1. Introduction

The Circular Economy (CE) is viewed as a systematic solution framework designed to address global challenges related to resource use and the environment (Geng et al., 2019). This concept has attracted considerable attention from policymakers, business practitioners, and researchers (Farooque et al., 2022; Genovese et al., 2023). The goal of CE is to create a zero-waste product process by transitioning from a linear model of material-energy flow to a closed-loop system that is recoverable and renewable (Patwa et al., 2021; Triguero et al., 2022). Currently, CE has been extensively studied and implemented at macro-level eco-regions and meso-level eco-industrial parks (Farooque et al., 2022; Liu et al., 2023), with some management and research experience also reported at the micro-level of corporate practices.

For example, Braz and Marotti De Mello (2022) analyzed the critical components of managing supply networks in a circular economy within the complex adaptive systems of enterprises through multiple case studies. Their focus was on how companies organize and manage supply chain members, emphasizing the coordination mechanisms among network partners. Additionally, Figge et al. (2021) employed multi-level selection theory and mathematical models to demonstrate that enhancing overall ecological efficiency in a circular economy leads to improved corporate ecological efficiency. This enhancement is predicated on the sharing of activities, processes, and collaboration. They emphasized that while digital technology plays a significant role in this process, it is insufficient (Cenamor et al., 2019; Figge and Thorpe, 2023; Figge et al., 2021).

Platform technology, or digital platforms, is closely linked to the circular economy and is widely utilized. Digital platforms are technologies that allow businesses to standardize, modify, and distribute data at scale (de Reuver et al., 2018; Jovanovic et al., 2022). They facilitate closer connections, effective communication, and more efficient automation among enterprises, consumers, and suppliers, thus expanding the boundaries of business operations (Broekhuizen et al., 2021; Cenamor et al., 2019). Sedera et al. (2016) described digital platforms as an evolutionary form of information technology infrastructure, including social media, mobile computing, and e-commerce platforms. Through digital platforms, direct engagement with external stakeholders allows one party’s active participation to enhance the business value for market participants on the other side (Cenamor et al., 2019; de Reuver et al., 2018; Jovanovic et al., 2022). Consequently, the emergence of digital platforms expands the boundaries of business activities, challenging the fundamental principles of traditional enterprise value creation (Rohn et al., 2021).

Digital platforms, including blockchain, big data analysis, cloud technology, industrial simulation, and the Internet of Things, are open, affordable, and widely accessible (Broekhuizen et al., 2021). For example, Bumble Bee employs a blockchain-based cloud platform to enhance and modernize the security and traceability of its seafood delivery, while Alibaba leverages digital platform technology to ensure food safety and promote a sustainable supply chain network by monitoring product delivery information from production to final consumption. These efficient information systems exhibit reliability, security, transparency, and intelligent execution, rendering them highly valuable in the practical application of CE (de Reuver et al., 2018; Ha et al., 2023). Furthermore, digital platforms play a critical role in promoting CE by providing substantial support (Rosa et al., 2020).

The internal mechanisms of digital platforms in promoting CE have not been thoroughly explored and remain a significant research question. Most existing literature relies on single-case deduction studies of individual enterprises or cross-case analyses of multiple enterprises (Genovese et al., 2023; Jansen et al., 2022). Although the findings have substantial implications for the advancement of CE, they are not universally applicable. This implies that the strategic adjustments and technological investments that result in high CE performance in some enterprises may not be suitable for all, even within the same industry. Moreover, in practice, it has been observed that while digital platforms enhance information integration, decision-making quality, and resource efficiency, they may also increase the complexity of business processes (Di Maria et al., 2022; Jovanovic et al., 2022). For example, General Electric (GE) encountered operational conflicts during the adoption of digital platforms, resulting in business failures.

Simultaneously, the complexity of the value creation process implies that adopting digital platforms may not directly result in changes to enterprises’ practices and behaviors for CE. Deeper transformations are necessary, including enhancing the dynamic capabilities of enterprises and innovating business models (Ahmed et al., 2022; Braz and Marotti De Mello, 2022; Broekhuizen et al., 2021). Research has demonstrated that various digital platforms have transparently altered the methods of enterprises’ value creation and competitive advantage (Chandna, 2022). This not only necessitates that enterprises redesign their operational processes but also develop the corresponding resources and capabilities to support new customer value creation (Ancillai et al., 2023). Digital platforms are shifting the focus of enterprise value creation towards networks, necessitating a significant transition to more externally oriented organizations (Ha et al., 2023; Jonkman et al., 2022).

Therefore, in the complex relationship between digital platforms and CE, there likely exists an unknown system capable of generating value for CE. This study aims to explore the internal mechanisms by which digital platforms influence CE from the perspective of value creation.

Exploring the connection between digital platforms and the CE through the lens of value creation is both innovative and aligned with current business practices. Firstly, a corporation’s value creation system delineates how enterprises enter markets and generate value, distinguishing them from other organizations (Freudenreich et al., 2020). Secondly, the primary obstacles for enterprises in achieving CE are organizational rather than technical, particularly concerning value creation systems (Lüdeke-Freund et al., 2019). Lastly, the failure of GE demonstrates that merely integrating digital platforms into existing corporate practices is insufficient. The fundamental reason is that the connection between digital platforms and CE requires firms to reconsider their value creation systems within the supply chain context. Value creation encompasses the broader activities of generating and delivering value. Within the supply chain context, value creation systems facilitate an understanding of the contemporary business environment, where firms operate as interconnected networks rather than isolated entities. Consequently, an enterprise’s value creation system must not only transform its internal business model but also collaborate in co-creating and transferring value with other companies (Codini et al., 2023).

Given the current emphasis on the critical role of value creation in the development of the CE, this study identifies and elaborates on the components of a value creation system. We deduce business model innovation and closed-loop supply chains from two aspects of the value creation process. The research findings not only address the relevant studies and reports on integrating business model innovation and closed-loop supply chains (Lüdeke-Freund et al., 2019) but also advance the fields of CE and value creation.

The structure of the remaining study is as follows:

Section 2 reviews the current state of research on the research question. By reviewing the literature, the research proposes and constructs the theoretical model.

Section 3 develops the research hypotheses.

Section 4 presents the sample characteristics used in the analysis and examines the validity of the data and model.

Section 5 details the data analysis process and summarizes the verification results. Finally, the theoretical contributions and practical implications of the study are discussed in

Section 6.

2. Literature Review

2.1. Circular Economy

Natural resource scarcity is a crucial factor impacting economic efficiency and production continuity. In an overproducing modern economy, meeting the needs and desires of a growing population demands significant natural resources, which are being progressively depleted. Consequently, scholars and practitioners have implemented numerous attempts and initiatives. These measures assist companies in reducing or even eliminating natural resource consumption while closing the material cycle to prevent waste generation (Lüdeke-Freund et al., 2019; Nikolaou et al., 2021; Suhandi and Chen, 2023). It is widely recognized that these practices are central to CE, requiring all economic participants to shift from linear to circular thinking (Geng et al., 2019).

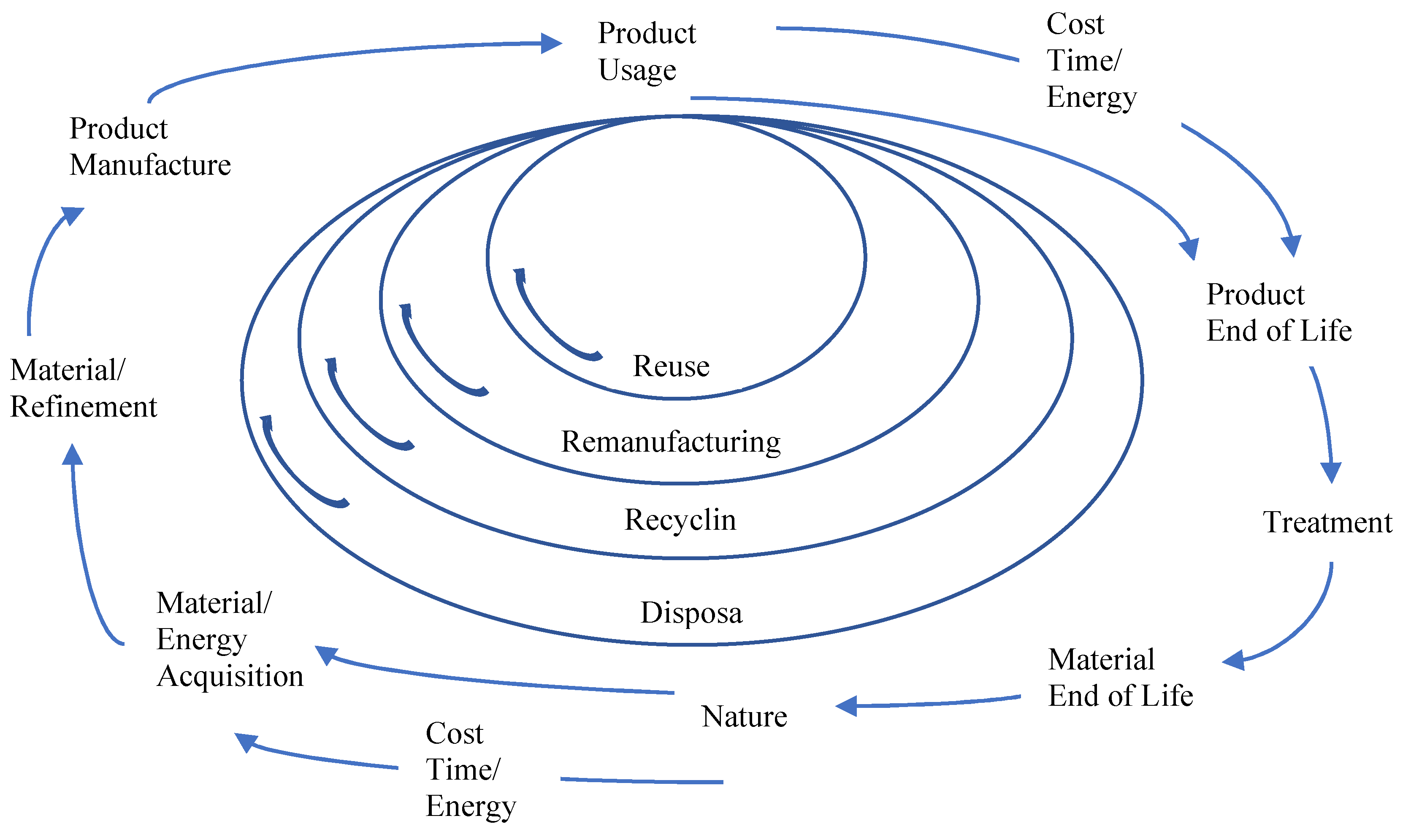

CE is based on a social production-consumption system, aiming to maximize material and energy utilization within the economic framework while controlling throughput. Its principles involve using periodic material flows, renewable energy, and cascading material and energy flows (Nikolaou et al., 2021). Based on research in engineering and natural sciences, Korhonen et al. (2018) proposed the material flow model shown in

Figure 1. In product recycling, items are reused, remanufactured, and refurbished, requiring fewer resources and energy and proving more economical than traditional material recovery from waste products. The longer a resource stays within the inner cycle, the greater its value. In the material cycle, once raw materials are extracted and processed into products, it makes economic and commercial sense to utilize the value generated for as long as possible. This entails maintaining the function/service and use value of products in the economic cycle for as long as possible (Suhandi and Chen, 2023). This approach also tends to yield environmental benefits compared to the traditional linear model of extraction, production, use, and disposal in the modern global economy.

Therefore, CE primarily focuses on enhancing natural resource conservation and environmental protection. Scholars define it as “a regenerative economic system that minimizes resource input, waste discharge, and energy leakage by slowing, closing, and narrowing material and energy loops.” Enterprises can achieve this through sustainable design, maintenance, repair, reuse, remanufacturing, refurbishment, and recycling (Kirchherr et al., 2017).

The CE concept is a compilation of ideas from various emerging fields and semi-scientific concepts (Genovese et al., 2023; Nikolaou et al., 2021). This includes areas such as industrial ecology, clean production, socio-ecological systems, and economic performance (Suhandi and Chen, 2023). The most influential foundational concepts of CE are the “cradle-to-cradle” notion of “ecological benefits” developed by business practitioners and the industrial ecology concept of envisioning industrial ecosystems (Braungart et al., 2007; Geng et al., 2019).

Research on CE can be categorized into three distinct levels: the national and regional level, the industrial management level, and the enterprise supply chain level (Nikolaou et al., 2021). At the national and regional levels, policymakers establish policies and norms aimed at achieving sustainability goals, focusing on integrating CE principles into national strategies (Liu et al., 2023). The EU and China, as early adopters of CE principles in their development strategies, have implemented these policies (Farooque et al., 2022). McDowall et al. (2017) conducted a large-scale analysis of the effectiveness of these policies. They found that both CE policies have achieved notable successes in environmental performance, despite the differing institutional systems of the two regions.

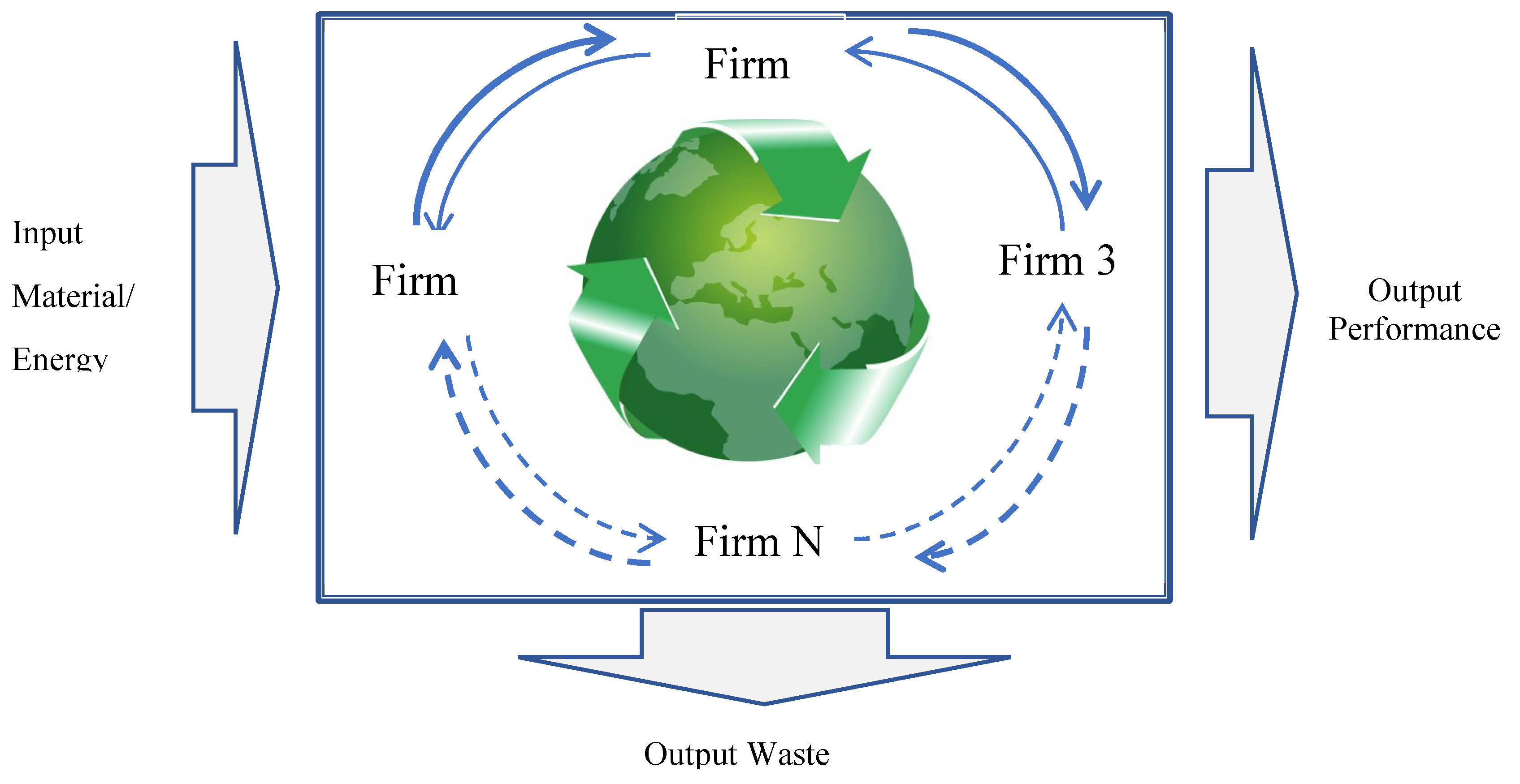

The second level involves cooperation between enterprises to advance sustainable development. At this level, enterprises facilitate the effective exchange of waste materials, achieving a cradle-to-cradle material cycle (Braungart et al., 2007). For instance, principles of industrial ecology and symbiosis are employed to develop eco-industrial parks (Gomes et al., 2023). In eco-industrial parks, the waste from one company can serve as raw materials for another (Figge et al., 2021). To illustrate this,

Figure 2 depicts a cradle-to-cradle supply chain model by simplifying complex supply relationships. For example, Firm2’s products flow to the downstream market (represented by thick lines), while Firm1’s returns from Firm2 may include accounts, waste products, or intangible information and market opportunities (represented by thin lines). Therefore, enterprises in a circular supply chain establish strong material and information interactions, necessitating effective communication and coordination (Braz and Marotti De Mello, 2022).

The third level of analysis focuses on the firm level. At this level, classical CE principles are integrated into operational and production processes, including reuse, recycling, redesign, remanufacturing, and refurbishment. This level emphasizes the actions taken by individual firms to address sustainability issues. To aid firms in optimizing the reusability of production materials and reducing natural resource consumption, researchers have proposed various methods and practices. These include carbon emissions/carbon footprints, green finance, blockchain/Internet of Things technology, renewable materials, and circular economy business models (Ferasso et al., 2020).

While practitioners and scholars have employed diverse approaches from various fields to study CE, this also highlights significant theoretical and practical inconsistencies and gaps that challenge scholars and policymakers in designing effective CE strategies (Genovese et al., 2023; Nikolaou et al., 2021). Academic journals show substantial interest in CE and sustainable development (Nikolaou et al., 2021), contributing significantly to the development of CE concepts (Kirchherr et al., 2017; Korhonen et al., 2018), evaluation index systems, and performance assessments (Corona et al., 2019; Moraga et al., 2019). However, existing literature weakly integrates technological solutions from engineering and natural sciences with social sciences. The goal is to bridge technological and material life cycles to address the economic, managerial, and social objectives of contemporary society.

This study aims to enhance the linkage between technology and CE within economic management and social sciences and to investigate the impact of digital platforms on CE. The research will integrate concepts from the meso industry layer and the micro-enterprise layer to develop a value creation system that enables enterprises to achieve CE and address gaps in current research.

2.2. Value Creation System in Circular Economy

At the firm level, CE practices involve integrating circular principles into the supply chain to achieve zero waste. Implementing CE requires the efforts of all members within the supply chain (see

Figure 2). In modern production and consumption systems, individual companies control only a limited segment of the process and are insufficient to address the systemic requirements of CE practices. Therefore, the entire supply chain activities of enterprises need to be re-examined (Ferasso et al., 2020; Korhonen et al., 2018). The key to adjusting supply chain practices lies with focal enterprises. Research on CE practices in manufacturing enterprises primarily focuses on four areas: technology-driven factors, institutional pressure, market demand, and organizational culture (Grafstrom and Aasma, 2021; Nikolaou et al., 2021).

Research on technology-driven CE highlights the information advantages provided by advanced information technology applications, including transparency, sharing, and integration (Grafstrom and Aasma, 2021; Rosa et al., 2020). The significance of technology application is evident in the value-creation process within and across organizational boundaries (Chandna, 2022; Jonkman et al., 2022). The value-creation process involves the activities through which an organization or group creates and delivers value, focusing on the network level rather than on individual organizations (Gomes et al., 2023; Jonsson et al., 2008). Consequently, value can be generated not only within a single company but also through interactions between different companies (Freudenreich et al., 2020).

Two crucial concepts in the value creation process are core competence and relationship roles (Jonsson et al., 2008). Core competencies encompass the essential activities, resources, and capabilities needed in the value-creation process. Conversely, the value creation process involves various participants, their roles, and their interrelationships. Participants may include partners, suppliers, and distributors, who collectively contribute to value creation (Freudenreich et al., 2020). Thus, core competence and relational roles shape how enterprises create value and the value output they generate (Jonsson et al., 2008; Ludeke Freund et al., 2019). This study contends that the value creation system linking digital platforms and CE consists of core enterprises’ capabilities or resources for circular and sustainable development—specifically, business model innovation—and well-defined relationships and role positioning with other value creation participants, specifically, the closed-loop supply chain.

Business models operate within a dynamic triangle comprising business strategy, information and communication technology, and business organization (Zott et al., 2011). Different business models offer various benefits, providing companies with flexibility and opportunities to sustain existing advantages and foster innovation (Carayannis et al., 2015). This implies that a company’s business model is not static. Instead, companies should adapt their business models in line with technological advancements to ensure sustained market performance and competitive advantage (Ancillai et al., 2023).

Business model innovation refers to the ability to reconfigure existing resources and capabilities. This innovation alters how firms create and capture value for their stakeholders. It is considered both a strategic choice and a continuous strategic orientation for enterprises (Codini et al., 2023). Incorporating social and environmental priorities into organizational development goals leads to the transformation of existing business models. Consequently, enterprises seeking CE benefits naturally innovate their business models to align with CE goals (Freudenreich et al., 2020).

Regarding the relationships and roles within the value creation system,

Figure 2 illustrates an essential structure in the operation of CE: the closed-loop supply chain.

A closed-loop supply chain is defined as “a design and operational system that maximizes the creation and recovery of value throughout the entire life cycle of material products” (Brydges, 2021). It involves the relationship and collaboration between various economic and non-economic actors (Zhou and Smulders, 2021). Additionally, it facilitates both the forward and reverse flow of resources and capabilities among related companies and supply chains (Brydges, 2021). This system reflects the flow of energy and material within CE context and highlights the role of participants and the flow of value in the value creation system.

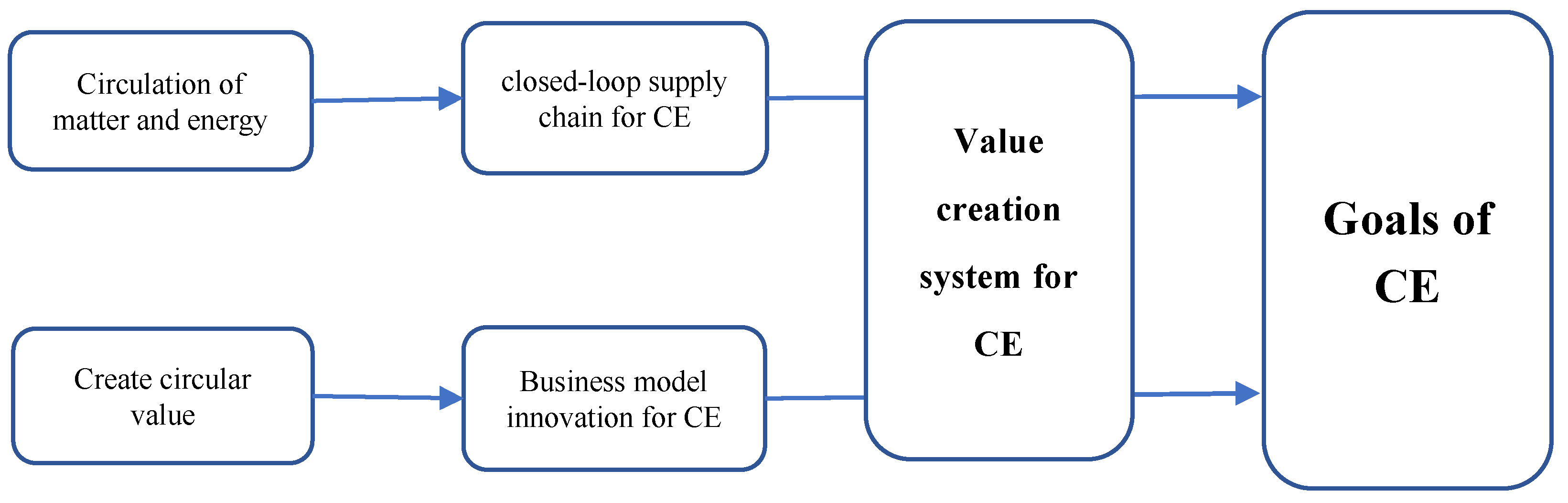

The study found that business model innovation and the closed-loop supply chain jointly constitute the value creation system linking digital platforms with CE (

Figure 3). This perspective is supported by the research of Ludeke Freund et al. (2019) and Geissdoerfer (2018), which highlights the crucial role of new business models and closed-loop supply chains in advancing CE theory. Business model innovation is essential for achieving CE, as it transforms how companies create and deliver value. However, achieving CE performance requires more than just changes within a single enterprise; it necessitates the cooperation and participation of all supply chain members (Gomes et al., 2023). The closed-loop supply chain defines the roles and relationships involved in transmitting and acquiring value within the value creation system.

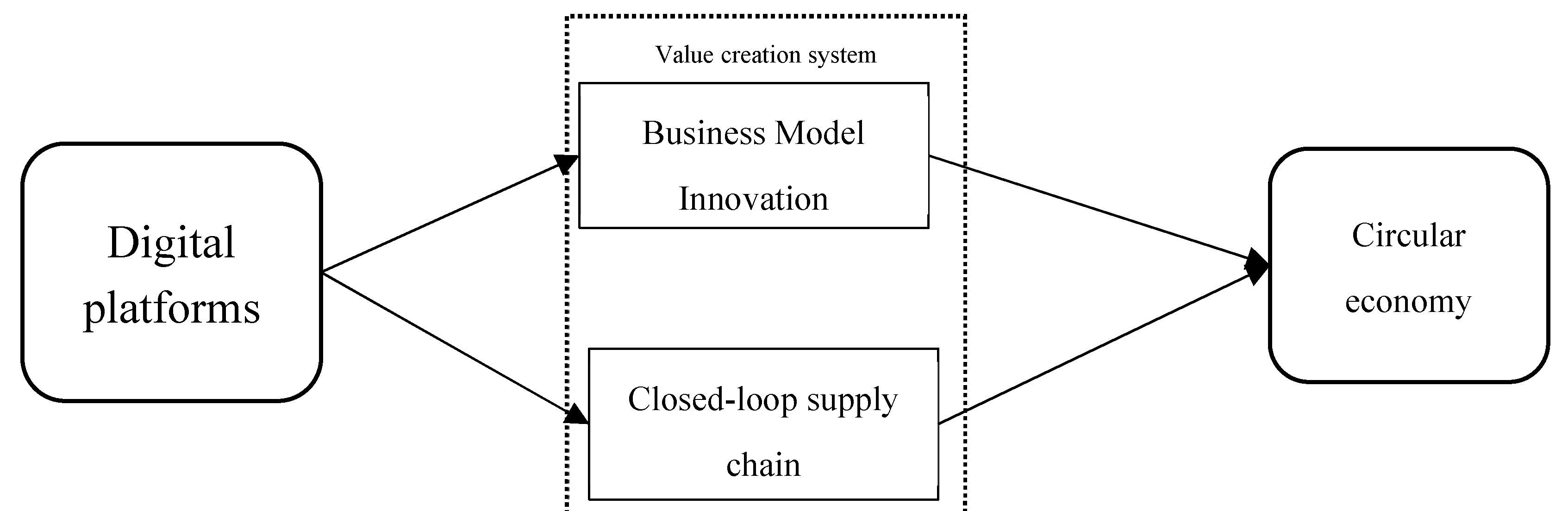

Currently, there is a lack of empirical data on the relationship between enterprise value creation systems and CE. To address this gap, the study posits that while closed-loop supply chains and business model innovation are distinct factors, together they form the value creation system for CE. The study also demonstrates the positive role of this system in linking digital platforms with CE through quantitative research methods. Based on these insights, we developed the research model presented in

Figure 4.

4. Research Methods

4.1. Questionnaire Development

The instrument of this study was specifically designed to investigate the performance of firms utilizing digital platforms in CE development. Hile existing literature offers some guidance on constructing operational measures in this field, it does not fully address the unique context of this study. Therefore, we defined our measurement items by adapting accepted concepts and constructs from previous research to fit our specific context. This approach ensures that the measurement instrument is both theoretically grounded and contextually appropriate. Detailed operationalization of the tool is provided in

Appendix A.

To ensure the suitability and effectiveness of the questionnaire, we undertook the following steps. First, we reviewed relevant literature to identify indicators associated with the constructs of interest, prioritizing indicators from quantitative studies where possible. Next, we developed a draft questionnaire based on these indicators. This draft was then rigorously evaluated by four Ph.D. scholars and practitioners, leading to improvements in indicator wording and a reduction in the number of indicators. The questionnaire was subsequently translated from English to Chinese, as we hypothesized that providing the questionnaire in the native language might enhance the response rate. Finally, we conducted a preliminary test of the questionnaire with several companies before proceeding with the formal survey. The data obtained from the formal survey met the measurement criteria outlined in

Section 5.1.

4.2. Constructs and Measures

The application of digital platforms(DP) allows firms to utilize external information and knowledge resources for competitive advantage. In this study, the measurement of digital platform applications focuses on assessing the extent to which these platforms facilitate information exchange with partners. Based on the maturity scale proposed by Cenamor et al. (2019), the study evaluated the level of information integration achieved by firms using four distinct items.

This study utilizes the dimensions of business model innovation (BMI) proposed by Clauss (2017), which include new products, new customers/markets, new channels, new customer relationships, new capabilities, new technologies, new processes, new partnerships, new revenue models, and new cost structures. However, during the pre-test phase, it was observed that the factor loadings for new products, new customers/markets, new channels, new customer relationships, new revenue models, and new cost structures were below 0.7. Consequently, based on the research of Xie et al. (2022), the study focuses on four dimensions—new capabilities, new technologies, new partnerships, and new business processes—to measure business model innovation.

Closed-Loop Supply Chain (CLSC) encompasses a series of interconnected projects and activities within a closed-loop network designed to achieve CE objectives. This study employs the 6-item scale developed by De Giovanni (2022) to measure CLSC performance. Drawing on the work of Corona et al. (2019) and Kristensen and Mosgaard (2020), the study uses six core features—reduce, reuse, recycle, redesign, remanufacture, and recover—as metrics for evaluating CE performance. The degree to which these features are performed indicates the level of CE achieved by the enterprise. Measurement variables were assessed using a five-point Likert scale, where 1 represents “strongly disagree” and 5 represents “strongly agree.”

To ensure the authenticity and validity of the samples, we first verified that the selected enterprises were familiar with the concept of digital platforms. Enterprises that lacked awareness of digital platform technologies were excluded from the sample. Next, by including a question, “Is your company using any of the following digital platform technologies?” we eliminated enterprises that did not use any digital platform technologies to maintain the rigor of the study. Finally, we controlled for basic characteristics of the enterprises, such as industry type, nature of the enterprise, size, and years in operation.

4.3. Data Collection

As the largest developing economy in the world, China is a major manufacturing hub with numerous enterprises that can impact the environment. In 2008, China incorporated CE into the strategic goal of national development (Farooque et al., 2022; Liu et al., 2023; McDowall et al., 2017). At the same time, the development and application of digital platforms in China are also relatively mature (Ha et al., 2023). Therefore, selecting enterprises from the China Circular Economy Association as samples is a highly appropriate choice. The survey was conducted between August 2023 and January 2024.

In conducting the survey, we requested respondents to voluntarily provide their contact information to facilitate follow-up surveys and ensure careful completion of the questionnaire. A total of 458 companies were contacted via email or telephone, with 324 responding. Among these, 32 respondents reported a lack of familiarity with digital platform technologies, and 17 indicated that their companies had not adopted any of these technologies. Consequently, from the 275 valid responses, we excluded 8 samples with incomplete information and 9 samples with uniform numerical answers. Additionally, we discarded 15 questionnaires completed by respondents with less than one year of experience at their current company. Thus, a total of 243 sample data were used to test the research hypotheses (

Table 1).

To assess our proposed structural model, we first evaluated the measurement model and reported the relevant indicators according to recommended standards. Next, we assessed the structural model and tested the hypotheses through path analysis and bootstrap procedures.

4.4. Assessing Respondent Bias

To assess non-response bias, we evaluated samples collected at different times. Independent sample tests were performed on control variables, such as organizational size, as well as on key independent variables in the model. No significant differences were found, indicating that non-response bias was not a major concern in this study.

The research design addressed common method bias (CMB) using several strategies. First, the questionnaire was organized to avoid reflecting the model order depicted in

Figure 4, thereby minimizing potential bias in the tested relationships. Second, measurement questions for each construct were spread across different sections to prevent respondents from deducing causal relationships. Third, multiple statistical techniques were employed to test for CMB. The common latent factor technique, with a linear estimate of 0.236, was below the threshold of 0.500. Furthermore, we assessed the fit indices of the common method factor model, the study model, and the model with the common method factor (

Table 2). The inclusion of the common method factor did not lead to a significant improvement in model fit indices, suggesting that CMB is not a major concern. Based on the survey design and these test results, we conclude that CMB does not compromise the validity of the study data.

6. Discussion

While a connection between digital platforms and the advancement of CE has been established, the specifics of how digital platforms can aid enterprises in achieving circular development remain unclear (Di Maria et al., 2022; Rosa et al., 2020). This study aims to elucidate how digital platforms influence CE through the value creation system. Our main objective is to explain the impact of digital platforms on CE via the mediation of the value creation system. The results indicate that improved business model innovation and more effective closed-loop supply chain practices are linked to enhanced CE within the value-creation system. Furthermore, the study identifies that both business model innovation and closed-loop supply chains mediate the relationship between digital platforms and CE. These findings provide valuable insights into the theoretical understanding of how digital platforms can support CE, contributing significantly to the existing literature on CE.

6.1. Theoretical Contribution

Digital platforms serve as a channel for information exchange between supply chain partners and are a major source of external information. They supplement the external supply chain information (Li et al., 2020), and can advance the CE of manufacturing enterprises. Achieving CE requires a timely response to internal and external market information, and such comprehensive information may not always be gathered within the company. This implies that a company may not be able to achieve CE independently and requires collaboration with other partners (Chiu and Lin, 2022). Consequently, the CE development model demands that the diverse information of the enterprise supply chain is leveraged innovatively and that it aligns with the strategic consensus among supply chain partners. In other words, achieving CE involves not only gathering diverse information from supply chain members to foster innovation but also forming strategic consensus and resource complementarity with partners.

Firstly, unlike previous studies that have explored the impact of digital platforms on CE from a dynamic capabilities perspective, this paper elucidates and demonstrates the critical role of the value creation system. This advancement is crucial because firms in developing countries are usually constrained by resources and capabilities in realizing CE. Starting from the two aspects of the ability and relationship of the value creation process, this paper discusses the principle of business model transformation and closed-loop supply chain as the ability and relationship respectively to create the performance value of CE. It is discussed that the principle of creating performance value of CE consists of business model innovation and closed-loop supply chain as capabilities and relationships respectively.

Secondly, business model innovation and closed-loop supply chain are identified as integral components of the value creation system, thereby broadening the scope of value creation in the context of CE. To achieve sustainable social development, various industries are gradually moving towards the development mode of eco-industrial parks. By incorporating closed-loop supply chains as a key element of the value creation system, this paper extends value creation beyond the firm. Since Porter proposed the concept of a value chain, closed-loop supply chains have emerged as crucial models for value creation (Triguero et al., 2022). The closed-loop supply chain is an indispensable and unavoidable mode of production and operation for enterprises to pursue the development of CE. It is also worth mentioning that when enterprises carry out CE-oriented business model innovation, they have to join the closed-loop supply chain as a mode of material and value transmission. It can be said that closed-loop supply chains are both a mode of creating CE value and an unavoidable pathway for realizing CE.

Finally, by elucidating the mechanism of business model innovation and closed-loop supply chain in the relationship between digital platforms and CE, this study contributes to the existing literature on digital platforms and CE. More specifically, the findings provide evidence supporting research on business model innovation within the context of technological innovation. Although the relevant goals of CE can be achieved by using digital platforms, the inevitability of the relationship between the two is weak (Rosa et al., 2020). Business model innovation enabled by digital platform technology can inject novelty into the industrial ecosystem and enable gradual sustainability transformation, such as product recycling, renovation, and restoration. Similarly, the use of digital platforms also effectively improves the operational efficiency and benefits of a closed-loop supply chain. It not only makes the exchange of information between supply chain members more convenient. More critically, digital platforms can provide users with more real-time and accurate materials and information through integrated information, which reduces the cost and inventory loss caused by incomplete information in forward and reverse supply chains. Therefore, it can be said that business model innovation and closed-loop supply chain are pivotal factors for CE that enterprises try to achieve through technological innovation.

At the same time, our data results also confirm our conjecture, that is, when business model innovation and closed-loop supply chain exist, digital platforms will play a better role in promoting the performance of CE. Therefore, it is reasonable and effective to regard business model innovation and business model innovation as two key factors that constitute a firm’s value creation system and study their key role in creating CE value. This paper contributes to the literature in the field of digital platforms and CE research by providing a new perspective on how firms can achieve circular and sustainable development in the context of current resources.

6.2. Practical Significance

Our findings suggest that DPs are important resources for CE and that the value creation system is a key factor for CE’s success. This finding is important for managers, which can help developing country firms achieve their CE goals. For example, previous research has shown that digital platforms promote CE by changing the capabilities and information access of focal firms (Di Maria et al., 2022). The Internet, communications, and computer revolutions are slowly eating away at the traditional model of development, and executives have to recognize and accept these new realities. Many enterprises turn to technology investment and neglect the coordination adjustment of value creation systems, which leads to failure.

The conclusion is critical to the management transformation value creation system. Business model innovation is a key factor in the success of CE, which is widely recognized by the industry. However, the key role of the closed-loop supply chain in the value-creation process is also worthy of attention. Closed-loop supply chains are often thought of as mere reverse product recycling. Managers often ignore the market and opportunity information they carry, as well as the impact of the reverse circulation of waste products on the distribution of positive goods (Brydges, 2021). Practitioners should pay attention to the operation of their closed-loop supply chain and the opportunities and information that are entangled in the operation of this process.

6.3. Limitations and Research Prospects

Although this study makes significant contributions to the literature, providing valuable insights for managers and policymakers seeking to leverage the relationship between digital platforms and CE, it also has limitations.

The study highlighted the crucial role of business model innovation as a capability within the relationship but did not address the implementation process or the potential challenges of business model innovation with the help of digital platforms. This is an important area of concern. Future research should deepen the discussion on the nature of how to transform business models for CE. This will help us to have a deeper understanding of business model transformation or circular business model in the context of CE.

This study demonstrates the significant contributions of business model innovation and closed-loop supply chains within the value-creation process, focusing on only two elements. Future research could also expand the current analysis by further considering specific technologies and activities within the value chain. In addition, the study discussed the role of business model innovation as a capability in the relationship, without discussing its implementation and the challenges that business model innovation may encounter with the help of digital platforms. This is a matter of concern.

In addition, the sample used in the study only represents the characteristics of enterprises in China, a developing country, which has certain limitations of geographical and regional economic characteristics. Future research can consider using multi-country samples for analysis, which will point out a paradigm for global enterprises to refer to.