1. Introduction

The issue of reducing consumption has become highly significant today, both for internal combustion vehicles and electric vehicles. Fuel efficiency is especially crucial for internal combustion engines due to the concerns about emissions and the strict regulations surrounding them [

1,

2,

3]. On the other hand, for electric vehicles, minimizing energy consumption is key to addressing some of their most pressing challenges, particularly the limited driving range and the long battery recharging times [

4].

A useful technique to reduce the impacts in the use phase and the fuel or energy consumption of vehicles [

5,

6] is to reduce the mass of the vehicle [

7,

8,

9,

10,

11,

12]. This process is commonly referred to as “vehicle lightweighting” in the automotive field.

The vehicle lightweighting can be achieved in different ways: through material substitution and design and construction changes, using lighter materials, while maintaining the required strength characteristics [

5,

9,

13,

14,

15,

16,

17]; and minimizing the size of the battery pack adopting alternative/hybrid powertrains [

18,

19,

20], ad hoc regenerative braking logics and range management logics [

21,

22,

23], and/or improve battery efficiency, for example by changing their chemistry [

21,

24] or studying alternative battery cooling systems [

25,

26].

Numerous scientific studies, such as [

7,

27,

28,

29,

30], present the outcomes of the vehicle lightweighting using the Fuel Reduction Value (FRV), which is measured in L/(100 km ∙ 100 kg). In the context of internal combustion vehicles, the FRV index stands for the liters of gasoline or diesel saved every 100 km, resulting from a 100 kg reduction in vehicle mass.

However, when referring to electric vehicles, consumption is no longer referred to fuel consumption, but to the variation of energy stored in the battery pack. If the study is then conducted using the FRV index, as in the case of [

30], the latter index will represent the equivalent liters per 100 km and per 100 kg of lightweighting. An alternative is to analyze the lightweighting outcome on the basis of the Energy Reduction Value (ERV) index, expressed in kWh/(100 km ∙ 100 kg), which corresponds to the energy savings every 100 km, every 100 kg of mass reduction. Studies [

31,

32,

33] use ERV coefficient, and, in particular, [

33] considers FRV index for the internal combustion vehicles and the ERV index for electric vehicles.

Scientific papers [

28,

29] show how the FRV coefficient changes based on the vehicle class considered, therefore depending on the size/volume of the vehicle considered. However, they do not identify the specific vehicle parameters responsible for this variation, in this way it might seem that this change is simply due to the variation in the vehicle weight. In contrast, the focus of [

32] is the research and analysis of the vehicle parameters that influence the lightweighting results of electric vehicles, thus considering the ERV index.

However, the study [

32] was conducted on standardized driving cycles, in particular on the WLTC and on the US06 cycles, finally comparing the outcome of the vehicle lightweighting obtained on different standard driving cycles and showing how this outcome varies according to the cycle considered. What is missing from the work presented in [

32] is the analysis of the parameters that influence the lightweighting result based on a real-world driving cycle.

Non-legislative driving cycles are widely used in research focused on energy efficiency and pollution assessment. They have been utilized in studies covering topics from performance prediction to vehicle design [

34]. In fact, vehicle emissions are influenced by driving cycles, which are primarily determined by traffic conditions [

35]. Given the possible strong variability of local traffic, or from city to city, for the same geographical area, the standardized driving cycles often cannot be representative of all cases [

34].

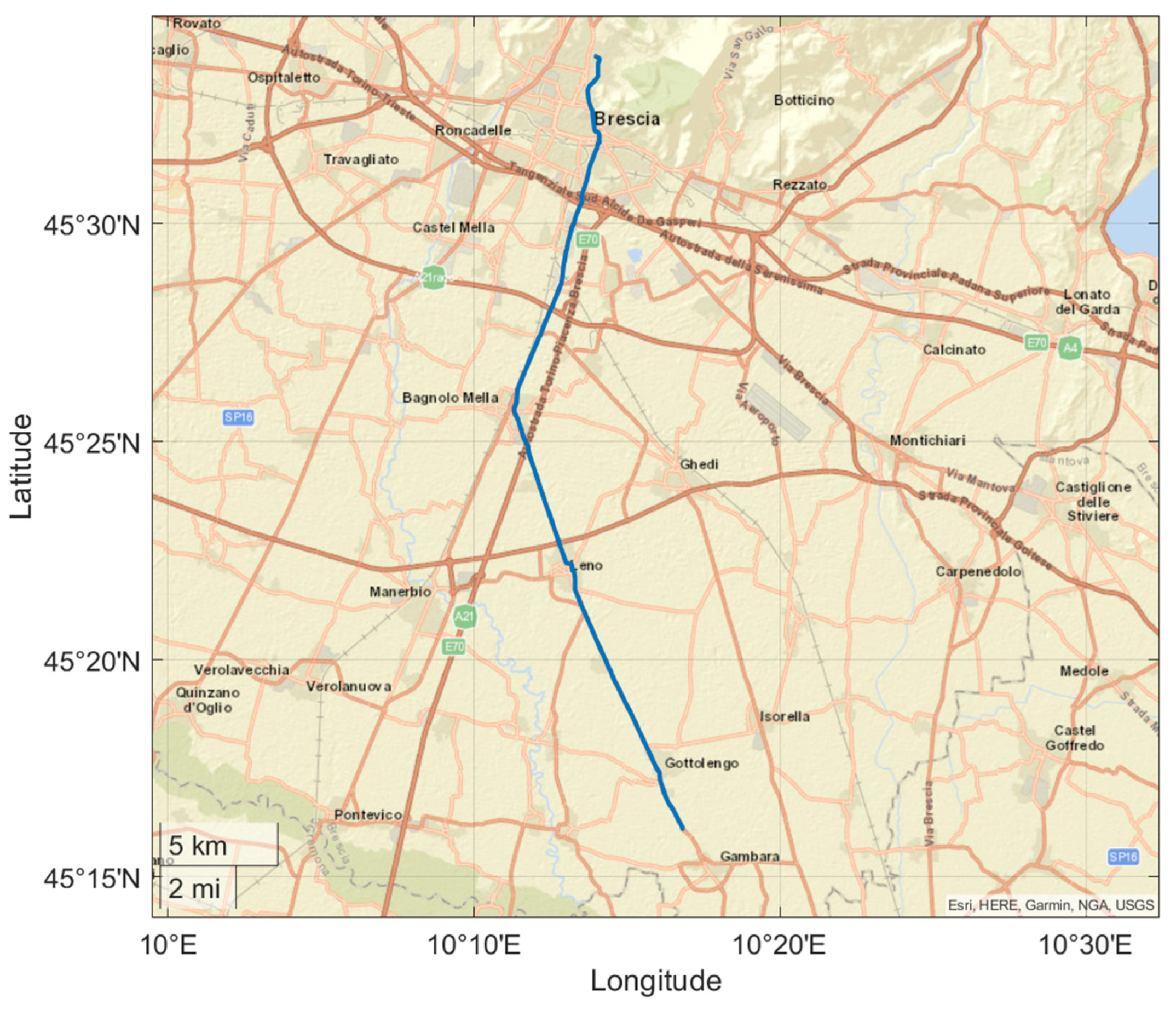

This paper is therefore focusing on the use of a real-world driving cycle to estimate the impact of the vehicle lightweighting, considering the north of Italy as the reference working area, specifically the province of Brescia, in Lombardy region. In this regard, the outcome of the lightweighting has been evaluated on a real-world cycle acquired on board the vehicle equipped with a GPS antenna, on a representative home-to-work journey, from a town in the province of Brescia, crossing the city center, up to the north of the municipality of Brescia.

Finally, the results obtained using the real-world driving cycle were compared with those coming from different standard cycles, to try and establish which standard driving cycle is the more representative of the chosen case (northern Italy, Lombardy region, home-to-work journey from the province to the municipality of Brescia) [

36].

In this work, it has been found that in order to achieve an accurate calculation of the ERV index it is crucial to correctly define the rolling resistance coefficient, the aerodynamics coefficients, the battery pack parameters, and transmission efficiency for both the real-world driving cycle and the standardized driving cycles, while the inertia contribution can be considered negligible. Finally, it has been also found that the standardized driving cycle that best fits the real-world scenario is the Artemis Urban Cycle.

This paper is organized as follows:

Section 2 outlines the adopted methodology, detailing the reference vehicles used in this study, the reference real driving cycle, the simulation tool utilized, the vehicle parameters under investigation, and a brief description of the simulations conducted;

Section 3 presents the results of the study, and the considerations derived from them;

Section 5 provides concluding remarks, summarizes the most relevant information from

Section 4, and proposes future works.

2. Materials and Methods

The aim of this study is to assess the vehicle parameters that affect the outcomes of lightweighting, considering vehicle categories M and N1 [

37]. To conduct this analysis, several simulations with variable vehicle mass were performed using the last version of the model described in [

38] to estimate energy consumption across a real driving cycle, representative of the geographical context considered: northern Italy, Lombardy region, province of Brescia.

2.1. Reference Vehicles

For this work, the same reference vehicles as in study [

32] were considered, i.e. two opposite vehicle types: a utility compact car (segment B) of M category, and a light commercial vehicle of N1 category. Where the B segment vehicle is the consolidated “CompactCar” model from VI-CarRealTime (VI-Grade), but without endothermic engine and with the electric driveline of the “Fiat 500e Hatchback 42 kWh” instead [

39,

40], a popular car in Italy and Europe, characterized by an 87 kW electric motor, a single reduction transmission ratio of 9.6, and a 42 kWh battery pack. On the other side, the N1 category vehicle is the same one used in [

38] for the validation of the tool during simulations of low performance vehicles, but with a total transmission ratio of 6.22.

For the two vehicle models (compact car of M category and N1 vehicle),

Table 1 reports the model parameters used for the purpose of this study.

It was chosen to simulate the two vehicle models without regenerative braking, to avoid the results to be influenced by a regenerative braking logic with different behaviors depending on the vehicle considered.

2.2. Driving Cycle

For this study, a real-world driving cycle was considered, representing a home-to-work journey for all the people who live in northern Italy, commuting from the province and crossing the city to reach their workplace.

For the driving cycle acquisitions, a GPS antenna connected to a MoTeC ADL2 [

41] data acquisition system was used. The GPS receiver is a LOCOSYS - LS23036 [

42], with an update rate of up to 10 Hz and a position accuracy of 2.5 meters.

Figure 1 shows the installation position of the GPS receiver and the location in the vehicle of the data acquisition system.

The vehicle used is a Suzuki Jimny, light duty vehicle model (N1) from 2021. The vehicle weight is 1065 kg (empty weight), it is powered by petrol with a nominal engine power of 102 CV (75 kW). It is equipped with a 4WD 5-gears transmission and with reduced gears. The measurements were carried out with the gearbox in standard mode (reduced gear and 4WD disengaged).

With this vehicle, equipped with the MoTeC ADL2/GPS data acquisition system, several driving cycles including speed profile, altitude profile, and other information were acquired. Among all of them, the most representative driving cycle was chosen (see

Figure 2), excluding cycles characterized by extraordinary events that rarely occur, for example heavy rain, strong wind, stops at petrol stations, emergency braking with activation of the ABS system, roadworks, etc.

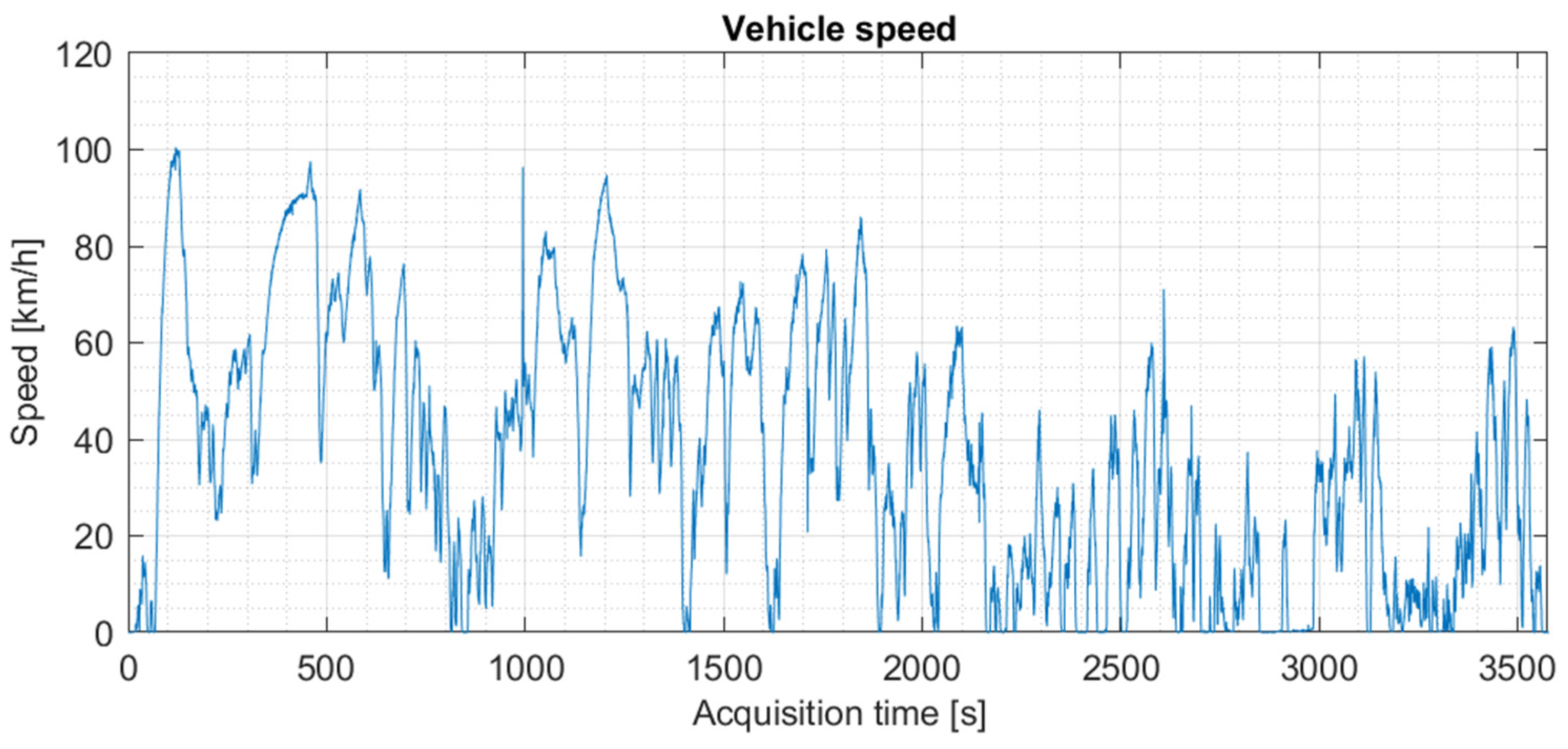

The chosen reference real-world driving cycle was acquired from 8:15 to 9:15 am, starting from the province of Brescia, from a place located between the towns of Gambara and Gottolengo, and arriving at the engineering faculty of the University of Brescia. This route includes the crossing the Brescia city center during the time of the day with highest level of traffic. The acquired speed profile, reported in

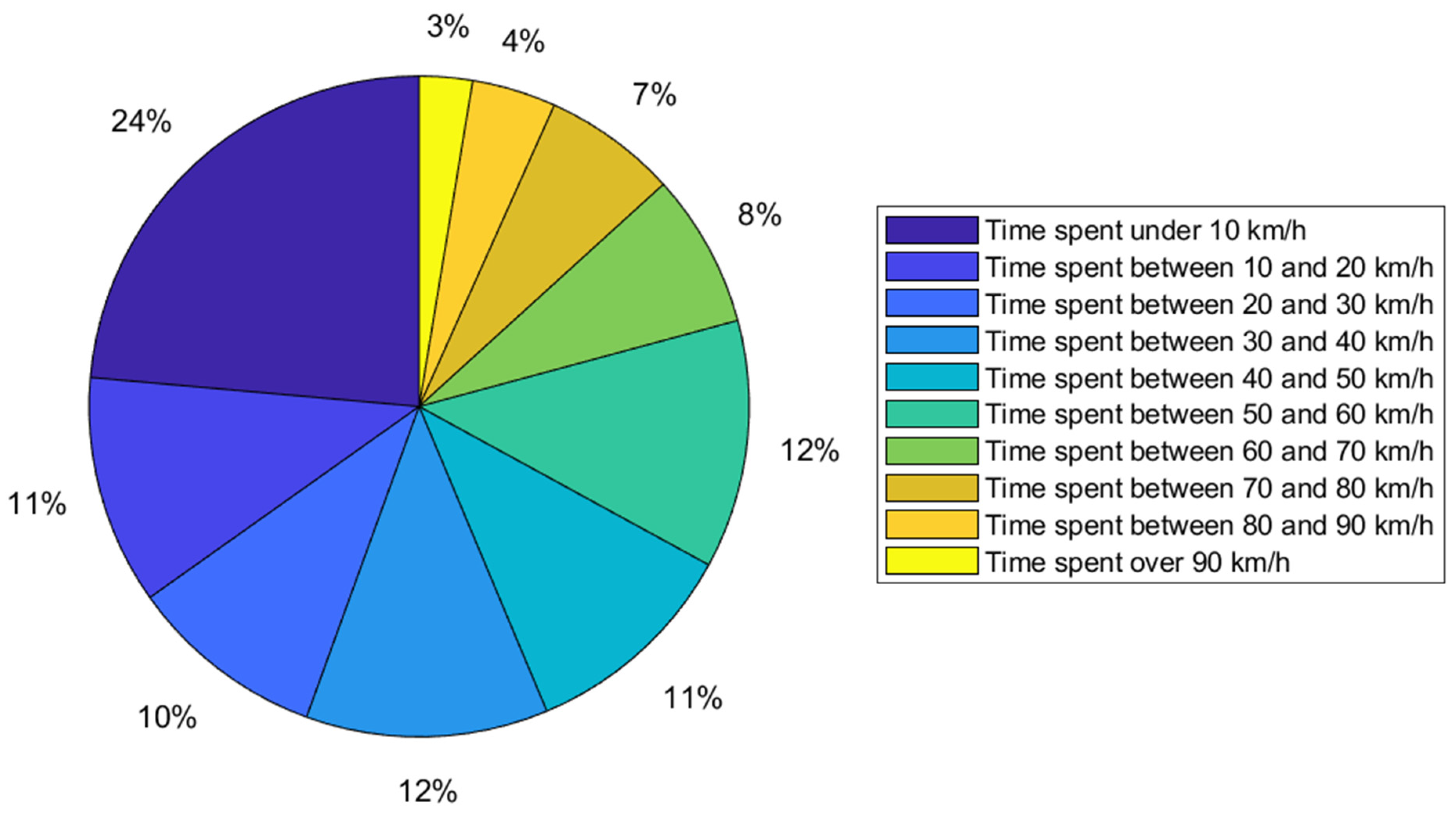

Figure 3, is characterized by many phases at zero speed, a maximum speed of 100.5 km/h and an average speed of 36.1 km/h.

The reference real-world driving cycle is a mixed cycle, urban and extra-urban, and in this journey approximately 40 minutes are spent at speeds below 50 km/h, approximately 18 minutes are spent at speeds between 50 and 90 km/h, while only about 1 minute is spent at speeds above 90 km/h. For more information see also

Figure 4.

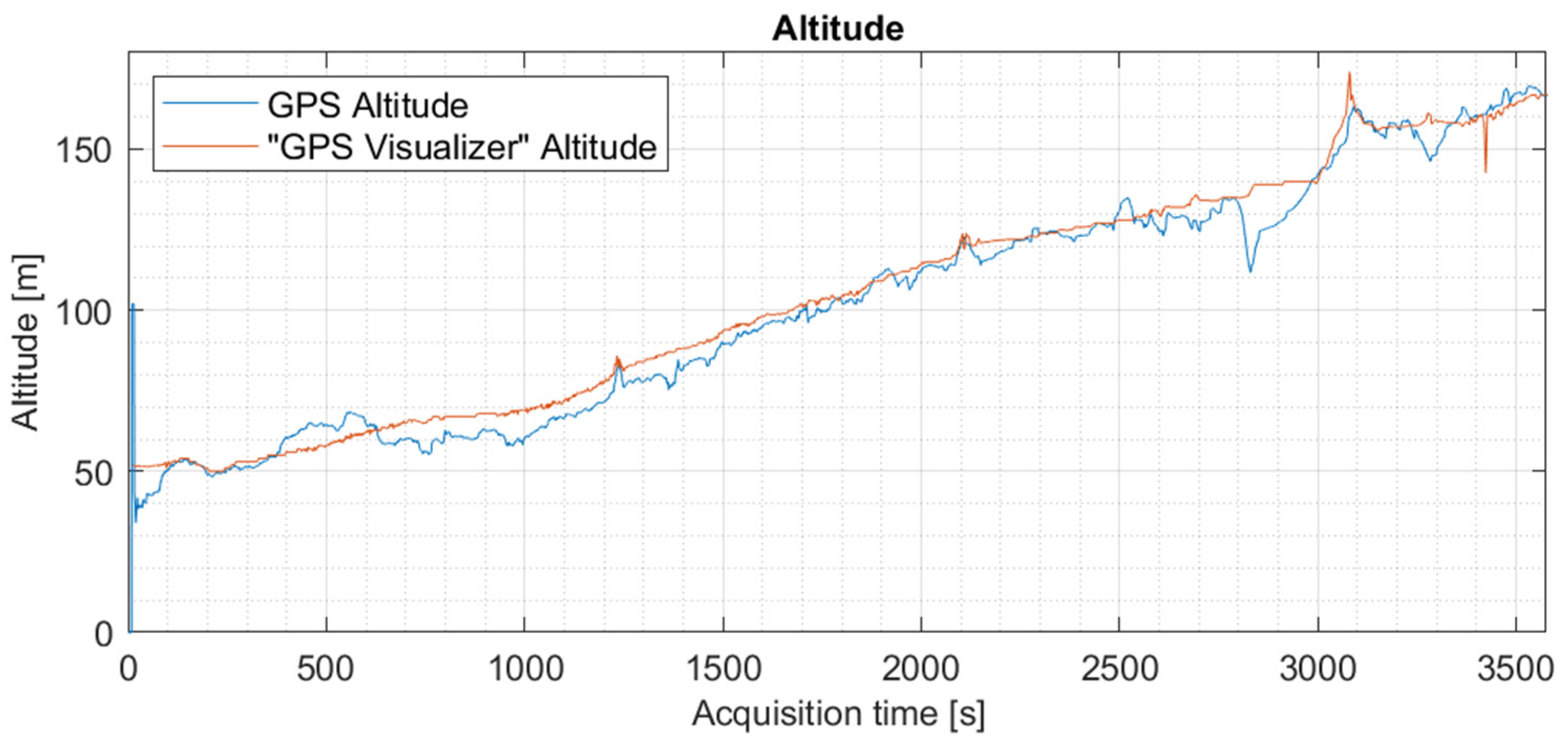

GPS systems are known to provide accurate longitude and latitude data, while they typically provide imprecise altimetric information. For this reason, it was decided to use a software available on the web, “GPS Visualizer” [

43], to obtain a more precise altimetric profile of the real cycle acquired. This tool allows to obtain altimetric data starting from latitude and longitude data, using different DEMs (Digital Elevation Models) sources. In particular, it is possible to set “GPS Visualizer” so that it automatically uses the best source among various DEMs. The altimetry profile obtained is reported in

Figure 5 and compared to the profile acquired directly with the GPS on board the vehicle.

The effects of lightweighting on real driving cycle, for both reference vehicles, were compared with the following standard driving cycles:

2.3. Simulation Tool

For the simulation, the last version of TEST (Target-speed EV Simulation Tool) model [

38] was used. This is a vehicle longitudinal dynamics simulation tool that enables the simulation of both the mechanical and electrical behaviors of fully electric or hybrid electric vehicles. The model is presented in [

38] (for more information, see also [

49,

50]), and the latest version also includes the integration described in [

18,

19,

22,

32].

2.4. Parameters of the Vehicle (and of Its Model) Which Can Affect the Lightweighting Results

In this study, the variability of the outcome given by the lightweighting was analyzed as a function of the variation of the same parameters considered in [

32], the following:

Battery pack parameters (nominal voltage, capacity, and internal resistance);

Aerodynamic parameters;

Transmission efficiency;

Rolling resistance, in particular changing the rolling friction coefficient;

Moments of inertia of the electric motor, of the rotating parts of the transmission, and of the wheels;

Total transmission ratio (including wheel ratio given by the wheel radius);

Finally, the driving cycle considered is also a fundamental parameter to take into account, therefore the results obtained considering the real-world driving cycle were compared with those obtained on different standardized driving cycles.

2.5. Set of Simulations

In this study, “set of simulation” (or “simulation set”) means the collection of simulations, conducted for the same driving cycle and for the same vehicle model, differentiated only by the mass of the vehicle. In particular, for the compact car models, simulations were carried out starting from 700 kg, up to 2500 kg, for every 50 kg of variation in vehicle weight. For the N1 vehicle, always every 50 kg, but from 700 kg up to 3500 kg, which corresponds to the maximum permitted weight for light commercial vehicles. 700 kg for a commercial vehicle is unrealistic, but the simulations were pushed up to this value for easier comparison with the results of the compact car.

A first set of simulations for each reference vehicle model (compact car and N1) was obtained by providing the real-world speed profile acquired via GPS as input to the TEST model and, for each single simulation, by varying the mass of the vehicle under examination. Then, these sets of simulations were initially repeated by setting all the inertia contributions of the two vehicle models to zero.

Further sets of simulations, always on the real driving cycle, instead concern the compact car, in which one or more parameters have been modified, imposing them equal to those of the reference N1 category vehicle. The modified parameters for each simulation set are as follows:

Battery pack parameters (nominal voltage, capacity, and internal resistance);

Aerodynamics;

Trasmission efficiency;

Rolling friction coefficient;

Moments of inertia (of motor, transmission, and wheels);

All the previous parameters simultaneously;

Motor reduction ratio, transmission ratio and wheel radii;

All of the above parameters simultaneously.

Finally, for this work, the simulation sets obtained for study [

32] were considered, in particular relating to the compact car and N1 models, without regenerative braking, on the standard cycles reported at the end of section “2.2. Driving Cycle”. These simulations were finally compared with those obtained on the real driving cycle covered by this study.

3. Results

This section presents the results of the simulation sets conducted, with consequent considerations.

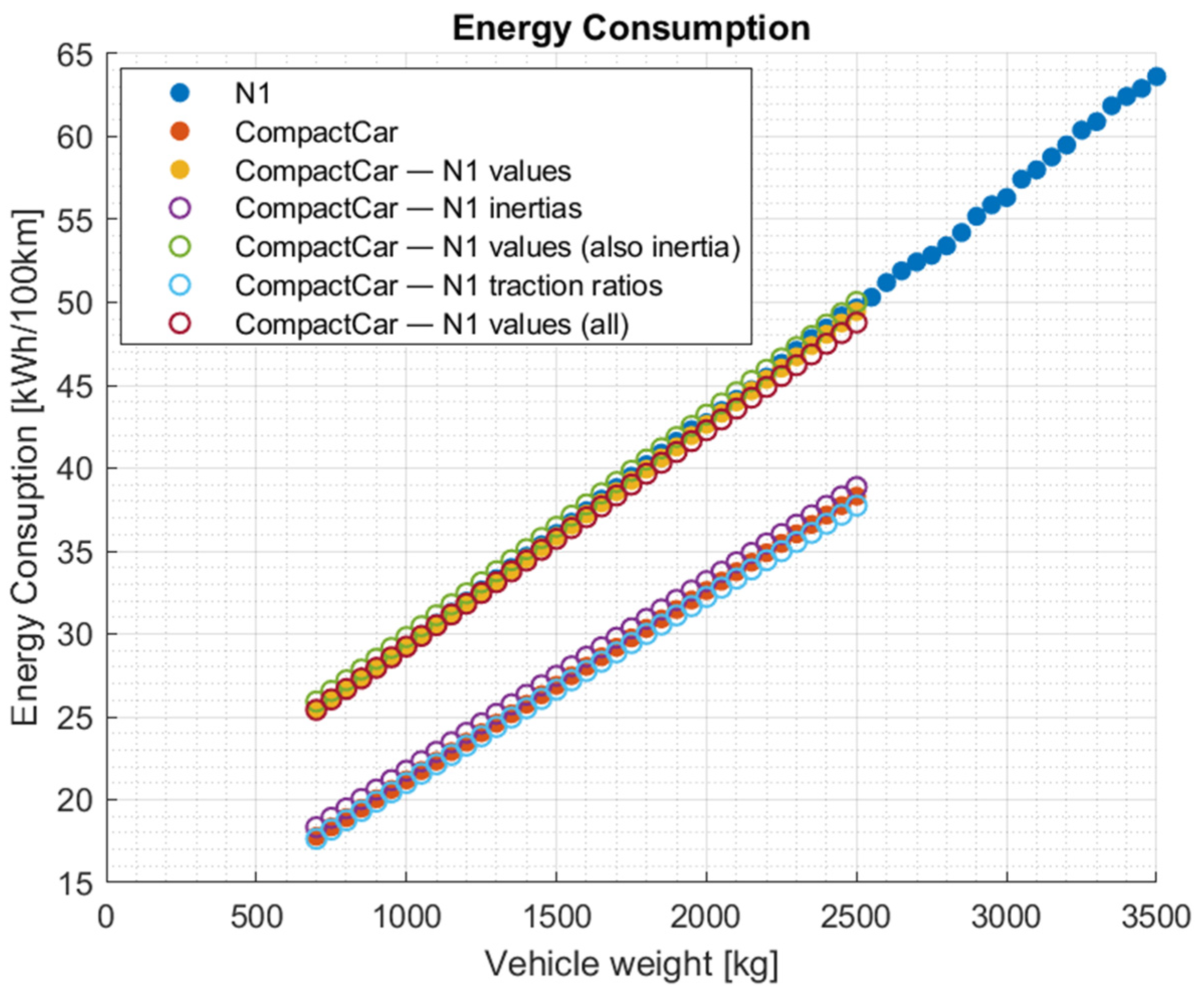

3.1. Consumption Analysis

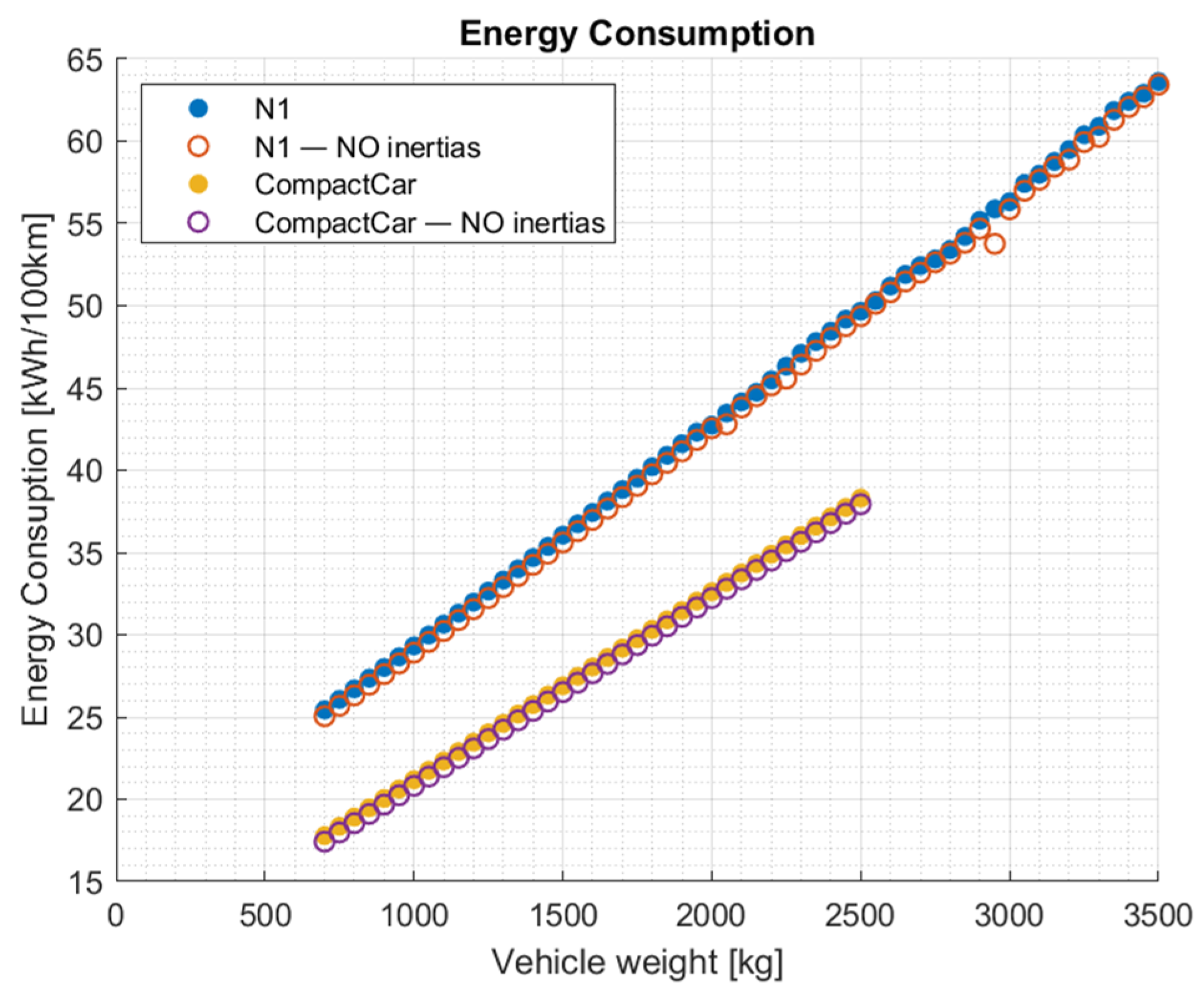

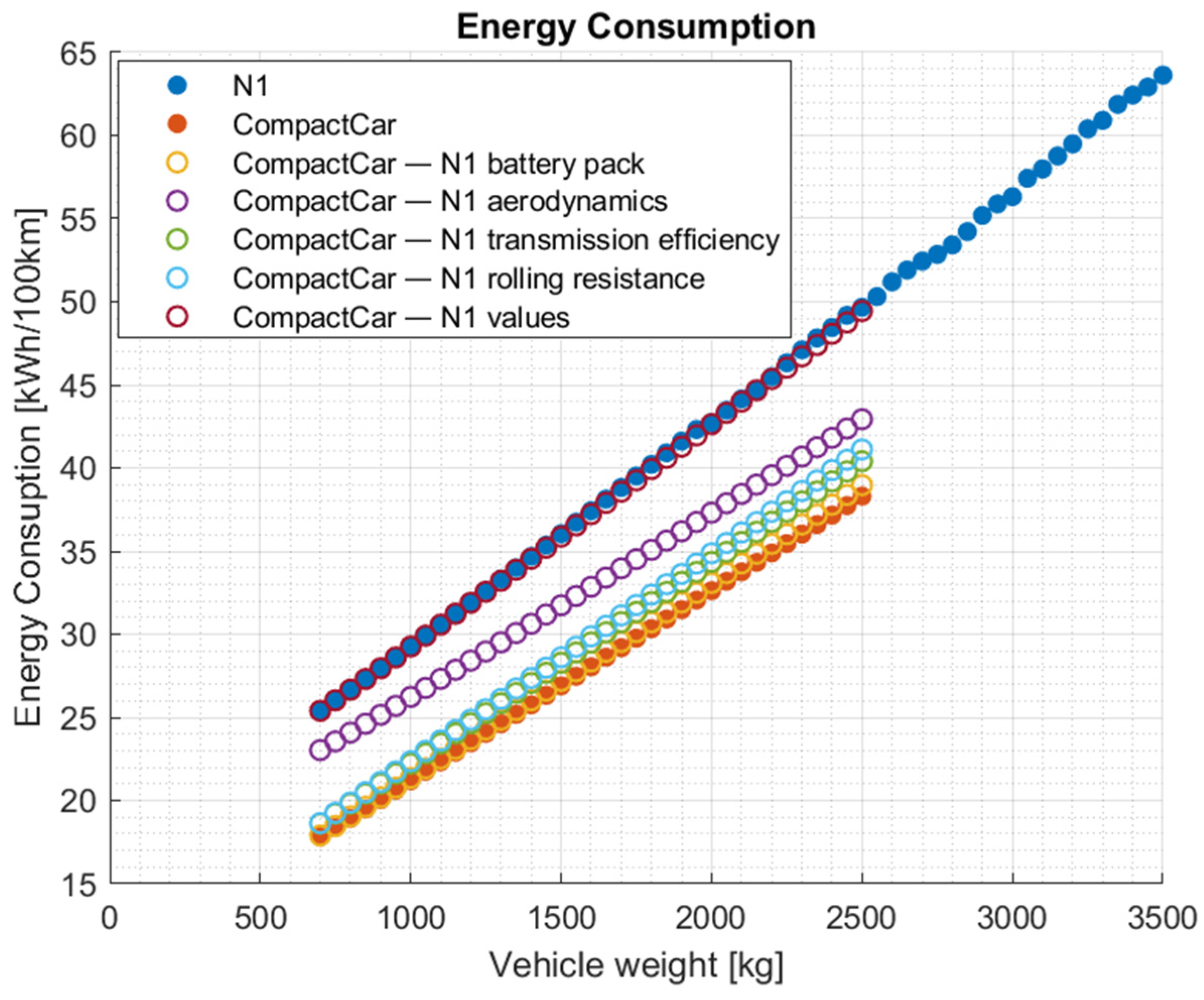

Figure 6 shows the results of the simulation sets obtained for the compact car and N1 vehicle models, with and without inertia contributions. In particular, the results are reported in terms of average energy consumption over the real-world cycle as a function of vehicle weight.

From

Figure 6, the inertia can be considered negligible, as obtained for study [

32] for the WLTC and US06 standard driving cycles.

In

Figure 6, it is also possible to see that there is an error for the consumption result for the simulation on the N1 model without inertia contribution, with the vehicle weight equal to 2950 kg. In fact, this consumption value is not aligned with the other data trend.

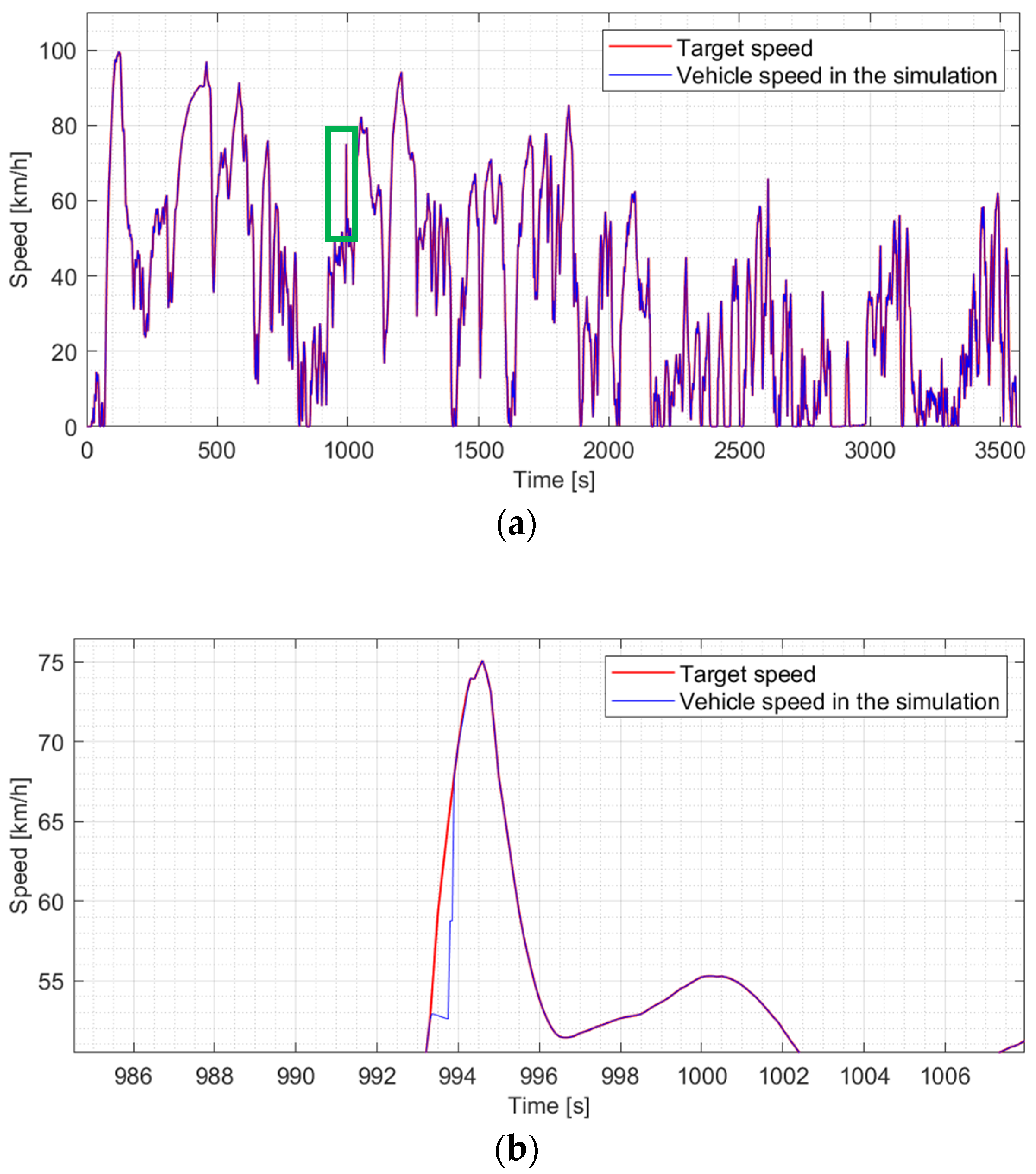

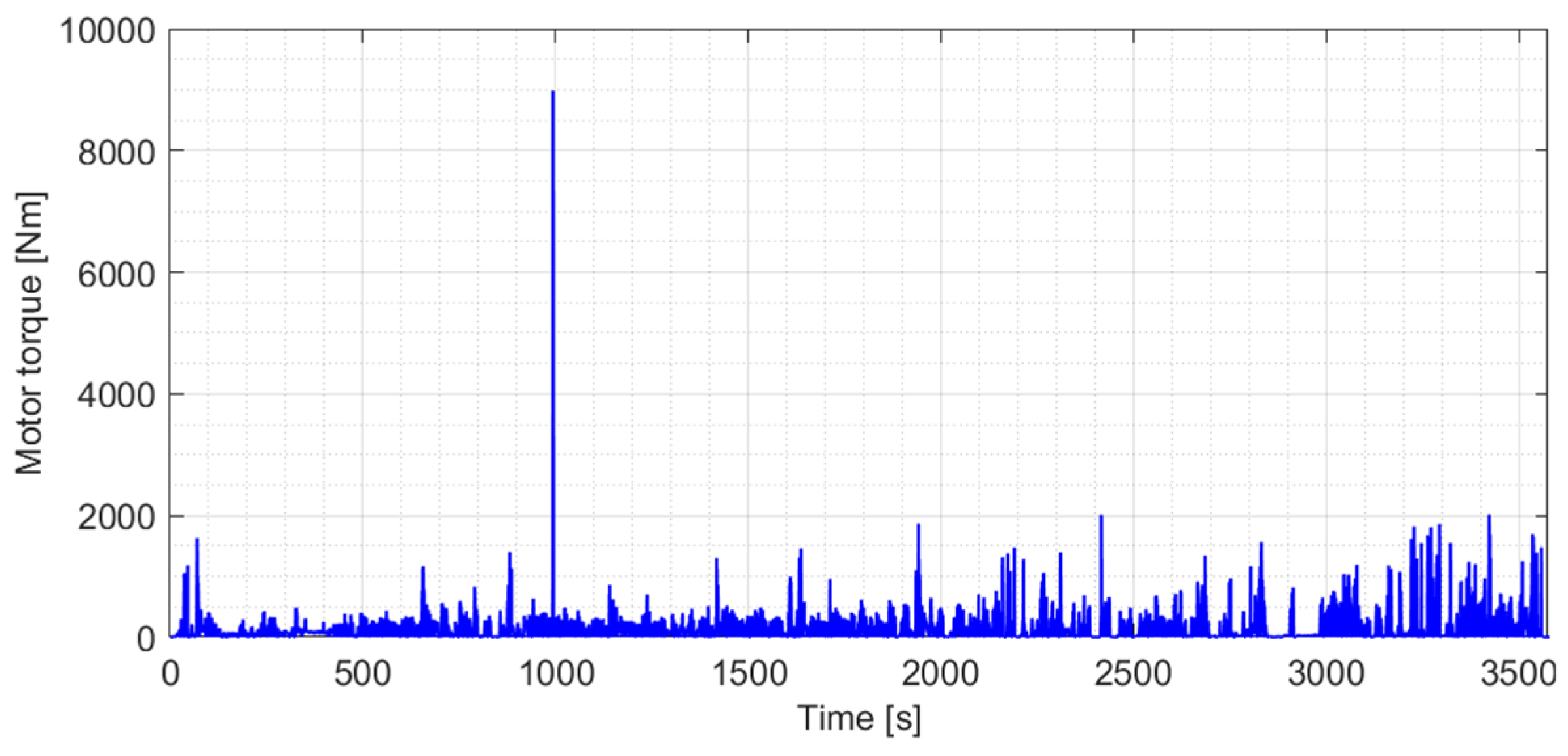

In particular, this problem is due to the fact that the vehicle, for high weights, has difficulty following the speed target, in the area of 994 seconds elapsed from the start of the simulation, due to the excessively high acceleration. In this regard,

Figure 7 shows a comparison between the target speed and the vehicle speed during the simulation, for a vehicle weight of 2950 kg, and without inertia contributions. In fact, as can be observed in

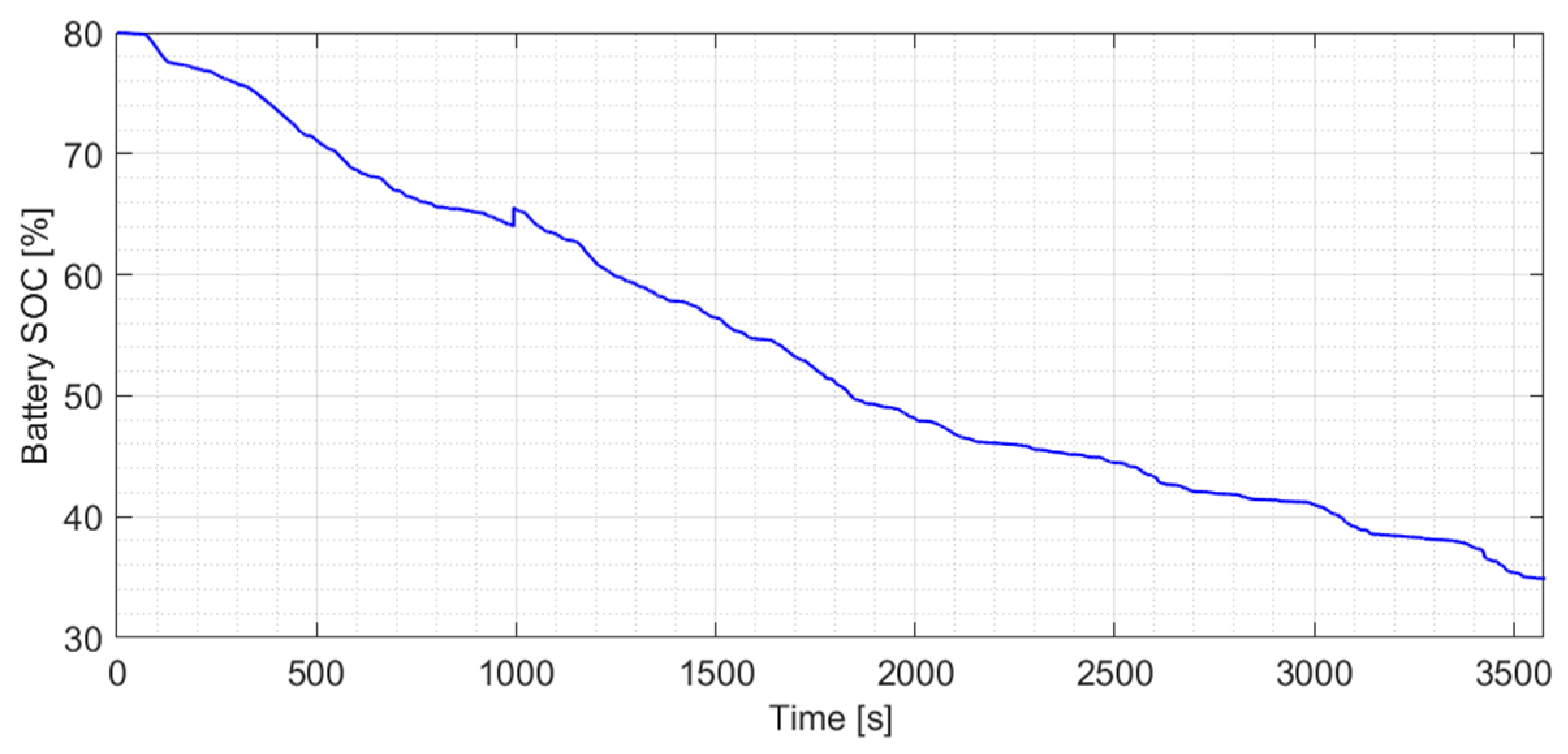

Figure 8, the high acceleration of that stretch leads to a high torque request, which cannot be satisfied by the vehicle under examination. A torque limit of 10 000 Nm was implemented in the model used for the simulations, in order to allow it to travel the imposed speed profiles without incurring limitations; but this limitation still occurs in the case in question (weight equal to 2950 kg), leading to a calculation error: a positive peak is noted in the voltage of the battery pack, a negative peak in the pack current (which therefore corresponds to the current absorbed by the battery pack itself), these two variables lead to a negative peak in the power of the batteries (which corresponds to the power absorbed by the pack), all resulting in the battery SOC (State of Charge) trend as reported in

Figure 9 (see in particular the increase of SOC in the area around 1000 seconds). However, the resolution of this tool calculation error is not of vital importance for the study in question, since what is important is the trend of the average consumption over the real driving cycle as the weight of the vehicle varies and not the individual consumption relative to each weight considered.

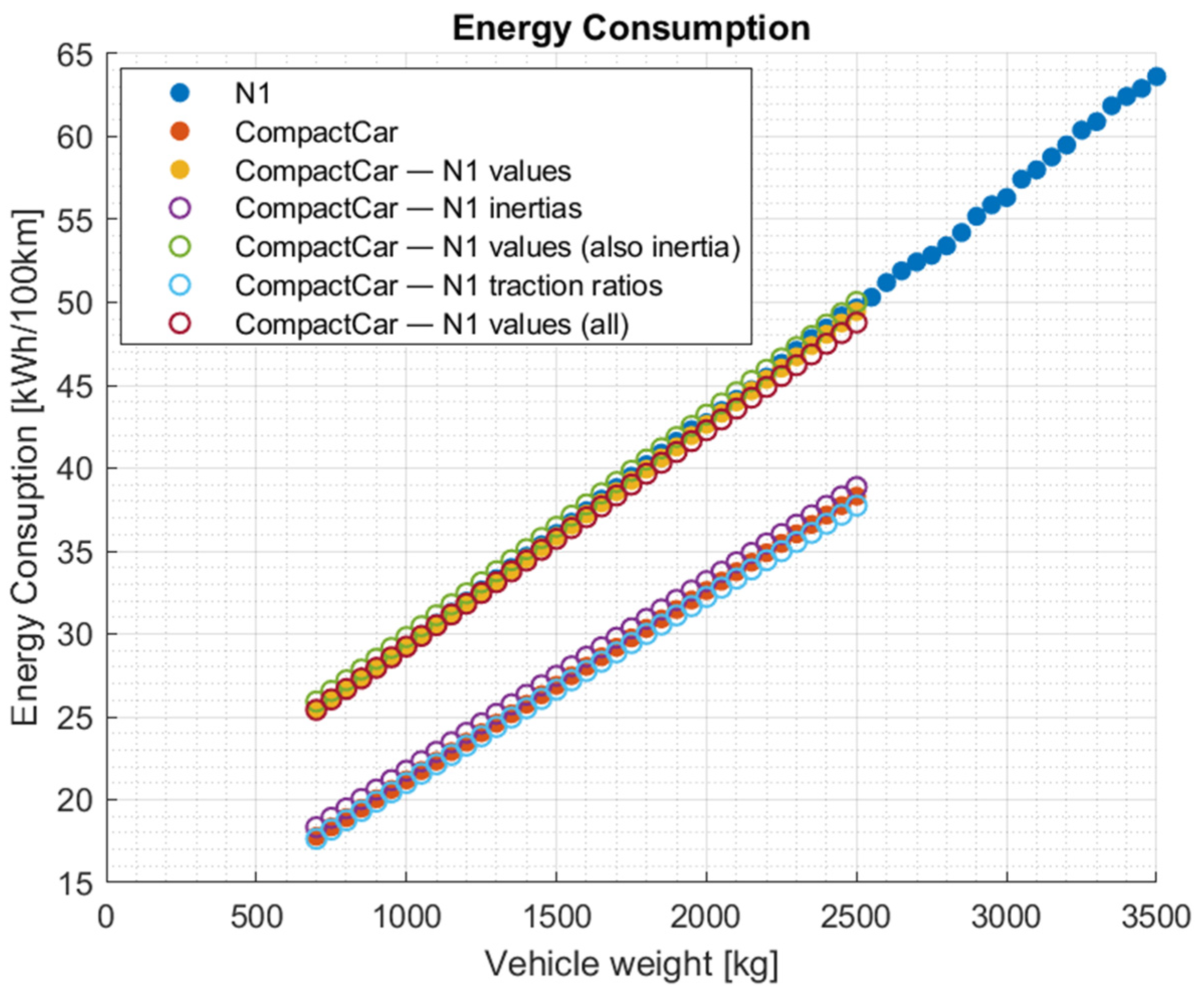

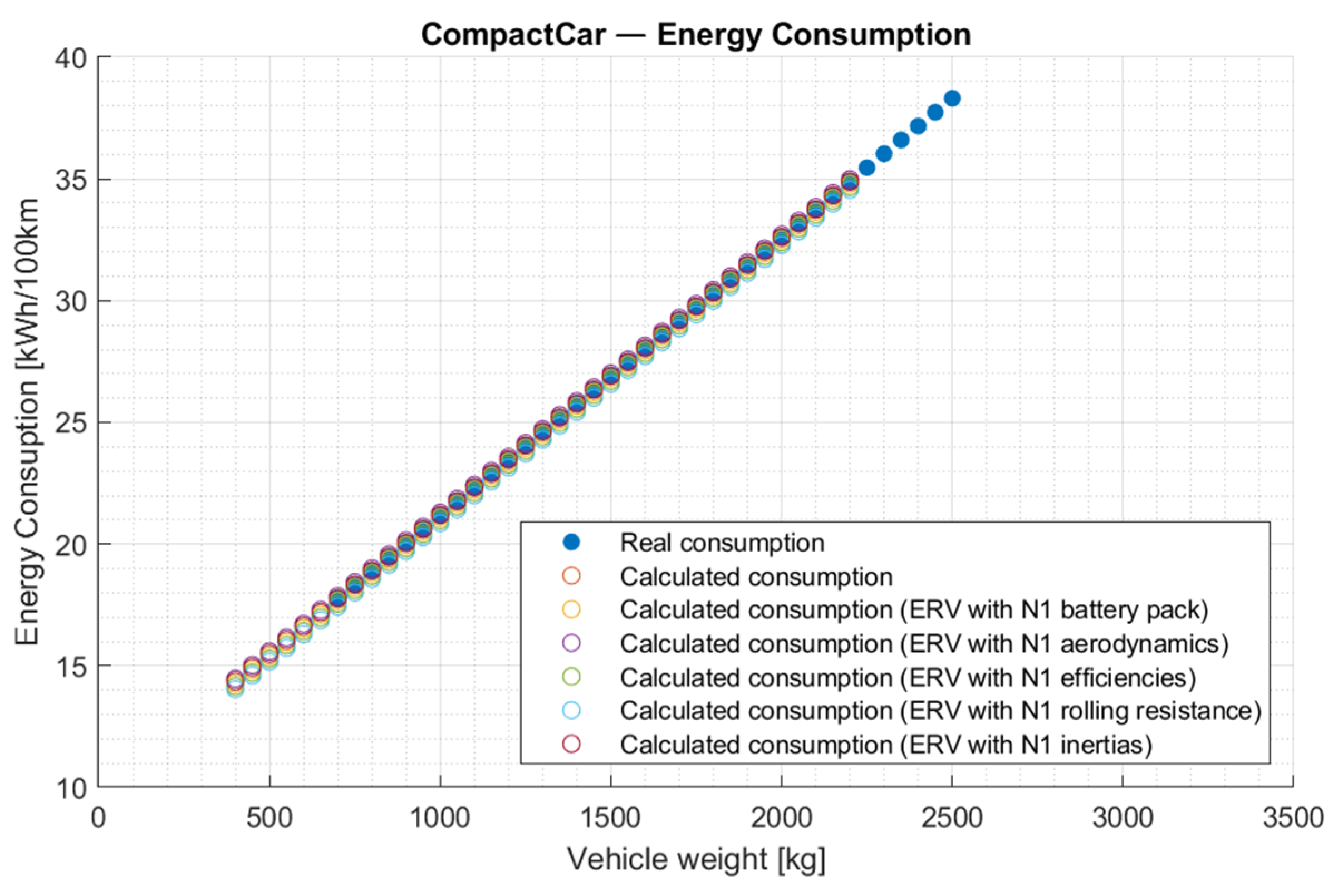

Figure 10 shows the average energy consumption for the sets of simulations for the compact car and N1 models, compared with those of compact car model with some N1 parameters, relating the battery pack, the aerodynamic, the trasmission efficiency, the rolling resistance, and all the above features simultaneously.

From

Figure 10 it is possible to see that the contribution that has the greatest impact on consumption is aerodynamics, followed in the following order by rolling resistance, transmission efficiency, and battery pack. In particular, the last contribution can be considered negligible. Once again, the same considerations were obtained which are also valid for the standard driving cycles [

32].

Furthermore, even for the real driving cycle, as for the standards, the modification of the rolling resistance coefficient involves a greater variation in the slope of the average cycle consumption curve as a function of the vehicle weight, while the modification of the aerodynamics, as we will see better below, involves a less influential variation to this slope.

In the graph shown in

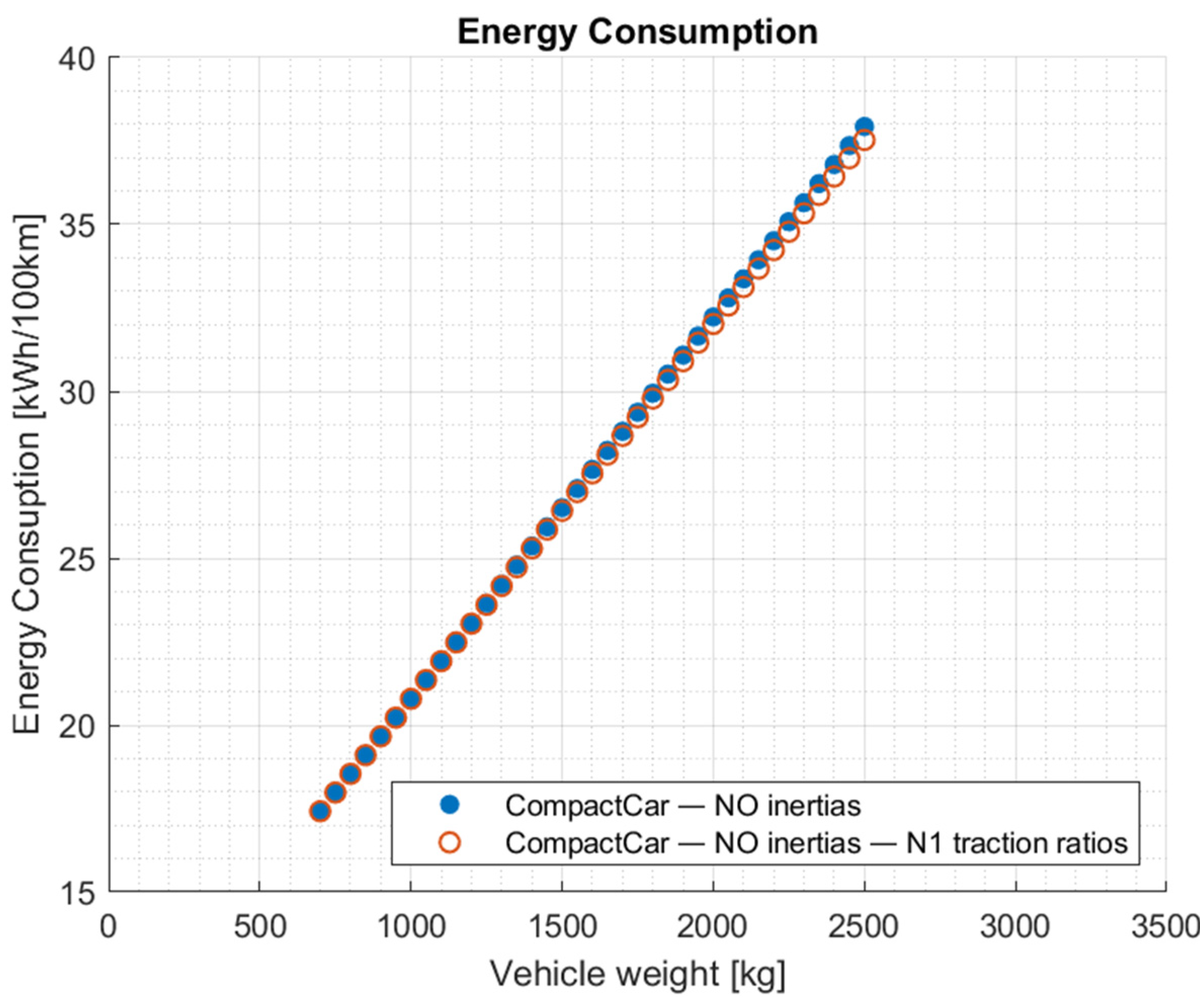

Figure 10, the curve corresponding to the compact car with battery pack, aerodynamics, transmission efficiency, and rolling resistance parameters identical to those of the N1 vehicle closely aligns with the curve of the N1 class vehicle, for low vehicle weights, while for higher weights, torque limitations begin to intervene which cause the driving cycle to deviate slightly from the target in some small areas, with a consequent slight drop in consumption. This is because inertia, as previously defined, is negligible, and the total transmission ratios (and wheel radii) do not influence the regenerative braking recovery, which is absent (for more details see [

32]). In this case, the transmission ratios only affect the contribution of inertia (see

Figure 11 and

Figure 12). In particular, this is visible in

Figure 11, for low vehicle weights, for higher weights the average consumption with different transmission ratios differs. Most likely due to the difficulty of the heavy vehicle to faithfully follow the imposed real driving cycle, which is “dirtier” than a standard one and characterized by phases of greater acceleration.

Unless there are limitations for high vehicle weights, the considerations obtained in this section are the same as those obtained for the WLTC (class 3b) and US06 standard cycles in study [

32].

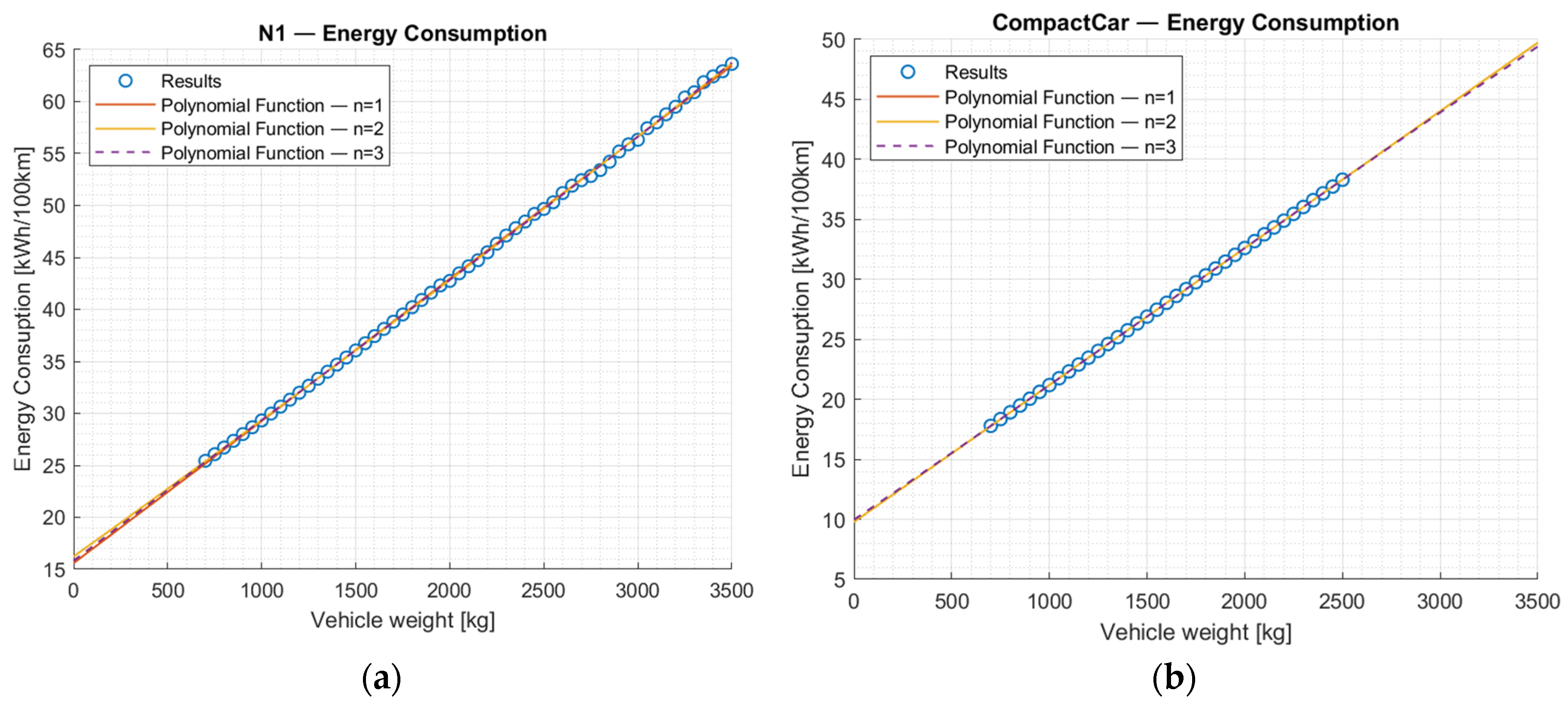

3.2. Polynomial Interpolation and ERV Index

In this section, we will examine the polynomial functions that best represent the curves previously shown in

Section 3.1. Specifically, first, second, and third-degree polynomial functions were analyzed to approximate the selected curve, with the parameters obtained using MATLAB’s “polyfit” function. The function used for polynomial interpolation is presented in Equation (1) of [

32], and below in Equation (1).

Here, represents the average energy consumption in kWh/100 km, for the curve analyzed, and refers to the vehicle weight (in 100 kg). The coefficients , , , and are the polynomial coefficients determined by the MATLAB “polyfit” function.

Figure 13 shows the curves, relating, respectively, to the N1 vehicle and the compact car, obtained by means of the polynomial functions.

As can be observed in

Figure 13, all three polynomial functions (first, second and third degree) approximate the represented curves very well. For their description it is therefore sufficient to approximate with the first-degree polynomial, for greater simplicity. The same result was also observed in all other simulations conducted (with altered parameters).

Table 2 presents the values of the polynomial coefficients that approximate the consumption–weight curves, with the coefficients obtained using MATLAB’s “polyfit” function. Only the coefficients for the first-degree polynomials are reported, as the second- and third-degree polynomials have negligible

and

coefficients, which are several orders of magnitude smaller than the other two coefficients (

and

). In fact, as shown in

Figure 13, the curve under consideration can be approximated with sufficient accuracy using only a first-degree polynomial, and the same situation applies to the polynomials corresponding to the curves from all the previous simulations conducted.

As mentioned in the introduction section, the FRV index is often referenced in the literature when calculating the energy savings associated with vehicle lightweighting. For electric vehicles, however, it is more appropriate to calculate an equivalent index, the ERV index, which corresponds to the

coefficient of the first-degree polynomial, presented in

Table 2 for each simulated vehicle model.

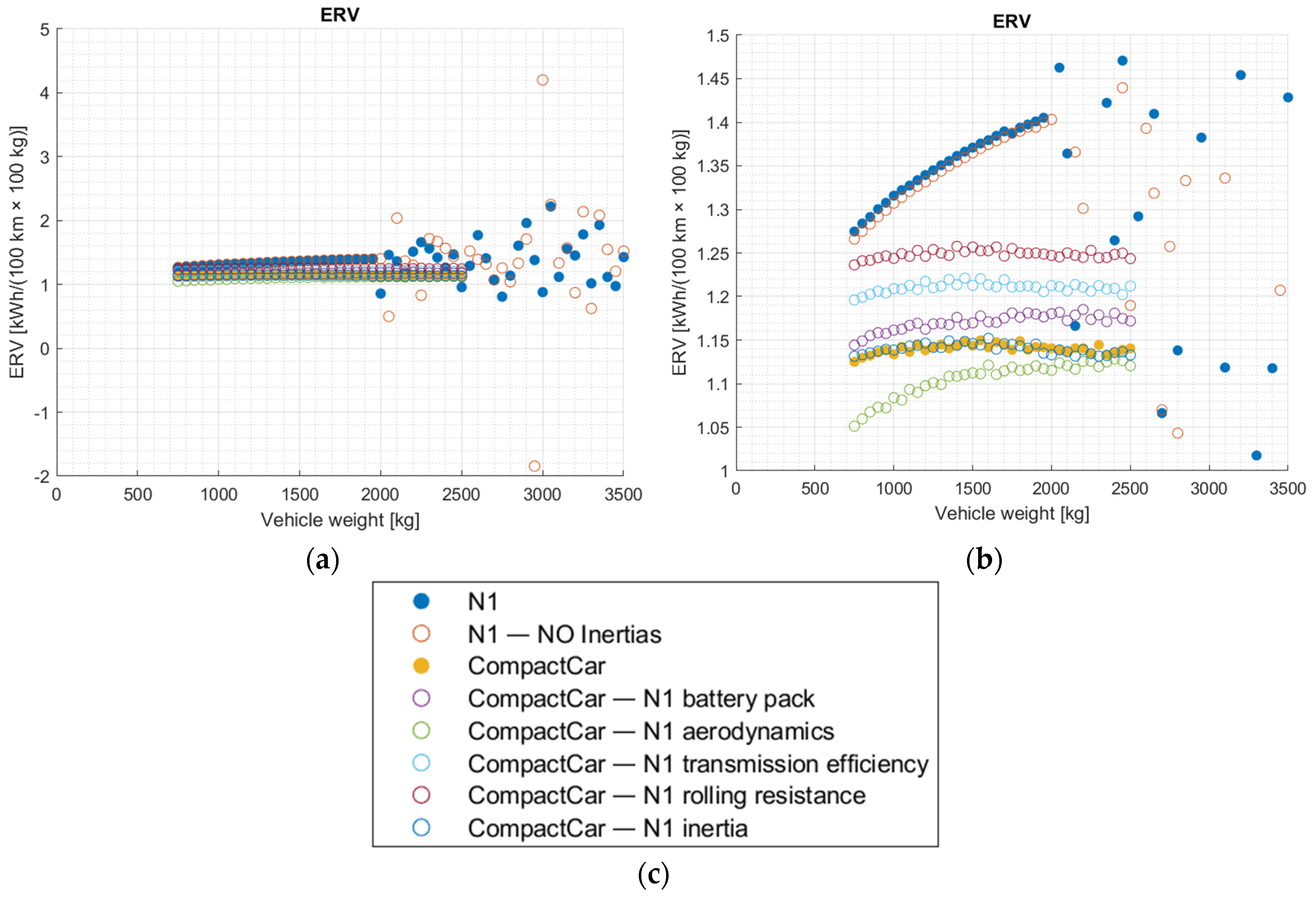

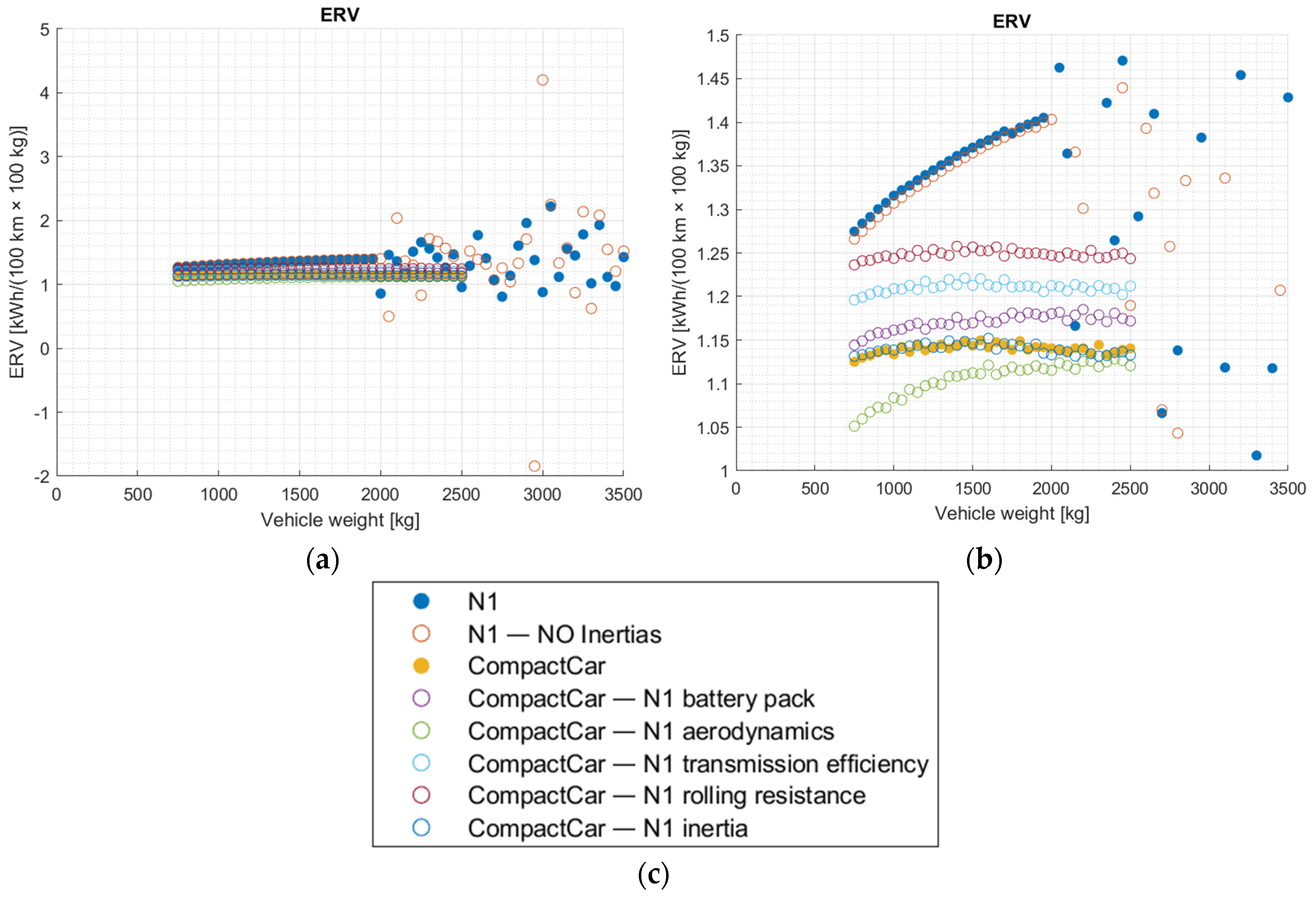

Figure 14 reports the ERV index, calculated for each pair of average consumptions on the reference real driving cycle, for consecutive weights; for further information refer to Equation (2) of [

32].

From

Figure 14(a) it can be seen that the technique consisting in obtaining the ERV index point by point is not effective for high vehicle weights. This is due to the limitations that arise when the vehicle is not equipped with sufficient performance in order to follow the acceleration targets. This phenomenon was not observed in [

32] for the WLTC and US06 standardized cycles, in fact, the standard driving cycles are usually characterized by low accelerations, which are not very realistic. The real driving cycles, unlike the standardized ones, are therefore able to cause a crisis in the simulation tools, thus resulting more difficult to manage.

For low vehicle weights,

Figure 14(b) shows some aspects already previously identified, namely that, for example, inertia has little influence on consumption variation and is therefore negligible in the context of this study, which focuses on evaluating the impact of vehicle lightweighting. Moreover, for the same vehicle model, the ERV index increases as the vehicle weight increases. This indicates that heavier vehicles benefit more from lightweighting for the same weight reduction. Additionally, it is possible to observe which parameters (when equal to those of a higher-class vehicle, such as class N1 in this case) raise the ERV index and which lower it. For example, it can be observed that rolling resistance has a major influence on the ERV index, i.e. on the slope of the average energy consumption curve as a function of weight.

To estimate the reduction in average consumption over real driving cycles following the vehicle lightweighting, it is therefore more appropriate to obtain the ERV index as the coefficient of the first-degree polynomial function that approximates the average consumption curve identified by means of simulations.

Now, for each compact car weight, starting from the same vehicle but with an additional 300 kg of weight, the ERV index obtained from the polynomial function is used to determine the average consumption on the reference driving cycle. Furthermore, multiple ERV indices are assumed, reported in

Table 2, obtained by assuming errors in the construction of the model, in particular by mistakenly setting one or more parameters equal to those of the N1 category vehicle. The result of these tests is reported in

Figure 15.

Figure 15 shows that an incorrect definition of the model does not cause significant errors in the evaluation of a 300 kg weight reduction, as long as the vehicle’s actual consumption in the given real driving cycle is known, as obtained in [

32] for the WLTP and US06 standard cycles. This approach reveals a contrasting situation compared to evaluating lightweighting based on the consumption curve obtained through vehicle model simulations. In the latter case, as shown in

Figure 10, an incorrect assessment of the vehicle model parameters, in particular relating the aerodynamics, can cause a non-negligible error. In fact, increasing the aerodynamic resistance coefficient, as seen in

Figure 10, raises the consumption curve, but it has little effect on the slope of the curve itself.

Therefore, if the consumption data for the reference cycle is available and we want to assess the results of a hypothetical lightweighting, it is more convenient to use the constant ERV index approach (polynomial interpolation) for more realistic conclusions. The same consideration has also been deduced for the standard driving cycles analyzed in [

32].

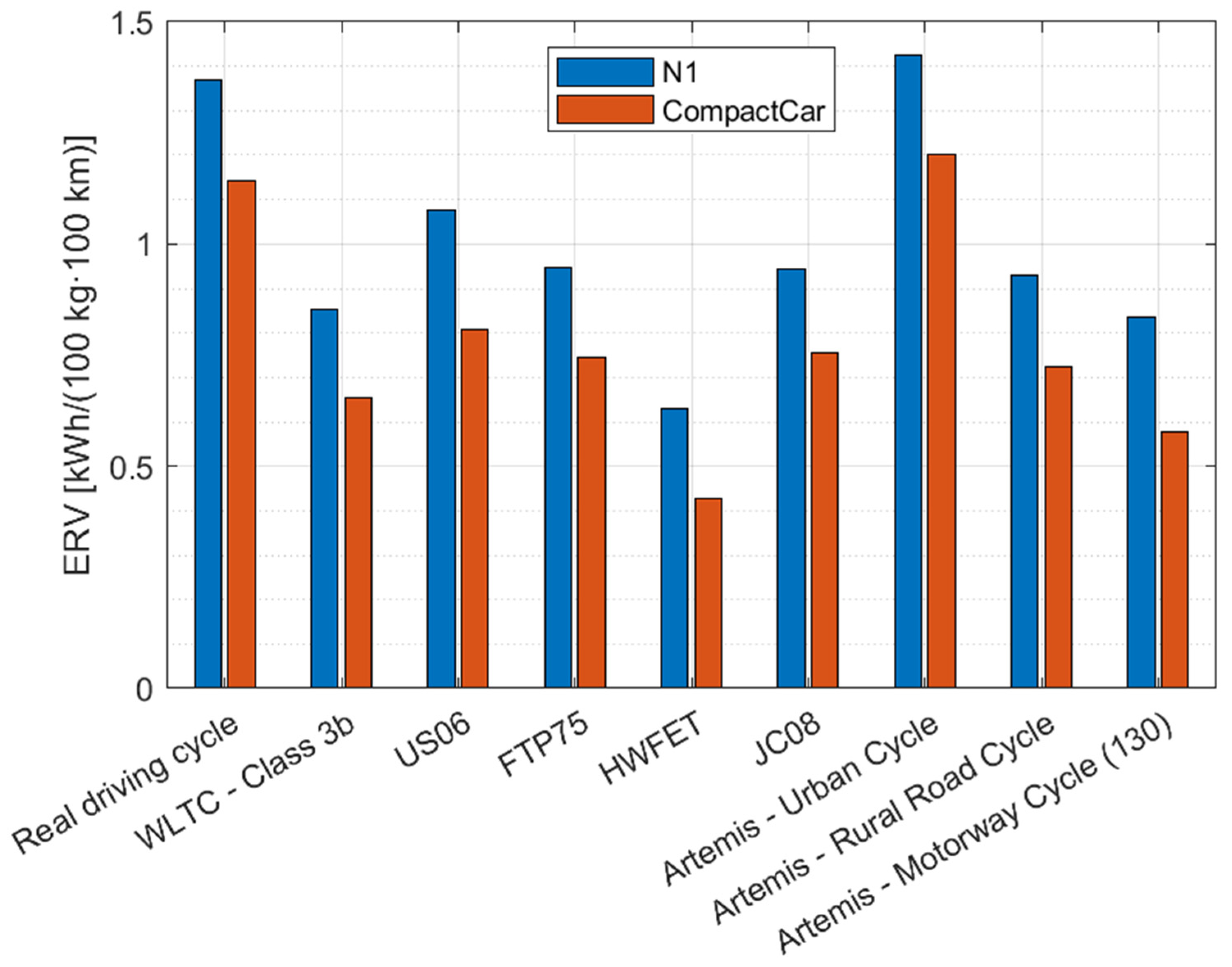

3.3. Comparison Between the Reference Real-World Driving Cycle and Standard Cycles

In this section, the consumption curves obtained for the real reference driving cycle is compared with the curves obtained for different standardized cycles [

32]. This with the ultimate aim of evaluating which standard driving cycle can be most representative of the real case under examination, and which of these can therefore be useful for estimating the impact of vehicle lightweighting for the case of northern Italy.

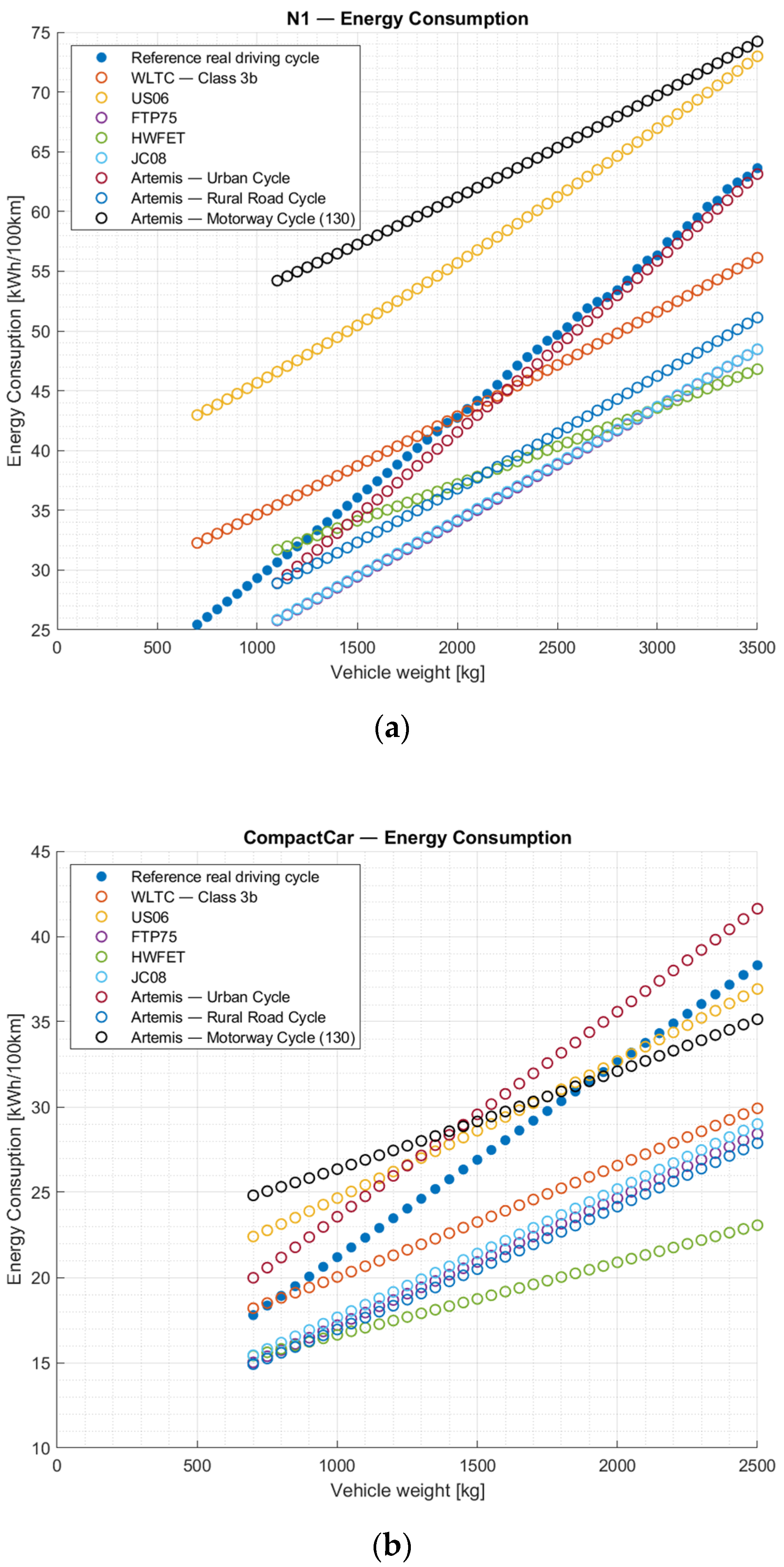

Figure 16 shows the average energy consumption obtained from various sets of simulations across the reference real driving cycle and different regulated cycles [

32]. Specifically, each point on the graph represents the average energy consumption on the analyzed cycle, determined by running a simulation with the TEST model on the respective cycle, with a pre-set weight (as indicated on the x-axis of the graph).

From

Figure 16(a) it can be observed that for light commercial vehicles (category N1), the standard driving cycle that best represents the real case object of this study is the Artemis Urban Cycle. It should be remembered that the real driving cycle considered is representative of home-work trips, from the province of Brescia, crossing the city of Brescia, in the Lombardy region, in northern Italy.

For the compact vehicle, however, there is no standardized driving cycle that accurately approximates the real reference driving cycle. However, it can be noted that the slope of the consumption curve calculated on the real cycle is quite close to the slope of the curve obtained for the Artemis Urban Cycle. It follows that this last cycle can be useful for estimating the outcome of the lightweighting also for compact cars, provided that only the ERV index is considered.

The closeness of the ERV indices relating to the Artemis Urban Cycle speed profile with the indices obtained on the real driving cycle, for both vehicles, can also be observed in

Table 3 (for N1 category vehicle) and in

Table 4 (for compact car), remembering that the ERV index corresponds to the

coefficient of the first-degree polynomial function.

Finally, from

Figure 16, it is also possible to observe how, as the weight of the vehicle varies, a standard driving cycle can underestimate or overestimate energy consumption. For example, for the N1 category vehicle, on the considered home-work travel, the WLTC driving cycle will underestimate real consumption if the weight of the vehicle is less than approximately 2100 kg, vice versa, for higher weights, it will overestimate them.

4. Discussion

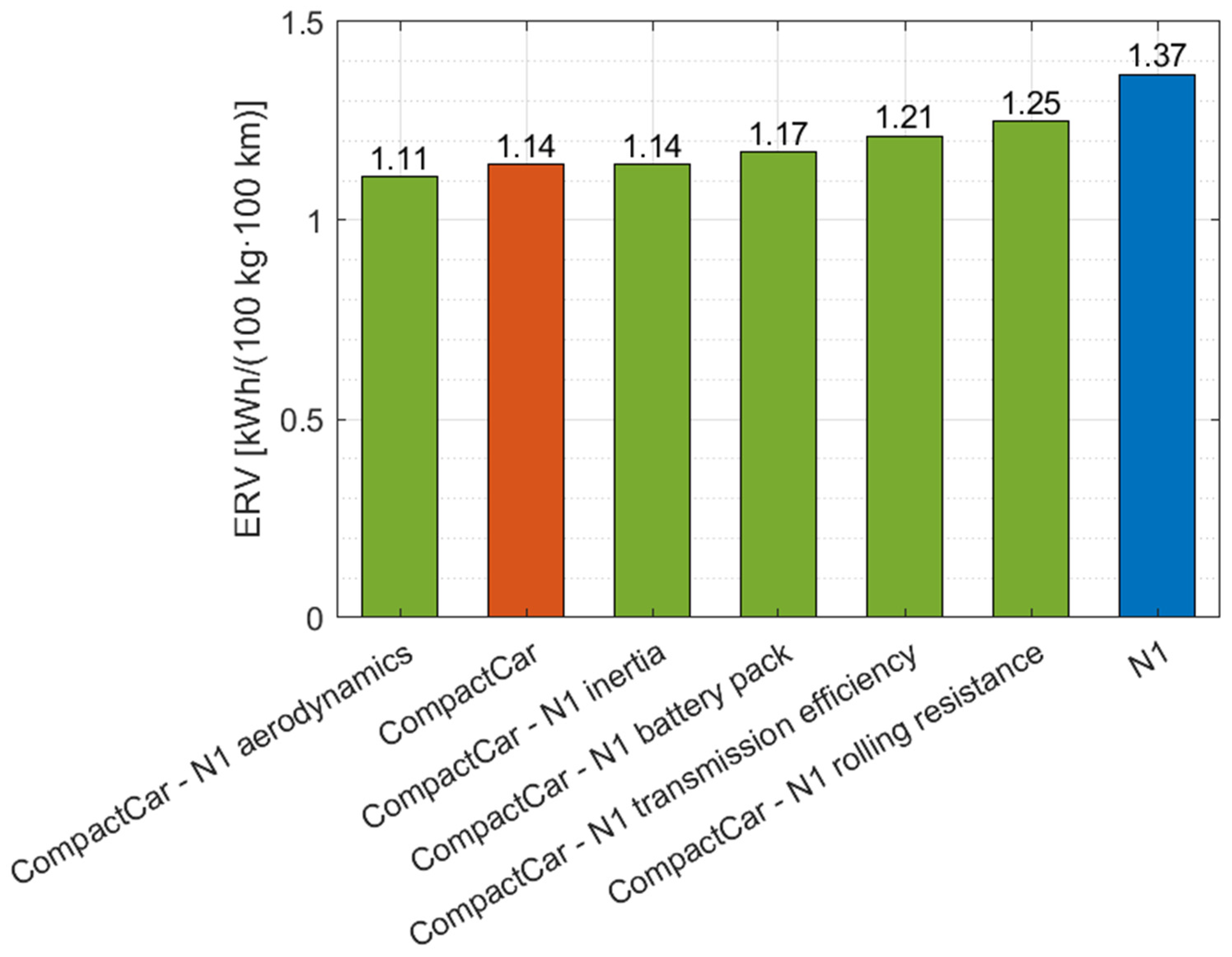

In this paper, the outcome of vehicle lightweighting on a real-world driving cycle was analyzed, with a focus on identifying which vehicle model parameters have the greatest influence on the results and, consequently, which parameters must be estimated more accurately for a proper analysis. In particular, one objective is to compare the results obtained on the real-world cycle with those obtained in [

32] using the WLTC (class 3b) and US06 standard driving cycles.

As seen in [

32] for the two standard cycles, also for the real cycle the contribution of the moments of inertia on energy consumption can be considered negligible, for both N1 category vehicle and compact car. Instead, the aspect that has the greatest impact on higher consumption is the increase in aerodynamic resistance, followed by rolling resistance, while the aspect that least affects consumption is the battery pack, followed by the efficiency of the transmission.

In particular, the increase in aerodynamic drag has a significant impact on the absolute value of the average vehicle consumption on the real cycle; however, it does not lead to a notable change in the slope of the consumption curve, as observed in [

32] for the two normed cycles.

Finally, to estimate the vehicle consumption accurately and therefore to effectively evaluate the outcome of the lightweighting, it may be sufficient to correctly set the vehicle model parameters relating to the battery pack, aerodynamics, transmission efficiency and rolling resistance, as stated in [

32]. While as regards the functions that approximate the consumption curves identified through simulations, it is enough to consider the first-degree polynomial functions for a good level of precision.

The ERV index, useful to analyzed the lightweighting results for electric vehicles, expressed in kWh/(100 km ∙ 100 kg), increases as the vehicle weight rises for the same vehicle model. This implies that heavier vehicles benefit more from lightweighting for the same amount of weight reduction. The vehicle parameters that most influence the ERV index are the transmission efficiency and those relating to the battery pack. Aerodynamics, on the other hand, has little influence since it modifies consumption in a non-negligible way, but not the slope of the average consumption curve as a function of vehicle weight. This therefore applies to the reference real-world driving cycle considered in this study, as seen in [

32] for the WLTC (class 3b) and US06 standard cycles.

Figure 17 summarizes the ERV indices obtained on the reference real-world driving cycle, for the different vehicle models.

Then, the results obtained on the real-world driving cycle, in terms of consumption as the vehicle weight varies, were compared with the results obtained in [

32] for different standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; and Artemis Urban, Rural Road, and Motorway Cycle.

From this comparison it has been found that, for light commercial vehicles (N1 category), the standard driving cycle that best fits the home-to-work journey in reference geographic area considered is the Artemis Urban Cycle. In fact, the curve of the average consumption on the cycle as a function of the vehicle weight matches well between the real-world cycle and the Artemis Urban Cycle.

This standardized cycle can be considered useful for estimating the lightweighting result also for compact cars. In fact, although in this case the consumption curve obtained on the real cycle does not match that of the Artemis Urban Cycle, the slope of this curve (which corresponds approximately to a straight line) is about the same. The reference real-world driving cycle and the Artemis Uban Cycle therefore have in common the ERV index referred to compact vehicles.

Finally,

Figure 18 summarizes the outcome of the vehicle lightweighting for different driving cycles, presenting the ERV indices obtained for the various cycles for both the N1 category vehicle and the compact car. From this figure it is possible to see that, for the case study of this paper, the most representative standard driving cycle for both the vehicles is the Artemis Urban Cycle, in fact this cycle has ERV indices very similar to those calculated for the real driving cycle.

5. Conclusions

In In this study, the research conducted in [

32] was replicated using a real-world driving cycle, recorded via GPS on a vehicle to represent typical home-to-work commutes in northern Italy, specifically around the city and province of Brescia in Lombardy.

In fuel efficiency literature, the Fuel Reduction Value (FRV) index, expressed in L/(100 km ∙ 100 kg), is commonly used to estimate fuel savings from vehicle lightweighting. For electric vehicles, however, an equivalent index—the Energy Reduction Value (ERV)—expressed in kWh/(100 km ∙ 100 kg), is more appropriate, as it directly measures energy savings without converting them to fuel-equivalent liters.

The actual ERV for a given vehicle model generally increases with vehicle weight, meaning that heavier vehicles gain greater benefits from the same level of weight reduction. However, assuming a constant ERV across weight variations is a reasonable approximation within the same vehicle model. This holds especially true for the specific real-world driving cycle examined, where consumption patterns for both N1-category vehicles and compact cars, as weight varies, are well approximated by linear relationships (i.e., first-degree polynomial functions).

In this study, it was observed that for an accurate calculation of the ERV index—even for the selected real-world driving cycle, and consistent with standardized cycles such as the WLTC (class 3b) and US06 cycles analyzed in [

32]—it is crucial to accurately define parameters such as rolling resistance coefficient, aerodynamics, battery pack characteristics, and transmission efficiency, while the impact of inertia can be considered negligible.

The results obtained on the real-world driving cycle, in terms of average energy consumption as a function of vehicle weight and ERV index, were then compared with those from several standardized cycles: WLTC (class 3b), US06, FTP75, HWFET, JC08, and the Artemis Urban, Rural Road, and Motorway cycles [

32]. Among these, the Artemis Urban Cycle was identified as most representative of home-to-work travel from the province of Brescia to the city center. Specifically, for N1-category vehicles, the average consumption on the real cycle closely aligns with the Artemis cycle across all vehicle weights. For compact cars, this alignment holds true only with respect to the ERV index, which, when the base vehicle’s consumption is known, serves as a valuable indicator for assessing potential lightweighting outcomes.

Future work will focus on building a comprehensive vehicle database across various classes, enabling precise estimation of the parameters that most influence lightweighting outcomes, following the approach outlined here and in [

32]. This database would ideally include the ERV index for each vehicle across a set of standardized cycles and, where possible, multiple real-world cycles that represent distinct regions or types of journeys. Additionally, the goal would be to identify the standardized cycle that best corresponds to each real-world cycle.

Author Contributions

Conceptualization, G.S., and D.C.; methodology, G.S.; software, G.S.; formal analysis, G.S., M.G., and D.C.; data curation, G.S., A.C., and P.M.; writing—original draft preparation, G.S.; writing—review and editing, G.S., D.C., and M.G.; visualization, M.G. and D.C.; supervision, M.G. and D.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the European Union, NextGenerationEU, see below.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the University of Brescia’s privacy policy.

Acknowledgments

This study was financed by the European Union—NextGenerationEU (National Sustainable Mobility Center CN00000023, Italian Ministry of University and Research Decree n. 1033—17/06/2022, Spoke 11—Innovative Materials & Lightweighting). The opinions expressed are those of the authors only and should not be considered as representative of the European Union or the European Commission’s official position. Neither the European Union nor the European Commission can be held responsible for them. CUP D83C22000690001.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Abbreviation |

Description |

| Af |

Frontal area of the vehicle |

|

, , ,

|

Coefficients of the polynomial |

| Cx |

Longitudinal aerodynamic coefficient (drag) |

| DEM |

Digital Elevation Model |

| EPA |

U.S. Environmental Protection Agency |

| ERV |

Energy Reduction Value |

| EV |

Electric Vehicle |

| FRV |

Fuel Reduction Value |

| FTP75 |

Standard driving cycle (FTP75) described in the EPA Federal Test Procedure (FTP) |

| GPS |

Global Position System |

| HWFET |

EPA Highway Fuel Economy Cycle |

| JC08 |

Japanese Emission Test Cycle |

| SFTP |

EPA Supplemental Federal Test Procedure |

| SFTP-US06 |

Standard driving cycle (US06) described in the EPA Supplemental Federal Test Procedure (SFTP) |

| TEST |

Target-speed EV Simulation Tool |

| WLTC |

Worldwide Harmonized Light-Duty Vehicles Test Cycle |

| WLTP |

Worldwide Harmonized Light-Duty Vehicles Test Procedure |

|

Vehicle weight (expressed in 100 kg) |

|

Polynomial interpolation function, energy consumption expressed in kWh/(100 km) |

References

- European Council; Council of the European Union Stricter CO2 Emission Standards for Cars and Vans Signed Off by the Council Available online: https://www.consilium.europa.eu/en/press/press-releases/2019/04/15/stricter-co2-emissionstandards-for-cars-and-vans-signed-off-by-the-council/ (accessed on 30 August 2022).

- European Law Brussels, 3 April 2019. PE-CONS 6/19. Regulation of the European Parliament and of the Council Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011 (Recast). Available online: https://data.consilium.europa.eu/doc/document/PE-6-2019 -INIT/en/pdf (accessed on 30 August 2022).

- European Parliament and Council of the European Union Ordinary Legislative Procedure 2021/0197(COD) Available online: https://oeil.secure.europarl.europa.eu/oeil/popups/ficheprocedure.do?reference=2021/0197(COD)&l=en (accessed on 8 January 2024).

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles. In; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2018; pp. 1–11.

- Lewis, G.M.; Buchanan, C.A.; Jhaveri, K.D.; Sullivan, J.L.; Kelly, J.C.; Das, S.; Taub, A.I.; Keoleian, G.A. Green Principles for Vehicle Lightweighting. Environ Sci Technol 2019, 53, 4063–4077. [CrossRef]

- Spreafico, C. Can Modified Components Make Cars Greener? A Life Cycle Assessment. J Clean Prod 2021, 307, 127190. [CrossRef]

- Koffler, C.; Rohde-Brandenburger, K. On the Calculation of Fuel Savings through Lightweight Design in Automotive Life Cycle Assessments. Int J Life Cycle Assess 2010, 15, 128–135. [CrossRef]

- Delogu, M.; Zanchi, L.; Dattilo, C.A.; Pierini, M. Innovative Composites and Hybrid Materials for Electric Vehicles Lightweight Design in a Sustainability Perspective. Mater Today Commun 2017, 13, 192–209. [CrossRef]

- MacKenzie, D.; Zoepf, S.; Heywood, J. Determinants of US Passenger Car Weight. International Journal of Vehicle Design 2014, 65, 73. [CrossRef]

- Kim, H.C.; Wallington, T.J. Life-Cycle Energy and Greenhouse Gas Emission Benefits of Lightweighting in Automobiles: Review and Harmonization. Environ Sci Technol 2013, 47, 6089–6097. [CrossRef]

- Helms, H.; Lambrecht, U. The Potential Contribution of Light-Weighting to Reduce Transport Energy Consumption. Int J Life Cycle Assess 2007, 12 (1), 58–64.

- Candela, A.; Sandrini, G.; Gadola, M.; Chindamo, D.; Magri, P. Lightweighting in the Automotive Industry as a Measure for Energy Efficiency: Review of the Main Materials and Methods. Heliyon 2024, 10, e29728. [CrossRef]

- Cheah, L.; Heywood, J. Meeting U.S. Passenger Vehicle Fuel Economy Standards in 2016 and Beyond. Energy Policy 2011, 39, 454–466. [CrossRef]

- Caffrey, C.; Bolon, K.; Kolwich, G.; Johnston, R.; Shaw, T. Cost-Effectiveness of a Lightweight Design for 2020-2025: An Assessment of a Light-Duty Pickup Truck. 2015. [CrossRef]

- Kollamthodi, S.; Kay, D.; Skinner, I.; Dun, C.; Hausberger, S. The Potential for Mass Reduction of Passenger Cars and Light Commercial Vehicles in Relation to Future CO2 Regulatory Requirements Available online: https://climate.ec.europa.eu/system/files/2016-11/ldv_downweighting_co2_report_en.pdf (accessed on 14 November 2022).

- Lutsey, N. Review of Technical Literature and Trends Related to Automobile Mass-Reduction Technology. In; Institute of Transportation Studies, University of California, Davis: Davis: CA, USA, 2010; Vol. UCD-ITS-RR-10-10, pp. 1–40.

- Giordano, G. Plastics Power a New Generation of Electric Vehicles. Plastics Engineering 2019, 75, 24–33. [CrossRef]

- Zecchi, L.; Sandrini, G.; Gadola, M.; Chindamo, D. Modeling of a Hybrid Fuel Cell Powertrain with Power Split Logic for Onboard Energy Management Using a Longitudinal Dynamics Simulation Tool. Energies (Basel) 2022, 15, 6228. [CrossRef]

- Sandrini, G.; Gadola, M.; Chindamo, D.; Zecchi, L. Model of a Hybrid Electric Vehicle Equipped with Solid Oxide Fuel Cells Powered by Biomethane. Energies (Basel) 2023, 16, 4918. [CrossRef]

- Sandrini, G.; Gadola, M.; Chindamo, D.; Magri, P. Application of Solid Oxide Fuel Cells on Hybrid Electric Vehicles Operating in Fleet. Transportation Research Procedia 2023, 70, 20–27. [CrossRef]

- Osborne, J. FEATURE: Light Speed—How Electric Cars Are Driving a New Wave of Lightweighting. Institution of Mechanical Engineers Available online: https://www.imeche.org/news/news-article/feature-light-speed-how-electric-cars-are-driving-a-new-wave-of-lightweighting (accessed on 14 November 2022).

- Sandrini, G.; Chindamo, D.; Gadola, M. Regenerative Braking Logic That Maximizes Energy Recovery Ensuring the Vehicle Stability. Energies (Basel) 2022, 15, 5846. [CrossRef]

- Sandrini, G.; Gadola, M.; Chindamo, D.; Magri, P. Efficient Regenerative Braking Strategy Aimed at Preserving Vehicle Stability by Preventing Wheel Locking. Transportation Research Procedia 2023, 70, 28–35. [CrossRef]

- Sandrini, G.; Có, B.; Tomasoni, G.; Gadola, M.; Chindamo, D. The Environmental Performance of Traction Batteries for Electric Vehicles from a Life Cycle Perspective. Environmental and Climate Technologies 2021, 25. [CrossRef]

- Sandrini, G.; Chindamo, D.; Gadola, M.; Candela, A.; Magri, P. Primary and Secondary Vehicle Lightweighting Achieved by Acting on the Battery Thermal Management System. In AVEC 2024, LNME; Mastinu, G., et al., Eds.; Springer, 2024; pp. 308–314.

- Sandrini, G.; Chindamo, D.; Gadola, M.; Candela, A.; Magri, P. Study of Different Thermal Management Systems for Traction Batteries to Obtain Vehicle Lightweighting. Heliyon. UNDER REVIEW.

- Kim, H.C.; Wallington, T.J.; Sullivan, J.L.; Keoleian, G.A. Life Cycle Assessment of Vehicle Lightweighting: Novel Mathematical Methods to Estimate Use-Phase Fuel Consumption. Environ Sci Technol 2015, 49, 10209–10216. [CrossRef]

- Del Pero, F.; Delogu, M.; Pierini, M. The Effect of Lightweighting in Automotive LCA Perspective: Estimation of Mass-Induced Fuel Consumption Reduction for Gasoline Turbocharged Vehicles. J Clean Prod 2017, 154, 566–577. [CrossRef]

- Delogu, M.; Del Pero, F.; Pierini, M. Lightweight Design Solutions in the Automotive Field: Environmental Modelling Based on Fuel Reduction Value Applied to Diesel Turbocharged Vehicles. Sustainability 2016, 8, 1167. [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model To Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ Sci Technol 2016, 50, 11226–11233. [CrossRef]

- Del Pero, F.; Berzi, L.; Antonacci, A.; Delogu, M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines 2020, 8, 51. [CrossRef]

- Sandrini, G.; Gadola, M.; Chindamo, D.; Candela, A.; Magri, P. Exploring the Impact of Vehicle Lightweighting in Terms of Energy Consumption: Analysis and Simulation. Energies (Basel) 2023, 16, 5157. [CrossRef]

- Pero, F. Del; Delogu, M.; Berzi, L.; Dattilo, C.A.; Zonfrillo, G.; Pierini, M. Sustainability Assessment for Different Design Solutions within the Automotive Field. Procedia Structural Integrity 2019, 24, 906–925. [CrossRef]

- Gebisa, A.; Gebresenbet, G.; Gopal, R.; Nallamothu, R.B. Driving Cycles for Estimating Vehicle Emission Levels and Energy Consumption. Future Transportation 2021, 1, 615–638. [CrossRef]

- Tzirakis, E.; Pitsas, K.; Zannikos, F.; Stournas, S. Vehicle Emissions and Driving Cycles: Comparison of the Athens Driving Cycle (ADC) with ECE-15 and European Driving Cycle (EDC). Global NEST Journal 2013, 8, 282–290. [CrossRef]

- Chindamo, D.; Gadola, M. What Is the Most Representative Standard Driving Cycle to Estimate Diesel Emissions of a Light Commercial Vehicle? IFAC-PapersOnLine 2018, 51, 73–78. [CrossRef]

- United Nations Consolidated Resolution on the Construction of Vehicles (R.E.3) Available online: https://unece.org/fileadmin/DAM/trans/main/wp29/wp29resolutions/ECE-TRANS-WP29-78-r2e.pdf (accessed on 23 February 2023).

- Sandrini, G.; Gadola, M.; Chindamo, D. Longitudinal Dynamics Simulation Tool for Hybrid Apu and Full Electric Vehicle. Energies (Basel) 2021, 14. [CrossRef]

- Electric Vehicle Database - Fiat 500e Hatchback 42 KWh Available online: https://ev-database.org/car/1285/Fiat-500e-Hatchback-42-kWh (accessed on 23 January 2023).

- FleetNews Electric Car and van Data - Fiat 500e Hatchback 42 KWh Price and Specifications. Available online: https://www.fleetnews.co.uk/electric-fleet/electric-car-and-van-data/fiat/500e-1285 (accessed on 23 January 2023).

- MoTeC ADL2 - Obsolete Available online: https://www.motec.com.au/products/ADL2%20-%20Obsolete?catId=51 (accessed on 26 September 2024).

- LOCOSYS Technology Inc. Datasheet of GPS Mouse, LS2303x Series Available online: https://www.locosystech.com/en/product/gps-mouse-ls2303x.html (accessed on 26 September 2024).

- GPS Visualizer Available online: https://www.gpsvisualizer.com/profile_input (accessed on 26 September 2024).

- European Parliament and Council COMMISSION REGULATION (EU) 2017/1151 Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32017R1151 (accessed on 2 October 2024).

- EPA - United States Environmental Protection Agency EPA US06 or Supplemental Federal Test Procedure (SFTP) Available online: https://www.epa.gov/emission-standards-reference-guide/epa-us06-or-supplemental-federal-test-procedure-sftp (accessed on 23 February 2023).

- EPA - United States Environmental Protection Agency EPA Federal Test Procedure (FTP) Available online: https://www.epa.gov/emission-standards-reference-guide/epa-federal-test-procedure-ftp (accessed on 2 May 2023).

- Japan Inspection Organization - Certification and Inspection Agency in Japan Japanese JC08 Emission Test Cycle Available online: https://japaninspection.org/japanese-jc08-emission-test-cycle/ (accessed on 2 May 2023).

- IMEE STANDARDIZED DRIVE CYCLES Available online: https://imee.pl/pub/drive-cycles (accessed on 2 May 2023).

- Chindamo, D.; Gadola, M.; Romano, M. Simulation Tool for Optimization and Performance Prediction of a Generic Hybrid Electric Series Powertrain. International Journal of Automotive Technology 2014, 15, 135–144. [CrossRef]

- Chindamo, D.; Economou, J.T.; Gadola, M.; Knowles, K. A Neurofuzzy-Controlled Power Management Strategy for a Series Hybrid Electric Vehicle. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering 2014, 228, 1034–1050. [CrossRef]

Figure 1.

Location (a) of the GPS receiver (red circle), installed on the vehicle hood via magnetic connection, and (b) of the MoTeC ADL2 data acquisition unit, on the passenger mat, inside a protective box.

Figure 1.

Location (a) of the GPS receiver (red circle), installed on the vehicle hood via magnetic connection, and (b) of the MoTeC ADL2 data acquisition unit, on the passenger mat, inside a protective box.

Figure 2.

Home-to-work commute real-world reference driving cycle.

Figure 2.

Home-to-work commute real-world reference driving cycle.

Figure 3.

Acquired speed profile of the reference real driving cycle.

Figure 3.

Acquired speed profile of the reference real driving cycle.

Figure 4.

Time spent at different vehicle speed range, as a percentage of total travel time (about 59.67 minutes).

Figure 4.

Time spent at different vehicle speed range, as a percentage of total travel time (about 59.67 minutes).

Figure 5.

Altimetry profile obtained through “GPS Visualizer” [

43] tool using GPS latitude and longitude vs. altimetry profile directly acquired from GPS on board the vehicle.

Figure 5.

Altimetry profile obtained through “GPS Visualizer” [

43] tool using GPS latitude and longitude vs. altimetry profile directly acquired from GPS on board the vehicle.

Figure 6.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the N1 category vehicle model (“N1”) and for the same model, but with zero inertia contributions (“N1 — NO inertias”); for the compact car model (“CompactCar”) and for the same model, but with zero inertia contributions (“CompactCar — NO inertias”).

Figure 6.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the N1 category vehicle model (“N1”) and for the same model, but with zero inertia contributions (“N1 — NO inertias”); for the compact car model (“CompactCar”) and for the same model, but with zero inertia contributions (“CompactCar — NO inertias”).

Figure 7.

Target speed and vehicle speed in the simulation vs. time elapsed since the beginning of the simulation itself, for the N1 vehicle without moments of inertia and with a weight of 2950 kg: (

a) for the entire simulation; (

b) an enlargement relative to the green box in

Figure 1(a).

Figure 7.

Target speed and vehicle speed in the simulation vs. time elapsed since the beginning of the simulation itself, for the N1 vehicle without moments of inertia and with a weight of 2950 kg: (

a) for the entire simulation; (

b) an enlargement relative to the green box in

Figure 1(a).

Figure 8.

Motor torque vs. time elapsed since the beginning of the simulation, for the N1 vehicle without moments of inertia and with a weight of 2950 kg.

Figure 8.

Motor torque vs. time elapsed since the beginning of the simulation, for the N1 vehicle without moments of inertia and with a weight of 2950 kg.

Figure 9.

Battery SOC (State of Charge) vs. time elapsed since the beginning of the simulation, for the N1 vehicle without moments of inertia and with a weight of 2950 kg.

Figure 9.

Battery SOC (State of Charge) vs. time elapsed since the beginning of the simulation, for the N1 vehicle without moments of inertia and with a weight of 2950 kg.

Figure 10.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the following vehicle models: N1 vehicle (“N1”), compact car (“CompactCar”); compact car with the N1 battery pack on board (“CompactCar — N1 battery pack”); compact car with the aerodynamic coefficients of the N1 vehicle (“CompactCar — N1 aerodynamics”); compact car with the transmission efficiency equal to that of the N1 vehicle (“CompactCar — N1 transmission efficiency”); compact car with the rolling resistance coefficient equal to that of the N1 vehicle (“CompactCar — N1 rolling resistance”); and, finally, compact car with all the parameters previously mentioned equal to those of N1 vehicle (“CompactCar — N1 values”).

Figure 10.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the following vehicle models: N1 vehicle (“N1”), compact car (“CompactCar”); compact car with the N1 battery pack on board (“CompactCar — N1 battery pack”); compact car with the aerodynamic coefficients of the N1 vehicle (“CompactCar — N1 aerodynamics”); compact car with the transmission efficiency equal to that of the N1 vehicle (“CompactCar — N1 transmission efficiency”); compact car with the rolling resistance coefficient equal to that of the N1 vehicle (“CompactCar — N1 rolling resistance”); and, finally, compact car with all the parameters previously mentioned equal to those of N1 vehicle (“CompactCar — N1 values”).

Figure 11.

Average energy consumption on the reference real driving cycle, according to the vehicle weight, for the following vehicle models: compact car without inertia (“CompactCar — NO inertias”); compact car with transmission ratios (and wheel radii) equal to those of the N1 vehicle and without inertia (“CompactCar — NO inertias — N1 traction ratios”).

Figure 11.

Average energy consumption on the reference real driving cycle, according to the vehicle weight, for the following vehicle models: compact car without inertia (“CompactCar — NO inertias”); compact car with transmission ratios (and wheel radii) equal to those of the N1 vehicle and without inertia (“CompactCar — NO inertias — N1 traction ratios”).

Figure 12.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the following vehicle models: vehicle of category N1 (“N1”), compact car (“CompactCar”); compact car with the battery pack of the N1 vehicle on board, with the aerodynamic coefficients, the efficiency of the transmission, and with the rolling resistance coefficient of the N1 vehicle (“CompactCar — N1 values); compact car with the same moments of inertia as vehicle N1 (“CompactCar — N1 inertias”); compact car with the battery pack, aerodynamics, transmission efficiency, rolling resistance, and moments of inertia of the N1 vehicle (“CompactCar — N1 values (also inertia)”); compact car with the transmission ratios and wheel radii of the N1 vehicle (“CompactCar — N1 traction ratios”); and, finally, compact car with all the previously mentioned parameters equal to those of the N1 vehicle, i.e., the parameters relating to the battery pack, aerodynamics, transmission efficiency, rolling resistance, moments of inertia, transmission ratios, and wheel radii (“CompactCar — N1 values (all)”).

Figure 12.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the following vehicle models: vehicle of category N1 (“N1”), compact car (“CompactCar”); compact car with the battery pack of the N1 vehicle on board, with the aerodynamic coefficients, the efficiency of the transmission, and with the rolling resistance coefficient of the N1 vehicle (“CompactCar — N1 values); compact car with the same moments of inertia as vehicle N1 (“CompactCar — N1 inertias”); compact car with the battery pack, aerodynamics, transmission efficiency, rolling resistance, and moments of inertia of the N1 vehicle (“CompactCar — N1 values (also inertia)”); compact car with the transmission ratios and wheel radii of the N1 vehicle (“CompactCar — N1 traction ratios”); and, finally, compact car with all the previously mentioned parameters equal to those of the N1 vehicle, i.e., the parameters relating to the battery pack, aerodynamics, transmission efficiency, rolling resistance, moments of inertia, transmission ratios, and wheel radii (“CompactCar — N1 values (all)”).

Figure 13.

Average energy consumption on reference real driving cycle, as a function of the vehicle weight. Curves relating to the results were obtained by means of simulations (“Results”), and curves were obtained thanks to the polynomial approximation of the first (“n = 1”), second (“n = 2”), and third degree (“n = 3”) for (a) the N1 vehicle; and (b) the compact car.

Figure 13.

Average energy consumption on reference real driving cycle, as a function of the vehicle weight. Curves relating to the results were obtained by means of simulations (“Results”), and curves were obtained thanks to the polynomial approximation of the first (“n = 1”), second (“n = 2”), and third degree (“n = 3”) for (a) the N1 vehicle; and (b) the compact car.

Figure 14.

ERV index, calculated for the reference real driving cycle and calculated between a simulation performed at a given vehicle weight and the simulation with the vehicle weight immediately lower than that under examination (considering the set of simulations performed), as a function of the vehicle weight, for the following vehicle models: N1 category vehicle (“N1”); N1 vehicle with zero inertia (“N1 — NO Inertias”); compact car (“CompactCar”); compact car with the N1 battery pack on board (“CompactCar — N1 battery pack”); compact car with the aerodynamic coefficients of the N1 vehicle (“CompactCar — N1 aerodynamics”); compact car with transmission efficiency equal to that of the N1 vehicle (“CompactCar — N1 transmission efficiency”); compact car with the N1 vehicle rolling resistance coefficient (“CompactCar — N1 rolling resistance”); and, finally, compact car with moments of inertia equal to those of the N1 vehicle (“CompactCar — N1 inertia”). In particular, in (a) the graph with all the ERV index calculated; in (b) the graph with the y-axis limited between 1 and 1.5 kWh/(100km∙100kg); in (c) the legend valid for both graphs.

Figure 14.

ERV index, calculated for the reference real driving cycle and calculated between a simulation performed at a given vehicle weight and the simulation with the vehicle weight immediately lower than that under examination (considering the set of simulations performed), as a function of the vehicle weight, for the following vehicle models: N1 category vehicle (“N1”); N1 vehicle with zero inertia (“N1 — NO Inertias”); compact car (“CompactCar”); compact car with the N1 battery pack on board (“CompactCar — N1 battery pack”); compact car with the aerodynamic coefficients of the N1 vehicle (“CompactCar — N1 aerodynamics”); compact car with transmission efficiency equal to that of the N1 vehicle (“CompactCar — N1 transmission efficiency”); compact car with the N1 vehicle rolling resistance coefficient (“CompactCar — N1 rolling resistance”); and, finally, compact car with moments of inertia equal to those of the N1 vehicle (“CompactCar — N1 inertia”). In particular, in (a) the graph with all the ERV index calculated; in (b) the graph with the y-axis limited between 1 and 1.5 kWh/(100km∙100kg); in (c) the legend valid for both graphs.

Figure 15.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the compact car, obtained through simulations with the TEST model (“Real consumption”), and considering the ERV obtained through polynomial interpolation, for the following vehicle models (lightweighting by 300 kg): CompactCar (“Calculated consumption”); CompactCar with the vehicle battery pack N1 on board (“Calculated consumption (ERV with N1 battery pack)”); CompactCar with the aerodynamic coefficients of vehicle N1 (“Calculated consumption (ERV with the N1 aerodynamics)”); CompactCar with the transmission efficiency equal to that of the N1 vehicle (“Calculated consumption (ERV with N1 efficiencies)”); CompactCar with the vehicle rolling resistance coefficient of N1 (“Calculated consumption (ERV with N1 rolling resistance)”); and, finally, CompactCar with moments of inertia of vehicle N1 (“Calculated consumption (ERV with N1 inertias)”).

Figure 15.

Average energy consumption on the reference real driving cycle, as a function of vehicle weight, for the compact car, obtained through simulations with the TEST model (“Real consumption”), and considering the ERV obtained through polynomial interpolation, for the following vehicle models (lightweighting by 300 kg): CompactCar (“Calculated consumption”); CompactCar with the vehicle battery pack N1 on board (“Calculated consumption (ERV with N1 battery pack)”); CompactCar with the aerodynamic coefficients of vehicle N1 (“Calculated consumption (ERV with the N1 aerodynamics)”); CompactCar with the transmission efficiency equal to that of the N1 vehicle (“Calculated consumption (ERV with N1 efficiencies)”); CompactCar with the vehicle rolling resistance coefficient of N1 (“Calculated consumption (ERV with N1 rolling resistance)”); and, finally, CompactCar with moments of inertia of vehicle N1 (“Calculated consumption (ERV with N1 inertias)”).

Figure 16.

Average energy consumption, for (

a) the N1 category vehicle and (

b) compact car, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

Figure 16.

Average energy consumption, for (

a) the N1 category vehicle and (

b) compact car, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

Figure 17.

ERV index, obtained from the “polyfit” MATLAB function, on the reference real driving cycle, for the N1 vehicle, for the compact car, and for the compact car with the following parameters, aspects, and components of the N1 vehicle: aerodynamics; moments of inertia; battery pack; transmission efficiency; and rolling resistance.

Figure 17.

ERV index, obtained from the “polyfit” MATLAB function, on the reference real driving cycle, for the N1 vehicle, for the compact car, and for the compact car with the following parameters, aspects, and components of the N1 vehicle: aerodynamics; moments of inertia; battery pack; transmission efficiency; and rolling resistance.

Figure 18.

ERV index, obtained from the “polyfit” MATLAB function, for different standard driving cycles, for the N1 vehicle and for the compact car [

32].

Figure 18.

ERV index, obtained from the “polyfit” MATLAB function, for different standard driving cycles, for the N1 vehicle and for the compact car [

32].

Table 1.

Model parameters used for the purpose of this study, for the compact car (M category) and for the N1 category vehicle [

32].

Table 1.

Model parameters used for the purpose of this study, for the compact car (M category) and for the N1 category vehicle [

32].

| Analyzed Parameters |

Compact Car Value |

N1 Value |

| Transmission efficiency |

1 |

0.9409 |

| Af ∙ Cx * |

1.034 m2

|

2.1 m2

|

| Vertical aerodynamic coefficient |

−0.026 m2

|

0 |

| Rolling friction coefficient |

0.01 |

0.015 |

| Total gear ratio |

9.6 |

6.22 |

| Front wheel radius |

0.2987 m |

0.35 m |

| Rear wheel radius |

0.3005 m |

0.35 m |

| Moment of inertia of each wheel |

0.882 kg m2 |

1.09 kg m2

|

| Moment of inertia of the motor |

0.02 kg m2

|

0.086 kg m2

|

| Moment of inertia of the transmission |

0.0001 kg m2

|

0.01 kg m2

|

| Battery capacity |

42 kWh (105 Ah) |

120 Ah |

| Number of battery cells in series |

96 |

108 |

| Number of battery cells in parallel |

2 |

1 |

| Nominal battery pack voltage |

400.0 V |

356.1 V |

| Internal resistance of the battery pack |

0.086 Ω |

0.097 Ω |

Table 2.

Coefficients of the polynomial functions that approximate the consumption curves, as a function of the vehicle weight, obtained by means of simulations on the various vehicle models.

Table 2.

Coefficients of the polynomial functions that approximate the consumption curves, as a function of the vehicle weight, obtained by means of simulations on the various vehicle models.

| Vehicle Model |

Model description |

|

|

| N1 |

N1 model |

1.368 |

15.592 |

N1—

NO inertias

|

N1 model without inertia contributions |

1.365 |

15.201 |

| CompactCar |

Compact car model |

1.141 |

9.782 |

CompactCar—

NO inertias

|

Compact car model without inertia contributions |

1.141 |

9.406 |

CompactCar—

N1 battery pack

|

Compact car model with the N1 battery pack on board |

1.172 |

9.633 |

CompactCar—

N1 aerodynamics

|

Compact car model with the aerodynamic coefficients of the N1 vehicle |

1.109 |

15.149 |

CompactCar—

N1 transmission efficiency

|

Compact car model with the transmission efficiency equal to that of the N1 vehicle |

1.211 |

10.110 |

CompactCar—

N1 rolling resistance

|

Compact car model with the rolling resistance coefficient equal to that of the N1 vehicle |

1.250 |

9.875 |

CompactCar—

N1 values

|

Compact car model compact car with all the above-mentioned parameters equal to those of the N1 vehicle |

1.339 |

15.862 |

CompactCar—

N1 inertias

|

Compact car model with the same moments of inertia as vehicle N1 |

1.141 |

10.345 |

CompactCar—

N1 values (also inertia)

|

Compact car model compact car with all the above-mentioned parameters (also moments of inertia) equal to those of the N1 vehicle |

1.342 |

16.385 |

CompactCar—

N1 traction ratios

|

Compact car model with the transmission ratios and wheel radii of the N1 vehicle |

1.119 |

9.832 |

CompactCar—

N1 inertias and traction ratios

|

Compact car model with the moments of inertia, the transmission ratios and wheel radii of the N1 vehicle |

1.118 |

10.031 |

CompactCar—

N1 values (all)

|

Compact car model compact car with all the above-mentioned parameters equal to those of the N1 vehicle, including moments of inertia, traction ratios, and wheel radii |

1.303 |

16.209 |

Table 3.

Coefficients of the polynomial functions (first-degree) which approximate the consumption curves as a function of the vehicle weight obtained by means of simulations on the N1 category vehicle model, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

Table 3.

Coefficients of the polynomial functions (first-degree) which approximate the consumption curves as a function of the vehicle weight obtained by means of simulations on the N1 category vehicle model, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

| Driving Cycle |

|

|

| Reference real driving cycle |

1.368 |

15.592 |

| WLTC—Class 3b |

0.852 |

25.995 |

| US06 |

1.077 |

34.562 |

| FTP75 |

0.946 |

15.229 |

| HWFET |

0.630 |

24.647 |

| JC08 |

0.944 |

15.362 |

| Artemis — Urban Cycle |

1.426 |

13.082 |

| Artemis — Rural Road Cycle |

0.929 |

18.344 |

| Artemis — Motorway Cycle (130) |

0.835 |

44.654 |

Table 4.

Coefficients of the polynomial functions (first-degree) which approximate the consumption curves as a function of the vehicle weight obtained by means of simulations on the compact car model, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

Table 4.

Coefficients of the polynomial functions (first-degree) which approximate the consumption curves as a function of the vehicle weight obtained by means of simulations on the compact car model, on the reference real driving cycle and on the following standard driving cycles: WLTC (class 3b); US06; FTP75; HWFET; JC08; Artemis Urban Cycles; Artemis Rural Road Cycle; Artemis Motorway Cycle (130) [

32].

| Driving Cycle |

|

|

| Reference real driving cycle |

1.141 |

9.782 |

| WLTC—Class 3b |

0.654 |

13.488 |

| US06 |

0.809 |

16.549 |

| FTP75 |

0.746 |

9.742 |

| HWFET |

0.426 |

12.370 |

| JC08 |

0.754 |

10.114 |

| Artemis — Urban Cycle |

1.203 |

11.528 |

| Artemis — Rural Road Cycle |

0.723 |

9.709 |

| Artemis — Motorway Cycle (130) |

0.482 |

21.253 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).