1. Introduction

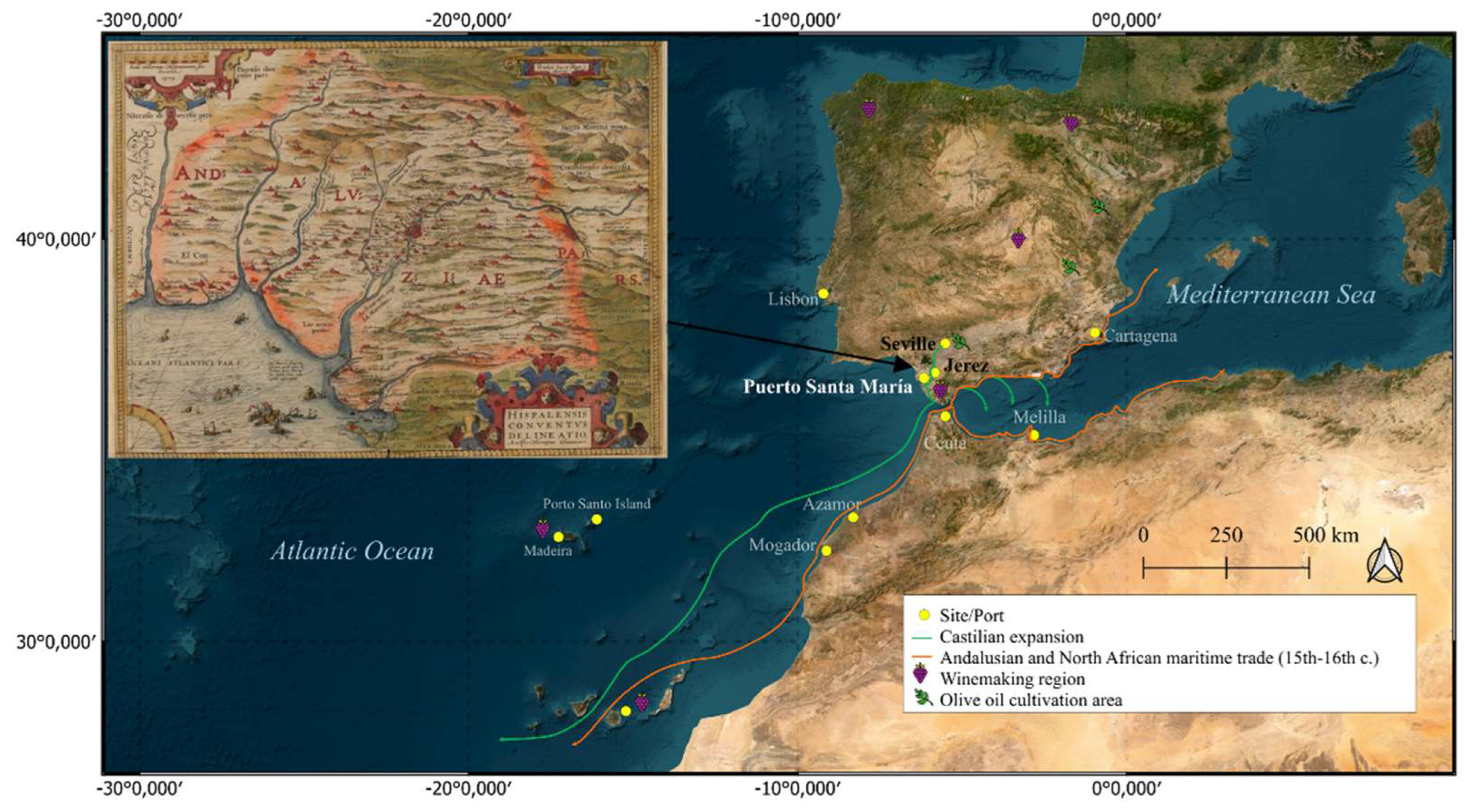

The economic transformation of Andalusia during the Early Modern Age was profoundly shaped by the expansion of transatlantic trade, catalyzed by the increasing demand from urban centers. While local and regional trade remained significant, it was Andalusia’s strategic geographic positioning along key Atlantic routes that played a decisive role in facilitating external commerce and driving economic development (

Figure 1).In this context, understanding the production processes and technological innovations in ceramic manufacturing in Jerez de la Frontera becomes paramount for unraveling the dynamics of early globalization. The archaeometric investigation of these production technologies provides essential insights into the evolution and transmission of artisanal skills, ceramic forms, and manufacturing techniques, as well as the continuity and renovation of long-standing craft traditions.

This study presents the preliminary results of both archaeological and archaeometric analyses conducted on ceramics from the Convent of Santo Domingo in Jerez de la Frontera, dating from the late 15th to the early 17th centuries. By adopting a multidisciplinary methodology—integrating petrographic analysis, X-ray diffraction (XRD), and inductively coupled plasma mass spectrometry (ICP-MS)—this research delves into the mineralogical and chemical composition of the ceramics, providing critical data on the production techniques, material provenance, and technological characteristics of Jerez’s ceramic tradition. These findings contribute significantly to the broader understanding of ceramic production during the nascent phases of globalization, particularly in relation to the expansion of Iberian colonial networks in the Atlantic world.

The ceramic assemblage was recovered in the excavation of the vaults filling of Santo Domingo’s convent, offering a rare and valuable perspective on the material culture used in Jerez de la Frontera during a particularly transformative period. These ceramics are pivotal to decode the productive and economic strategies that supported the Iberian kingdoms’ colonial expansion in key Atlantic territories. While medieval ceramic production in Andalusia has been the subject of considerable scholarly attention, the study of early modern pottery production sites remains an underexplored area. This research aims to contribute to bridge this gap by examining the typology and technological innovations in Jerez’s ceramic production, a major regional production center, where comprehensive archaeometric studies have been largely absent until now.

1.1. Historical Background of Jerez de la Frontera and the Convent of Santo Domingo

Jerez de la Frontera has long been a prominent center for agricultural production and trade, a role it has played especially since its conquest by the Crown of Castile in 1246. Its strategic location along the Guadalete River, particularly the port of El Portal, facilitated the city's access to maritime trade networks. As part of the Kingdom of Seville, which became a significant region within the Crown of Castile during the 15th century, Jerez witnessed substantial economic growth. The city’s September fair became a pivotal event for wine contracting, cementing Jerez’s status as a major hub in the wine industry and fostering a long-lasting viticulture tradition. Integral to this urban economy was the corporation of artisans, particularly those involved in the manufacture of ceramic containers, which were essential to both local consumption and broader commercial networks [

1,

2,

3].

Despite the socio-political and economic disruptions caused by the “

Reconquista” and the decline of certain industries, such as viticulture during wartime, Jerez maintained its relevance within the regional trade system. The city’s connections to the nearby ports of Santa María and Sanlúcar de Barrameda, key commercial nodes in the Guadalquivir basin, were instrumental in sustaining its economic vitality. During the reign of the Catholic Monarchs, merchant capitalism and an oligarchic structure became foundational to royal policy in Andalusia, positioning Jerez as a focal point of urban and economic centralization. The artisanal production of ceramic containers not only supported local economies but also played a crucial role in foreign trade during this period, as documented in historical accounts from the 15th and 16th centuries [

4,

5,

6,

7]. These vessels were essential in the large-scale commercial trade, reflecting the broader socio-economic significance of ceramic production in Jerez.

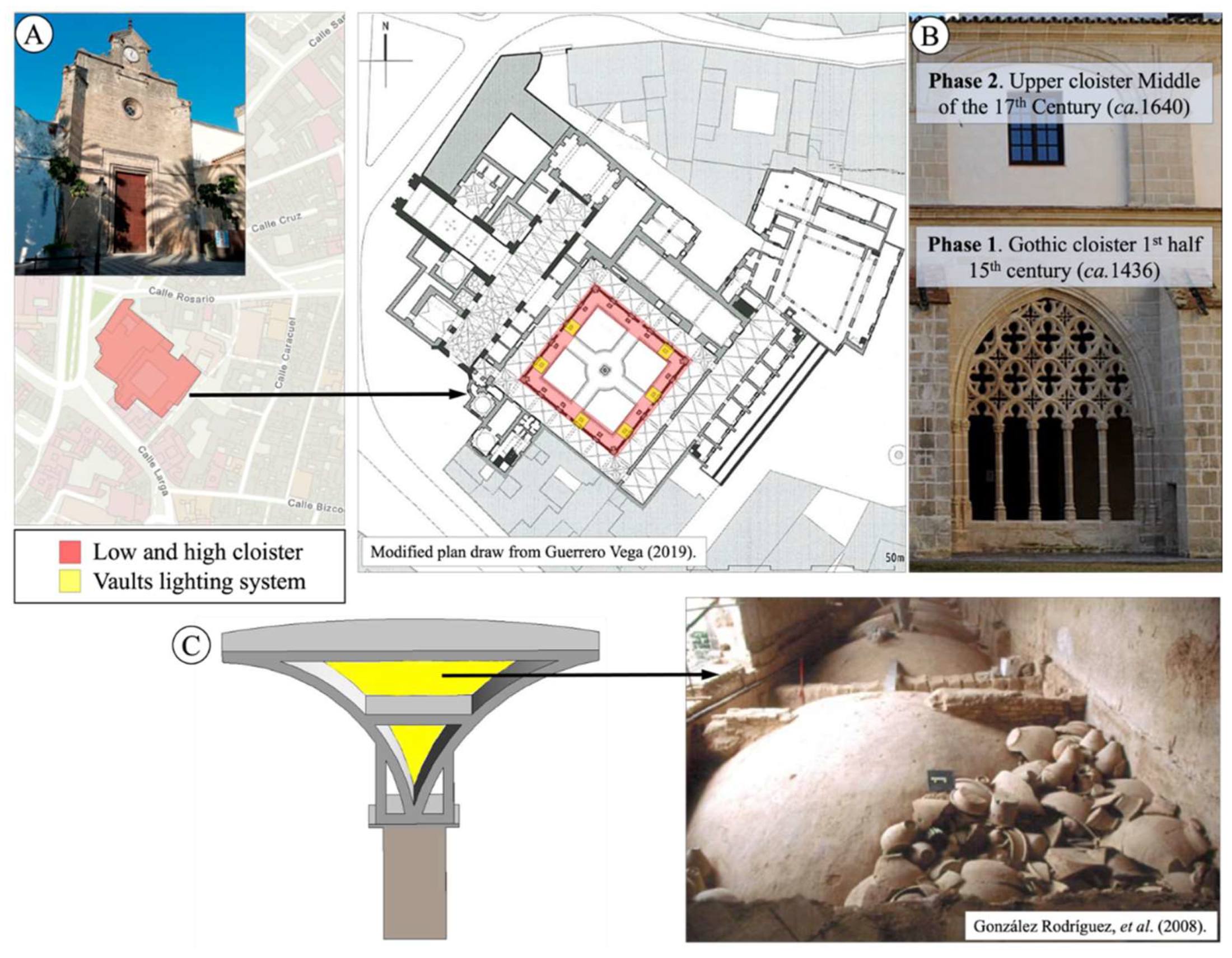

Regarding Early Modern civic and religious buildings’ archaeology, the excavation of their vault fillings provides invaluable chronological, cultural, and environmental data. The Convent of Santo Domingo, established shortly after the Christian conquest, under the reign of Alfonso X of Castile, serves as a key archaeological site. Originally functioning as a fortified structure and warehouse, the convent was object of crucial renovations during the 15th century, such as the construction of the gothic cloister. Later, around the middle of the 17th century, a second floor was added to the said cloister. To build these vaulted ceilings, broken ceramics (also known as

loza quebrada) were used to fill the vaults in the lightest way possible. For that, they applied preferably large containers, mostly ceramic wastes from local potters [

8,

9] (

Figure 2). The possibility of comparing the archaeological materials recovered from different construction phases of the convent allows us also to better understand changes in the economic and social dynamics of Jerez during this period, revealing significant insights into daily life, craft production, and trade activities within a broader Atlantic and Mediterranean framework.

1.2. A Brief Geological Background of Southwestern Andalusia

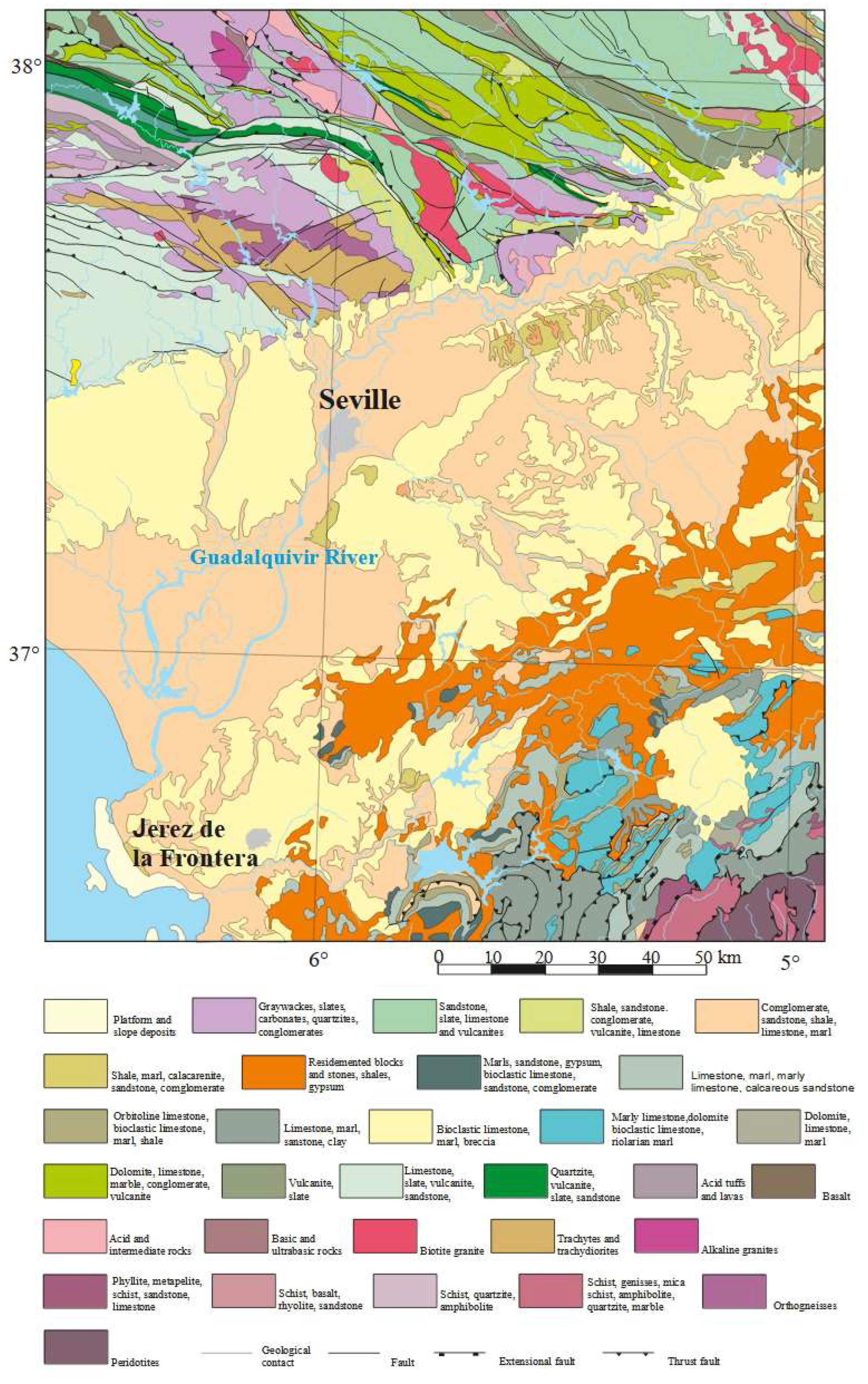

The geological complexity of Southwestern Andalusia is the result of a long and dynamic evolution, giving rise to two prominent mountain systems: the Iberian Massif and the Baetic Cordillera (

Figure 3). The Iberian Massif, situated to the north of the Guadalquivir Basin, encompasses the mountain ranges of Córdoba, Seville, and Huelva. This massif is composed of highly metamorphosed Precambrian formations, including gneisses, slates, and quartzites, interspersed with volcanic intrusions, as well as Cambrian sequences dominated by sandstones, conglomerates, and limestones. These ancient formations have been tectonically and thermally modified during the Hercynian orogeny, a major geodynamic event that shaped much of the Iberian Peninsula's structural framework. In particular, the Hercynian uplift contributed significantly to the exposure of deep-seated metamorphic rocks, providing a rich source of raw materials [

10].

The Guadalquivir Basin itself, positioned between these two tectonic domains, has been subject to multiple phases of marine transgression and regression since the Miocene. These processes have deposited thick sequences of marine and continental sediments, including clays, marls, and limestones, interspersed with

olistostromes—chaotic deposits resulting from gravity-driven mass wasting events. Stratigraphic and sedimentological investigations have revealed the significance of these deposits in reconstructing the paleogeography and tectonic evolution of the region during the Mesozoic and Cenozoic eras [

11,

12].

In the Jerez region, the geological setting is defined by extensive alluvial plains formed primarily by the depositional dynamics of the Guadalquivir River system. These plains are characterized by upper Miocene formations, particularly calcareous sandstones, which are rich in both macrofossils and clay minerals, indicative of alternating marine and fluvial depositional environments. The presence of these materials suggests complex sedimentary processes shaped by both tectonic uplift and subsidence, as well as eustatic sea-level changes during the Miocene and Pliocene [

13]. Furthermore, the region has been significantly affected by Pliocene to Quaternary tectonic activity, which has modulated local geomorphological features and influenced the spatial distribution of these sedimentary units.

Geological and climatic conditions have also played a pivotal role in the formation and classification of soils in the Jerez area. The predominant soil types—Vertisols, Cambisols, and Luvisols—are closely linked to the underlying geology and the hydrological regime of the Guadalquivir Basin. Vertisols, typically found in the deeper valleys and low-lying marshes, are characterized by high clay content, which leads to significant expansion and contraction with moisture changes, influencing their agricultural use. Cambisols, recognized by their yellowish-brown to reddish hues, are primarily associated with siliceous sandstones and iron oxides, reflecting significant weathering processes. Luvisols, with their higher clay content and characteristic argillic horizons, are widespread and contribute to the region's high agricultural productivity [

14].

These soil types are not only critical for modern agricultural practices but also represent key environmental factors that influenced the availability and selection of raw materials by ancient potters. The mineralogical composition of these soils, rich in clay minerals such as illite, kaolinite, and smectite, would have been essential for ceramic production in Jerez. The interplay between local geology, edaphic environments, and ceramic technology offers critical insights into resource management strategies and the technological decisions of potters in Southwestern Andalusia.

2. Materials and Methods

2.1. Sampling Strategy and Typological Characterization

The 7 ceramic samples analyzed in this study were recovered from the vault fillings in the cloister of the Convent of Santo Domingo, belonging to its second phase of construction, started from the end of the 16th century until the middle of the 17th century (Barrionuevo, 2008/09: 257). Although, within the archaeological context, we rely on this author’s work and the technical reports derived from archaeological excavations, the analyzed samples would correspond to the second construction phase of the convent. The assemblage consists of production wastes’ fragments, which constituted around 80% of the materials used to fill the said vaults. This characteristic explains why these vessels were so well-preserved and why it was possible to achieve complete reconstructions of the forms.

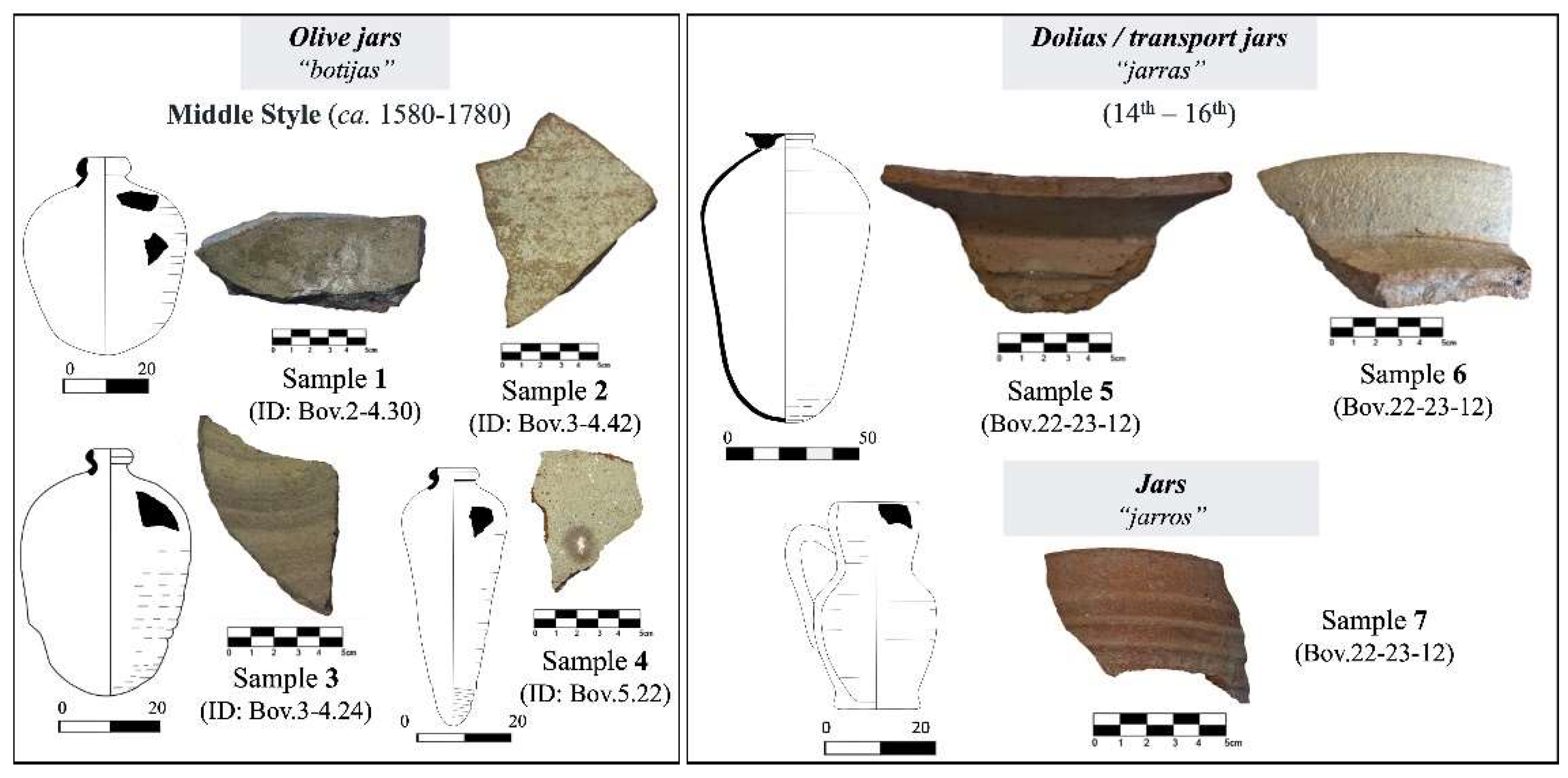

The study and establishment of a typological classification of these ceramics from Jerez was already published by the archaeologist F. Barrionuevo. Our shards are representative of the

dolia, olive jars, and jugs (

Figure 4). The

dolia, commonly identified, as medieval containers for olive oil trade, are large transport jars primarily associated with Seville’s commercial activities from the 14th to early 16th centuries [

15]. The fact that these jars were uncovered in the deepest vaults of the cloister points to their significant use in the foundational construction phases of the convent, implying a close connection between the construction materials and commercial networks of the time.

The olive jars, commonly referred in written sources as botijas, are large storage and transportation containers that trace their design origins to the amphorae used by various ancient Mediterranean civilizations. These jars were integral to the transatlantic and regional trade networks, particularly for the storage of olive oil, wine, and other liquid goods.

Some of these olive jars display interior coatings of lead glaze, likely applied to improve the jar's impermeability and prevent contamination of the contents. Morphologically, they are defined by a circular mouth, a pronounced high shoulder, and a concave or flat base. These features can vary considerably and have been the focus of typological and chronological studies aiming to differentiate their regional production centers, phases of trade expansion and their distribution across consumption sites [

21,

22,

23,

24,

25].

The jugs were functional vessels, often used for serving liquids like water and wine. Typically, they have a single handle, an outlined spout, and are partially glazed on the interior and exterior. Those from Jerez had a honey-colored glaze in the interior surface, and in the exterior, just along its mouth and neck [

8,

24,

25].

For comparative purposes we also analyzed ceramic fragments from Seville, a major Andalucian pottery production center. These materials include 15 forms from an early production phase (15th century) and 25 forms from the later one (16th century). A study that has been supported by the chronological and typological analysis from multiple ceramic wastes assemblages found in Seville [

15,

16,

17,

18,

19,

20].

Concerning archaeometry, the methodology employed in this study follows rigorous parameters, focusing on the representativity and statistical validity of the selected ceramic samples. Indeed, in archaeometric research, it is essential to prioritize the diagnostic value of ceramic samples when dealing with assemblages from archaeological contexts. The selection of samples in this study was guided by well-established criteria that emphasize the interpretive potential of key typological variants. By focusing on distinct ceramic forms, the study maximizes the informational output from a limited number of samples. A particularly important strategy given the logistical and preservation constraints often encountered in archaeological fieldwork.

Each sample was chosen for its ability to reflect specific technological features, such as firing conditions, raw material composition, and production techniques. This selection process and methodological rigor ensures that the results provide a comprehensive understanding of ceramic production processes in Jerez de la Frontera and can be confidently extrapolated to represent wider ceramic production practices within the Andalucian region.

2.2. Techniques

- -

Petrography (Optical Microscopy-OM).

Petrographic analysis was carried out using a polarized optical microscope (Nikon LVPol-100 and SZ750), equipped with objectives providing x5, x10, x20, and x50 magnification. The methodology employed followed established protocols in ceramic petrography, geology, and soil science [

26,

27,

28,

29,

30]. This analysis focused on identifying and characterizing inclusions, tempers, clay matrices, voids, and surface finishes. Observations were made using both Plane Polarized Light (PPL) and Crossed Polarized Light (XPL). These techniques are critical for determining the fabric and production characteristics of the ceramics, particularly regarding the selection of raw materials, formation techniques, and decorative methods. The clay matrix, observed at a microscopic level, provided insights into its homogeneity and the presence of natural or intentional temper materials, which play a significant role in defining the mechanical and thermal properties of ceramics.

This detailed microstructural analysis is essential not only for reconstructing the technological choices made by the ancient potters but also for understanding post-firing treatments and surface finishes. By cross-examining the clay matrix, tempers and visible traces of production processes (such as molding or wheel-throwing), the petrographic analysis contributes to identify production techniques and technological innovations.

- -

X-Ray Diffraction Analysis (XRD).

XRD was employed to determine the mineralogical composition of the ceramic fragments. This analysis aimed to identify both primary and secondary crystalline phases, crucial for inferring firing temperatures and production techniques. The formation of neo-crystalline phases during firing, such as mullite and spinel, serves as an indicator of the specific thermal conditions to which the ceramics were exposed. This technique is widely used in ceramic analysis, and several parameters were considered [

31,

32,

33,

34].

The analysis was conducted using a PANalytical Xpert PRO diffractometer, which is equipped with a copper tube (λCuKα = 1.5418 Å), a vertical goniometer in Bragg-Brentano geometry, a programmable divergence slit, a secondary monochromator, and a PixCel detector. The operational conditions were set at 40 kV and 40 mA, with the scan range covering 5 to 70º 2θ, which is sufficient to capture the most relevant mineralogical phases present in ceramics. The diffractograms obtained from these scans were interpreted using established mineralogical reference databases and protocols for ceramic analysis. This technique is pivotal for assessing the thermal history of ceramics. By identifying phases such as quartz, feldspar, hematite, and the presence of vitrified clay components, the XRD data allow for an accurate estimation of the firing temperatures, which in turn provides insights into the technological capabilities and choices of the potters. Additionally, the presence of certain mineralogical phases can inform the provenance of the raw materials, indicating whether the clays were sourced locally or imported.

- -

Inductively Coupled Plasma Mass Spectrometry (ICP-MS).

ICP-MS was employed to analyze the elemental composition of the ceramics, with a particular focus on determining their provenance and the technological processes involved in their production. The analysis followed the established protocols outlined by Iñañez and colleagues, which are designed to ensure the precision and reliability of elemental data [

35,

36,

37]. In the first stage, we removed the external and internal surfaces of the ceramic material mechanically to prevent any post-depositional contaminants. We then ground approximately 5 grams of each ceramic using a planetary ball tungsten carbide cell mill. Finally, we calcined the ceramics at 900°C for one hour in an electric furnace under oxidizing conditions. The samples were subsequently processed and subjected to ICP-MS analysis using a NexION 300 ICP/MS (PerkinElmer, Ontario, Canada) in a laboratory clean room (class 100). Using 500 mg of LiBO

2 in Pt-Au crucibles, four drops of LiBr solution as a non-wetting agent, and propane melting equipment, the alkaline fusion method was utilized to create solutions of 250 mg unknown samples, blanks, and certified materials for external calibration (Geological Survey of Japan: andesite JA2, granodiorite JG-1a, granite JG-2, and basalt JB-3). Subsequently, the resultant solution was diluted (1:200) using standard solutions of in (50 μg L

-1) and Bi (10 μg L

-1) together with a mixture of 0.32 N HNO

3 and extremely dilute HF. On the one hand, the following analyte concentrations were carried out in standard mode:

27Al,

31P,

88Sr,

120Sn,

90Zr,

93Nb,

133Cs,

137Ba,

139La,

140Ce,

141Pr,

142Nd,

147Sm,

153Eu,

158Gd,

159Tb,

164Dy,

165Ho,

166Er,

169Tm,

174Tb,

175Lu,

180Hf,

181Ta,

206+207+208Pb,

232Th and

238U (Internal standards: In and Bi). On the other hand,

23Na,

24Mg,

28Si,

39K,

44Ca,

47Ti,

51V,

52Cr,

55Mn,

56Fe,

59Co,

60Ni,

63Cu and

66Zn (Internal standard: In) were analyzed in collision mode with He as cell gas. The introduction of the sample and the experimental setup were optimized to yield 20 scans, 1 read, and 3 replicates for each sample, with an integration period of 1000 ms for ICP-MS data gathering [

38,

39].

The ICP-MS analysis focused on detecting a wide range of major, minor, and trace elements, including but not limited to Si, Al, Fe, Ca, Mg, Na, K, Ti, Mn, and trace elements such as Zr, Nb, Y, and rare earth elements (REEs). These elements are crucial for determining the geological provenance of the raw materials used in the ceramics and for identifying any technological enhancements made during production (such as the deliberate addition of temper or other materials to improve the performance of the ceramic).

By analyzing the elemental composition, this technique provides a comprehensive overview of the materials’ provenance, and know the technological decisions made by potters. Variations in elemental concentrations can point to different clay sources, revealing whether the ceramics were produced locally or imported. Furthermore, specific elemental signatures related to high-temperature firing or tempering materials can offer insight into the technological sophistication of ceramic production processes.

3. Results

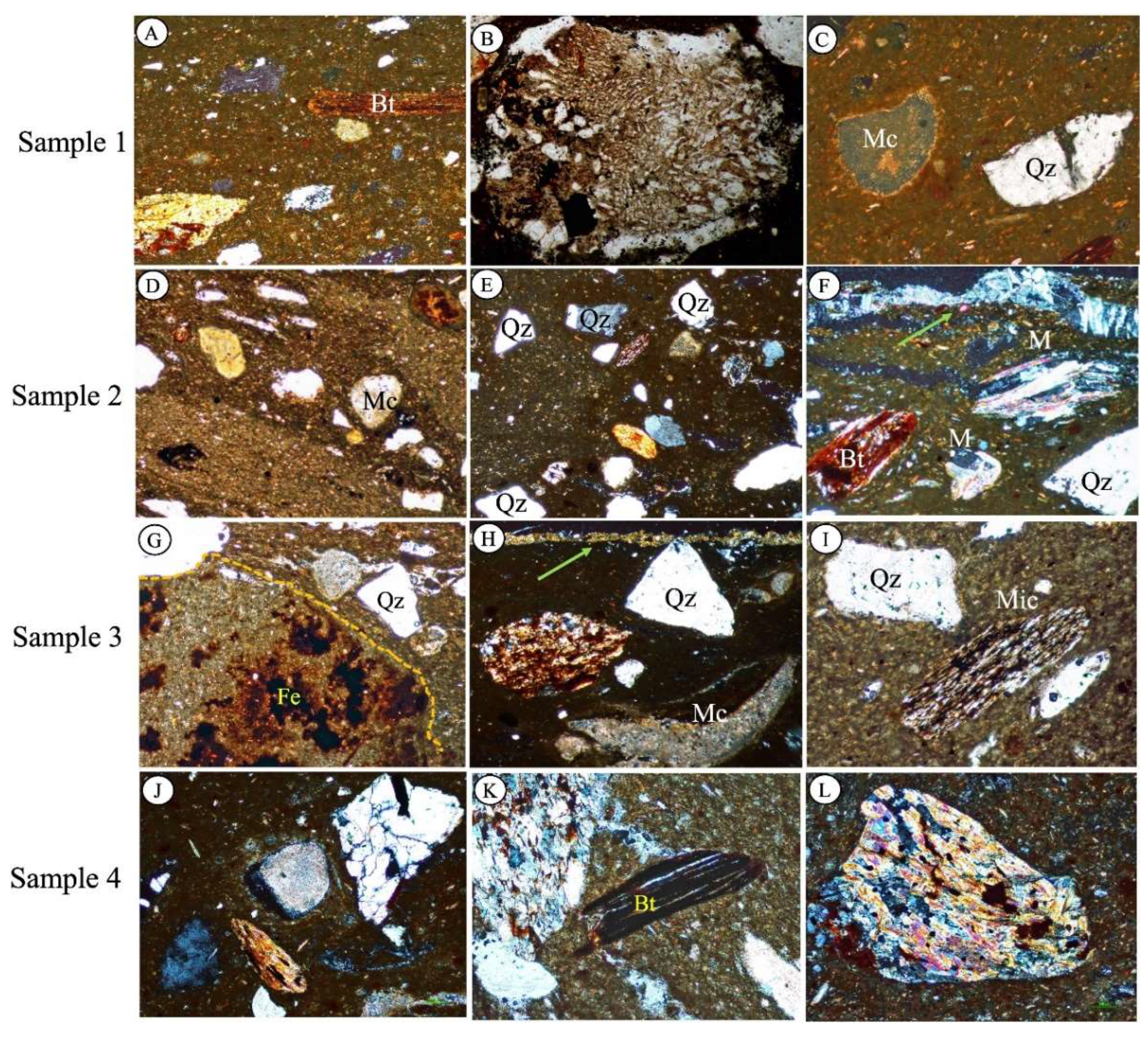

3.1. Petrography Analysis

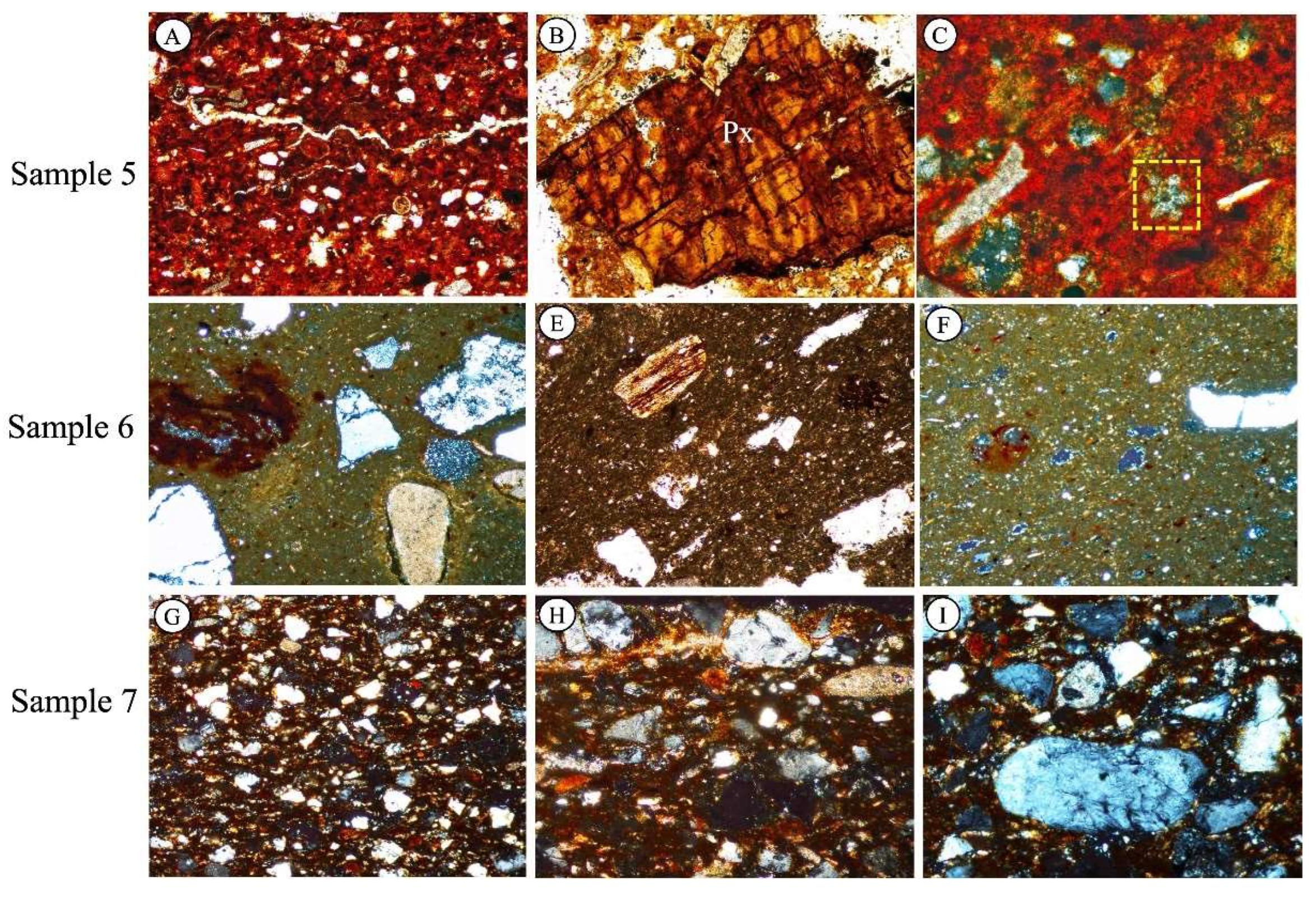

The petrographic analysis of the

dolia (

Figure 6) reveals distinct mineralogical and lithic compositions compared to the olive jars, suggesting differences in the sourcing of raw materials and production techniques. Sample 5 shows a mineralogical structure dominated by medium- and fine-sized quartz, pyroxenes, and clinopyroxenes, which are typically associated with igneous origins. These minerals suggest that the raw materials were sourced from regions with access to mafic or intermediate igneous rocks, such as volcanic or plutonic formations.

The presence of plagioclase feldspar, with its characteristic twinning and birefringence, further supports this igneous origin. The feldspar grains were likely derived from basaltic or andesitic rocks, providing a direct link to specific volcanic regions.

The clay matrix in these samples exhibits high birefringence, indicating a significant presence of well-crystallized phyllosilicates, likely derived from weathered igneous or metamorphic rocks. Iron oxide nodules appear as reddish-brown inclusions, indicative of an oxidizing firing atmosphere or post-depositional oxidation. The presence of these iron oxides suggests that the jars were fired at relatively high temperatures, sufficient to induce the formation of these iron phases.

An important discovery in the dolia samples is the presence of microfossils, including foraminifera, radiolarians, and sponge spicules. These fossils point to the incorporation of marine sediments into the ceramic paste, either intentionally as tempering material or naturally present in the clay. This is significant as it suggests that the raw materials were sourced from marine depositional environments, possibly coastal areas or sedimentary basins that experienced past marine transgressions.

Sample 6 shows a complex paste composition, with fragments of quartz, biotite, sedimentary rocks, phyllite, and calcite. The presence of phyllite indicates the inclusion of low-grade metamorphic materials, likely from tectonically active regions or eroded metamorphic terrains. The biotite displays typical pleochroism, ranging from brown to green, further supporting a metamorphic origin.

The vitrification of the clay matrix suggests that the dolia were fired at high temperatures, around 800-900°C, consistent with controlled production techniques aimed at creating durable storage vessels. The incomplete vitrification in some samples suggests that while the firing temperatures were high, they may not have been sustained long enough to fully vitrify the matrix.

The presence of iron oxide concretions, in combination with the microfossil inclusions and calcite, reinforces the hypothesis that the raw materials were derived from marine sedimentary environments. Calcite plays a key role in influencing the mechanical properties of the ceramics, as it decomposes at high temperatures, releasing CO₂ and creating voids, which would enhance the insulating properties of these ceramic containers.

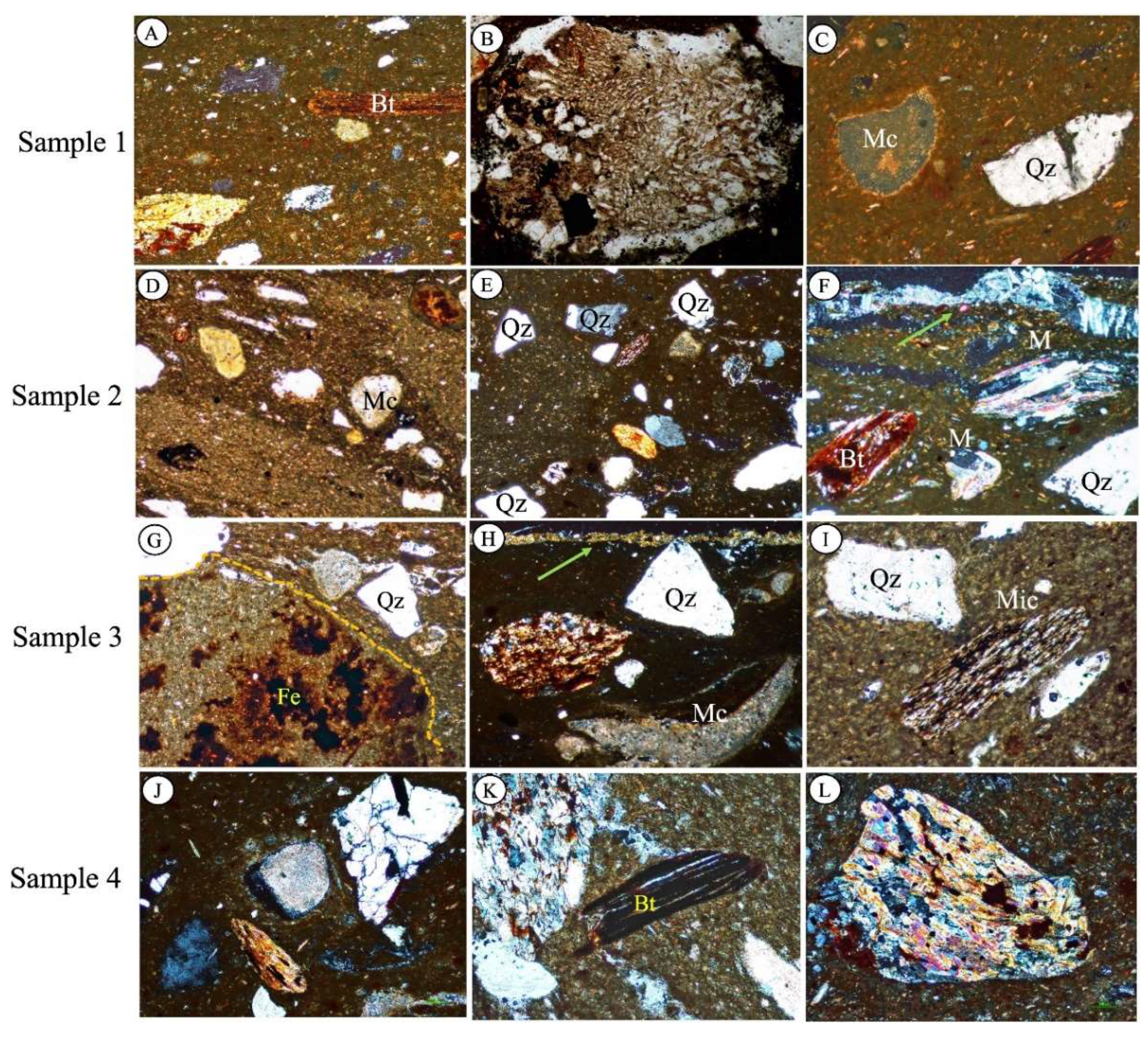

The petrographic analysis (

Figure 5) provides significant insights into the mineralogical composition and technological aspects of the olive jars. A consistent mineralogical profile across all specimens suggests uniformity in raw material selection and production techniques, pointing to a standardized manufacturing process for these transport vessels. The analysis reveals key details regarding the raw materials, their geological origins, and the production processes employed, which are crucial for understanding the provenance and technological sophistication behind olive jar production.

The predominant mineral observed in the samples is polycrystalline quartz, which appears colorless under plane-polarized light (PPL) and exhibits first-order gray interference colors under cross-polarized light (XPL). The quartz grains show low-relief characteristics and occasionally display recrystallization textures, suggesting thermal or mechanical alteration. This could indicate post-depositional processes or repeated exposure to moderate temperatures during the jars' use, such as contact with heated materials.

The presence of plagioclase was confirmed, identifiable by its characteristic polysynthetic twinning and gray interference colors. The presence of this feldspar points to an igneous origin, potentially from volcanic or plutonic sources, which were likely nearby. The durability of both quartz and plagioclase indicates that raw material selection prioritized resilient minerals, ideal for long-distance transport.

Lithic fragments, including sandstone and limestone, were identified within the samples, supporting the hypothesis that the temper materials were locally sourced from sedimentary formations, such as those in the Seville region or the Guadalquivir Basin, where sedimentary and metamorphic rocks coexist. These lithic inclusions are consistent with a sedimentary context, particularly fluvial or alluvial deposits, commonly found in these regions.

Of note is the presence of medium-grade metamorphic schists, characterized by a foliated texture and composed of minerals such as biotite, muscovite, chlorite, talc, and occasionally hornblende. The schist fragments exhibit typical metamorphic lamination, with both white and black micas indicating a regional metamorphic provenance, likely from the Sierra Morena or other metamorphic terrains in southwestern Spain. These metamorphic inclusions may have been intentionally selected as tempering agents due to their mechanical properties, or they could have been naturally present in the local clay sources.

The clay matrix of the olive jars displays a brown coloration with medium birefringence, indicating a well-consolidated and homogenous matrix. Embedded within the matrix are iron oxide concretions, likely hematite or goethite, which provide crucial information about the firing conditions. The iron oxides suggest that the jars were fired in an oxidizing atmosphere, resulting in the typical reddish hue seen in Mediterranean ceramics. These concretions may also reflect post-depositional weathering, pointing to the regional clay's richness in iron, further linking the materials to geological formations near Seville.

The mineralogical consistency across the samples’ points to a deliberate selection of tempering materials, focused on resilient minerals (quartz and plagioclase) and metamorphic lithic fragments to enhance the mechanical strength and durability of the olive jars. Additionally, the presence of marine microfossils, identified in earlier studies, suggests a complex provenance, with raw materials sourced from geologically diverse areas, including marine sedimentary environments.

The Guadalquivir Basin remains a likely source for these raw materials, given its rich deposits of sedimentary, metamorphic, and igneous rocks. The presence of iron oxide concretions and signs of vitrification suggest controlled firing processes, indicative of sophisticated ceramic production techniques.

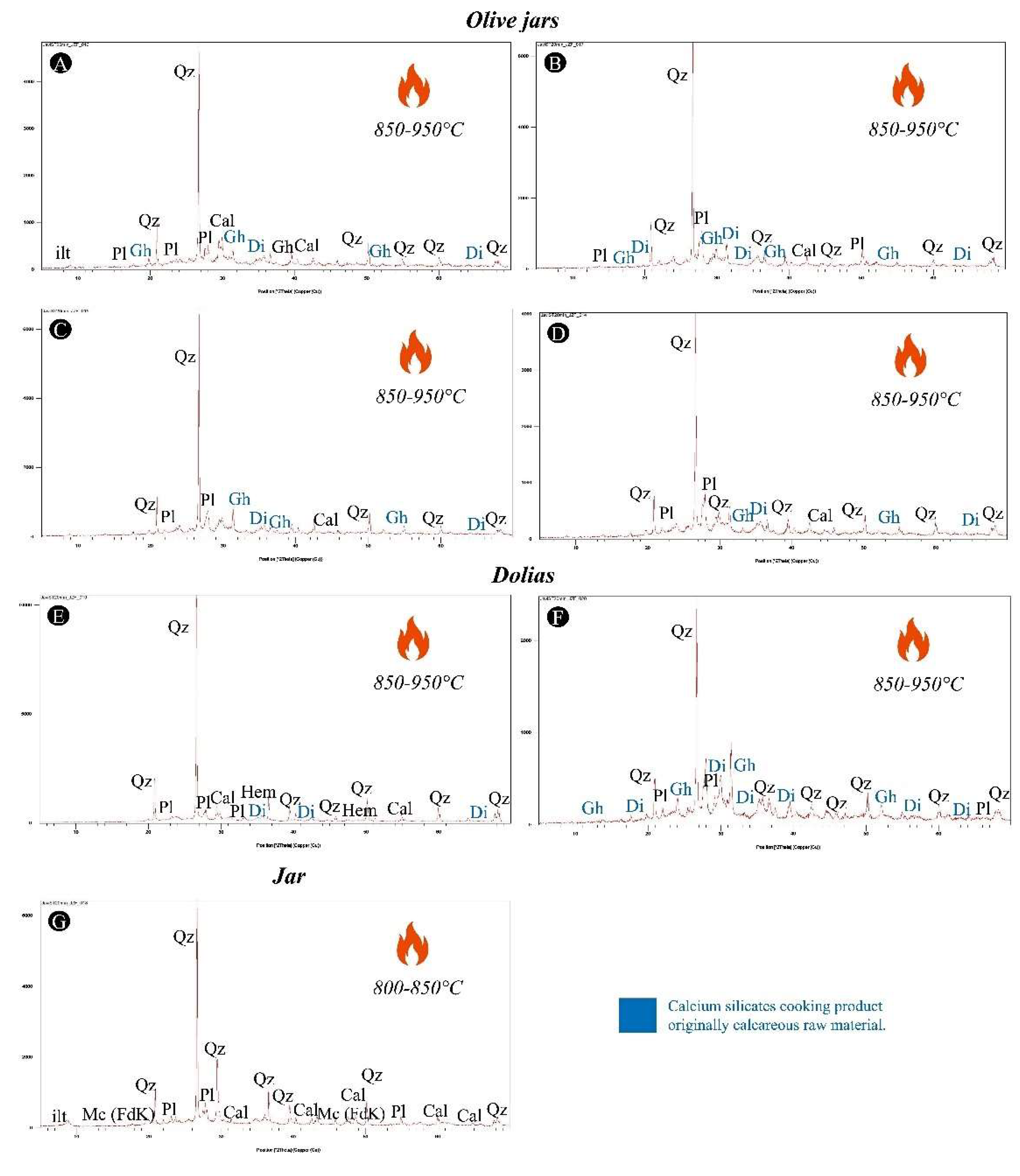

3.2. X-Ray Diffraction Analysis (XRD)

The XRD analysis provided essential information about the crystalline phases present in the ceramic samples, offering insights into the raw materials and firing technologies used. The identification of mineral phases such as quartz, plagioclase, gehlenite, and diopside allows for the estimation of firing temperatures and the reconstruction of the technological choices made by the potters.

The diffractograms (

Figure 7) show the presence of stable minerals like quartz (Qz), which remains stable up to 573°C before transitioning to β-quartz. Its continued presence in the 850-950°C range indicates stable firing conditions that did not induce quartz decomposition. Plagioclase (albite, Pl), gehlenite (Gh), and diopside (Di), which form at temperatures above 800°C, confirm that the ceramics were fired at sufficiently high temperatures to promote mineralogical transformations typical of well-fired ceramics.

The comparative analysis between olive jars and dolia reveals distinct firing environments. The Olive jars exhibit stable high-temperature phases such as gehlenite and diopside, indicating controlled firing above 850°C, while the Dolia show greater variability, with a higher presence of calcite (Cal), suggesting that the firing temperatures were not as consistently high, or the firing environment was more heterogeneous.

Calcite (Cal) may persist in lower-fired ceramics or those fired at temperatures insufficient to fully decompose carbonates (typically >850°C). Lastly, calcite is a calcium carbonate that can be part of the raw material of these ceramics. Its presence can indicate that the ceramics have not reached high enough temperatures to decompose this carbonate. However, it can also form as a secondary phase due to alteration or recarbonation processes [

39]. Hematite (Hem) is a key indicator of oxidizing conditions during firing. Its formation occurs at high temperatures and suggests that some samples were fired in an oxygen-rich atmosphere, leading to the oxidation of iron-bearing phases.

3.3. Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

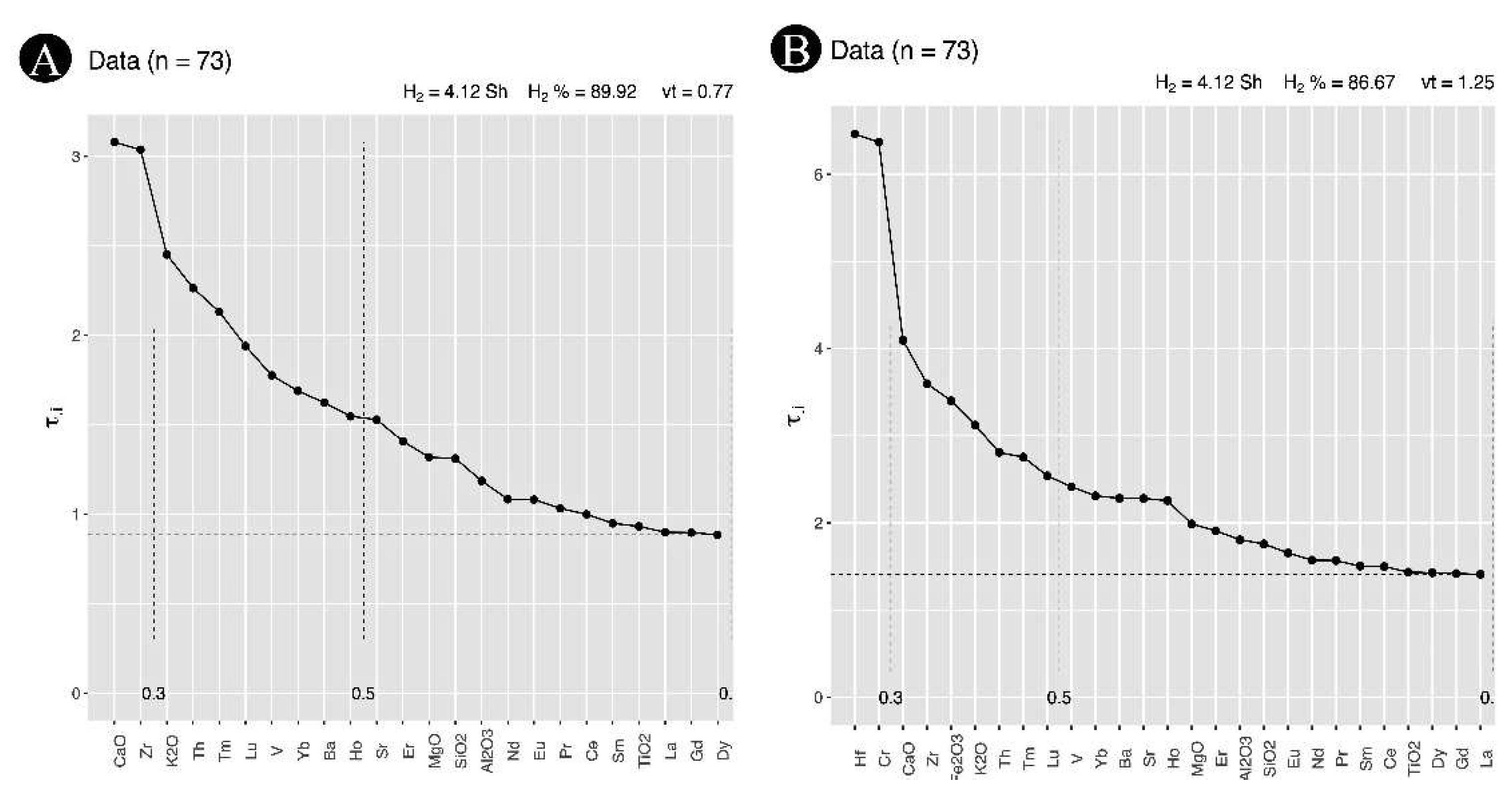

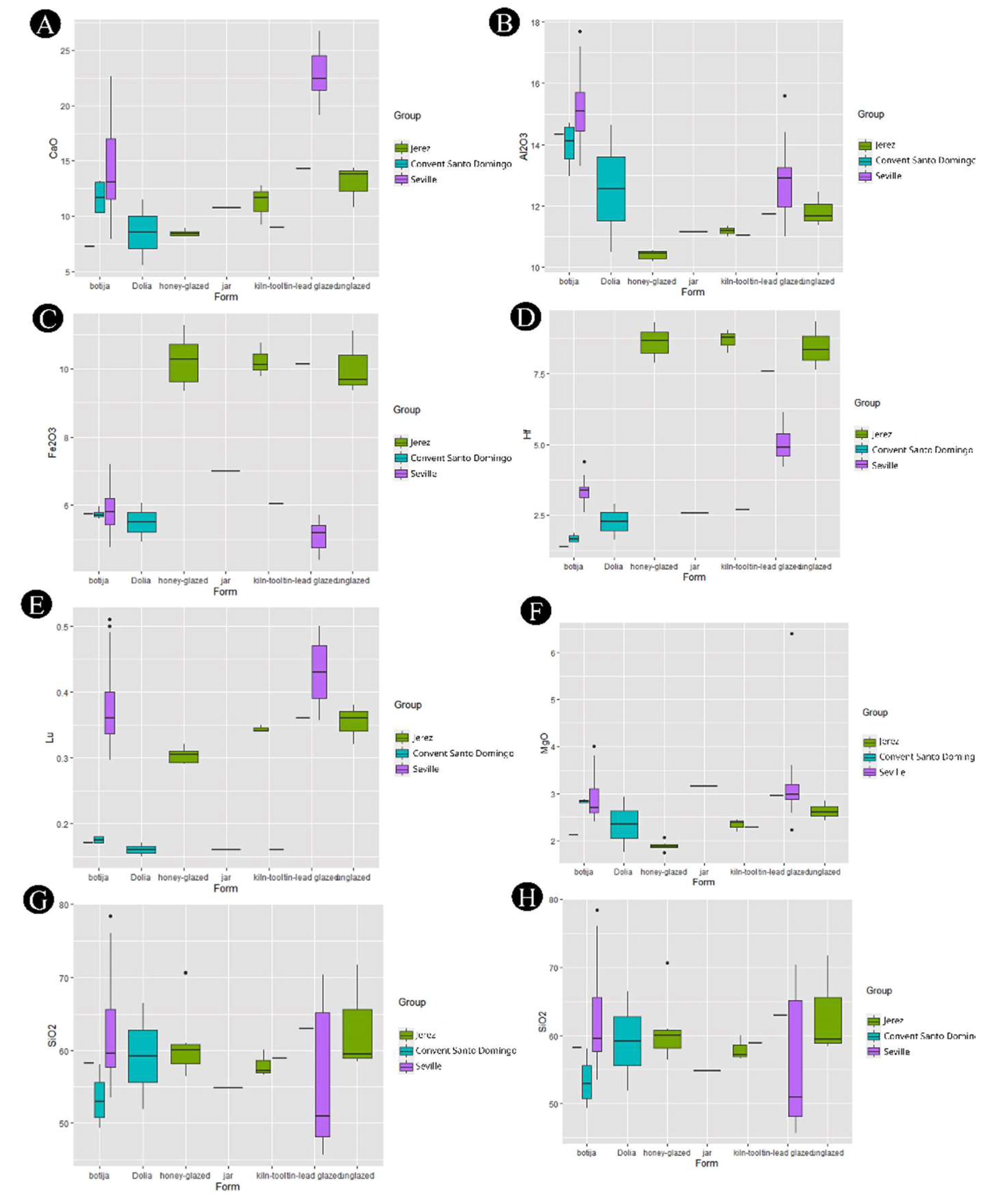

A total of 73 ceramic samples were selected for this compositional study using ICP-MS, including those from Jerez and reference groups from Seville. Among these, Sev 03 corresponds to majolica ceramics and decorated wares, while Sev 05 includes olive jars (botijas) and ceramic transport containers. This analysis aimed to define reference groups based on chemical composition to determine the provenance of the samples, with particular focus on ceramics from Jerez and Seville reference groups. The results of this chemical analysis have been corroborated by petrographic studies to ensure consistency and reliability.

To assess the elemental variability across the samples, a Compositional Variation Matrix (CVM) was employed. This method allows for the identification of chemical concentration variability in the analyzed elements, providing insight into the monogenic or polygenic nature of the ceramic paste. The total variation value (vt) serves as an indicator of this variability [

40].

In the present study, the analysis of 73 ceramic samples revealed a mean relative total variation (vt) value of 0.77 (

Figure 8A), indicative of significant contributions from compounds such as CaO, Zr, K₂O, Th, and Tm. Conversely, a second subset of data yielded a mean relative value of 1.25 (

Figure 8B), highlighting the dominance of elements like Hf, Cr, and CaO. In both cases, certain elements such as Mn, Cr, Hf, and Fe were excluded in subsequent analyses to refine the interpretation of the compositional variation and ensure more accurate clustering results. These findings suggest that the analyzed specimens, predominantly olive jars, are enriched in calcium carbonate and show notable concentrations of zirconium (Zr), potassium (K₂O), and thorium (Th).

Further petrographic XRD analyses corroborate that most of the samples exhibit paste compositions consistent with olive jars, with minimal presence of other ceramic types. The decision to exclude Mn, Cr, Hf, and Fe was based on their disproportionate influence on the overall chemical variability, which could obscure the underlying compositional patterns of the samples.

A cluster analysis was conducted using the ArchFlow package in R [

41,

42,

43,

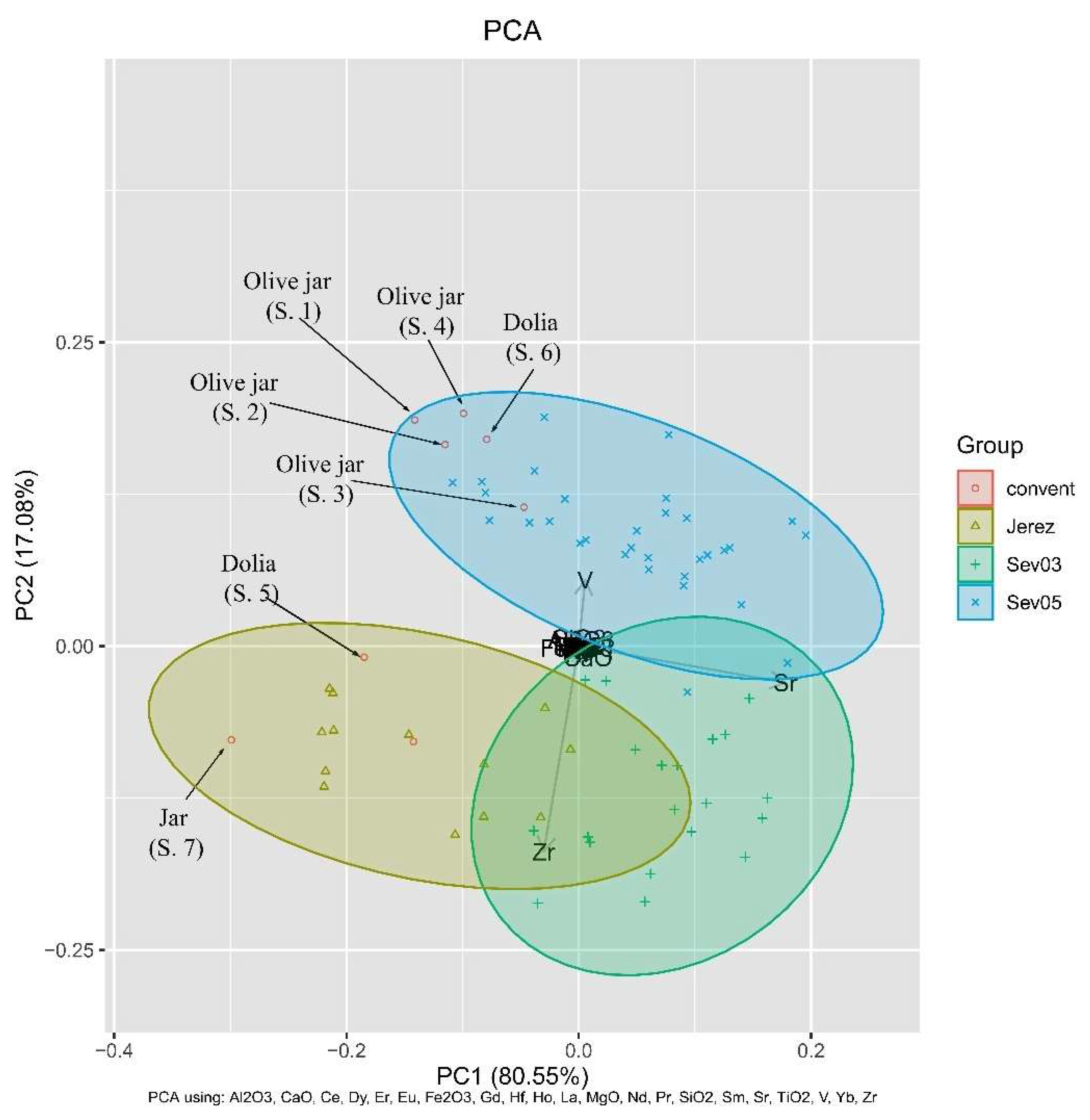

44]. This multivariate statistical approach employed the squared Euclidean distance and centroid algorithm to group the samples based on chemical similarities after performing a centered log-ratio transformation of the analyses retained post-matrix variation calculation. The resulting clusters were plotted based on the subcomposition of key elements, including Al₂O₃, CaO, Ce, Dy, Er, Eu, Fe₂O₃, Gd, Hf, Ho, La, MgO, Nd, Pr, SiO₂, Sm, Sr, TiO₂, V, Yb, and Zr. The Principal Component Analysis (PCA) (

Figure 9) shows the results of the multivariate analysis, where samples from Jerez and Seville are plotted. The first principal component (PC1) accounts for 80.55% of the total variation, while the second principal component (PC2) explains 17.08% of the variance. The PCA chart effectively differentiates the chemical profiles of the samples, clustering the olive jars and

dolia into distinct groups based on their elemental composition.

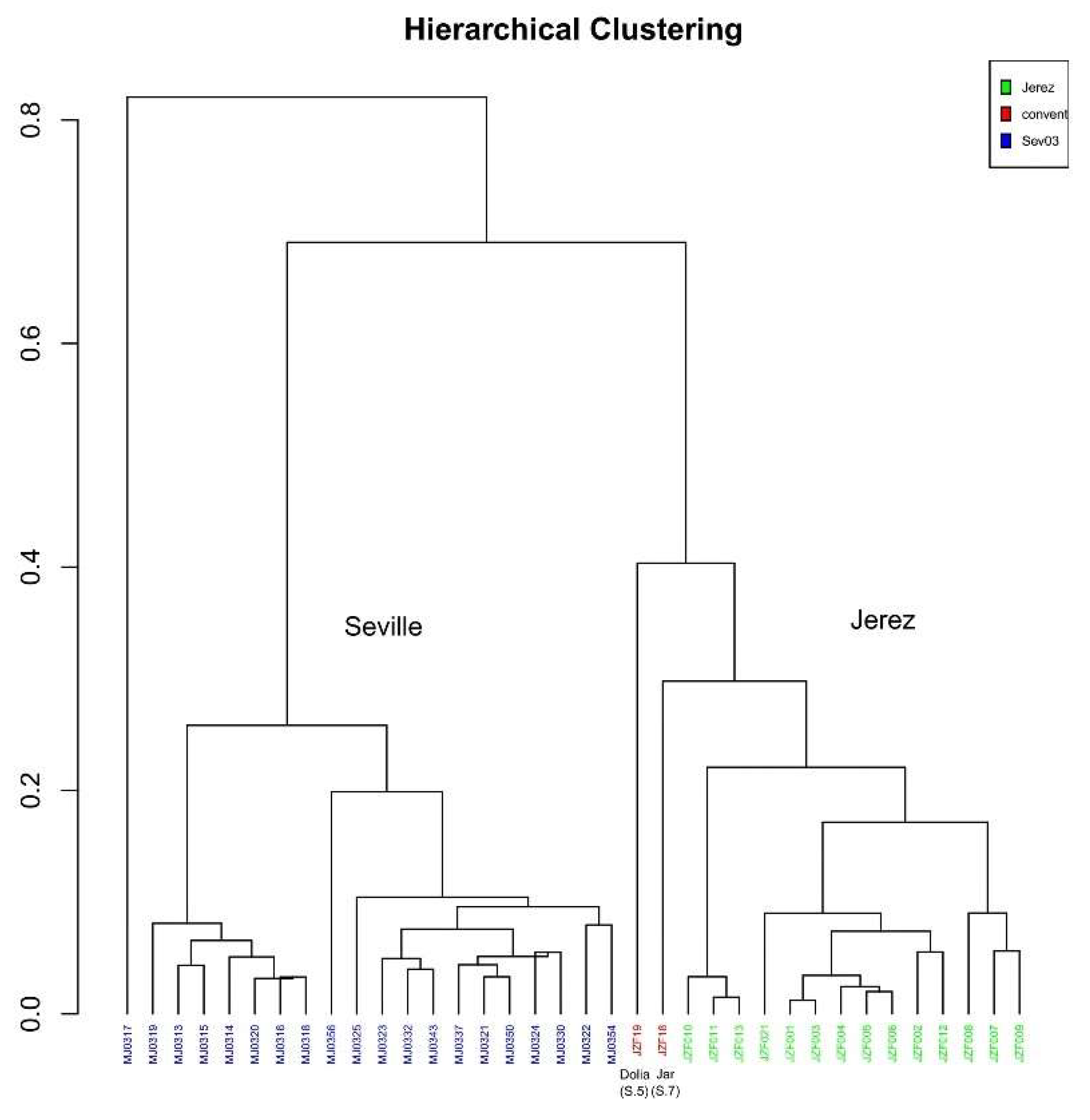

The hierarchical cluster analysis (

Figure 10) further supports the differentiation of production centers. This analysis reveals two primary clusters, corresponding to the ceramic production centers of Jerez and Seville. The hierarchical dendrogram clearly shows the separation between these two groups based on the chemical relationships established through the compositional analysis. Notably, the samples from Seville form a cohesive cluster, whereas those from Jerez show slight internal variability but remain distinct as a group. In addition, the mean Fe₂O₃ content was calculated for both Seville and Jerez samples. The Seville samples exhibited a notably higher concentration of Fe₂O₃, suggesting differences in the clay sources or firing conditions between the two production centers. This finding reinforces the distinct technological practices employed at each site, as reflected in the hierarchical clustering and multivariate analyses.

4. Discussion

The petrographic analysis of the olive jars exposes a consistent mineralogical composition, highlighting uniformity in the selection of raw materials and, very likely, the production methods employed. The dominant mineral observed is polycrystalline quartz, a highly durable and common material, which appears colorless PPL and shows first-order gray interference colors in XPL. This mineral is well known for its resistance to both chemical weathering and mechanical abrasion, generally being part of the raw material itself. Some quartz grains exhibit recrystallization textures, which may indicate post-depositional thermal or mechanical alteration.

In addition, plagioclase feldspar was identified, characterized by banded twinning and moderate gray interference colors. The presence of plagioclase likely originates from nearby igneous formations. Moreover, the identification of sandstone, limestone, and pebble fragments supports a sedimentary origin for the tempering materials, further linking the ceramics to the geological formations of the Seville region and the Guadalquivir Basin. These sedimentary inclusions, along with the presence of metamorphic rocks such as schists, provide a complex picture of material sourcing. The medium-grade metamorphic schist fragments, characterized by laminar minerals such as mica (biotite and muscovite), chlorite, talc, and hornblende, point to raw materials originating from regional metamorphic terrains. These metamorphic inclusions, with their characteristic schistose texture, likely contributed to the mechanical strength of the olive jars, a property that would have been particularly useful for long-distance trade and transport.

The clayey matrix of the olive jars is brown, with medium birefringence, and contains iron oxide concretions, probably hematite or goethite, indicative of an oxidizing firing atmosphere. These concretions also suggest post-depositional weathering processes or natural oxidation of iron-bearing minerals within the clay, reinforcing the link to local clay sources rich in iron. The reddish hue of the olive jars, characteristic of Mediterranean ceramics, further supports this interpretation. The presence of marine microfossils in some samples suggests that the raw materials were sourced from sedimentary basins with marine influences, possibly from coastal areas near the Guadalquivir River.

As for the dolia, although they share some similarities with the olive jars, they show notable differences in material composition. The petrographic analysis of Sample 5 shows quartz, pyroxenes, and clinopyroxenes, suggesting an igneous origin for the raw materials. These minerals are commonly associated with volcanic or plutonic environments, indicating that the dolia may have been produced using materials sourced from regions with mafic and intermediate igneous rocks. The clayey matrix of the dolia exhibits high birefringence and contains iron oxide nodules, again indicating an oxidizing firing atmosphere, although with more variability compared to the olive jars.

One of the more intriguing findings in the dolia is the presence of microfossils, such as foraminifera, radiolarians, and sponge spicules. These inclusions point to the use of marine sediments in the clay mixture, further supporting a coastal or marine sedimentary origin for the raw materials, a characteristic of the Jerez de la Frontera region. The presence of calcite in some dolia, particularly in Sample 6, suggests that these vessels were fired at lower or more variable temperatures, as calcite typically decomposes above 850°C. This, together with the presence of hematite, indicates a more oxidizing but less controlled firing process compared to the olive jars.

The XRD analysis supports these petrographic findings by identifying key crystalline phases that provide insight into the firing temperatures and material selection. Quartz remains a dominant phase, stable up to 573°C, while plagioclase confirms the presence of feldspathic materials in both olive jars and dolia. The identification of gehlenite and diopside in both types of vessels is particularly significant, as these minerals suggest firing temperatures of 850-950°C, indicating that the ceramics were subjected to controlled high-temperature firing. The consistent presence of these high-temperature minerals in the olive jars suggests a more uniform firing process, while the variability in calcite content in the dolia points to potential differences in kiln management or functional requirements between the two vessel types.

The ICP-MS analysis further corroborates these findings by providing a detailed chemical characterization of the samples. The Compositional Variation Matrix (CVM) analysis revealed significant contributions from elements such as CaO, Zr, K₂O, Th, and Tm, with a total variation value (vt) of 0.77 for the olive jars. In contrast, the dolia samples exhibited greater chemical variability, with Hf, Cr, and CaO contributing to a vt of 1.25. This compositional variation reflects the different production practices and material sourcing strategies employed for the two types of vessels. Despite the limited sample size, these robust statistical techniques—such as PCA and Cluster Analysis—allow for the detection of significant chemical groupings, further reinforcing the validity of the results. The PCA reduced the complexity of the dataset, with PC1 explaining 80.55% of the variance and PC2 accounting for 17.08%, effectively distinguishing between the ceramic production centers of Seville and Jerez.

The statistical validity of the conclusions is further supported by the rigorous application of cluster analysis and Log-Centroidal Transformation, which enabled the identification of clear chemical groupings despite the limited number of samples. The hierarchical clustering analysis revealed clear distinctions between the Seville and Jerez production centers, with the Seville samples showing higher concentrations of Fe₂O₃, suggesting differences in clay sources or firing conditions between the two regions.

5. Conclusions

Since the Late Middle Ages, intense mobility and connectivity between cities, people, goods, and ideas, by both sea and land, became increasingly prominent across the Hispanic kingdoms. This phenomenon was particularly accentuated in the western ports, reflecting the broader context of early globalization in the Atlantic [

45,

46]. However, it is through the combined use of archaeological and archaeometric studies that we have been able to form a more comprehensive and nuanced sight of ceramic production, particularly those intended for transportation and daily use.

The Convent of Santo Domingo in Jerez de la Frontera represents a significant archaeological site that has undergone various structural and functional changes over time. The archaeological materials recovered from the ceiling vaults have provided us with critical insights into the ceramic production of the region. Olive jars documented in the convent were manufactured in the Guadalquivir Basin of Lower Andalusia (primarily in and around Seville) and their presence in Jerez attests the city’s involvement in the Atlantic trade, which could have been transported from Seville to Jerez to be filled with wine and transported. Despite their diverse pastes, colors, and surface finishes, olive jars exhibit a homogeneous firing temperature, indicative of a very homogeneous production process. Studies have demonstrated the standardization of these containers based on their measurements, specifically correlating their body and mouth shape [

47,

48]. Furthermore, ongoing research has explored the variations and adaptations in production techniques across workshops, as well as the heterogeneity in artisanal knowledge among Iberian potters, reflecting the continuous exploitation of production sites over time [

49,

50].

However, a pivotal aspect of this research lies in the apparent contradiction in the dating of dolia between Seville and Jerez. Our hypothesis, based on the tightly constrained production dates of jars in Seville, suggests that their manufacture never extended beyond 1600, a period when the prototype olive jars were already widespread across the Atlantic trade routes, as evidenced by the findings in Jerez. Therefore, it seems plausible that dolia were originally used in the fillings of the first Gothic cloister, dating back to approximately 1436—a coherent date for this typology. These large vessels may have been repurposed when the cloister was remodeled in 1609, appearing together despite belonging to chronologically distinct typologies. This overlap in material culture raises the possibility that older vessels were reused during later phases of construction.

Moreover, the presence of both Sevillian and Jerezanian dolia in the convent suggests the incorporation of Jerez into the production of these large transport vessels, likely as the city sought to join the flourishing Atlantic trade. This scenario mirrors the development seen at the production center in Palos de la Frontera, where ceramics featuring Sevillian typologies, with a very short production period, from the late 15th century to the early 16th century. The use of these ceramic forms underscores the rapid expansion and adaptation of local production centers to meet the demands of global commerce. To verify this hypothesis, further typological and archaeometric studies will be necessary in future research.

Regarding the local production in Jerez, it appears that olive jars were not manufactured locally, but imported from Seville, even though ceramic production played a vital role in the region’s wine industry. Archaeological and historical evidence from the ancient Roman province of Baetica confirms the long-standing significance of winemaking, particularly the use of dolia for the processing, fermentation, and storage of wine. These large ceramic vessels were typically lined with beeswax, vegetable resins, or mineral resins, offering insight into their technological sophistication and their role in the wine production process.

The growth of Jerez’s wine production and oil industry had far-reaching impacts on both rural life and the Atlantic diffusion of ceramic containers. Historical data highlight the local wine market in Jerez, its economic significance, and its competition with other establishments, such as

bodegones. The cultivation of vines and the production of wine in Jerez not only shaped the social and economic landscape of the region but also enabled the expansion of trade routes that extended beyond Andalusia, reaching destinations such as the Canary Islands, England, Flanders, and the American territories [

49]. The success of this industry was facilitated by royal roads, ports, and inland settlements, all of which played a crucial role in the circulation of goods and ideas during this period.

Looking forward, it is essential to develop further studies with a larger sample size to expand our understanding of Jerez’s ceramic production, namely its typology and chronology. The diverse ecosystems of Andalusia provided the necessary resources for the cultivation of products such as wine, and olive oil, as well as rich clay deposits for pottery production. By the 15th century, Andalusian ceramics had established connections across broader European and African markets, accelerating and deepening their integration into global trade networks. Despite the overarching influence of trade in controlling ceramic production and technology, local variations in form and style persisted, especially in the major ports of the Atlantic Expansion during the Early Modern Age.

In conclusion, this study underscores the complex and dynamic nature of ceramic production in Andalusia, where local traditions intersected with global trade demands. The detailed archaeometric analyses of dolia, olive jars, and other ceramic forms from sites in Jerez and Seville provide valuable insights into the technological innovations, production strategies, and economic imperatives that shaped the region’s ceramic industry, as reported in recent archaeometric studies on the production of botijas, for example. The integration of Jerez into the broader Atlantic trade, as well as the interplay between local and imported ceramic types, reflects the adaptive strategies of Andalusian potters during this formative period of Early Globalization.

Author Contributions

Conceptualization, S.G.R. and J.G.I.; methodology, J.G.I. and S.G.R. software, J.G.I.; validation, J.G.I.; formal analysis, S.G.R. and J.G.I.; investigation, S.G.R., J.G.I., F.A.C., A.T., J.B.T; resources, J.G.I. and G.A.; data curation, S.G.R. and J.G.I.; writing—original draft preparation, S.G.R.; writing—review and editing, , S.G.R., J.G.I., F.A.C. A.T., J.B.T, JSZ and G.A.; visualization, S.G.R. and J.G.I.; supervision, J.G.I.; project administration, J.G.I; funding acquisition, J.G.I., S.G.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Project: “Archaeology and Archaeometry of the Iberian Atlantic Expansionism in North Africa and the Macaronesian islands (15th-16th centuries): pottery, settlement, and Trade” (CERIBAM), Grant PID2020-113198GB-I00. This project is funded by MCIN/AEI/10.13039/501100011033 and by the European Regional Development Fund “A Way of Making Europe” through the European Union.

Acknowledgments

The authors express their sincere gratitude to the University of the Basque Country (UPV/EHU) for their institutional support and to the Maria Zambrano Grant for the Attraction of International Talent, funded by Next Generation EU (MAZAM22/11 Saúl Guerrero Rivero). Special thanks are extended to SGIker (General Research Services) of the University of the Basque Country UPV/EHU for providing access to their analytical facilities and technical assistance throughout this research. This article also had the support of CHAM (NOVA FCSH / UAc), through the strategic project sponsored by FCT (UIDB/04666/2020) —

https://doi.org/10.54499/UIDB/04666/2020.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Collantes de Terán Sánchez, A. El encabezamiento de alcabalas en Jerez de la Frontera en 1515. In Estudios de historia moderna en homenaje al profesor Antonio García-Baquero; Álvarez y Santaló, L. C., Coord.; Universidad de Sevilla: Sevilla, 2009; pp. 311–320.

- González Zalacaín, R. J.; Muñoz Gómez, V. Jerez y el mar en la Baja Edad Media. In 750 aniversario de la incorporación de Jerez a la Corona de Castilla: 1264-2014; Sánchez Herrero, J., González Jiménez, M., Dirs.; Barea Rodríguez, M. A., Romero Bejarano, M., Coords.; Ayuntamiento de Jerez: Jerez, Spain, 2014; pp. 307–327. ISBN: 9788487194702.

- Aznar Vallejo, E. La regulación de los oficios del mar en Andalucía. In Gentes del mar en la ciudad atlántica medieval; Solorzano Telechea, J. A., Arízaga Bolumburu, B., Andrade, A. A., Eds.; Instituto de Estudios Riojanos: Spain, 2012; pp. 95–122. [Google Scholar]

- Edwards, J.H. Oligarchy and Merchant Capitalism in lower Andalusia under the Catholic Kings: the case of Córdoba and Jerez de la Frontera. Hist. Instit. Docum. 1977, 4, 11–33. [Google Scholar] [CrossRef]

- O'Flanagan, P. Port Cities of Atlantic Iberia, C. 1500-1900; Ashgate: Great Britain, 2008. [Google Scholar]

- Lister, F. C.; Lister, R. H. Andalusian Ceramics in Spain and New Spain. A Cultural Register from the Third Century B.C. to 1700; The University of Arizona Press: Tucson, 1976. [Google Scholar]

- Rallón, F. E. Historia de la Ciudad de Xerez de la Frontera y de los Reyes que la dominaron desde su primera fundación; Martín Gutierrez, E., Ed.; Universidad de Cádiz: Spain, 1999 [ca.1650]. DOI: https://tiendaeditorial.uca.es/descargas-pdf/84-7786-575-2-completo.pdf.

- Barrionuevo Contreras, F. J. “Loza quebrada” de relleno de bóvedas de los claustros de Santo Domingo de Jerez de la Frontera. Rev. Hist. Jerez 2008-2009, 14–15, 255–285. DOI: https://dialnet.unirioja.es/servlet/articulo?codigo=6713155.

- Guerrero Vega, J. M. Espacio y construcción en la Arquitectura Religiosa Medieval de Jerez de la Frontera (s. XIII-XV); Editorial Universidad de Sevilla: Spain, 2019.DOI: https://dialnet.unirioja.es/servlet/tesis?codigo=48690.

- Gutiérrez Mas, J. M.; Algarra, A. M.; Domínguez Bella, S.; Moral Cardona, J. P. Introducción a la Geología de la Provincia de Cádiz; University of Cadiz: Spain, 1991. DOI: http://hdl.handle.net/10498/25341.

- Ortega, E.; Lozano, F. J.; Martínez, F. J.; Bienes, R.; Gallardo, J. F.; Asensio, C. Soils of the Mediterranean Areas. In The Soils of Spain; Gallardo, J., Ed.; World Soils Book Series; Springer, 2016; pp. 153–186. DOI: https://doi-org.ehu.idm.oclc.org/10.1007/978-3-319-20541-0_5.

- Junta de Andalucía. Contextualización geológica de Andalucía: una aproximación a la Geodiversidad Andaluza; Consejería de Medio Ambiente Dirección General de Gestión del Medio Natural, Junta de Andalucía: Spain, 2011. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Environmental Management (Soil Quality Standards) Regulations; 2007. DOI: https://faolex.fao.org/docs/pdf/tan151538.pdf.

-

The Soils of Spain; Gallardo, J. F., Ed.; World Soils Book Series; Springer: New York, 2016. [Google Scholar] [CrossRef]

- Amores Carredano, F.; Chisvert Jiménez, N. Tipología de la cerámica común bajomedieval y moderna sevillanas (siglos XV-XVIII): I, la loza quebrada de rellenos de bóveda. SPAL 1993, 2, 269–325. [Google Scholar] [CrossRef]

- Barrionuevo Contreras, F. J. “Loza quebrada” de relleno de bóvedas de los claustros de Santo Domingo de Jerez de la Frontera. Rev. Hist. Jerez 2008-2009, 14–15, 255–285. DOI: https://dialnet.unirioja.es/servlet/articulo?codigo=6713155.

- Pleguezuelo, A.; Librero, A.; Espinosa, M.; Mora, P. “Loza quebrada” procedente de la Capilla del Colegio-Universidad de Santa María de Jesús (Sevilla). SPAL 1999, 8, 263–292. [Google Scholar] [CrossRef]

- Ramos Casquero, A. Caracterización estructural de los rellenos situados en el trasdós de bóvedas de edificios históricos; Doctoral Dissertation, Universidad Politécnica de Madrid (UPM), 2015. [CrossRef]

- López Torres, P. “Loza Quebrada” procedente de la bóveda de la capilla de San Isidoro. SPAL 2018, 27(1), 283–296. [Google Scholar] [CrossRef]

- Jiménez Sancho, A. Rellenos cerámicos en las bóvedas de la Catedral de Sevilla. In Actas del Tercer Congreso Nacional de Historia de la construcción; Sevilla, Gracini, A., Coord., 2000; pp. 561–568.DOI: https://dialnet.unirioja.es/servlet/articulo?codigo=605951.

- Avery, G. Pots as Packaging: The Spanish Botija and Andalusian Transatlantic Commercial Activity, 16th–18th Centuries; Doctoral Dissertation, University of Florida, Gainesville, 1997.DOI: https://archive.org/details/potsaspackagings00aver.

- Goggin, J. M. The Spanish Olive Jar: An Introductory Study; Yale University Publications in Anthropology: New Haven, 1960. [Google Scholar]

- Lister, F. C.; Lister, R. H. Descriptive Dictionary for 500 Years of Spanish-Tradition Ceramics (13th Through 18th Centuries); Special Publication Series, 1; Society for Historical Archaeology, 1976.

- Zunzunegui, A. P. Recipientes cerámicos utilizados en el comercio de Indias. Bol. Americanista 1965, 19(27), 21–38. DOI: https://revistes.ub.edu/index.php/BoletinAmericanista/article/view/12661.

- Sánchez, J. M. La cerámica exportada en el siglo XVI a través de la documentación del Archivo General de Indias (I). Laboratorio de Arte 1996, 9, 125–142.DOI: https://dialnet.unirioja.es/servlet/articulo?codigo=1343175.

- Albero Santacreu, D. Materiality, Techniques and Society in Pottery Production; De Gruyter Open: Warsaw, Berlin, 2014. [Google Scholar] [CrossRef]

- Quinn, P. Thin Section Petrography, Geochemistry and Scanning Electron Microscopy of Archaeological Ceramics; Archaeopress: Oxford, 2022. [Google Scholar] [CrossRef]

- MacKenzie, W. S.; Adams, A. E. Atlas en Color de Rocas y Minerales en Lámina Delgada; MASSON, S.A.: Barcelona, Spain, 1997. [Google Scholar]

- Bullock, P.; Federoff, N.; Jongerius, A.; Stoops, G.; Tursina, T.; Babel, U. Manual para la descripción de secciones delgadas de suelos; Colegio de Postgraduados: Mexico, 1999. [Google Scholar]

- Kapur, S.; Mermut, A.; Stoops, G. New Trends in Soil Micromorphology; Springer: New York, 2008. [Google Scholar] [CrossRef]

- Stanjek, H.; Häusler, W. Basics of X-ray Diffraction. Hyperfine Interactions 2004, 154, 107–119. [Google Scholar] [CrossRef]

- Waseda, Y.; Matsubara, E.; Shinoda, K. X-Ray Diffraction Crystallography: Introduction, Examples and Solved Problems; Springer: Berlin, 2011. [Google Scholar] [CrossRef]

- Maggetti, M. Phase analysis and its significance for technology and origin. In Archaeological Ceramics; Olin, J. S., Franklin, A. D., Eds.; Smithsonian Institute Press: Washington D.C, 1982; pp. 121–133. [Google Scholar]

- Maritan, L.; Mazzoli, C.; Freestone, I. Modelling changes in mollusc shell internal microstructure during firing: Implications for temperature estimation in shell-bearing pottery. Archaeometry 2007, 49(3), 529–541. [Google Scholar] [CrossRef]

- Iñañez, J. G. , Buxeda i Garrigós, J., Speakman, R. J., & Glascock, M. D. (2008). Chemical characterization of majolica pottery from the main production centers of the Iberian Peninsula (14th-18th centuries). Journal of Archaeological Science, 35(2), 425-440.

- Iñañez, J. G.; Bettencourt, J.; Coelho, I. P. Hit and sunk: provenance and alterations of ceramics from seventeenth-century Angra D shipwreck. Archaeological and Anthropological Sciences 2020, 12, 182. [Google Scholar] [CrossRef]

- García de Madinabeitia, M. E.; Lorda, G. J. I.; Ibarguchi. Simultaneous determination of major to ultratrace elements in geological samples by fusion-dissolution and inductively coupled plasma mass spectrometry techniques. Anal. Chim. Acta. 2008, 625(2), 117–130. [CrossRef]

- Sanchez-Garmendia, U.; Carvalho, P.; Bettencourt, J.; Silva, R.; Arana, G.; Iñañez, J. Submerged and reused: an archaeometric approach to the early modern ceramics from Aveiro (Portugal). J. Archaeol. Sci. Rep. 2020, 34(Part A), 102648. [Google Scholar] [CrossRef]

- Buxeda i Garrigós, J.; Cau Onativeros, M. Á. Identificación y significado de la calcita secundaria en cerámicas arqueológicas. Complutum 1995, 6, 293.DOI: https://revistas.ucm.es/index.php/CMPL/article/view/CMPL9595120293A.

- Buxeda i Garrigós, J.; Kilikoglou, V. Total variation as a measure of variability in chemical data sets. In Patterns and Process: A Festschrift in Honor of Dr. Edward V. Sayre; Van Zelst, L., Ed.; Smithsonian Center for Materials Research and Education: Suitland, Maryland, 2003; pp. 185–198. [Google Scholar]

- R CORE TEAM. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, 2014. [Google Scholar]

- Calparsoro, E. Transdisciplinar methodologies on medieval and post-medieval pottery analysis: an archaeometric approach to Basque and Riojan productions. Doctoral Dissertation, University of the Basque Country (UPV/EHU), 2019. DOI: http://hdl.handle.net/10810/42596.

- Calparsoro, E. (2018). R scripts for reproducible research on archaeological ceramics compositional data. Zenodo. [CrossRef]

- Calparsoro, E. GitHub Website https://github.com/esteful/arch_flow.git (Accessed September, 2024).

- Busto-Zapico, M. Standardization and Units of Measurement Used in Pottery Production: the Case of the Post-Medieval Botijuela or Spanish Olive Jar Made in Seville. Post-Medieval Archaeology 2020, 54(1), 42–59. [CrossRef]

- Peacock, C. A. From Olive This: A characterization of the Spanish olive jar in Mid-16th Century New Spain. Master’s Thesis, Department of Anthropology, The University of West Florida, 2023. DOI: https://ircommons.uwf.edu/esploro/outputs/99380178697006600.

- Guerrero-Rivero, S. Caracterización arqueométrica en el estudio de producción cerámica en México y Andalucía durante los periodos virreinal y republicano. Doctoral Dissertation, National School of Anthropology and History (ENAH), Mexico, 2018. [Google Scholar] [CrossRef]

- Guerrero-Rivero, S.; Tenorio, D.; Jiménez-Reyes, M.; Junco, R.; López Reyes, M. C. Commercial interaction at the port of Acapulco, Mexico, during the Viceregal period: a provenance study of ceramic containers and regional wares. J. Archaeol. Sci. Rep. 2020, 29, 102163. [Google Scholar] [CrossRef]

- Pérez González, S. M.; Mingorance Ruiz, J. A. La construcción del mercado local del vino de Jerez de la Frontera a finales de la Edad Media: normativa y espacios. Historia Agraria 2022, 86, 41–70. [Google Scholar] [CrossRef]

- Pérez González, S. M.; Mingorance, J. A. La exportación del vino y las pasas de Jerez de la Frontera a finales de la Edad Media. J. Medieval Iberian Stud. 2020, 12, 383–403. [Google Scholar] [CrossRef]

Figure 1.

Map illustrating key sites, ports, and maritime trade routes in the region, alongside the historical map

"Hispalensis Conventus, sive Andaluziae Pars", by Abraham Ortelius (1579: map 15), Autuerpiaie, Ed. Christoph. Plantinus. URL:

https://bvpb.mcu.es/es/consulta/registro.do?id=399622 .

Figure 1.

Map illustrating key sites, ports, and maritime trade routes in the region, alongside the historical map

"Hispalensis Conventus, sive Andaluziae Pars", by Abraham Ortelius (1579: map 15), Autuerpiaie, Ed. Christoph. Plantinus. URL:

https://bvpb.mcu.es/es/consulta/registro.do?id=399622 .

Figure 2.

A) The Convent of Santo Domingo, highlighting the cloister vaults; B) Architectural details showing the two distinct construction phases: Phase 1, a Gothic cloister from the first half of the 15th c. (ca. 1436), and Phase 2, an upper cloister built during the mid-17th c. (ca. 1640); C) A detailed 3D digital reconstruction of one of the cloister vaults (3D digitalization by Jaione Korro Bañuelos, UPV/EHU).

Figure 2.

A) The Convent of Santo Domingo, highlighting the cloister vaults; B) Architectural details showing the two distinct construction phases: Phase 1, a Gothic cloister from the first half of the 15th c. (ca. 1436), and Phase 2, an upper cloister built during the mid-17th c. (ca. 1640); C) A detailed 3D digital reconstruction of one of the cloister vaults (3D digitalization by Jaione Korro Bañuelos, UPV/EHU).

Figure 3.

Geodiversity of the Seville-Jerez de la Frontera region, Spain. Modified from Rodríguez-Fernández, et al., 2018.

Figure 3.

Geodiversity of the Seville-Jerez de la Frontera region, Spain. Modified from Rodríguez-Fernández, et al., 2018.

Figure 4.

Pottery fragments Convent of Santo Domingo analyzed archaeometrically (Drawings and photograph’s by L. Gondim and S. Guerrero; adapted from Barrionuevo, 2008-2009).

Figure 4.

Pottery fragments Convent of Santo Domingo analyzed archaeometrically (Drawings and photograph’s by L. Gondim and S. Guerrero; adapted from Barrionuevo, 2008-2009).

Figure 6.

Sample 5: A) high-birefringence plagioclase accompanied by microfossils and elongate voids (x5, PPL); B) pyroxene exhibiting signs of physical alteration, potentially linked to diagenetic processes (x10, PPL); C) calcareous nanofossil (foraminifera), indicating a marine sedimentary origin. Sample 6: D) carbonate inclusion and quartz within a well-vitrified clay matrix, supporting the identification of high-temperature processes (x5, PPL); E) sedimentary fragment (phyllite), indicative of low-grade metamorphism (x5, PPL); F) iron oxide impregnations within the clay matrix, highlighting secondary alteration phases (x5, PPL). Sample 7: G) medium silt-sized inclusions (x5 NX); H) quartz, micrite, and calcite in voids (x10 NX); I) sand inclusions (x10 NX).

Figure 6.

Sample 5: A) high-birefringence plagioclase accompanied by microfossils and elongate voids (x5, PPL); B) pyroxene exhibiting signs of physical alteration, potentially linked to diagenetic processes (x10, PPL); C) calcareous nanofossil (foraminifera), indicating a marine sedimentary origin. Sample 6: D) carbonate inclusion and quartz within a well-vitrified clay matrix, supporting the identification of high-temperature processes (x5, PPL); E) sedimentary fragment (phyllite), indicative of low-grade metamorphism (x5, PPL); F) iron oxide impregnations within the clay matrix, highlighting secondary alteration phases (x5, PPL). Sample 7: G) medium silt-sized inclusions (x5 NX); H) quartz, micrite, and calcite in voids (x10 NX); I) sand inclusions (x10 NX).

Figure 5.

Sample 1: A) Biotite displaying moderate to high pleochroism, with color variations from brown to yellowish-brown (x5 PPL); B) sedimentary rock fragment containing volcanic components, indicative of provenance (x10 NX); C) post-depositional micrite within a clay matrix, accompanied by quartz inclusions (x10 NX). Sample 2: D) fine micritic particles aggregated within a clay matrix (x5 PPL); E) quartz fragments embedded in an initially well-vitrified clay matrix (x5 NX); F) Biotite, mica, and microcrystalline inclusions distributed within voids spaces (x10 NX). Sample 3: G) argillaceous inclusion with deposition iron impregnations (x5 PPL); H) quartz grains, micrite within voids, and a superficial calcareous deposit adhering to the exterior surface of the sherd (x5 NX); I) mica-schist fragment, suggesting metamorphic origin (x10 NX). Sample 4: J) argillaceous inclusion with iron nodule impregnations, suggestive of localized depositional conditions (x5 PPL); K) Surface deposit on the sherd composed of quartz, micrite in voids, and an externally adhered calcareous layer (x5 NX); L) mica-schist fragment, indicative of high-grade metamorphic prove-nance (x10 NX).

Figure 5.

Sample 1: A) Biotite displaying moderate to high pleochroism, with color variations from brown to yellowish-brown (x5 PPL); B) sedimentary rock fragment containing volcanic components, indicative of provenance (x10 NX); C) post-depositional micrite within a clay matrix, accompanied by quartz inclusions (x10 NX). Sample 2: D) fine micritic particles aggregated within a clay matrix (x5 PPL); E) quartz fragments embedded in an initially well-vitrified clay matrix (x5 NX); F) Biotite, mica, and microcrystalline inclusions distributed within voids spaces (x10 NX). Sample 3: G) argillaceous inclusion with deposition iron impregnations (x5 PPL); H) quartz grains, micrite within voids, and a superficial calcareous deposit adhering to the exterior surface of the sherd (x5 NX); I) mica-schist fragment, suggesting metamorphic origin (x10 NX). Sample 4: J) argillaceous inclusion with iron nodule impregnations, suggestive of localized depositional conditions (x5 PPL); K) Surface deposit on the sherd composed of quartz, micrite in voids, and an externally adhered calcareous layer (x5 NX); L) mica-schist fragment, indicative of high-grade metamorphic prove-nance (x10 NX).

Figure 7.

Sample 1: A) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Ilt=Illite (mica). Sample 2: B) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 3: C) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 4: D) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 5: E) Qz=Quartz; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Hem=Hematite. Sample 6: F) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. G) Qz=Quartz; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Il=Illite (mica); Hem=Hematite; Mc (FdK)=Microcline.

Figure 7.

Sample 1: A) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Ilt=Illite (mica). Sample 2: B) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 3: C) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 4: D) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. Sample 5: E) Qz=Quartz; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Hem=Hematite. Sample 6: F) Qz=Quartz; Gh= Ghelenite; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite. G) Qz=Quartz; Di= Diopside; Pl=Plagioclase (albite); Cal=Calcite; Il=Illite (mica); Hem=Hematite; Mc (FdK)=Microcline.

Figure 8.

Matrix variation graph of 73 samples of comparision. A) Graph without Mn, Cr, Hf, and Fe (vt = 0.77). B) Graph without excluding Mn (vt = 1.25).

Figure 8.

Matrix variation graph of 73 samples of comparision. A) Graph without Mn, Cr, Hf, and Fe (vt = 0.77). B) Graph without excluding Mn (vt = 1.25).

Figure 9.

Principal component analysis of 73 samples. Ellipses represent 90% of statistical membership probability Ba.

Figure 9.

Principal component analysis of 73 samples. Ellipses represent 90% of statistical membership probability Ba.

Figure 9.

Hierarchical clustering dendrogram illustrating the chemical relationships among ceramic samples, highlighting two distinct chemical groups corresponding to Seville and Jerez. The Seville group (denoted as Sev03, represented by a "green halo" in previous PCA analyses) forms a cohesive cluster, indicating a relatively homogeneous chemical composition characteristic of a single production or raw material source.

Figure 9.

Hierarchical clustering dendrogram illustrating the chemical relationships among ceramic samples, highlighting two distinct chemical groups corresponding to Seville and Jerez. The Seville group (denoted as Sev03, represented by a "green halo" in previous PCA analyses) forms a cohesive cluster, indicating a relatively homogeneous chemical composition characteristic of a single production or raw material source.

Figure 11.

Boxplots illustrating the elemental composition (expressed as oxides) across different ceramic forms, separated by groups from distinct origins: Jerez (Jerez Set 1, Jerez Set 2, Convent Santo Domingo) and Seville. Each subplot (A-H) represents the concentration distribution of specific oxides in the ceramic samples, providing insights into the variability within and between regional production centers.

Figure 11.

Boxplots illustrating the elemental composition (expressed as oxides) across different ceramic forms, separated by groups from distinct origins: Jerez (Jerez Set 1, Jerez Set 2, Convent Santo Domingo) and Seville. Each subplot (A-H) represents the concentration distribution of specific oxides in the ceramic samples, providing insights into the variability within and between regional production centers.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).