Submitted:

16 November 2024

Posted:

19 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

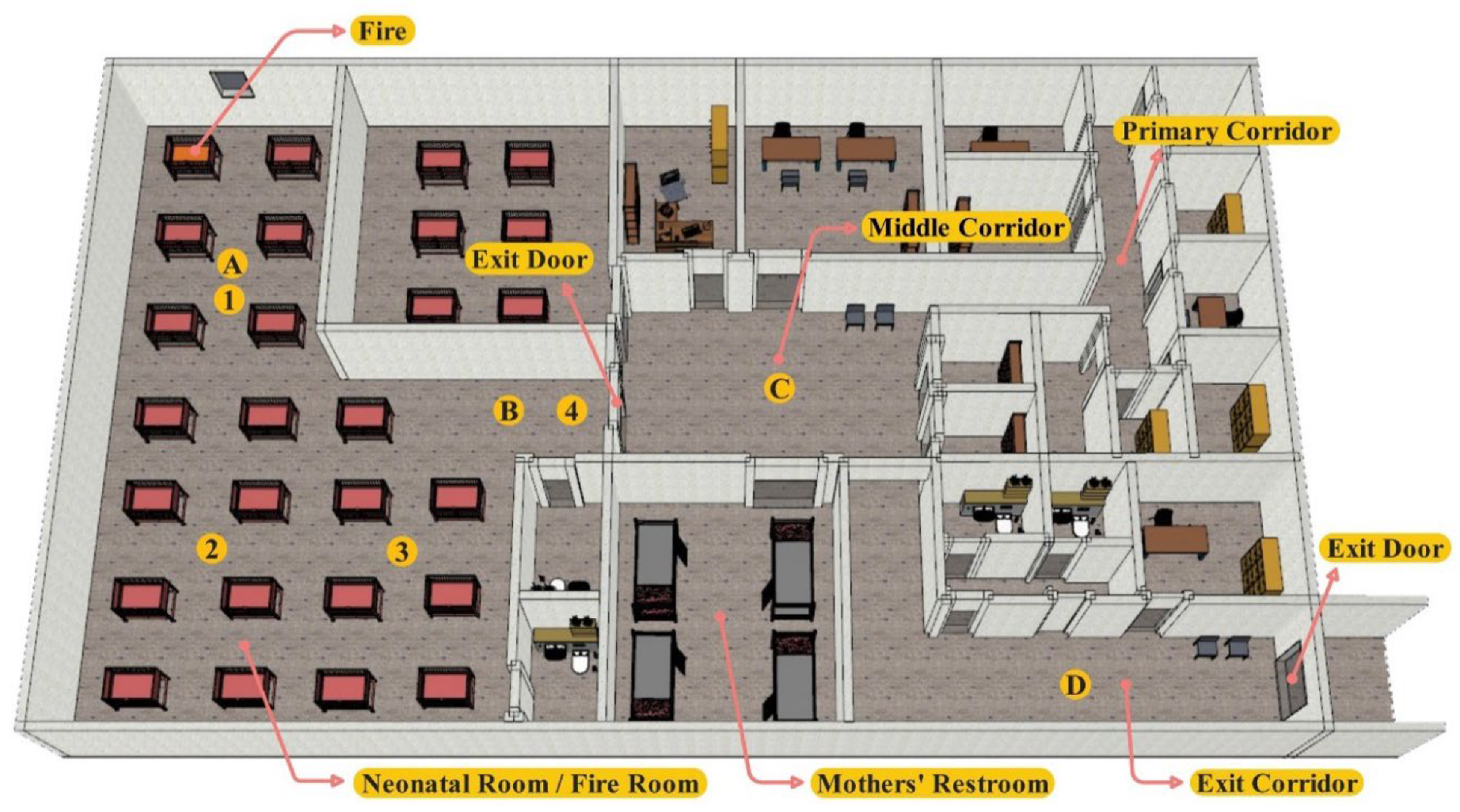

2.1. Sketching Up the 3D Structure of a Building and Specifying Its Internal Details

2.2. Importing Fire Simulation Data

2.3. Determination of Scenarios

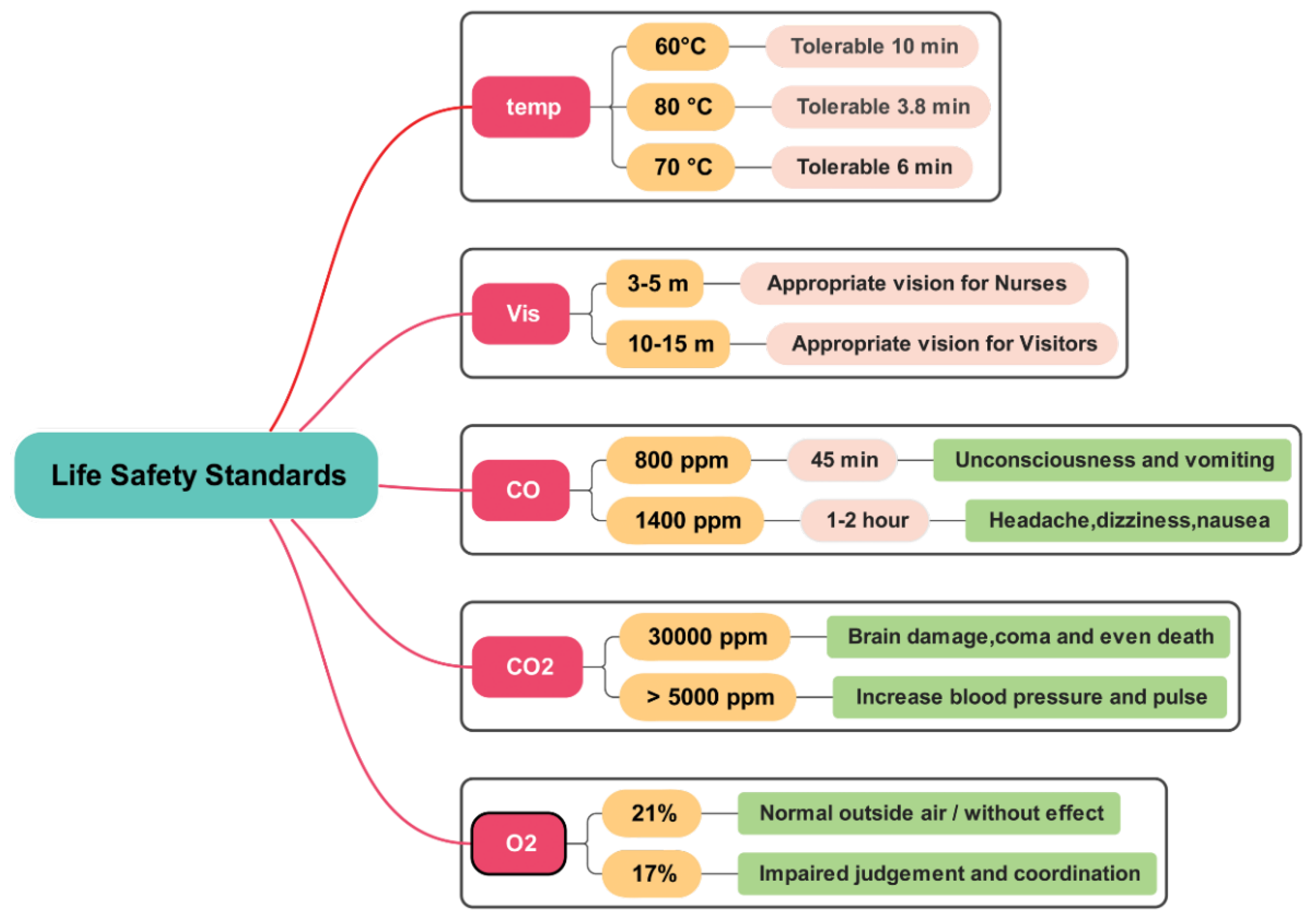

2.4. Definition of Human Life Safety Standard

3. Results

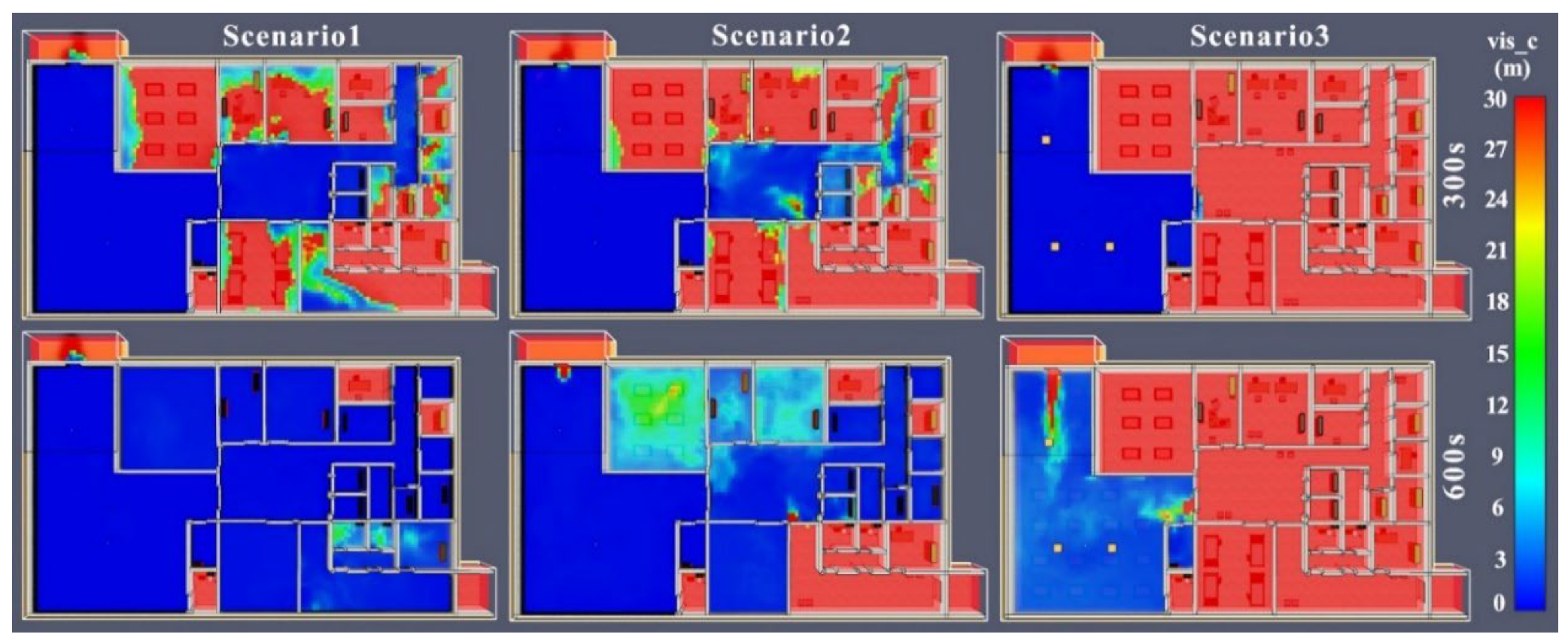

3.1. 3D View of Smoke Spread

3.2. 3D Visibility

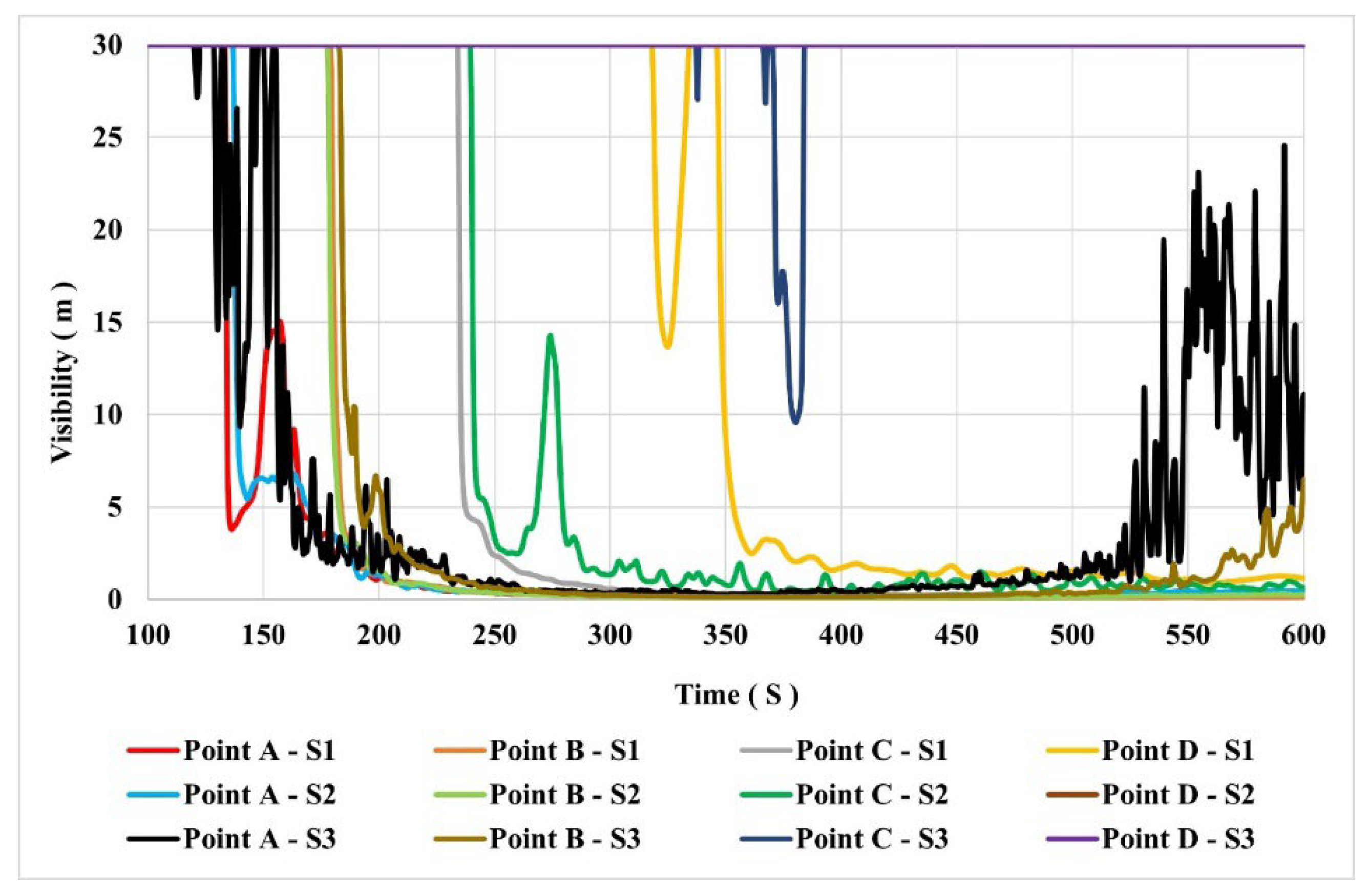

3.3. Visibility Figure

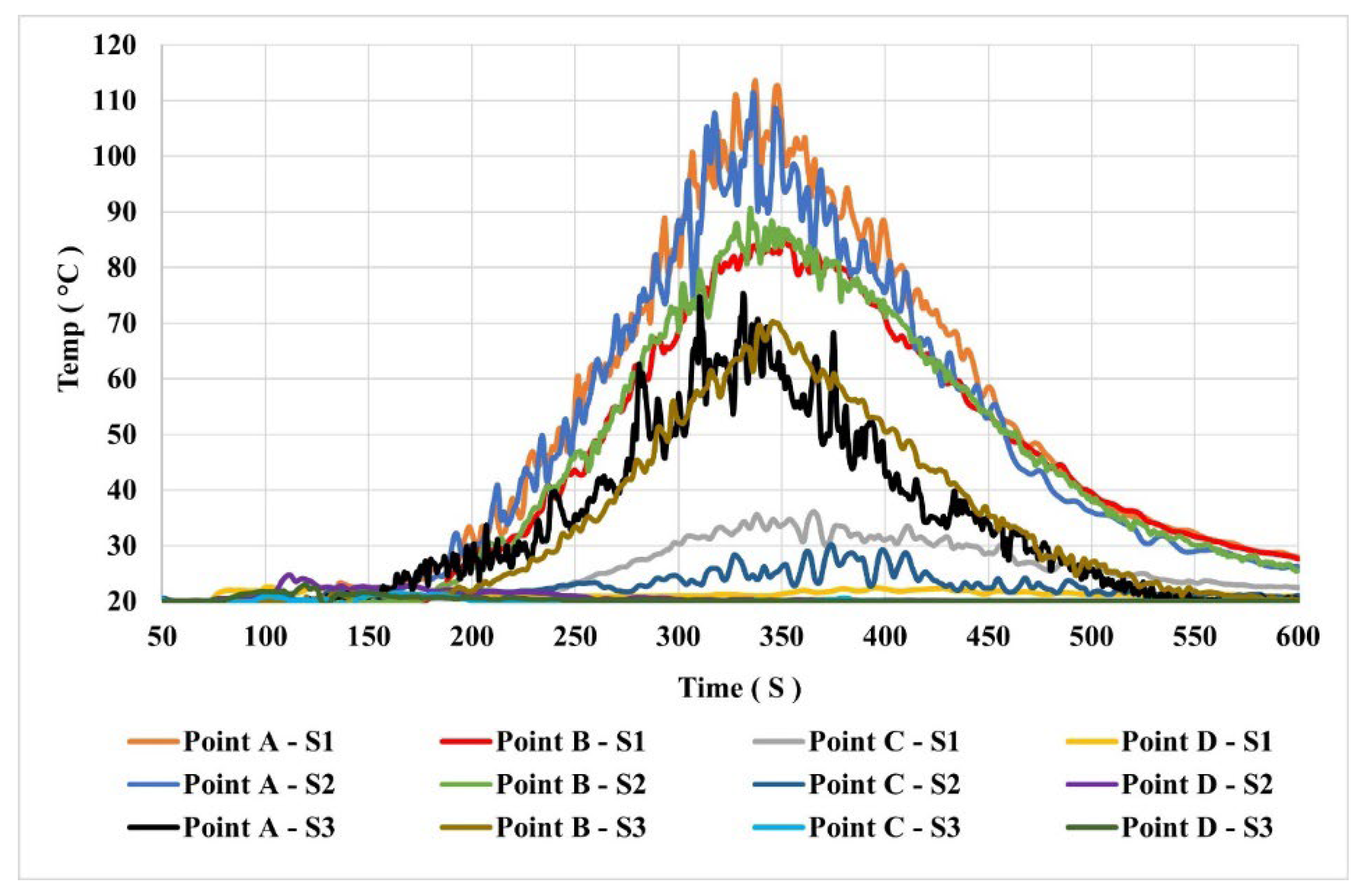

3.5. Temperature Profiles Figure

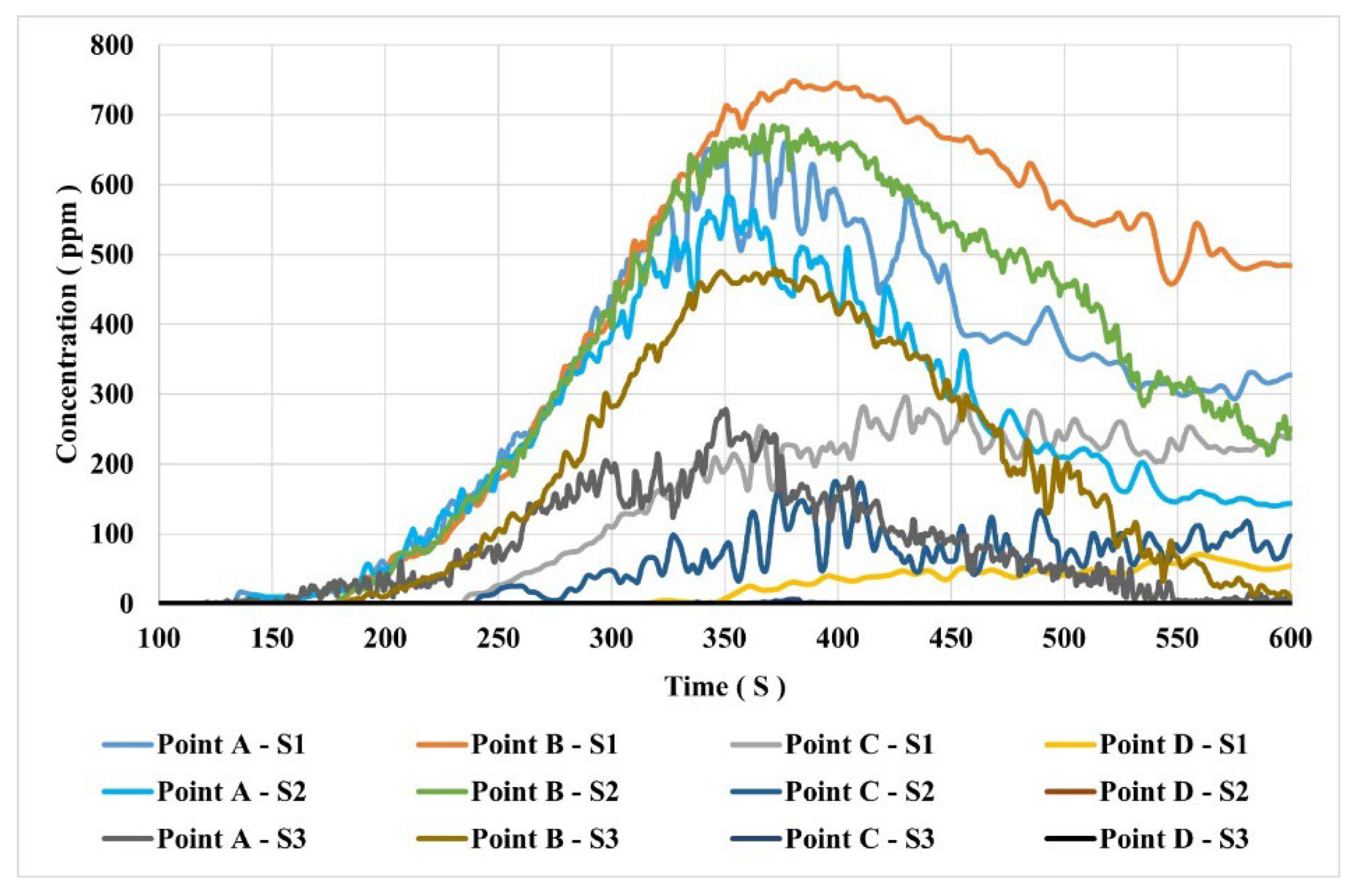

3.6. CO Concentration Figure

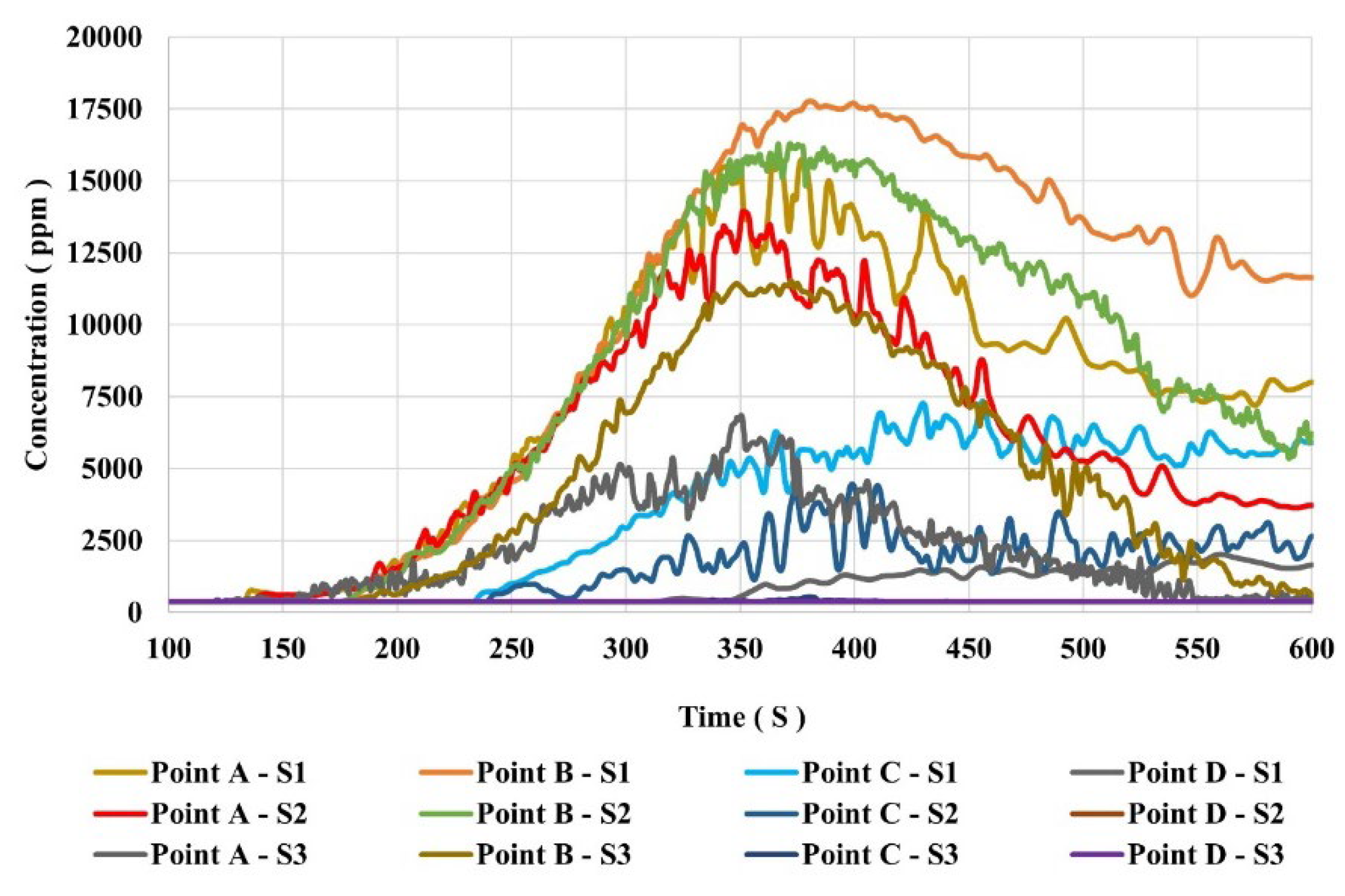

3.7. CO2 Concentration Figure

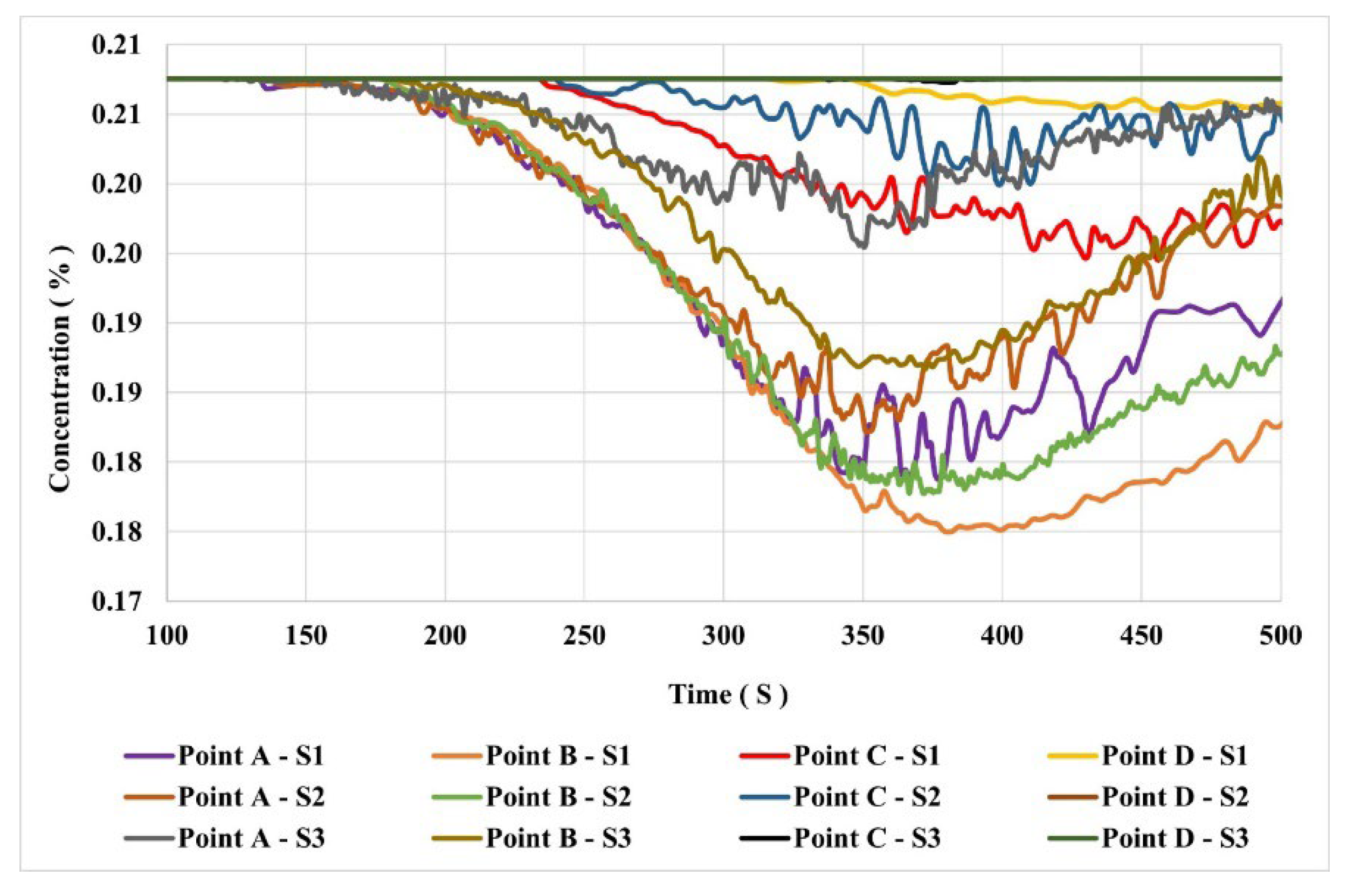

3.8. Oxygen Concentration Figure

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouache R, Ruparathna R, Sadiq R, Hewage K. Fire risk assessment model for residential buildings using bow-tie method. The University of British Columbia. 2018.

- Cai Q, Tang S, He L, Hu Q, Li Z, Zhang C. A safety risk decision approach to fire secondary accidents in operating subway environment. FRESENIUS ENVIRONMENTAL BULLETIN. 2022;31(7):6800-18.

- Zhi-Xiang X, Xiao-Fang Z, Hua S, Wen-Li G. Applied research of performance-based fire protection design in a large building. Procedia Engineering. 2011;11:566-74. [CrossRef]

- HR S. Analyzing the Risk of Fire in a Hospital Complex by" Fire Risk Assessment Method for Engineering"(FRAME). International Archives of Health Sciences. 2014;1(1).

- Alibeigi M, Goli NA, Safarabadi M, Choghaee M, Eyni E, Jokar A. Assessing the level of preparedness of Arak teaching hospitals for dealing with natural disasters and unexpected events in 2016. J Adv Pharm Educ Res. 2019;9(Suppl 2):111.

- HOSSEINI SH, Seddighi A, HOSSEINI AH. Pathology of Mashhad hospitals with emphasis on passive defense approach case study: Razavi and Emam Reza hospitals. 2014.

- Sahebi A, Jahangiri K, Alibabaei A, Khorasani-Zavareh D. Factors influencing hospital emergency evacuation during fire: A systematic literature review. International journal of preventive medicine. 2021;12. [CrossRef]

- Shafiei E, Yousefi K, Sahebi A. Lessons learned; hospital emergency evacuation in Ilam, Iran. 2019.

- Rahmani A, Salem M. Simulation of fire in super high-rise hospitals using fire dynamics simulator (FDS). Electronic Journal of General Medicine. 2020;17(3):5. [CrossRef]

- Sharma R, Bakshi H, Banerjee A. Fire safety hazards: How safe are our hospitals? Indian journal of community medicine. 2020;45(1):104-5.

- Habibi E. Evaluation of the Risk of Fire by FRAME method and survey effect of sprinkler system existence, on the level of fire risk in the University hospital in 2016.

- Lu S, Mei P, Wang J, Zhang H. Fatality and influence factors in high-casualty fires: A correspondence analysis. Safety science. 2012;50(4):1019-33. [CrossRef]

- Hurley MJ, Gottuk DT, Hall Jr JR, Harada K, Kuligowski ED, Puchovsky M, et al. SFPE handbook of fire protection engineering: Springer; 2015.

- Zaroushani V, Khajehnasiri F. Challenges on Hospital Fire Safety during COVID-19 Crisis. Journal of Health and Safety at Work. 2022;12(2):237-43.

- Bahranifard A, Rahzani K, Rad AAM, Malekpour M. Proposing an optimization procedure and applying management performance in health and medical emergency on preparedness of emergency department in suburb city hospitals. 2017.

- Hokmabadi R, Mahdinia M, Zaree R, Mirzaee M, Kahsari P. Fire risk assessment by FRAME in a hospital complex. Journal of University of Medical Sciences. 2017;9(2):173-82. [CrossRef]

- Sarsangi V, Saberi H, Malakutikhah M, Sadeghnia M, Rahimizadeh A, Aboee Mehrizi E. Analyzing the risk of fire in a hospital complex by “fire risk assessment method for engineering”(FRAME). International Archives of Health Sciences. 2014;1(1):9-13.

- Bashyal C, Mishra K, Aithal P. Fire Safety Compliance Among Hospital Buildings: A Case Study from Nepal-Asia. Bashyal, C, Mishra, AK, and Aithal, PS (2022) Fire Safety Compliance Among Hospital Buildings. 2022:33-57. [CrossRef]

- Hashem S, Kouhpaei A. Fire Risk Assessment. 2nd ed.Tehran, Iran: Fanavaran Publication; 2018. pp. 71-73.

- Hashemi A. The Use of Fire Dynamics Simulation in the Analysis of a Fire Incident in an Office Building,Semnan University, Iran. 2020.

- Hu G, editor Research on the Fire of High-rise Residential Building Based on Pyrosim Numerical Simulation. IOP Conference Series: Earth and Environmental Science; 2020: IOP Publishing.

- Mousavipour S-S, Sohrabizadeh S. Emergency evacuation of the Neonatal Intensive Care Unit (NICU) during disasters: A systematic literature review. Acta Medica Iranica. 2021. [CrossRef]

- Smith VC, Dukhovny D, Zupancic JA, Gates HB, Pursley DM. Neonatal intensive care unit discharge preparedness: primary care implications. Clinical pediatrics. 2012;51(5):454-61.

- Chowdhury K. Fires in Indian hospitals: root cause analysis and recommendations for their prevention. Journal of clinical anesthesia. 2014;26(5):414-24. [CrossRef]

- Long X, Zhang X, Lou B. Numerical simulation of dormitory building fire and personnel escape based on Pyrosim and Pathfinder. Journal of the Chinese Institute of Engineers. 2017;40(3):257-66. [CrossRef]

- Pyrosim User Manual, Thunderhead Engineering, National Science Foundation, manhattan, 2023.

- McGrattan K, Hostikka S, Floyd J, McDermott R, Vanella M. NIST Special Publication 1018-1. Fire Dynamics Simulator. Technical Reference Guide. Volume 1: Mathematical Model.- November 19, 2021.

- Kim H-J, Lilley DG. Heat release rates of burning items in fires. Journal of propulsion and power. 2002;18(4):866-70. [CrossRef]

- Hurley MJ, Gottuk DT, Hall Jr JR, Harada K, Kuligowski ED, Puchovsky M, et al. SFPE Handbook, 5th Edition, Tables A.38 and A.39 Springer; 2015.

- Bilge Mİ. CFD simulation of train fire in the İstanbul metro tunnel: Middle East Technical University; 2018.

- Foschia M. Assessment of the software Fire Dynamics Simulator (FDS) for fire simulation in train convoyes. 2017.

- Shin S-K, Bae Y-H, Choi J-H. Evaluating fire risk of long-term care hospitals for the elderly. Fire science and engineering. 2021;35(6):53-60. [CrossRef]

- Conrad AN. Data inaccuracies in Texas state agency testing for ambient and indoor carbon dioxide concentrations 2005-2011.

- Liang T, Liu J, Tao P, editors. The implementation of the numerical simulation by utilization of pyrosim on the rectification of the hazard of fires. Proceedings of the 11th International Conference on Computer Modeling and Simulation; 2019.

- Behbahani F, Hamzei M, Mehrdoost Z, Moghiman M. Temperature and smoke profile of fire in the parking of a commercial building with Pyrosim software. Journal of New Applied and Computational Findings in Mechanical Systems. 2022;1(4):50-6.

| Surfaces and objects | Material and composition ratio (m) |

|---|---|

| Wall | Plaster 0.05 - Concrete 0.35 |

| Table | Wood 0.06 - Metal 0.005 |

| The chair | Foam 0.08 - Fabric 0.003 - Metal 0.005 |

| hospital bed | Foam 0.1 - Fabric 0.005 - Metal 0.005 |

| ceiling | Concrete 0.3- plaster 0.1 |

| Surface Materials | Density (Kg/m3) |

Heat Conductivity (W/m·K) | Heat Capacity (kJ/kg·K) | Heat of Combustion (Kj/mol) |

|---|---|---|---|---|

| Foam | 28 | 0.05 | 1/7 | 25400 |

| Cloth | 100 | 0.1 | 1/357 | - |

| Concrete | 2280 | 8/1 | 1/04 | - |

| Wood | 540 | 0.166 | 2/4 | 196500 |

| Gypsum Plaster | 1440 | 0.48 | 0.84 | - |

| Iron | 7900 | 80 | 0.45 | - |

| Scenario | Scenario Specifications | |||||

| Control equipment | No. | Time and Method of Activation |

Installation Location | Flow rate (m³/s) | D (m) | |

| 1 | Fire starts without control devices | |||||

| 2 | Portable exhaust Model: BTF-60 |

1 | Smoke detector + 2 min | Point 6 | 3/99 | 0/5 |

| 3 | Ceiling exhaust Model: Zilabag |

3 | Smoke detector | Point 1,3,4 | 1/33 | 0/5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).