Submitted:

07 November 2024

Posted:

07 November 2024

You are already at the latest version

Abstract

Keywords:

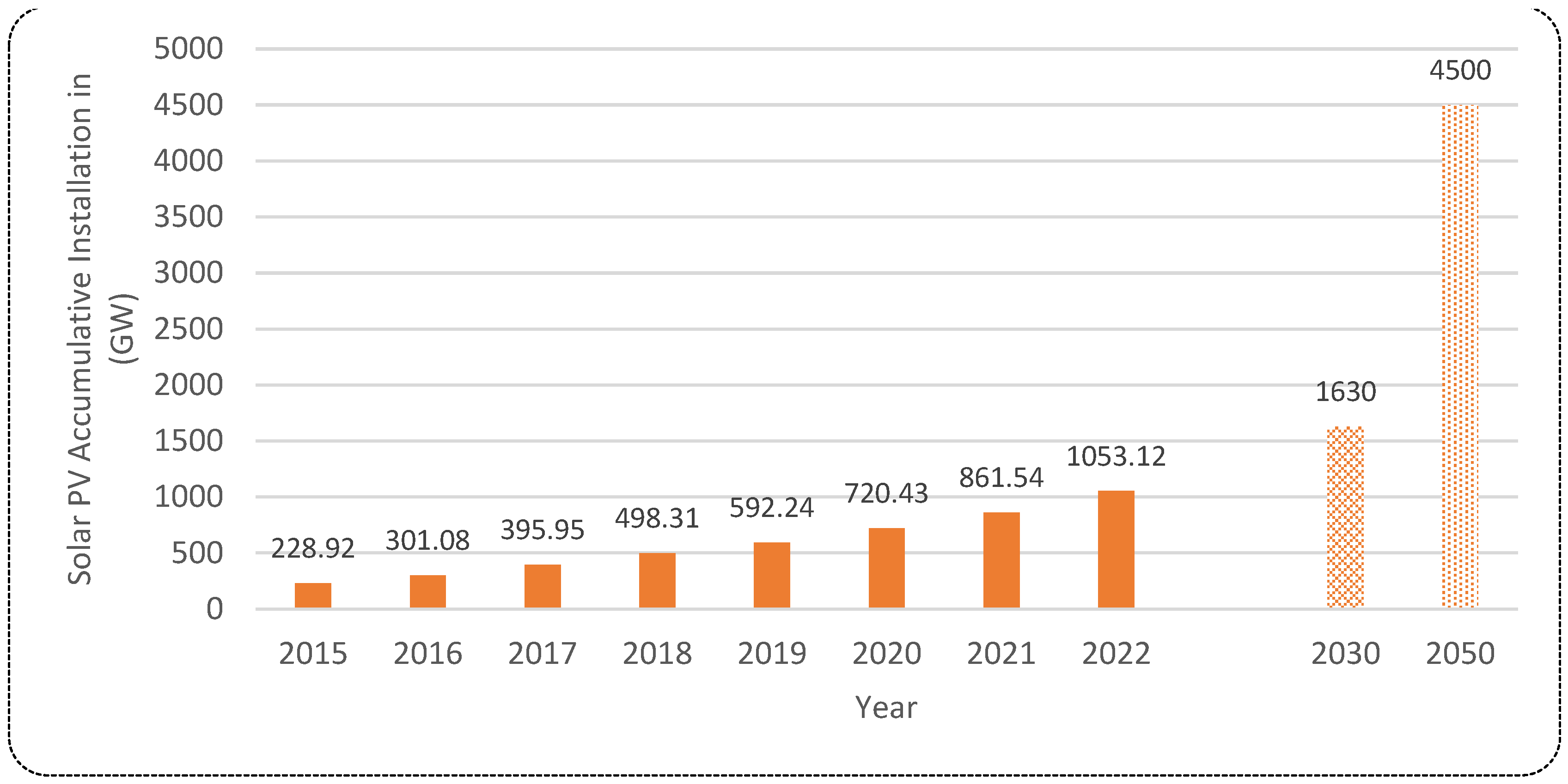

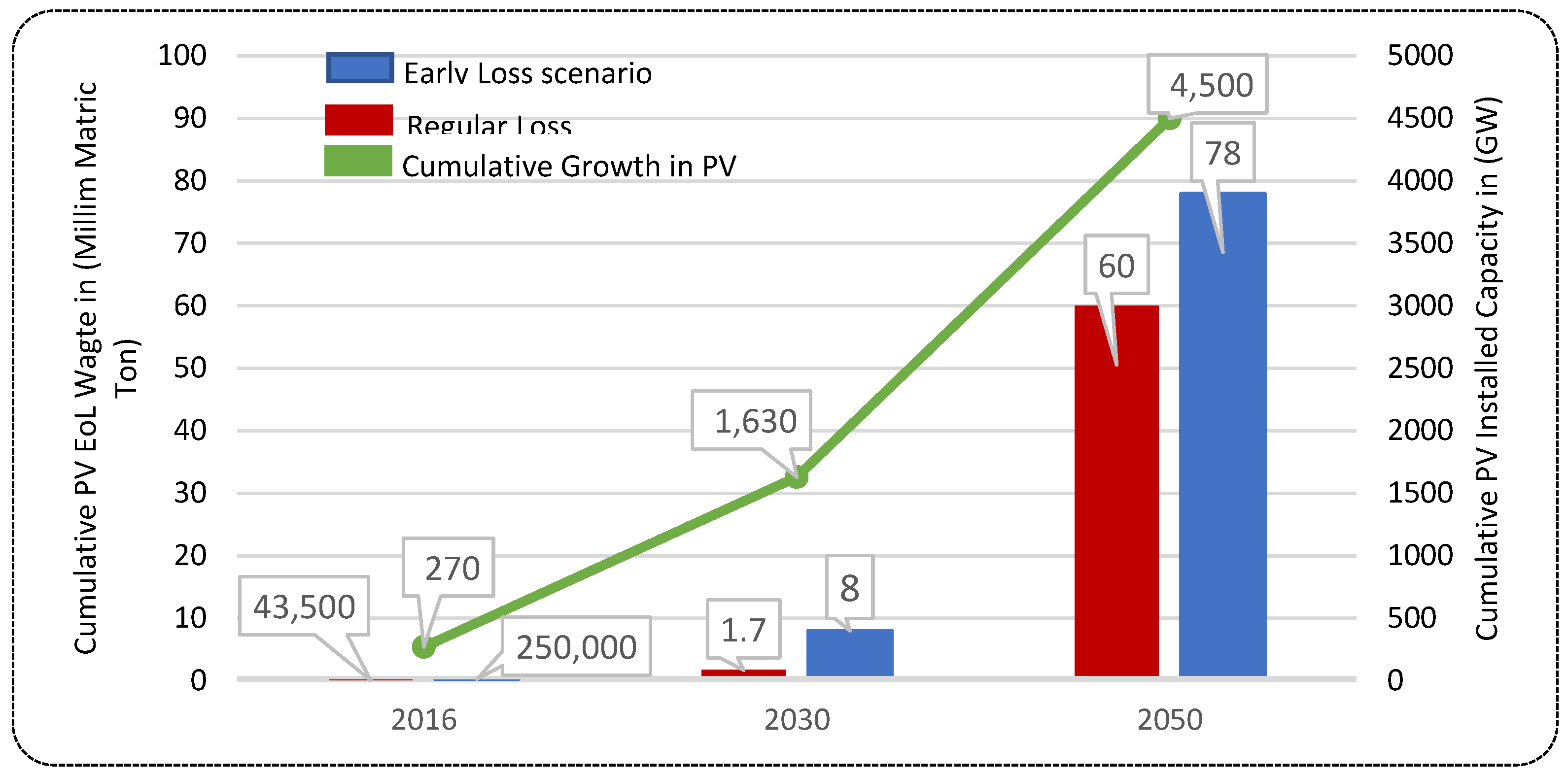

1. Introduction

- Standard Loss Scenario: This scenario predicts that PV panels will gradually degrade in efficiency over a typical lifespan of 25 to 30 years. As the panels age, their energy output declines progressively, eventually falling below the threshold for viable operational use. End-of-life options in this scenario include the decommissioning and disposal of the panels, with an emphasis on recycling to reclaim valuable components such as silicon and silver while preventing environmental contamination.

- Early Loss Scenario: This scenario addresses premature failures and significant efficiency reductions before panels reach their expected lifespan, classified into 'infant,' 'mid-life,' and 'wear-out' stages.

- ▪

- Infant failures occur typically within the first four years, with the most common within two years of installation.

- ▪

- Mid-life failures are generally observed between the fifth and eleventh years.

- ▪

- Wear-out failures appear from the twelfth year onwards, leading up to the projected end-of-life at 30 years.

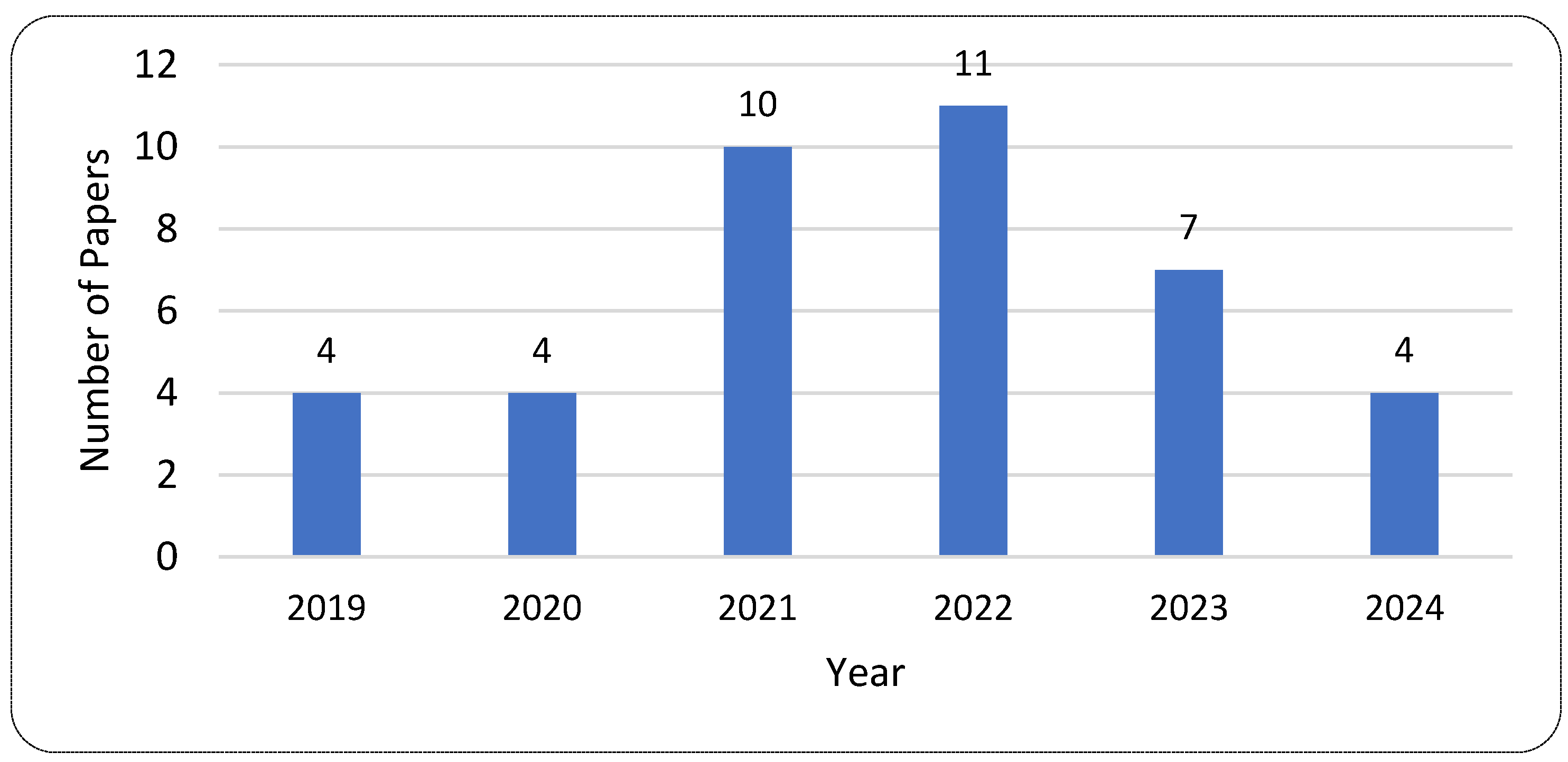

2. Literature Survey

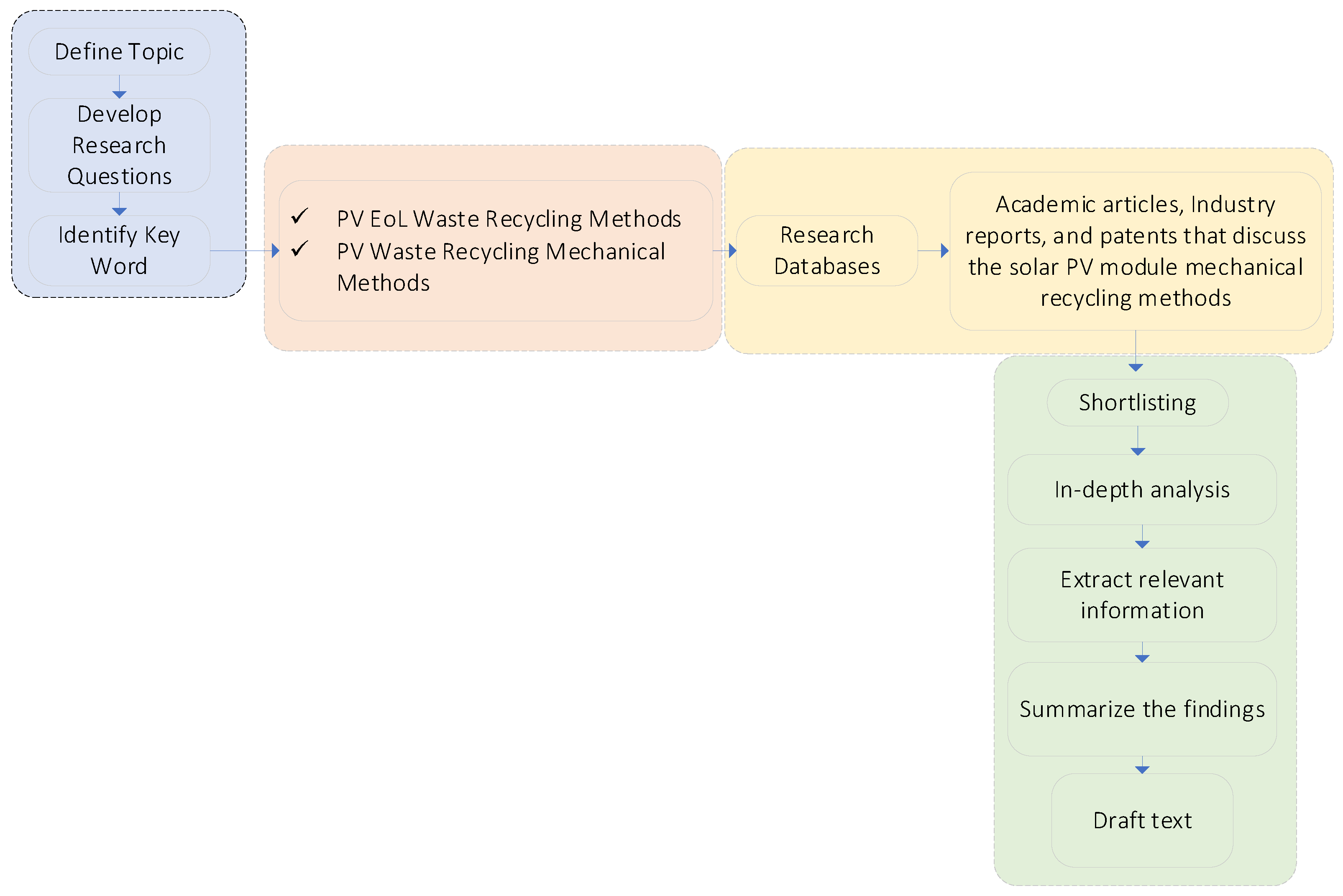

3. Research Methodology

- ▪

- What are the current mechanical recycling methods available for PV EoL waste?

- ▪

- How effective are these mechanical methods in recycling PV modules?

- ▪

- What are the benefits and limitations of each method?

- ▪

- PV EoL Waste Recycling Methods

- ▪

- PV Waste Recycling Mechanical Methods

- ▪

- Academic Articles: Peer-reviewed papers that discuss mechanical recycling methods for PV modules.

- ▪

- Industry Reports: Documents from industry stakeholders that provide insights into practical applications and the effectiveness of recycling methods.

- ▪

- Patents: Information on patented technologies and innovations in mechanical recycling of PV waste.

- ▪

- Google Scholar

- ▪

- ScienceDirect

- ▪

- IEEE Xplore

- ▪

- Scopus

- 6. Shortlisting Relevant Sources

- ▪

- The collected literature is then shortlisted based on relevance to the research questions. Criteria for shortlisting include:

- ▪

- Direct discussion on mechanical recycling methods for PV modules.

- ▪

- Recent publications to ensure up-to-date information.

- ▪

- Sources that provide empirical data and detailed descriptions of recycling processes.

- 7. In-depth Analysis involves:

- ▪

- Evaluating the effectiveness of different mechanical recycling methods.

- ▪

- Analyzing the processes, technologies, and outcomes reported in the literature.

- ▪

- Comparing the benefits and limitations of each method.

- 8. Extraction of Relevant Information focusing on:

- ▪

- Descriptions of mechanical recycling techniques.

- ▪

- Performance metrics and results from practical implementations.

- ▪

- Comparative analysis of different methods.

- 9. Summarizing the Findings

- ▪

- The extracted information is summarized to provide a clear and concise overview of the current state of mechanical recycling methods for PV EoL waste. This summary highlights:

- ▪

- The most commonly used methods.

- ▪

- Innovations and advancements in the field.

- ▪

- Gaps and challenges that need further research.

- 10. Drafting the Research Article

- ▪

- Based on the summarized findings, the research article is drafted.

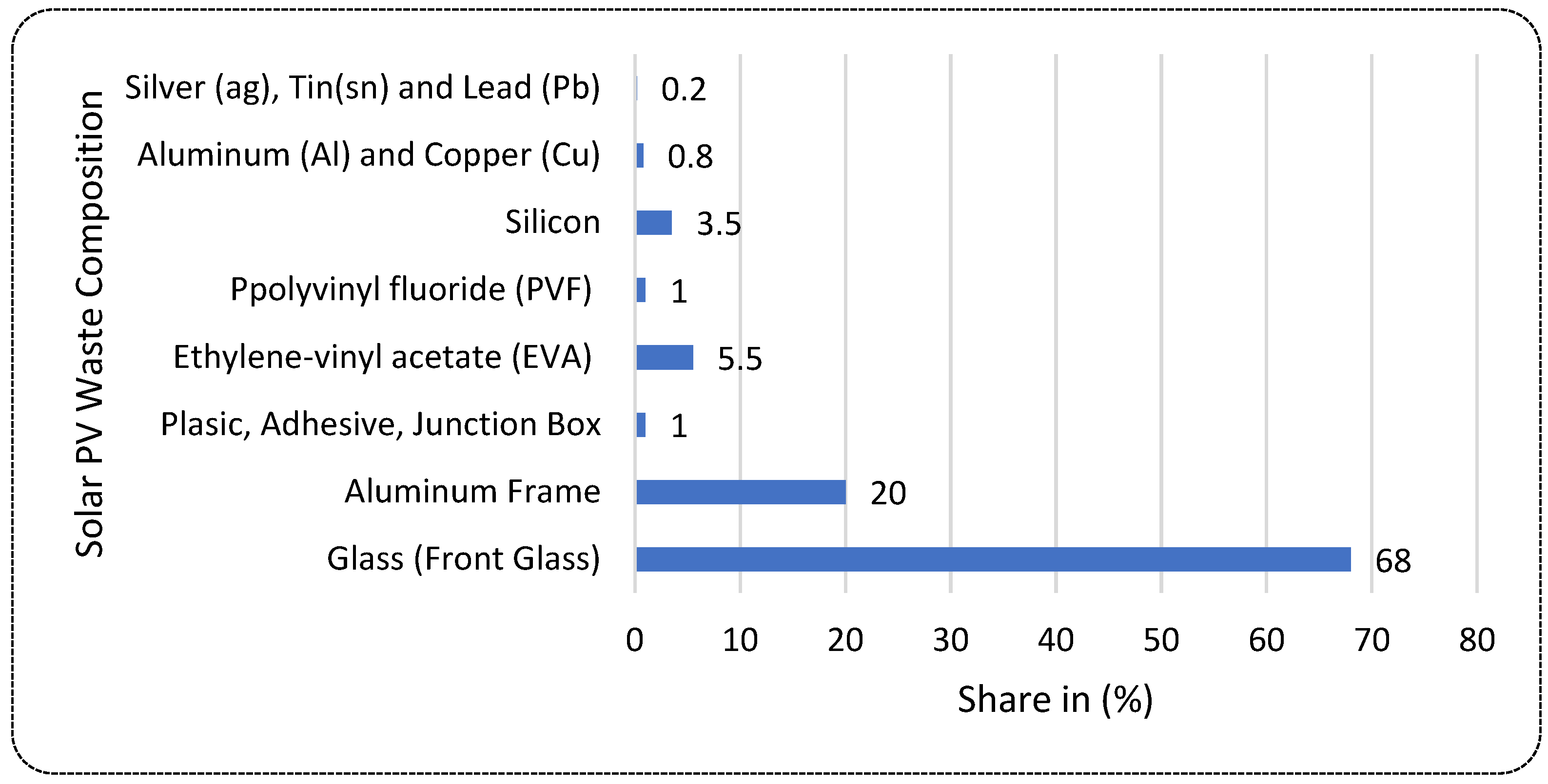

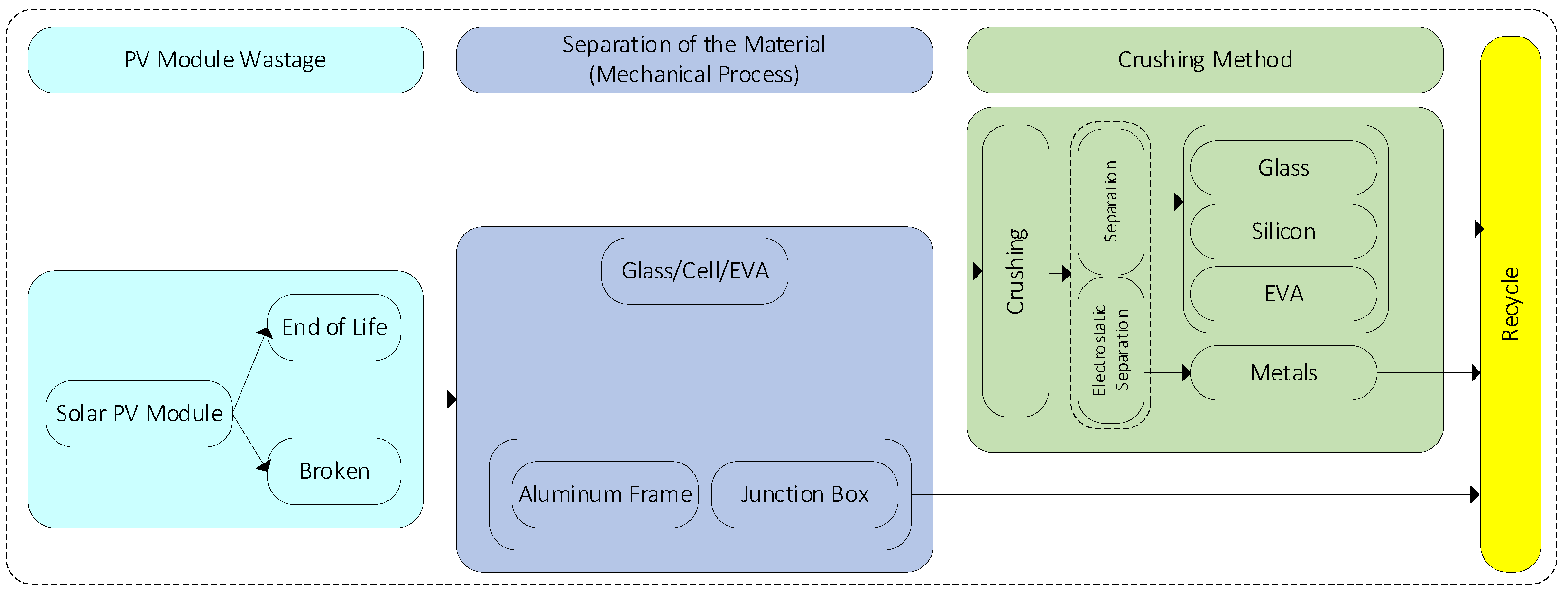

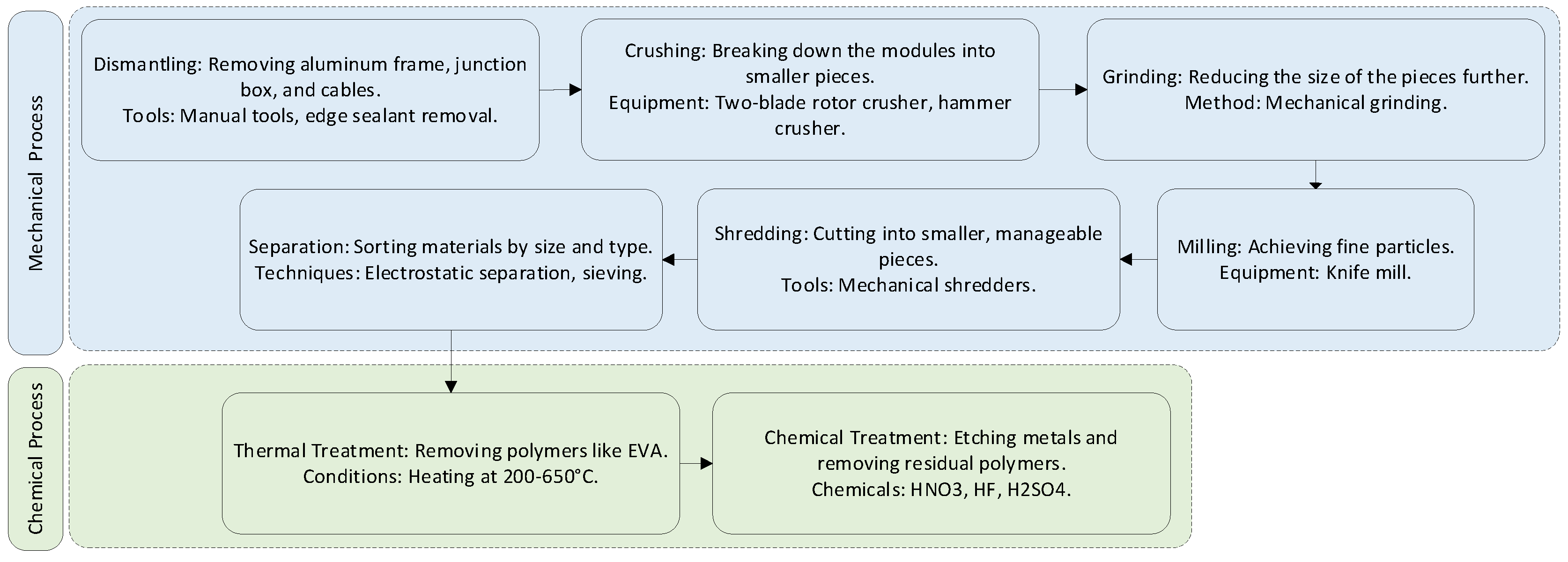

4. Mechanical Recycling Process

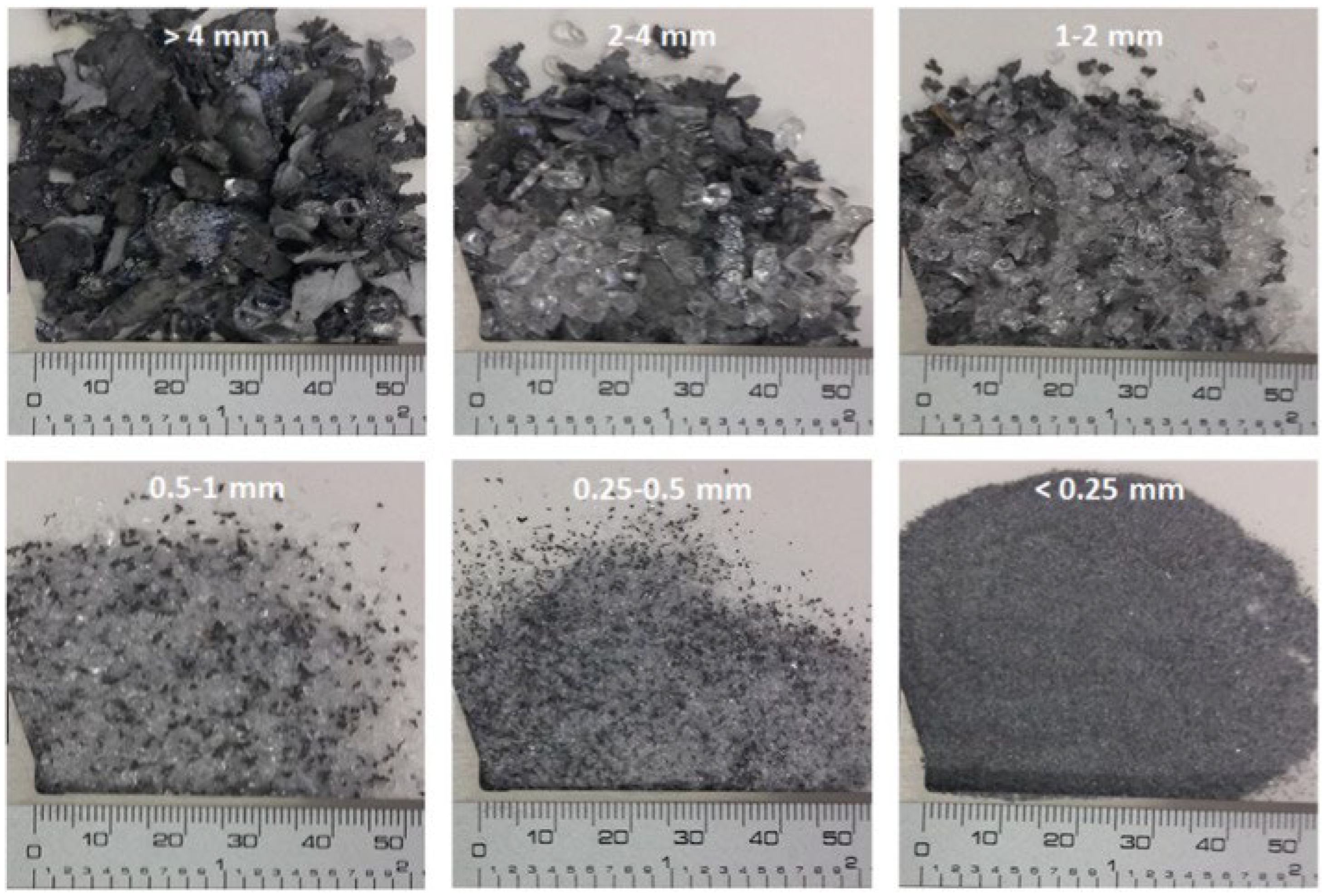

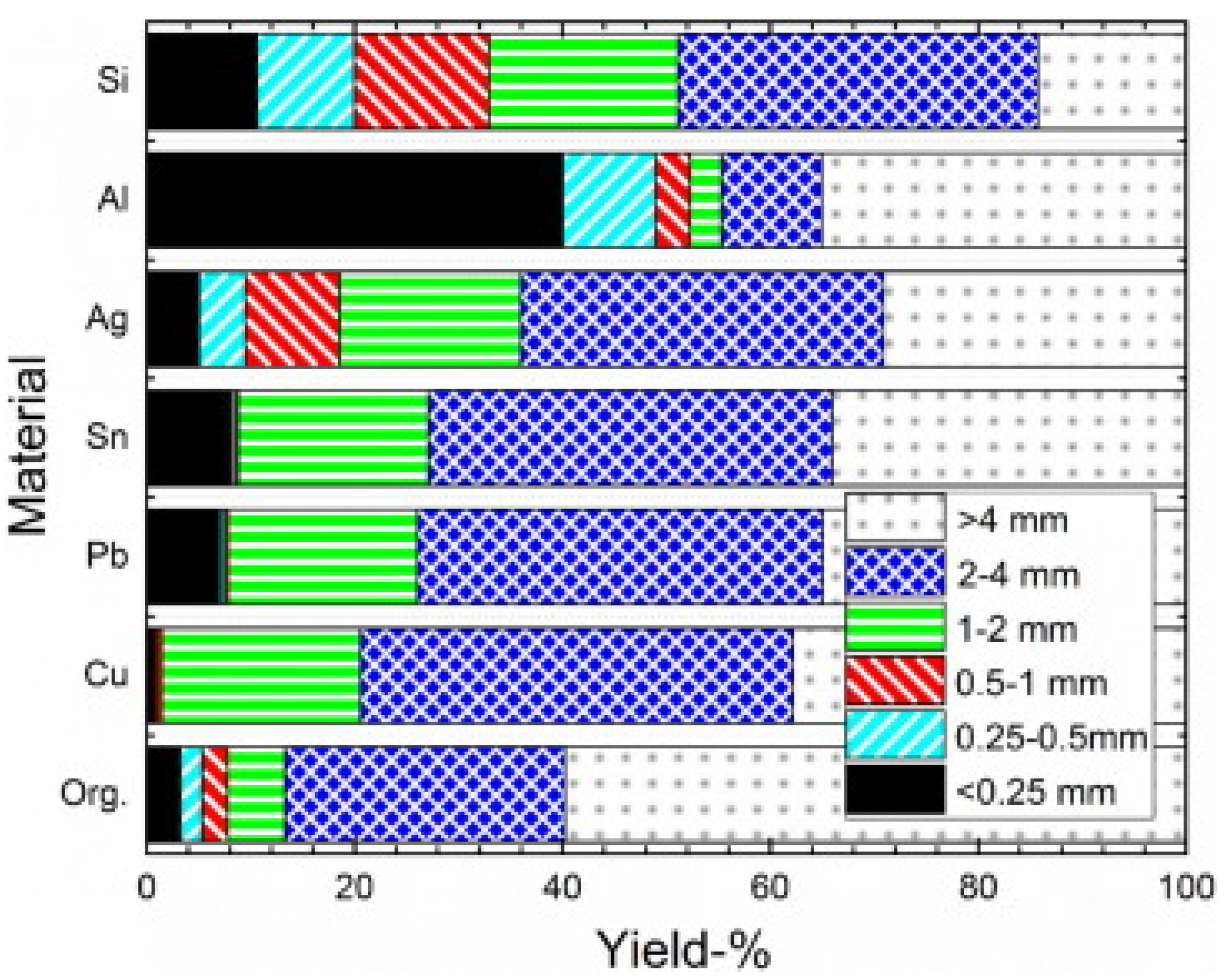

4.1. Crushing

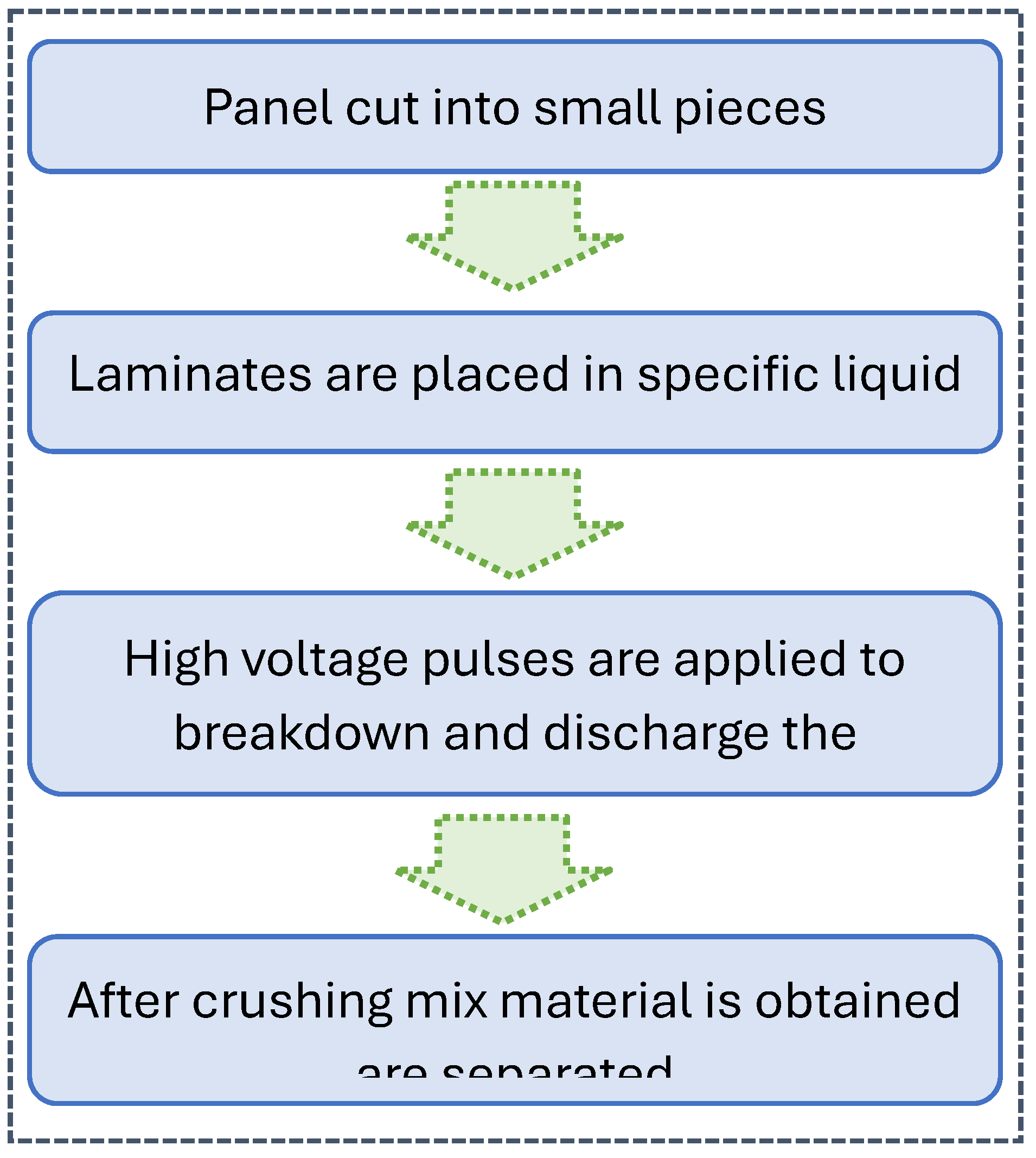

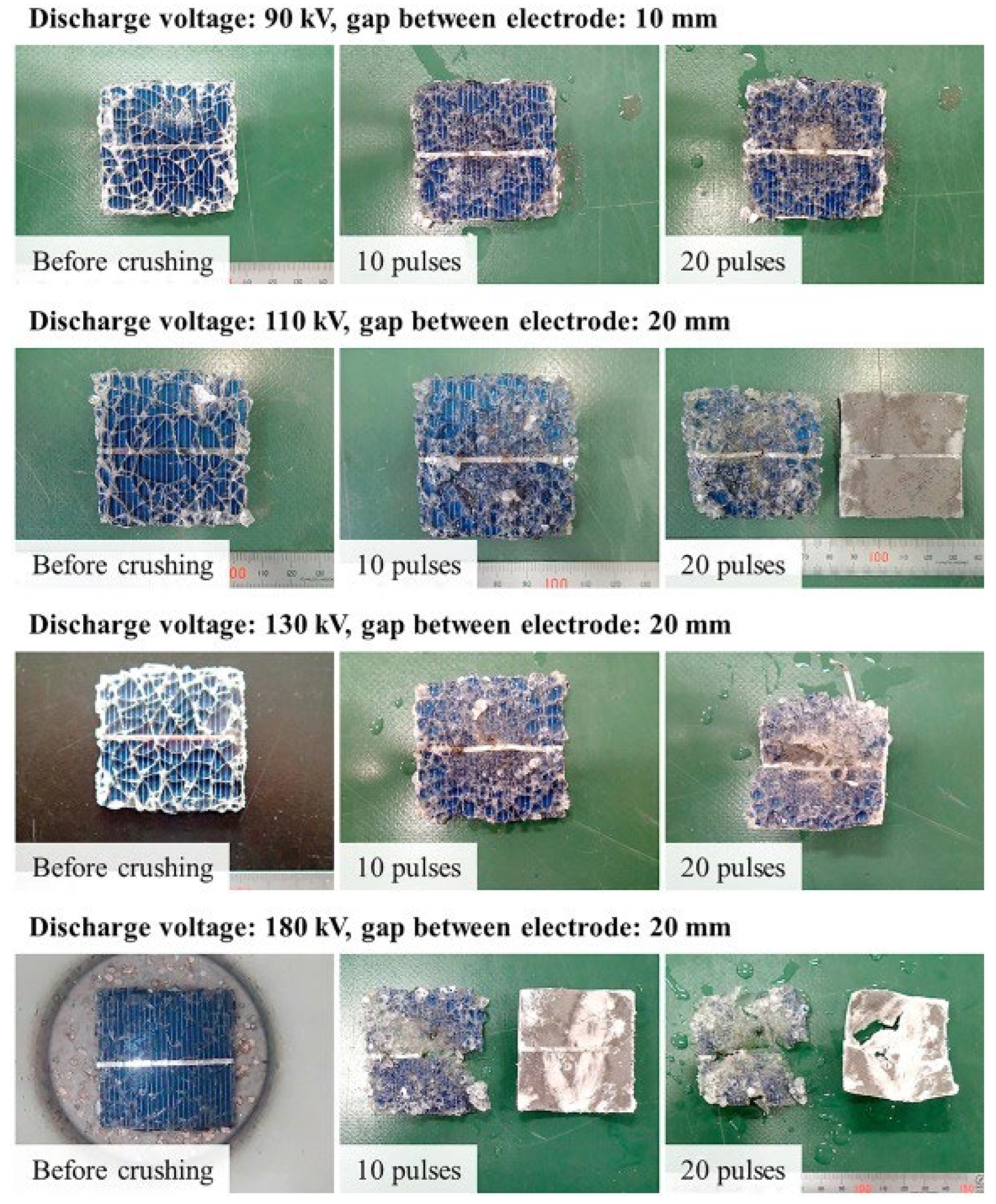

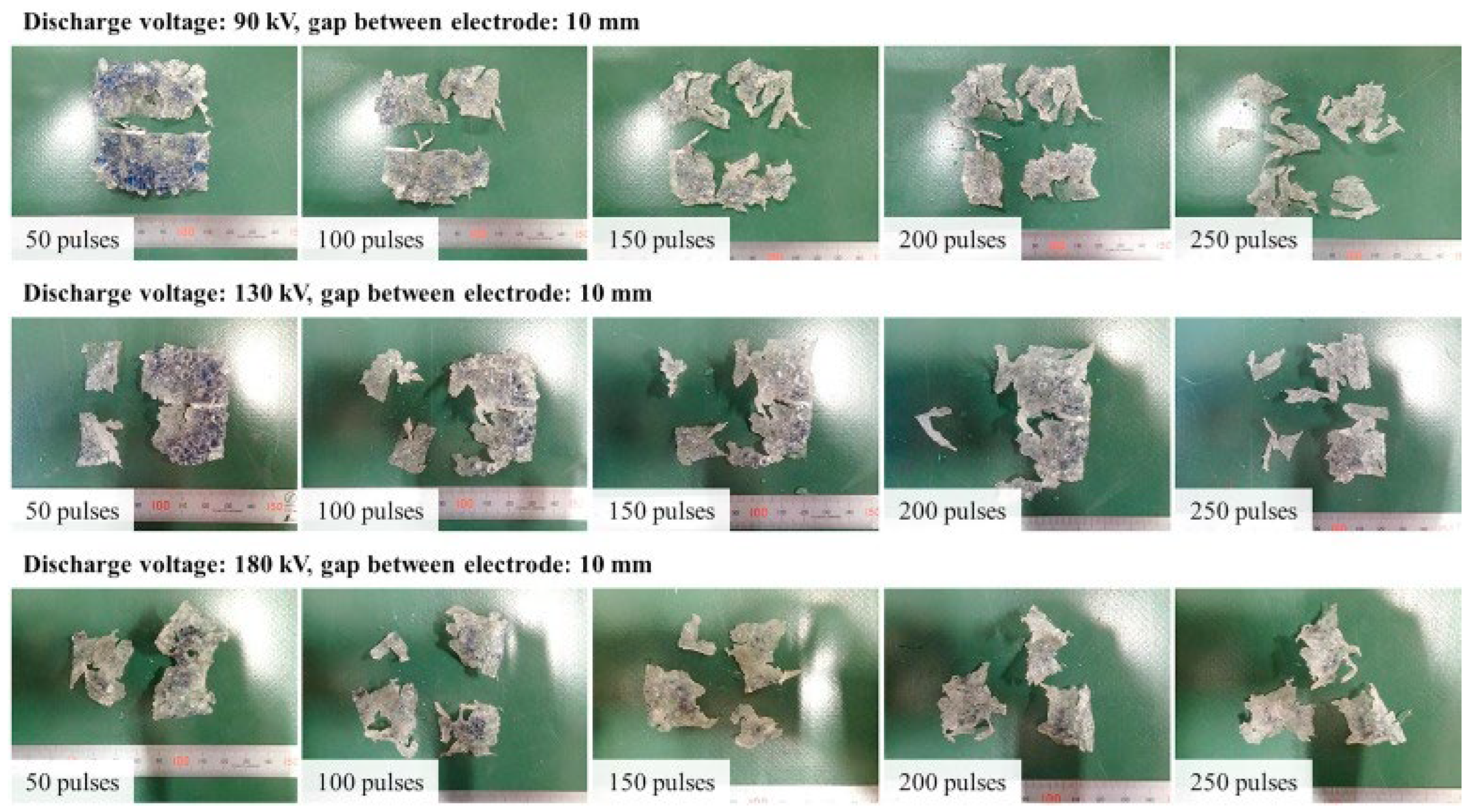

4.2. High Voltage Pulse Crushing (HVPC)

4.2.1. Primary Crushing Step

4.2.2. Secondary Crushing Step

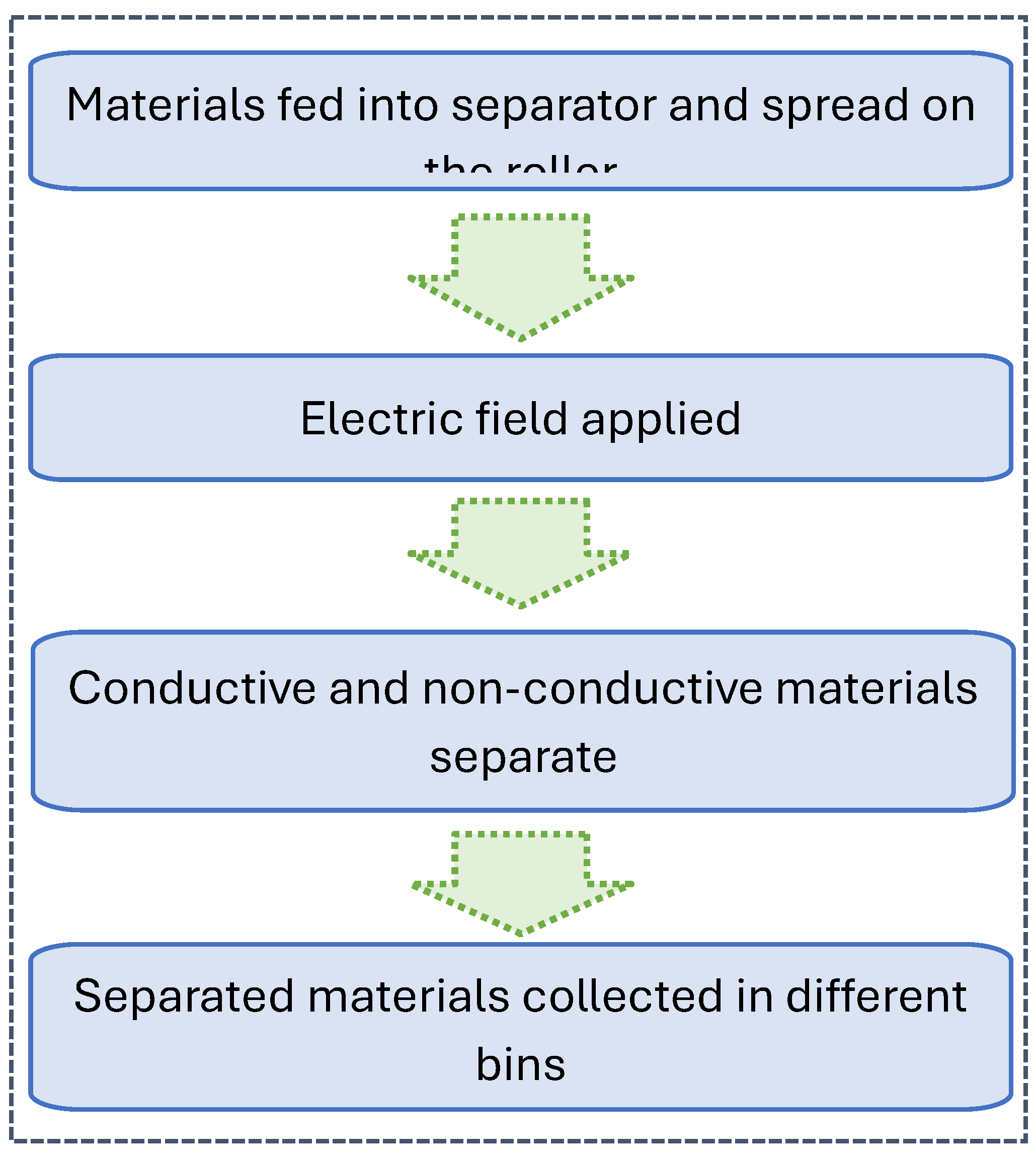

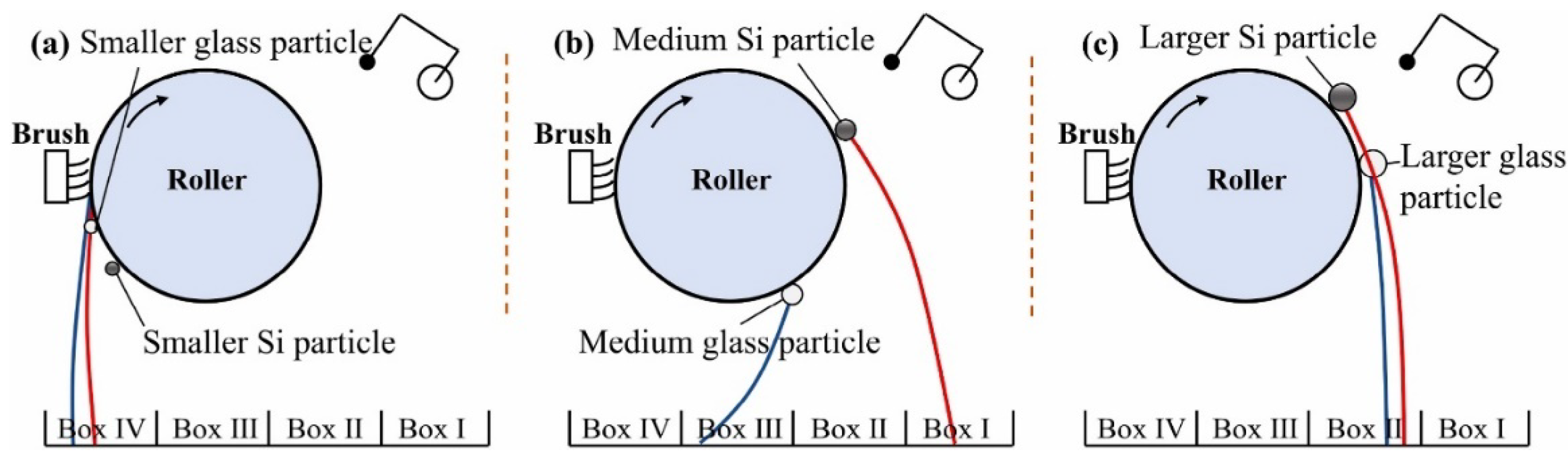

4.3. Electrostatic Separation (ESS)

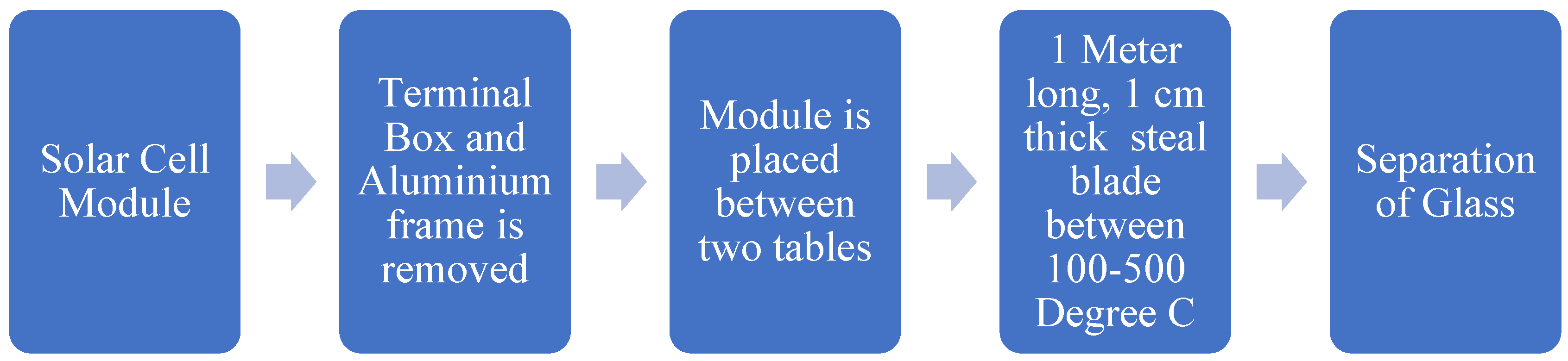

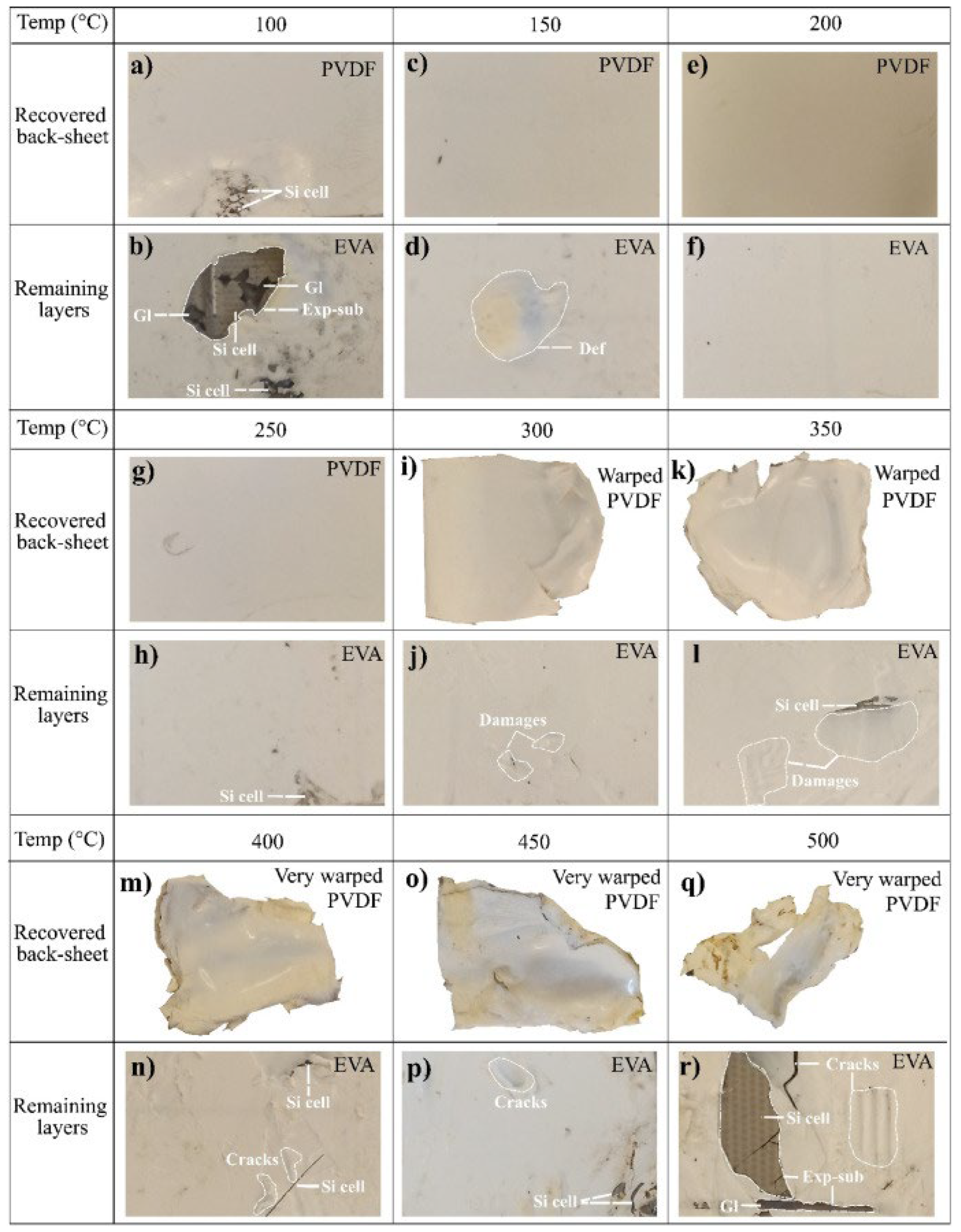

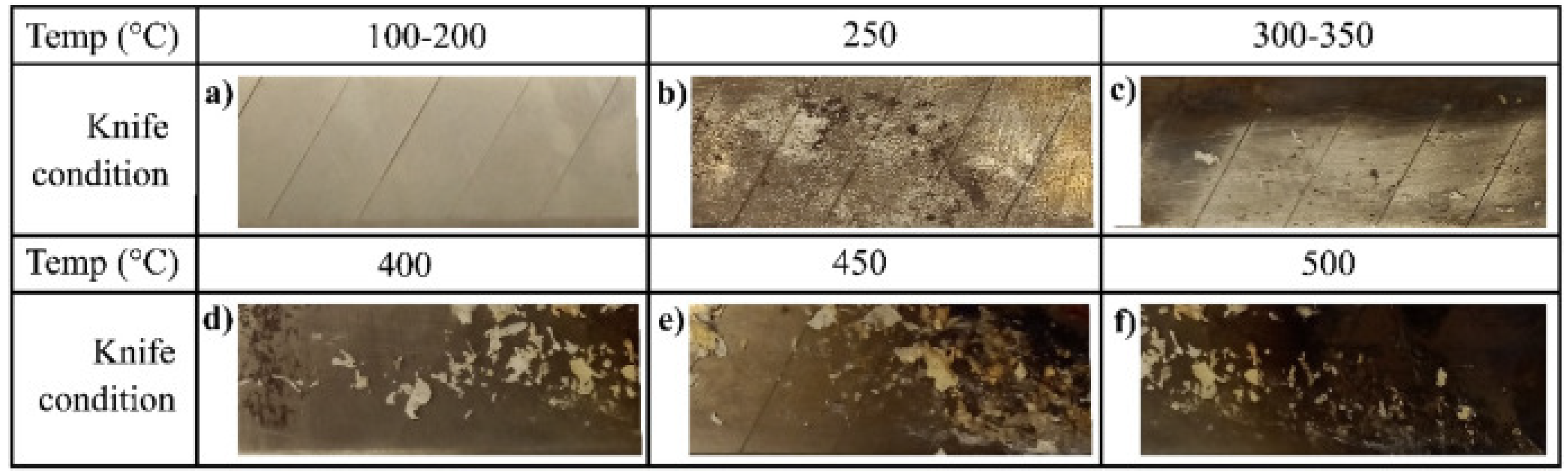

4.4. Hot Knife Based Delamination Process

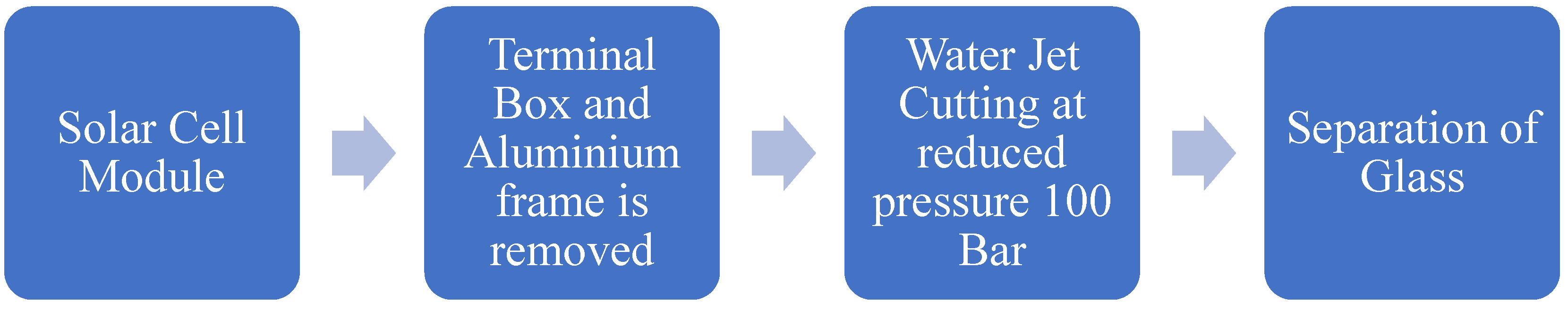

4.5. Water Jett Cutting of Solar PV

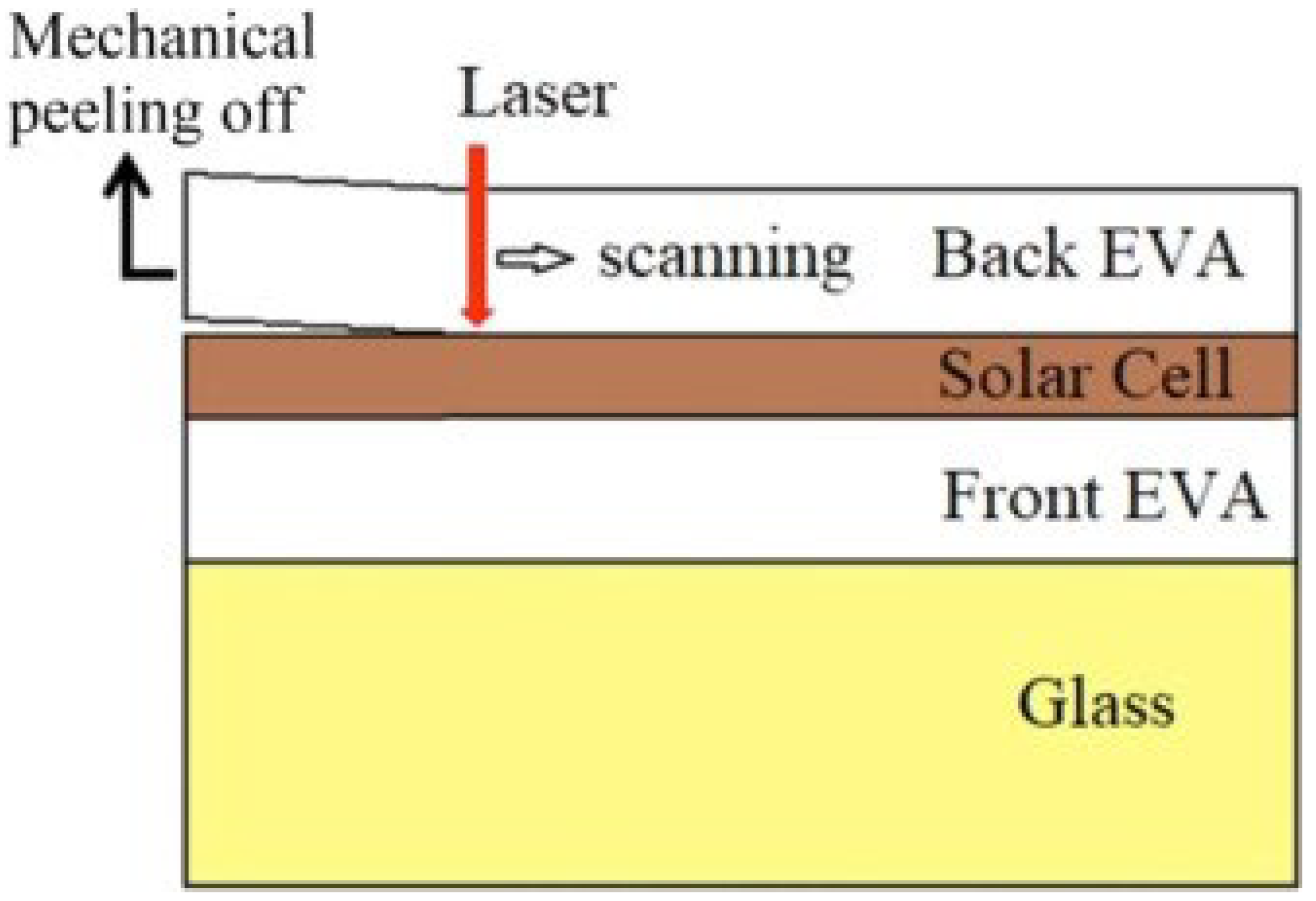

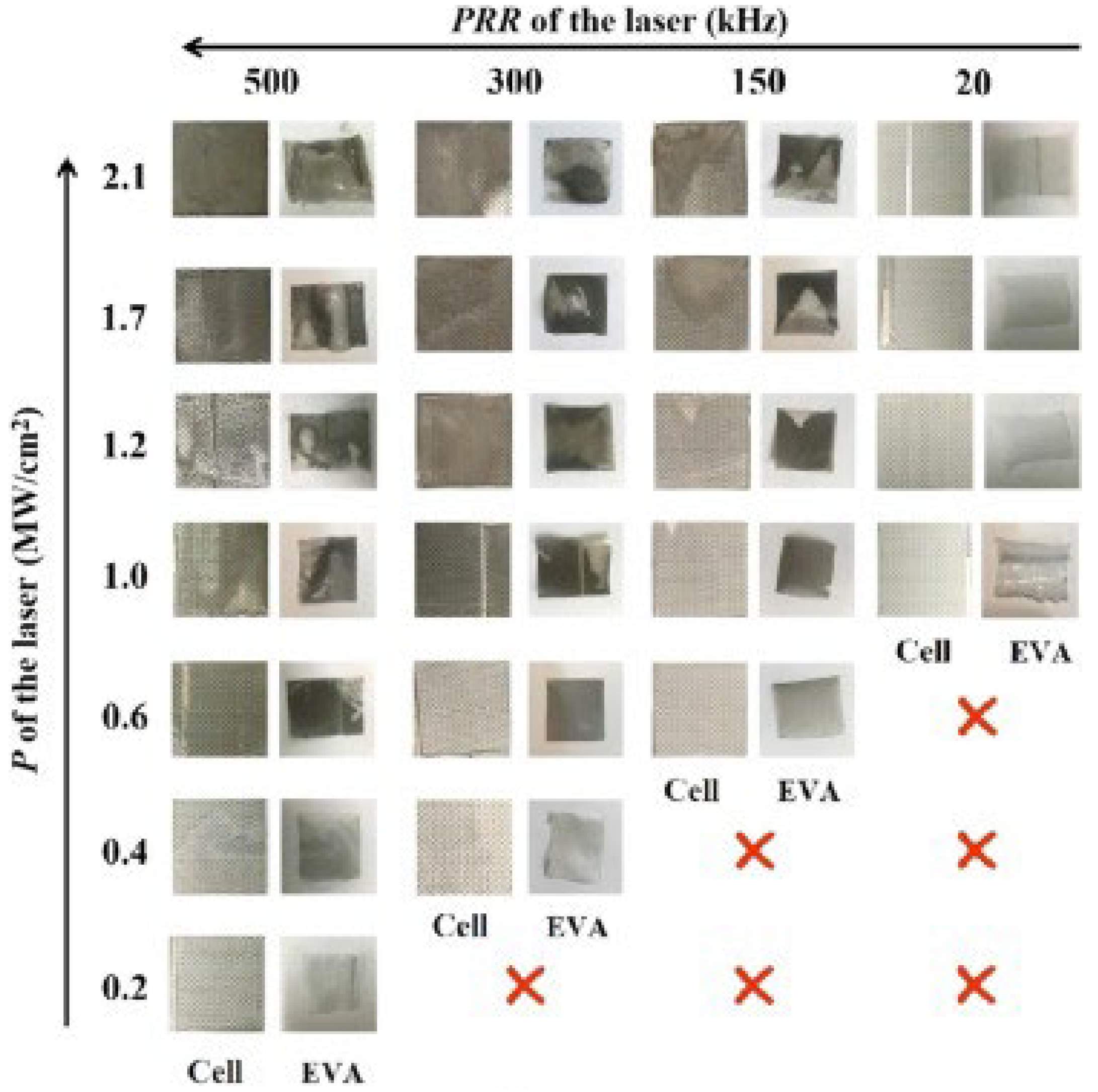

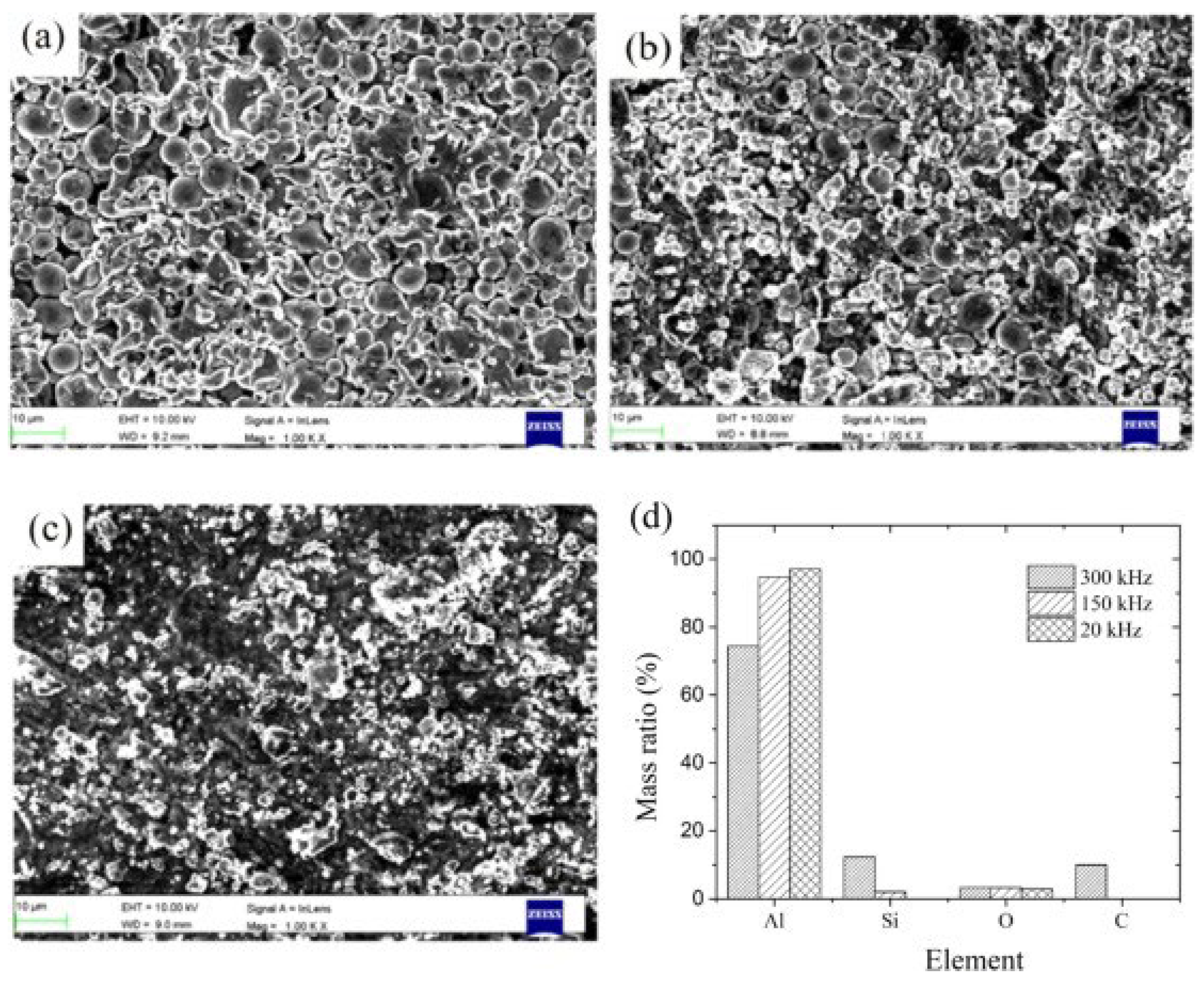

4.6. Laser Irradiation

5. Discussion

6. New Proposed Method

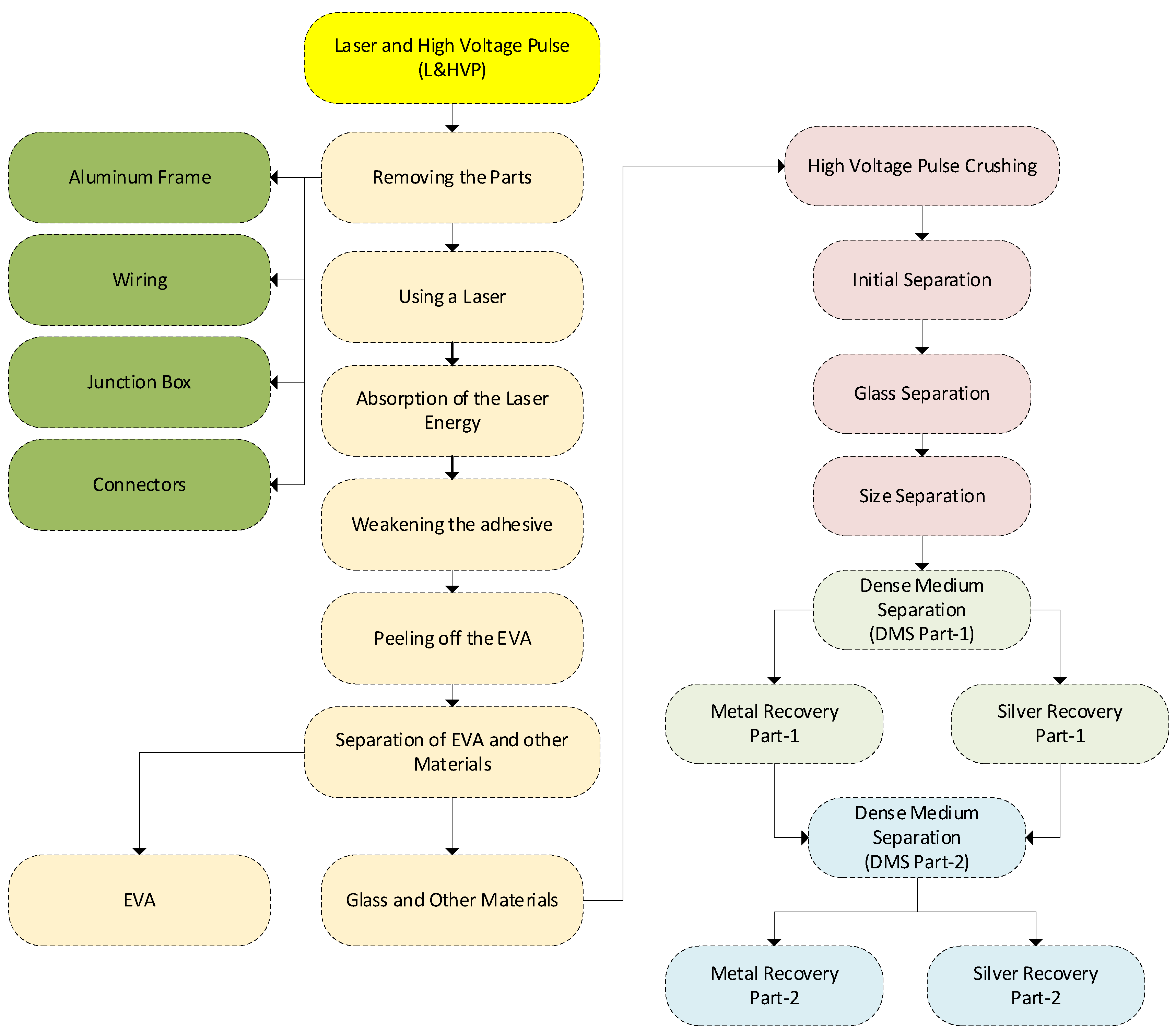

6.1. Laser and High Voltage Pulse (L&HVP)

6.2. How It Works:

- Prior to recycling, specific components are removed from the solar panels to prepare them for subsequent processing steps.

- Enhanced Component Separation: Lasers are used to sever connections between different components, making disassembly and material recovery more efficient.

- EVA Recovery: The laser effectively breaks the bonds within the ethylene-vinyl acetate (EVA) encapsulant, allowing for its easy extraction. Recovering EVA is crucial for sustainable recycling, as it can either be reused or safely disposed of.

7. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- A. Ali et al., “Solar Photovoltaic Module End-of-Life Waste Management Regulations: International Practices and Implications for the Kingdom of Saudi Arabia,” 2024. [CrossRef]

- M. S. Chowdhury et al., “An overview of solar photovoltaic panels’ end-of-life material recycling,” Energy Strateg. Rev., vol. 27, p. 100431, 2020. [CrossRef]

- W. Van Opstal and A. Smeets, “Circular economy strategies as enablers for solar PV adoption in organizational market segments,” Sustain. Prod. Consum., vol. 35, pp. 40–54, 2023. [CrossRef]

- International Renewable Energy Agency, “GLOBAL RENEWABLES OUTLOOK,” 2020. [Online]. Available: https://www.irena.org.

- A. Ali, S. A. Malik, M. Shafiullah, M. Z. Malik, and M. H. Zahir, “Policies and regulations for solar photovoltaic end-of-life waste management: Insights from China and the USA,” Chemosphere, vol. 340, p. 139840, 2023. [CrossRef]

- International Renewable Energy Agency (IRENA), “End-of-life management: Solar Photovoltaic Panels,” 2016. [Online]. Available: https://www.irena.org/.

- International Renewable Energy Agency, “Renewable Energy Target Setting,” 2015. [Online]. Available: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2015/IRENA_RE_Target_Setting_2015.pdf.

- P. Nain and A. Kumar, “Initial metal contents and leaching rate constants of metals leached from end-of-life solar photovoltaic waste: An integrative literature review and analysis,” Renew. Sustain. Energy Rev., vol. 119, p. 109592, 2020. [CrossRef]

- A. Mulazzani, P. Eleftheriadis, and S. Leva, “Recycling c-Si PV Modules: A Review, a Proposed Energy Model and a Manufacturing Comparison,” 2022. [CrossRef]

- F. Del Pero, M. Delogu, L. Berzi, and M. Escamilla, “Innovative device for mechanical treatment of End of Life photovoltaic panels: Technical and environmental analysis,” Waste Manag., vol. 95, pp. 535–548, 2019. [CrossRef]

- A. Paiano, “Photovoltaic waste assessment in Italy,” Renew. Sustain. Energy Rev., vol. 41, pp. 99–112, 2015. [CrossRef]

- V. Fiandra, L. Sannino, and C. Andreozzi, “Photovoltaic waste as source of valuable materials: A new recovery mechanical approach,” J. Clean. Prod., vol. 385, p. 135702, 2023. [CrossRef]

- D. Yadav, A. Kumar Saraf, and N. Singh Rathee, “Assessment of PV waste generation in India,” Mater. Today Proc., 2023. [CrossRef]

- A. Divya, T. Adish, P. Kaustubh, and P. S. Zade, “Review on recycling of solar modules/panels,” Sol. Energy Mater. Sol. Cells, vol. 253, p. 112151, 2023. [CrossRef]

- D. Sah, Chitra, and S. Kumar, “Investigation and recovery of copper from waste silicon solar module,” Mater. Chem. Phys., vol. 296, p. 127205, 2023. [CrossRef]

- J. Wang, Y. Feng, and Y. He, “The research progress on recycling and resource utilization of waste crystalline silicon photovoltaic modules,” Sol. Energy Mater. Sol. Cells, vol. null, p. null, 2024. [CrossRef]

- G.-J. Wang, Q. Liao, and H. Xu, “Anticipating future photovoltaic waste generation in China: Navigating challenges and exploring prospective recycling solutions,” Environ. Impact Assess. Rev., vol. null, p. null, 2024. [CrossRef]

- K. K. Hei, P. Savaget, S. Fukushige, and A. Halog, “The Necessity for End-of-Life Photovoltaic Technology Waste Management Policy: A Systematic Review,” J. Clean. Prod., vol. null, p. null, 2024. [CrossRef]

- V. Souza, A. M. R. Figueiredo, and M. M. dos Santos Bortolocci Espejo, “Challenges and strategies for managing end-of-life photovoltaic equipment in Brazil: Learning from international experience,” Energy Policy, vol. null, p. null, 2024. [CrossRef]

- A. Aşkın, Ş. Kılkış, and B. Akinoglu, “Recycling photovoltaic modules within a circular economy approach and a snapshot for Türkiye,” Renew. Energy, vol. null, p. null, 2023. [CrossRef]

- P.-H. Chen, W.-S. Chen, C. Lee, and J. Wu, “Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques,” Sustainability, vol. null, p. null, 2023. [CrossRef]

- G. Yan, M. Zhang, Z. Sun, P. Zhao, and B. Zhang, “Recycling technology of end-of-life photovoltaic panels: a review,” Energy Sources, Part A Recover. Util. Environ. Eff., vol. 45, pp. 10890–10908, 2023. [CrossRef]

- H. A. Cheema, S. Ilyas, H. Kang, and H.-J. Kim, “Comprehensive review of the global trends and future perspectives for recycling of decommissioned photovoltaic panels.,” Waste Manag., vol. 174, pp. 187–202, 2023. [CrossRef]

- J. Ko et al., “Review on Separation Processes of End-of-Life Silicon Photovoltaic Modules,” 2023. [CrossRef]

- P. M. Tembo and V. Subramanian, “Current trends in silicon-based photovoltaic recycling: A technology, assessment, and policy review,” Sol. Energy, vol. 259, pp. 137–150, 2023. [CrossRef]

- H. Trivedi, A. Meshram, and R. Gupta, “Recycling of photovoltaic modules for recovery and repurposing of materials,” J. Environ. Chem. Eng., vol. 11, no. 2, p. 109501, 2023. [CrossRef]

- X. Wang, X. Tian, X. Chen, L. Ren, and C. Geng, “A review of end-of-life crystalline silicon solar photovoltaic panel recycling technology,” Sol. Energy Mater. Sol. Cells, vol. 248, p. 111976, 2022. [CrossRef]

- N. Dhawan and S. Agrawal, “Recycling of discarded photovoltaic solar modules for metal recovery,” Mining, Metall. Explor., vol. 39, pp. 2539–2550, 2022. [CrossRef]

- M. S. Lim et al., “Experimental, economic and life cycle assessments of recycling end-of-life monocrystalline silicon photovoltaic modules,” J. Clean. Prod., vol. null, p. null, 2022. [CrossRef]

- H. Yu, M. Hasanuzzaman, N. Rahim, N. Amin, and N. N. Adzman, “Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review,” Sustainability, vol. null, p. null, 2022. [CrossRef]

- R. Deng, Y. Zhuo, and Y. Shen, “Recent progress in silicon photovoltaic module recycling processes,” Resour. Conserv. Recycl., vol. null, p. null, 2022. [CrossRef]

- G. Granata, P. Altimari, F. Pagnanelli, and J. De Greef, “Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective,” J. Clean. Prod., vol. null, p. null, 2022. [CrossRef]

- X.-Q. Xu, D. Lai, W. Wang, and Y. Wang, “A systematically integrated recycling and upgrading technology for waste crystalline silicon photovoltaic module,” Resour. Conserv. Recycl., vol. null, p. null, 2022. [CrossRef]

- M. Theocharis et al., “An Integrated Thermal and Hydrometallurgical Process for the Recovery of Silicon and Silver from End-of-Life Crystalline Si Photovoltaic Panels,” Waste and Biomass Valorization, vol. 13, pp. 4027–4041, 2022. [CrossRef]

- K. Li et al., “A Green Method to Separate Different Layers in Photovoltaic Modules by Using Dmpu as a Separation Agent,” SSRN Electron. J., vol. null, p. null, 2022. [CrossRef]

- L. El-Khawad, D. Bartkowiak, and K. Kümmerer, “Improving the end-of-life management of solar panels in Germany,” Renew. Sustain. Energy Rev., vol. 168, p. 112678, Oct. 2022. [CrossRef]

- X.-Q. Xu, D. Lai, G. Wang, and Y. Wang, “Nondestructive silicon wafer recovery by a novel method of solvothermal swelling coupled with thermal decomposition,” Chem. Eng. J., vol. null, p. null, 2021. [CrossRef]

- T. Dobra, D. Vollprecht, and R. Pomberger, “Thermal delamination of end-of-life crystalline silicon photovoltaic modules,” Waste Manag. Res., vol. 40, pp. 96–103, 2021. [CrossRef]

- P. Dias et al., “Comprehensive recycling of silicon photovoltaic modules incorporating organic solvent delamination – technical, environmental and economic analyses,” Resour. Conserv. Recycl., vol. 165, p. 105241, 2021. [CrossRef]

- R. Deng, P. Dias, M. M. Lunardi, and J. Ji, “A sustainable chemical process to recycle end-of-life silicon solar cells,” Green Chem., vol. null, p. null, 2021. [CrossRef]

- S. Pang et al., “Enhanced separation of different layers in photovoltaic panel by microwave field,” Sol. Energy Mater. Sol. Cells, vol. 230, p. 111213, 2021. [CrossRef]

- G. Ansanelli, G. Fiorentino, M. Tammaro, and A. Zucaro, “A Life Cycle Assessment of a recovery process from End-of-Life Photovoltaic Panels,” Appl. Energy, vol. 290, p. 116727, 2021. [CrossRef]

- P. S. S. Camargo, A. Domingues, J. Palomero, A. C. Kasper, P. Dias, and H. Veit, “PHOTOVOLTAIC MODULE RECYCLING: THERMAL TREATMENT TO DEGRADE POLYMERS AND CONCENTRATE VALUABLE METALS,” Detritus, vol. null, p. null, 2021. [CrossRef]

- C. Wang, K. Feng, X. Liu, P. Wang, W. Chen, and J. Li, “Looming challenge of photovoltaic waste under China’s solar ambition: A spatial–temporal assessment,” Appl. Energy, vol. null, p. null, 2021. [CrossRef]

- S. Mahmoudi, N. Huda, and M. Behnia, “Multi-levels of photovoltaic waste management: A holistic framework,” J. Clean. Prod., vol. 294, p. 126252, 2021. [CrossRef]

- X. Li, H. Liu, J. You, H. Diao, L. Zhao, and W. Wang, “Back EVA recycling from c-Si photovoltaic module without damaging solar cell via laser irradiation followed by mechanical peeling.,” Waste Manag., vol. 137, pp. 312–318, 2021. [CrossRef]

- P. Tembo, M. Heninger, and V. Subramanian, “An Investigation of the Recovery of Silicon Photovoltaic Cells by Application of an Organic Solvent Method,” ECS J. Solid State Sci. Technol., vol. null, p. null, 2020. [CrossRef]

- R. Deng et al., “Remanufacturing end-of-life silicon photovoltaics: Feasibility and viability analysis,” Prog. Photovoltaics Res. Appl., vol. 29, pp. 760–774, 2020. [CrossRef]

- C. Farrell et al., “Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules,” Renew. Sustain. Energy Rev., vol. null, p. null, 2020. [CrossRef]

- R. Deng, N. Chang, Z. Ouyang, and C. Chong, “A techno-economic review of silicon photovoltaic module recycling,” Renew. Sustain. Energy Rev., vol. null, p. null, 2019. [CrossRef]

- R. Wang et al., “Pyrolysis-based separation mechanism for waste crystalline silicon photovoltaic modules by a two-stage heating treatment,” RSC Adv., vol. 9, pp. 18115–18123, 2019. [CrossRef]

- S. Mahmoudi, N. Huda, Z. Alavi, M. T. Islam, and M. Behnia, “End-of-life photovoltaic modules: A systematic quantitative literature review,” Resour. Conserv. Recycl., vol. null, p. null, 2019. [CrossRef]

- M. F. Azeumo, C. Germana, N. M. Ippolito, M. Franco, P. Luigi, and S. Settimio, “Photovoltaic module recycling, a physical and a chemical recovery process,” Sol. Energy Mater. Sol. Cells, vol. 193, pp. 314–319, 2019. [CrossRef]

- D. Strachala, J. Hylský, K. Jandova, J. Vaněk, and Š. Cingel, “Mechanical Recycling of Photovoltaic Modules,” ECS Trans., vol. 81, no. 1, p. 199, 2017. [CrossRef]

- C. Libby, S. Shaw, G. Heath, and K. Wambach, “Photovoltaic Recycling Processes,” in 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), 2018, pp. 2594–2599. [CrossRef]

- J. Li and others, “Recycling Si in waste crystalline silicon photovoltaic panels after mechanical crushing by electrostatic separation,” J. Clean. Prod., vol. 415, p. 137908, 2023. [CrossRef]

- F. Pagnanelli and others, “Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies,” Waste Manag., vol. 59, pp. 422–431, 2017. [CrossRef]

- S.-M. Nevala and others, “Electro-hydraulic fragmentation vs conventional crushing of photovoltaic panels -- Impact on recycling,” Waste Manag., vol. 87, pp. 43–50, 2019. [CrossRef]

- Y. Sim, Y. B. Tay, H. K. Pham, and N. Mathews, “A facile crush-and-sieve treatment for recycling end-of-life photovoltaics,” Waste Manag., vol. 156, pp. 97–106, 2023. [CrossRef]

- A. Ghahremani, S. D. Adams, M. Norton, S. Y. Khoo, and A. Z. Kouzani, “Delamination Techniques of Waste Solar Panels: A Review,” 2024. [CrossRef]

- S. Preet and S. T. Smith, “A comprehensive review on the recycling technology of silicon based photovoltaic solar panels: Challenges and future outlook,” J. Clean. Prod., vol. 448, p. 141661, 2024. [CrossRef]

- P. Zhao and others, “Analysis and optimization of the selective crushing process based on high voltage pulse energy,” Miner. Eng., vol. 185, p. 107697, 2022. [CrossRef]

- Y. Akimoto, A. Iizuka, and E. Shibata, “High-voltage pulse crushing and physical separation of polycrystalline silicon photovoltaic panels,” Miner. Eng., vol. 125, pp. 1–9, 2018. [CrossRef]

- M. Xue, J. Li, and Z. Xu, “Management strategies on the industrialization road of state-of- the-art technologies for e-waste recycling: the case study of electrostatic separation—a review,” Waste Manag. Res., vol. 31, no. 2, pp. 130–140, Nov. 2012. [CrossRef]

- P. Dias, L. Schmidt, L. B. Gomes, A. Bettanin, H. Veit, and A. M. Bernardes, “Recycling Waste Crystalline Silicon Photovoltaic Modules by Electrostatic Separation,” J. Sustain. Metall., vol. 4, no. 2, pp. 176–186, 2018. [CrossRef]

- J. Guo et al., “An overview of the comprehensive utilization of silicon-based solid waste related to PV industry,” Resour. Conserv. Recycl., vol. 169, p. 105450, 2021. [CrossRef]

- R. A. de Souza and H. M. Veit, “Study of electrostatic separation to concentrate silver, aluminum, and silicon from solar panel scraps,” Circ. Econ., vol. 2, no. 1, p. 100027, 2023. [CrossRef]

- Z. N. Ndalloka, H. V. Nair, S. Alpert, and C. Schmid, “Solar photovoltaic recycling strategies,” Sol. Energy, vol. 270, p. 112379, 2024. [CrossRef]

- T.-Y. Wang, J.-C. Hsiao, and C.-H. Du, “Recycling of materials from silicon base solar cell module,” in 2012 38th IEEE Photovoltaic Specialists Conference, 2012, pp. 2355–2358. [CrossRef]

- J. Park, W. Kim, N. Cho, H. Lee, and N. Park, “An eco-friendly method for reclaimed silicon wafers from a photovoltaic module: from separation to cell fabrication,” Green Chem., vol. 18, no. 6, pp. 1706–1714, 2016. [CrossRef]

- P. Dias, S. Javimczik, M. Benevit, and H. Veit, “Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules,” Waste Manag., vol. 60, pp. 716–722, 2017. [CrossRef]

- J.-K. Lee, J.-S. Lee, Y.-S. Ahn, and G.-H. Kang, “Efficient Recovery of Silver from Crystalline Silicon Solar Cells by Controlling the Viscosity of Electrolyte Solvent in an Electrochemical Process,” 2018. [CrossRef]

- M. M. Lunardi, J. P. Alvarez-Gaitan, J. I. Bilbao, and R. Corkish, “A review of recycling processes for photovoltaic modules,” Sol. Panels Photovolt. Mater., vol. 30, 2018.

- M. Wahman, A. Surowiak, K. Berent, and P. Szymczak, “Eco-efficient removal of polymer back sheet fraction and material separation from solar cell waste,” Sol. Energy, vol. 264, p. 112085, 2023. [CrossRef]

- V. Fiandra, L. Sannino, C. Andreozzi, F. Corcelli, and G. Graditi, “Silicon photovoltaic modules at end-of-life: Removal of polymeric layers and separation of materials,” Waste Manag., vol. 87, pp. 97–107, 2019. [CrossRef]

- M. Tammaro, J. Rimauro, V. Fiandra, and A. Salluzzo, “Thermal treatment of waste photovoltaic module for recovery and recycling: Experimental assessment of the presence of metals in the gas emissions and in the ashes,” Renew. Energy, vol. 81, pp. 103–112, 2015. [CrossRef]

- M. Wahman, A. Surowiak, B. Ebin, and K. Berent, “PV back sheet recovery from c-Si modules using hot knife technique,” Sol. Energy Mater. Sol. Cells, vol. 276, p. 113067, 2024. [CrossRef]

- L. Xinology Co., “Water Jet Cutting Machine: Introduction.” Accessed: Jun. 01, 2024. [Online]. Available: http://www.xinology.com/Glass-Processing-Equipments-Supplies-Consumables/glass-cutting/water-jet-cutting/overview/overview.html.

- TMC, “A Window Of Opportunity Through Water Jet Cutting.” Accessed: Jun. 01, 2024. [Online]. Available: https://www.tmcwaterjet.co.uk/news-blog/recycling-glass-a-window-of-opportunity-through-water-jet-cutting/.

- E. Bellini., “Water jet tech to recover glass from end-of-life solar panels.” Accessed: Jun. 02, 2024. [Online]. Available: https://www.pv-magazine.com/2023/01/20/water-jet-tech-to-recover-glass-from-end-of-life-solar-panels/.

- WJS, “Waterjet cutting turns waste into added value.” Accessed: Jun. 02, 2024. [Online]. Available: https://www.waterjetsweden.com/articles/waterjet-cutting-turns-waste-into-added-value.

- X. Li, H. Liu, J. You, H. Diao, L. Zhao, and W. Wang, “Back EVA recycling from c-Si photovoltaic module without damaging solar cell via laser irradiation followed by mechanical peeling,” Waste Manag., vol. 137, pp. 312–318, 2022. [CrossRef]

| S. No. | Article/Reference No. | Year of Publication |

Paper Objectives |

|---|---|---|---|

| 1. | The research progress on recycling and resource utilization of waste crystalline silicon photovoltaic modules [16] | 2024 | Reviews advancements in recycling and resource utilization techniques for waste crystalline silicon PV modules. |

| 2. | Anticipating future photovoltaic waste generation in China: Navigating challenges and exploring prospective recycling solutions [17] | 2024 | Analyzes future PV waste generation in China and proposes recycling solutions to address anticipated challenges. |

| 3. | The Necessity for End-of-Life Photovoltaic Technology Waste Management Policy: A Systematic Review [18] | 2024 | Provides a systematic review of the need for policies governing the management of EoL PV technology waste. |

| 4. | Challenges and strategies for managing end-of-life photovoltaic equipment in Brazil: Learning from international experience [19] | 2024 | Focuses on strategies and challenges in managing EoL PV waste in Brazil, drawing lessons from global practices. |

| 5. | Recycling photovoltaic modules within a circular economy approach and a snapshot for Türkiye [20] | 2023 | Discusses recycling of PV modules within the circular economy framework with a specific focus on Türkiye. |

| 6. | Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques [21] | 2023 | Offers a thorough review of the historical and advanced techniques for recycling crystalline silicon solar panels. |

| 7. | Recycling technology of end-of-life photovoltaic panels: a review [22] | 2023 | Reviews of various technologies available for recycling EoL PV panels. |

| 8. | Comprehensive review of the global trends and future perspectives for recycling of decommissioned photovoltaic panels [23] | 2023 | Examines global trends and future perspectives on the recycling of decommissioned PV panels. |

| 9. | Review on Separation Processes of End-of-Life Silicon Photovoltaic Modules [24] | 2023 | Focuses on separation processes involved in recycling EoL silicon PV modules. |

| 10. | Current trends in silicon-based photovoltaic recycling: A technology, assessment, and policy review [25] | 2023 | Assesses current trends in silicon-based PV recycling technologies and reviews relevant policies. |

| 11. | Recycling of Photovoltaic Modules for Recovery and Repurposing of Materials [26] | 2023 | Investigates methods for recycling PV modules to recover and repurpose materials. |

| 12. | A review of end-of-life crystalline silicon solar photovoltaic panel recycling technology [27] | 2022 | Reviews existing technologies for recycling EoL crystalline silicon solar PV panels. |

| 13. | Recycling of discarded photovoltaic solar modules for metal recovery [28] | 2022 | Discusses techniques for recovering metals from discarded PV modules. |

| 14. | Recycling c-Si PV Modules: A Review, a Proposed Energy Model and a Manufacturing Comparison [9] | 2022 | Reviews c-Si PV module recycling and proposes an energy model along with manufacturing comparisons. |

| 15. | Experimental, economic and life cycle assessments of recycling end-of-life monocrystalline silicon photovoltaic modules [29] | 2022 | Conducts economic and life cycle assessments for recycling monocrystalline silicon PV modules. |

| 16. | Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review [30] | 2022 | Provides a comprehensive review of global challenges and prospects for PV material disposal and recycling. |

| 17. | Recent progress in silicon photovoltaic module recycling processes [31] | 2022 | Reviews recent advancements in recycling processes for silicon PV modules. |

| 18. | Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective [32] | 2022 | Assesses the techno-economic aspects of recycling solar PV panels from a waste management perspective. |

| 19. | A systematically integrated recycling and upgrading technology for waste crystalline silicon photovoltaic module [33] | 2022 | Proposes an integrated technology for recycling and upgrading waste crystalline silicon PV modules. |

| 20. | An Integrated Thermal and Hydrometallurgical Process for the Recovery of Silicon and Silver from End-of-Life Crystalline Si Photovoltaic Panels [34] | 2022 | Discusses a combined thermal and hydrometallurgical process for recovering silicon and silver from EoL crystalline Si PV panels. |

| 21. | A Green Method to Separate Different Layers in Photovoltaic Modules by Using Dmpu as a Separation Agent [35] | 2022 | Introduces an environmentally friendly method for separating layers in PV modules using Dmpu. |

| 22. | Improving the end-of-life management of solar panels in Germany [36] | 2022 | Examines strategies for enhancing EoL management of solar panels in Germany. |

| 23. | Nondestructive silicon wafer recovery by a novel method of solvothermal swelling coupled with thermal decomposition [37] | 2021 | Presents a novel method for non-destructive recovery of silicon wafers using solvothermal swelling and thermal decomposition. |

| 24. | Thermal delamination of end-of-life crystalline silicon photovoltaic modules [38] | 2021 | Explores thermal delamination techniques for recycling EoL crystalline silicon PV modules. |

| 25. | Comprehensive recycling of silicon photovoltaic modules incorporating organic solvent delamination – technical, environmental and economic analyses [39] | 2021 | Analyzes technical, environmental, and economic aspects of recycling silicon PV modules using organic solvent delamination. |

| 26. | A sustainable chemical process to recycle end-of-life silicon solar cells [40] | 2021 | Proposes a sustainable chemical process for recycling EoL silicon solar cells. |

| 27. | Enhanced separation of different layers in photovoltaic panel by microwave field [41] | 2021 | Investigates the use of microwave fields for enhancing layer separation in PV panels. |

| 28. | A Life Cycle Assessment of a recovery process from End-of-Life Photovoltaic Panels [42] | 2021 | Conducts a life cycle assessment of a recovery process for EoL PV panels. |

| 29. | Photovoltaic Module Recycling: Thermal Treatment to Degrade Polymers And Concentrate Valuable Metals [43] | 2021 | Explores the use of thermal treatment to degrade polymers and concentrate valuable metals in PV module recycling. |

| 30. | Looming challenge of photovoltaic waste under China’s solar ambition: A spatial–temporal assessment [44] | 2021 | Provides a spatial-temporal assessment of the PV waste challenge in China. |

| 31. | Multi-levels of photovoltaic waste management: A holistic framework [45] | 2021 | Proposes a holistic framework for multi-level PV waste management. |

| 32. | Back EVA recycling from c-Si photovoltaic module without damaging solar cell via laser irradiation followed by mechanical peeling [46] | 2021 | Describes a method for recycling back EVA from c-Si PV modules using laser irradiation and mechanical peeling. |

| 33. | An Investigation of the Recovery of Silicon Photovoltaic Cells by Application of an Organic Solvent Method [47] | 2020 | Investigates the recovery of silicon PV cells using an organic solvent method. |

| 34. | Remanufacturing end-of-life silicon photovoltaics: Feasibility and viability analysis [48] | 2020 | Analyzes the feasibility and viability of remanufacturing EoL silicon PVs. |

| 35. | An overview of solar photovoltaic panels’ end-of-life material recycling [2] | 2020 | Provides an overview of EoL material recycling for solar PV panels. |

| 36. | Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules [49] | 2020 | Discusses technical challenges and opportunities in achieving a circular economy for waste PV modules. |

| 37. | A techno-economic review of silicon photovoltaic module recycling [50] | 2019 | Reviews the techno-economic aspects of silicon PV module recycling. |

| 38. | Pyrolysis-based separation mechanism for waste crystalline silicon photovoltaic modules by a two-stage heating treatment [51] | 2019 | Investigates a pyrolysis-based separation mechanism for waste crystalline silicon PV modules. |

| 39. | End-of-life photovoltaic modules: A systematic quantitative literature review [52] | 2019 | Provides a systematic quantitative literature review of EoL PV modules. |

| 40. | Photovoltaic module recycling, a physical and a chemical recovery process [53] | 2019 | Examine both physical and chemical recovery processes in PV module recycling. |

| Technique | Advantages | Disadvantages |

|---|---|---|

| Crushing |

|

|

| High Voltage Pulse Crushing |

|

|

| ElectrostaticSeparation |

|

|

| Hot KnifeCutting |

|

|

| Water JetCutting |

|

|

| Laser Cutting |

|

|

| Techniques | Glass | Silicon (Si) | Aluminum (Al) | Silver (Ag) | Copper (Cu) | Tin (Sn) | Lead (Pb) | EVA |

|---|---|---|---|---|---|---|---|---|

| Crushing | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✘ |

| High Voltage Pulse Crushing |

✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✘ |

| Electrostatic Separation |

✘ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✘ |

| Hot Knife Cutting | ✓ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✓ |

| Water Jet Cutting | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✘ |

| Laser Irradiation | ✘ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).