1. Introduction

Machining is a fundamental process in the manufacture of parts and components that has evolved significantly throughout history along with the development of technology. Initially, manual techniques and rudimentary tools dominated the industrial scene. However, with the advent of mechanization and automation, increasingly sophisticated methods of shaping materials have been developed. One of the most relevant aspects in this context is the evolution of cooling and lubrication systems used during the cutting process.

Traditionally, machining has been associated with the use of cutting fluids, whose main function is to reduce friction, dissipate the heat generated and evacuate the chips. But, in recent decades, there has been a growing interest in dry and semi-dry machining, which dispenses with or minimizes the use of these fluids. The need to optimize manufacturing processes, reduce costs and minimize environmental impact [

1] has driven the search for alternatives to conventional machining. In the late 20

th and early 21

st century, research in the field of dry and semi-dry machining intensified. Advances in cutting tool design, advanced coatings and computer numerical control (CNC) systems have made the development of this technology possible.

The first significant advances came in the late 1980s and early 1990s with the introduction of coatings such as titanium nitride (TiN) on cutting tools [

2]. These coatings improved wear resistance and enabled machining operations at higher speeds. Even so, preliminary research into the possibility of machining without coolants was carried out, but the results were limited due to the restrictions of cutting materials and machine tools at the time.

In the 2000s, the development of multi-layer coatings and the optimization of their composition led to a significant increase in tool life under dry machining conditions which, together with the development of high-speed, high-precision CNC machine tools, allowed the advantages of cutting tools and dry machining processes to be exploited to the full [

3].

Nowadays, simulation and process optimization have become essential tools to find the best dry and semi-dry cutting conditions. Also, the integration of air-cooling systems [

4], chip evacuation systems and temperature sensors enabled more precise control of cutting conditions which allowed dry and semi-dry machining to be extended to a wide variety of industries, such as aerospace, automotive and medical.

The most widely used technique today is Minimum Quantity Lubrication (MQL) machining, which involves applying a minimal amount of lubricant in the form of fog or spray directly to the cutting zone [

5]. It is one of the most popular due to its versatility and efficiency. Another popular dry machining technique is the use of compressed air to remove chips and cool the tool [

4]. It is a simple and economical method but can be less effective in high-speed machining operations. Finally, purely dry machining, although less common than the above techniques, is increasingly used in applications where surface quality is critical and complete elimination of fluid contamination is required.

No single method is best for all applications. The choice of the most appropriate method requires careful analysis of the factors in each case.

2. Materials and Methods

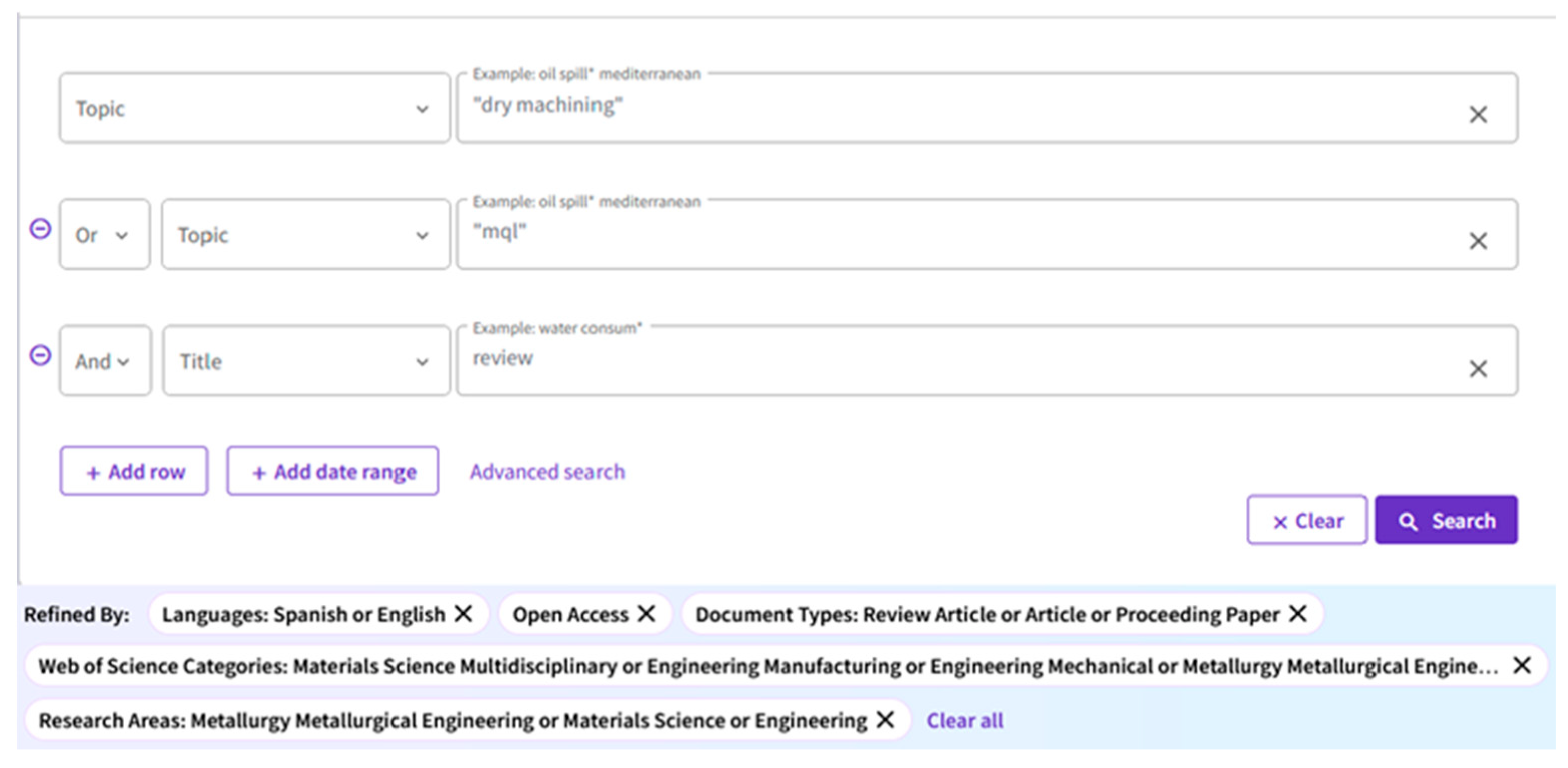

The search for documents related to this topic has been made following an adaptation to PRISMA methodology to the field of manufacturing engineering. The search has been performed using the Web of Science (WoS) tool, whose database is supplied by Thomson Reuters and is integrated into ISI Web of Knowledge (WoK).

Table 1 collects the criteria used in the search:

After several iterations, it is concluded that the Boolean combination of the topic ‘Dry Machining’ for dry machining and ‘MQL’ for semi-dry machining combined with ‘Review’ is the most efficient when it comes to delimiting the most complete documents for a review of the process trends over several years and to know the state of the art. With the configuration proposed in

Table 1, 425 results are obtained. To refine the search, the results were narrowed down to categories belonging to materials science, manufacturing engineering, mechanics or aerospace, leaving this search with 327 final articles.

Figure 1 shows the search strategy used:

However, this is still too large a number of documents which would be very difficult to analyze, so it is proposed to filter the articles with the most citations to make a final screening. But instead of selecting a cut-off number of citations, it is proposed to segregate it by periods so that a chronological analysis can be made by epochs and an evolution in trends can be established. In this way, the years will be grouped five by five and the research with the most citations in those periods will be analyzed.

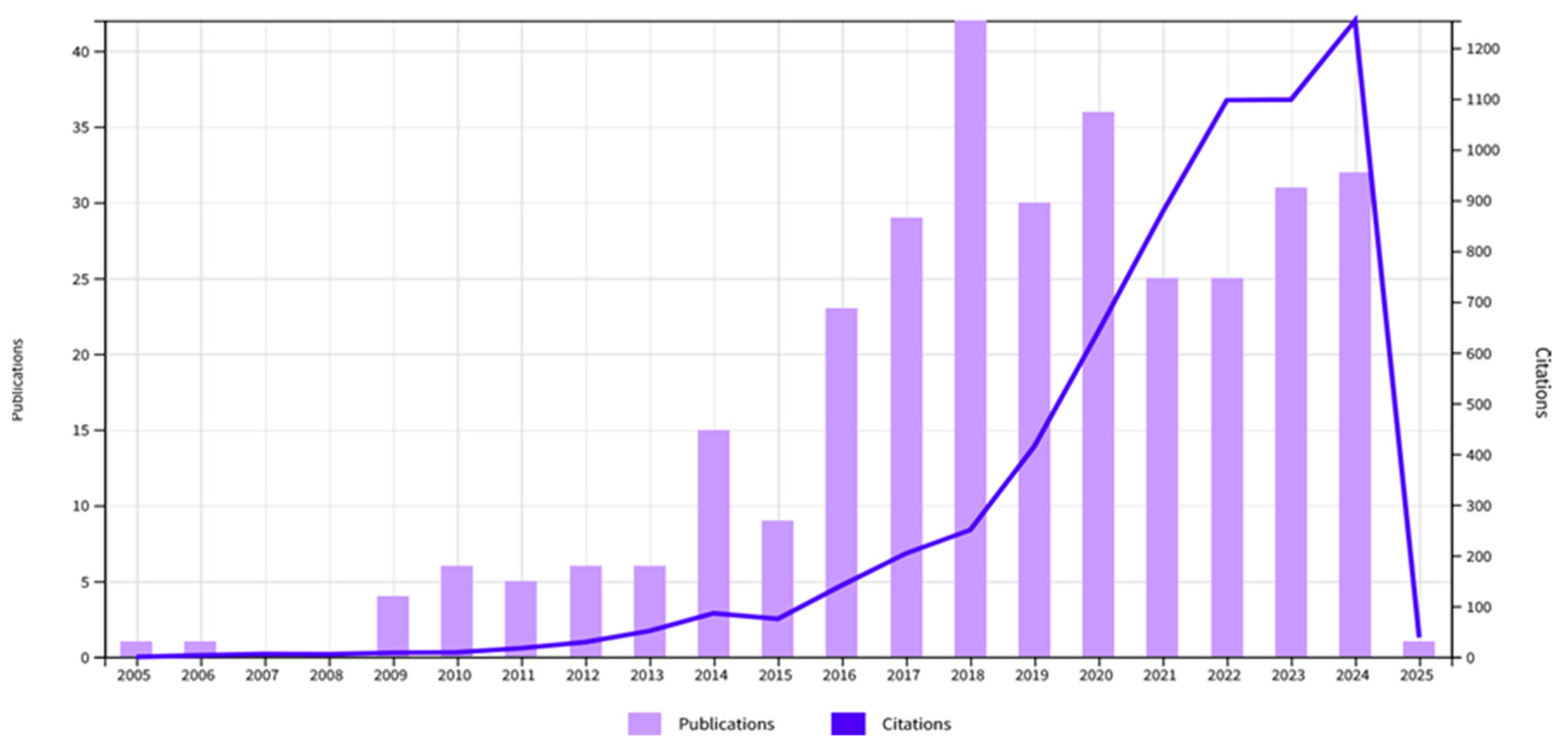

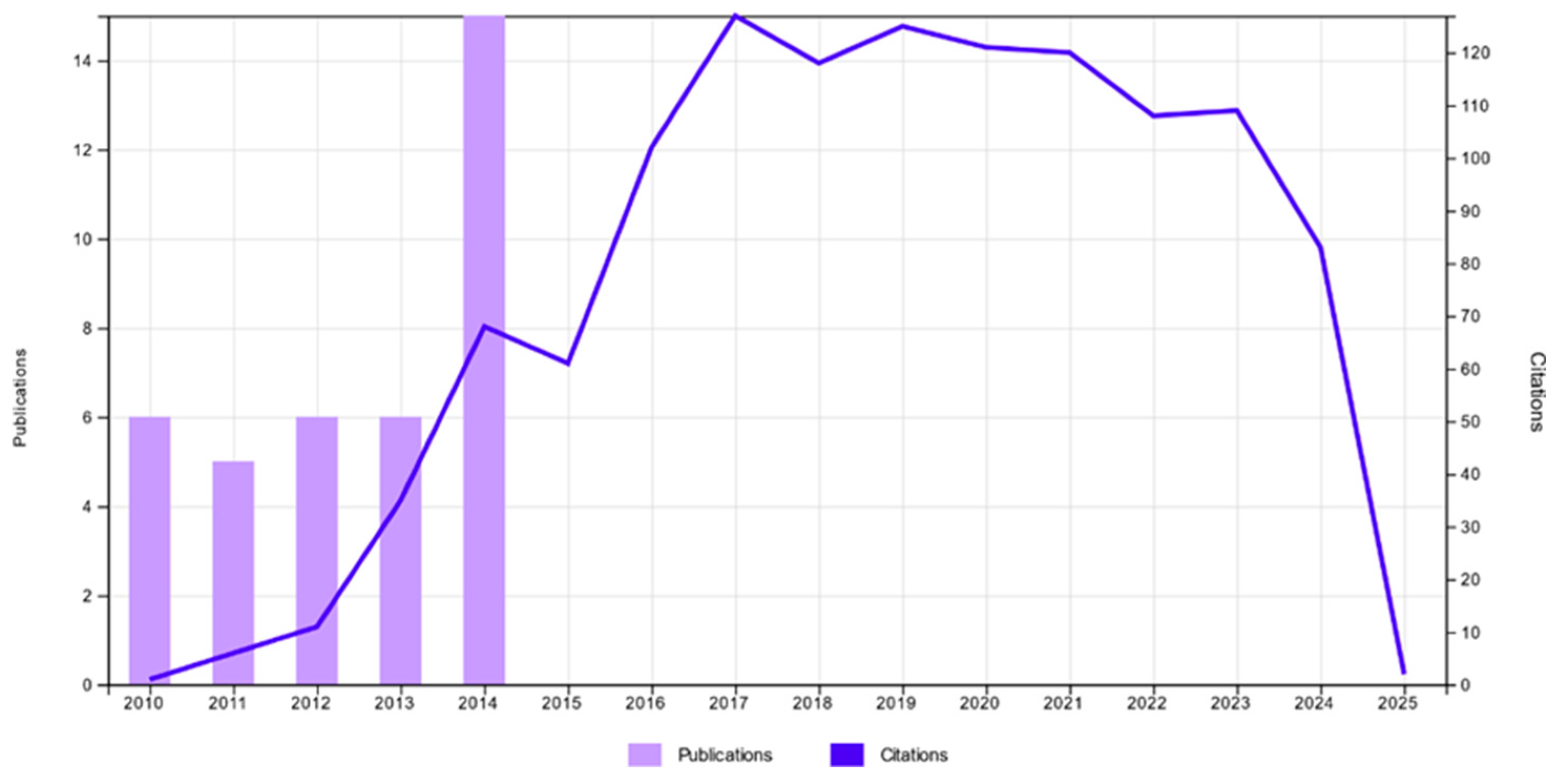

In order to have a more graphic view of the results, the diagram that relates the results according to the number of publications and citations per year is extracted (

Figure 2):

From this figure it can be seen that a significant increase in both the number of publications and the number of citations is evident over the period analyzed. This indicates a growing interest of the scientific and industrial community in dry and semi-dry machining techniques, especially in recent years. The peak in publications was in 2018 which is perhaps when this process was consolidated.

Once global information has been obtained in large numbers by means of this diagram, the following grouping of years will be carried out for the analysis of the publications in a segregated manner:

Period 1: 2005, 2006, 2007, 2008 y 2009

Period 2: 2010, 2011, 2012, 2013 y 2014

Period 3: 2015, 2016, 2017, 2018 y 2019

Period 4: 2020, 2021, 2022, 2023, 2024 y 2025

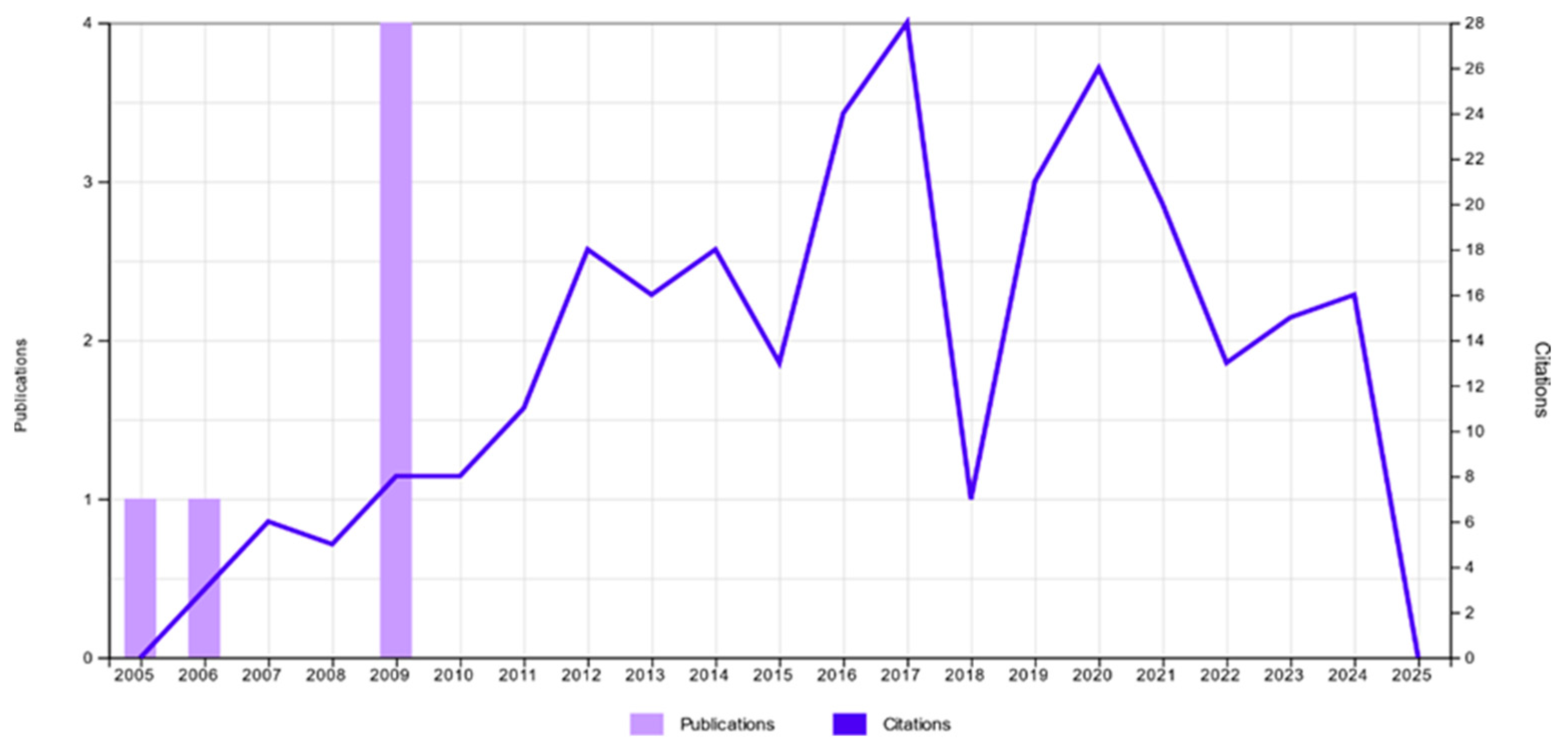

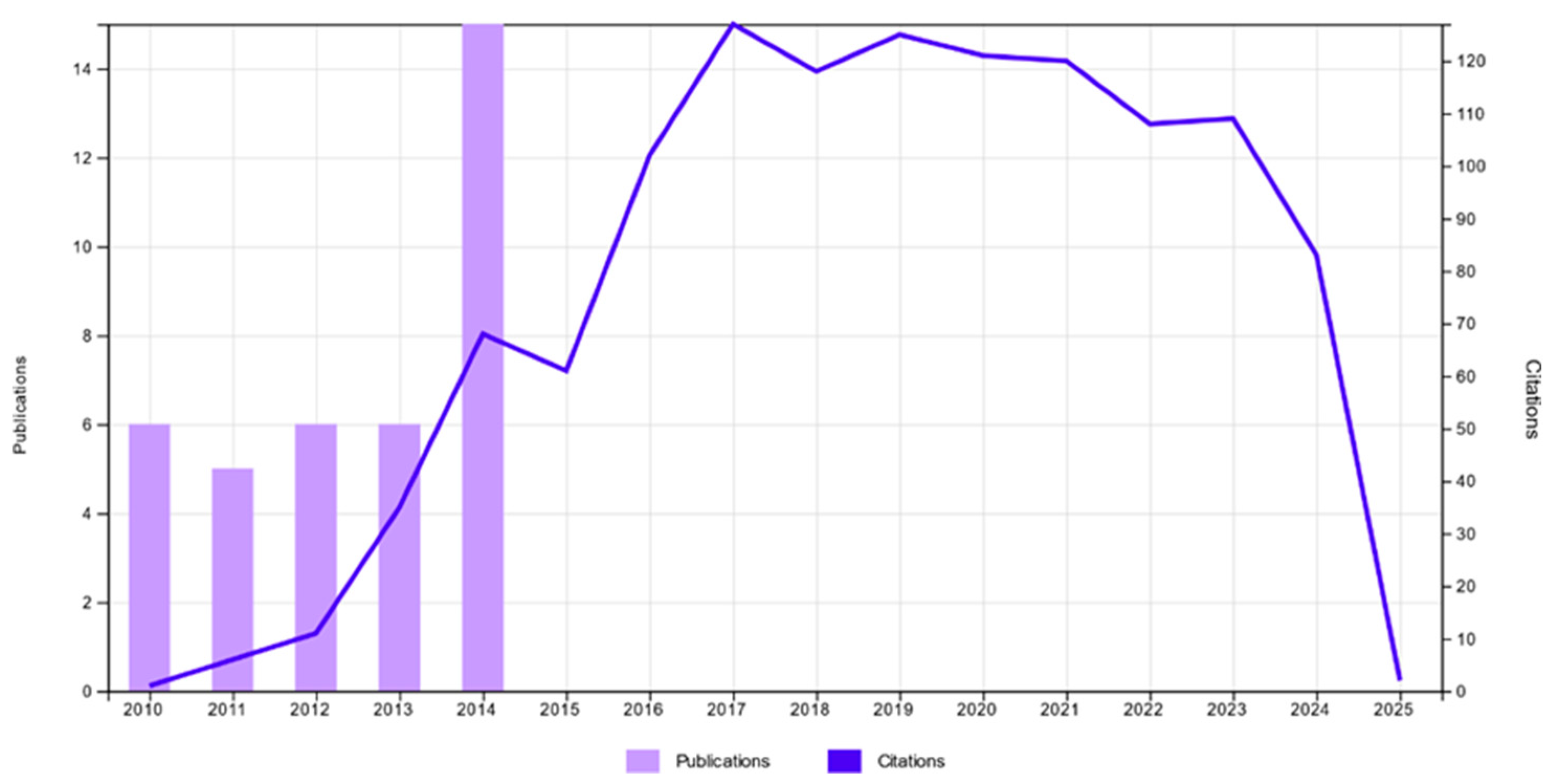

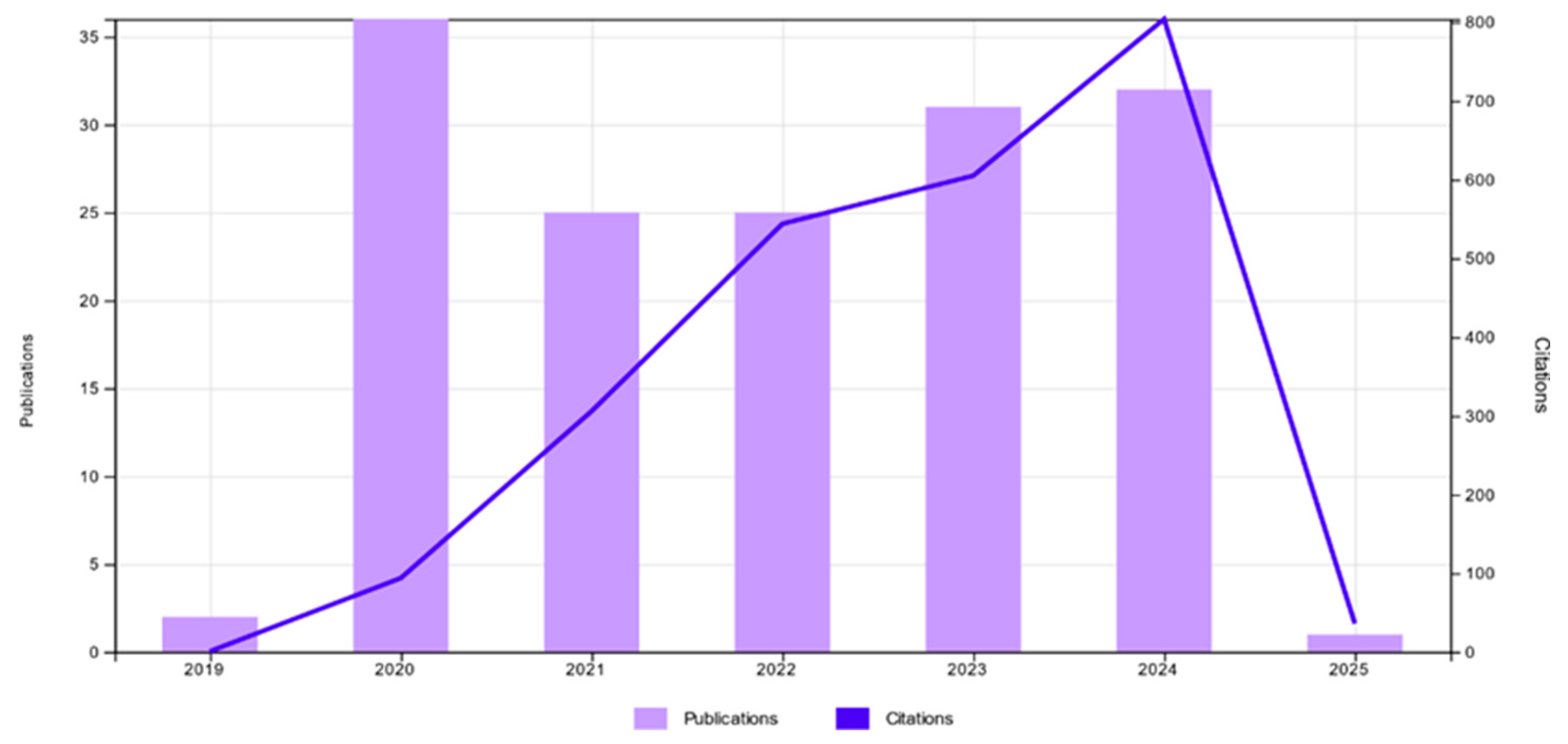

In order to better understand the importance of each period, the data for each period have been segregated into separate diagrams, resulting in

Figure 3,

Figure 4,

Figure 5 and

Figure 6, which represent the publications of each period and then the evolution of their citations over the total number of citations.

During the initial period, the first publications on the dry or semi-dry machining process appeared. These were very few and concentrated mainly in 2009, when a total of 4 publications were obtained in our search. More important are the number of citations of these publications, which, although at the beginning were not very numerous, but in the period 2016-2020 grew significantly coinciding with the period of more publications on the subject.

In this period, the increase in the number of publications is notable with respect to the previous one, especially in 2014, when the number of publications doubled with respect to the rest of the years, indicating an explosion of interest in this subject with a total of 38. As in the previous period, the highest number of citations is concentrated in the years 2016-2020.

This is the period of explosion in terms of publications on dry and semi-dry machining of the selected ones with a total of 133, with 2018 standing out as the highest in the whole series. There is a significant increase with respect to previous periods, which shows that the subject had a great interest in the scientific community, perhaps motivated by the advances and industrialization of the process. There is also a significant increase in citations in the later period, which indicates that these publications were important references from then on.

Finally, in the last period belonging to the present, the rhythm of publications is maintained up to 152 but without reaching the peak of 2018, indicating that there is no reduction of interest in the subject. In terms of citations, there is a significant increase compared to previous periods, which means that this machining process is no longer only investigated in itself but is also taken into account for research and documents related to other machining topics as part of the process.

Once each period has been statistically analyzed and given the large number of publications that contain some of them, it was decided to sift through them in order of number of citations in order to obtain a sufficient number of representative and quality articles on the area. In this way the information will be more manageable and easier to manage. In addition to the criteria of the number of citations, it will also be done by periods so that there is always a minimum representation of each one, so that conclusions can be drawn as to what the trend of each period was.

To quantify these criteria, it is decided that the following articles from each period will be selected:

Period 1: 3 Articles with the largest number of citations

Period 2: 6 Articles with the largest number of citations

Period 3: 6 Articles with the largest number of citations

Period 4: 6 Articles with the largest number of citations

In this way, a sample of 21 publications is obtained, which are the most relevant for each period in order to analyze trends. A smaller number of publications have been selected for Period 1, as the relevance is lower and only 6 of them have been filtered out in the search.

3. Results

The results obtained after searching and filtering the data are very revealing depending on the period, both statistically as we have seen in the previous section and in terms of trends as we will see below. The evolution of these trends has been constant over time, orienting the research to the context of existing technological and industry needs.

A classification of documents by period is established in which the information extracted from each of them will be analyzed.

During the first period evaluated (

Table 2) the first relevant studies on dry and semi-dry machining emerged mainly in Europe and Brazil, the search for more efficient and sustainable alternatives in manufacturing processes has driven research into this process. Some of the pioneering fields to which these studies are directed are the aeronautical and biomedical sectors, since the use of materials with a high strength/weight ratio is increasing, such as titanium alloys, which are increasingly used. These alloys are very difficult materials to cut and cause high tool wear due to the high temperatures they are subjected to. That is why the two most cited articles of this period [

6,

7] investigate the dry machining of these alloys, particularly the Ti-6Al-4V alloy, also known as grade 5 titanium alloy, widely used for aircraft engine components or even for surgical implants.

In the work of Cantero et al. [

6], the evolution of tool wear in a dry drilling operation and its effects on hole quality are studied. From this study it is extracted that by using moderate cutting parameters and using carbide tools it is possible to perform dry drilling on this titanium alloy, however, they start to talk about temperature control as this can produce microstructural changes on the workpiece material. Same case for the work of Calamaz et al. [

7], where dry machining using tungsten carbide tools is also investigated by correlating experiments with SPH numerical simulation where the cutting process is simulated to analyze the relationship between cutting forces and tool wear.

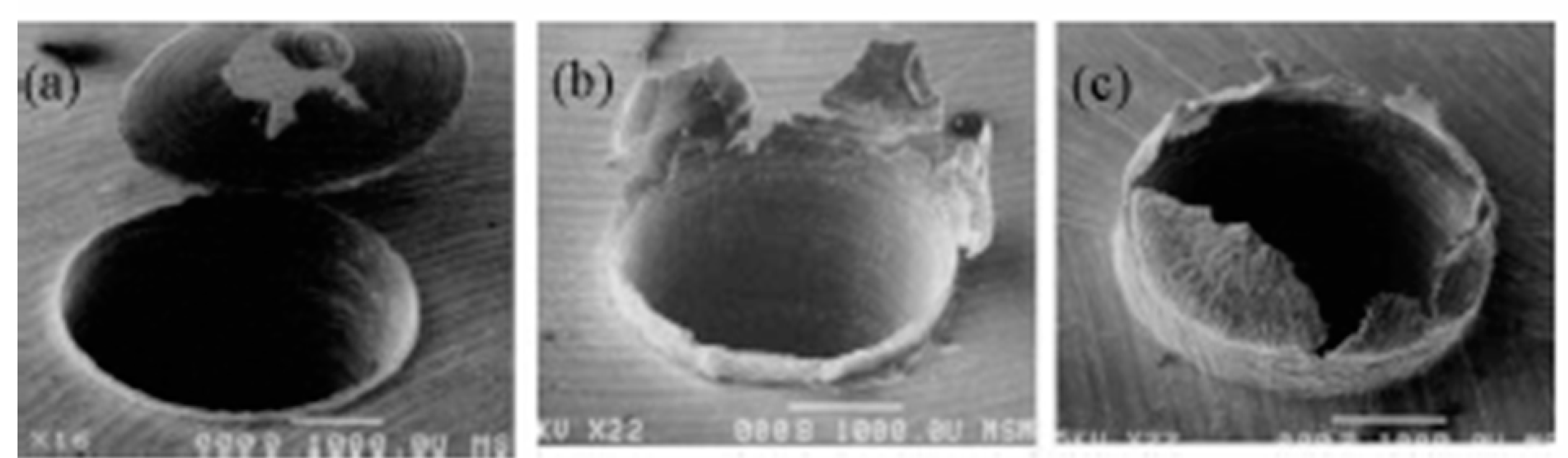

On the other hand, Costa et al. [

8] focused their studies on burr size comparing dry drilling, with MQL and with conventional flood cutting fluid. Among the most interesting conclusions of this paper is that dry machining produces smaller burrs but produces high tool wear, while with the use of MQL the tool life was extended but formed burrs of type I and III (

Figure 7) that are more difficult to remove unlike conventional lubrication that generates uniform burrs of type II (

Figure 7). It is also observed that once there is considerable wear on the tool, the burrs are reduced at higher cutting speeds.

In the second period evaluated (

Table 3), the increase of research in the field of dry lubrication is quite evident, and it is already a technique that is beginning to be relevant in the industrial field. The appearance of new coatings and tool geometries broadens the possibilities of dry machining. The same happens with the improvement of MQL spraying technology that maximizes the efficiency of this type of lubricant. As in the previous period, the focus of research on dry or semi-dry machining continues to be on machining parts for specific industries such as aerospace, aeronautics, automotive or biomedicine. Therefore, the most common materials under study in this period will continue to be titanium [

10,

11] and aluminium alloys [

10,

14], to which high-strength materials such as Inconel 718 [

9], which is gradually beginning to appear in this research, or AISI4140 steel [

13] will have to be added. We also find some cases of CFRP composite material which is a material widely used in aeronautics [

12].

Devillez et al. [

9] focuses their study on the machining of Inconel 718, a nickel-chromium alloy used for applications requiring high temperature and fluence resistance. In addition, it is a highly corrosion-resistant material with high mechanical properties that is mainly used in the aerospace, automotive and petroleum industries. Its machining is quite complicated as it must strain harden, although it is shown that quite acceptable finishes can be obtained with the use of a coated carbide tool. The residual stresses and microhardnesses detected were approximately of the same order as wet machining provided that it is done with optimized cutting parameters.

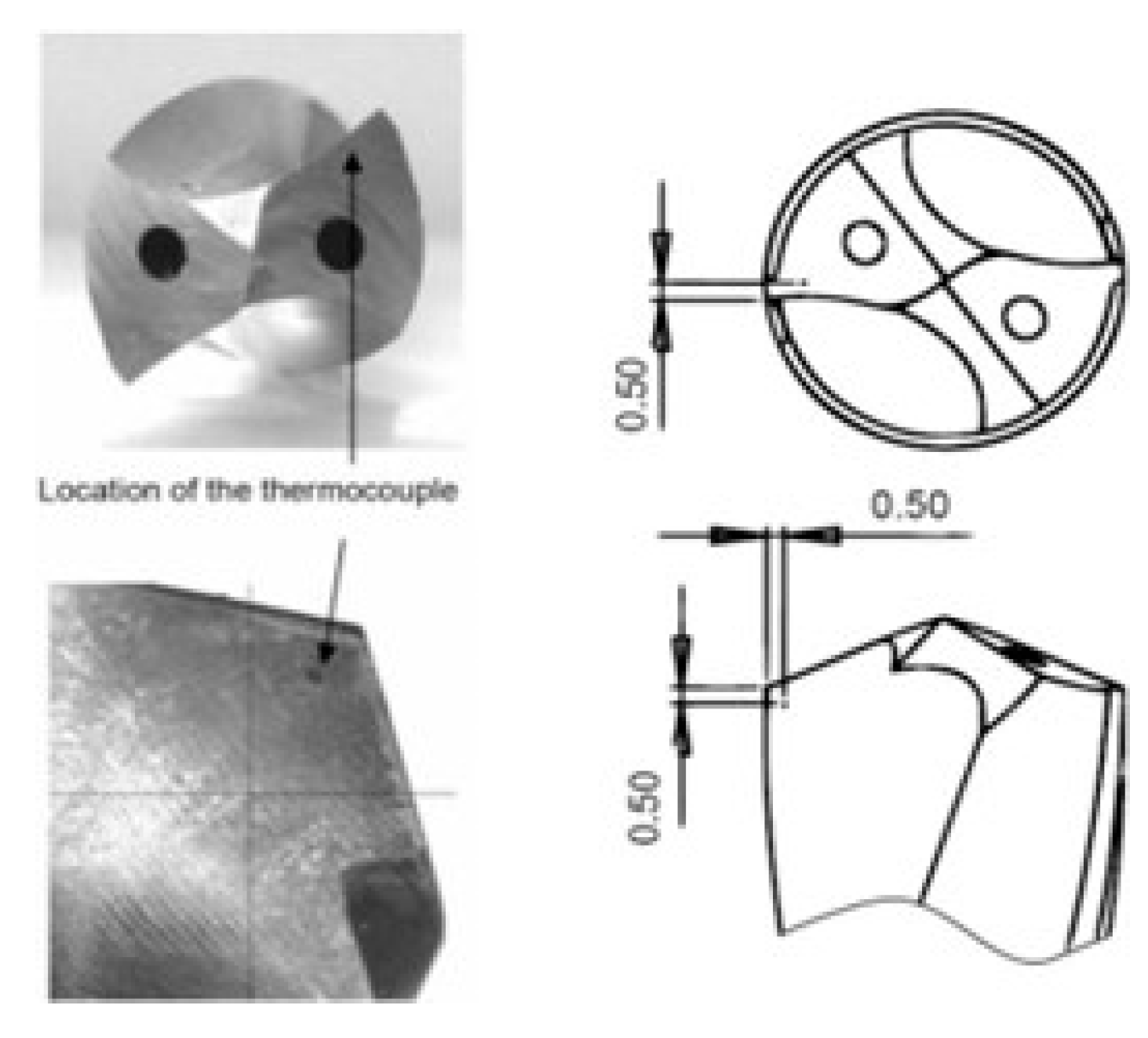

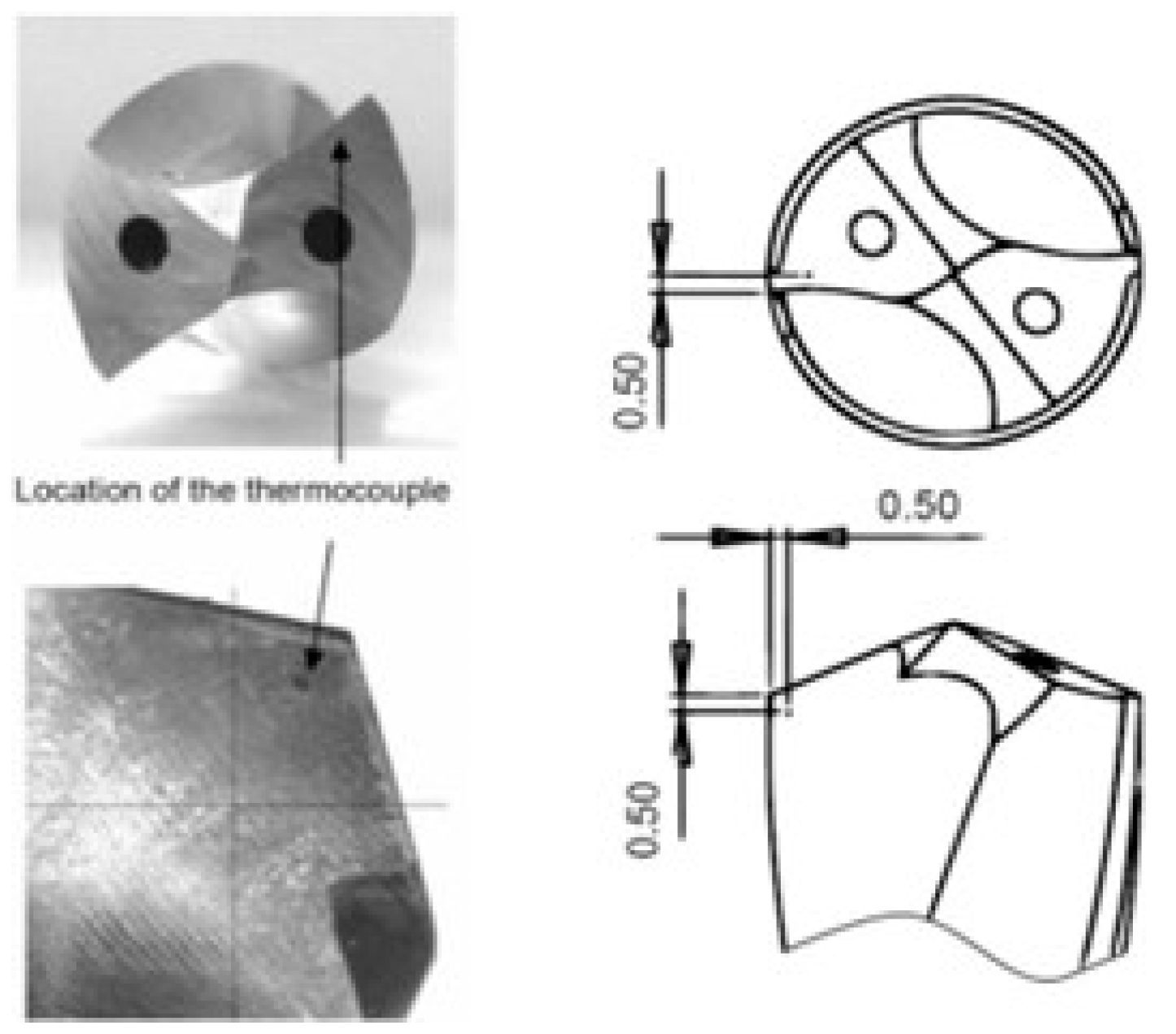

Another topic that is starting to become more and more important in research will be the temperature measurement during machining and its effects. Le Coz et al. [

10] investigate about it in their paper using MQL machining on titanium alloy and dry milling on aluminium alloys. In this way they look for new ways for temperature measurement using a thermocouple integrated in the cutting tool (

Figure 8), close to the cutting face and using a tool-holder with a wireless transmitter and an antenna to transmit the data. It was demonstrated that this system is easy to use and does not affect the rigidity of the cutting system contributing to the optimization of machining processes using rotating cutting tools.

Also, the improvement of finite element software tools leads to more and more confidence on them to simulate cutting conditions and their effects. This is the case of the paper by Calamaz et al. [

11] on the numerical simulation of dry machining of a Ti-6Al-4V titanium alloy using a constitutive law that incorporates the strain softening phenomenon. The model created adequately predicts the cutting forces at low speeds but slightly underestimates the forces at high speeds due to the lack of consideration of tool wear.

However, the focus of research is still on the effects of parameters and the effects on the material and tool during dry or semi-dry machining. Iskandar et al. [

12] inquiries into the droplet size of MQL and its effects on temperature and cutting forces which in turn affect tool wear and superficial quality. The study will be conducted on CFRP composite material and among the main conclusions are the importance of achieving good atomization of large number of small droplets at high axial velocity which provides longer tool life and better machining finish.

In France, Claudin et al. [

13] have analysed the influence of a pure oil on the coefficient of friction at the tool-material interface during machining of AISI4140 steel with a TiN-coated carbide tool. Among the findings is that, machining dry, the coefficient of friction varies between 0.5 and 0.15 as the sliding speed increases from 10 to 300 m/min. With the use of oil, the coefficient of friction decreases significantly at low speeds (V < 150 m/min), remaining constant around 0.1 regardless of speed. In addition, oil significantly reduces the absolute amount of heat transferred, regardless of sliding speed.

Finally, the last relevant study of this period [

14] presents a detailed analysis of the interaction between superficial finish and residual stresses in the orthogonal machining process of AA7075-T651 alloy under dry conditions. It was identified that the superficial finish is highly sensitive to cutting parameters, with particular relevance to the formation of bonded edges (BUE) and the interaction between the tool and iron-rich intermetallic particles. This study demonstrates that, through precise control of cutting parameters, it is possible to optimize both the superficial finish and the residual stress state in dry machining, providing a useful approach for industrial applications seeking to improve the quality and performance of machined parts.

In the third period (

Table 4) the dry and semi-dry machining process is already a well-established part of the machining industry in general. This can be seen in the significant increase in research on the subject worldwide as it can be considered the most prolific recent period in this aspect. Unlike other eras, this period is beginning to focus its studies on sustainability as a primary motivator as environmental regulations and pressure to reduce carbon footprints will drive even greater adoption of these techniques. Also, increased automation and customization of technologies continue to refine the application of MQL and enable safer and more efficient dry machining.

In this period, more than research on dry or semi-dry machining in very important materials for strategic sectors, we start to talk about alternatives such as the use of cryogenic machining [

1] or solid lubricants [

19]. We are also starting to talk about machine learning to predict tool wear [

16] and as mentioned at the beginning, the sustainability perspective is already part of almost all papers mainly because of the awareness of the subject, cost reduction and compliance with increasingly stringent environmental standards.

Mainly this is the main theme in the review on the subject formulated by Sen et al. [

15] in which sustainability in minimum quantity lubrication (MQL) applied to machining is addressed. In it, he emphasizes the need to move towards more sustainable lubrication methods that reduce the environmental impact compared to conventional techniques. Already in this document we start to talk about the MQCL or what would be the same a MQL with an added coolant that will become important later. Among the conclusions we can find that the high initial costs and health and environmental concerns associated with alternative lubricants, such as vegetable oils and nanofluids, remain significant barriers to their widespread adoption. Despite this, MQL is observed to be gaining interest as a greener alternative, especially in more sustainable process manufacturing.

Benedicto et al. [

1] also focus their research on the trend towards sustainability and efficiency in machining processes. They re-emphasize the negative effects that cutting fluids have on the environment and worker health, which motivates companies to look for more efficient and sustainable alternatives (

Figure 9). According to Benedicto and colleagues, dry machining and technologies such as MQL and solid lubricants appear to be the most viable options, but companies must balance performance, costs and sustainability when choosing the most suitable solution for their specific processes. Sustainable lubricants such as vegetable oils are starting to be talked about, but costs are a barrier to their application in industry.

Also, Rahim et al. [

17] discusses the negative effects of using mineral cutting fluids in machining processes, especially in terms of environmental impact, operator health and process costs. This study shows how sustainable machining techniques, specifically MQL with synthetic ester, can offer an efficient and environmentally friendly solution to the traditional use of mineral fluids. Experimental results support the viability of MQL as a favourable alternative, both for reducing operating costs and improving the safety and efficiency of the manufacturing process ahead of dry machining and cryogenic machining.

However, not all documents focus on sustainability. Gouarir et al. [

16] present a methodology that combines machine learning with adaptive control to predict and manage tool wear in machining processes. The high accuracy of the model and the ability to dynamically adjust to process conditions are important advantages. However, the practical implementation of this system on a large scale may be limited by costs and the need for more experiments to confirm the repeatability and extensibility of the results.

This period also includes research more typical of earlier periods such as that performed by Pradhan et al. [

18] in which he investigated on the machining parameters of Ti-6Al- 4V alloy using SNMA120408 cutting inserts in dry machining and their correlation to model the behaviour using finite elements. It was concluded that increasing the cutting speed causes an increase in tangential forces, resulting in a decrease in the contact length between the tool and chip, furthermore, a shorter contact length contributes to a better superficial quality and a reduction in the tool wear rate.

Another interesting advance is the use of solid lubricants in the machining process with MQL lubrication. In this case Paturi et al. [

19] analyses the impact of the solid lubricant tungsten disulfide (WS2) on the superficial quality of parts machined in Inconel 718. The addition of WS2 powder in micron size to the base oil emulsion reduces the friction between the cutting superficies, improving the finish quality by approximately 35%. An analysis of variance (ANOVA) and multiple linear regression approach was used to understand how cutting parameters affect superficial roughness and reinforcing the validity of these results. This study also highlights the sustainability perspective with in most of this period, the use of WS2-assisted MQL is proposed as an efficient solution to reduce the environmental impact of traditional cutting fluids.

Finally, the fourth period (Table 6) will be reached, which includes the last 5 years up to the present. The dry and semi-dry machining process is a process that is already quite developed, but it continues to generate the interest of researchers as can be seen in the number of papers generated and cited during the last five years. In this period, research is focused on advances in the lubricants themselves, such as the use of carbon nanoparticles or additives such as extreme pressure (EP) or anti-wear (AW) additives to MQL.

Tribology is also starting to become important in these machining processes. This is the science that studies friction, wear and lubrication between surfaces in relative contact and seeks to minimize this friction through the selection of suitable materials, optimization of tool geometry and the use of lubricants or coolants. This will be very important for the development of tools that help to extend tool life.

In 2022, Cui et al. [

20] published an article in which a detailed analysis is made on the advances in minimum quantity lubrication (MQL) with the use of nanolubricants, in particular, carbon-based nano-enhancers (CGNs) in the machining of titanium and nickel alloys for the aerospace industry. It is intended to provide a solution to the difficulty of machining these materials with MQL due to the high heat generation during the process, which presents challenges, such as tool wear and surface quality. This makes it difficult to replace the use of traditional cutting fluid. Among the main findings of this research are that the use of CGNs in MQL reduces friction between the tool and the workpiece, which improves machining efficiency. In addition, the addition of CGNs demonstrated improvements in tool performance, surface quality and tool life compared to conventional MQL.

Pimenov et al. [

21] also investigate on cooling techniques in the machining of titanium alloys to find a more sustainable alternative to traditional cooling. In principle it is a similar study to that already raised in previous periods, but makes an interesting comparison between MQL cooling, cryogenic cooling and high-pressure cooling (HPC). Among the main conclusions obtained we have that cryogenic refrigeration improves superficial quality, but it is expensive and requires specialized equipment. The use of MQL reduces fluid consumption, but the choice of the right fluid is crucial for good results. High-pressure cooling is efficient in reducing temperatures, but its implementation can require expensive systems and consumes more energy.

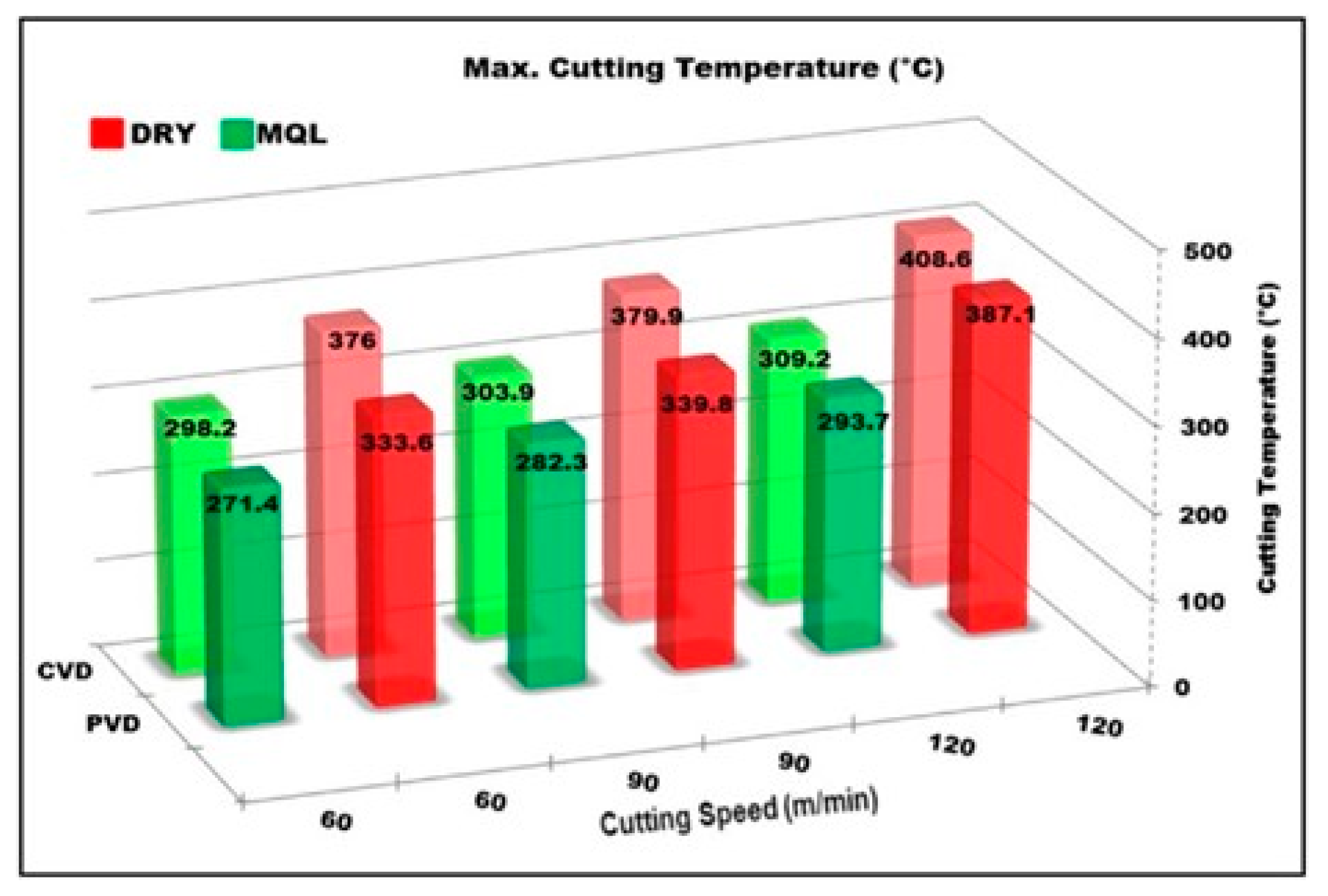

Following this line of research, Ozbek et al. [

22] investigates the effects of cutting tool vibrations and temperature in the cutting zone in relation to the type of tool coating, superficial roughness (Ra and Rz), tool wear and tool life. In this experiment, two types of coatings were used for cutting tools, chemical vapor deposition (CVD) and physical vapor deposition (PVD), with different cutting speeds (60, 90 and 120 m/min) and a constant depth of cut (1 mm). The results showed that, compared to dry cutting, the MQL technique achieved a significative reduction in cutting temperature (about 100°C less,

Figure 10), a decrease in the amplitude of tool vibrations, and an improvement in surface roughness (Ra and Rz) of up to 91%. In addition, tool life increased significantly: by 267% more for CVD-coated tools and by 200% for PVD-coated tools.

Another quite recurrent topic in this period is the use of semi-dry machining with MQCL+EP/AW as can be seen in the articles [

23] and [

24] and the tribological aspects obtained after its use. Maruda et al. [

23] performs a detailed analysis of the metrological and tribological aspects of machined surfaces obtained after a turning process using different cooling and lubrication methods. The study focuses on comparing the effects of different methods, such as dry machining, minimum cooling lubrication (MQCL), minimum cooling lubrication with EP/AW modifications (MQCL+EP/AW) and minimum lubrication (MQL). The MQCL+EP/AW method, which uses EP/AW (pressure extremes/anti-wear) additives, is shown to be the most effective in terms of reducing surface roughness and increasing tool life. In addition, it was observed that tribofilm (lubricant film) forms on the superficies machined with these methods, improving tribological properties and reducing wear and friction. Some recent developments in lubrication and cooling technology are also mentioned, such as the use of nanoparticles, electrostatic modifications (EMQL), and cold air in combination with minimal lubrication.

On the other hand, and along the same lines, Szczotkarz et al. [

24] describe a detailed analysis of the impact of minimum lubrication methods (MQL and MQCL+EP/AW) on the reduction of tool wear during the machining of 316L stainless steel. It is found that the use of MQL reduces tool wear by approximately 9% compared to the MQCL+EP/AW method and by 21% compared to dry machining. In contrast, the use of EP/AW additives in the MQCL method can form a tribofilm layer on the cutting tool, which helps to reduce wear. However, if this layer is broken, adhesive wear can result.

Finally, Abas et al. [

25] propose a novel investigation on the optimisation of cutting process parameters in Aluminium 6026-T9 turning operations using olive oil as minimum quantity lubricant (MQL) in both dry and lubricated conditions. The control parameters measured include the profile of superficial roughness (Ra, Rq, Rz), tool life and material removal rate. Using statistical methods such as analysis of variance (ANOVA) and the CRITIC approach helps to identify the optimal combinations of cutting parameters to maximise efficiency in terms of surface quality, material removal and tool life. Among the most important findings are that the use of MQL with olive oil not only improves tool life and surface quality, but also reduces negative impacts on the environment and human health, compared to the use of conventional lubricants or dry cutting.

4. Conclusions

Dry and semi-dry machining has proven to be a constantly evolving field, driven by the need to balance efficiency, sustainability and competitiveness in manufacturing. Through the analysis of publications between 2005 and 2025, a significant increase in scientific and industrial interest in these techniques is evident, reflected in both the number of publications and the number of citations accumulated.

In the first period (2005-2009), initial studies focused mainly on difficult to machine materials, such as titanium alloys, highlighting tool wear and the difficulties associated with the absence of cutting fluids. Although few, those works laid the foundations for further research.

The second period (2010-2014) marked a growth in the number of publications and the development of advanced tools and coatings, such as Minimum Quantity Lubrication (MQL) systems. The introduction of simulation technologies, such as finite element models, allowed a better understanding of cutting parameters and their effects on tool performance and part quality. In addition, interest began to emerge in temperature measurement as a critical factor in process optimization.

In the third period (2015-2019), dry and semi-dry machining reached a point of maturity in terms of industrial adoption, and sustainability was positioned as a central topic. Research expanded into alternatives such as solid lubricants, cryogenic machining and the use of machine learning techniques to predict tool wear. This period was also notable for the implementation of more sophisticated approaches to optimizing machining performance in complex materials such as Inconel 718 and titanium alloys.

Finally, in the fourth period (2020-2025), research focused on the development of advanced lubricants, such as carbon-based nanolubricants and EP/AW tribological additives, which improve efficiency and tool life. In addition, hybrid approaches were explored, such as MQCL, which combines minimal lubrication with active cooling, integrating sustainability and efficiency. This period also brought an increased focus on tribology, studying friction and wear of surfaces to extend tool life.

Despite progress, future goals include overcoming barriers such as the high initial costs of sustainable technologies, ensuring the industrial viability of green lubricants, and improving predictive and optimization systems through artificial intelligence. The integration of emerging technologies such as advanced sensors and dynamic simulations will be key to maximizing the potential of dry and semi-dry machining, enabling these processes to become the global industry standard. In this context, commitment to sustainability and technological innovation will continue to be the driving force behind the development of these techniques in a greener and more efficient future.