1. Introduction

Concrete modular construction involves manufacturing 3D modules in an off-site factory, transferring them to the site, and assembling them on-site using different modular connections. These modules are prefabricated as three-dimensional volumetric units prefinished with fixtures and fittings in a factory. These modules are individual room elements assembled and connected to form a complete building through inter-module connections. Modular construction has become increasingly popular recently, offering numerous advantages to the construction industry. These advantages include a speedy construction process, high-quality control, reduced on-site workload, minimal shuttering and scaffolding requirements, optimal use of materials, lower labour costs, sustainability, and a lower environmental impact [

1,

2]. Owing to the advantages of modular construction and its rapid development in recent times, there has been a significant shift in the research focus.

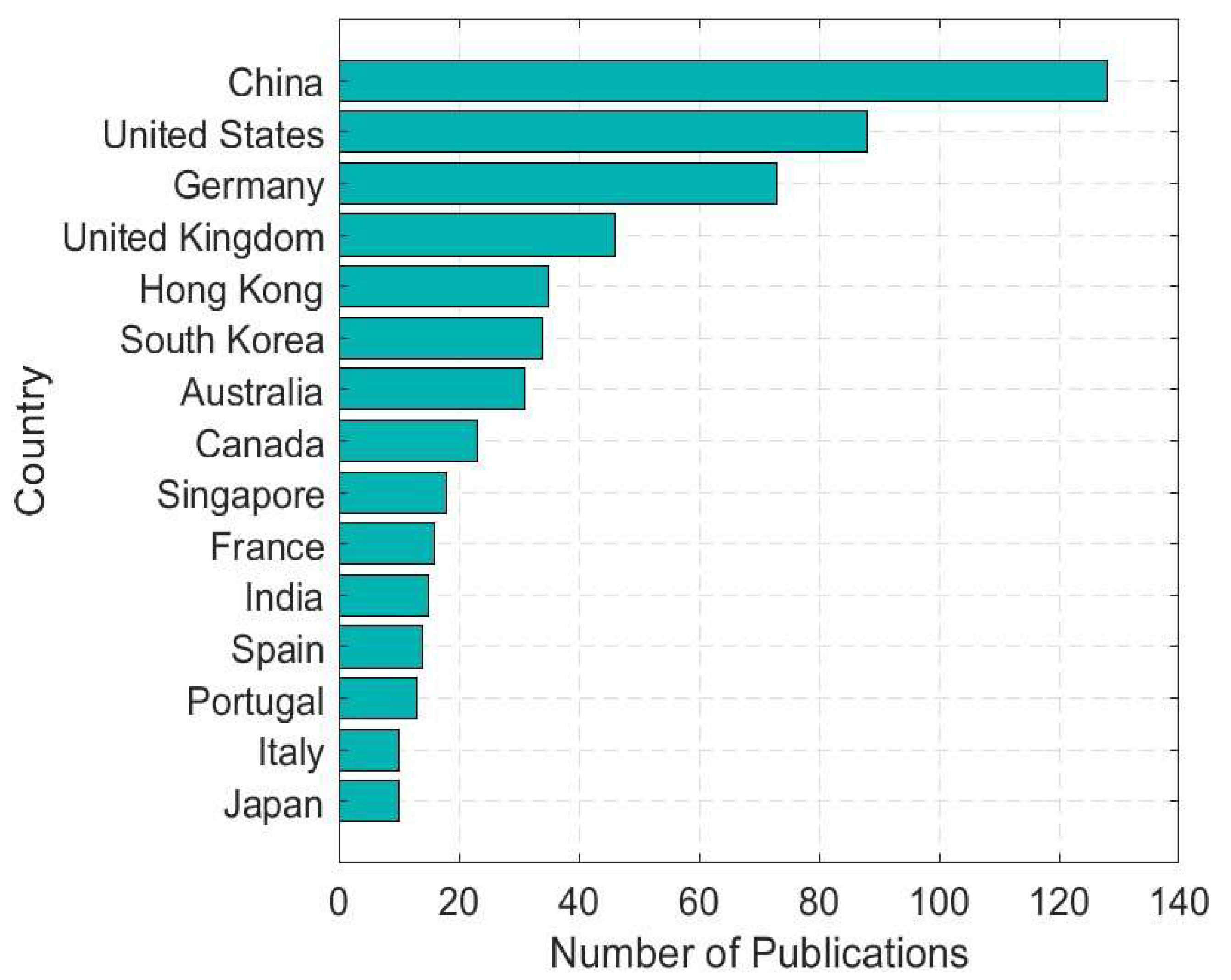

Globally, modular technology is garnering widespread application in the construction industry. The amount of prefabrication is significantly high in countries like China [

3,

4], the United States (U.S.) [

5], Germany [

6] and the United Kingdom (U.K.) [

7,

8]. There has been a significant shift in the construction industry, moving towards more off-site prefabrication and reducing on-site construction to accommodate the sustainability and labour demands [

9,

10,

11]. Although precast technology is widespread globally, modular construction has only gained attention in recent years, as evidenced by the increasing number of research articles published in this field, as shown in

Figure 1. China, the U.S., and Germany have published over 70 articles indicating their advancement in precast modular construction. The U.K., Hong Kong, South Korea and Australia have published over 30 articles on modular construction, showing the emerging trend in prefabricated construction in those countries [

12,

13,

14]. Following this descending trend, other countries have shifted their focus towards modular construction in recent years, reflecting this in their publications [

15,

16].

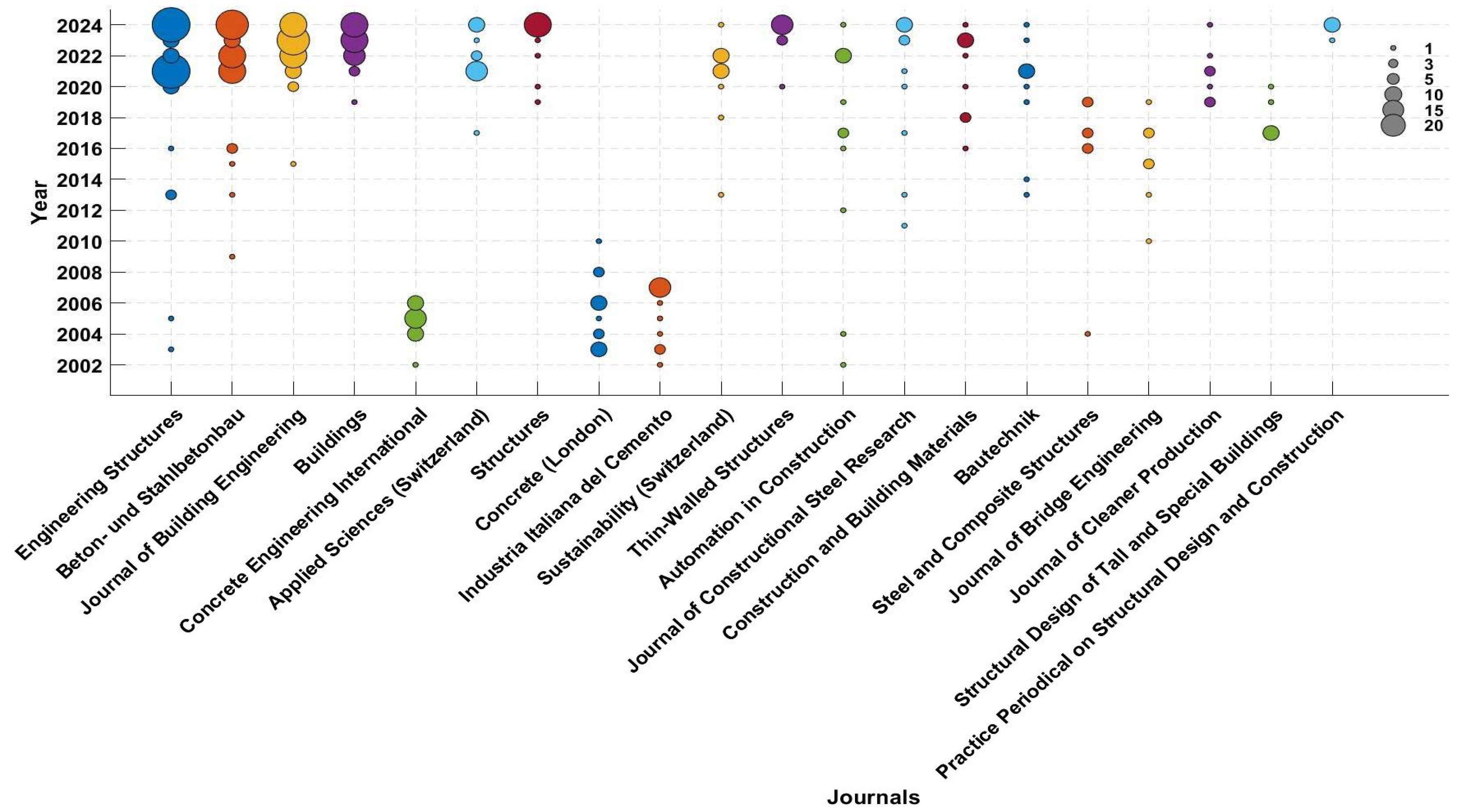

Figure 2 shows the top 20 publication sources based on the number of articles on concrete modular construction published from 2000. It can be seen that the leading publications on modular construction are from Engineering Structures, Beton- und Stahlbetonbau, Journal of Building Engineering and Buildings. A significant upward trend since 2020 shows the rapid development of modular construction in recent years.

Connections influence precast and modular constructions' structural performance, stability, and integrity. In contrast to monolithic construction, which inherently possesses continuity, modular and precast construction systems depend on connections to facilitate force transfer among discrete components. While substantial research has been conducted on connection systems in precast structures such as grouted connections [

17,

18], bolted connections [

19,

20], and hybrid connections [

20,

21], there remains a notable gap in analysing these connections specifically within the context of modular construction. Addressing precast structural elements is essential to bridge this gap, as the existing studies provide foundational insights into connection methodologies and their load transfer mechanisms. This serves as a basis for the design of connections and their implementation in modules, which form the structural systems in modular construction. These connections can be collectively categorised as composite connections, as they often involve the interaction of distinct materials such as steel and grout or concrete collaborating to achieve structural continuity. This composite interaction improves modular construction's strength, ductility, and installation efficiency. Recent research has involved experimental and numerical evaluations to study the composite connections under different loading scenarios, emphasising lateral cyclic, monotonic, and pushover load tests to analyse their capacity for bearing loads, ductility, and failure patterns, providing the basis for assessing their applicability in modules. This paper thoroughly reviews these investigations and assesses the structural performance of composite connections, offering insights into their feasibility, practicality, and applicability within modular construction contexts. From this point onward, the discussion on connections will primarily address them within the context of precast structural elements, providing a comprehensive foundation for evaluating their applicability in modular construction systems.

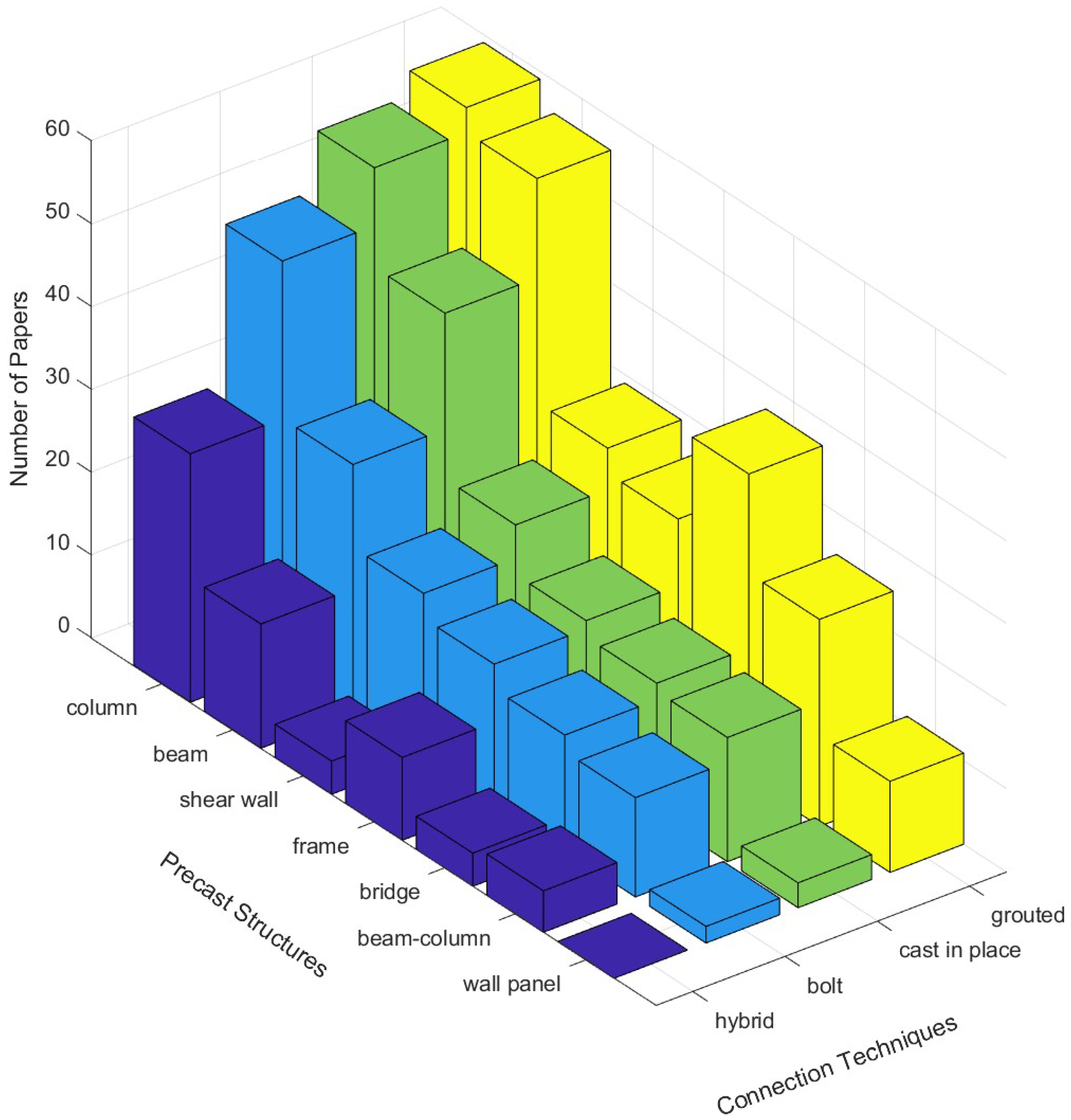

A comprehensive analysis of studies from the previous two decades was conducted, focusing on precast structural components and their connection methodologies to comprehend the recent advancements in precast technology and modern construction methodologies. The selection criteria involved organising research publications based on keywords relevant to precast structural components encompassing walls, beams, columns, beam-column joints, frames, and bridges. The resultant papers were then further categorised according to the connection methodologies implemented, including grouted couplers, bolted connections, cast-in-place joints, and hybrid systems.

Figure 3 illustrates the distribution of these studies, emphasising the prevalence of various connection techniques across distinct precast structures.

Among the diverse connection methodologies, grouted coupler connections have been extensively investigated. These connections are frequently researched due to their effective force transmission, ease of implementation, and compatibility with seismic-resistant designs [

21]. Similarly, bolted connections have been thoroughly examined, particularly for their benefits in rapid assembly, structural stability, and potential for reuse. They are particularly suitable for modular construction and are efficiently driven by prefabrication.

Conversely, cast-in-place joints predominantly appear in investigations as a benchmark for comparative analysis against precast alternatives. These studies often evaluate variances in stiffness, failure modes, and construction feasibility, reinforcing the benefits of precast solutions regarding quality control and construction efficiency. The significance of hybrid connections has also garnered attention in recent years, integrating mechanical fasteners, grouted sleeves, or partially cast-in-place elements to enhance structural integrity and adaptability [

22]. Although the body of research on hybrid systems remains relatively limited compared to well-established methodologies, the increasing emphasis on these techniques indicates a rising interest in superior connection solutions to improve seismic resilience and construction efficiency.

The analysis reveals that grouted and bolted connections continue to lead research efforts due to their structural dependability and extensive application within the industry. At the same time, hybrid systems signify a burgeoning trend. Investigations concerning cast-in-place joints primarily function as benchmarks, illustrating the progression from conventional monolithic construction to precast modular solutions. The distribution of research highlights the ongoing evolution of connection technologies, concentrating on enhancing efficiency, resilience, and adaptability in precast construction.

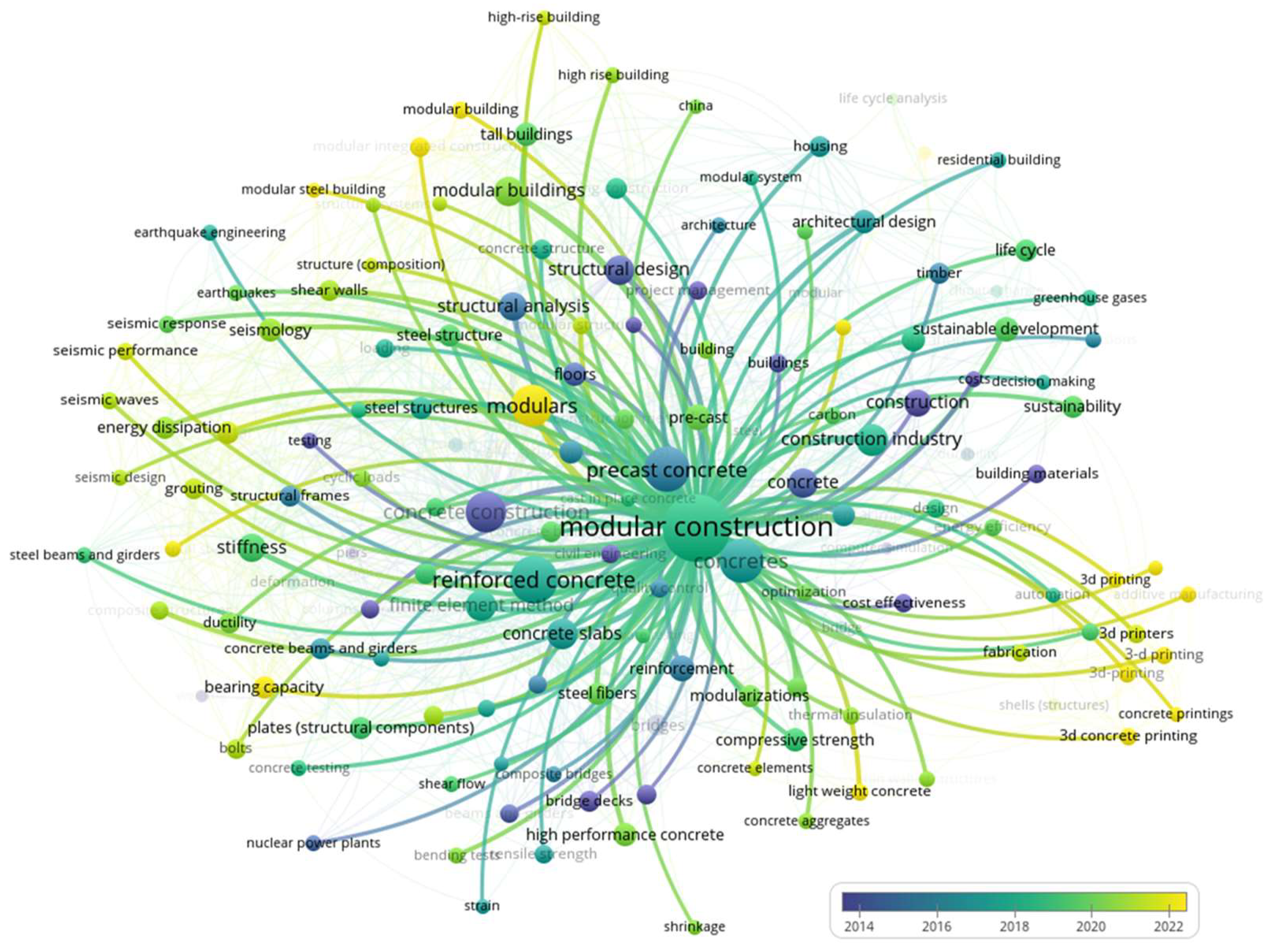

Cluster analysis of keyword co-occurrence within modular construction literature elucidates the interrelation and prevalence of terminology utilised in this domain, as shown in

Figure 4. The visualisation of this network, depicting nodes as keywords and edges as their co-occurrence, underscores significant trends spanning from 2014 to 2022. The size of the nodes signifies the frequency of terms, while the colour gradient transitioning from blue to yellow signifies the temporal aspect, thus illustrating the evolution of keyword utilisation. Fundamental keywords like 'modular systems,' 'cementitious materials,' 'reinforced concrete techniques,' and 'precast elements' appear vital, emphasising their significance in scholarly debates.

Following 2020, yellow lines denote connections to newly emerging key terms, including 'seismic performance,' 'bearing capacity,' and '3D printing.' In contrast, the blue and green lines from 2014 to 2020 correspond to foundational concepts such as 'structural design,' 'building materials,' and 'bridge decks.' This transition reflects the evolving landscape of research focus and novel technologies' adaptation to contemporary challenges.

This shift in research focus is accentuated in recent years by the rise of significant terminology pertinent to seismic performance within modular construction, as illustrated in

Figure 4. Seismic performance is paramount, particularly in areas prone to seismic activity. Achieving the seismic resilience of concrete modular systems necessitates tackling the distinctive challenges that prefabricated volumetric units and their interconnections present. Advanced research is focused on refining connection methods to enhance energy dissipation and structural stability during seismic occurrences. For example, novel approaches such as ductile connectors [

17,

23,

24] and bolted joints are under investigation to bolster the capacity of these systems to absorb and dissipate seismic forces, thereby minimising the likelihood of structural failure. Integrating seismic isolation mechanisms into modular edifices is another promising strategy to alleviate seismic impacts and enhance overall safety [

25]. s the corpus of research expands, it becomes essential to weave these technological innovations into the design and execution of modular construction to guarantee that these systems not only fulfil but surpass requisite safety criteria.

This study focuses on various connection techniques adopted in various precast elements. The connections range from simple bolted connections to more complex composite connections, thus illustrating a spectrum of design intricacies to improve performance demands, such as in scenarios of extreme seismic demands. Emphasis is also placed on Non-Destructive Evaluating algorithms and techniques [

26] that can assess the performance of composite connections both throughout their service life and after seismic events. A cradle-to-grave understanding of the performance of composite connections can be achieved by integrating health monitoring devices. Such an approach represents an enhancement over traditional non-destructive evaluation (NDE) techniques [

27], providing continuous, real-time monitoring and deeper insights into the health of composite connections throughout their lifecycle.

The rest of the manuscript is organised as follows:

Section 2 explores how modular construction distinguishes itself from other precast techniques and their advantages.

Section 3 reviews the design methodology and the factors involved in the design process of modular construction.

Section 4 discusses experimental studies on connections across various precast structures, comparing them within modular construction scenarios.

Section 5 presents discussions and recommendations for future research, followed by section 6, which concludes the study.

2. Materials and Methods

2.1. Types of Precast Systems

In prefabricated construction, precast systems are crucial in influencing contemporary building practices. Among these, precast beams and columns are fundamental components characterised by their one-dimensional form. These elements are produced in specialised off-site facilities, ensuring precision and quality. They are then transported to the construction site, where they are assembled, providing essential support and structural integrity to various building designs [

28,

29].

Similarly, precast slabs and walls serve as critical two-dimensional panels that facilitate the creation of expansive and functional spaces within buildings. These components undergo rigorous quality checks in controlled, off-site environments before being transported for on-site assembly [

30]. Their role is integral in modern architectural designs' floor and wall systems, highlighting their importance in enhancing construction efficiency and ensuring consistent quality [

31,

32].

Regarding three-dimensional construction, precast concrete modules represent a sophisticated evolution in prefabricated building techniques. These modules are meticulously prefinished in dedicated factories, integrating extensive automation to enhance precision and efficiency [

33]. Upon transportation to the construction site, they are assembled into permanent structures. This method is regarded as the pinnacle of prefabricated construction due to its high precast ratio and streamlined assembly process [

34].

Table 1 presents various levels of precast systems that are currently in practice. The levels range from raw materials and individual components to sophisticated modules fully integrated building systems reflecting the evolution and complexity of precast construction techniques. Understanding these varied precast systems lays the groundwork for an extensive examination of how modular construction measures against alternative precast methods, especially regarding efficiency, cost-effectiveness, and structural soundness. This comparative assessment will clarify each strategy's distinct benefits and possible drawbacks, offering a well-rounded view of contemporary prefabrication techniques.

2.2. Comparison of Modular Construction with Other Precast Techniques

Modular construction is distinguished by its unique benefits compared to other precast construction methodologies. Conventional precast systems often necessitate supplementary components for structural integration; however, modular construction generally incorporates these components within the modules [

35]. This methodology significantly improves structural performance and simplifies construction, enhancing efficiency and effectiveness. Regarding seismic performance, precast concrete modules demonstrate greater resilience when compared to steel modules, rendering them especially beneficial in areas susceptible to substantial seismic events [

36], such as New Zealand, Japan, and Chile, where the preservation of structural integrity is paramount.

Considerations regarding weight also play a crucial role in distinguishing these systems. While precast concrete modules are typically heavier than their steel counterparts, which may present challenges during lifting operations for taller edifices, utilising specialised construction equipment can effectively address these hurdles [

37]. Such machinery is engineered to accommodate the differences in weight, ensuring the successful execution of projects despite the added weight.

Furthermore, modular construction exhibits heightened effectiveness in high-rise structures featuring multiple repeated units [

37], though high-rise modular buildings remain comparatively uncommon. This scarcity can be attributed to a limited comprehension of their structural responses to lateral forces, such as seismic and wind loads, essential for guaranteeing safety and stability.

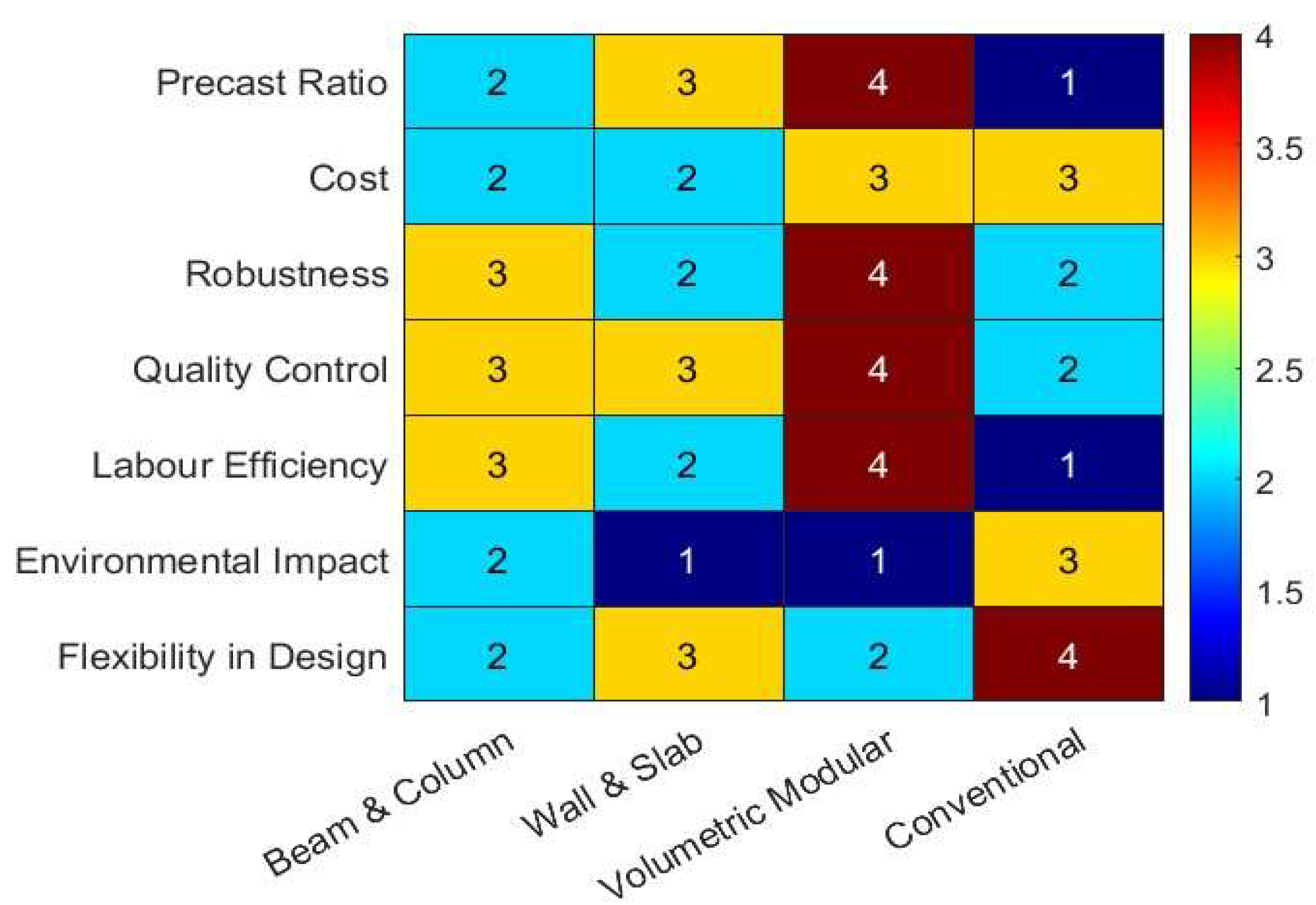

A heatmap (

Figure 5) visualisation is utilised, standardising the performance of Beam & Column, Wall & Slab, Volumetric Modular, and Conventional construction on a continuum from 1 (Low) to 4 (Very High) to provide a more precise comparison of these construction methodologies. The qualitative evaluations were established based on knowledge gleaned from a comprehensive literature review, considering critical performance metrics: Precast Ratio, Cost, Robustness, Quality Control, Labour Efficiency, Environmental Impact, and Design Flexibility. The qualitative scoring is comprehensively synthesised from scholarly investigations, comparative studies, and practical applications [

38,

39,

40,

41,

42,

43,

44].

For Precast Ratio, the score indicates the degree of precast component employment, with higher scores signifying a stronger dependence on precast techniques. Cost assessments considered material, labour, and transportation costs, where higher scores denote increased cost-effectiveness. Robustness evaluations concentrated on structural strength and longevity, granting higher scores to techniques exhibiting exceptional long-term performance. Quality Control ratings were based on the accuracy and consistency achieved in offsite production, with higher scores signifying superior quality management. Labour Efficiency ratings reflect the effectiveness of labour deployment, assigning higher scores to techniques that require less onsite labour. Environmental Impact ratings evaluated aspects such as material waste and energy use, with higher scores indicating maximum ecological footprint. Lastly, Design Flexibility assessed the adaptability of each construction technique to diverse architectural styles, with higher scores reflecting increased flexibility.

The qualitative evaluations for each criterion were converted into quantitative scores on a scale of 1 to 4, ensuring uniformity and objectivity in comparing the various construction techniques. The scoring methodology was based on detailed benchmarks from comprehensive literature and case studies [

38,

39,

40,

41,

42,

43,

44]. For instance, a score of 4 was conferred to methodologies that consistently exhibited superior results across multiple studies, whereas a score of 3 denoted elevated performance with minimal restrictions or limitations. Similarly, scores of 2 and 1 were allocated based on recognised challenges or decreased efficacy in particular contexts. For example, the score of the Labour Efficiency criterion encompassed quantifiable indicators such as labour hours saved and deployment effectiveness. In contrast, the Environmental Impact was based on material wastage and energy consumption data. These methodical evaluations were designed to reduce subjectivity and provide stakeholders with an equitable comparison of the methodologies.

The Precast Ratio received the highest Volumetric Modular Construction (4) rating due to its prefabricated characteristics. At the same time, Beam & Column and Wall & Slab systems garnered moderate scores due to their substantial on-site assembly requirements. Conventional construction (1), characterised by minimal use of precast components, was assigned the lowest rating. Financial considerations favoured Wall & Slab and Beam & Column (2) because their reduced initial investment relative to Volumetric Modular (3) necessitated enhanced manufacturing precision and transportation logistics. Robustness was rated highest for Volumetric Modular construction (4) since its prefabricated units provide superior structural integrity when adequately connected. At the same time, other precast methodologies exhibited variability depending on their reinforcement and connection techniques.

Quality Control and Labour Efficiency demonstrated that Volumetric Modular construction surpassed alternative methods, profiting from regulated factory conditions and diminished site labour requirements. In contrast, Conventional construction received the lowest score in Labour Efficiency due to its considerable demands for an on-site workforce. Environmental Impact assessments have shown that Volumetric Modular and Wall & Slab systems obtained the lowest ratings (1), indicating lesser material usage and transportation needs. Beam & Column construction earned a moderate rating (2), whereas Conventional construction displayed the most significant environmental effects (3) as a result of its higher material consumption and on-site operations.

Design Flexibility, an essential element of architectural adaptability, was rated highest for Conventional construction (4), trailed by Wall & Slab (3) due to their enhanced capacity for alterations. Limited by its prefabricated nature, Volumetric Modular construction obtained a moderate score (2), illustrating a compromise between efficiency and adaptability.

This comparative investigation underscores each precast methodology's unique strengths and weaknesses. While Beam & Column and Wall & Slab strategies compromise efficiency and flexibility, Conventional construction retains a high degree of adaptability but lacks the advantages associated with precast integration. Among all approaches, Volumetric Modular construction stands out as the most sophisticated method, excelling in precast efficiency, labour optimisation, and structural resilience. Despite its elevated initial expenses and restricted design flexibility, its exceptional quality control, expedited construction timelines, and durability render it an optimal choice for contemporary, large-scale, and high-performance building endeavours.

To further assess modular construction thoroughly, it is vital to examine this approach's myriad benefits, particularly regarding speed, cost-effectiveness, quality assurance, and environmental sustainability. These advantages highlight the potential of modular construction to transform the building sector.

2.3. Advantages of Modular Construction

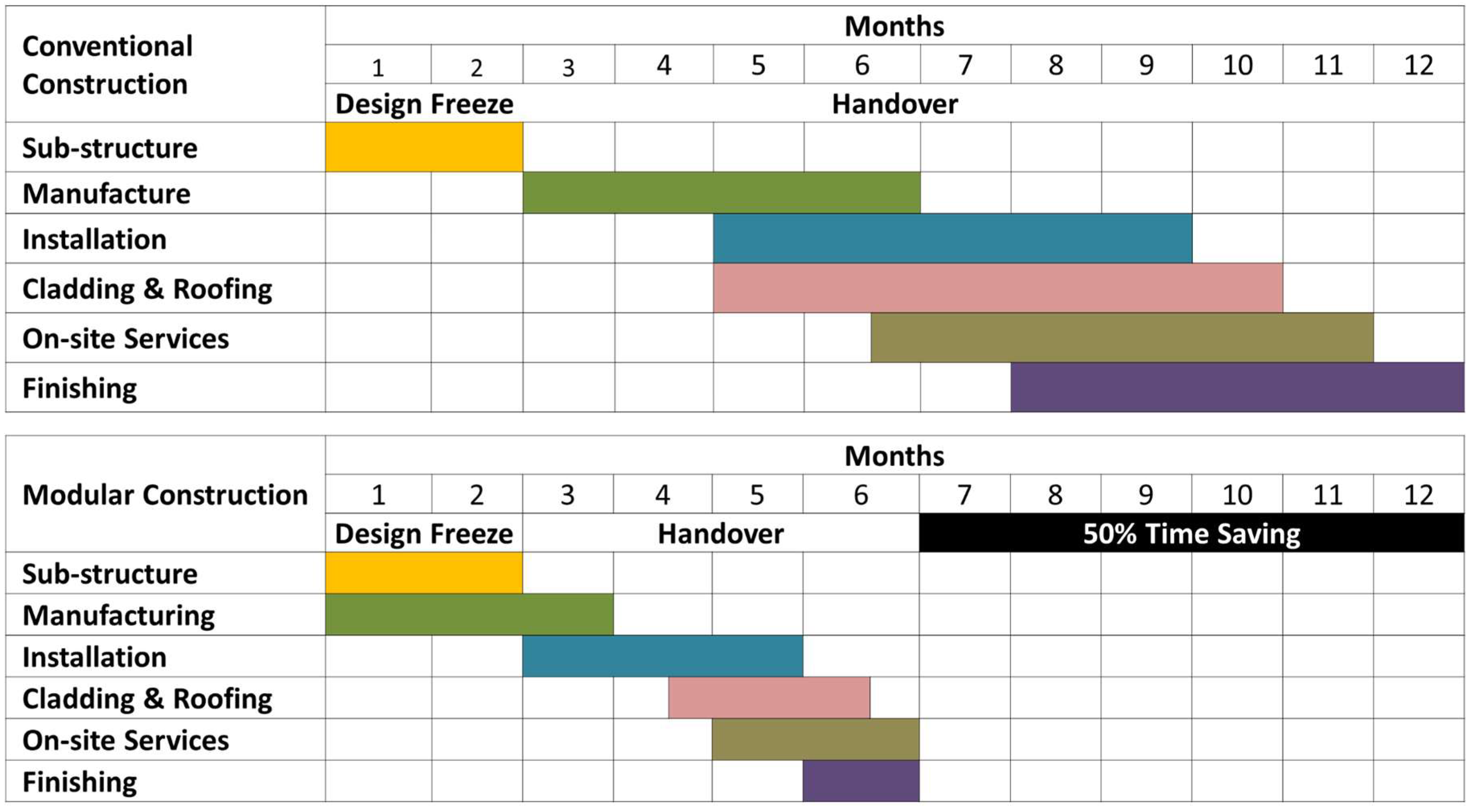

Modular construction methodologies present numerous advantages when compared with conventional cast-in-situ techniques. Such advantages encompass expedited construction durations, financial savings, enhanced labour efficiency, and ecological benefits. Modular construction can reduce project timelines by approximately 50% [

45]. This reduction is feasible due to the simultaneous nature of off-site manufacturing and on-site assembly, accelerating the overall construction timeline. The comparative analysis of construction timelines (

Figure 6) illustrates that modular construction can significantly reduce the duration required compared to traditional methodologies.

Beyond the aspect of time efficiency, modular construction also proves to be financially advantageous. It can potentially lower total construction expenditures by nearly 20% [

45]. This financial efficiency arises from mass-producing modules within a controlled factory environment, reducing labour costs and minimising material waste.

Labour efficiency represents another critical advantage. Incorporating automation and robotics in manufacturing processes lessens the reliance on manual labour. This advancement assists in alleviating labour shortages and addressing the challenges posed by an ageing workforce within the construction sector. Modular techniques are well-suited to navigate these labour dynamics, rendering them essential for contemporary construction practices.

The environmental advantages associated with modular construction are also noteworthy [

46]. This approach can diminish on-site waste by as much as 90%. Such a reduction fosters sustainable building practices and adheres to prevailing environmental standards to mitigate ecological footprints. These advantages subsequently pave the way for innovative design methodologies. As modular construction continues to evolve, it increasingly aligns with design principles that prioritise efficiency and sustainability. Understanding these design considerations is vital for fully harnessing the capabilities of modular techniques in contemporary construction initiatives.

3. Area of Research

3.1. Design of Modular Buildings

Modular construction utilises specific design frameworks to ensure strong and efficient structures, notably the Modular Equivalent Frame Method (MEFM) and the Equivalent Shear Wall Method (ESWM). The MEFM focuses on designing two-way slab systems supported by columns, creating two-dimensional frames and adjusting column stiffness to match slab conditions, allowing for separate gravity load analyses [

47]. This method preserves wall volume within concrete modules while ensuring the structural integrity of beams and columns.

The ESWM designs modular buildings for lateral loads, notably from seismic events, conceptualising the structure as vertical shear walls for stability. It allocates lateral loads based on wall stiffness and evaluates shear forces and bending moments to ensure load capacity, thus protecting the structure and its occupants. While MEFM analyses gravity loads for slabs, ESWM targets lateral loads with an emphasis on seismic resistance, with MEFM breaking modules into frames for analysis and ESWM treating the structure as shear walls for lateral load response [

48].

These frameworks significantly impact the comprehensive design and assembly of modular structures. Crucial aspects, including materials, arrangement of modules, hoisting and installation processes, and connections, are vital to guarantee the effectiveness and sustainability of modular construction practices. Grasping these components is imperative for enhancing the design and execution of modular techniques within construction initiatives.

3.2. Design Considerations in Modular Construction

The design of modular constructions involves numerous essential elements, each of which is pivotal in guaranteeing the efficacy and productivity of the building process. These elements comprise the choice of materials, arrangement of modules, methods of installation, and the nature of connections.

3.2.1. Material

The primary factor involved in the mix design of concrete used in modules is the demoulding strength. The modules in the off-site factory are generally de-moulded after 12 to 24 hours of casting so that another module is ready for casting, facilitating the rapid manufacturing process of modular construction [

1]. The typical demoulding strength of concrete required and the strength of concrete at 28 days is given in

Table 2. It is seen that the demoulding strength is generally 50% of that of the required 28 days of strength. Rapid hardening cement, steam curing, and electrical heating are used to accelerate the early age strength of concrete during the manufacture of concrete modules. Self-Compacting Concrete (SCC) has been increasingly used in modular construction as it provides better finishes to walls and reduces the use of vibrators.

3.2.2. Layout of Modules

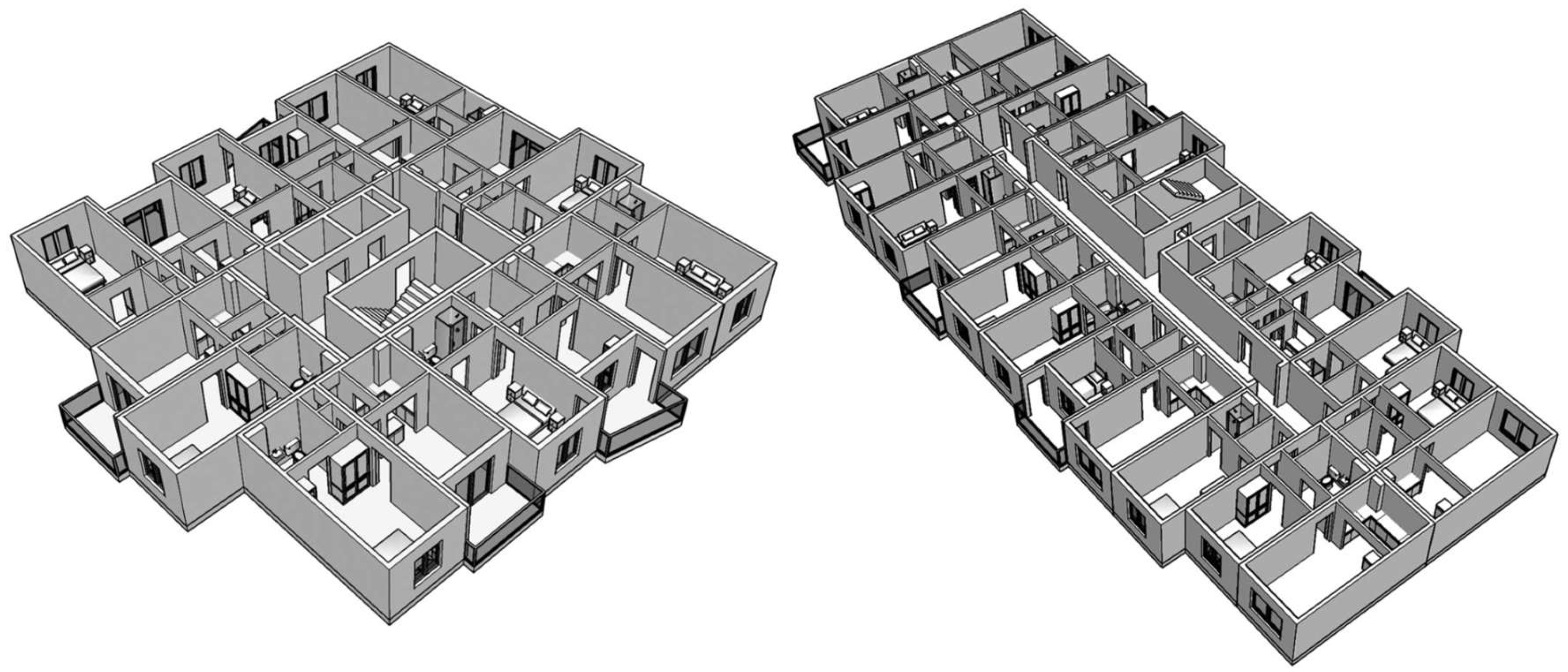

The design of the layout of modules is mainly affected by the size, modularisation, weight of the module and ease of transportation. The size of the module and modularisation of the building should be designed with coordination between the designer and module manufacturer so that the module formwork moulds are used efficiently. Proper vertical alignment of load-bearing walls should be ensured while designing the module layout. Generally, two methods of module layout are adopted in modular construction: (i) cluster of modules and (ii) corridor arrangement of modules as shown in

Figure 7 [

37]. The cluster configuration entails the organisation of multiple modules surrounding a central core or communal area, typically for functions such as shared amenities, stairways, or elevators. This design is frequently employed in residential or hotel buildings, where modules can effectively utilise common spaces while preserving structural efficiency. Cluster configurations provide compact designs and reduce the necessity for extensive interconnections between modules. The corridor configuration of modules presents a linear design, with modules arranged along a corridor or passageway. This layout is favoured in institutional constructions, such as schools and hospitals, where accessibility and circulation are prioritised. Corridor configurations guarantee uninterrupted connectivity between modules and enhance the straightforward incorporation of services such as heating, ventilation, air conditioning (HVAC), plumbing, and electrical systems along the corridor axis.

3.2.3. Lifting, Transportation and Installation

Installation is a key aspect of modular technology. Design considerations for installation include the crane capacity at the precast yard and on-site, transport, and access to the site [

49]. Serviceability limit checks should be performed to prevent cracks in the concrete slab wall distortion during handling and transporting. The lifting points must be strategically positioned so that sufficient bond anchorage can be developed to hoist the entire module safely and that the load distribution to all lifting points is uniform [

50]. A steel collar frame is used to hoist the module so that the module would not be subject to inclined forces from the lifting wires.

Logistics for module transportation from factory to site determines each module design's maximum size and volume, affecting the number of modules to complete the layout design. The modules' size is finalised so they can be transported on public roads.

The handling stresses caused by dynamic forces during handling, lifting and erection are considered in the flexural design of the modules. Load factors are to be applied to the self-weight of the module to allow for the safe handling, transportation and erection of modules (

Table 3). During transportation, a higher load factor of 1.5 is applied due to increased vibrations and impact forces encountered on the road. In contrast, yard handling and erection require a load factor 1.2 to account for smaller dynamic effects during lifting and positioning. These load factors are integral to design calculations, ensuring the structural integrity of the modules is preserved across all stages and safeguarding against damage during handling and assembly. This underscores the significance of accounting for dynamic effects in modular construction to mitigate risks associated with handling and installation.

3.2.4. Connections

Connections are the key elements in modular buildings, providing structural integrity by connecting the modules horizontally and vertically. Three main types of connections are involved in modular construction: (i) module-to-foundation connection, (ii) module-to-module connection, and (iii) joints within the module.

Module-to-module interconnections represent a crucial aspect of modular construction, enabling the interaction between complete 3D modules or "cells" to maintain structural integrity. Conversely, prefabricated construction generally consists of connections between singular precast structural components, such as slab-to-wall or wall-to-wall linkages. Although this review predominantly emphasises modular construction, the studies reviewed throughout are primarily on investigations concerning connections among individual precast components. Given the limited research pertaining to connections in concrete modules, this paper examines the attributes of various connection methodologies in precast systems to assess their appropriateness for implementation in modular construction frameworks.

The connection between the vertical modules is crucial for structural behaviour, especially in high-rise buildings. They directly affect the building stiffness and its corresponding response under the wind, seismic and lateral design action conditions [

51]. The horizontal module connection forming the floor diaphragm contributes to building stiffness. In particular, the peripheral and internal ties shall be provided per the Building Code Requirements [

52]. The modules should be laterally connected and designed to effectively transfer the horizontal forces to the building's lateral load-resisting system. The connections are designed based on the tensile and shear stresses at the joints, according to clause 4.9.4 of IS.11447:1985 [

53] Vertical and horizontal connections are designed as keyed joints per Indian standards, according to clause 11.7.5 of AS 3600:2018 as per Australian standards [

54] and according to clause 5.3.7. of BS.8110 as per British standards [

55]. Further details about different types of connection systems are presented in the next section.

3.3. Connection Techniques in Precast Systems

In precast construction, connections are vital for ensuring the structural integrity and performance of the assembly. Various techniques, including dry, wet, and hybrid connections, offer distinct advantages and have specific failure mechanisms. Understanding the methodologies of these connection techniques in precast systems is crucial, as they provide valuable information for the development of dependable connection strategies for modular construction, in which similar performance is required.

3.3.1. Dry Connections

Bolted connections, called dry connections, involve bolts to unite precast elements. Their rapid assembly and disassembly make them especially suitable for temporary structures. Nevertheless, their rigidity may be inferior to that offered by traditional methods. Bolted connections facilitate load transfer through friction and bearing between the bolt and the joined elements, effectively distributing shear forces [

19] both laterally and vertically [

56]. Standard failure modes include bolt yielding, thread stripping, or bending of the bolts [

57]. Embedded steel plates, secured by bolts within precast components, simulate monolithic connections and improve performance, particularly in seismic regions [

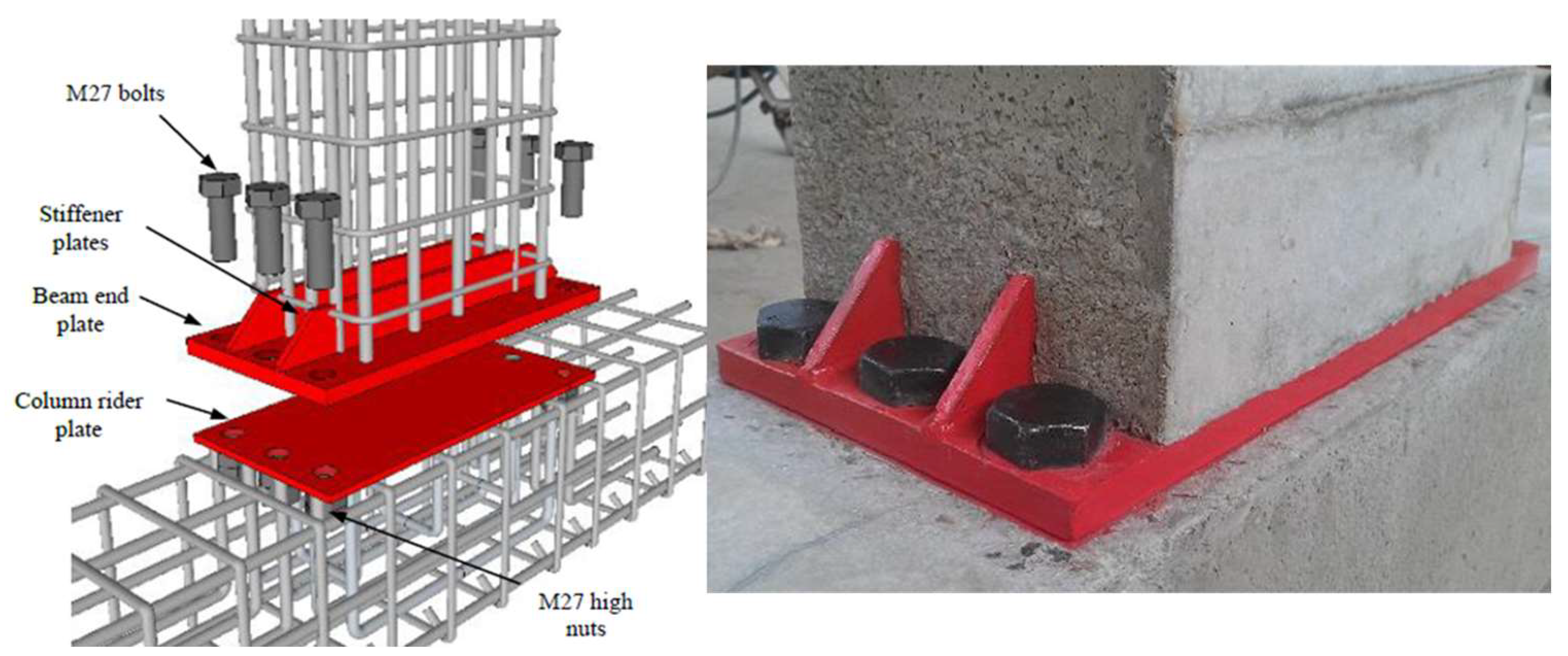

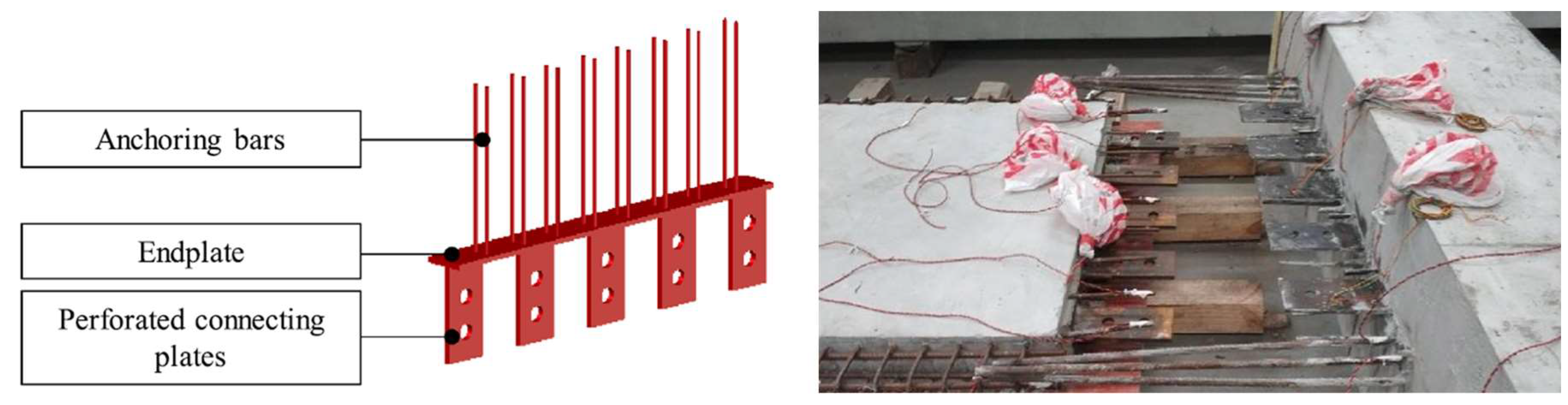

58]. Failures may arise from the yielding of the steel plates or bolts or buckling caused by significant compressive loads. Typical bolted connections, with and without embedded steel plates, are presented in

Figure 8 and

Figure 9. It can be seen from these figures that bolted connections primarily rely on steel plates and bolts for load transfer. In contrast, embedded plate connections integrate anchoring bars and embedded plates to enhance structural integrity. Given their rapid assembly and disassembly capabilities, dry connections have significant potential for adaptation in modular construction, especially for scenarios requiring efficient on-site assembly.

3.3.2. Wet Connections

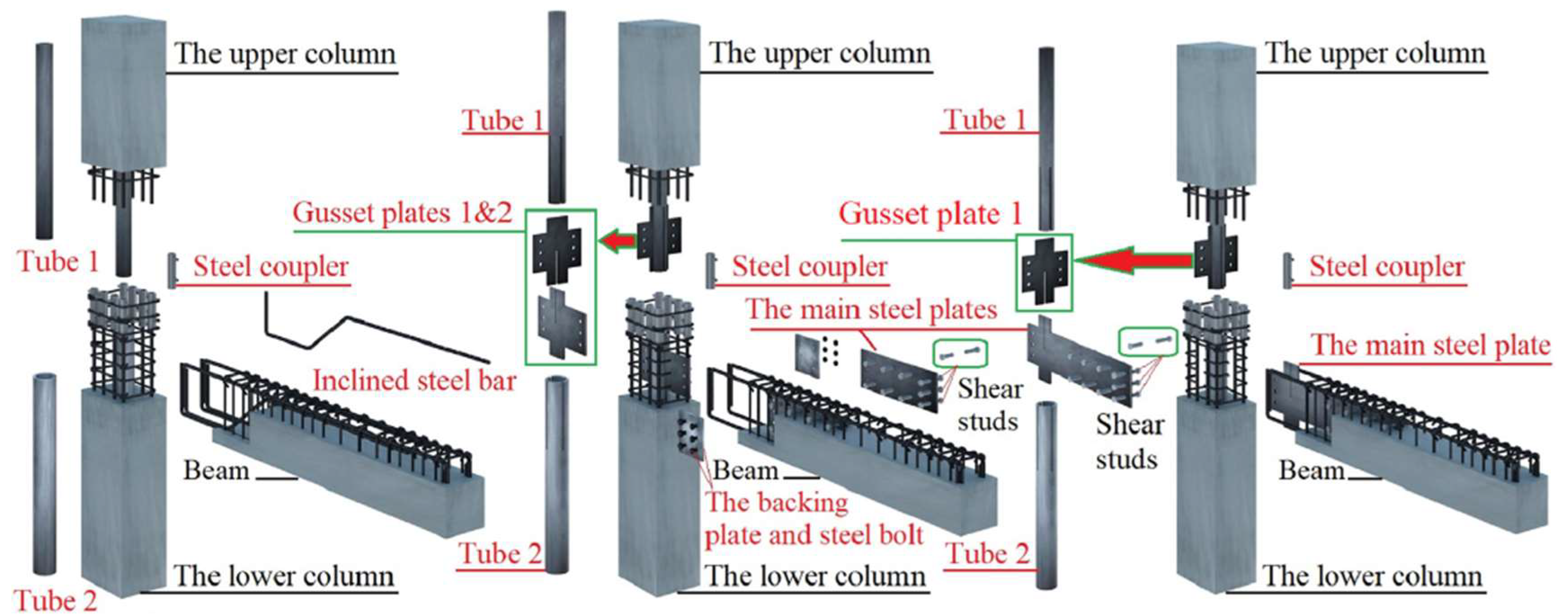

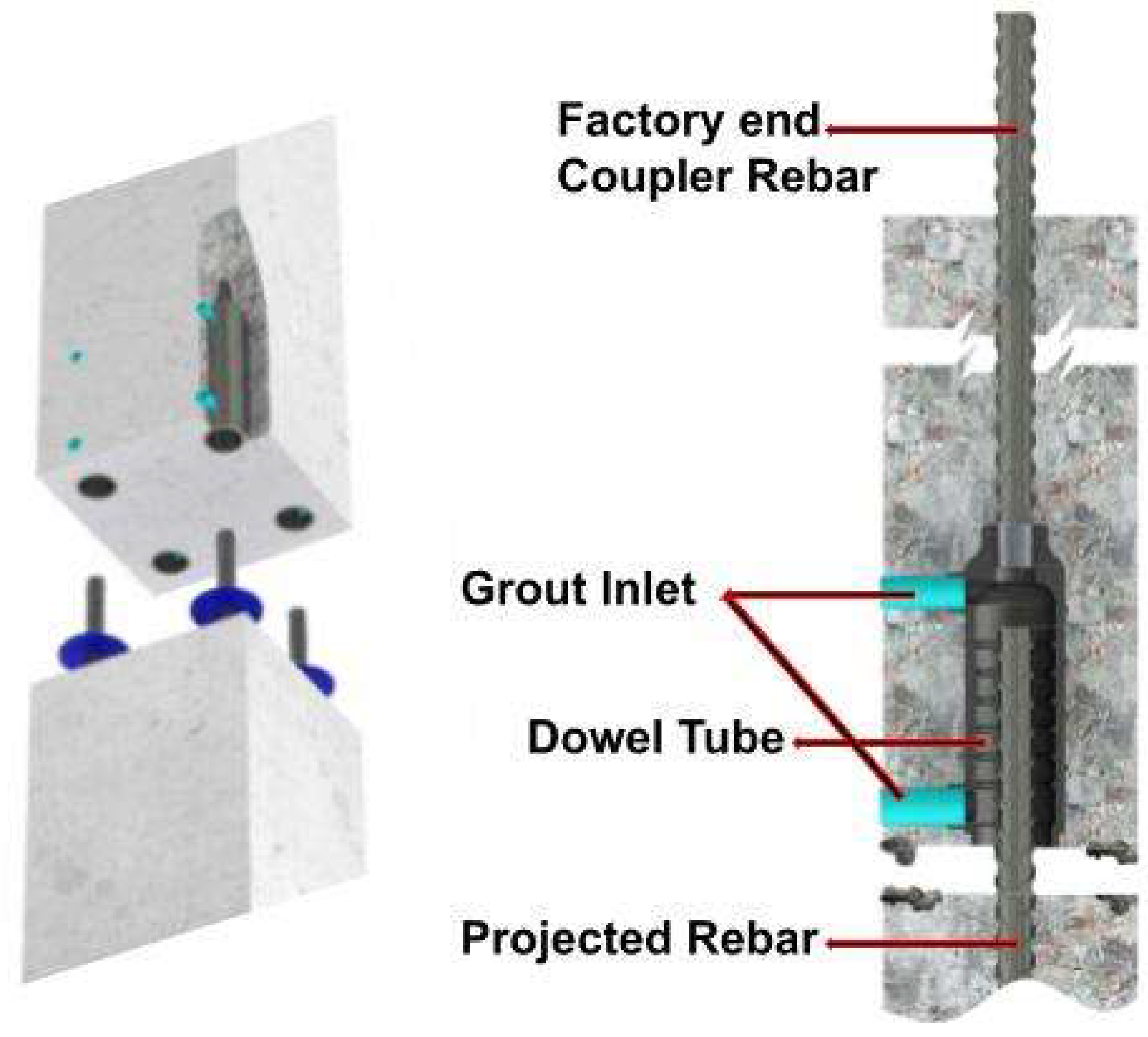

Grouted sleeve couplers connect longitudinal steel bars within precast elements as shown in

Figure 10. They augment stiffness and strength near the joint, thereby imitating monolithic connections during seismic occurrences. Failures typically result from yielding steel bars or grout or cracking surrounding concrete when subjected to high loads [

18]. Cast-in-situ portions entail casting concrete at joints after the assembly of precast elements, ensuring reinforcement continuity and bolstering structural integrity. Possible failure scenarios encompass cracking cast-in-situ concrete, yielding the reinforcement bars, or bond failure between precast and cast-in-situ concrete elements [

60]. As shown in

Figure 11, the hybrid connection system employs steel couplers, gusset plates, and primary steel plates to interconnect precast elements. The figure further delineates the incorporation of inclined steel bars, shear studs, and backing plates, which collectively improve load transfer efficiency, ductility, and seismic resilience. This exemplifies the intricacy and durability of hybrid connections in precast construction by illustrating the coordinated function of various steel components in effectively distributing loads and mitigating localised failures under elevated stress conditions. By offering enhanced strength, stiffness, and ductility, hybrid connections could be highly beneficial for modular construction in high-rise applications, where superior load transfer and seismic resilience are critical.

3.3.3. Hybrid Connections

Incorporating steel sections, whether or not complemented by bolts, to connect precast elements provides superior seismic performance in strength, stiffness, and ductility. This approach is particularly advantageous for high-rise constructions. Failures commonly arise from yielding steel sections or bolts, buckling under compressive forces, or cracking within the surrounding concrete [

61]. As shown in

Figure 11, the hybrid connection system employs steel couplers, gusset plates, and primary steel plates for the interconnection of precast elements. The figure further delineates the incorporation of inclined steel bars, shear studs, and backing plates, which collectively improve load transfer efficiency, ductility, and seismic resilience. This exemplifies the intricacy and durability of hybrid connections in precast construction by illustrating the coordinated function of various steel components in effectively distributing loads and mitigating localised failures under conditions of elevated stress.

The connection methodologies described in this section, initially designed for precast systems, establish a basis for investigating their relevance to modular construction. The experimental findings and attributes of these connections, analysed in recent studies presented in the subsequent section, provide essential information for evaluating their appropriateness in modular systems.

Figure 11.

Hybrid connection systems [

62].

Figure 11.

Hybrid connection systems [

62].

3.4. Experimental Studies on Connections

Researchers have undertaken experimental investigations of various connection types, including grouted sleeve couplers, metal ducts, and steel plate bolted connections, to evaluate their mechanical capabilities when subjected to tensile and compressive forces. These assessments frequently incorporated large-scale experiments to analyse the strength and deformability of precast assemblies with grouted coupler connections and bolted connections and compared them with cast in situ joints.

Table 4 and

Table 5 summarise the recent studies reported in the literature on dry and wet connections in precast structures and the main parameters studied in each research. Most of these investigations have concentrated on parameters including load-carrying capacity, ductility, stiffness, and seismic performance, which are essential for assessing the appropriateness of connections in modular construction. This underscores the significance of lateral and seismic performance as pivotal focal points in these studies, thereby indicating a necessity to delve deeper into these dimensions. A comprehensive chart that compares the qualitative findings of these investigations is provided in the following section, 'Connections in Modular Construction Scenario' to facilitate a more precise comparison of various connection methodologies in modular construction.

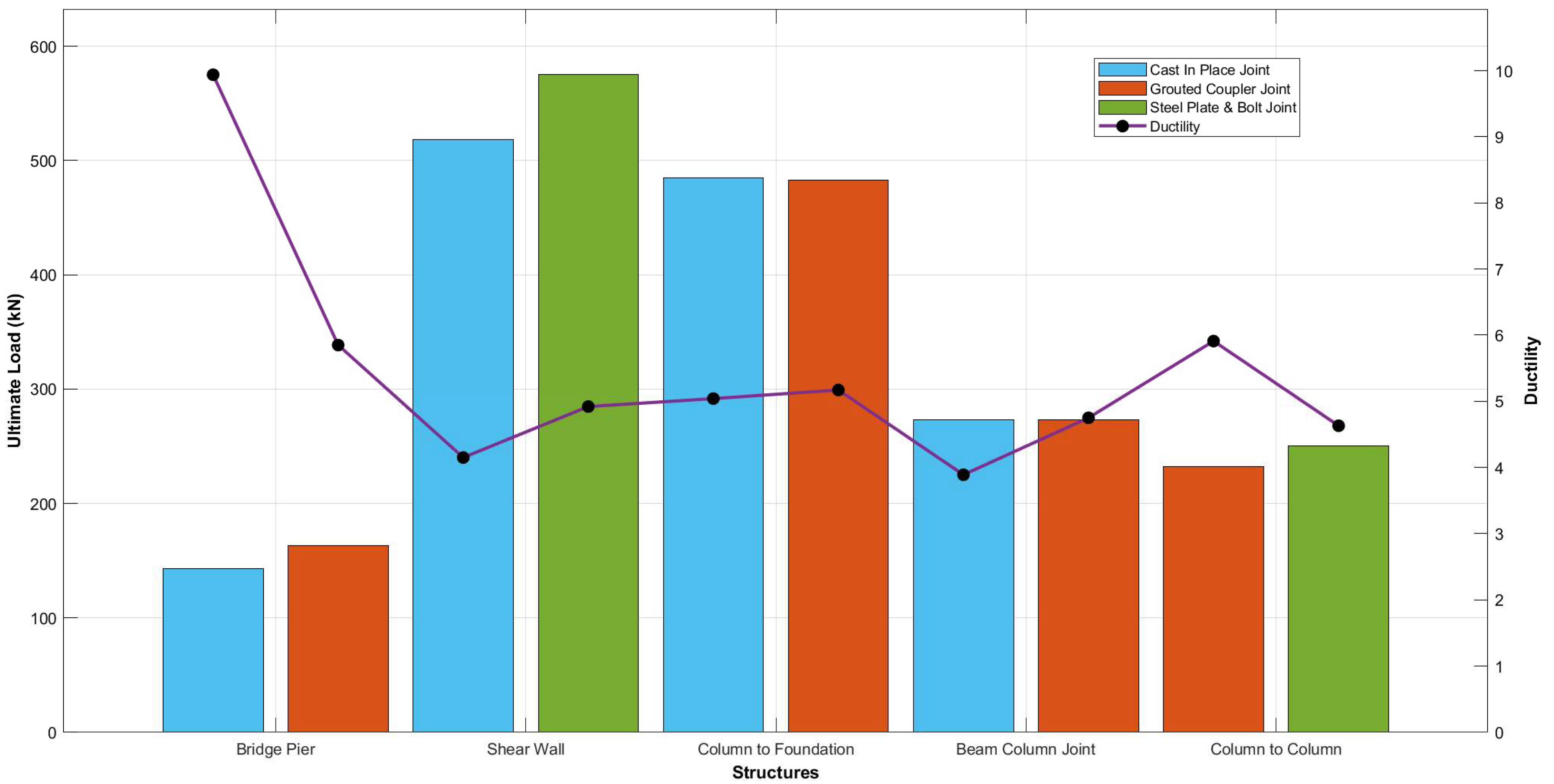

Figure 12 illustrates a comprehensive comparison of ultimate load and ductility across a range of structures, comprising bridge pier [

78,

79], shear wall [

58], column to the foundation [

80], beam-column joint [

81], and column-to-column [

82], assessed through various connection types: cast in place joint, grouted coupler joint, and steel plate & bolt joint. For example, the bridge pier utilising a grouted coupler joint demonstrates a maximum load of 163 kN and ductility of 5.85. In comparison, the cast-in-place joint reveals a lower maximum load of 143 kN yet a considerably higher ductility of 9.94, suggesting superior deformation capability under applied stress. Shear walls incorporating steel plate and bolt joints attain the highest maximum load of 575 kN and enhanced ductility of 4.92, in contrast to cast-in-place joints, which register a 518 kN peak load and a ductility of 4.15. This pattern persists among other structures, where grouted coupler joints typically display elevated ductility and steel plate & bolt joints present superior maximum loads, highlighting the inherent trade-offs between various connection types regarding load capacity and flexibility. The graph illustrates the distinctions between two connection types for each structural configuration, as the initial experimental investigations predominantly centred on juxtaposing a particular connection type with cast-in-place construction, in alignment with their methodological approaches.

3.4.1. Non-Destructive Evaluation of Connections

Building upon experimental investigations that analyse the structural efficacy of diverse connection systems, non-destructive evaluation (NDE) methodologies have surfaced as supplementary approaches to examine connections' internal quality and integrity without inflicting damage. These practices are crucial in precast connections, where aspects like compactness, identifying defects, and bond strength are essential for maintaining the structure's long-lasting durability and load-bearing strength.

Ultrasonic Testing (UT) is a prominent technique that uses high-frequency guided waves [

26] to identify internal defects, including voids, cracks, and inadequate grout compactness. UT has effectively detected anomalies within grout-filled sleeve connections by assessing wave attenuation patterns along reinforcement bars [

83]. Nevertheless, challenges such as wave dispersion in thick or heavily reinforced concrete sections may compromise its reliability when utilised in complex structural connections

Acoustic Emission (AE) Monitoring provides real-time detection capabilities by capturing elastic waves produced from crack propagation, debonding, and void formation during loading and grouting activities. This technique has demonstrated efficacy in identifying compactness concerns and detecting early-stage defects, thereby improving the monitoring of connection performance both during construction and under service conditions [

84].

Another technique, Impact-Echo (IE) testing, assesses internal compactness by examining reflected acoustic wave patterns, which can disclose incomplete grout filling, voids, or other irregularities that may undermine the connection's load-bearing capacity [

27].

Table 6 presents a comparative overview of the applied NDE techniques, their primary evaluation parameters, and key observations to summarise the findings from these NDE studies.

Incorporating these non-destructive evaluation (NDE) methodologies into the assessment of composite joints, structural dependability can be significantly enhanced, and quality control protocols can be implemented within modular construction practices. As these techniques undergo further optimisation, they present the possibility of advanced monitoring systems proficient in real-time damage identification and predictive maintenance.

3.5. Connections in Modular Construction Scenario

The evaluation of precast concrete connections within modular construction necessitates a qualitative analysis of diverse performance metrics tailored to the specific requirements of modular systems. While the comparative data is derived from studies on various precast structural configurations, these evaluations have been adapted to align with their application in modular construction, where prefabricated units typically weigh between 10 and 15 tons and require efficient and reliable assembly techniques.

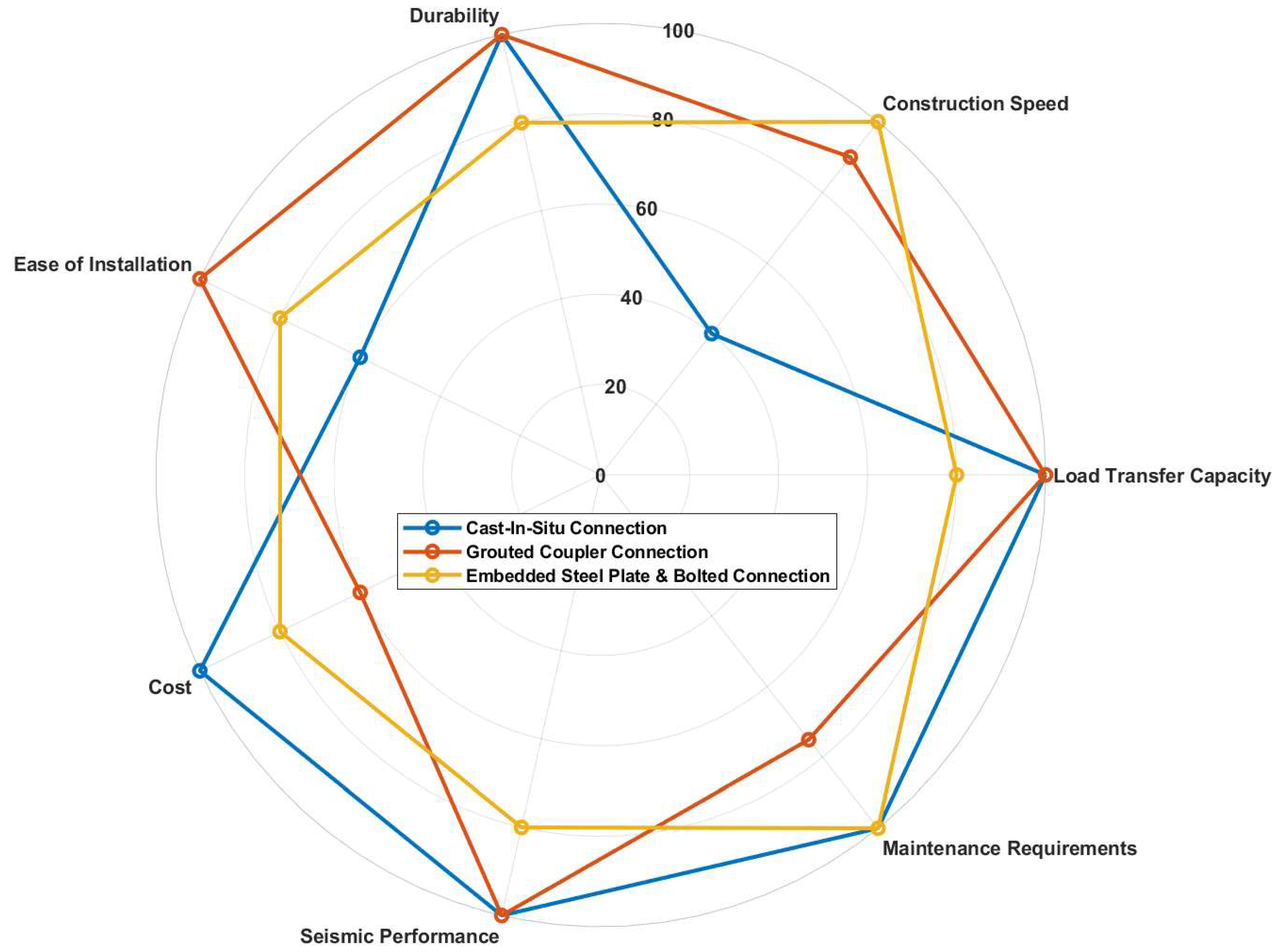

To facilitate this analysis, the radar chart (

Figure 13) provides a comparative framework, summarising key factors such as load transfer capacity, seismic performance, durability, cost, construction speed, ease of installation, and maintenance requirements. These scores are synthesised from experimental results, analytical findings, and literature studies detailed in

Table 4 and

Table 5, offering valuable insights into the suitability of different connection methodologies for modular construction scenarios.

Each performance metric was analysed and scored from 0 to 100, where 0 reflects the lowest performance, and 100 reflects the highest performance. The scoring methodology was predicated upon a comprehensive examination of experimental investigations, and comparative evaluations elucidated in the referenced

Table 4 and

Table 5. For instance, Load Transfer Capacity signifies the capability of the connection to efficiently convey loads between modules, with elevated scores denoting superior performance. Seismic performance assesses the robustness of the connection in the face of seismic forces, with increased scores indicating enhanced resistance to seismic events. Durability evaluates the protracted performance and resilience against deterioration, with elevated scores reflecting more robust connections. Cost scrutinises the economic ramifications, with diminished costs yielding higher scores. Construction Speed measures the temporal efficiency of the connection's installation, with expedited installations receiving higher scores. Ease of Installation assesses the intricacy and exertion required for assembly, with less complex installations achieving higher scores. Maintenance Requirements evaluate the continuous upkeep necessities, with reduced maintenance demands resulting in higher scores. By standardising these performance metrics on a 0 to 100 scale, the radar chart visually delineates each connection technique's comparative strengths and weaknesses, thereby offering a lucid and succinct comparison for stakeholders engaged in the construction sector.

The load transfer capacity is a critical determinant of connection performance, directly impacting structural stability and force transmission efficiency. Connections utilising cast-in-situ and grouted couplers achieved the highest ratings owing to their provision of monolithic or near-monolithic behaviour, which facilitates effective stress distribution under both static and dynamic conditions. Notably, grouted couplers gain advantages from mechanical interlocking and grout confinement, which enhance the transfer of axial and shear forces. Connections employing embedded steel plates and bolts received slightly lower scores due to the inherent risk of slip at the interface, potentially causing stress concentrations at the bolt locations. Research findings [

65,

66,

67] regarding bolted connections in precast frameworks suggest that, while they exhibit adequate load-bearing capacity, their performance in response to significant cyclic loads is contingent upon factors such as bolt pre-tensioning and slip behaviour.

The seismic performance of connections is intricately linked to their ductility, energy dissipation capabilities, and adaptability to cyclic deformations. Connections made with cast-in-situ techniques exhibited the highest levels of seismic resilience, functioning monolithically and providing enhanced ductility. Grouted coupler connections also performed admirably, especially when designed with confinement reinforcement, as experimental investigations into precast beam-column joints have demonstrated their effective energy dissipation capabilities. Connections featuring embedded steel plates and bolts displayed moderate seismic performance, as their inherent dry assembly characteristics may result in localised stress concentrations, thereby diminishing overall ductility. Nevertheless, bolted systems can be engineered with energy-dissipating elements to improve their seismic performance.

The durability evaluation focused on the material's performance as time progressed and its resistance to external influences. Connections utilising cast-in-situ and grouted coupler methods received the highest durability ratings, as their concrete-embedded designs significantly reduced exposure to external degradation agents. Conversely, embedded steel plates and bolted connections scored lower due to potential corrosion hazards, necessitating protective coatings and routine inspections. Longitudinal studies on exposed bolted joints within precast bridges and industrial facilities have revealed an increased vulnerability to moisture infiltration and rust, which, if not addressed, could culminate in connection failure.

Cost considerations are paramount in modular construction, where efficiency and economic viability are critical factors. Connections made with cast-in-situ methods were assigned the lowest score, as they typically entail considerable on-site labour, extensive formwork, and prolonged curing periods. In contrast, grouted couplers and embedded steel plates and bolted connections received higher ratings due to their facilitation of quicker installations with diminished labour expenses. The grouted coupler system achieves a harmonious balance between cost efficiency and performance, rendering it a financially viable option for modular construction, particularly as the repetitive use of connection elements further optimises overall costs.

Construction speed was significantly affected by the requirements of on-site operations. Embedded steel plates and bolted connections received the highest ranking, as they offer immediate structural stability upon installation, thereby reducing on-site labour. Grouted coupler connections were rated below due to their need for precise alignment while permitting rapid post-grouting assembly. Conversely, cast-in-situ connections scored the lowest, attributable to extended curing durations and the demand for supplementary site activities.

The evaluation of installation ease was determined by the feasibility of managing 10 to 15-ton concrete modules within modular construction. Grouted coupler connections achieved the highest rank, enabling straightforward alignment and joining with minimal equipment, thereby diminishing installation time and intricacy. Following were embedded steel plates and bolted connections, necessitating careful bolt tightening but eliminating the need for wet processes. Cast-in-situ connections were rated lowest, given their extensive on-site workload, requirements for formwork preparation, and alignment issues, rendering them less favourable for modular assembly where efficiency is critical.

Maintenance considerations were assessed based on anticipated long-term care. Cast-in-situ connections demanded the least maintenance due to their monolithic nature, which removes weak points. Grouted coupler connections necessitated moderate maintenance, primarily for grout integrity assessments in high-seismic contexts. In contrast, embedded steel plates and bolted connections required the most maintenance, as regular bolt tensioning and corrosion protection are essential to sustain their long-term performance.

In summary, the qualitative ratings depicted in the radar chart offer a comprehensive view of the strengths and weaknesses of each connection method in the context of modular construction. Grouted coupler connections present the optimal balance between seismic performance, durability, and installation ease, rendering them a favoured option for modular structures. Embedded steel plates and bolted connections demonstrate superiority in construction speed and flexibility, albeit with the necessity for diligent maintenance. Cast-in-situ connections deliver enhanced seismic resilience; however, they are encumbered by on-site workload and prolonged construction durations. Choosing an appropriate connection method should be informed by project-specific criteria, weighing structural performance, efficiency, and cost implications.

4. Discussion and Recommendations for Future Work

This investigation offers critical perspectives on modular construction and its extensive benefits, emphasising the design factors essential for effectively executing modular edifices. While limited research exists specifically on connections in concrete modules, this study bridges the gap by reviewing various connection techniques in precast systems and evaluating their suitability in the modular construction context. By synthesising insights from experimental studies and performance metrics, this review lays the groundwork for further exploration into connection methodologies tailored specifically for modular construction.

The findings of this research indicate that modular construction techniques noticeably improve efficiency, particularly in high-rise structures, by optimising manufacturing workflows, accelerating on-site assembly, and enhancing overall construction quality. The benefits associated with modular construction, including reduced construction duration, financial savings, and heightened safety, are thoroughly documented, establishing it as an attractive alternative to traditional construction paradigms. While these composite connections (including grouted, bolted, and hybrid) have demonstrated significant potential, particularly in their seismic performance, enhancement is necessary to augment their reliability under seismic conditions. Experimental investigations have indicated that grouted systems perform better in seismic contexts than alternative connection types. However, additional advancements are imperative to optimise these systems for enhanced assurance regarding their behaviour during seismic occurrences, which encompasses improving load transfer mechanisms, ductility, and failure resistance. Addressing these enhancements is essential for facilitating the widespread implementation of composite connection systems in modular construction.

Future research should delve into the seamless integration of various connection types within modular structures, examining their compatibility with different modular systems and assessing their impact on structural performance during assembly and in-service conditions. A particularly critical area for investigation is the seismic performance of these connections, especially under extreme seismic environments characterised by phenomena such as directivity effects and more extended pulse periods in ground motions [

85]. These conditions, observed in significant earthquakes like the Myanmar earthquake [

86] caused by super shear rupture, pose unique challenges to modular construction systems. Understanding the response of composite connections under such dynamic loading scenarios is essential for enhancing earthquake resilience. Detailed studies on how these connections behave under supershear-induced ground motions [

87] and other seismic loads will be instrumental in ensuring the stability and safety of modular structures in earthquake-prone regions. Alongside these technical explorations, developing comprehensive design standards and guidelines tailored for modular construction is imperative. It should address specific challenges like joint flexibility, load transfer mechanisms, and the interaction of modular units. Finally, future studies should explore innovative and adaptive connection solutions, leveraging advanced materials and technologies further to enhance the efficiency and resilience of modular structures, potentially revolutionising the field through hybrid connections and automated assembly techniques.

5. Conclusions

Modular construction has developed into a transformative approach in the construction industry, yielding significant benefits such as enhanced productivity, decreased financial outlays, and superior quality in construction outcomes. This review thoroughly examined its design principles, connection techniques, and obstacles, yielding a detailed comprehension of its present status and prospects.

Modular construction has proven its capacity to shorten project timelines by as much as 50% and decrease costs by around 20%, mainly due to the incorporation of offsite manufacturing and optimised processes.

Volumetric modular construction has been shown to reduce on-site labour activities by transferring up to 80% of work offsite, greatly minimising site disruptions and improving safety and accuracy.

Composite connections show significant improvements in load transfer mechanisms, boosting efficiency by 15-30% and reaching superior maximum loads, such as 575 kN for bolted connections as opposed to 518 kN for cast-in-place joints.

The application of Non-Destructive Evaluation (NDE) techniques enhances the assessment of internal quality and structural integrity in composite connections, supporting durability, and effective real time monitoring in modular construction.

Despite its benefits, the widespread implementation of modular construction faces obstacles, including connection effectiveness, adherence to regulations, and maintaining structural integrity during transportation and assembly.

Continued research into automated assembly technologies, frameworks that resist seismic activity, and advanced composite connection systems will foster further innovations and assist in overcoming current challenges within modular construction practices.