Submitted:

22 April 2025

Posted:

22 April 2025

You are already at the latest version

Abstract

Keywords:

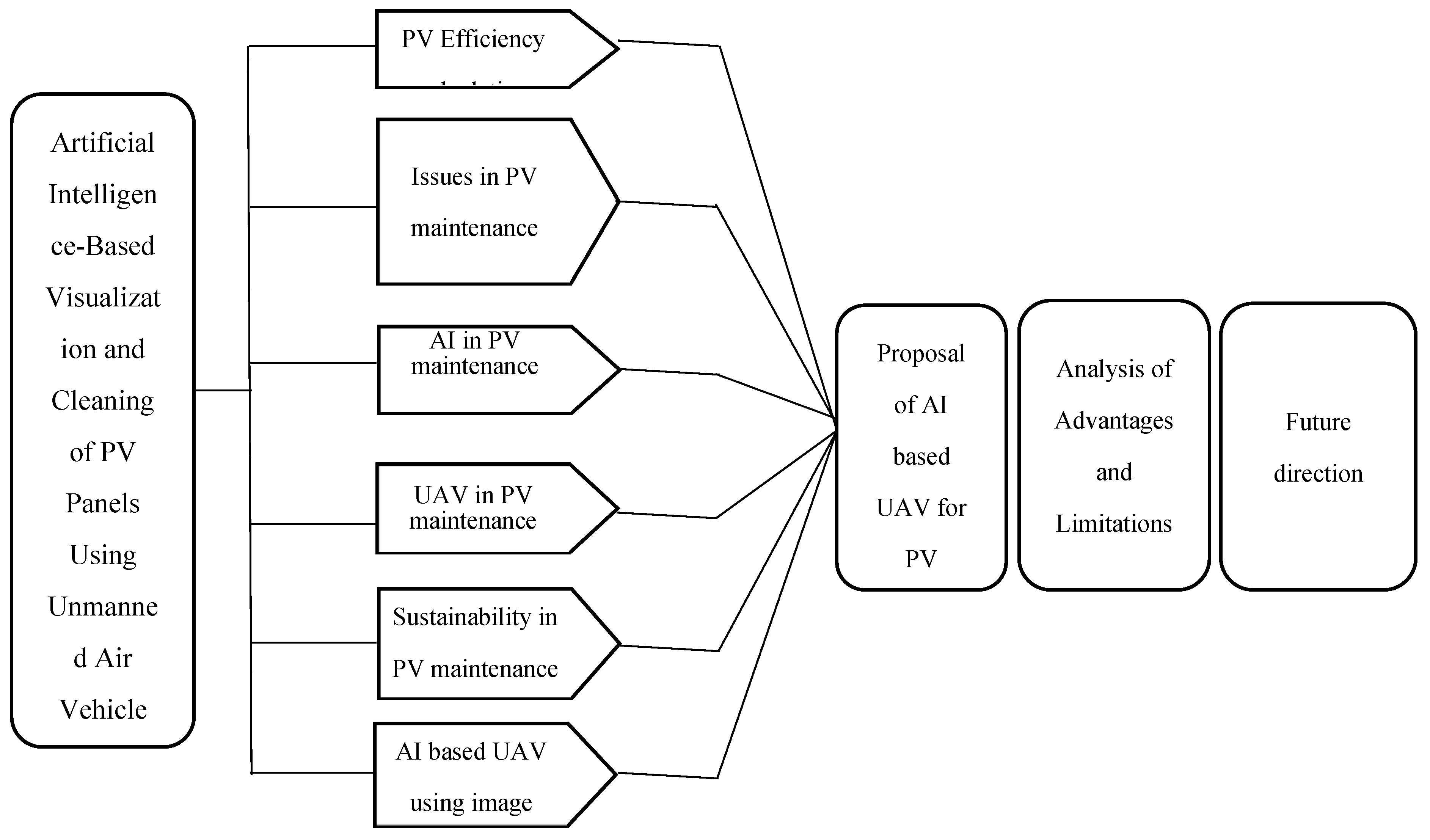

1. Introduction

1.1. Overview

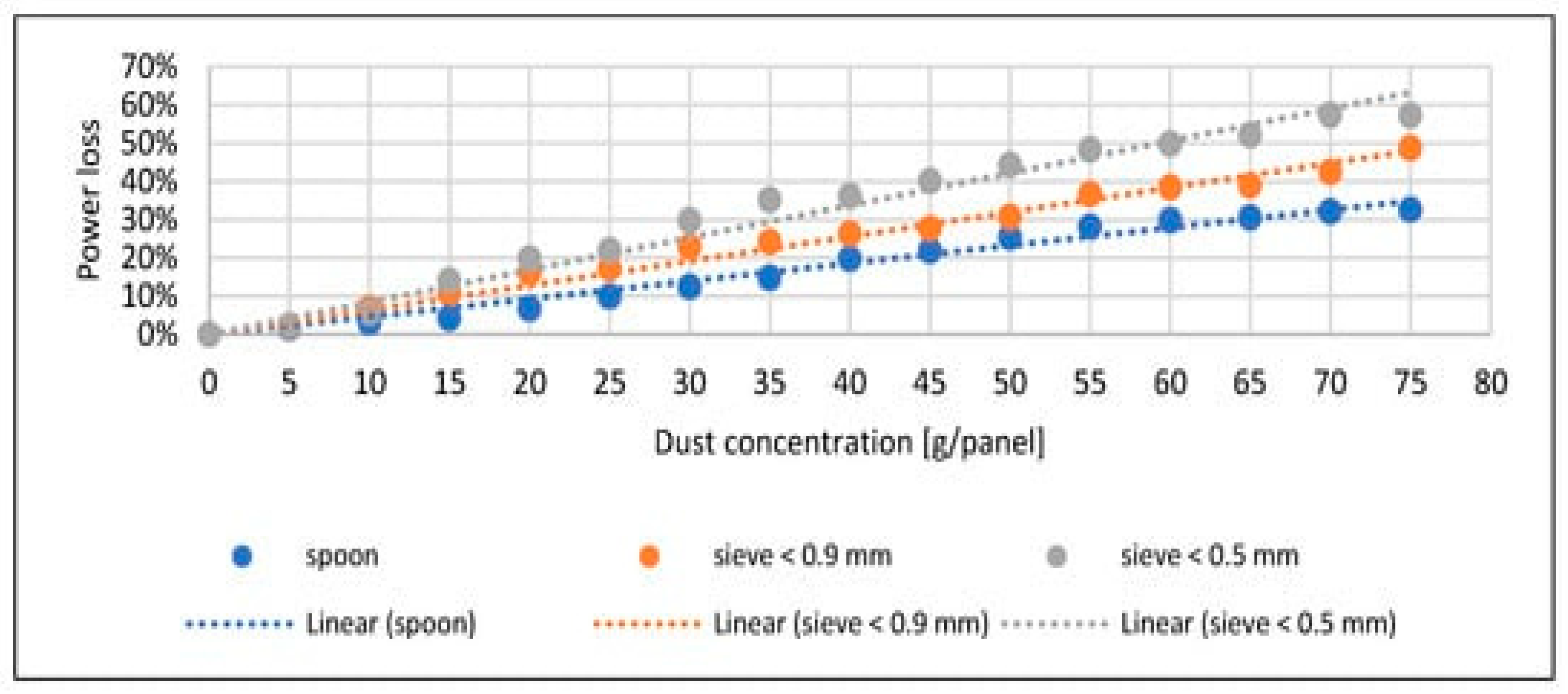

| Dust density in g/m2 | Output power loss in % |

|---|---|

| 2 | 8 |

| 4 | 13 |

| 6 | 20 |

| 8 | 28 |

| 10 | 38 |

1.2. PV Panel Efficiency Calculation

- PV will give less efficiency due to higher temperature

- Solar irradiance varies due to geographical location

- Angle of PV panel installation

- Shading due to trees and nearby building walls

- Panel quality and wire quality

- Solar panel mismatch in the series connection

- Dirt and dust on the PV panel

2. Issues in Photovoltaic Maintenance

2.1. Role of Artificial Intelligence in Photovoltaic System Maintenance

2.2. Role of UAVs in PV System Maintenance

2.3. Sustainability Considerations in PV Maintenance

2.4. Review of the AI-Based UAV for PV Module Cleaning Using Image Capturing

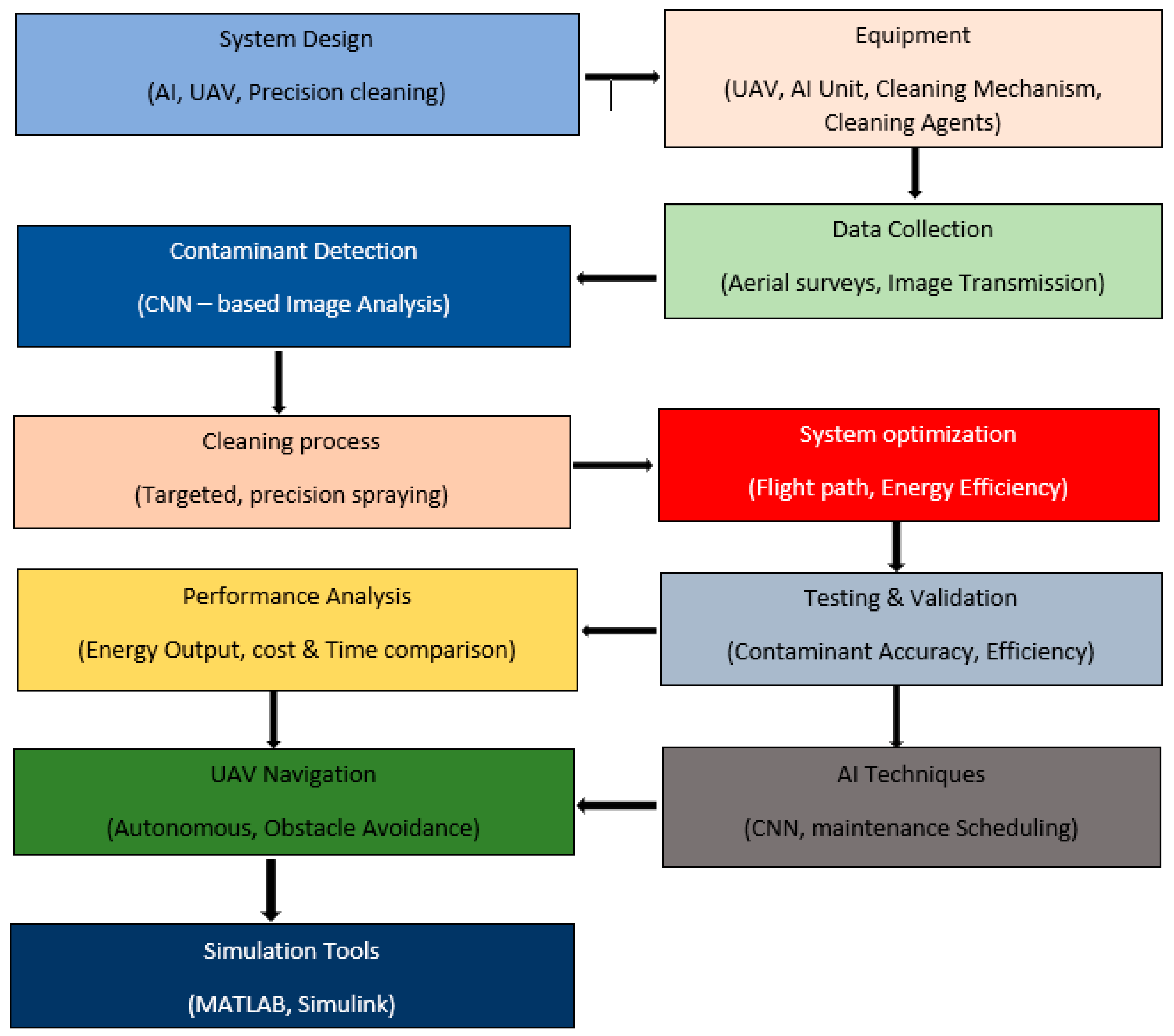

3. Materials, Methods, System Design, and Control of the Proposed Methodology

- Developing a compact glazed UAV for system integration presents an engineering challenge. The UAV's capacity is assessed based on weight, power consumption, and operational efficiency limitations. Autonomous navigation in large solar farms poses challenges, particularly in avoiding obstacles and ensuring complete panel coverage. Flight path optimisation and collision avoidance algorithms are essential to fulfil these requirements. They must be robust, fail-safe, and adhere to established design principles. This system can have the following specific objectives:

- Contaminant Detection: Utilize AI algorithms on high-definition aerial images to identify areas of dirt, dust, and other impurities on photovoltaic panels.

- Precision Cleaning: Facilitate focused cleaning of UAVs using reduced water, chemicals, and other limited resources.

- Labor Reduction: Decrease the necessity for manual labour in maintaining large-scale solar farms, thereby minimising associated risks and operational complexities.

3.1. Economic Limitations

3.2. Sustainability Considerations

3.3. Environmental Limitations

3.4. Constraints Related to Health and Safety

3.5. Constraints of Social Standards

4. Methodology to Develop the Proposed Design

4.1. Methodology

4.1.1. Equipment and Materials

- Unmanned Aerial Vehicle (UAV) and cameras: UAV is Equipped with high-resolution cameras and environmental sensors to generate detailed aerial imagery of photovoltaic panels.

- AI Processing Unit: facilitates convolutional neural networks (CNNs) for image analysis, enabling the identification of contaminants, including dirt and debris.

- Cleaning Mechanism: A precision-controlled spray nozzle affixed to a lightweight module utilises a biodegradable cleaning fluid designed for application via a UAV.

- Cleaning Agents: Environmentally friendly fluids with superior dirt removal capabilities while utilising minimal water.

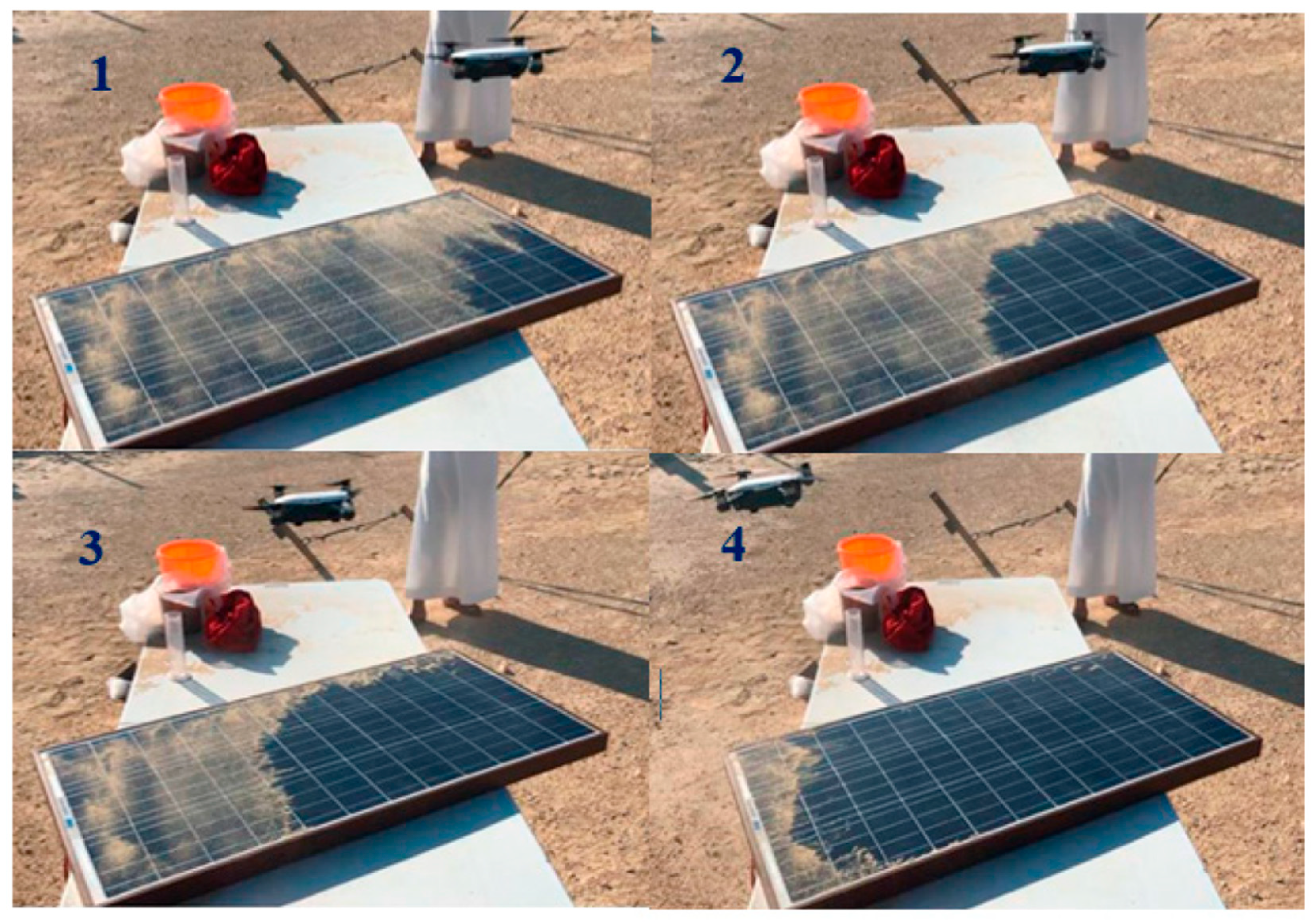

4.1.2. Procedure

4.1.3. Software and Techniques

- Artificial Intelligence Techniques:

- UAV Navigation and Control:

- Simulation and Validation Tools:

5. Results and Discussion

Expected Results

6. Conclusion and Future Works

Future Works

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jathar, L. D., Nikam, K., Awasarmol, U. V., Gurav, R., Patil, J. D., Shahapurkar, K., Soudagar, M. E. M., Khan, T. M. Y., Kalam, M. A., Hnydiuk-Stefan, A., Gürel, A. E., Hoang, A. T., & Ağbulut, Ü. (2024). A comprehensive analysis of the emerging modern trends in research on photovoltaic systems and desalination in the era of artificial intelligence and machine learning. Heliyon, 10(3), e25407. [CrossRef]

- Oman Solar Report (2023), www.pvknowhow.com Available at: https://www.pvknowhow.com/solar-report/oman/#:~:text=As%20of%20the%20latest%20data,in%20Oman%20is%20as%20follows%3A&text=Natural%20Gas%2093%25,Wind%201%25 [ Accesed on 21 Mar 2025].

- Patrick Amoatey, Amer Al-Hinai, Abdullah Al-Mamun, Mahad Said Baawain, A review of recent renewable energy status and potentials in Oman, Sustainable Energy Technologies and Assessments, Volume 51,2022,101919,ISSN 2213-1388. [CrossRef]

- Hudedmani, M. G., Joshi, G., Umayal, R. M., & Revankar, A. (2017). A Comparative Study of Dust Cleaning Methods for the Solar PV Panels. Advanced Journal of Graduate Research, 1(1), 24–29. [CrossRef]

- Najmi N, Rachid A. A Review on Solar Panel Cleaning Systems and Techniques. Energies. 2023; 16(24):7960. [CrossRef]

- Solar Panel Maintenance: Taking Care of Your Panels - TheGreenAge. (2018). Available at: https://www.thegreenage.co.uk/solar-panel-maintenance/( Accessed on 21 March 2025).

- Pruthviraj, U., Kashyap, Y., Baxevanaki, E., & Kosmopoulos, P. (2023). Solar Photovoltaic Hotspot Inspection Using Unmanned Aerial Vehicle Thermal Images at a Solar Field in South India. Remote Sensing 2023, Vol. 15, Page 1914, 15(7), 1914. [CrossRef]

- Dellosa, J. T., & Palconit, E. C. (2021). Artificial Intelligence (AI) in Renewable Energy Systems: A Condensed Review of its Applications and Techniques. 21st IEEE International Conference on Environment and Electrical Engineering and 2021 5th IEEE Industrial and Commercial Power System Europe, EEEIC / I and CPS Europe 2021 - Proceedings. [CrossRef]

- Matusz-Kalász, D., & Bodnár, I. (2021). Operation Problems of Solar Panel Caused by the Surface Contamination. Energies 2021, Vol. 14, Page 5461, 14(17), 5461. [CrossRef]

- Anna Michail, Andreas Livera, Georgios Tziolis, Juan Luis Carús Candás, Alberto Fernandez, Elena Antuña Yudego, Diego Fernández Martínez, Angelos Antonopoulos, Achilleas Tripolitsiotis, Panagiotis Partsinevelos, Eftichis Koutroulis, George E. Georghiou, A comprehensive review of unmanned aerial vehicle-based approaches to support photovoltaic plant diagnosis, Heliyon, Volume 10, Issue 1, 2024, e23983, ISSN 2405-8440. [CrossRef]

- Nezamisavojbolaghi, M., Davodian, E., Bouich, A., Tlemçani, M., Mesbahi, O., & Janeiro, F. M. (2023). The Impact of Dust Deposition on PV Panels’ Efficiency and Mitigation Solutions: Review Article. Energies 2023, Vol. 16, Page 8022, 16(24), 8022. [CrossRef]

- Al-Housani, M., Bicer, Y., & Koç, M. (2019). Experimental investigations on PV cleaning of large-scale solar power plants in desert climates: Comparison of cleaning techniques for drone retrofitting. Energy Conversion and Management, 185, 800–815. [CrossRef]

- Yue Tan Zhang, Jin Tuan Zhang, Yue Liu, Kun Liu, QiPeng Wang, Spray-on steady-state study of multi-rotor cleaning uncrewed aerial vehicle in operation of photovoltaic power station, Energy Reports, Volume 11,2024,Pages 5638-5653, ISSN 2352-4847. [CrossRef]

- Majeed, R.; Waqas, A.; Sami, H.; Ali, M.; Shahzad, N. Experimental investigation of soiling losses and a novel cost-effective cleaning system for PV modules. Sol. Energy 2020, 201, 298–306.

- UAS Vision. (2021). Airobotics to Develop Solar Panels Cleaning Drone System – UAS VISION. Available at: https://www.uasvision.com/2021/12/09/airobotics-to-develop-solar-panels-cleaning-drone-system/ (Accessed on 21 March 2025).

- iFBOT. (2024). IFBOT Portable and Autonomous Solar Panel Cleaning Robot. Available at: https://www.ifbot.com/ (Accessed on 21 March 2025).

- A Patil, S., R Patil, A., Chougule, V. N., & Sanamdikar, S. T. (2024). Design and Analysis of Automated Solar Panel Cleaning System. Current World Environment, 18(3), 1032–1045. [CrossRef]

- Milidonis, K., Eliades, A., Grigoriev, V., & Blanco, M. J. (2023). Unmanned Aerial Vehicles (UAVs) in the planning, operating and maintaining concentrating solar thermal systems: A review. Solar Energy, 254, 182–194. [CrossRef]

- Almalki, F. A., Albraikan, A. A., Soufiene, B. O., & Ali, O. (2021). Utilizing Artificial Intelligence and Lotus Effect in an Emerging Intelligent Drone for Persevering Solar Panel Efficiency. Wireless Communications and Mobile Computing, 2022(1), 7741535. [CrossRef]

- Mani, M., & Pillai, R. (2010). Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renewable and Sustainable Energy Reviews, 14(9). [CrossRef]

- S. S. Sarkis et al., "Novel Design of a Hybrid Drone System for Cleaning Solar Panels," 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 2022, pp. 1-6. [CrossRef]

- K. M. Mishra, K. Babu M, S. C. U and M. Nithya, "Drone Based Solar Panel Cleaning System," 2024 International Conference on Power, Energy, Control and Transmission Systems (ICPECTS), Chennai, India, 2024, pp. 1-5. [CrossRef]

- Akay, S, S., Özcan, O., Özcan, O., Yetemen, Ö. Efficiency analysis of solar farms by UAV-based thermal monitoring. Engineering Science and Technology, an International Journal, 2024, 53, 101688. [CrossRef]

- Xie, Tianyu, Yutong Jiang, Chenglin Wang, and Hongtao Ni. 2025. “A Drone System for PV Panel Cleaning Based on YOLOv8 and Automated Flight Path Planning”. World Scientific Research Journal 11 (2): 47-54.

- Kumar, B. P. (2024). Solar Panel Dirt Detection and Cleaning System. African Journal of Biological Sciences, 6(5), 10537–10548. [CrossRef]

- Nabti, M., Bybi, A., El Ayachi, C., & Garoum, M. (2022). Machine learning for predictive maintenance of photovoltaic panels: cleaning process application. E3S Web of Conferences, 336. [CrossRef]

- Bendaoudi, Z., Namoune, A., Kadous, N., Bellebna, Y., Yanallah, K., & Tilmatine, A. (2024). An Improved Electrostatic Cleaning System for Dust Removal from Photovoltaic Panels. Journal of Engineering Science and Technology Review, 17(1), 109–115. [CrossRef]

- Olayiwola, O., & Camara, F. (2024). Challenges and Opportunities for Autonomous UAV Inspection in Solar Photovoltaics. E3S Web of Conferences, 572. [CrossRef]

- Olorunfemi, B. O., Ogbolumani, O. A., & Nwulu, N. (2022). Solar Panels Dirt Monitoring and Cleaning for Performance Improvement: A Systematic Review on Smart Systems. Sustainability 2022, Vol. 14, Page 10920, 14(17), 10920. [CrossRef]

- Sherman, M., Gammill, M., Raissi, A., & Hassanalian, M. (2021). Solar uav for inspecting and monitoring photovoltaic (Pv) systems in solar power plants. AIAA Scitech 2021 Forum, 1–10. [CrossRef]

- Y. P. Huang, S. Kshetrimayum and F. E. Sandnes, "UAV-Based Automatic Detection, Localization, and Cleaning of Bird Excrement on Solar Panels," in IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 55, no. 3, pp. 1657–1670, March 2025. [CrossRef]

- Linhong Chen, Siyuan Fan, Shengyao Sun, Shengxian Cao, Tianyi Sun, Peng Liu, Han Gao, Yanhui Zhang, Wei Ding, A detection model for dust deposition on photovoltaic (PV) panels based on light transmittance estimation, Energy, Volume 322, 2025,135284,ISSN 0360-5442. [CrossRef]

- Rehman, S., Mohandes, M. A., Hussein, A. E., Alhems, L. M., & Al-Shaikhi, A. (2022). Cleaning of Photovoltaic Panels Utilizing the Downward Thrust of a Drone. Energies 2022, Vol. 15, Page 8159, 15(21), 8159. [CrossRef]

- Talal Al Haddabi, Amuthakkannan Rajakannu, Hamood Al Hasni, "Design and Development of a Low-Cost Parabolic Type Solar Dryer and its Performance Evaluation in Drying of Kingfish – A Case Study in Oman," International Journal of Engineering Trends and Technology, vol. 72, no. 12, pp. 195-214, 2024. Crossref. [CrossRef]

| Cleaning Methodology | Disadvantages |

|---|---|

| Mechanical Scrubbing Method | More water and chemical consumption |

| Manual Cleaning Method | Risk involved; Not suitable for large scale PV systems |

| Water Jet methods | Not suitable in water scarcity places |

| Unmanned Aerial vehicle | Need a suitable system to identify the dirt/dust places; Need effective appliance for cleaning |

| Robotic aram based cleaning | Lack Scalability |

| Microcontroller based arms | High cost and need more skill to handle; Temp sensitive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).