1. Introduction

The energy sector is undergoing a profound transformation driven by the urgent need to decarbonize operations, improve infrastructure efficiency, and enhance system resilience. These objectives are being pursued in an environment shaped by increasingly stringent regulatory frameworks, the integration of renewable sources, and growing public expectations for sustainability [

1]. Within this evolving landscape, the ability to manage critical energy assets effectively throughout their lifecycle has become a strategic priority for utilities, manufacturers, and operators [

2,

3].

In response, digitalization has emerged as a foundational enabler of modern asset management. The convergence of the Internet of Things (IoT), cloud computing, artificial intelligence (AI), and big data analytics has paved the way for new paradigms in operations and maintenance [

4,

5,

6,

7,

8,

9]. One of the most transformative developments in this space is the concept of the Digital Twin—a dynamic, virtual representation of a physical asset that continuously synchronizes with real-world data. These digital replicas integrate historical records, real-time telemetry, and predictive models, allowing for continuous assessment of performance, degradation, and operational risk.

However, unlocking the full potential of digital twins requires a robust and structured data infrastructure [

10,

11,

12,

13]. Capturing data alone is not sufficient; it must be properly organized, contextualized, and linked to actionable decision-support mechanisms [

14,

15,

16,

17]. A particularly critical aspect of this data infrastructure is the ability to assess the health status of assets in a way that is both comprehensive and operationally meaningful. This is where the Asset Health Index (AHI) becomes central.

The AHI is a methodology that condenses a range of variables—including operational conditions, reliability indicators, usage intensity, and degradation patterns—into a single, interpretable score that reflects the asset’s current condition [

18]. By synthesizing both real-time and historical data, the AHI facilitates predictive maintenance planning, risk prioritization, and long-term asset investment strategies [

19]. As such, it plays a key role in shifting asset management from reactive to proactive modes.

Despite its value, the integration of AHI into digital twin frameworks remains limited in practice. Many organizations rely on fragmented, non-standardized implementations that lack interoperability, scalability, or transparency. In particular, the lack of a structured data model for organizing and linking the various components involved—physical hierarchy, operational monitoring, reliability data, and maintenance decisions—creates barriers to effective deployment. Moreover, without such a model, the health status computed via AHI cannot be reliably integrated into automated workflows or digital twin simulations.

To address this gap, this paper proposes a structured data model for the integration of AHI into Digital Twins applied to energy converters, with a particular focus on DC/AC inverters used in photovoltaic and energy storage systems. The model draws upon internationally recognized standards such as ISO 14224 [

20], which provides guidelines for asset breakdown structures and reliability data, and digital architectures such as RAMI 4.0 [

21] and the Industrial Internet Reference Architecture (IIRA) [

22]. These foundations ensure that the proposed approach is compatible with existing industrial practices while enabling modern digital capabilities.

The model is organized into a set of interconnected domains that collectively support asset identification, criticality assessment, real-time monitoring, health evaluation, and risk-based decision-making. A Unified Modeling Language (UML) class diagram formalizes the relationships among these domains, making the architecture transparent and extensible. Furthermore, the model is implemented using Microsoft Azure cloud services, leveraging its suite of IoT, data processing, and visualization tools to automate the calculation of the Asset Health Index and facilitate scalable deployment.

To demonstrate the practical applicability of this approach, the paper presents a case study involving three high-capacity energy converters operating in different environmental and load conditions. The analysis illustrates how variations in operating stress, maintenance history, and environmental exposure are captured through the AHI and how these insights support differentiated maintenance strategies. The case also shows how the cloud-based implementation enables continuous monitoring and rapid feedback for asset managers.

The remainder of this paper is structured as follows:

Section 2 reviews the functional role of energy converters and summarizes current trends in digital twin applications within this asset class.

Section 3 introduces the proposed asset data model, explaining its structure and alignment with international standards.

Section 4 presents the UML class diagram that formalizes the model architecture.

Section 5 applies the model in a real-world scenario, demonstrating its utility and flexibility. Finally,

Section 6 presents the conclusions and outlines future lines of research.

2. Background

2.1. The Critical Role of Energy Converters and the Advancements in their Digitalization

Energy converters are essential components of modern power systems, enabling the transformation of energy from one form to another to support efficient, reliable, and sustainable distribution. Their function is particularly relevant in applications such as renewable energy infrastructures, battery energy storage systems (BESS), and industrial power networks, where they facilitate the integration of intermittent sources and ensure proper load balancing and energy flow optimization. The performance of these units directly impacts energy efficiency, system reliability, and operational costs [

23].

However, these devices are subject to a variety of operational stresses that can lead to critical failures. Among the most common issues are thermal degradation, insulation breakdown, semiconductor malfunction, and electromagnetic interference. Such problems often result in unplanned downtime, reduced efficiency, and increased maintenance needs. In critical infrastructures—such as utility grids or industrial manufacturing plants—malfunctions may trigger widespread disruptions and safety hazards [

24].

To address these challenges, a comprehensive life cycle cost (LCC) approach is necessary. This methodology considers all phases of asset ownership, including design, operation, maintenance, and decommissioning, helping decision-makers evaluate long-term sustainability and cost-effectiveness. When paired with digital monitoring and predictive maintenance strategies, LCC analysis supports extended equipment lifespan and the prevention of unexpected failures [

25].

The engineering and operational management of these systems are increasingly being enhanced through digitalization and Model-Based Systems Engineering (MBSE). These methodologies enable robust modeling, simulation, and verification from early design to full deployment. MBSE facilitates the early detection of design inefficiencies, improves traceability of requirements, and shortens integration times. When coupled with digital twins, MBSE also enables real-time system validation and performance optimization. Tools such as System Composer by MathWorks have proven effective in supporting architecture design and system-level verification [

26].

Reliable operation depends on monitoring a range of key parameters, including voltage, current, temperature, power output, efficiency, and harmonic distortion. These indicators allow operators to assess device conditions in real time and detect early signs of degradation. With the support of IoT-enabled sensors, machine learning, and advanced analytics, operators can deploy real-time diagnostics and predictive models that enhance resilience and reduce operational risk. As highlighted in [

27], the convergence of digitalization and asset intelligence enables energy systems to evolve toward smarter, more adaptive infrastructures aligned with Industry 4.0 principles.

In conclusion, these conversion systems are central to the functionality and reliability of today’s energy infrastructure. The complexity of their operation and the risks associated with failure demand a comprehensive approach that integrates lifecycle thinking, predictive analytics, and digital twin technologies. A structured, digital strategy is thus essential to ensuring their long-term performance and reliability.

2.2. Digital Twin Implementation for Energy Converters

The adoption of digital twin technology in energy converters provides significant advantages, including real-time performance monitoring, enhanced predictive maintenance, and lifecycle optimization. By creating a virtual replica of physical assets, digital twins enable improved diagnostics and operational efficiency, reducing downtime and enhancing decision-making processes.

Cloud-based and on-premise digital twin solutions present key differences. Cloud solutions offer scalability, remote access, and advanced analytics powered by AI and machine learning. On the other hand, on-premise solutions provide greater data security and lower latency for critical applications, making them suitable for sensitive industrial environments.

Major cloud platforms for digital twin implementations include Microsoft Azure Digital Twins, Google Cloud IoT, Amazon AWS IoT TwinMaker, and FIWARE. These platforms provide robust infrastructure and tools for real-time monitoring, simulation, and analytics of energy assets.

Azure Digital Twins stands out for energy converters due to its seamless integration with Azure IoT Hub, AI-driven analytics, and scalable data processing. It allows energy companies to optimize operations by enabling predictive maintenance, reducing failures, and enhancing energy efficiency.

Azure is one of the most employed platforms for digital twin on industrial assets, and for the energy converters it has been developed a economic and simple architecture for any size of company. A robust digital twin architecture for energy converters integrates several Azure modules to ensure efficient data acquisition, processing, and visualization. The following components form the backbone of this architecture are the following as basis [

28]:

Azure IoT Hub – Serves as the main communication gateway between energy converters and the cloud. It enables secure, bi-directional communication, allowing real-time data collection and remote control. This module is essential for managing many connected devices while ensuring data integrity

Azure IoT Central – Provides a scalable, low-code interface for managing IoT devices. It simplifies device provisioning, monitoring, and data visualization, making it easier to deploy and manage energy converter networks at scale.

Azure Functions – Facilitates serverless data processing. It triggers data cleaning, normalization, and aggregation tasks when new telemetry is received. This automation ensures that only high-quality, structured data is sent to analytics platforms, reducing computational overhead.

Azure Data Explorer – Offers advanced time-series analysis and anomaly detection. This module enables real-time analytics on large datasets, supporting predictive maintenance and fault detection in energy converters.

Power BI – Provides intuitive dashboards and visualizations, allowing operators to monitor key performance indicators (KPIs), detect anomalies, and generate predictive insights based on historical data.

This simple and cost-efficient architecture for Energy Converters provides the following advantages:

Improved Diagnostics: The integration of IoT Hub and Data Explorer enables real-time anomaly detection, identifying potential issues before they escalate into failures.

Enhanced Predictive Maintenance: The combination of Azure Functions and IoT Central automates data processing and device management, ensuring timely insights into asset health.

Scalability and Cost Efficiency: The use of serverless computing with Azure Functions and managed services like IoT Central reduces infrastructure costs while maintaining high performance.

Comprehensive Visualization: Power BI offers user-friendly dashboards that enhance decision-making, providing stakeholders with actionable intelligence for optimizing energy conversion processes.

This architecture represents a cost-effective, scalable, and high-performance solution for implementing digital twins in energy converters, leveraging Azure’s powerful suite of cloud-based tools to drive operational efficiency and reliability.

2.3. AHI Development and Practical Issues in Digital Twin Implementation

As industries adopt digital transformation initiatives, the integration of Asset Health Index (AHI) methodologies into digital twin ecosystems is becoming increasingly relevant. Digital twins offer a virtual environment in which asset behavior can be simulated, monitored, and optimized in near real-time. In this context, the AHI serves not only as a monitoring tool but also as a predictive feature that enables early detection of failure risks and supports what-if analysis of maintenance strategies [

5,

29].

While the theoretical foundations of the AHI are well-established, its practical application within digital twin environments remains a developing field. For example, health indices have been used in the energy sector for asset prioritization, particularly in power transformers and rotating equipment, using historical and real-time data such as temperature, load, and dissolved gas analysis [

30]. In railways and aviation, similar indices—while not always formally referred to as “AHI”—are used to assess asset degradation and plan maintenance interventions based on usage patterns, fault history, and environmental factors [

31].

However, many of these implementations remain siloed or tailored to specific asset types. Integration into full-fledged digital twin architectures — enabling real-time updates and predictive simulation based on health indices — remains limited. In many industrial settings, AHI computations are performed periodically and offline, based on exported data, which undermines the potential of digital twins as living models for continuous decision-making [

32].

From the literature, two main approaches can be observed. One is standards-based, aligning models with frameworks such as ISO 14224 for failure data or ISO 55000 for asset management. This ensures consistency but often involves significant effort in data modeling and integration. The other is more pragmatic or ad hoc, relying on simplified spreadsheets or proprietary logic within SCADA or CMMS platforms. While faster to deploy, these approaches tend to lack scalability and transparency.

Common implementation barriers include poor data quality, unclear model design, and the need to define update frequency and input selection. Without a robust asset data structure linking condition monitoring, reliability history, and operational metadata, the AHI may lose effectiveness as a tool for comprehensive digital asset management.

3. Asset Data Model

The digitalization of assets is a multifaceted process that requires comprehensive frameworks to manage and optimize assets across their lifecycle. To fully harness the potential of digitalization, a structured approach is essential—one that incorporates different aspects of asset management. Drawing from established standards such as ISO/IEC/IEEE 42010:2011, EN IEC 81346:2022, ISO 14224:2016 and architectures like RAMI 4.0 and IIRA, we propose four key models that address the various dimensions of asset digitalization and management. These models not only align with existing systems engineering principles but also enhance the integration, monitoring, and decision-making capabilities of digitalized assets.

Based on this, a suitable recommendation would be to collect data to populate the following asset models [

33]:

Asset Definition Model (ADM). The Asset Definition Model provides a comprehensive framework for defining the structure, properties, and relationships of an asset within a digital system. This model aligns with the standards of ISO/IEC/IEEE 42010:2011, which emphasizes the need for a well-structured architecture description that defines the fundamental components and relationships of a system. The ADM is essential for creating a digital twin of the asset, ensuring that the digital representation is complete and can serve as the foundation for further processes, such as monitoring and maintenance. Additionally, the EN IEC 81346:2022 standard on object classification further supports this model by offering a systematic way to categorize and manage asset data within complex systems, ensuring consistency and interoperability across platforms.

Asset Criticality Model (ACM). The Asset Criticality Model addresses the prioritization of assets based on their impact on operations and their associated risks. This model is critical in ensuring that digitalization efforts focus on the most essential assets, maximizing value and minimizing downtime. RAMI 4.0, with its emphasis on asset lifecycle and hierarchical structures, supports this model by integrating the importance of criticality within the broader context of Industry 4.0. The ACM helps organizations focus on the assets that are most likely to influence operational efficiency and safety, ensuring that resources are allocated effectively in both short-term and long-term management.

Asset Monitoring Model (AMM). The Asset Monitoring Model facilitates real-time condition monitoring of assets using IoT networks and other digital technologies. This model draws from both RAMI 4.0 and IIRA, which emphasize the need for interconnected systems and continuous data flow between physical assets and digital systems. By integrating IoT sensors and signal processing, the AMM enables real-time visibility into asset conditions, supporting predictive maintenance and minimizing unplanned downtime. This model also resonates with the Asset Administration Shell (AAS) in RAMI 4.0, which acts as the digital representation of the physical asset, ensuring seamless data exchange and analysis.

Intelligent Asset Management Models (IAMMs). The Intelligent Asset Management Models provide a higher-level view of asset health and performance, utilizing advanced analytics to deliver actionable insights. These models are closely tied to Asset Performance Management (APM) and Asset Investment Planning (AIP) systems and supports the goals of ISO 55000 on asset management, which emphasizes the need for integrating asset management practices into broader organizational goals. The IAMMs enable organizations to predict future asset conditions, optimize maintenance schedules, and align asset management with business objectives. Asset’s health index model provides critical insights for long-term asset management planning, ensuring that digitalization efforts lead to sustainable value creation.

3.1. AHI Data Model

The Intelligent Asset Management Models (IAMM) represents the final layer in asset digitalization, focusing on integrating real-time and historical asset data for advanced decision-making processes. Once an asset’s data has been captured, processed, and structured (via the Asset Definition and Monitoring Models), and its criticality is addressed (via the Asset Criticality Model), the need arises to connect this data with human reasoning and decision-making tools.

Intelligent asset management relies heavily on the development and integration of robust data models that allow for the digital execution of key methodologies, such as RCFA, RCM, CBM, RAMS, LCC, AHI, etc. These data models provide the essential framework to capture, organize, and analyze the wealth of information generated by industrial assets, supporting decision-making processes that drive asset optimization.

The organization of asset data into structured models—covering identification, criticality, monitoring, and intelligent management—lays the foundation for the effective deployment of advanced maintenance techniques in a digital environment.

The integration of these data models ensures that decision-making processes are streamlined, and that predictive analytics and simulation tools are leveraged to generate actionable insights. This approach enables organizations to move beyond manual methods, optimizing maintenance strategies and aligning them with broader business goals through data-driven insights.

For the present article, the methodology proposed to be implemented as part of the Intelligent Asset Management Models (IAMM) is the Asset Health Index (AHI). The AHI provides a key tool for evaluating and monitoring the health status of assets comprehensively, integrating both historical and real-time data. Its ability to synthesize information into a single indicator facilitates informed decision-making and the prioritization of maintenance strategies, aligning asset management with organizational objectives.

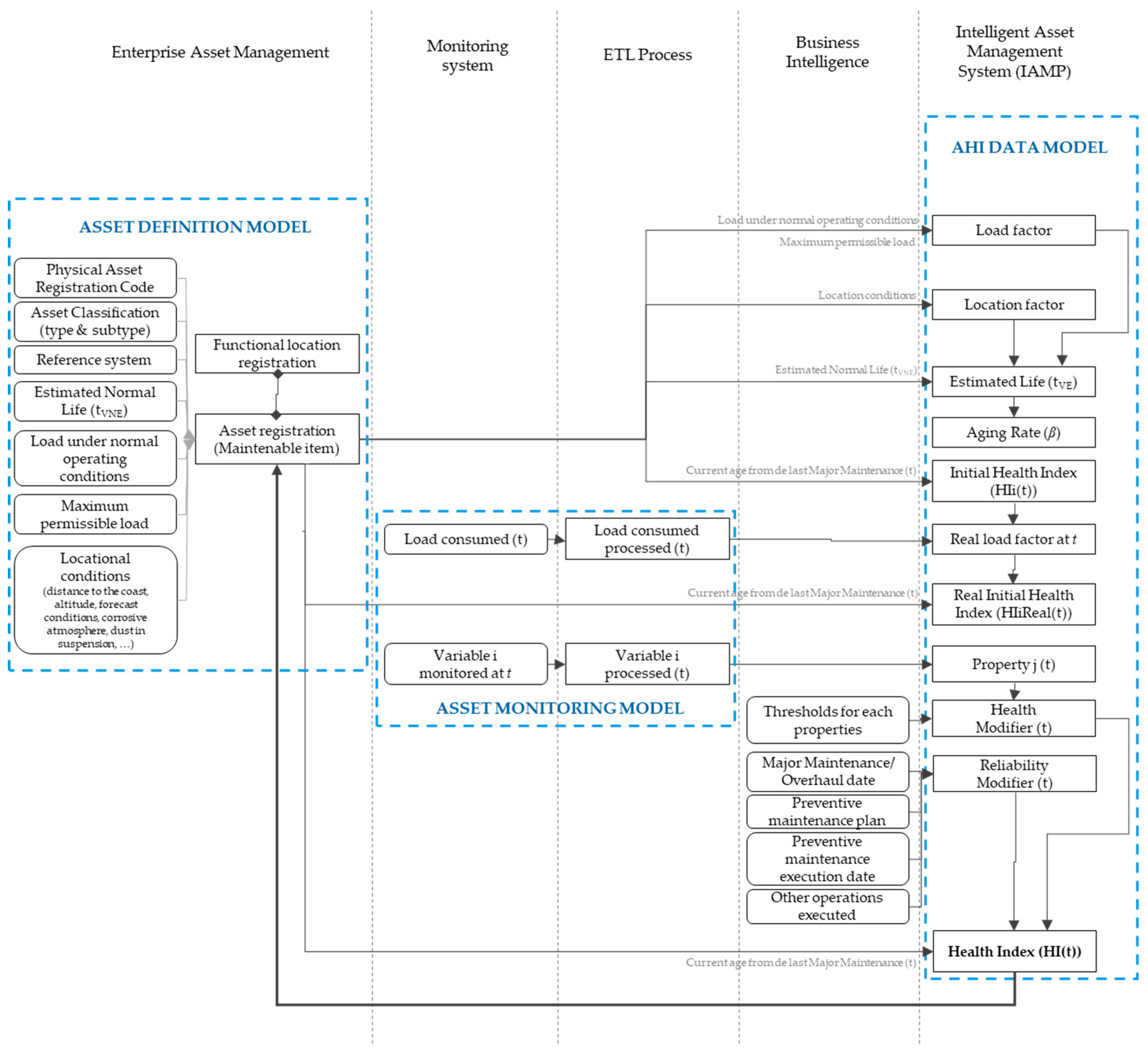

Assuming a high level of criticality for the asset and without delving into the criticality model itself,

Figure 1 illustrates the proposed data model required to achieve an advanced level of maturity in asset digitalization, taking into account the information system in which each activity is developed. This data model establishes a comprehensive framework for managing and analysing asset information, beginning with the precise definition of the physical asset within its designated functional location.

A critical component of this framework is the monitoring model, which systematically records the information generated within the Internet of Things (IoT) network. This enables the continuous assessment of the asset's condition through a structured process encompassing the sensing, extraction, transformation, and loading (ETL) of data. This data pipeline ensures that relevant information is efficiently processed and made available for subsequent analysis, forming the foundation for determining the asset's health status.

The proposed health index data model takes this a step further by interpreting the processed variables through a series of well-defined indicators. These indicators serve as a means to assess the asset's operational performance and condition, allowing for the generation of health and reliability modifiers based on the insights derived from the data. These modifiers play a pivotal role in accurately determining the current health status of the asset under analysis, enabling informed decision-making processes and supporting predictive maintenance strategies aligned with the overall objectives of asset optimization and organizational efficiency.

This integrated approach underscores the critical importance of leveraging structured data models in achieving high levels of digitalization and operational excellence in asset management.

4. UML Diagram Class for the Data Model Proposed

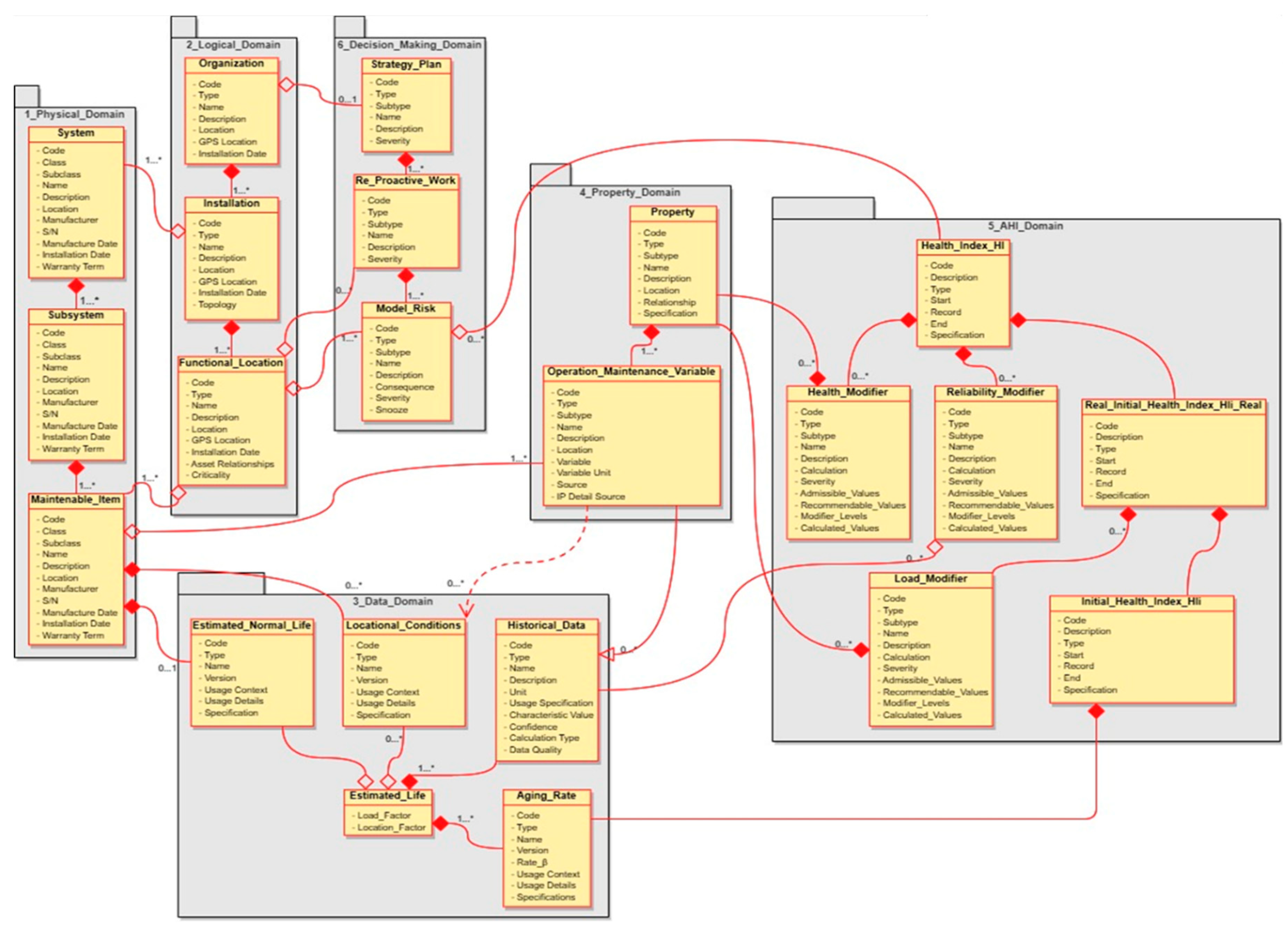

The UML diagram (

Figure 2) represents the Asset Health Index (AHI) Data Model for Digital Implementation, emphasizing the sources of information and the relations among them. For this purpose, the diagram is structured into different information domains that interconnect, facilitating comprehensive asset health assessment inside a structured model for complete asset management.

The UML diagram shows an explanation of the primary classes and their interrelations, focusing on the calculation of a AHI and its provided Risks serving as specific purpose in asset health assessment and maintenance management, deploying it in a optimized and economic architecture in Azure Cloud Solutions with the idea to provide support to operational and strategic decisions.

Each multiple domains of the UML diagram are divided in the main classes according to mostly employed asset management systems.

Physical Domain

This domain represents the physical assets attributes and describing the relations of the parts, that is, owing to a hierarchical breakdown of assets according to standards such as ISO 14224.

System: The highest-level entity that includes subsystems.

Subsystem: Defines a part of the system (e.g., bogies, wheels).

Maintainable Item: The specific components subject to maintenance (e.g., wheel bearings, brakes).

These classes are interconnected, in a hierarchical tree with relations of 0 to many upwards.

Logical Domain

This section links assets to their functional locations within the entire organization.

Organization, Segment as sections of the plant or network, and Functional Location define where the assets are placed.

Topology and asset relationships between physical and logical domain must be ensured for traceability within the organization.

In this domain the relationship among classes is also in a hierarchical tree with relations of 0 to many upwards.

Property Domain

This domain handles variables affecting asset condition and operation, some in real time and others offline.

Operation & Maintenance Variable: Captures operation and monitored parameters, and some reliable calculations, that can affect asset health.

Property: Based on previous variables defines measurable asset and processed characteristics (e.g., temperature, vibration), and any combination of them (e.g. power efficiency).

Any maintainable item has several O&M variables, that have to be particularized for employing in the asset health assessment, and store for future and batch analysis.

Data Domain

This domain includes historical data and calculations based on manufacturer and company specifications to be used in asset health assessment.

Locational Conditions has to be considered to adjust estimations based on environmental factors that can contribute to reduce or improve the health of the same assets in different functional locations.

Estimated Normal Life and Aging Rate therefore are developed as a previous prediction of asset deterioration considering the specifications and locational conditions in general.

AHI Domain (Asset Health Index)

This domain is the development that integrates the necessary information on real time as a virtual entity of the asset producing the health score of assets using this composition from bottom to top:

Initial Health Index (HIi)

Real Initial Health Index (HIiReal), that includes the affections due to load operating circumstances.

Load Modifier, recommended based on real time data.

Health Modifier, mainly based on real time data.

Reliability Modifier, based on reliability calculations such as MTBF, MTTR, Availability, number of preventives, frequency of preventives, overhauls, etc.

Final Health Index (HI(t)) which incorporates the affections to asset life by O&M properties and the reliability history.

Each modifier adjusts the health score based on the real circumstances that affect the assets.

Decision-Making Domain

This domain supports risk-based decision-making by integrating:

Strategy Plan: Defines maintenance and asset strategies.

Proactive Work: Represents predefined maintenance tasks to minimize or eliminate the risks.

Model Risk: The most critical class, which assesses the risk level of the assets according to the Final Health Index, producing warnings at different prioritization levels and for operative, tactical and strategic decisions.

5. Implementing the UML Model in Azure Cloud Solutions

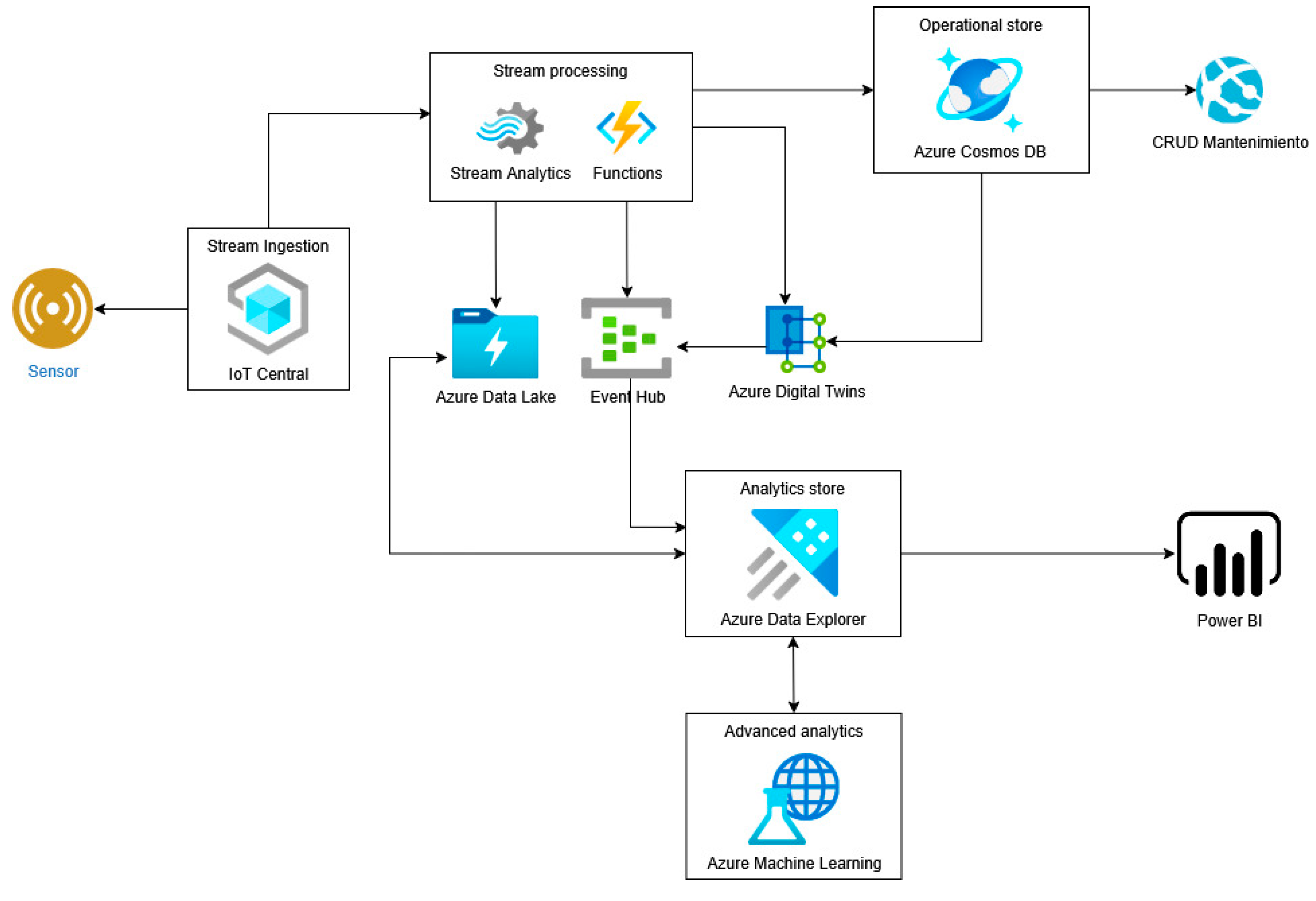

The UML model can be deployed using Microsoft Azure Cloud Services (

Figure 3).

The risk-model of AHI determines the probability of failure based on asset health, operational conditions, and historical trends. The calculation follows these steps:

Step 1: Data Acquisition and Ingestion

Step 2: Data Store and Processing

Store Manufacturer and organization specifications and statistics parameters for reliability modifiers in a Cosmos DB.

Azure Machine Learning can be used to trains models for asset health prediction and for defining the level of risks.

-

Preprocess Historical Data with Azure Functions and real-time data with the Azure Data Explorer

Previous maintenance records, failure rates, environmental conditions from Cosmos DB.

Stored in Azure Data Lake Storage for analysis.

Step 3: Health Index Calculation

-

Azure Functions automate health index calculations, applying the different modifiers: load, health and reliability, storing all in the Azure Data Lake Storage. Each modifier represents specific risk adjustments.

Health Modifier: Accounts for environmental conditions.

Reliability Modifier: Based on past failures.

Load Modifier: Adjusts for operational stress.

Azure Data Lake Storage archives historical asset data.

Azure Logic Apps automates predictive maintenance alerts, and Azure Functions trigger maintenance actions based on risk level.

Step 4: Digital Twin Integration

Azure Digital Twins creates virtual representations of assets and predict maintenance scheduling.

DTDL (Digital Twins Definition Language) maps health attributes with the virtual assets.

Azure Digital Twins Explorer visualizes asset conditions.

Visualization in Azure Power BI generating real-time dashboards.

In summary, using Azure Cloud Services to implement this UML model provides several advantages:

Scalability: Azure Digital Twins can model complex systems.

Real-Time Analysis: Azure Event Hubs and Data Explorer process sensor data instantly.

Automated Decision-Making: Azure Functions trigger maintenance actions.

Cost Optimization: Serverless architecture minimizes operational costs.

Enhanced Visualization: Power BI and Digital Twins Explorer improve insights.

The UML diagram represents a comprehensive Asset Health Index model that evaluates in energy assets risks using real-time data, historical records, and predictive models. By deploying this framework in Azure Cloud, manufacturers and their clients can optimize asset maintenance, minimize downtime, and enhance safety standards.

6. Application for Energy Converters

Energy converters, particularly DC/AC inverters, are key components in modern energy generation and storage systems. In the case of photovoltaic (PV) fields and battery energy storage systems (BESS), these devices transform energy from direct current (DC) into alternating current (AC). This step is essential for ensuring compatibility with commercial power grids.

In the context of this study, the converters process an input voltage of 1525 V DC with a maximum current of 1600 A. Their AC output is characterized by a voltage of 690 V and a maximum current of 3200 A. These specifications highlight the converters' high capacity to handle significant power levels, making them fundamental elements in large-scale renewable energy systems, such as solar parks and hybrid facilities that combine storage and generation.

An analysis of historical failure data for the converters considered in this case study reveals a recurring pattern: power devices and capacitors account for more than 50% of recorded failures. This underscores the importance of focusing on these two critical components to improve system reliability and durability.

Failures in power devices are directly linked to thermal stress, which results from fatigue in solder joints. This phenomenon occurs due to constant thermal fluctuations that cause expansion and contraction of the materials. As these cycles repeat, microcracks form in the solder joints, increasing their thermal resistance. This rise in resistance leads to additional overheating of the materials, amplifying thermal fluctuations and accelerating the degradation process. This cycle of cumulative damage impacts both the performance and the lifespan of the devices.

On the other hand, capacitors are subject to gradual wear due to factors such as temperature, electrical overload, and the characteristics of dielectric materials. Aging of these components can result in a loss of capacity, an increase in internal impedance, and ultimately failures that affect converter stability.

Implementing an Asset Health Index (AHI) requires a comprehensive understanding of the available operational and monitoring variables. In this case, real-time data was collected on key parameters, including:

Electrical variables: Voltage, current, harmonics, and power factor.

Thermal variables: Device temperature, thermal gradients, and overheating events.

Mechanical variables: Vibrations, mechanical stresses, and noise levels.

Operational and maintenance events: History of corrective and preventive interventions, downtime, and failure records.

Based on this data, the health status of three converters installed in different functional locations, each operating under specific conditions, was evaluated:

Converter 1: This converter operates in a moderate environment with relatively stable conditions, and its load remains close to the expected values. Extreme temperature variations are uncommon in this scenario. However, before its first major maintenance (overhaul), an increase in the Health Index (above 7) is observed, coinciding with the onset of a series of recurring failures. This reflects significant degradation of the converter, indicating that long-term operational conditions, although moderate, have impacted the integrity of its critical components.

Converter 2: This converter operates under a load environment that exceeds the expected specifications, with frequent temperature fluctuations. As a result, failures begin to occur at an early stage of its lifecycle, prompting the first overhaul to be performed earlier than planned. This intervention restores its operational condition, eliminating the initial cause of failures. Following this corrective measure, the converter operates for a greater number of hours before requiring the next overhaul, demonstrating the effectiveness of preventive and corrective maintenance in demanding environments.

Converter 3: This converter operates in an environment characterized by irregular load and frequent temperature fluctuations. Despite these conditions, the number of recorded failures is low, and its Health Index remains close to the initially predicted value. This suggests that adaptive designs and operational strategies of the converter have effectively mitigated risks associated with fluctuating operational conditions, ensuring reliable and consistent performance.

The analysis demonstrated how variations in boundary conditions affect the performance and longevity of the converters. The Health Index enabled proactive identification of converters at higher risk of failure, thereby optimizing predictive maintenance scheduling and ensuring continuous system operation.

This approach not only enhances the reliability of energy converters but also reduces maintenance costs and minimizes downtime. The combination of advanced monitoring and health assessment also lays the foundation for more effective integration of converters into digital twin systems, enabling precise simulations and high-accuracy failure predictions.

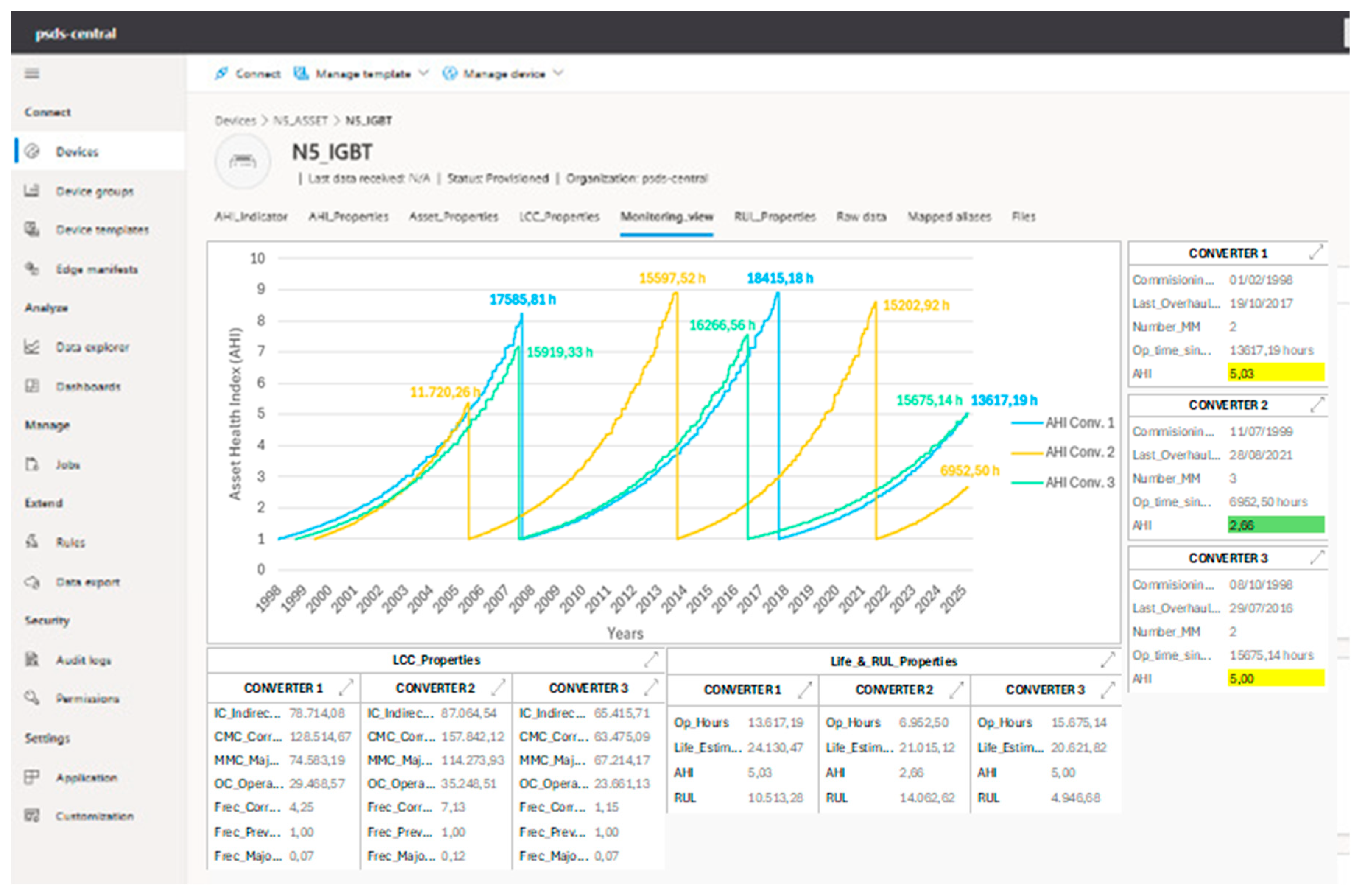

Figure 4 illustrates the development of the Health Index (AHI) calculation for the three converters analysed, as visualized through a Business Intelligence application.

Key observations from the AHI representation in

Figure 4 include:

Converter 1: This converter was the first to be commissioned, followed by Converters 2 and 3. Initially, an overhaul was scheduled for each converter after 10 years of operation. Consequently, the first overhaul was planned for Converter 1. However, it was decided to perform the overhaul on both Converters 1 and 3 to compare their levels of degradation, despite Converter 1 having approximately 2,500 additional operating hours. The results confirmed greater degradation in Converter 1, which began experiencing increasingly recurrent failures after surpassing 15,000 hours of operation. In contrast, Converter 3, with a similar number of operating hours, had not yet shown such failures.

Converter 2: Unlike the other converters, Converter 2 exhibited a higher level of degradation, accumulating more failures at an earlier stage. This necessitated advancing its first overhaul to approximately 12,000 operating hours. After the overhaul, the recurring failures were resolved. However, the degradation rate of Converter 2 remained higher compared to Converters 1 and 3. This was attributed to the more demanding operating conditions it was subjected to. Consequently, it became evident that the frequency of preventive maintenance and major overhauls for Converter 2 would need to be adjusted to ensure optimal performance.

Converter 3: The second overhaul for Converter 3 was carried out earlier than the second overhaul for Converter 1, despite both having accumulated roughly the same operating hours (~16,000 hours). Notably, the degradation in Converter 3 was greater than that in Converter 1. Following this second overhaul, Converter 3 demonstrated the capacity to sustain more operating hours. As a result, it was decided to extend the operating period of Converter 1 before scheduling its second overhaul.

Converter 2 (third overhaul): A third overhaul was performed on Converter 2 to address its accelerated degradation under high-stress conditions.

Current Monitoring Practices: Presently, the degradation status of the converters is closely monitored using the AHI as a key indicator. Risk levels are established based on the index, enabling informed decision-making regarding maintenance and operation.

7. Conclusions

This paper presented a structured data model designed to enable the integration of Asset Health Index (AHI) methodologies within Digital Twins for energy converters. The proposed model addresses the need for a systematic, scalable, and standards-aligned approach to asset health assessment in the context of digitalization and predictive maintenance. By organizing asset-related information into interconnected domains—covering asset definition, criticality, monitoring, intelligent management, and decision-making—the framework provides the necessary infrastructure to support real-time condition evaluation, reliability analysis, and risk-based maintenance planning.

The model was formalized using a Unified Modeling Language (UML) class diagram and implemented in a cloud-native architecture using Microsoft Azure services. This practical implementation demonstrates the model’s adaptability to real-world industrial environments, where scalability, interoperability, and automation are critical success factors. The integration of AHI into the Azure-based digital twin architecture facilitates continuous data ingestion, automated health index calculation, and visualization through business intelligence tools, enabling timely and informed decision-making.

A case study involving high-capacity DC/AC converters illustrated the application of the proposed framework under varying operational conditions. The results confirmed that the AHI provides meaningful differentiation in asset behavior over time, supporting the early detection of degradation, the optimization of maintenance schedules, and the extension of useful life. In particular, the study showed how environmental stressors, usage intensity, and maintenance history affect the health trajectory of identical assets, reinforcing the importance of contextualized asset data models.

The contributions of this work are threefold: (i) the development of a structured, standard-compliant data model tailored for AHI implementation; (ii) the demonstration of its deployment in a scalable digital architecture; and (iii) the validation of its effectiveness through empirical analysis. This integrated approach not only supports operational efficiency but also aligns asset management practices with sustainability and resilience goals, offering a robust foundation for digital transformation initiatives in the energy sector.

Future research will explore the integration of machine learning techniques to dynamically adapt AHI modifiers and improve predictive accuracy. Additionally, further work is needed to generalize the model to other asset classes and industry sectors, and to quantify the economic impact of AHI-based decision-making over the asset lifecycle. The continued convergence of digital twin technologies, cloud platforms, and advanced analytics will open new opportunities for autonomous and intelligent asset management systems.

Author Contributions

Conceptualization, J.F.G.F, E.C.F and A.C.M; methodology, E.C.F and A.C.M; software, J.F.G.F; validation, J.F.G.F, E.C.F and A.C.M; formal analysis, J.F.G.F, E.C.F and A.C.M; investigation, J.F.G.F, E.C.F and A.C.M; resources, A.C.M.; data curation, J.F.G.F, E.C.F and A.C.M; writing—original draft preparation, J.F.G.F, E.C.F and A.C.M.; writing—review and editing, J.F.G.F, E.C.F and A.C.M..; visualization, E.C.F.; supervision, J.F.G.F and A.C.M.; project administration, J.F.G.F and A.C.M.; funding acquisition, A.C.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been developed as part of the AMADIT Project (PID2022-137748OB-C32), funded by MCIN/AEI/10.13039/501100011033/FEDER, EU.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Adebayo, T.S.; Ullah, S. Towards a sustainable future: The role of energy efficiency, renewable energy, and urbanization in limiting CO2 emissions in Sweden. Sustainable Development 2024, 32, 244–259. [Google Scholar] [CrossRef]

- Viet, N.T.; Kravets, A.G. The New Method for Analyzing Technology Trends of Smart Energy Asset Performance Management. Energies 2022, 15, 6613. [Google Scholar] [CrossRef]

- Dashti, R.; Hosseini, A. Asset management optimization in smart grids. Environ Prog Sustain Energy 2022, 41, e13824. [Google Scholar] [CrossRef]

- Biswas, A.R.; Giaffreda, R. IoT and cloud convergence: Opportunities and challenges. In Proceedings of the 2014 IEEE World Forum on Internet of Things, WF-IoT 2014; pp. 375–376. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, J.; Kiritsis, D. The emergence of cognitive digital twin: vision, challenges and opportunities. Int J Prod Res 2022, 60, 7610–7632. [Google Scholar] [CrossRef]

- Ansari, S.; Ansari, A. Using IoT Enabled Predictive Maintenance to Enhance Business Operations: Benefits and Challenges. In Proceedings of the 7th Edition Global Conference on Wireless and Optical Technologies, 2024., GCWOT 2024. [Google Scholar] [CrossRef]

- Jamarani, A.; Haddadi, S.; Sarvizadeh, R.; Haghi Kashani, M.; Akbari, M.; Moradi, S. Big data and predictive analytics: A systematic review of applications. Artificial Intelligence Review 2024, 57, 1–77. [Google Scholar] [CrossRef]

- Cheng, X.; Chaw, J.K.; Goh, K.M.; Ting, T.T.; Sahrani, S.; Ahmad, M.N.; Abdul Kadir, R.; Ang, M.C. Systematic Literature Review on Visual Analytics of Predictive Maintenance in the Manufacturing Industry. Sensors 2022, 22, 6321. [Google Scholar] [CrossRef]

- Hafeez, M.A.; Procacci, A.; Coussement, A.; Parente, A. Challenges and opportunities for the application of digital twins in hard-to-abate industries: a review. Resour Conserv Recycl 2024, 209, 107796. [Google Scholar] [CrossRef]

- Mihai, S.; Yaqoob, M.; Hung D, V. , et al. Digital Twins: A Survey on Enabling Technologies, Challenges, Trends and Future Prospects. IEEE Communications Surveys and Tutorials 2022, 24, 2255–2291. [Google Scholar] [CrossRef]

- Friederich, J.; Francis, D.P.; Lazarova-Molnar, S.; Mohamed, N. A framework for data-driven digital twins of smart manufacturing systems. Comput Ind 2022, 136, 103586. [Google Scholar] [CrossRef]

- Teng, S.Y.; Touš, M.; Leong, W.D.; How, B.S.; Lam, H.L.; Máša, V. Recent advances on industrial data-driven energy savings: Digital twins and infrastructures. Renewable and Sustainable Energy Reviews 2021, 135, 110208. [Google Scholar] [CrossRef]

- Rico, M.; Taverna, M.L.; Galli, M.R.; Caliusco, M.L. Context-aware representation of digital twins’ data: The ontology network role. Comput Ind 2023, 146, 103856. [Google Scholar] [CrossRef]

- Meierhofer, J.; Schweiger, L.; Lu, J.; Züst, S.; West, S.; Stoll, O.; Kiritsis, D. Digital Twin-Enabled Decision Support Services in Industrial Ecosystems. Applied Sciences 2021, 11, 11418. [Google Scholar] [CrossRef]

- Frantzén, M.; Bandaru, S.; Ng, A.H.C. Digital-twin-based decision support of dynamic maintenance task prioritization using simulation-based optimization and genetic programming. Decision Analytics Journal 2022, 3, 100039. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Applied Sciences 2022, 12, 5727. [Google Scholar] [CrossRef]

- Walker, B. (2017) DNO COMMON NETWORK ASSET INDICES Health & Criticality-Version 1.1 VERSION CONTROL.

- Serra, J.; Crespo, A.; Gómez, J. (2019) Analysis of the impact of the Asset Health Index in a Maintenance Strategy.

- ISO 14224, 2016 - Petroleum, petrochemical and natural gas industries—Collection and exchange of reliability and maintenance data for equipment. https://www.iso.org/standard/64076.html.

- Alvanchi, A.; TohidiFar, A.; Mousavi, M.; Azad, R.; Rokooei, S. A critical study of the existing issues in manufacturing maintenance systems: Can BIM fill the gap? Comput Ind 2021, 131, 103484. [Google Scholar] [CrossRef]

- Lin S-W (2022) Industrial Internet Reference Architecture (IIRA).

- Frank, A.G. ; Mendes GHS, Ayala, N. F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol Forecast Soc Change 2019, 141, 341–351. [Google Scholar]

- Alonso del Valle, J.; Viera Pérez, J.C.; González Vega, M.; Anseán González, D.; García Fernández, V.M. ; Blanco Viejo CJ (2019) Sistemas de almacenamiento masivo de energía con baterías (BESS): Estado actual y tendencias de futuro. 2019. [Google Scholar]

- Watkins, C.B.; Varghese, J.; Knight, M.; Petteys, B.; Ross, J. (2020) System architecture modeling for electronic systems using mathworks system composer and simulink. AIAA/IEEE Digital Avionics Systems Conference - Proceedings. [CrossRef]

- Dollinger, D.; Rhein, J.; Schmiechen, K.; Holzapfel, F. (2021) Be Lean - How to Fit a Model-Based System Architecture Development Process Based on ARP4754 into an Agile Environment. AIAA/IEEE Digital Avionics Systems Conference - Proceedings. [CrossRef]

- Luz Martín-Peña, M.; Díaz-Garrido, E. ; Sánchez-López JM (2018) The digitalization and servitization of manufacturing: A review on digital business models. 27.

- Azure Digital Twins Documentation - Tutorials, API Reference|Microsoft Learn. https://learn.microsoft.com/en-us/azure/digital-twins/. 2025.

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput Ind 2019, 113, 103130. [Google Scholar] [CrossRef]

- Shen, C.; Kaufmann, P.; Hachmann, C.; Braun, M. Three-stage power system restoration methodology considering renewable energies. International Journal of Electrical Power & Energy Systems 2018, 94, 287–299. [Google Scholar]

- Lee, J.; Bagheri, B. ; Kao H-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. 2015. [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. International Journal of Advanced Manufacturing Technology 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Candón, E.; Crespo, A.; Guillén, A.; Gómez, J.; López, J. Asset Digitalization Strategy using IoT Platforms and Asset Health Model. IFAC-PapersOnLine 2024, 58, 216–221. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).