1. Introduction

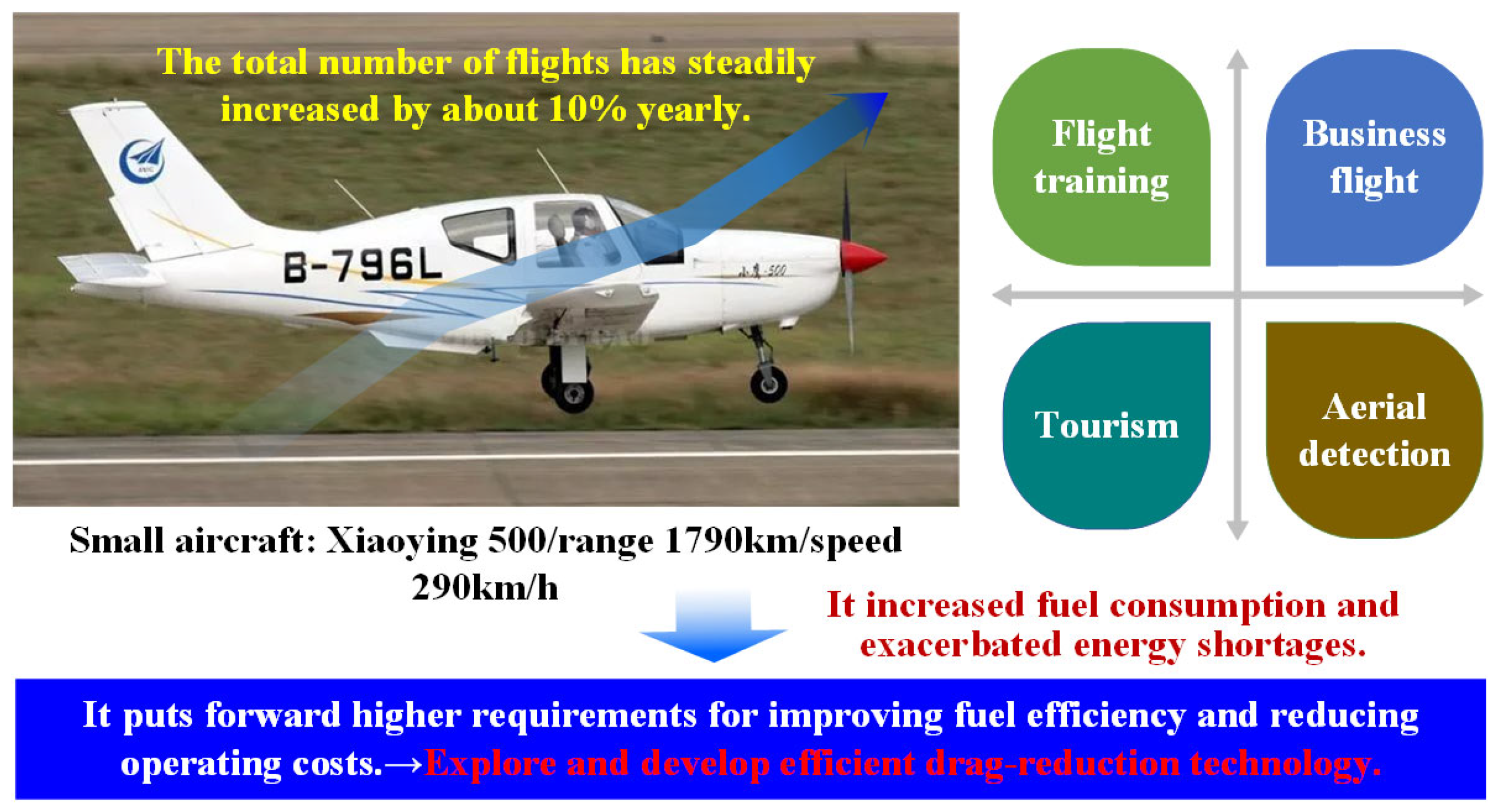

With the continuous expansion of the general aviation field in the civil aviation industry, the total number of small aircraft flights is steadily increasing at about 10% per year, which has increased fuel consumption and exacerbated energy shortages [

1]. Therefore, small aircraft have higher requirements for improving fuel efficiency and reducing operating costs when performing tasks such as flight training, business flights, and tourism (as shown in

Figure 1) [

2]. Exploring and developing efficient, safe, and reliable drag reduction technologies can improve the aerodynamic efficiency of small aircraft and directly affect flight safety and environmental sustainability [

3], which has important practical significance and profound strategic value.

Compared to ultrafast lasers (e.g., femtosecond lasers), nanosecond laser etching offers a cost-effective solution for industrial-scale microgroove fabrication. It has become an emerging drag-reduction strategy to prepare microgrooves on aircraft skin materials (such as 7075 aluminum alloy) [

4]. This method effectively reduces aerodynamic drag by changing the interaction between the aircraft surface and the surrounding air, demonstrating great potential for application [

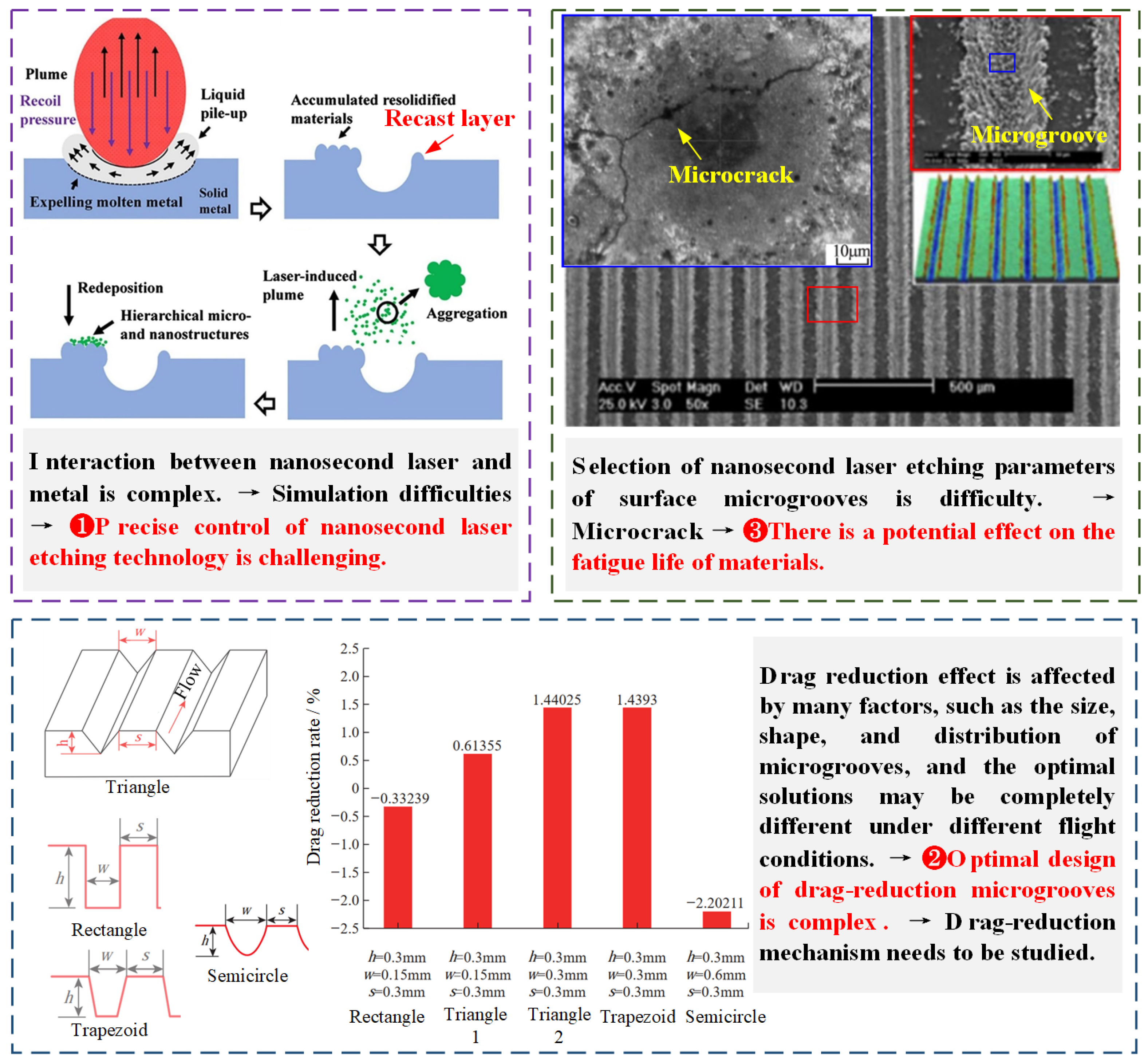

5]. However, nanosecond laser longer pulse duration (typically 10–100 ns) induces pronounced thermal effects, leading to recast layers and microcracks that may compromise material integrity [

5]. This trade-off between scalability and precision underscores the need for advanced thermal management strategies. Therefore, this technology still faces multiple challenges (as shown in

Figure 2): the precise control of nanosecond laser etching technology is extremely difficult, requiring precise changes in material surface morphology at the micrometer level, involving complex physical phenomena such as thermal effects, phase transitions, and dynamic processes of laser material interactions [

6,

7], which places extremely high demands on numerical simulation technology (challenges ①). The optimization problem of microgroove design is equally complex, and the drag reduction effect of microgrooves is influenced by various factors such as their size, shape, and distribution [

3]. These factors may have completely different optimal solutions under different flight conditions (such as cruise speed), and further research is needed on the mechanism of microgroove drag reduction (challenges ②). The potential impact of microgroove preparation on material fatigue life is also a major challenge, as nanosecond laser etching may introduce stress concentration or microcracks on the surface or microstructure of metal materials, thereby affecting their long-term performance and safety (challenges ③) [

8,

9].

In response to the above challenges, from the research directions of numerical simulation of microgroove drag reduction, nanosecond laser etching experiments of microgrooves, and numerical simulation of laser processing, the problems of existing methods in various directions at home and abroad are analyzed, providing process guidance and reference for the research of small aircraft wall drag reduction.

2. Numerical Simulation Study on Microgroove Drag Reduction

Since the 1970s, when NASA Langley Research Center first revealed that down-stream microgroove surfaces can effectively reduce wall friction resistance, microgroove drag reduction technology has become a research hotspot in turbulent drag reduction [

5]. This discovery challenges the traditional view that the smoother the surface, the lower the drag, and provides a new perspective for turbulence drag reduction [

10].

With the development of computational fluid dynamics (CFD) technology, numerical simulation has become an essential means of studying the drag reduction mechanism of microgrooves. By finely simulating the flow field, scholars can delve into the influence of microgrooves on fluid flow and reveal their drag reduction principles. Domestic and foreign scholars have extensively researched wall drag reduction for large civil aircraft, such as A320 passenger planes [

5]. Luchini et al. [

11] elucidated how microgroove surfaces effectively reduce turbulent drag by studying parallel and cross flows in the viscous sublayer of microgroove surface flow. Research by Martin et al. [

12] showed that downstream microgrooves help block the lateral development of vortices, thereby reducing turbulent drag. Choi [

13] found that microgrooves can significantly reduce velocity fluctuations in the near-wall boundary layer and decrease wall pressure fluctuations. In addition, Fuaad et al. [

14] confirmed the drag reduction effect of surface sinusoidal microgrooves through direct numerical simulations (DNS), demonstrating that the flow direction of the sinusoidal microgroove structure can induce stable secondary flow, thereby reducing frictional resistance.

Although domestic research started relatively late, domestic scholars have made significant progress by adopting advanced numerical simulation methods such as Large Eddy Simulation (LES) and the RANS. Liu et al. [

15] used the LES method to study the entropy production changes caused by microgrooves, providing a new theoretical basis for drag reduction optimization of microgrooves. Hu et al. [

16] used the Reynolds averaged method (RANS) to study the numerical calculation method of flow field based on the surface shape characteristics of longitudinal microgrooves, further enriching the numerical simulation research on drag reduction of microgrooves. Based on the RANS, Xiao et al. [

17] found that a large area near the surface of microgrooves contains airflow with shallow velocity, forming a gas film that can effectively reduce airflow resistance and achieve drag reduction. Inspired by the research methods of the scholars above, Wang et al. [

6] proposed a high-precision and efficient numerical simulation method for microgroove drag reduction based on the RANS. This method adopts a computational domain model at the micrometer scale, overcoming the problem of enormous model establishment and computational complexity caused by microgroove sizes being much smaller than aircraft sizes. This method can provide a valuable reference for solving challenges ②.

Through the joint efforts of domestic and foreign scholars, significant results have been achieved in the numerical simulation research of microgroove drag reduction. As shown in

Table 1, although LES provides unparalleled turbulence structure resolution, its computational strength limits its practical application to full-scale aircraft. On the contrary, the RANS based method can effectively analyze large surfaces, but it oversimplifies the near wall flow physics, resulting in overestimation of drag reduction rate [

16]. As shown in

Figure 3, in previous simulations of microgroove drag reduction, it is usually to first extract the microgroove cross-section after removing the recast layer or the theoretically designed microgroove cross-section as the unit cross-section and then stretch and array the unit cross-section to establish the microgroove surface of its computational domain model [

6]. However, the microgroove cross-sections in the direction of nanosecond laser etching are not strictly consistent [

6,

7]. Therefore, in the past, using microgroove cross-sections to establish a computational domain model for drag reduction simulation inevitably led to deviations in fluid analysis results and did not consider the recast layer at the edge of the microgroove (as shown in

Figure 2, there is a recast layer at the edge of the nanosecond laser etched microgroove), which may over-look its potential impact on drag reduction effect; In addition, there is currently insufficient research accumulation on wall drag reduction for small aircraft. The above issues have constrained the engineering application process of nanosecond laser etching technology in small aircraft wall drag reduction.

3. Experimental Study on Nanosecond Laser Etching of Microgrooves

Since the microgroove drag reduction technology has attracted extensive attention in the scientific community, nanosecond laser etching, as an accurate microgroove processing technology, has gradually become a hot spot in material processing [

18]. Nanosecond laser etching uses a laser beam with high energy density to produce micro-scale physical or chemical changes on the material surface to realize the precise processing of microgrooves [

7,

19]. The research of this technology not only expands the boundary of microgroove drag reduction applications and provides new theoretical and technical support for microgroove processing [

20].

Internationally, many research teams have revealed the processing mechanism and influencing factors of nanosecond laser etching of microgrooves through experimental research. Takayama et al. [

21] conducted a series of nanosecond laser etching experiments on the surface of single crystal diamond, explored the influence of processing times on the microgroove morphology, and found that the microgroove morphology showed a specific change rule with the increase of processing times. Charee et al. [

22] studied the influence of laser etching on the quality of microgrooves from two aspects: laser parameters and processing environment. It proposed a method of optimizing processing parameters to reduce microgroove damage. Sahu et al. [

23] studied the in-fluence of laser parameters and auxiliary gas pressure on the side wall cone angle of the microgroove through experiments, established a regression model, and obtained the influence law of the interaction of process parameters on the side wall cone angle. In addition, Okamoto et al. [

20] proposed a two-step scanning method to prepare micro-grooves with large sizes and high quality on single crystal diamonds.

Zhang et al. [

24] used a high-energy nanosecond laser to process composites under high-pressure auxiliary gas. They used single-factor experiments to explore the influence of pulse width on the quality of microgrooves. Similarly, Zhang et al. [

25] examined the impact of a single factor on microgroove etching results, studied the material removal behavior of single crystal diamond in multiple infrared nanosecond pulsed laser ablation, and revealed the laser etching mechanism. Further, Xing et al. [

26,

27] explored the influence of various factors on the processing results. During the nanosecond laser manufacturing process of microgrooves on the surface of the microcrystalline diamond, the influence of laser parameters on the surface quality, microgroove size, and other responses was studied through single-factor and multi-objective optimization experiments, and the high-quality preparation of microgrooves was achieved. After that, Wang et al. [

4,

28] proposed a multi-objective optimization method based on the response surface method and genetic algorithm in nanosecond etching TC4 titanium alloy surface microgrooves and obtained the best combination of laser parameters. In addition, Wang et al. [

29] studied the nanosecond laser processing of micro grooves on the surface of TC4 titanium alloy in the air and liquid environment. They found that the processing in the static liquid environment slightly improved the recast layer.

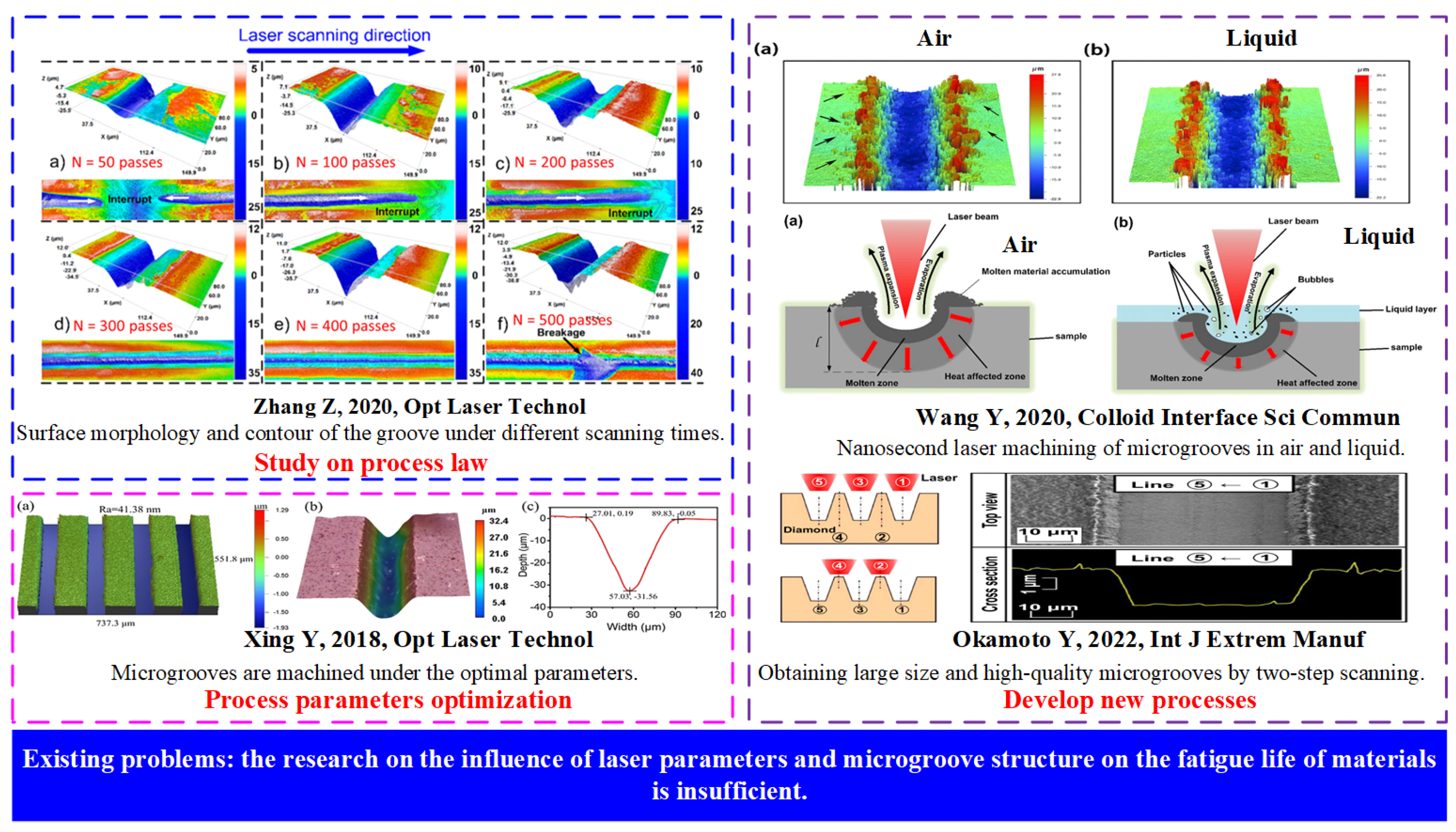

As shown in

Figure 4, scholars at home and abroad mainly realize high-quality nanosecond laser preparation of microgrooves from process law research, process parameter optimization, and the development of new processes. The above research tends to remove the recast layer to make the microgroove section size and characteristics closer to the design parameters, which not only increases the workload but also may ignore its potential impact on the drag reduction effect (the same as the problem de-scribed in

Figure 3). In addition, there needs to be more research on the influence of laser parameters and microgroove structure on the fatigue life of aircraft skin materials after etching microgrooves, which limits the application of nanosecond laser etching micro-groove on drag reduction technology in small aircraft wall drag reduction. Therefore, nanosecond laser etching microgrooves on drag reduction technology, considering the fatigue life of materials, will be a direction for future research.

4. Research on Numerical Simulation of Laser Processing

In exploring the laser machining process, the numerical simulation method has become an indispensable tool in the guidance of precision machining materials by its ability to visually display the machining process and mechanism. It can not only help to understand the complex process of laser material interaction but also accurately predict the processing results and provide a scientific basis for optimizing processing parameters.

Constructing an effective finite element model is crucial to realizing the numerical simulation of laser processing. Stein et al. [

30] pioneered establishing a two-dimensional finite element model for pulsed laser processing of photovoltaic materials. Although this model fails to consider the immediate evaporation removal of the material during irradiation, it provides an approximate estimate of the laser processing profile by predicting the region beyond the gasification temperature. Further, Vasantgadkar et al. [

31] developed this model, considering the target's temperature-dependent characteristics, plasma shielding effect, and absorption rate, significantly improving the model's accuracy in predicting the ablation depth. Benton et al. [

32] expanded to the three-dimensional model. They analyzed the influence of laser processing parameters and material thermophysical properties on the processing effect through COMSOL software, which further enriched the research dimension of laser processing numerical simulation. Wang et al. [

33] made significant progress on this basis, taking into account the immediate removal effect of materials in the ablation process, providing a new perspective for understanding the ablation depth under high laser energy density. Courtois et al. [

34] proposed a new method that calculates the laser reflection by solving Maxwell equations, which improves the model's prediction accuracy and facilitates the coupling with other physical process equations, providing a new tool for the numerical simulation of laser processing.

A series of explorations have been conducted on laser processing simulation methods in China, and Zhang et al. [

35,

36] established a three-dimensional finite element model of nanosecond pulsed laser processing. To simulate nanosecond pulsed laser ablation morphology, ABAQUS was redeveloped based on Fortran language to quickly remove materials that have reached the vaporization temperature. Chu et al. [

37] established a comprehensive transient two-dimensional finite element model for laser drilling, considering the effects of laser beam spatial distribution and material phase change latent heat on the hole and provided the small hole's transient temperature field distribution and interface evolution process. Similarly, Zhang et al. [

38,

39] used an im-proved level set method to track the solid/liquid/gas interface of laser drilling, considering complex dynamic effects including gravity, recoil pressure of metal vapor, surface tension, and Marangoni effect, revealing the mechanism of laser drilling. Furthermore, Liang et al. [

40] successfully simulated the spiral drilling of large pores on the surface of titanium alloys using the method above. Wang et al. [

41] proposed a high-precision and efficient numerical simulation method for nanosecond laser processing based on de-formation geometry technology. This method is based on the principle of energy conservation to perform periodic continuity equivalence on pulsed lasers, significantly improving computational efficiency. The response surface method is used to modify the finite element model under the action of equivalent lasers to ensure computational accuracy. Next, Niu et al. [

42] successfully calculated the asymmetric heat transfer direction and thermal stress difference between the front and rear edges in inclined drilling using this method to solve the problem of thermal barrier coating delamination during laser drilling. Zhao et al. [

43] established a complex, comprehensive three-dimensional finite element model that couples heat transfer and molten metal flow during laser etching, revealing the mechanism of titanium alloys' nanosecond laser etching.

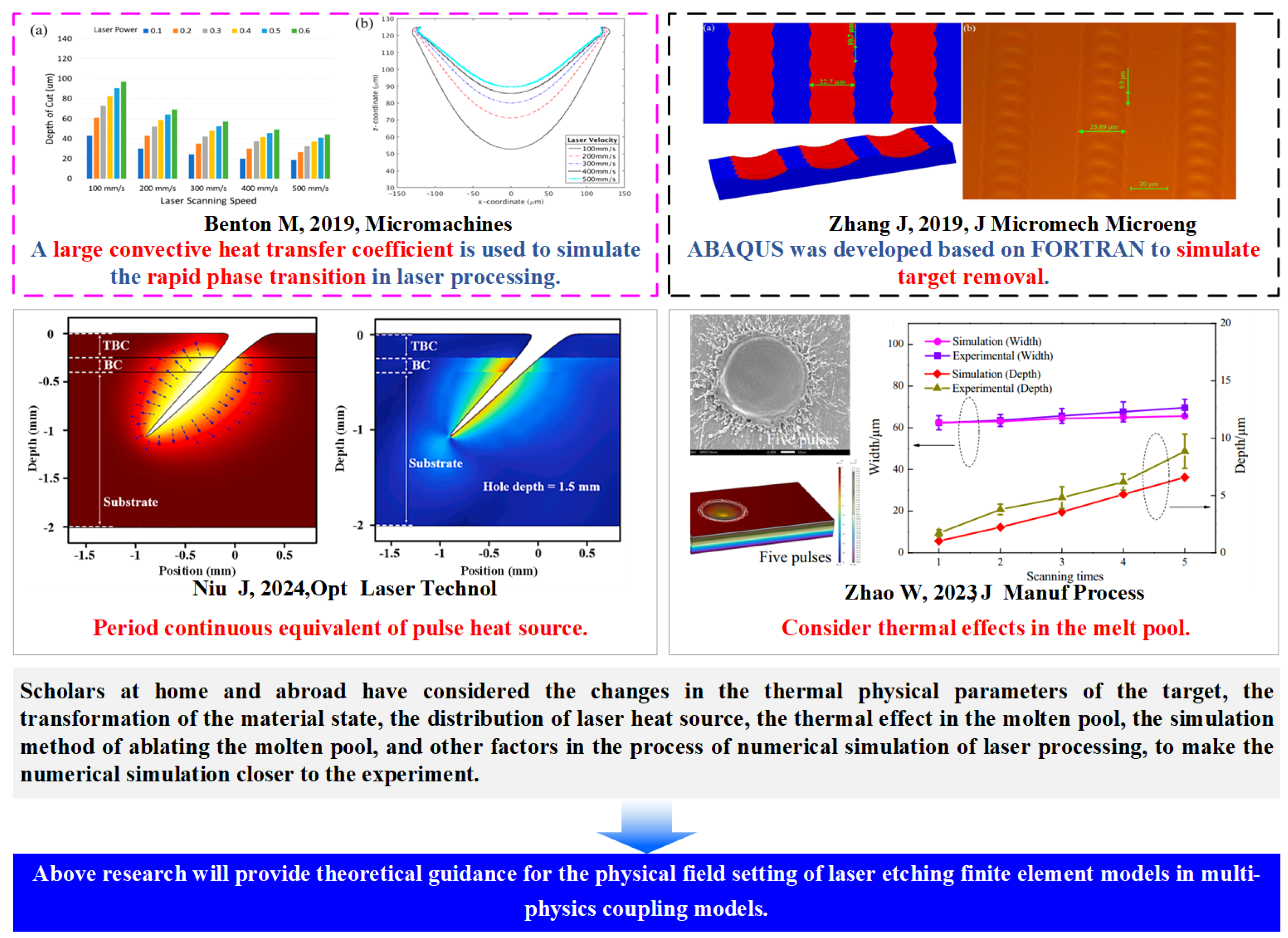

As shown in

Figure 5, the focus of domestic and foreign scholars on numerical simulation of laser processing is on what methods can be used to accurately predict the laser processing results. Therefore, factors such as changes in thermal properties of the target material, material state transition, laser heat source distribution, thermal effects in the melt pool, and simulation methods for ablating the melt pool are considered to make the numerical simulation more closely related to the experimental process. Comprehensive analysis of the second and third parts of this paper, combined with this chapter, future models should adopt a coupled framework that links laser processing simulations (predicting microgroove morphology and recast layers) with CFD analyses (evaluating drag reduction performance). It enables real-time optimization of both processing parameters (e.g., pulse energy, scanning speed) and microgroove designs.

5. Conclusions and Prospect

This review comprehensively evaluates the advancements, challenges, and future directions of nanosecond laser etching for microgroove-based drag reduction on small aircraft surfaces. Key findings from numerical simulations, experimental studies, and laser processing modeling are synthesized to highlight the technology’s potential and limitations.

5.1. Key Conclusions

(1) Drag reduction performance: Optimized microgrooves fabricated via nanosecond laser etching demonstrate the reduction in aerodynamic drag under controlled experimental conditions. However, the scalability of these results to full-scale aircraft remains constrained by discrepancies between idealized numerical models and real-world microgroove morphologies. Current simulations often oversimplify laser-induced features (e.g., non-uniform cross-sections, recast layers), leading to overestimated drag reduction rates.

(2) Laser-material interaction: Nanosecond laser etching offers a cost-effective method for industrial-scale microgroove fabrication. Yet, thermal effects inherent to nanosecond pulses—such as recast layers, microcracks, and residual stresses—compromise material integrity and long-term durability. Experimental studies have focused predominantly on optimizing groove geometry and process parameters, with limited attention to fatigue life implications.

(3) Modeling limitations: Existing numerical frameworks (e.g., RANS, LES) face trade-offs between computational efficiency and accuracy. While RANS enables full-aircraft simulations, it inadequately resolves near-wall turbulence. Conversely, LES captures fine-scale flow dynamics but is computationally prohibitive. A unified approach integrating laser processing simulations with CFD analyses is essential to bridge these gaps.

5.2. Critical Challenges

(1) Morphological inconsistencies: The cross-sectional variability of nanosecond laser-etched microgrooves and the presence of recast layers are often neglected in drag reduction models, introducing uncertainties in performance predictions.

(2) Fatigue life neglect: The impact of laser-induced surface modifications (e.g., stress concentrations, microcracks) on the fatigue life of aircraft skin materials remains understudied, hindering certification-ready applications.

(3) Lack of small aircraft focus: Most research targets large civil aircraft, leaving a knowledge gap in drag reduction strategies tailored to small aircraft operating at lower Reynolds numbers.

5.3. Future Directions

To address these challenges, a multidisciplinary framework is proposed:

(1) Coupled multi-physics modeling: Develop integrated models that combine laser-material interaction simulations (predicting microgroove morphology and thermal damage) with high-fidelity CFD analyses. Such models will enable real-time optimization of laser parameters (e.g., pulse energy, scanning speed) and microgroove designs for specific flight conditions.

(2) Fatigue life integration: Establish experimental protocols to quantify the relationship between laser-processed microgrooves, surface integrity, and fatigue resistance. Machine learning techniques could accelerate the identification of parameter sets that balance drag reduction with material durability.

(3) Small aircraft specialization: Prioritize studies on microgroove configurations optimized for small aircraft aerodynamics, including low-speed cruise and turbulent boundary layer characteristics.

By advancing these strategies, nanosecond laser etching can transition from laboratory innovation to industrial implementation, offering a sustainable pathway to enhance fuel efficiency and operational sustainability in the rapidly expanding general aviation sector.

Acknowledgments

This work was supported by the Jiangsu Provincial Natural Science Foundation Youth Science Fund (grant number BK20241404).

Conflicts of Interest

The author declares no conflicts of interest.

Xulin Wang received his PhD from the School of Mechanical Engineering, Dalian University of Technology, Dalian, China, in 2023. He is currently a lecturer and master's supervisor at the School of General Aviation and Flight at Nanjing University of Aeronautics and Astronautics and a member of the Chinese Society of Aeronautics and Astronautics and the Chinese Society of Mechanical Engineering. Focusing on the safe operation and maintenance of civil aircraft, he is researching the basic theory and application of laser manufacturing.

Zhenyuan Jia received his PhD in mechanical engineering from Dalian University of Technology, Dalian, China, in 1990. He is currently a professor and a doctoral supervisor at the Key Laboratory for Precision and Non-traditional Machining Technology of the Ministry of Education, Dalian University of Technology, and the president at Dalian University of Technology. His research interests include precision machining, precision measurement, and function material components.

Jianwei Ma received his PhD from the School of Mechanical Engineering, Dalian University of Technology, Dalian, China, in 2011. He is currently a professor at the Institute of Advanced Manufacturing Technology, Dalian University of Technology. His research interests focus on precision machining, robot-assisted processing planning and control, laser processing, and process control.

Wei Liu received his PhD in mechanical engineering from Dalian University of Technology, Dalian, China, in 2007. He is currently a professor and dean at the School of Mechanical Engineering, Dalian University of Technology. His research interests include precise measurement and control of geometric and physical quantities in complex environments, intelligent detection, and intelligent manufacturing.

References

- Ren, H.; Liu, Y.X.; Zou, Y.Y.; Zhang, N.N. Information element design of cabin of small aircraft based on AHP. Packaging Engineering 2022, 43, 232–238. [Google Scholar] [CrossRef]

- Dong, N.Q. A research on the situation, difficulties and countermeasures of China’s general aviation development. Journal of Beijing Institute of Technology (Social Sciences Edition) 2014, 16, 110–117. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, C.; Wang, Z.X. Simulation analysis on drag reduction performance of characteristic parameters of V-groove on local approximate plane. Aeronautical Manufacturing Technology 2021, 64, 86–99. [Google Scholar] [CrossRef]

- Wang, X.L.; Jia, Z.Y.; Ma, J.W.; Han, D.X.; Gui, C.H.; Qi, X.Q.; Liu, W. Research on nanosecond laser processing of basic unit for ridge surface: forming condition of microgroove and micro-ridge structure on TC4 surface. Opt. Eng. 2022, 64, 046105. [Google Scholar] [CrossRef]

- Wang, C.J.; Cheng, L.D.; Xue, S.X.; Chen, P.Y.; Liu, B.S.; Ding, H.; Sun, J.; Xu, Z.H.; Wang, X.W. Manufacturing technologies of bionic micro-structures for drag reduction: a review. Journal of Netshape Forming Engneering 2019, 11, 88–98. [Google Scholar] [CrossRef]

- Wang, X.L.; Ma, J.W.; Jia, Z.Y.; Gui, C.H.; Qi, X.Q.; Liu, W. Nanosecond laser high-precision fabrication of microgrooves on TC4 surface: Morphology simulation and drag reduction performance of microgrooves. J. Laser Appl. 2022, 34, 042047. [Google Scholar] [CrossRef]

- Yu, K.C.; Shi, H.C.; Zhang, P.L.; Yu, Z.S.; Yan, H.; Lu, Q.H. Micro/nanoengineering of functionalized metal surfaces based on short/ultra-short-pulsed lasers: a review. J. Mater. Sci. 2024, 59, 1819–1866. [Google Scholar] [CrossRef]

- Liu, X.C.; Yang, F.Z.; Luo, J.; Wei, H.M. Study and analysis of microtexture laser machining in tool surface. Tool Engineering 2019, 53, 74–77. [Google Scholar] [CrossRef]

- Yan, Y.Z.; Ji, L.F.; Bao, Y.; Jiang, Y.J. Theory analysis and experiment verification on crack characters during laser processing ceramics. Chinese Journal of Lasers 2008, 35, 1401–1408. [Google Scholar] [CrossRef]

- Zhou, J.; Ou, P.; Liu, P.Q.; Guo, H. Numerical evaluation method of turbulence drag reduction with riblets. Acta Aeronautica et Astronautica Sinica 2017, 38, 120263. [Google Scholar] [CrossRef]

- Luchini, P.; Manzo, F.; Pozzi, A. Resistance of groove surface to parallel flow and cross-flow. J. Fluid Mech. 1991, 228, 87–109. [Google Scholar] [CrossRef]

- Martin, S.; Bhushan, B. Fluid flow analysis of continuous and segmented riblet structures. RSC Advances 2016, 6, 10962–10978. [Google Scholar] [CrossRef]

- Choi, K.S. Near-wall structure of a turbulent boundary layer with riblets. J. Fluid Mech. 1989, 208, 417–458. [Google Scholar] [CrossRef]

- Fuaad, P.A.; Prakash, K.A. Enhanced drag-reduction over superhydrophobic surfaces with sinusoidal textures: A DNS study. Comput. Fluids 2019, 181, 208–223. [Google Scholar] [CrossRef]

- Liu, M.; Li, S.G.; Wu, Z.R.; Wang, S.L.; Deng, Y.H. Entropy generation analysis for grooved structure plate flows. Chinese Journal of Computational Physics 2020, 37, 182–188. [Google Scholar] [CrossRef]

- Hu, H.B.; Song, B.W.; Liu, Z.Y.; Huang, Q.G.; Pan, G. Research at the computational methods of flow fields over riblets surface. Acta Aerodynamica Sinica 2011, 29, 348–354. [Google Scholar]

- Xiao, G.J.; He, Y.; Huang, Y.; He, S.; Wang, W.X.; Wu, Y. Bionic microstructure on titanium alloy blade with belt grinding and its drag reduction performance. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2021, 235, 2230–2239. [Google Scholar] [CrossRef]

- Takayama, N.; Asaka, S.; Yan, J.W. Nanosecond pulsed laser irradiation of sapphire for developing microstructures with deep V-shaped grooves. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2018, 52, 440–450. [Google Scholar] [CrossRef]

- Sahu, A.K.; Jha, S. Microchannel fabrication and metallurgical characterization on titanium by nanosecond fiber laser micromilling. Mater. Manuf. Process. 2020, 35, 279–290. [Google Scholar] [CrossRef]

- Okamoto, Y.; Okubo, T.; Kajitani, A.; Okada, A. High-quality micro-shape fabrication of monocrystalline diamond by nanosecond pulsed laser and acid cleaning. Int. J. Extreme Manuf. 2022, 4, 025301. [Google Scholar] [CrossRef]

- Takayama, N.; Yan, J.W. Mechanisms of microgroove formation on single-crystal diamond by a nanosecond pulsed laser. J. Mater. Process. Technol. 2017, 243, 299–311. [Google Scholar] [CrossRef]

- Charee, W.; Qi, H.; Zhu, H.; Saetang, V. Coaxial water and air jet-assisted laser micromachining of titanium. Int. J. Adv. Manuf. Technol. 2022, 121, 5605–5616. [Google Scholar] [CrossRef]

- Sahu, A.K.; Jha, S. Microchannel fabrication and metallurgical characterization on titanium by nanosecond fiber laser micromilling. Mater. Manuf. Process. 2020, 35, 279–290. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Huang, T.; Liu, Z.; Zhang, X.; Lu, J.L.; Xiao, R.S. High fluence nanosecond laser machining of SiCp/AA2024 composite with high pressure assistant gas. J. Manuf. Process. 2018, 31, 560–567. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.L.; Wang, Q.W.; Su, H.H.; Fu, Y.C.; Xu, J.H. Investigation on the material removal behavior of single crystal diamond by infrared nanosecond pulsed laser ablation. Opt. Laser Technol. 2020, 126, 106086. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Liu, L.; Wu, Z.; Wang, X.S.; Huang, P.; Tang, L. Fabrication and characterization of micro-channels on Al2O3/TiC ceramic produced by nanosecond laser. Ceram. Int. 2018, 44, 23035–23044. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Liu, L.; Hao, X.Q.; Wu, Z.; Huang, P.; Wang, X.S. Micro-channels machining on polycrystalline diamond by nanosecond laser. Opt. Laser Technol. 2018, 108, 333–345. [Google Scholar] [CrossRef]

- Wang, X.L.; Jia, Z.Y.; Ma, J.W.; Han, D.X.; Qi, X.Q.; Gui, C.H.; Liu, W. Optimization of nanosecond laser processing for microgroove on TC4 surface by combining response surface method and genetic algorithm. Opt. Eng. 2022, 61, 086103. [Google Scholar] [CrossRef]

- Wang, Y.T.; Zhao, X.Y.; Ke, C.J.; Yu, J.; Wang, R. Nanosecond laser fabrication of superhydrophobic Ti6Al4V surfaces assisted with different liquids. Colloid Interface Sci. Commun. 2020, 35, 100256. [Google Scholar] [CrossRef]

- Stein, P.; Garcia, O.; Morales, M.; Huber, H.P.; Molpeceres, C. Nanosecond laser fabrication of superhydrophobic Ti6Al4V surfaces assisted with different liquids. Appl. Surf. Sci. 2012, 258, 9288–9291. [Google Scholar] [CrossRef]

- Vasantgadkar, N.A.; Bhandarkar, U.V.; Joshi, S.S. A finite element model to predict the ablation depth in pulsed laser ablation. Thin Solid Films 2010, 519, 1421–1430. [Google Scholar] [CrossRef]

- Benton, M.; Hossan, M.R.; Konari, P.R.; Gamagedara, S. Effect of process parameters and material properties on laser micromachining of microchannels. Micromachines 2019, 10, 123. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Shen, N.G.; Befekadu, G.K.; Pasiliao, C.L. Modeling pulsed laser ablation of aluminum with finite element analysis considering material moving front. Int. J. Heat Mass Transf. 2017, 113, 1246–1253. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S.; Balabane, M. A new approach to compute multi-reflections of laser beam in a keyhole for heat transfer and fluid flow modelling in laser welding. J. Phys. D-Appl. Phys. 2013, 46, 505305. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhao, L.; Rosenkranz, A.; Song, C.W.; Yan, Y.D.; Sun, T. Nanosecond pulsed laser ablation on stainless steel combining finite element modeling and experimental work. Adv. Eng. Mater. 2019, 21, 1900193. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhao, L.; Rosenkranz, A.; Song, C.W.; Yan, Y.D.; Sun, T. Nanosecond pulsed laser ablation of silicon - finite element simulation and experimental validation. J. Micromech. Microeng. 2019, 29, 075009. [Google Scholar] [CrossRef]

- Chu, Q.C.; Yu, G.; Lu, G.Q.; He, X.L.; Zheng, C.Y.; Xu, Y.T. Two-dimensional numerical investigation for the effects of laser process parameters on hole type during laser drilling. Chinese Journal of Lasers 2011, 38, 0603001. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Shen, Z.H.; Ni, X.W. Modeling and simulation on long pulse laser drilling processing. Int. J. Heat Mass Transf. 2014, 73, 429–437. [Google Scholar] [CrossRef]

- Zhang, T.Z.; Zhang, C.; Li, J.; Zhang, H.C.; Lu, J. Formation mechanism of recast laser in millisecond laser drilling of Ti6Al4V alloys. Acta Optica Sinica 2017, 37, 144–153. [Google Scholar] [CrossRef]

- Liang, Y.C.; Feng, G.; Li, XG.; Sun, H.R.; Xue, W.; Zhang, K.P.; Li, F.P. Simulation analysis of nanosecond laser processing of titanium alloy based on helical trepanning. Applied Sciences-Basel 2022, 12, 9024. [Google Scholar] [CrossRef]

- Wang, X.L.; Jia, Z.Y.; Ma, J.W.; Liu, W.; Han, D.X.; Gui, C.H.; Qi, X.Q. Research on simulation of nanosecond pulsed laser processing for TC4 titanium alloy: A novel model simplification and correction method. Opt. Laser Technol. 2022, 147, 107635. [Google Scholar] [CrossRef]

- Niu, J.; Yang, J.; Tan, J.Q.; Qin, Z.Y.; Chen, L.; Jia, T.Q.; Xu, H.X. Study of the TBC delamination in nanosecond laser percussion drilling of inclined film cooling holes. Opt. Laser Technol. 2024, 169, 110077. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, Z.; Hu, J. Numerical simulation and experimental analysis on nanosecond laser ablation of titanium alloy. J. Manuf. Process. 2023, 99, 138–151. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).