Submitted:

04 November 2024

Posted:

06 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental setup and method

3. Results and discussions

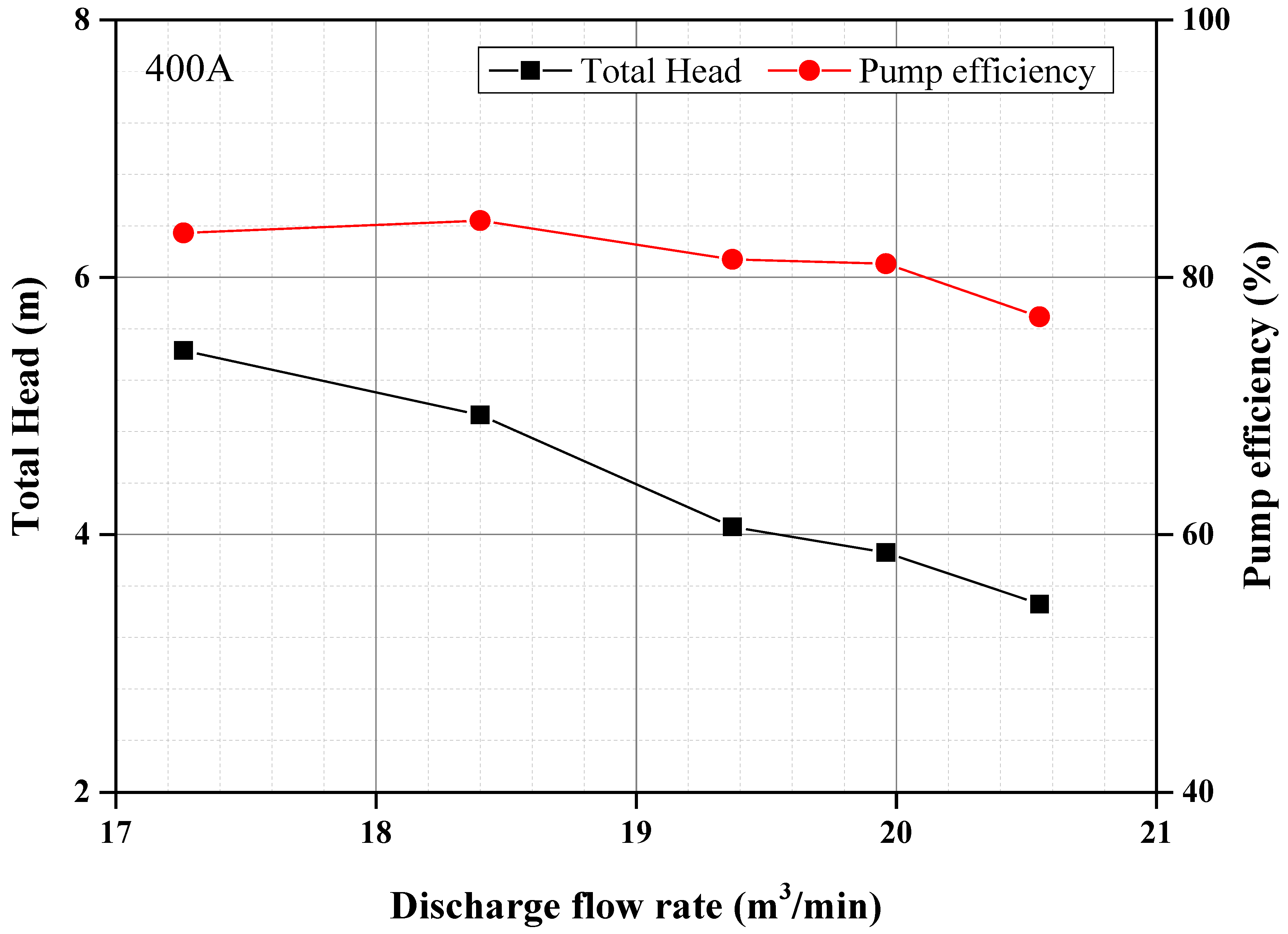

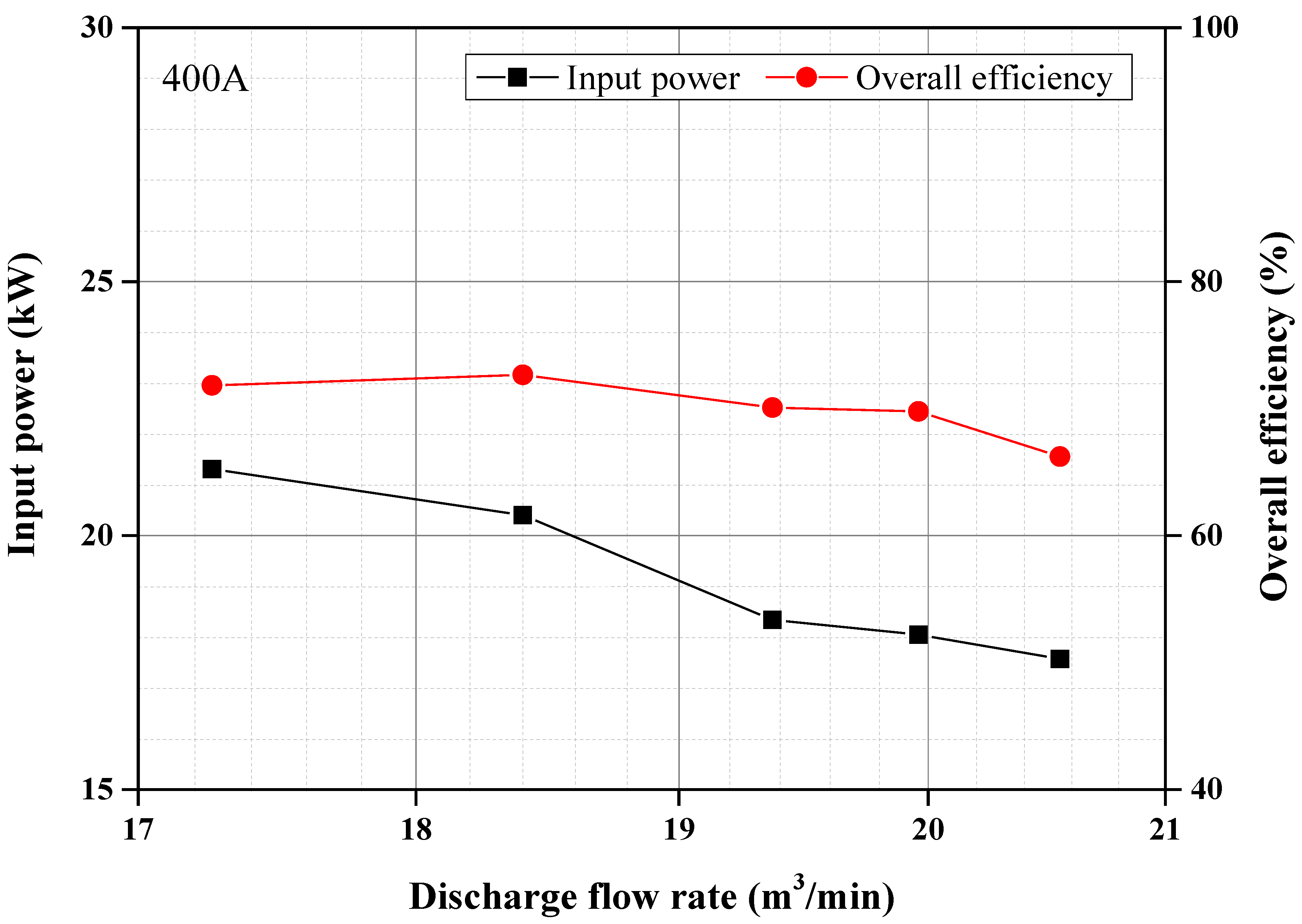

3.1. Performance test results of 400A submersible pump for drainage

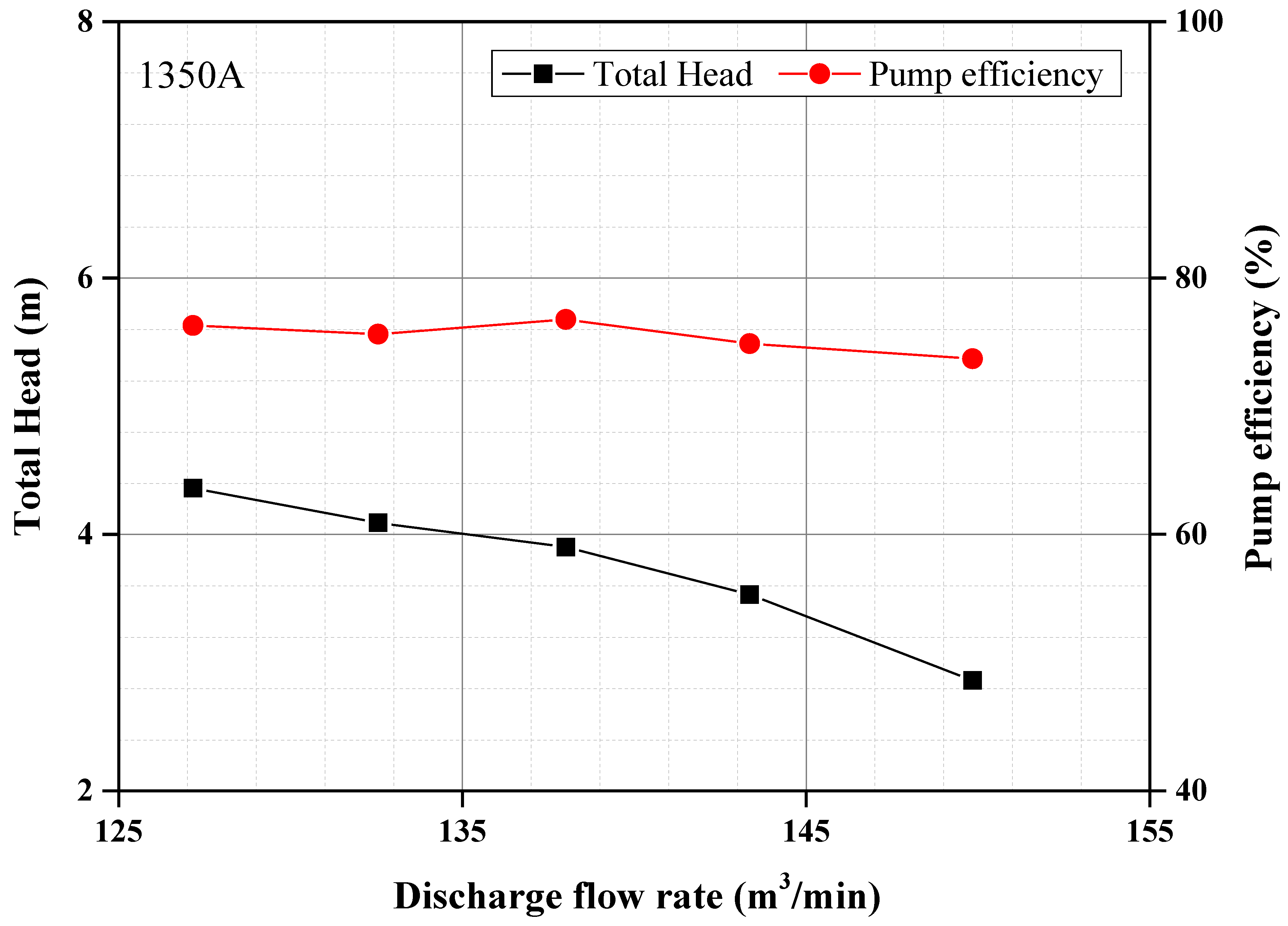

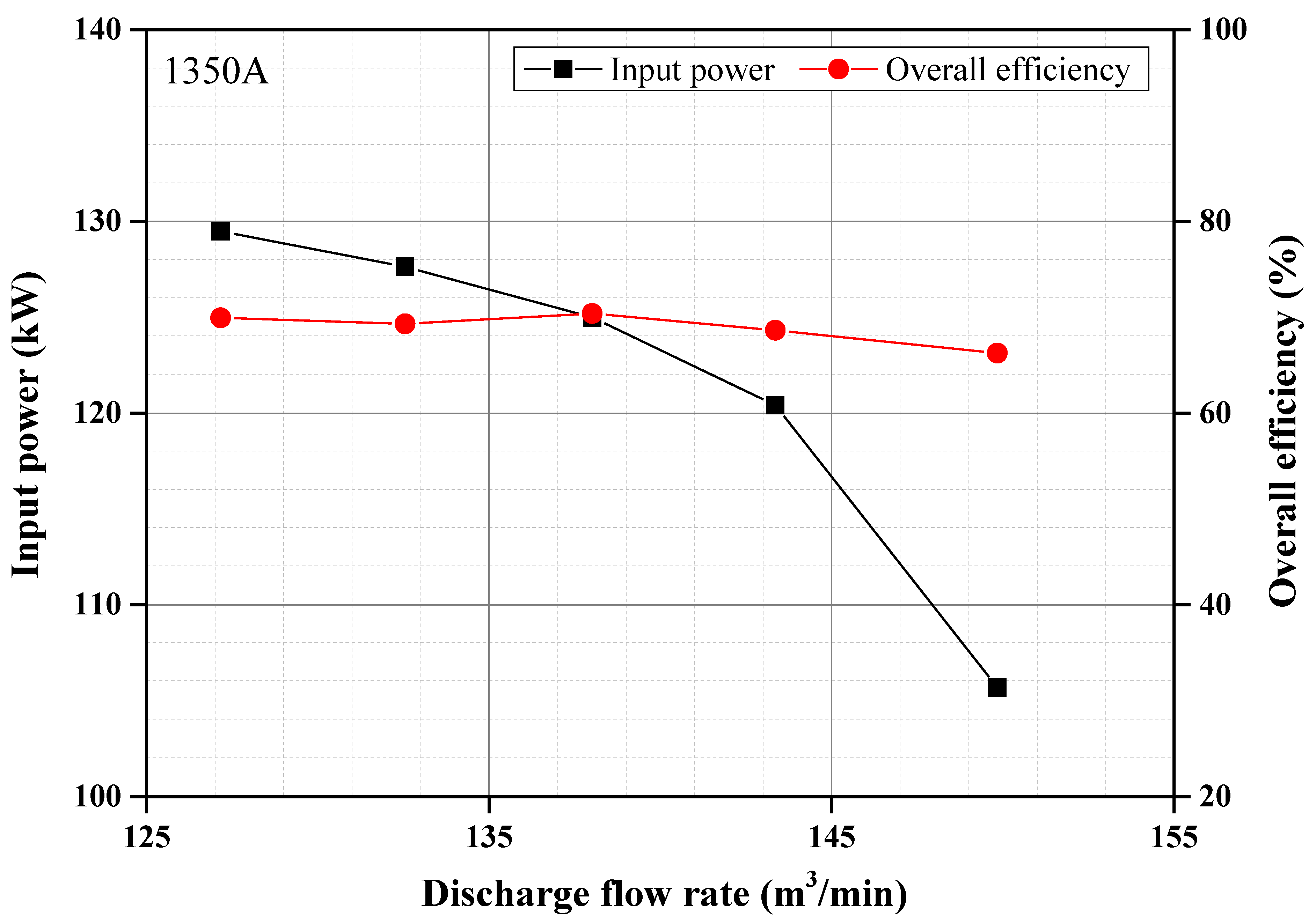

3.2. Performance test results of 1350A submersible pump for drainage

4. Conclusion

Acknowledgments

| Nomenclature | |

| L | Pump shaft power, kW |

| Lgr | Input power, kW |

| g | gravitational acceleration, 9.8 m/s2 |

| H | Total head, m |

| Q | Discharge flow rate, m3/min |

| Greek symbols | |

| η | Pump efficiency, % |

| ηgr | Overall efficiency, % |

| ρ | Density of liquid, kg/m3 |

References

- MONEY TODAY. Available online: https://m.mt.co.kr/renew/view.html?no=2020101109498255465 (accessed on 11 October 2020).

- Hello tv NEWS. Available online: http://news.lghellovision.net/news/articleView.html?idxno=423763 (accessed on 26 June 2023).

- Kim, Y.; Kim, K.; Heo, M. Effect of Geometric Parameters on Hydraulic Performances of a Submersible Axial Flow Pump with Swept Impeller. 2018 Korean Society for Fluid Machinery Winter Conference. 2018, 11, 313–314. [Google Scholar]

- Lee, K.; Won, J.; Yoon, J.; Hwang, H.; Par, S.; Jung, H.; Yun, B.; Kang, S. Numerical Study on Blade Shape Optimization to Improve the Efficiency of Axial Submersible Pumps. 2021 Korean Society for Fluid Machinery Winter Conference. 2021, 12, 438–439. [Google Scholar]

- Kim, Y.; Shim, H.; Kim, K. Hydraulic Performance Characteristics of a Submersible Axial-Flow Pumpwith Different Angles of Inlet Guide Vane. The KSFM Journal of Fluid Machiney. 2018, 21, 34–40. [Google Scholar] [CrossRef]

- An, D.; Kim, H. Numerical Study on Submersible Pumps with a Vortex Reduction Function. Journal of the Korean Society of Manufacturing Process Engineers. 2019, 18, 83–92. [Google Scholar]

- Suh, S.; Rakibuzzaman, M.; Kim, H. Cavitation and clogging analyses of a submersible drainage pump. 2021 Korean Society for Fluid Machinery Winter Conference. 2021, 12, 152–153. [Google Scholar]

- Suh, S.; Rakibuzzaman, M.; Song, K.; Song, K. A study on performance improvement of a submersible drainage pump. 2021 Korean Society for Fluid Machinery Winter Conference. 2021, 12, 148–149. [Google Scholar]

- Seo, T.; Lee, K. A Parametric Study on Impeller Shape for Improving the Efficiency of a Submersible Axial Flow Pump. 2022 Korean Society of Mechanical Engineers Conference. 2022, 11, 1849–1850. [Google Scholar]

- Park, S.; Lee, M.; Kim, J.; Kim, Y. Numerical Study on the Influence of Suction Part Shape on the Performance Characteristics of Submersible Pump for Wastewater. 2017 Korean Society of Mechanical Engineers Conference. 2017, 11, 2553–2556. [Google Scholar]

- Costa, E.A.; Rebello, C.M.; Santana, V.V.; Reges, G.; Silva, T.O.; Abreu, O.S.L.; Ribeiro, M.P.; Foresti, B.P.; Fontana, M.; Nogueria, I.B.R.; Schnitman, L. An uncertainty approach for Electric Submersible Pump modeling through Deep Neural Network. Heliyon. 2024, 10, e24047. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.; Raveendran, R.; Huang, B. Real-time Performance Monitoring of Electrical Submersible Pumps in SAGD Process. IFAC PapersOnLine. 2021, 54-11, 139–144. [Google Scholar] [CrossRef]

- Valdés, J.P.; Becerra, D.; Rozo, D.; Cediel, A.; Torres, F.; Asuaje, M.; Ratkovich, N. Comparative analysis of an electrical submersible pump’s performance handling viscous Newtonian and non-Newtonian fluids through experimental and CFD approaches. J. Pet. Sci. Eng. 2020, 187, 106749. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Xi, B.; Shi, W.; Wang, C.; Ji, L.; Song, X.; He, Z. Inter-stage performance and energy characteristics analysis of electric submersible pump based on entropy production theory. Pet. Sci. 2024, 21, 1354–1368. [Google Scholar] [CrossRef]

- Sperlich, A.; Pfeiffer, D.; Burgschweiger, J.; Campbell, E.; Bech, M.; Gnirss, R.; Ernst, M. Energy Efficient Operation of Variable Speed Submersible Pumps: Simulation of a Ground Water Well Field. Water 2018, 10, 1255. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, W.; Hang, J.; Shi, W.; Yan, H.; Zhu, Y. Numerical Investigation of a High-Speed Electrical Submersible Pump with Different End Clearances. Water 2020, 12, 1116. [Google Scholar] [CrossRef]

- Han, C.; Liu, J.; Yang, Y.; Chen, X. Influence of Blade Exit Angle on the Performance and Internal Flow Pattern of a High-Speed Electric Submersible Pump. Water. 2023, 15, 2774. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Z.; Li, L.; Wang, C.; Teng, K.; He, Q.; Zhou, J.; Li, S.; Cao, W.; Wang, X.; Wang, H. Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump. Water 2024, 16, 789. [Google Scholar] [CrossRef]

- KS B 6301: 2019, Testing methods for centrifugal pumps, mixed flow pumps and axial flow pumps. Korean Standards Association. 2019, 1–43.

| Item | 400A | 1350A | |

|---|---|---|---|

| Pump | Rotating speed | 1167 rpm | 438 rpm |

| Discharge flow rate | 17.0 m3/min | 135 m3/min | |

| Consumption power | 19 kW | 130kW | |

| Total head | 4.0 m | 3.5m | |

| Pump efficiency | 70.0% | 76.35 | |

| Motor | Frequency | 60Hz | 60 |

| Volatge | 380V | 380 | |

| Electric current | 41.0A | 302.0A | |

| Number of poles | 6P | 16P | |

| Power | 19kW | 130kW | |

| Efficiency | 86.08% | 91.68% | |

| Item | Specification |

|---|---|

| Working fluid | Water |

| Temperature(oC) | 17.2 |

| Density(kg/m3) | 998.738 |

| Discharge flow rate(m3/min) | (400A)17.26, 18.4, 19.37, 19.96, 20.55 |

| (1350A)127.16, 132.55, 138.01, 143.36, 149.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).