1. Introduction

The extraction of nickel and cobalt in the eastern region of Cuba is carried out from limonitic minerals (rich in iron) in vertical autoclaves at a pressure of 3619,7 kPa and a temperature of 240 °C. Under these conditions it is achieved that the iron solution is almost zero, so that nickel and cobalt are selectively solubilized and in greater quantity. This process involves several multiple reactions, being the selectivity to form the desired product a very important aspect to analyze. Poor selectivity requires waste or loss of reagent to achieve the given amount of desired product [1, 2, 3].

Worldwide, it is recognized that the most efficient and economical technology for obtaining nickel is the High Pressure Acid Leach, known as HPAL. Studies carried out on the different nickel production technologies [4, 5], indicate that HPAL is the most economical alternative for processing nickel ores [

6], even for low grade ores. The trends in acid leaching processes are: operating the autoclaves with temperatures between 260 and 270 °C; indirectly heating feed pulps; employ direct preparation technology and hypersaline water [7, 8]. Among the factors involved in the transport process of hydromix for the acid leaching process, the effects of particle size distribution, pH, and mineralogical composition can be analyzed. The concentration of solids and the temperature of the suspension are of primary interest in this investigation. The temperature determines the operating conditions of HPAL [

9], as the degree of solubility of the metals oxidized with sulfuric acid directly depends on temperature. In the bibliography consulted there is no reference to previous investigations of the behavior of the rheological parameters of the preheated pulp that is processed in the leaching plant.

Lateritic pulps are non-Newtonian fluids and have as a fundamental characteristic that their viscosity is a function of the velocity gradient even when the temperature and other constant conditions are maintained. Its rheological properties, which are of special interest to design the efficient operation of the pumping system: μ

a, apparent viscosity of the suspension (Pa·s); τ

0, initial shear stress (Pa); K, consistency index (Pa·s n), is a measure of the viscous degree of the material; n, flow index (dimensionless, which is a measure of the degree of non-newtonian behavior of the material. In general, n varies little with changes in temperature and concentration; on the other hand, K is highly affected by the variations of these variables. Initial shear stress and plastic viscosity change significantly with temperature and solids. Surprisingly, systems like dense emulsions, colloidal pastes, foams or granular materials exhibit many rheological properties in common. All of these systems can flow like a liquid when a high enough external stress is applied, but they get stuck in a rigid amorphous state below a critical yield point [

10].

In principle, the behavior of the fluid, as long as there is no reaction or physical process, could follow one according to Arrhenius's Law. In general, a decrease in viscosity with increasing temperature has been observed in most liquids and suspensions [11-13]; in the case of pseudoplastic fluids, the most affected parameter is the consistency index, which denotes little impact on the flow index [14, 15]. The decrease in viscosity is due to two main causes [16-18]: decrease in the viscosity of the dispersing medium and weakening of the structures formed by the particles with increasing temperature. Very few studies have been carried out on the effect of temperature in the case of laterite suspensions [19, 20, 21], According to the results obtained, it is confirmed that shear stress and viscosity, as well as other rheological characteristics, decrease as the temperature increases and this is the typical behavior expected in most liquids and suspensions. This analysis was carried out with temperatures between 28, 35 and 40 °C. It was verified in the research process that the preheated pulp reaches values of up to 90 °C, without determining to date the behavior of the rheological parameters at these temperature values.

The main limitation of the research carried out by various authors [14, 15, 18, 22, 23] is that temperature variations are not considered in the rheological behavior of the fluid, despite playing a key role on the structure and properties of the material. As concluded by [24-28] on the influence of rheological properties on the behavior of the operational characteristics of pumping equipment, the simplest method for obtaining the operating parameters and reconstruction of the characteristics by a varying viscosity, is based on the use of specific correction coefficients for each fluid, obtained experimentally.

The bibliographic review described in the present investigation does not give a satisfactory answer to the problem at hand. In most cases, the phenomenology of non-newtonian fluids is treated, which, though they provide the basis for the research, do not fully describe the phenomenon under study (the transport of fluids at temperatures higher than that of the environment and the irregularities of the flow in turbulent regime).

The objective of this research is to verify, in the current exploitation conditions with mineral deposits with low grade, the behavior of the rheological parameters for concentrations between 37 and 48% (p/p) of solids, when n <1, if the plastic behavior of the lateritic pulps is maintained at a temperature of 90 °C as well as its impact on the energy parameters of the pumping system.

2. Materials and Methods

Once the factors that may influence the rheological parameters been chosen, laboratory work and mathematical processing of the experimental data is required, as well as a large volume of historical data of the thickening and preheating process of pulps that allow the characterization of the main mineral suspensions that are handled in this stage of the production process.

In the operation database, reported during the last 5 years, as well as the reports of the mechanical and operational characteristics of the pumps used in the process, to define the solids concentration, it was determined that the solids concentration of the raw pulp ranges between (36-46)%, although the most frequent value is around 43%, due to changes in the characteristic of the mineral fed, so that the desired value by design of 48% of content of solids to the discharge of the thickeners, which must be sent to the Leaching Plant is not attained. When preheating the raw pulp, due to the addition of water vapor, the solids content decreases by (1,5-3)%, 40% solids is the highest frequency value, which negatively affects the acid/ore ratio and the percentage of nickel and cobalt extracted (see

Table 1).

It was determined in the investigation that the preheating process is not carried out at 82 °C as indicated in the operations manual, see

Table 2.

2.1. Equipment

The equipment used was the following: HAAKE VT 550 for rheological measurements, Mettler Toledo digital technical balance, Ohaus dryer balance, IKA RW 28 mechanical impeller agitator, Cimarec thermal plate, Master Flex Model 77601-10 water pump, Humber thermostat. The chemical composition of the studied samples was determined by the X-ray fluorescence method, also known as the X-ray Method on a PW 1480 X-ray Fluorescence Spectrometer (Philips). The determination of the granulometric distributions of the studied samples was carried out by means of a particle size analyzer of the "Analysette 22" COMPACT type.

2.2. Preparation of Mineral Suspensions

To carry out the experiments, the operating range of the Thickener and Leaching Plants was determined, according to the program used in the company for process control (CITECT). The experimental work was developed in the Acid Pressure Leaching Laboratories of the Center for the Development of the Nickel Industry (CEDINIQ), the Chemical Laboratory of the company and the University of Moa.

To carry out the experiments, the procedure and the sampling program established in each plant were followed. During six alternate weeks, depending on the mining front and every one hour, from 7 am to 7 pm, samples of 500 mL of pulp were collected at selected points in a 1000 mL volumetric to prepare 12 composites in 20 L containers, see

Table 3. A total of five samples of 200 g were prepared with three replicates for the concentrations of solids selected from the Composite Samples by Demonstrative Production Unit, contained in covered 250 mL flasks.

A chemical and granulometric analysis was carried out on each composite sample and the mineral number was determined. As the chemical and granulometric compositions are maintained at the historical values of the company, four composites MC1, MC6, MC11, MC4 were selected to perform the rheological analysis, due to the differences between their mineral numbers. The samples MC5, MC2, MC9, MC7, MC12 remain as a database to validate the mathematical models obtained. The samples were left at rest to settle and the water was removed by decantation in order for them to reach 48% (p/p), as the upper limit in the experiments. To obtain the fixed solids, each of the samples was diluted using the procedure used in the company, considering that the density of laterite is 3,55 g / cm3 and that of water is 0,9963 g/cm3.

2.3. Variable Selection

The rheological properties or dependent variables that are of special interest are: μa: apparent viscosity of the suspension ; 0: initial shear stress, K: consistency index; n: flow rate, which are responses when certain properties of the pulps vary experimentally, namely: s: characteristic parameter of the granulometry (Polydispersion Coefficient); % S: solids content (mass of solids in the pulp); T: temperature; Nrmin: mineral number (it is determined from the knowledge of the chemical composition of the lateritic pulp).

The arithmetic mean and the standard deviation of the corresponding measured variables were calculated and taken as the sample values, which, due to their intervals, positively supported the precision of the sampling process, with 420 samples. To validate the use of these properties as independent variables, of models used to explain the behavior of the rheological properties of the pulps, linear models were determined from the data obtained, (r is the correlation coefficient) and the validity of the level of influence of the independent variables on the dependent variables was verified by hypothesis tests.

2.4. Rheological Measurements

After preparing the suspensions of each sample, at the percentages of solids defined for the experiments (37, 40, 43, 46 and 48% (p/p)), the rheological measurements were started at room temperature and then the temperature was increased (from 28 to 90 °C), heating the pumped water until the value of each measurement was reached and stabilized.

For rheological measurements, a HAAKE 550 brand rotational viscometer was used, to which a flow pump was connected to recirculate the water at different temperatures to preheat the pulp. In the viscometer, a standard SV DIN type sensor was used and not an ellipse type SV2 sensor, since it was not available. The possibility of pulp sedimentation during the measurement process and the corresponding decreased precision was considered. To obtain the shear stress values, three replicates were measured for each value of the velocity gradient and the corresponding arithmetic mean, standard deviation and coefficient of variation that did not exceed 5% were determined.

3. Results and Discussion

Investigation of the properties of raw and preheated lateritic pulp has been deepened, based on the experiment and study of its main transportation characteristics; Thus it was possible to determine the use of specific mathematical models that fit the studied fluid.

3.1. Chemical Composition of Lateritic Suspensions

According to the Thickener Plant Operations Manual, the pulp that is fed as raw material is sent from the Pulp Preparation plant with 25% (p/p) solids and 10% (p/p) sand; It has 9 elements, which are shown in

Table 4. The product pulp retains the same chemical properties as the fed pulp, only its percentage of solids increases to values between 46 and 48% (p/p).

Taking the previous values as a reference, the four selected pulps were chemically analyzed and the results obtained are presented below, in

Table 5.

The mineral raw material that enters the HPAL process has an iron content of the order of (35,5 to 53,4)%, including other components such as aluminum (2.23-5.99)% and magnesium of (0.1 at 3.3)%, this confirms the ferruginous nature of typical laterite samples, in which iron oxides are abundant. In the mineralogical composition of materials with poor sedimentation, a marked difference is detected between the coarse and the fine fraction, because while the fraction (<0,074 mm) is made up of mineralogical phases traditionally known in laterites as goethite, hematine and magnetite, in the coarse granulometric class, silicates of magnesium silicate are present: chlorite, olivine and quartz, which are light metal minerals that provide a low density; its presence in the pulp constitutes an unfavorable factor for sedimentation [29, 30]. The mineral number Nrmin characterizes the behavior of the pulp in sedimentation [

31]. It has been found that when 7 <Nrmin <14, the pulp has good sedimentation in the process because there is an adequate correlation between light and heavy (ferrous) metals.

3.2. Granulometric Analysis

In the granulometric distributions of the four composite samples, it can be seen that they are all made up of small particles, less than 50 µm, which are those that confer plastic properties to the pulps. There is a predominance of fine fractions in general and the D80 corresponds to that of particles smaller than 7 µm, which indicates that 80% of the sample has a diameter less than this value, therefore, the finest particles are majority and determine the sedimentation rate of this mineral, as well as its rheological behavior, that is, the particles of all these materials have a behavior typical of polydisperse systems.

3.3. Experimental Results of Rheology in Raw and Preheated Pulp

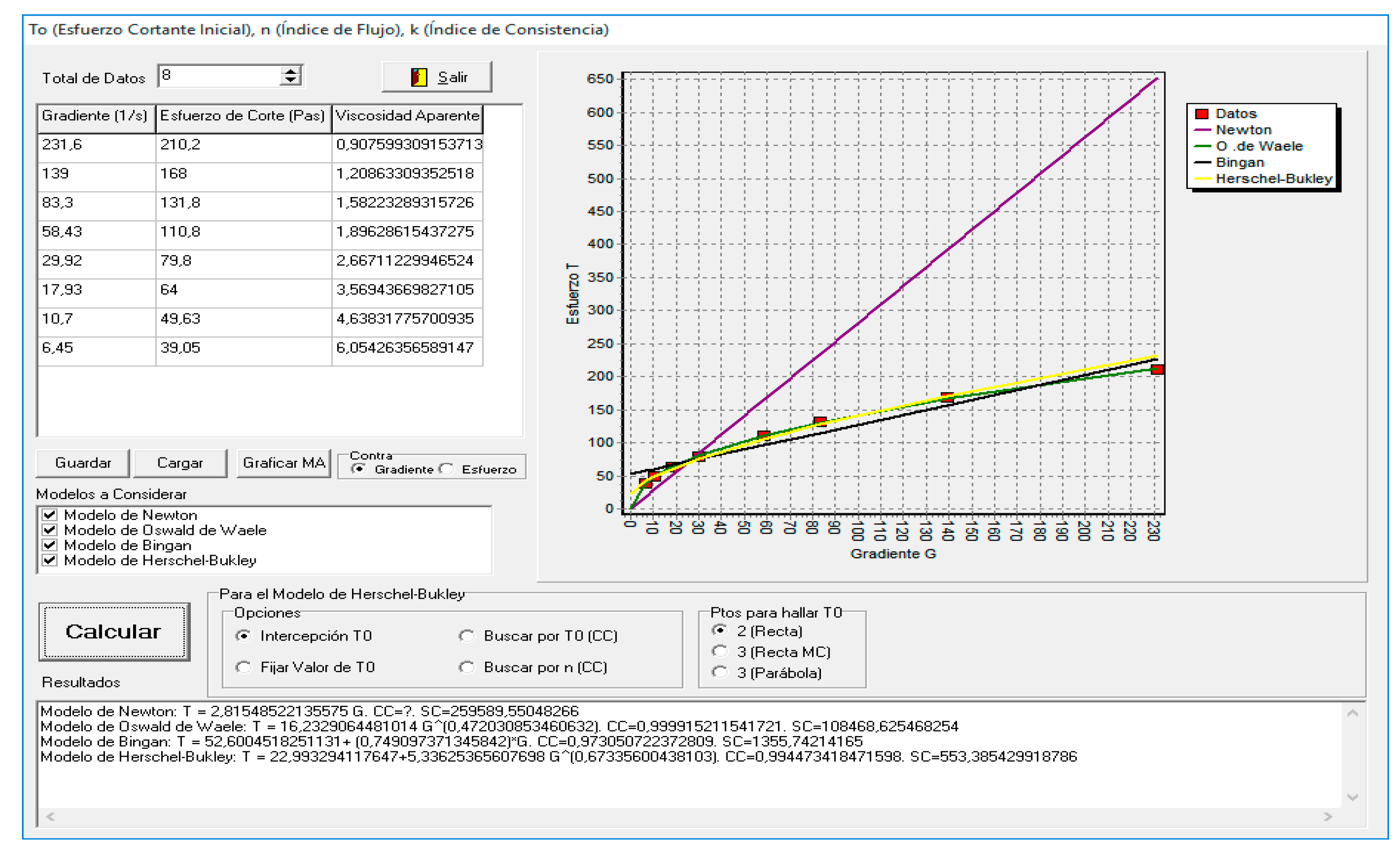

At present, modern viscometers have software that allows them to make the analysis of the models from the readings of the velocity gradient and shear stress. Examples of these applications are the Rheocalct of the Brookfield viscometer and Rheowin 4 for Windows 8 from HAAKE, more modern than the one used in this research. Due to not having it available, a computer application was designed for the modeling of the flow curves by means of least squares adjustments of the most well-known rheological models. In each case, the correlation coefficient is reported as an indicator of the quality of the models and is shown in

Figure 1.

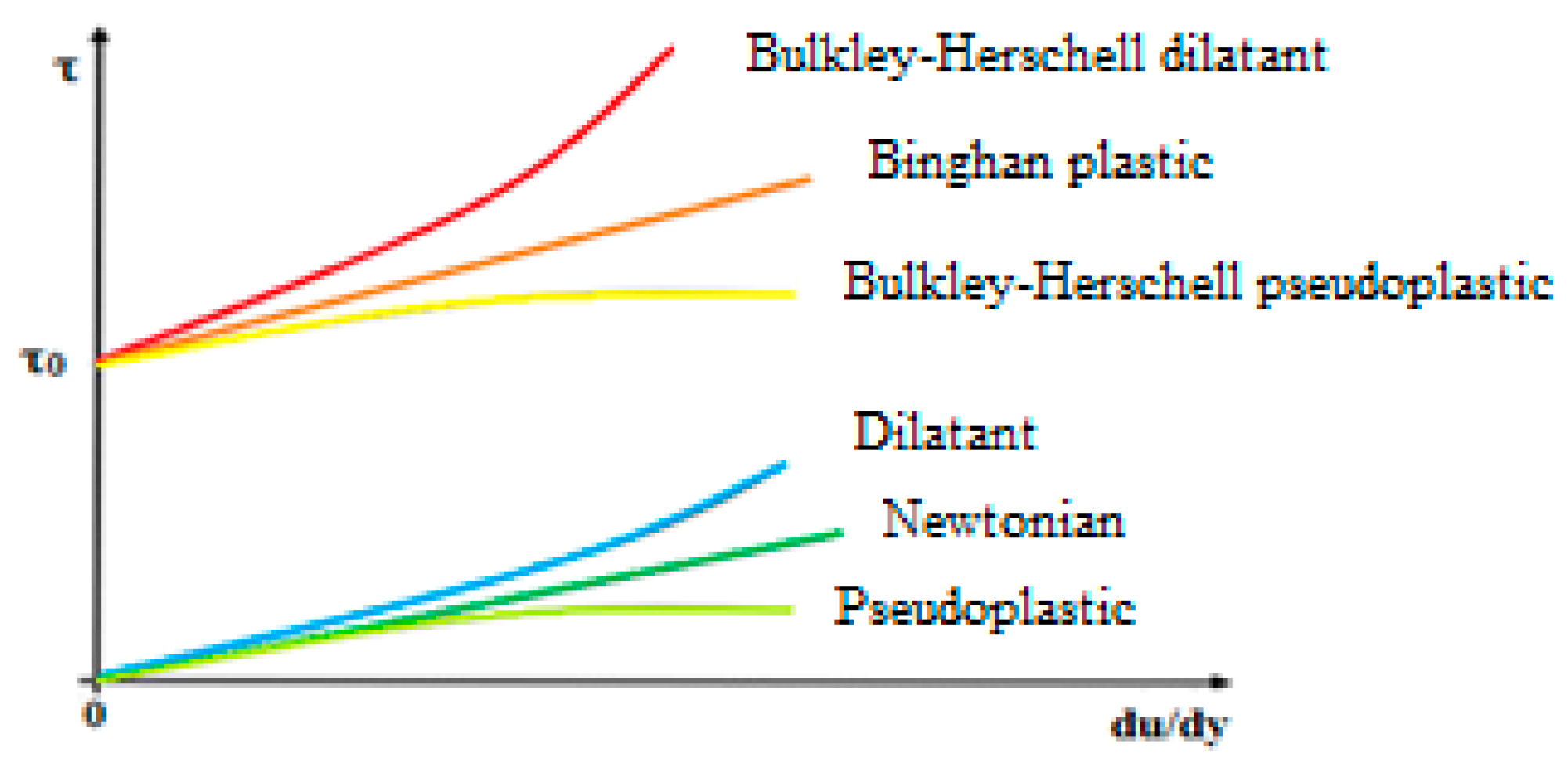

The flow curve is the basic tool for the rheological analysis of a flow system, and of a fluid. Based on its shape, it is possible to identify the rheological nature of the material, as well as determine the viscosity and the fundamental rheological characteristics (depending on the model used) under different working or operating conditions. The most general rheological classification of viscous fluids is presented by [32, 33], indicating a variant to that of Bingham fluids supported by the classical one, which indicates two more possibilities for non-Newtonian fluids that begin to move from of a certain shear stress but whose performance index "n" is greater or less than 1.

Due to the results obtained in this research and the experimentation carried out with samples of lateritic hydromixes that reach solids concentrations of 48% (p /p) and a temperature of 90 ºC, it is proposed to represent them in two new types, see

Figure 2 and are the following: Bulkley-Herschell dilatant, when n> 1 and Bulkley-Herschell pseudoplastic, when n <1.

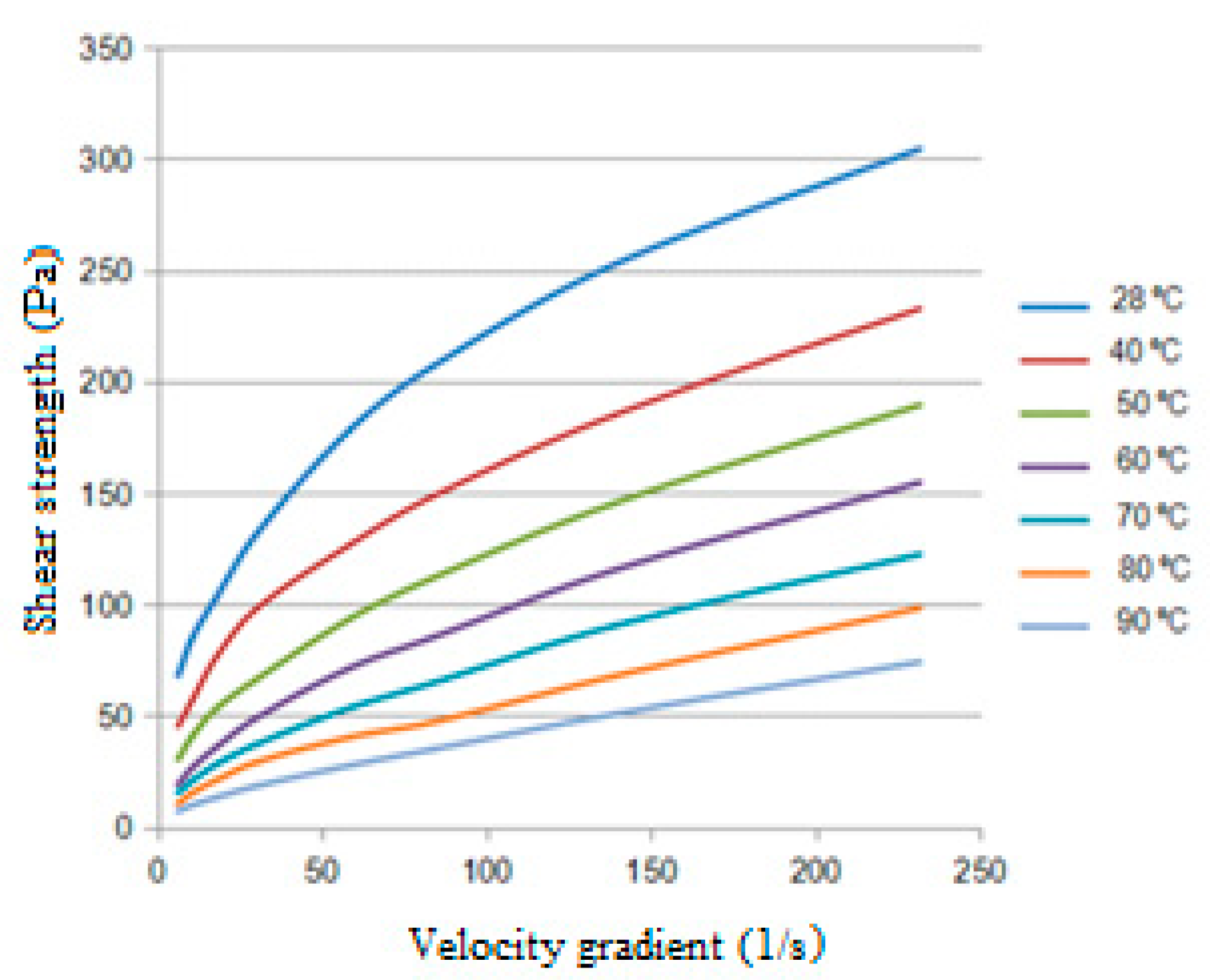

From the analysis of the graphs of the values of shear stress and velocity gradient, see

Figure 3, it is inferred that all the samples conform to the pseudoplastic Bulkley-Herschell model and the rheological parameters are obtained (initial shear stress, index of consistency and flow rate).

The results obtained present the typical behavior of non-Newtonian suspensions for solid concentrations of (37 to 48)% (p/p), and temperature of (28 to 90 ºC), see

Table 6, which will allow determining the influence of rheological parameters in the lateritic hydromix pumping system

In the results obtained in the analysis of the sample of the TKA thickener, the trend of the rheological parameters is verified: by increasing the concentrations of solids at room temperature, the initial shear stress and the consistency index increase and the flow index decreases. This behavior is as expected; it shows the plastic properties of lateritic hydromixes. In the more dilute suspensions they exhibit lower initial shear stress values due to a lower interaction between the particles, since the repulsion forces are higher; However, in the most concentrated suspensions, the particles are close to each other, prevailing the Van der Waals forces, which contributes to the formation of flocs and aggregates that give rise to much stronger structures and, therefore, to higher initial shear stress values. It is confirmed then that at high temperatures the plastic properties of the lateritic pulp tend to decrease, presenting a pseudoplastic behavior; hence the high viscosity problems that sometimes occur with lateritic pulps occur at room temperature.

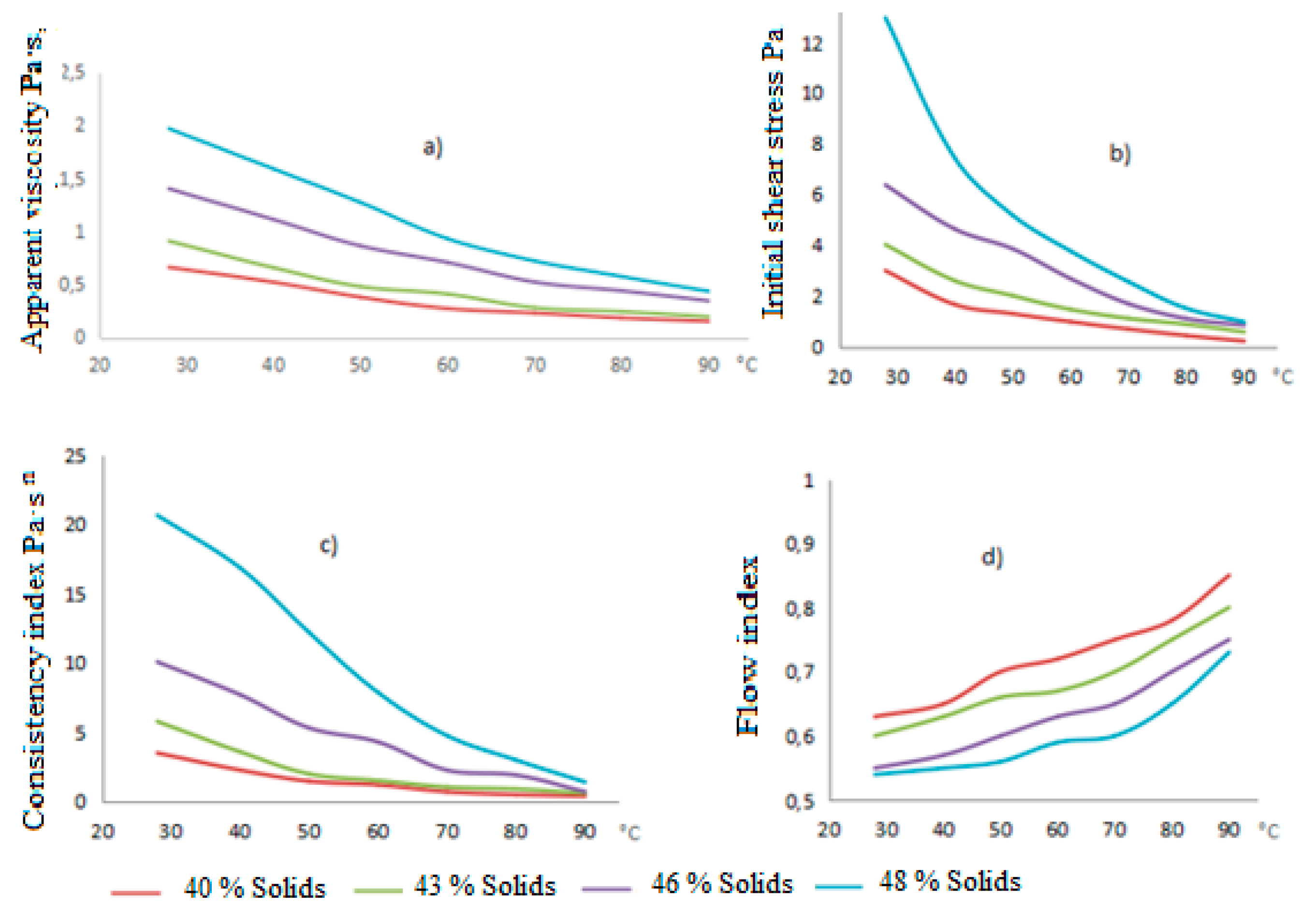

In

Figure 4, it is noted that the values of apparent viscosity, initial shear stress and consistency index, decrease when the temperature increases, while the values of flow index increase; this is the typical behavior expected in most liquids and suspensions. It is confirmed then that at high temperatures the plastic properties of lateritic pulps decrease, because they show a behavior similar to pseudoplastic materials. It is highlighted that the apparent viscosity of the lateritic pulp decreases with the increase in temperature, in it can be seen that for the lower values of the velocity gradient there is a significant change in viscosity, which is coincident with literature [17, 18, 25].

The results obtained justify the objective of the research to know the rheological parameters of lateritic pulps in order to design and evaluate their transport systems, a very important aspect when working with this type of fluid. With this temperature analysis, technological improvements in the acid leaching process can be considered [

34], such as indirect heating of the pulps or the use of water at 70 °C.

3.4. Energy Parameters of the Pumping System

To evaluate the practical worth of the research results, a computer application [

35] was developed to automate the main procedures, which has been designed and programmed in Delphi 7.0 [

36], which facilitates decision-making in the operations of the lateritic hydromix pumping systems, given the need to obtain adequate predictions of the rheological parameters for whatever the measured values of solids concentration and temperature in the actual production process are.

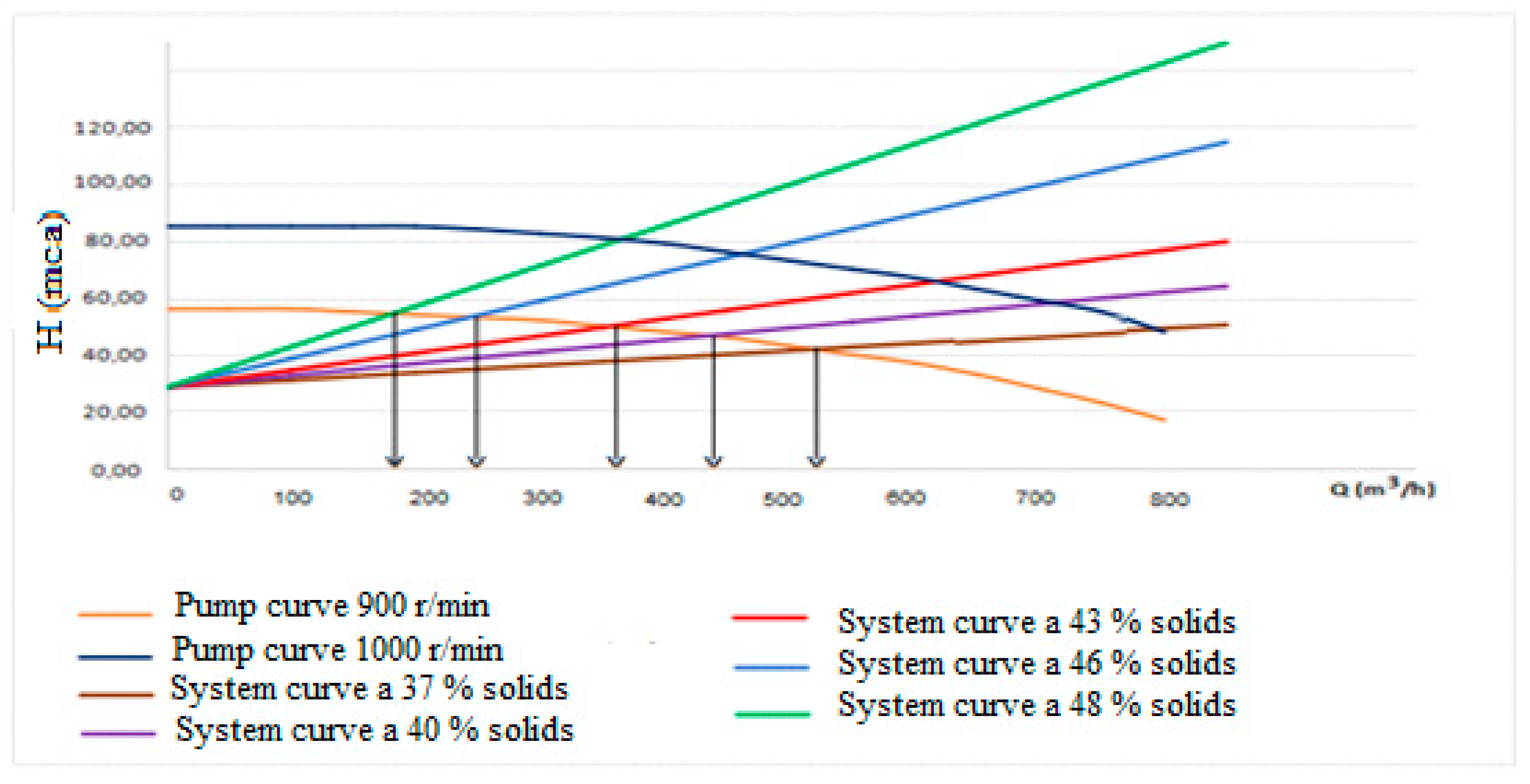

The main results of the Balance of Mechanical Energy (BEM) [32, 37, 38] are presented in

Table 7, and it can be seen that for different concentrations of solids and rheological parameters there is a variation of the characteristics of the parameters of the hydraulic network with a higher pumping power to guarantee the desired flow.

In the case of natural limonitic pulps (untreated) with a high concentration of solids, they are considered non-pumpable, so it is necessary to inject water into the cone of the settler for pumping. Under these conditions, the pulp is diluted at the entrance of the preheater and the autoclave, which causes a decrease in production. To achieve the productivity of the TKA thickener centrifugal pump at 48% (p/p) solids, they have to overcome a pumping head of 82.10 m and a pumping power of 294.58 kW.

With regard to the operation of the pumping systems, the regulation and control systems that allow obtaining the desired flow and pressure must be taken into account, as well as the problems of cavitation, instabilities and transients that may occur [39, 40]. Once the cavitation diagnosis has been made and without detecting anomalies regarding their occurrence, the operational diagnosis of the system is carried out based on the verification that it is delivering the required flow to the process (Q

req) for which this transport service is provided. This is possible as long as the operating flow (Q

op) is greater than or equal to the required flow, that is, Q

op ≥ Q

req. Otherwise, the system does not provide the necessary industrial requirements, so action must be taken to guarantee its efficiency through changes in the operating parameters, the selection of a new pump or the redesign of the system. The economic criterion must decide between the alternatives that are formulated [

41].

Part of this operational diagnosis is the comparison between the operating flow and the flow for the point of maximum efficiency (Q

d). A pumping equipment is operating efficiently when the operating flow has an efficiency that differs up to 10% from the maximum efficiency of the pump [42-44]. This procedure is proposed, which allows evaluating the pumping system from the knowledge of the rheological properties of lateritic hydromixes and the relationship with the load-discharge characteristic curves of networks and pumps [

45]. The results are shown in

Figure 5. The operating point is determined in the current operating conditions of the extraction pumping system of the thickener tanks.

For the daily production of the Leaching Plant, 9,000 to 10,000 t/day of mineral are needed, which is equivalent to 375 and 417 t/h. Between 1600 and 1800 t/day must be extracted from each thickener, for an extraction flow from 450 to 478 m3/h and a solids content of 48% (p/p). In the current operating conditions, the rheological parameters are not taken into account and the transported fluid is characterized as Newtonian. The extraction flow is reduced when the solids concentration exceeds 45% (p/p) to less than 200 m3/h.

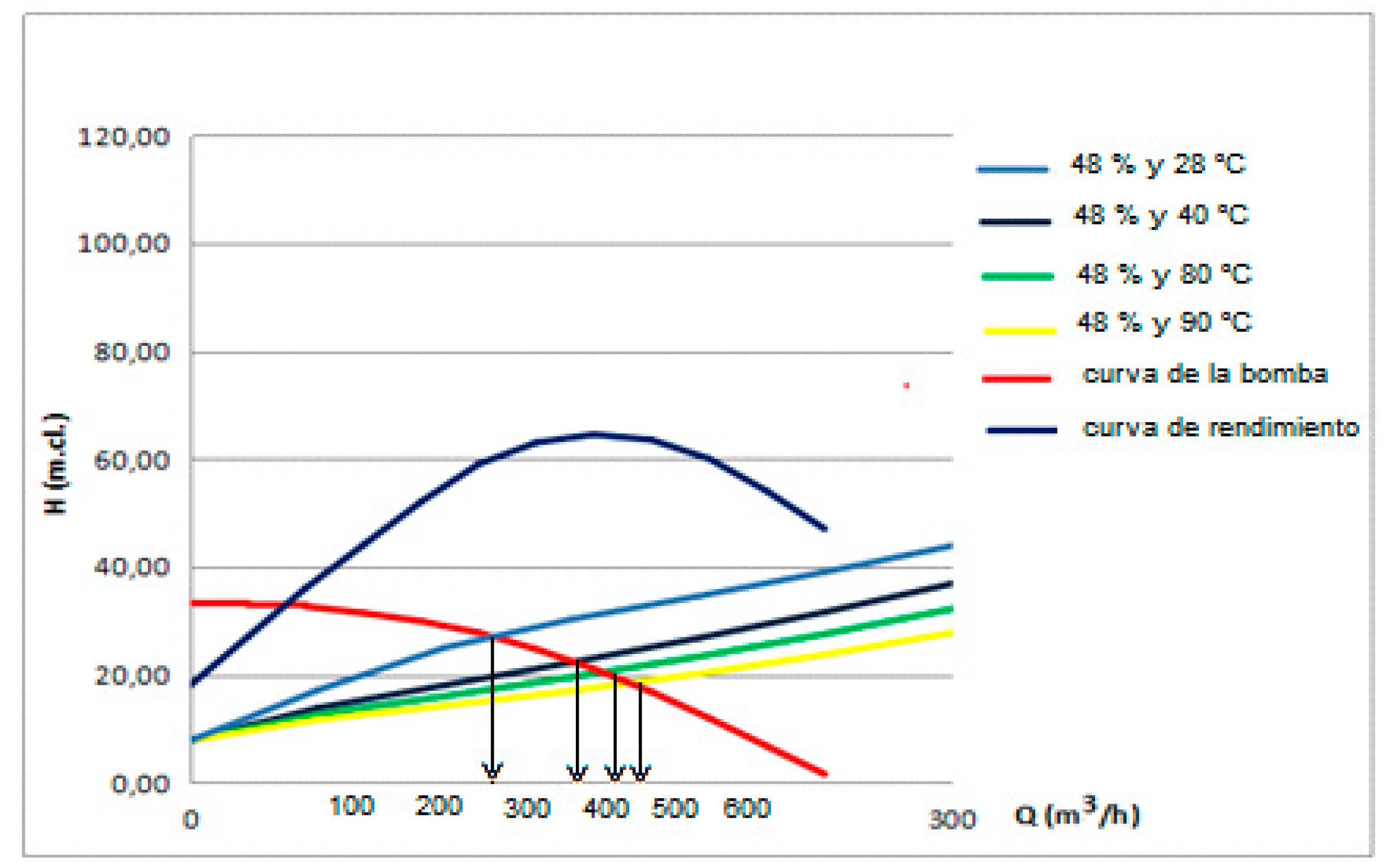

In

Table 8, it can be seen that as the temperature increases, less pumping power is required and this is precisely due to the influence of temperature on the rheological parameters of the pulp. The apparent viscosity and initial shear stress values decrease. It is found that the lateritic hydromix at high temperature increases the flow index, without becoming a Newtonian fluid.

In

Figure 6, the operating point is shown with the results obtained in the investigation where it is evident that with the increase in temperature up to 90 °C, lateritic hydromixes are pumpable at 48% (p/p) of solids concentration and extraction volumes of over 450 m

3/h are reached in the thickener.

Through a diagnosis of the operation in the analyzed facilities, the assertion was based that at present the pumping capacity is reduced to 60%, as the maximum efficiency points of the installed pumps are not considered. Based on simulations and predictions provided by the computer application, it was established that the results obtained have practical utility for making technological decisions that generate positive economic and environmental impact.

4. Conclusions

Mathematical models of rheological parameters are obtained that determine the influence of temperature and solids concentration on the productivity of the raw and preheated lateritic hydromix pumping system such as flows, loads, hydraulic losses, power and efficiency that determine the point of maximum efficiency for the transport of lateritic hydromixes. The influence of temperature on the apparent viscosity is determined with an increase in the flow index, without losing its non-Newtonian behaviour. The results obtained will allow to increase the productivity of 1600 t/day in the Thickener Plant, with high concentrations of solids that will allow to evaluate the technological improvements in HPAL that are applied internationally. Considering that lateritic pulps exhibit a non-Newtonian rheological behavior, with an increase in apparent viscosity in the transport of pulps with a high percentage of solids and the analysis of the aforementioned investigations, it can be assumed that the main variables that participate in the evaluation of the efficiency of the pump-motor assembly are: apparent viscosity (µa), density determined by the concentration of the solid material, pressure loss (ΔP), flow rate (Q), hydraulic power (Nh) and electrical power (Nm ).

Author Contributions

Conceptualization, G.H.-R., R.M.-R., L.A.d.P., J.M., A.B.-S. and J.F.-O.; Methodology, G.H.-R. R.M.-R. and E.F.-S.; Software, G.H.-R., L.P.-G. and L.G.-P. Investigation, G.H.-R., R.M.-R., L.P.-G., L.P.-P., L.A.d.P., J.M., A.B.-S. and J.F.-O.; Validation, G.H.-R., E.F.-S., J.M. J.F-O; Writing—original draft preparation, G.H.-R., R.M.-R. and L.P.-G.; Writing—review and editing, G.H.-R., R.M.-R., L.P.-G and L.G.-P.; Visualization, G.H.-R., E.F.-S. and L.P.-G.; Supervision, G.H.-R., L.G.-P., L.A.d.P., A.B.-S., J.M.; All authors have read and agreed to the published version of the manuscript.”.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available from the corresponding authors upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- H. J. Keenan, Keyes, G., Thermodynamics Properties of Steam, 1986.

- R. E. Treybal, Operaciones de Transferencia de Masa”. 2da Edición, 1990.

- Önal, M.A.R., & Topkaya, Y.A., "Pressure acid leaching of Çaldağ lateritic nickel ore: An alternative to heap leaching". Hydrometallurgy, 142, 98–107, 2014.

- J. Castellanos, Hernández, A.N., "El futuro de la laterita de níquel," presented at the Reunión de Experto Interoceanmetal (IDM), Polonia y CUARTA CONVENCION DE LA TIERRA, GEOCIENCIAS, 2011.

- L. Chaviano, "Mejoras tecnologícas para las plantas con Lixiviación Ácida a Presión," in Lixiviación Ácida a Presión, Ciudad Habana, 2015.

- McDonald, R. G., & Whittington, B.I., "Atmospheric acid leaching of nickel laterites review. Part I. Sulphuric acid technologies". Hydrometallurgy, 91, 35–55, 2008. doi:10.1016/j.hydromet.2007.11.009.

- S. J. Castellanos, Hernández, M. N., "Procesamiento de minerales niquel arcillosos y de mala sedimentación por lixiviación acida a presión," presented at the Congreso Internacional de Minería y Metalurgia. MINEMETAL 2016. ISBN. 978-959.7117-73-5, Matanza. Cuba, 2016.

- M. E. Chalkley, Matos, W , R., Ellenwood , S. , "Successfully adapting to continuing challenges at the moa joint venture," presented at the Congreso Internacional de Minería y Metalurgia. MINEMETAL 2016 Mantanza. Cuba, 2016.

- Mackenzie, M., Virnig, M., & Feather, A., "The recovery of nickel from high-pressure acid leach solutions using mixed hydroxide product LIX®84-INS technology". Minerals Engineering, 19, 1220–1233, 2006. https://doi.org/10.1016/j.mineng.2006.01.003.

- A. Coniglio, A. Fierro, H.J. Herrmann, M. Nicodemi, Unifying Concepts in Granular Media and Glasses, 2004.

- S. Balagui, Mohammadifar, M. y Zargaraan, A, "Physicochemical and rheological characterization of gum tragacanth exudates from six species of iranian astragalus," Journal of Food Biophys, vol. 15 No 4, pp. 59-71, 2010. https://doi.org/10.1007/s11483-009-9144-5.

- A. Bourbon, Pinheiro, A., Ribeiro, C., Miranda, C., Maia, J., Teixeira, J. y Vicente, A., "Characterization of galactomannans extracted from seeds of gleditsia triacanthos and sophorajaponica through shear and extensional rheology," Journal of Food Hydrocolloid, vol. 12 2010.

- R. Colby, "Structure and linear viscoelasticity of flexible polymer solutions: comparison of polyelectrolyte and neutral polymer solutions," Journal of Rheological, vol. 24, 2010. https://doi.org/10.1007/s00397-009-0413-5.

- R. Andrade, Torres, R., Montes, E., "Efecto de la temperatura en el comportamiento reológico de pulpas orgánicas," Revista de la Facultad de Agronomía. , vol. III (26), pp. 599-612, 2009.

- S. Vandresen, Quadri, M., De Souza, J. y Hotza, D, "Temperature effect on the rheological behavior of carrot juices," Journal of Food Engineering, vol. 29, 2009. https://doi.org/10.1016/j.jfoodeng.2008.11.01.

- L. Garcell, "Composición mineralógica de las suspensiones de limonita de Moa, en períodos de sedimentación normal y crítica. Informe investigativo. ISPJAM, Facultad de Ingeniería química," Facultad de Ingeniería química1993.

- H. Laurencio, Delgado, Y, "Influencia de la temperatura en las propiedades reológicas de la emulsión de petróleo pesado," Minería y Geología, vol. 24 2008.

- S. Trapeznikov, "Fundamentación de los regímenes de temperaturas de trabajo de los oleoductos superficiales en caliente," Tesis Doctorado, Instituto de Minas de San Petersburgos, Rusia, 2011.

- A.P. Avotins, Ahlschlager, S. S., Wicker, R. G., "The Rheology and Handling of Laterite Slurries," presented at the International Lateritic Symposium, 1979.

- L. Pérez, Cardero, Y., Lamoth, Y., Garcell, L., "Estudio del comportamiento reológico de una suspensión industrial de laterita," Revista Tecnología Química, vol. XXVIII (1), 2008.

- Kaya, Ş., & Topkaya, Y.A., "High pressure acid leaching of a refractory lateritic nickel ore". Minerals Engineering, 24, 1188–1197, 2011. https://doi.org/10.1016/j.mineng.2011.05.004.

- M. Dak, Verma, R., Jaaffrey, S., "Effect of temperatures and concentration on rheological properties of kesar," Journal of Food Engineering, vol. 28, 2007.

- Ma, B., Yang, W., Yang, B., Wang, C., Chen, Y., & Zhang, Y., "Pilot-scale plant study on the innovative nitric acid pressure leaching technology for laterite ores". Hydrometallurgy, 155, 88–94, 2015. doi:10.1016/j.hydromet.2015.04.016.

- J. Bienvenido, "Modelo de un sistema de bomba, tanque y red," Voluntad Hidráulica, vol. 3, 1973.

- A.H. Laurencio, " Método para la determinación de parámetros racionales de transporte por tuberías del combustible cubano crudo mejorado 650," Tesis Doctorado, Ingeniería Mecánica, Instituto Superior Minero Metalúrgico de Moa, 2012.

- León, Percy, F., "Ahorro de energía por control de velocidad en el sistema de bombeo de Guarapo," Centroazúcar, vol. 1, 2000.

- F. Santos, Martin, M, "Modelos matemáticos para la determinación aproximada de la forma de la caracteristica de trabajo de una bomba centrífuga.," Centro Azucar, vol. 1, 1999.

- M. Turiño, "Determinación aproximada de la característica de funcionamiento de una bomba centrifuga," Centro azúcar, vol. 3, 1999.

- F. Almaguer, "Composición de las pulpas limoníticas de la planta Pedro Sotto Alba” (Parte II). Período de Crisis de Sedimentación," Revista Minería y Geología, vol. XIII (1), pp. 27-30, 1996.

- A. Rojas, Beyris, P., "Influencia de la composición mineralógica en la sedimentación del material limonítico de frentes de explotación de la industria "Pedro Sotto Alba"," Minería y Geología., vol. XI (1), 1994.

- d. A. Colectivo, "Manual de Operaciones Planta de Espesadores," E. P. S. Alba, Ed., ed, 2010.

- A. Levenspiel, Engineering Flow and Heat Exchange, 1986.

- P. T. Slatter, "The rheological characterisation of sludges”," IAWQ Journal. Wat. Sci. Tech, vol. 6, 1997.

- Büyükakinci, E., Topkaya, Y.A., "Extraction of nickel from lateritic ores at atmospheric pressure with agitation leaching". Hydrometallurgy 97 (1–2), 33– 38, 2009. doi:10.1016/j.hydromet.2008.12.014.

- R. G. Hernández, "Modelación de los parámetros reológicos de las pulpas lateríticas y su influencia en el sistema de bombeo," Doctoral, Departamento de Ingeniería Eléctrica, Instituto Superior Minero Metarlúrgico de Moa, 2017.

- Borland., "Delphi ", 7.0 ed, 2002.

- L. Garcell, Flujo por tuberías de suspensiones minerales no newtonianas. Universidad de Oriente, 2001.

- Z. Rabinovich, Hidraúlica: Editorial Pueblo y Educación, 1987.

- Nekrasov, Hidráulica. Moscú, Rusia: Editorial Mir, 1990.

- V. Streeter, Benjamin, E. y Bedford, K, Mecánica de fluidos. Novena Edición, 2000.

- M. Turiño, "Procedimientos metodológicos para la determinación del punto de operación en sistemas de bombeo mediante modelos matemáticos.," Tesis Doctorado, Mecánica, Universidad Central de las Villas, 1996.

- [R. G. L. Hernández, L, Rojas, H,L; Ramírez, S,B; Mariño, Pérez. A, "Modelos matemáticos de parámetros reológicos y su influencia en el sistema de bombeo de fluidos no newtonianos.," Colombiana de Química, vol. vol. 47, pp. 52-60, 2018.

- L. H. Pérez, G; Garcell, L, "Influencia del comportamiento reológico de las pulpas lateríticas en la eficiencia de bombeo," Tecnología Química vol. Vol. 42, No.3, 2021.

- H. G. Pérez L., L. Garcell, "Modelo granulométrico y de viscosidad relativa de pulpa limonítica del proceso de lixiviación ácida," Revista Tecnología Química, vol. Vol.40, No.2, 2020.

- R. Hernández, G., León, A., Salazar, E., "Mathematical modeling of the load correction coefficient of the lateritic of hydromixtures pumping," DYNA, vol. 86, pp. 19-27, 2019.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).