1. Introduction

India ranks as the sixth-largest producer of broiler chickens globally, with an annual output of over 480 million broiler chicks. The country’s broiler meat production reaches approximately 4.5 million tons, with 60-70% of production driven by vertically integrated, structured farms accounting for nearly 80% of the total chicken meat output [

1]. Tamil Nadu, a southern state of India (11° 7’ 37.6428’’ N and 78° 39’ 24.8076’’ E), holds the fifth position in broiler production, contributing 0.5 million tons, or around 10% of India’s total broiler meat production [

2]. The majority of broiler farms in Tamil Nadu are concentrated in the north-western tropical semi-arid agro-climatic zones, with farm sizes ranging from 1,200 to 40,000 birds per flock [

3]. The intensive nature of broiler production generates significant quantities of poultry litter (PL), a mixture of manure, feathers, spilled feed, and bedding material [

4,

5]. On an average, one kilogram of bedding material is used per bird, and each bird produces approximately 1.0 to 1.5 kilograms of litter during a 47-day production cycle [

6,

7]. With this scale of production, India generates an estimated 1.2 million tons of broiler poultry litter annually.

In Tamil Nadu, coconut coir pith (CP) is widely used as a bedding material for broiler farms, especially in the north-western tropical semi-arid regions, where 95.5% of farmers rely on CP, an agro-industrial by-product of the coconut coir fiber extraction process [

3,

8]. India, being the world’s largest coconut producer, generates large quantities of coconut by-products. Coconut coir pith, which constitutes 50-60% of the pericarp, is a lignocellulosic waste containing about 40.9% lignin and a carbon-to-nitrogen (C/N) ratio of 58:1 to 112:1 [

8,

9]. Managing poultry litter effectively is a critical challenge for broiler farmers. The accumulation of litter after each production cycle, which lasts between 42 to 48 days, poses environmental risks due to its high ammonia content and potential for self-heating. Most broiler farmers remove and heap used litter outside the poultry houses, leading to odor, fly breeding, and nutrient loss through volatilization. Vermicomposting has emerged as an important technology for achieving sustainable and ecologically friendly farming practices. Vermicomposting provides a solution to the current demand for sustainable development by transforming poultry litter into nutrient-rich compost, so addressing environmental concerns. In this controlled bio-oxidative process, earthworms and microorganisms work together to convert organic wastes into high-quality organic manure. In general, vermicomposting promotes sustainable agriculture by converting a variety of wastes, including solid organic wastes, livestock andwaste, and biosolids, into beneficial compounds that improve plant growth. In addition, vermicomposting play an integral role in the carbon nexus via the interconnectability of carbon sequestration, improvement of soil health, and sustainable food production.

However, the high ammonia concentration in poultry litter and the challenges of heat generation during decomposition limit its direct use in vermicomposting. Previous research [

10,

11] has focused primarily on poultry manure as a co-compost material, often in combination with other substrates. Studies by Khan et al. and Ravindran & Mnkeni [

10,

11] optimized the C/N ratio using wastepaper and poultry excreta for vermicomposting. Nevertheless, there is a gap in research on poultry litter as the primary substrate. Given the volume of waste generated by broiler production and the need for improved nutrient recycling, the bioconversion of poultry litter into vermicompost is both an environmental and economic priority. In this study, poultry litter was pre-composted with coconut coir pith and farmyard manure (FM) as carbon sources, then subjected to vermicomposting using

Eudrilus eugeniae earthworms at varying C/N ratios. This research aims to optimize the vermicomposting process for poultry litter, enhancing nutrient recovery, reducing environmental pollutants, and offering a profitable waste management solution for broiler farmers. This work therefore contributes to the effective conversion of waste materials (viz., poultry litter) into nutrient-rich vermicompost, which improves soil fertility. By utilizing carbon sources such as coconut coir pith, the technique can contribute to carbon sequestration, lessening the consequences of climate change, and providing an effective waste management solution for poultry farms. This strategy not only helps to convert waste into a useful resource, but it also promotes agricultural sustainability and environmental protection. As such the objectives of this study were: 1) To optimize the C:N ratio of commercial BPL with coconut coir pith waste, 2) To assess the

Eudrilus eugeniae earthworm’s performance in commercial BPL and determine its suitability for large-scale vermicomposting and 3) To ascertain the plant nutrients dynamics during the vermicomposting process in commercial BPL after optimization.

2. Materials and Methods

2.1. Sources and Location of the Study

The PL required for aerobic composting and vermicomposting was collected from commercial broiler farms located near the Veterinary College and Research Institute, Namakkal, Tamil Nadu, India (11.1614° N, 78.1614° E) at the end of the production cycle and CP was used as litter material. The carbonaceous material like for optimizing C/N viz., CP and FM were collected from the local coir extraction industry and dairy farm of the instate, respectively, the Epigeic earthworms Eudrilus eugeniae were obtained from commercial vermicomposting units and cultured in partially composted FM worm bed and the entire study was carried out for a period of 12 months.

2.2. Vermicomposting Methodology

The bioconversion of PL was done in two stages, in the first stage, microbial pre-composting (thermophilic static pile) was done with 250 kg of compost mixture followed by vermicomposting. Optimization of PL for C/N ratio of 25, 30 and 35 had been done with CP waste and FM. The chemical properties of individual ingredients were analyzed on dry weight (

Table 1) and the C/N was optimized and the compost recipe was formulated as per the formula recommended by the USDA-NRCS[

12], the physicochemical properties of compost recipe before start of composting process is given in

Table 2. The moisture content was stabilized to 65 % by the addition of water. Three different compost combinations were formed keeping PL and FM as two controls and the different treatment combinations used in this study are as follows:

PLCP25 – PL + CP + water (25.2: 1 C:N ratio) : 1.88 : 0.28 : 1.3

PLCP30 – PL + CP + water (30.18: 1 C:N ratio) : 1.88 : 0.77 : 1.59

PLCP35 – PL +CP + water (35.14 : 1 C:N ratio) : 1.25 : 0.90 : 1.29

PL – PL + water (21.95 : 1 C:N ratio) : 1.84 : 0.00 : 1.1 (control 1)

PLCPFM25 – PL + CP + FM + water (25.26 : 1 C:N ratio) : 0.94 : 0.99 : 0.13 : 1.23

PLCPFM30 – PL + CP + FM + water (30.12 : 1 C:N ratio) : 0.78 : 0.82 : 0.46 : 2.07

PLCPFM35 – PL + CP + FM + water (35.42 : 1 C:N ratio) : 0.62 : 0.66 : 0.73 : 2.02

FM – FM + water (25.26: 1 C:N ratio) : 2.0 :1.2 (control 2)

2.3. Thermophilic Composting (Microbial Pre-Compost)

Thermophilic composting was done for the purpose of eliminating toxic gases like ammonia and converting complex substance to simple organic matter [

11] to provide favourable environment for the earth worms. Based on the C: N ratio, BPL was mixed with CCP and FYM and windrows were formed and the total weight of the feed stock from each treatment prepared for thermophilic composting was about 250 Kg. the windrows were formed after addition of required quantity of water to adjust the moisture level of 60 % (

Figure 1). A complete thermophilic phase was allowed for primary composting and when the pile reached the ambient temperature or 40°C, the mixture was turned again for aeration and again allowed for secondary phase of composting after rehydration [

13]. When the temperature of the secondary stage composting reached the ambient temperature, the composting process was considered finished and the materials were moved for vermi-bed preparation.

2.4. Vermicomposting

Precast concrete cement rings of 90 cm inner diameter and height of 30 cm were used for the study with an open surface area of 0.64 m

2. Two such rings were kept one above the other to increase the height to 60 cm, a total of 24 vermi-bin units were used for the study and each treatment was replicated thrice simultaneously (

Figure 2). A 50 kg of pre-compost feedstock (on dry weight basis) was used for the study. The larger lumps/cakes were broken into small pieces and vermi-bin was filled with feedstock and water was added up to reach a moisture level of 70 to 75 % and were mixed thoroughly. The moisture level of 70 to 75 % was maintained throughout the study period by periodic sprinkling. The Clitellate earth worm stock

Eudrilus eugeniae were introduced into the treatment groups and each test bin had an earthworm live biomass of one kg worms, corresponding to a stocking density of 1.6 kg worm/m

2 [

14]. Each bin was filled with 50 kg of feed stock at the rate of feeding of 0.75 kg/day/kg of worm. The earthworm castings were collected at weekly intervals and stored in dry bags.

2.5. Physicochemical Analysis and Earthworm Activity

The compost samples (250 g) were collected at the end of both pre-composting and vermicomposting and were stored in an airtight polythene bag and transferred immediately for moisture estimation. Respective samples were also collected in sterile plastic bags and sealed airtight and stored in refrigerators for bacteriological examination. Feedstock to vermicompost conversion ratio [

15] and earthworm biomass gain [

16] was calculated after the end of 90 days trial period as described below:

Feed substrate to vermicompost ratio (FVCR) = HVC / IFS x 100

FVCR : Feed substrate to vermicompost ratio

HVC : Harvested vermicompost (vermicast) on dry weight basis

IFS : Initial feed substrate given on dry weight basis

Total biomass gain (BMG) was calculated as

BMG = ( FEWB – IEWB) / IEWB x 100

BMG = Biomass gain (percentage)

FEWB = Final earthworm biomass (kg)

IEWB = Initial earthworm biomass (kg)

2.6. Chemical Properties of Compost Samples

The chemical properties viz., pH, Electrical conductivity (EC), and total dissolved salts (TDS) were measured (Systronics 308 model) with an aqueous solution (1:10 w/v compost-water extract) of compost sample [

17]. The total ash content was analyzed by assessing loss on ignition in a muffle furnace at 550°C for 5 hours and the total organic matter (TOM) was calculated by gravimetric loss on ignition. The total carbon was calculated from the total organic matter value using the conventional “Van Bemelem Factor” of 1.724 as described by earlier workers [

17,

18], total Kjeldahl Nitrogen (Keltec2100 nitrogen distillation system -FOSS), total P as per AOAC 965.01 (Spectophotometric, model Lamda 25, Perkin Elmer), Ca (as per AOAC 927.02, titration method),and K was analysed using Flame photometer [

19].

Microbial Load

Sterile samples collected at the beginning, end of pre-composting and after vermicomposting were serially diluted in 10 fold steps using sterile triple glass distilled water. Plate count agar for total bacterial count (TBC), Eosine Methylene Blue (EMB) agar for

E. coli and Brilliant green agar (BGA) for

salmonella were used. The microbial numbers were expressed as log

10 colony forming units per gram of sample [

20]. The seed germination test was carried out using common fodder seeds in 1:10 aquous extract and Relative seed germination percentage was calculated by modifying the method suggested by Tiquia

et al. [

21].

2.7. Statistical Analysis

The collected data were systematically analyed by ANOVA using the IBM- SPSS (version 28) software platform. All significant results yielded by ANOVA analysis were subjected to post-hoc, Tukey’s HSD test to identify which groups differed significantly between them.

2.8. Ethical Approval

In this experiment, no animal or human intervention investigations were conducted.

3. Results

3.1. Pre Composting

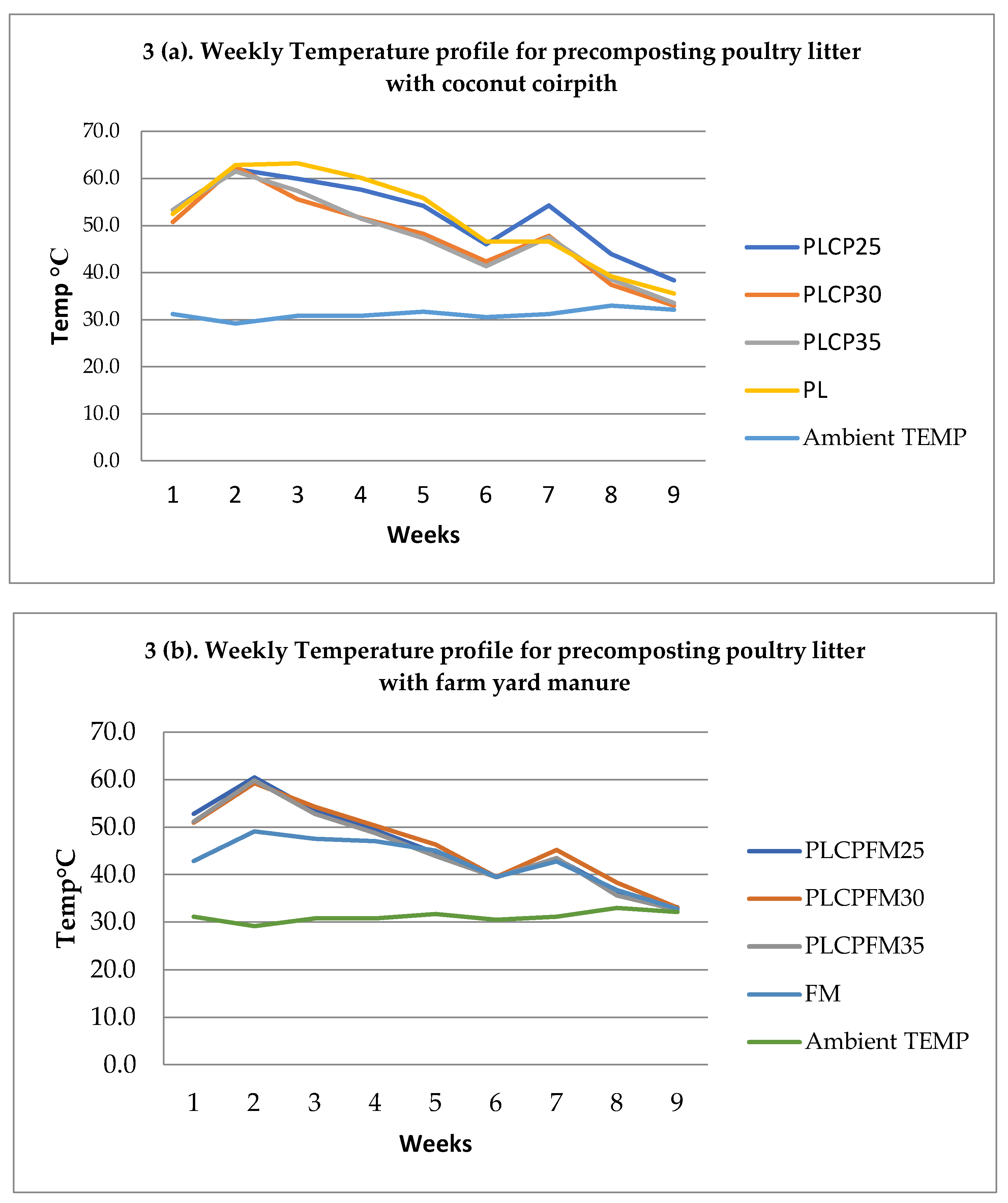

The highest mean weekly temperature was attained during 2

nd week and gradually declined and reached the ambient temperature on 9

th week. Peak temperature was recorded during the thermophilic phase and was ranged between 69.3 and 55.4 °C during primary stage of pre-composting and ranged between 58.0 and 45.9 °C during secondary cycle (

Figure 3). The PLCP25 recorded the highest temperature of 69.3°C and the entire treatment group except FM had good thermophilic phase. The persistency of thermophilic temperature (>55°C) continuously for days together is important for bio-security aspect of compost recipe and it ranged between 34 and 2 days. The lowest days was noticed in FM (2 days) control and the highest was in PLCP25 (25:1) group (34 days) during primary stage (

Table 3). The pre-composting period is a combination of thermophilic and mesophilic phase of composting. During primary stage of pre-composting it ranged between 38 and 25 days and during secondary stage it ranged between 16 and 4 days and overall composting period ranged between 54 and 31 days . The longest duration was observed in PLCP25 and shortest duration was noticed in FM. The physicochemical property of pre-composed compost substrate is given in respective vermicomposting tables.

3.2. Feed Substrate to Vermicompost Conversion Ratio and Earthworm Biomass Gain

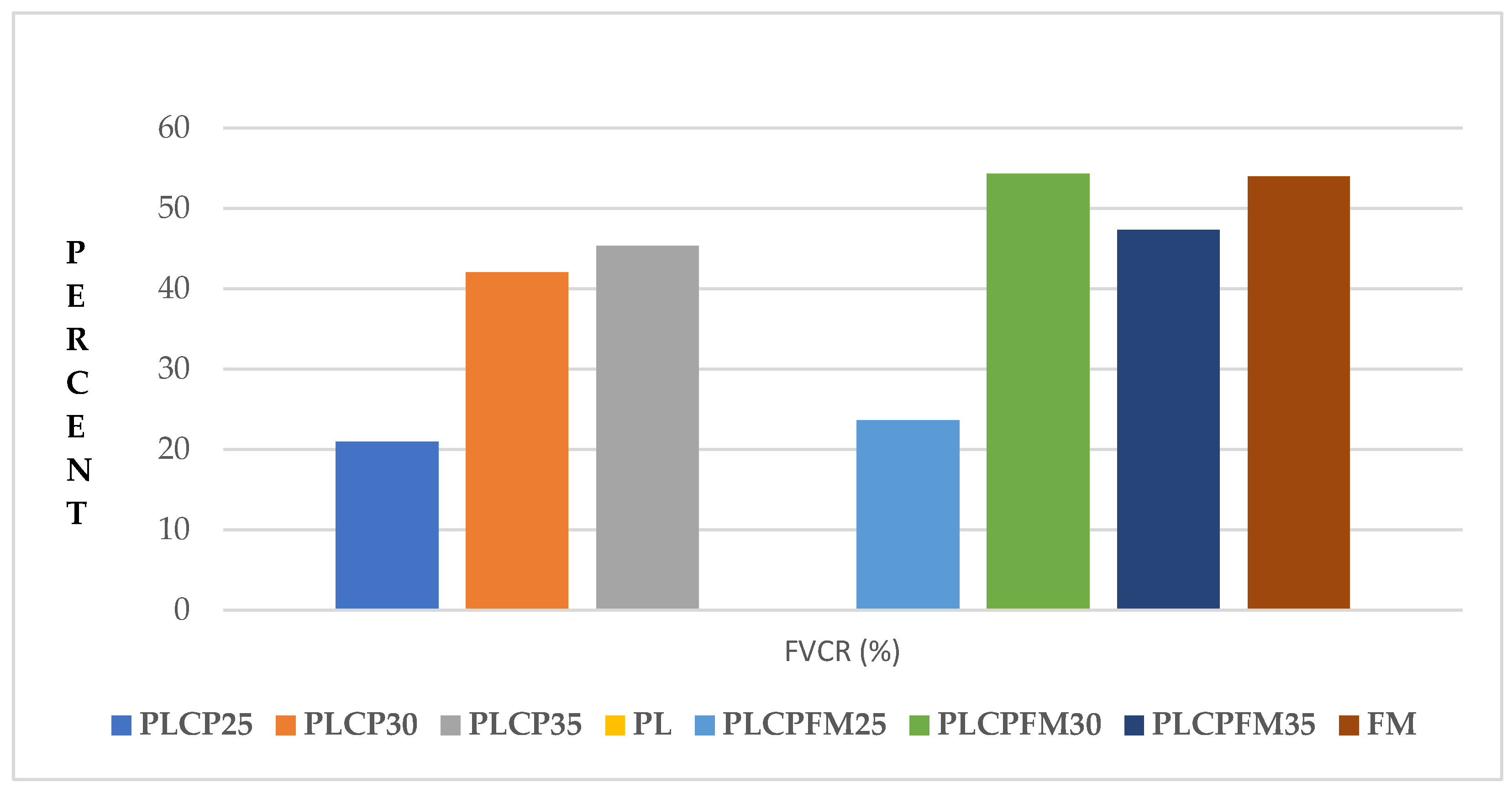

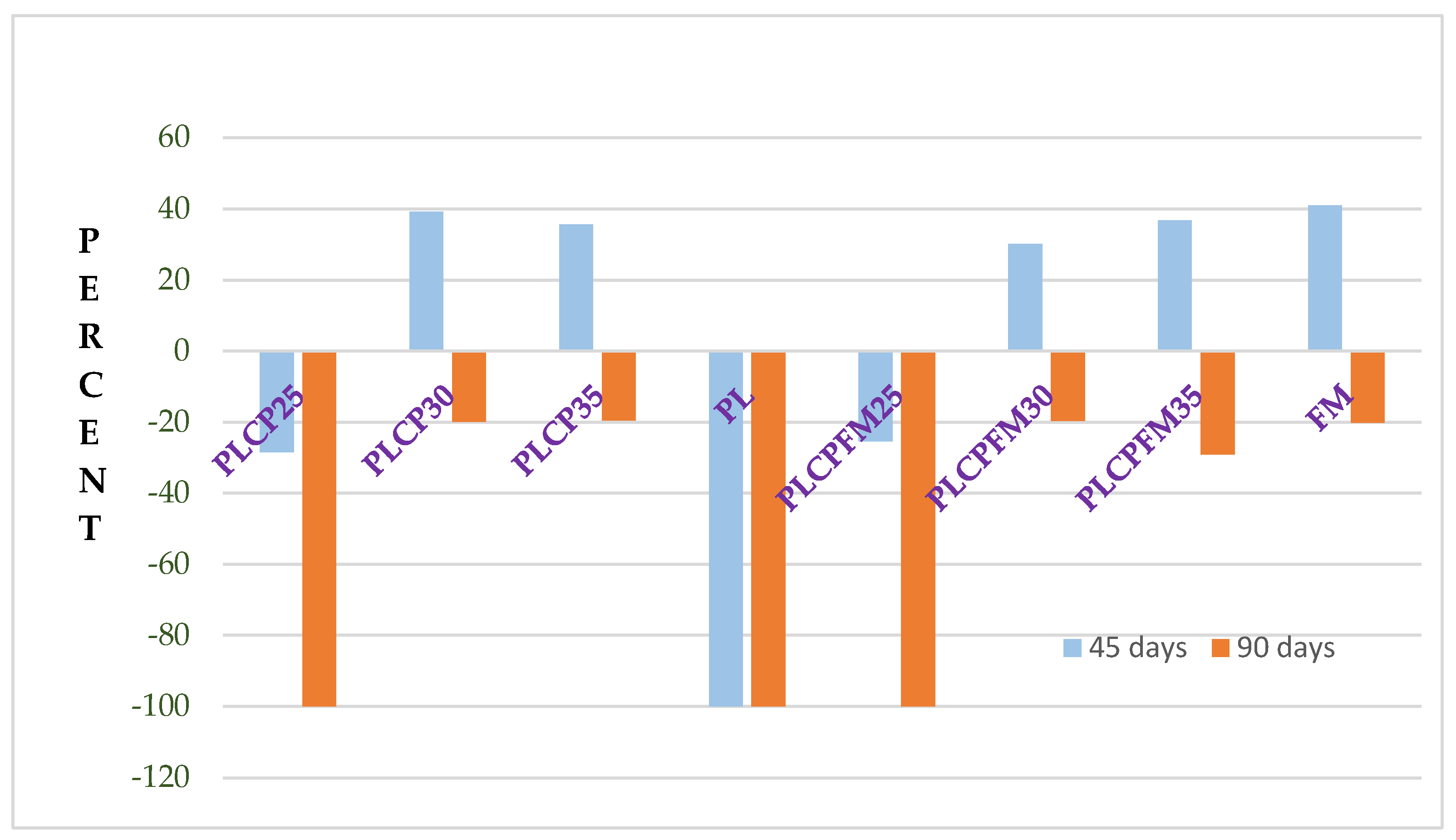

The mean FVCR (

Table 4) was highest in FM control bins followed by PLCPFM35 (35:1) and PLCPFM30 (30:1) and least in PLCPFM25 bins (25:1). The earthworms could not able to survive in PL control bin (PL) and FVCR declined gradually when C: N was reduced, PLCP35 (35:1) bins with CP substrate had similar FVCR as that of FM substrate bins. In this study, up to 45 days, earthworm biomass gain was noticed in PLCP30, PLCP35, PLCPFM30, PLCPFM35, and FM bins and no survivability of earthworm was noticed when pre-composted PBL was used without optimization of C: N (PL bins). Subsequently, there was a decline in the BMG noticed at the end of 90 days of vermicomposting, 100 % mortality of earthworm was noticed in PLCP25, PL, PLCPFM25 and a decline in BMG was noticed in other groups, the decline was significantly (P<0.05) high in PLCPFM35 bins (

Figure 4) and remaining bins had uniform decline.

HVC- Harvested Vermicompost FVCR- Feed Substrate to Vermicompost Conversion Ratio.

3.3. Physicochemical Changes

The mean vermi-bed temperature was almost uniform and statistically did not differ significantly (P>0.05) between treatments and vermi-bed temperature was around 32°C up to 6

th week and there was slight increase (33°C) between 7

th and 9

th week and again declined to 32°C up to 13

th week, which coincided with the mean maximum and minimum temperatures of the vermicomposting yard. The RH ranged between 60.33 and 78.83 %. A declining trend in pH during the process of vermicomposting was noticed and significantly (P<0.05) higher pH was noticed in PL, FM and PLCP25 and other treatment groups did not differ significantly (P>0.05). At the end of the vermicomposting trial except PL and FM, all other samples showed slightly acidic pH (

Table 5). The highest decline was in PLCP25 followed by PLCPFM35, PLCPFM25, PLCP35, PLCP30 and the lowest was in PLCPFM30 .The EC declined during the vermicomposting process, there was a significant (P>0.05) difference in EC between treatments, the values did not differ significantly (P>0.05) in treatment groups where there were good earthworm activities viz., PLCP30 and PLCP35 in the PL+CP group and PLCPFM30

, PLCPFM35 and FM in PL+FM group. The percentage of decline in EC ranged between 40.54 and 73.22. The highest decline was in PLCPFM25 followed by PLCP35

, PLCPFM35, PLCP30, PL

, PLCPFM30, PLCP25 and the lowest was in FM

. Ash, TOM and TOC. The mean ash content increased when vermicomposting activity was in progress. Although the differences between treatment groups are significant (P<0.05) no clear trend could be established. The percentage of increase ranged between 44.51 and 8.46 % and the highest increase was in PLCP30 followed by PLCPFM30

, PLCP35

, PLCPFM35

, PLCP25, PLCPFM25, FM and the least increase was in PL.

A declining trend in TOM and TOC (

Table 6) was noticed from 1

st day to 90

th day of sampling and the difference between treatments was highly significant (P<0.01) except of PLCPFM25 and PLCPFM30 bins, the reduction was the highest in PLCPFM35 followed by PLCPFM30, PLCP35, PLCP30, FM, PLCP25, PLCPFM25 and the least reduction was noticed in PL.

3.4. Total Nitrogen (TKN) and C: N Ratio

A steady increase in TKN was noticed when the vermicomposting process advanced. At the end of 45th day the difference between treatments was highly significant (P < 0.01), but PLCP25, PLCP30 and PL treatment groups did not differ significantly (P > 0.05), similarly, PLCP35, PLCPFM35 and FM groups did not differ significantly (P > 0.05). At the end of 90th day, a further increase (except PL) in TKN was noticed. The highest TKN was noticed in PLCP30 and the lowest in PLCPFM35. The difference between treatments were highly significant (P<0.05) but PLCP25 and PLCP30, PL and PLCPFM25, PLCPFM25 and PLCPFM30, PLCPFM35 and FM , PLCP35 and FM did not differ significantly (P>0.05) between themselves. Wider the C:N ratio, a decrease in TKN content was noticed viz., PLCP25 > PLCP30 > PLCP35 in PL groups, PLCPFM25 > PLCPFM30 > PLCPFM35 (FM group). The percentage of increase was high in PLCP35 (22.65) followed by PLCP25 (16.22), PLCPFM35 (14.37) and other treatment groups except PL, which recorded uniform increments ranged between 9.81 and 11.58 %.

The increase in TKN and reduction in TOC during vermicomposting recorded further decline in C/N ratio. In the entire treatment group the C/N ratio was less than 20 and the trend corresponded with the initial C/N ratio. Though the C/N between treatment groups differ significantly (P<0.05), PLCP25 and PLCPFM25, PLCP35 and PLCPFM35, PL and FM had uniform C/N which corresponded with their initial C : N ratio (except PLCP30 and PLCPFM30 which differ significantly). Except PL which registered 9.01 % increase in C/N other treatment group had an increase of 29.34 and 18.85 % C/N.

3.5. Major Plant Nutrients

At the end of 90 days, the Ca content of all the treatment groups (

Table 7) did not differ significantly (P>0.05) except PL which had significantly (P<0.05) higher Ca content. Except for FM, where there was a decline in Ca all other treatment groups had increased Ca content, the least increment was noticed in PL and PLCP25, where earthworm activity was either less or nil. On the other hand, the treatment groups (except FM) where earthworm activity was good had a higher percentage of increase in Ca content. The highest P was recorded in PL and PLCPFM25 wherein there was no earthworm activity. Except PL, all other treatment groups did not differ significantly (P>0.05). The least increment in P had been recorded in PLCP25 followed by PLCP30 and PL and a higher increment was recorded in PLCP35 followed by PLCPFM25, PLCPFM30, PLCPFM35

, and FM where vermicomposting was good. The K (g kg

-1) at the end of 45

th day of vermicomposting showed an increasing trend, it was high in PL followed by PLCPFM30, PLCPFM35, and PLCPFM25. The difference between the treatments was highly significant (P<0.01) except PLCP35 and PL

, PLCPFM25 and PLCPFM30 which did not differ between the treatments.

3.6. Microbial Changes

The initial total bacterial count (TBC) was ranged between 8.98 ± 0.06 and 7.90 ± 0.02 log10 cfu/g. The PL had significantly higher (P<0.05) TBC (8.98 log10 cfu/g) followed by PLCP25 (8.68 log10 cfu/g), FM, PLCPFM25 and PLCP35 registered uniform TBC (8.17 to 8.27 log10 cfu/g) and did not differ significantly (P>0.05). The TBC count reduced gradually during the pre-composting period and at the end of pre-composting it was between 6.88 ± 0.02 and 6.31 ± 0.04 log10 cfu/g while at the end of vermicomposting, the TBC ranged between 5.87 and 5.32 log10 cfu/g. Furthermore, E. coli count was not observed at the initial stage of the process, nor after pre-composting and vermicomposting. The initial salmonella count ranged between 5.08 ± 0.02 and 5.51 ± 0.01 log10 cfu/g. Except PL which recorded the highest count (PL control) other treatment mixtures had almost uniform count and no Salmonella count was detected in FM (FM control) subsequent to pre-composting and in vermicomposting.

3.7. Compost Maturity Test

To assess compost maturity, phytotoxic substances, if present, were detected using a germination test. The germination percentage of common fodder seeds viz. cow pea, bajra and sorghum are presented in

Table 8. The analysis of variance test revealed no significant (P>0.05) difference between the treatments during pre-composting and after vermicomposting. The seed germination was lower in pre-composted sample and excellent in vermicompost, which indicated that all the finished compost and vermicompost are suitable as soil amendments.

The germination percentage at the end of pre-composting ranged between 77.58 and 88.64 %. The harvested vermicompost was also subjected to a germination test, yielding even better results, with percentages ranging between 96.67 and 100.00 %. These results indicate that the finished vermicompost is an excellent soil amendment.

4. Discussion

4.1. Feed Substrate to Vermicompost Conversion Ratio

Poultry litter presents a challenge as a feed substrate due to its high salt and ammonia nitrogen content, both of which are toxic to earthworms. To mitigate these issues, poultry litter should be pre-composted [

22] or pre-washed before use. In the present experiment, pre-composting of broiler poultry litter (PL) was performed after optimizing the carbon-to-nitrogen (C/N) ratio to between 25 and 35. Despite pre-composting, maintaining uniform moisture levels, and ensuring an ambient temperature, no earthworm activity was observed in the PL treatment, where PL alone was used as the feed substrate. This finding aligns with the observations of Joshi et al. [

23], who reported mortality of

E. fetida worms when seeded in broiler poultry litter. They attributed this to poor decomposition of the deep litter material and high levels of C/N and ammonia nitrogen. In treatments PLCP25 and PLCPFM25, vermicomposting was successful up to 45 days; however, earthworm activity declined sharply afterward, with 100 % mortality observed by 90 days. In treatments PLCP30, PLCP35, PLCPFM30, PLCPFM35 and FM, vermicomposting was more successful, with the highest feed-to-vermicast conversion rate (FVCR) recorded in the FM-alone group (

Figure 5), where no PL was included in the feed substrate.

The current results indicated that the PL alone or PL at a C/N ratio of 25, even when combined with CP or FM, could not support earthworm activity. This is consistent with the findings of Mashur et al. [

24], who studied the survivability and biomass gain of

E. fetida using various organic materials in equal combination with PL. They reported 100 % mortality of earthworms in treatments with PL, PL+ market organic waste, and PL+ household organic waste, with a 68.1 % mortality rate in PL+ beef rumen content and the lowest mortality of 27.4 % in PL+ rice straw.

The present research highlights that optimizing the C/N ratio of poultry litter can significantly (P<0.05) enhance vermicomposting. This observation is strongly supported by Ravindran and Mnkeni [

11], who found that

E. fetida biomass increased with C/N ratios of 40 and 50 and was lowest at a C/N ratio of 70, possibly due to the availability of easily metabolizable organic matter at these ratios. PL can be effectively used as a substrate for vermicomposting if the C/N ratio is optimized to either 30:1 or 35:1. FM can also be effectively used for vermicomposting in combination with PL at a C/N ratio of 30:1 or 35:1 but not at 25:1, where the PL content is higher. The results of this experiment clearly indicate that poor earthworm activity is not due to the C/N ratio alone, as evidenced by the excellent FVCR in FM, where the C/N ratio at the beginning of pre-composting was 25:1 and before vermicomposting was 19.58:1, but use of PL as substrate makes the difference and while using PL the C/N need to be optimized above 30:1. Furthermore, reports by Parente et al. [

25] suggest that the use of veterinary drugs, especially fluoroquinolone-contaminated PL, strongly affects earthworm reproduction, survivability, and biomass gain. These findings highlight the need for further exploratory research into contaminants that impact the vermicompostability of PL.

4.2. Earthworm Biomass Gain

The earthworm biomass gain in this study reflects the weight gain and reproduction of earthworms in the provided feed substrate. An initial feedstock of 1000 g was used, and after 45 days, the gain in earthworm biomass was observed in the following order: FM > PLCP30 > PLCPFM35 > PLCPFM30 > PLCP35. The rate of biomass gain did not differ significantly (P > 0.05) among these treatments, suggesting that optimizing the C: N ratio between 30:1 and 35:1 had a beneficial effect on earthworm biomass gain (

Figure 6). The percentage increase in biomass ranged from 41.13 to 30.20 %, correlating with the FVCR. At the end of 90 days, earthworm biomass ranged from 804.00 ± 14.42 to 709.33 ± 62.46 g, indicating a 19.60 to 29.07 % decline in biomass. Similar observations were reported by Garg et al. [

26], who noted an initial increase in worm biomass followed by a decline in the later stages of vermicomposting. Yadav and Garg [

27] also found that the growth rate of earthworms was initially rapid in all waste mixtures (cow dung + poultry droppings + food industry sludge), followed by a stabilized growth rate and eventually a decrease. The reduction in growth rate during the later phase of vermicomposting, as observed by Suthar[

28], might be due to the exhaustion of the feed substrate. Garg et al. and Yadav and Garg [

26,

27] reported a similar reduction in growth rate after the 7th to 9th week of vermicomposting. Mashur et al. [

24] explored various combinations of cultivation media containing horse, goat, cow, and chicken manures with different organic wastes. They reported a negative total earthworm (

E. foetida) biomass yield when using broiler manure as a feed substrate. In the present study, at the end of the vermicomposting trial in treatments PLCP25, PL, and PLCPFM25, earthworm biomass was negligible, consistent with the findings of Giraddi and Meenatchi [

15]. However, an increase in earthworm biomass when using poultry waste as a substrate has been reported by several studies [

10,

11,

29]. From this experiment, it can be concluded that a C/N between 30:1 and 35:1 supports earthworm biomass gain and further research are needed about the frequence of loading feeding substrate and any other toxic residues responsible for decline in earthworm biomass.

4.3. Physicochemical Changes

The mean weekly temperature of the vermi-bed ranged between 32 and 33.5°C, which is above the recommended temperature range from 25 to 30°C for optimal vermicomposting in tropical countries[

22]

. A decline in pH was observed during the vermicomposting process, particularly at the end of the 45

th day. The final pH ranged between 6.48 and 7.03, with all treatments except FM having an acidic pH. The shift towards acidity could be attributed to the mineralization of nitrogen and phosphorus into nitrites/nitrates and orthophosphates, as well as the bioconversion of organic material into intermediate species of organic acids [

26,

27,

30]. However, some studies [

11] reported an increase in pH.

The electrical conductivity (EC) showed a declining trend during the vermicomposting process, with a 40.54 to 73.22 % reduction observed. This decline in EC aligns with findings by Ravindran and Mnkeni [

11], who also reported a decrease in EC. The lower EC values in the final vermicompost products across all treatments may result from lower mineral concentrations, possibly due to the metabolism and bioaccumulation of minerals/metal ions by the earthworms. Mahaly et al. [

31] also reported a decline in EC during the vermicomposting of distillery sludge waste with tea leaf residues, suggesting that the utilization of soluble salts by microorganisms for microbial biomass synthesis and by earthworms may contribute to this decrease. Conversely, Swarnam et al. [

30] documented an increase in EC due to the reduction of organic matter and the concentration of minerals.

The biodegradation of organic matter by earthworms and microbes led to a loss of organic matter, corresponding with an increase in ash content. This finding is consistent with studies by Atiyeh et al. and Maboeta and Van Rensburg [

32,

33], who reported an increase in ash content during vermicomposting, likely due to a faster rate of decomposition and mineralization.

Total Organic Matter (TOM) was lower in treatment groups containing high amounts of PL, such as PLCP25, PL, and PLCPFM25. Further loss of TOM was observed at the end of the 90th day of vermicomposting. Ndegwa and Thompson and Canche et al. [

16,

34] also documented a reduction in volatile solids. The TOM loss might be due to the fragmentation of particle size by the earthworms during digestion, which facilitates microflora in degrading more organic matter. In this trial, the percentage loss of organic matter was highest in PLCPFM35 and PLCPFM30 (FM group) and PLCP35 and PLCP30 (PL group). The initial C ratio had a directly proportional influence on the loss of organic matter, with a wider C ratio (35:1) resulting in more degradation (PLCPFM35 and PLCP35).

Similar to TOM, TOC content also declined during the vermicomposting process. After the introduction of earthworms, carbon content was measured from the harvested vermicompost on the 45

th day, showing a decline ranging between 30.35 and 36.09 %. A further decline was noted in the 90

th day vermicompost, ranging between 29.29 and 33.84 %. Garg and Kaushik [

35] reported a wide range of TOC loss (30 to 42 %), while Yadav and Garg [

27] reported a 16 to 38 % TOC loss. Kaviraj and Sharma [

36] reported a 20 to 45 % TOC loss, with even higher percentages reported earlier [

11,

30,

37]. The combined action of earthworms and microorganisms likely caused the C loss from the substrate in the form of CO2 [

38].

4.4. Total Nitrogen and C: N Ratio

The total Kjeldahl nitrogen (TKN) content increased as the initial carbon-to-nitrogen (C/N) ratio decreased, with the differences being statistically significant (P<0.05). These results are consistent with the findings of Yadav and Garg [

27]. In this experiment, the percentage increase in TKN ranged from 9.81 to 22.65 %, which was associated with strong earthworm activity. Jayakumar et al. [

37] reported a 55 % increase in TKN during the vermicomposting of turkey litter. Similarly, Ravindran and Mnkeni [

11]observed an increase in TKN content while optimizing the C/N ratio during the composting of chicken manure. They noted that the initial TKN ranged from 5.3 to 17.50 g/kg, increased to 6.3 to 18.0 g/kg at the end of pre-composting, and further increased to 10.6 to 19.8 g/kg by the end of vermicomposting. The largest increase in TKN was observed in the 50:1 C/N group. Other researchers [

26,

28,

39] have also reported increases in TKN during the vermicomposting of various organic materials.

The increase in nitrogen content in the manure could be attributed to several factors, including the loss of organic carbon, earthworm activities such as ammonia excretion, the addition of nitrogen in the form of mucus, enzymes released from the earthworm gut, the mineralization of carbon-rich materials, the action of nitrogen-fixing bacteria present in the waste material, and the mineralization of organic nitrogen [

27,

30,

40]. The researchers, Atiyeh et al. [

32] suggested that earthworms enhance nitrogen mineralization, significantly impacting nitrogen transformation in manure, resulting in nitrogen retention in the nitrate form. Conversely, Tahir and Hamid [

41] reported a reduction in nitrogen content after vermicomposting. Parvaresh et al. [

42] noted that the nitrogen content remained unchanged compared to the initial value during vermicomposting. Based on these findings, it can be concluded that vermicomposting of poultry litter, after optimizing the C/N ratio (30:1 to 35:1), can produce finished compost rich in nitrogen.

The C/N ratio serves as an indicator of compost maturity, reflecting changes in the relative concentrations of total organic carbon (TOC) and TKN. According to Ravindran et al. [

43] a C/N ratio below 20:1 in the final product indicates mature vermicompost. In the present experiment, the finished vermicompost had a C/N ratio ranging from 19.37 to 13.34, with the differences between treatments being highly significant (P<0.01). The percentage decrease in the C/N ratio during vermicomposting ranged from 18.85 to 29.34 %, except for PL. Garg et al. and Yadav [26, 27) reported a decrease in the C/N ratio in vermicomposting food industry waste. Jayakumar et al. [

37]observed a 48.54 % reduction in the C/N ratio (from 36.57 to 18.82) during vermicomposting turkey litter with cow dung. The initial and final C/N ratios showed a decline ranging from 20.85 to 55.5 %, consistent with Ravindran and Mnkeni [

11], who reported that, after optimizing the C/N ratio at various levels, the finished vermicompost had a C/N ratio below 20:1. They suggested that the reduction might be due to the rapid breakdown of organic matter for microbial metabolism.

Similar findings have been reported in the vermicomposting of other organic wastes, including cow manure [

32], coconut husk and spent coconut flakes [

41], and a C/N reduction of 80.9 to 83.9 % during the vermicomposting process, with initial values of 50.2 and 75.9 and final values of 9.58 and 12.2 for cow dung and biogas slurry, respectively [

39].

4.5. Major Plant Nutrients

The degradation of organic matter by earthworms and microbes resulted in an increase in total calcium (TCa) concentration in the vermicompost. The percentage increase was significant (P<0.05) in vermi-bins with good vermicompostability, except for FM, and lower in PL and PLCP25. This finding aligns with previous studies [

27,

28,

35,

39] who also reported an increase in TCa content during the vermicomposting of various organic wastes. However, similar to the observed reduction of TCa in farmyard manure (FM). It was suggested by Lakshmi Prabha et al. [

44] that the high initial TCa in poultry manure and the production of calcium carbonate by the calciferous gland of earthworms could be reasons for the increase in TCa in the finished vermicompost.

At the end of vermicomposting, the majority of the vermicompost samples had uniform total phosphorus (TP) content. This result is comparable with the findings of Garg et al. [

26], who recorded a 35.8 to 66.7 % increase in TP while composting food industry waste with cow dung and poultry droppings. Swarnam et al.[

30] reported an even higher percentage increase in TP (593 to 841 %) while composting coconut husk with pig slurry and poultry manure. The increase in TP can be attributed to the mineralization and mobilization of phosphorus by bacterial and faecal phosphatase activity of earthworms, as well as acid production by microbial activity, resulting in the solubilization of insoluble phosphorus and potassium [

45].

The percentage increase in total potassium (TK) during vermicomposting ranged from 10.66 to 49.13 %. Pramanik [

46] noted a 59 to 77 % increase, while Swarnam et al. [

30] observed a 38 % increase, in TK content. In contrast, Garg and Kaushik [

35] observed a drop in TK content in the final product of textile mill waste and poultry droppings vermicompost, speculating that leaching of TK by excess water drained through the feed mix could be the cause.

4.6. Microbial Changes

The total bacterial count (TBC) showed a declining trend during the process of pre-composting and vermicomposting. The initial count ranged between 8.98 and 7.90 log10 CFU/g and declined to a range of 6.31 to 6.88 log10 CFU/g. These findings are consistent with the earlier findign [

47] who observed that the thermophilic phase reduced the population of mesophilic organisms, leading to a reduction and stabilization in TBC count. Similar trends in TBC count were reported by and Gharaei et al. [

48] during the composting of broiler poultry litter (PL).

In the present study, no E. coli was detected during pre-composting or vermicomposting. Gharaei et al. 48] found that deep stacking with varying moisture levels reduced

E. coli and other coliforms. Sivakumar et al. [

47] also reported a reduction in coliforms during the aerobic composting of dead birds. Vermicomposting further reduces coliform counts, as observed by who reported a 90 % reduction in faecal coliforms from sewage sludge and water hyacinth vermicomposting. The earlier reports [

34,

41,

49] also observed a reduction or complete elimination of faecal coliforms. The antibacterial properties of the coelomic fluid released by earthworms during vermicomposting may contribute to pathogen elimination [

50]. Monroy et al. [

49]demonstrated that feed substrate passing through the earthworm gut decreased total coliforms by as much as 85 %.

At the beginning of the experiment, the Salmonella count ranged between 5.20 and 5.51 log10 CFU/g and was reduced to a non-detectable level by the end of pre-composting and subsequent vermicomposting. Gharaei et al. [

50] reported that various poultry litter management methods, including deep stacking, reduced Salmonella to non-detectable levels. Similarly, Canche et al. , and Monroy et al. [

34,

49] observed a reduction in Salmonella counts during vermicomposting.

4.7. Contribution to the Sustainability of This Research and Future Direction

The commercial broiler and layer operation produces around 38.33 million tonnes of poultry manure annually [

51], which is an excellent source of plant nutrients [

52]. Composting waste reduces environmental risk by converting it into a stable nutrient-rich soil amendment as well as mitigating environmental issues associated with raw manure and providing a safer and more stable soil amendment [

53]. Vermicomposting is essential for the stabilization of solid organic waste and sustainable waste management. Environmental impacts include ammonia volatilization, plant nutrient conservation, and the recycling of poultry waste into the agricultural system. At the farmer level, a commitment to the circular economy through the reuse and recycling of leftovers through composting ensures soil nutrients and increases productivity [

54]. The demand for inorganic fertilizer is ever increasing; it was estimated that approximately 29.84 million metric tons were consumed in India between 2022 and 2023, with N, P2O5, and K2 consumption of 20.21, 7.92, and 1.72 million MT, respectively, and organic fertilizer production of approximately 20.75 million MT (N+P2O5) [

52,

55]. Reducing and replacing inorganic fertilizer is crucial from an environmental standpoint. To ensure agricultural sustainability, the reliance on inorganic fertilizer must be decreased, which can only be accomplished by efficiently utilizing organic wastes. The current study investigated the possibilities for biocoversion of BPL using earthworms and discovered that optimizing C/N is critical for improved vermicompostability. Vermicomposting is a promising approach that has received a lot of attention for its potential to improve agricultural sustainability [

54,

56,

57].

5. Conclusions

This study found that PL alone or at a C/N ratio of 25, even when combined with CP or FM, did not promote earthworm activity. The current study shows that altering the C/N ratio in poultry litter can significantly increase vermicomposting. This experiment showed that a C:N ratio of 30:1 to 35:1 increases earthworm biomass. Furthermore, replenishing the substrate at 45-day intervals provides the earthworms with a steady supply of nutrients, resulting in increased biomass gain. At the same time, more research is needed to investigate the possibility of other factors such as antibiotic, chemical, insecticide, and pesticide residues in BPL, which may play a critical role in BPL vermicompostability. Further studies of loading rate and vermicompostability of commercial BPL are more important and a cost analysis is also required to determine the economic viability of any large-scale vermicomposting application for converting BPL into valuable products that improve crop development and output. These additional compensation studies will assist farmers in making more informed decisions about adopting this technique. It is also critical to look into the long-term impacts of employing vermicompost made from BPL on soil health, crop yield, and environmental sustainability.

Author Contributions

Conceptualization: S.K and S.N.R; Methodology: S.K and S.N.R; Software, S.K and A.K.T, P.M; Validation, S.K, P.M, B.N, S.R and M.T; Formal analysis, A.K.T, S.K and S.N.R; Investigation, S.K. and S.N.R.; Resources, S.K, D.A.P and D.K; Data curation, S.K, S.B.N and A.K.T; Writing—S. K,S.N.R and A.K.T; Review and editing, S.K, A.K.T., D.A.P, D.K and S.B.N;.V.D. All authors have read and agreed to the published version of the manuscript.”

Funding

This research received no external funding

Institutional Review Board Statement

This study did not require ethical approval.

Informed Consent Statement

Not applicable.

Data Availability Statement

According to university policies, the data in this work can be obtained upon request from the corresponding author.

Acknowledgments

The authors acknowledge the support rendered by Tamil Nadu Veterinary and Animal Sciences University, Chennai – 600 052 Tamil Nadu, India for the support.

Conflicts of Interest

There are no conflicts of interest among the authors

References

- Report, 2022. National Action Plan for Egg & Poultry-2022 For Doubling Farmers’ Income by 2022. Department of Animal Husbandry, Dairying & Fisheries Ministry of Agriculture & Farmers Welfare, Government of India.

- BAHS. Basic Animal Husbandry Statistics – 2023. Government of India, Ministry of Fisheries Animal Husbandry and Dairying, Department of Animal Husbandry and Dairying, Krishi Bhavan, New Delhi, India, 2023. https://dahd.nic.in/sites/default/filess/BAHS2023.pdf.

- Thirunavukkarasu, M., Sivakumar, K., Ramesh, V., Purushothaman, M.R., Murali, N., Mahimairaja, S. A survey profile on broiler poultry litter production and disposal in Tamil Nadu, India. Int. J. Curr. Microbiol. App. Sci. 2019, 8(12): 782-789. [CrossRef]

- Yousaf, A., Mehmood, A., Ren, J., Lee, C.K.M. Sustainable recycling of poultry litter to value-added products in developing countries of South Asia. J. Clean. Prod. 2022, 357, 132029. [CrossRef]

- Zhang, L., Ren, J.Z., Bai, W. A review of poultry waste-to-wealth: Technological progress, modeling and simulation studies, and economic-environmental and social sustainability. Sustainability 2023, 15: 1-23. [CrossRef]

- Mathialagan, P., Rajkumar, N.V. Renewable energy (Poultry litter). Final report submitted to Tamil Nadu Energy Development Agency, Government of Tamil Nadu, India, 2012.

- Ma, Q., Paudel, K.P., Bhandari, D., Theegala, C., Cisneros, M. Implications of poultry litter usage for electricity production. Waste Manag. 2019, 95, 493–503. [CrossRef]

- Ravindranath, D.A., Radhakrishnan, S. Coir pith—wealth from waste: A reference. Coir Board, Ministry of Micro, Small and Medium Enterprise, Government of India, Cochin, 2016. http://coirboard.gov.in/wp-content/uploads/2016/07/Coir-Pith.pdf.

- Lebedeva, D., Hijmans, S., Mathew, A.P., Subbotina, E., Samec, J.S.M. Waste-to-fuel approach: Valorization of lignin from coconut coir pith. ACS Agric. Sci. Technol. 2022, 2, 349−358. [CrossRef]

- Khan, A.M.A., Hamilton, D.W., Lemmons, M.L. Pretreatment methods for vermicomposting of poultry litter. ASAE Annual Meeting Paper Number 067009, 2006. [CrossRef]

- Ravindran, B., Mnkeni, P.N.S. Bio-optimization of the carbon-to-nitrogen ratio for efficient vermicomposting of chicken manure and waste paper using Eisenia fetida. Environ. Sci. Pollut. Res. 2016, 23(17): 16965–16976. [CrossRef]

- USDA-NRCS. Composting: Environmental Engineering National Engineering Handbook. United States Department of Agricultural-Natural Resources Conservation Service, 637, 2000.

- Sivakumar, K., Saravana Kumar, V.R., Jagatheesan, P.N.R., Viswanathan, K., Chandrasekaran, D. Seasonal variations in composting process of dead poultry birds. Bioresour. Technol. 2008, 99: 3708–3713. [CrossRef]

- Ndegwa, P.M., Thompson, S.A., Das, K.C. Effects of stocking density and feeding rate on vermicomposting of biosolids. Bioresour. Technol. 2000, 71: 5-12. [CrossRef]

- Giraddi, R.S., Meenatchi, R. Recycling of sheep and poultry manure using earthworm Eudrilus eugeniae (Kinberg). Karnataka J. Agric. Sci. 2008, 21: 583-585.

- Ndegwa, P.M., Thompson, S.A. Integrating composting and vermicomposting in the treatment and bioconversion of biosolids. Bioresour. Technol. 2001, 76(2): 107-112. [CrossRef]

- Ogunwande, G.A., Lawrence, A.O., Ogunjimi, O., Osunade, J.A. Fate of compost nutrients as affected by co-composting of chicken and swine manures. Int. Agrophys. 2014, 28: 177-184.

- Navarro, A.F., Cegarra, J., Roig, A., Garcia, D. Relationship between organic matter and carbon contents of organic wastes. Bioresour. Technol. 1993, 44: 203-207. [CrossRef]

- AOAC. Official Methods of Analysis. Association of Official Analytical Chemists, 19th ed., Gaithersburg, Maryland, USA, 2012.

- Quinn, P.J., Carter, M.E., Markey, B.K., Carter, G.R. Clinical Veterinary Microbiology. Mosby-Year Book Europe Limited, London, 1992, pp. 61-65.

- Tiquia, S.M., Tam, N.F.Y., Hodgkiss, I.J. Effects of composting on phytotoxicity of spent pig-manure sawdust litter. Environ. Pollut. 1996, 93: 249-256. [CrossRef]

- Barik, T., Gulati, J.M.L., Garnayak, L.M., Bastia, D.K. Production of vermicompost from agricultural wastes- a review. Agric. Rev. 2011, 31(3): 172-183.

- Joshi, T.N., Nepali, D.B., Sah, R., Bhattarai, T., Midmore, D.J. A comparison of composting and vermicomposting for the disposal of poultry waste. Anim. Prod. Sci. 2020, 60(8): 986-992. [CrossRef]

- Mashur, M., Bilad, M.R., Hunaepi, N., Huda, N., Roslan, J. Formulation of organic wastes as growth media for cultivation of earthworm nutrient-rich Eisenia foetida. Sustainability 2021, 13(18): 10322. [CrossRef]

- Parente, C.E., Silva, E.O., Sales Júnior, S.F., Hauser-Davis, R.A., Malm, O., Correia, F.V., Saggioro, E.M. Fluoroquinolone-contaminated poultry litter strongly affects earthworms as verified through lethal and sub-lethal evaluations. Ecotoxicol. Environ. Saf. 2021, 207: 111305. [CrossRef]

- Garg, V.K., S. Suthar, and Anoop Yadav. Management of food industry waste employing vermicomposting technology. Bioresour. Technol., 2012, 126: 437–443. [CrossRef]

- Yadav, Anoop, and V.K. Garg. Recycling of organic wastes by employing Eisenia fetida. Bioresour. Technol., 2011, 102: 2874–2880. [CrossRef]

- Suthar, Surindra. Bioconversion of post-harvest crop residues and cattle shed manure into value-added products using earthworm Eudrilus eugeniae Kinberg. Ecol. Eng., 2008, 32(3): 206-214. [CrossRef]

- Masin, Carolina Elisabet, Maria Emilia Fernandez, Maia Raquel Lescano, and Cristina Susana Zalazar. Bioconversion of Agro-Industrial Wastes: Combined Compost and Vermicompost Processes Using Eisenia fetida for Stabilization of Poultry Litter. International Journal of Recycling of Organic Waste in Agriculture, 2020, 9(2): 133–144. [CrossRef]

- Swarnam, T.P., A. Velmurugan, Sanjay Kumar Pandey, and S. Dam Roy. Enhancing nutrient recovery and compost maturity of coconut husk by vermicomposting technology. Bioresour. Technol., 2016, 207: 76-84. [CrossRef]

- Mahaly, M., A.K. Senthilkumar, S. Arumugam, C. Kaliyaperumal, and N. Karupannan. Vermicomposting of distillery sludge waste with tea leaf residues. Sus. Environ. Res., 2018, 28: 223-227. [CrossRef]

- Atiyeh, Rola M., Jorge Dominguez, Scott Subler, and Clive A. Edwards. Changes in biochemical properties of cow manure during processing by earthworms (Eisenia andrei) and the effects on seedling growth. Pedobiologia, 2001, 44: 709-724. [CrossRef]

- Maboeta, M.S., and L. Van Rensburg. Bioconversion of sewage sludge and industrially produced woodchips. Water, Air, and Soil Pollution, 2003, 150: 219–233. [CrossRef]

- Canche Rodriguez, L.G., L. Cardoso-Vigueros, T. Maldonado-Montiel, and M. Martinez-Sanmiguel. Pathogen reduction in septic tank sludge through vermicomposting using Eisenia fetida. Bioresour. Technol., 2010, 101: 3548–3553. [CrossRef]

- Garg, V.K., and P. Kaushik. Vermistabilization of textile mill sludge spiked with poultry droppings by an epigeic earthworm Eisenia foetida. Bioresour. Technol., 2005, 96: 1063–1071. [CrossRef]

- Kaviraj, S.S., and S. Sharma. Municipal solid waste management through vermicomposting employing exotic and local species of earthworms. Bioresour. Technol., 2003, 90: 169–173. [CrossRef]

- Jayakumar, M., T. Sivakami, D. Ambika, and N. Karmegam. Effect of turkey litter (Meleagris gallopavo L.) vermicompost on growth and yield characteristics of paddy, Oryza sativa (ADT-37). Afr. J. Biotechnol., 2011, 10(68): 15295-15304.

- Dominguez, J., and C.A. Edwards. Vermicomposting organic wastes: a review. In: Shakir, S.H., Mikha, W.Z.A. (Eds.), Soil Zoology for Sustainable Development in the 21st Century. Cairo, 2004, pp. 369–396.

- Yadav, Anoop, Renuka Gupta, and V.K. Garg. Organic manure production from cow dung and biogas plant slurry by vermicomposting under field conditions. Int. J. Recycl. Org. Waste Agricult., 2013, 2: 21. [CrossRef]

- Plaza, C., R. Nogales, N. Senesi, E. Benitez, and A. Polo. Organic matter humification by vermicomposting of cattle manure alone and mixed with two-phase olive pomace. Bioresour. Technol., 2008, 99: 5085–5089. [CrossRef]

- Tahir, Twana A., and Fauziah S. Hamid. Vermicomposting of two types of coconut wastes employing Eudrilus eugeniae: a comparative study. Int. J. Recycl. Org. Waste Agricult., 2012, 1: 7. [CrossRef]

- Parvaresh, A., H. Movahedian, and L. Hamidian. Vermistabilization of municipal wastewater sludge with Eisenia fetida. Iranian J. Env. Health Sci. Eng., 2004, 1(2): 43-50.

- Ravindran, B., Jonathan W.C. Wong, Ammaiyappan Selvam, and Ganesan Sekaran. Influence of microbial diversity and plant growth hormones in compost and vermicompost from fermented tannery waste. Bioresour. Technol., 2016, 217: 200-204. [CrossRef]

- Lakshmi Prabha, M., N. Nagalakshmi, and M. Shanmuga Priya. Analysis of nutrient contents in vermicompost. Eur. J. Mol. Biol. Biochem., 2015, 2(1): 42–48.

- Pramanik, P., G.K. Ghosh, P.K. Ghosal, and P. Banik. Changes in organic-C, N, P, and K and enzyme activities in vermicomposts of biodegradable organic wastes under liming and microbial inoculants. Bioresour. Technol., 2007, 98: 2485–2494. [CrossRef]

- Pramanik, P. Changes in microbial properties and nutrient dynamics in bagasse and coir during vermicomposting: Quantification of fungal biomass through ergosterol estimation in vermicompost. Waste Manage., 2010, 30: 787–791. [CrossRef]

- Sivakumar, K., V. Ramesh Saravana Kumar, P.N. Richard Jagatheesan, K. Viswanathan, and D. Chandrasekaran. Microbial changes associated with composting of dead birds. Indian Vet. J., 2008, 85: 526-528.

- Gharaei, H.B., Y. Rouzbehan, H. Fazaeli, and J. Rezaei. Effect of deep-stacking broiler litter on pathogenic bacteria, intake, digestibility, microbial protein supply, and rumen parameters in sheep. Anim. Feed Sci. Technol., 2015, 199: 73–83. [CrossRef]

- Monroy, F., M. Aira, and J. Dominguez. Changes in density of nematodes, protozoa, and total coliforms after transit through the gut of four epigeic earthworms (Oligochaeta). Appl. Soil Ecol., 2008, 39: 127-132. [CrossRef]

- Panikkar, A.K., S.J. Riley, and S.P. Shrestha. Risk management in vermicomposting of domestic organic waste. Environ. Health., 2004, 4(2): 11–19.

- Prabakaran, R., Ezhil Valavan, S. Wealth from Poultry Waste: An Overview. World’s Poultry Science Journal 2021, 77(2), 1-15. [CrossRef]

- Thirunavukkarasu Maruthamuthu, Sivakumar Karuppusamy, Ramesh Veeramalai, Murali Nagarajan, Purushothaman Manika Ragavan, Mahimairaja Santiago, Bharathy Nallathambi, Anandha Prakash Singh Dharmalingam, Karthika Radhakrishnan, Ajaykumar Ramasamy, Shri Rangasami Silambiah Ramasamy and Thriruvenkadan Aranganoor Kannan Physicochemical Characterization of Broiler Poultry Litter from Commercial Broiler Poultry Operation in Semiarid Tropics of India. Agriculture 2024, 14(10), 1708. [CrossRef]

- Ghadimi, M., Sirousmehr, A., Ansari, M.H., Ghanbari, A. Organic Soil Amendments Using Vermicomposts under Inoculation of N2-Fixing Bacteria for Sustainable Rice Production. PeerJ 2021, 9, 10833. [CrossRef]

- Katiyar, R.B., Sundaramurthy, S., Sharma, A.K., Arisutha, S., Pratap-Singh, A., Mishra, S., Ayub, R., Jeon, B.-H., Khan, M.A. Vermicompost: An Eco-Friendly and Cost-Effective Alternative for Sustainable Agriculture. Sustainability 2023, 15(20), 14701. [CrossRef]

- Report, Annual Review of Fertilizer Production and Consumption 2022-23. Indian J. Fertil. 2023, 19, 91–99.

- Lim, S.L., Wu, T.Y., Lim, P.N., Shak, K.P.Y. The Use of Vermicompost in Organic Farming: Overview, Effects on Soil and Economics. J. Sci. Food Agric. 2015, 95, 1143–1156. [CrossRef]

- Mohite, D.D., Chavan, S.S., Jadhav, V.S., Kanase, T., Kadam, M.A., Singh, A.S. Vermicomposting: A Holistic Approach for Sustainable Crop Production, Nutrient-Rich Bio Fertilizer, and Environmental Restoration. Discover Sustainability 2024, 5, 60. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).