Submitted:

31 October 2024

Posted:

01 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

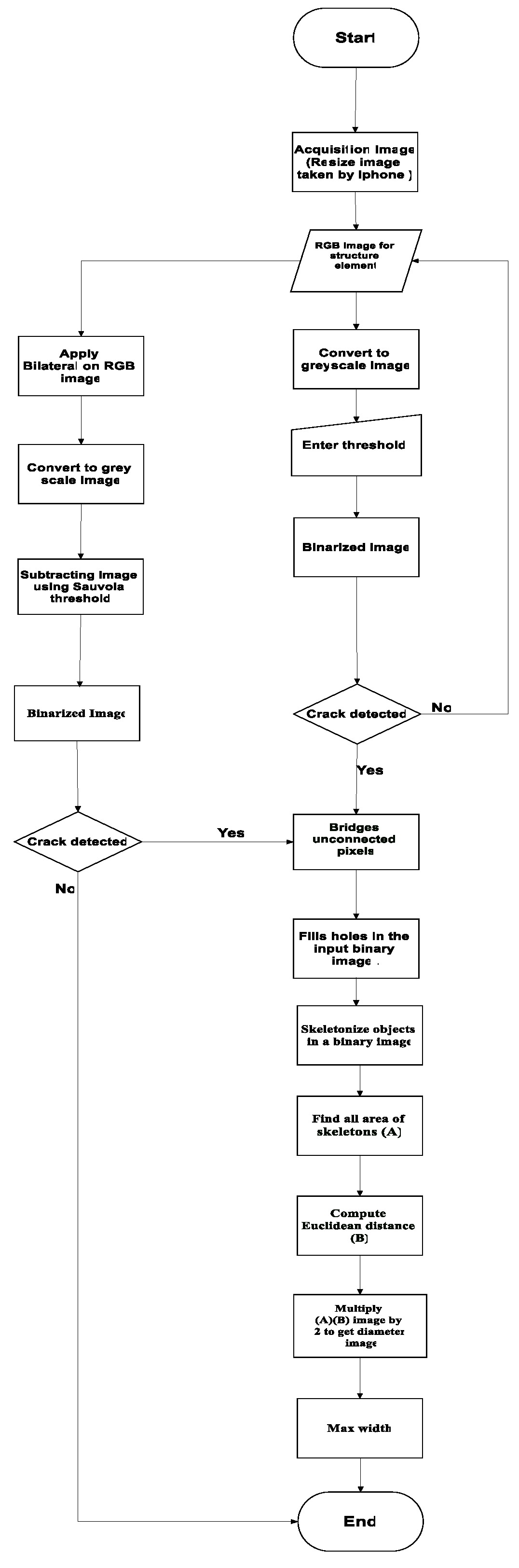

2.1. Overview of Developed Method

2.2. Experimental Setup and Data Acquisition

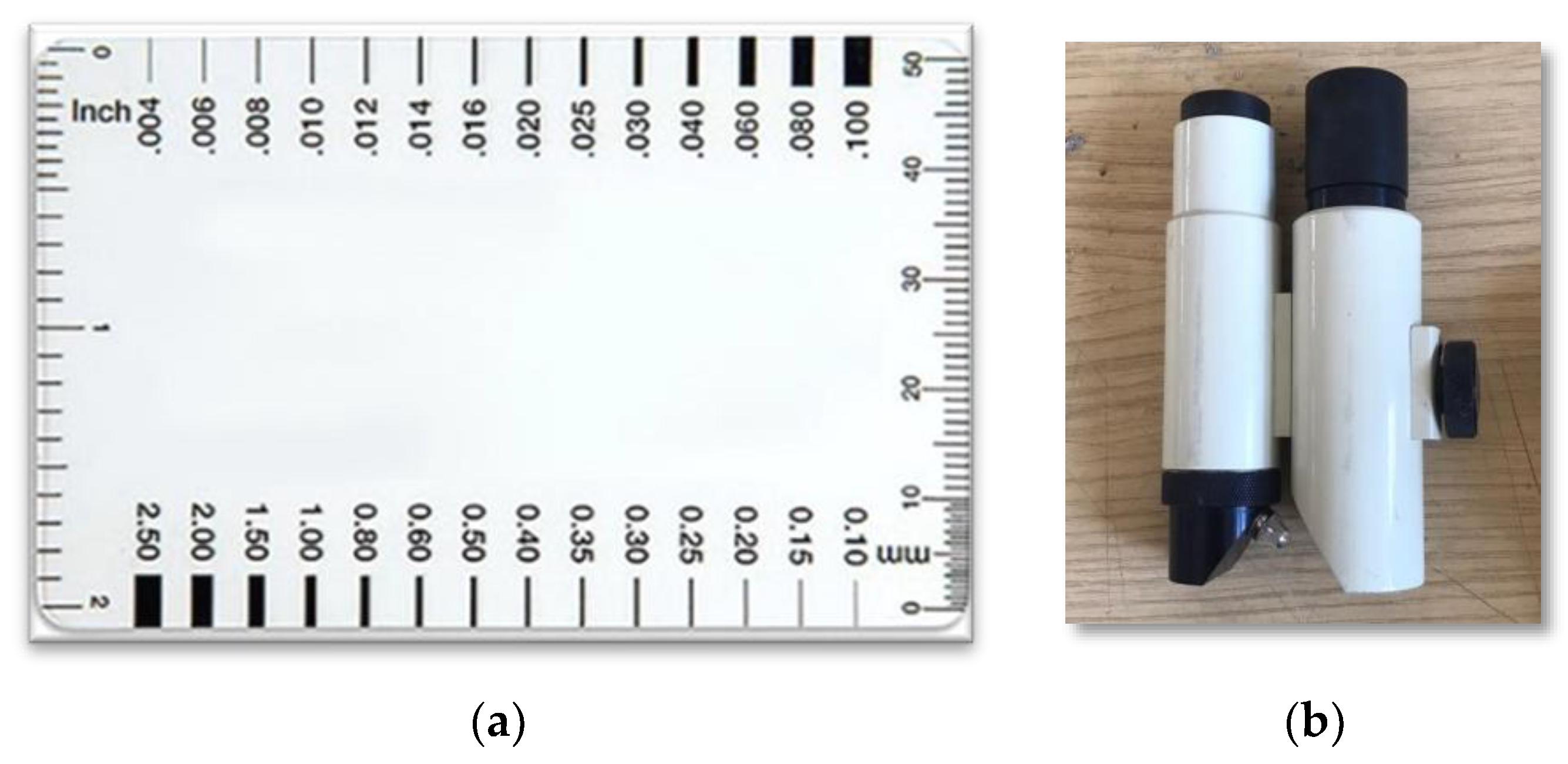

2.3. Determining Ground Truth and Labelling Images

2.4. Algorithm Development

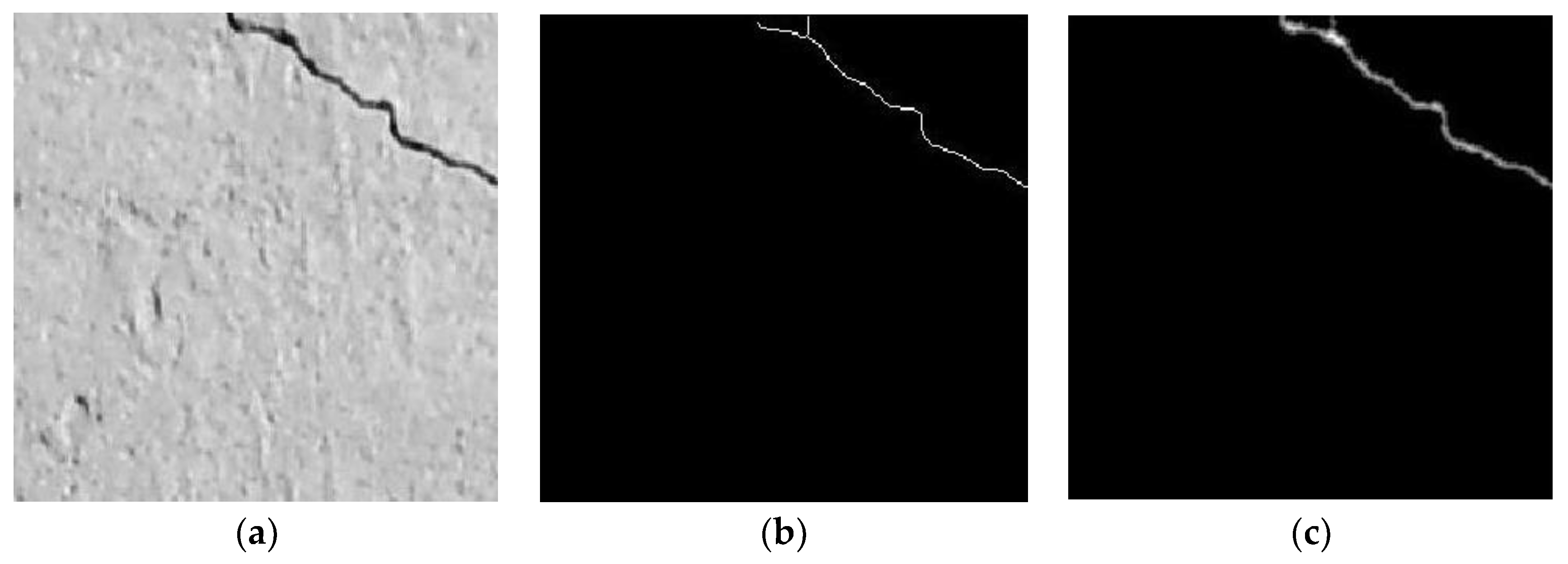

2.4.1. Image Pre-Processing

Bilateral Filter Pre-Processing

Subtraction Processing Pre-Processing

2.4.2. Image Thresholding

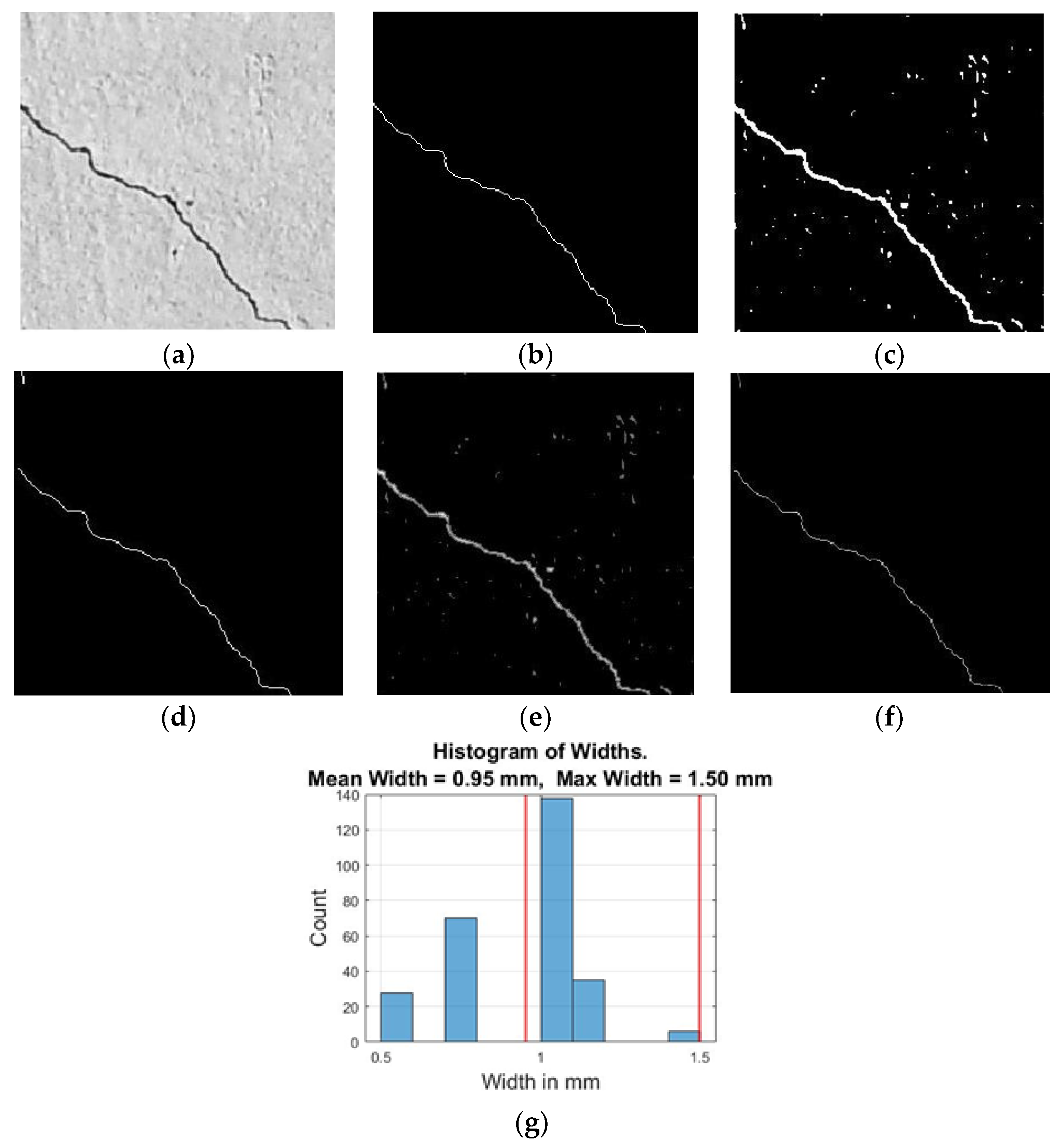

2.4.3. Morphological Operation

2.4.4. Euclidean Distance Transform

2.5. Implementation Crack Width Measurement Model

3. Results

3.1. Crack Detection

- True Positive (TP): If detection with IOU ≥ 0.5, which means a correct detection

- False Positive (FP): If an IOU < 0.5, which means a wrong detection. Additionally, the prediction can be considered as FP

- A wrong detection. Detection with an IOU < 0.5. Additionally, if the object is spotted by the model even though it is not in the picture, the prediction is considered false positive (FP).

- False Negative (FN): A ground truth not detected [if IOU with ground truth = 0, wrong detection].

3.2. Crack Width Measurement

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdelalim, A.M. Quantitive Assessment of Deteriorated Rc Structures due to Reinforcing Steel Corrosion. Int. Conf. Civ. Arch. Eng. 2012, 9, 1–12. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L. Condition Assessment of Reinforced Concrete Bridges: Current Practice and Research Challenges. Infrastructures 2018, 3, 36. [Google Scholar] [CrossRef]

- Agdas, D.; Rice, J.A.; Martinez, J.R.; Lasa, I.R. Comparison of Visual Inspection and Structural-Health Monitoring As Bridge Condition Assessment Methods. J. Perform. Constr. Facil. 2016, 30. [Google Scholar] [CrossRef]

- Abdelkhalek, S.; Zayed, T. Comprehensive Inspection System for Concrete Bridge Deck Application: Current Situation and Future Needs. J. Perform. Constr. Facil. 2020, 34, 03120001. [Google Scholar] [CrossRef]

- Abdelkader, E.M.; Moselhi, O.; Marzouk, M.; Zayed, T. Hybrid Elman Neural Network and an Invasive Weed Optimization Method for Bridge Defect Recognition. Transp. Res. Rec. J. Transp. Res. Board 2020, 2675, 167–199. [Google Scholar] [CrossRef]

- Kruachottikul, P., N. Cooharojananone, G. Phanomchoeng, T. Chavarnakul, K. Kovitanggoon, D. Trakulwaranont, and K. Atchariyachanvanich. Bridge Sub Structure Defect Inspection Assistance by using Deep Learning. Proc., 2019 IEEE 10th International Conference on Awareness Science and Technology, Morioka, Japan, IEEE, New York, 2019.

- Hoang, N.-D. Detection of Surface Crack in Building Structures Using Image Processing Technique with an Improved Otsu Method for Image Thresholding. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- ACI 201-1R Guide for making a Condition Survey of Concrete in Service.

- ACI 345R-91 Guide for Concrete Highway Bridge Deck Construction.

- Barkavi, T. & Chidambarathanu, N. (2019). Processing digital image for measurement of crack dimensions in concrete. Civil Engineering Infrastructures Journal, 52(1), 11-22.

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P. A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure. Adv. Eng. Informatics 2015, 29, 196–210. [Google Scholar] [CrossRef]

- Yang, G.; Wu, J.; Hu, Q. Rapid detection of building cracks based on image processing technology with double square artificial marks. Adv. Struct. Eng. 2018, 22, 1186–1193. [Google Scholar] [CrossRef]

- Abdelkader, E.M. On the hybridization of pre-trained deep learning and differential evolution algorithms for semantic crack detection and recognition in ensemble of infrastructures. Smart Sustain. Built Environ. 2021, 11, 740–764. [Google Scholar] [CrossRef]

- Jain, R. , & Sharma, R. S. (2018, July). Predicting Severity of Cracks in Concrete using Fuzzy Logic. In 2018 International Conference on Recent Innovations in Electrical, Electronics & Communication Engineering (ICRIEECE) (pp. 2976-2976). IEEE.

- Mohan, A.; Poobal, S. Crack detection using image processing: A critical review and analysis. Alex. Eng. J. 2018, 57, 787–798. [Google Scholar] [CrossRef]

- Noh, Y.; Koo, D.; Kang, Y.-M.; Park, D.; Lee, D. Automatic crack detection on concrete images using segmentation via fuzzy C-means clustering. 2017 International conference on applied system innovation (ICASI), Sapporo, Japan, May 13–17, 2017; pp. 877–880. [CrossRef]

- Zhao, X.; Li, S.; Su, H.; Zhou, L.; Loh, K.J. (2018, September). Image-based comprehensive maintenance and inspection method for bridges using deep learning. In Smart Materials, Adaptive Structures and Intelligent Systems (Vol. 51951, p. V002T05A017). American Society of Mechanical Engineers.

- Abdelkader, E. M. Moselhi, O., Marzouk, M., & Zayed, T. (2020). Evaluation of Spalling in Bridges Using Machine Vision Method. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction (Vol. 37, pp. 1136-1143). IAARC Publications.

- Li, G.; Liu, Q.; Zhao, S.; Qiao, W.; Ren, X. Automatic crack recognition for concrete bridges using a fully convolutional neural network and naive Bayes data fusion based on a visual detection system. Meas. Sci. Technol. 2020, 31, 075403. [Google Scholar] [CrossRef]

- Ong, J.C.; Ismadi, M.-Z.P.; Wang, X. A hybrid method for pavement crack width measurement. Measurement 2022, 197. [Google Scholar] [CrossRef]

- Cardellicchio, A. , Ruggieri, S., Nettis, A., Patruno, C., Uva, G., & Renò, V. (2022, May). Deep learning approaches for image-based detection and classification of structural defects in bridges. In International Conference on Image Analysis and Processing (pp. 269-279). Cham: Springer International Publishing.

- Yu, H. Research on Bridge Condition Monitoring Based on Image Processing Technology and Bridge Crack Detection Algorithm. In 2023 2nd International Conference on 3D Immersion, Interaction and Multi-sensory Experiences (ICDIIME) (pp. 412-416). IEEE.

- de León, G.; Fiorentini, N.; Leandri, P.; Losa, M. A New Region-Based Minimal Path Selection Algorithm for Crack Detection and Ground Truth Labeling Exploiting Gabor Filters. Remote. Sens. 2023, 15, 2722. [Google Scholar] [CrossRef]

- Bae, H.; An, Y.-K. Computer vision-based statistical crack quantification for concrete structures. Measurement 2023, 211. [Google Scholar] [CrossRef]

- Kao, S.-P.; Chang, Y.-C.; Wang, F.-L. Combining the YOLOv4 Deep Learning Model with UAV Imagery Processing Technology in the Extraction and Quantization of Cracks in Bridges. Sensors 2023, 23, 2572. [Google Scholar] [CrossRef]

- Tran, T.S.; Nguyen, S.D.; Lee, H.J.; Tran, V.P. Advanced crack detection and segmentation on bridge decks using deep learning. Constr. Build. Mater. 2023, 400. [Google Scholar] [CrossRef]

- Shalaby, Y.M.; Badawy, M.; Ebrahim, G.A.; Abdelalim, A.M. Condition assessment of concrete structures using automated crack detection method for different concrete surface types based on image processing. Discov. Civ. Eng. 2024, 1, 1–16. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. SDNET2018: An annotated image dataset for non-contact concrete crack detection using deep convolutional neural networks. Data Brief 2018, 21, 1664–1668. [Google Scholar] [CrossRef]

- Tomasi C, Manduchi R. Bilateral fltering for gray and color images. In Sixth international conference on computer vision (IEEE Cat. No. 98CH36271). 1998, January; 839–846. IEEE.

- Pham TQ, Van Vliet LJ. Separable bilateral fltering for fast video preprocessing. In 2005 IEEE International Conference on Multimedia and Expo. 2005, July; 4. IEEE.

- Saxena, LP. Niblack’s binarization method and its modifcations to real-time applications: a review. Artif Intell Rev. 2019;51(4):673–705.

- Ji, X.; Miao, Z.; Kromanis, R. Vision-based measurements of deformations and cracks for RC structure tests. Eng. Struct. 2020, 212, 110508. [Google Scholar] [CrossRef]

- Jang, K. , An, Y. K., Kim, B., & Cho, S. (2021). Automated crack evaluation of a high-rise bridge pier using a ring-type climbing robot. Computer-Aided Civil and Infrastructure Engineering, 36(1), 14-29.

- Peddireddy, R. P. R. , & Semwal, S. K. (2018). Implementation of Distance Transformation in the Processing Language.

- Image Analyst. Thresholding an image. 2024. https://www.mathworks.com/matlabcentral/fleexchange/29372-thresholding-an-image. MATLAB Central File Exchange. Accessed 14 July 2024.

- Sokolova, M.; Lapalme, G. A systematic analysis of performance measures for classification tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

- Ogwok, D. & Ehlers, E. M. (2022, November). Jaccard Index in Ensemble Image Segmentation: An Approach. In Proceedings of the 2022 5th International Conference on Computational Intelligence and Intelligent Systems (pp. 9-14).

- Yang, G.; Wu, J.; Hu, Q. Rapid detection of building cracks based on image processing technology with double square artificial marks. Adv. Struct. Eng. 2018, 22, 1186–1193. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, Z.; Liu, J.; Shu, J.; Zhang, H. A Binocular Vision-Based Crack Detection and Measurement Method Incorporating Semantic Segmentation. Sensors 2023, 24, 3. [Google Scholar] [CrossRef] [PubMed]

- Nyathi, M.A.; Bai, J.; Wilson, I.D. Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms. Appl. Sci. 2023, 13, 4981. [Google Scholar] [CrossRef]

- Abdelalim, A.M. A novel diagnostic prognostic approach for rehabilitated RC structures based on integrated probabilistic deterioration models. Int. J. Decis. Sci. Risk Manag. 2019, 8, 119. [Google Scholar] [CrossRef]

- Mohamed, N.A.; Abdel-Alim, A.M.; Ghith, H.H.; Sherif, A.G. Assessment and Prediction Planning of R.C Structures Using BIM Technology. Eng. Res. J. 2020, 167, 394–403. [Google Scholar] [CrossRef]

- Abdelalim,A.M., Nahla Ali Mohamed fahmy, Hatem Hamdy Ghith, Alaa Gamal sheriff (2020). Condition Assessment and Deterioration Prediction of RC Structures, International Journal of Civil and Structural Engineering Research, 8(1), 173-181, available at: https://www.researchpublish.com/papers/condition-assessment-and-deterioration-prediction-of-rc-structures.

| Classification | Description |

|---|---|

| Fine | Generally less than ( lmm ) wide. |

| Medium | Between (lmm) and (2mm) wide. |

| Wide | Over (2mm) wide |

| Variable | Mean | SE Mean | St.Dev | Minimum | Q1 | Median | Q3 | Maximum |

|---|---|---|---|---|---|---|---|---|

| Actual (mm) | 1.5167 | 0.0719 | 0.6705 | 0.5000 | 1.0000 | 1.5000 | 2.0000 | 4.0000 |

| Model (mm) | 1.5474 | 0.0744 | 0.6942 | 0.5000 | 1.0583 | 1.5800 | 2.1000 | 4.2330 |

| Error | 0.03075 | 0.00667 | 0.06220 | -0.100 | 0 | 0.00500 | 0.06600 | 0.23300 |

| Abs Error | 0.04696 | 0.00546 | 0.05093 | 0 | 0 | 0.04080 | 0.0800 | 0.23300 |

| MAPE% | 3.010 | 0.273 | 2.551 | 0 | 0 | 4.125 | 5.333 | 7.143 |

| Squared Error ( | 0.00477 | 0.00107 | 0.0099 | 0 | 0 | 0.00166 | 0.006400 | 0.05429 |

| Bias (mm) | 0.03075 |

|---|---|

| MAE (mm) | 0.04696 |

| MAPE% | 3.01% |

| RMSE (mm) | 0.0690 |

| RMSE% | 4.55% |

| Classification | Fine | Medium | Wide | Total |

|---|---|---|---|---|

| Fine | 11 | 11 | 0 | 22 |

| Medium | 0 | 43 | 5 | 48 |

| Wide | 0 | 0 | 17 | 17 |

| Total | 11 | 54 | 22 | 87 |

| Data Source. | Type of camera | Precision | Recall | Specificity | Accuracy | F1-Score |

|---|---|---|---|---|---|---|

| Bridge Deck (SDNET 2018) | 16 MP Nikon camera | 98.32% | 99.43% | 95.83% | 97% | 98.87% |

| Existing RC Bridge | iPhone 7 Plus | 63.5% | 97.75% | 96.04% | 76.66% | 77.00% |

| Image No | actual width (mm) | Bilateral filter | Absolute error | Median filter | Absolute error | Wiener filter | Absolute error |

|---|---|---|---|---|---|---|---|

| 1 | 0.7 | 0.8 | 0.1 | 0.8 | 0.1 | 0.8 | 0.1 |

| 2 | 2 | 2.3 | 0.3 | 2.4 | 0.4 | 2.6 | 0.6 |

| 3 | 2 | 1.9 | 0.1 | 1.3 | 0.7 | 1.7 | 0.3 |

| 4 | 1.6 | 1.3 | 0.3 | 1.6 | 0 | 1.8 | 0.2 |

| 5 | 1.5 | 2 | 0.5 | 1.9 | 0.4 | 1.7 | 0.2 |

| MAE (mm) | 0.166 | 0.205 | 0.179 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).