1. Introduction

Magnetic sensors are essential in a wide range of applications, each requiring specific properties from both the sensors and the accompanying signal processing systems. These requirements often include a high signal-to-noise ratio, excellent stability, and minimal dimensions to enable precise measurements in non-homogeneous magnetic fields. Additionally, rapid response times are critical for studying dynamic processes.

To address these diverse demands, we have developed advanced integrated Hall elements. These include horizontal Hall elements, which are sensitive to magnetic fields perpendicular to the chip surface, and vertical Hall elements, which detect in-plane field components parallel to the chip surface (see Section 2).

For applications demanding precise magnetic measurements of the total B-field at a single point, where the size of the field-sensitive volume is critical, we have introduced a compact 3-axis Hall sensor (Section 3). In cases requiring fast and precise measurements of high field gradients, the world’s smallest magnetic camera offers a compact and efficient solution (Section 4).

Another key requirement for precise measurement is high stability and a very good signal-to-noise ratio. To achieve these aspects, the magnetic sensor systems have to be combined with suitable electronics, as exemplified by the 3MH6-E Teslameter (Section 5). In extreme environments, such as cryogenic temperatures down to 1 K, we have developed a cryogenic low-noise magnetic field transducer capable of accurate 3D magnetic field measurements (Section 6).

For applications requiring the measurement of extremely low magnetic fields, integrated Hall sensors may not achieve the necessary signal-to-noise ratio. While fluxgate sensors can measure low fields, their bulkiness makes them unsuitable for high field gradient scenarios. To overcome these challenges, we developed a 3D Nano-Teslameter based on magneto-resistive sensors capable of measuring fields in the nanotesla (nT) range (Section 7).

Dynamic measurements, such as the quality control of permanent magnets and electric motors, require fast response times and the precise coordination of accurate Hall probe positioning with high-resolution magnetic measurements. For these applications, we introduced the 3D Mapper (Section 8).

To achieve the most favorable performance-to-price ratio for mass applications, it is advantageous to use a standard technology such as CMOS, with everything integrated on a single chip, as demonstrated by the ANYCS sensor (Section 9).

Finally, an additional limitation for precise measurements is the non-orthogonality of the 3-axis sensors. Orthogonality calibration is addressed in (Section 10).

This paper outlines the development and application of these advanced magnetic sensing technologies, showcasing solutions tailored for both specialized and mass-market needs.

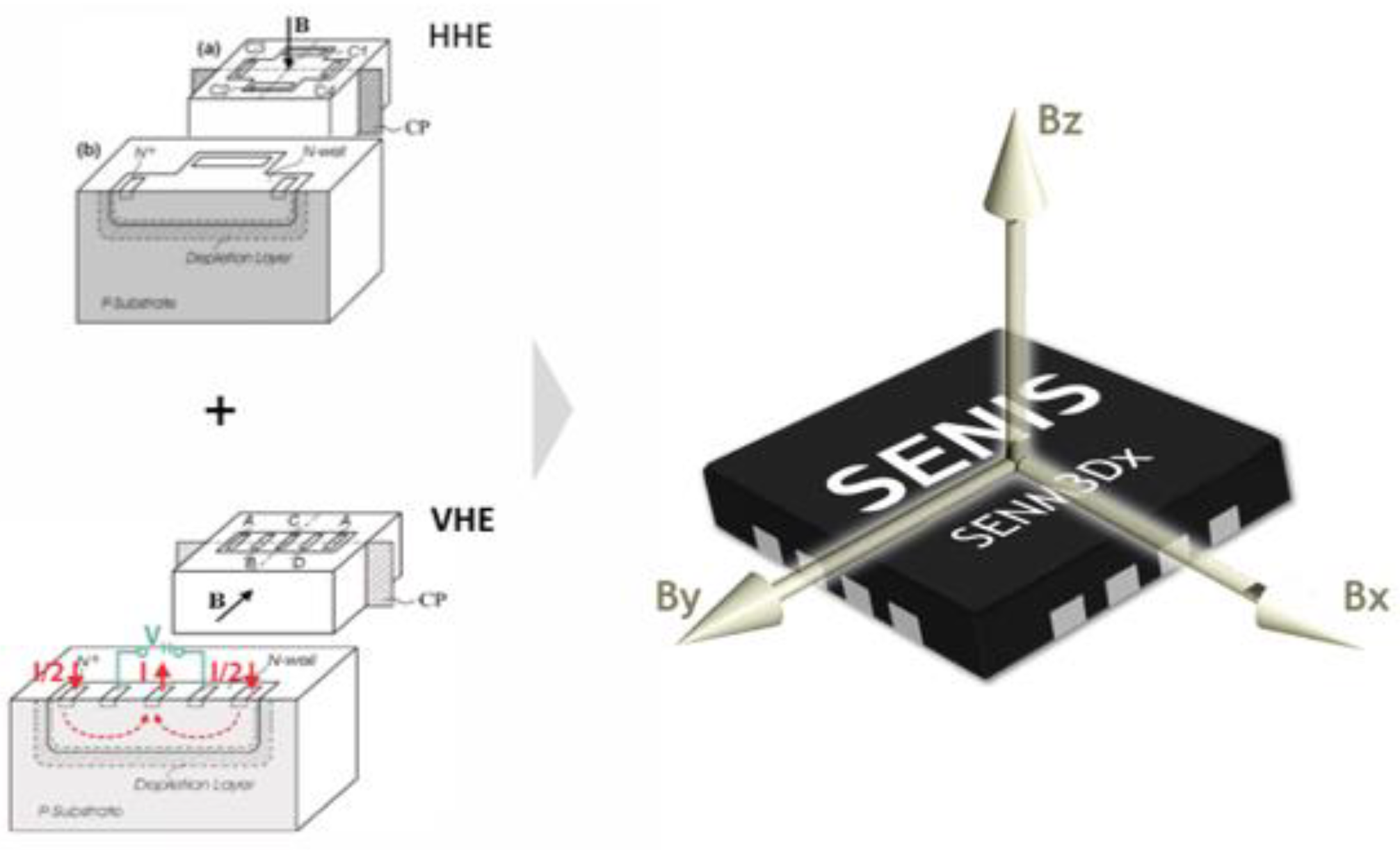

2. SENIS Vertical Hall Element - for in-Plane Field Components Parallel to the Chip Surface

The "vertical" Hall element measures magnetic fields parallel to the chip surface. The Hall plate is positioned perpendicular to the chip surface in integrated CMOS technology. The latest generation of vertical Hall elements has properties very similar to those of high-quality integrated horizontal Hall elements. It can be easily combined with horizontal Hall elements and integrated electronics. SENIS specializes in the design of compact, high-resolution Vertical and Horizontal Hall sensors, developed under the leadership of Popovic [

1] and his team.

The latest advancements feature a patented Vertical Hall sensor utilizing silicon CMOS technology, achieving a noise-equivalent magnetic field spectral density (NEMFsd) at f>10×fc of 120 nT⋅V/sqrtHz/Vb, where Vb is the biasing voltage [

2]. This sensor delivers a high signal-to-noise ratio comparable to horizontal Hall sensors and is the first commercially available sensor with such performance metrics. It enables a magnetic resolution of 1 μT in the novel 3D sensor [

3], described in Section 3. This performance is 20 times better than some published results of vertical Hall sensors, which achieve a resolution of 20 μT at 1 kHz [

4].

Integrating vertical and horizontal Hall elements within CMOS technology enables the creation of versatile magnetic sensors. These sensors can be configured for various applications, including 3D Hall sensors for comprehensive magnetic field mapping, 2D sensors for magnetic angle measurements, and Hall sensors for electric current measurements. Additionally, arrays of 3D sensors can form a 3D magnetic field camera, ideal for detailed magnet inspection.

3. 3D Hall Sensor

The combination of vertical and horizontal Hall elements from Section 2 results in a 3D Hall sensor with 3-axis properties for measuring Bx, By, and Bz magnetic flux densities at virtually the same point. It can be designed very compactly. The 3D Hall sensor can be used as a probe for high-precision magnetometers (see Section 6). Alternatively, it can be integrated with electronics in CMOS technology as an integrated 3-axis sensor chip.

3D Hall sensors are capable of measuring all three magnetic field components simultaneously within a field-sensitive volume (FSV). The size of the FSV is crucial for measurement accuracy, particularly in high-gradient magnetic fields. Errors attributed to the size of the FSV have been analyzed, emphasizing the importance of a small FSV for accurately characterizing magnetic structures and minimizing measurement errors [

5].

Integrated 3D Hall sensors combine horizontal and vertical Hall elements to provide accurate measurements with high spatial resolution. Currently, the 3D Hall sensor with the smallest FSV on the market is the SENM3Dx sensor [

3]. This sensor measures all three components of the magnetic field (Bx, By, and Bz) simultaneously at a single location. It is designed with three groups of mutually orthogonal Hall-effect elements, each equipped with dedicated biasing circuits and amplifiers. This configuration enables the sensor to achieve a high spatial resolution of only 100×100×10 μm

3, as shown in

Figure 1.

The 3D Hall sensor is applied as a Hall probe in SENIS's advanced magnetic measurement instruments. Applications of the SENIS 3D Hall sensor also extend to robotics, such as in the magnetic gripper feet of the inspection robot ANYmal [

6].

Besides the FSV, an additional limitation for precise measurements is the non-orthogonality of the 3-axis sensor's coordinate system relative to the magnetic field orientation. Particularly in inhomogeneous fields, non-orthogonality and misalignment must be carefully quantified and compensated for precise measurements. Orthogonality calibration is addressed in

Section 10.

4. The World’s First True 3D Magnetic Field Camera

To capture the magnetic field quickly and precisely, a matrix of 3D sensors is utilized, also known as a magnetic field camera. There are cameras consisting of single packaged 3D Hall sensors, or there is a newly developed camera with integrated 3D Hall sensors.

Figure 2 shows the SENIS 3D Magnetic Camera [

7], which was nominated for the AMA Innovation Award 2024 [

8]. The camera features a compact chip positioned within its small head. The camera simultaneously measures all three magnetic field components (Bx, By, Bz), providing comprehensive and accurate pictures of magnetic fields. With a spatial resolution of 100 µm between the 3D pixels and a tiny field sensitive volume of 27µm x 9µm x 4µm in each pixel, the camera offers unprecedented precision in magnetic field measurement. This is particularly important when measuring complex fields with high field gradients. With 16,000 pixels, the camera can acquire 7 magnetic images within one second, making it ideal for both inline and offline inspection of magnetic systems.

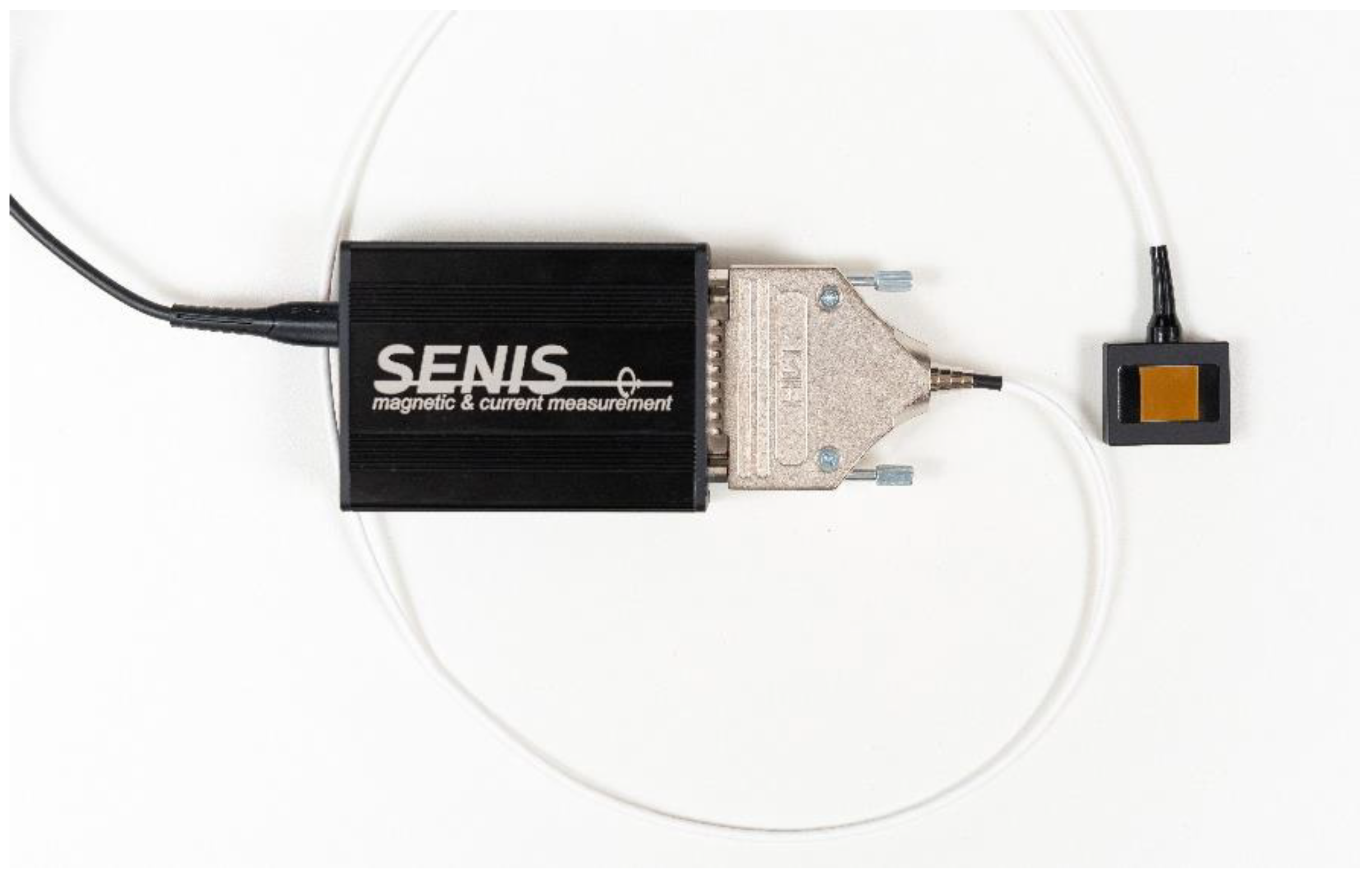

5. Low Noise Teslameter with Compact 3D Hall Probe

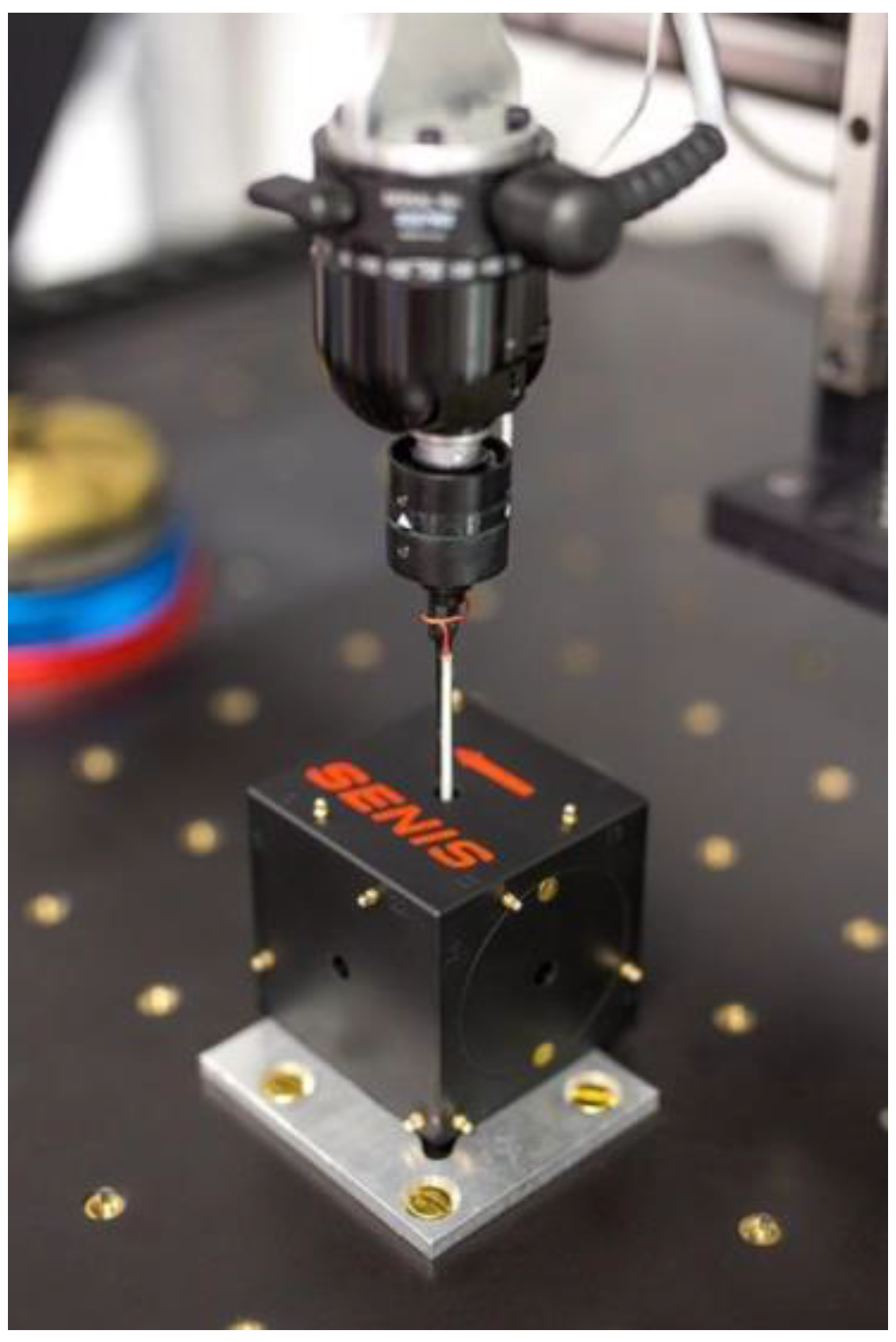

High-accuracy, low-noise Teslameters require a combination of sensors and signal-processing electronics. An example of this is the SENIS Low Noise Teslameter, shown in

Figure 3. The probe contains only the 3-axis Hall elements and a temperature sensor, while all power supply and signal processing are handled in the electronic box, which houses our proprietary analog signal processing electronics, ADC (Analog-to-Digital Conversion), and digital signal processing. These systems enable the linearization of non-linearities originating in both the Hall elements and the analog electronics, compensating for them to achieve the results we are discussing.

The Low Noise Teslameter, including a 3D Hall probe, features a highly accurate magnetic field-to-analog-voltage transducer, providing temperature-compensated output signals for the Bx, By, and Bz components and the total B-field. This device also includes a digital module for automatic data acquisition via a USB serial interface, facilitating easy integration into measurement systems using various programming tools [

9].

Key features include:

Teslameter with integrated 3-axis Hall Probe (Bx, By, Bz) and Temperature sensor

Total B-field measurement at one point

Overall 3D (Bx, By, Bz) magnetic field sensitive volume (FSV) of the Hall IC: only 0.10 x 0.01 x 0.10 mm3

Very high mutual orthogonality between the measurement axes of the probe: < 0.1º

Full probe interchangeability is ensured: Each 3D Hall probe can be interchangeable with any other 3D Hall probe and any other 3MH6-E instrument, this in the terms of keeping the overall measurement DC accuracy of better than 100 ppm (0.01%)

Probe Dimensions (length, width, thickness): 8.0mm x 4.0mm x 0.9mm;

Measurement of DC & AC magnetic fields

Triggers internal and external – Single shot, Manual and Continuous

Four selectable magnetic field ranges: 100mT, 500mT, 2T, 20T (calibrated up to 9T)

Probe interchangeability is ensured (Interchangeable Hall probes with calibration data stored in an integrated EEPROM)

Very high magnetic DC resolution: better than 1ppm (@2T range: 1µT for perpendicular and 2µT for planar (|| with the probe plane) field components)

Frequency bandwidth: DC – 2.5kHz (-3dB)

Selectable sampling rate up to 7.5ks/sec

High temperature stability: < 20ppm/°C

Temperature compensated, both probe and electronic box

24-bit A/D Convertor

Auto range, zeroing, hold, Max/Min values

Over small ranges, version 3MH6-S offers a resolution of 0.5 µT.

Thanks to its ability to measure both the orientation and amplitude of the magnetic flux density vector, it serves as a reference device in metrology, replacing NMR teslameters.

Applications include moving the probe in space in a non-uniform field (eg insertion device of field gradient mapping), see

Figure 4 and some other examples and references [

10]. The 3MH6-E is also applied in the HITRIplus project led by CERN [

11].

The 3MH6-E sensor's ability to measure the magnetic field at a "point" with excellent angular resolution makes it highly effective for non-uniform fields. In contrast, competing probes with a larger FSV, such as those used in NMR sensors, are suitable only for uniform magnetic fields.

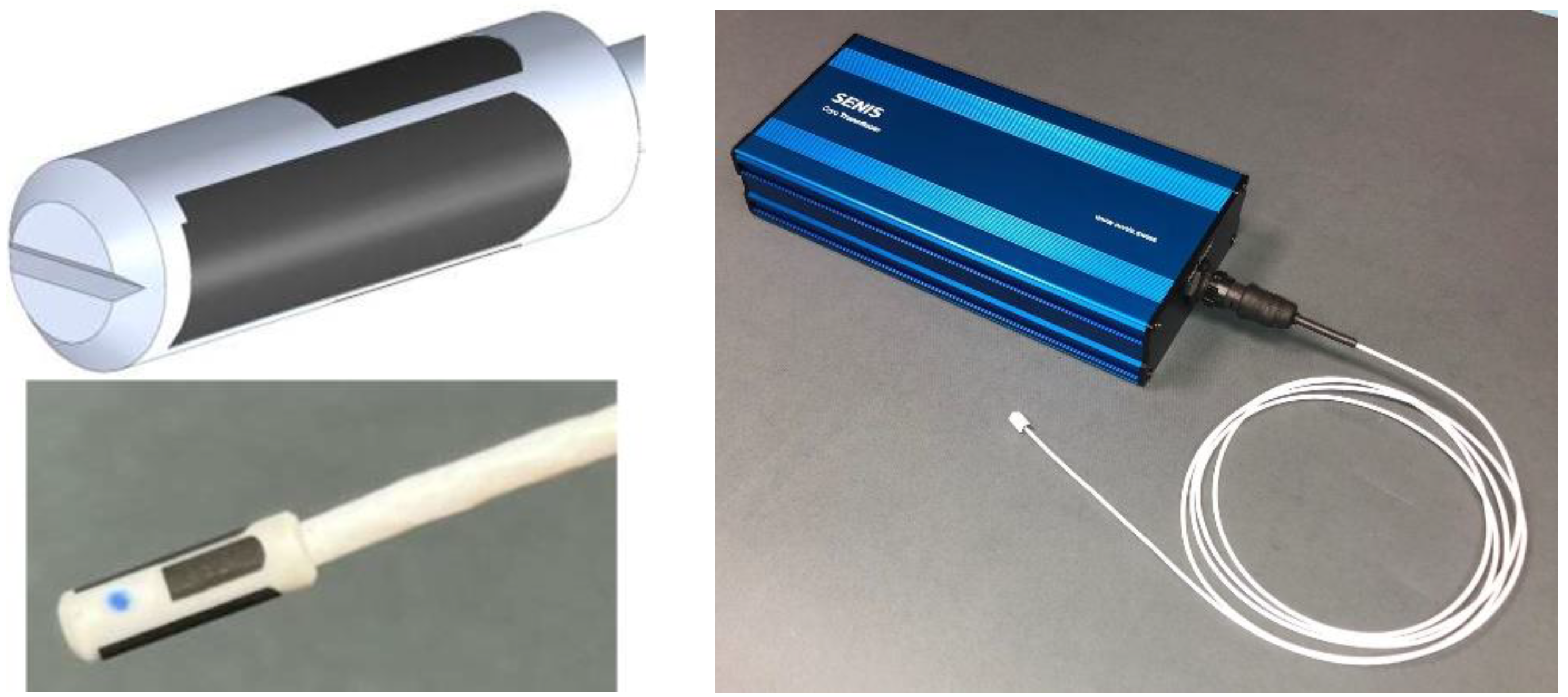

6. Cryogenic Low-Noise Magnetic Field Transducer

The SENIS K3A cryogenic low-noise magnetic field transducer [

12] is engineered for accurate magnetic field measurements at cryogenic temperatures down to 1 K, and calibrated magnetic field ranges up to 9T, see

Figure 5. The latest cylindrical-shaped probe, with a diameter of less than 3 mm and a length of 10 mm, is the world’s smallest 3-axis cryogenic Hall probe,

Figure 5, suitable for measurements within apertures with cross-sections ≥ 3 mm.

This probe integrates three high-resolution Hall sensors, ensuring excellent angular accuracy (orthogonality error < 2°) and negligible planar Hall effect. The robust alumina ceramic (Al2O3) housing enhances mechanical and electrical stability, while the spinning-current technique used in the electronic box reduces offsets, low-frequency noise, and planar Hall effect.

7. 3D Nano-Teslameter

The 3NTA2 Nano-Teslameter, see

Figure 6 is a high-precision instrument designed for measuring magnetic fields from nanoTesla (nT) to 100 µT (1 Gauss), with an optional extension up to 500 µT (5 Gauss) [

13]. Utilizing advanced Anisotropic Magneto Resistance (AMR) sensor technology, it offers exceptional sensitivity. The system includes a compact 3D probe with exceptional spatial resolution, a non-ferrite electronic module for signal conditioning, and user-friendly LabVIEW software for data acquisition and visualization. Key features include multi-axis measurement capability, long probe extension (up to 40 m), temperature compensation, and high-resolution 16-bit AD converters, making it ideal for applications requiring precise magnetic field analysis, like monitoring and active cancelation of environmental magnetic fields, measuring stray magnetic fields of electrical machines, or directional drilling.

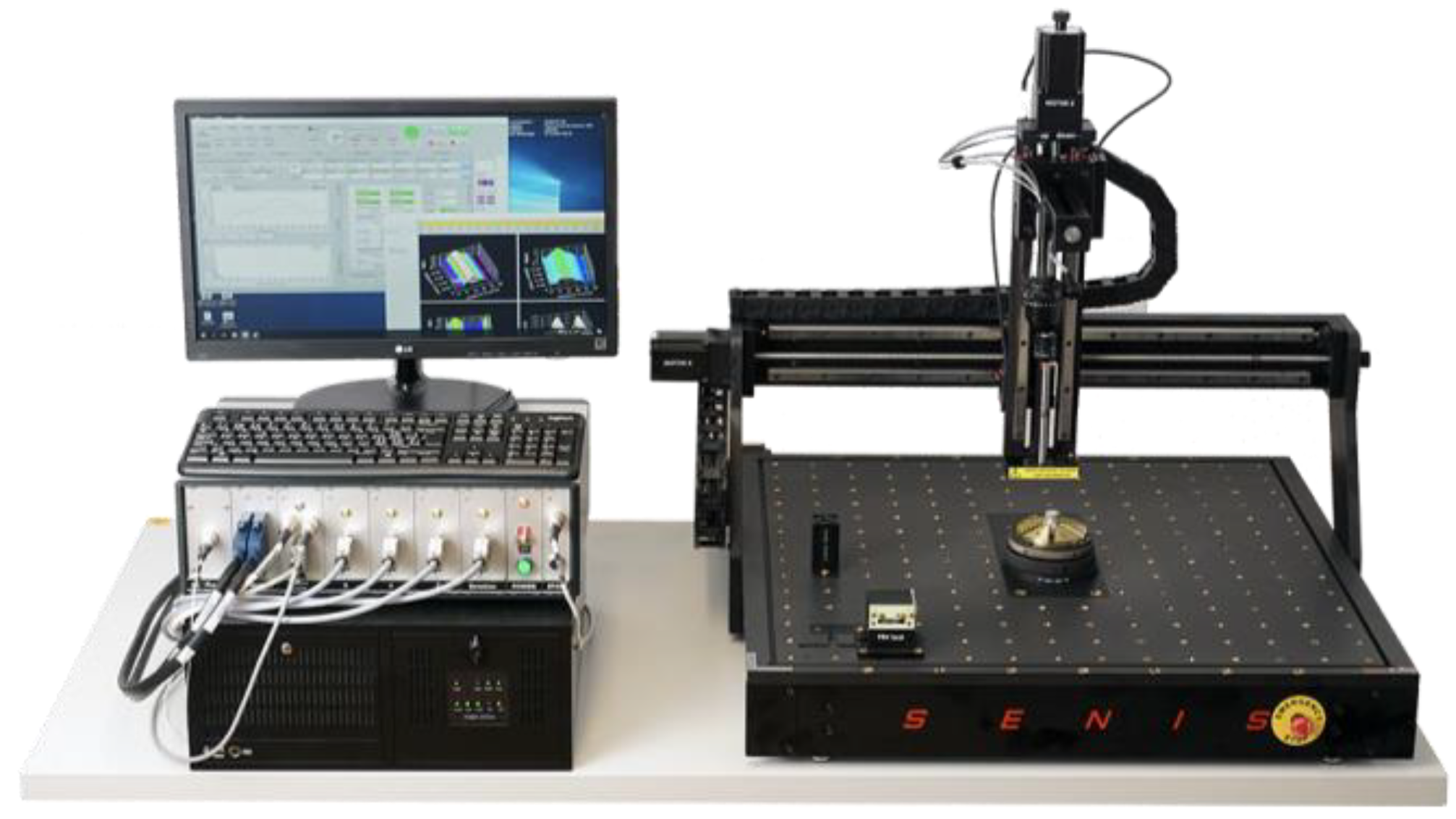

8. 3D Magnetic Field Mapper

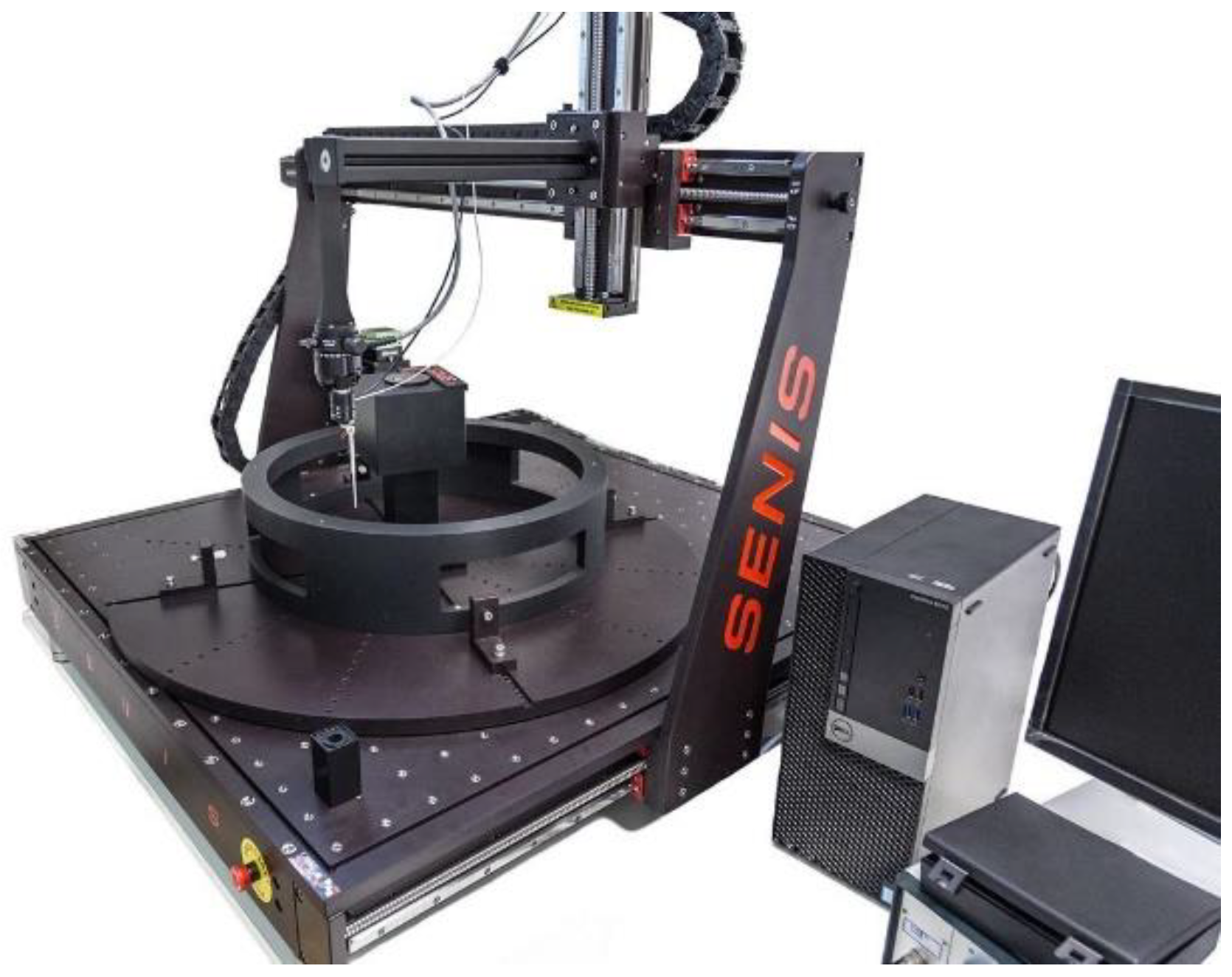

The SENIS magnetic field mapping systems,

Figure 7 are high-end, fully automated tools for mapping magnetic fields around permanent magnets and electromagnets [

14]. These systems utilize a true 3-axis Hall probe to measure all three magnetic field components simultaneously, with high accuracy and repeatability.

The motion control unit allows precise probe positioning along three axes and a rotational stage. The intuitive software enables customizable scanning profiles and data visualization. The mapper is extensively used in the automotive industry, consumer markets, and particle accelerator departments for magnet system development and quality assessment. For instance, the LinearBeam team [

15] applies the mapper to characterize permanent magnet quadrupoles to focus the proton beam produced by a Linac accelerator for proton therapy. The mapper software provides near real-time measurements, allowing for a first-order evaluation of the quadrupole gradients. Porsche applies the mapper for rotor control of electric motors [

10], Siemens measures large heavy rotors of 60kg and more [

10], and the space industry measures thrusters, as shown in

Figure 8.

9. Current Sensor

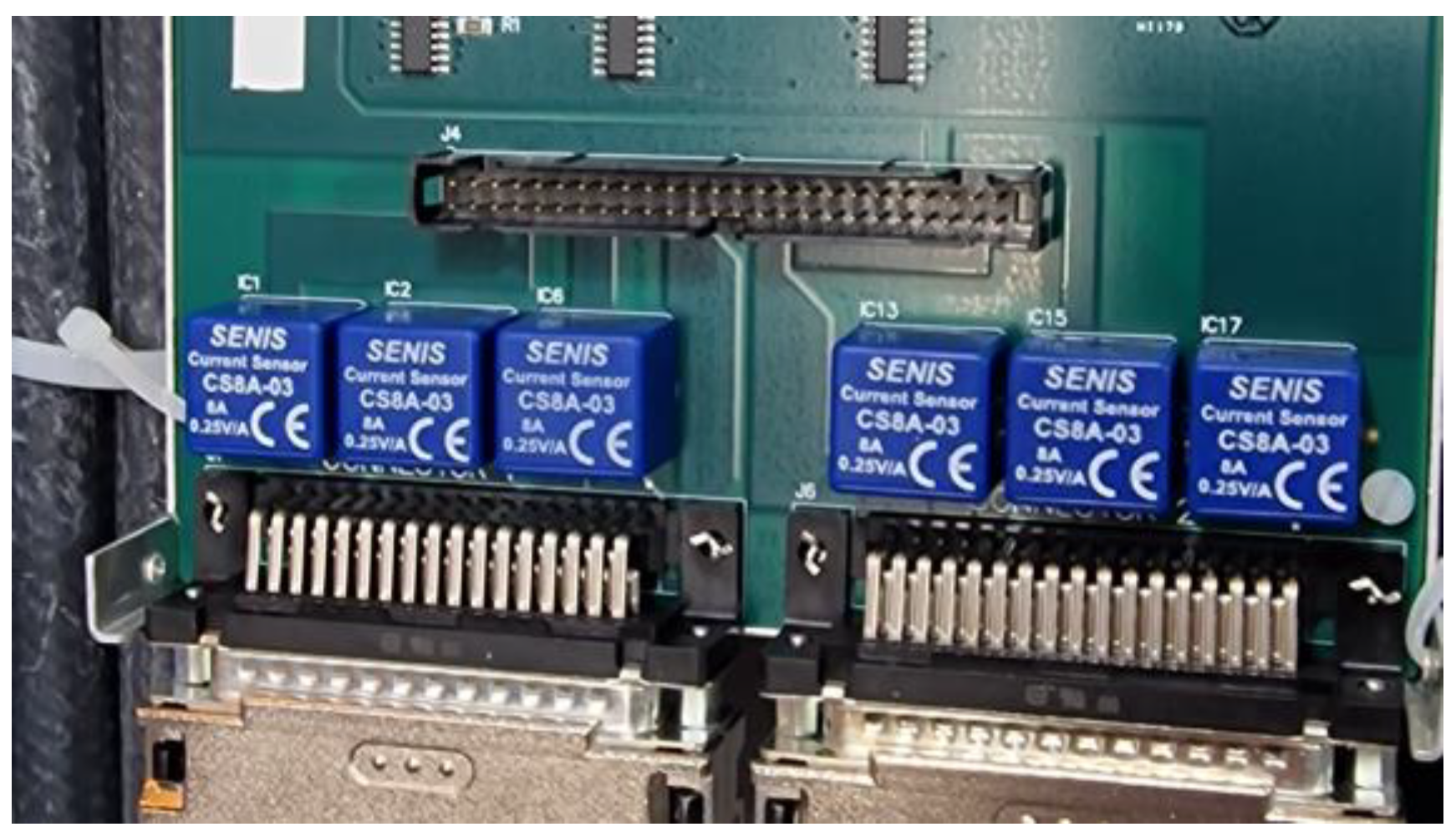

Measuring current through the associated magnetic field allows for the measurement of small currents. In this case, the magnetic field, which carries information about the current, must be amplified. The current flows through a coil where the magnetic sensor is placed, along with electronics for calibration. A version of such a current sensor is applied for monitoring systems in high-energy physics applications, for example, the SENIS CS series current sensors [

16] are applied in the LHCb SciFi detector for monitoring boards at CERN [

17], see

Figure 9.

On the other hand, there are cases where the current is strong enough to generate a large magnetic field. In these cases, the current does not need to be interrupted, and a coil is not required. The magnetic sensor is placed close to the conductor, see

Figure 10. For such applications, which are becoming increasingly important in electrical vehicles, there is a demand for sensors with a good performance-to-price ratio, so an integrated sensor is needed.

The presented current sensor is based on the Hall effect. Based on the known concept of the combination Hall-Coil [

19,

20], and some new ideas including SENIS proprietary technology [

21] that support its implementation, we developed the new integrated magnetic sensor, the SENIS SENCS1Dx [

22], also known as ANYCS, with extraordinary features: magnetic sensitivity direction either perpendicular to, or parallel with the chip surface, frequency bandwidth from DC to 1MHz, equivalent magnetic field noise 40uT, and high stability against temperature changes. The SENCS1Dx is a fully integrated sensor for the magnetic field perpendicular to the chip surface, whereas, for the magnetic field parallel to the chip surface, it should be combined with a suitable external coil.

10. Multi-Axis Magnetic Sensor Calibration and Reference Calibration Tool

The SENIS Calibration Laboratory is ISO 17025 accredited and holds two patents for the orthogonality calibration of 3-axis sensors and a calibration tool [

23,

24]. Calibrating multi-axis magnetic sensors involves determining the sensitivity vector for each of its axes, which is done by measuring the sensor output voltage at multiple positions along each axis. When the properties of the calibration magnetic field are precisely known, the sensitivity vector for a 3-axis sensor can be determined efficiently using only three unique sensor orientations. This significantly reduces the complexity and setup requirements. The proprietary SENIS calibration tool is instrumental in achieving this efficiency.

The calibration tool consists of stable permanent magnets positioned to create a homogenous magnetic field within a specific zone. This field structure, combined with the tool’s geometric design, enables precise alignment for 90° rotations in roll, pitch, and yaw, which is essential for consistent and accurate measurements. The tool also secures the sensor’s field-sensitive volume (FSV) in a fixed position, ensuring uniform exposure to the magnetic field. The calibration setup includes a cuboidal device capable of rotating the sensor precisely by 90° in each direction. SENIS performs in-house orthogonality calibration for its 3D Hall probes, specifically used in the Teslameter 3MH6-E, reducing the orthogonality error down to 0.1°. The calibration tools are also available to SENIS customers.

Figure 11 illustrates a magnetometer customer verifying the B-field and the orthogonality of its 3-axis Hall probes using SENIS’s patented cube and algorithm (provided in a protected Excel file), and

Figure 12 shows the orthogonality calibration of the 3D Hall probe in the SENIS Mappers (where the algorithm is integrated within the mapper software).

Exemplary Calibration Methods

Sensitivity Calibration: When the magnetic field’s orientation is known, as with the SENIS Calibration Tool, only three sensor positions are needed to determine the sensitivity vector components, simplifying the calibration process.

Multi-Axis Sensor Calibration: Each axis is calibrated independently using the Sensitivity Calibration method. This approach can be extended to sensors with two or three axes.

Broad Sensor Type Adaptability: These calibration methods are versatile and applicable to various sensor types, including Hall effect sensors, magnetoresistors, and flux gates, regardless of whether the magnetic field source is a permanent magnet, Earth’s magnetic field, or an electromagnet.

11. Conclusions

SENIS’s contributions to magnetic field and electric current measurement demonstrate significant technological advancements that support both scientific research and industrial innovation. With high-resolution, compact design, and calibration technologies, SENIS sensors and instruments facilitate the fiducialization, alignment, and quality control of magnetic systems with unmatched precision. These tools serve critical roles in metrology, enabling accurate monitoring and measurements in fields such as accelerator physics, robotics, and medical technology. SENIS’s ongoing commitment to developing precise, low-noise sensors capable of operating in challenging environments, such as cryogenic conditions, exemplifies the potential of advanced sensor technology to drive progress across diverse scientific and engineering applications.

Funding

This work was supported by the internal resources of SENIS Group, Switzerland, as well as by collaborative research programs, including the HITRIplus project led by CERN.

Acknowledgments

The authors express their sincere gratitude to the team at SENIS Group, Switzerland, for their exceptional contributions to the development and production of advanced sensors and instruments for magnetic field and electric current measurements. Special thanks are extended to SENIS customers for their references and feedback, as well as to the researchers and engineers at national laboratories worldwide and other collaborative partners for their dedication to integrating and applying SENIS technology in high-impact projects.

Conflicts of Interest

All authors are affiliated with SENIS Group, Switzerland. The authors declare that there is no conflict of interest regarding the publication of this work. While all contributors are from the same organization, the findings presented are based on objective research.

References

- Popovic, R. S. (2003). Hall Effect Devices, second edition, CRC Press.

- SENIS Patent EP14176835. 8 Vertical Hall Device.

- SENIS AG, “3D Hall sensor SENM3Dx", https://www.senis.swiss/sensors/3dhall-3-axis-hall-magnetic- sensor-senm3dx/.

- Fraunhofer IIS, HALLinONE®. Online [Accessed ] https://www.iis.fraunhofer.de/content/dam/iis/de/doc/il/ics/sensorsysteme/MagnetfeldSensor_de.pdf. 12 November.

- Stuck, A, Mijalkovic, M, Popovic Renella, D, “Practical limitations of accurate magnetic measurements in industrial applications“, IMEKO TC4 Conference, 2023. 2023.

- Popovic Renella, D. , Kaltenbacher, T., Spasic, S., Cavelti, A., Valsecchi, G., Nachtigall, L., Hutter, M., “Revealing the potential of a new 3D Hall sensor in advanced inspection robotics”, Acta IMEKO, vol. 13 (2024) no. 4, pp. 1-5. [CrossRef]

- SENIS AG, “3D Magnetic Field Camera SEN-3D-CAM". https://www.senis.swiss/mappers/sen-3d-cam- magnetic-field-camera/.de/en/press/actionprogram/ama-innovation- award-2024/.

- AMA Innovation Award 2024, https://www.sensor-test.de/en/press/actionprogram/ama-innovation- award-2024/. 2024.

- SENIS Low Noise Teslameter 3MH6-E: https://www.senis.swiss/applications/magnetometers/teslameter-digital/3mh6- e-high-precision-teslameter-with-interchangeable-hall-probes.

- Applications of SENIS measurement devices: https://www.senis.swiss/applications/.

- HITRIplus project: https://www.hitriplus.eu/.

- SENIS Cryogenic Low-Noise Magnetic Field Transducer: https://www.senis.swiss/magnetometers/analog- magnetic-field-transducers/k3a-cryogenic-low-noise-magnetic-field-transducer/.

- SENIS Nano-Teslameter: https://www.senis.swiss/magnetometers/teslameter-digital/3nta2-3-axis-nano- teslameter/.

- SENIS Magnetic Field Mapping System: https://www.senis.swiss/mappers/.

- Linear Beam application: https://senis.wpengine.com/wp-content/uploads/2023/03/Senis-LinearBeam.pdf.

- SENIS Current Sensor: https://www.senis.swiss/current-transducers/cs-03-series-pcb-mount-current- sensor-modules/.

- SENIS CS applied in LHCb SciFi detector at CERN: https://www.senis.swiss/wp-content/uploads/2024/07/Reference-CERN-CS.pdf.

- SENIS Bus Bar Sensor: https://www.senis.swiss/current-transducers/bbm-03-lv-series-low-medium-bus- bar-current-sensor/.

- N. Karrer, P. Hofer-Noser, “Device with wide passband for measuring electric current intensity in a conductor”, Patent US 6,366,076 B1, 2002.

- J. Jiang, K.A.A. Makinwa, “Multipath Wide-Bandwidth CMOS Magnetic Sensors”, IEEE J. Solid-State Circuits. (2016) 1–12. [CrossRef]

- Patent 2022110921071100DE, “Magnetfeldsensorsystem mit einem temperaturgangskompensierten Ausgangssignal sowie Verfahren für die Temperaturgangskompensation eines Ausgangssignals eines Magnetfeldsensorsystems”, 2022.

- SENIS® ANYCS current sensor IC with high bandwidth from DC-1MHz, https://www.senis.swiss/sensors/anycs-current-sensor-sencs1dx/.

- Patent EP16196608.0 Calibration tool for calibrating a magnetic sensor.

- 20Patent PCT/EP2022/072389 Method and apparatus for calibrating a magnetic sensor and/or a calibrating magnet22.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).