Submitted:

06 November 2024

Posted:

07 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Chemicals

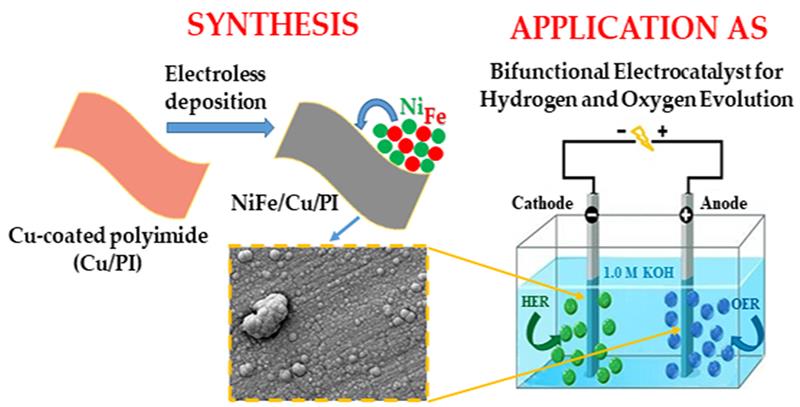

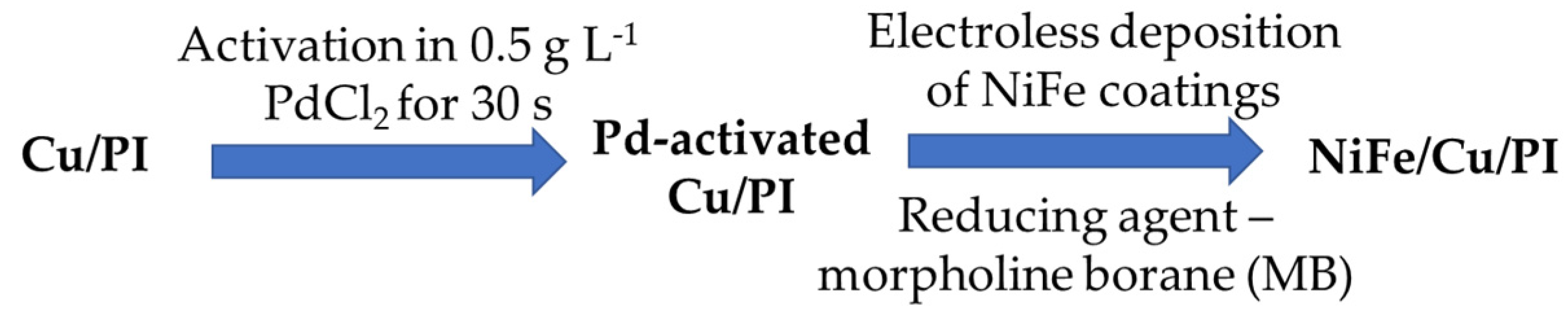

3.2. Electroless Plating of NiFe Coatings on Polyimide Coated with Cu Film

3.3. Characterization of Coatings

3.4. Electrochemical Measurements of HER and OER

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, Y.; Yao, J.; Wang, P.; Li, Z.; Zhou, H.; Xu, C. Perspective of hydrogen energy and recent progress in electrocatalytic water splitting. Chin. J. Chem. Eng. 2022, 43, 282–296. [Google Scholar] [CrossRef]

- Hota, P.; Das, A.; Maiti, D.K. A short review on generation of green fuel hydrogen through water splitting. Int. J. Hydrogen Energy 2023, 48, 523–541. [Google Scholar] [CrossRef]

- Elsapagh, R.M.; Sultan, N.S.; Mohamed, F.A.; Fahmy, H.M. The role of nanocatalysts in green hydrogen production and water splitting. Int. J. Hydrogen Energy 2024, 67, 62–82. [Google Scholar] [CrossRef]

- Solanki, R.; Patra, I.; Ahmad, N.; Kumar, N.B.; Parra, R.M.R.; Zaidi, M.; Yasin, G.; Kumar, T.Ch.A.; Hussein, H.A.; Sivaraman, R.; Majdi, H.Sh.; Alkadir, O.K.A.; Yaghobi, R. Investigation of recent progress in metal-based materials as catalysts toward electrochemical water splitting. J. Environ. Chem. Eng. 2022, 10, 108207. [Google Scholar] [CrossRef]

- Li, X.-P.; Huang, C.; Han, W.-K.; Ouyang, T.; Liu, Z.-Q. Transition metal-based electrocatalysts for overall water splitting. CCL 2021, 32, 2597–2616. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Ou, C.; Zhang, Y.; Wang, W.; Dong, S.; Dong, X. Transition metal-based self-supported anode for electrocatalytic water splitting at a large current density. Coord. Chem. Rev. 2023, 495, 215381. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, L.; Guo, S. Noble metal-free electrocatalytic materials for water splitting in alkaline electrolyte. EnergyChem 2021, 3, 100053. [Google Scholar] [CrossRef]

- Wang, X.; Yu, X.; Bai, J.; Yuan, G.; He, P.; Zhu, Y.; Wu, S.; Qin, F.; Ren, L. Interface engineering assisted Fe-Ni3S2/Ni2P heterostructure as a high-performance bifunctional electrocatalyst for OER and HER. Electrochim. Acta 2023, 458, 142524. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, C.; Ran, M.; Zheng, Y.; Li, C.; Jiang, Y.; Yan, X. Fe-doped promotes phosphorization and dispersibility of Ni catalysts for efficient and stable HER and OER. Int. J. Hydrogen Energy 2024, 63, 133–141. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Huang, H.; Deng, G.; Wang, J.; Chen, X.; Gao, T. Ammonia-assisted Ni particle preferential deposition in Ni-Fe pyrophosphates on iron foam to improve the catalytic performance for overall water splitting. J. Colloid Interf. Sci. 2024, 665, 573–581. [Google Scholar] [CrossRef]

- Xu, W.; Qiu, R.; Mao, X.; Yan, X.; Peng, B.; Shen, Y. One-step fabrication of amorphous Ni-Fe phosphated alloys as efficient bifunctional electrocatalysts for overall water splitting. J. Non-Cryst. Solids 2022, 587, 121598. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Gao, J.; Jin, W.; Xiao, W.; Xin, L.; Xiao, Z.; Xu, G.; Dai, C.; Zhang, H.; Wu, Z.; Wang, L. Anionic phosphorous and sulfur regulate self-supported Ni-Fe-based electrocatalyst for water-splitting under large current density. Fuel 2024, 367, 131445. [Google Scholar] [CrossRef]

- Han, P.; Tan, T.; Wu, F.; Cai, P.; Cheng, G.; Luo, W. Nickel-iron borate coated nickel-iron boride hybrid for highly stable and active oxygen evolution electrocatalysis. CCL 2020, 31, 2469–2472. [Google Scholar] [CrossRef]

- Dai, Z.; Du, X.; Zhang, X. The synthesis of Ni-Co-Fe-Se@NiCo-LDH nanoarrays on Ni foam as efficient overall water splitting electrocatalyst. J. Alloys Compd. 2023, 946, 169451. [Google Scholar] [CrossRef]

- Shi, Y.; Li, C.; Tu, Y.; Jiang, Y.; Xiao, W.; Zhu, S.; Lv, P.; Yan, X. Surface reconstruction of Fe doping NiC2O4 by the electrocatalytic reaction to improve the performance of overall water splitting. Ceram. Int. 2024, 50, 36340–36348. [Google Scholar] [CrossRef]

- Lu, P.; Zhao, H.; Jiang, X.; Yang, L.; Xie, G.; Xie, T.; Jiang, L. Electroless deposition synthesis of composite catalysts Ni-Fe-P-Ni(OH)2/NF with superior overall water splitting performance. J. Environ. Chem. Eng. 2024, 12, 114039. [Google Scholar] [CrossRef]

- Zeng, L.; Yang, L.; Lu, J.; Jia, J.; Yu, J.; Deng, Y.; Shao, M.; Zhou, W. One-step synthesis of Fe-Ni hydroxide nanosheets derived from bimetallic foam for efficient electrocatalytic oxygen evolution and overall water splitting. CCL 2018, 29, 1875–1878. [Google Scholar] [CrossRef]

- Xiao, M.; Jiao, L.; Xiang, D.; Gao, P.; Fu, J.; Naseri, A.; Huang, S. Synergistic electronic structure tuning of self-assembled hollow hierarchical Ni-Fe-Co-P nanowire arrays on carbon cloth for enhanced water splitting. J. Alloys Compd. 2023, 968, 171883. [Google Scholar] [CrossRef]

- Shao, S.; Li, X.; Guo, R.; Wang, J.; Sheng, M. Ni-Fe-P nanoparticles encapsulated in carbon nanotubes supported on carbon cloth for overall water splitting. Mater. Lett. 2023, 352, 135204. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, S.C.; Park, G.; Seol, J.H.; Lim, D.; Choi, S.; Jo, C.; Baeck, S.H.; Lim, J.; Lee, S. U.; Park, S. Atomic-level insights into bioinspired Fe/Ni bimetallic active sites on carbon nitrides for electrocatalytic O2 evolution. J. Chem. Eng. 2024, 85, 149799. [Google Scholar] [CrossRef]

- Kalusulingam, R.; Ravi, K.; Mathi, S.; Yadhav, N.; Mikheykin, A.S.; Biradar, A.V.; Srinivasan, K.; Myasoedova, T.N. Bimetallic Ni–Fe nanoparticles encapsulated with biomass-derived N-doped graphitic carbon core-shell nanostructures an efficient bifunctional electrocatalyst for enhanced overall seawater splitting and human urine electrolysis. Mater. Today Sustain. 2024, 27, 100864. [Google Scholar] [CrossRef]

- Abdelrahim, A.M.; El-Moghny, M.G.A.; El-Deab, M.S. Interface construction of Ni(OH)2/Fe3O4 heterostructure decorating in-situ defected graphite felt for enhanced overall water splitting. Int. J. Hydrogen Energy 2024, 81, 173–186. [Google Scholar] [CrossRef]

- Kim, T.; Lee, J.; Kim, N.; Lee, S.; Gu, M.; Kim, B.-S. Redox-active polyimides for energy conversion and storage: from synthesis to application. Chem. Com. 2023, 59, 153–169. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, T.; Wang, C. An advanced flower-like Co-Ni/PI-CNT film electrocatalyst for oxygen evolution reaction. J. Alloys Compd. 2017, 729, 19–26. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, J.; Zhang, S.; Liu, Y.; Ye, J.; Fan, W.; Debroye, E.; Liu, T. Atomically dispersed iridium on polyimide support for acidic oxygen evolution. ACS Nano 2024, 18, 22095–22103. [Google Scholar] [CrossRef]

- Wang, T.; Li, X.; Jiang, Y.; Zhou, Y.; Jia, L.; Wang, C. Reduced graphene oxide-polyimide/carbon nanotube film decorated with NiSe nanoparticles for electrocatalytic hydrogen evolution reactions. Electrochim. Acta 2017, 243, 291–298. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, C.; He, X.; White, T.; D. Demaree, J.; Griep, M.; Lina, J. Monolithic electrochemical cells for overall water splitting. J. Power Sources 2018, 397, 37–43. [Google Scholar] [CrossRef]

- McGovern, M.S.; Garnett, E.C.; Rice, C.; Masel, R.I. , Wieckowski, A. Effects of Nafion as a binding agent for unsupported nanoparticle catalysts. J. Power Sources 2003, 115, 35–39. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Antwi-Afari, M.F.; Mi, H.-Y.; Liu, C. A state-of-the-art review of polyimide foams research. Constr. Build. Mater. 2024, 437, 136961. [Google Scholar] [CrossRef]

- Zhu, G.X.; Lu, T.L.; Han, L.; Zhan, Y.Z. Graphitic carbon nitride (g–C3N4) as an efficient metal-free Fenton-like catalyst for degrading organic pollutants: The overlooked non-photocatalytic activity. Water Sci. Technol. 2020, 81, 518–528. [Google Scholar] [CrossRef]

- Zahra, R.; Pervaiz, E.; Baig, M.M.; Rabi, O. Three-dimensional hierarchical flowers-like cobalt-nickel sulfide constructed on graphitic carbon nitride: Bifunctional non-noble electrocatalyst for overall water splitting. Electrochim. Acta 2022, 418, 140346. [Google Scholar] [CrossRef]

- Bian, H.; Chen, T.; Chen, Z.; Liu, J.; Li, Z.; Du, P.; Zhou, B.; Zeng, X.; Tang, J.; Liu, C. One-step synthesis of mesoporous cobalt sulfides (CoSx) on the metal substrate as an efficient bifunctional electrode for overall water splitting. Electrochim. Acta 2021, 389, 138786. [Google Scholar] [CrossRef]

- Ejeta, S.Y.; Imae, T. Cobalt incorporated graphitic carbon nitride as a bifunctional catalyst for electrochemical water-splitting reactions in acidic media. Molecules 2022, 27, 6445. [Google Scholar] [CrossRef] [PubMed]

- Trotochaud, L.; Ranney, J.K.; Williams, K.N.; Boettcher, S.W. Solution-cast metal oxide thin film electrocatalysts for oxygen evolution. J. Am. Chem. Soc. 2012, 134, 17253–17261. [Google Scholar] [CrossRef] [PubMed]

- Ganguly, A.; McGlynn, R.J.; Boies, A.; Maguire, P.; Mariotti, D.; Chakrabarti, S. Flexible bifunctional electrode for alkaline water splitting with long-term stability. ACS Appl. Mater. Interf. 2024, 16, 12339–12352. [Google Scholar] [CrossRef] [PubMed]

- Jiao, L.; Zhou, Y.X.; Jiang, H.L. Metal–organic framework-based CoP/reduced graphene oxide: high-performance bifunctional electrocatalyst for overall water splitting. Chem. Sci. 2016, 7, 1690–1695. [Google Scholar] [CrossRef]

- Naruškevičius, L.; Tamašauskaitė-Tamašiūnaitė, L.; Žielienė, A.; Jasulaitienė, V. A Co-based surface activator for electroless copper deposition. Surf. Coat. Technol. 2012, 206, 2967–2971. [Google Scholar] [CrossRef]

- Hyman, M.; Naruškevičius, L.; Budilovskis, D. US10920321B2 (2021-02-16).

- Zhou, T.; Cao, Z.; Zhang, P.; Ma, H.; Gao, Z.; Wang, H.; Lu, Y.; He, J.; Zhao, Y. Transition metal ions regulated oxygen evolution reaction performance of Ni-based hydroxides hierarchical nanoarrays. Scientific Reports 2017, 7, 46154. [Google Scholar] [CrossRef]

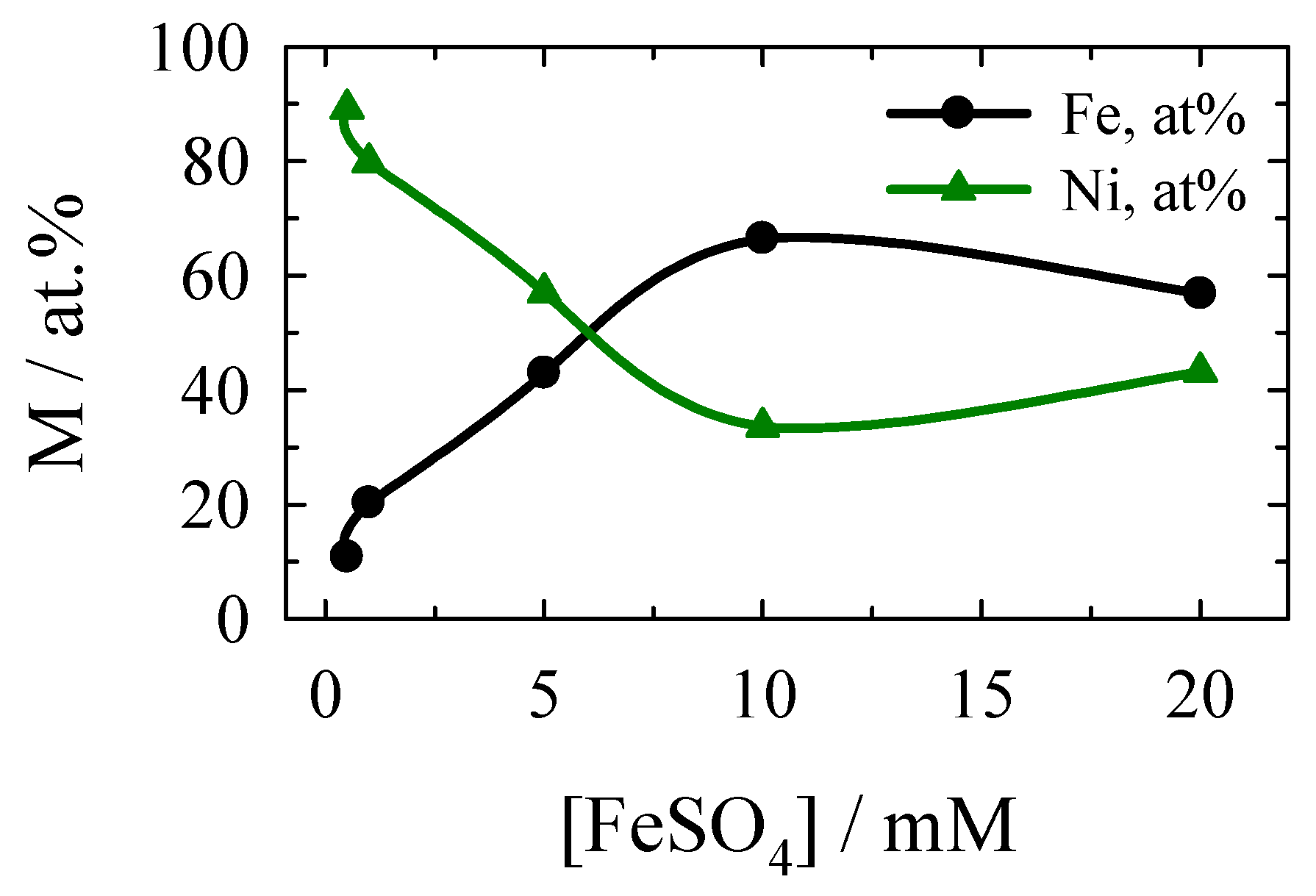

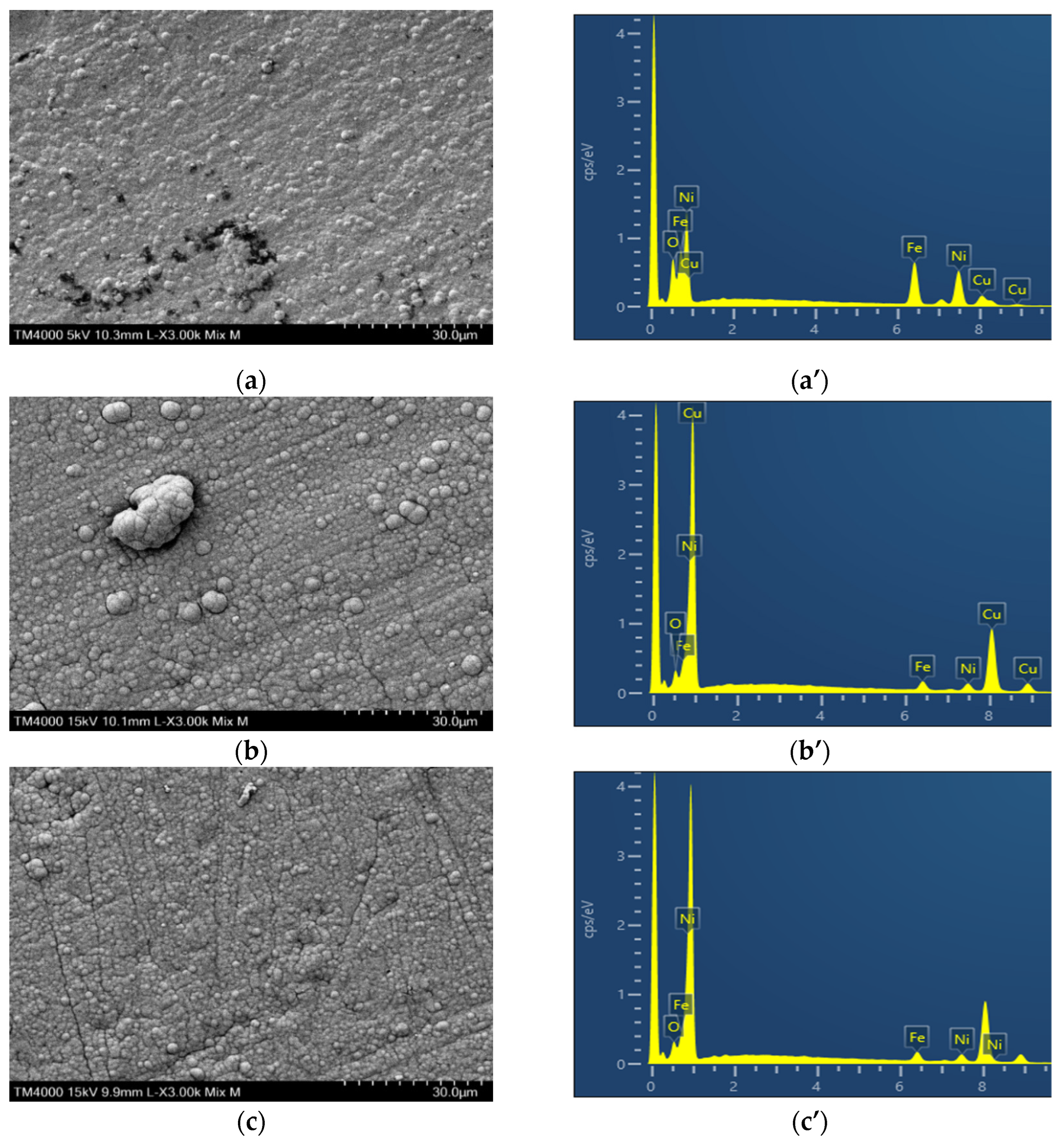

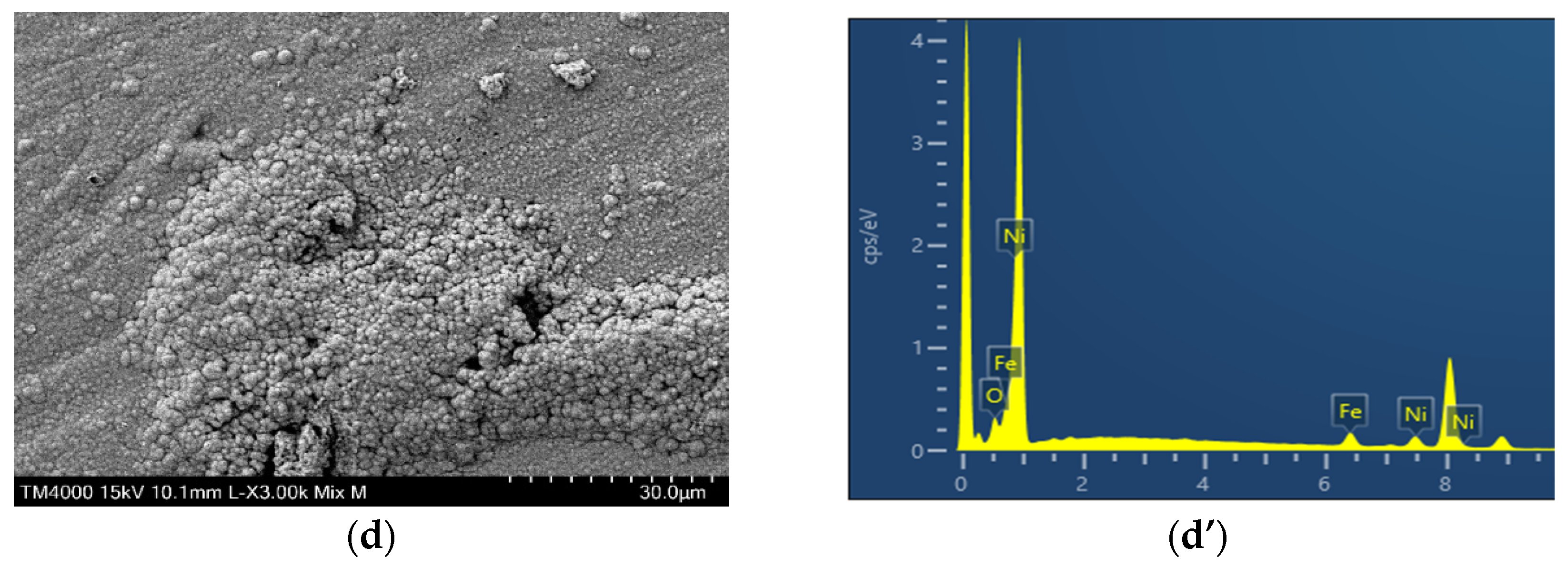

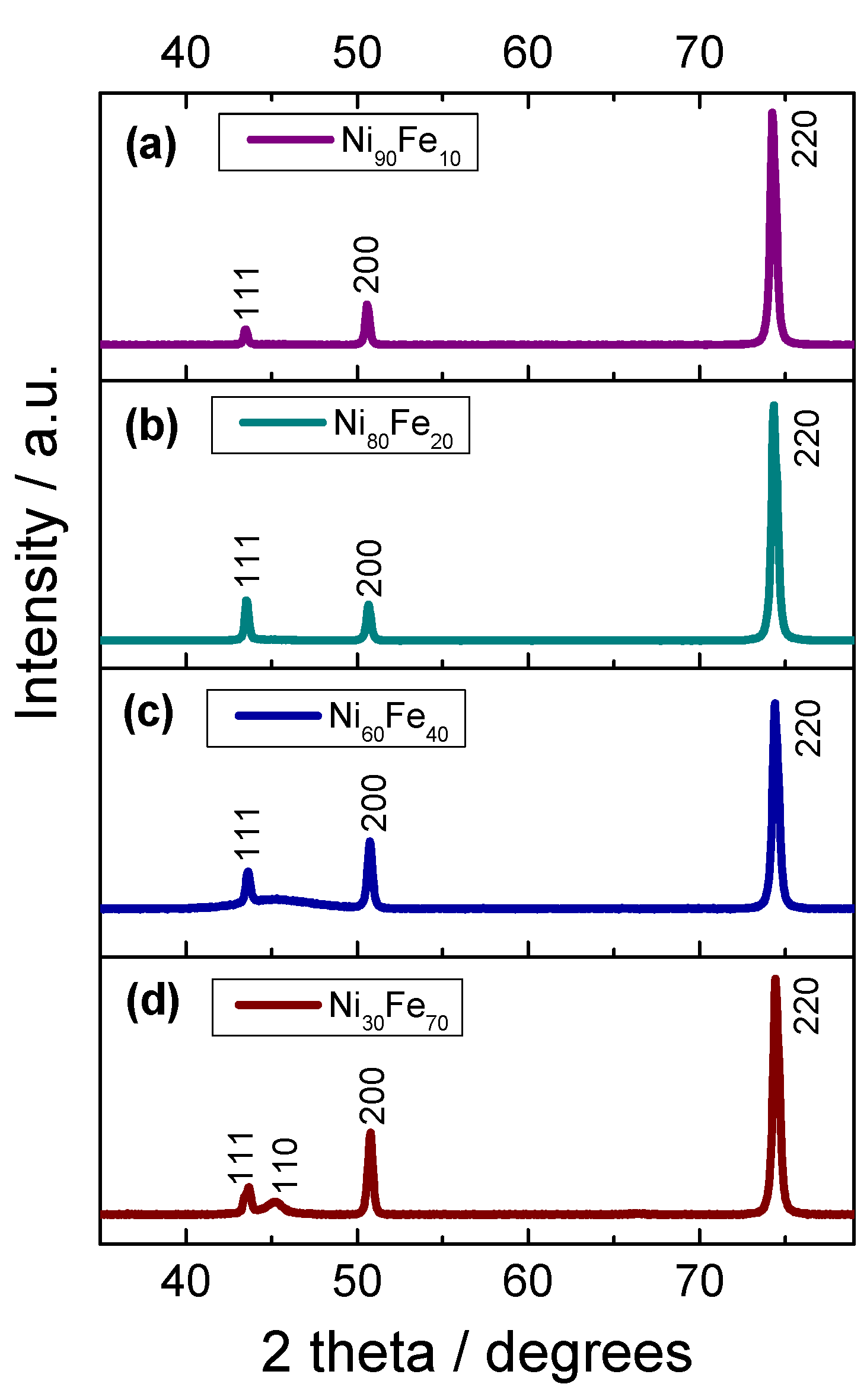

| Sample | Metal loading in the coatings, mg cm−2 |

Element, at. % | Coating denoted as | |||

|---|---|---|---|---|---|---|

| Ni | Fe | Ni+Fe | Ni | Fe | ||

| No. 1 | 0.4805 | 0.9060 | 1.3865 | 34.60 | 65.30 | Ni30Fe70 |

| No. 2 | 0.6305 | 0.4521 | 1.0826 | 58.24 | 41.76 | Ni60Fe40 |

| No. 3 | 2.9040 | 0.6995 | 3.6035 | 80.60 | 19.40 | Ni80Fe20 |

| No. 4 | 2.3400 | 0.2695 | 2.6095 | 89.70 | 10.30 | Ni90Fe10 |

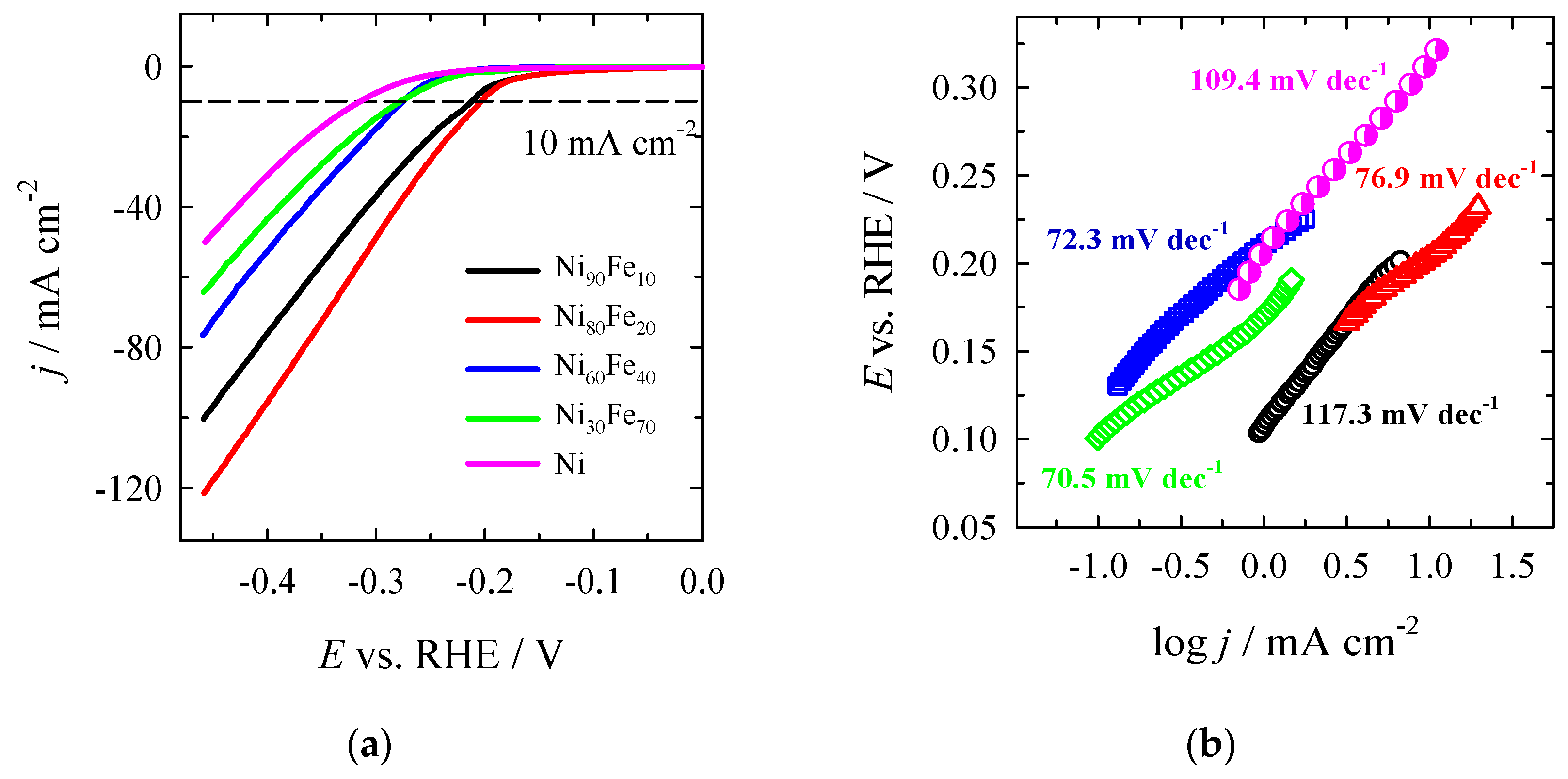

| Sample |

Eonset, V at j = −1 mA cm−2 |

η10*, mV | Tafel slope, mV dec−1 |

|---|---|---|---|

| Ni | −0.1722 | −303.4 | 109.4 |

| Ni90Fe10 | −0.1081 | −211.9 | 117.3 |

| Ni80Fe20 | −0.0928 | −202.7 | 76.9 |

| Ni60Fe40 | −0.2113 | −276.3 | 72.3 |

| Ni30Fe70 | −0.1710 | −278.4 | 70.5 |

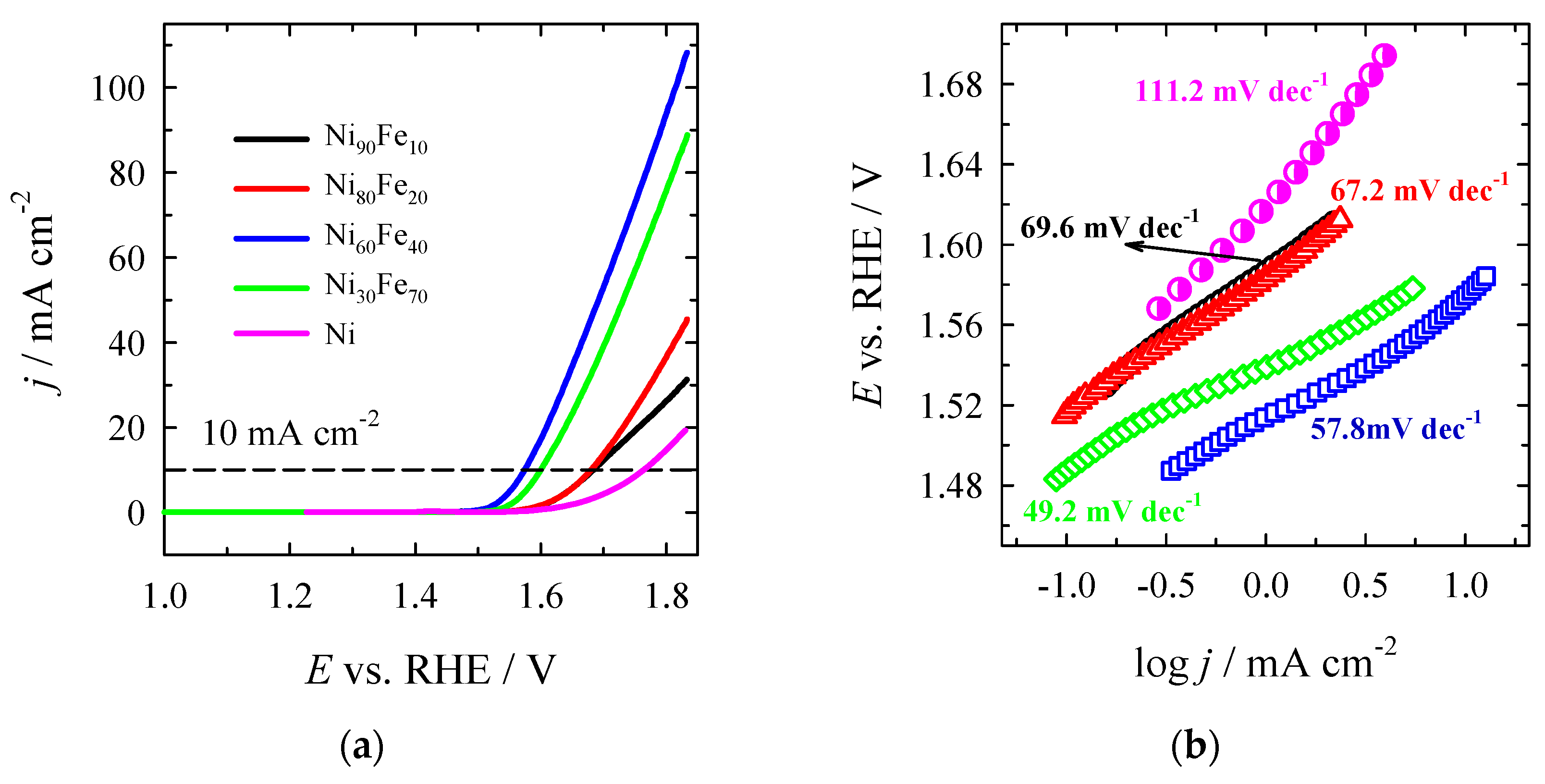

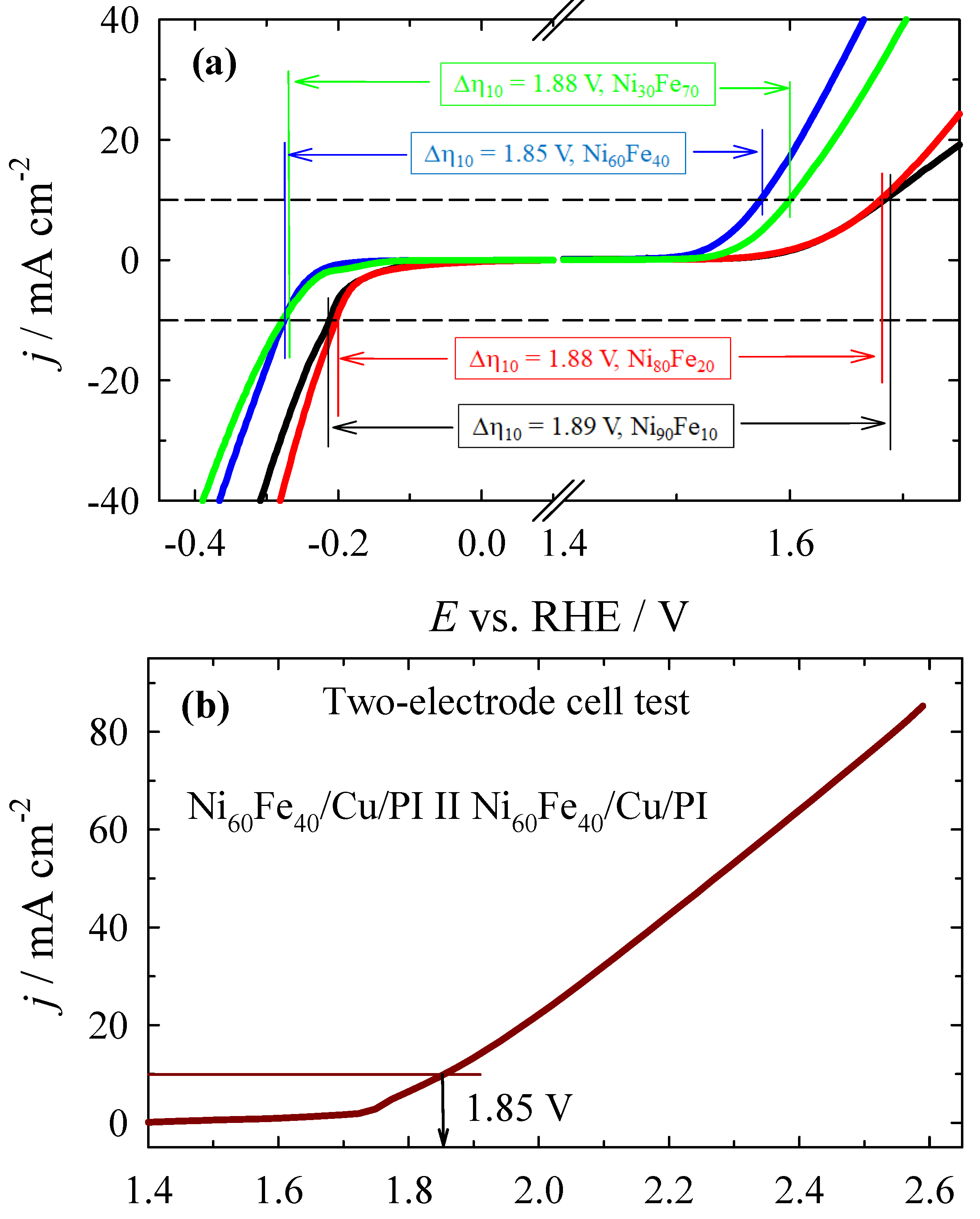

| Sample | Eonset, V at j = 1 mA cm−2 | ηonset, mV | E, V at j = 10 mA cm−2 | η10*, mV | Tafel slope, mV dec−1 |

| Ni | 1.6163 | 386.3 | 1.7621 | 532.1 | 111.2 |

| Ni90Fe10 | 1.5868 | 356.8 | 1.6842 | 454.2 | 69.6 |

| Ni80Fe20 | 1.5829 | 352.9 | 1.6802 | 450.2 | 67.2 |

| Ni60Fe40 | 1.5162 | 286.2 | 1.5747 | 344.7 | 57.8 |

| Ni30Fe70 | 1.5390 | 309.0 | 1.5999 | 369.9 | 49.2 |

| Sample | Composition of plating solution, M | Plating conditions | |||||||

| NiSO4 | MB | NH2CH2COOH | FeSO4 | EDTA | CH2(COONa)2 | pH | T, oC | t, min | |

| No. 1 | 0.14 | 0.2 | 0.2 | 0.01 | 0.05 | 0.1 | 7 | 60 | 60 |

| No. 2 | 0.005 | ||||||||

| No. 3 | 0.001 | ||||||||

| No.4 | 0.0005 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).