Submitted:

25 April 2025

Posted:

25 April 2025

Read the latest preprint version here

Abstract

Keywords:

1. Introduction

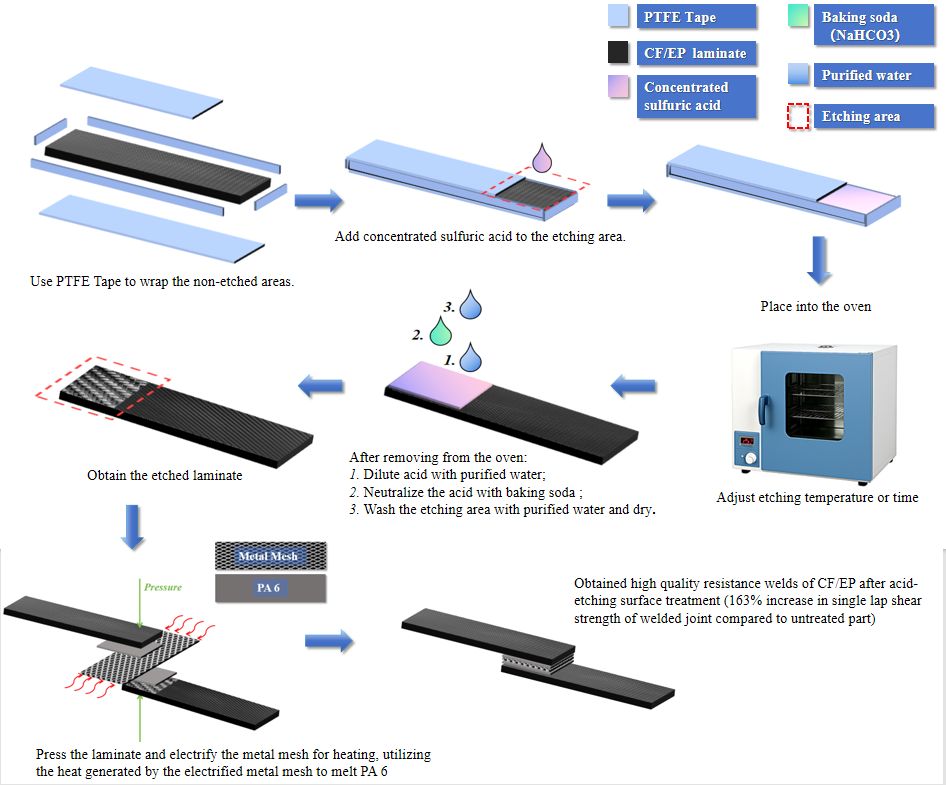

- Low cost: The technique only requires the use of concentrated sulfuric acid as the main treatment medium, and does not require expensive additional equipment (e.g., plasma emitting equipment, high-precision mechanical grinding equipment, or laser etching equipment), which greatly reduces the cost of the treatment (the purchasing price of the industrial-grade concentrated sulfuric acid is about 57 to 143 USD per ton).

- Ease of operation: mild treatment conditions (50°C, 45 minutes), low equipment requirements, easy control of process parameters, and seamless integration into existing production processes.

- Scalability: Since the etching area can be freely selected, the Acid-etching technology can easily realize large-area, continuous surface treatment, which is particularly suitable for the needs of large-scale industrialized production.

2. Experimental Methods

2.1. Raw Materials

2.2. Material Preparation

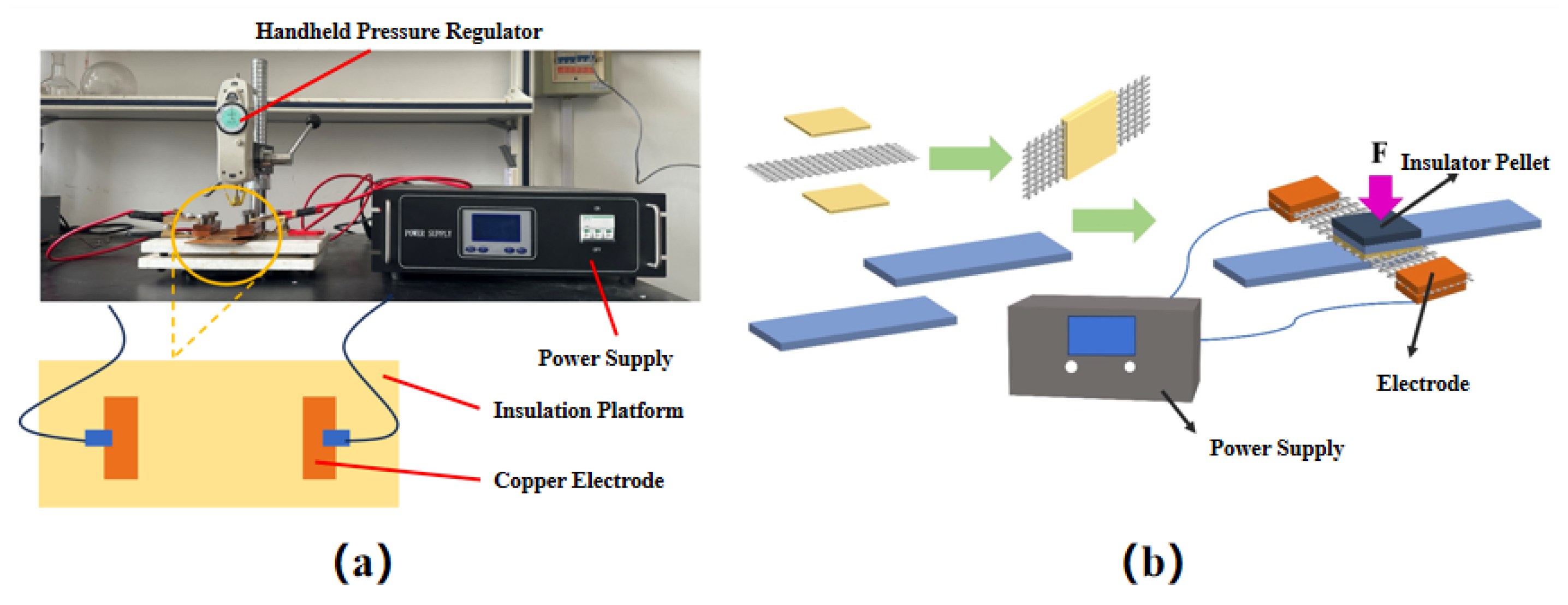

2.3. Material Preparation

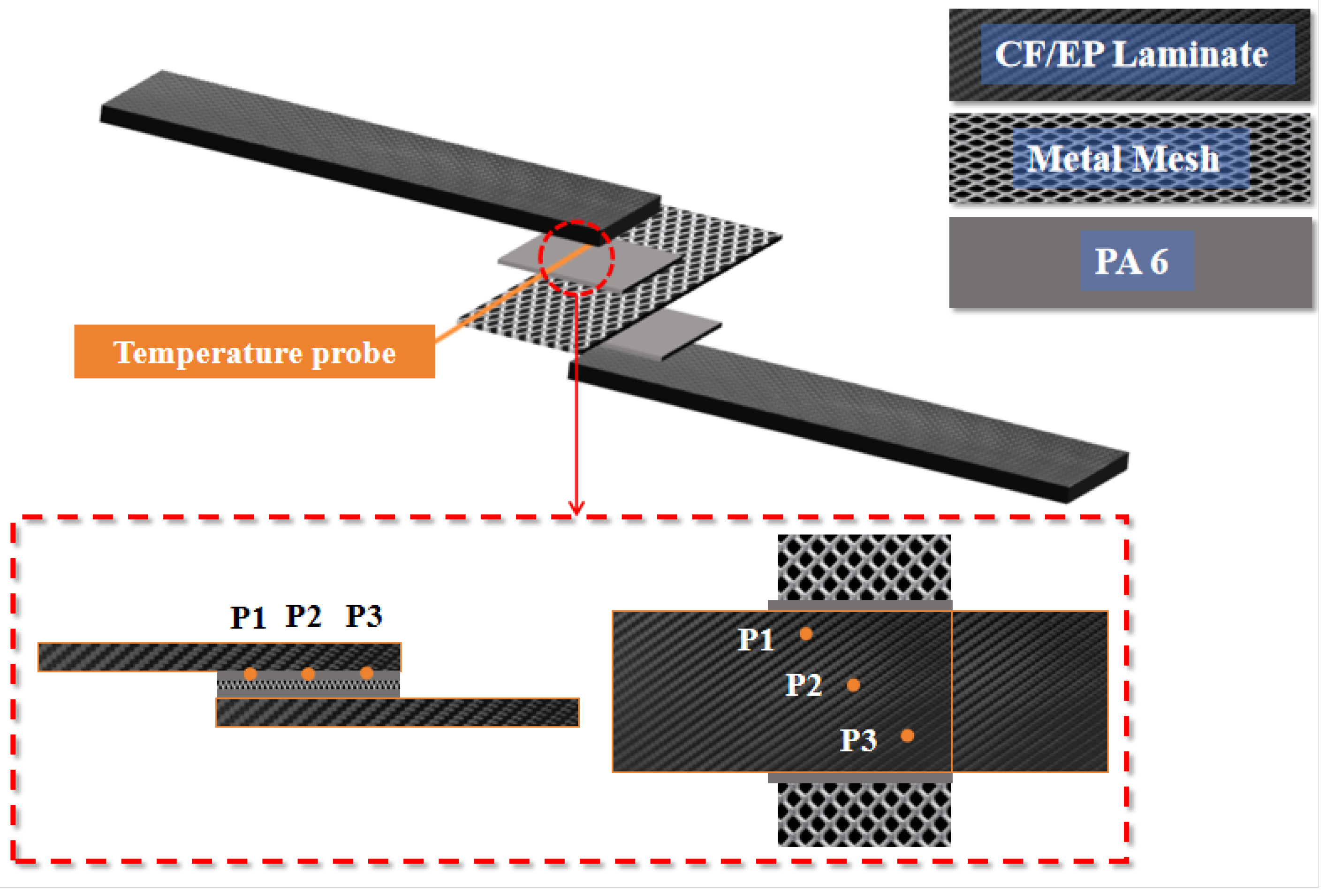

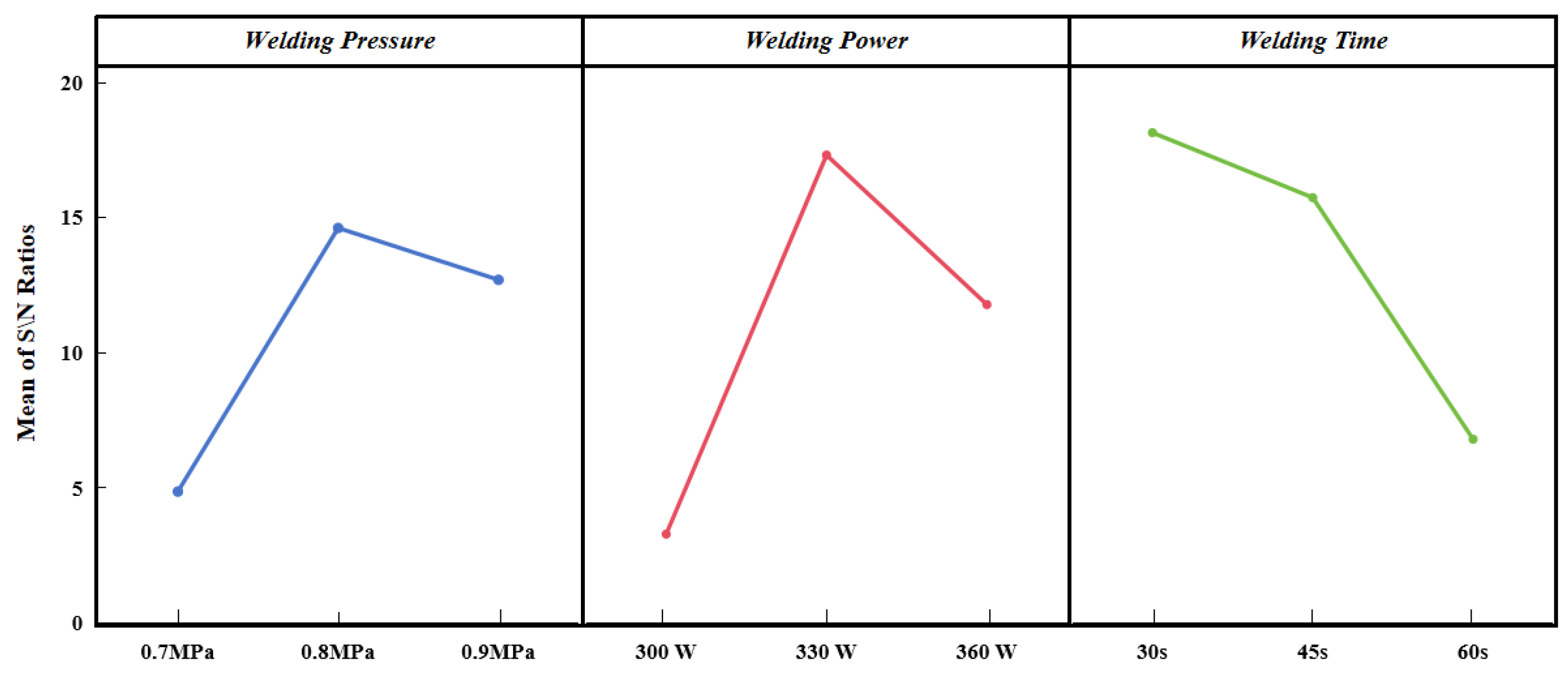

2.4. Determine the Resistance Welding Process Parameters

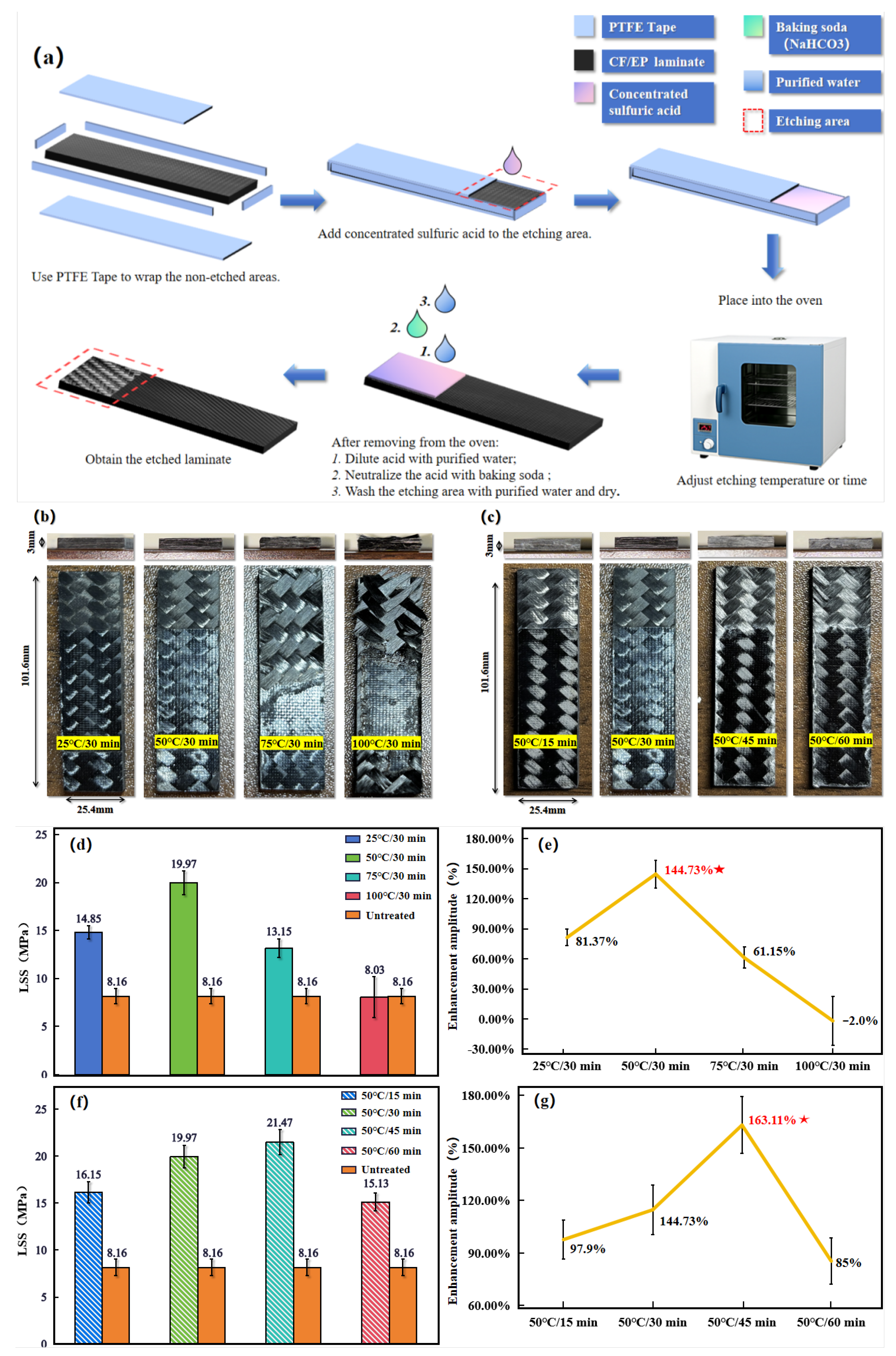

3. Acid-Etching Surface Treatment and Characterization of Mechanical Property of Treated Welded Joint

4. Effect of Acid-Etching on the Physical Properties of Laminate Surfaces

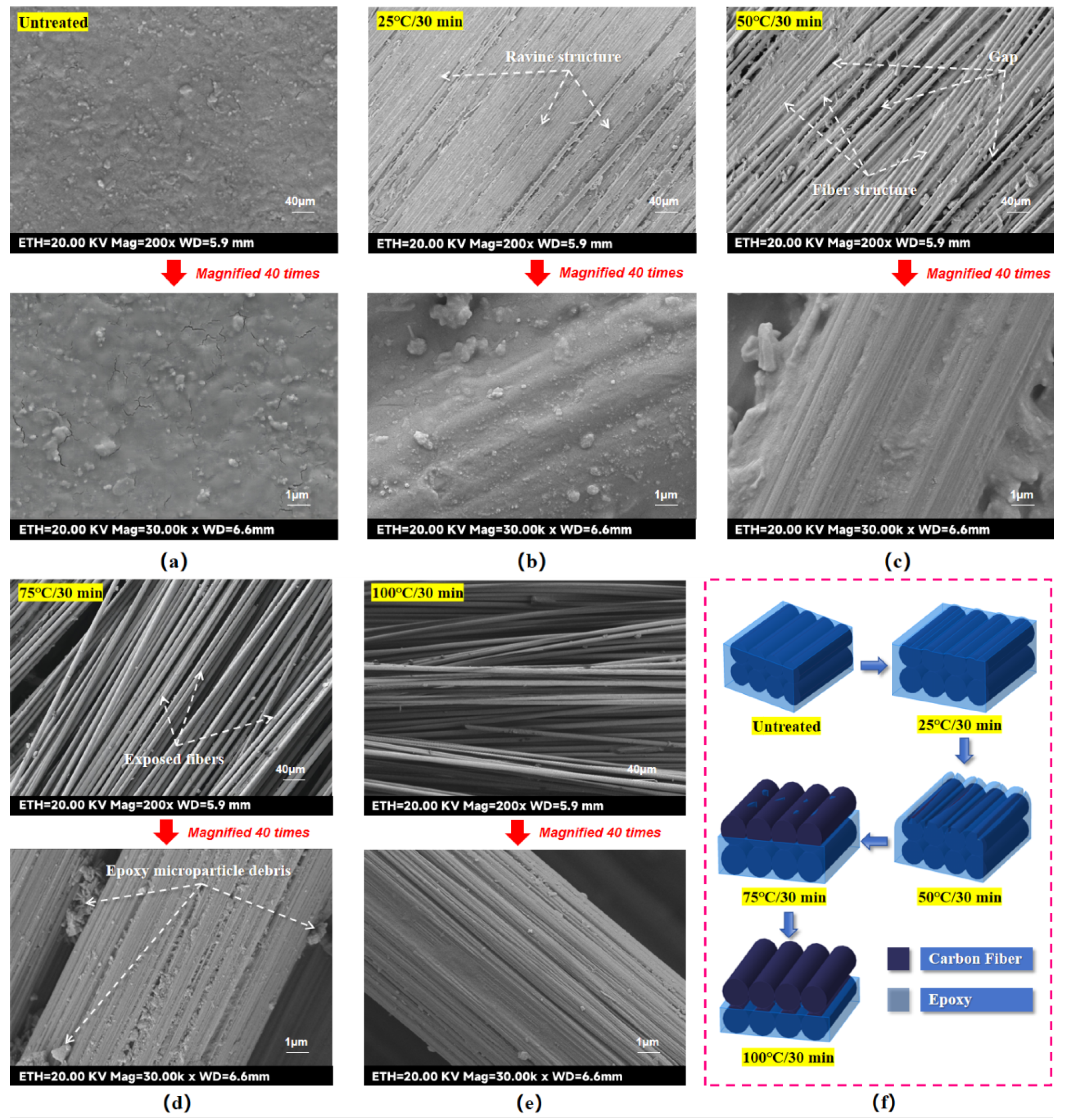

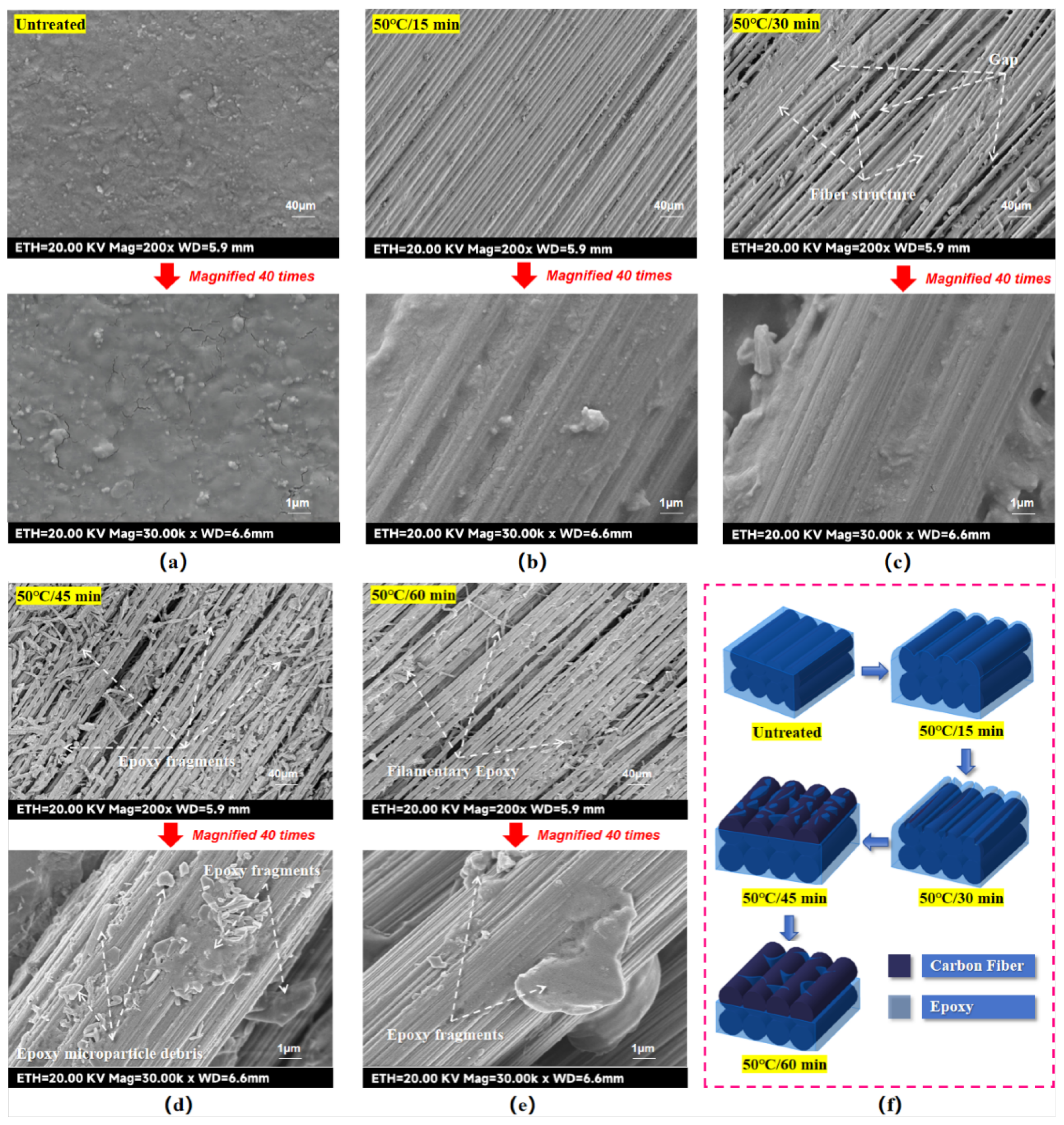

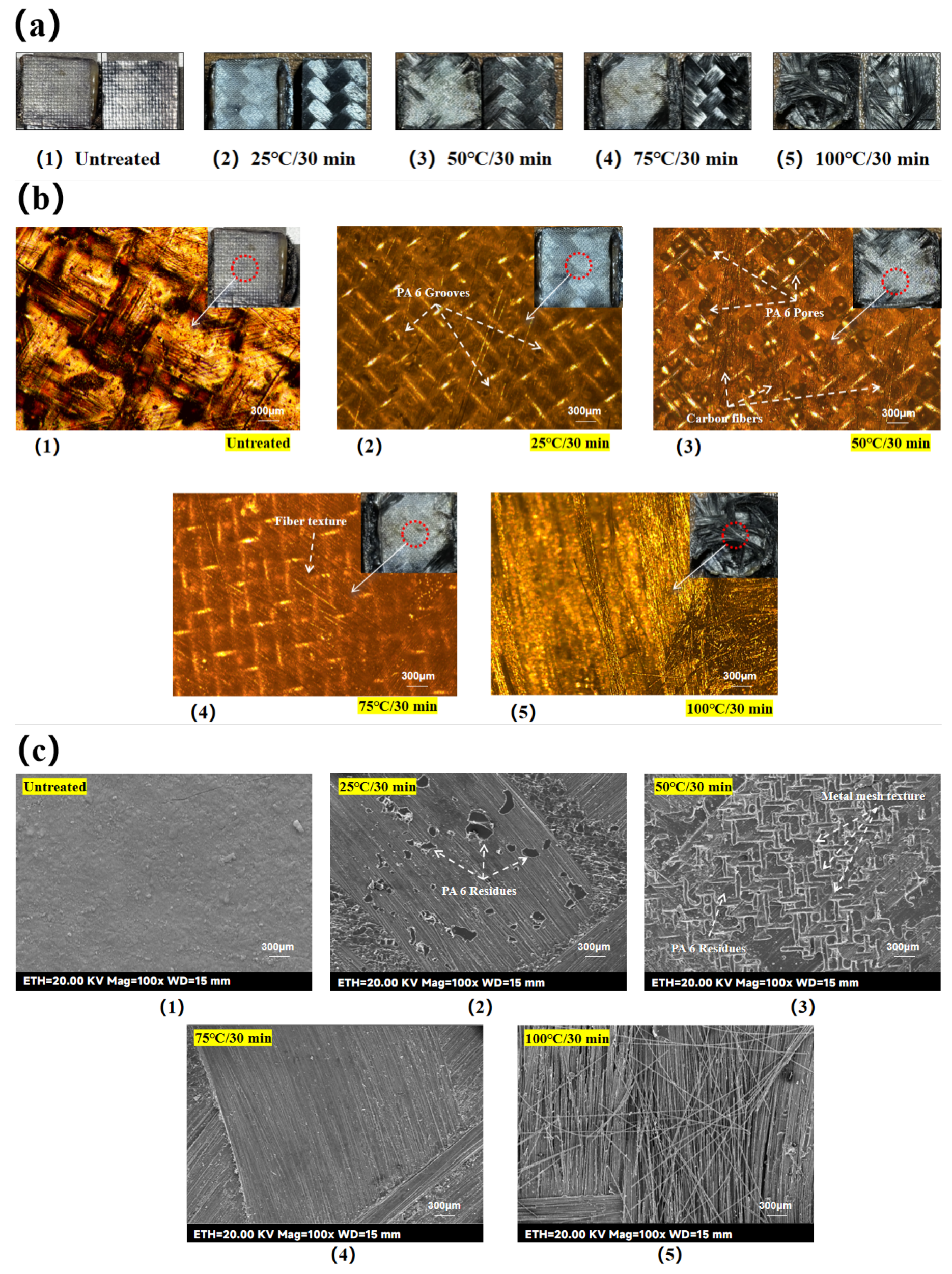

4.1. Temperature-Variable Experimental Groups Micro Morphology and Roughness Analysis

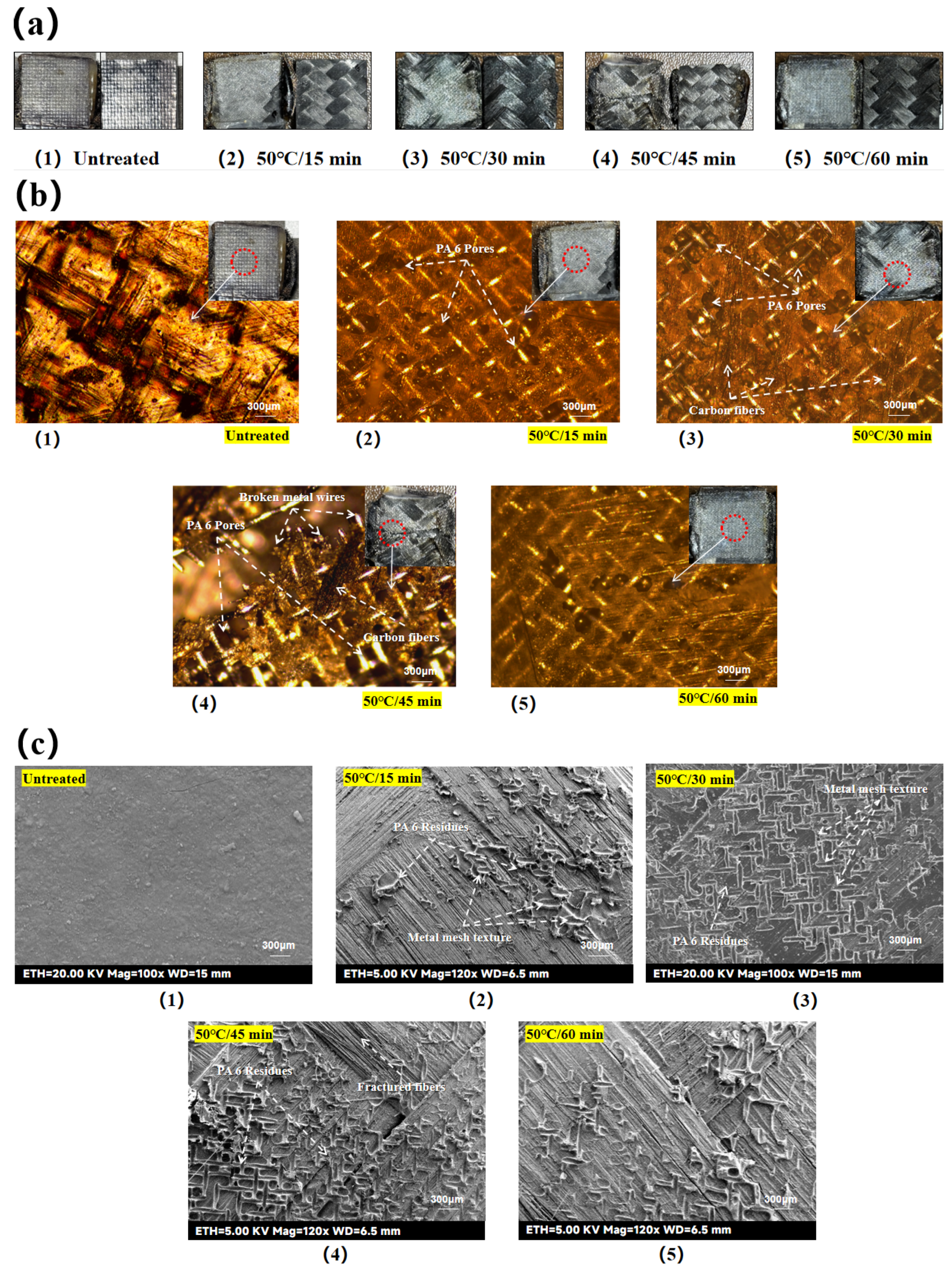

4.2. Time-Variable Experimental Groups Micro Morphology and Roughness Analysis

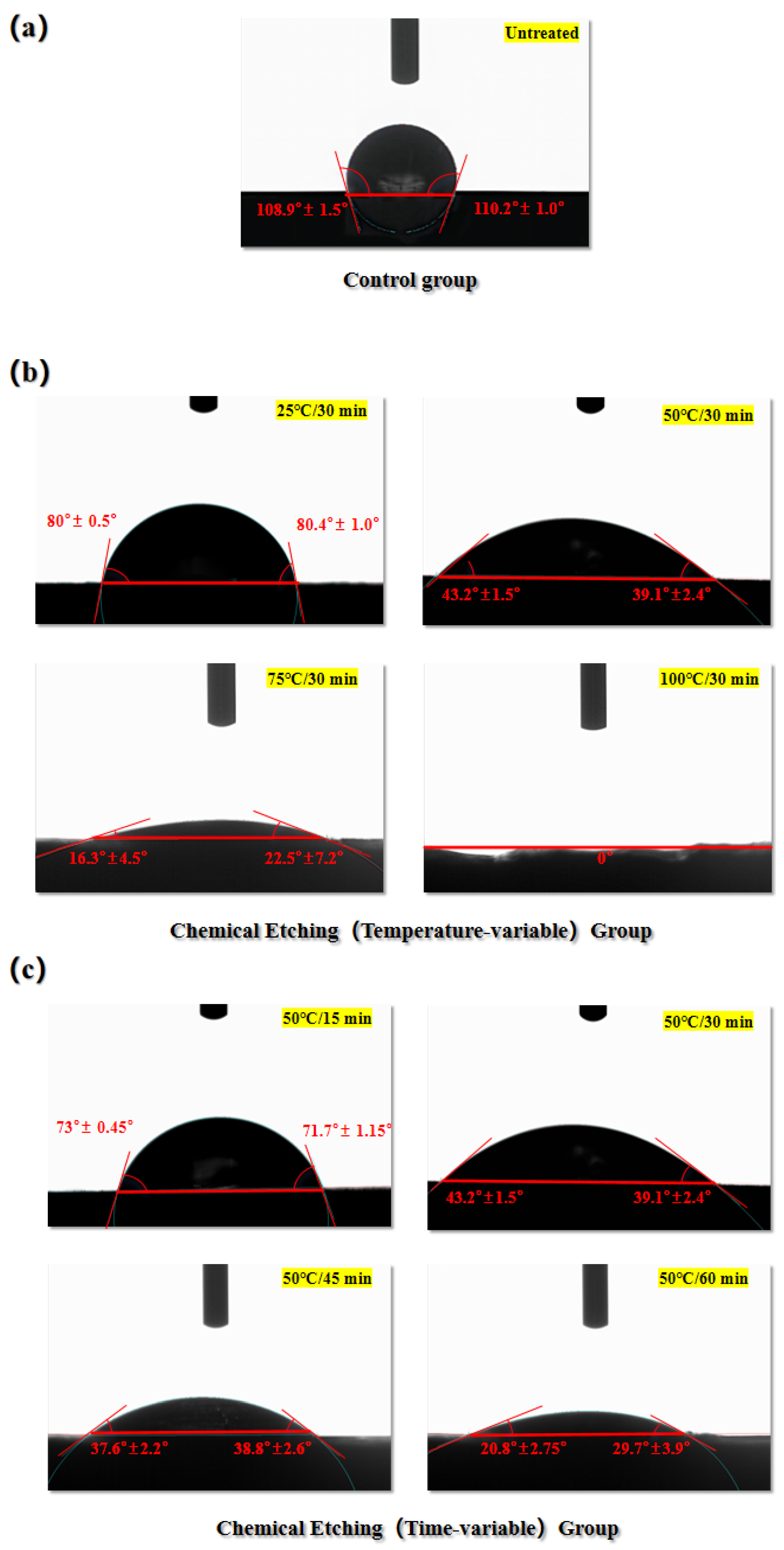

4.3. Surface Wettability Analysis

5. Effect of Acid-Etching on the Surface Chemistry of Laminates

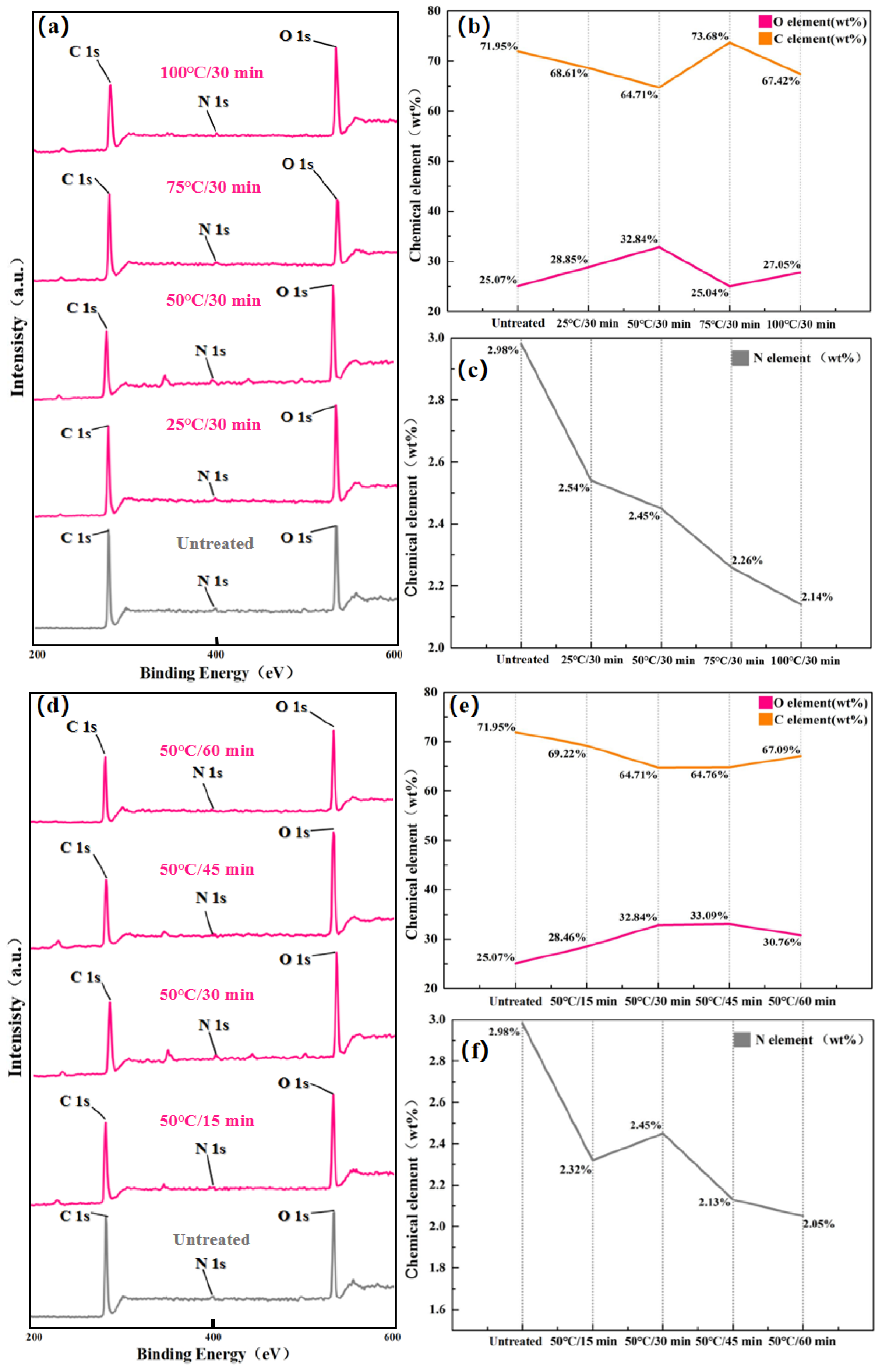

5.1. Surface Chemical Element Content Analysis

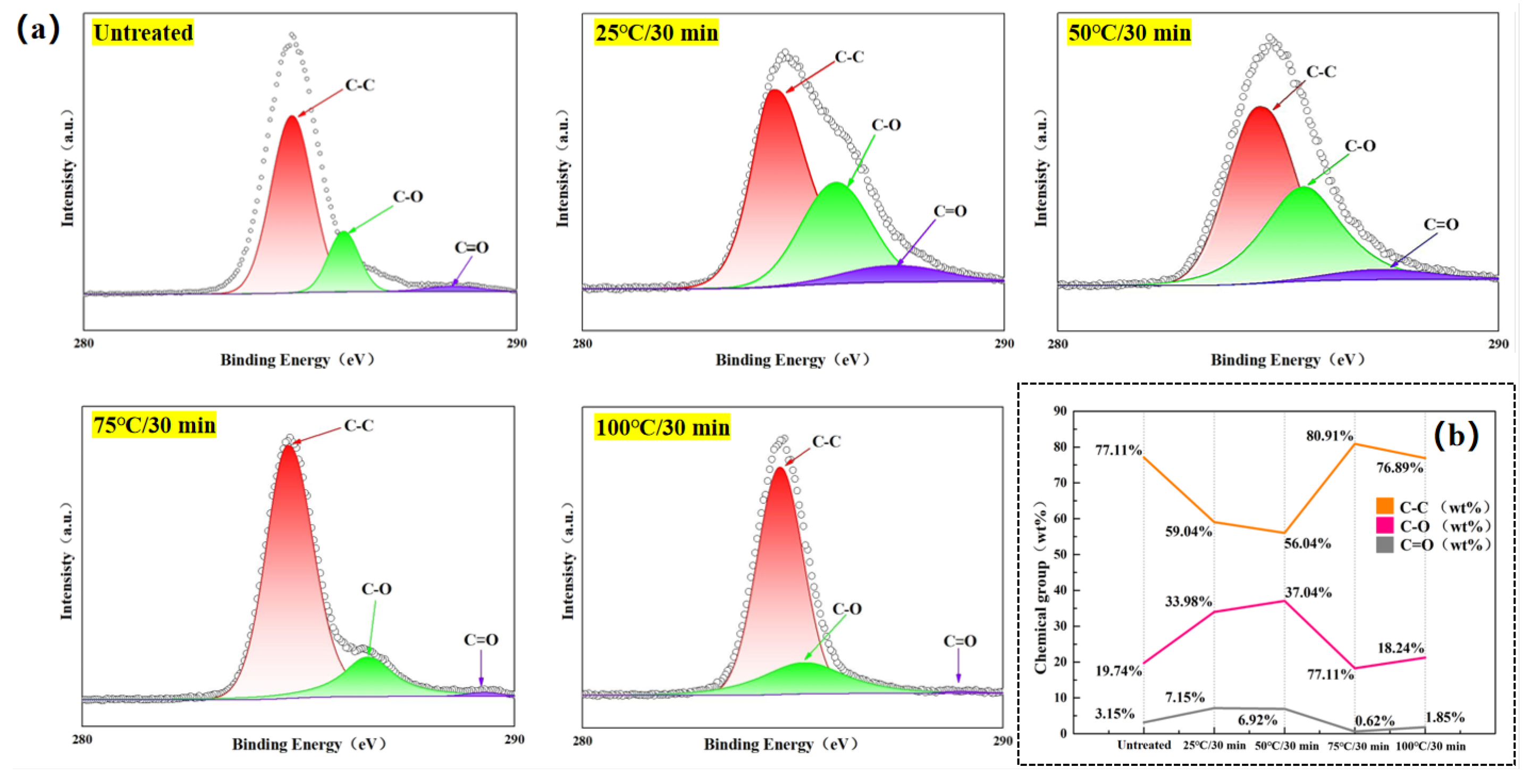

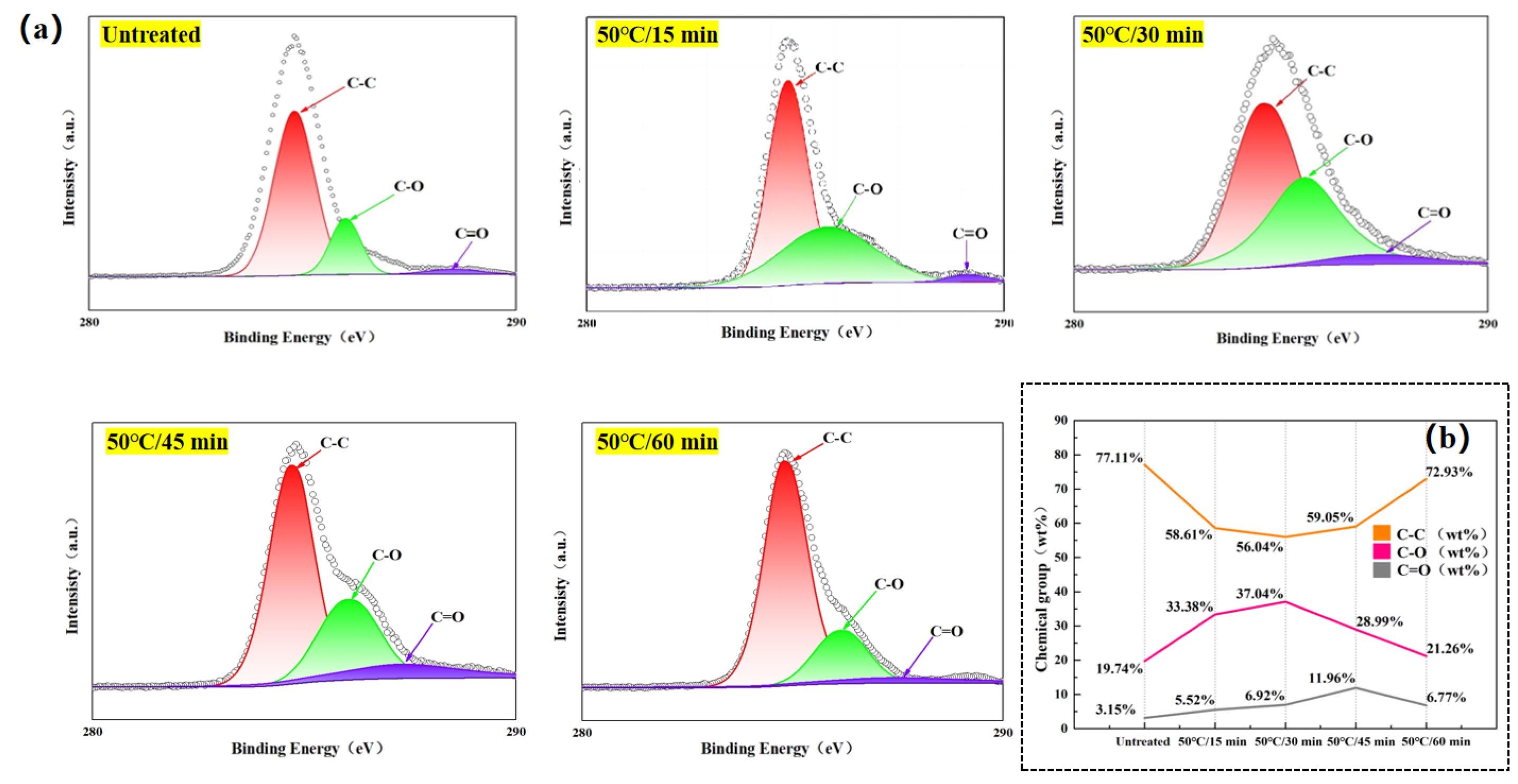

5.2. Surface Chemical Groups Content Analysis

5.3. Summary of the Effect of Acid-Etching on the Laminate Surface

6. Quality Analysis of Welded Joints

6.1. Quality Analysis of Welded Joints in Temperature-Variable Experimental Groups

6.2. Quality Aanalysis of Welded Joints in Time-Variable Experimental Groups

6.3. Summary of the Effect of Acid-Etching on the Strength of Welded Joints

-

bonding mechanismSurface treatment of laminates at 50 °C/45 min Acid-etching parameters results in the formation of a high-roughness structure on the laminate surface, with a significant increase in the content of reactive functional groups and the surface wettability, at the same time, avoids the problem of fiber destabilization caused by excessive etching.

-

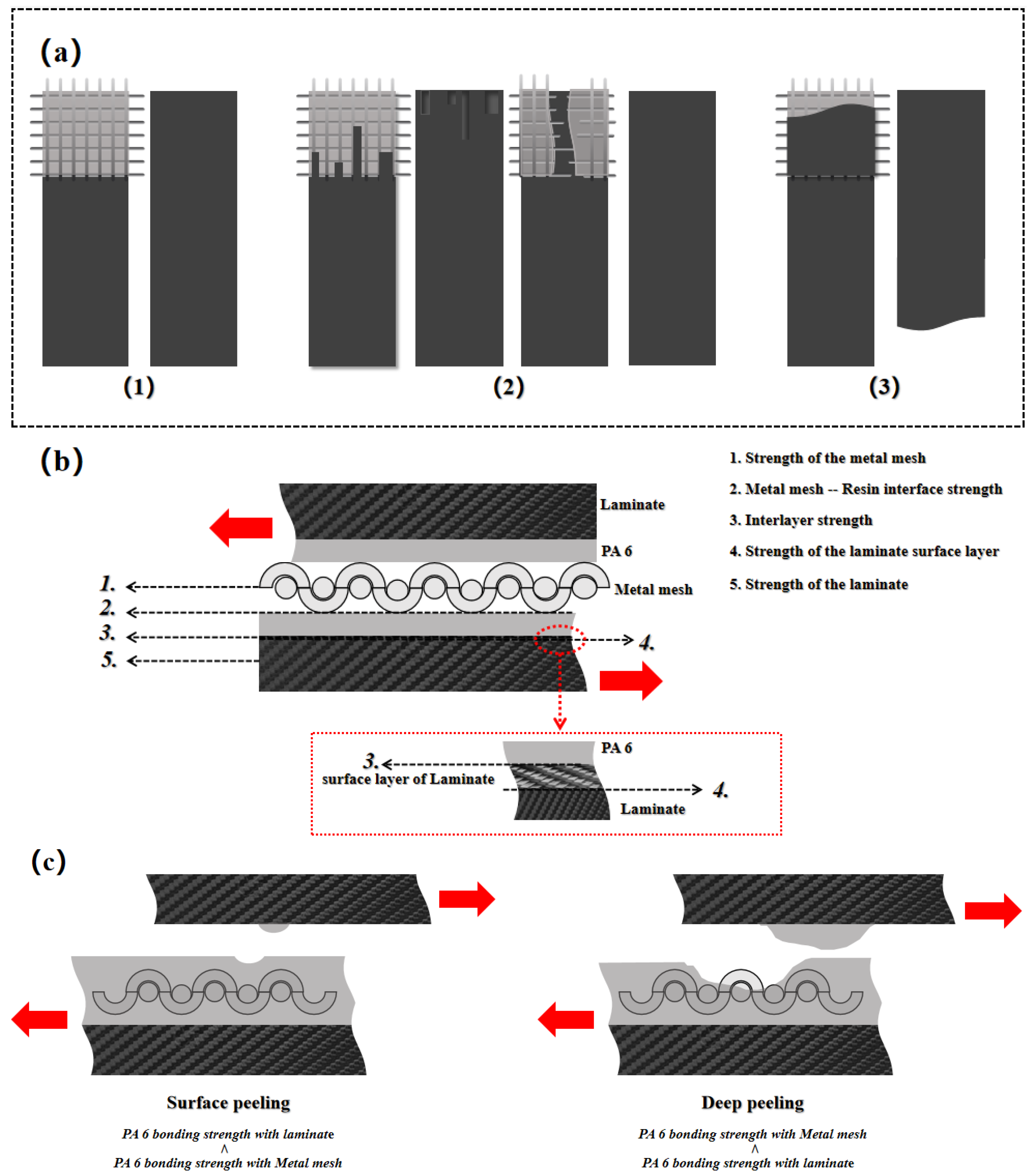

Unique failure interfacesCF/EP resistance-welded joints have a variety of failure interfaces. In addition to the failure interface within the laminate itself, which causes the sample failure and does not give any information about the quality of the welded joint, there are four types of failure interfaces, namely, interface between the laminate surface and the PA6, interface between the PA6 and the metal mesh, interface between the surface fibers and the laminate surface and the metal mesh itself. The failure interface of the 50 °C/45 min experimental group is a mixture of all possible failure interface except the failure interface within the laminate itself. This indicates that except the failure interface within the laminate itself, all other interfaces of the welded joints are involved in the tensile process, which is a direct manifestation of the welding joint LSS is close to its limit.

-

Parameter optimization advantages50 °C/45 min experimental group compared to short-term experimental groups or low-temperature experimental groups (such as 50 °C/15 min experimental group and 25 °C/30 min experimental group): Appropriate extension of the etching time and increase the etching temperature so that the Acid-etching is more adequate.50 °C/45 min experimental group compared with high-temperature experimental groups or a long period of time experimental groups (such as 75 °C/30 min experimental group and 50 °C/60 min experimental group): Reasonable control of etching time and etching temperature can effectively avoid the sparse arrangement of surface fibers, the decrease of surface roughness, and the loss of active chemical groups 50 °C/45 min experimental group compare with over-etching experimental groups (e.g., 100 °C/30 min experimental group): The structural integrity of the fibers is retained and the risk of internal defects is eliminated. The experimental data show that the LSS of the 50 °C/45 min experimental group is 21.47 ± 1.21 MPa, which is 161% ± 14% higher than that of the untreated samples, proving that the optimal Acid-etching parameter is 50 °C/45 min.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jerome, PORA. Composite materials in the airbus A380-from history to future. In Proceedings of the 13th International Conference on Composite Materials (ICCM-13); Beijing, China, 2001.

- Lu, B.; Wang, N. The Boeing 787 dreamliner designing an aircraft for the future. Journal of Young Investigators 2010, 4026, 34. [Google Scholar]

- Smith, B. The Boeing 777: The development of the Boeing 777 was made possible by the development of breakthrough materials. Advanced Materials & Processes 2003, 161, 41–45. [Google Scholar]

- Hanna, C.; Ienina, I.; Taruta, M. Use of composite materials in civil aviation. New Integrations of Modern Education in Universities 2023, 310. [Google Scholar]

- Lockheed Martin. F-22 RAPTOR: Air dominance for the 21st century. Advanced Materials & Processes 1998, 153. [Google Scholar]

- Ravichandran, B.; Balasubramanian, M. Joining methods for Fiber Reinforced Polymer (FRP) composites - A critical review. Composites Part A: Applied Science and Manufacturing 2024, 108394.

- Cui, X.; Tian, L.; Wang, D.S.; Dong, J.P. Summary of thermosetting composite material welding. In Journal of Physics: Conference Series; 2021, 1765. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. Journal of Materials Research and Technology 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Brauner, C.; Nakouzi, S.; Zweifel, L.; Tresch, J. Co-curing behaviour of thermoset composites with a thermoplastic boundary layer for welding purposes. Advanced Composites Letters 2020, 29, 2633366X20902777. [Google Scholar] [CrossRef]

- Li, G.; Yin, L.; Wang, D.; Xiong, X.; Zhao, P.; Tan, C. The thermal and mechanical properties of thermosetting composites prepared for welding by the improved TP hybrid interlayer. Journal of Adhesion Science and Technology 2022, 36, 1135–1152. [Google Scholar] [CrossRef]

- Grace, J.M.; Gerenser, L.J. Plasma treatment of polymers. Journal of Dispersion Science and Technology 2003, 24(3-4), 305–341. [CrossRef]

- Srinivasan, V.; Smrtic, M.A.; Babu, S.V. Excimer laser etching of polymers. Journal of Applied Physics 1986, 59, 3861–3867. [Google Scholar] [CrossRef]

- Xu, S.; Shen, K.; Han, M.; Zhang, H.; Lan, J.; Lin, J.; Cao, H.; Zheng, G. Surface nano-crystallisation and mechanical properties of TiTa composite materials after surface mechanical grinding treatment. Materials Characterization 2023, 206, 113458. [Google Scholar] [CrossRef]

- Anatech USA. SCE Series Technical Specifications. Available online: https://www.anatechusa.com (accessed on 1 May 2024).

- Barnes Aerospace. Horizontal Material Grinders. Available online: https://www.barnesaero.com (accessed on 1 May 2024).

- Plasma Etch Inc. BT Series Plasma Transmitters. Available online: https://www.plasmaetch.com (accessed on 1 May 2024).

- Universal Laser Systems. PLS6.150D Industrial Etcher. Available online: https://www.ulsinc.com (accessed on 1 May 2024).

- Berglund, L.A. Thermoplastic resins. In Handbook of Composites; Publisher: Springer, 1998. [Google Scholar]

- ASTM International. Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM D5868-01, 2023.

- Xiong, X.; Wang, D.; Wei, J. et al. Resistance welding technology of fiber reinforced polymer composites: A review. J. Adhes. Sci. Technol. 2021, 35, 1593–1619. [Google Scholar] [CrossRef]

- Barazanchy, D.; Pandher, J.; Van Tooren, M.J. The edge-effect in thermoplastic induction welding. In Proceedings of the AIAA Scitech 2021 Forum; 2021; p. 1890. [Google Scholar]

- Zhao, Y.; Zhao, G.; Li, M. et al. The effect of surface treatment on the resistance welding technology for carbon fiber/epoxy resin composites. Appl. Compos. Mater. 2024, 31, 201–221. [Google Scholar] [CrossRef]

- Karna, S.K.; Sahai, R. An overview on Taguchi method. Int. J. Eng. Math. Sci. 2012, 1, 1–7. [Google Scholar]

- Kohout, J. Modified Arrhenius equation in materials science, chemistry and biology. Molecules 2021, 26. [Google Scholar] [CrossRef]

- Azeem, M.; Boughattas, A.; Wiener, J. et al. Mechanism of liquid water transport in fabrics: A review. Fibres Text. 2017, 4, 58–65. [Google Scholar]

- Miyama, M.; Yang, Y.; Yasuda, T. et al. Static and dynamic contact angles of water on polymeric surfaces. Langmuir 1997, 13, 5494–5503. [Google Scholar] [CrossRef]

- Law, K.Y. Water–surface interactions and definitions for hydrophilicity, hydrophobicity and superhydrophobicity. Pure Appl. Chem. 2015, 87, 759–765. [Google Scholar] [CrossRef]

- Seah, M.P. The quantitative analysis of surfaces by XPS: A review. Surf. Interface Anal. 1980, 2, 222–239. [Google Scholar] [CrossRef]

- Hartung, J.; Gottwald, T.; Špehar, K. Selectivity in the chemistry of oxygen-centered radicals-the formation of carbon-oxygen bonds. Synthesis 2002, 2002, 1469–1498. [Google Scholar] [CrossRef]

- Teoh, W.C.; Yeoh, W.M.; Mohamed, A.R. Evaluation of different oxidizing agents on effective covalent functionalization of multiwalled carbon nanotubes. Fullerenes Nanotub. Carbon Nanostruct. 2018, 26, 846–850. [Google Scholar] [CrossRef]

- Glockler, G. Carbon–oxygen bond energies and bond distances. J. Phys. Chem. 1958, 62, 1049–1054. [Google Scholar] [CrossRef]

- Shi, H.; Villegas, I.F.; Bersee, H.E.N. Strength and failure modes in resistance welded thermoplastic composite joints: Effect of fibre–matrix adhesion and fibre orientation. Compos. Part A Appl. Sci. Manuf. 2013, 55, 1–10. [Google Scholar] [CrossRef]

| Welding Power | T1 | T2 | T3 | T | |

|---|---|---|---|---|---|

| 270 W | 97.3 S | 186.7 s | 103.3 s | 129.0 s | |

| 300 W | 30.0 s | 27.7 s | 57.3 s | 38.3 s | |

| 330 W | 19.0 s | 22.7 s | 48.3 s | 29.7 s | |

| 360 W | 17.7 s | 13.3 s | 32.3 s | 20.7 s |

| Welding Parameters | Levels 1 | Levels 2 | Levels 3 | |

|---|---|---|---|---|

| Welding Power | 300 W | 360 W | 390 W | |

| Welding Pressure | 0.7 MPa | 0.8 MPa | 0.9 MPa | |

| Welding Time | 30 s | 45 s | 60 s |

| NO. | Welding Power | Welding Pressure | Welding Time | |

|---|---|---|---|---|

| A | 300 W | 0.7 MPa | 30 s | |

| B | 300 W | 0.8 MPa | 45 s | |

| C | 300 W | 0.9 MPa | 60 s | |

| D | 360 W | 0.7 MPa | 30 s | |

| E | 360 W | 0.8 MPa | 45 s | |

| F | 360 W | 0.9 MPa | 60 s | |

| G | 390 W | 0.7 MPa | 30 s | |

| H | 390 W | 0.8 MPa | 45 s | |

| I | 390 W | 0.9 MPa | 60 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).