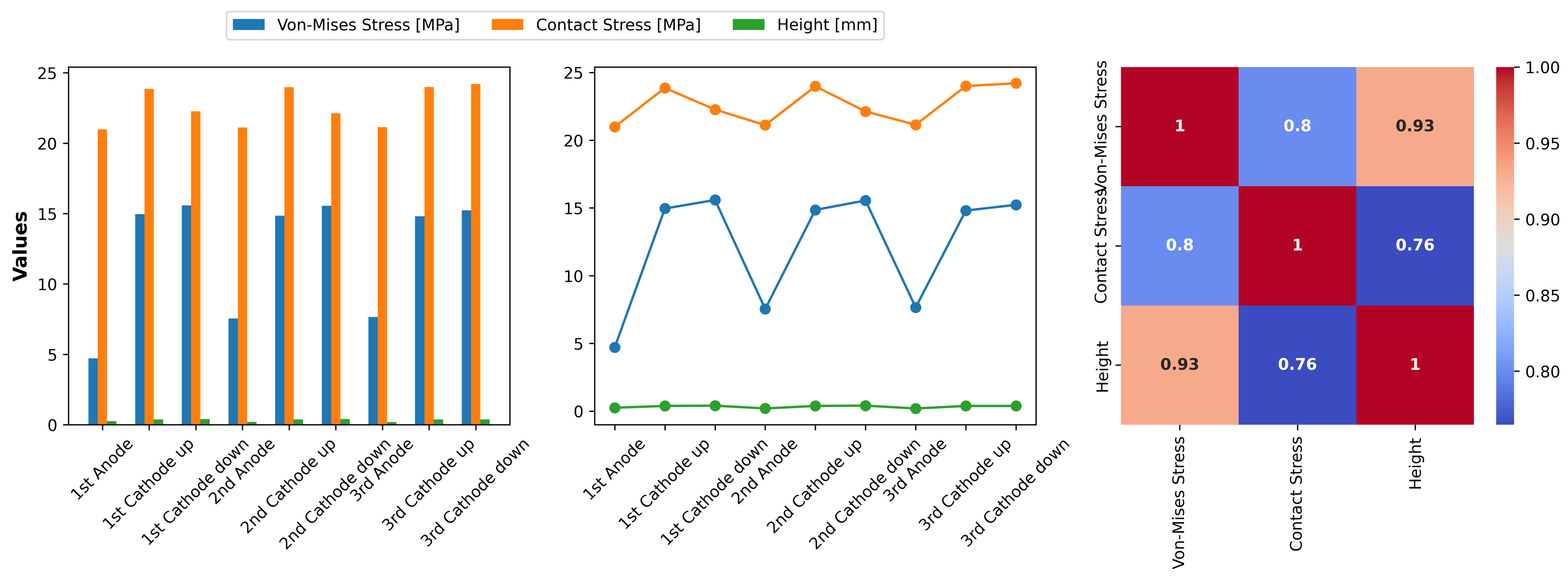

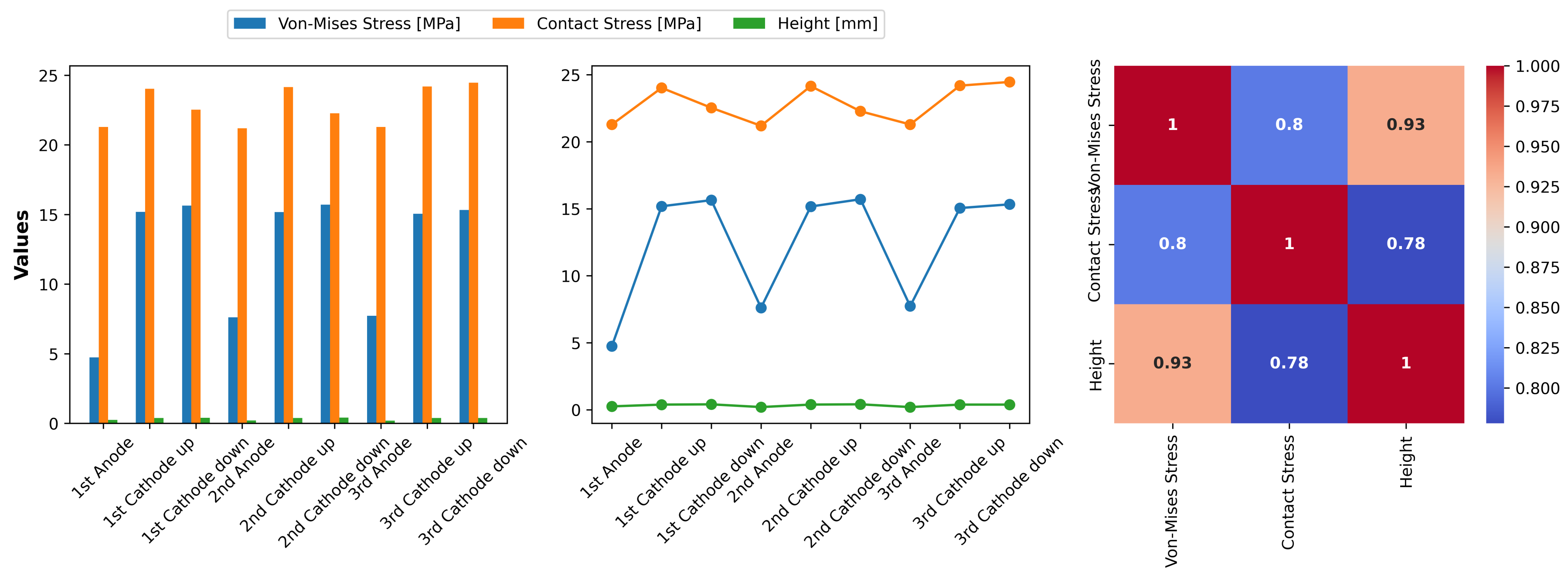

The stress and deformation behaviors of EPDM and LSR under different aging conditions, as evaluated using the Mooney-Rivlin, Ogden, and Yeoh models, reveal significant findings. These distinct differences between the two materials, reflecting their respective resistances to stress and deformation, are of utmost importance in materials science and polymer engineering. The comparison of von Mises stress, contact stress, and deformation (height) for EPDM and LSR under various aging conditions, using the Mooney-Rivlin, Ogden, and Yeoh models, reveals critical insights into the material behavior of both elastomers.

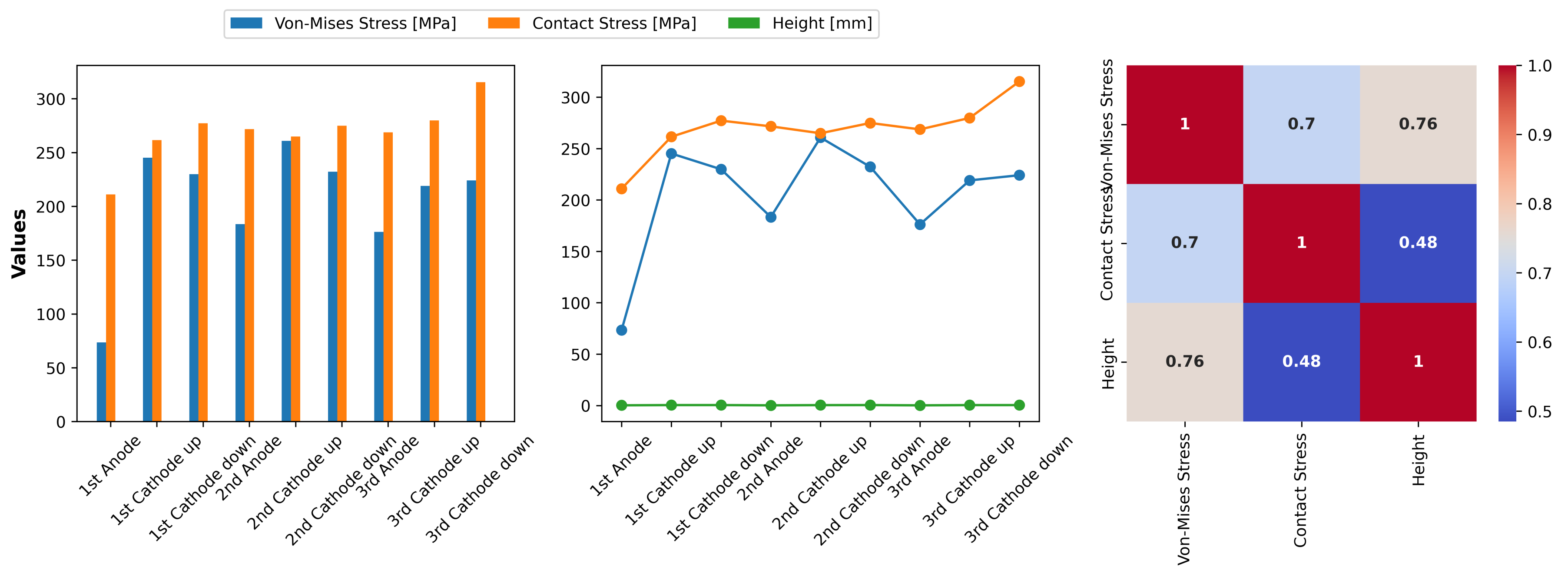

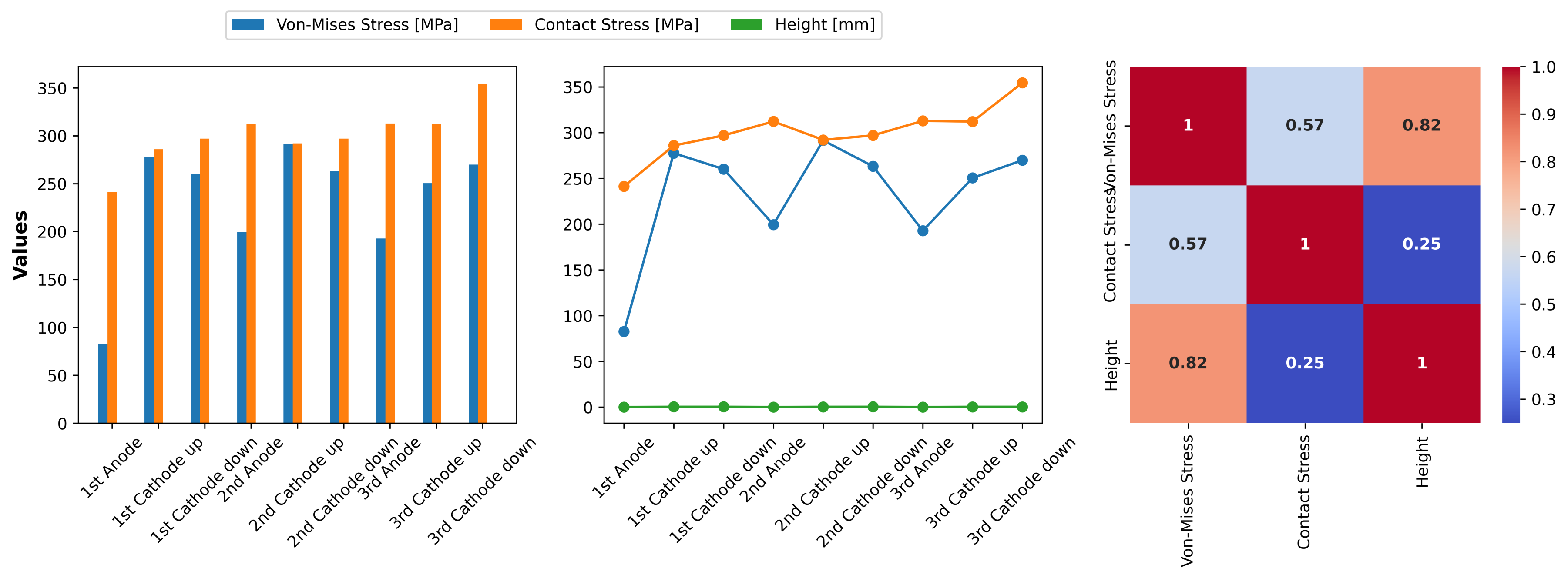

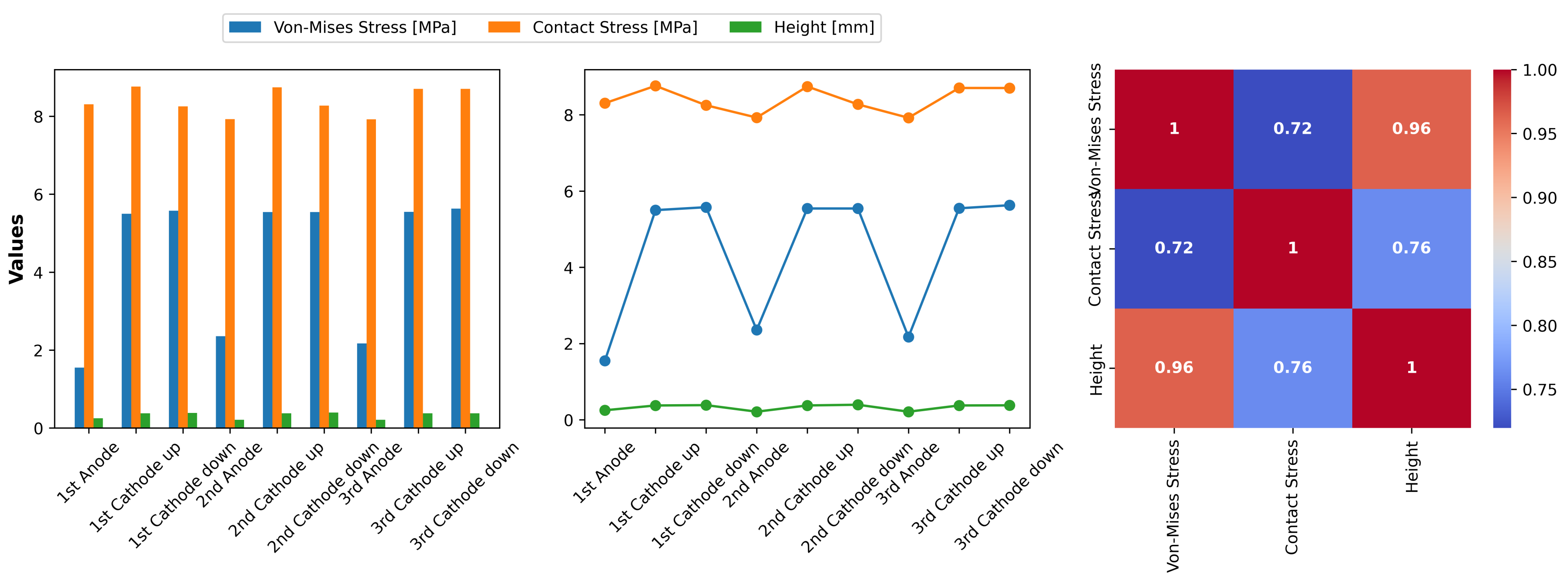

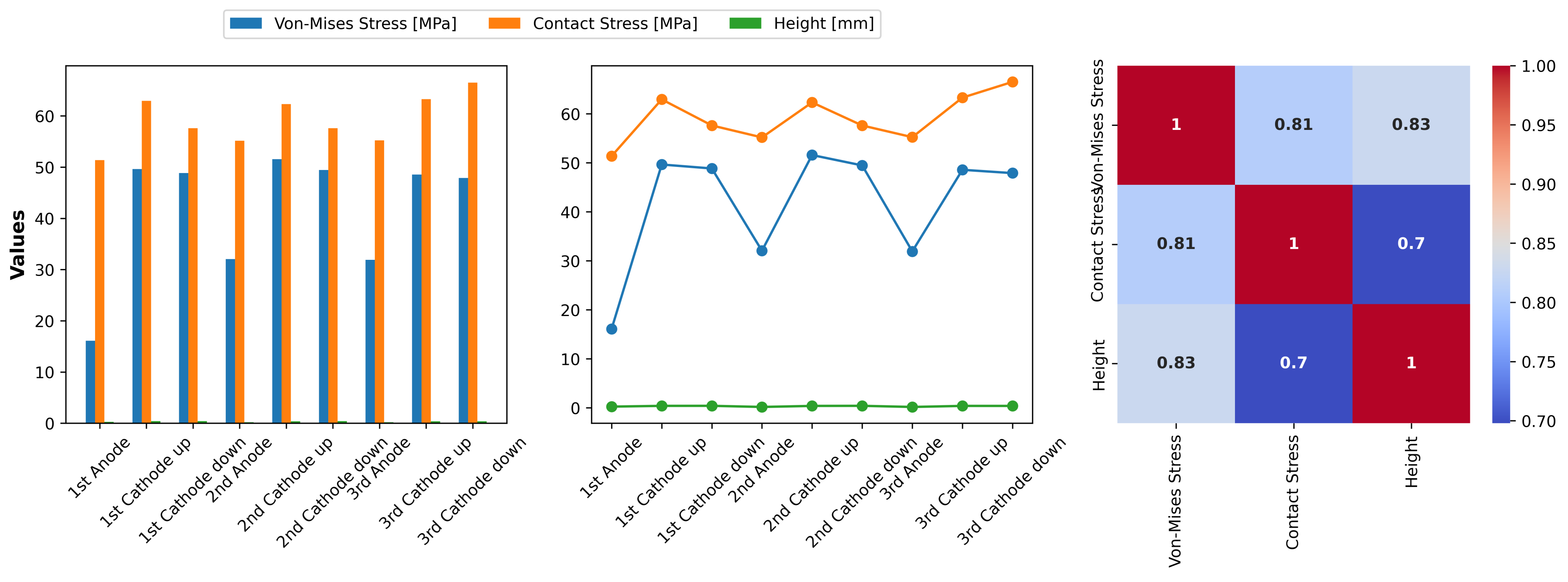

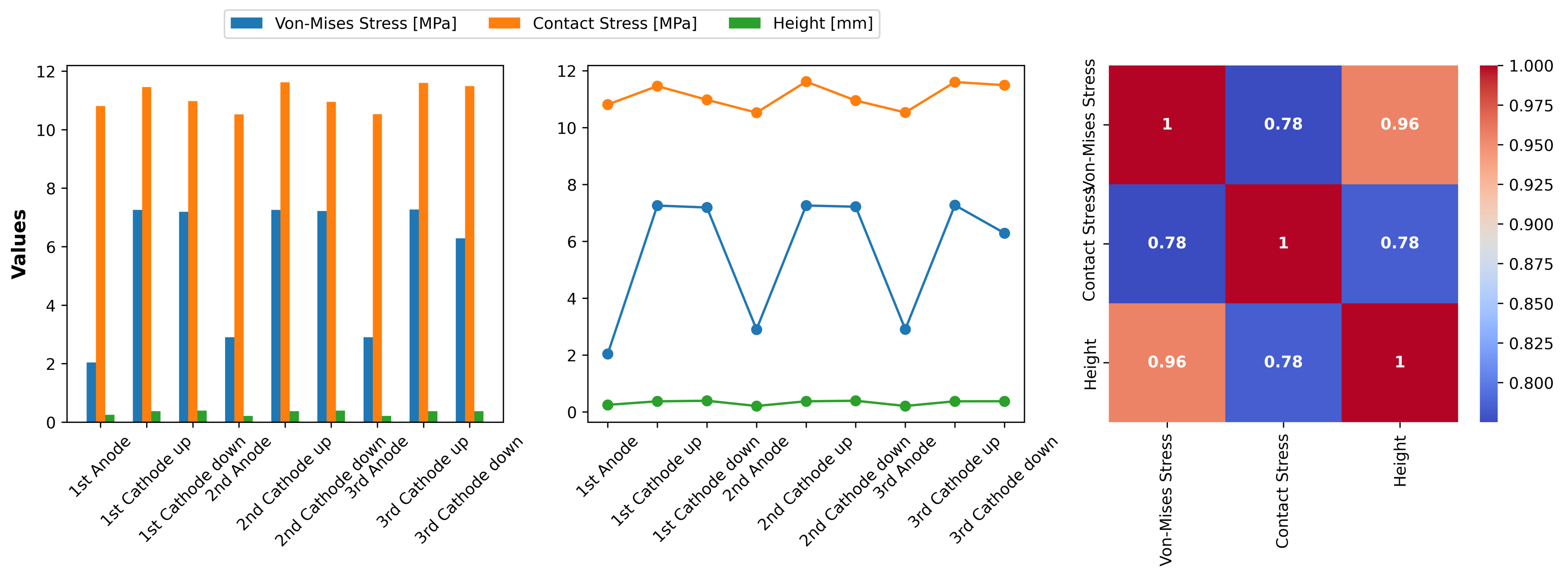

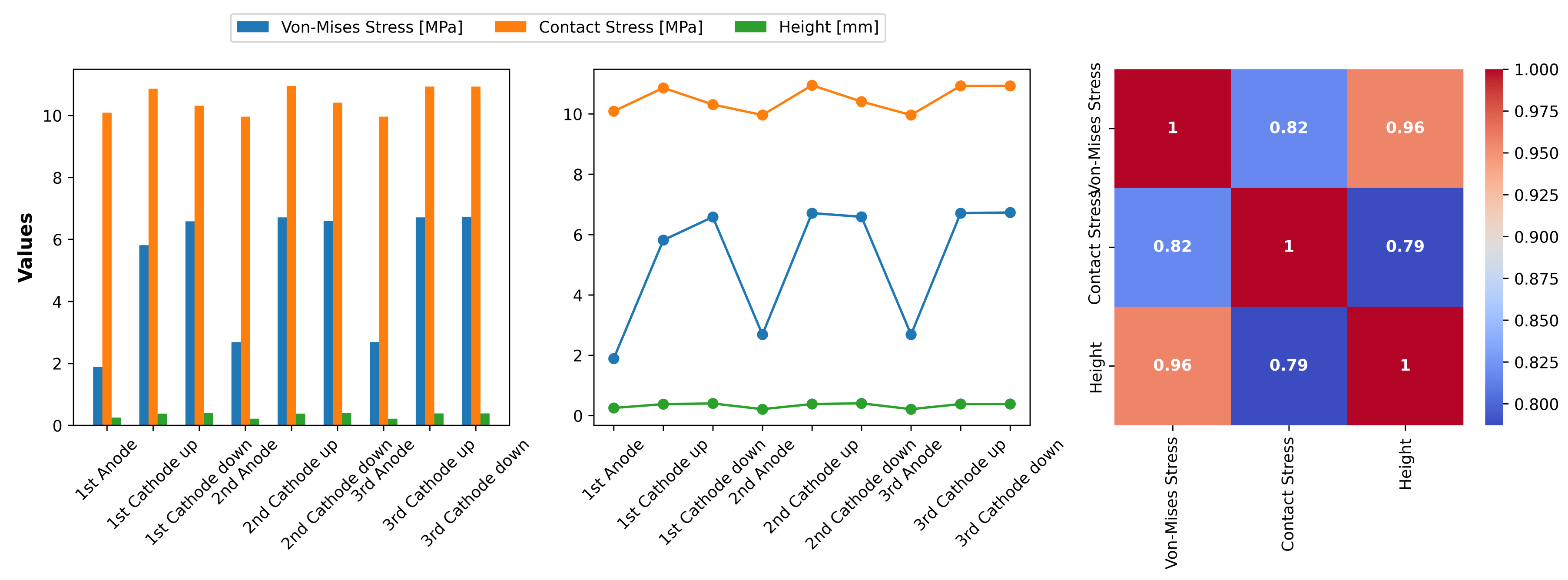

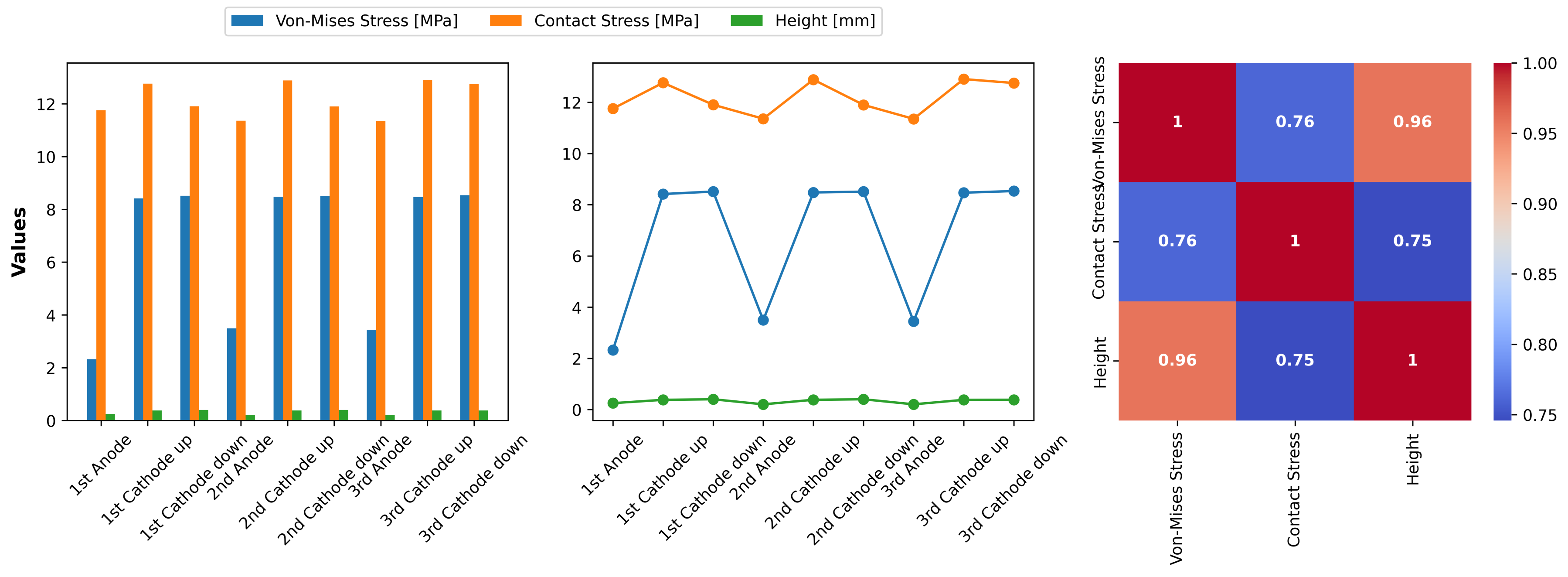

As shown in

Table 4, the von Mises stress values for EPDM are generally lower than those for LSR under all conditions. For example, under no aging, the von Mises stress at the 1st Cathode Up for EPDM is 14.96 MPa using the Mooney-Rivlin model, while LSR shows a significantly higher value of 24.17 MPa under the same conditions. The same trend holds for heat and heat + sulfuric acid conditions. This indicates that LSR tends to experience more significant stress than EPDM, likely due to its more elastic nature. The Mooney-Rivlin model consistently shows the highest stress for both materials, with the Ogden model yielding the next highest values, followed by the Yeoh model.

Table 5 provides contact stress comparisons, further emphasizing the higher stress endured by LSR compared to EPDM. For instance, at the 1st Cathode Down location under heat conditions, LSR shows a contact stress of 296.93 MPa with the Ogden model, whereas EPDM records a much lower value of 22.53 MPa. Across all models and aging conditions, LSR shows a higher contact stress response, which aligns with its greater flexibility and susceptibility to deformation under stress. The Ogden model yields the highest contact stress across the board, followed by the Mooney-Rivlin and Yeoh models. Deformation measurements presented in

Table 6 show that, despite the higher stress experienced by LSR, its deformation remains similar to that of EPDM. Under heat + sulfuric acid conditions, the 1st Cathode Up position shows a deformation of 0.3851 mm for EPDM (Mooney-Rivlin model) and 0.3800 mm for LSR. This indicates that, while LSR tends to deform more under stress than EPDM, the overall deformation across different models and conditions remains relatively consistent for both materials. The Ogden model generally records the highest deformation values, reflecting its capacity to capture more significant elastic deformations.

The results show that LSR tends to experience more significant stress and contact stress than EPDM across all conditions and models, though both materials exhibit similar deformation values. These findings suggest that LSR is more responsive to stress and suitable for flexible applications. At the same time, EPDM maintains its integrity under high-stress conditions, making it ideal for applications prioritizing rigidity and durability.

The Mooney-Rivlin, Ogden, and Yeoh models each provide distinct insights into the mechanical behavior of LSR and EPDM materials under different aging conditions. They present unique and overlapping observations on von Mises stress, contact stress, and material height.

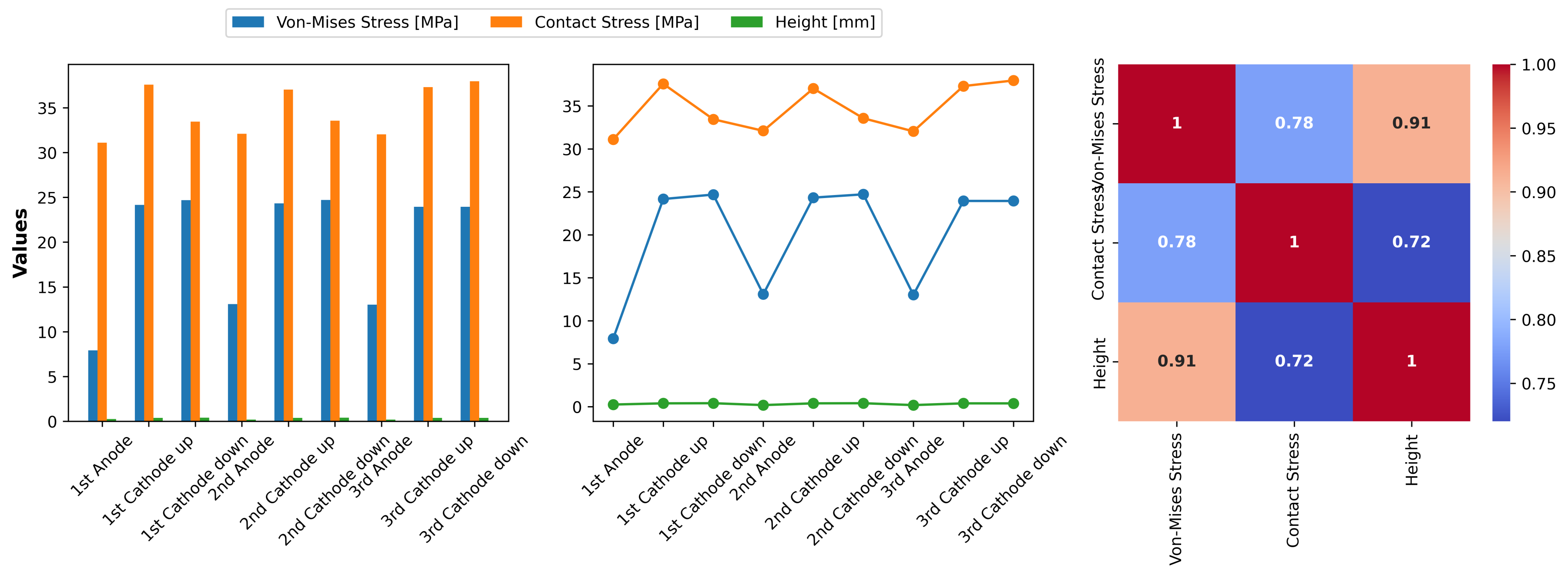

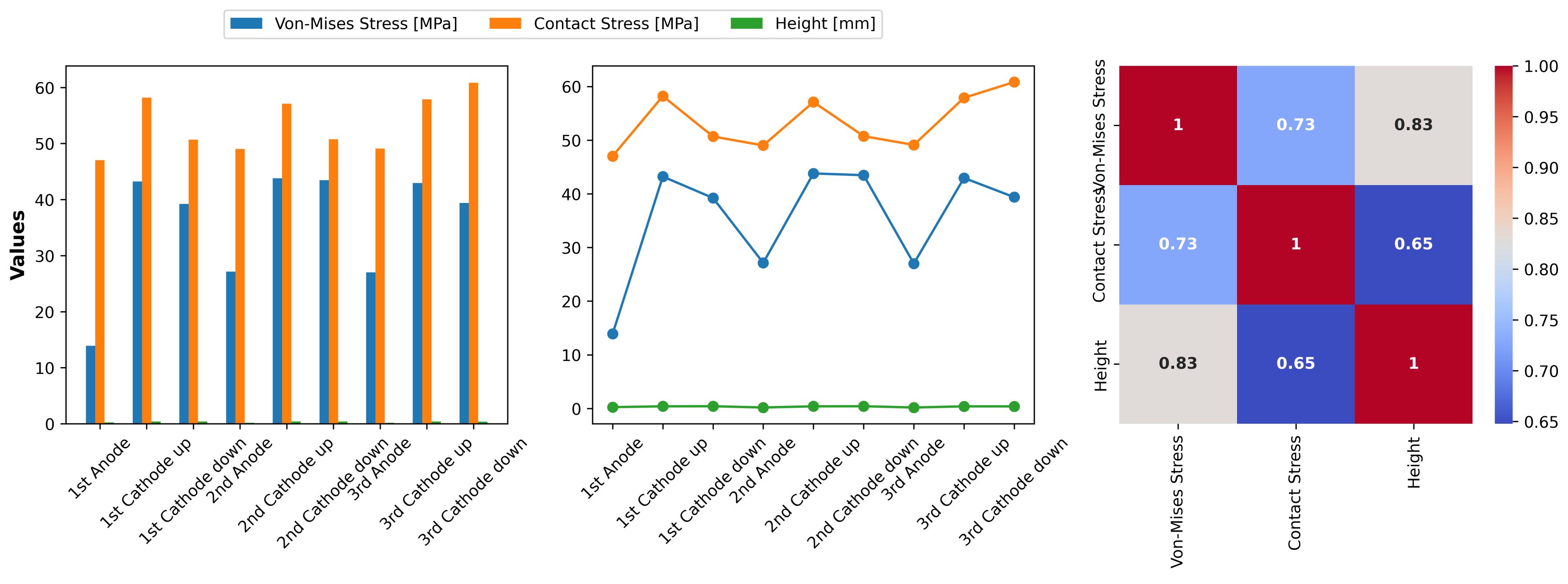

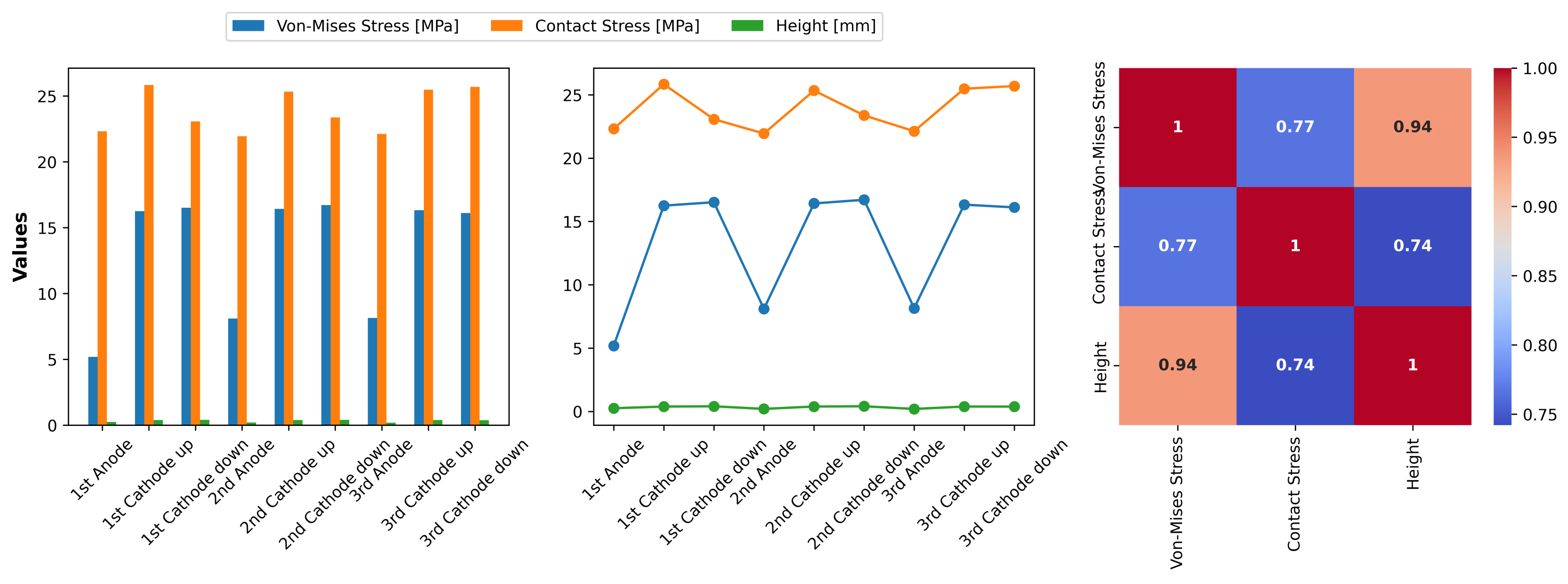

Starting with LSR, the Mooney-Rivlin model offers a foundational understanding of stress distribution in its “No Aging” condition (

Figure A1). Here, we observe baseline stress levels across all tested locations, with notably higher contact stress in the 1st Cathode positions, hinting at potential stress concentration zones in unaged LSR. This scenario shifts under “Heat Aging” (

Figure A2), where von Mises stress significantly increases, especially at the cathode positions, suggesting that thermal exposure induces a degree of rigidity in LSR. However, in the “Heat + Sulfuric Acid Aging” condition (

Figure A3), there is a slight reduction in both von Mises and contact stress, indicating that sulfuric acid may counteract the thermal rigidity, softening the material and thereby reducing its stress resistance.

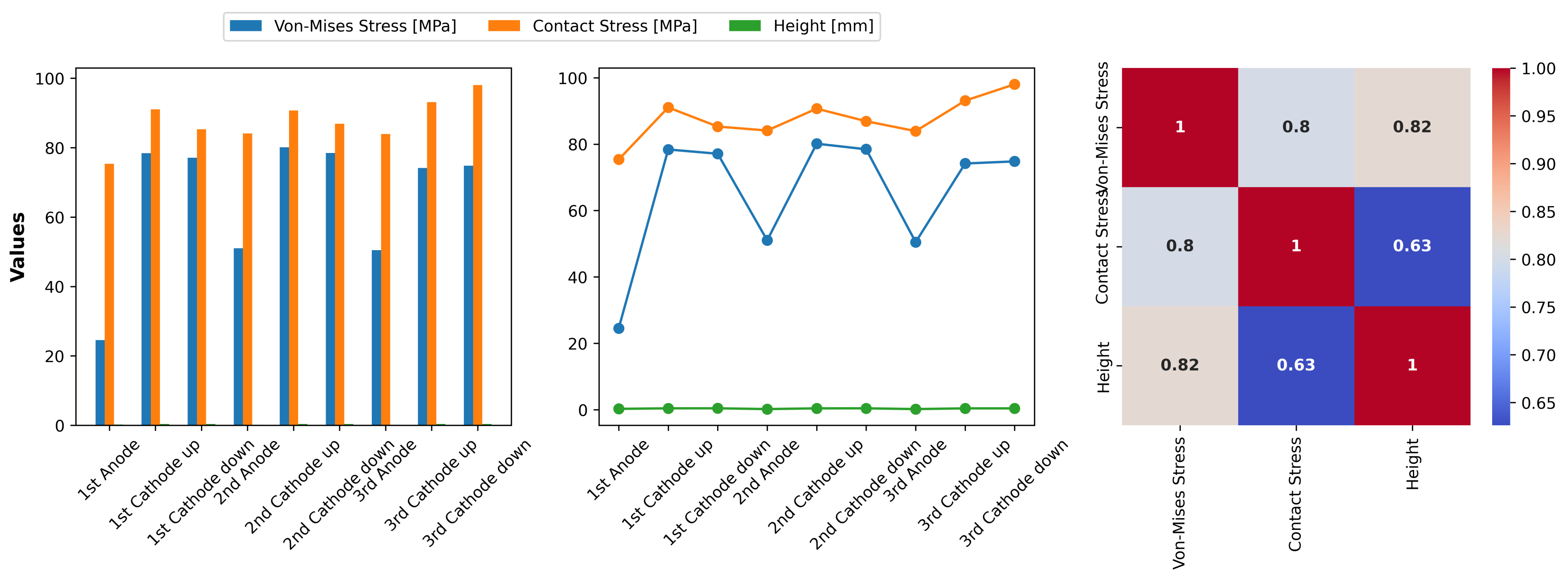

The Ogden model, in the “No Aging” state (

Figure A4), presents a similar baseline to Mooney-Rivlin but shows heightened sensitivity to elasticity changes under “Heat Aging” (

Figure A5). Both von Mises and contact stress increase markedly at the anode and cathode locations, implying that heat exacerbates material rigidity when elasticity-sensitive parameters are considered. Upon exposure to “Heat + Sulfuric Acid Aging” (

Figure A6), stress levels drop substantially compared to the heat-only condition, reinforcing the notion that sulfuric acid induces a degradation in LSR’s structural integrity, counteracting the rigidifying effect of heat. This degradation aligns with the Mooney-Rivlin findings, bolstering the hypothesis that sulfuric acid compromises the material’s resilience.

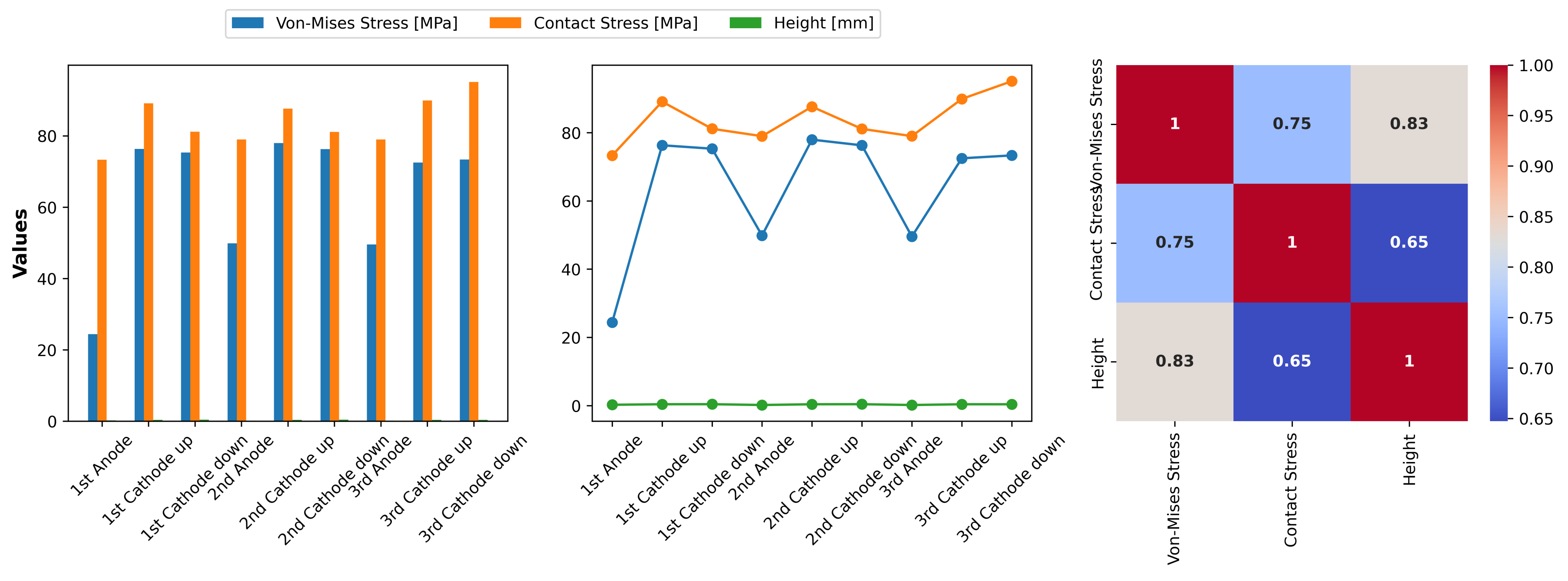

The Yeoh model complements this analysis with further insights into LSR’s deformation tendencies. In the “No Aging” condition (

Figure A7), the distribution of height and stress levels mirrors that of previous models. Under “Heat Aging” (

Figure A8), both stress types rise, confirming that thermal exposure stiffens the material. However, “Heat + Sulfuric Acid Aging” (

Figure A9) reveals reduced stress values and subtle deformations in height, implying that acid exposure not only reduces rigidity but also affects the material’s deformation capacity, likely due to chemical softening. This pattern suggests that the Yeoh model captures not only stress variations but also subtle shifts in material deformation, aligning well with observed chemical degradation effects.

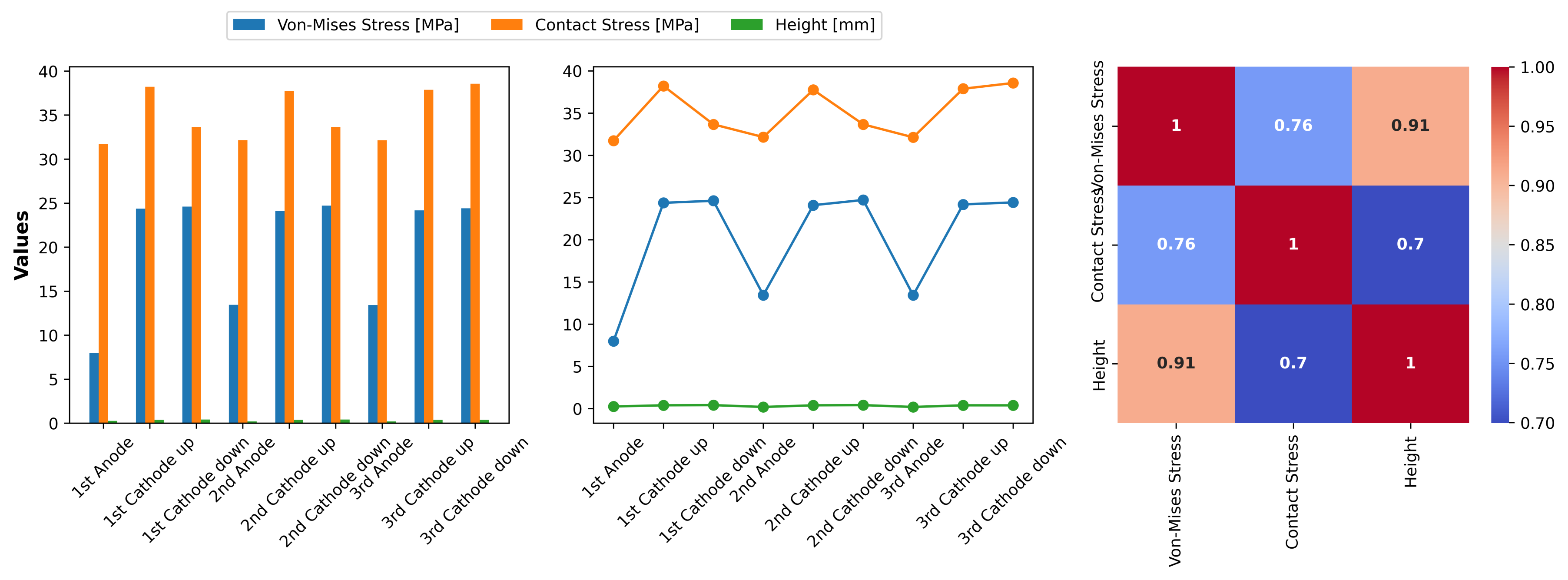

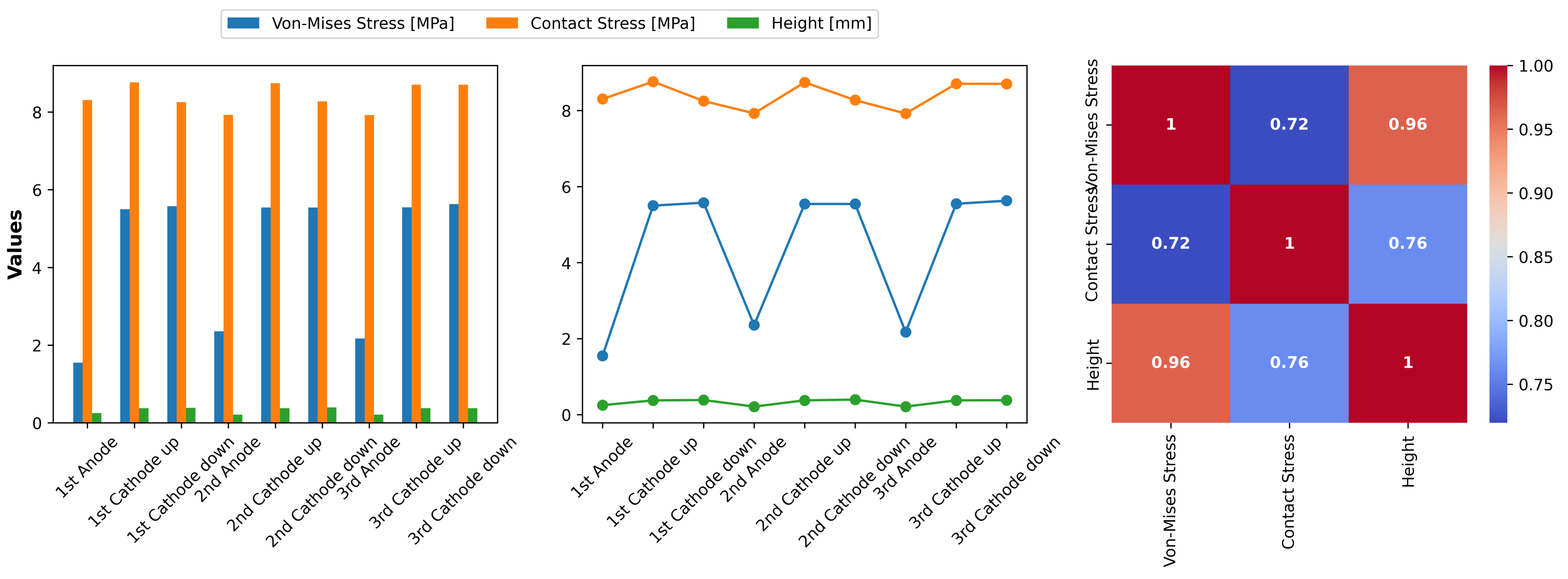

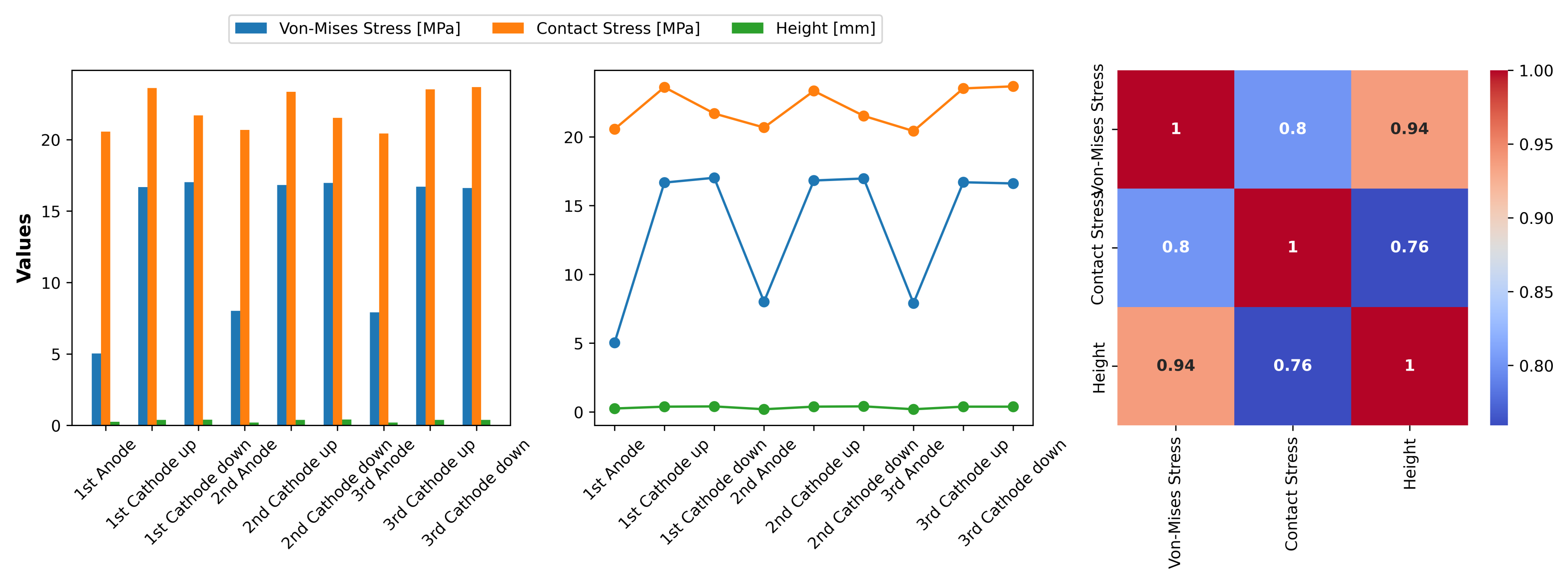

Turning to EPDM, the Mooney-Rivlin model (

Figure A10–

Figure A12) consistently reflects von Mises stress responsiveness to aging, showing EPDM’s higher stress capacity in No Aging compared to heat and acid-aged conditions. The strong correlation between von Mises and contact stress underscores an even distribution of external pressure within the material. However, the model displays limited sensitivity to changes in height, holding these values nearly constant, which suggests it may be less effective at detecting physical deformations over time.

The Ogden model (

Figure A13–

Figure A15) offers a sharper focus on height changes, particularly under prolonged Heat and Sulfuric Acid Aging. This model’s pronounced contact stress response underscores increased EPDM’s rigidity under combined aging conditions, indicating that it might be more apt for failure prediction under extreme conditions. The Ogden model’s tendency to emphasize stress concentration more than the Mooney-Rivlin model implies its utility in scenarios where chemical exposure affects the physical properties of EPDM.

In contrast, the Yeoh model (

Figure A16–

Figure A18) demonstrates a balanced sensitivity to stress and height changes across all aging conditions. Its ability to capture stress variations comparable to the Ogden model while interpreting subtle height shifts highlights its versatility and reliability. The Yeoh model’s stress resilience under Severe Aging conditions, particularly with acid exposure, suggests its efficacy in long-term durability predictions for EPDM, making it particularly useful when both mechanical and chemical degradation factors are of interest.

In conclusion, the LSR and EPDM analyses across the Mooney-Rivlin, Ogden, and Yeoh models illustrate a cohesive narrative of how heat and sulfuric acid aging differentially affect these materials. These findings have significant implications for engineering applications, providing a comprehensive understanding of how these materials perform under varying environmental stressors. The Mooney-Rivlin model offers a foundational overview of stress behaviors; the Ogden model emphasizes elasticity and failure points under severe conditions and the Yeoh model balances stress and deformation sensitivity. For EPDM, the Mooney-Rivlin model offers a simplified perspective with limited deformation insights, the Ogden model is suited for extreme aging sensitivity, and the Yeoh model’s balanced response aids in understanding long-term durability. These combined insights underscore the importance of a multi-model approach in understanding LSR and EPDM performance and reliability.

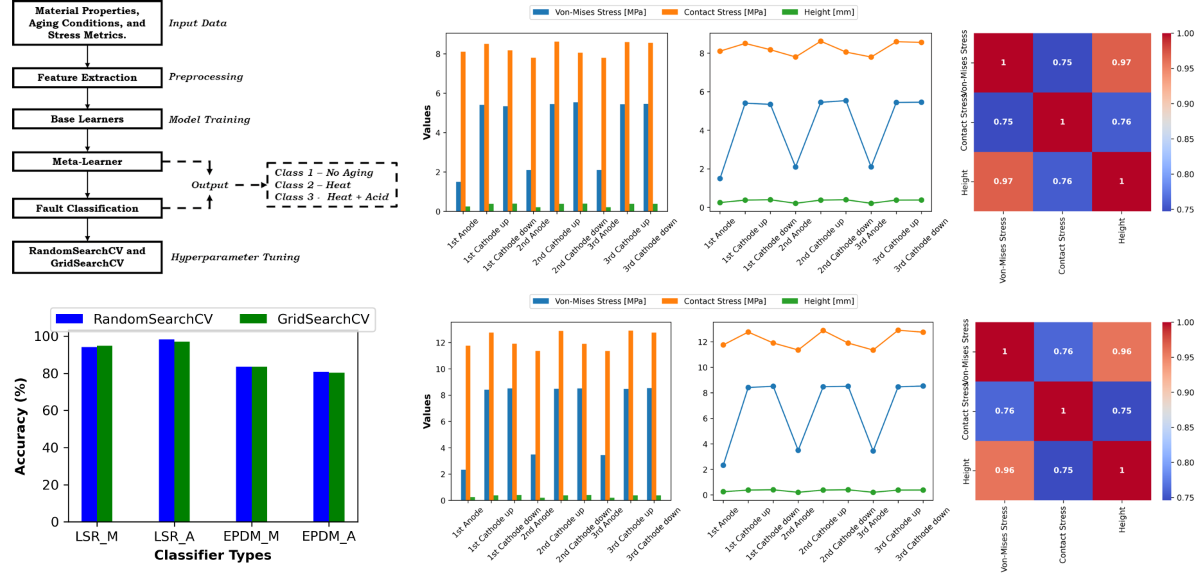

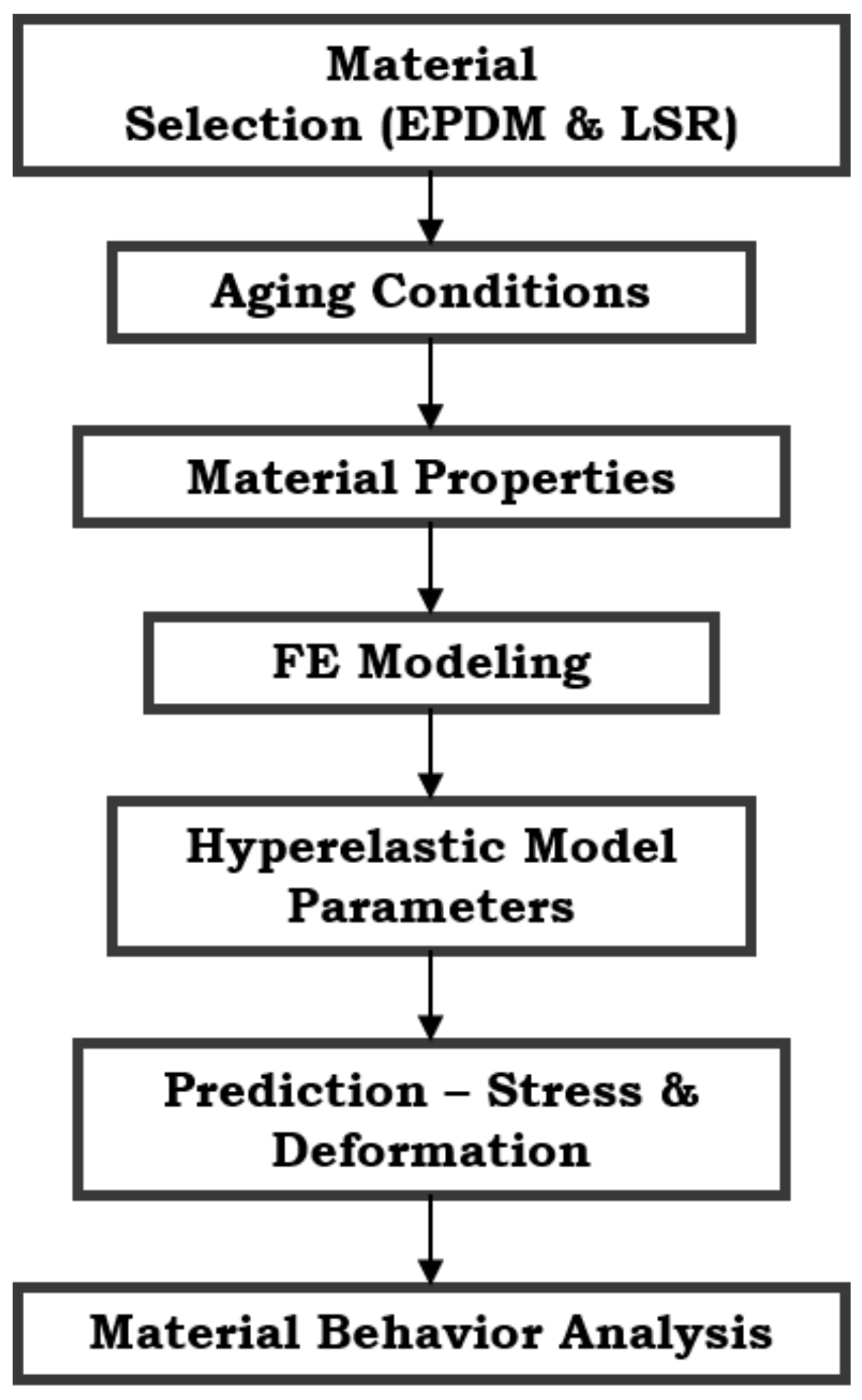

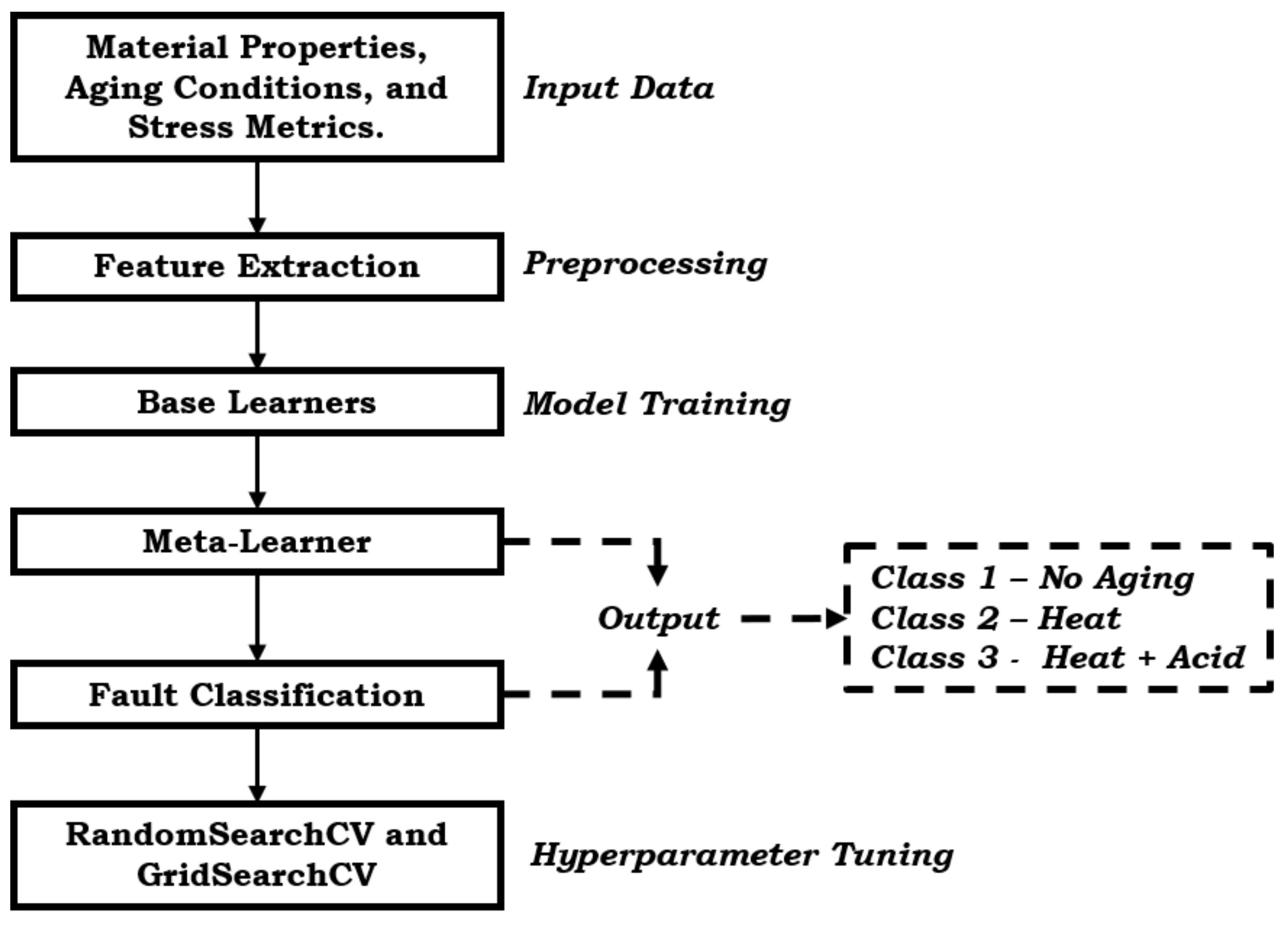

5.4. EL Performance Metrics

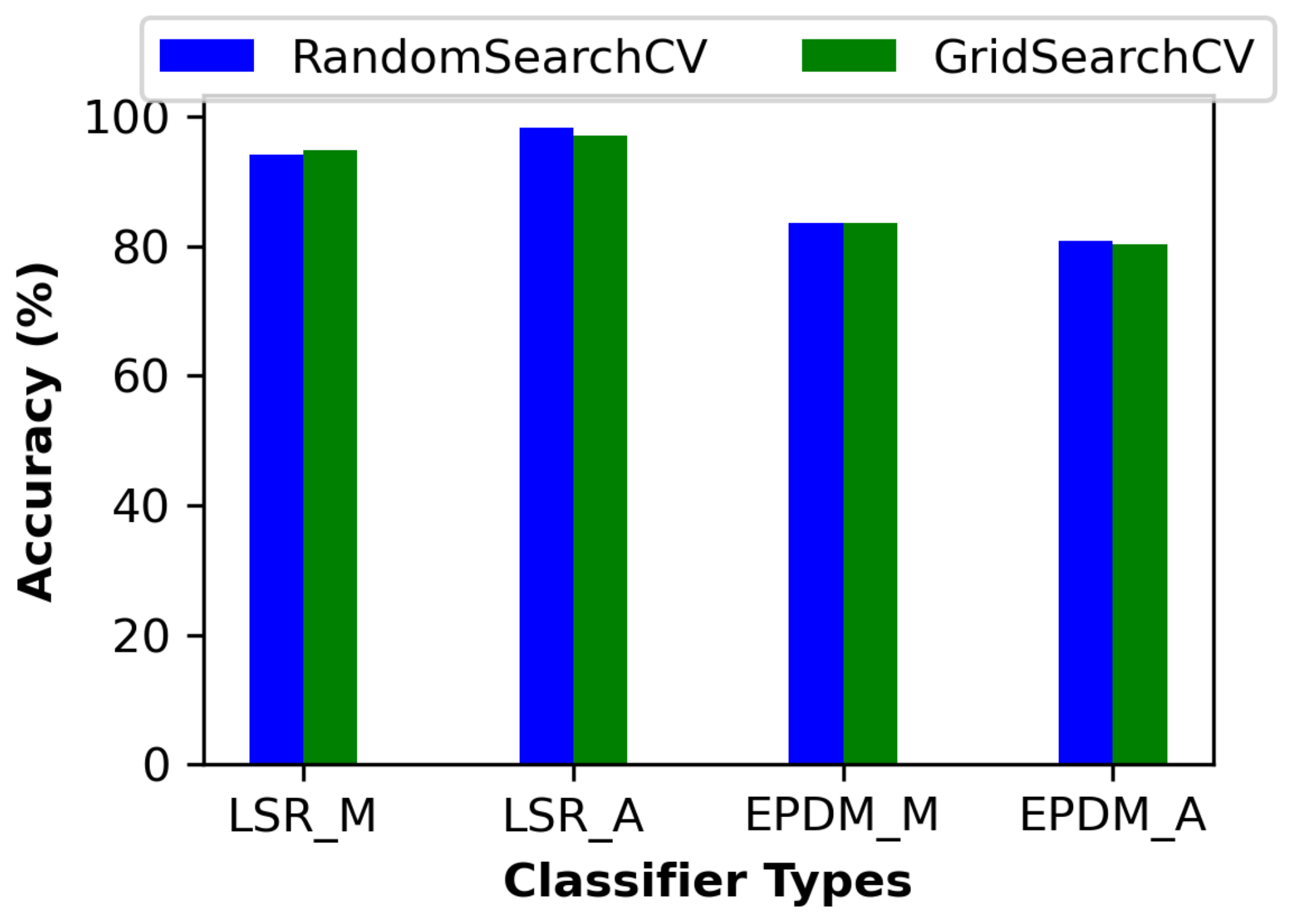

The EL model’s performance was evaluated using standard classification metrics, including accuracy, precision, recall, and F1-score. These metrics were computed for the model and classifications of aging types for EPDM and LSR materials.

The LSR Model Type and Aging Type classification results demonstrate strong and reliable performance across both search methods. For Model Type, RandomSearchCV achieved an accuracy of 0.95, with the optimal hyperparameters tuned for SVM using a linear kernel. GridSearchCV produced a similar result with a slight reduction in accuracy at 0.94. These scores indicate satisfactory balance across precision, recall, and F1-score across all classes (

Table 7). For Aging Type, RandomSearchCV outperformed slightly, delivering a higher test accuracy of 0.98, particularly effective in identifying class 1 with high precision and recall values. GridSearchCV, with an accuracy of 0.97, maintained consistent performance across classes, showing that both methods effectively capture the aging effect on LSR materials (

Table 8).

In the case of EPDM, the classification results for both Model Type and Aging Type also show robustness. For Model Type, both RandomSearchCV and GridSearchCV achieved a test accuracy of 0.84, confirming the model’s effectiveness in recognizing EPDM material types (

Table 9). When focused on Aging Type, RandomSearchCV achieved a slightly higher accuracy of 0.81, with a high recall of 0.93 in class 0, highlighting the model’s ability to detect specific aging conditions accurately. GridSearchCV’s accuracy was slightly lower, at 0.80, but showed consistent results, confirming its effectiveness (

Table 10).

These results, highlighted in the Tables, underscore the effectiveness of both search methods in delivering high classification accuracy, precision, and recall. RandomSearchCV displayed a marginal edge in optimizing complex aging classifications, demonstrating its slight advantage in capturing nuanced patterns in aging-related tasks across EPDM and LSR materials.

The comparison of classifier performance on LSR and EPDM datasets, as shown in

Table 11 illustrated in

Figure 8, highlights the clear advantage of using a stacked ensemble model combining RF and SVM, particularly for accurately classifying both Model Type and Aging Type. The alternative classifiers used for comparison against the stacked ensemble model were randomly selected from the literature to represent a diverse range of commonly applied machine learning techniques, ensuring a robust benchmarking context and further underscoring the superior performance of the ensemble approach in this study.

The stacked model achieves significantly higher accuracy than individual classifiers like XGBoost, MLP, and DNN. For LSR, the stacked model attains 95% accuracy for the Model Type and 98% for the Aging Type, underscoring its strong capability to capture complex data patterns. In contrast, DNN, which performs moderately well for LSR Aging Type classification at 70% accuracy, falls short compared to the ensemble approach. XGBoost and MLP achieve lower accuracies of approximately 70% and 62% for Model Type and Aging Type, respectively, demonstrating their limited effectiveness with LSR data.

Similarly, in the EPDM dataset, the stacked model maintains its superior performance, achieving 84% accuracy for the Model Type and 83% for the Aging Type. While DNN shows promise in aging-type classification with 76% accuracy, it remains less consistent in precision and recall than the stacked model. XGBoost reaches 69% accuracy for the EPDM Model Type but continues to underperform relative to the ensemble model. The bar chart further illustrates the impact of hyperparameter search techniques, with RandomSearchCV slightly outperforming GridSearchCV in most cases. Notably, RandomSearchCV helps the stacked model reach its highest scores, such as 98% accuracy for the LSR Aging Type and 83% for the EPDM Aging Type, underscoring its utility in fine-tuning ensemble models for complex, non-linear classification tasks, such as distinguishing aging conditions in different material types.

In summary, the stacked ensemble approach, integrating the predictive strengths of RF and SVM, is the most effective classifier for both datasets and classification tasks. Its impressively high accuracy and reliability make it a valuable tool for predictive maintenance applications in PEMFC gasket materials, providing a robust solution for anticipating material degradation. This analysis emphasizes that while individual models like DNN may be viable alternatives in specific cases, ensemble methods deliver superior performance, ensuring robustness and precision in classification tasks crucial for industrial applications.